Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Save energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

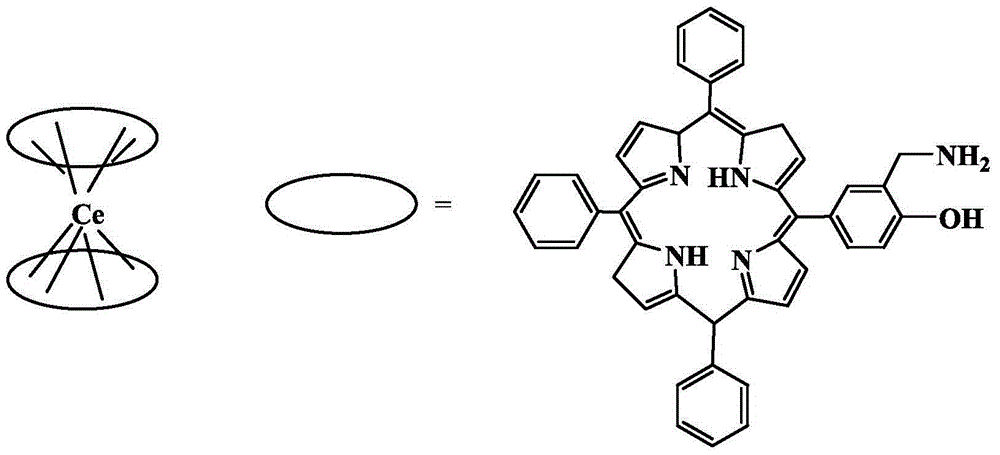

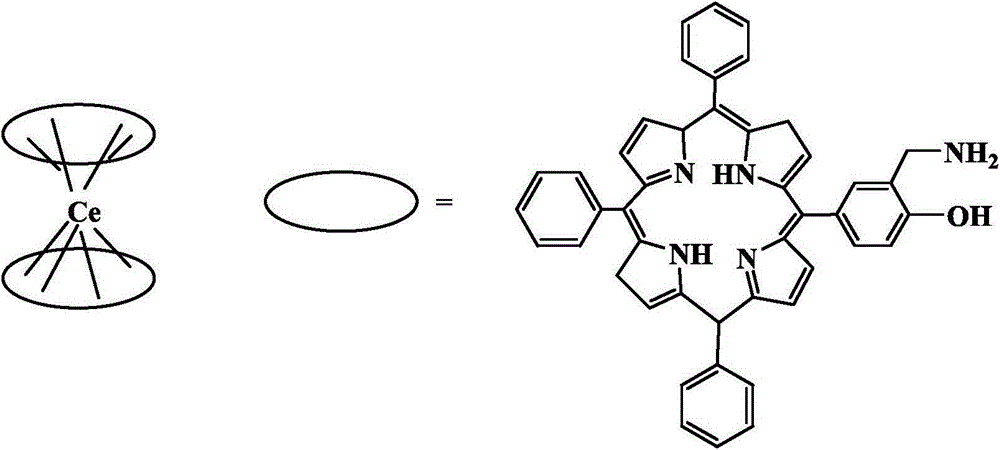

Water-soluble double-layer sandwich-type Ce metalloporphyrin complex and application of complex in microcontact printing technique

ActiveCN104447820AHigh resolutionSmooth responseInksGroup 3/13 element organic compoundsWater solublePolymer substrate

The invention relates to a water-soluble double-layer sandwich-type Ce metalloporphyrin complex and application of the water-soluble double-layer sandwich-type Ce metalloporphyrin complex in a microcontact printing technique. Metal patterns are prepared on the surface of a polymer substrate commonly used in the electronics industry by taking bis(5-(4'-hydroxy-3'-aminomethylphenyl)-10,15,20-triphenyl porphyrin) complexed Ce aqueous solution as microcontact printing ink, and a new thought is provided for the microcontact printing industry.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Manufacturing process of high-carbon tool steel SK85 cold-rolled wide steel strip

The invention discloses a manufacturing process of a high-carbon tool steel SK85 cold-rolled wide steel strip. The process is characterized in that steel is subjected to converter smelting, LF furnacerefining and slab continuous casting to obtain continuous casting slabs with the thickness ranging from 210 mm to 230 mm, the continuous casting slabs are heated and subjected to hot continuous rolling and laminar cooling to reach the coiling temperature, a hot-rolled wide steel strip with the thickness ranging from 2.5 mm to 6.0 mm is obtained, the coiled hot-rolled wide steel strip is put in storage and slowly cooled to the room temperature, and the obtained metallographic structure is thin-sheet-shaped pearlite; the total reduction of first cold rolling is controlled to be 20%-50% after acid pickling of the hot-rolled wide steel strip, then spheroidizing annealing is conducted, the Vickers hardness HV5 is 180 or below, and the spheroidizing rate is 92% or above; after the steel strip is subjected to primary spheroidizing annealing, secondary cold rolling is conducted, the total reduction of cold rolling is controlled to be 30%-85%, and a cold-rolled wide steel strip with the finished product specification being 0.70-3.00 mm thick is obtained; the steel strip subjected to secondary cold rolling is further spheroidized and annealed, the Vickers hardness HV5 is 175 or below, and the spheroidizing rate is 94% or above; and then third cold rolling is conducted, the total reduction of cold rolling is controlled to be 50%-85%, and the cold-rolled wide steel strip with the finishedproduct specification being 0.10-0.70 mm thick is obtained.

Owner:新余钢铁股份有限公司

Automatic exit and entry certificate handling device and method thereof

PendingCN106846661AShorten the timeSave energyData processing applicationsApparatus for meter-controlled dispensingEngineeringCard reader

The invention discloses an automatic exit and entry certificate handling device and a method thereof. The device comprises a shell, a touch display screen, a digital camera, a picture color printer, a laser printer, an identity card reader, an endorsement module, a control module, a lifting chair, and a lifting part, wherein the touch display screen, the digital camera, the picture color printer, the laser printer, the identity card reader, the endorsement module and the control module are arranged on the rear part in the shell, the lens of the digital camera faces to the front part in the shell, the lifting chair and the lifting part are arranged on the front part in the shell, and the lifting part is used for driving the lifting chair to go up or down; and the touch display screen, the digital camera, the picture color printer, the laser printer, the identity card reader, the endorsement module and the lifting part are respectively connected to the control module. The device disclosed by the invention can enable users to independently apply for new exit and entry certificates and endorse exit and entry certificates for the second time, and thereby, not only is the efficiency of certificate handling increased, but also the time and energy of the users are saved.

Owner:GUANGZHOU HUABIAO SCIENCEAND TECH DEV CO LTD

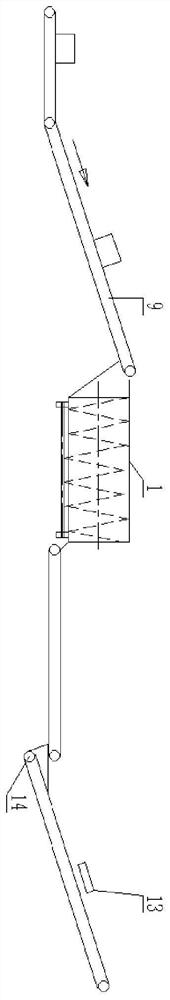

Mold/non-mode combined pulling process and device

InactiveCN102133582AImproving the process conditions of drawing formingReduce consumptionDrawing profiling toolsEngineeringMechanical engineering

The invention belongs to the technical field of metal plastic processing, and particularly provides a mold / non-mold combined pulling process and a device. The device is characterized in that a pulling mold is directly installed between a heater and a cooling machine of a non-mold pulling device, the waste heat of non-mold pulling is utilized fully, so that the mold puling and sizing with temperature can be completed before the non-mold pulling is molded, and the surface quality is improved. In the invention, the pulling force is reduced greatly, the intermediate heat treatment or heating process of the traditional process is saved, the mold consumption is reduced, the energy resource is saved, the production cost is lowered, a high-quality metal product can be pulled and molded in short flow range, and the advantages that the deformation amount of the non-mold pulling is large, the precise of the mold pulling size is high and the like can be realized.

Owner:UNIV OF SCI & TECH BEIJING

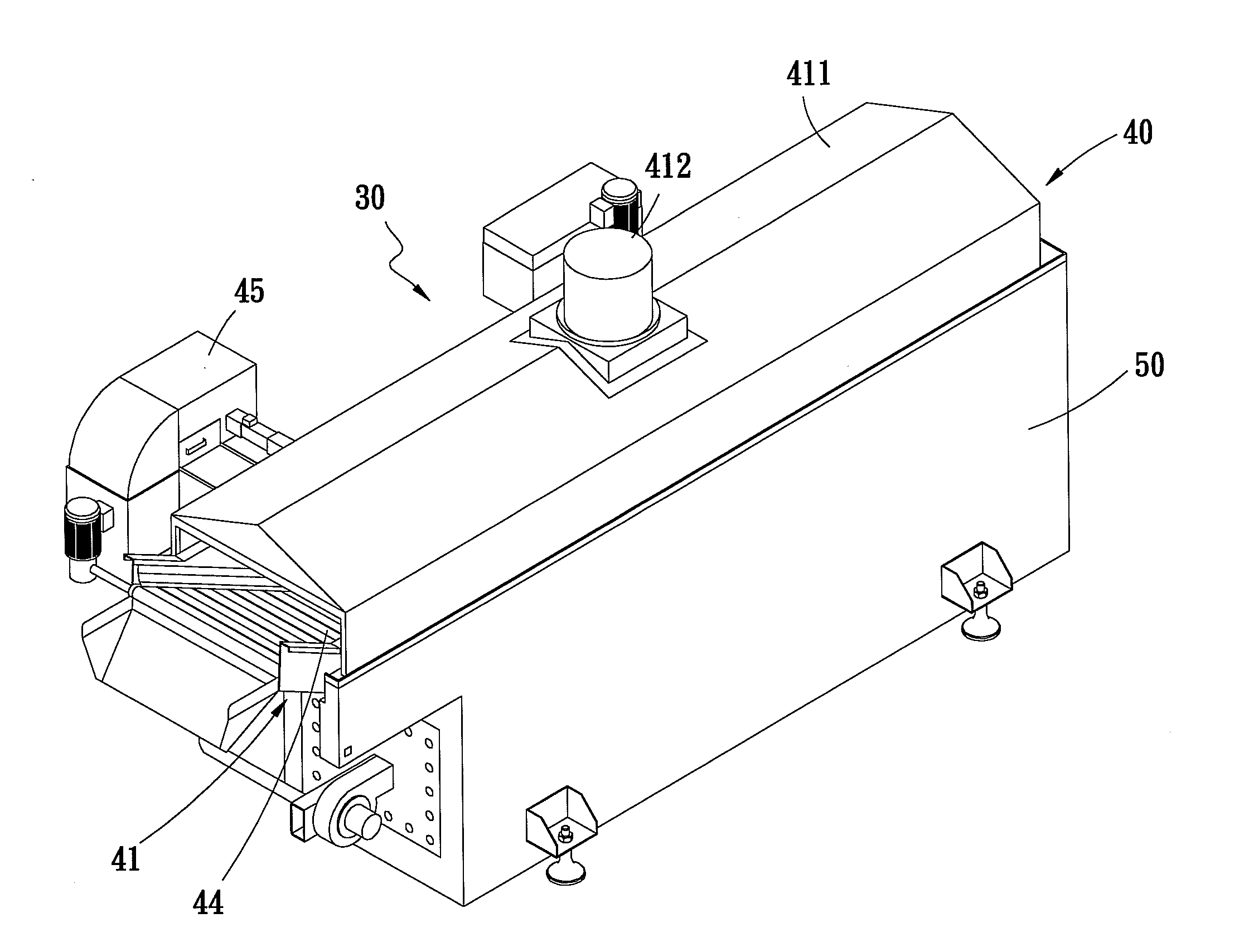

Online chip cleaning and drying equipment

ActiveCN102820242ASimple structureIngenious designDrying using combination processesSemiconductor/solid-state device manufacturingEngineeringVacuum chamber

The invention discloses online chip cleaning and drying equipment which comprises an automatic feeding mechanism, a spray type cleaning device, vacuum drying equipment and a positioning table. The vacuum drying equipment comprises a frame; a pair of drying conveying belts which are connected with a cleaning machine, support the two sides of a chip and horizontally move are arranged in the middle of the frame; a push plate which controls and supports the chip to move up and down through mechanical power is arranged on the frame below the part between the drying conveying belts; a first vacuum chamber provided with a vacuum sucker and an infrared heating tube is arranged right over the push plate; a second vacuum chamber which is movably connected with the first vacuum chamber through a connecting rod mechanism and provided with a sealing structure matched with the lower end of the first vacuum chamber is arranged on one side of the first vacuum chamber; and a vacuum adsorption hole corresponding to the chip is formed on one side of the second vacuum chamber corresponding to the first vacuum chamber and provided with the sealing structure. The equipment is simple in structure and skillful in design, automatically picks up chips, performs spray type cleaning and vacuum drying on the chip, dries the chip through thermal power in the vacuum environment, and prevents the chips from being damaged.

Owner:TONGLING TAIYANGDAO AGRI TECH CO LTD

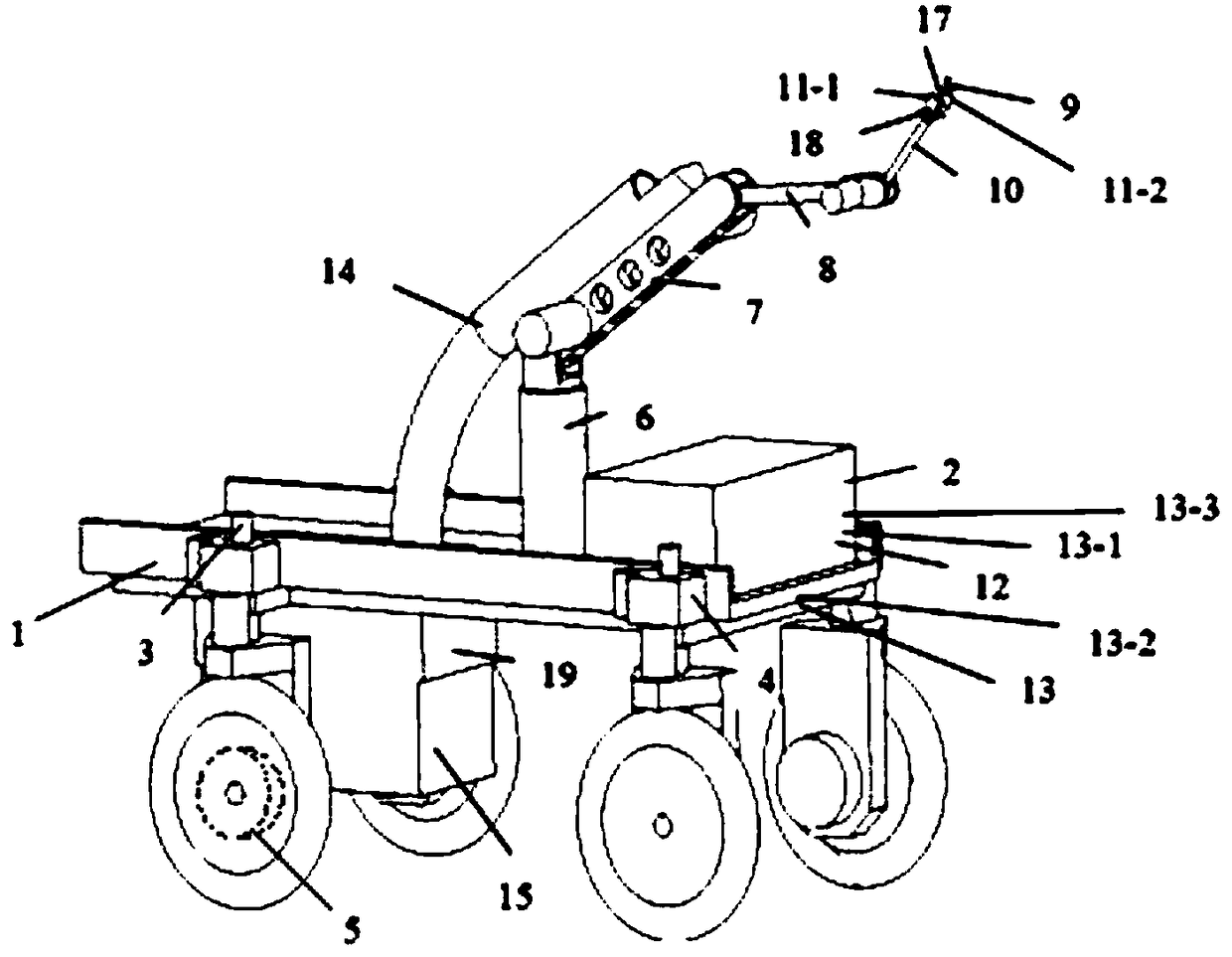

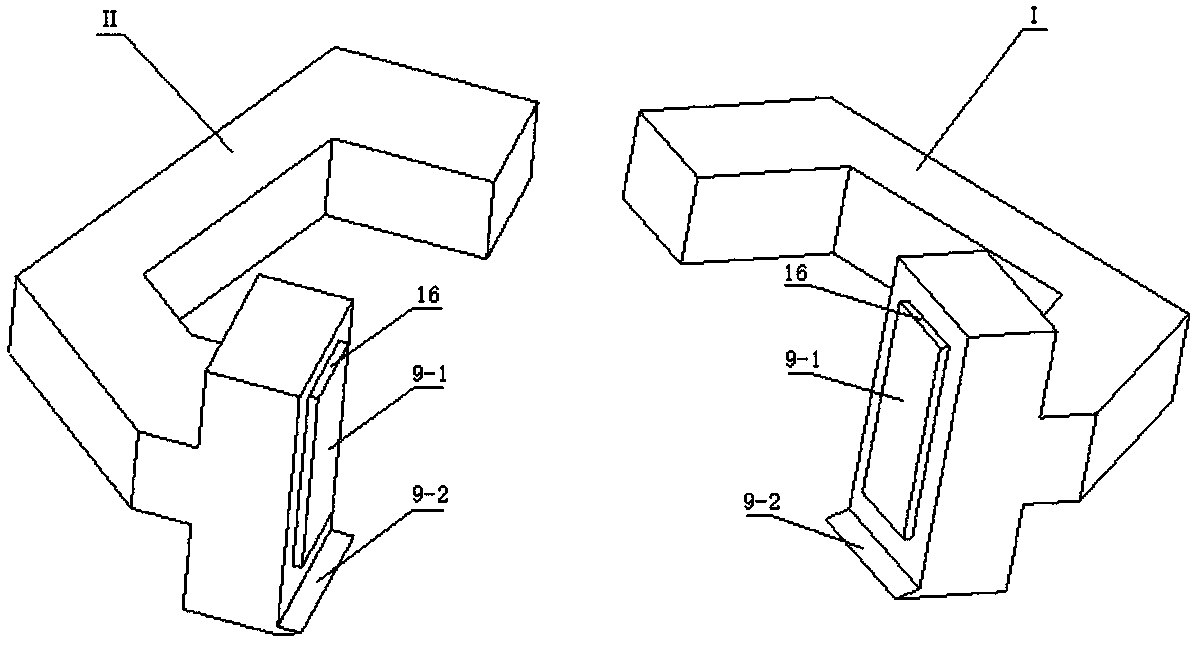

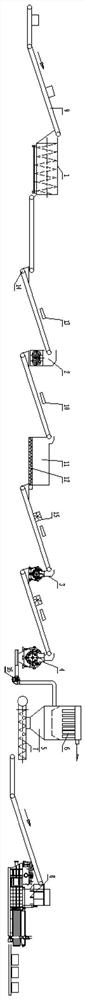

Robot and method for picking daylily

The invention discloses a robot and a method for picking daylily. According to the invention, a navigation walking system is adopted for navigation and positioning of the robot; a fruit picking systemis adopted for mechanical picking of the daylily; an object identification and positioning system is adopted for accurate identification and positioning in picking operation; a fruit collection device is adopted for timely collection of picked daylily; and an electric source and power control device is adopted for intelligent control to all systems. Through mechanical and electrical combination,and by combination of the growth characteristics and picking requirements of the daylily for highly-efficient picking, the manner of replacing manual labor with the robot is realized. The method provided by the invention controls the picking path of the robot for picking the daylily; three-dimensional coordinates of a feature point are obtained to be fed back to the electric source and power control device, so the feasibility and accuracy of the whole picking operation are guaranteed; and picking operation of the daylily is completed, and the picked daylily is timely collected, so the pickingand collection efficiency of the daylily is improved, the number of times of handling can be effectively reduced, and the quality of picked daylily is improved.

Owner:BEIFANG UNIV OF NATITIES

Multifunctional integrated cleaner unit machine

InactiveUS20100294004A1Small footprintReduce manufacturing costOther washing machinesTextiles and paperEngineeringSmall footprint

A multifunctional integrated cleaner unit machine includes a cabinet, washing basin and a full-automatic washing machine located in the cabinet. An enclosing frame is provided on an upper part of the cabinet. A cover corresponding with the full-automatic washing machine is hinged on the enclosing frame. A control panel and a main water inlet are provided at the enclosing frame. A dryer machine is located on one side of the full-automatic washing machine in the cabinet. The washing basin is located in the enclosing frame above the dryer machine. The washing machine, the washing basin and the dryer are combined into an integral machine with the security standard, thereby the multifunctional integrated cleaner unit machine has the advantages of small occupied area, low manufacturing cost, full functions, proper height, time saving in use, convenience, energy saving, convenient installation, little vibration and noise, low transporting cost and uniform integral style.

Owner:HU JIEBO

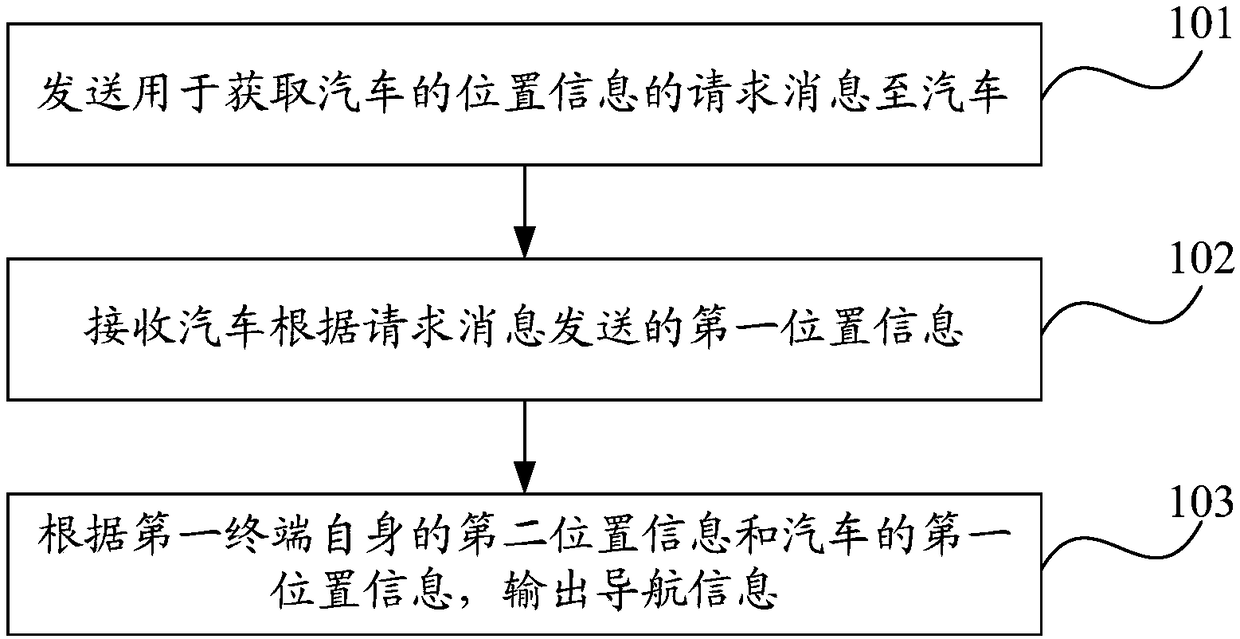

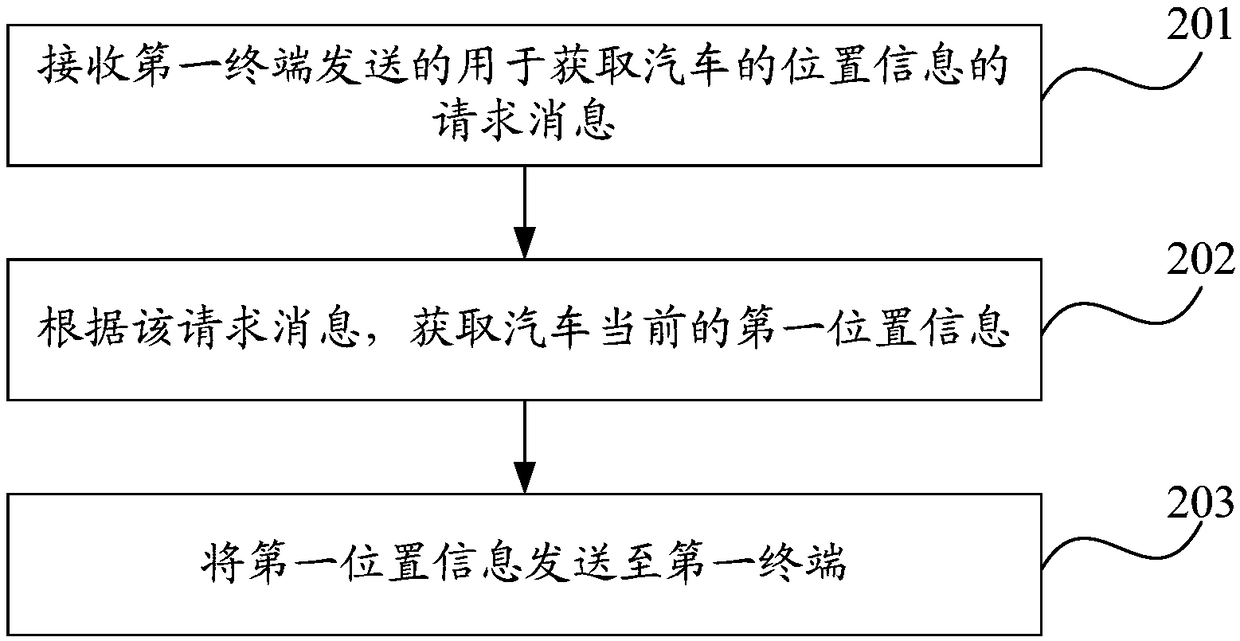

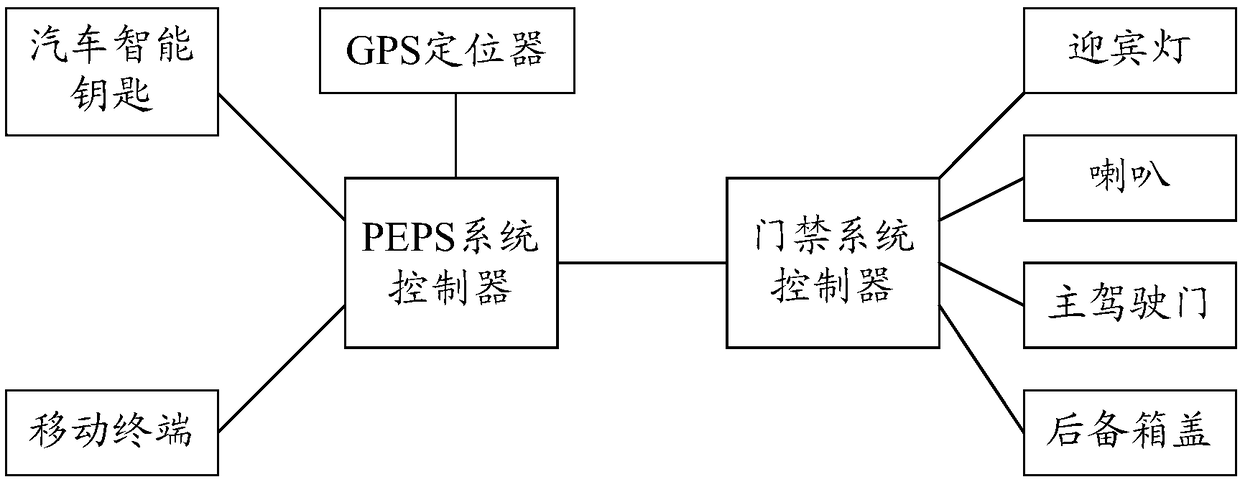

Automobile control method and device and automobile

InactiveCN108263388AShorten the timeSave energyElectric/fluid circuitAutomotive engineeringEngineering

Owner:BEIJING ELECTRIC VEHICLE

Ultrasonic continuous sterilization device and method thereof

The invention provides an ultrasonic continuous sterilization device, comprising a raw material tank, a heating device, a heat exchanging device, an ultrasonic processing device, a liquid storage device and a controller. The heating device is connected with the heat exchanging device. The raw material tank, the heat exchanging device, the ultrasonic processing device and the liquid storage device are sequentially connected through pipelines. The controller is respectively connected with the heating device, the heat exchanging device, the ultrasonic processing device and control valves on the pipelines. The ultrasonic processing device comprises an ultrasonic barrel, a plurality of ultrasonic probes, ultrasonic transducers and ultrasonic generators, wherein the ultrasonic transducers and the ultrasonic generators are arranged corresponding to the ultrasonic probes, the ultrasonic generators adopt different frequencies and are all arranged in the controller, and the ultrasonic probes are correspondingly distributed on the periphery of the ultrasonic barrel in a stagered junction mode. The invention also provides a method realized by the devices, i.e. feed liquid is firstly heated by the heat exchanging device, and then dynamic and continuous ultrasonic sterilization processing is carried out by the ultrasonic processing device. The invention adopts the technology combining low-temperature heating and ultrasonic processing, and has the advantages of good sterilization effect, high efficiency and the like.

Owner:SOUTH CHINA UNIV OF TECH

Drying machine control method, device, system and drying machine

InactiveCN107104860AEffective protectionEasy to operateTextiles and paperHome automation networksMachine controlCloud server

The present invention discloses a drying machine control method, a device, a system and a drying machine. The drying machine control method includes the steps of acquiring the features of to-be-dried clothes; sending the features to a cloud server to drive the cloud server to determine corresponding drying parameters according to the features; receiving drying parameters returned by the cloud server; controlling the operation of the drying machine according to the drying parameters. According to the technical scheme of the embodiment of the present invention, appropriate parameters are selected for different clothes, so that clothes are effectively protected. The drying effect is improved and the user operation is simplified. The operation is more convenient and more intelligent.

Owner:MIDEA GRP CO LTD

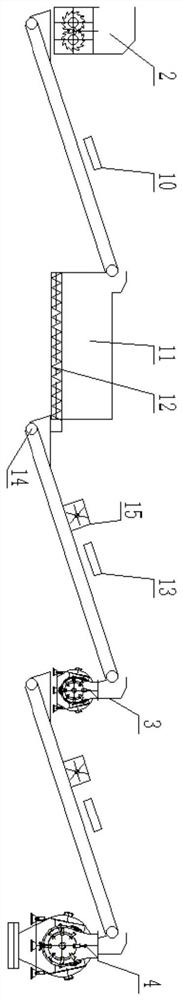

Concrete curing device carried by secondary lining trolley and using method of concrete curing device

PendingCN107269296ANovel ideaSimple structureUnderground chambersTunnel liningWater storage tankStructural engineering

A concrete curing device carried by a secondary lining trolley and a using method of the concrete curing device are disclosed. The device comprises a water spraying system, the water spraying system comprises a water storage tank (1), a water spring pipeline and a water pump, the water spraying pipeline comprises a left arc-shaped water spraying pipeline (2) and a right arc-shaped water spraying pipeline (3), a plurality of spray heads (9) are arranged on the left arc-shaped water spraying pipeline (2) and the right arc-shaped water spraying pipeline (3) correspondingly, the left arc-shaped water spraying pipeline (2) is connected with the water storage tank (1), and the right arc-shaped water spraying pipeline (3) is connected with the water storage tank (1). The method comprises the steps of enabling a left arch ring (6) and a right arch ring (10) to rise above a top formwork of the secondary lining trolley, enabling the left arch ring (6) and the right arch ring (10) to cross edge formworks of the secondary lining trolley, adjusting the distance between each spray head (9) and secondary lining concrete, enabling the left arc-shaped water spraying pipeline (2) and the right arc-shaped water spraying pipeline (3) to spray water, and conducting water spraying curing on the concrete. According to the concrete curing device carried by the secondary lining trolley and the using method of the concrete curing device, the purpose that the concrete is cured timely after lining is subjected to formwork removing is achieved, and the problem that at present, concrete cannot be cured timely some time is solved.

Owner:CHINA RAILWAY 11TH BUREAU GRP +1

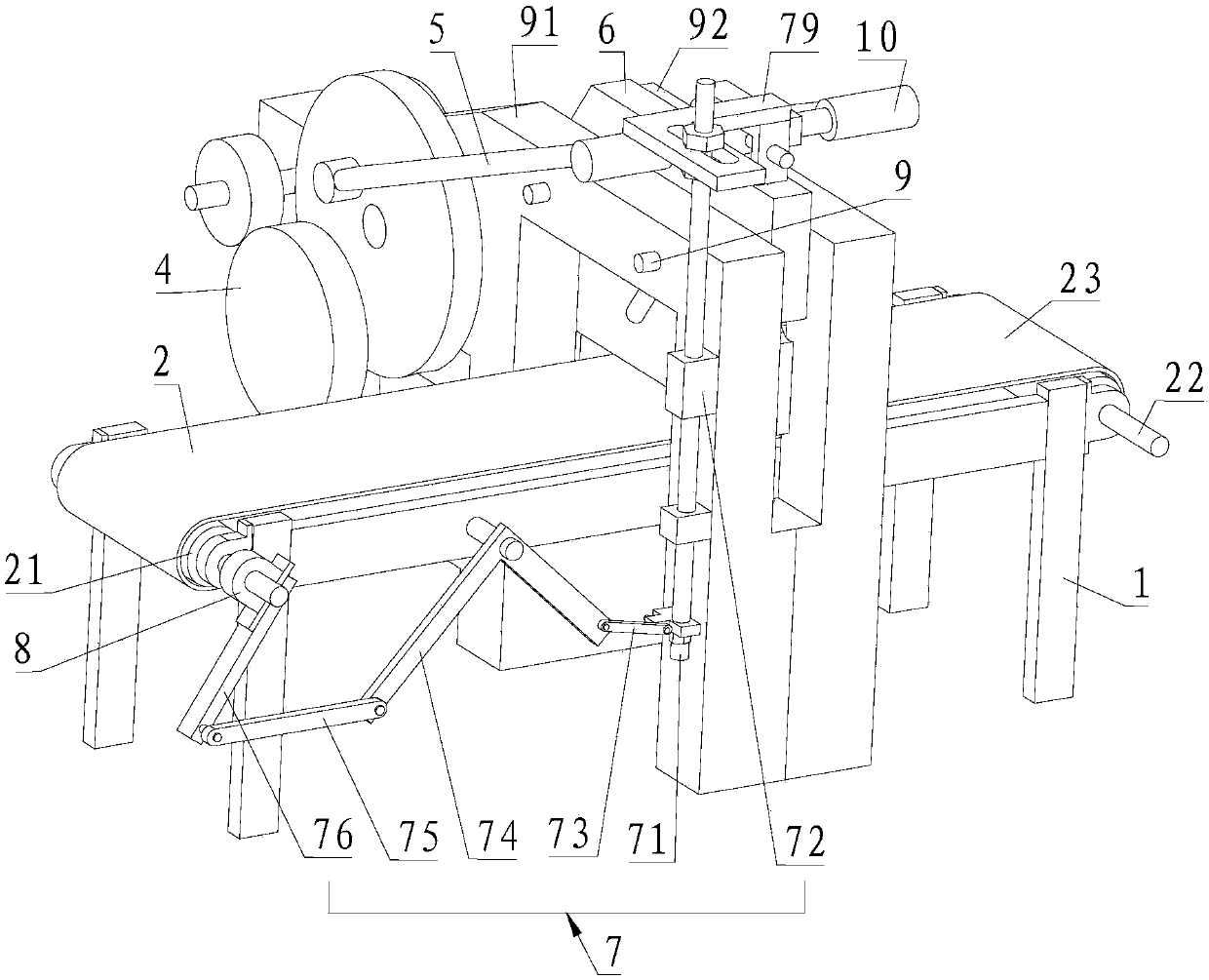

Film cutting device

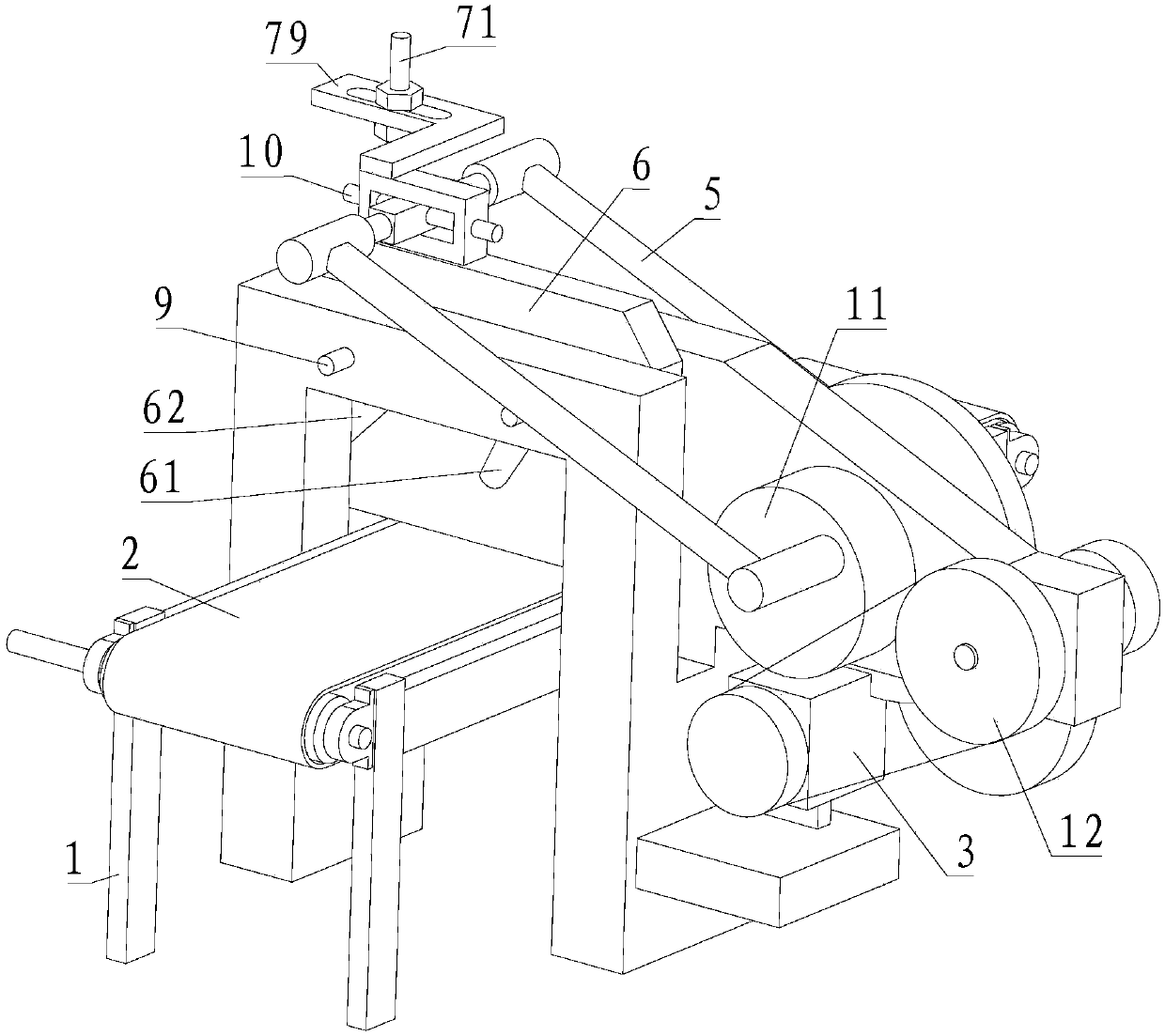

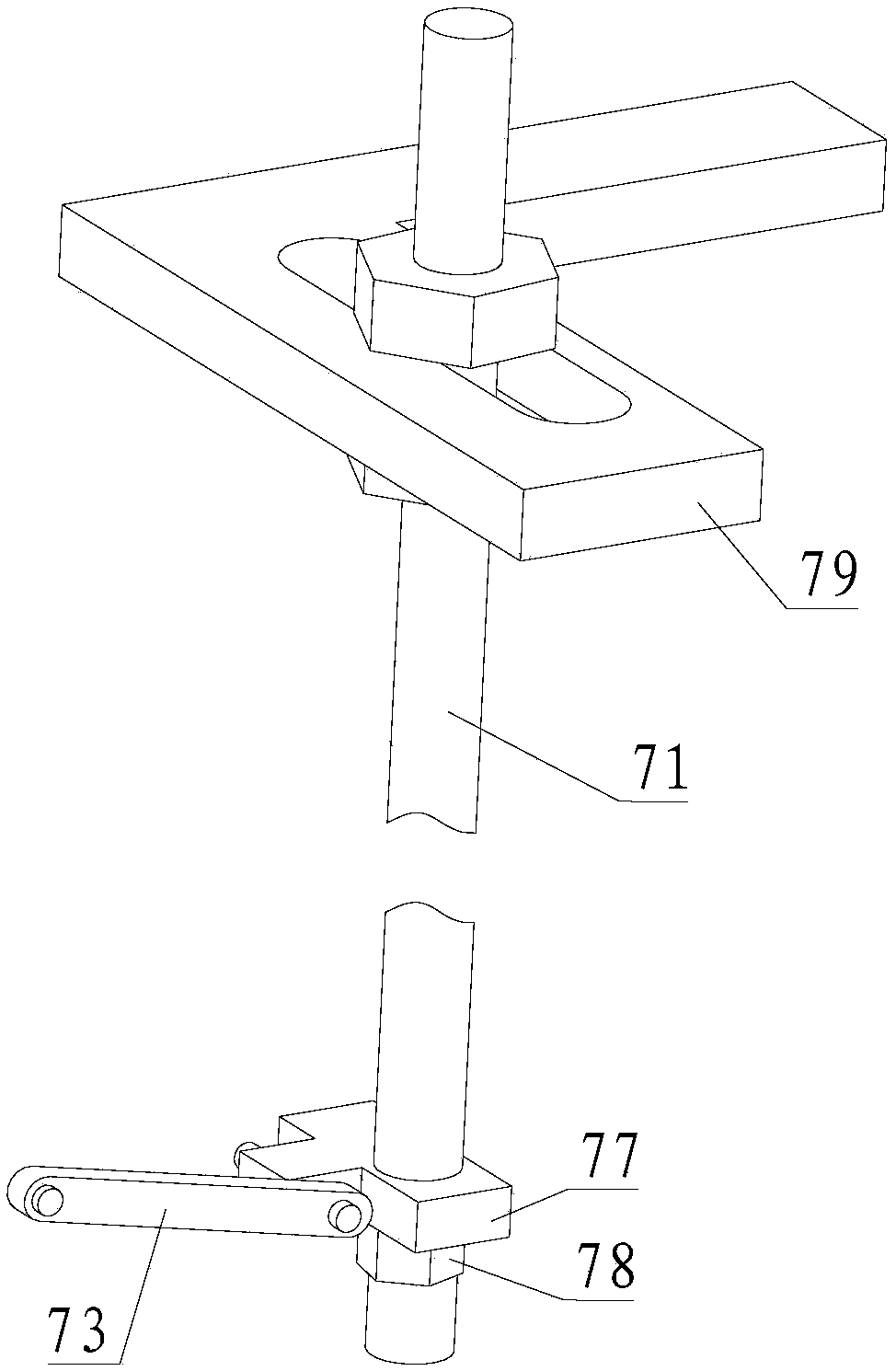

PendingCN107792707AReasonable and stable structureSimple system structureConveyorsArticle deliveryEngineeringGear drive

The invention provides a film cutting device comprising a machine frame and a conveyer belt assembly. The conveyer belt assembly comprises a first rolling shaft, a second rolling shaft and a conveyerbelt. The conveyer belt is connected to the first rolling shaft and the second rolling shaft in a sleeving manner. The film cutting device further comprises a motor, a gear transmission assembly, pullrods, a cutter, a connection rod mechanism and a one-way bearing. An output shaft of the motor is connected with the input end of the gear transmission assembly. One end of each pull rod is rotationally connected with the gear transmission assembly in an eccentric manner. The other end of each pull rod is rotationally connected with the upper end of the cutter. The cutter is located above the conveyer belt. The input end of the connection rod mechanism is connected with the upper end of the cutter. The output end is connected with the first rolling shaft through the one-way bearing. The motoris fixed to the machine frame. The motor drives the cutter to move up and down through the gear transmission assembly and the pull rods, the first rolling shaft is driven to conduct intermittent rotation through the connection rod mechanism and the one-way bearing, and the two actions of film cutting and feeding are achieved. The film cutting device is simple in system and saves energy.

Owner:王友炎

Tire assembly supporting device for whole vehicle manufacturing

InactiveCN107813853AIncrease productivityFast installationTyre repairingHand carts with multiple axesAutomotive engineeringLean manufacturing

The invention discloses a tire assembly supporting device for whole vehicle manufacturing. The tire assembly supporting device comprises a bottom plate, a through hole is formed in the center of the upper surface of the bottom plate, a threaded column is arranged in the through hole, the top end of the threaded column is fixedly connected with the lower surface of a first supporting plate, a threaded cylinder is in threaded connection with the surface of the threaded column and located above the through hole, and the surface of the threaded cylinder is fixedly connected with a first bearing. According to the tire assembly supporting device for whole vehicle manufacturing, the threaded column, the threaded cylinder, a first gear, a second gear, a fixing plate, a third gear, a second supporting plate, a protective block and an electric push rod are arranged, a tire can be steered, a worker does not manually lift and rotate the tire, so that labor of the worker is saved, the tire installing speed of the worker is increased, and vehicle production efficiency is improved.

Owner:JIAOZUO QUALITY & TECH SUPERVISION INSPECTION & TESTING CENT

Projection illuminating system

ActiveCN103470992AIncrease flexibilityMeet the needs of brightnessPoint-like light sourceElectric lightingProjection PrincipleControl system

The invention discloses a projection illuminating system which comprises a projection system, a control system and a reflection system, wherein the projection system is used for providing projection light of the projection illuminating system; the control system is used for controlling interconnection and communication between the systems; and the reflection system is used for converting the projection light emitted by the projection system into illuminating light in a specific range. According to the scheme disclosed by the invention, a projection principle is utilized to project basic light to the reflection system, a projection region is used as an illuminating light source and the reflected light is used for common illumination or special illumination. The projection illuminating system can provide the optimal flexibility for the illuminating environment and the high-efficiency light source and the projection system provide sufficient light utilizing efficiency for the projection illuminating system.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Laying head front nip and feed technique for producing wire roll with high speed under low temperature

InactiveCN101015839AReduce weldingReduce transportationRare end control deviceTemperature control deviceCarbon steelRebar

The invention relates to a spinneret front clamping technique for high-speed producing steel coil bar at low temperature under 750Deg. C as general carbon steel 400MPa, 500MPa or the like without micro elements (Nb, V, and Ti), wherein the rib steel bar spinning temperature is lower than 750Deg. C, the gas pressure of clamping roller gas source is higher than 7bar, the clamping force of the clamping roller is 4.5-7.0bar, therefore, the invention can stably produce high-strength rib steel coil bar without additive micro elements (Nb, V, and Ti), with uniform grains, energy saving and low cost.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

System and method for intelligently controlling air conditioner

InactiveCN102944051ASave energyLighting and heating apparatusSpace heating and ventilation safety systemsMicrocontrollerAutomatic control

The invention discloses a system for intelligently controlling an air conditioner. The system comprises at least one temperature sensor, wherein each temperature sensor is connected with a controller; the controller is respectively connected with an air conditioner switch and a display; each temperature sensor is arranged in a room; the controller is a singlechip or a digital signal processing (DSP) controller; and the display is a digital tube or a liquid crystal display screen. The invention also discloses a control method using the system. By the system and the method, the air conditioner can be automatically switched on and switched off according to indoor temperature; people can use the air conditioner conveniently; and energy is saved.

Owner:张小永

Hexahydroxy copolymer water-based pressure-sensitive adhesive without adhesive residue and preparation method of hexahydroxy copolymer water-based pressure-sensitive adhesive

The invention relates to a hexahydroxy copolymer water-based pressure-sensitive adhesive without adhesive residue and a preparation method of the hexahydroxy copolymer water-based pressure-sensitive adhesive. The preparation method of the hexahydroxy copolymer water-based pressure-sensitive adhesive comprises the following steps: (1) taking water as solvent, uniformly mixing polyvinyl alcohol, anionic surfactant, emulsifier and pH regulator, increasing temperature to 50 DEG C, and adding acrylic monomer, cross-linking monomer and polymerization degree regulator to react for 1h at the temperature of 60-65 DEG C, thus obtaining a pre-emulsified solution; (2) uniformly mixing 25% of pre-emulsified solution with 40% of initiator, increasing the temperature to 80-85 DEG C, adding the rest of pre-emulsified solution when the liquid turns blue, adding 20% of initiator every 1h so as to drip off all the initiator within 3h, at last replenishing surplus initiator, and keeping temperature for reflux for 1-1.5h at the temperature of 90 DEG C; and (3) lowering the temperature of the reaction liquid to 40 DEG C, adding a bridging agent, and after uniformly mixing the mixture, cooling the mixture to room temperature. The hexahydroxy copolymer water-based pressure-sensitive adhesive has the advantages of low price, high production rate, strippability and the like and can avoid the pollution of solvent type pressure-sensitive adhesive to environment, thus being an environment-friendly water-based strippable pressure-sensitive adhesive.

Owner:SHANGHAI ZHONGXIN YUXIANG CHEM

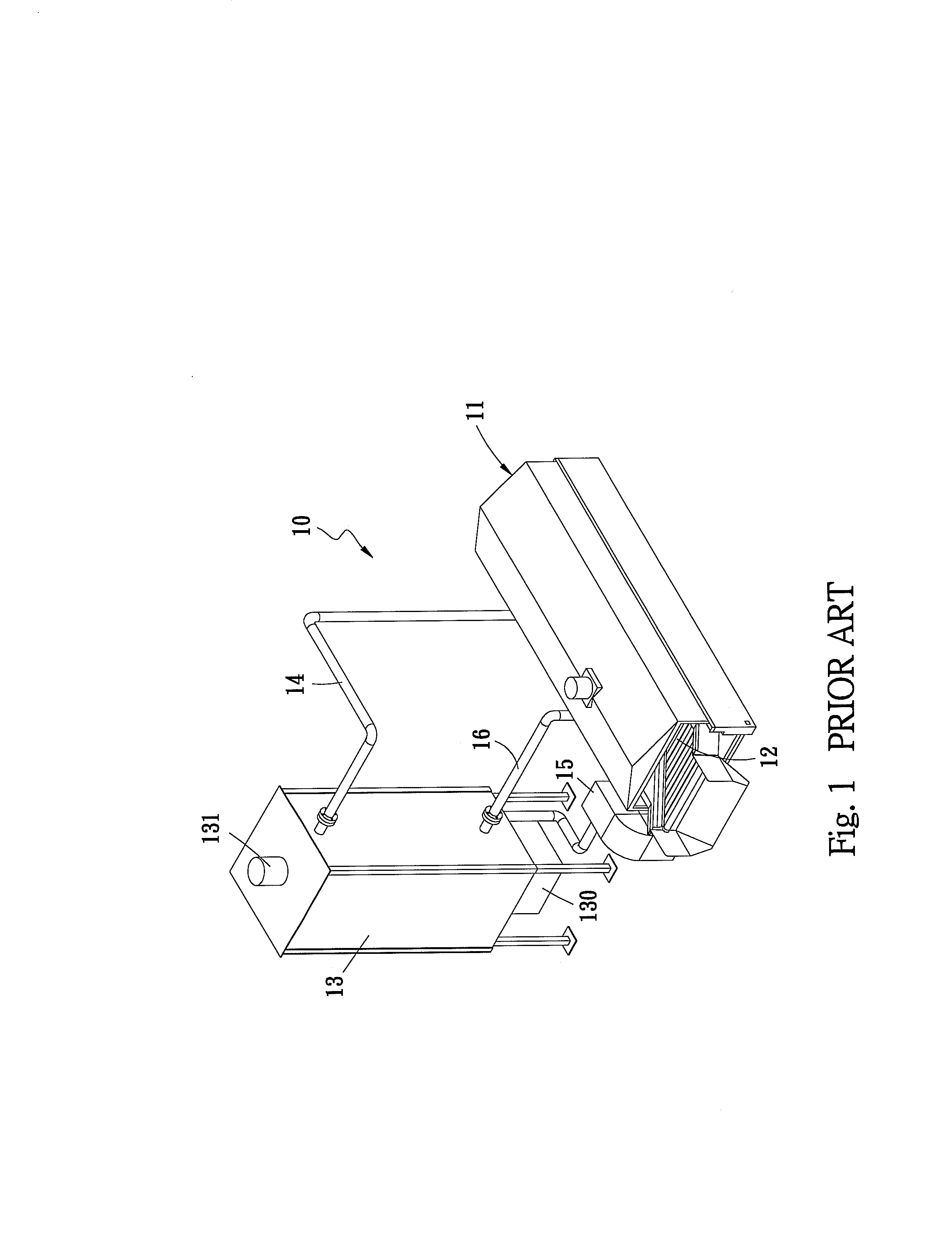

Machine for blasting abrasives

ActiveUS20120252327A1Simple structureSimple and novel structureRevolution surface grinding machinesGrinding drivesEngineeringAbrasive

The object of the present invention is to provide a machine for blasting abrasives that has a simple structure and that solves the problem of abrasives falling when the door for the gateway for the work is opened or closed. The machine for blasting abrasives comprises a chamber 11 for processing, a nozzle 13 that is provided within the chamber 11 for shooting the abrasives (shots) S onto the work W, and a jig 15 for holding the work W at a position facing the nozzle 13. A gateway 17 with a door 19 is formed in the ceiling 11a of the chamber 11. The size of the gateway 17 enables the work W to protrude from the chamber 11 by means of the jig 15 at a position corresponding to the jig 15 that is linearly moving up and down. The door 19 is provided within the chamber 11 so as to seal the gateway by linearly moving up and down and so as to create a vacant plane on the gateway for passing the work by horizontally moving.

Owner:SINTOKOGIO LTD

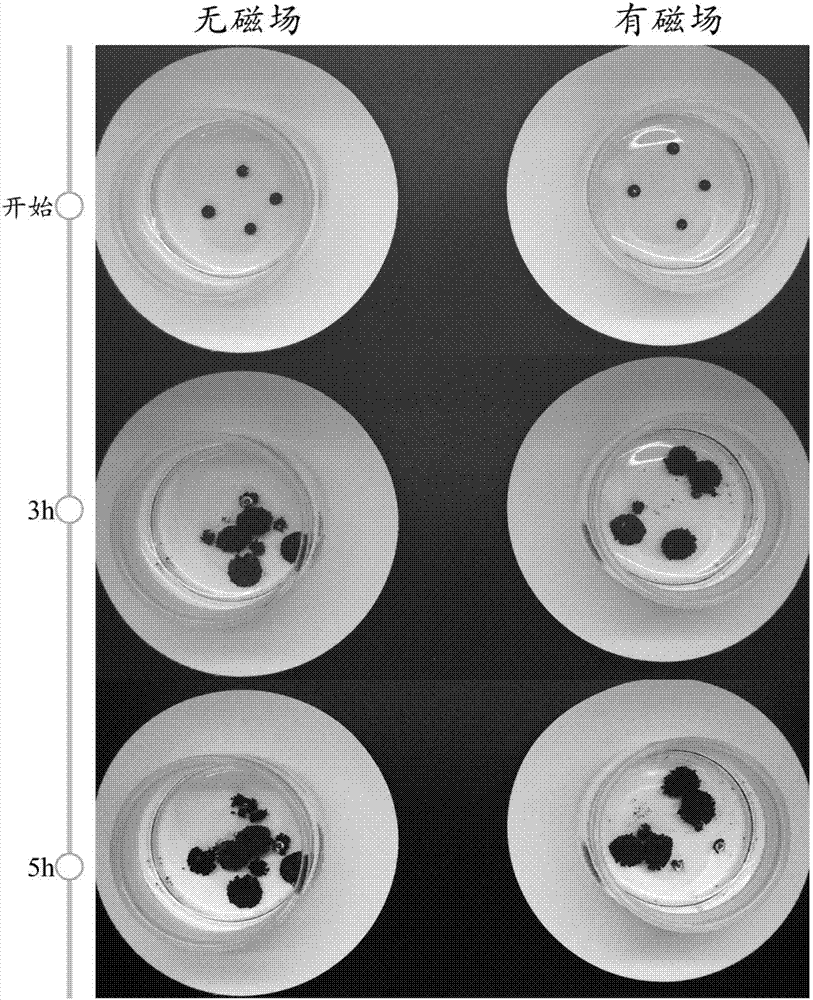

Method for regulating replacement reaction in solution by magnetic field

InactiveCN107511120AChange the potential differenceDiffusion of influenceEnergy based chemical/physical/physico-chemical processesProcess efficiency improvementSubject specificIon

The invention discloses a method for regulating a replacement reaction in a solution by a magnetic field. When a replacement reaction is generated in a solution, a magnetic field is extra added. According to the method, a magnetic field is extra added when a replacement reaction in a solution is generated, the potential difference between two reacting materials can be changed, and diffusion of ions in the solution toward a metal element can be influenced, so that the progress of the replacement reaction in the solution can be regulated. Time required by a replacement reaction in a solution can be greatly changed by utilizing an additional magnetic field under a condition of certain temperature. The method has a huge benefit value for reducing the reacting preparation cost, and accords with current development theme for saving energy and protecting environment.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Surface treatment box suitable for ball ink tube

Owner:徐州天泽乘龙机械制造有限公司

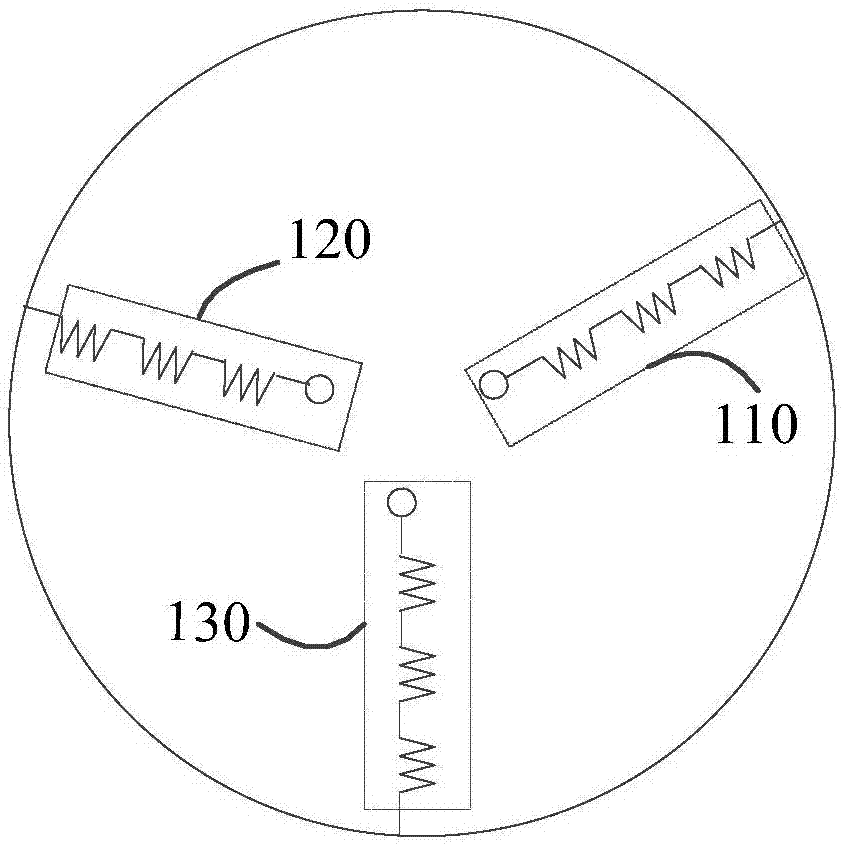

ZnO-Ni photic driving micropipe motor and preparation method thereof

InactiveCN109504953AControl the direction of motionEfficient use ofVacuum evaporation coatingSputtering coatingUltraviolet lightsEngineering

The invention relates to a ZnO-Ni photic driving micropipe motor and a preparation method thereof. The micropipe motor comprises a photocatalytic material tubular ZnO and a metal layer Ni. The micropipe motor uses hydrogen peroxide as a fuel and ultraviolet light as an excitation light source. A regulation mode of motion speed of the micropipe motor comprises fuel concentration, regulation light intensity or the content of metal Ni. The micropipe motor can effectively absorb excited electrons by utilizing the metallic properties of the Ni to reduce the charge recombination rate of ZnO, so thatthe photocatalytic performance of the ultraviolet light is effectively improved, and then the motor achieves a high-speed bubble movement in hydrogen peroxide solution; on the other hand, the magnetic properties of Ni can be used to achieve the effective motion direction control of the motor. In addition, the preparation process is simple, and the ZnO-Ni tubular photic driving micropipe motor with low cost, long service life, fast movement and controllable direction is prepared.

Owner:SOUTH CHINA NORMAL UNIV

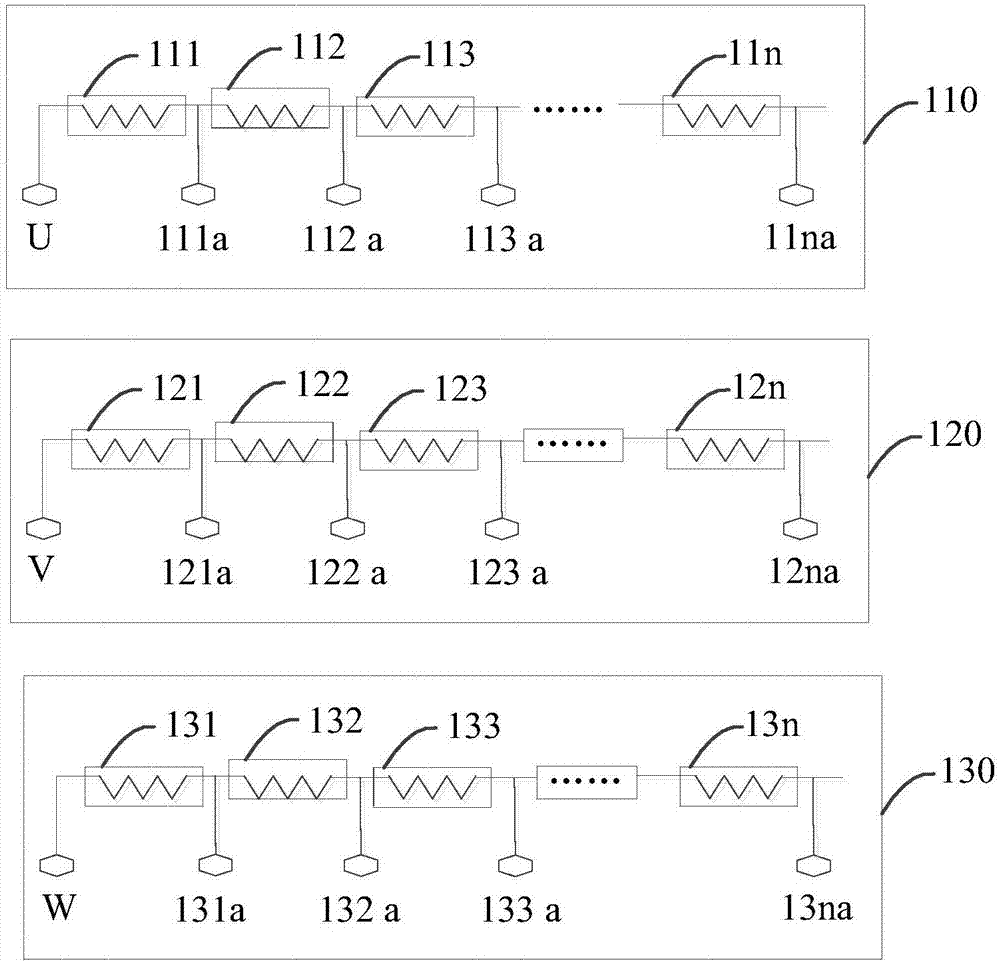

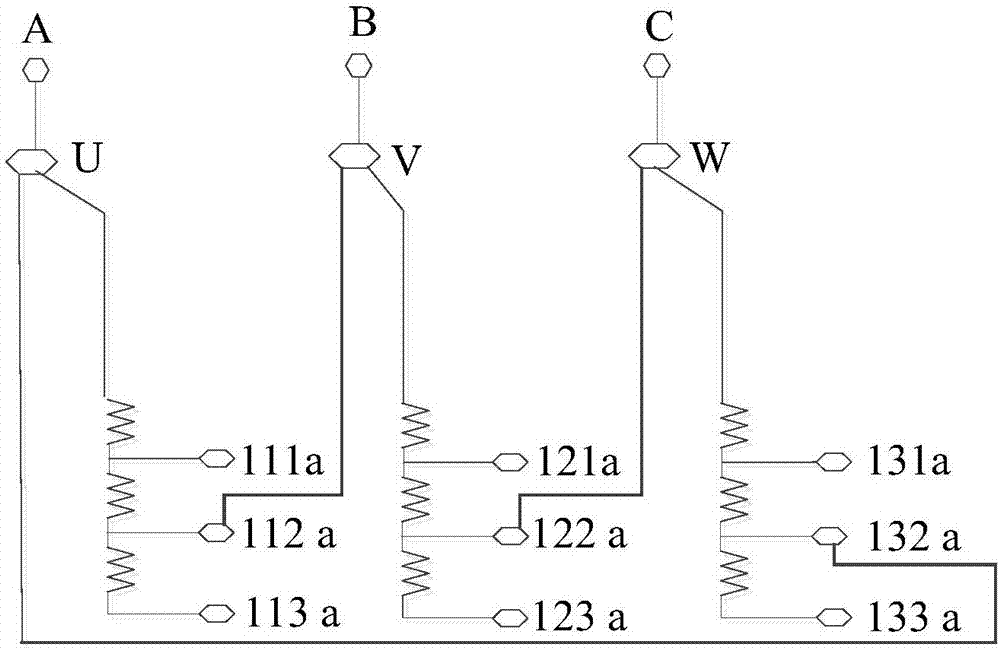

Electric motor

InactiveCN107231050ASave energySolve energy wasteWindings conductor shape/form/constructionConductor CoilElectric motor

Owner:PETROCHINA CO LTD

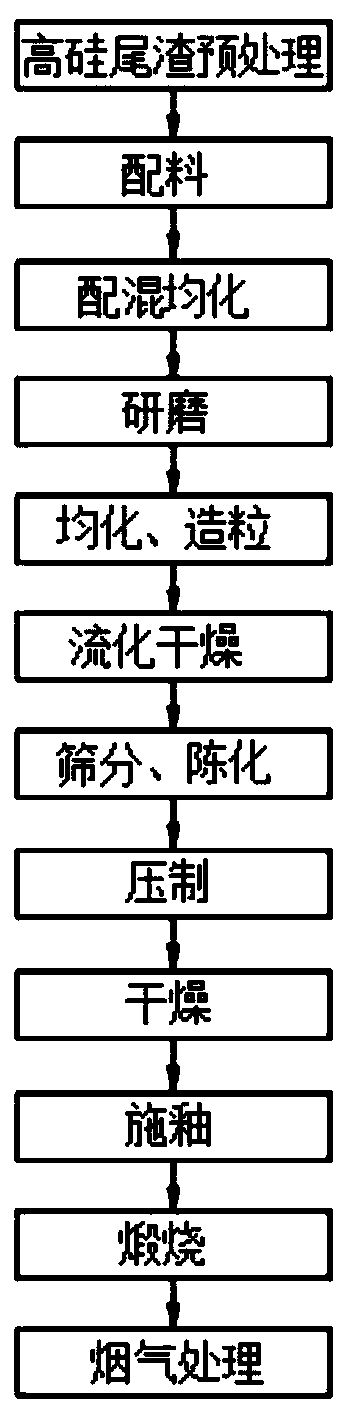

Method for preparing European type interlocked tiles by using high-silicon tailings

InactiveCN110041050APromote sustainable developmentReduce sulfur contentCeramic materials productionClaywaresAluminiumFlue gas

The invention discloses a method for preparing European type interlocked tiles by using high-silicon tailings and relates to the technical field of resource utilization of dressing and smelting wasteresidues. The method comprises the following steps: step 1) pretreating the high-silicon tailings; step 2) preparing materials; step 3) mixing and homogenizing; step 4) grinding; step 5) homogenizingand granulating; step 6) fluidizing and drying; step 7) sieving and ageing; step 8) compressing; step 9) drying; step 10) glazing; step 11) calcining, and step 12) treating flue gas. The method disclosed by the invention has the advantages of novel design and simple technology; the high-silicon tailings are utilized as a main raw material, harmless and resourceful utilization of the high-silicon tailings is achieved, and sustainable development of the whole golden industrial chain is improved; bauxite, Laiyang clay and quartz are utilized as auxiliary materials, so that the whole performance of a product is better; by means of high-temperature calcining, FeS2 in the high-silicon tailing can be slowly decomposed; thus, the sulfur content in the European type interlocked tiles is reduced, and the product is ensured to achieve environmental friendliness and reach the standard.

Owner:ZHAOYUAN ZHAOJIN JINHE TECH +1

Inorganic post-anchoring grouting slurry

The invention discloses an inorganic post-anchoring grouting slurry, and relates to the field of building materials. The invention aims at solving the problems of high energy consumption, low environment-medium corrosion resistance and long curing period of existing cement-based anchoring materials. The grouting slurry comprises the components of, by weight, 100 parts of finely ground slag powder, 50-70 parts of sodium water glass, 5-10 parts of aluminate cement, 1-3 parts of calcium stearate, 200-500 parts of quartz sand, 0.5-1.5 parts of lignin sulfonate, 1-3 parts of sodium metasilicate pentahydrate, and 3-5 parts of a retarder. With the grouting slurry formula provided by the invention, grouting slurry strength and durability are improved. Also, energy is saved, and the environment is protected.

Owner:CHONGQING CONSTR ENG MUNICIPAL TRAFFIC ENG

Meal ordering platform, system and method

InactiveCN109829795AShorten the timeSave energyIndividual entry/exit registersBuying/selling/leasing transactionsPaymentOperational costs

The invention discloses a meal ordering platform, system and method, and the platform comprises a meal ordering request obtaining unit which is used for obtaining a meal ordering request of a client,and the meal ordering request comprises but is not limited to the information of a meal ordering person, meal information, and the number of ordered meals; The meal ordering order generation unit is used for determining meal ordering information according to the meal ordering request, determining a target storage heat preservation box of the food according to the meal ordering information, and generating a meal ordering order after receiving settlement payment information of the client; And the meal taking information pushing unit is used for pushing the information of the heat preservation cabinet for storing the meal in the meal ordering order to the user after the meal is sent to the corresponding target storage heat preservation box, so that the operation cost of a catering enterprisecan be reduced while the meal ordering time and energy of the consumer are saved.

Owner:GUANGZHOU UNIV HUASOFT SOFTWARE COLLEGE

Deep shale gas drilling and exploiting method and fracturing device adopted in same

The invention relates to a deep shale gas drilling and exploiting method and a fracturing device adopted in the method. The method and the device mainly aim to solve the problem that the shale gas drilling and exploiting depth is limited currently. The method includes the steps that a vertical well and a horizontal well are drilled, and the fracturing device is arranged; the diameter of the vertical well is enlarged close to a fracturing working face, an expansion screen pipe is fed into an enlarged section, the diameter of the expansion screen pipe is enlarged, a pressurizer is installed in the enlarged section, a water inlet of an intermediate-pressure water pump arranged on the ground is connected with a water source through a pipeline, water, output by the intermediate-pressure water pump, 2 MPa -10 MPa in pressure is injected into the underground fracturing working face and serves as a power source of the pressurizer at the same time, a high-pressure cavity of the pressurizer conveys high-pressure water with the maximum pressure of 140 MPa to the high-pressure pipeline communicated with the fracturing working face, and accordingly shale can be easily fractured. The fracturing device comprises an acidizing device, a sand mulling device, a program control device, the pressurizer, the intermediate-pressure water pump and a control valve. The deep shale gas drilling and exploiting method and the fracturing device adopted in the method have the advantages that deeper shale gas can be exploited.

Owner:王及元

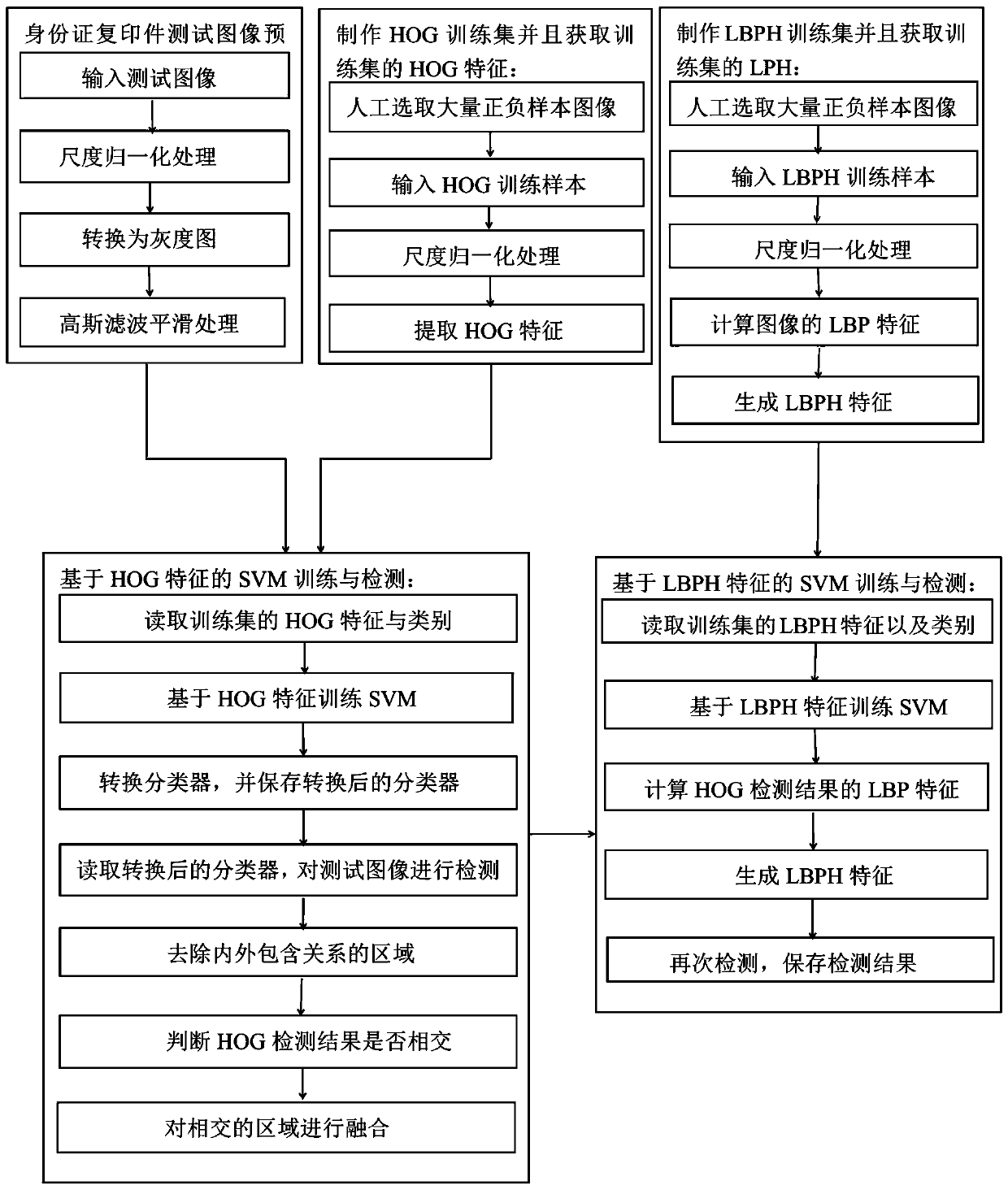

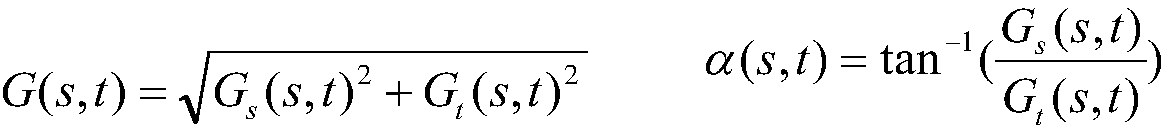

HOG and LBPH feature fused detection method for copy of identity card

ActiveCN108388920AImprove detection efficiency and detection accuracyAutomatic detectionCharacter and pattern recognitionNon identityNegative sample

Owner:FUZHOU UNIVERSITY

Magnetic suspension swivel chair

InactiveCN111657698ASave energyLarge suspension force of the structureStoolsAdjustable chairsMagnetic leakagePhysics

The invention belongs to the field of magnetic levitation, and particularly relates to a magnetic levitation swivel chair, which comprises a seat body, a bottom plate and a plurality of permanent magnet units arranged between the seat body and the bottom plate. Each permanent magnet unit comprises a plurality of permanent magnets arranged below the seat body and above the bottom plate at intervals, spacing bars used for spacing the permanent magnets, and a magnetic conductive plate arranged at the side end of the permanent magnet at the outermost end. The magnetic suspension swivel chair disclosed by the invention saves energy. The permanent magnet adopts a magnetic array, the structure suspension force is large, the tension and pressure requirements can be met, and the system is stable. The magnetic leakage is reduced by the spacing bars and the concentrating flux plates.

Owner:TIANJIN UNIV

Dry pulping system and dry pulping process

ActiveCN112853788AAvoid water pollution and wasteAvoid dust pollutionPaper recyclingFibrous raw materialsMaterial SeparationProcess engineering

The invention provides a dry pulping system. The dry pulping system comprises a scattering unit, a crushing unit, a material separation unit, an impurity removal unit and a packaging unit, wherein the scattering unit comprises a bale breaking machine; the crushing unit comprises a shredding machine, a scattering and crushing machine and a fiber regeneration machine; the material separation unit comprises a material separation bin and a pulse dust collector; the impurity removal unit comprises a light impurity removal mechanism and a heavy impurity removal mechanism; the packaging unit comprises a screw extruder and a packaging machine; and the bale breaking machine, the shredding machine, the scattering and crushing machine, the fiber regeneration machine and the packaging machine are connected through a belt conveyor. The invention further provides a dry pulping process. The dry pulping process comprises the dry pulping system and further comprises the step that (1) waste paperboards are scattered and fed into the shredding machine for coarse crushing so as to obtain a long-strip-shaped material with a width ranging from 60 mm to 80 mm and a length ranging from 170 mm to 300 mm.

Owner:SHANDONG JIEFENG MACHINERY MFG

Conveying frying machine

Owner:CHUAN YANG FOODS MACHINE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap