Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "Drill bit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drill bits are cutting tools used to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the shank in the chuck.

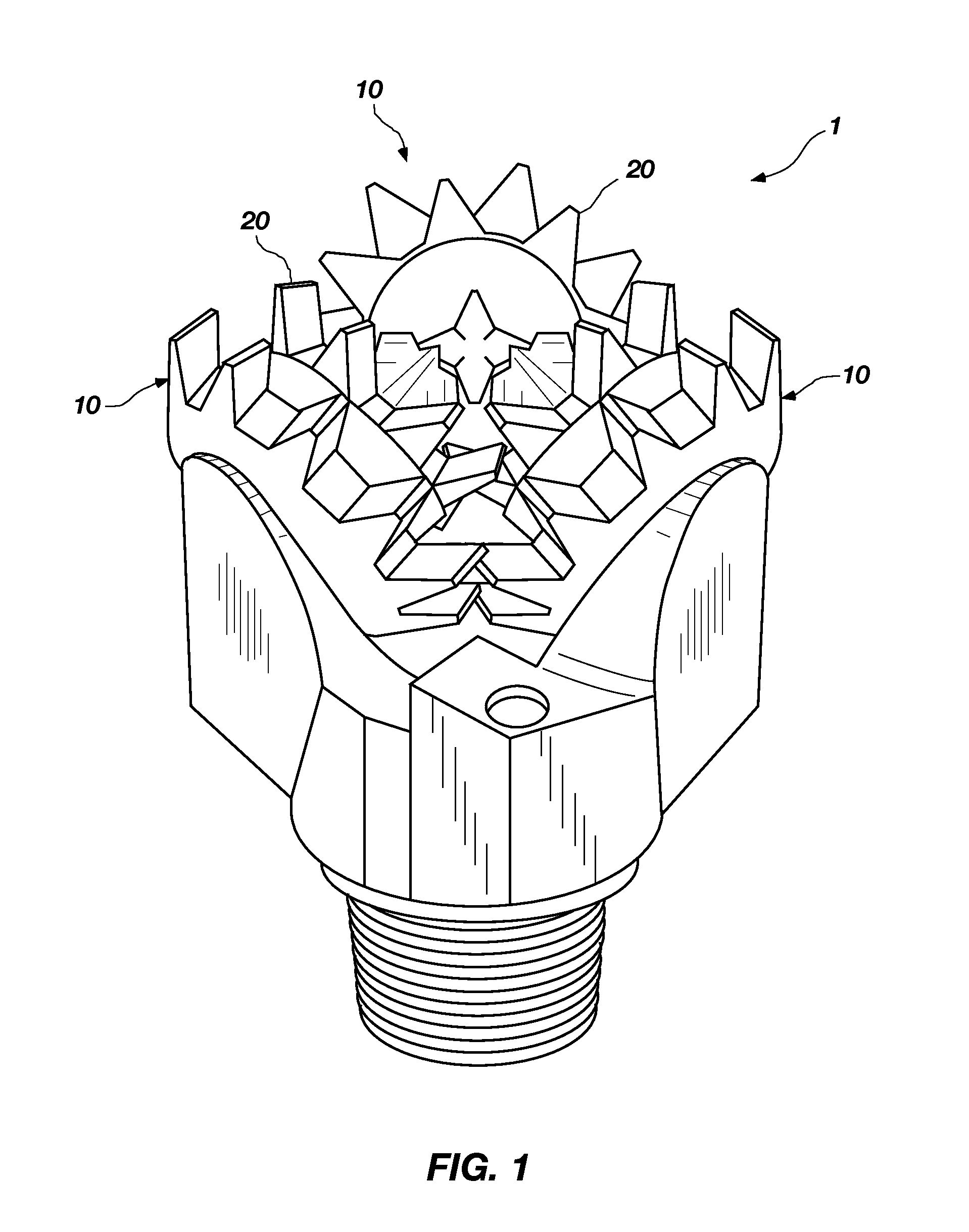

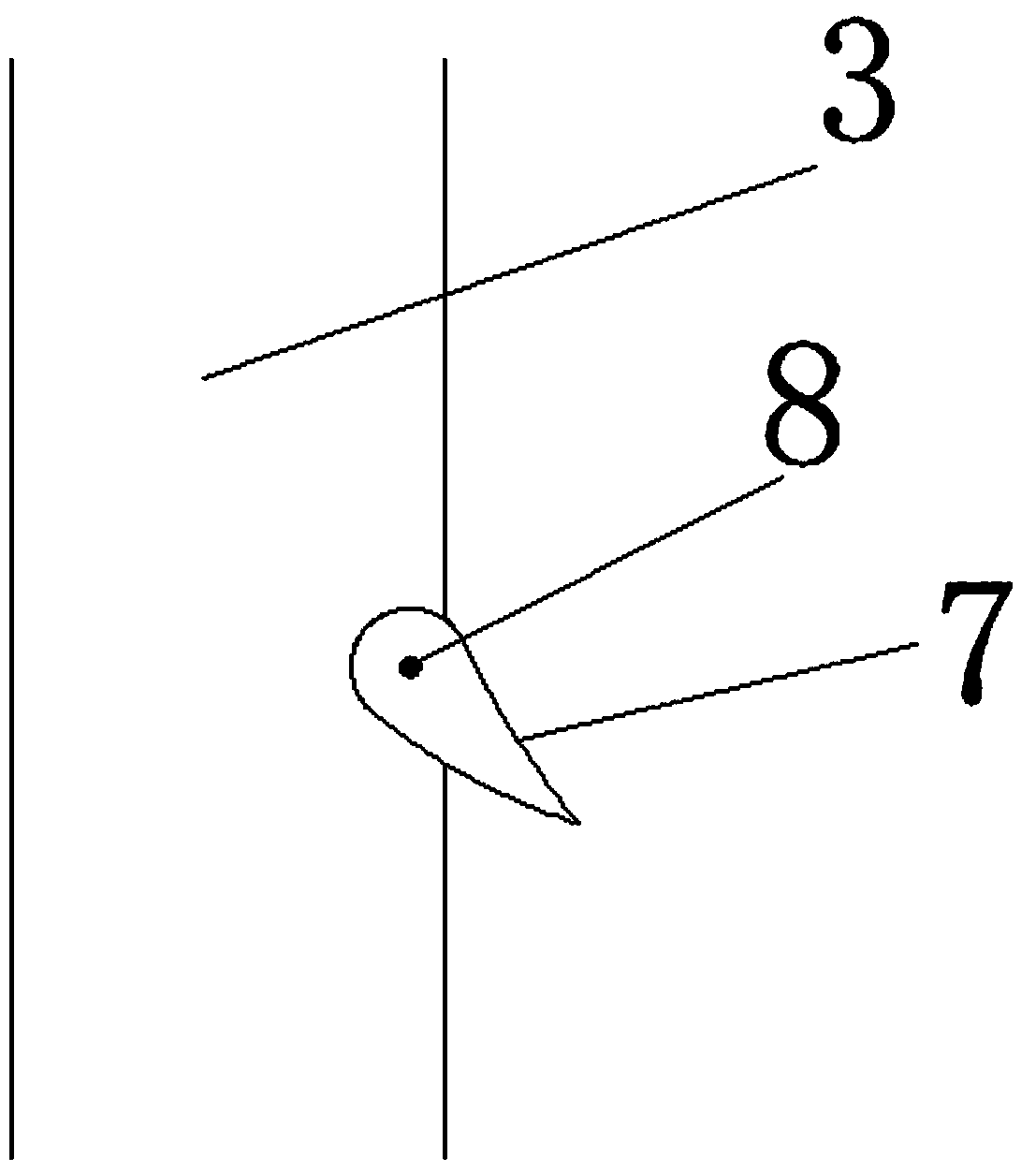

Pointed Diamond Working Ends on a Shear Bit

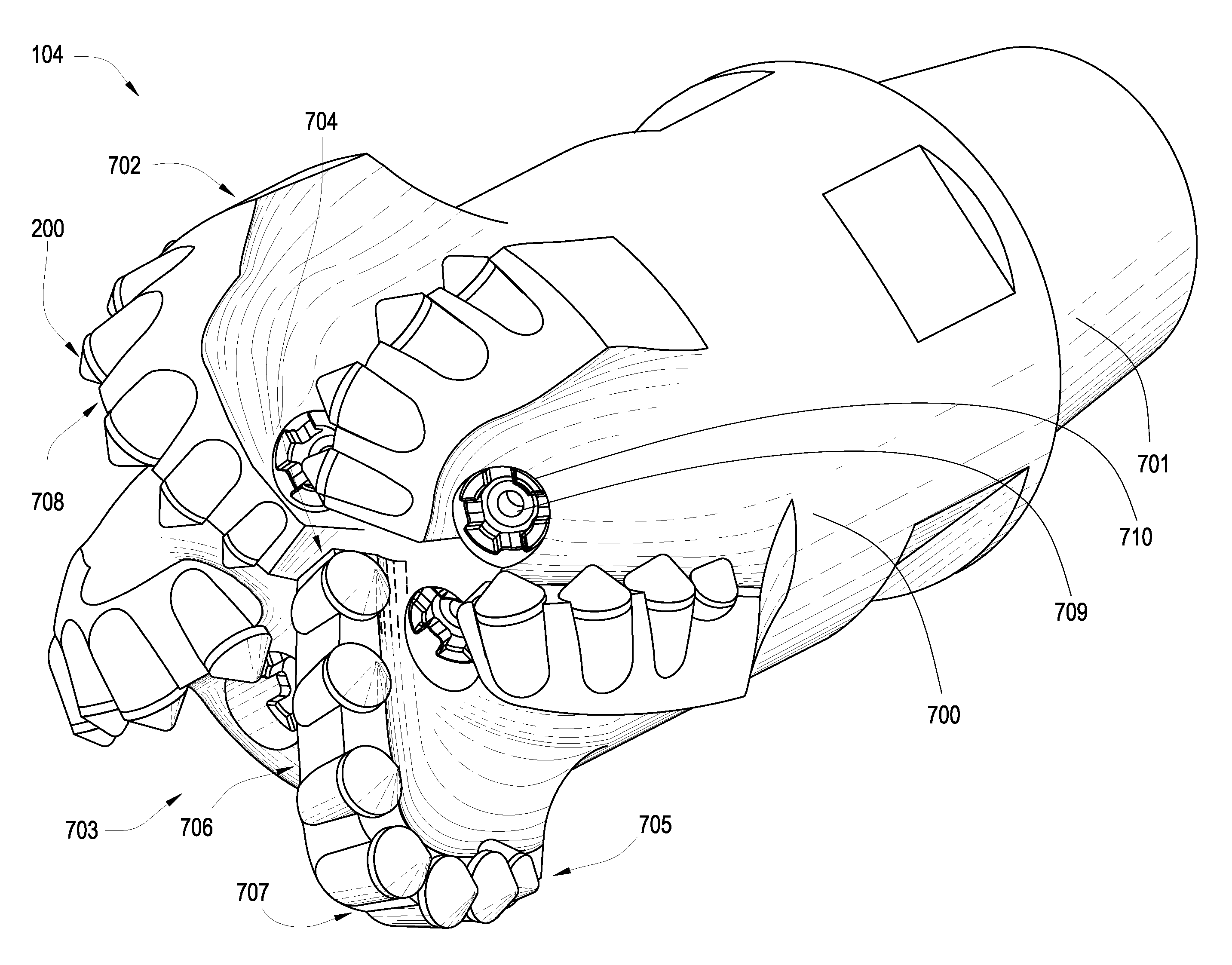

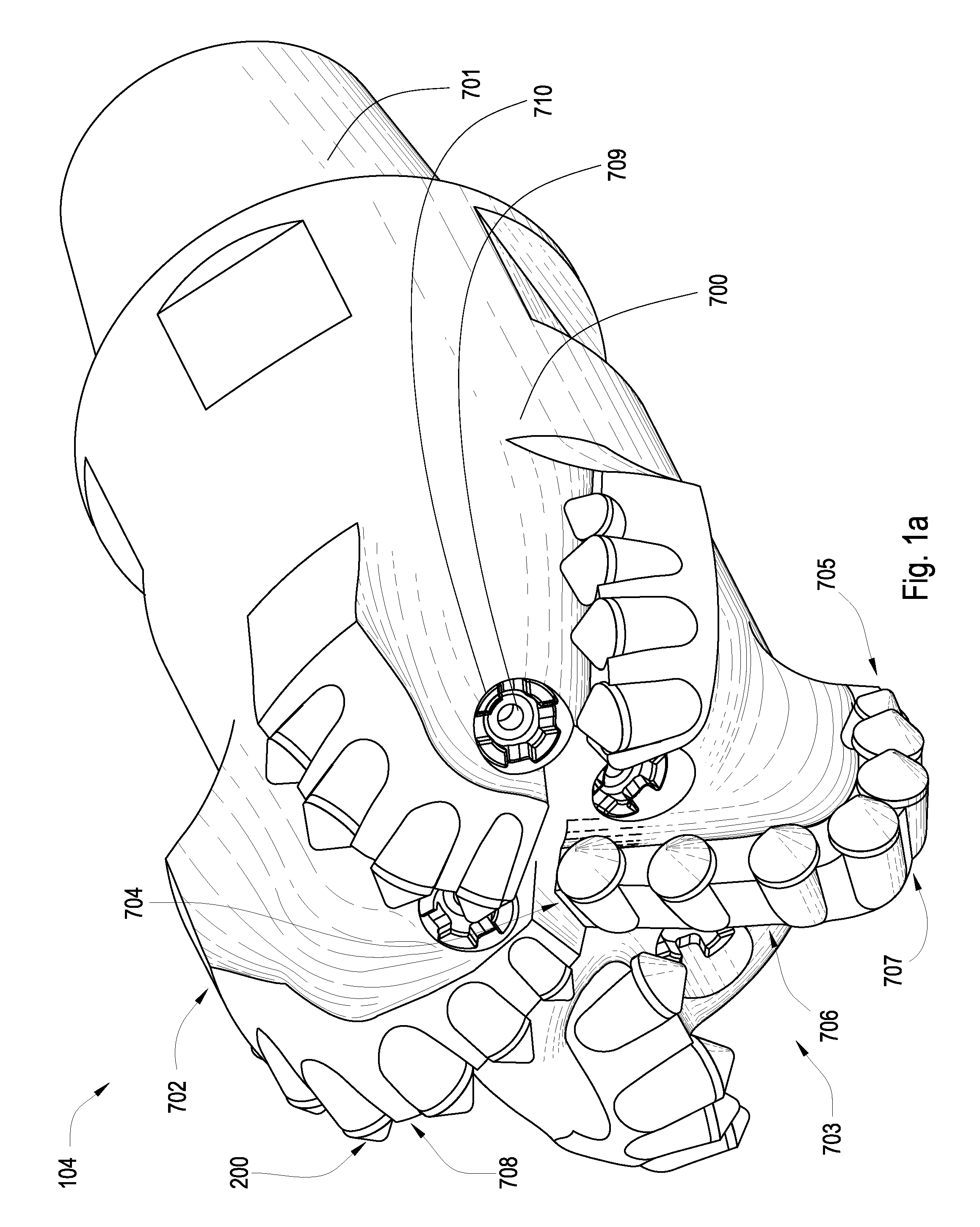

In one aspect of the present invention, a drill string has a drill bit with a body intermediate a shank and a working face. The working face has a plurality of blades converging at a center of the working surface and diverging towards a gauge of the working face. At least one blade has a cutting element with a carbide substrate bonded to a diamond working end with a pointed geometry. The diamond working end also has a central axis which intersects an apex of the pointed geometry. The axis is oriented between a 25 and 85 degree positive rake angle.

Owner:SCHLUMBERGER TECH CORP

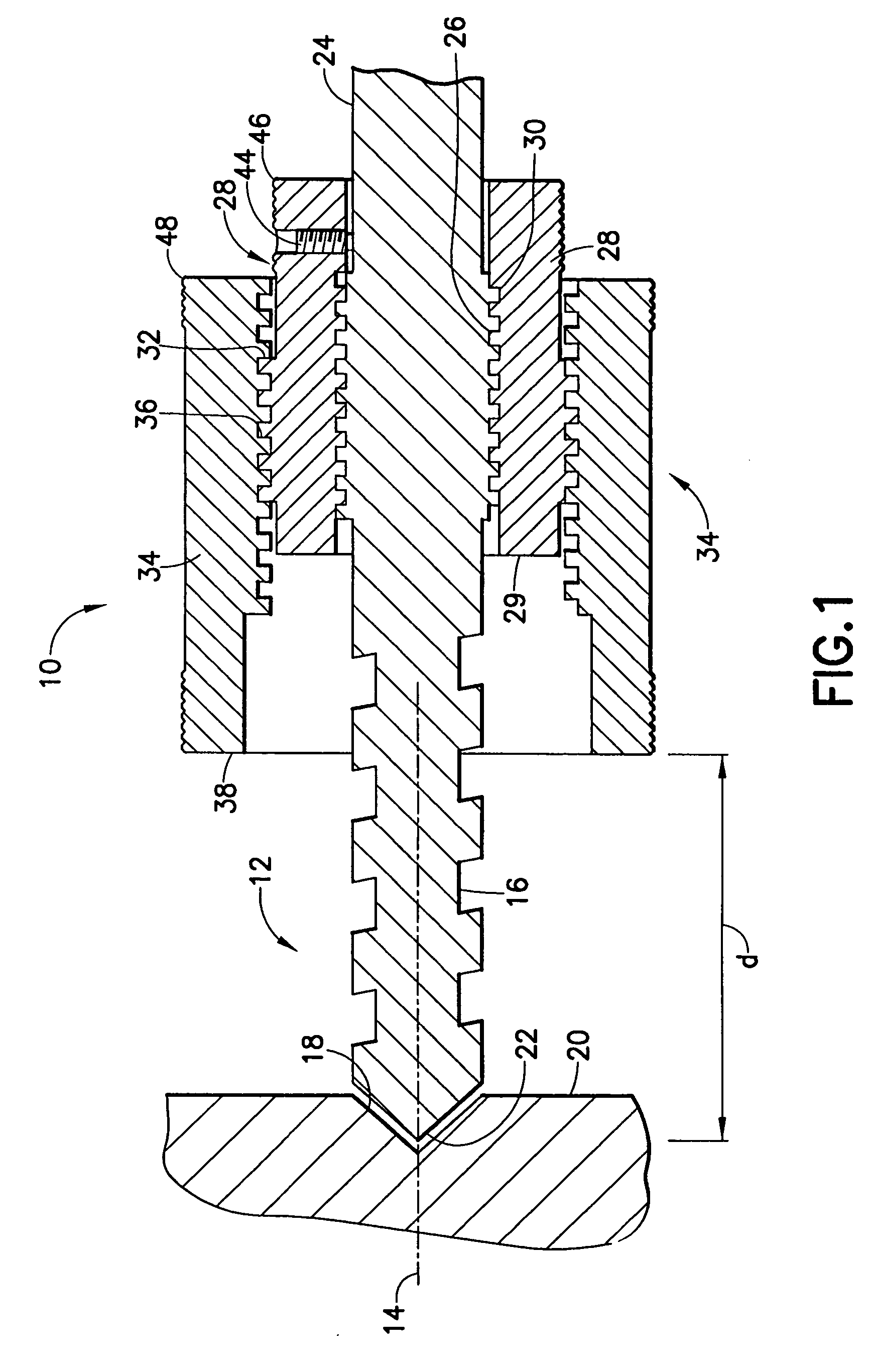

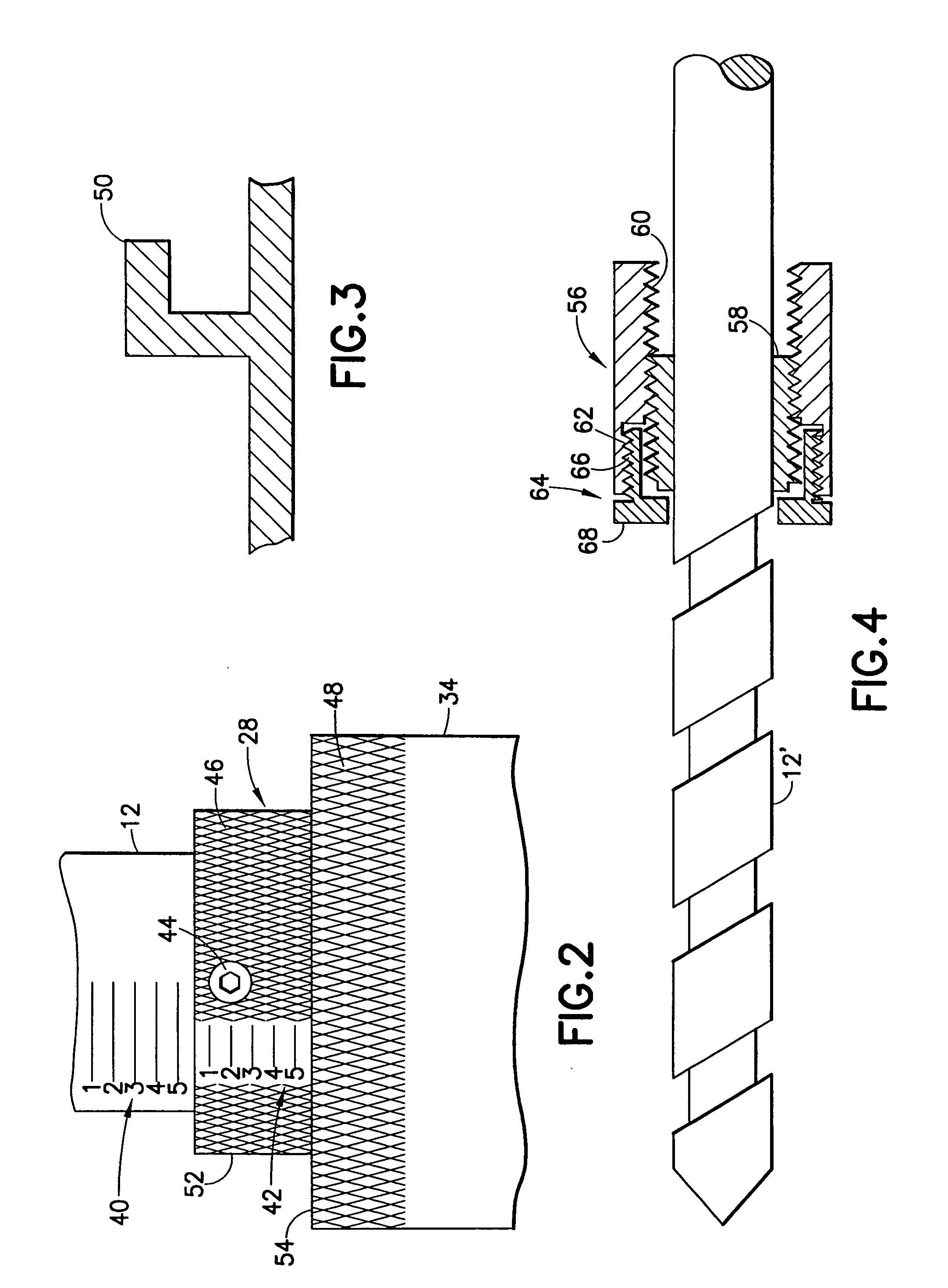

Sleeved stop for a drill bit

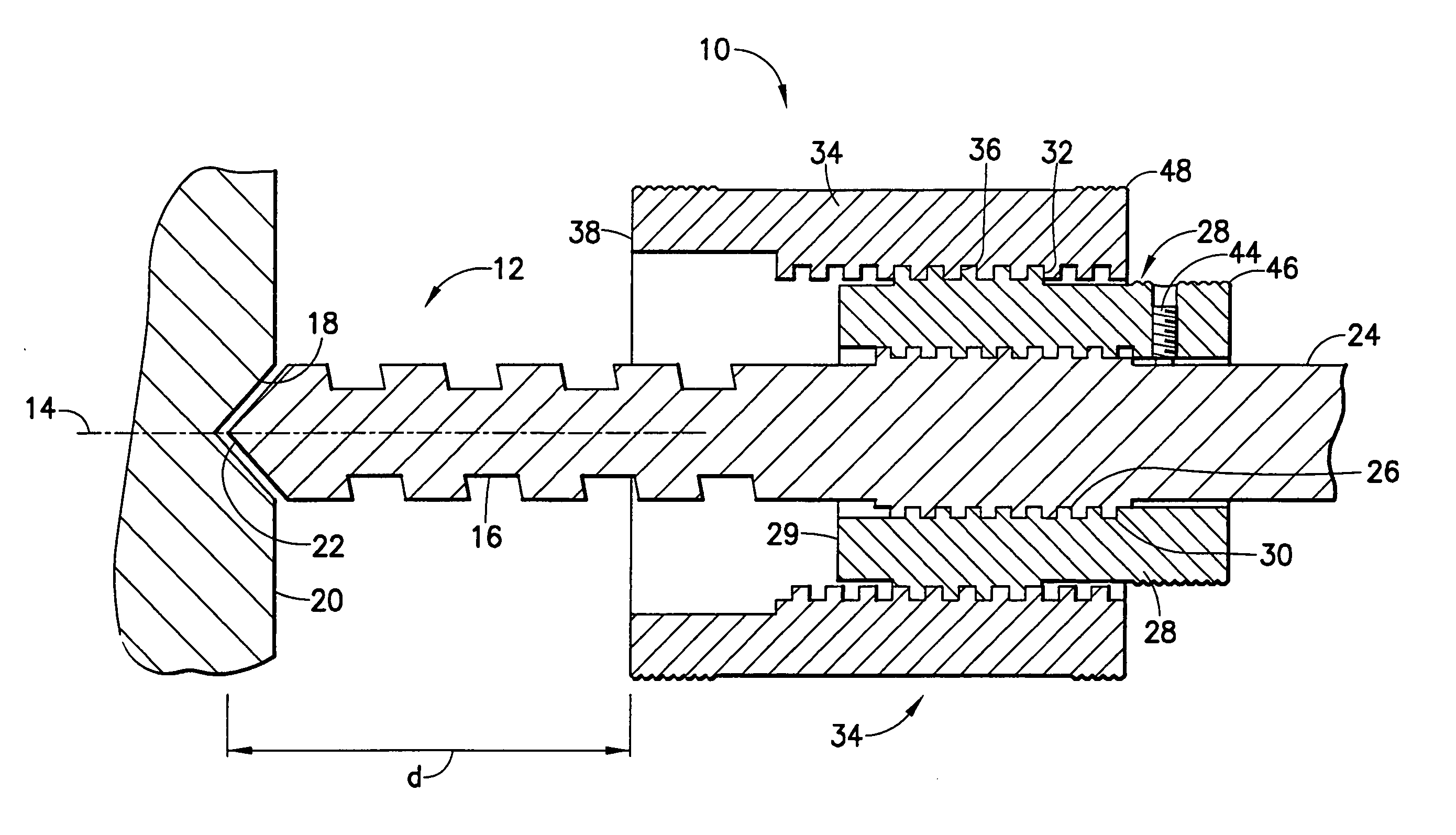

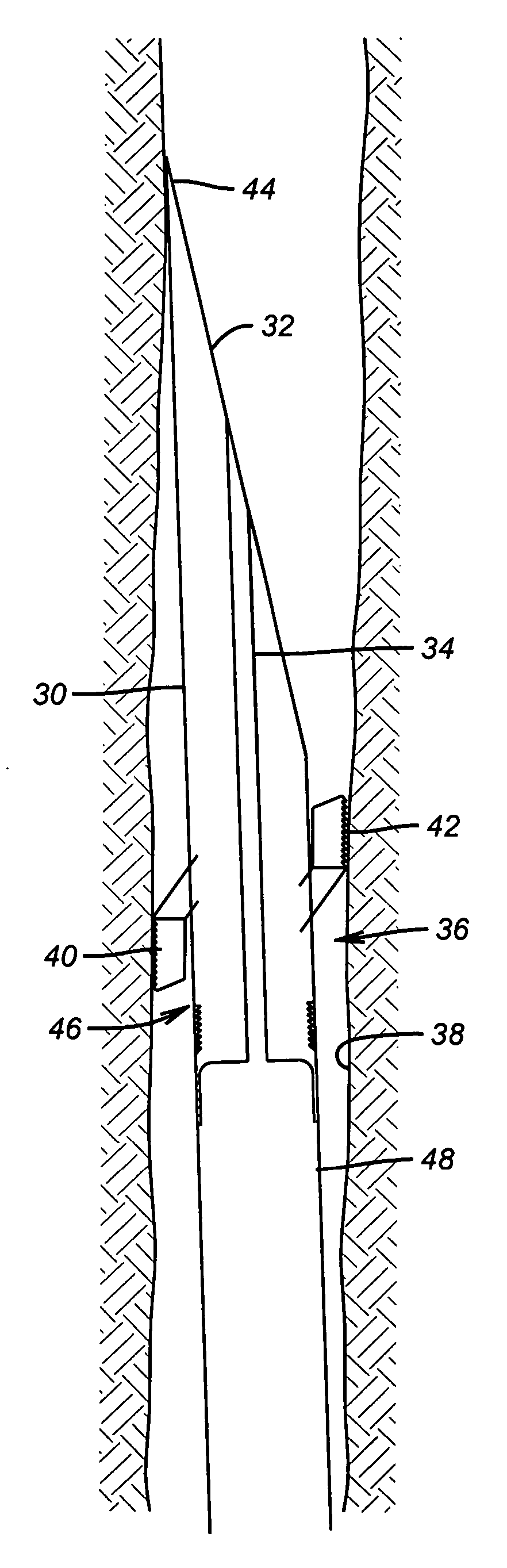

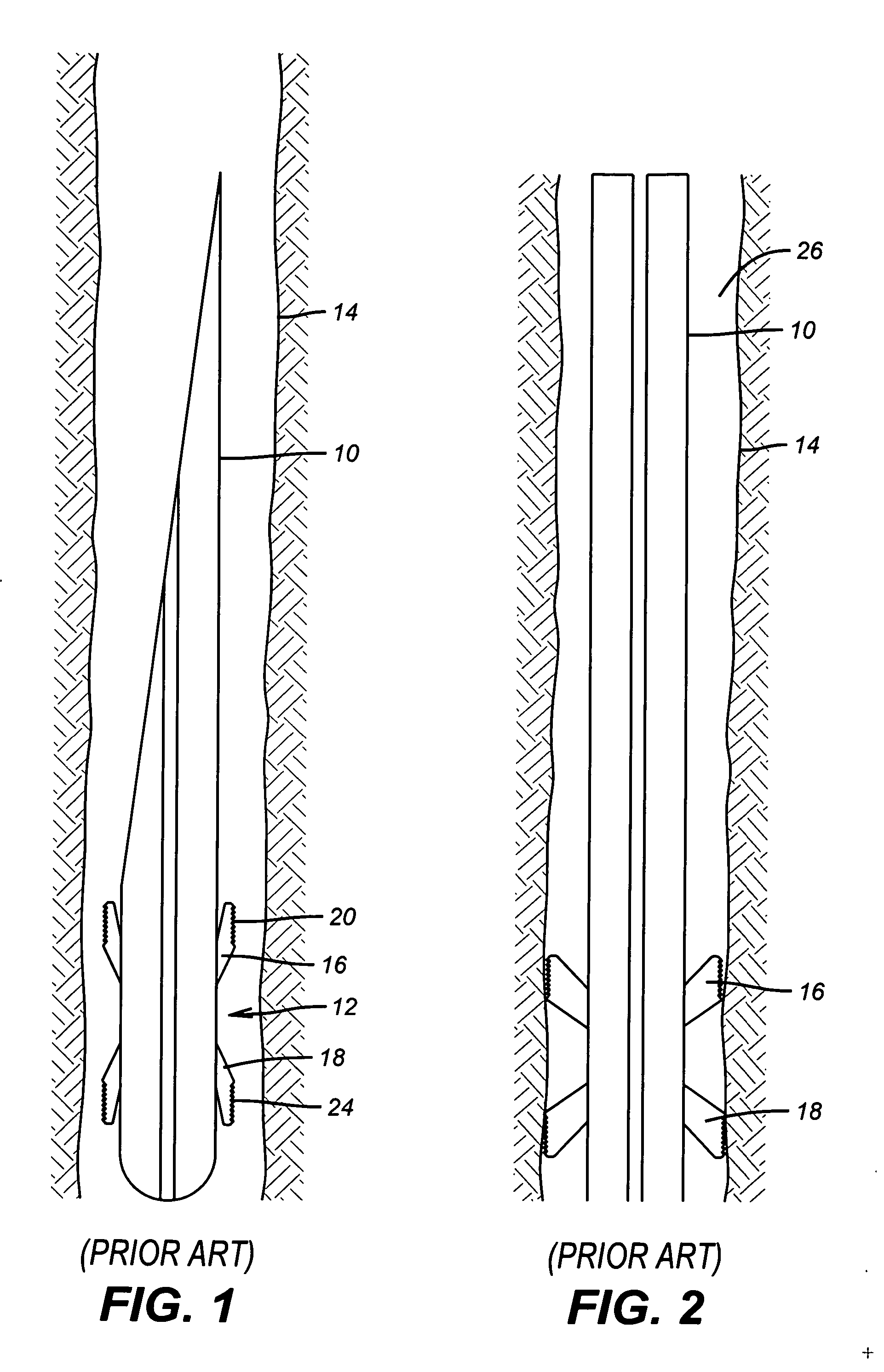

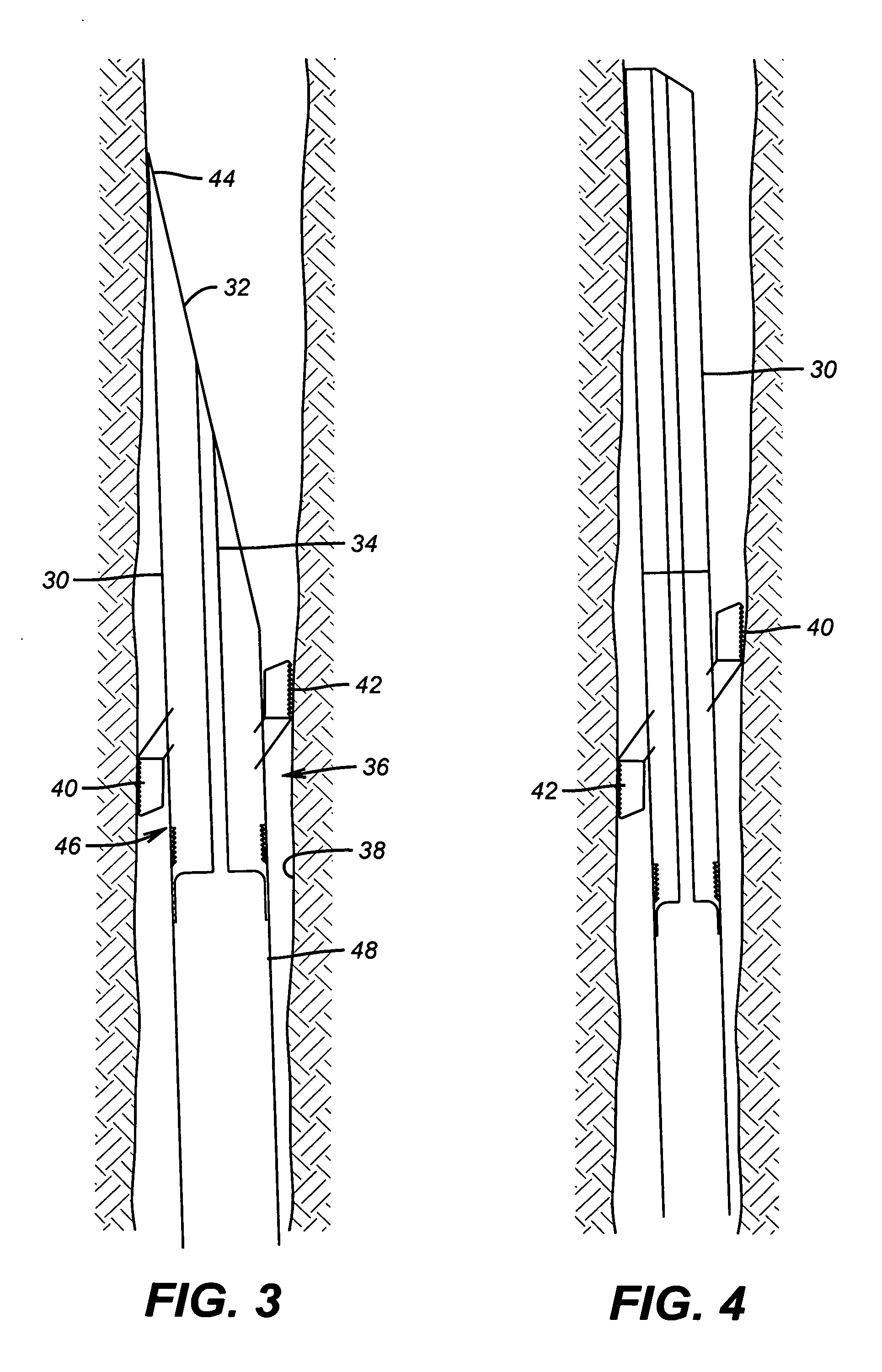

A stop for use with an electric drill bit, the stop having at least one threaded sleeve for positioning the stop relative to a surface into which the drill bit will extend. The stop may have both an inner and an outer sleeve. The sleeves are mounted coaxially, one inside the other about the drill bit. One of the sleeves, preferably the inner sleeve, provides coarse adjustment of the position of the shoulder relative to the tip of the bit, while the other, preferably the outer sleeve, provides fine adjustment of the position of the shoulder relative to the top of the bit.

Owner:3D SCAN GUIDE LLC

Special fixture for processing inclined conical nozzle steam passage and method thereof

InactiveCN101670527AGuaranteed accuracyImprove operational efficiencyPrecision positioning equipmentPositioning apparatusMilling cutterDrill bit

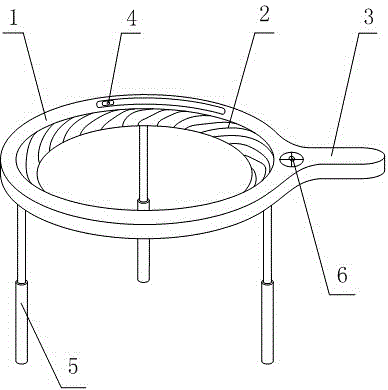

A special fixture for processing an inclined conical nozzle steam passage and a method thereof relate to a fixture for processing the inclined conical nozzle steam passage and a method thereof. The invention solves the problem that at present, no special fixture for processing the inclined conical nozzle steam passage exists, and when a tapered hole of the nozzle steam passage is processed, a drilling bit is difficult to be centered. An indexing plate of the special fixture is provided with twenty indexing through holes along the periphery direction; the center of a stepped through hole and the center of the indexing through holes are on one periphery; a spotting spindle is mounted on the indexing plate in a plug-in manner; the processing method is as follows: using a milling cutter with diameter of 13mm to feed from a P point so as to process a plane C which is vertical to the central line of the tapered hole to be processed; and stopping feeding when the milling cutter mills to a Q point, wherein the center of a hole pitch circle having diameter of 13mm and milled by the milling cutter is the core-bit of the drilling bit. The special fixture solves the problem that at present, nospecial fixture for processing the inclined conical nozzle steam passage exists; and the inclined conical hole of the nozzle stream passage processed by the method has high position accuracy.

Owner:HARBIN TURBINE

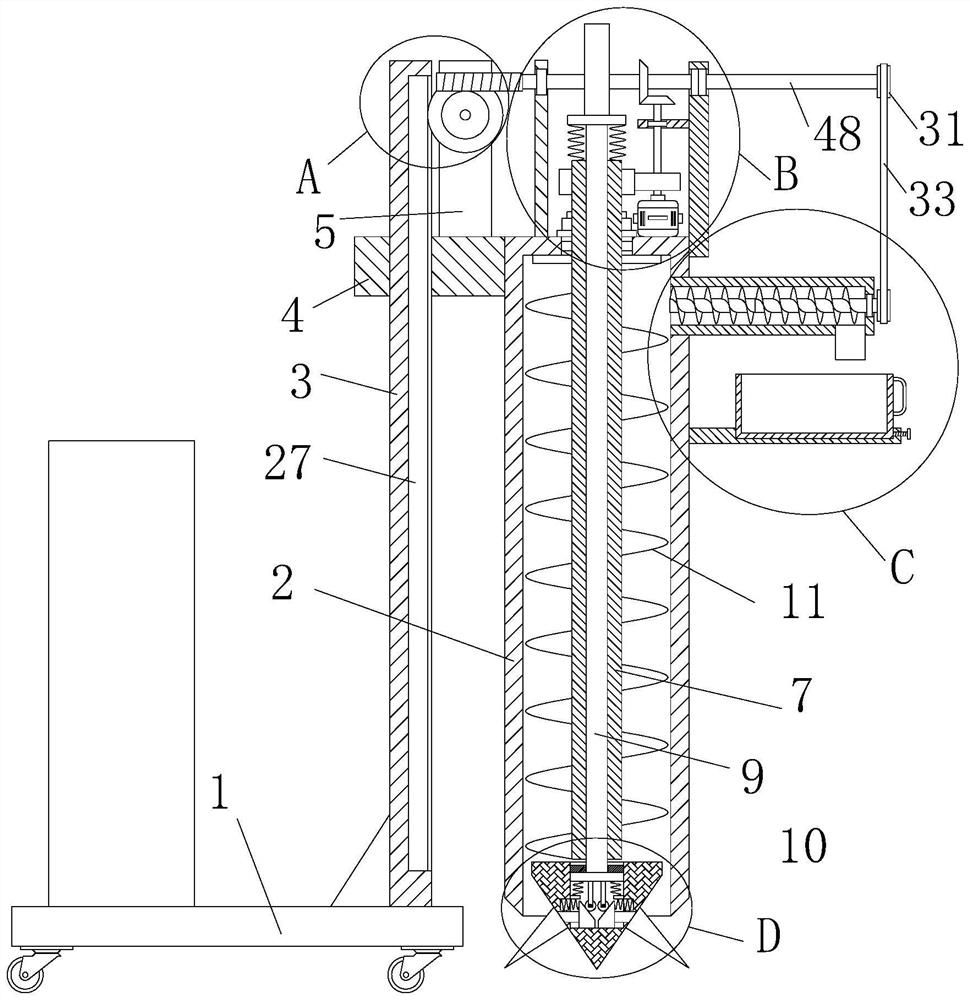

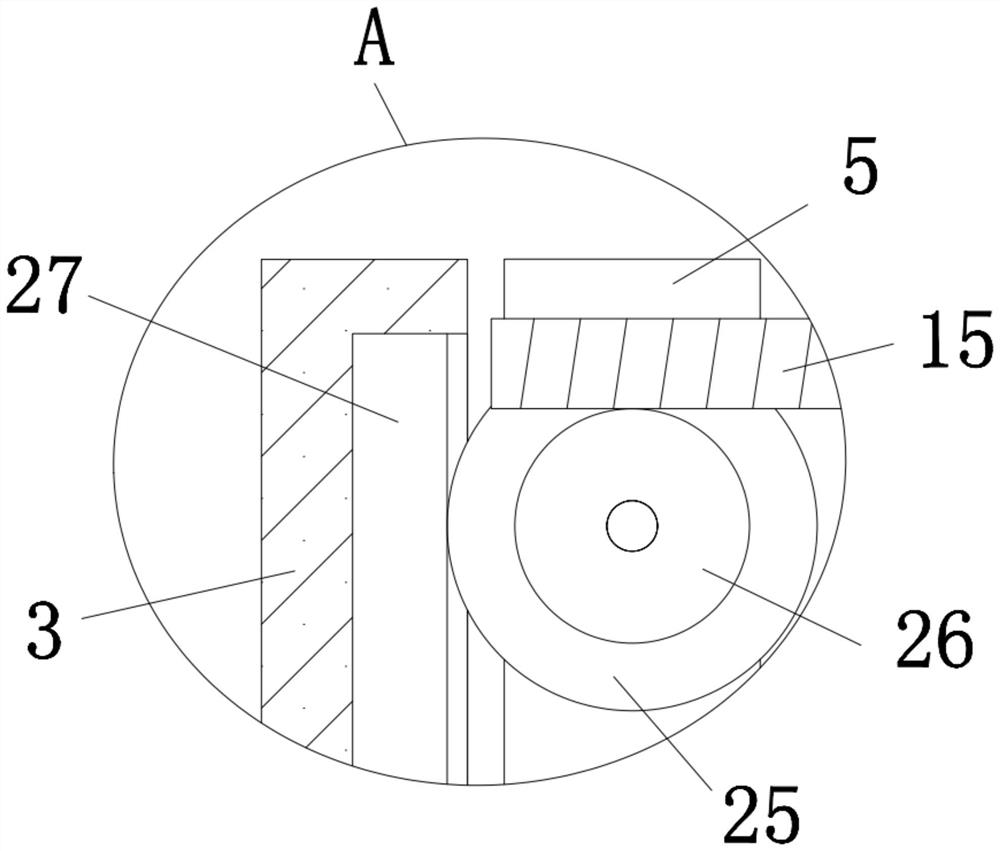

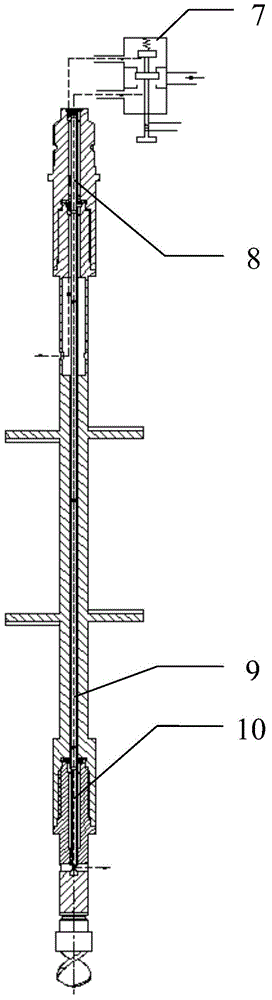

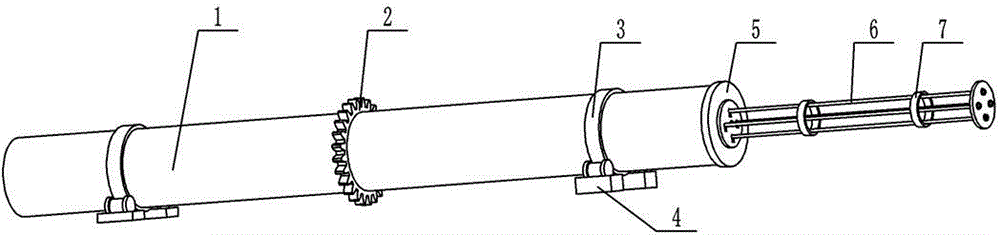

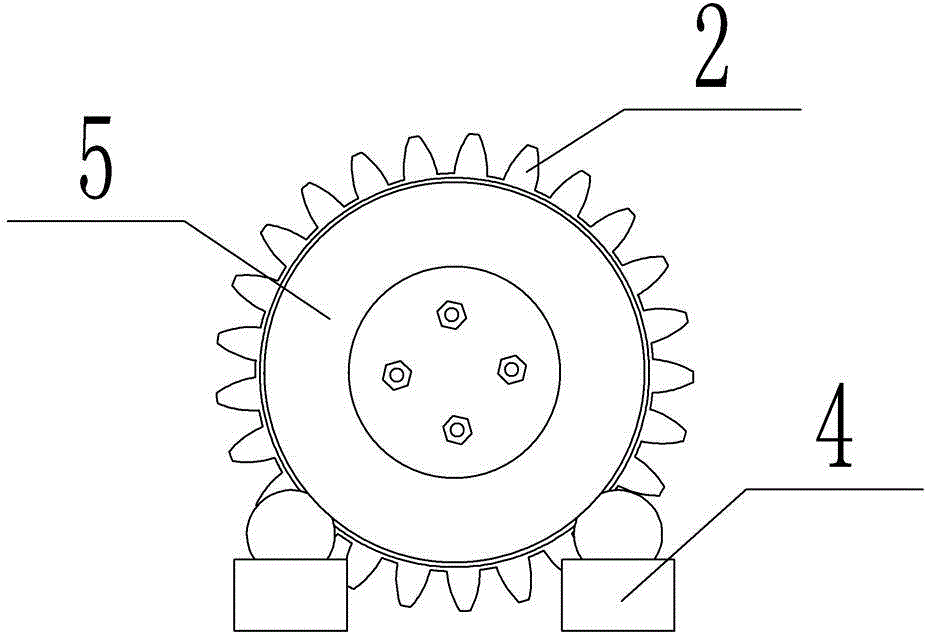

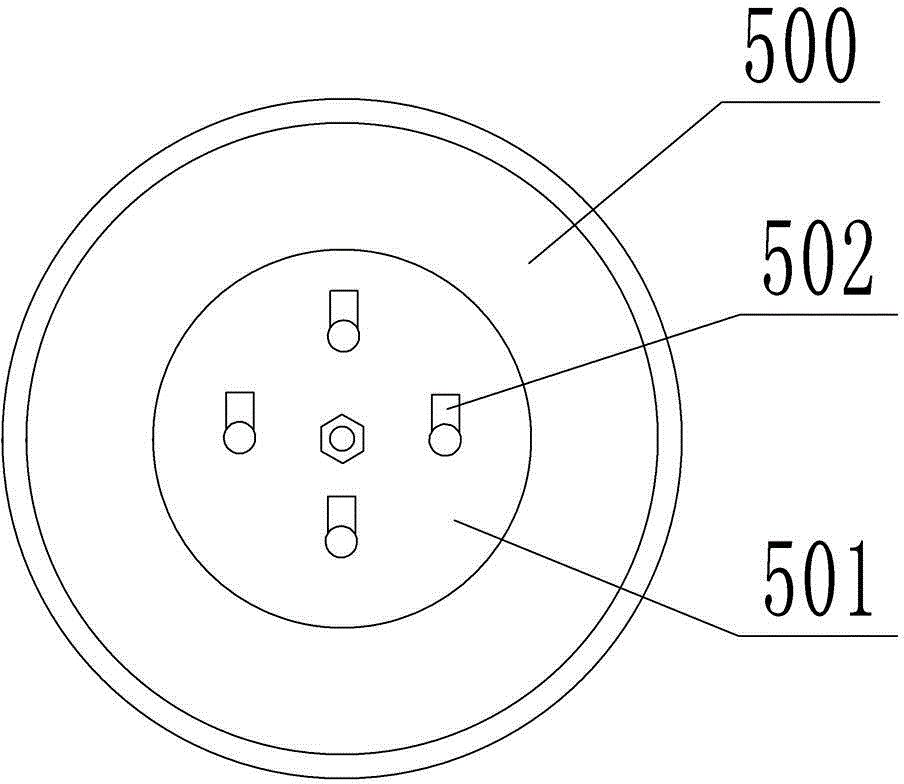

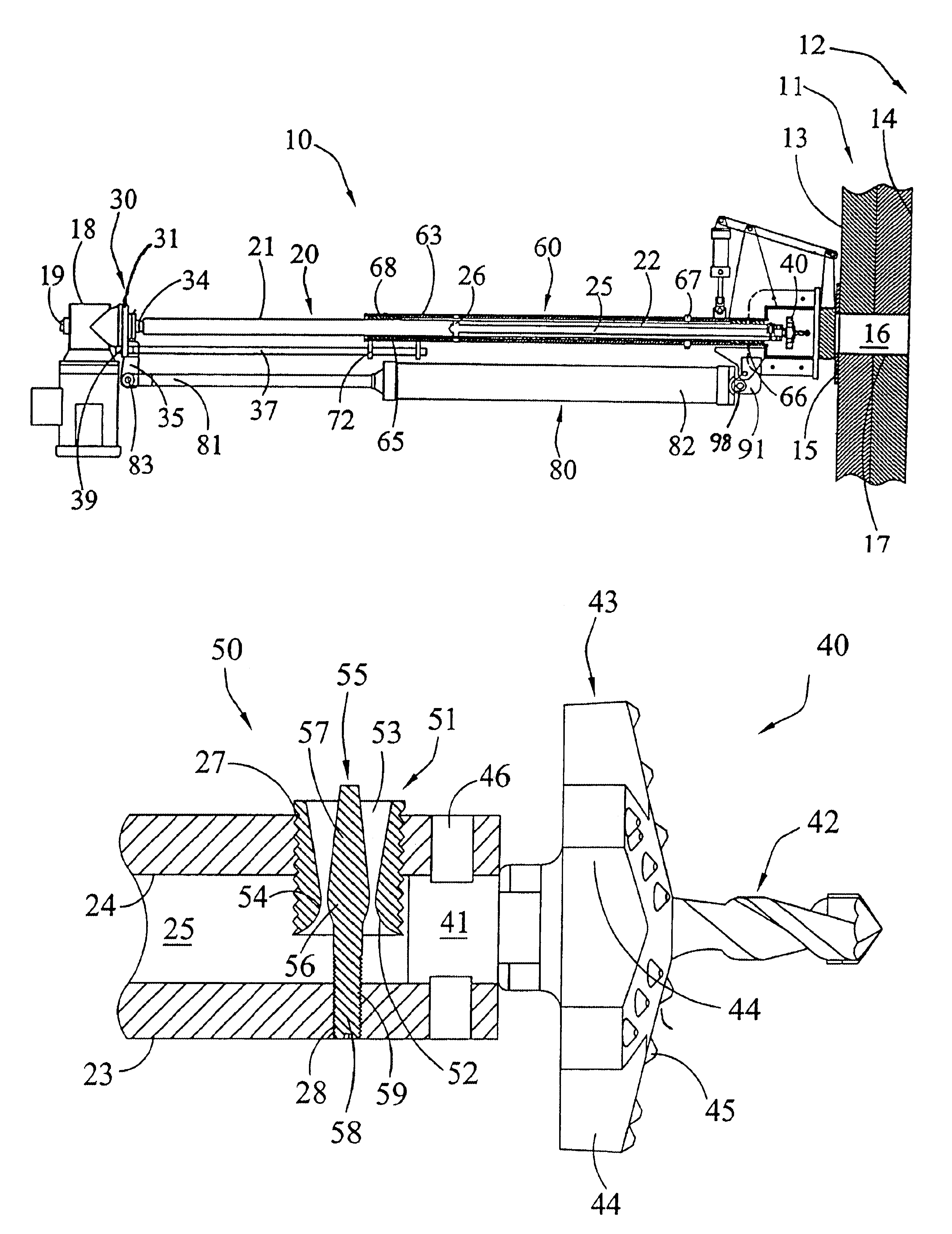

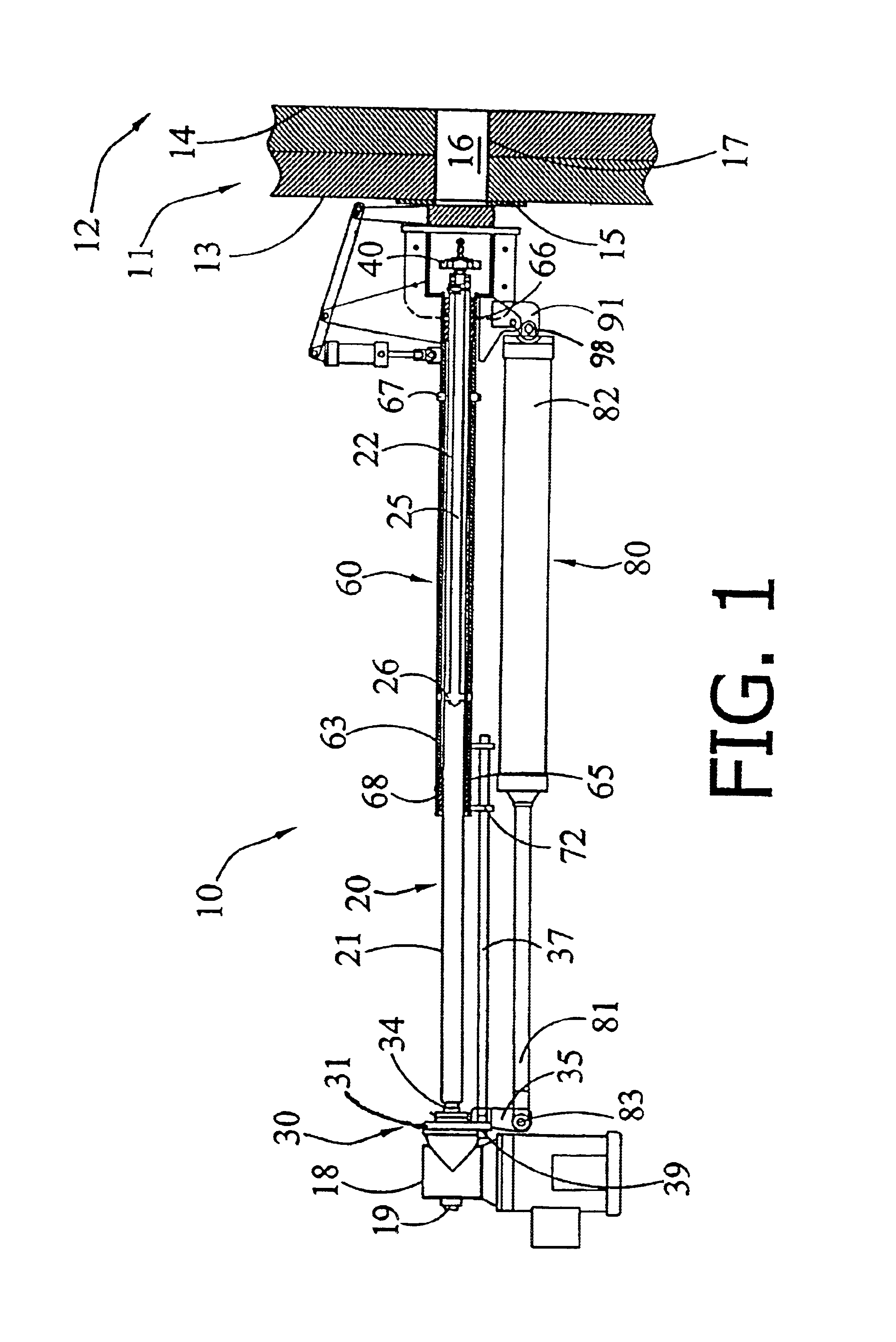

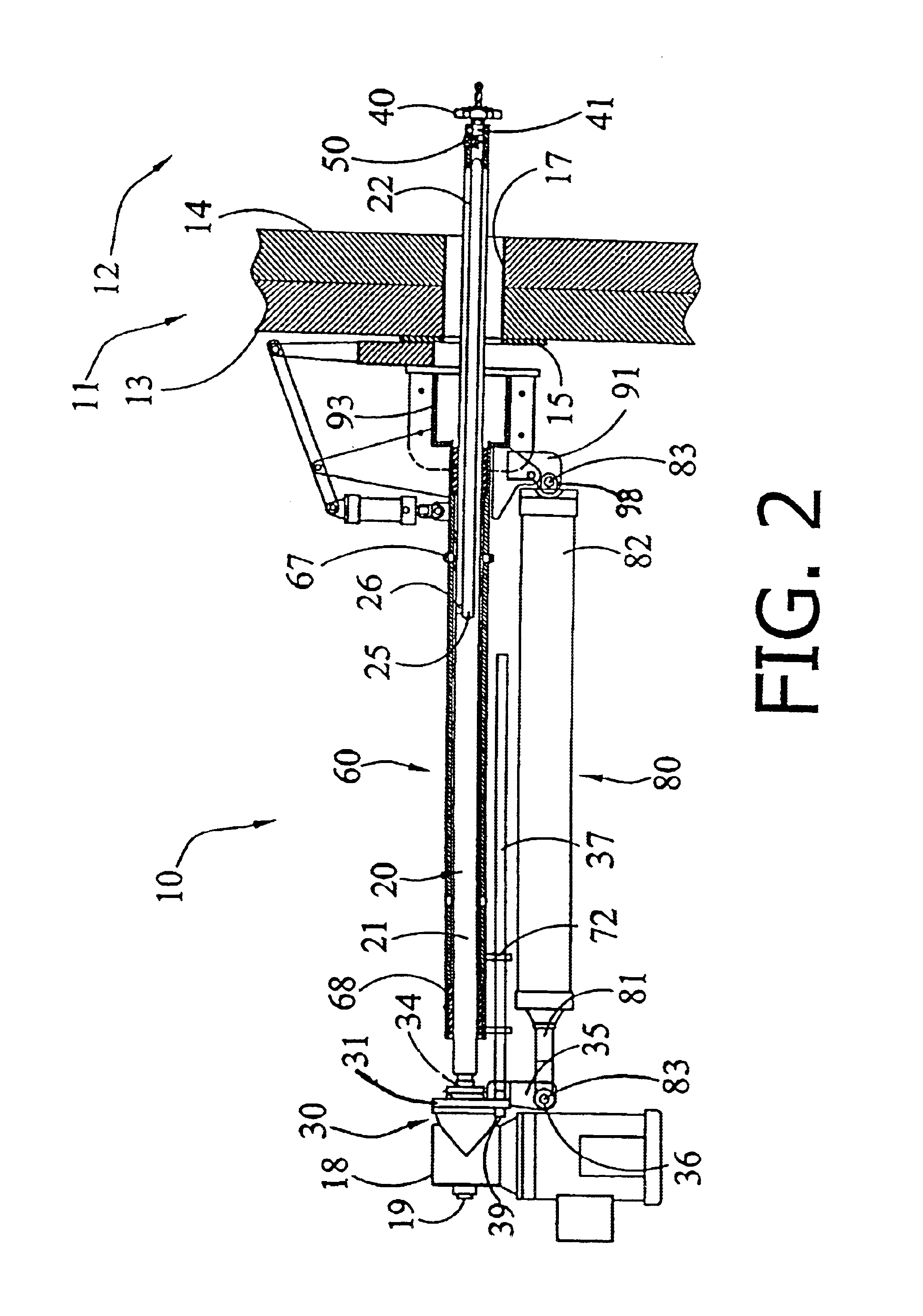

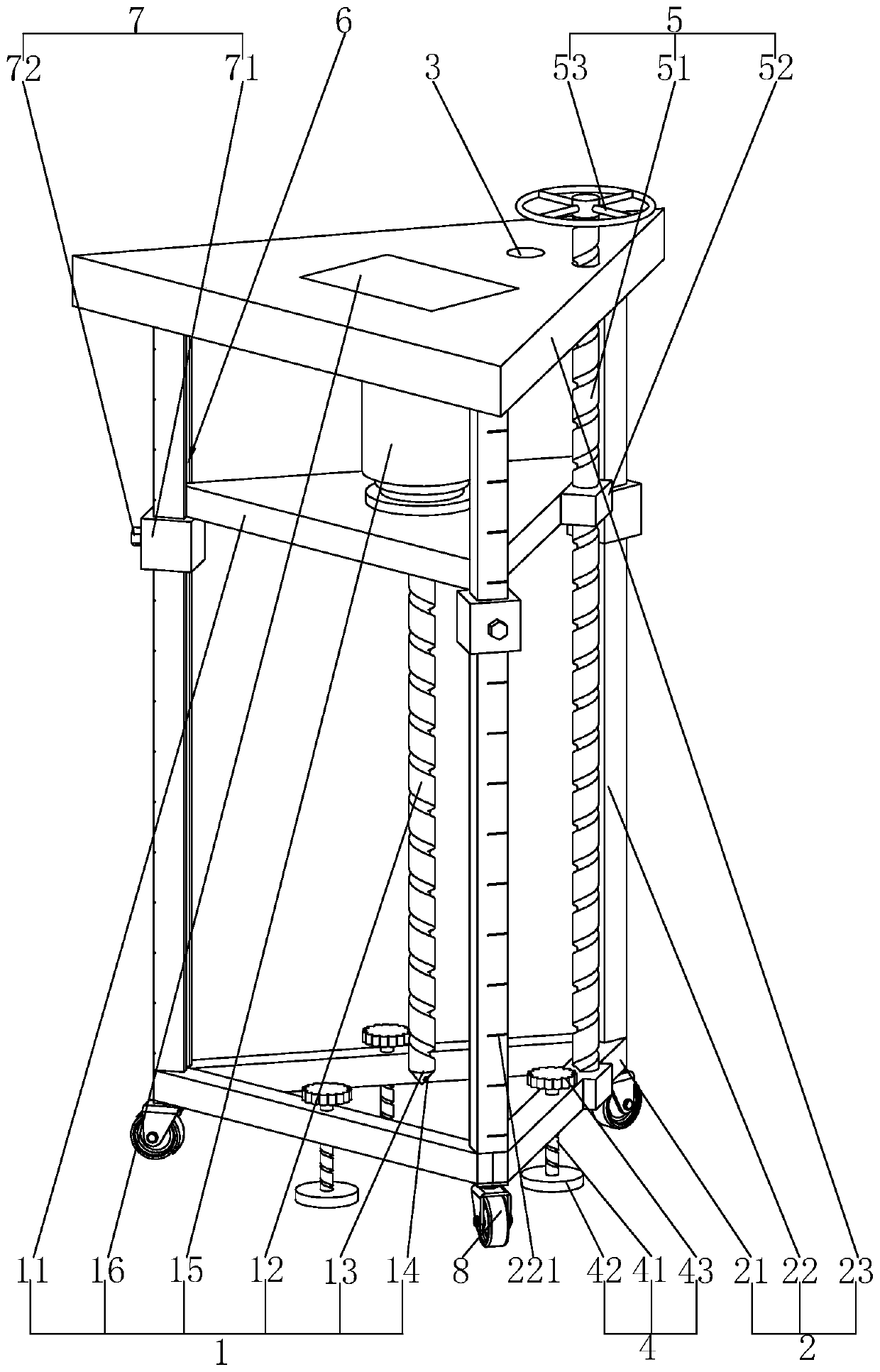

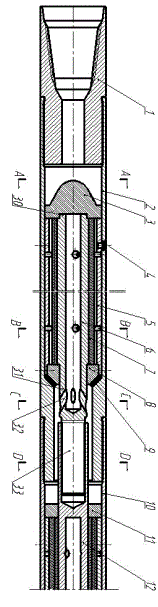

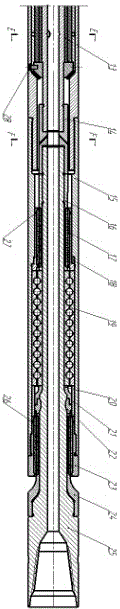

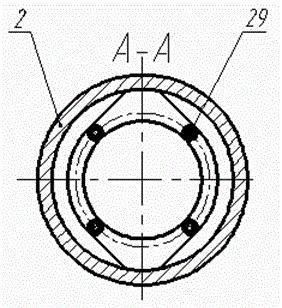

Single-hole geological radar automatic drilling rig arranged at cutter head center of tunneling machine

ActiveCN103696780ASo as not to damageHigh degree of automationTunnelsAutomatic control for drillingBorehole radarSpherical joint

The invention discloses a single-hole geological radar automatic drilling rig arranged at the cutter head center of a tunneling machine. The single-hole geological radar automatic drilling rig comprises an equipment entrance and exit hole, a rapid drilling machine, a borehole geological radar detection device and a carrying device, wherein the equipment entrance and exit hole is located at the cutter head center of the tunneling machine, the rapid drilling machine for the synchronous operation of tunneling and drilling and the borehole geological radar detection device are arranged in the hole, the carrying device comprises a carrying device support and an initiative angle adjusting device for adjusting an included angle between a drill bit of the rapid drilling machine or a borehole radar antenna hydraulic expansion link and the rotating axis of a cutter head of the tunneling machine, and the rapid drilling machine and the borehole geological radar detection device move relative to the device support, and the carrying device support is connected to the cutter head of the tunneling machine by a spherical joint for an equipment entrance and exit pipeline. The single-hole geological radar automatic drilling rig has the beneficial effects that the synchronous operation of tunneling and drilling can be realized, and the included angle between the eccentric casing drilling bit or the borehole radar antenna hydraulic expansion link and the rotating axis of the cutter head of the tunneling machine is adjusted.

Owner:SHANDONG UNIV

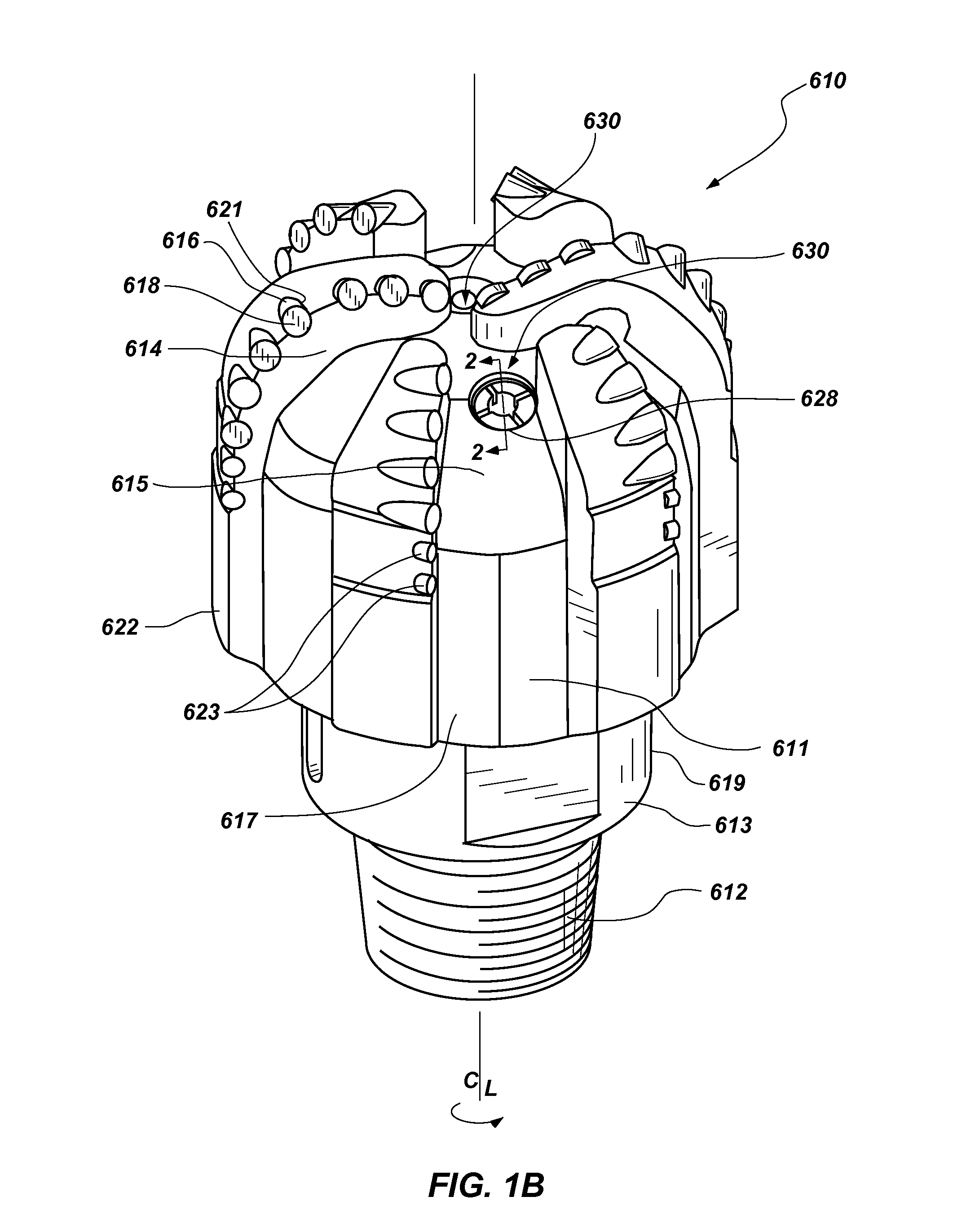

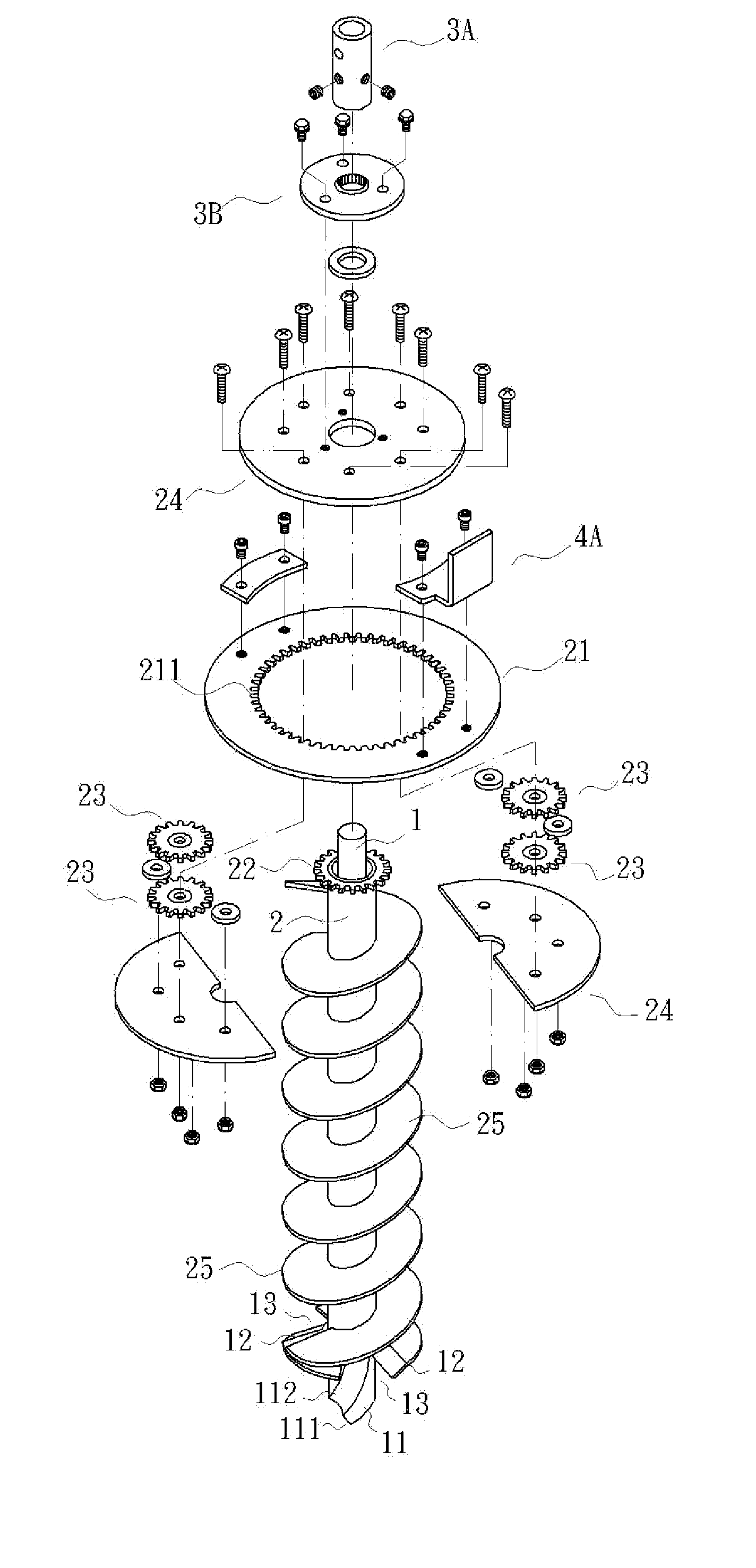

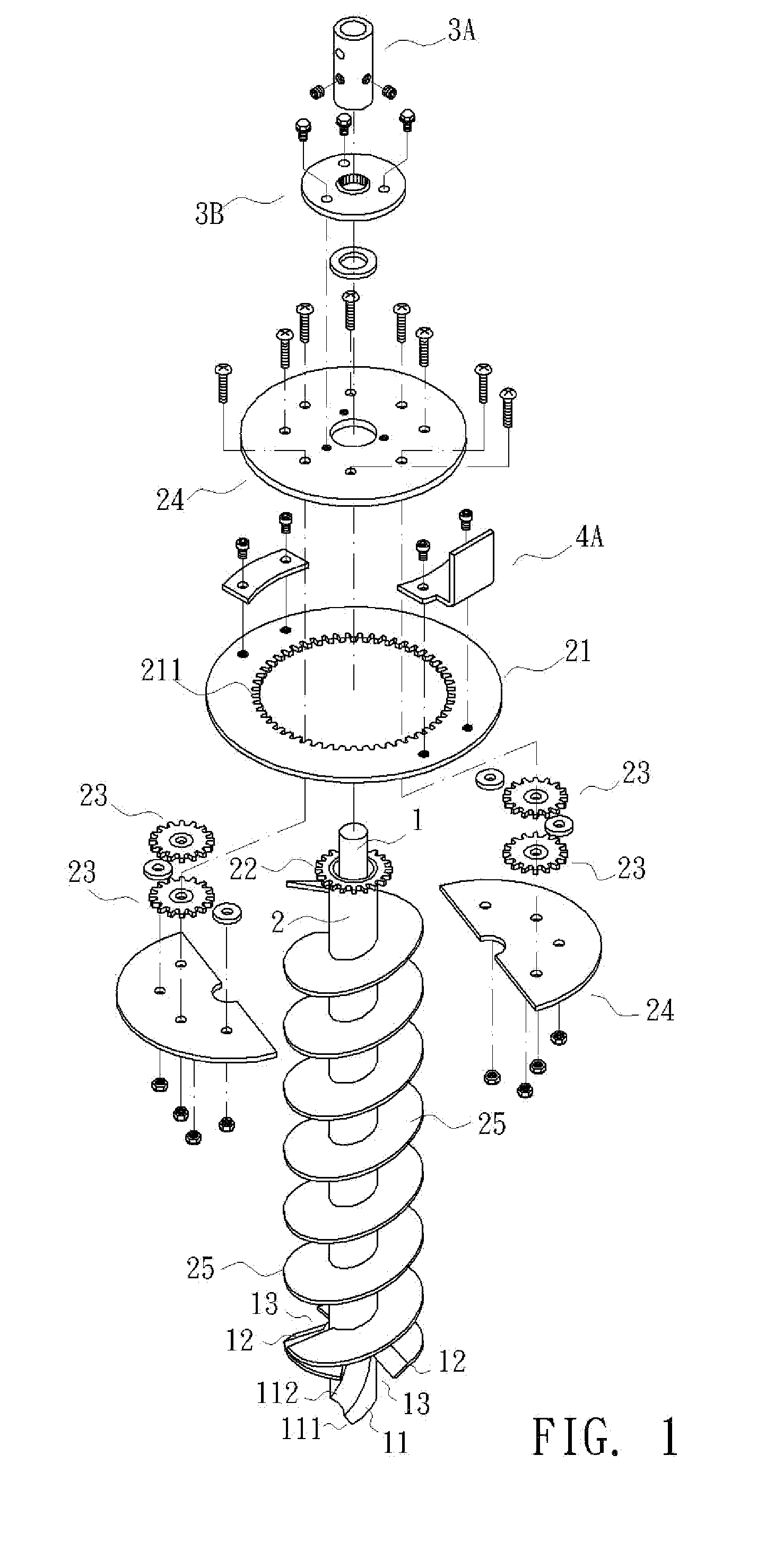

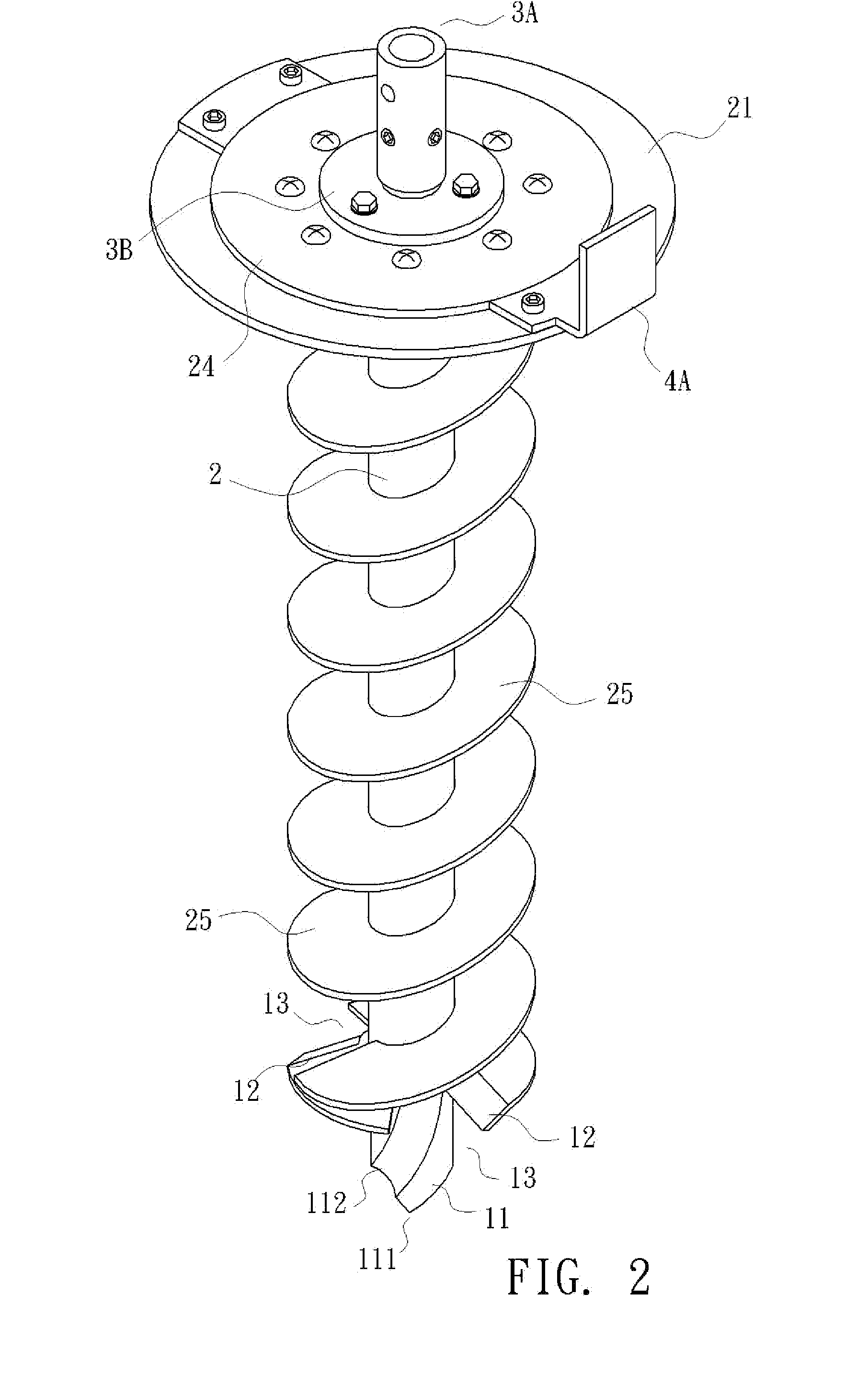

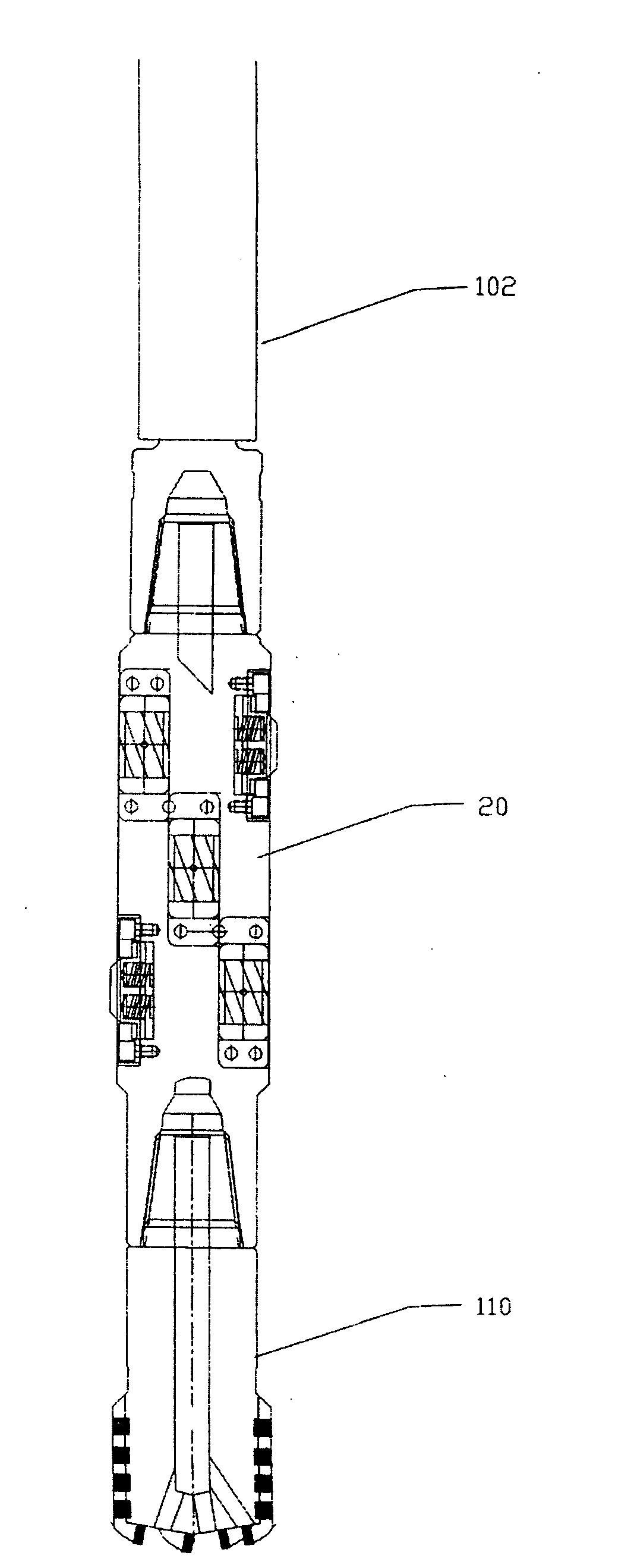

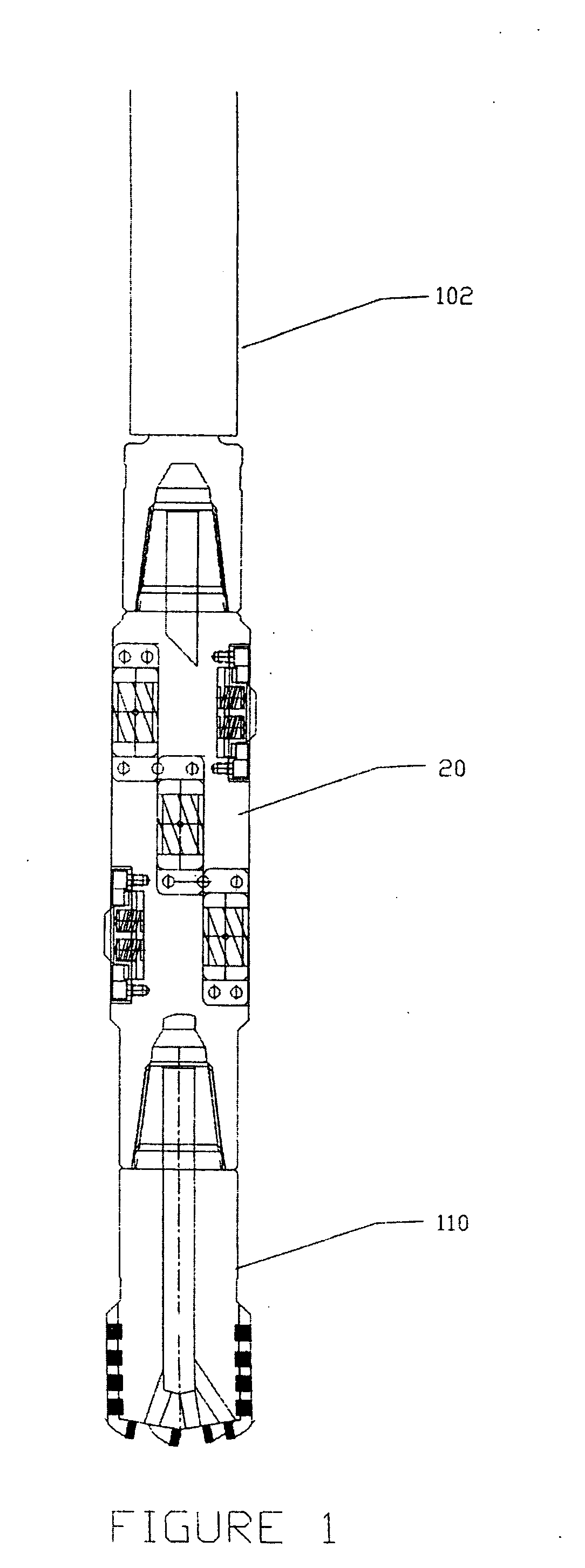

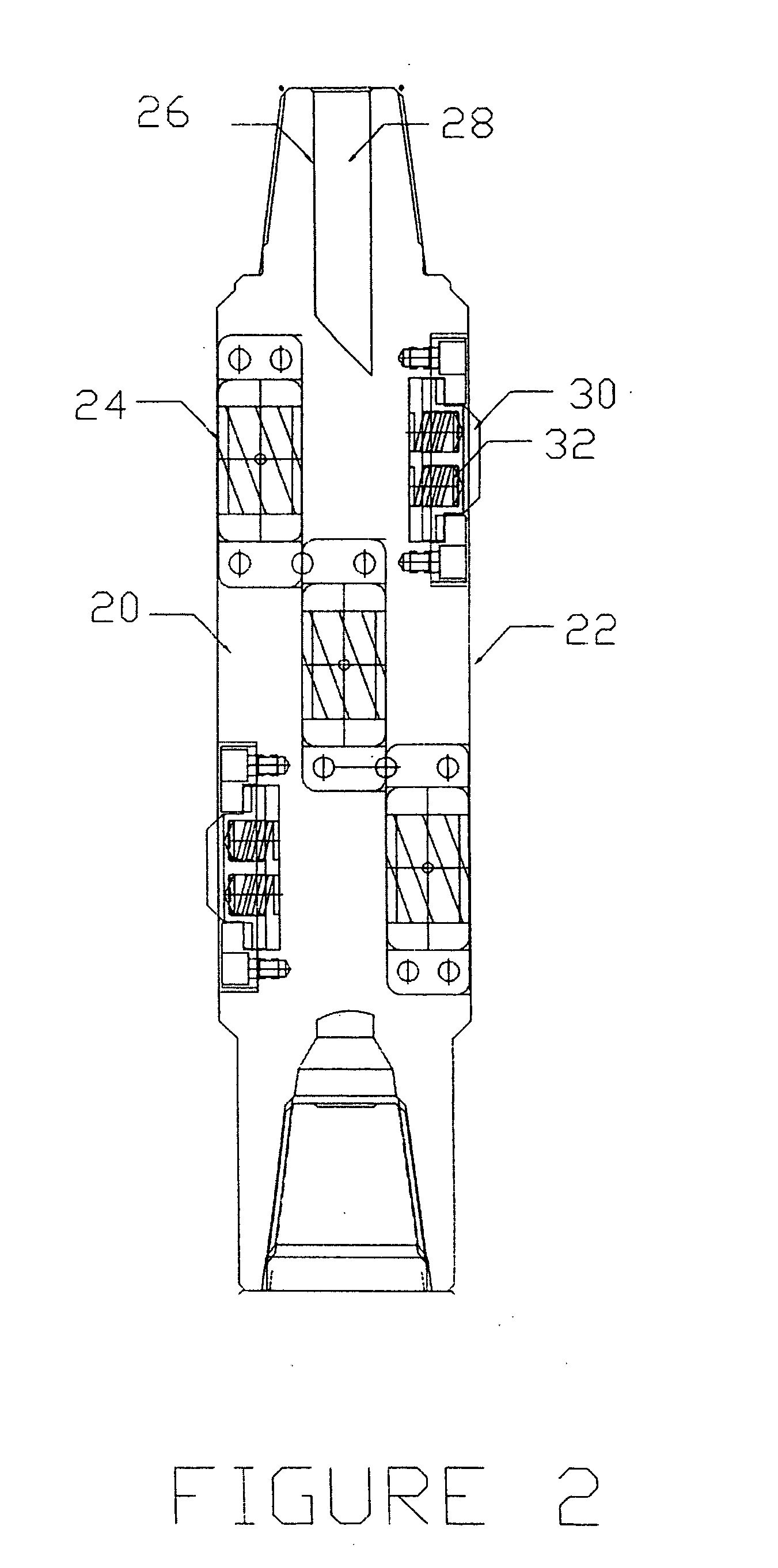

Planetary drill bit assembly for balancing reactive torque of drilling equipment in well drilling

ActiveCN101871328AImprove stabilityIncreased directional control capabilitiesDrilling rodsDirectional drillingWell drillingDrive shaft

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

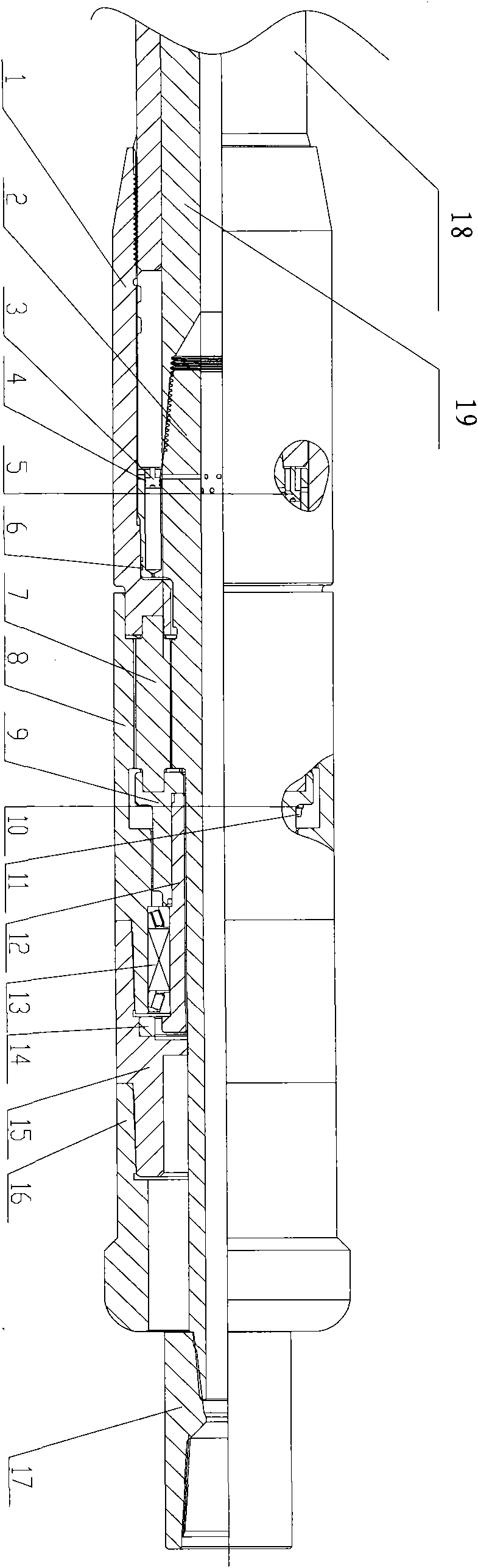

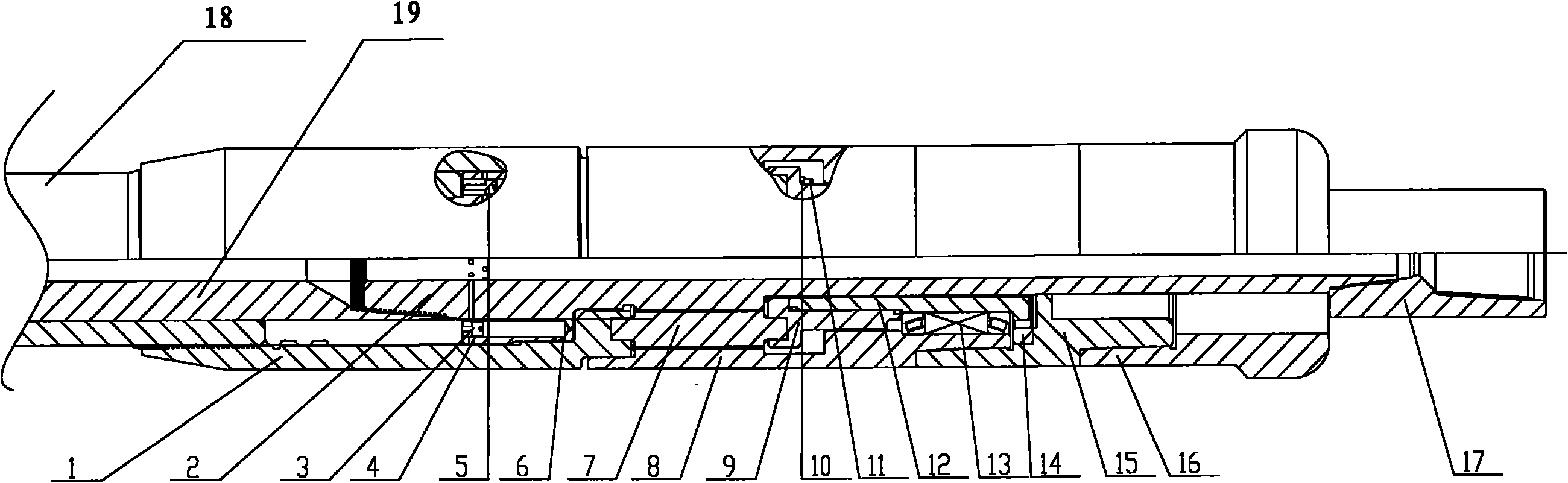

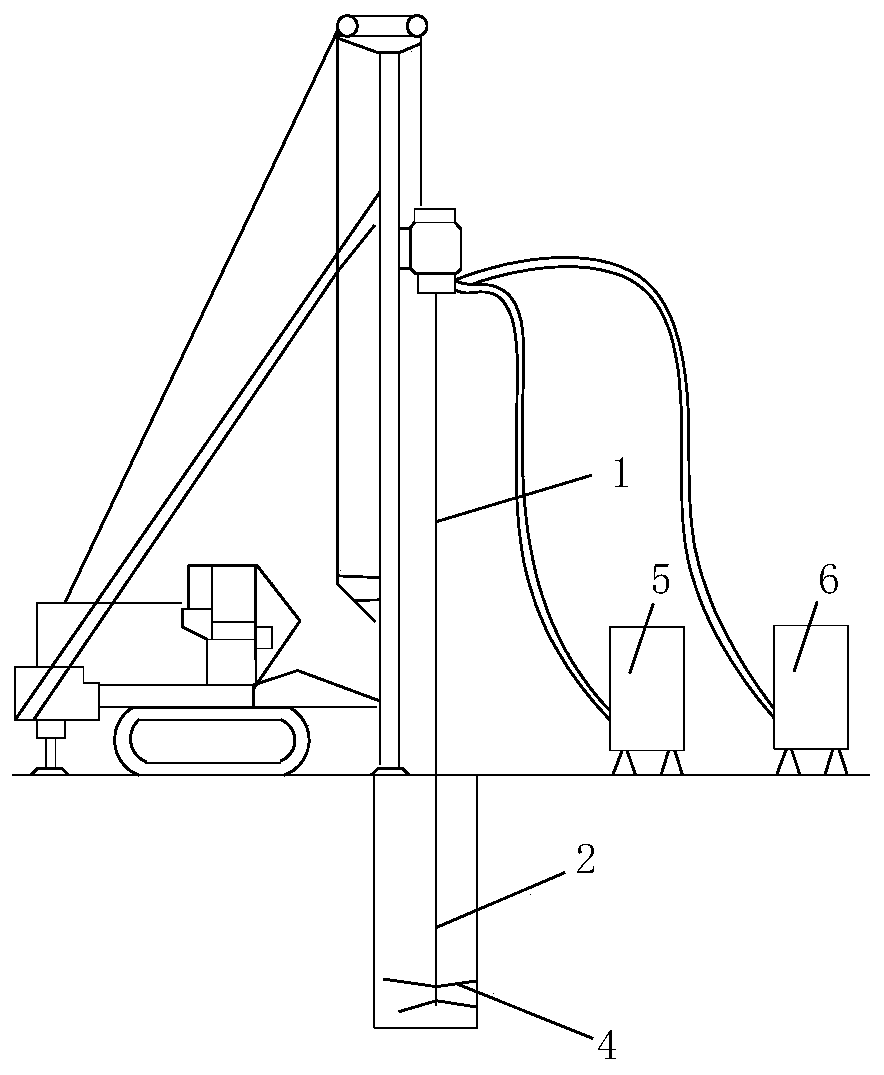

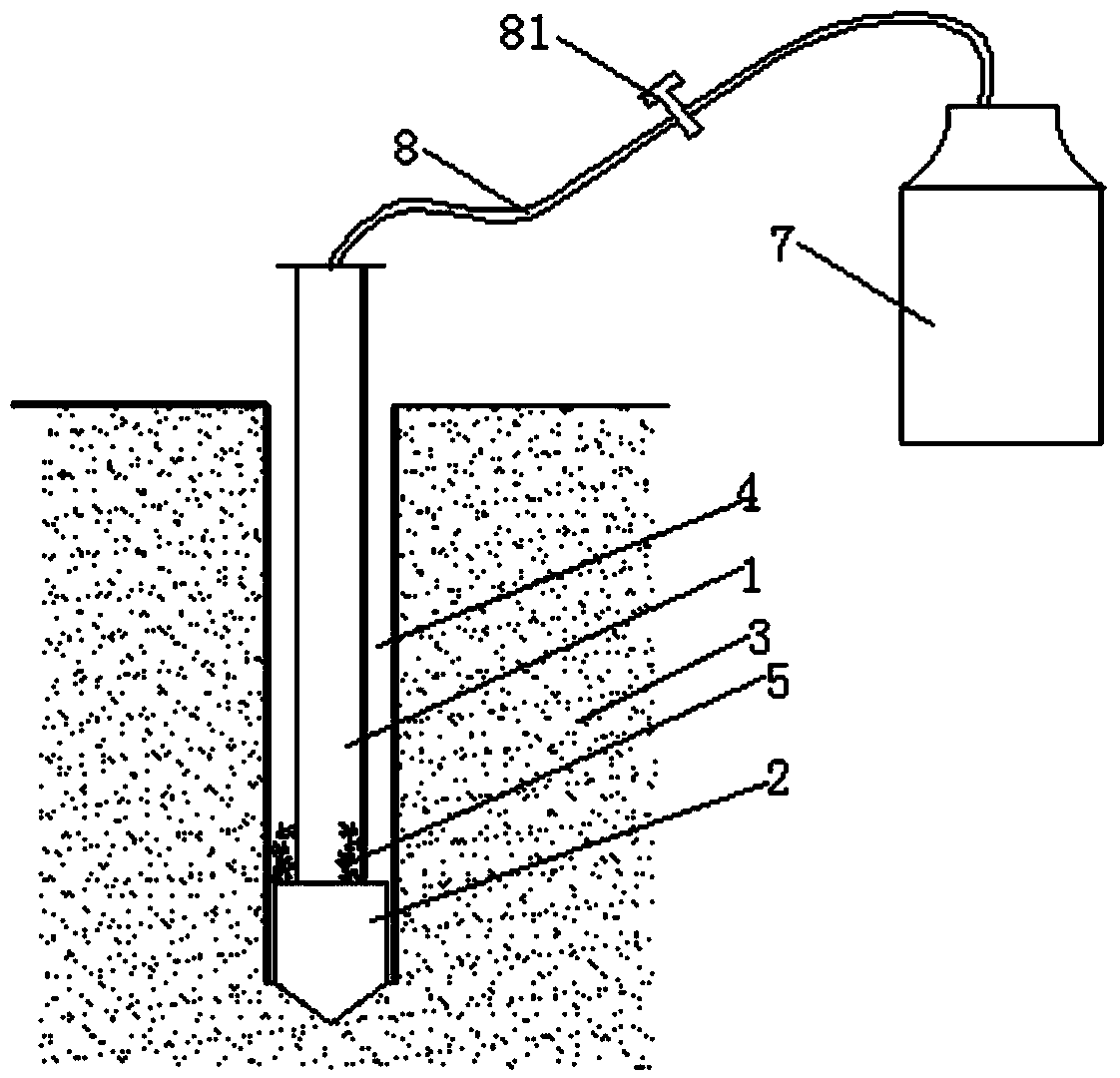

Reverse circulation drilling device and process for soft projecting coal seam

The invention provides a reverse circulation drilling device for a soft projecting coal seam. The device comprises a drilling machine, an active double-wall drilling rod, a double-channel pneumatic faucet; a power head is arranged on the drilling machine; the active double-wall drilling rod passes through the power head to be mounted; an inner pipe at one end of the active double-wall drilling rod is connected with a rubber pipe through the double-channel pneumatic faucet; a pulverized coal receiving device is connected to the tail end of the rubber pipe; an air box which communicates with internal and external pipe annular channels of the active double-wall drilling rod is arranged on the double-channel pneumatic faucet; the air box is connected with an air compressor through an air pipe; a drill bit is connected to the other end of the active double-wall drilling rod. With the adoption of the device, the disturbance to the coal seam can be minimized, so that the collapse in holes can be effectively prevented, and that the frequent drilling blocking accidents can be avoided; the circumstance that gas is concentrated is prevented, and therefore, the phenomenon of blowout through the holes can be effectively avoided; the production cost is low; in addition, the working environment at the construction field can be effectively improved; the purpose of drilling in collapse and reducing stratums synchronously by one drilling rod can be achieved.

Owner:周升风

Methods for automated application of hardfacing material to drill bits

Owner:BAKER HUGHES INC

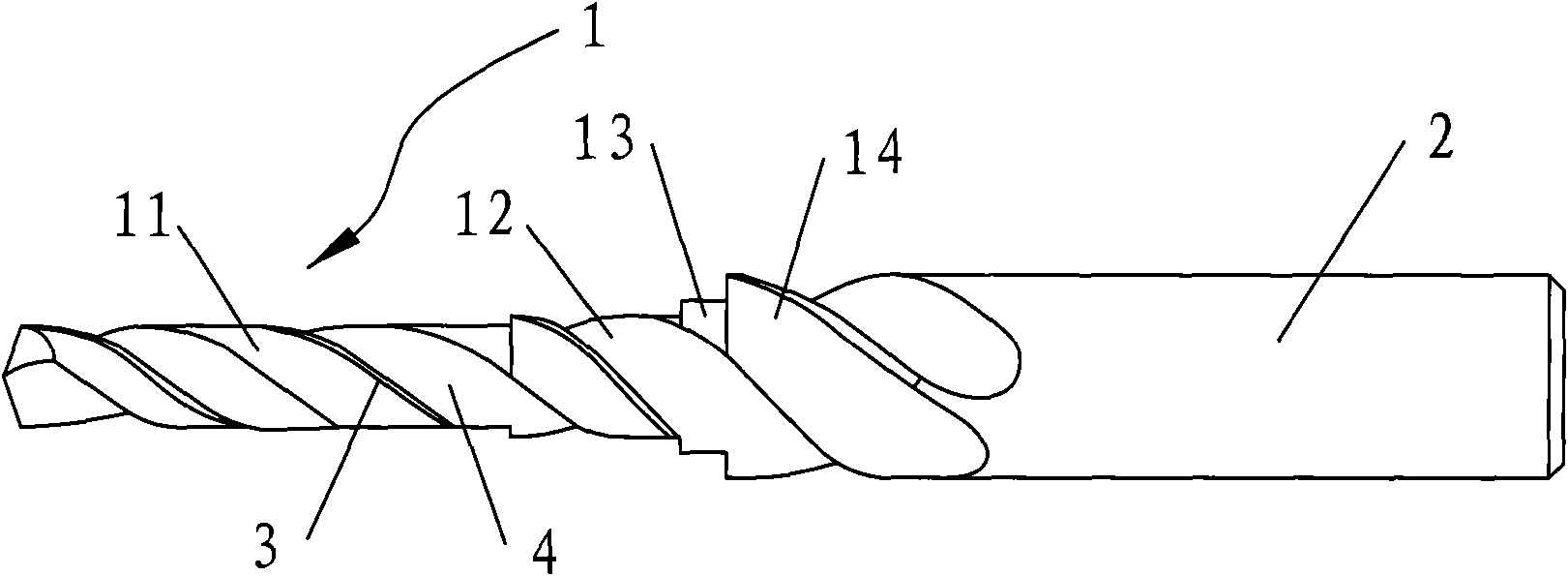

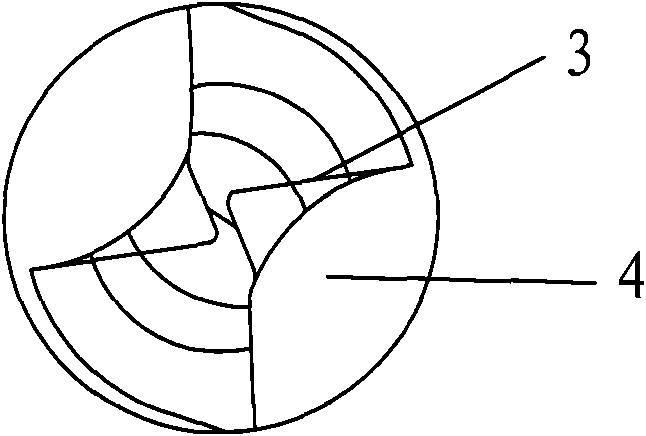

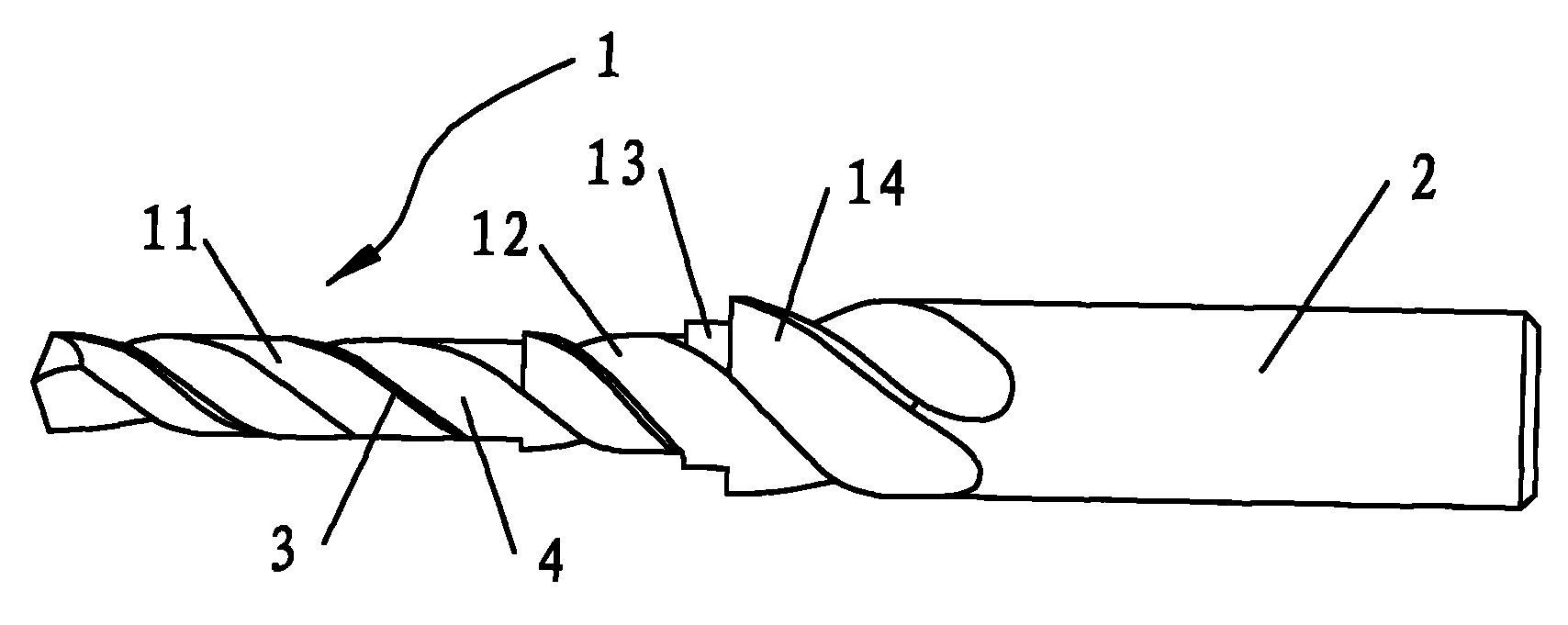

Step drill

InactiveCN101780555AImprove machining accuracyAvoid errorsTransportation and packagingTrepanning drillsEngineeringDrill bit

Owner:苏州富莱克精密工具有限公司

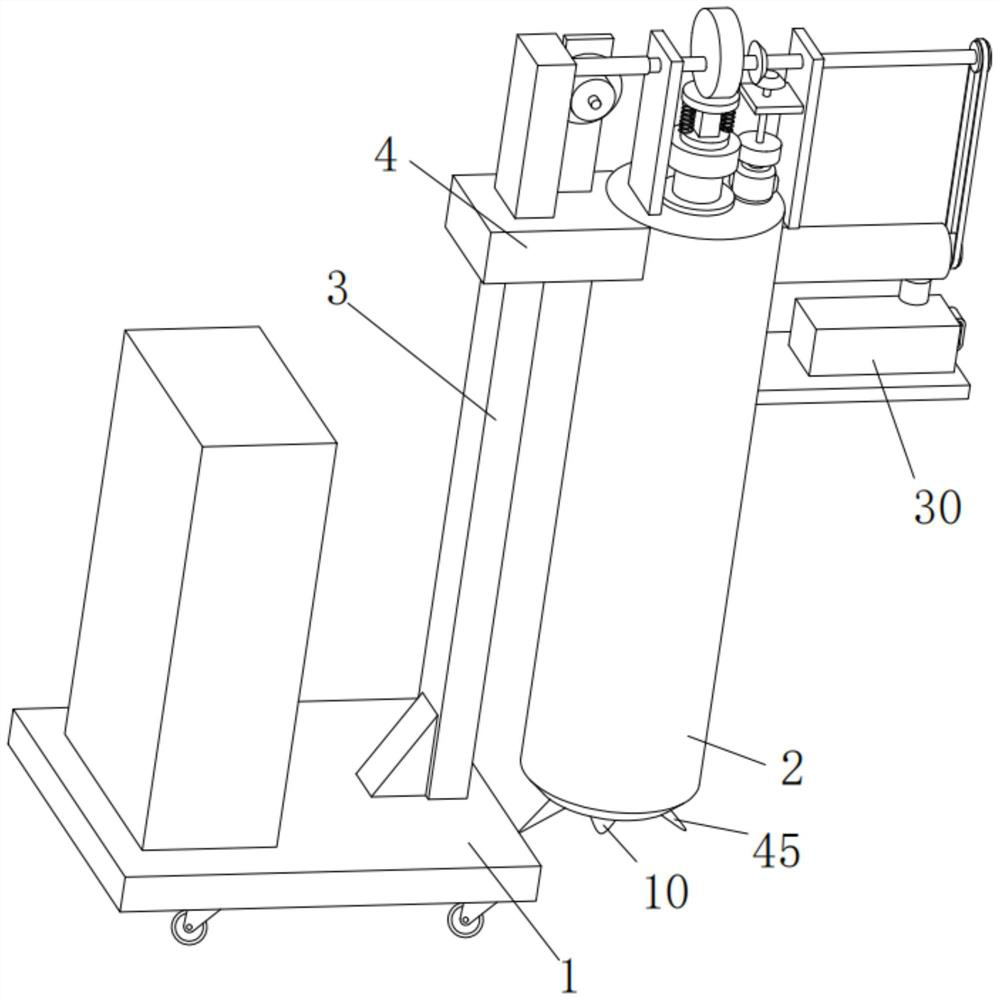

Surface drilling device for flocked cloth

InactiveCN107097292AHigh degree of automation integrationIncrease productivityLiquid surface applicatorsCoatingsDrill bitPetroleum engineering

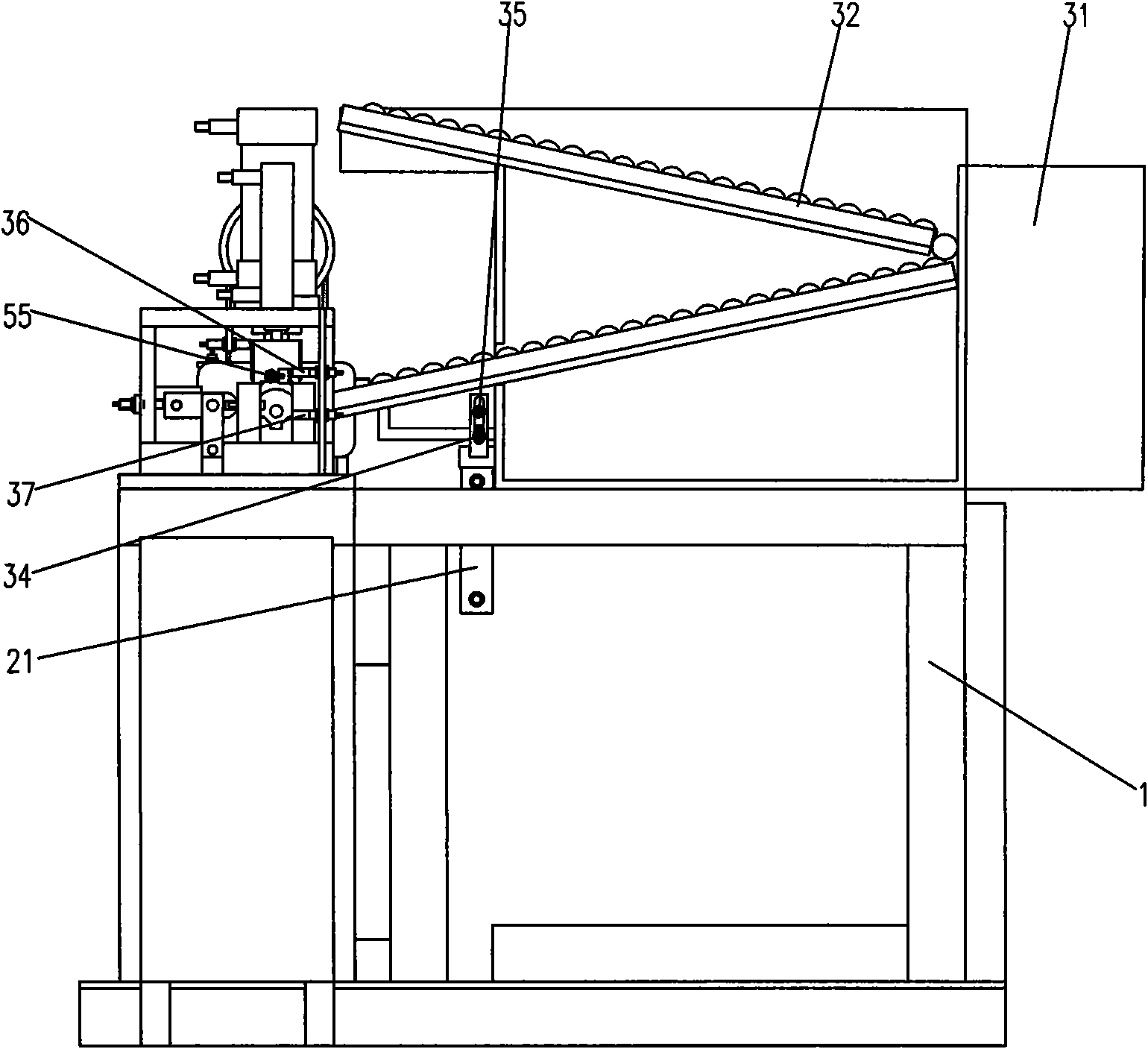

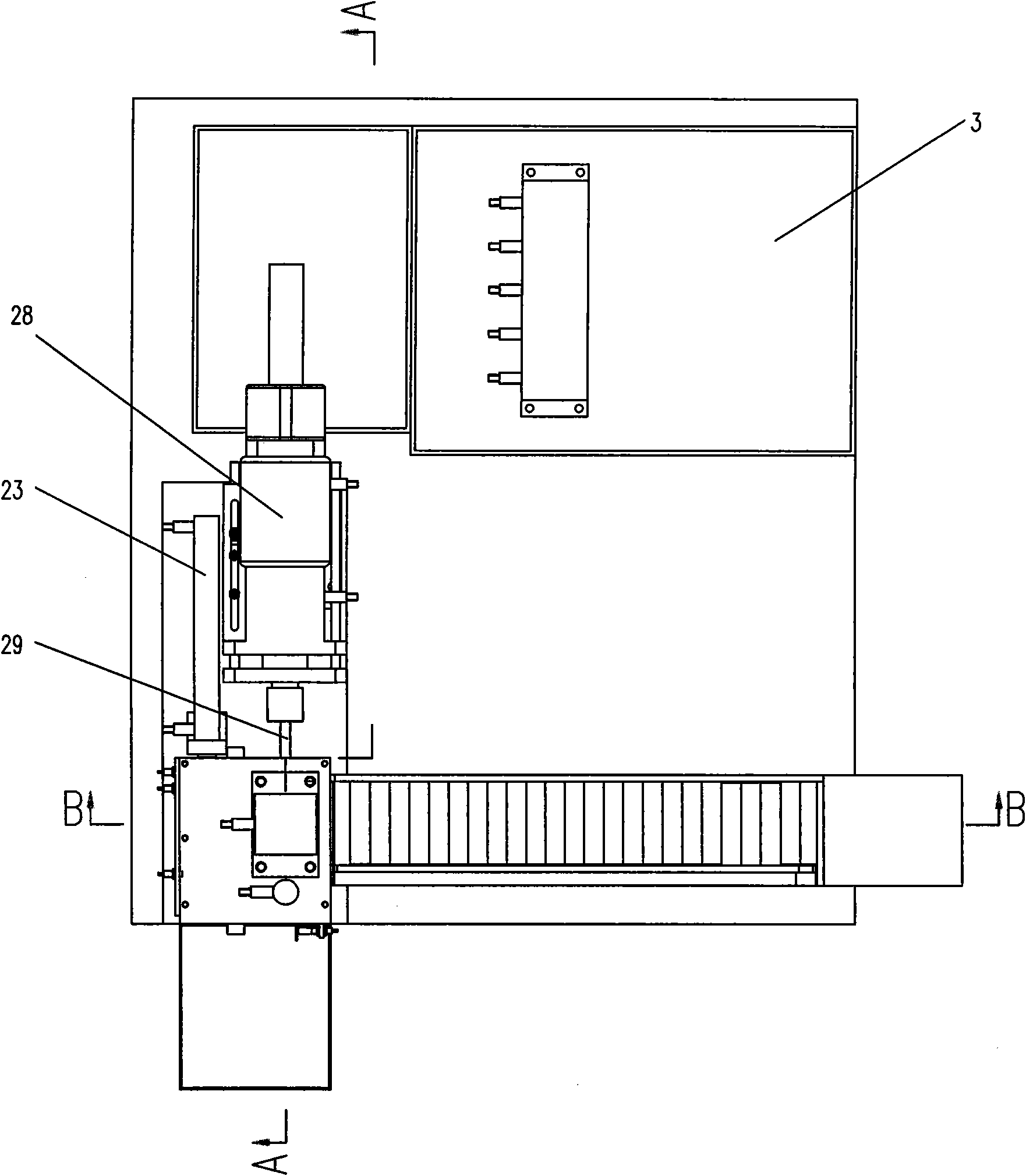

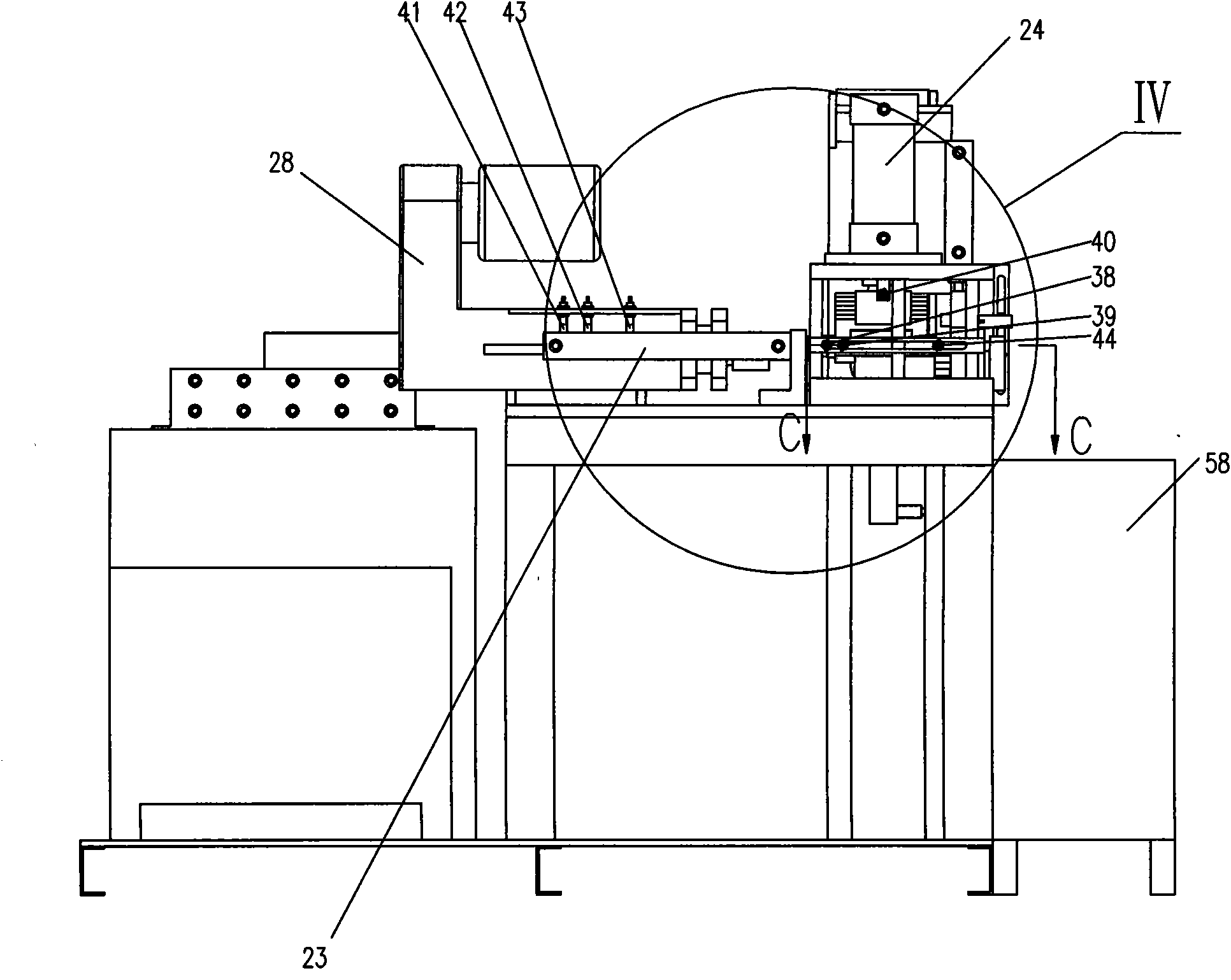

The invention discloses a surface drilling device for flocked cloth. The surface drilling device comprises a base and a movable drilling assembly arranged at the upper end of the base, wherein a fixture is inserted into a fixture fixed groove; the flocked cloth needing to drill is clamped on a sliding panel; the sliding panel is controlled by a servo motor to move leftwards and rightwards; successively, the movable drilling assembly moves by a control shaft fixed base of the servo motor; a drilling head is controlled by a lifting air cylinder to move downwards; and the drilling head is controlled by the motor to rotate to carry out drilling. The surface drilling device for the flocked cloth is high in automatic integration degree, is beneficial for improving production efficiency, and greatly reduces defective rate; meanwhile, by adopting a multi-shaft drilling way, the surface drilling device for the flocked cloth greatly improves the adjustability of the device, and is beneficial for improving the drilling efficiency.

Owner:JIASHAN SHENGLAISI CASHMERE

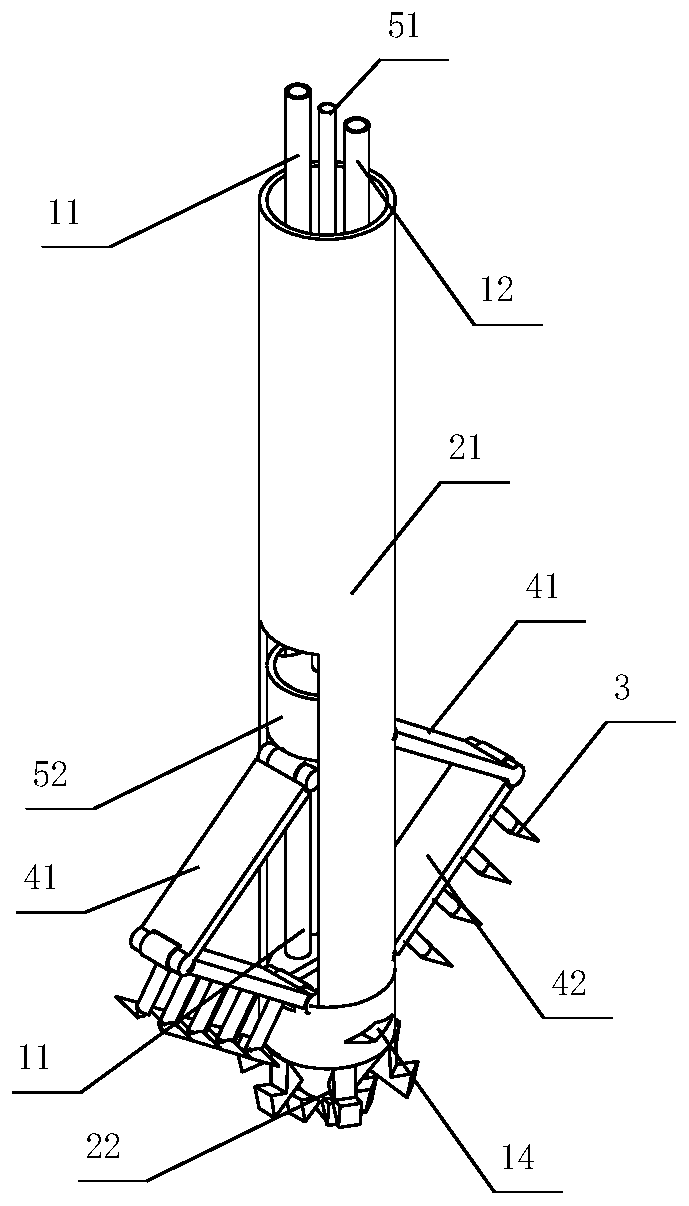

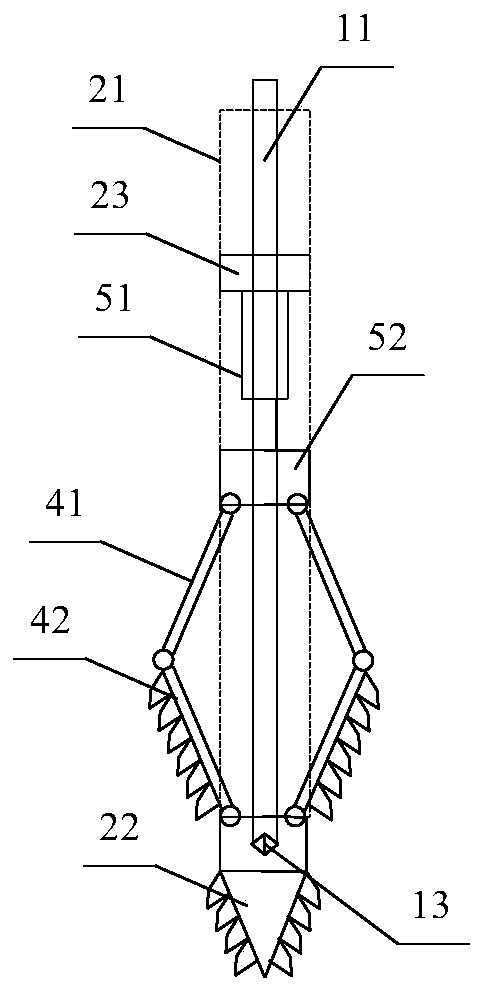

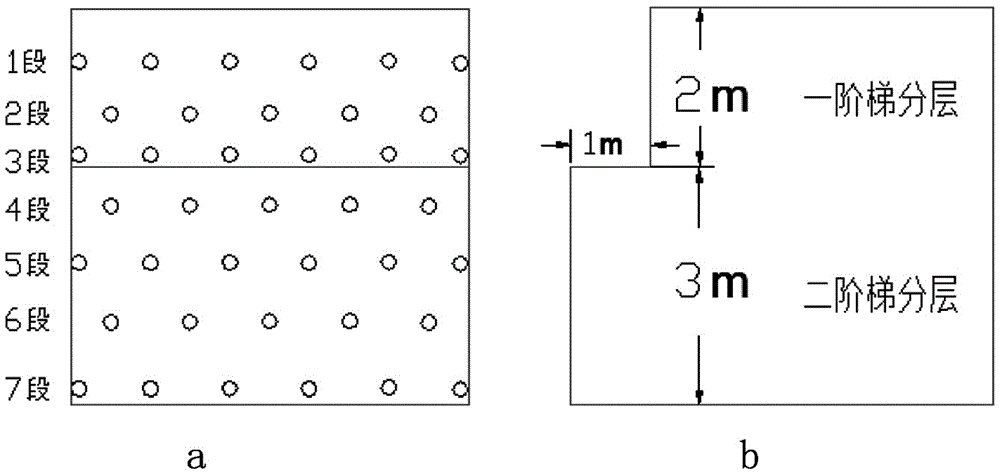

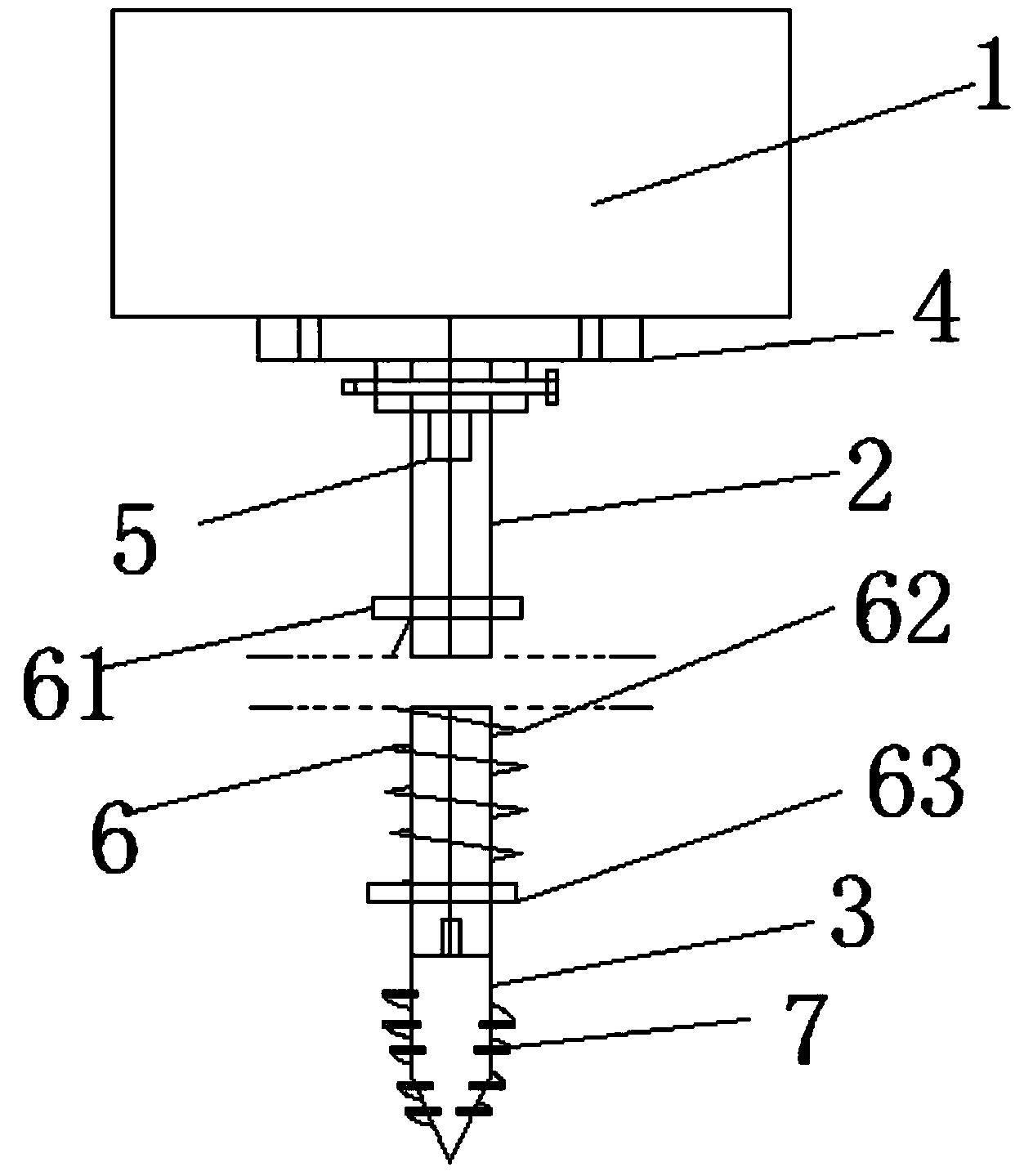

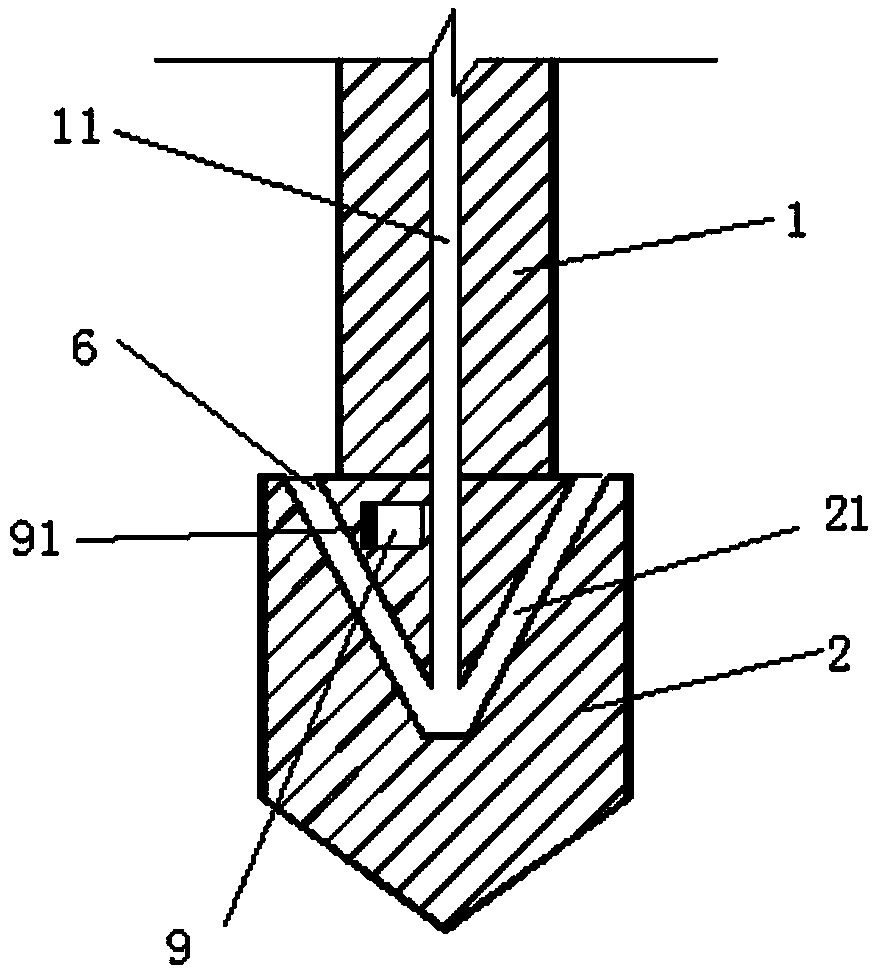

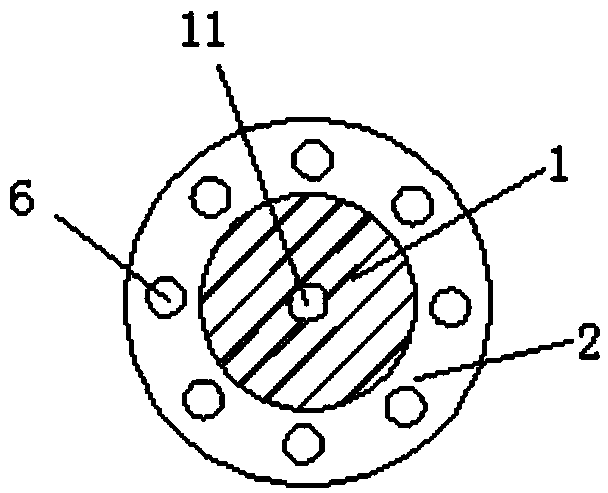

Diameter variable double high-pressure stir-spray pile and diameter variable method thereof

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +2

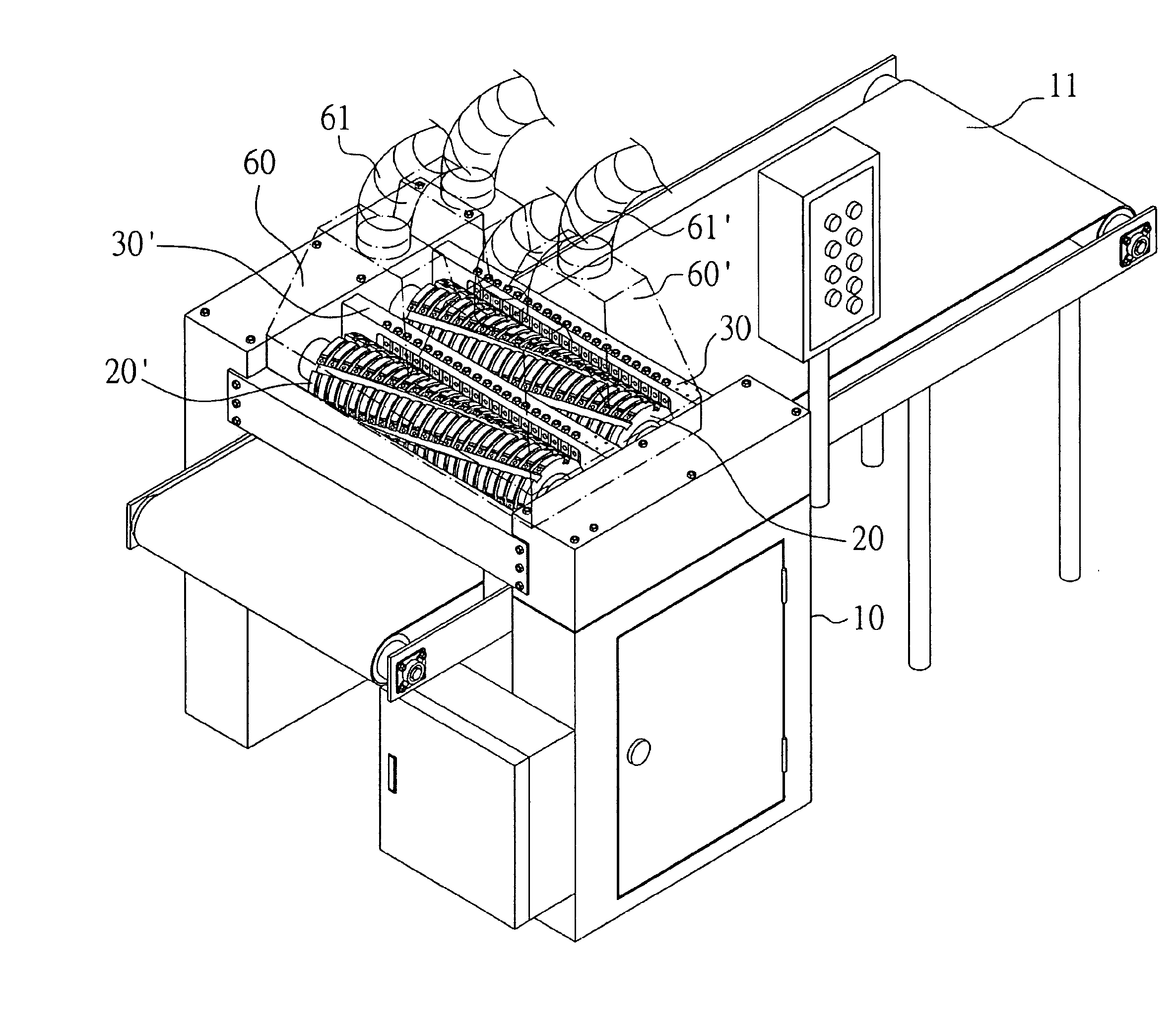

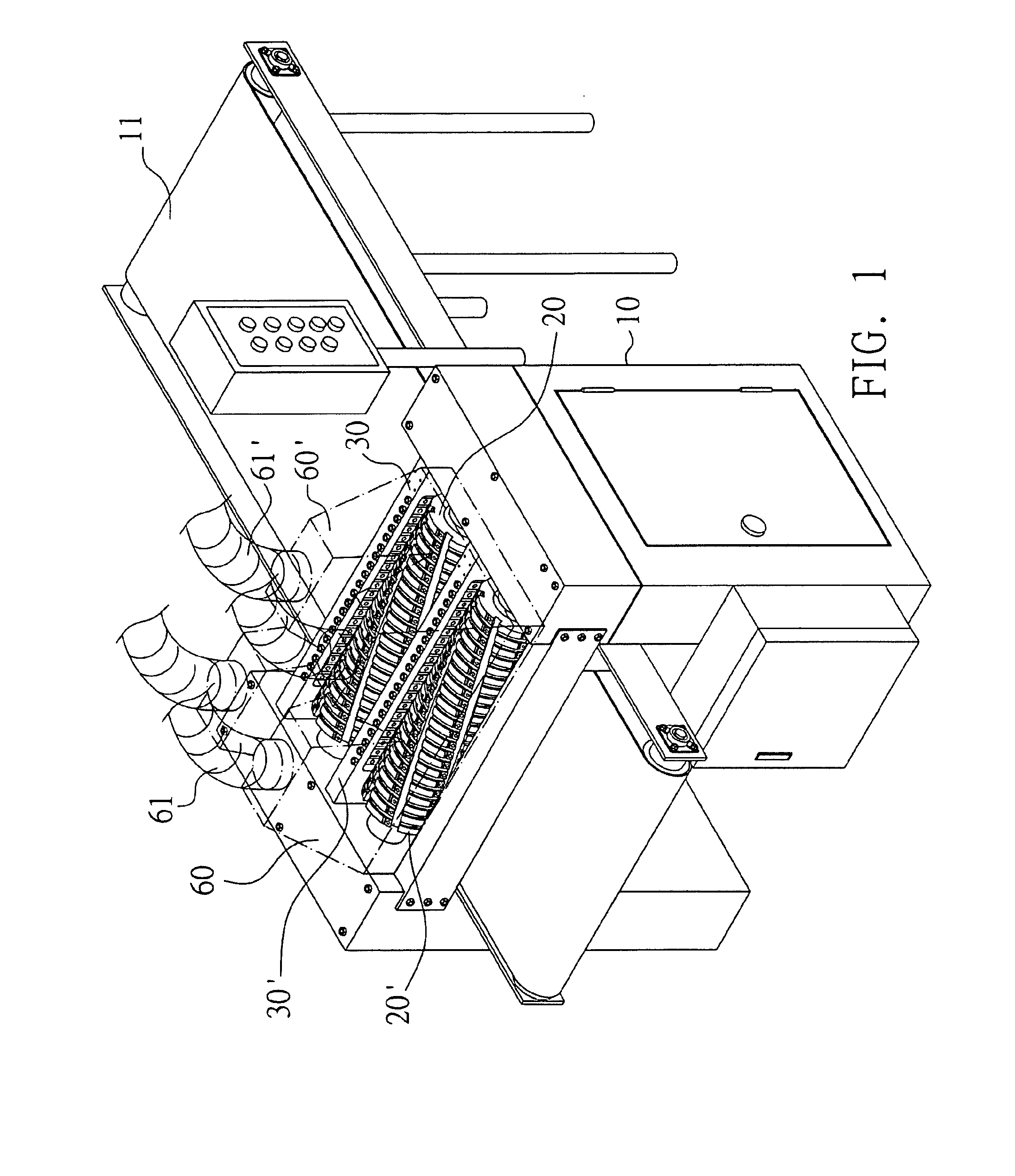

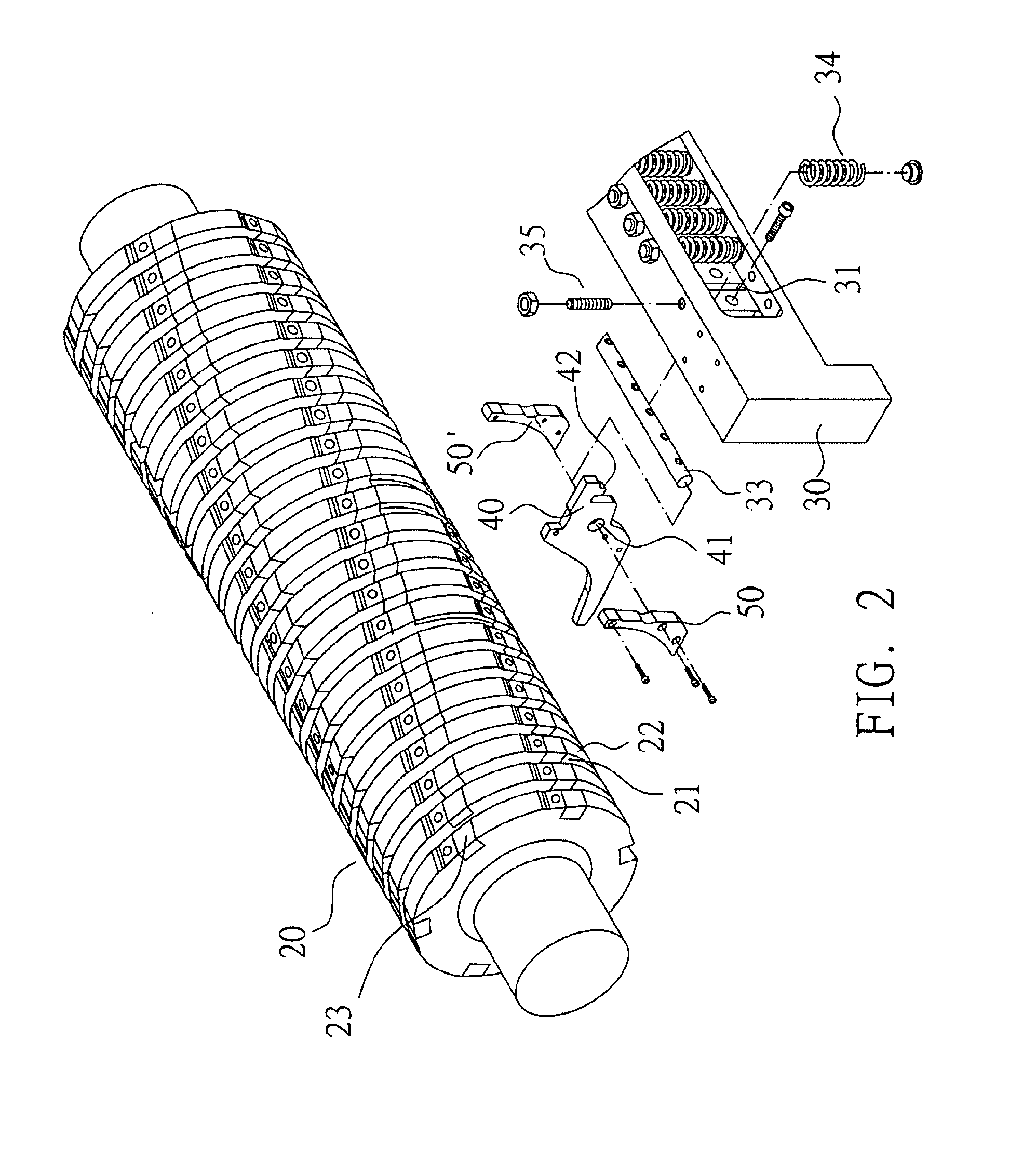

Stable wood planing assembly of a veneer wood planing machine

InactiveUS20090260718A1Improve qualityGuaranteed uptimeWood feeding arangementsThicknessing machinesEngineeringDrill bit

Owner:WANG YEN MING

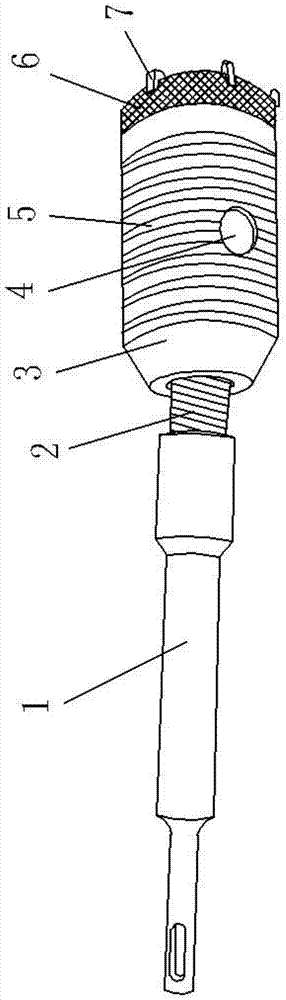

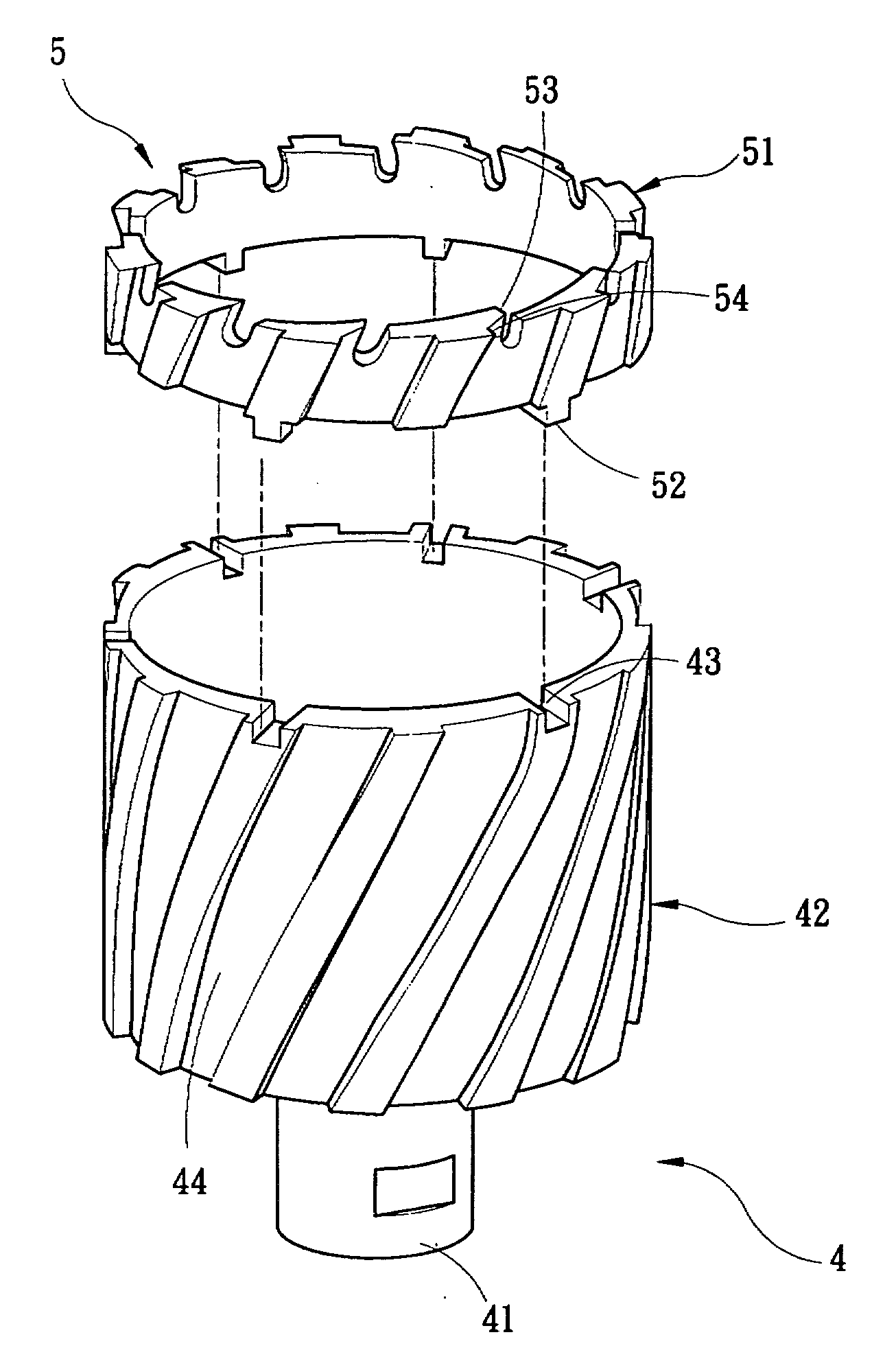

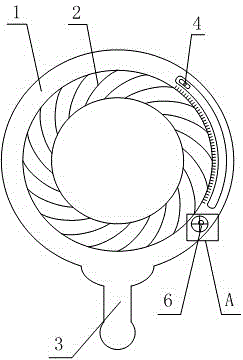

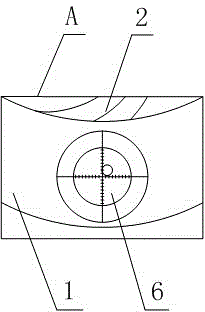

Drill bit of hollow drill and manufacturing method thereof

InactiveCN103752907AAnti-corrosionWith cleanTransportation and packagingTool adaptersWear resistantDrill bit

Owner:宁波神钻工具有限公司

Drilling machine

InactiveUS20090107729A1Different turning speedEarth drilling toolsDrilling rodsEngineeringMechanical engineering

Owner:CHAN YAO PANG

Soil sampling device for highway engineering road and use method thereof

PendingCN113404030AReduce manpower consumptionReduce difficultyIn situ soil foundationLow speedAgricultural engineering

Owner:谭小波

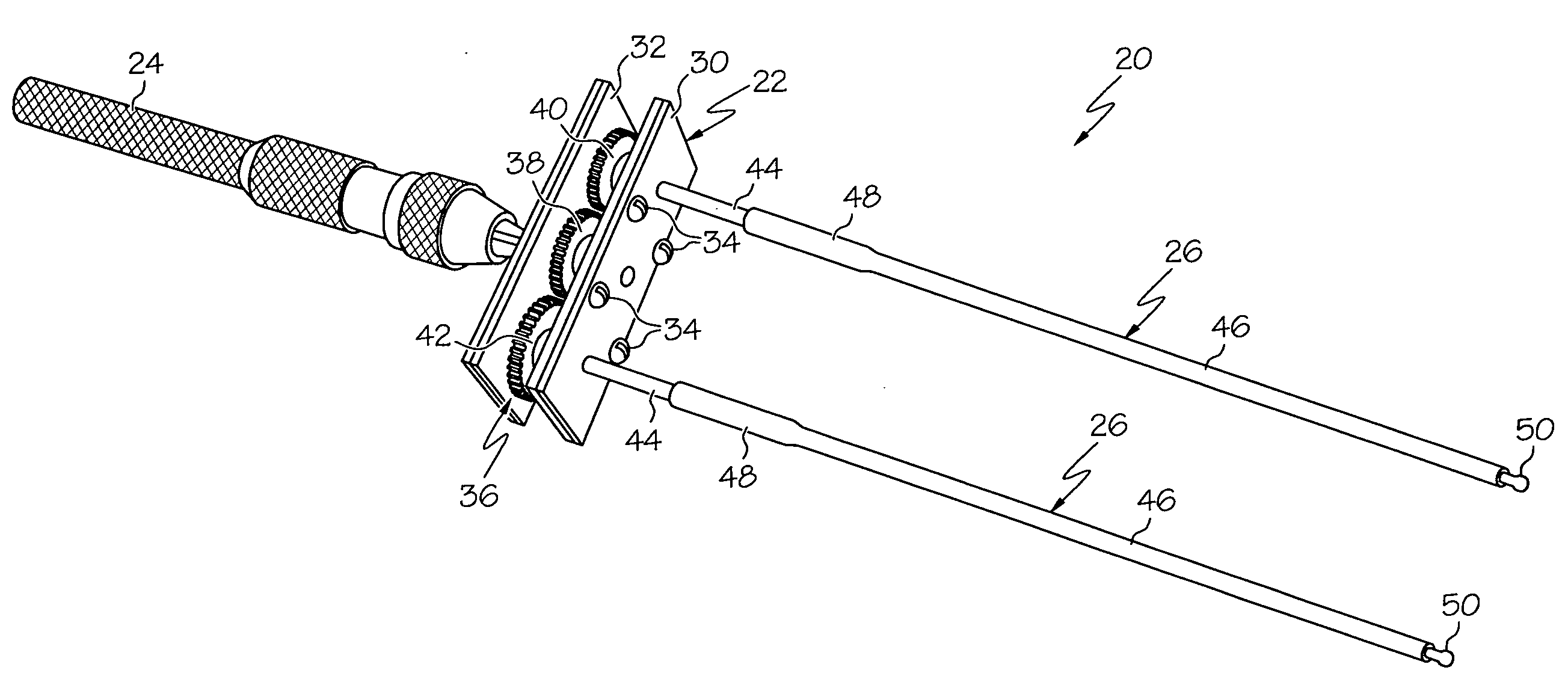

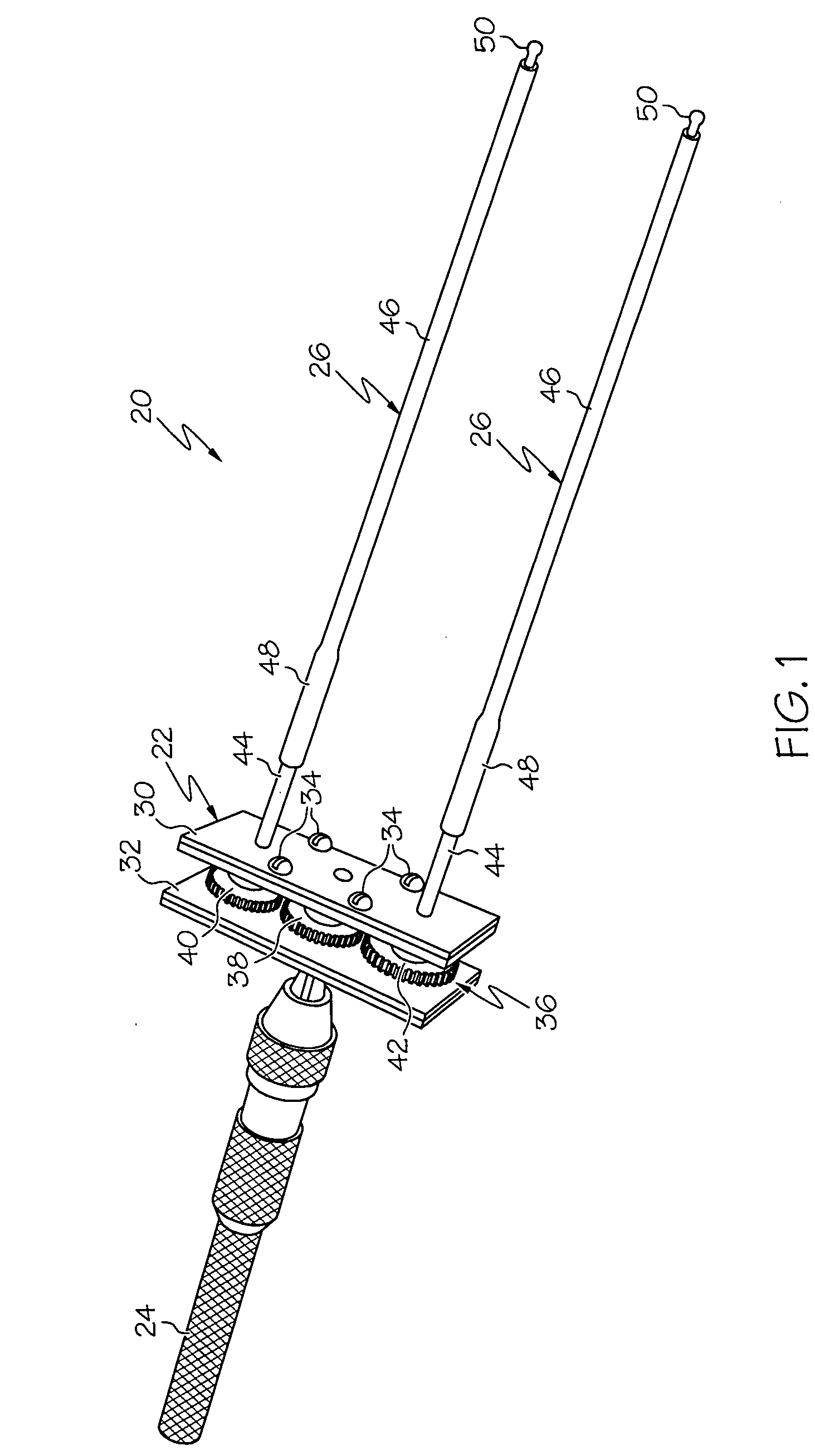

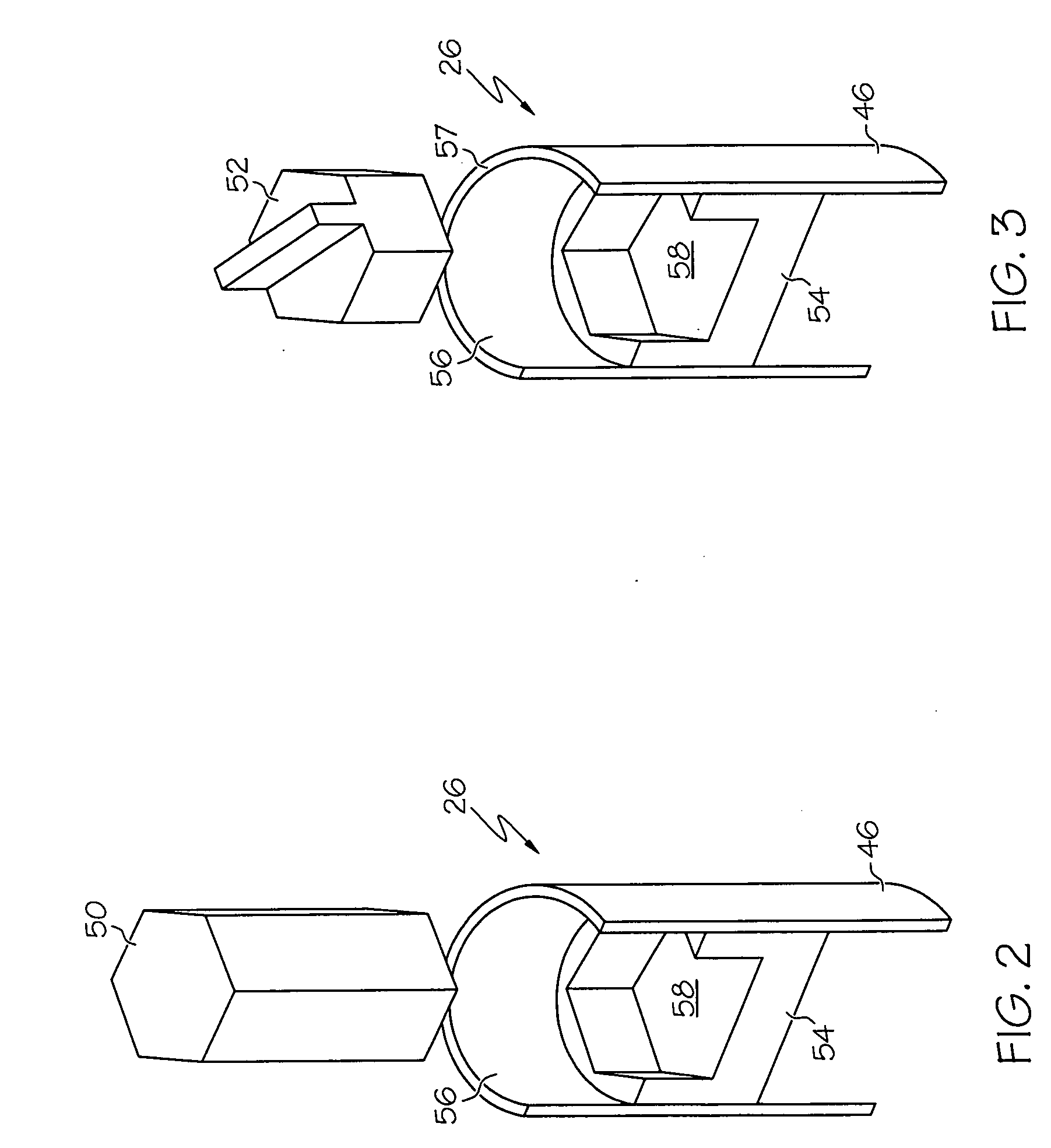

Dual screwdriver adaptable to connector assemblies of different types and sizes

A dual screwdriver is provided for connecting and disconnecting a connector assembly having first and second jackscrew guideposts. In one embodiment, the dual screwdriver includes a housing, a user input rotatably coupled to the housing, first and second manually-bendable shafts each rotatably coupled to the housing, and first and second bits mounted to the distal end portions of first and second manually-bendable shafts, respectively. The first and second bits are configured to matingly engage the first and second jackscrew guideposts. A gear train is disposed in the housing and mechanically couples the user input to the first and second manually-bendable shafts. The rotation of the user input drives the rotation of the first and second manually-bendable shafts and, therefore, the rotation of the first and second jackscrew guideposts when matingly engaged by the first and second bits, respectively.

Owner:HONEYWELL INT INC

Thick ore body mining method

Owner:HUBEI SHANSHUYA MINING SCI & TECH DEV

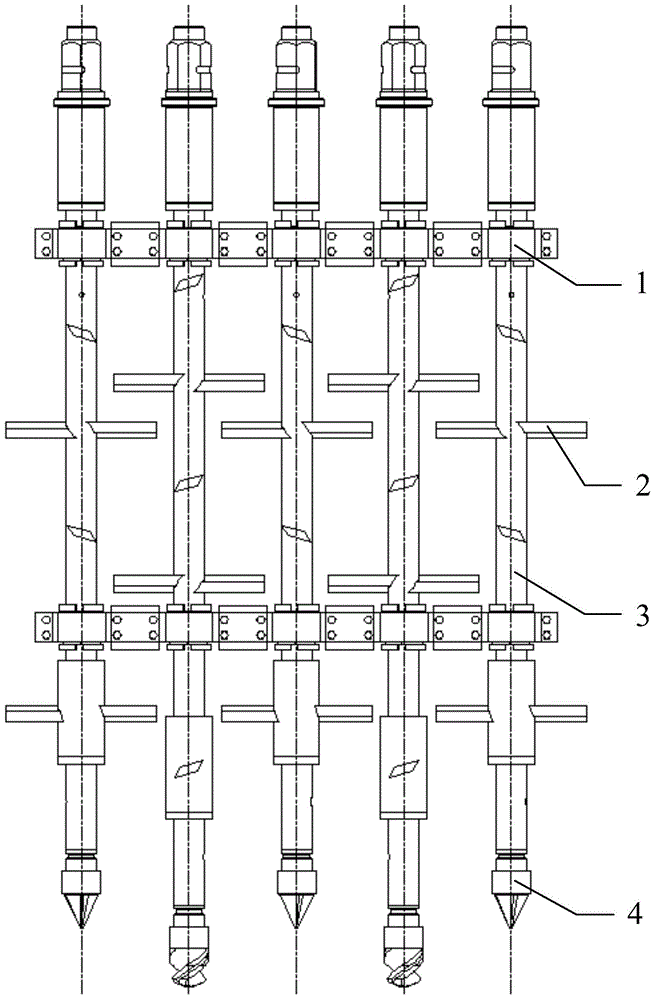

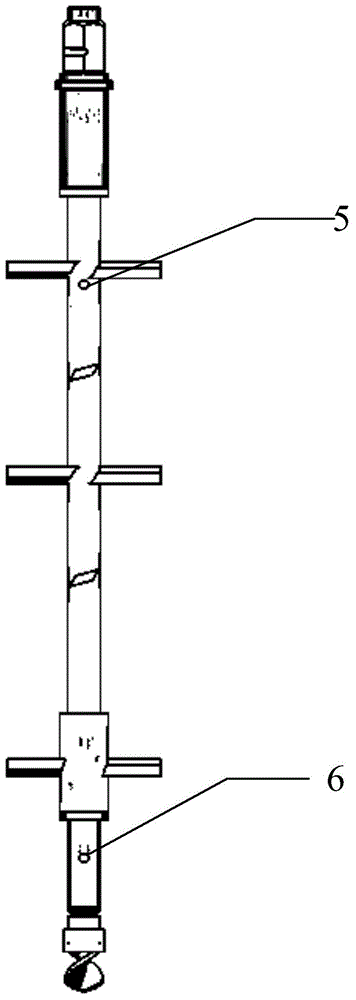

Cement-soil mixing pile device capable of vertically converting for spraying slurry and operation method of cement-soil mixing pile device

InactiveCN104563124AImprove mixing uniformityShorten the mixing timeBulkheads/pilesSoil mixingEngineering

Owner:SHANGHAI CHENGDI CONSTR +1

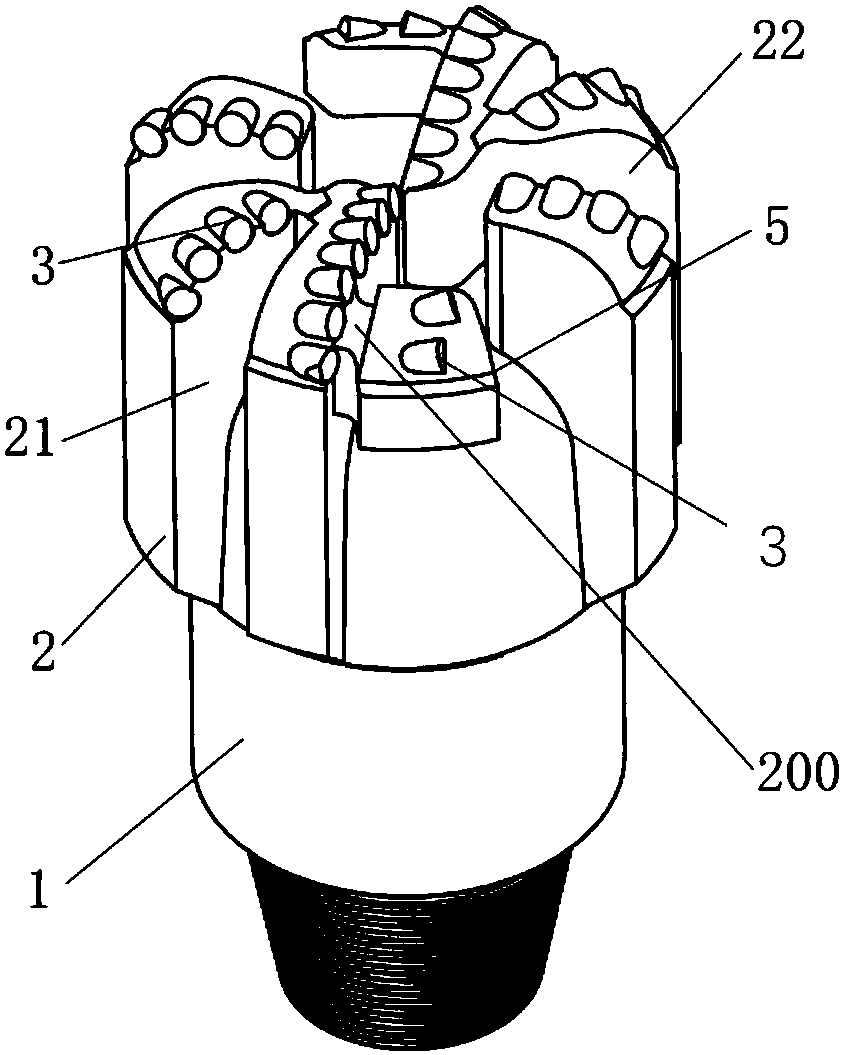

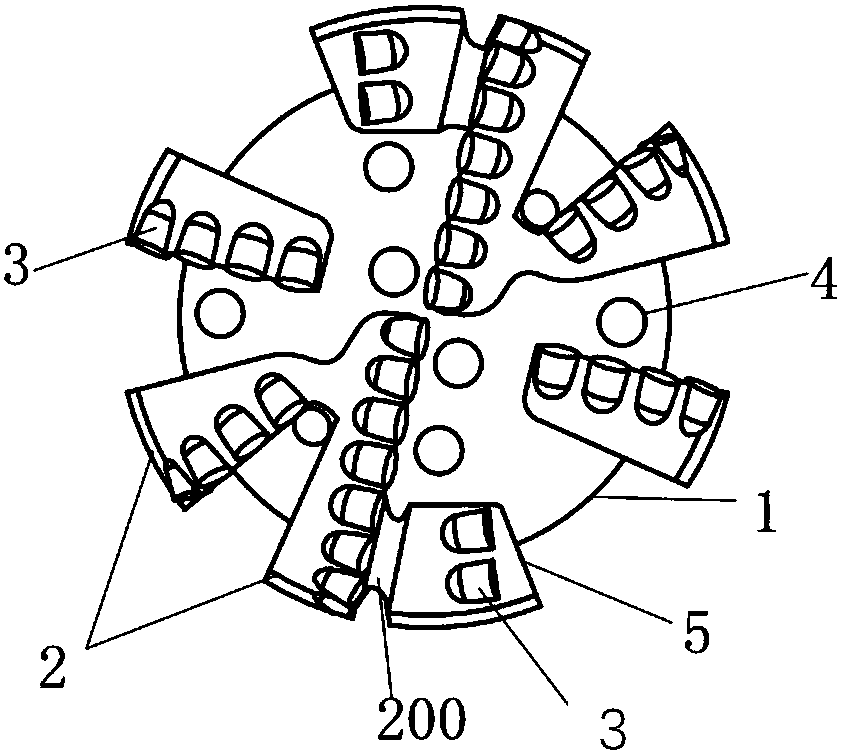

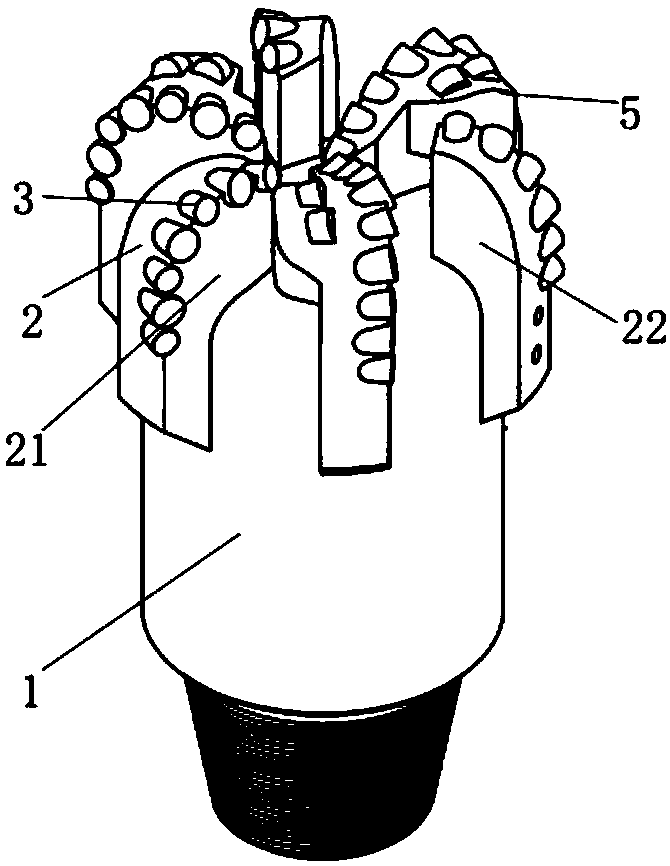

Diamond drill bit suitable for hard stratum drilling

Owner:SOUTHWEST PETROLEUM UNIV +1

Downhole/openhole anchor

Owner:BAKER HUGHES INC

Tensile machine for power dispatching grid construction

InactiveCN107872033AControl traction speedAvoid stickingApparatus for overhead lines/cablesSmall amplitudeCoupling

The invention discloses a tensile machine for power dispatching grid construction. The tensile machine comprises a base, universal wheels, a left extension board, bolts, a drilling bit, a handle, a right extension board, a lifting rod, a sucker, a locking shaft, an upright column, a retractable device, a guide wire device, a vertical rod, a first pulley and so on. The tensile machine has a reasonable, simple structure, has low production cost, is convenient to install, controls the traction force effectively under drive of a drive motor and a coupler; the base is fixed by the sucker and the drilling bit, so that the whole device swings with a smaller amplitude; a cable passes through an arc groove, then passes through between the first pulley and the second pulley and passes through an arcbase in sequence, the height of the arc groove is adjustable, a distance between the first pulley and the second pulley is adjustable, the arc base is elastic, so that the cable is not clamped or does not swing; and the tensile machine has high stability, can control the traction speed of the cable effectively, and is highly safe, thereby guaranteeing the construction efficiency effectively.

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

Automatic processing equipment for axle hole

InactiveCN102091798AReduce labor intensityImprove ergonomicsBoring/drilling componentsBoring/drilling machinesAutomatic test equipmentFuel tank

Owner:CHANGSHU TONGRUN AUTO ACCESSORY

Engineering drilling device

InactiveCN104165024AEasy to operatePlay a buffer roleReciprocating drilling machinesConstructionsEconomic benefitsPetroleum engineering

Owner:JIANGSU ENG EXPLORATION & SURVEYING INST

Rotary kiln for calcium aluminate powder

InactiveCN104986787AImprove work efficiencyReduce labor costsAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateEngineering

Owner:重庆骏成机械配件有限公司

Device for quickly drilling in frozen earth and construction method thereof

ActiveCN104110221AHigh speedDecrease phenomenonEarth drilling toolsDrill bitsNitrogenLiquid nitrogen

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method of avoiding the need for a scraper run in drill out operations and a downhole drilling motor assembly

Owner:TARTAN ENERGY GRP INC +1

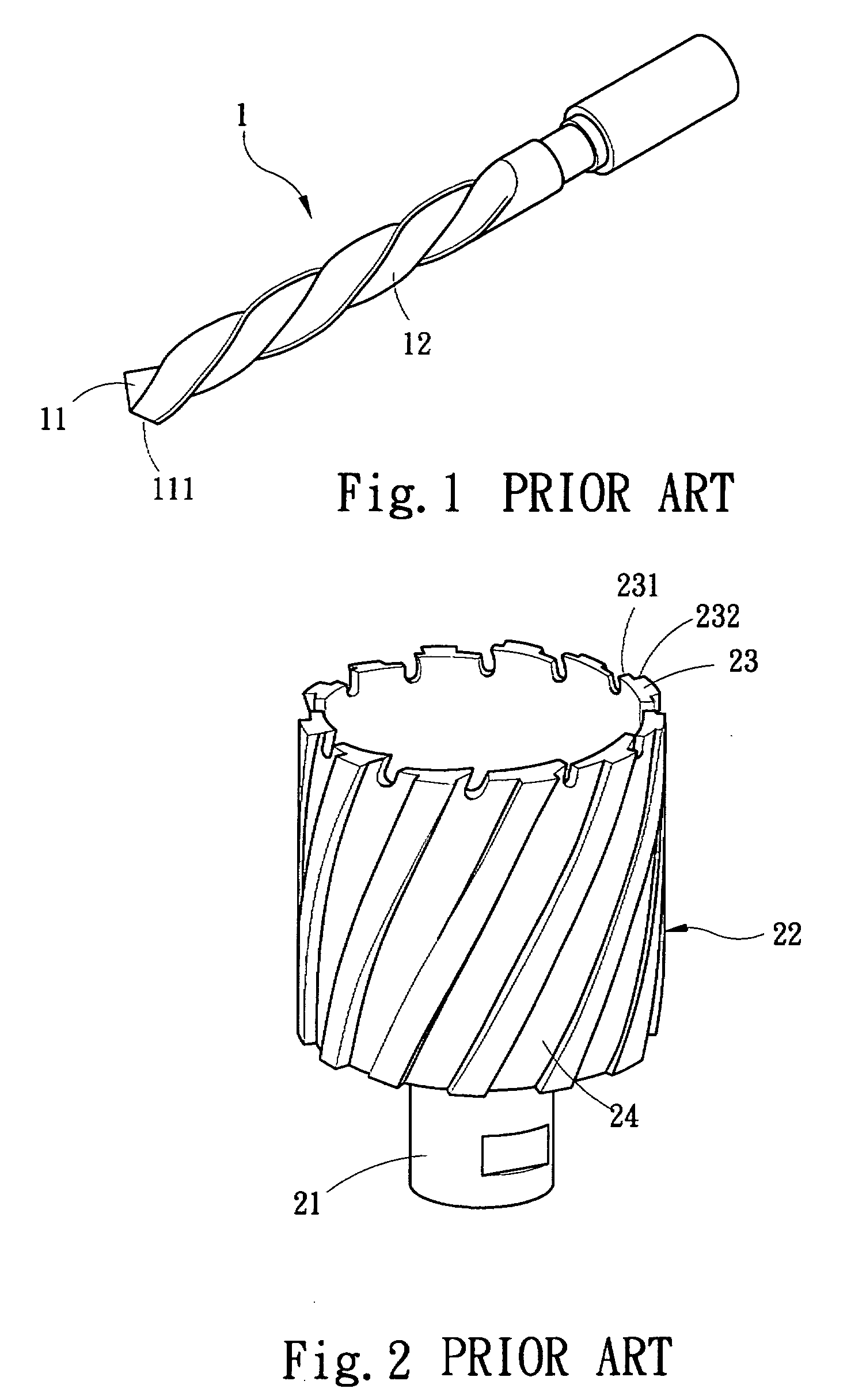

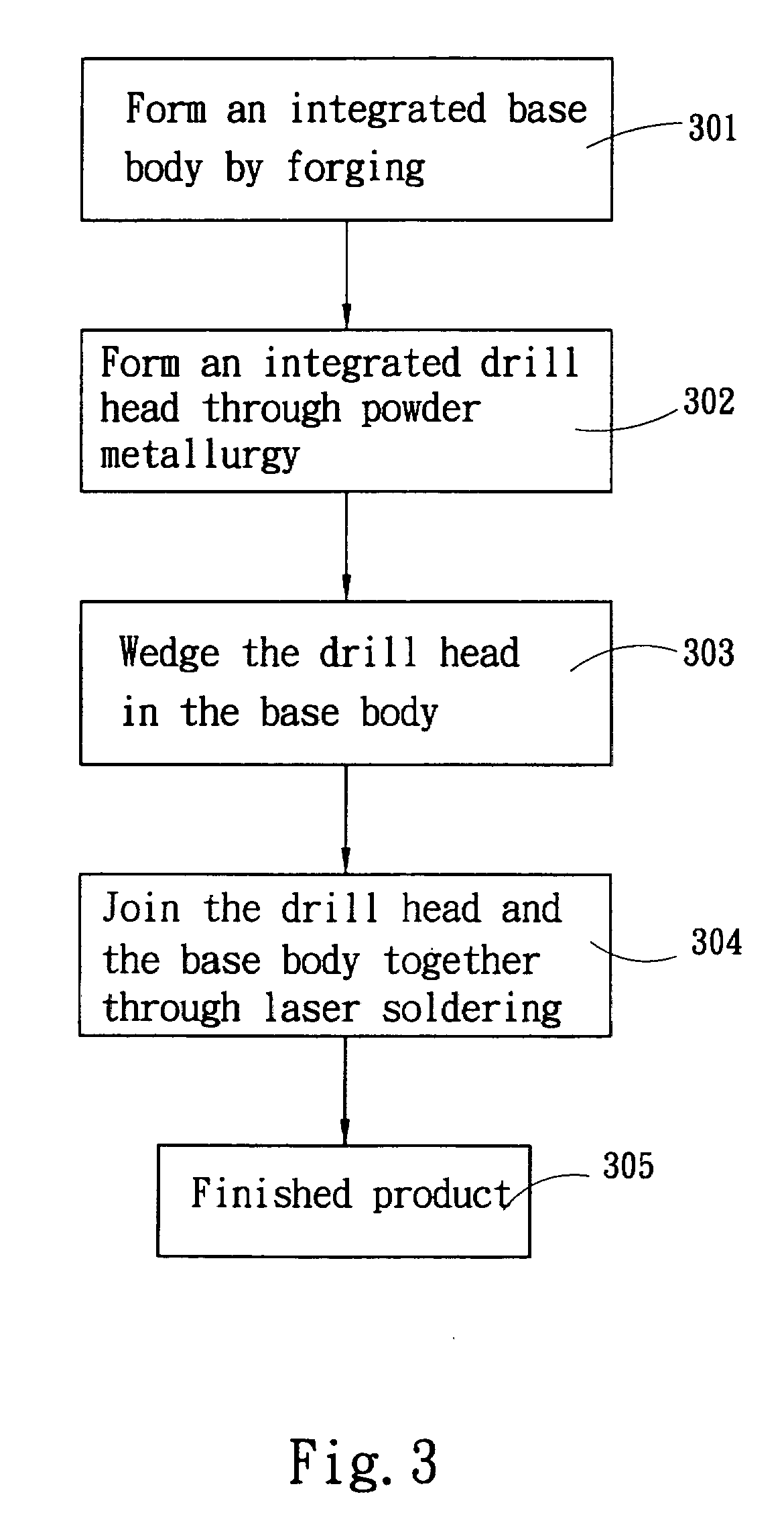

Method for manufacturing drill cutters and structure thereof

InactiveUS20080181735A1Low costEasy to makeTool workpiece connectionTransportation and packagingBarrel ShapedEngineering

Owner:TING FONG ELECTRIC & MACHINERY

Kiln cleaning apparatus

Owner:MARTIN ENG

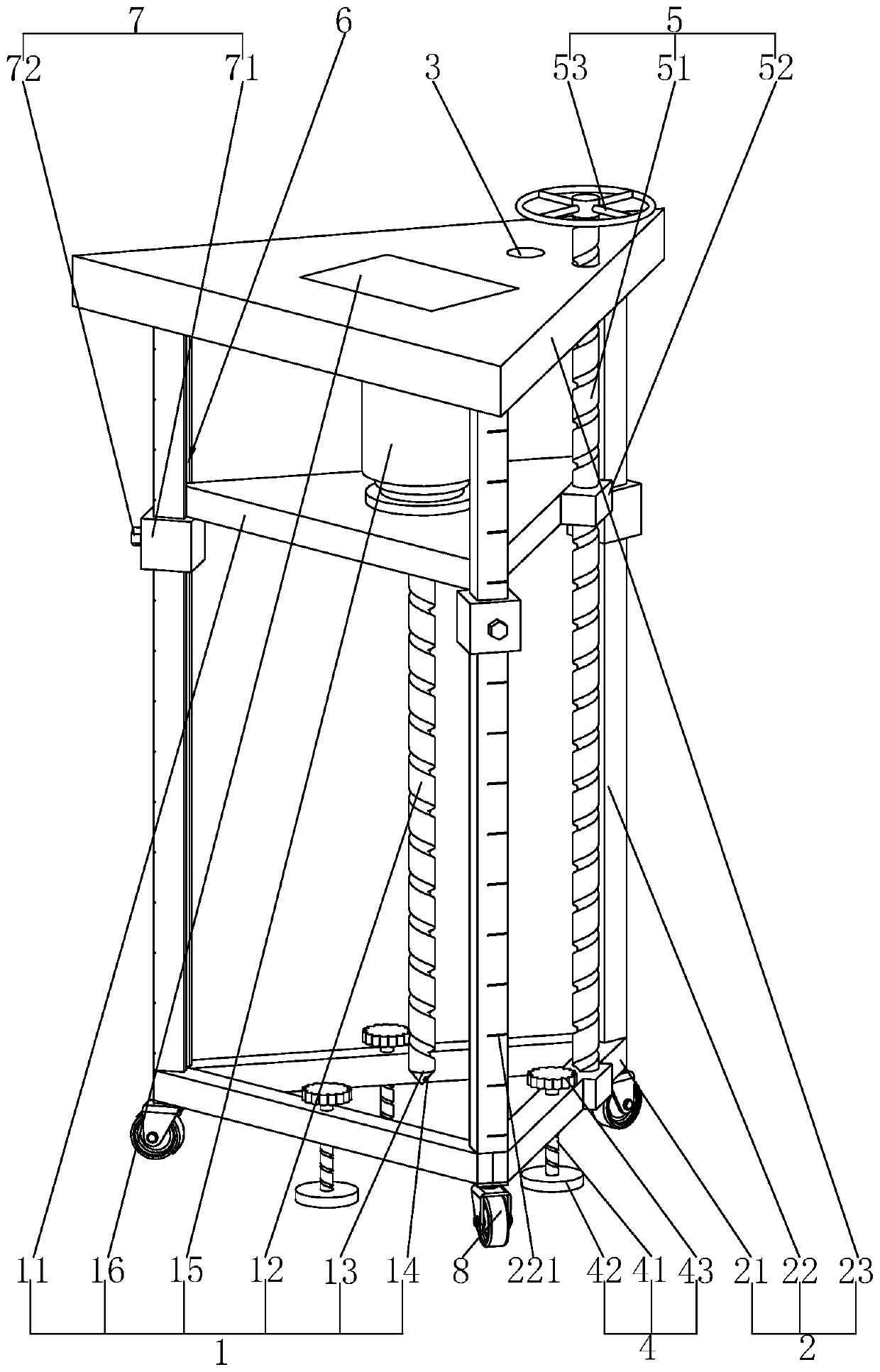

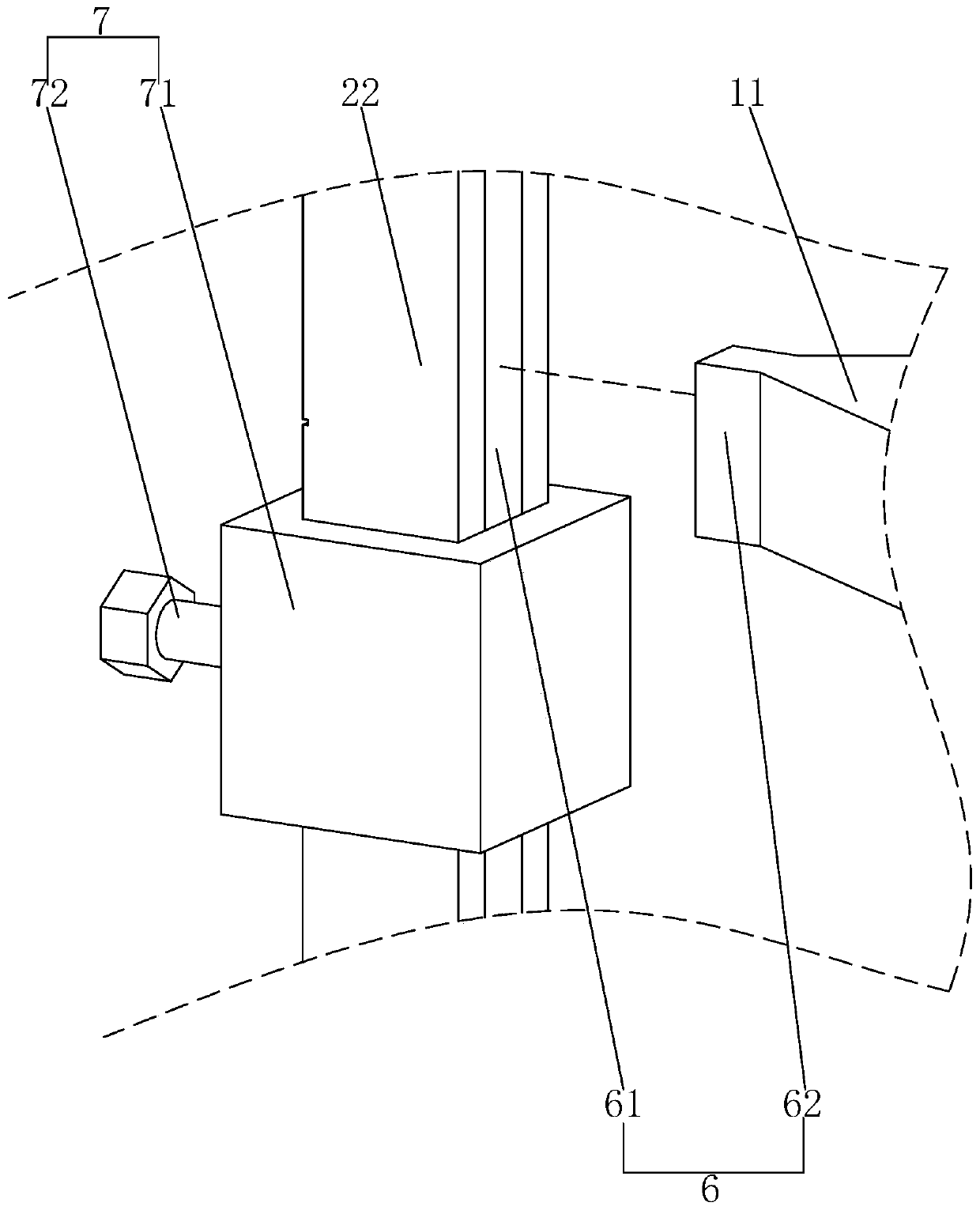

Floor lifting horizontal bit gauge

InactiveCN105547100APlace stableAvoid an unstable gripMechanical diameter measurementsMeasurement precisionComputer engineering

Owner:CHENGDU LIXIN SCI & TECH

Geological survey equipment and survey method thereof

Owner:商丘市水利建筑勘测设计院

Coaxial all-metal cam stator and rotor underground dynamical drilling tool

Owner:XI'AN PETROLEUM UNIVERSITY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap