Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25 results about "Production rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production rate, in terms of manufacturing, refers to the number of goods that can be produced during a given period of time. Alternatively, production rate is also the amount of time it takes to produce one unit of a good. In construction, this is the rate at which workers are expected to complete a certain segment, such as a road or building.

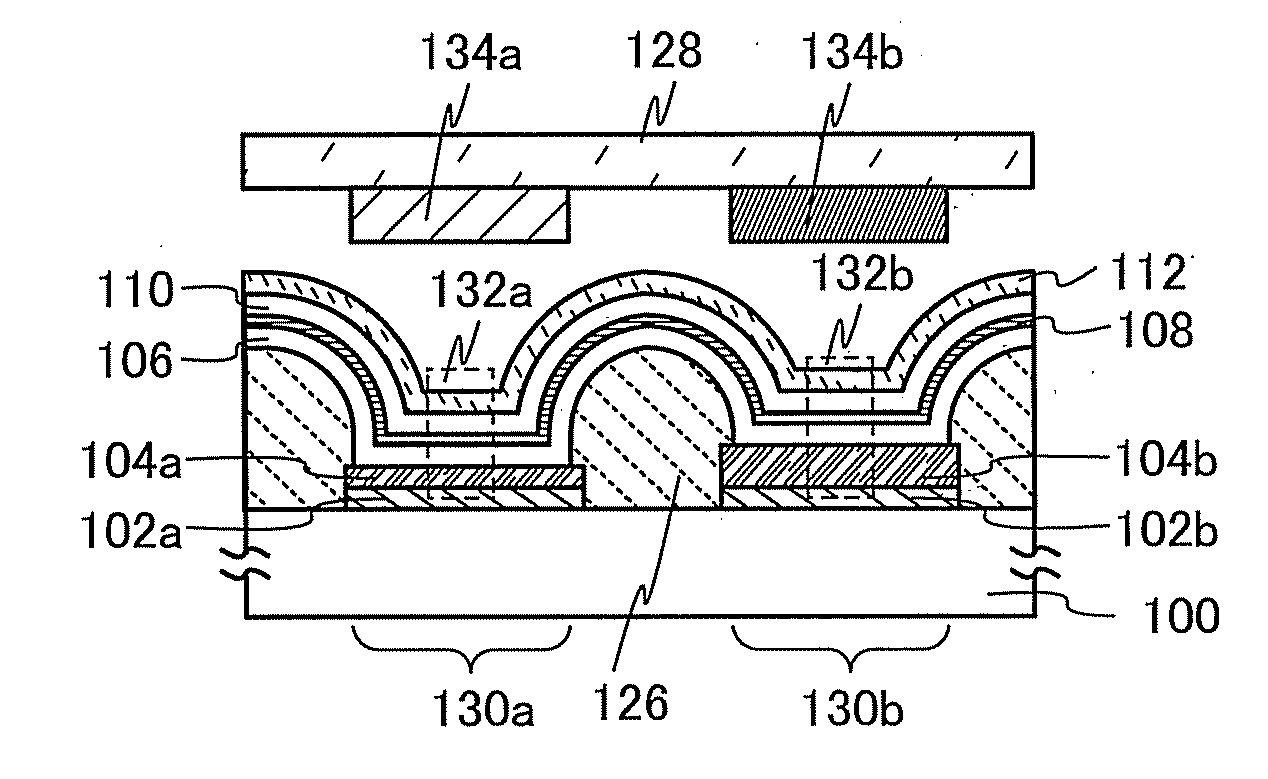

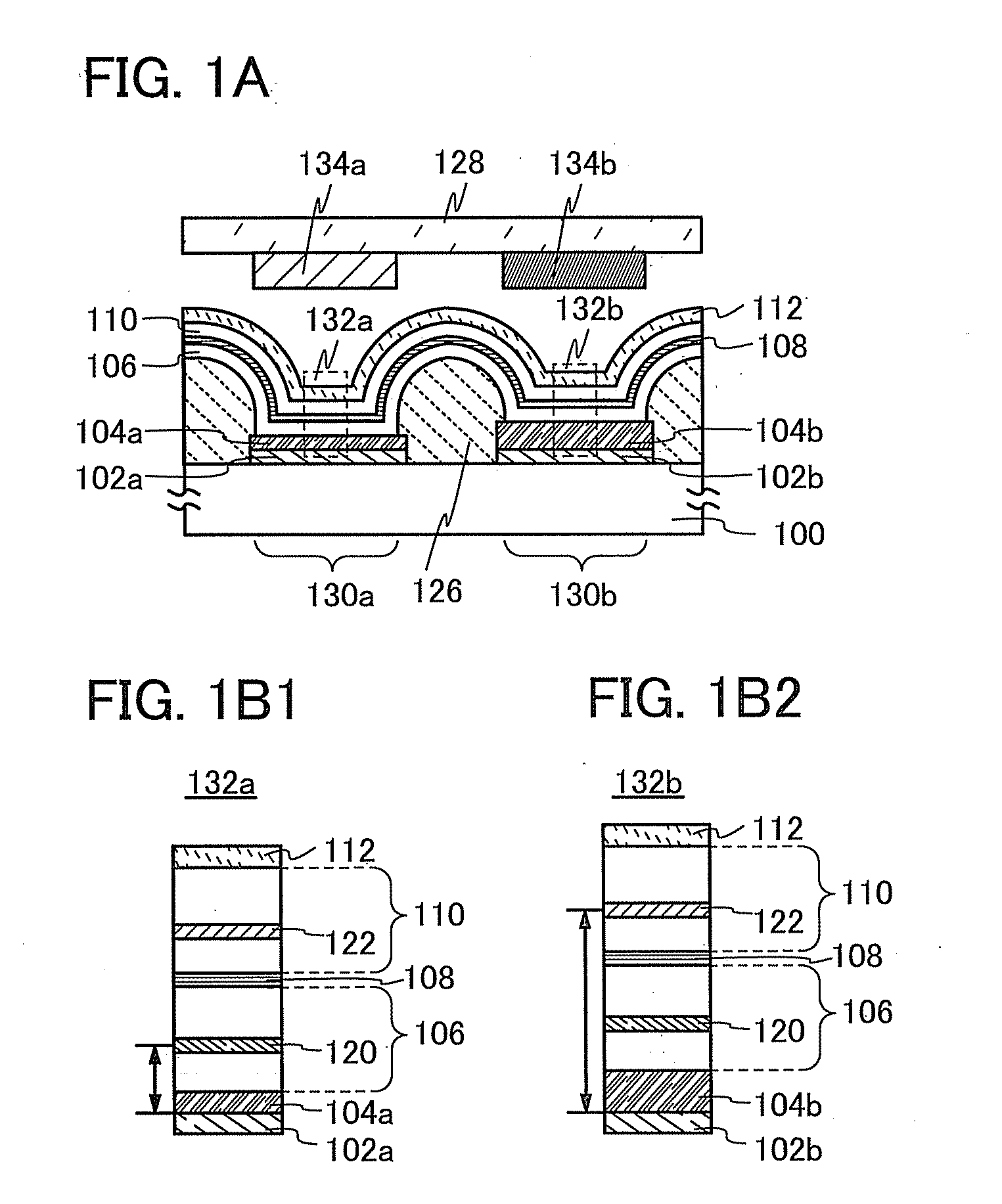

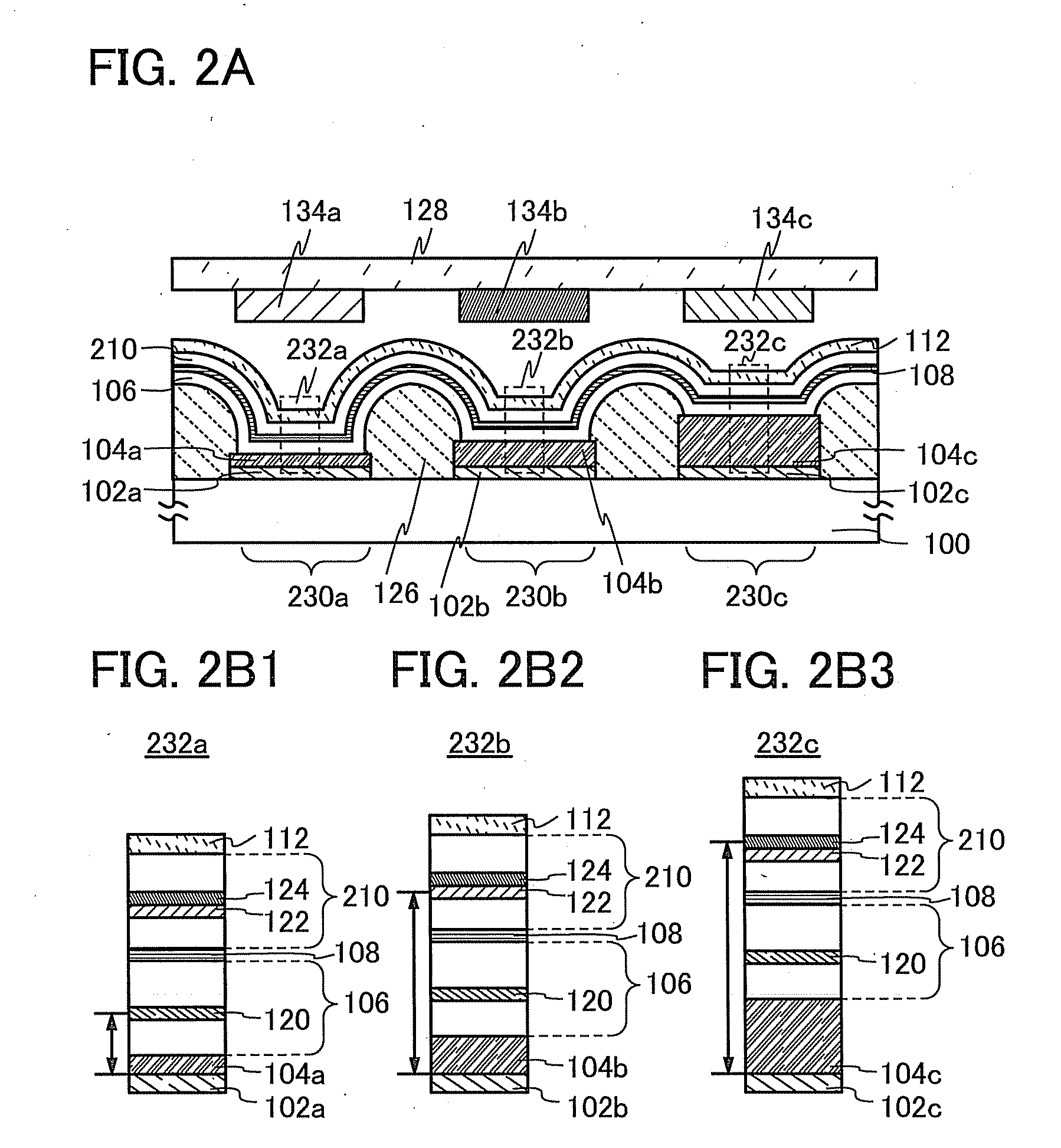

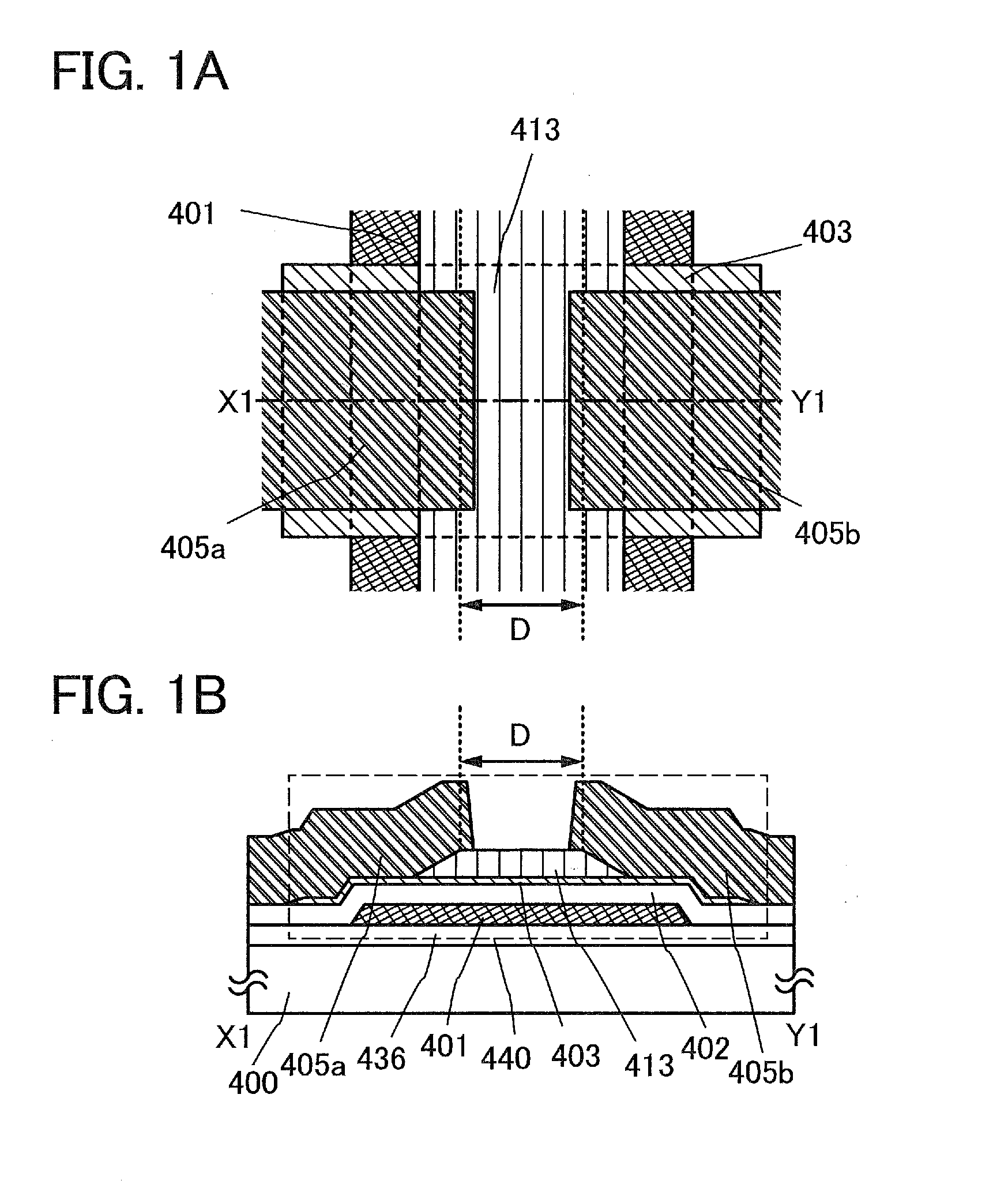

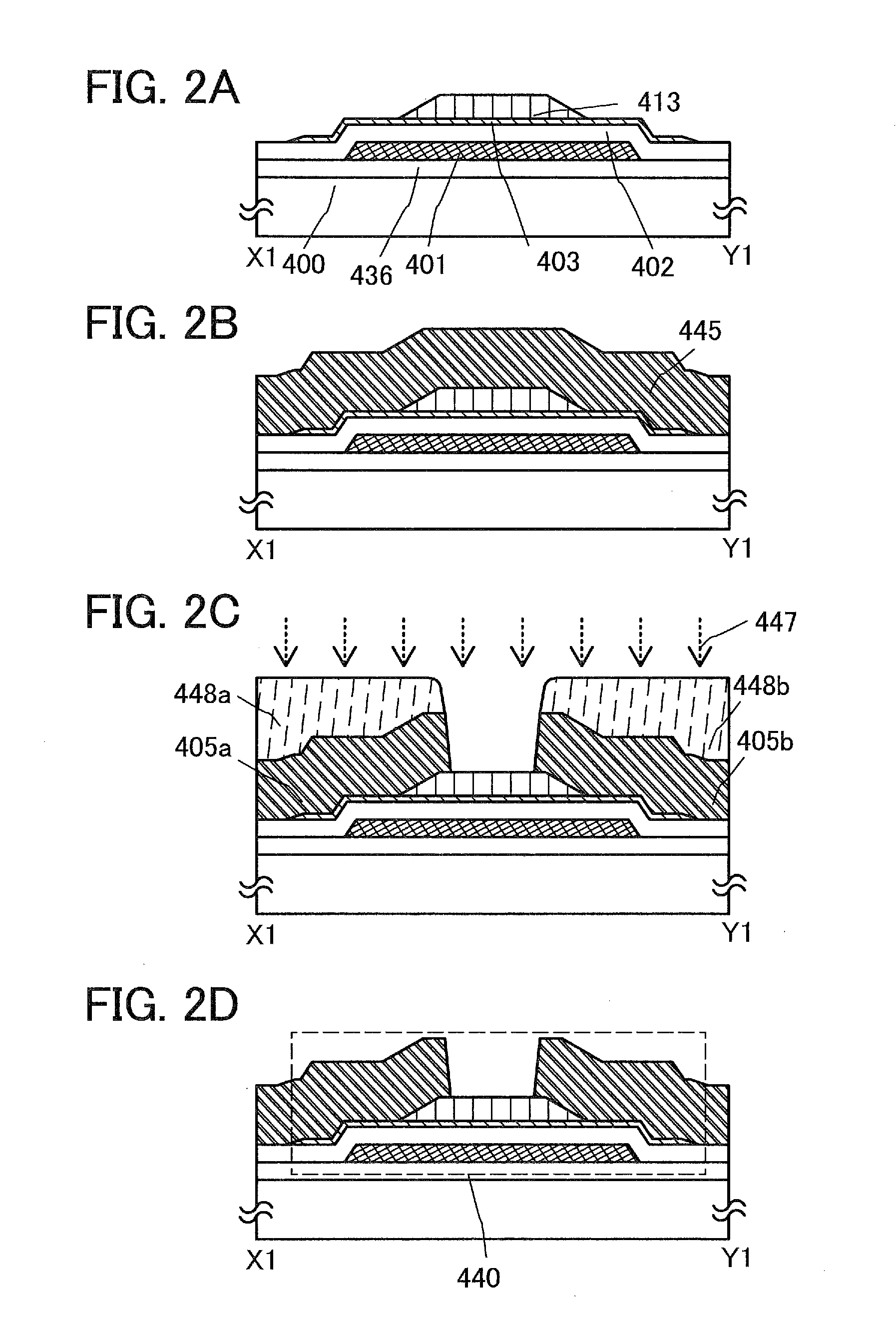

Light-Emitting Device and Display Device

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and method for manufacturing the same

ActiveUS20130082252A1Improve reliabilityHigh yieldTransistorSemiconductor/solid-state device manufacturingProduction rateIndium

Owner:SEMICON ENERGY LAB CO LTD

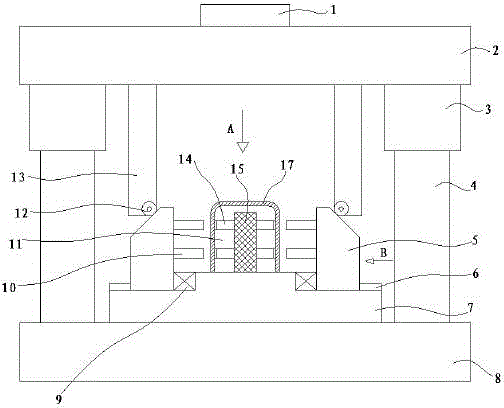

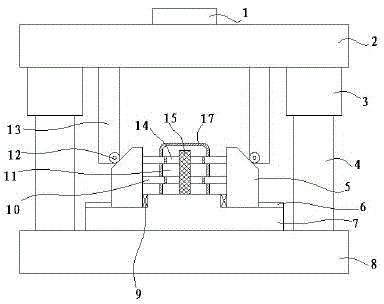

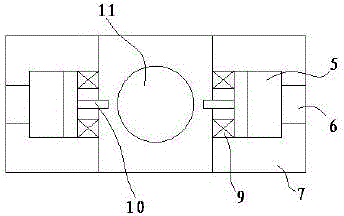

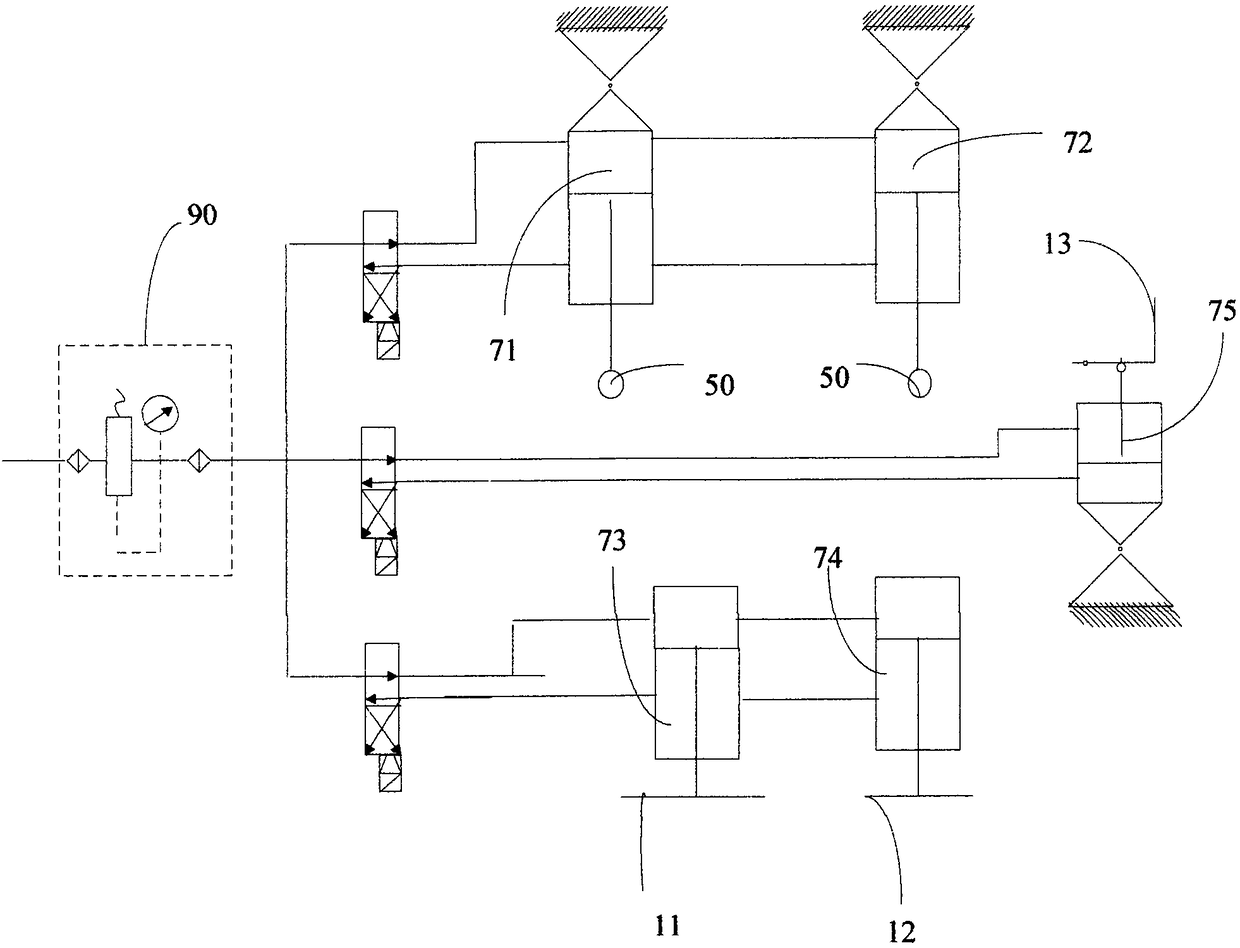

Short tranverse crankshaft connecting rod device of warp knitting machine

The invention discloses a short-stroke crankshaft connecting rod device for a tricot machine. The invention comprises eccentric shafts, a first shaft journal (4), a second shaft journal (5), a central wall plate (7), a grooved needle bed connected with a first eccentric shaft (1), a yarn guide needle bed crankshaft connecting rod mechanism, a stylet bed crankshaft connecting rod mechanism connected with a second eccentric shaft (2), and a sinker bed crankshaft connecting rod mechanism connected with a third eccentric shaft (3). The first shaft journal (4) and the second shaft journal (5) are respectively and fixedly connected with the end parts of the second eccentric shaft (2) and the third eccentric shaft (3). The second eccentric shaft (2), the first eccentric shaft (1) and the third eccentric shaft (3) are connected with each other in turn and are rotated around the first and second shaft journals (4, 5). The short-stroke crankshaft connecting rod device effectively shortens the motion stroke of weaving elements; the grooved needle travel is between 8 and 12 millimeters; the moving time of yarn guide needles is between 1.5 and 1.8 microseconds; the engine speed is improved to be 2500 to 3000 turns per minute; the noise is less than or equal to 85 decibels; the vibration is small; the energy consumption is low; the device is suitable for high-speed rotation; the power is small; and the productivity is obviously improved.

Owner:NEWTRY COMPOSITE

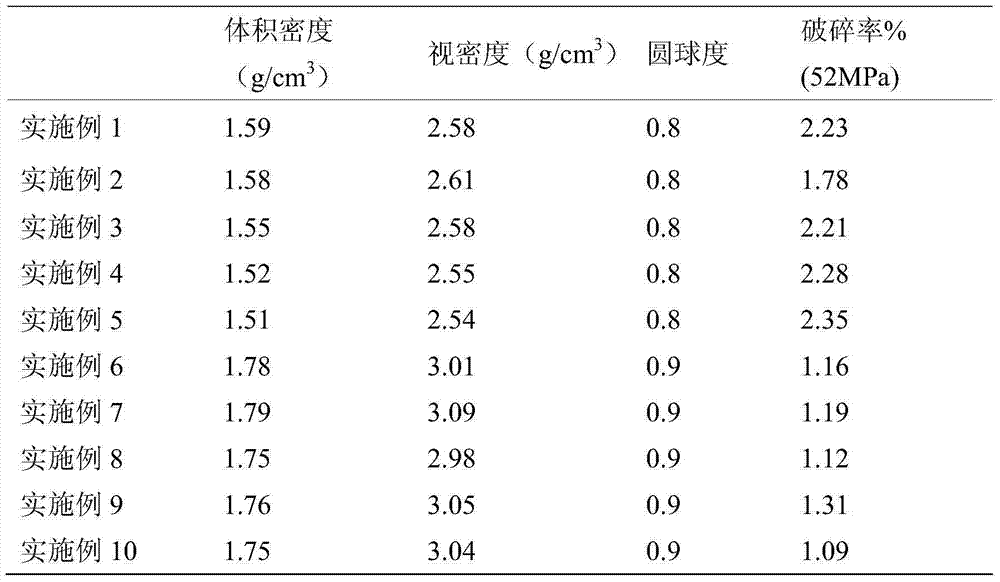

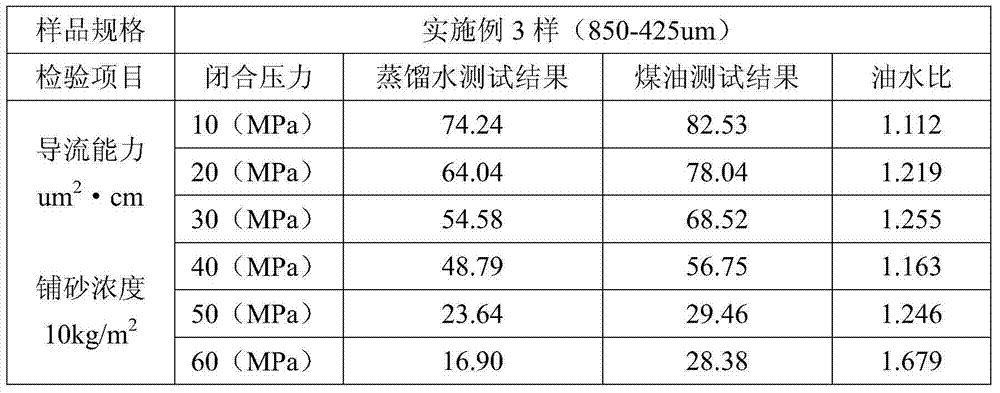

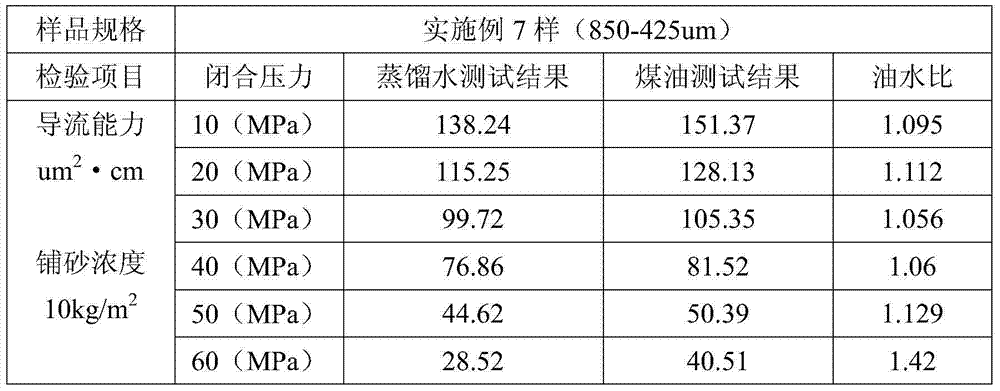

Preparation method of oleophilic hydrophobic coated proppant

InactiveCN104277821AIncrease oil outputIncrease productionFluid removalDrilling compositionProduction ratePlasticizer

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

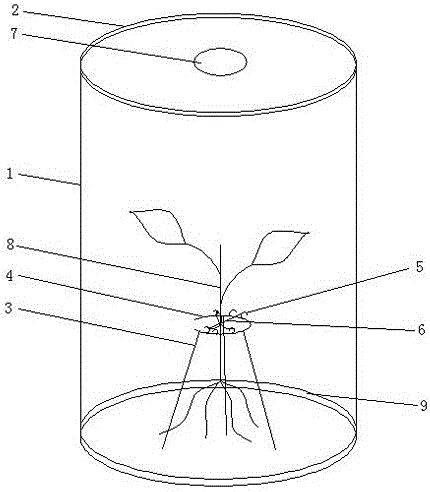

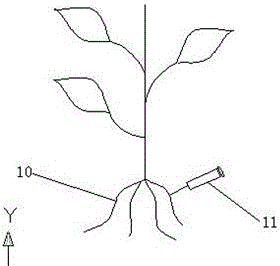

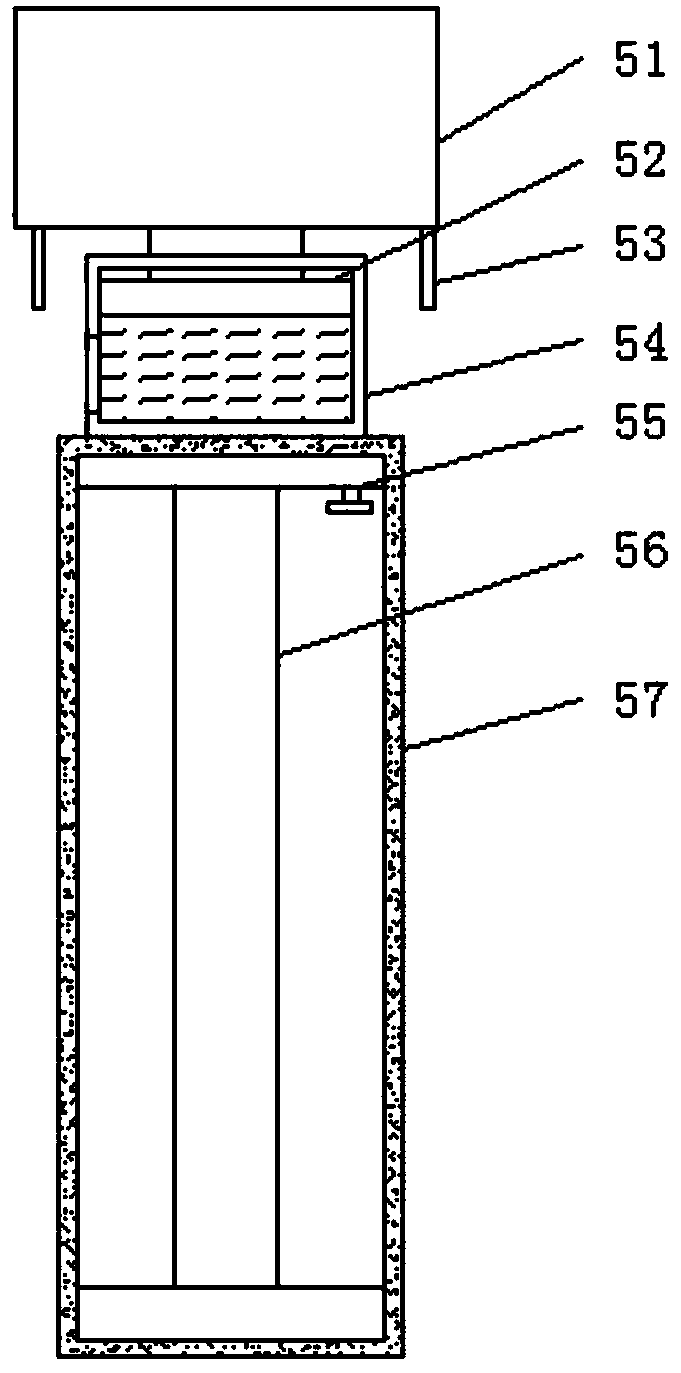

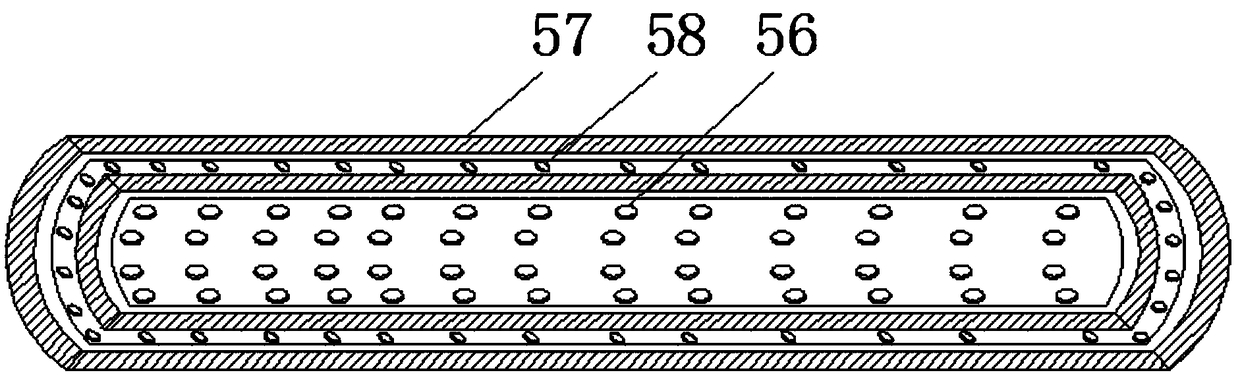

Culture method and culture container for in-vitro sterile host plant-mycorrhizal edible fungus intergrowth seedling

ActiveCN106576910ASpeed up breedingPrecision injectionCultivating equipmentsMushroom cultivationProduction rateRubber ring

Owner:INST OF EDIBLE FUNGI SHANXI ACAD OF AGRI SCI

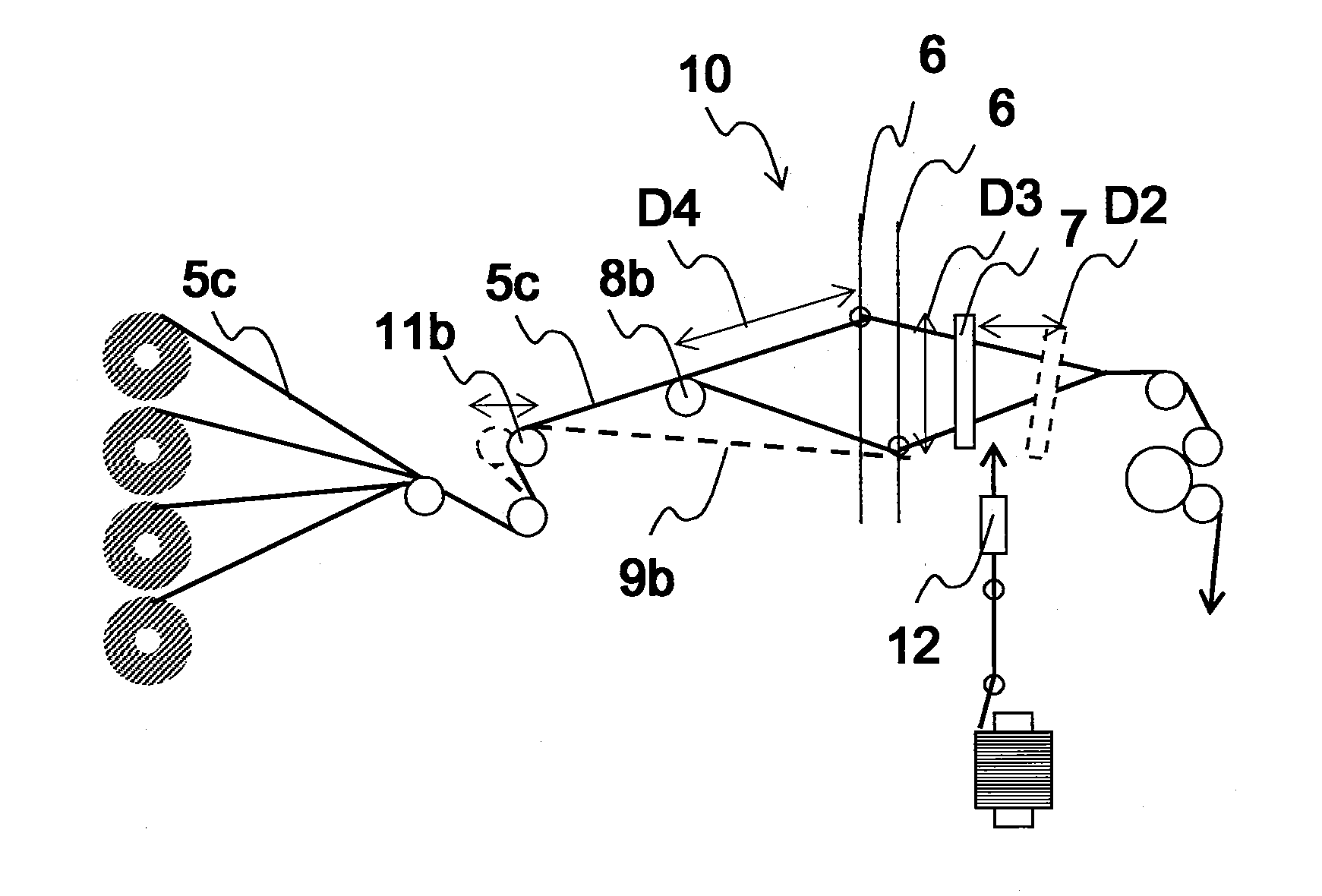

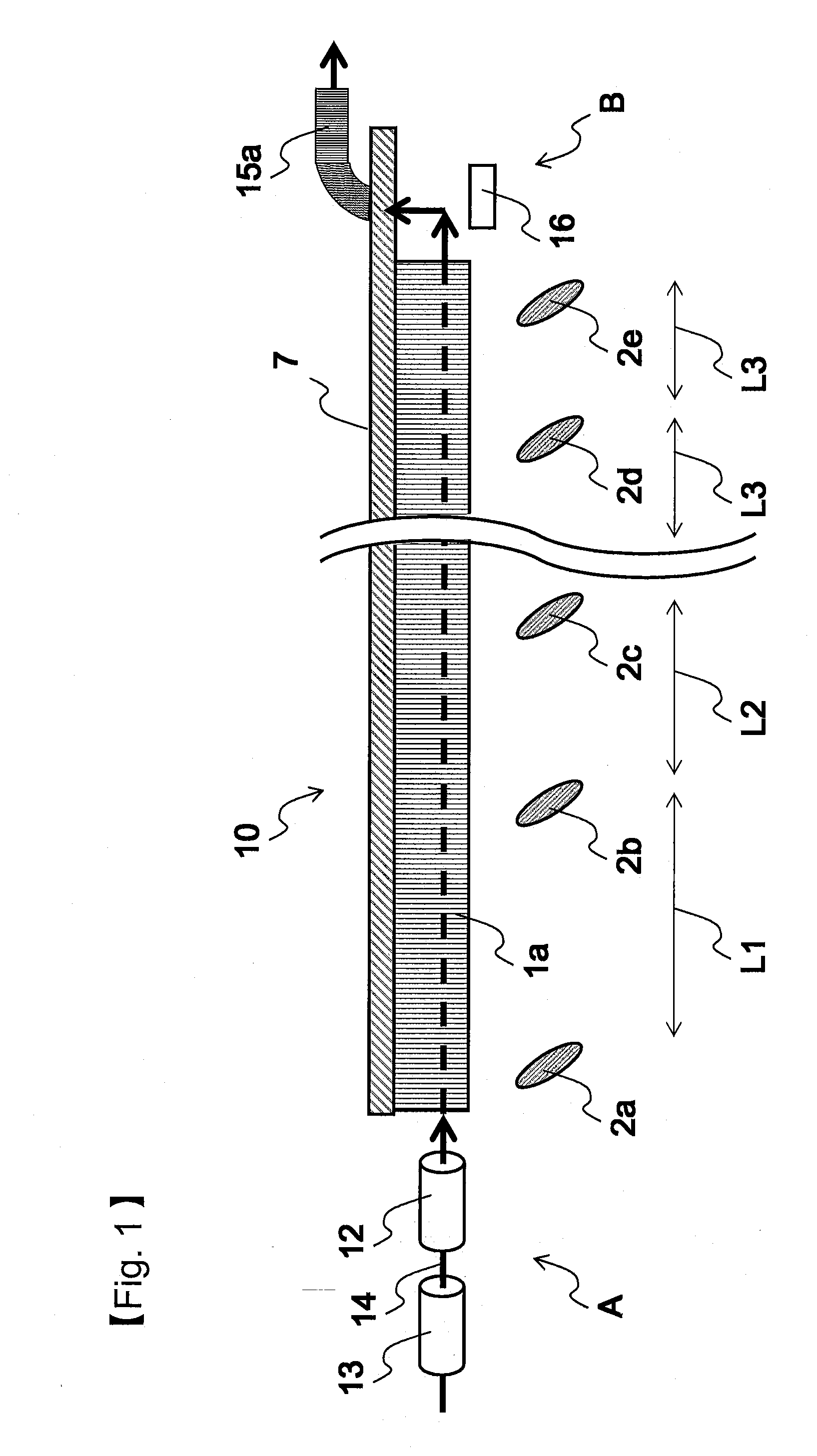

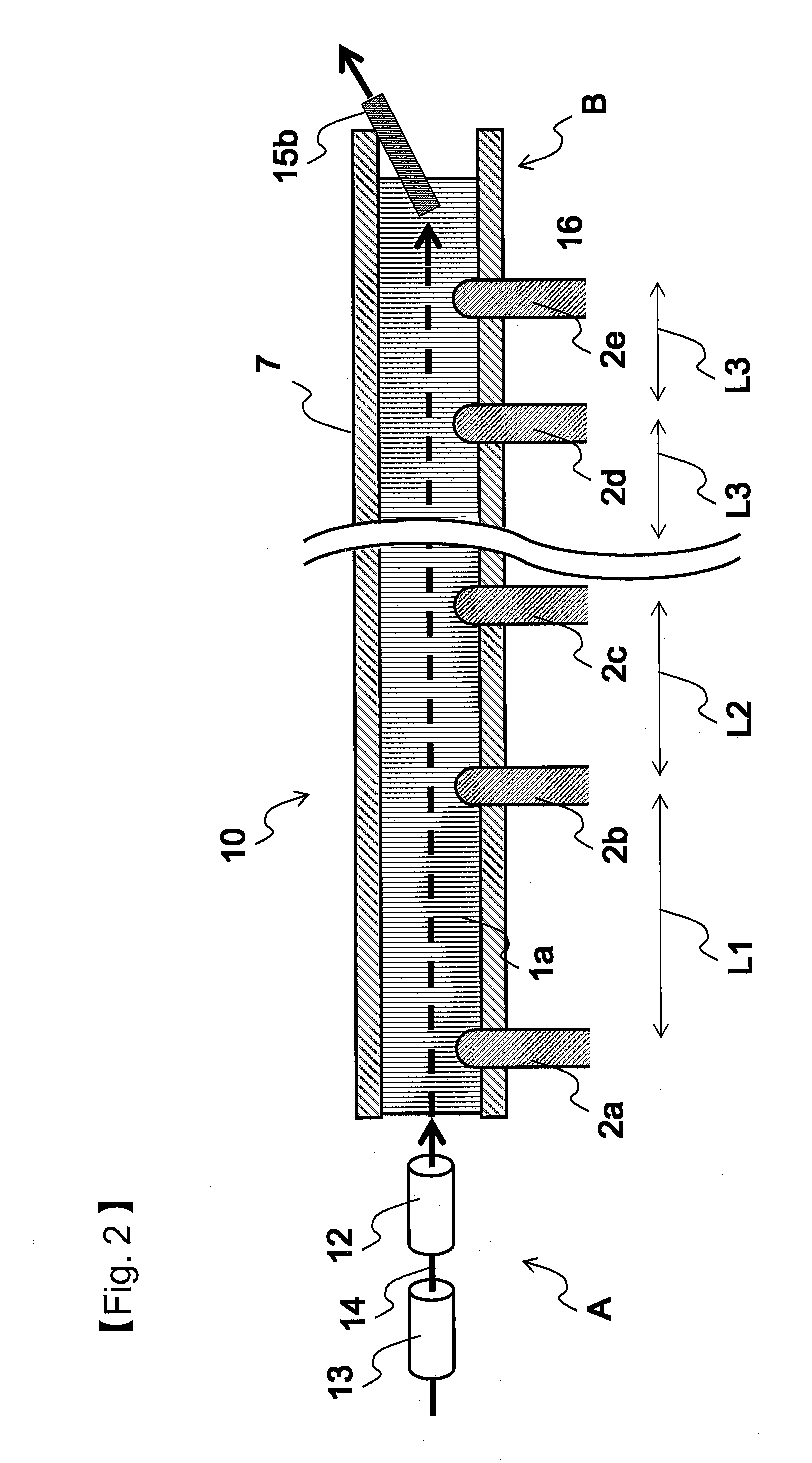

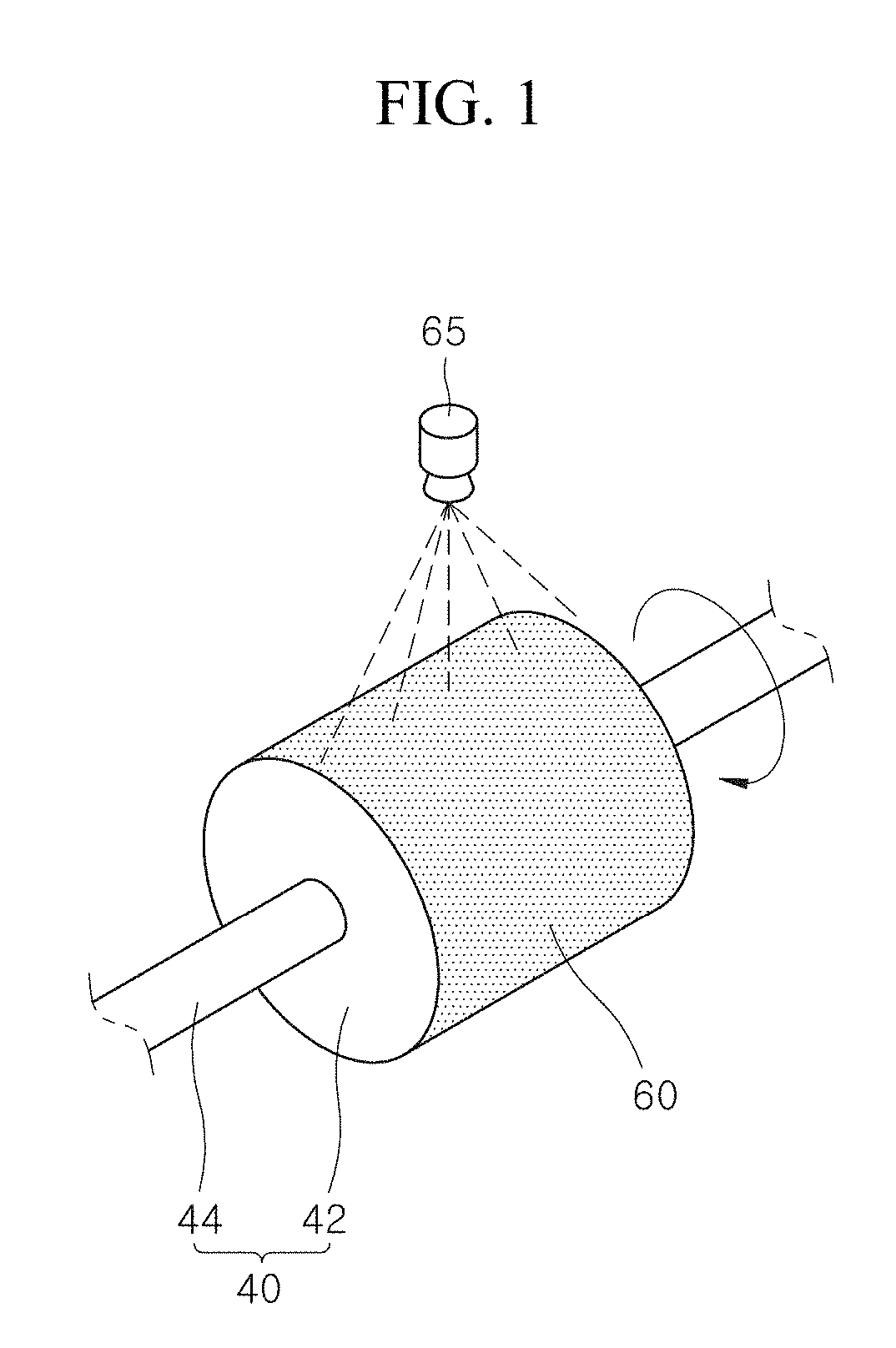

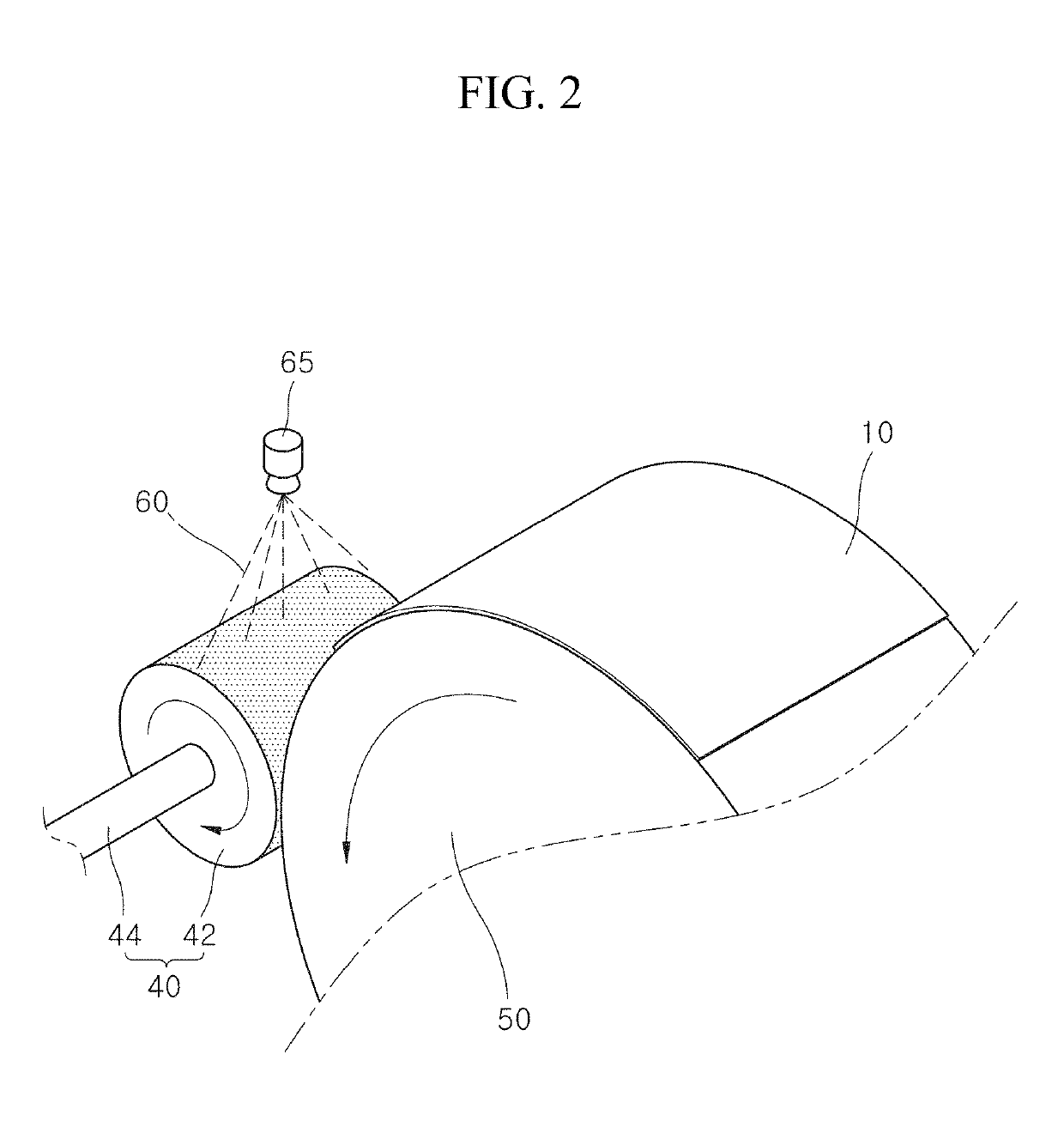

Method for producing carbon fiber woven fabric

ActiveUS20100032049A1Quality improvementImprove productivityLoomsWoven fabricsProduction rateCarbon fibers

Owner:TORAY IND INC

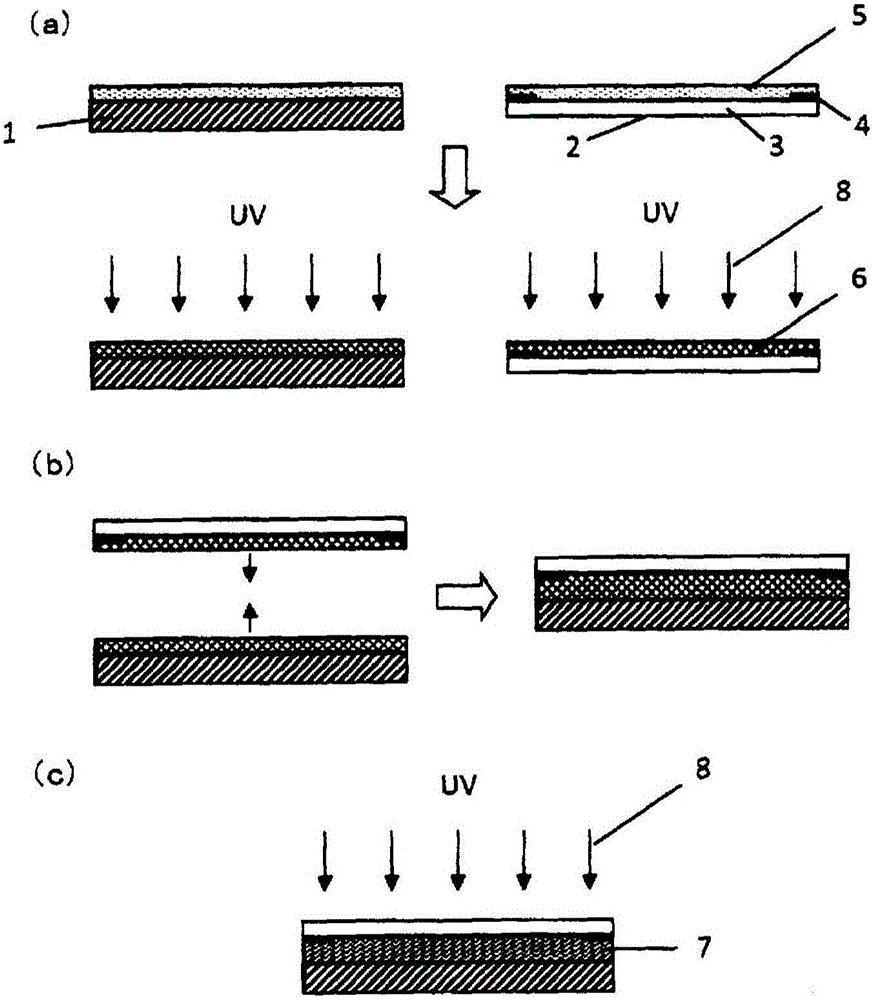

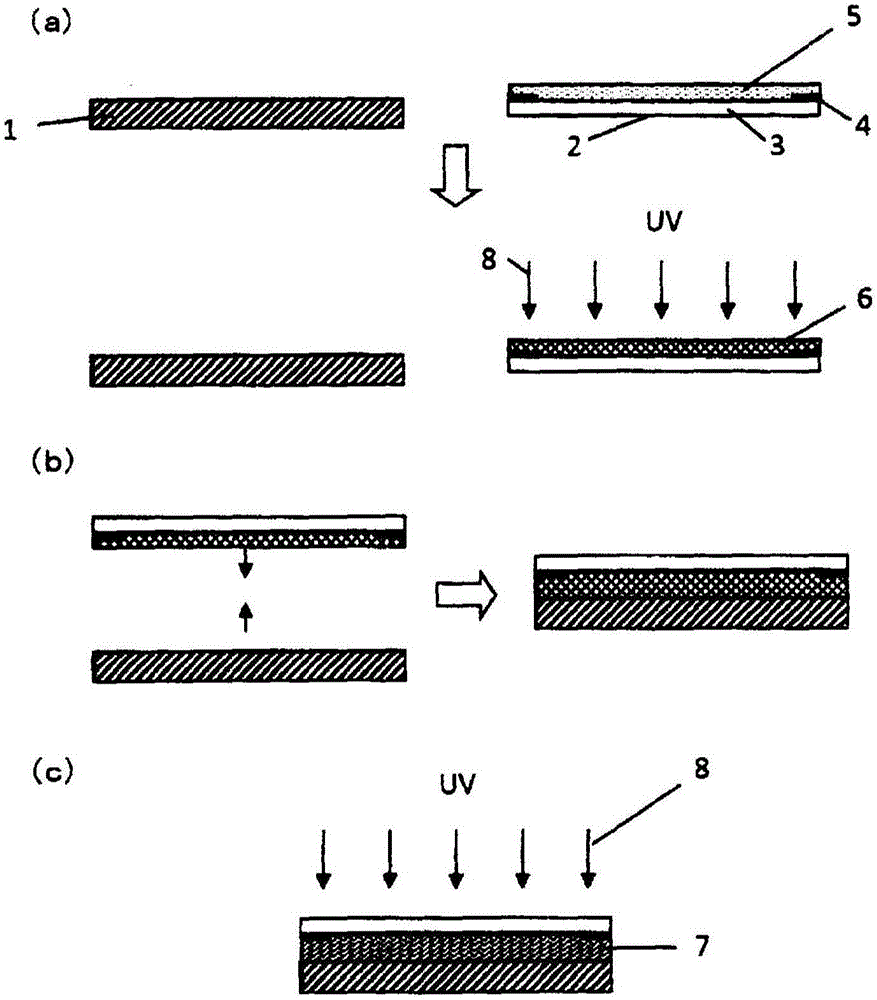

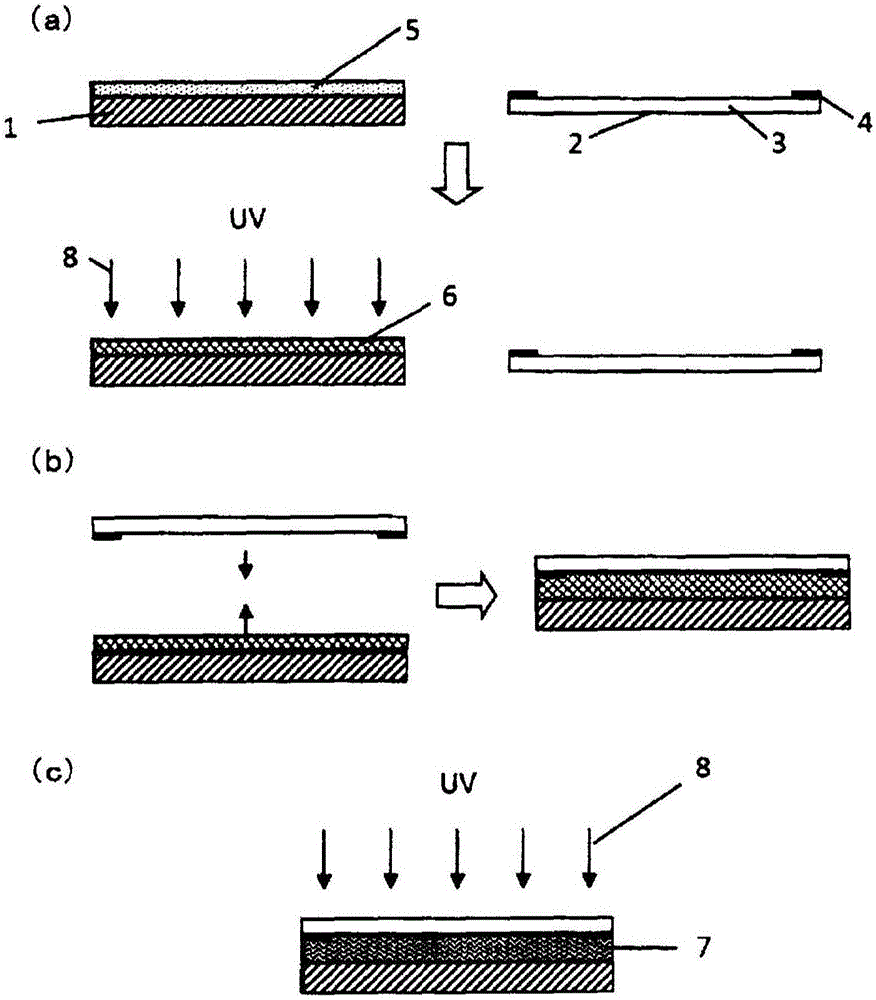

Uv-curable resin composition for use in touchscreen, and bonding method and article using said uv-curable resin

Owner:NIPPON KAYAKU CO LTD

Self-peelable protective coating for cogging and forging process of pure titanium or titanium alloy and production process of self-peelable protective coating

InactiveCN104371385ASimple coating processGood molding effectAlkali metal silicate coatingsProduction rateTitanium

Owner:BEIJING TIAN LICHUANG SCI & TECH OF GLASS DEV

Treatment method of chemical copper plating waste liquid

InactiveCN106957077ANo pollution in the processLow costWater contaminantsWaste water treatment from metallurgical processLiquid wasteProduction rate

Owner:GUILIN UNIV OF ELECTRONIC TECH

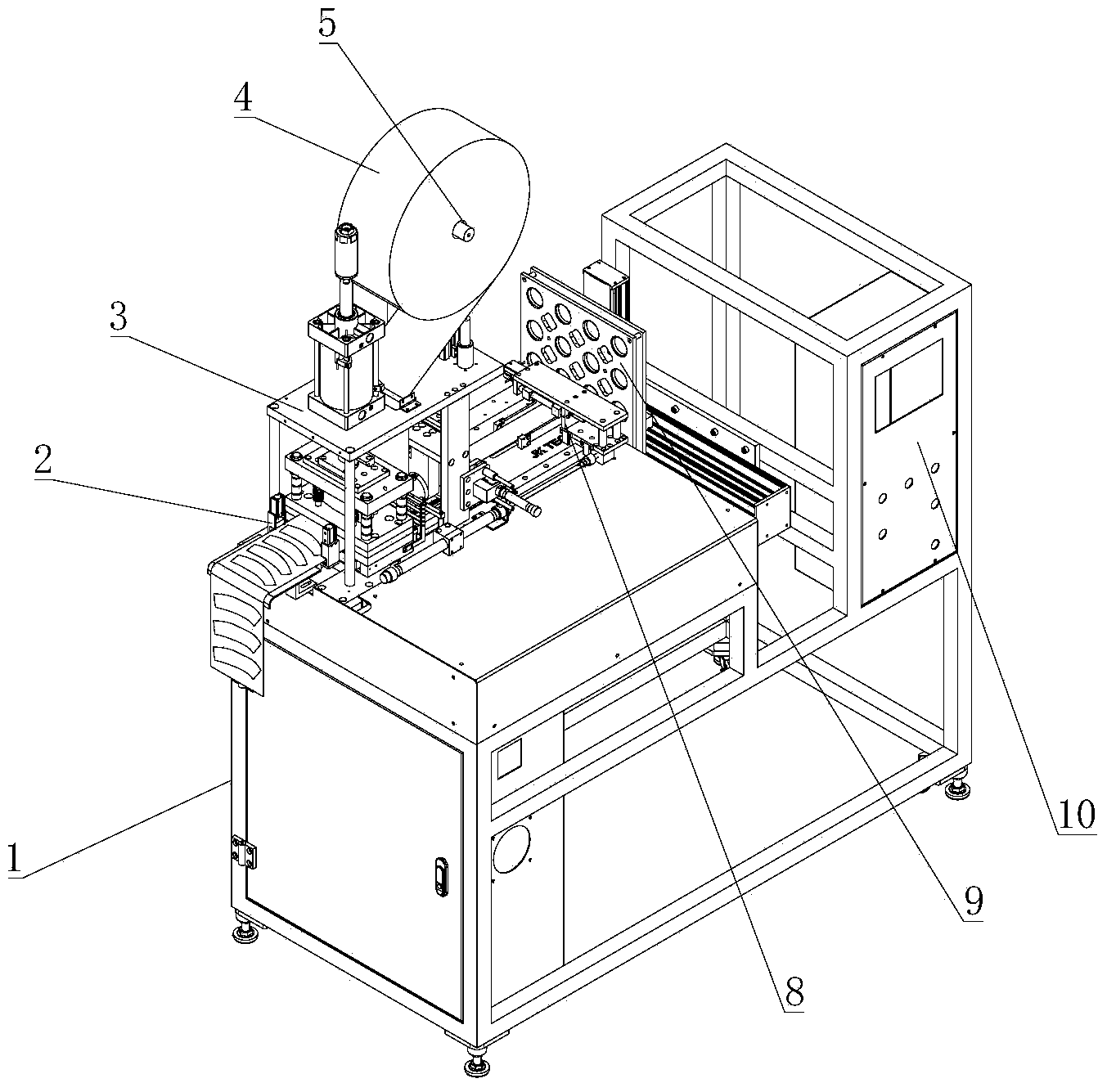

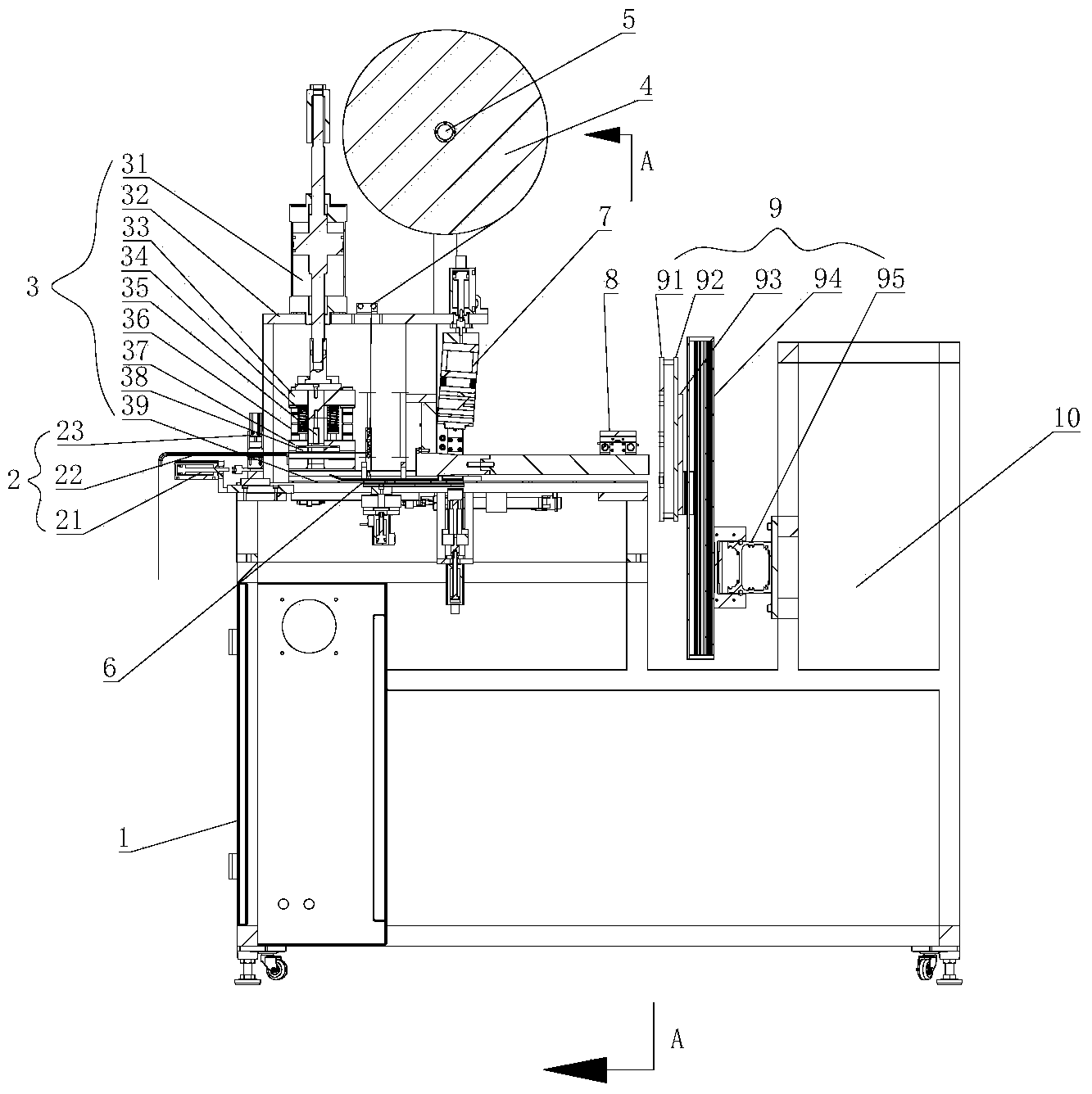

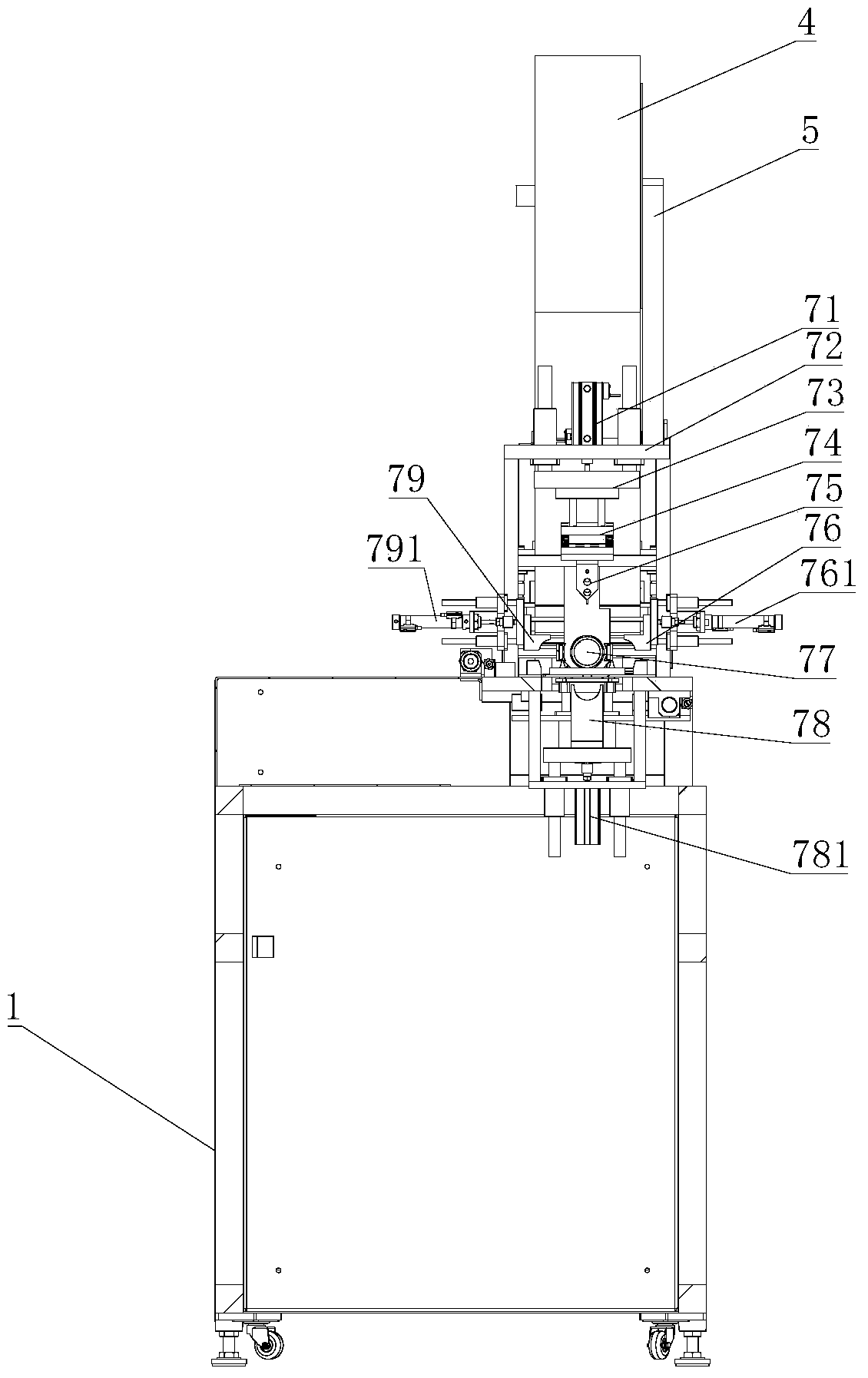

Full-automatic coffee screen cloth forming device

Owner:东莞市江坤自动化科技有限公司

Side punching die

Owner:宋盼锦

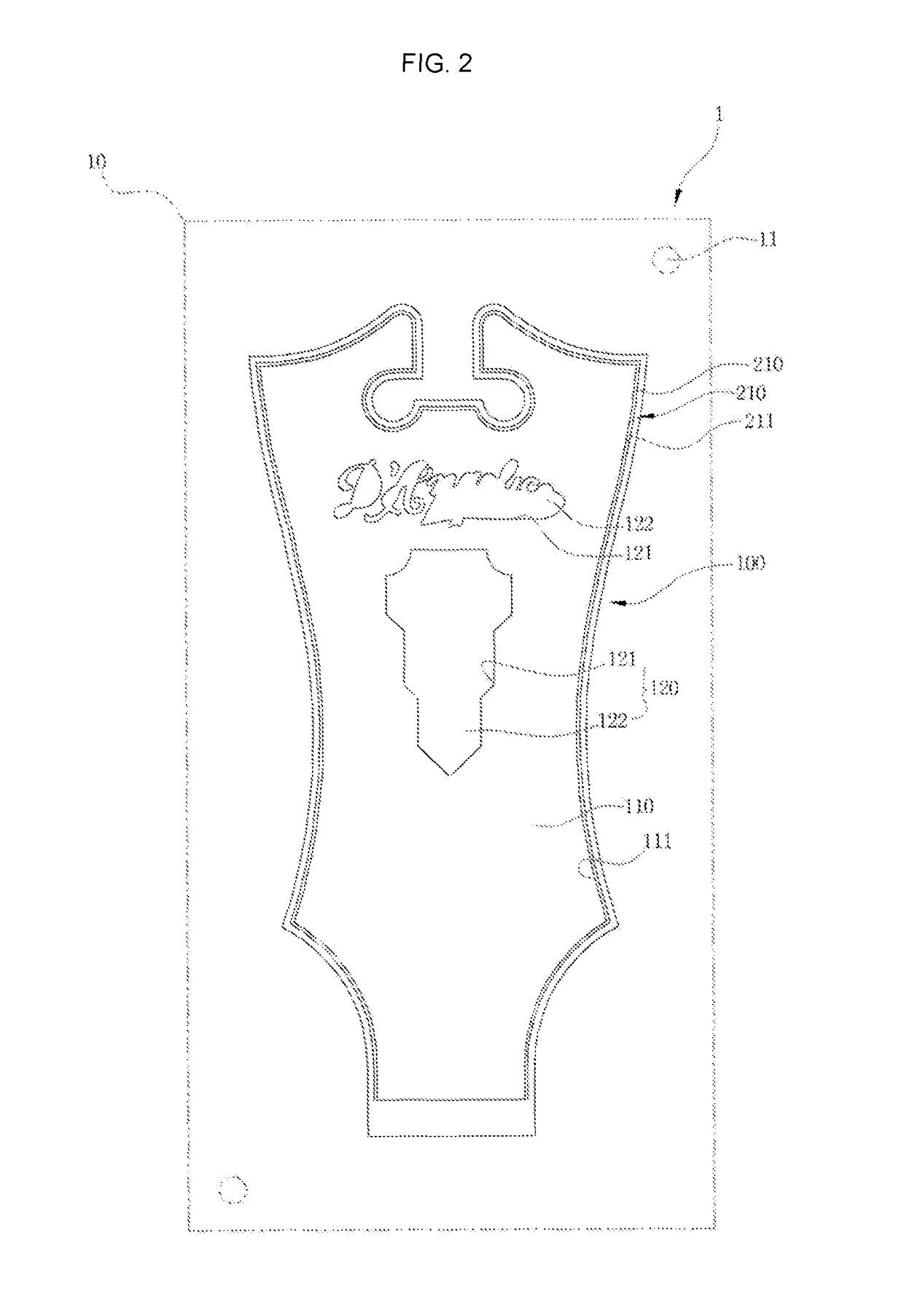

Decorative panel for guitar and manufacturing method thereof

Owner:LEE SE KANG

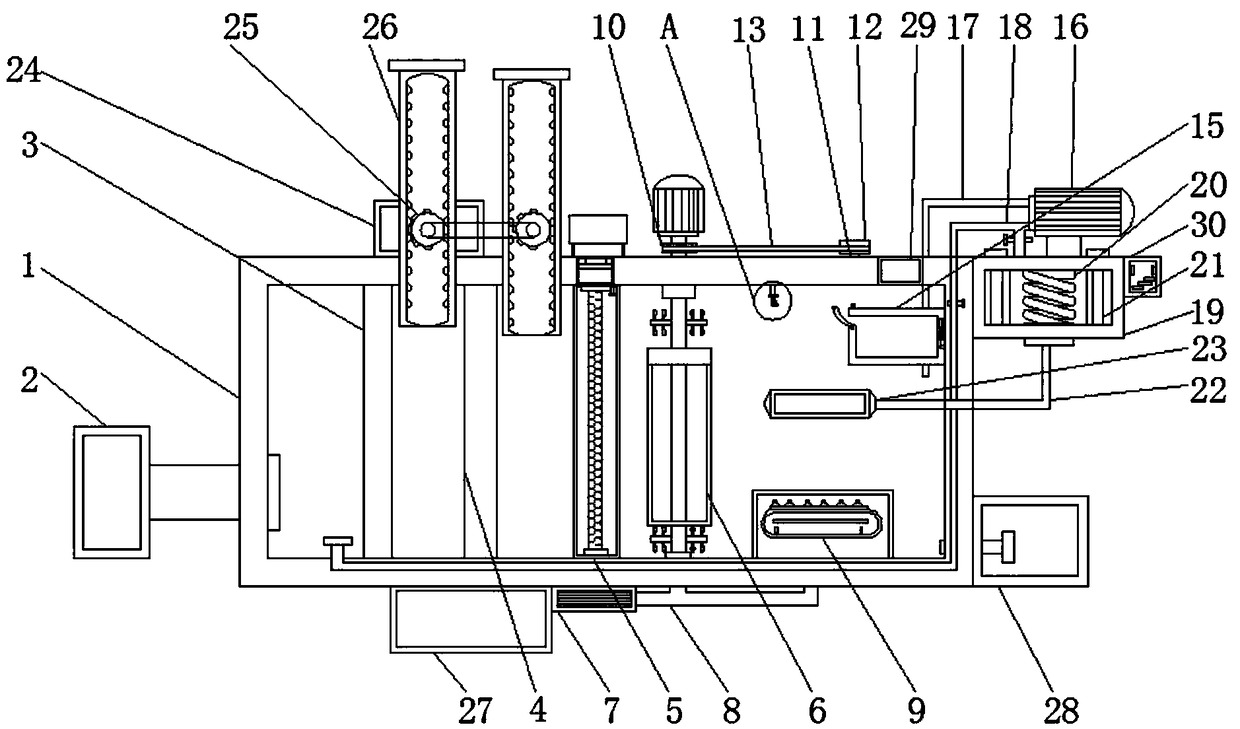

Medical gauze degreasing sewage treatment device

ActiveCN108821516AFatty/oily/floating substances removal devicesTreatment involving filtrationProduction rateWater pipe

Owner:陈剑璋

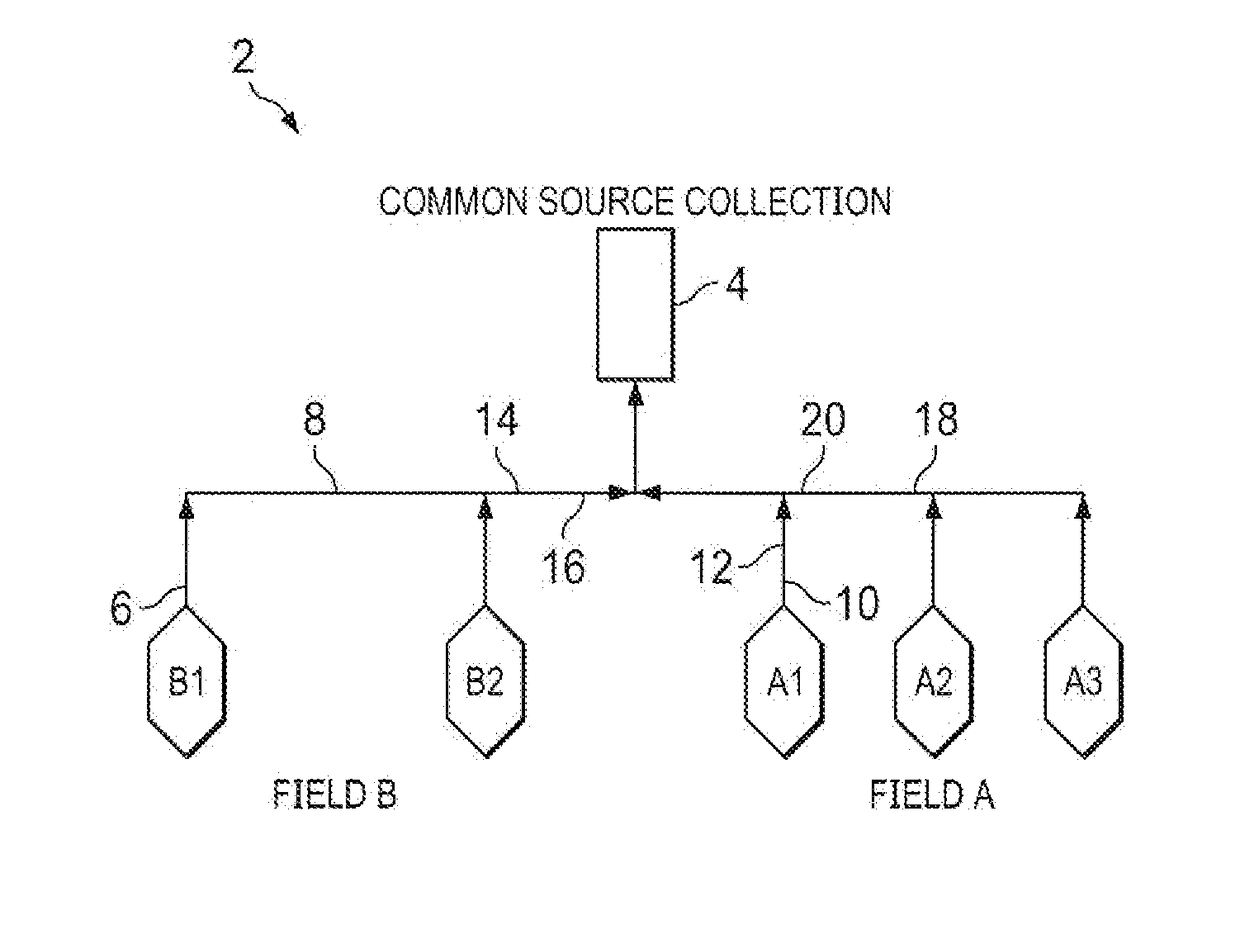

Method of allocating individual oil or water production contributions from multiple combined sources

InactiveUS20180080314A1Quick installationLess invasiveSurveyConstructionsProduction rateOil production

Owner:SPECTRUM TRACER SERVICES

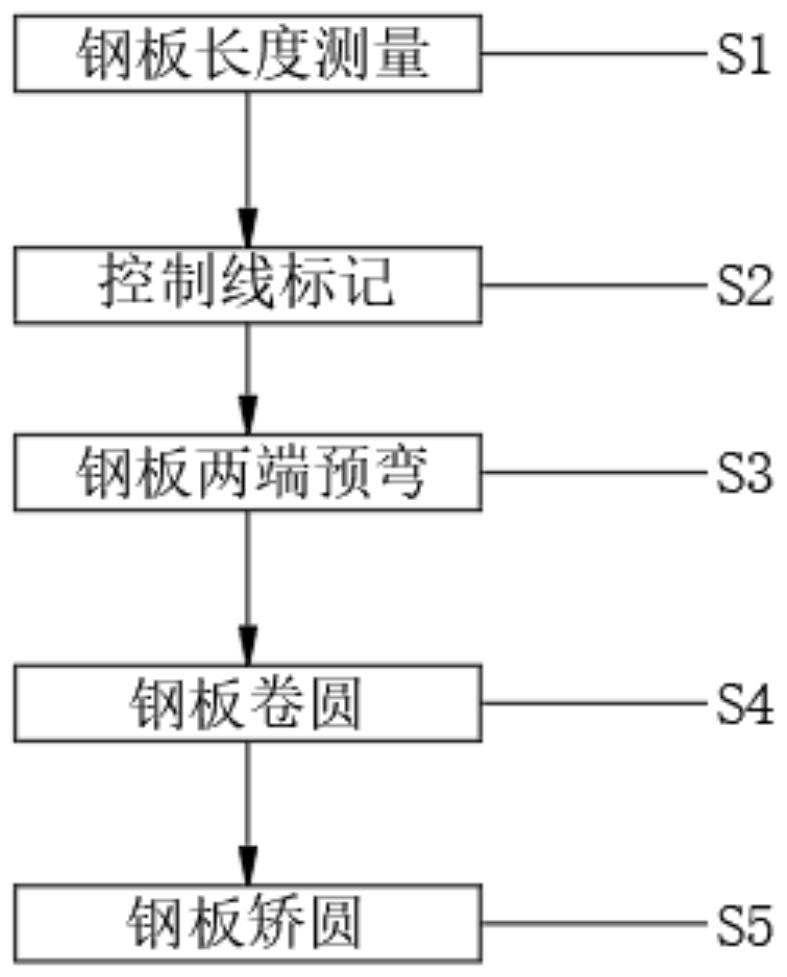

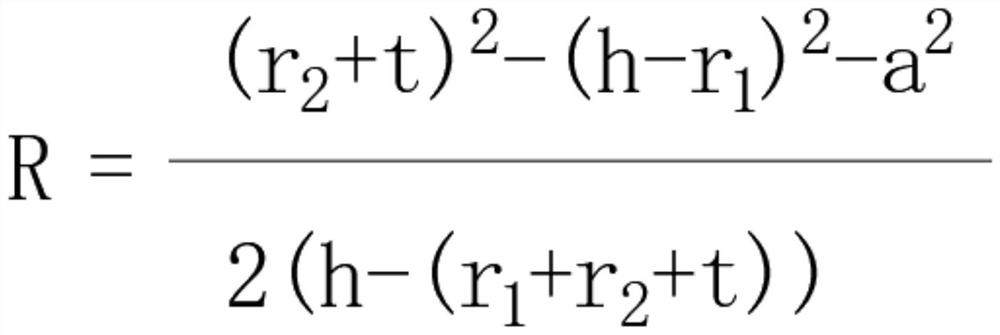

High-efficiency steel plate edge rolling machining process

PendingCN114515776AEfficient and precise pre-bending processingImprove pass rateMetal working apparatusProduction rateStructural engineering

Owner:江苏贝特起重设备有限公司

Energy-saving brick produced by sludge of sewage treatment plant and preparation method thereof

InactiveCN107162544ASolve resource problemsReduce secondary pollutionBuilding componentsProduction rateBrick

The invention belongs to the technical field of building materials, and provides an energy-saving brick produced by sludge of a sewage treatment plant and a preparation method thereof. The energy-saving brick produced by sludge of the sewage treatment plant is prepared from, by weight, 42-56 parts of sludge of sewage treatment plant, 12-16 parts of Chinese herbal medicine, 6-19 parts of quick lime, 6-13 parts of oyster powder, 1-7 parts of early strength agent, 1.05-3.07 parts of water reducing agent, 3-15 parts of flame retardant, and 7-18 parts of water. The invention aims to provide the energy-saving brick produced by sludge of the sewage treatment plant, and the energy-saving brick solves the problem of sludge resource; the preparation method of the energy-saving brick produced by sludge of the sewage treatment plant has advantages of reducing production cycle, being free from sintering and heat energy, saving time, improving the production yield, and reducing production cost; more importantly, the preparation method can relieve the secondary pollution caused by improper sludge disposal.

Owner:ANHUI KEHUI UNITED CERTIFICATION CO LTD

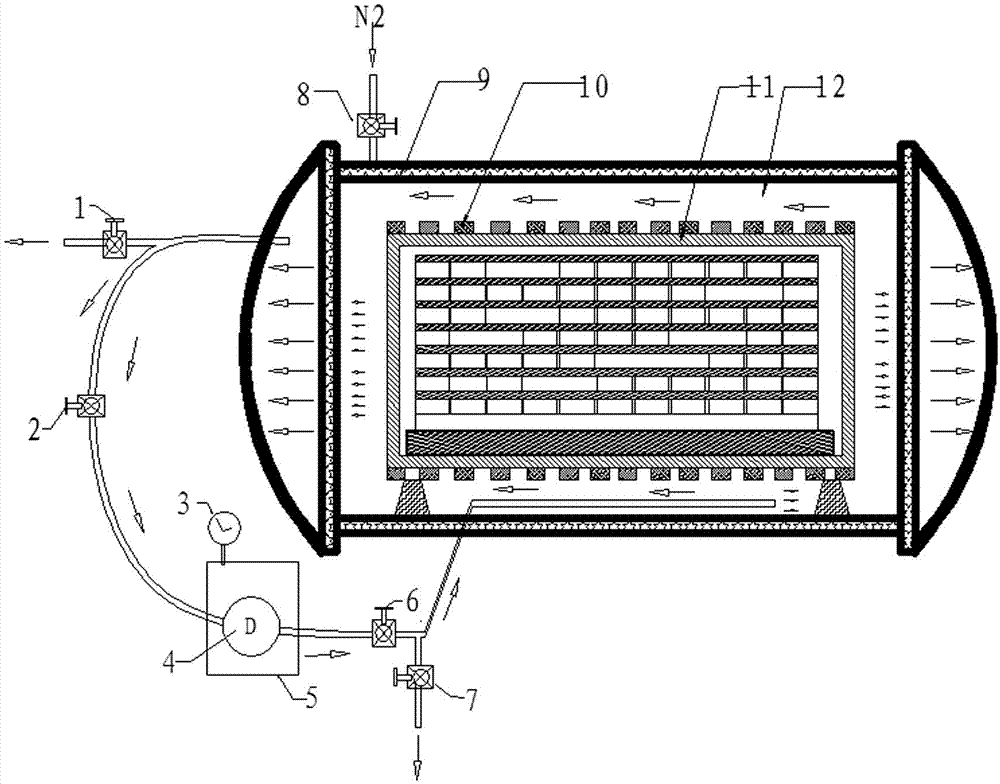

Process and apparatus for producing atmosphere for high productivity carburizing

Owner:PRAXAIR TECH INC

Process and apparatus for the polymerisation of olefins

Owner:INEOS SALES (UK) LTD

Discharging device of shaft furnace

PendingCN111895776ASolve the problem of not being able to nest horizontallySimple structureVertical furnacesProduction rateProcess engineering

The invention discloses a discharging device of a shaft furnace, and relates to the technical field of discharging devices. The discharging device of the shaft furnace comprises a supporting piece, adischarging piece and a driving device; one end of the supporting piece and one end of the discharging piece are connected with the driving device correspondingly, and the interior or the bottom of the supporting piece is in sliding fit with the discharging piece; and the length of the supporting piece is not smaller than the distance between two discharging openings in the shaft furnace. The discharging device is simple in structure and works intermittently, so that equipment maintenance is facilitated, and the operation rate is not affected; and the discharging device particularly does not need to work continuously at high temperature, so that the problem of discharging of high-temperature materials is solved, through high-temperature discharging, the production time is shortened, the production rate is improved, and energy consumption is saved for further melting and separating of the materials.

Owner:TANGSHAN ZHONGKE QIANHAI ENVIRONMENTAL PROTECTION TECH CO LTD +1

Preparation method for cold silks

InactiveCN106192043AReduce wasteAvoid enteringArtificial filaments from viscoseProduction rateChemical structure

The invention discloses a preparation method for cold silks. The preparation method comprises the following steps: preparing a mucilage glue stock solution; preparing a cold mucilage glue stock solution and adding a cold storage agent; treating before spinning and injecting dispersing agent; spinning, weaving and thus obtaining the final cold silks. According to the method, the physical mixing mode of adding auxiliaries is adopted, so that the chemical structure of the viscose is not changed and the effect of the frozen silk in the market is achieved; the technique is simple; the main production technique of the current conventional viscose is not changed; the pipeline mixing and injection method is adopted, so that the preparation of the easily cooling mucilage glue stock solution is realized and the investment is less; the productivity is high; the cold silk product can increase the living quality of people and also can meet the market requirement.

Owner:YIBIN HIEST FIBER

Powerful gas circulating and stirring device of vacuum induction sintering furnace

Owner:SHENYANG STARLIGHT ADVANCED CERAMICS

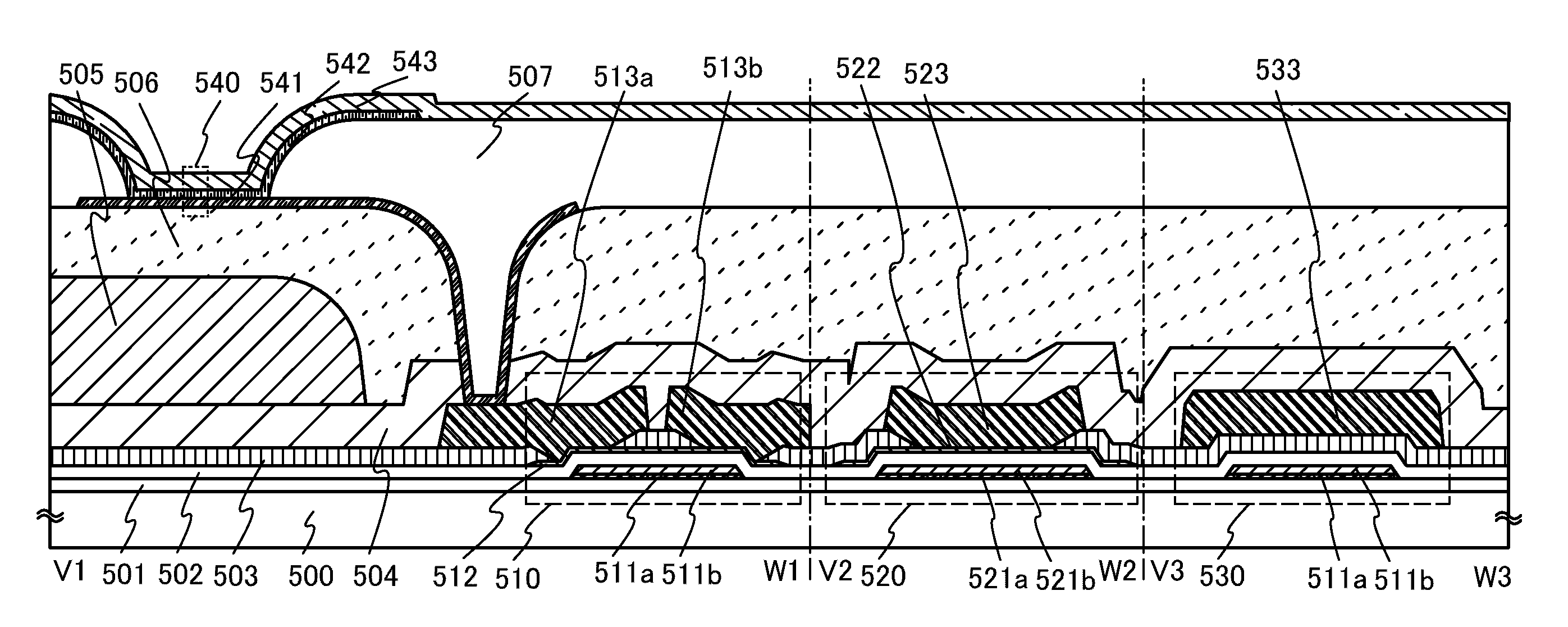

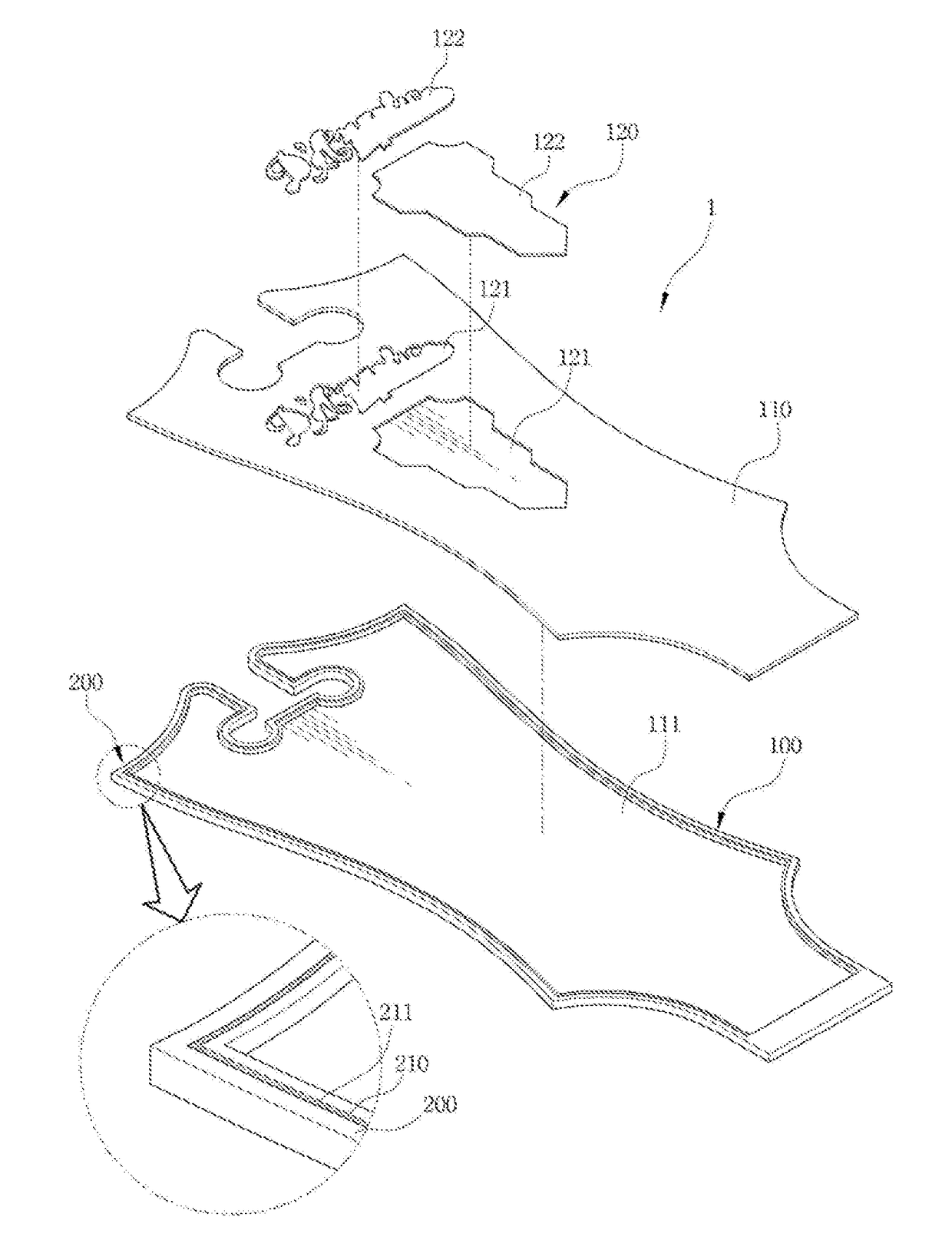

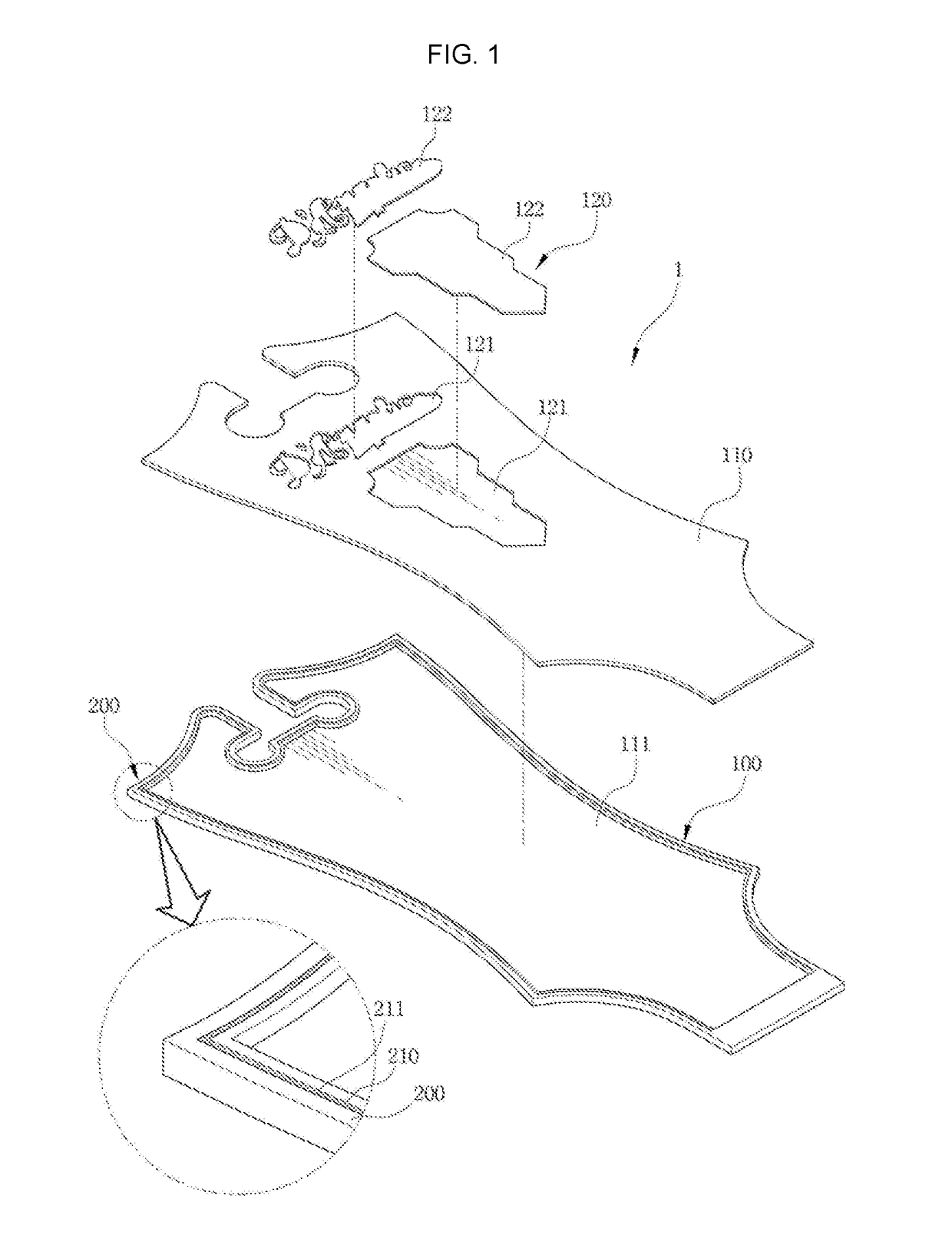

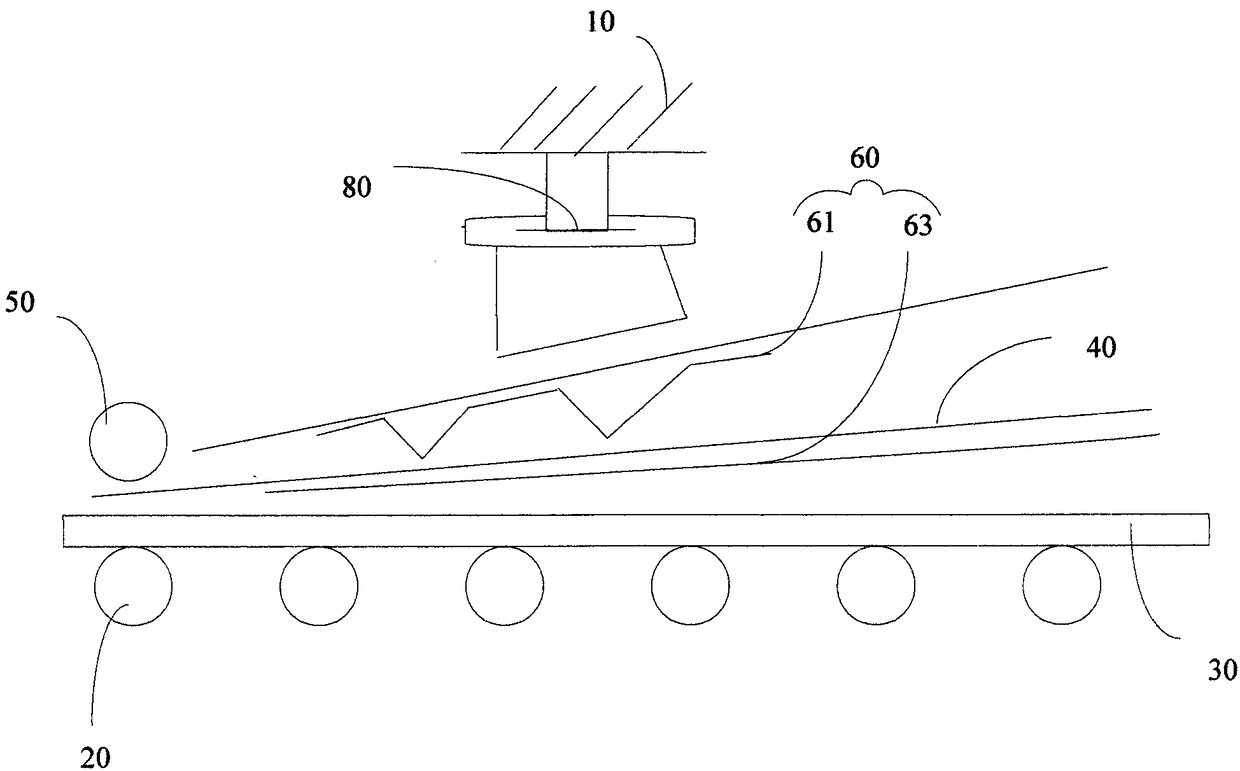

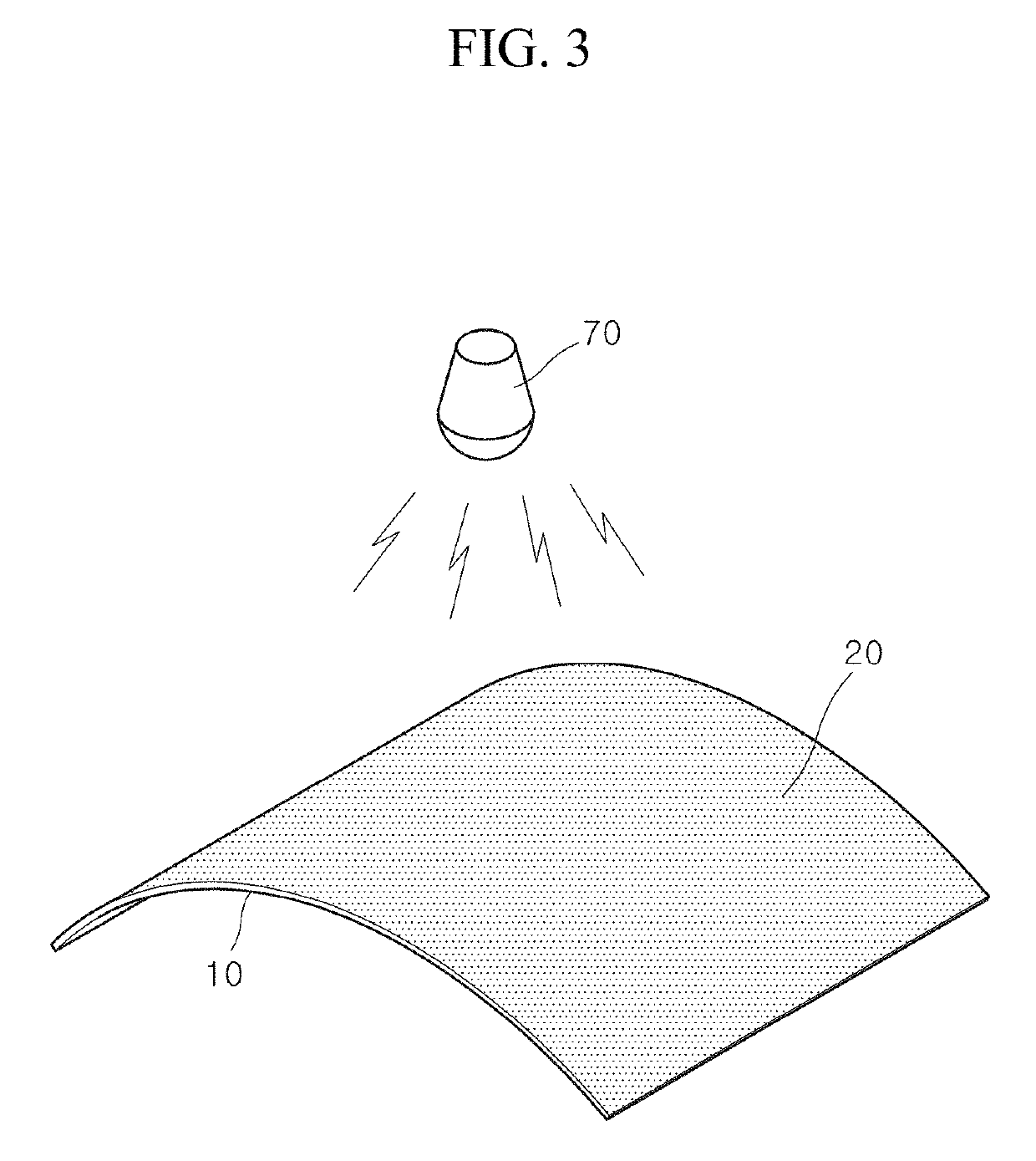

Curved stereoscopic image display device and manufacturing method thereof

InactiveUS20190146231A1Reduce processImprove productivityDigital data processing detailsPrinted circuit aspectsProduction rateSurface plate

Owner:KORTEK CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap