Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

137 results about "Economic benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

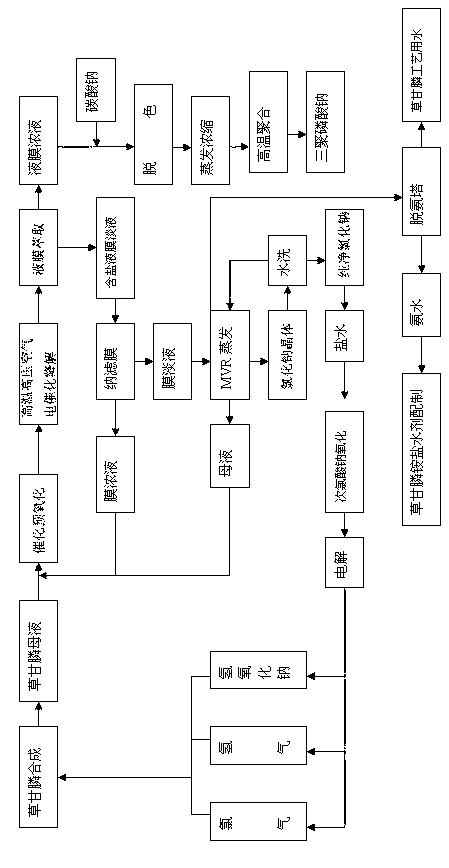

Cyclic production method of glyphosate

ActiveCN103012474AAvoid influenceReduce pollutionBiocideGroup 5/15 element organic compoundsEvaporationHigh pressure

Owner:HANGZHOU JINFADA CHEM IND

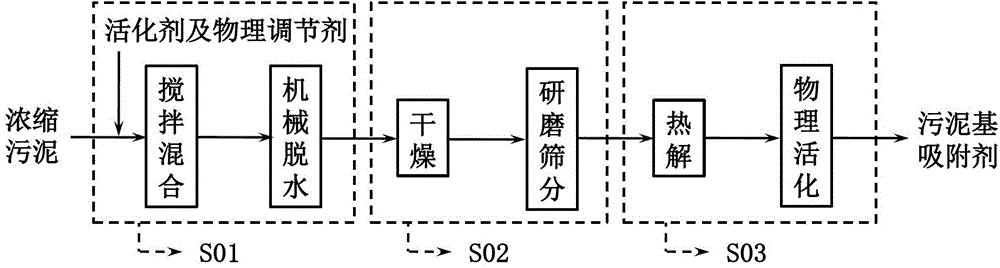

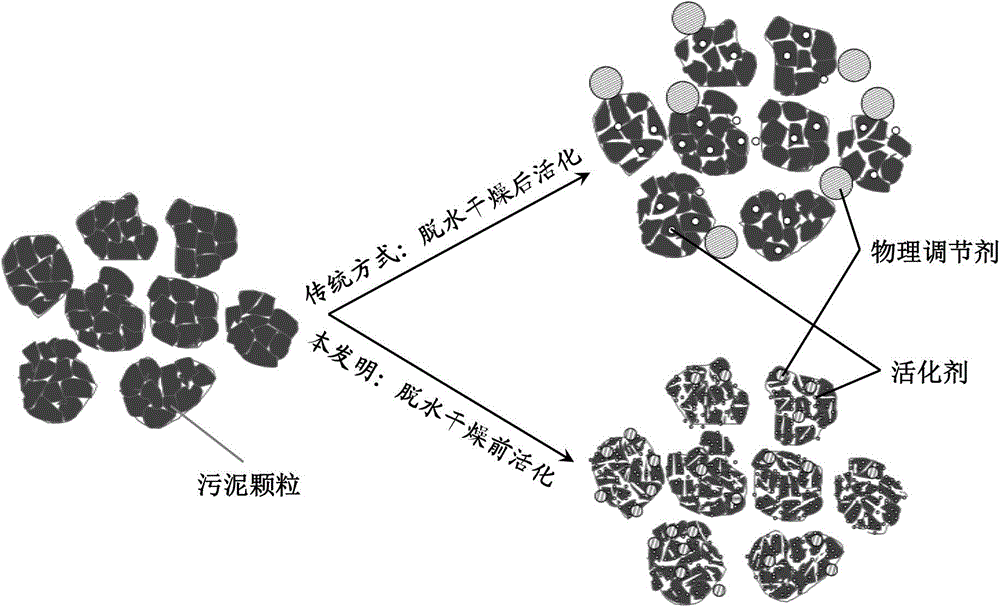

Sludge-based adsorbent used for desulfurization and demercuration of flue-gas and preparation method thereof

ActiveCN102745879AHigh porosityHigh adsorption activitySludge treatment by de-watering/drying/thickeningOther chemical processesSludge cakePhysical conditioning

Owner:HUAZHONG UNIV OF SCI & TECH

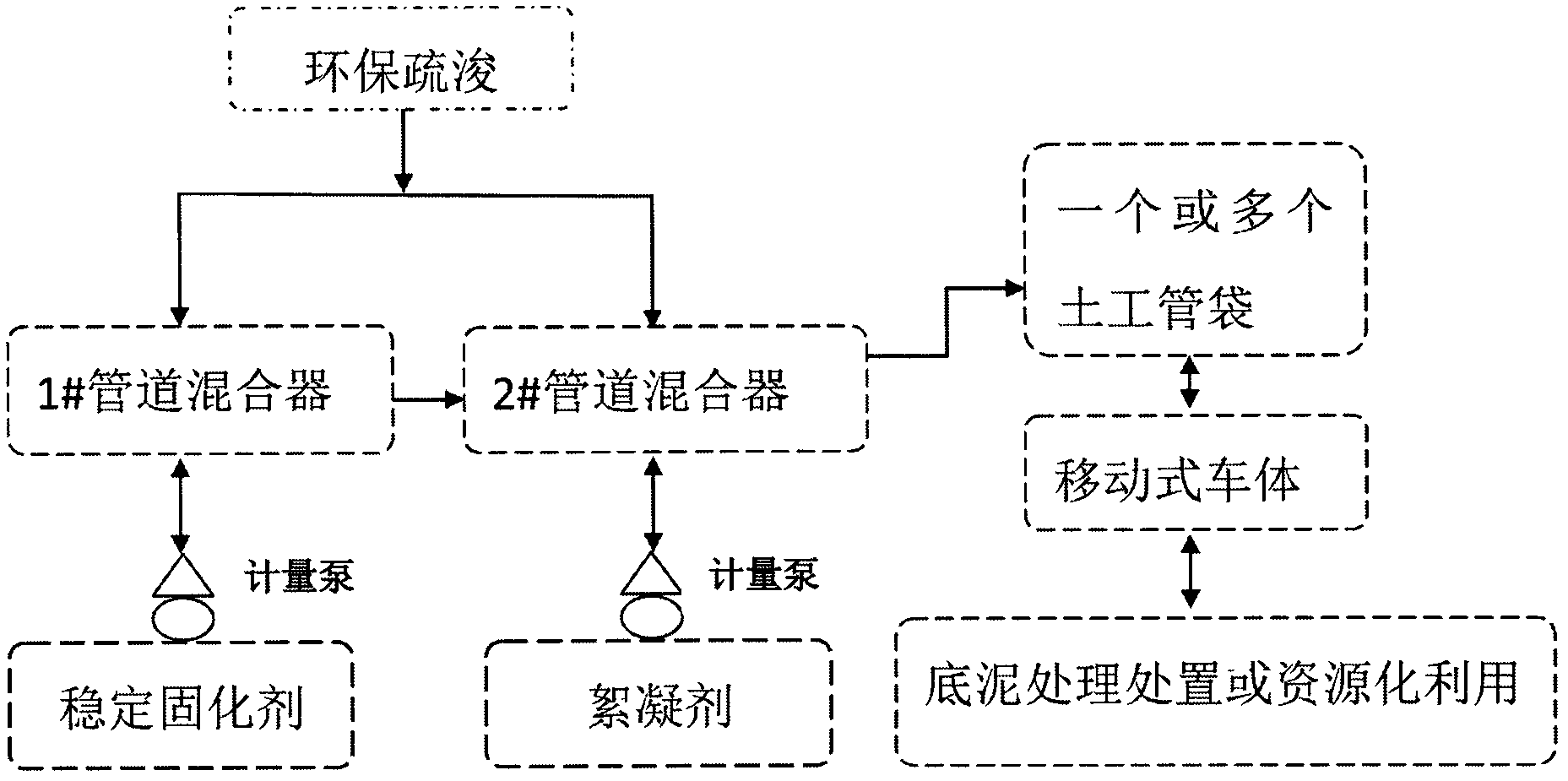

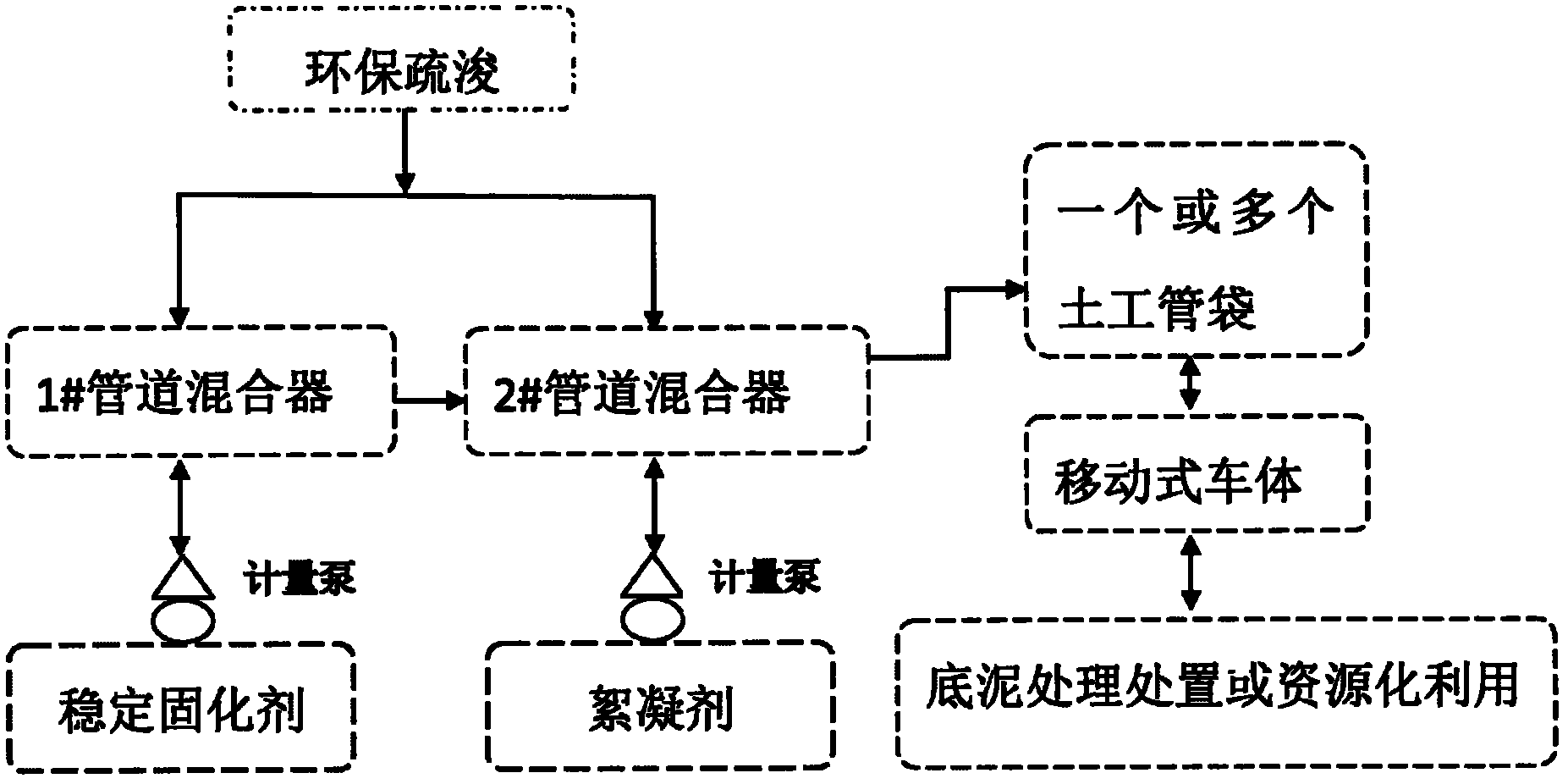

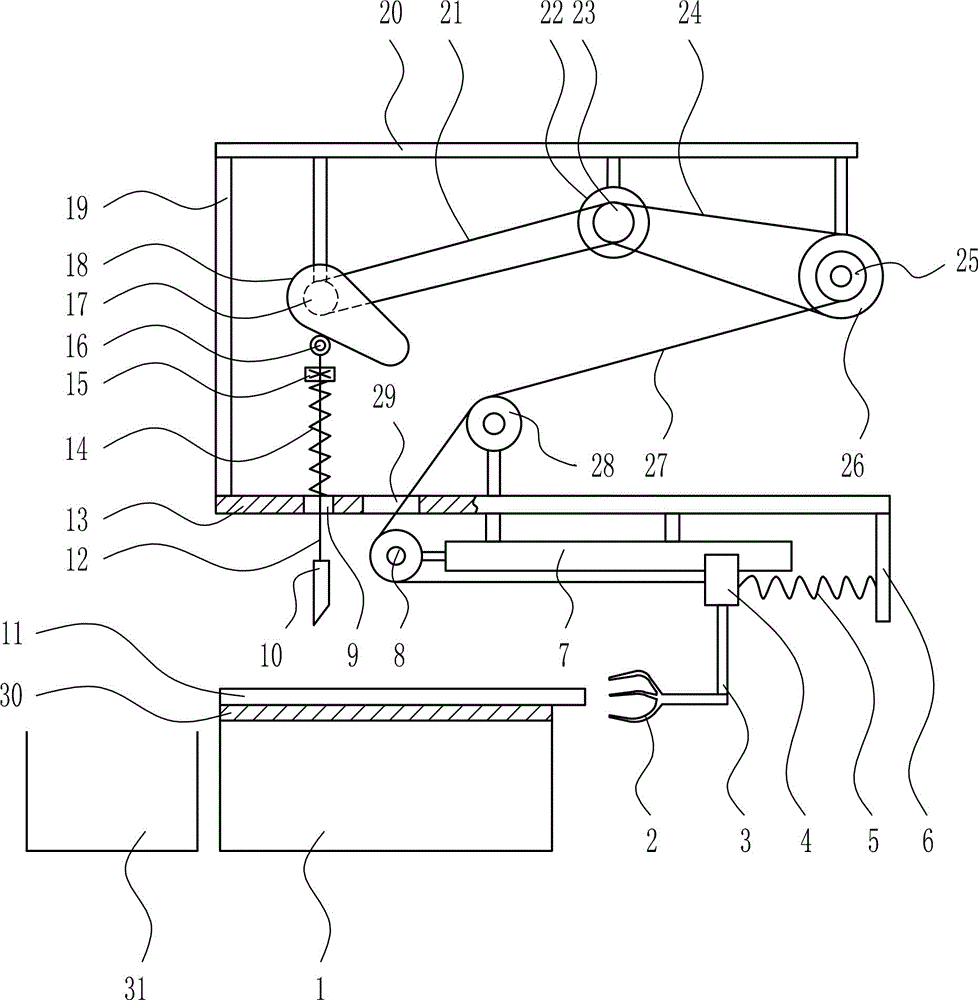

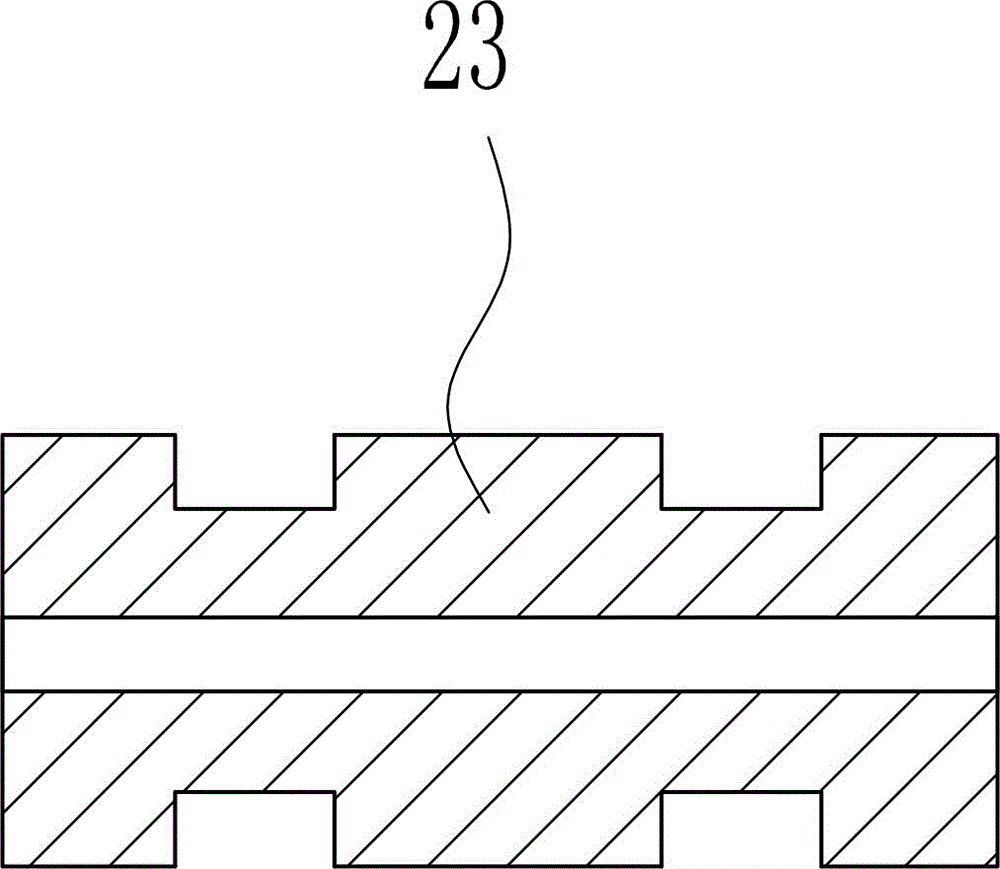

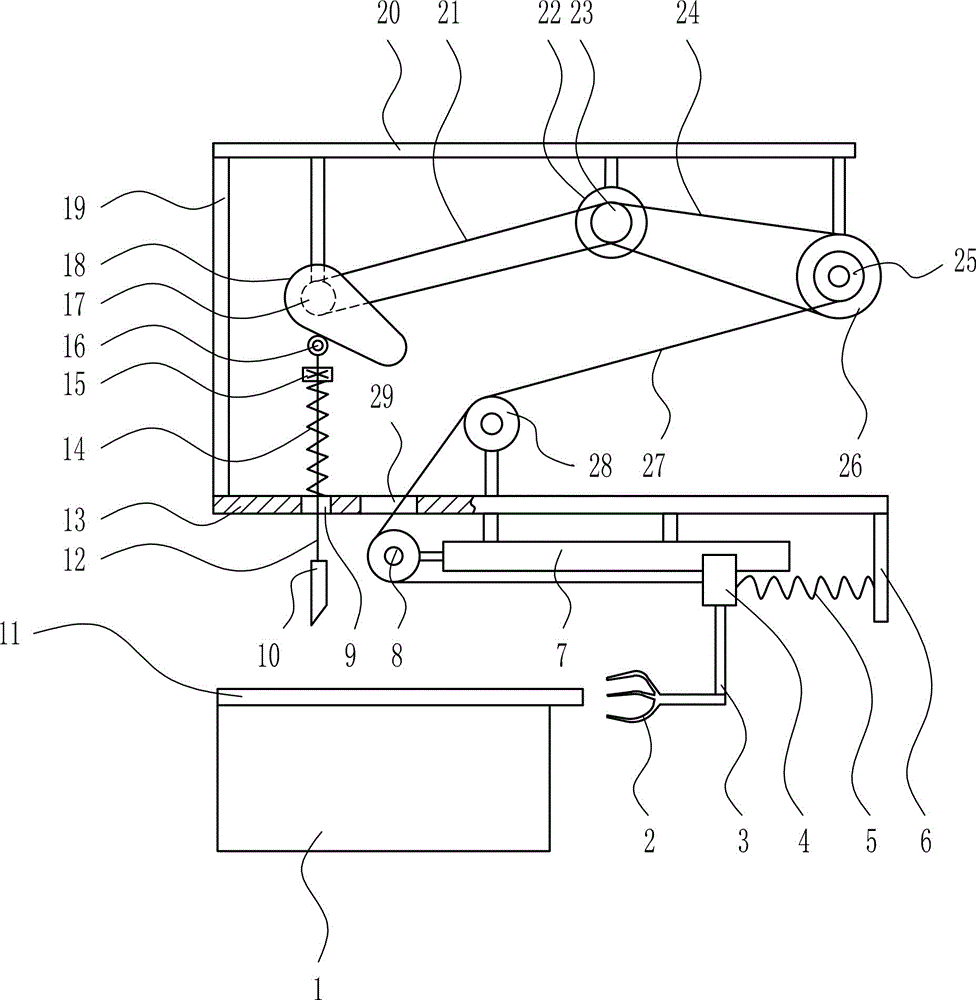

Mobile contaminated bottom mud bag pocket dewatering and volume reduction treatment method

InactiveCN102583950ASolve the problem of land occupationWill not cause secondary pollutionSludge treatment by de-watering/drying/thickeningSludgeResource utilization

Owner:TIANJIN ECOLOGY CITY ENVIRONMENTAL PROTECTION +1

AKD emulsion and preparation method thereof

ActiveCN104499363AThe emulsification process is streamlinedLow impurity contentWater-repelling agents additionWaxStarch gelatinization

The invention discloses an AKD emulsion and a preparation method thereof. According to the preparation method of the AKD emulsion, as the process of starch gelatinization is saved, and AKD waxes and other raw materials are simultaneously added in the emulsification process, the operation is simple, and the consumed time is obviously shortened. According to the preparation method, equipment and manpower inputs are reduced, and the inventory of the raw materials are also reduced; in addition, as the prepared emulsified product can be used while being produced, the aging rate of paper leaving the machine is high, the hydrolysis degree of the AKD is greatly lowered, the sizing effect is ensured, and the economical benefit is obvious.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

Efficient cutting device of hardware steel pipe

ActiveCN106180867AHigh hardnessAnti-crackTube shearing machinesDriving apparatusEconomic benefitsEngineering

Owner:开平力蒲卫浴有限公司

Ceramics particle strengthened composite material lining metal tube and manufacturing method thereof

InactiveCN101900227AExtended service lifeImprove wear resistanceCorrosion preventionPipe protection against corrosion/incrustationPolyesterManufacturing technology

The invention discloses a ceramics particle strengthened composite material lining metal tube and a manufacturing method thereof, belonging to the field of composite wear-resistant tubes. 4,4-Diphenylmethane diisocyanate (MDI), polyester glycol, 1,4-butanediol (BD), ceramics particles and the like serve as raw materials to prepare composite material liquid castables, and a centrifugal casting technology is adopted to cast polyurethane base ceramics particle strengthened composite material lining layers on the inner wall of an outer thimble. The invention has the beneficial effect that the prepared ceramics particle strengthened composite material lining metal tube has excellent abrasive resistance and corrosion-resistance and greatly improves service life. The raw materials of the invention are easy to be obtained, manufacturing technology is simple, cost is low and economic benefit is obvious and practical application and mass production are beneficial for factories.

Owner:XUZHOU SHENGHAI MACHINERY MFG TECH

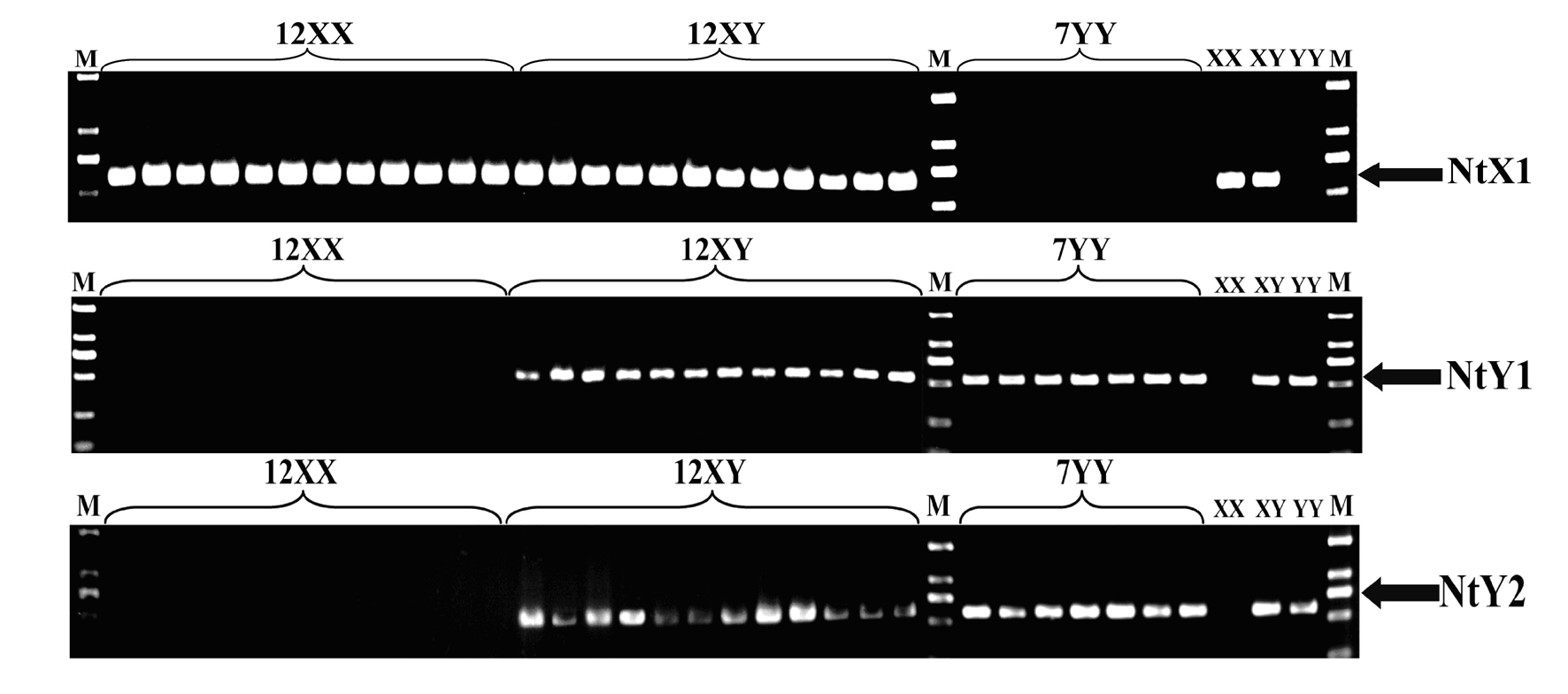

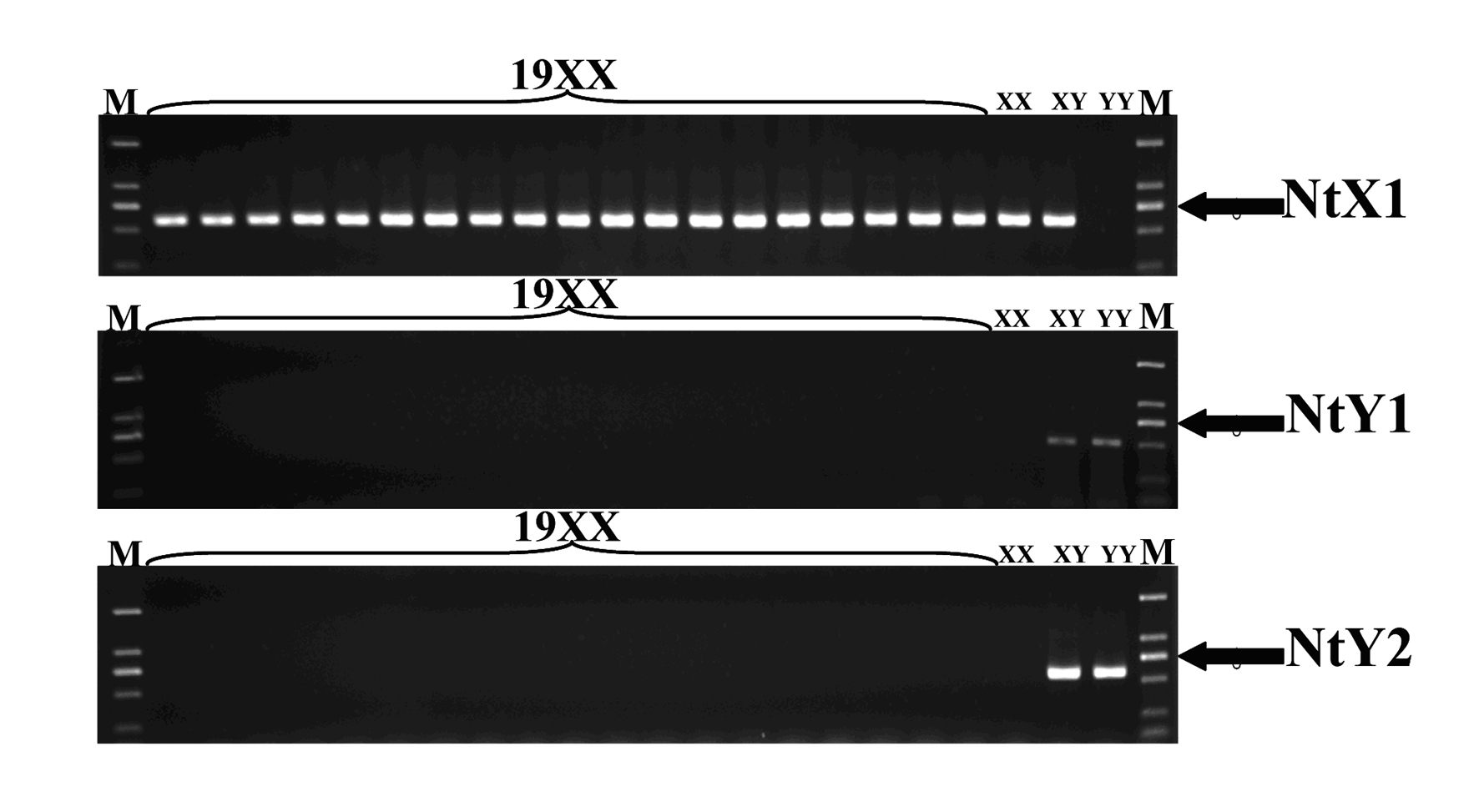

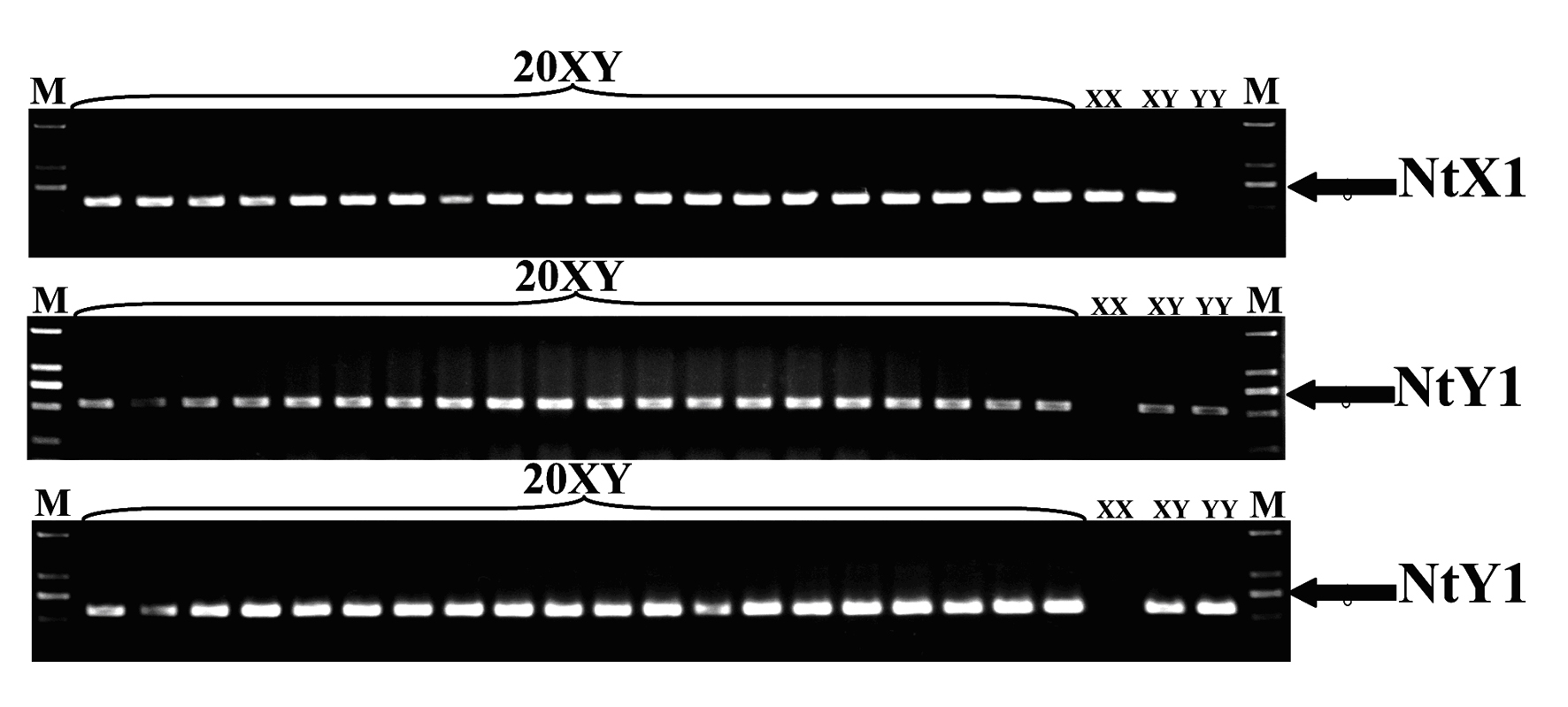

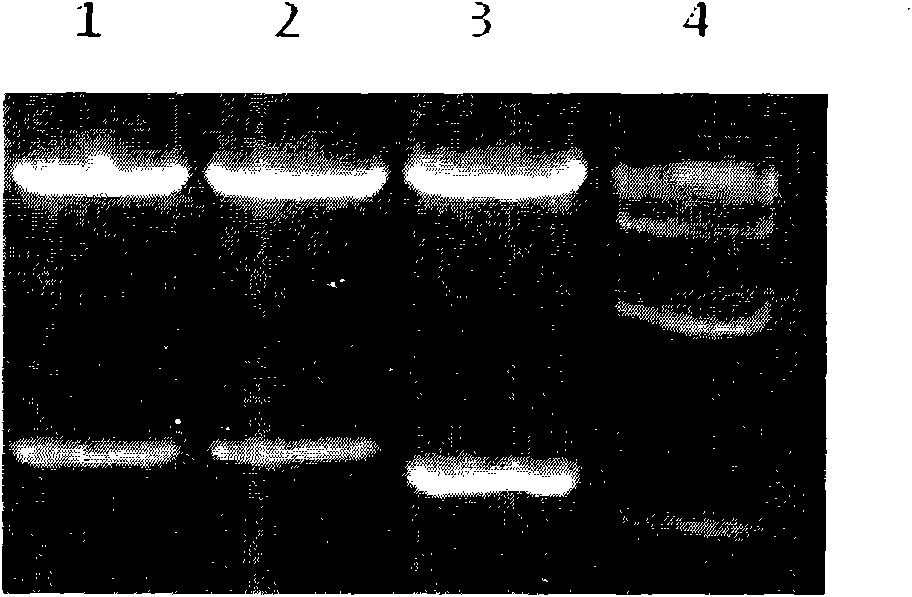

Specific molecular markers of sex chromosomes of Tilapia nilotica and genetic sex identification method

ActiveCN101962641AEconomic divisionQuick distinctionMicrobiological testing/measurementDNA/RNA fragmentationX chromosomeNile tilapia

Owner:SOUTHWEST UNIVERSITY

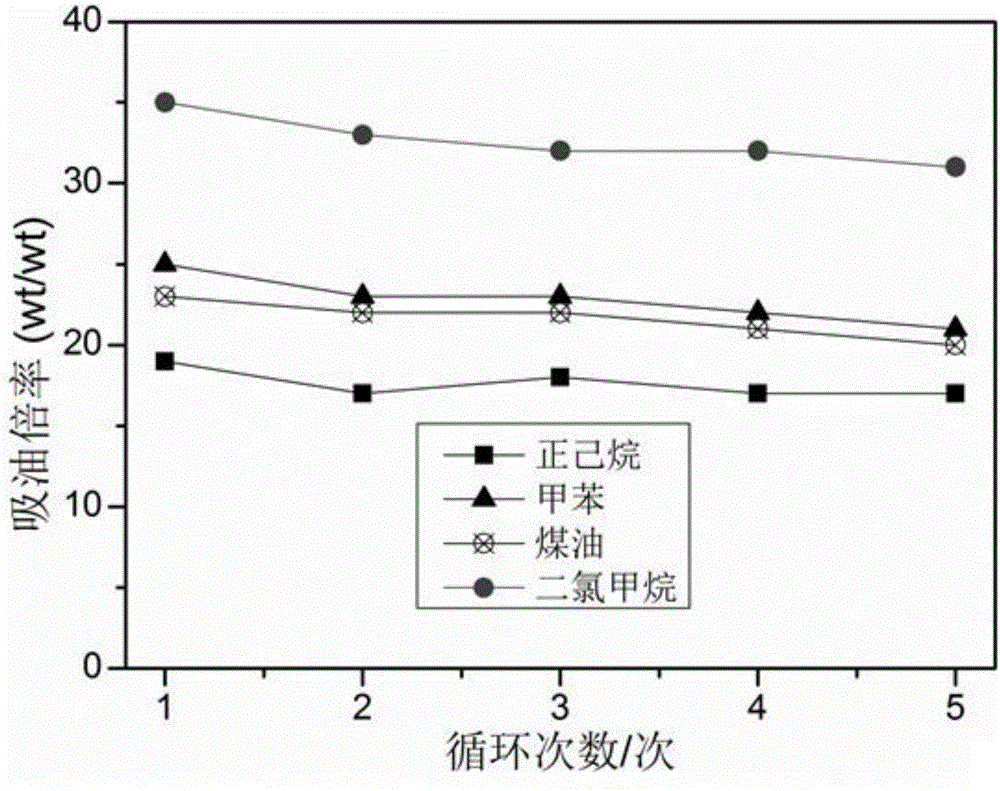

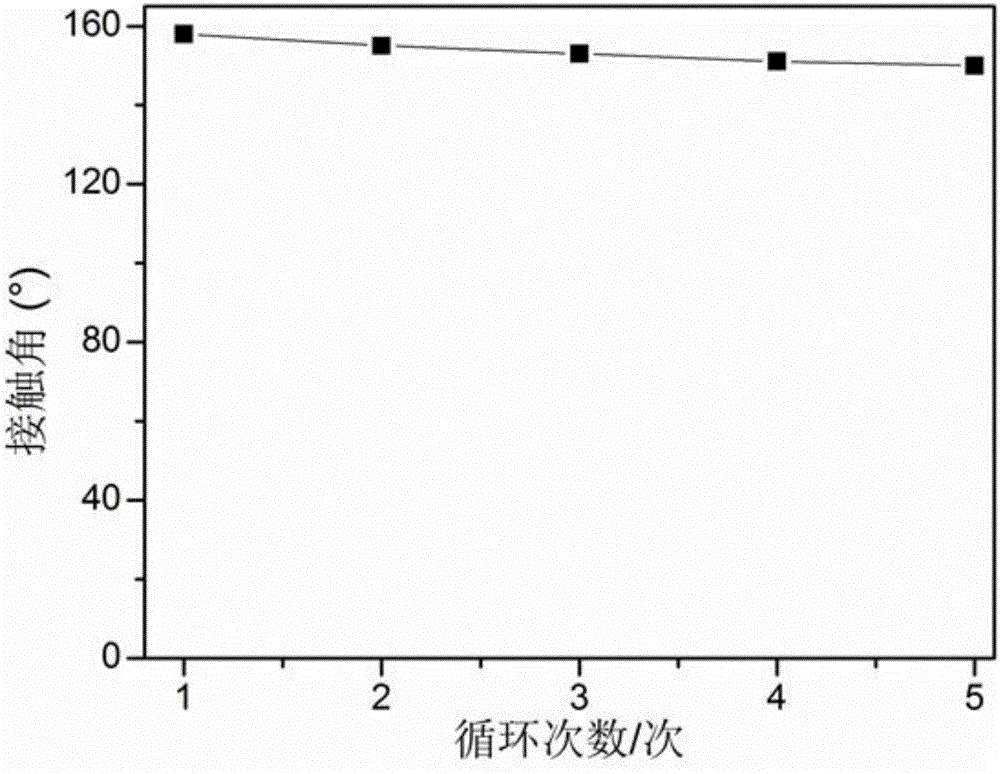

Preparation method for super-hydrophobic/super-oleophylic loofah sponge fiber and application thereof

InactiveCN106732463AEasy to degradeEasy to prepareOther chemical processesLiquid separationFiberPolymer science

Owner:FOSHAN UNIVERSITY

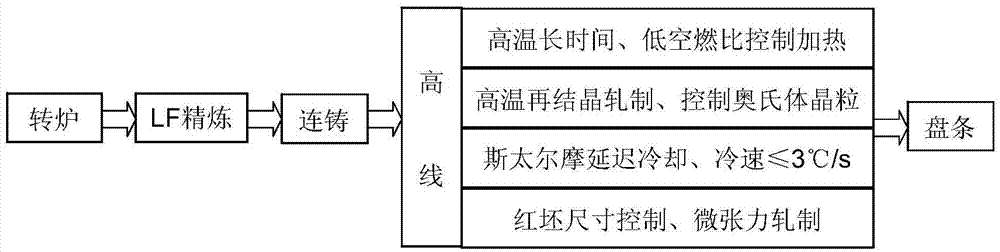

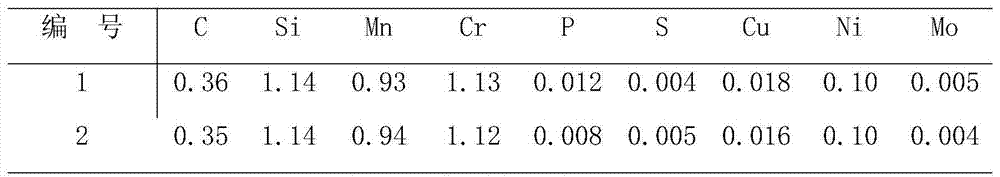

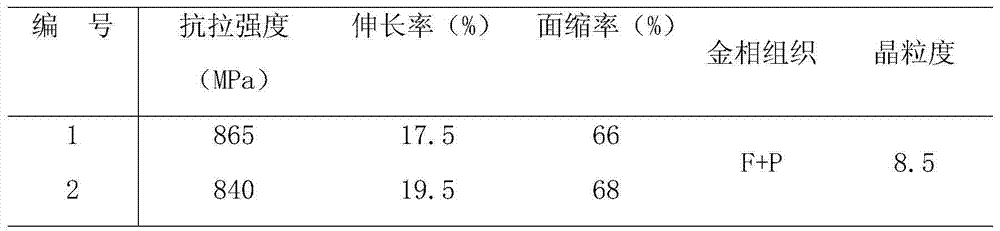

Production technology of wire rod for solid surfacing welding wires

ActiveCN103667925AReduce manufacturing costImprove deposition efficiencyWelding/cutting media/materialsSoldering mediaPearliteEconomic benefits

The invention discloses a production technology of a wire rod for solid surfacing welding wires. The wire rod comprises the components in percentage by weight as follows: 0.32-0.39% of C, 1.10-1.40% of Si, 0.80-1.10% of Mn, 1.10-1.40% of Cr, smaller than or equal to 0.025% of S, smaller than or equal to 0.025% of P, smaller than or equal to 0.30% of Ni, smaller than or equal to 0.25% of Cu, smaller than or equal to 0.10% of Mo and the balance of Fe and inevitable impurities. A process route comprises blowing by a converter, refining by an LF (ladle furnace), continuous casting and high-speed wire rolling. The solid surfacing welding wires produced through the technology have the advantages of low production cost, high deposition and welding efficiency, convenience in automatic operation and the like; according to the production technology of the wire rod for the solid surfacing welding wires, the component design of medium carbon and high silicon and chrome is adopted in chemical component, and the cost increase caused by addition of a large number of Ni, Mo, V, Ti alloys and the like in the past is avoided, so that the production technology has obvious economic benefits; the produced wire rod is stable in mechanical property, the tensile strength is 840-890 MPa, the elongation is 17%-20%, the area reduction is 60%-70%, the metallographic structure is F (ferrite) +P (pearlite), the grain size is grade 8.0-9.0, and the size deviation is + / -0.15 mm.

Owner:TIANJIN IRON & STEEL GRP

Comprehensive recycling treatment method of waste rare-earth fluorescent lamp

ActiveCN103627906AShort processReduce recycling costsProcess efficiency improvementLiquid wasteEconomic benefits

The invention discloses a comprehensive recycling treatment method of a waste rare-earth fluorescent lamp, which comprises the steps that S1, waste fluorescent powder, a waste glass tube and mercury-containing waste liquid are separated and recycled from the waste rare-earth fluorescent lamp; S2, the waste fluorescent powder is roasted; an obtained roasted ore is leached; a leaching solution and a leaching residue are obtained; S3, the leaching solution is subjected to extraction, reverse extraction and separation; alumina and rare-earth oxide are obtained; and S4, the leaching residue is subjected to digestion, extraction and purification; and a strontium-containing product is obtained. The waste rare-earth fluorescent lamp is separated, the obtained waste fluorescent powder and the obtained mercury-containing waste liquid are comprehensively recycled respectively by technologies of roasting, leaching, extraction, reverse extraction and the like, and then secondary valuable resources such as alumina, various rare-earth oxide and the strontium-containing product are comprehensively recycled from the waste fluorescent powder. The method is short in technological process and low in recycling cost, solves the problems of stockpiling, environmental pollution and the like caused by the industrial waste rare-earth fluorescent lamp, and has certain economic benefits and industrial significance.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

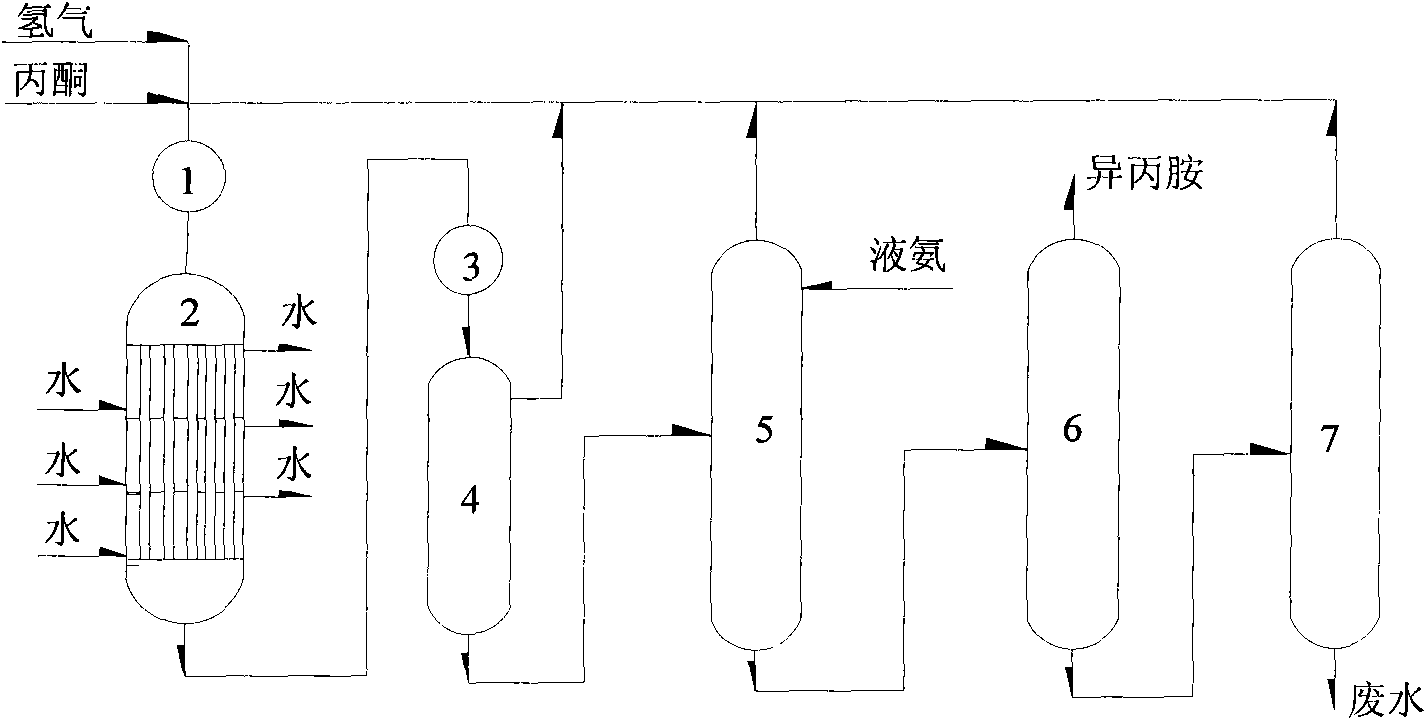

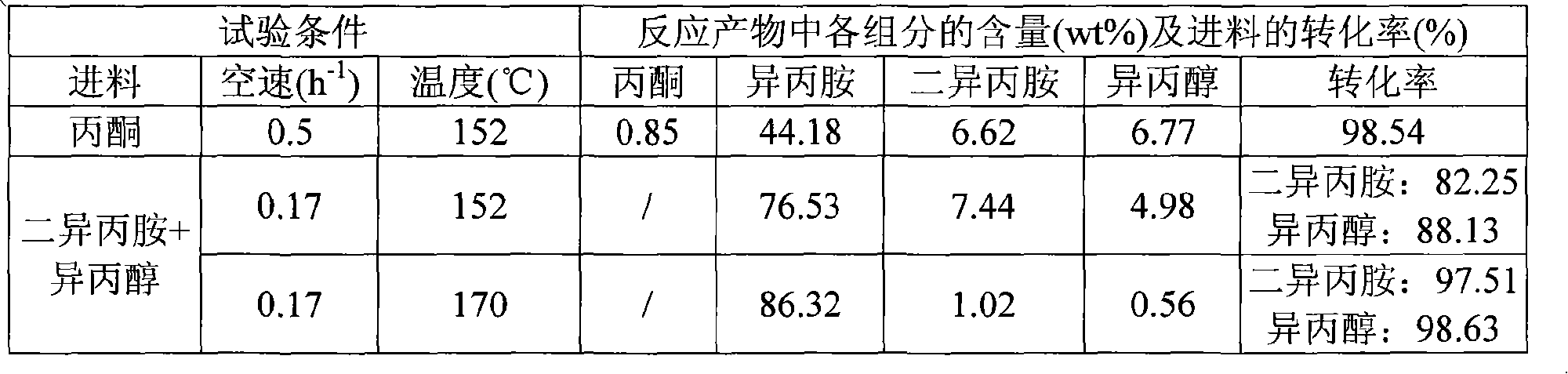

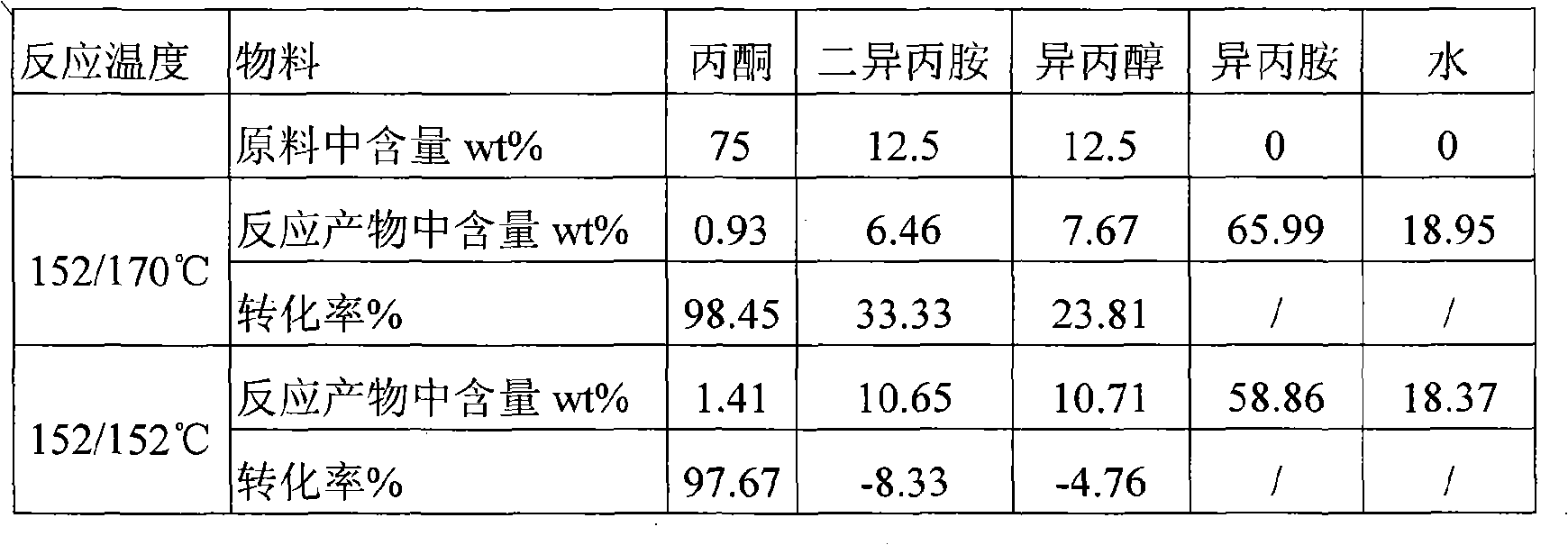

Method for producing isopropylamine

ActiveCN101684073AReduce heatReduce energy costsAmino compound purification/separationPreparation by reductive alkylationReaction temperatureEconomic benefits

Owner:CHINA PETROLEUM & CHEM CORP +1

Double-layer dragon fruit planting method

ActiveCN107258270AMeet the growth characteristicsIncrease productionExcrement fertilisersBioloigcal waste fertilisersDiseaseLand resources

Owner:罗明艺

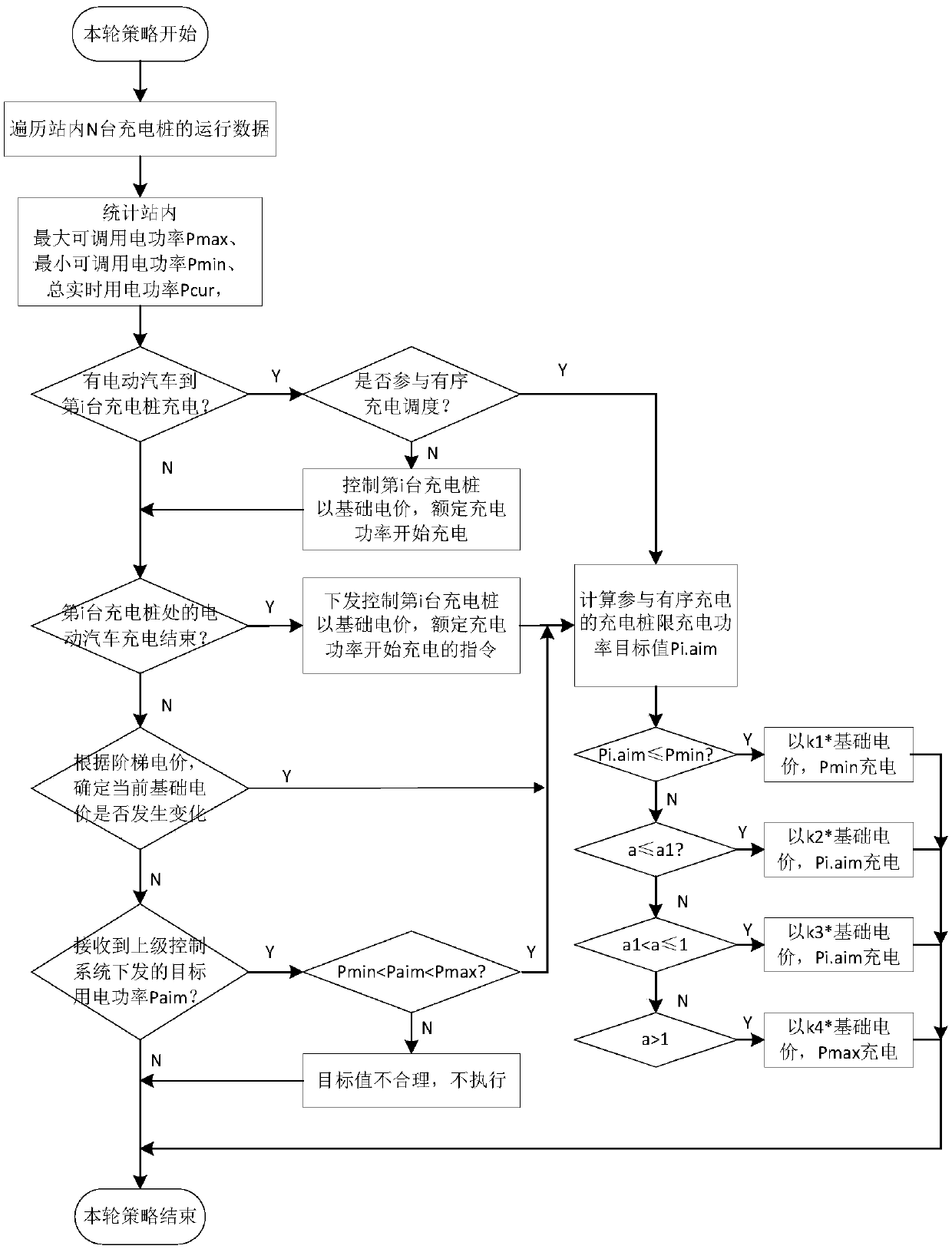

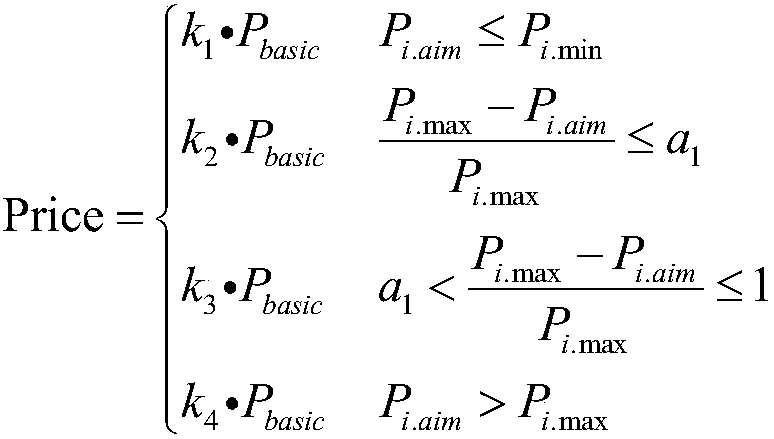

Electric vehicle charging station dispatching system and ordered charging control method

ActiveCN110015090AComprehensive management of charging powerReduce load fluctuationsCharging stationsElectric powerElectricityEconomic benefits

Owner:XUJI GRP +3

Multifunctional pig feed

InactiveCN106983024APromote growthImprove immunityFood processingAnimal feeding stuffLean meatQuinoline

The invention discloses multifunctional pig feed and belongs to the technical field of livestock feeding. The multifunctional pig feed comprises, by mass, corn, fermented soybean meal, traditional Chinese medicine residues, algae, bran, fish meal, soybean oil, calcium hydrophosphate, stone powder, compound enzymes, lysine, citric acid, L-methionine, threonine, tryptophan, vitamin premix, choline, organic trace element premix, bacillus subtilis, feeding probiotics, compound enzyme preparation, ethoxy quinoline, calcium propionate, oregano oil, an anti-stress agent and a physiological regulation agent. By the specific formula and the specific proportion, the multifunctional pig feed can effectively promote pig growth, increase lean meat yield, increase pig growth immunity and increase the economic benefits of pig raising.

Owner:武官福

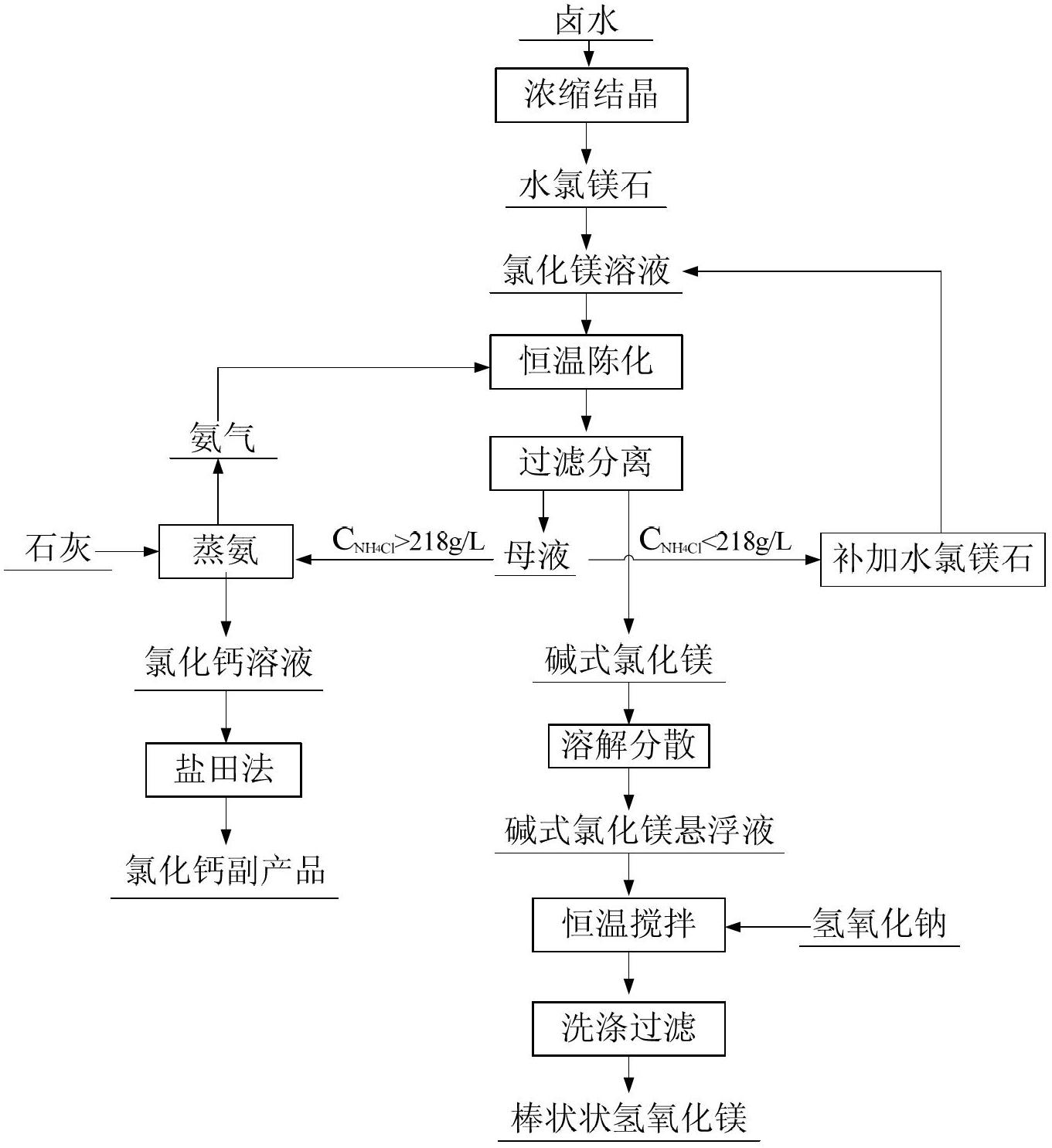

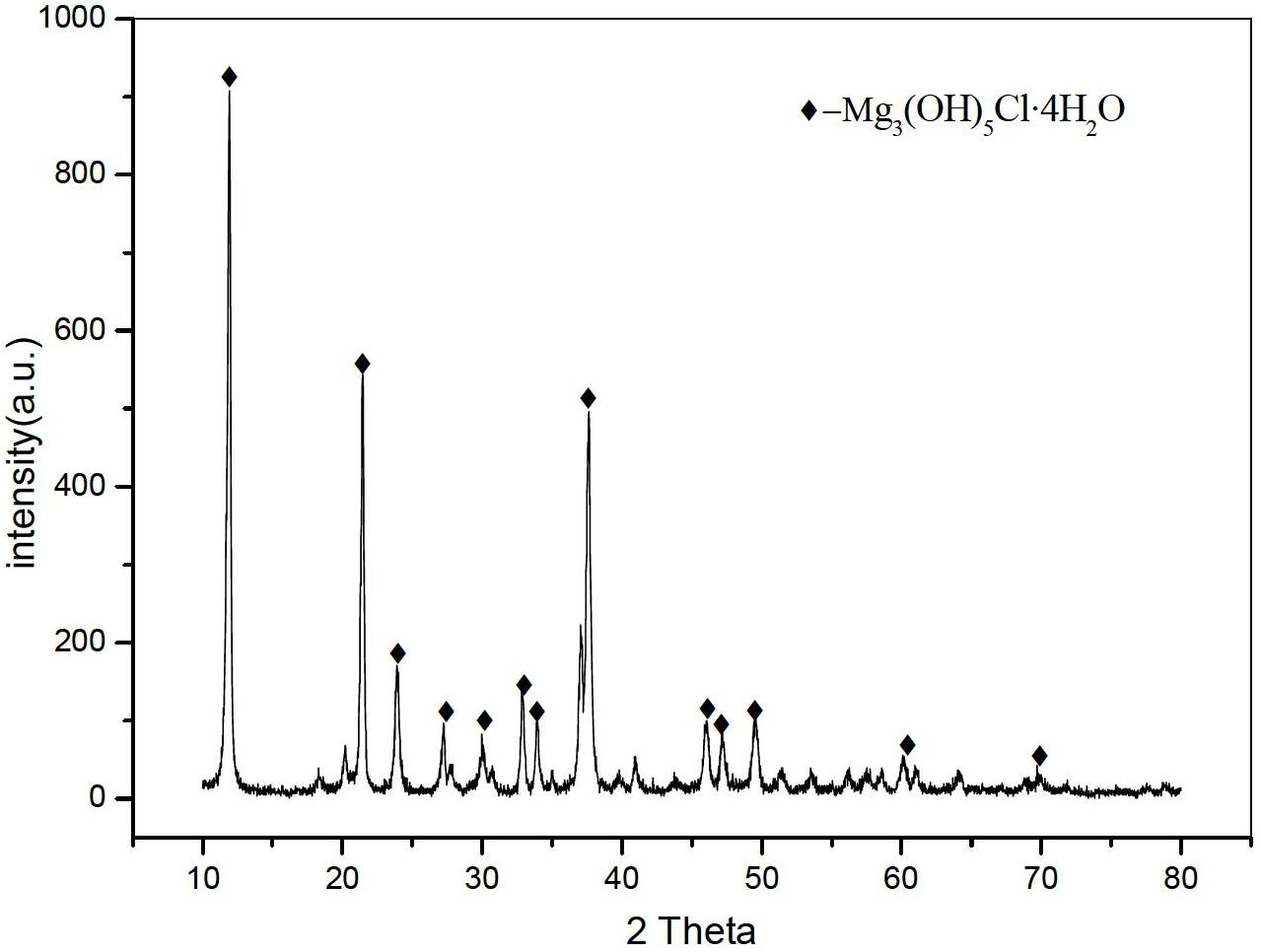

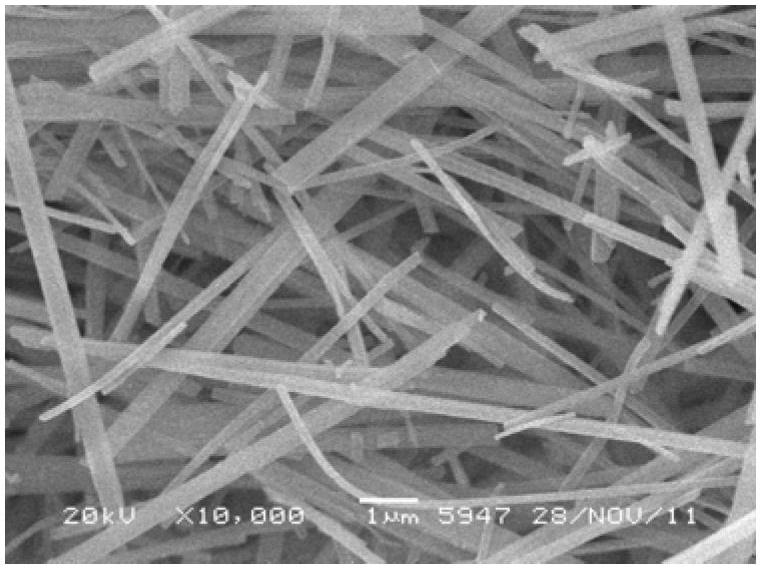

Method for preparing rod-like magnesium hydroxide from salt lake brine

InactiveCN102674409ALarge particlesImprove filtering effectCalcium/strontium/barium chloridesMagnesium hydroxidePotassiumSodium hydroxide

Owner:CENT SOUTH UNIV

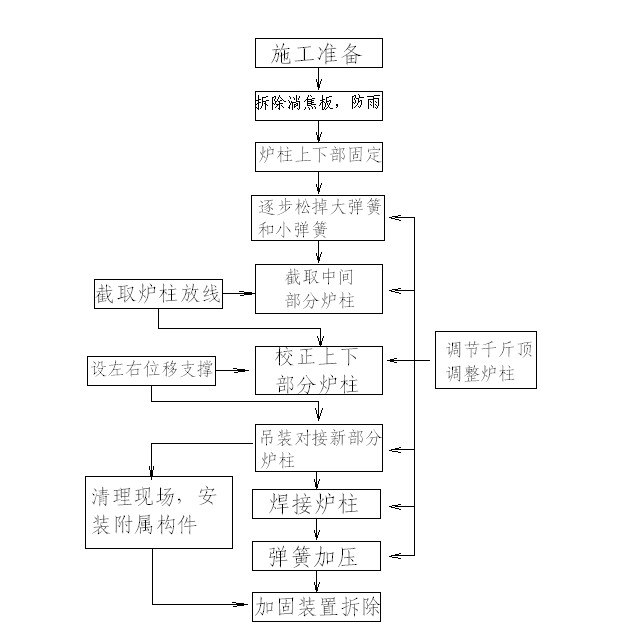

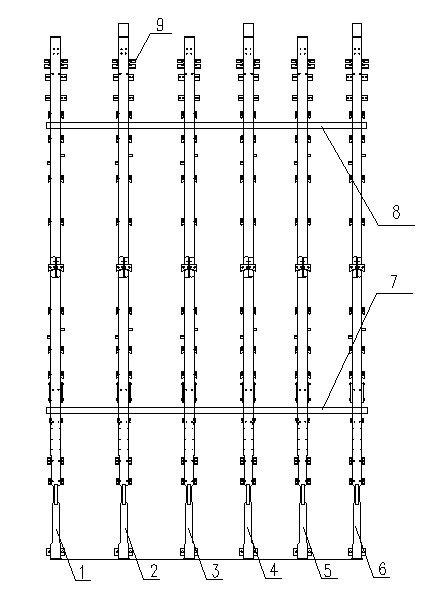

Thermal-exchange construction method of coke oven column

Owner:CHINA 22MCC GROUP CORP

Chromium-containing alloy bar material and preparation method thereof

ActiveCN109112398AImproved particle sizeAchieve fine grain strengthening effectChemical compositionEconomic benefits

The invention relates to a chromium-containing alloy bar material and a preparation method thereof. Al and N are added in a process of smelting steel with the trade mark of 40Cr to obtain the chromium-containing alloy bar material containing 0.020 to 0.030 weight percent of the Al and 0.007 to 0.010 weight percent of the N. Under the condition that existing equipment and technology are not changed, the problem that the grain size of the alloy bar material is large in a 40Cr steel low-rolling-ratio processing process is solved through adjusting chemical components; the grain size of a steel product is obviously changed under the matching effect of the Al and the N and a fine crystal reinforcing effect is realized. Under the same rolling condition, the grain size can be improved by 1.5 to 2.0 grades when being compared with that of existing 40Cr steel, and the problem that the capability of existing equipment is not enough so that the grain size is relatively high solved; the equipment investment is reduced and the chromium-containing alloy bar material has good economic benefits and application prospect.

Owner:CHENGDE JIANLONG SPECIAL STEEL

Power generation device utilizing ocean wave energy

ActiveCN107061121AAvoid damageReduce wastePiezoelectric/electrostriction/magnetostriction machinesMachines/enginesElectricityEconomic benefits

The invention provides a power generation device utilizing ocean wave energy. The power generation device comprises a piezoelectric energy harvesting device arranged on a levee. The piezoelectric energy harvesting device comprises piezoelectric structure units. Each piezoelectric structure unit comprises an arched copper plate. A plurality of piezoelectric films are mounted inside each piezoelectric structure unit. The two ends of the piezoelectric energy harvesting device are fixed on a sliding rail through connecting rods. The piezoelectric energy harvesting device is connected to a power source control device through a wire so as to output power energy. By utilizing the power generation device, damage of waves to the levee can be relieved, the life is prolonged, spontaneous power energy supply can be also obtained, energy resource waste is reduced, and great economic benefits are obtained.

Owner:ZHEJIANG UNIV

Glass ceramics made from high silicon iron tailings and manufacturing method thereof

The invention relates to the technical field of solid waste resource utilization, in particular to glass ceramics made from high silicon iron tailings, which is characterized by comprising the raw materials in parts by weight: 30-70 parts of the iron tailings, 15-40 parts of quartz, 5-20 parts of calcium carbonate, 3.5-6.5 parts of aluminum oxide, 8.5-9.5 parts of sodium carbonate, 4-5 parts of zinc oxide, 3-6 parts of barium carbonate and 1-3 parts of borax. The manufacturing method of the glass ceramics comprises the following steps: putting the glass ceramics blended materials in a kiln for melting into molten glass; allowing the molten glass to directly flow into water for water quenching to form glass particles; and paving the glass particles in a refractory die, crystallizing the paved particles in a tunnel kiln, a shuttle kiln or a chamber electric furnace, and grinding and cutting the crystallized glass ceramics to finally obtain the finished product of the glass ceramics. The invention can reduce stockpile of the tailings, alleviate environmental pollution, realize comprehensive resource utilization, improve product performances and lower production cost, thus having good social benefit and good economic benefit.

Owner:ANSTEEL GRP MINING CO LTD

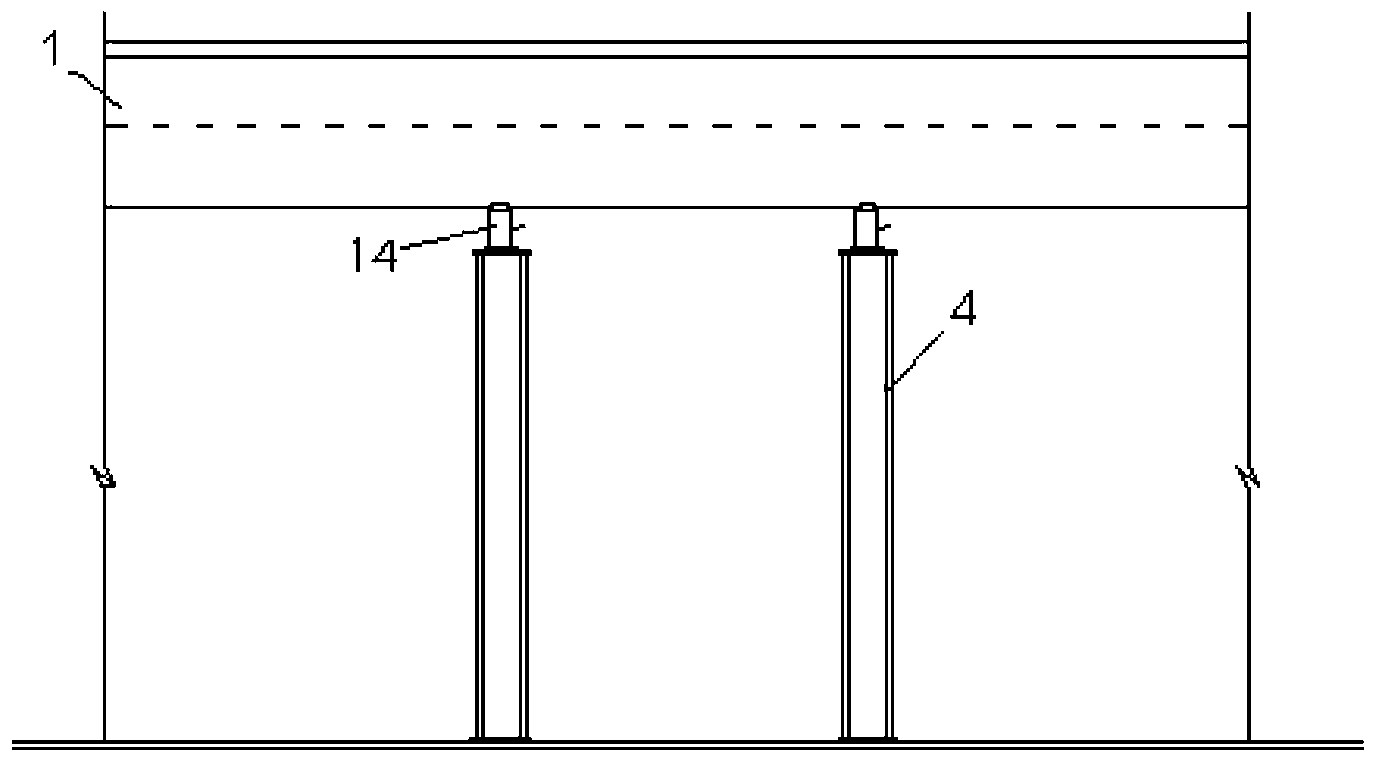

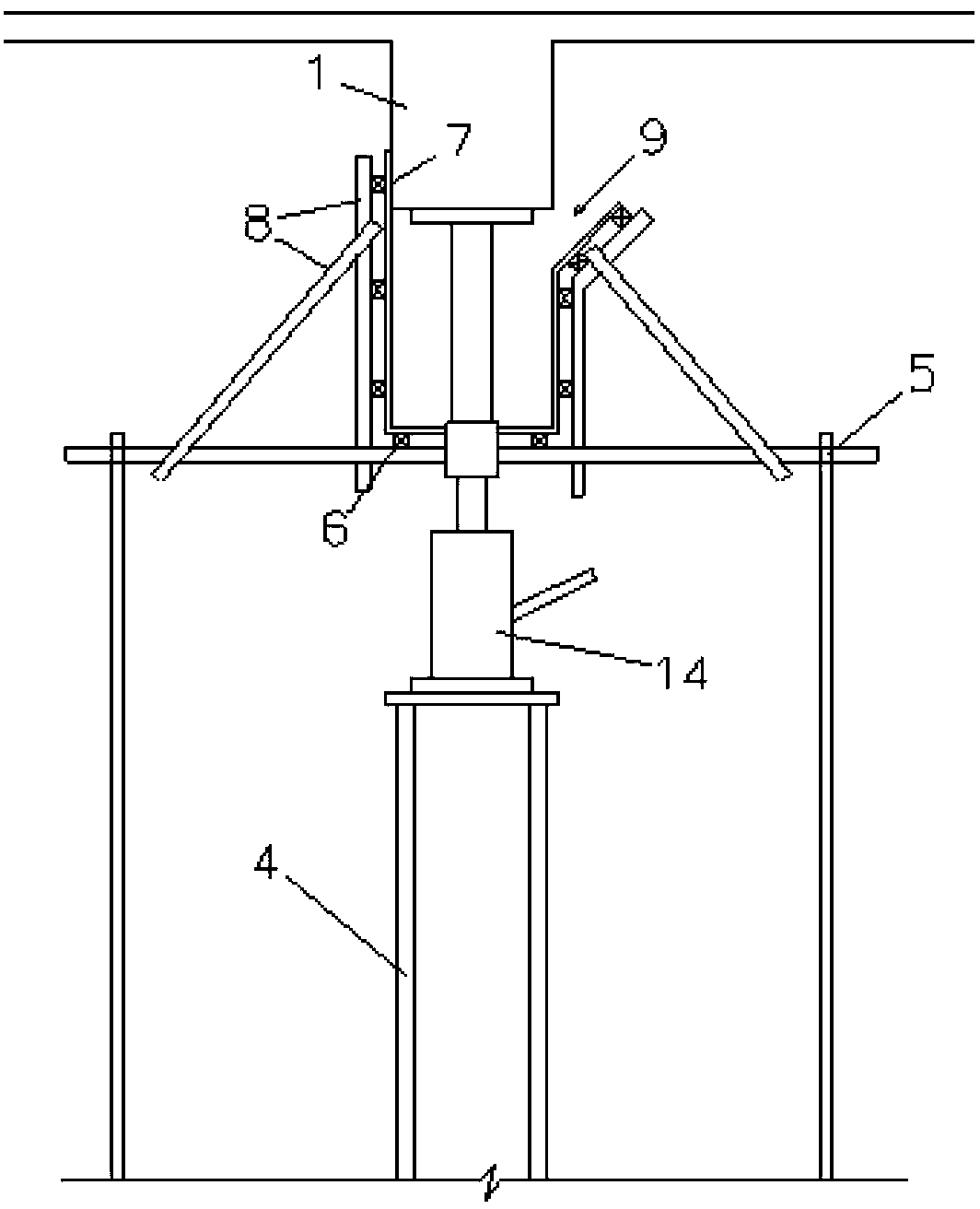

Device and method for decreasing columns and reinforcing girders of reinforced concrete members

ActiveCN103452328AImprove efficiencyLow costBuilding repairsReinforced concrete columnSocial benefits

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Duct system of sea wind (air) air conditioner by deep sea water cooling

InactiveCN1786597AImprove working environmentImprove the living environmentLighting and heating apparatusAir conditioning systemsOcean bottomEngineering

Owner:孙洪福

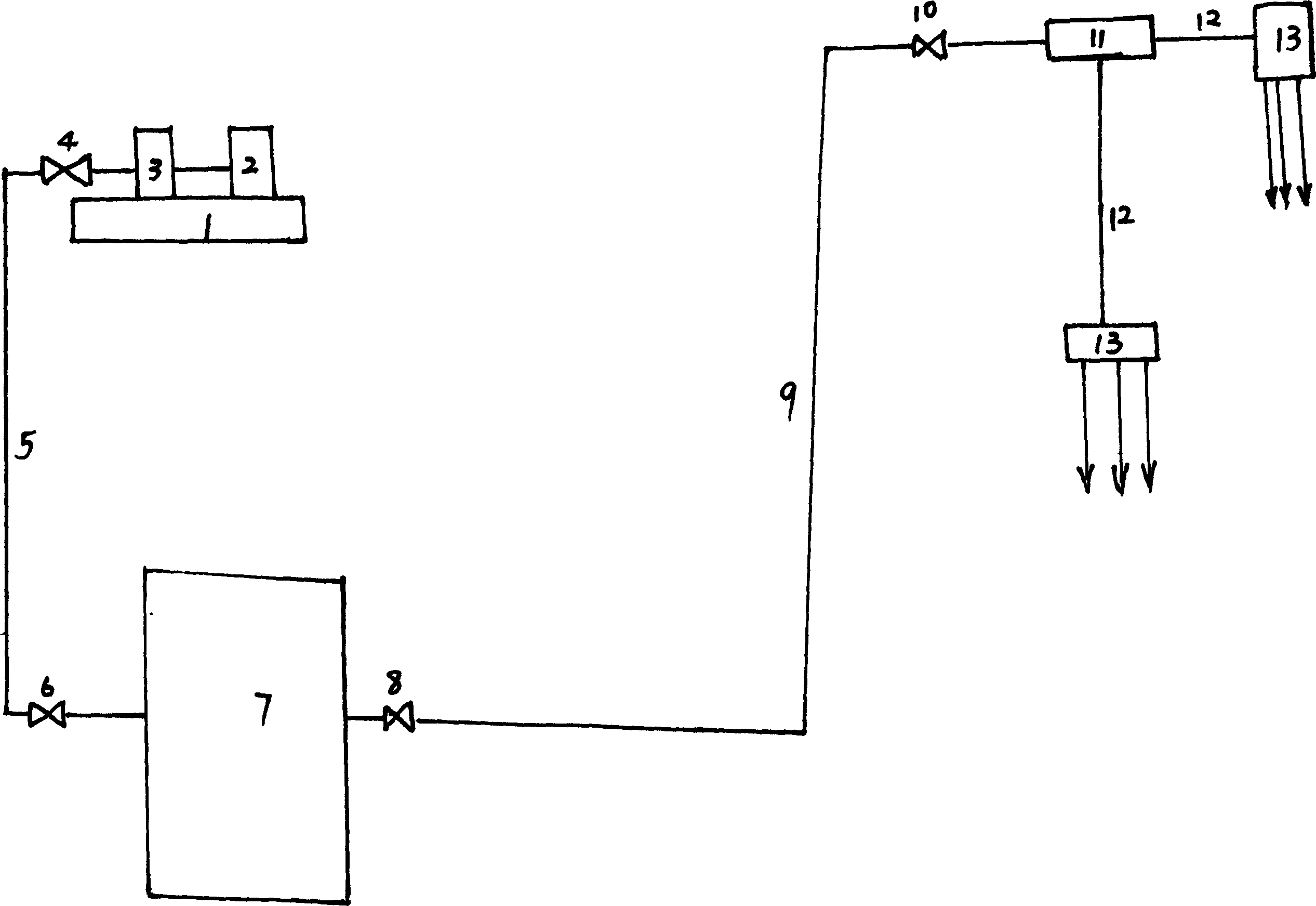

Method and device for comprehensively processing pig dung in large-scale pig farm

PendingCN110127970AEasy to handleSimple process conditionsBio-organic fraction processingSpecific water treatment objectivesPig farmsBiological filter

The invention discloses a method and a device for comprehensively processing pig manure in a large-scale pig farm. The method for comprehensively processing pig dung in the large-scale pig farm comprises the following steps: S1, the pig dung in pig houses is collected by a mechanical dung scraping facility, and is transported into a dung collecting tank; S2, the pig dung in the dung collecting tank is added into a fermentation tower by a screw conveyor, undergoes anaerobic dry fermentation to produce biogas, and then undergoes aerobic composting; S3, the biogas generated in the anaerobic dryfermentation process is introduced into and stored in a gas storage cabinet, odorous gas generated during the aerobic composting is introduced into a biological filter and is processed, the above produced organic fertilizer is transported to a curing workshop and is cured, and generated biogas slurry and leachate enter an anaerobic fermentation reactor by a pump, and are used to produce biogas; and S4, the biogas obtained in step S2 and step S3 is purified, and then used, the produced organic fertilizer is returned to the field, and the generated biogas slurry is used for irrigating crops after being discharged into an oxidation pond and processed. The method and the device have the advantage of good processing effect, simple process conditions, no secondary pollution and high economic benefits.

Owner:GUANGDONG GUANGKEN ANIMAL HUSBANDRY ENG RES INST CO LTD

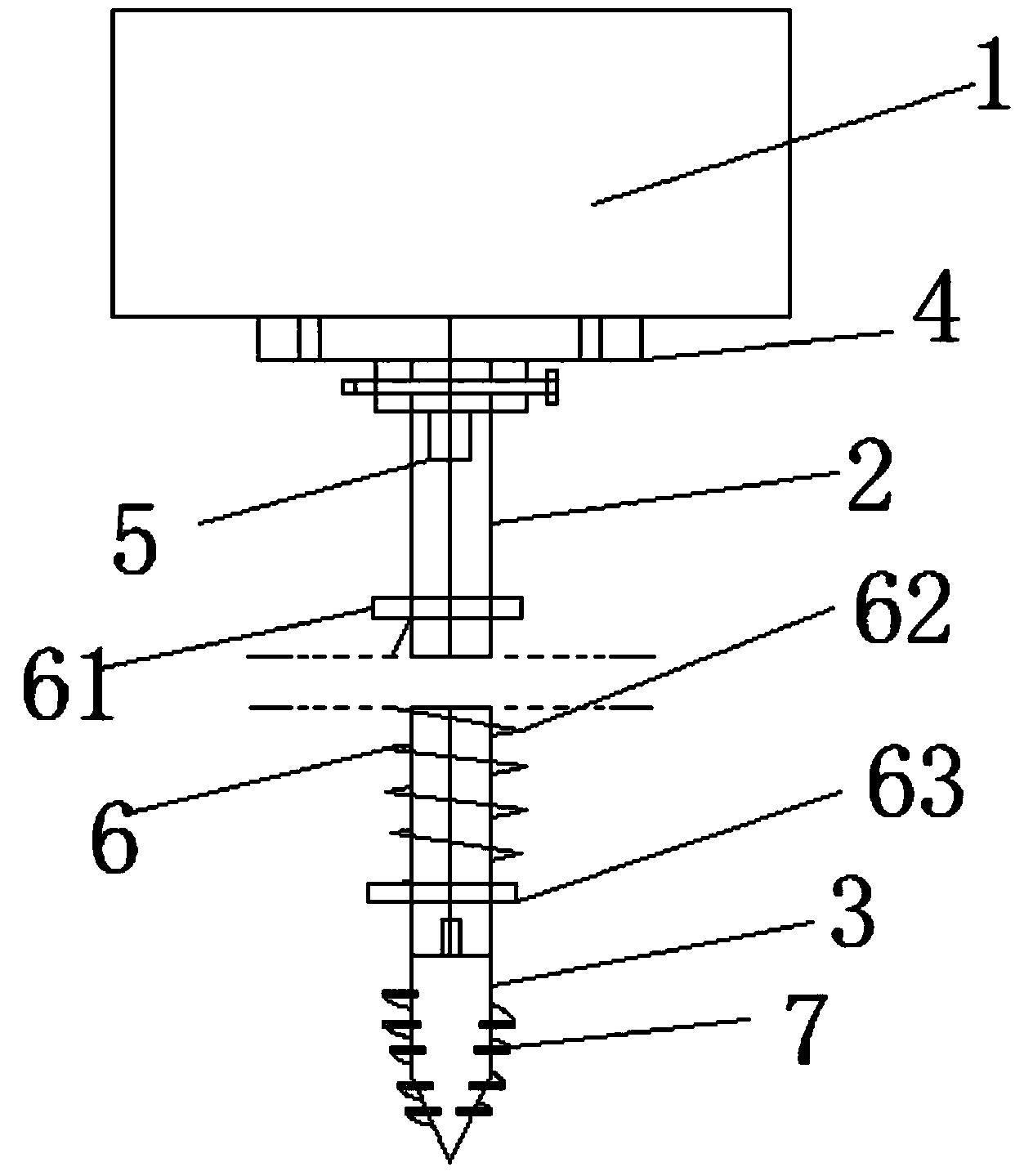

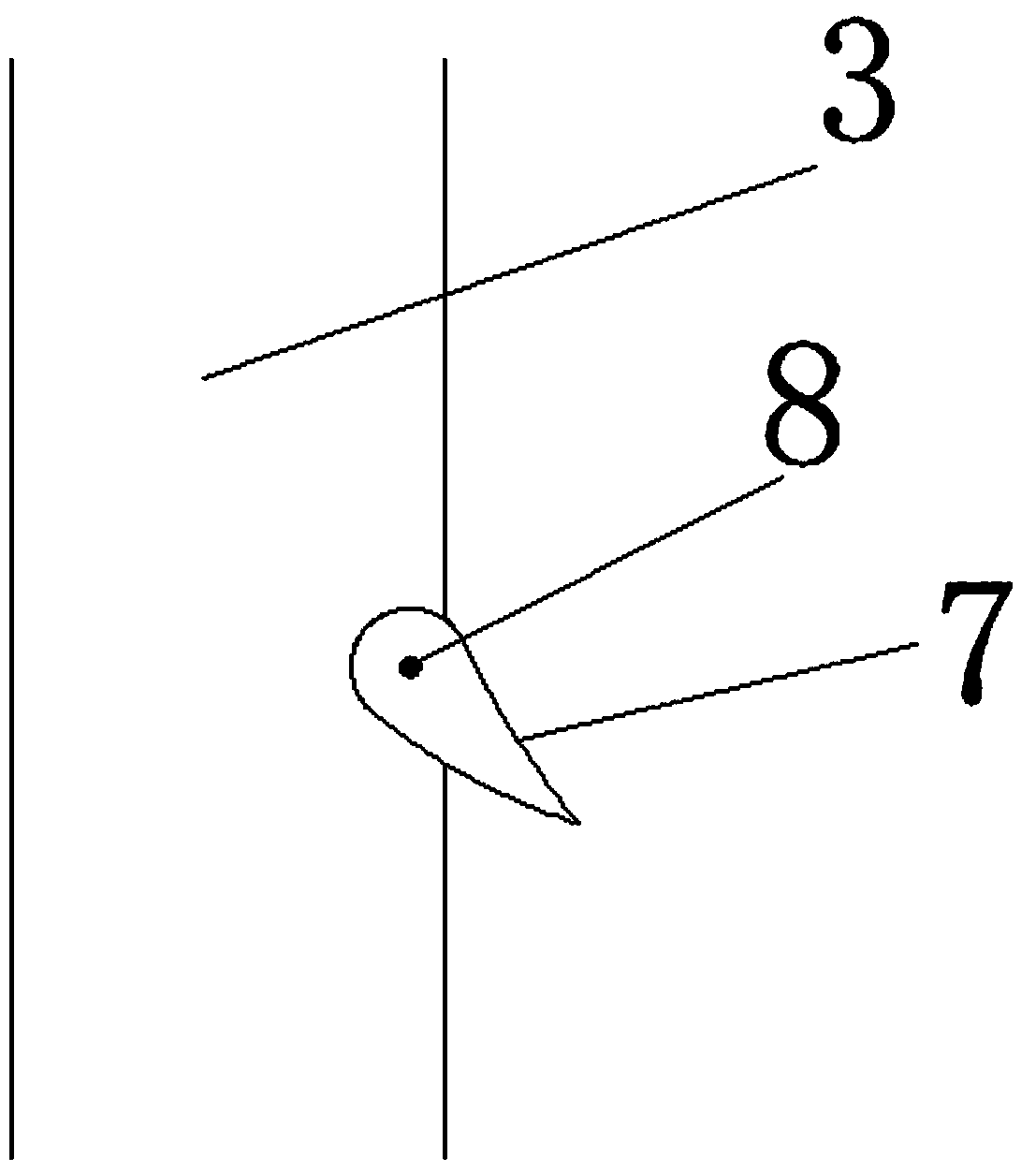

Engineering drilling device

InactiveCN104165024AEasy to operatePlay a buffer roleReciprocating drilling machinesConstructionsEconomic benefitsPetroleum engineering

Owner:JIANGSU ENG EXPLORATION & SURVEYING INST

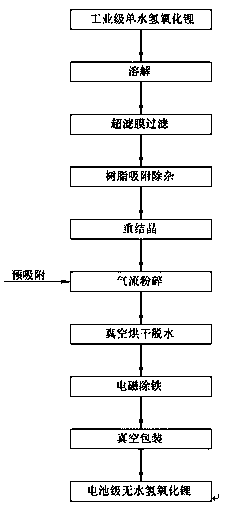

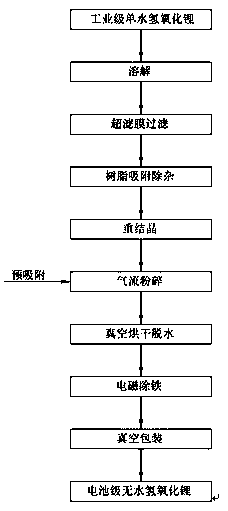

Preparation method of battery-grade anhydrous lithium hydroxide

InactiveCN111170342ASimple processEasy to operateLithium oxides/hydroxidesPhysical chemistryEconomic benefits

Owner:GANFENG LITHIUM CO LTD

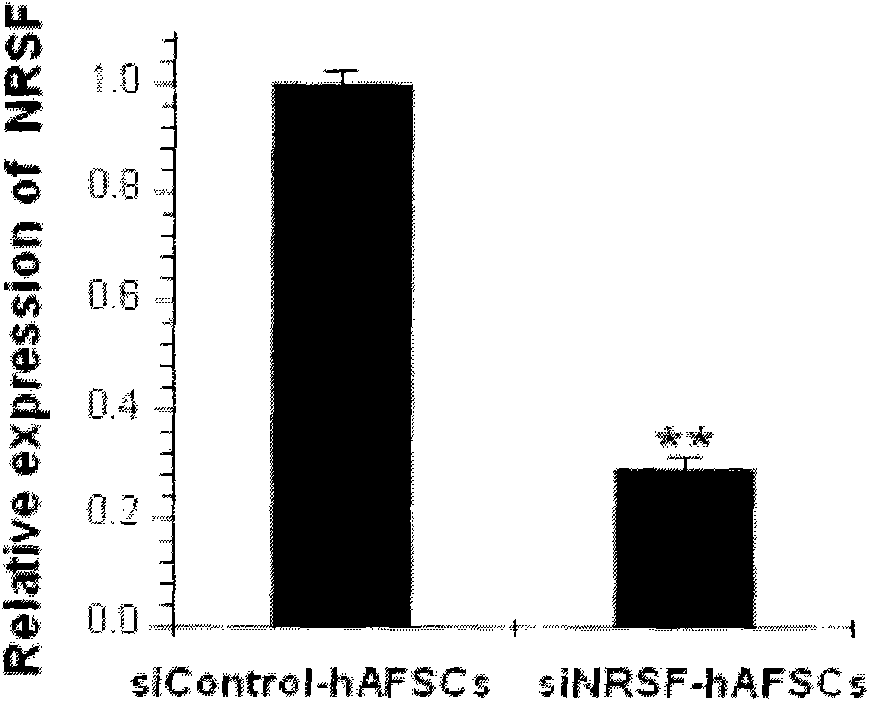

Method for inducing differentiation of stem cells into islet-like cells

InactiveCN102311940AMetabolism disorderMicrobiological testing/measurementIslet cellsCell engineering

Owner:FIELD OPERATION BLOOD TRANSFUSION INST OF PLA SCI ACAD OF MILITARY

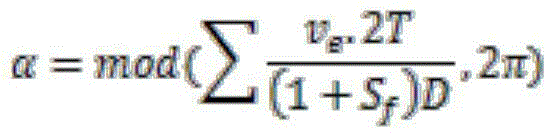

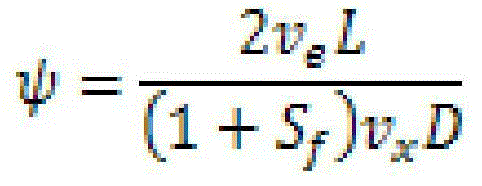

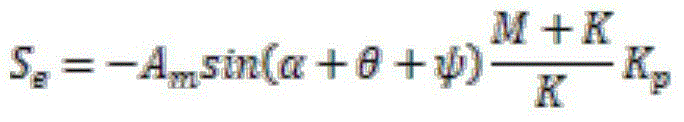

Eccentricity compensation method for cold rolling mill upstream rolling mill roll

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Method for expressing and purifying recombinant ethanol oxidase in pichia pastoris

The invention discloses a method for expressing and purifying recombinant ethanol oxidase rAOX. According to the method, an ethanol oxidase-poly-L-histidine expression vector pPIC9K-AOX-HIS is constructed first by a molecular biological technique, then the expression vector pPIC9K-AOX-HIS is linearized and transferred to pichia pastoris GS115, and thus, pichia pastoris engineering bacteria capable of expressing active recombinant ethanol oxidase are obtained, and part of recombinant ethanol oxidase can be secreted and expressed. Through optimization of the expression conditions of recombinant ethanol oxidase, the ethanol oxidase produced by the engineering bacteria may reach 1,862U / L. Meanwhile, the secretion and expression of the ethanol oxidase and the introduction of a poly-L-histidine tag simplify the purification process of the recombinant ethanol oxidase. According to the result of tests, the recombinant ethanol oxidase expressed by the engineering bacteria has much higher thermostability than pichia pastoris wide type ethanol oxidase. The operation in the whole process of the method is simple, so the method is suitable for industrial production and can create certain economic benefit.

Owner:ZHEJIANG DEQING HUINING BIOTECH

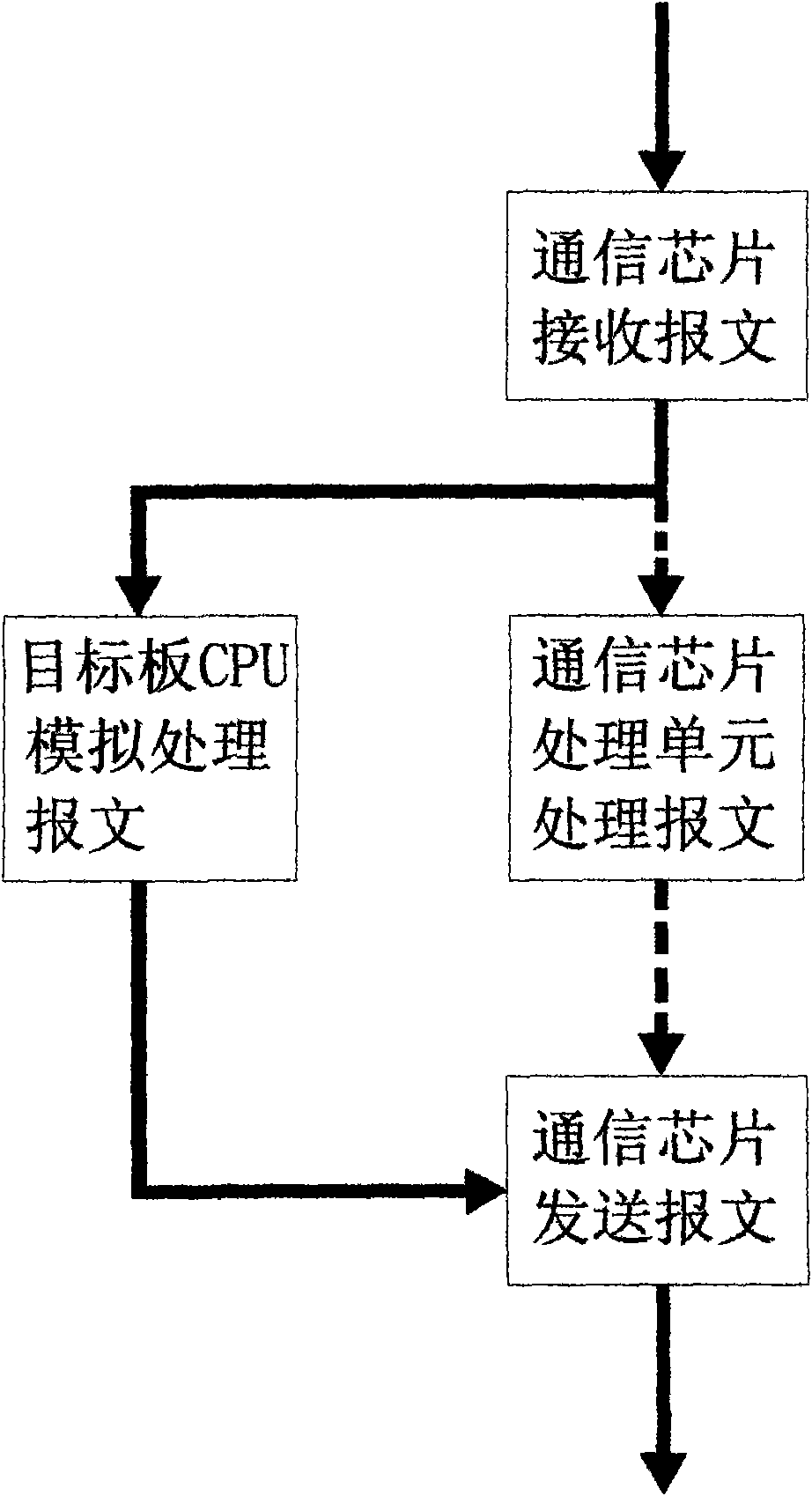

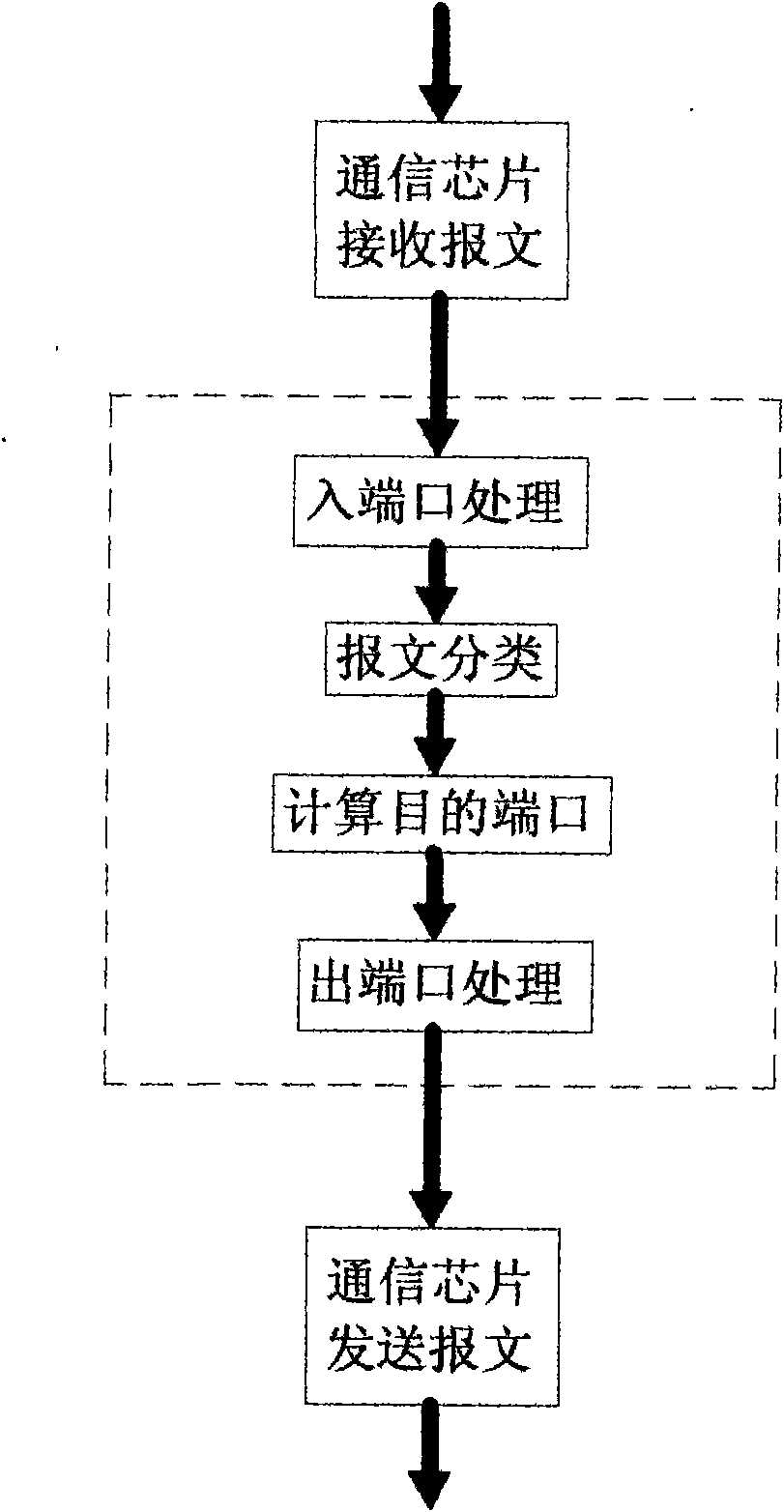

Message transmitting method based on analog communication chip technology

InactiveCN101674243AReduce complexityImprove reliabilityData switching networksComputer hardwareProcess logic

Owner:TAICANG T&W ELECTRONICS CO LTD

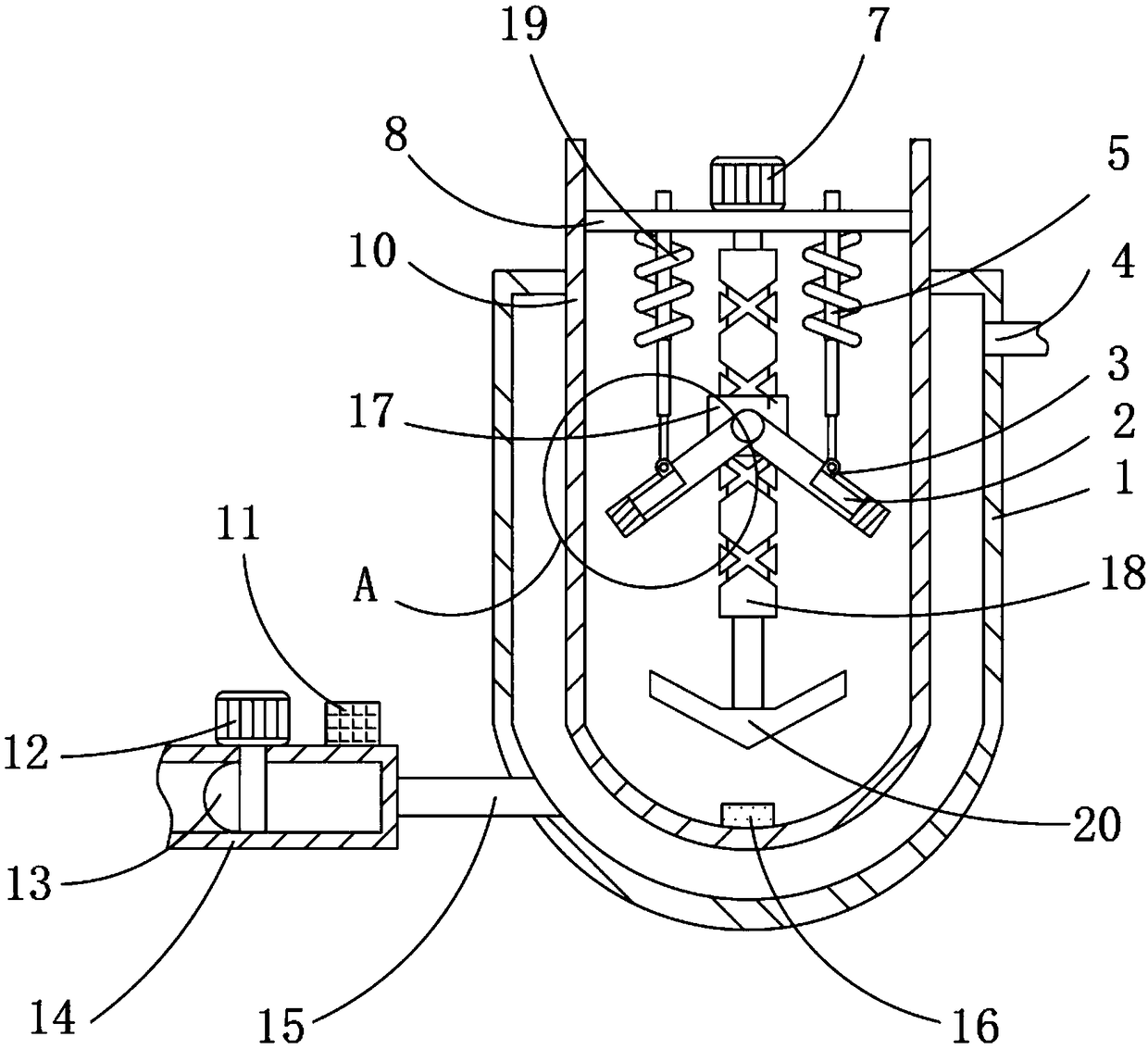

Printing and dyeing raw material mixing device

InactiveCN108686574AWell mixedRotary stirring mixersTransportation and packagingEconomic benefitsEngineering

Owner:ZHEJIANG XINGFEIER TECH CO LTD

Pineapple peeling machine and preparation method and device thereof

Owner:南通纳豉康食品有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap