Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69 results about "Punching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Punching is a forming process that uses a punch press to force a tool, called a punch, through the workpiece to create a hole via shearing. Punching is applicable to a wide variety of materials that come in sheet form, including sheet metal, paper, vulcanized fibre and some forms of plastic sheet. The punch often passes through the work into a die. A scrap slug from the hole is deposited into the die in the process. Depending on the material being punched this slug may be recycled and reused or discarded.

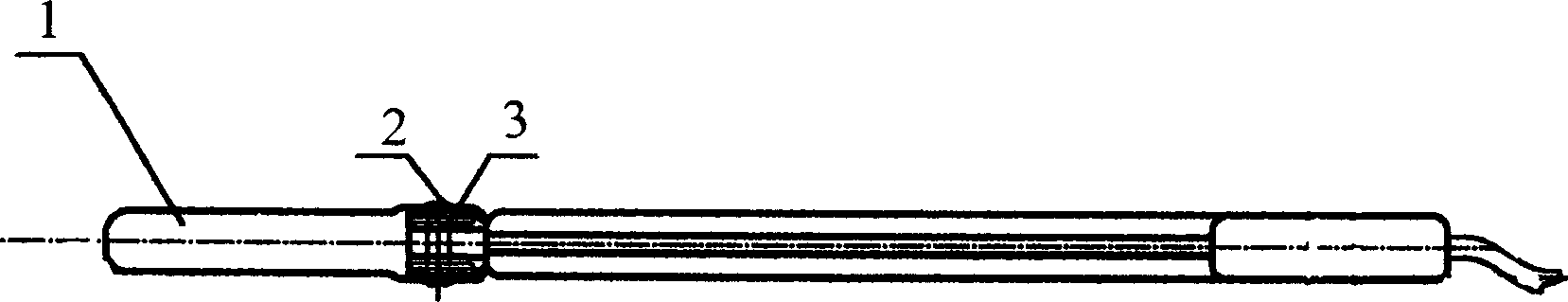

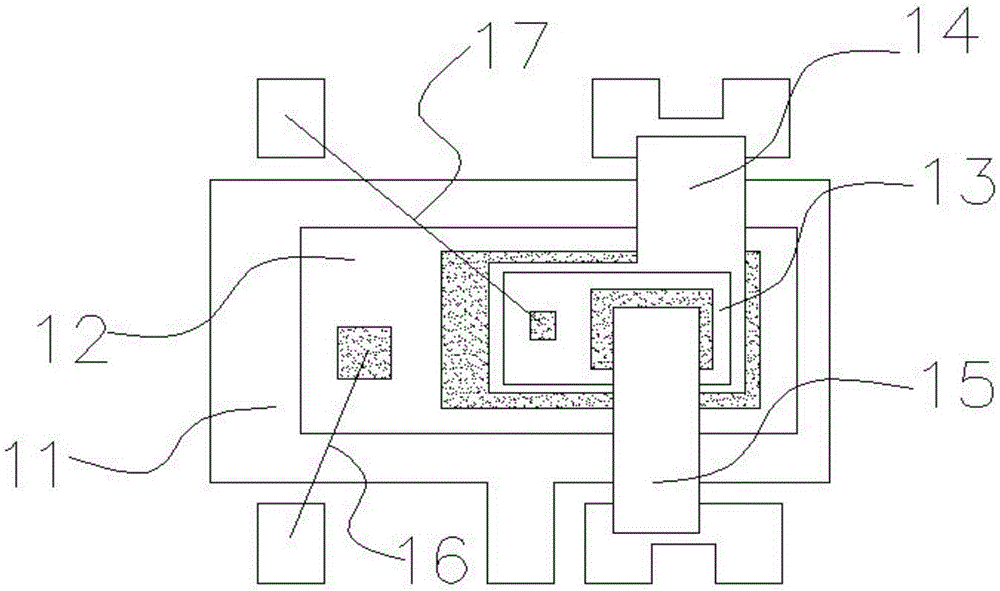

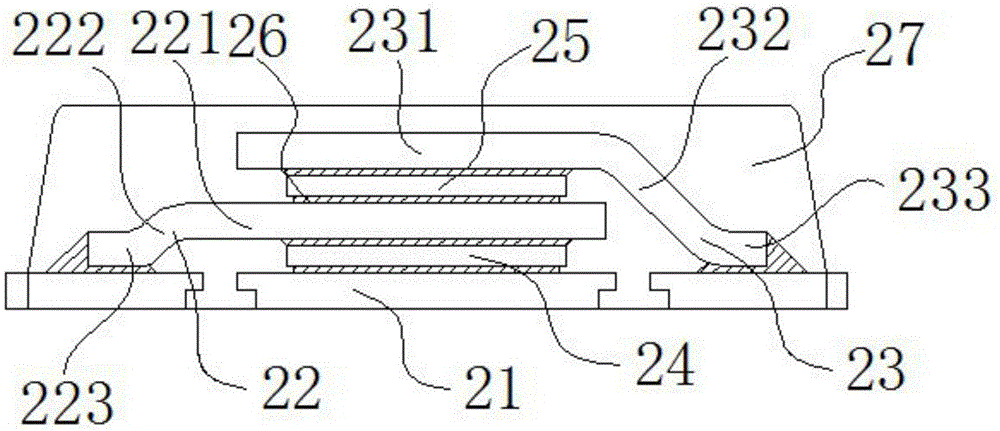

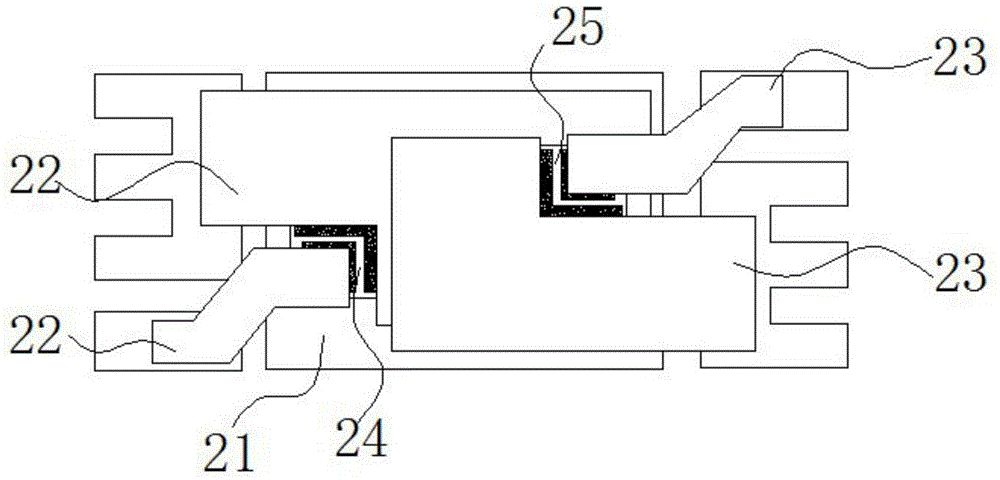

Surgical-instrument clamping mechanism, end effector and surgical mechanical arm with end effector

ActiveCN109303610AQuick releaseEliminate Track OffsetSurgical navigation systemsSurgical manipulatorsPunchingEngineering

Owner:SINOSURGICAL HEALTHCARE TECH BEIJING CO LTD

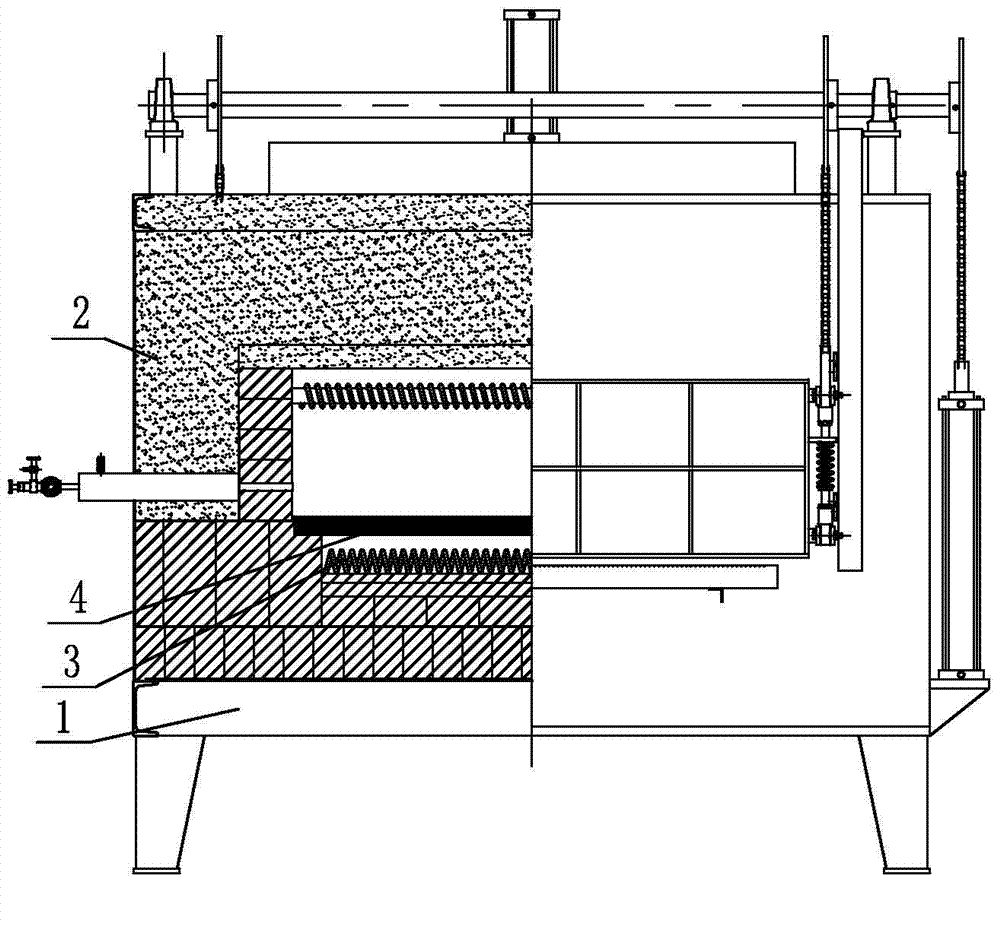

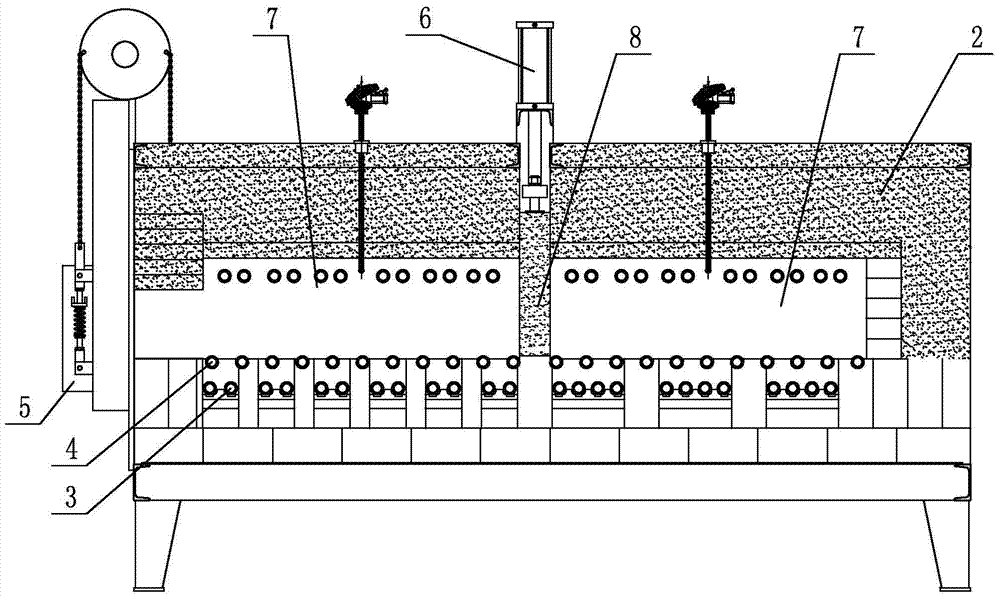

Mobile roller-type van-type heating furnace and hot-forming subsection strengthening technique

ActiveCN104729278AReduce volumeLess investmentFurnace typesHeat treatment furnacesPunchingRoom temperature

Owner:YANCHENG KEAO MECHAICAL

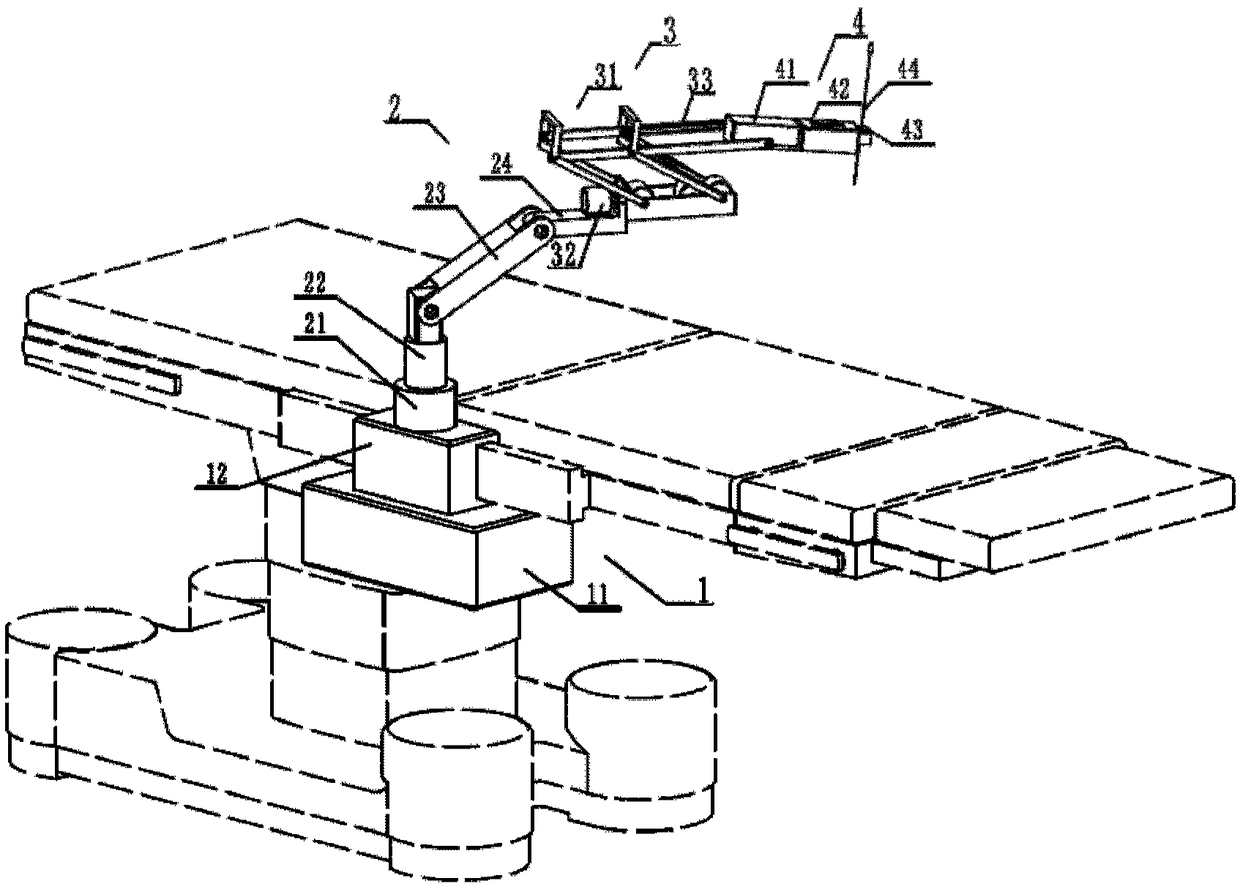

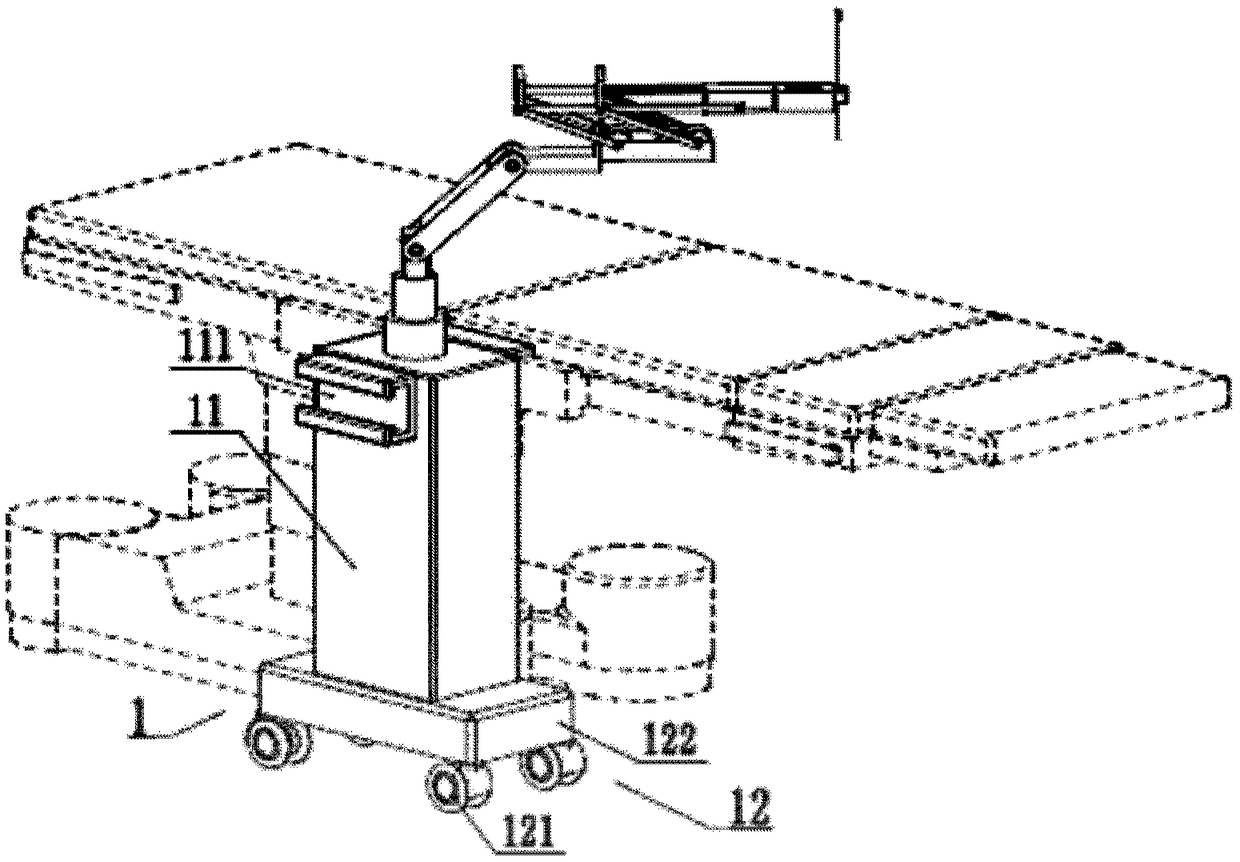

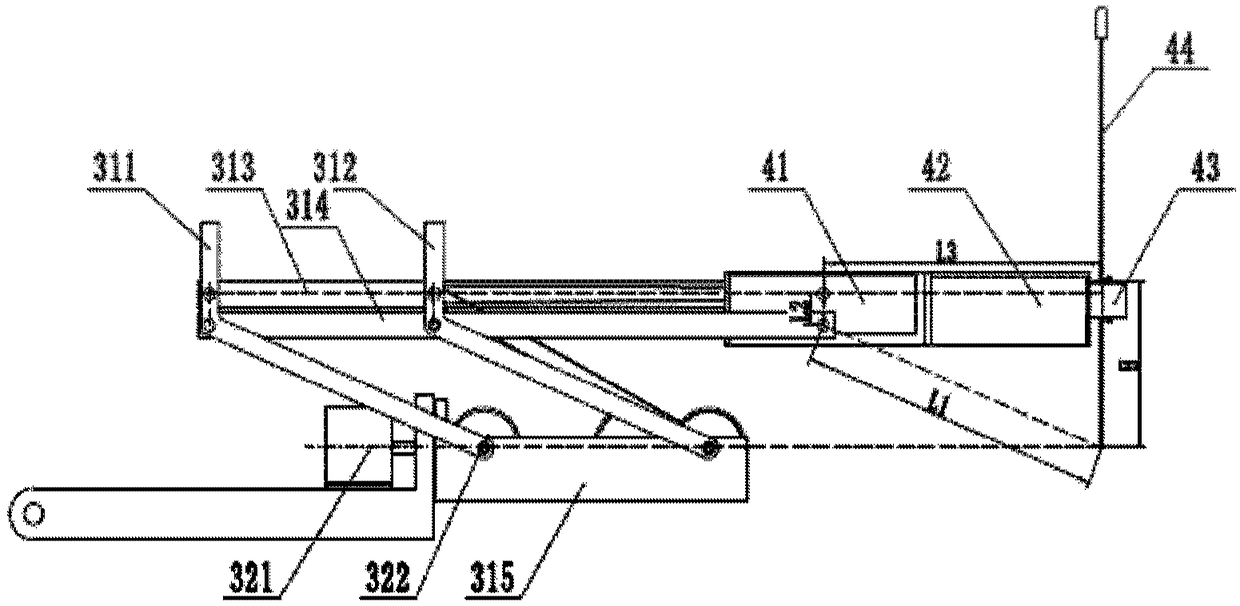

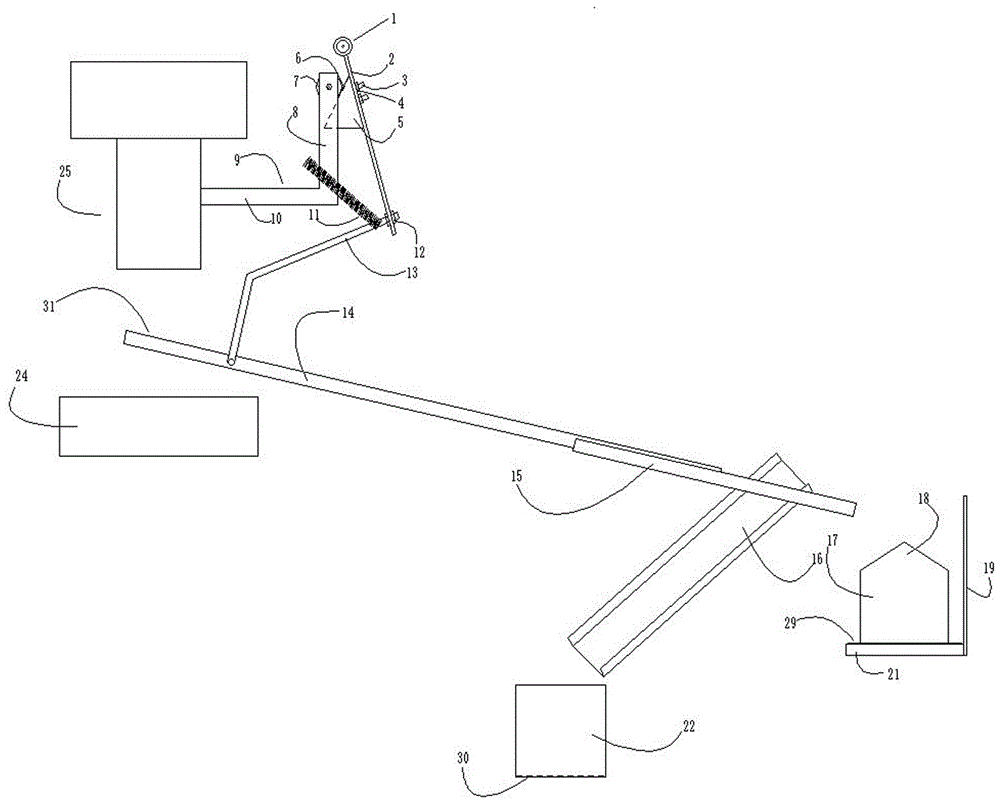

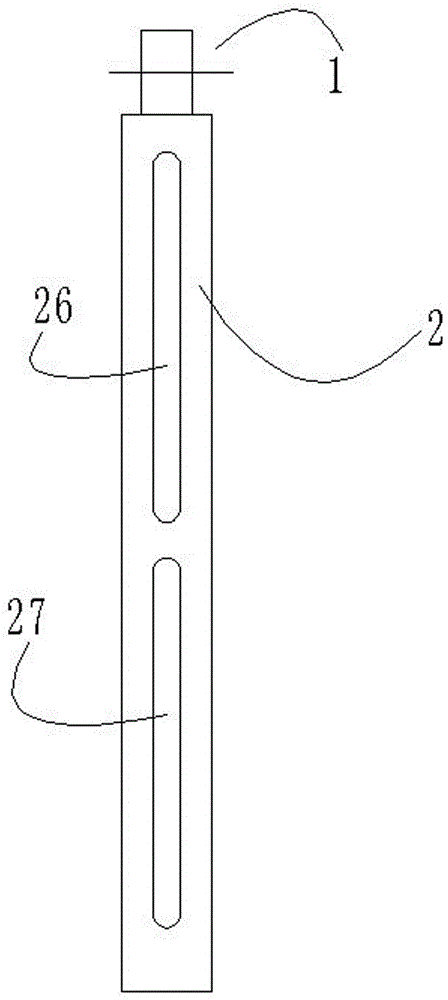

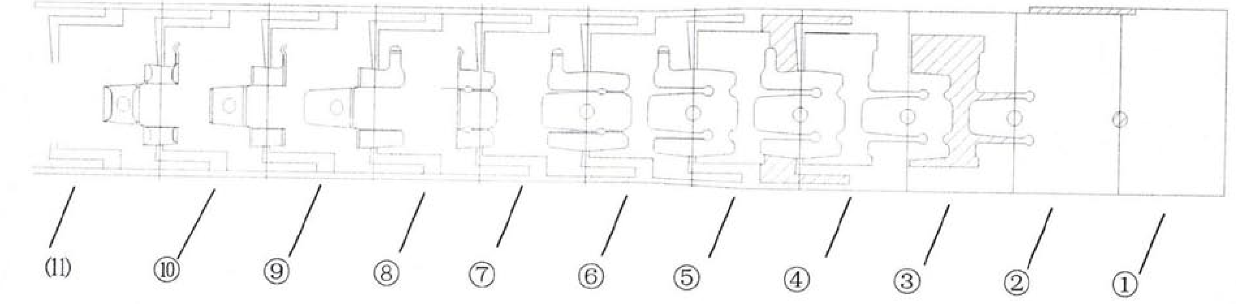

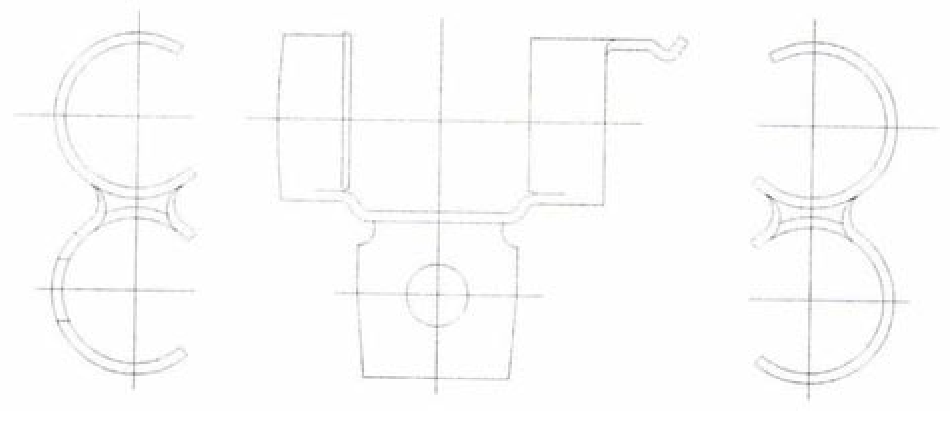

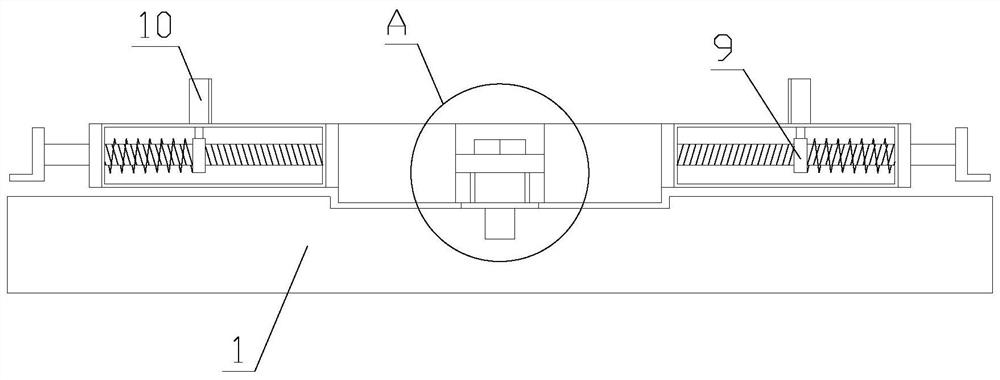

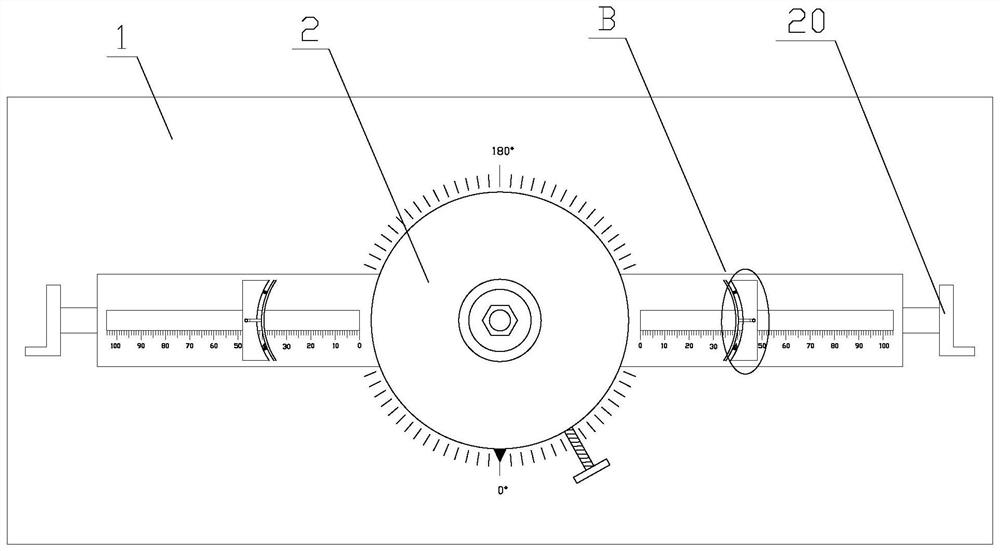

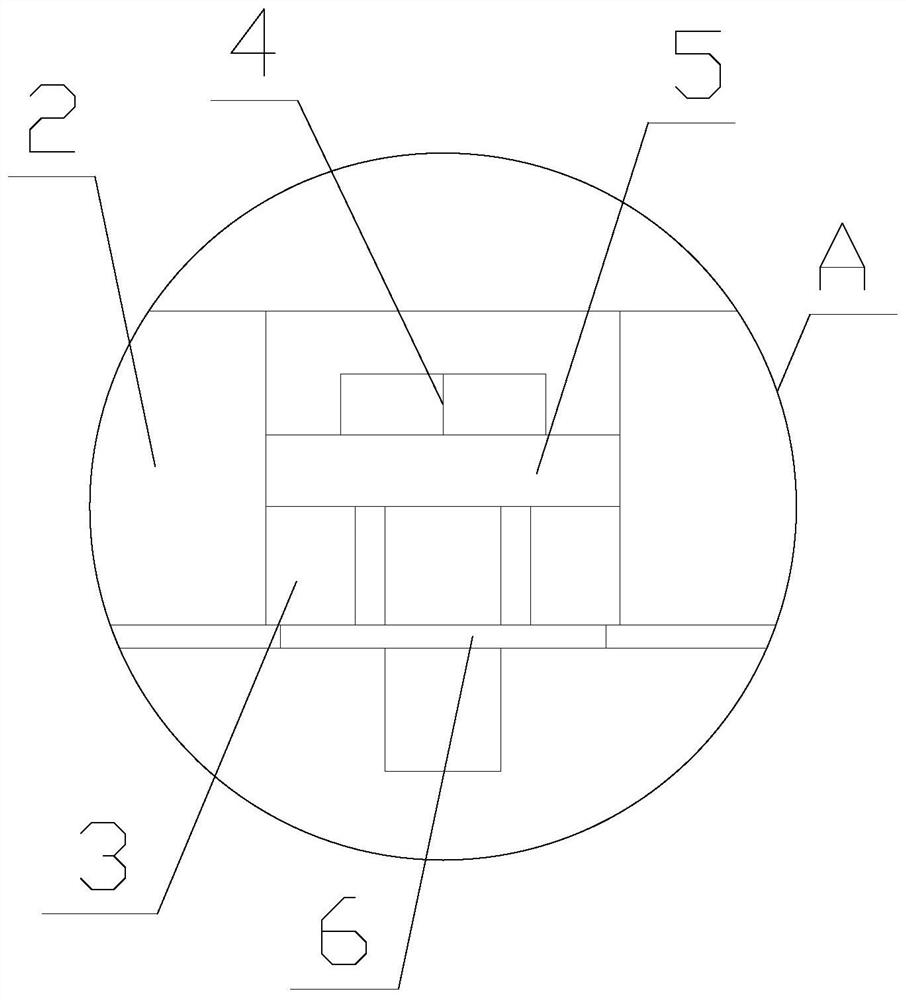

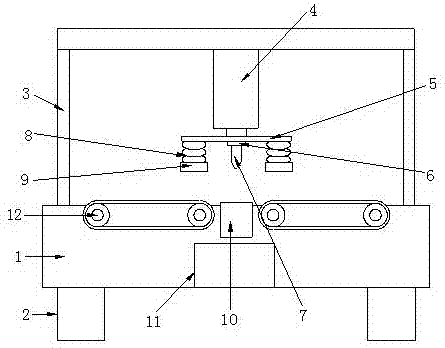

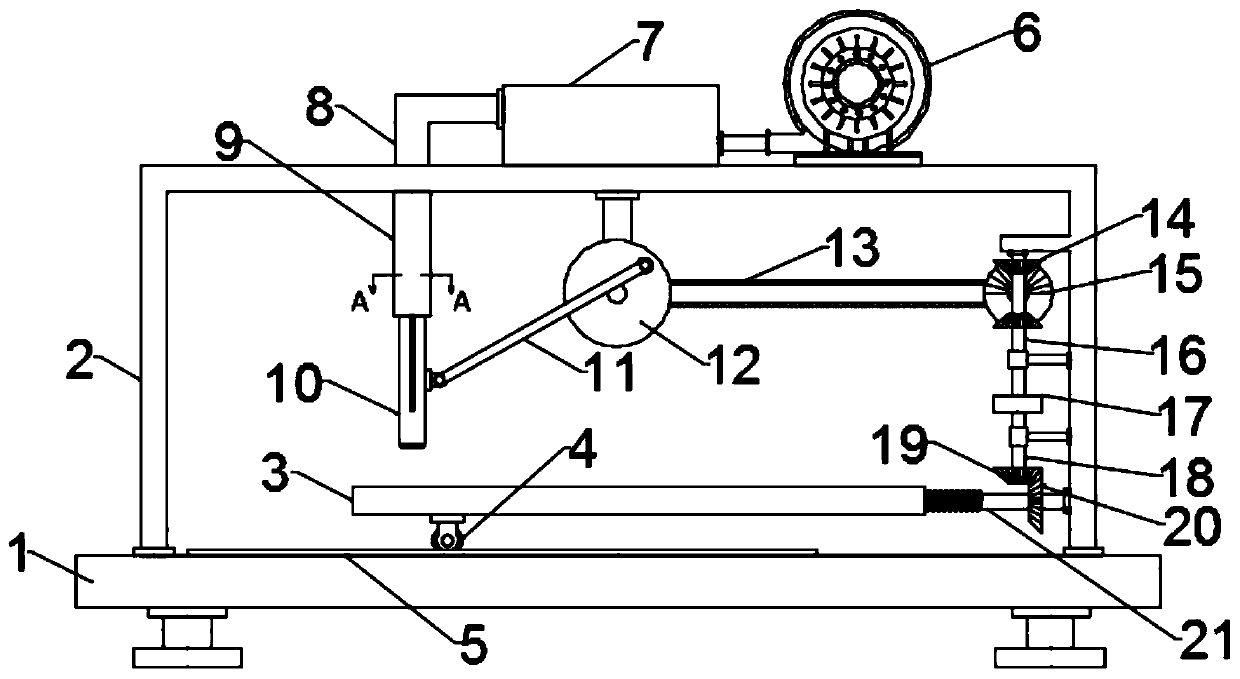

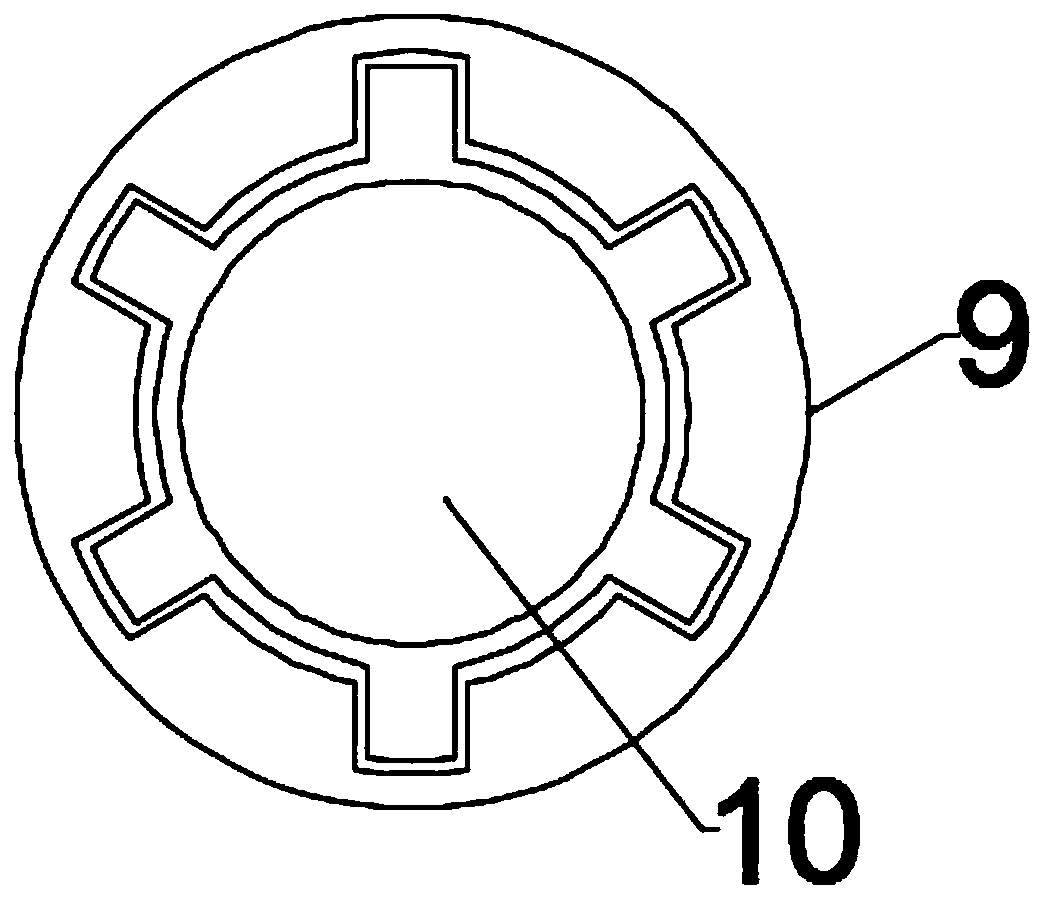

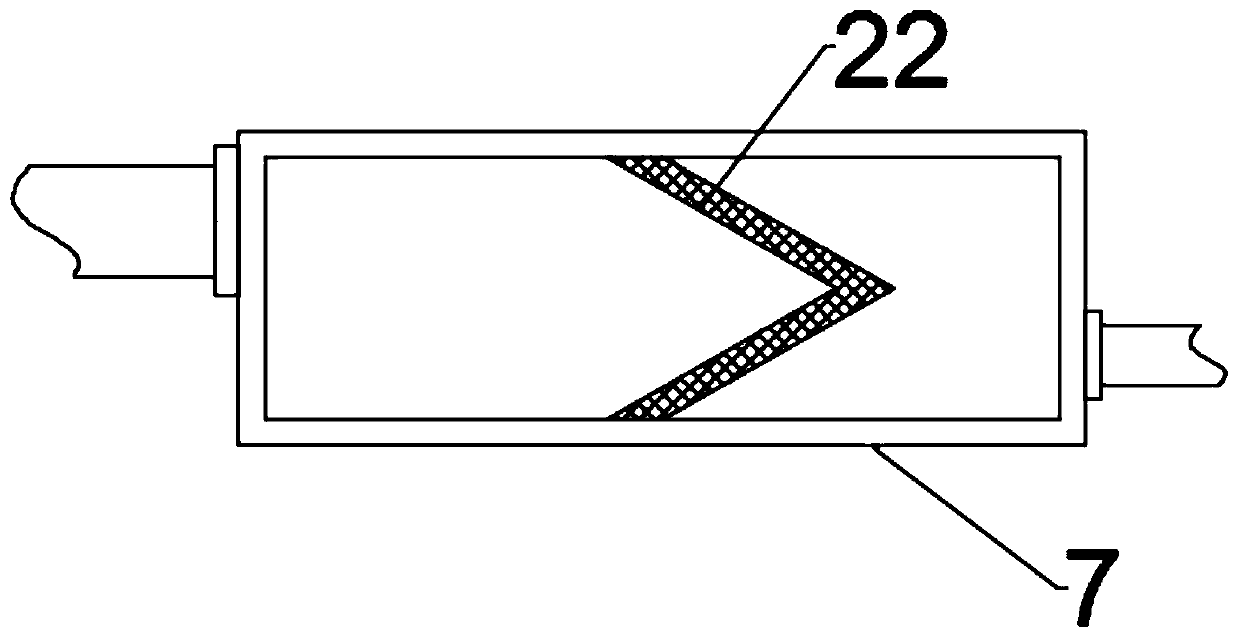

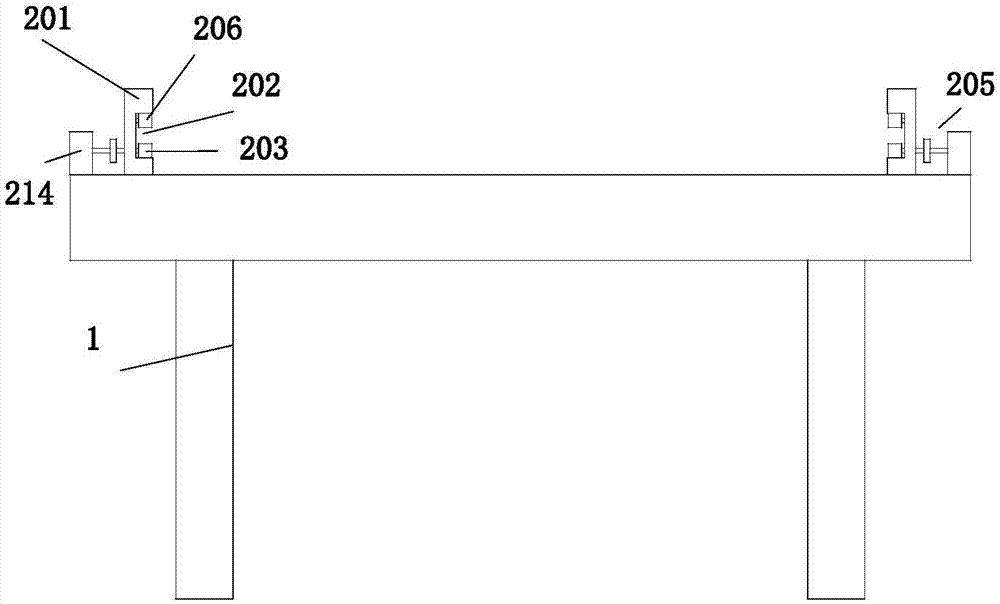

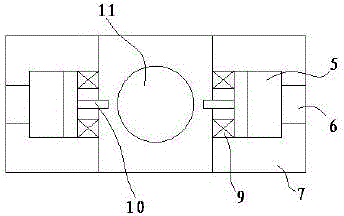

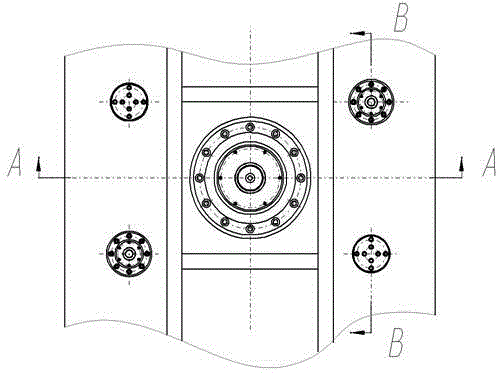

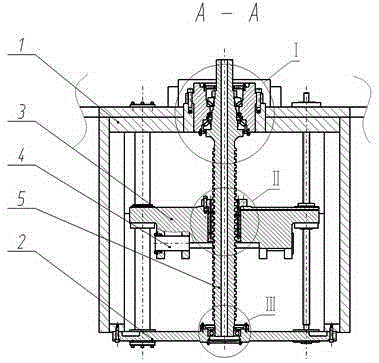

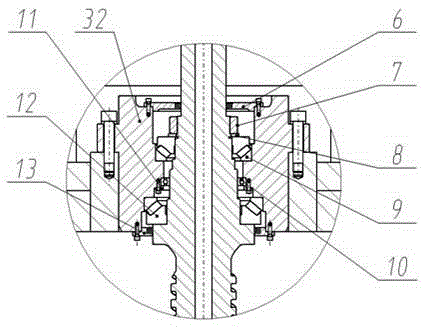

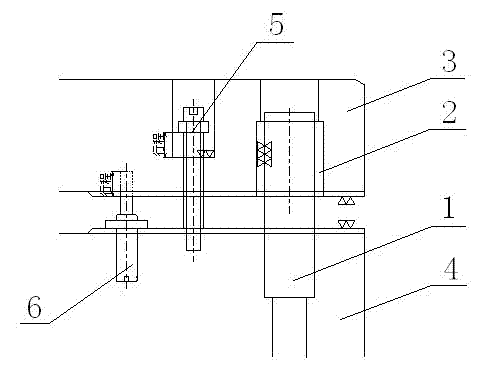

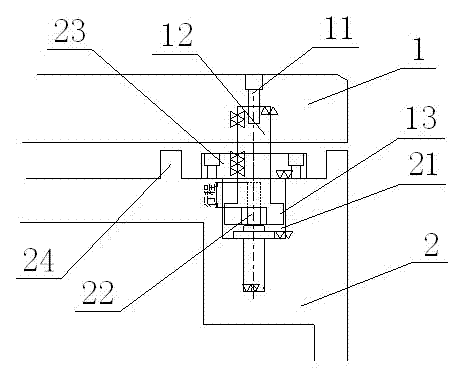

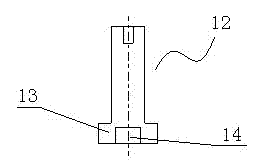

Numerical control machining device for key bit tooth punching

InactiveCN107262625AThe delivery path is reasonableEasy to controlMetal-working feeding devicesKeysNumerical controlPunching

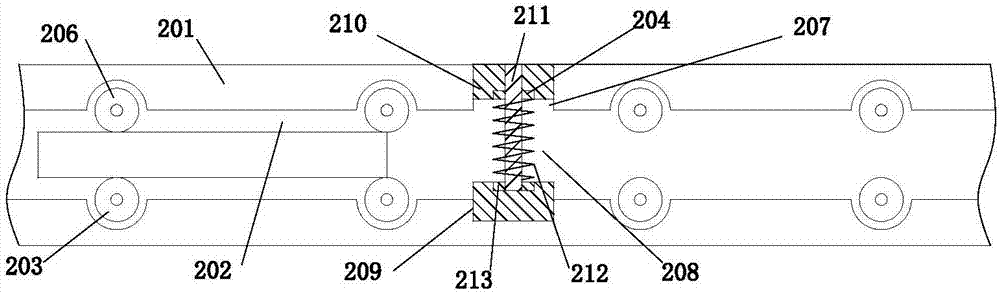

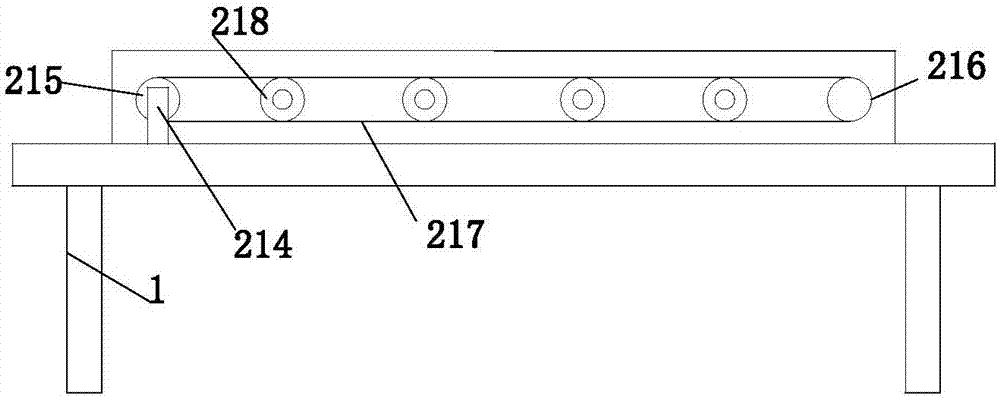

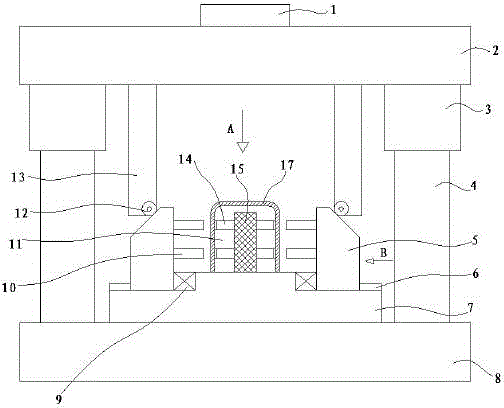

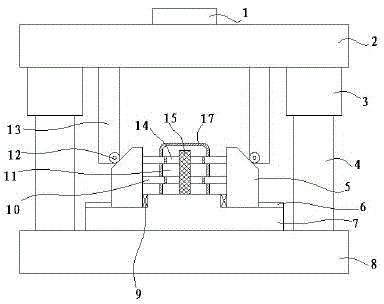

The invention discloses a numerical control machining device for key bit tooth punching. The numerical control machining device for key bit tooth punching comprises a rack which is provided with a feeding mechanism, a clamping mechanism, a tooth punching mechanism, a discharging mechanism, a ring stringing mechanism and a numerical control unit; the clamping mechanism is fixed behind the feeding mechanism which conveys a key to the clamping mechanism to be clamped; the tooth punching mechanism is arranged behind the clamping mechanism, and is used for punching teeth of the key clamped by the clamping mechanism; the discharging mechanism is connected with the feeding mechanism and the ring stringing mechanism, and is used for conveying the key subject to tooth punching to the ring stringing mechanism from the clamping mechanism; and the numerical control unit is connected with the feeding mechanism, the clamping mechanism, the tooth punching mechanism, the discharging mechanism and the ring stringing mechanism, and is used for controlling overall running of the device. According to the numerical control machining device for key bit tooth punching, the conveying path in the key tooth punching process is optimized, the whole tooth punching process of the key is smoother, machined tooth bits are more accurate, the work efficiency is improved, and the control cost is reduced.

Owner:ZHEJIANG XINGYU MASCH TECH CO LTD

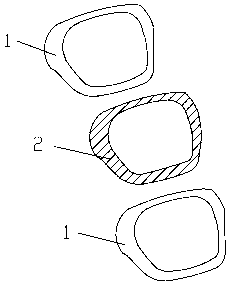

Novel spectacle material and production process thereof

InactiveCN103121322AHigh strengthImprove axial strengthLamination ancillary operationsLaminationSandwich likePunching

Owner:东莞炜创光学眼镜有限公司

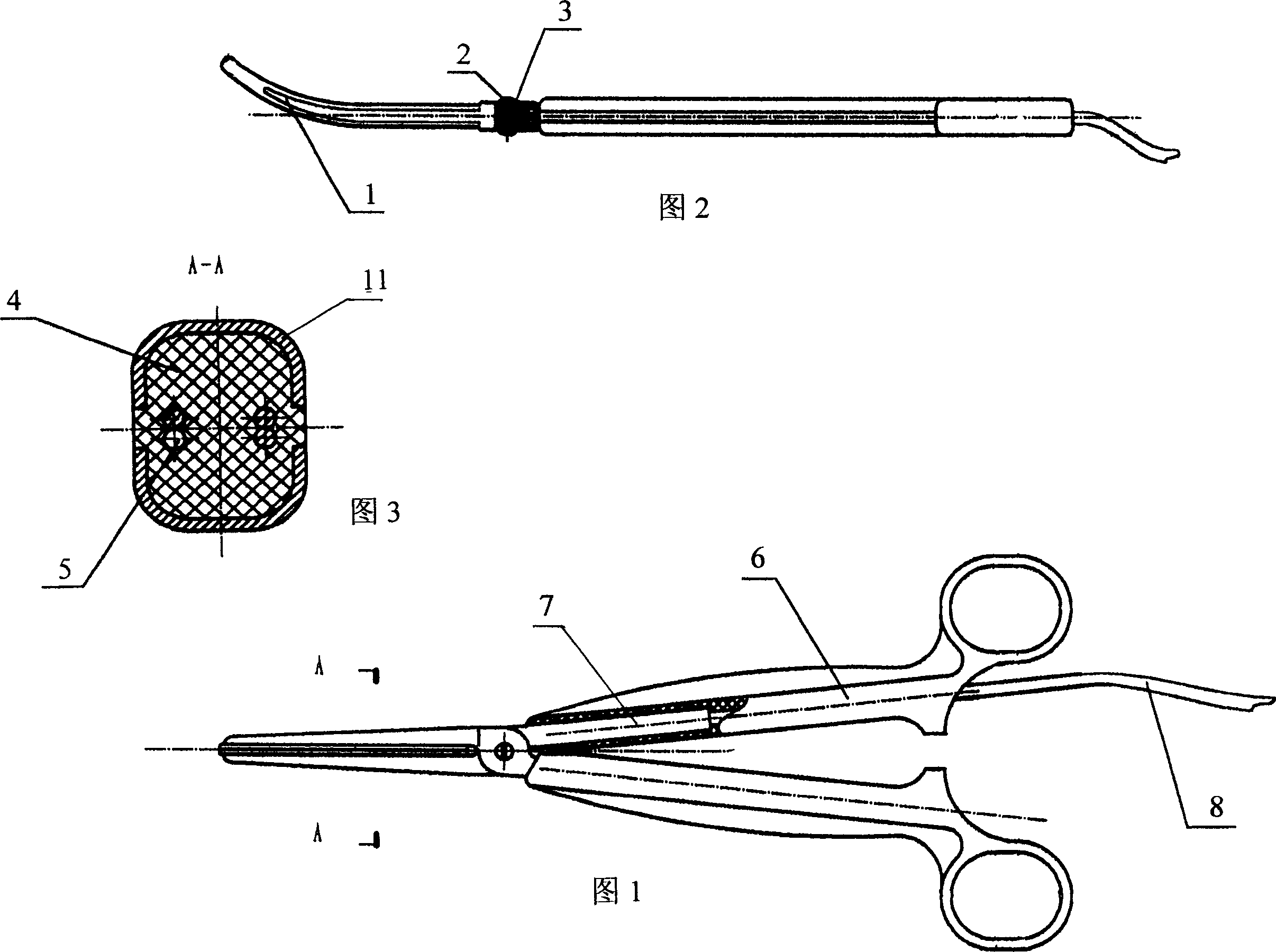

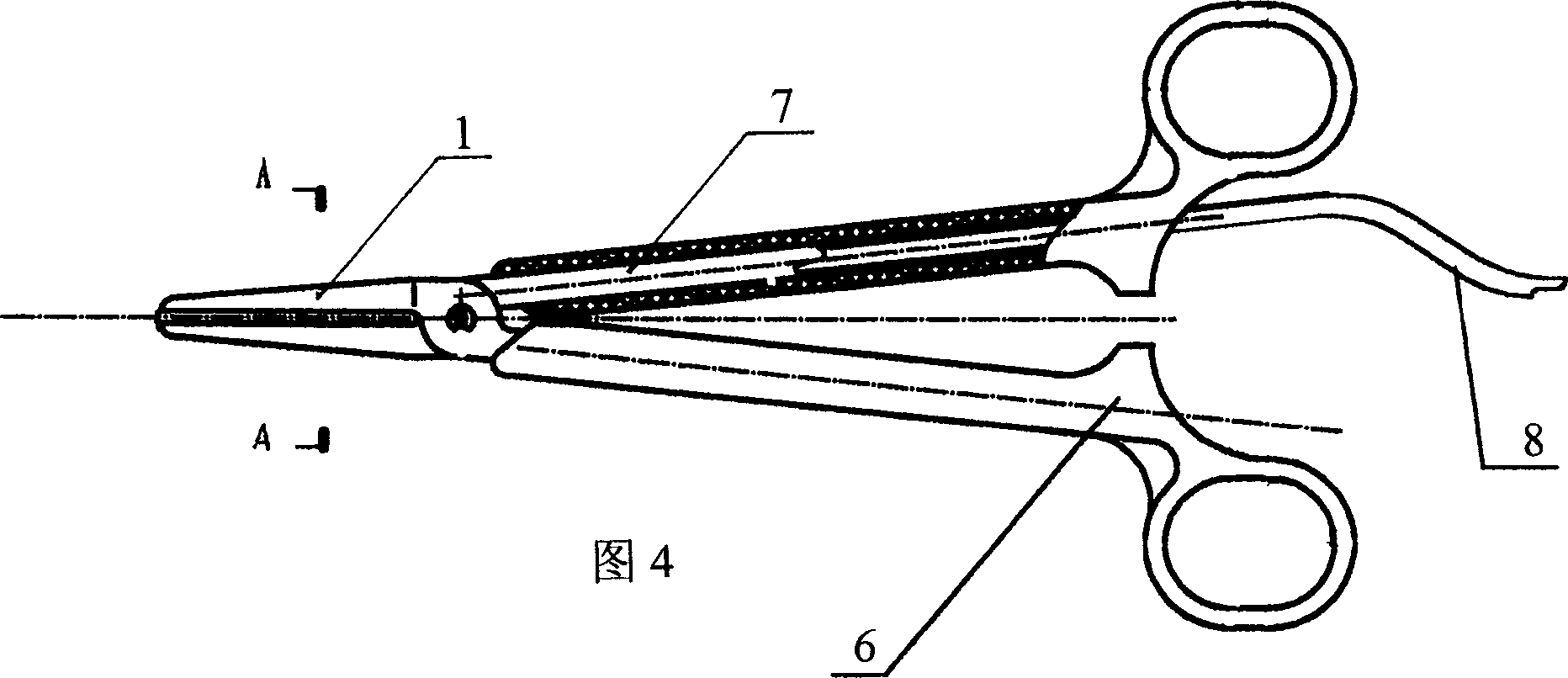

Fast ligaturing and closing electrical medical pliers and the making process

ActiveCN1608597AIncrease profitSimple and complicated processing procedureSurgical instruments for heatingCapacitancePunching

Owner:寿张根

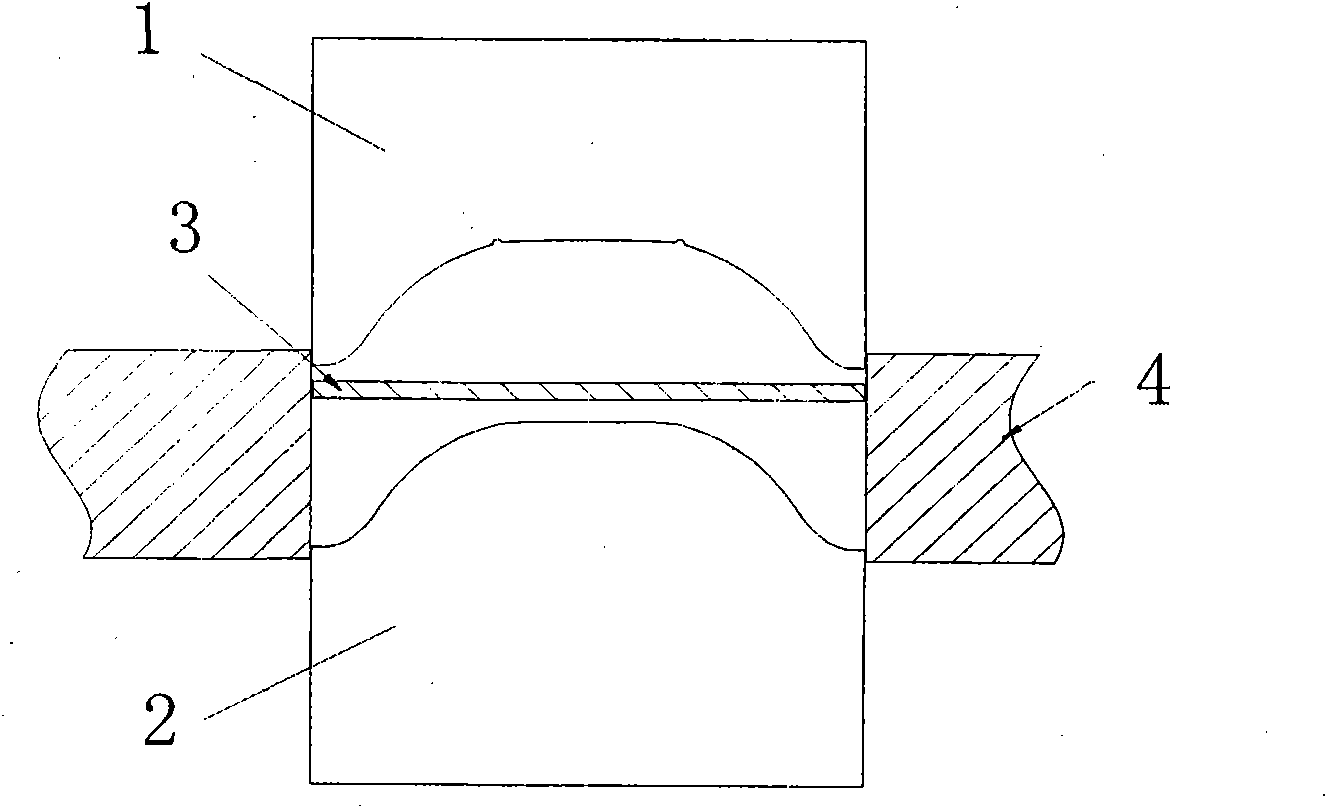

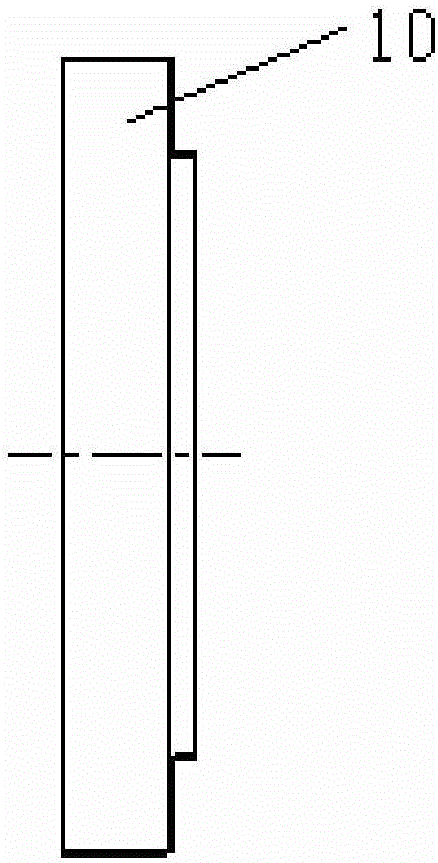

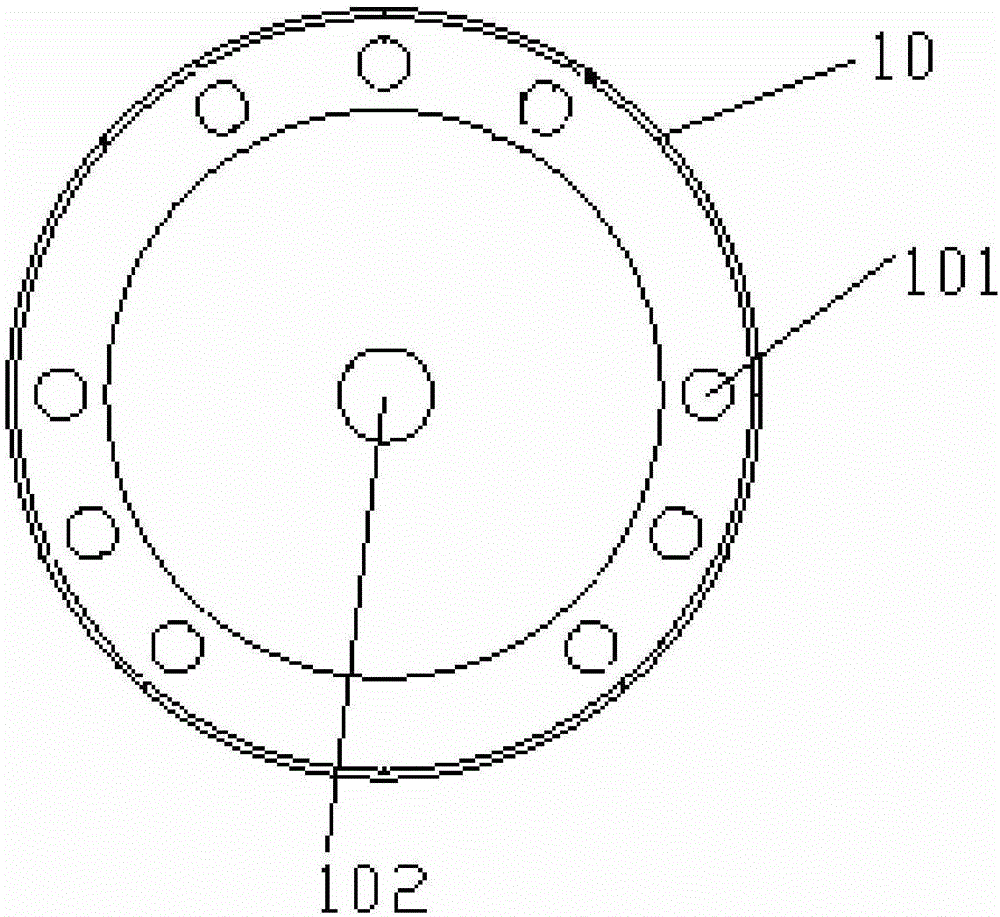

Manufacture process of bowl-shaped noble metal products and mold for manufacture process

ActiveCN102431372AFull patternHigh-qualitySpecial ornamental structuresEmbossing decorationsPunchingNoble metal

Owner:SHENYANG MINT CO LTD

Safe forcible entry and recovery method and system for lead-acid storage battery, and automatic operation method

PendingCN109786883AEasy dischargeEasy to separateSolid waste disposalWaste accumulators reclaimingRecovery methodPunching

The invention provides a safe forcible entry and recovery method and system for a lead-acid storage battery, and an automatic operation method, and relates to the technical field of the recovery processing of the lead-acid storage battery. The safe forcible entry and recovery method provided by the invention comprises the following steps that: punching: independently punching the upper cover and the shell bottom of a battery; discharging acid liquor: discharging the acid liquor in the battery from the holes; carrying out forcible entry on the upper cover and the shell bottom: independently cutting and removing the upper cover and the shell bottom; carrying out forcible entry on inter-trough polar plate connection: punching the junction of an inter-trough polar plate; and taking the polar plate and lead plaster: pushing the polar plate from the shell to be separated. Through the safe forcible entry and recovery method provided by the invention, the technical problems of lead-acid storage battery recovery in the prior art that materials are difficult in separation and recovery difficulty is big can be solved.

Owner:NINGXIA UNIVERSITY +1

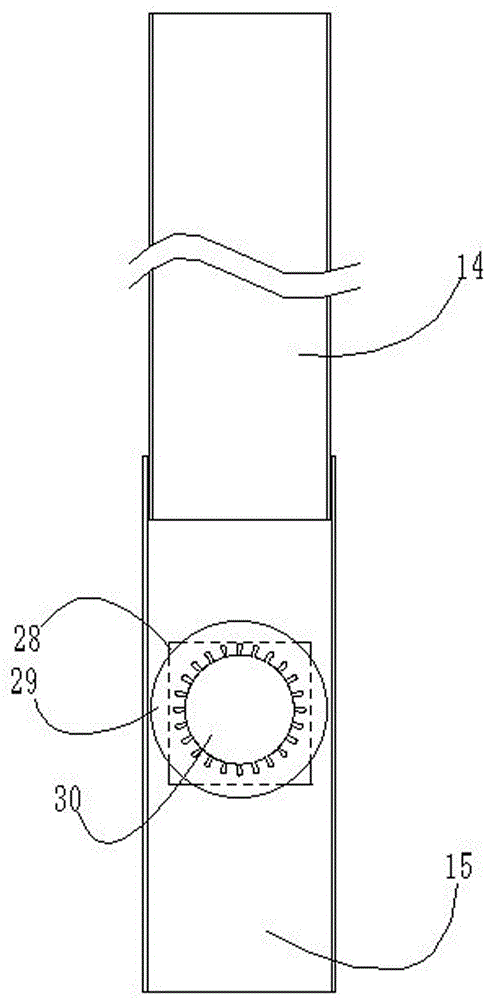

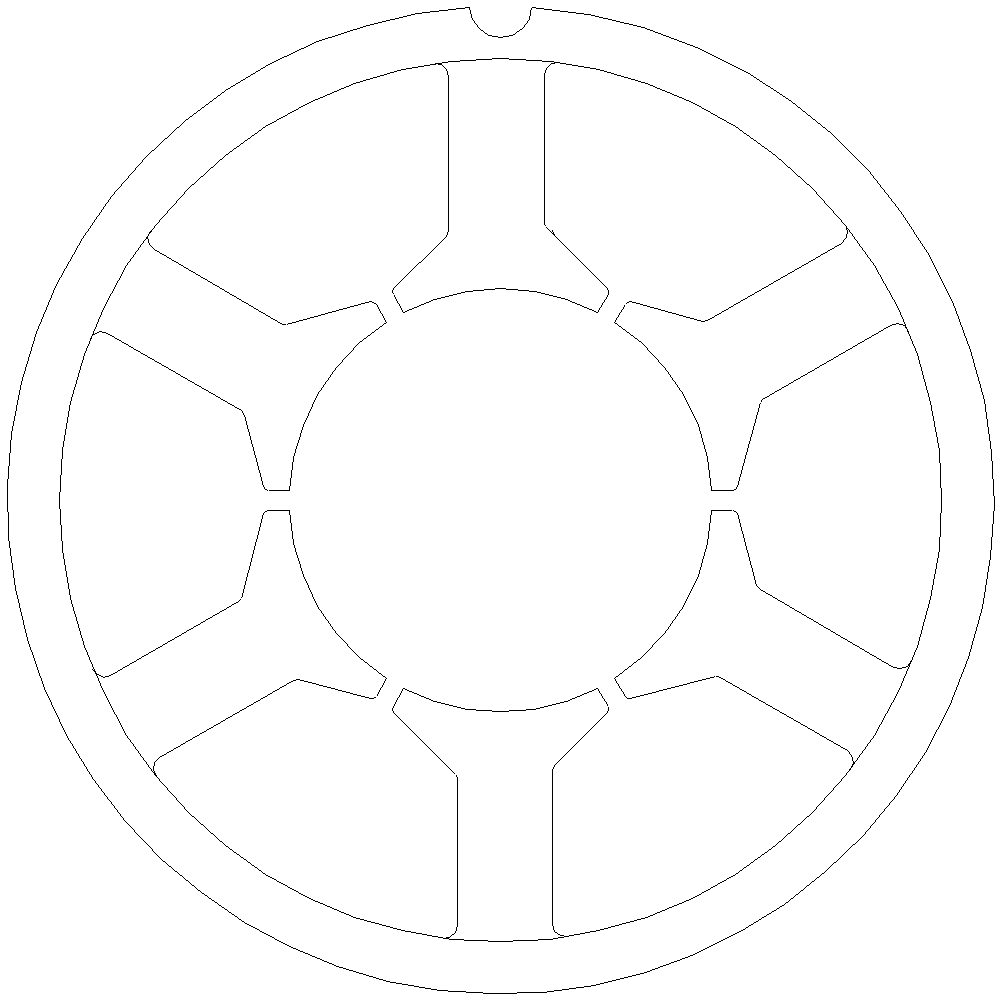

Motor punching manufacture apparatus and stator punching and rotor punching sorting device thereof

ActiveCN106270256AAvoid the labor-intensive problem of manual sortingImprove sorting efficiencyStripping-off devicesManufacturing stator/rotor bodiesPunchingEngineering

Owner:ZHENGZHOU DESHENGXIANG MOTOR MFG CO LTD

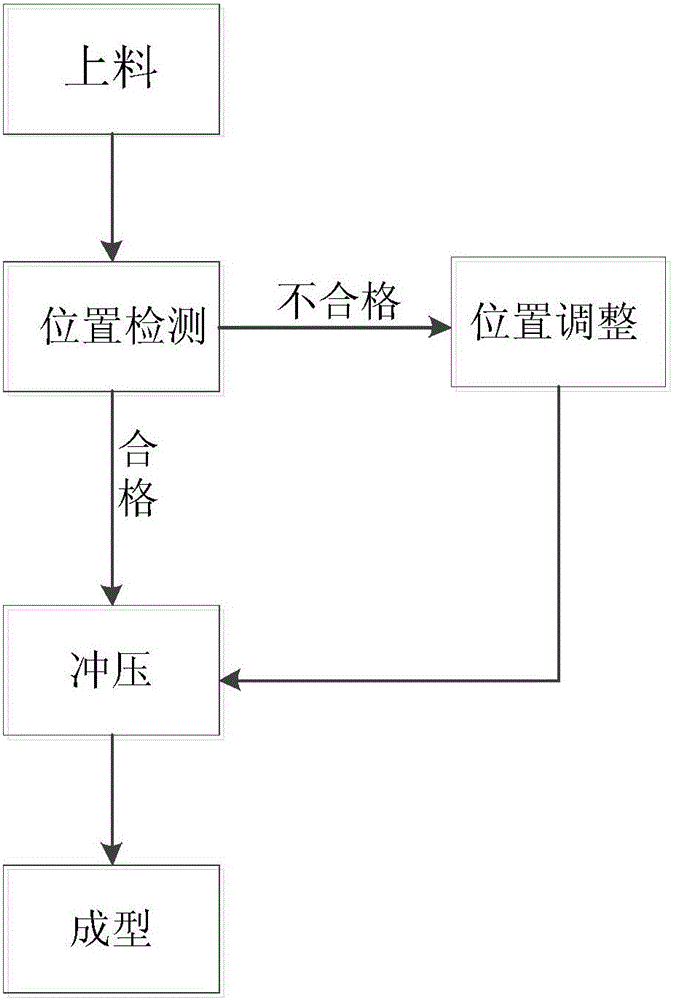

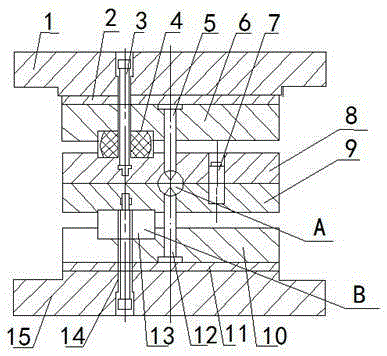

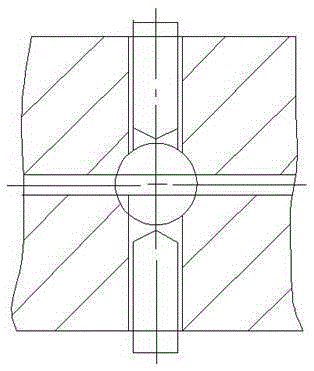

Middle frame punching die and punching technology

InactiveCN105710203AAvoid the chance of punching misalignmentQuality improvementPerforating toolsMetal working apparatusPunchingEngineering

Owner:昆山电子羽电业制品有限公司

Intelligent work clothes

InactiveCN103126125ARealize identificationRealize automatic check-inUniformsProtective garmentPunchingEngineering

The invention provides intelligent work clothes. The intelligent work clothes is characterized in that a radio frequency identification device (RFID) electronic tag is arranged on a chest of clothes in a sewing mode, and a large amount of information is stored in the RFID electronic label. When people enter into a gate of a company, a card reader at the gate can automatically read information of the RFID electronic tag of the trousers within 6m, and the intelligent work clothes can achieve automatic card punching and people identification.

Owner:XIAN ZONGHENG TEXTILE TECH

Drawing punching compound die

Owner:CHINA HANGFA SOUTH IND CO LTD

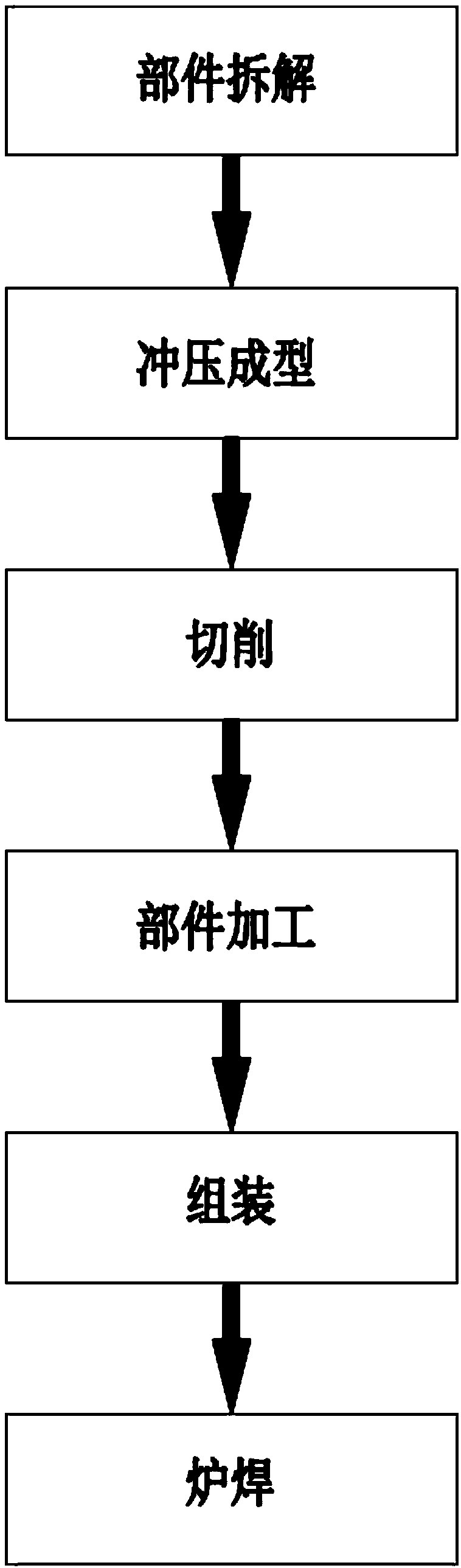

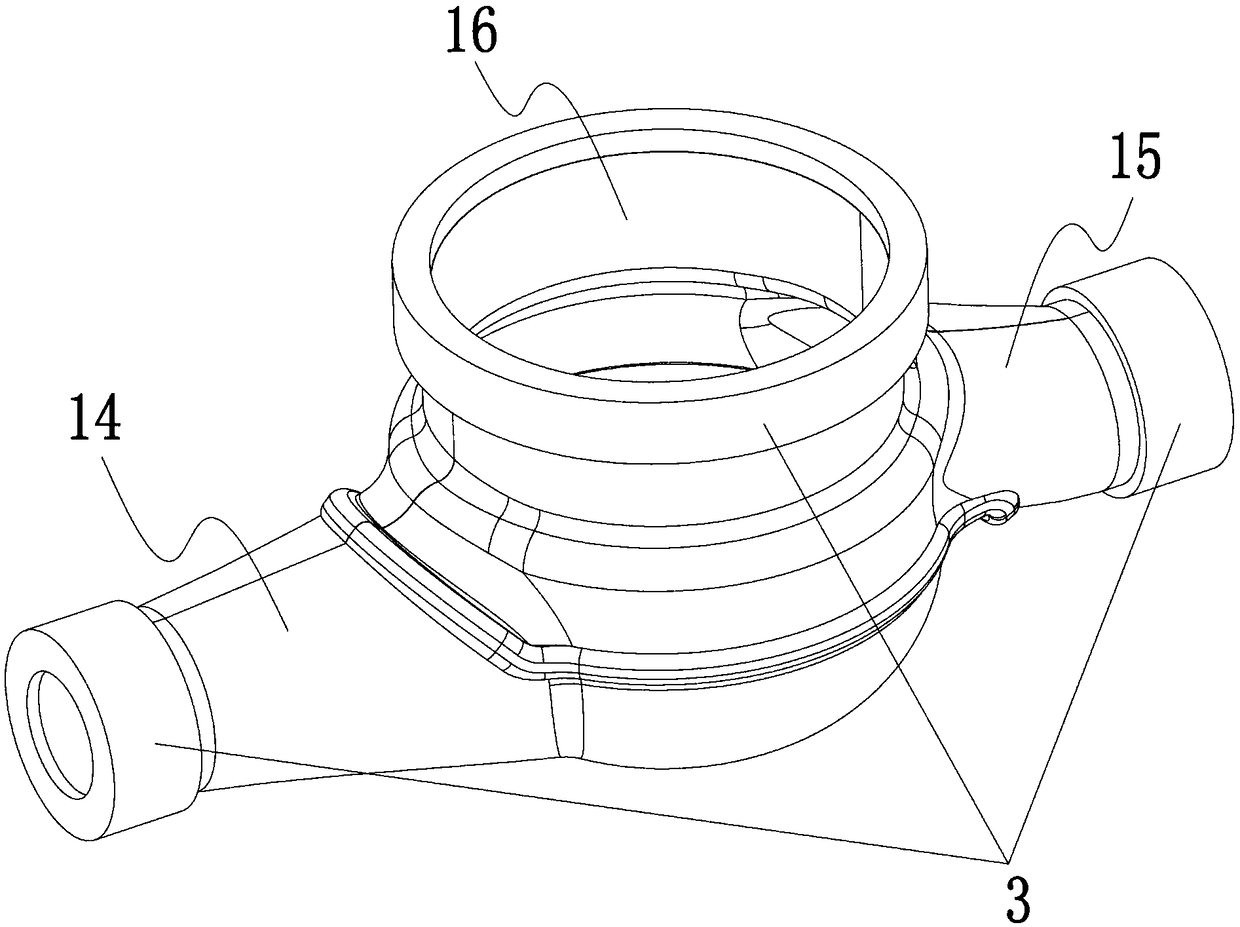

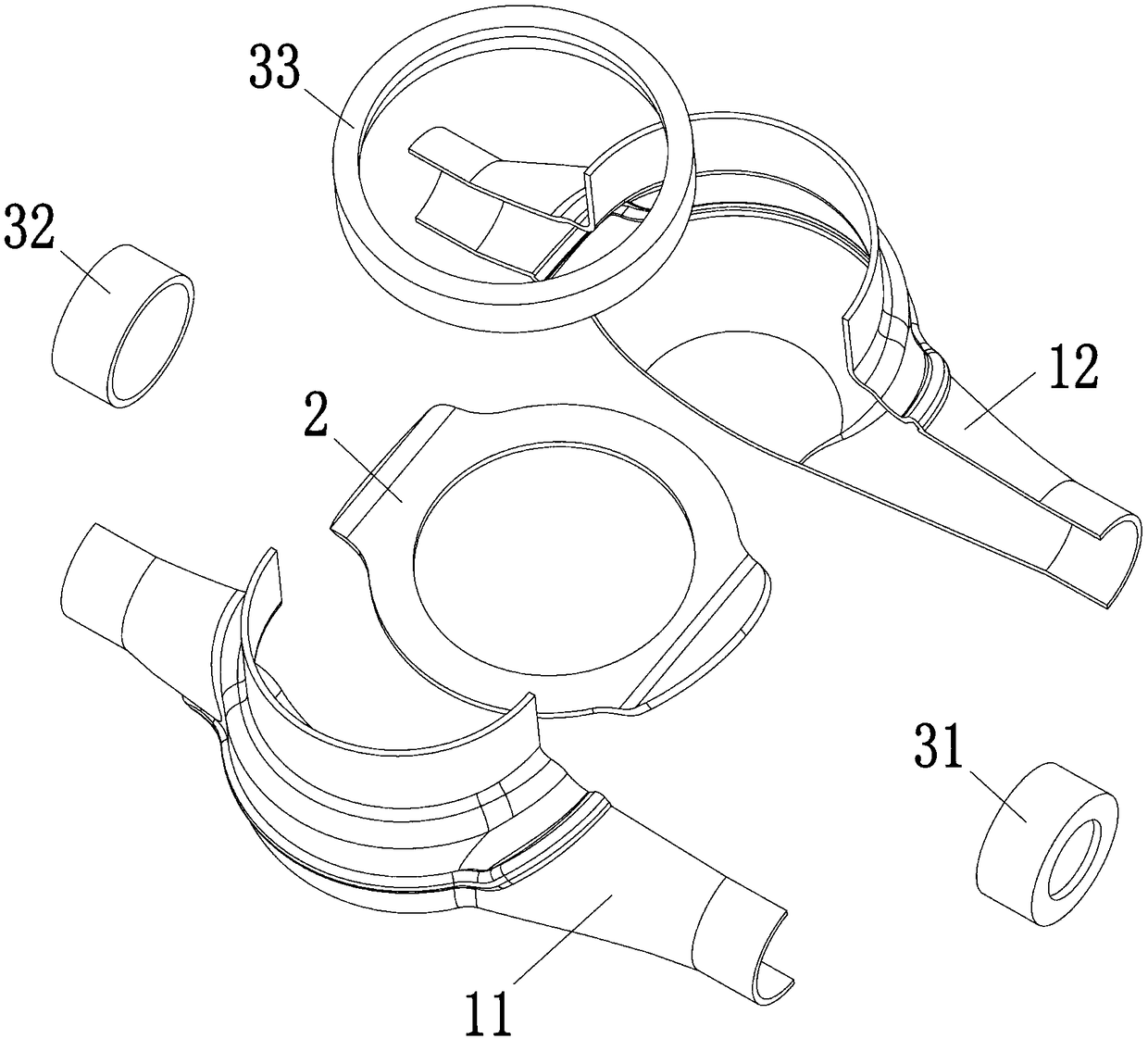

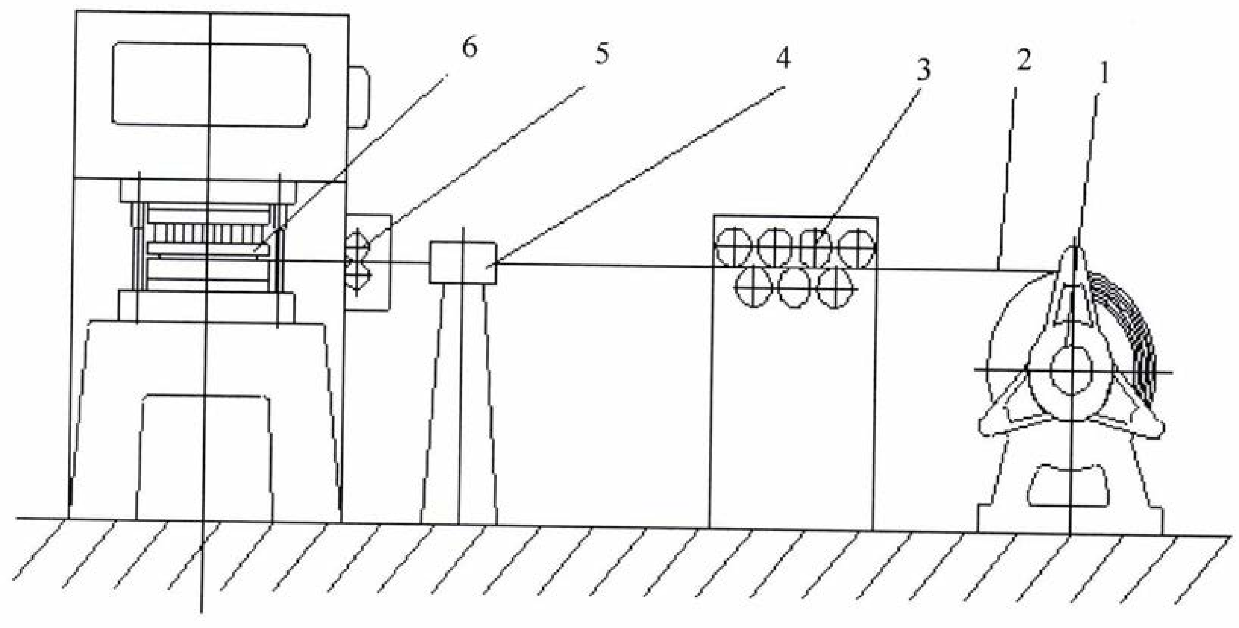

Stainless steel water meter shell blank and machining method thereof, stainless steel water meter shell and water meter

Owner:ZHEJIANG YOULIPU METROLOGY TECH CO LTD

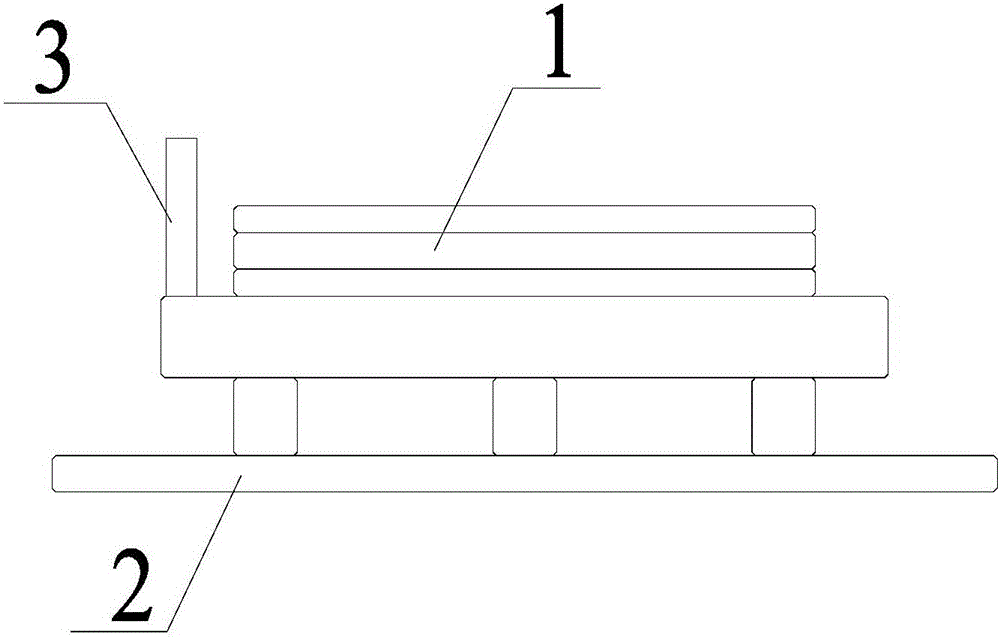

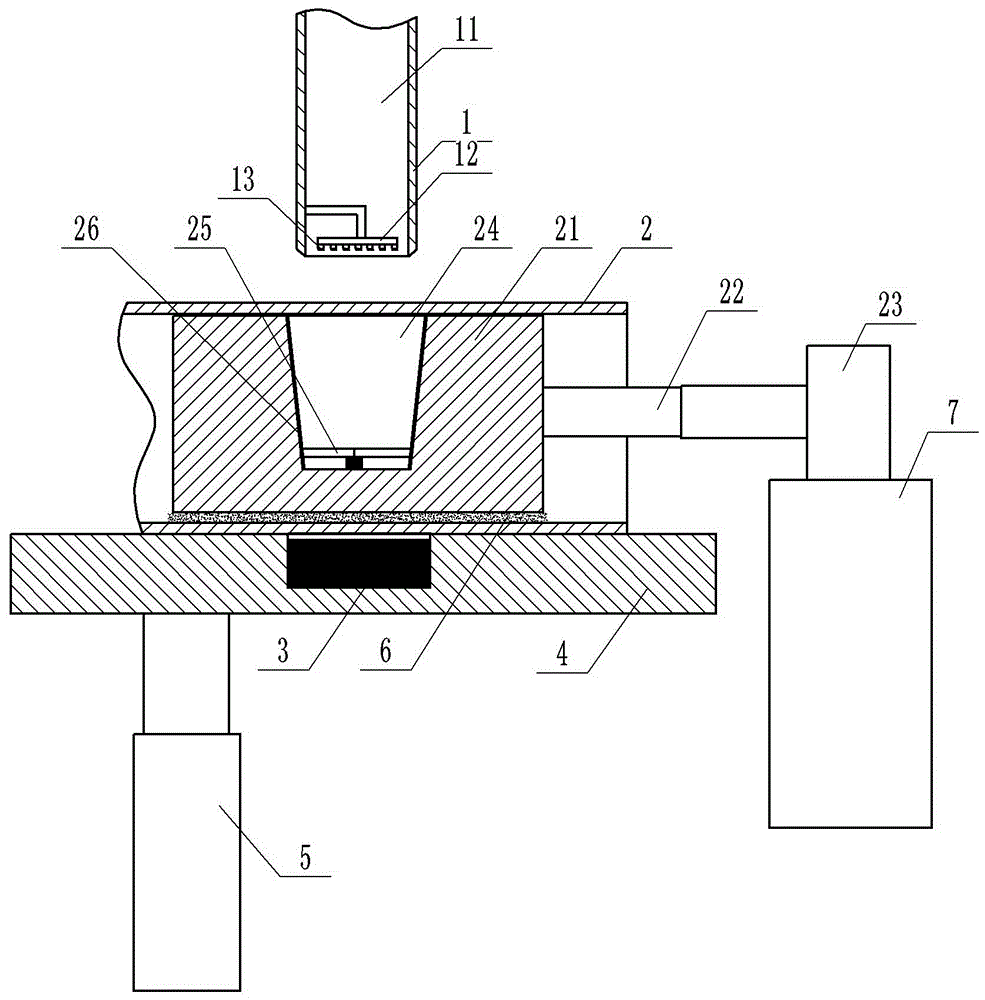

Automatic COF coil punching device

InactiveCN109109089ARealize automatic punchingImprove yieldCleaning using toolsCleaning using gasesPunchingEngineering

The invention provides an automatic COF coil punching device. The automatic COF coil punching device comprises a COF material strip, a rack, a cabinet and a UPS, and is characterized by further comprising a new material wheel, a protective film recycling wheel, a waste recycling wheel, ratchet wheels, a punching mechanism and a plurality of guide wheels, wherein the two ratchet wheels are vertically arranged on the portion, between the new feeding wheel and the protective film recycling wheel, of the rack; the punching mechanism is arranged between the two ratchet wheels; the punching mechanism comprises a mounting block, a Z-direction servo motor, a screw rod, a horizontal correction block, a finished product box and a punching die; the mounting block is vertically arranged on the rack; the Z-direction servo motor is vertically arranged on the mounting block; one end of the screw rod is connected with the output end of the Z-direction servo motor; the other end of the screw rod penetrates through a supporting block of the punching die; the other end of the screw rod and the supporting block of the punching die form a screw rod transmission structure; the horizontal correction block is horizontally connected to the rack and is rectangular; the punching die penetrates through the horizontal correction block and can move in the vertical direction through the screw rod transmission structure; and the finished product box is arranged below the punching die.

Owner:ZHEJIANG SEMIPEAK TECH CO LTD

A kind of automatic production method of elastic chain

ActiveCN106507885BReduce consumptionEven and reasonable feedingAmmunition loadingPunchingManufacturing technology

Owner:HEILONGJIANG NORTH TOOLS CO LTD

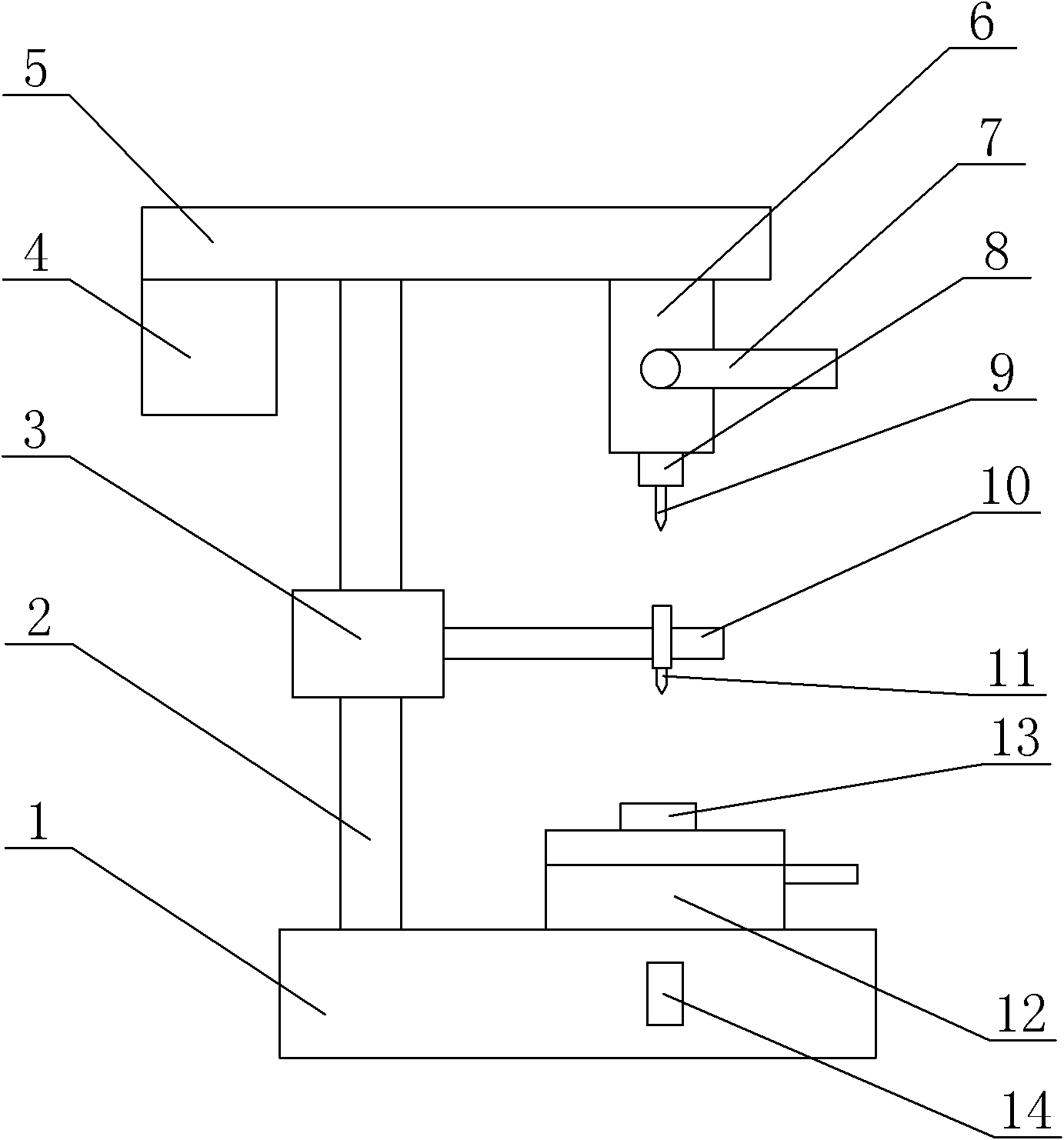

Laser positioning punching machine

InactiveCN102485388ASimple structureEasy to useDrilling/boring measurement devicesBoring/drilling machinesPunchingArchitectural engineering

Owner:XIAN DAYU PHOTOELECTRIC TECH

High-precision drilling machine punching device for circular plate

Owner:广州百士臣科技有限公司

Pipe punching equipment

Owner:CHONGQING YOUWEI PLASTIC CO LTD

Punching device capable of achieving conveying

InactiveCN107344197AImprove stabilitySimple and fast operationPerforating toolsMetal-working feeding devicesHydraulic cylinderPunching

Owner:SUZHOU HONGQIRUI AUTOMATION

Production system for soft foam die-cutting piece with large foaming holes

ActiveCN112573269AReduce contact areaAvoid bad strippingPackagingWebs handlingPunchingIndustrial engineering

The invention relates to a production system for a soft foam die-cutting piece with large foaming holes. The system comprises an auxiliary protective film discharging roller (11), a handle release film discharging roller (12), a first pre-punching attaching unit, a first punching die-cutting machine (3), a second pre-punching attaching unit, a second punching die-cutting machine (5), a finished product attaching unit and a die-cutting piece collecting roller (71). Compared with the prior art, the production system has the advantages that poor stripping is prevented, and the reject ratio of products can be reduced to almost zero.

Owner:SHANGHAI HAOBAI ZHIZAO PRECISION ELECTRONICS CO LTD

System and method for manufacturing conductive gate

InactiveCN102480848AAffect accuracyUsing optical meansConductive pattern formationPunchingEngineering

The invention discloses a system and a method for manufacturing a conductive gate. The method comprises the following steps of: printing a first group of stripes on the front side of a substrate; sintering the first group of stripes to form a first group of conductive stripes; according to the positions of the firs group of conductive stripes, determining positions which need to be punched; and drilling holes at the positions, depositing metal on the inner walls of the holes and sintering the deposited metal. Due to the adoption of a continuous printing technology in the method, high uniformity and high repeatability of the first group of manufactured stripes in the long range are ensured, the manufacturing process is simple, and the production efficiency is high. Moreover, the conductive strips are formed before punching, so that the restriction of the punched positions on the conductive stripes with strict requirements can be avoided.

Owner:SIEMENS AG

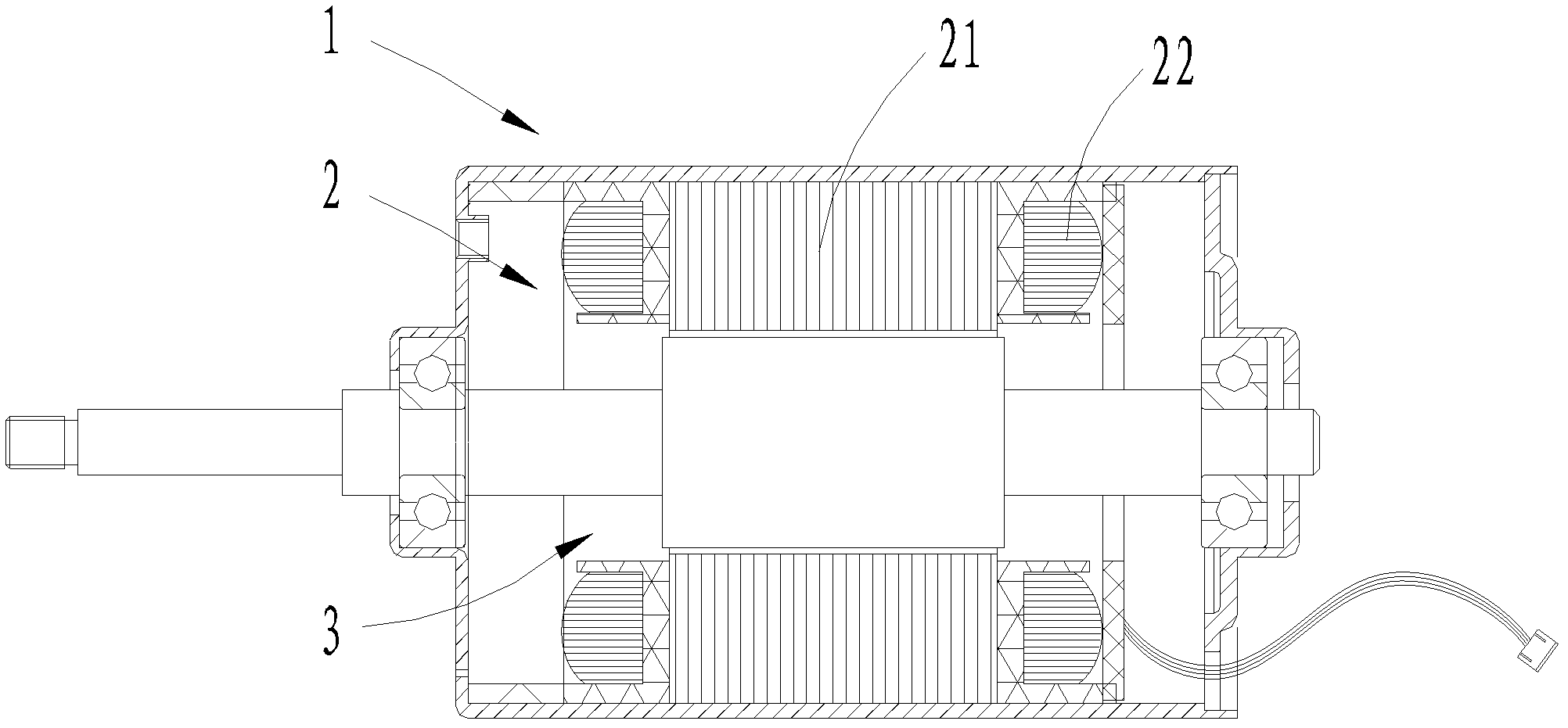

Motor

InactiveCN102437660AReduce disconnectionImprove craftsmanshipMagnetic circuit stationary partsManufacturing stator/rotor bodiesPunchingElectric machine

Owner:苏州正澳电器有限公司

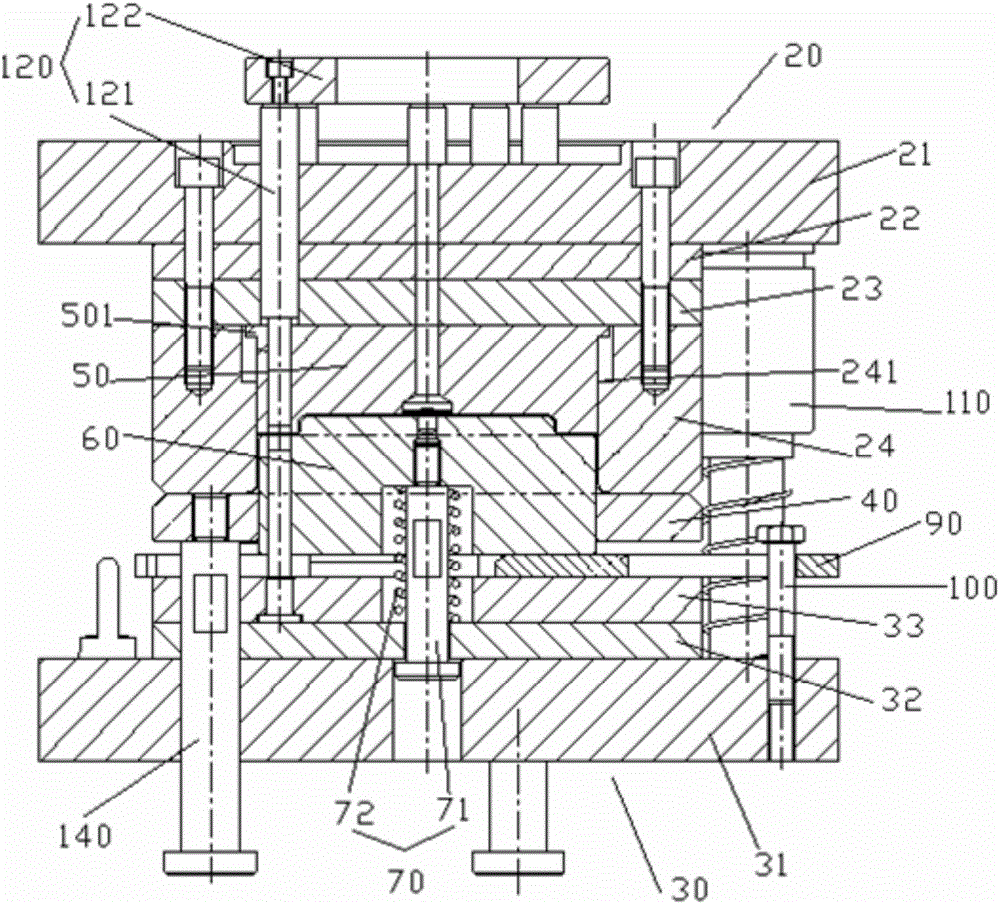

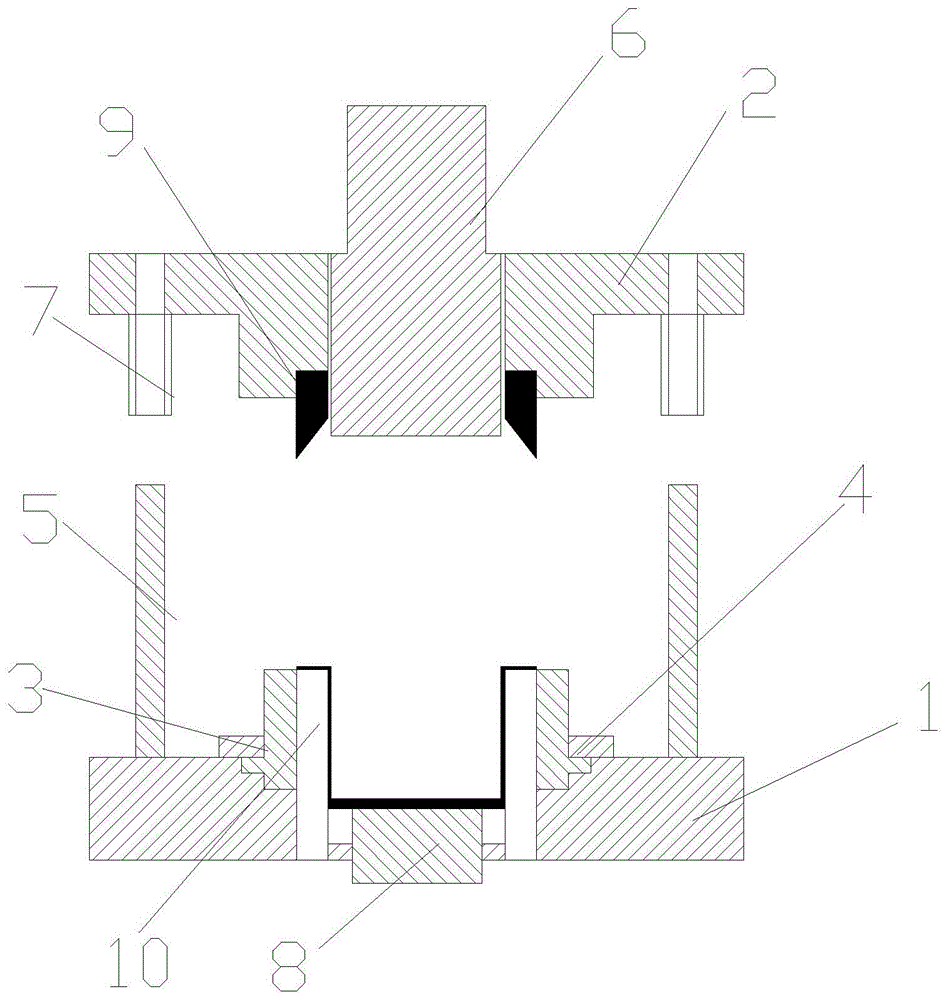

Punching forming clamp

InactiveCN104438879AGuaranteed stabilityImprove pass rateShaping toolsMetal-working feeding devicesPunchingEngineering

Owner:SUZHOU SONGSHUN HARDWARE

Non-woven fabric punching equipment capable of processing waste

InactiveCN111496902AInnovative designEasy to punchMetal working apparatusPunchingProcess engineering

Owner:温州晨曦工艺品有限公司

Plate conveying device of plate punching equipment

InactiveCN107572229APrevent deviationPrecise automatic deliveryDrilling machinesControl devices for conveyorsPunchingEngineering

Owner:ZHEJIANG YUEQIANG FURNITURE TECH CO LTD

Side punching die

Owner:宋盼锦

Combined lead screw driving device

ActiveCN105269850AImprove carrying capacityImprove transmission efficiencyPress ramMotor drivePunching

Owner:徐州艾奇机器人科技有限公司

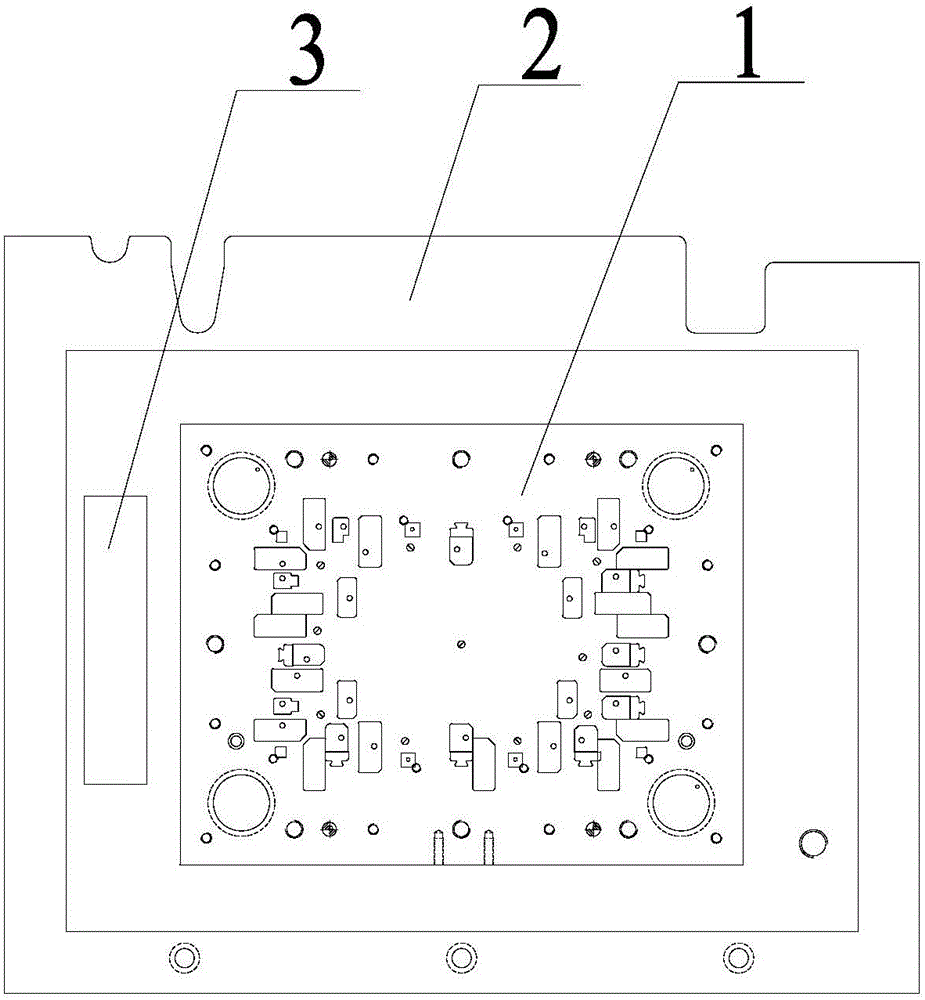

Multi-chip and multi-lap stack sandwich package structure and technique therefor

InactiveCN105633050AReduce package resistanceReduction of interconnection processSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductancePunching

Owner:JCET GROUP CO LTD

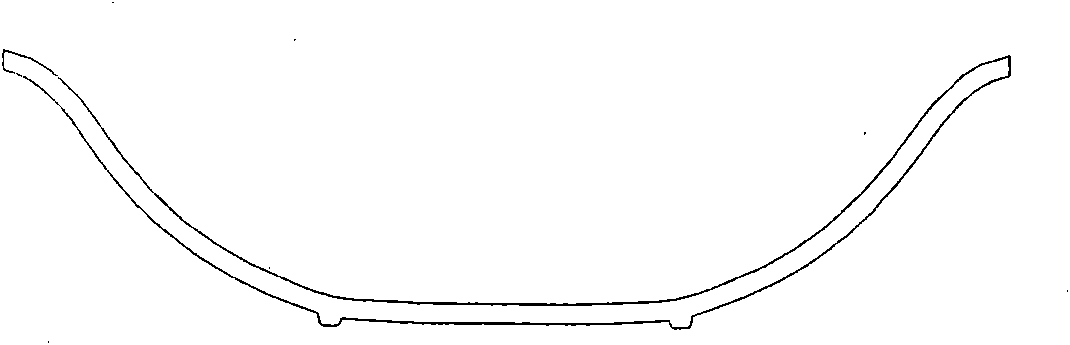

Limit returning and guiding integral structure

Owner:CHERY AUTOMOBILE CO LTD

Numerical control punching die structure for round pipe

Owner:CHANGZHOU JINHAIJI MACHINERY MFG

Nickel-copper alloy seamless tube

The invention discloses a nickel-copper alloy seamless tube. The nickel-copper alloy seamless tube comprises the following components: copper, iron, manganese, silicon, silicon, sulfur and the balance of nickel; the manufacturing steps of the nickel-copper alloy seamless tube comprise the following steps of: (1), preparing blank and checking the performances of the blank; (2), heating up the ingredients and punching; (3), polishing the blank; (4), carrying out thermal expansion molding treatment on the blank; (5), heating up the blank; (6), carrying out straightening, internal grinding, external grinding and flaw detection on the blank; and (7), carrying out checking, spraying, packaging, weighing and stock removal on the finished product. According to the nickel-copper alloy seamless tube disclosed by the invention, the surface corrosion performances of the product are improved, the performance standards are better, and the manufacturing cost is lowered; and moreover, the production process is simple.

Owner:SUZHOU BEST METAL PROD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap