Side punching die

A mold and punching technology, applied in the field of side punching molds, can solve the problems of reduced accuracy of curved parts, increased production costs, inaccurate positioning, etc., and achieve the effects of improving product quality and productivity, reducing production costs, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

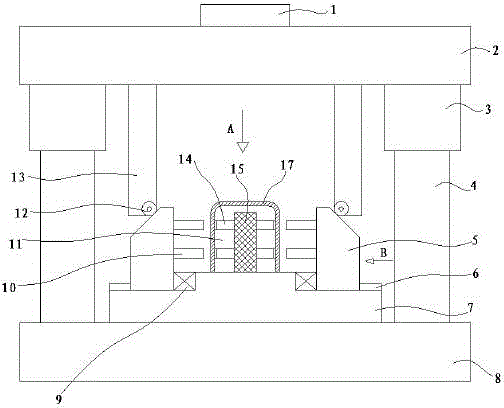

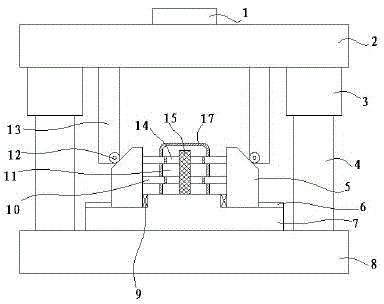

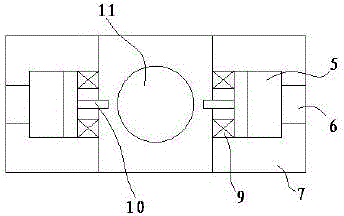

[0023] Referring to Figure 1, figure 2 , image 3 , Figure 4 with Figure 5 As shown, a side punching die includes a corresponding upper mold base 2 and a lower mold base 8, the lower surface of the upper mold base 2 is fixedly provided with an axle fixing block 13, and the upper surface of the lower mold base 8 is provided with Pad 7, the upper surface of the pad 7 is fixed with a die 11, the inside of the die 11 is provided with a lifting device, the upper surface of the pad is provided with a punch fixing block 5, and the punch fixing block 5 A male die 10 corresponding to the female die 11 is fixed inside.

[0024] The upper surface of the upper mold base 2 is provided with a mold handle 1, the lower surface of the upper mold base 2 is pr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap