Preparation method of battery-grade anhydrous lithium hydroxide

A technology of anhydrous lithium hydroxide and monohydrate lithium hydroxide, which is applied in the direction of lithium oxide; It is impossible to use synthetic ternary cathode materials to achieve the effects of increasing the economic and social benefits of the product, shortening the drying time, and increasing the added value of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

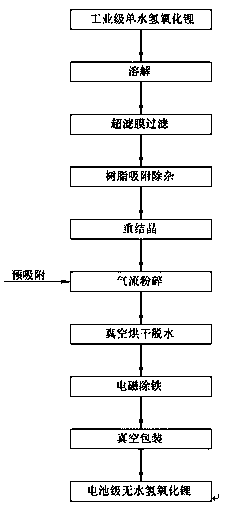

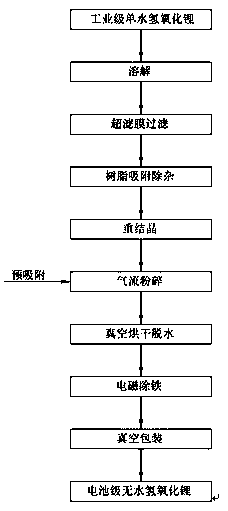

[0037] Such as figure 1 Shown, the present invention proposes the preparation method of battery grade anhydrous lithium hydroxide, and this preparation method comprises:

[0038] Step S101, dissolving, adding industrial-grade lithium hydroxide monohydrate and ultrapure water to stir and dissolve completely, and making lithium hydroxide aqueous solution;

[0039] Step S102, ultrafiltration membrane filtration, passing the lithium hydroxide solution through the ultrafiltration membrane, and filtering to remove impurities;

[0040] Step S103, the resin absorbs and removes impurities, and the leaching solution is respectively subjected to adsorption and removal of impurities by chelating resin and strong basic anion resin;

[0041] Step S104, recrystallization, using the MVR forced circulation evaporation crystallization technology to evaporate and crystallize the LiOH solution to precipitate lithium hydroxide crystals;

[0042] Step S105, jet milling, jet milling the recrystallize

Embodiment example 1

[0047] Dissolve 100kg of industrial-grade lithium hydroxide monohydrate in 1000L of pure water, stir and dissolve, then filter through an ultrafiltration membrane, and then adsorb and remove impurities through chelating resin and strong alkaline anions. 93 kg of refined lithium hydroxide monohydrate were obtained after MVR forced circulation evaporation and recrystallization, and D50 was 1.8 mm. Grinding with pre-treated air flow. Lithium hydroxide monohydrate with a D50 of 40um was obtained, dried in vacuum at 150°C for 3 hours, and iron was removed by using an electromagnetic iron remover to select a mesh-shaped magnetic inter-network under a magnetic field strength of 12000GS. Finally, the anhydrous lithium hydroxide product is obtained.

Embodiment example 2

[0049] Dissolve 120kg of industrial-grade lithium hydroxide monohydrate in 1000L of pure water, stir and dissolve, filter through an ultrafiltration membrane, and then remove impurities by adsorption of strong alkaline ions. 110 kg of refined lithium hydroxide monohydrate were obtained after MVR forced circulation evaporation and recrystallization, and D50 was 2.1 mm. Grinding with pre-treated air flow. Lithium hydroxide monohydrate with a D50 of 33um was obtained, dried in vacuum at 160°C for 2 hours, and iron was removed by using an electromagnetic iron remover to select a meshed magnetic inter-network under a magnetic field strength of 10000GS. Finally, the anhydrous lithium hydroxide product is obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap