Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Improve corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for enhancing surface of magnesium aluminium alloy by laser remelting

InactiveCN101532134AHigh strengthImprove corrosion resistanceMolten spray coatingSuperimposed coating processOxygenLaser beams

The invention relates to a method for enhancing the surface of magnesium aluminium alloy by laser remelting, aiming at enhancement processing of the surfaces of magnesium aluminium alloy plates and magnesium aluminium alloy rods by the methods of flame spraying of alloyed powder and laser remelting. The method is characterized by cleansing the surface of the magnesium aluminium alloy, carrying out oxy-acetylene flame spraying on the alloyed powder, namely aluminium nickel alloy powder, nickel-chromium-boron-silicon-iron master alloy powder and neodymium powder, carrying out remelting and curing on the surface of the magnesium aluminium alloy on a laser processor, carrying out omnibearing radiation by laser beams according to trace curves set by computer programs so that a nickel base alloy layer is melted and cured on the surface of the magnesium aluminium alloy to form the alloy layer, therefore, the hardness of the surface of magnesium aluminium alloy is greatly improved by 8-10 times as high as that before processing, the wearing resistance and corrosion resistance of the surface of magnesium aluminium alloy are greatly improved respectively by 56% and 56.4%. The method has short process flow, easy realization, safety, stability and reliability and firm solid melting layer, is not easy to fall off and can enhance the surfaces of the magnesium aluminium alloys with various profiles.

Owner:TAIYUAN UNIV OF TECH

Biodegradable medical magnesium alloy as well as preparation method thereof

The invention discloses a biodegradable medical magnesium alloy which consists of the following matters in percentage by weight: 1.0-3.0% of Zn, 0.20-1.50% of Y, 0.40-1.50% of Nd, 0.30-0.50% of Zr and the balance of Mg and inevitable impurity elements. Meanwhile, the invention discloses a preparation method of the alloy. The magnesium alloy is smelted to prepare common magnesium alloy. The use level of Zn, Y and Nd in furnace burden is 1.2-1.4 times the content of Zn, Y and Nd in the magnesium alloy, and the use level of Zr is 2-2.5 times the content of Zr in the magnesium alloy. According to the invention, the magnesium alloy overcomes the problems of cytotoxicity, excessively high corrosion rate and the like by adding rare earth elements Y, Nd and Zr into a magnesium-zinc alloy, and the potential difference with a matrix is reduced due to a lot of uniformly dispersed and distributed nano MgZn particle phases in the matrix by extrusion and processing, so that the corrosion resistance of the alloy is greatly improved, and the alloy has better mechanical properties.

Owner:ZHENGZHOU UNIV

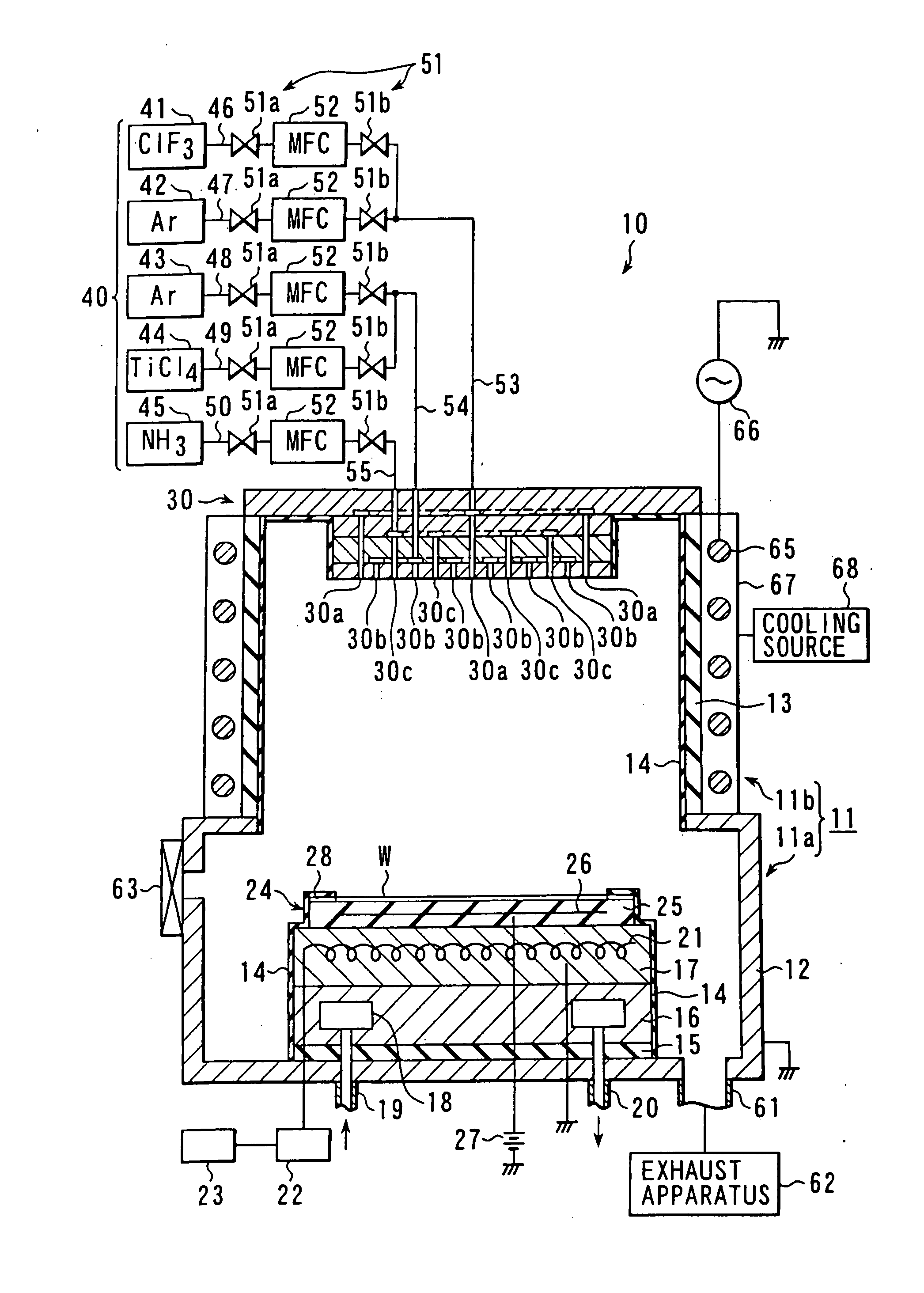

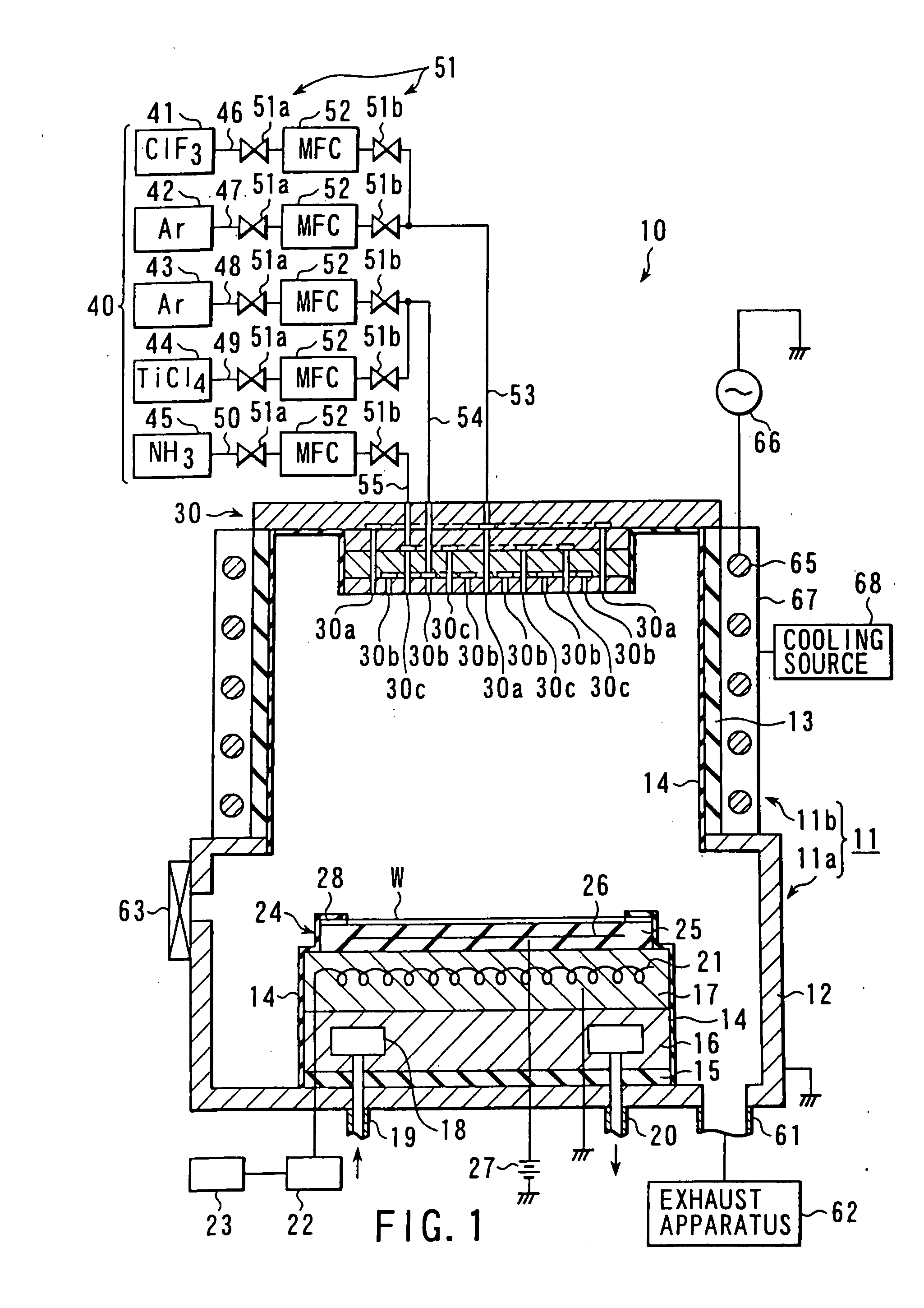

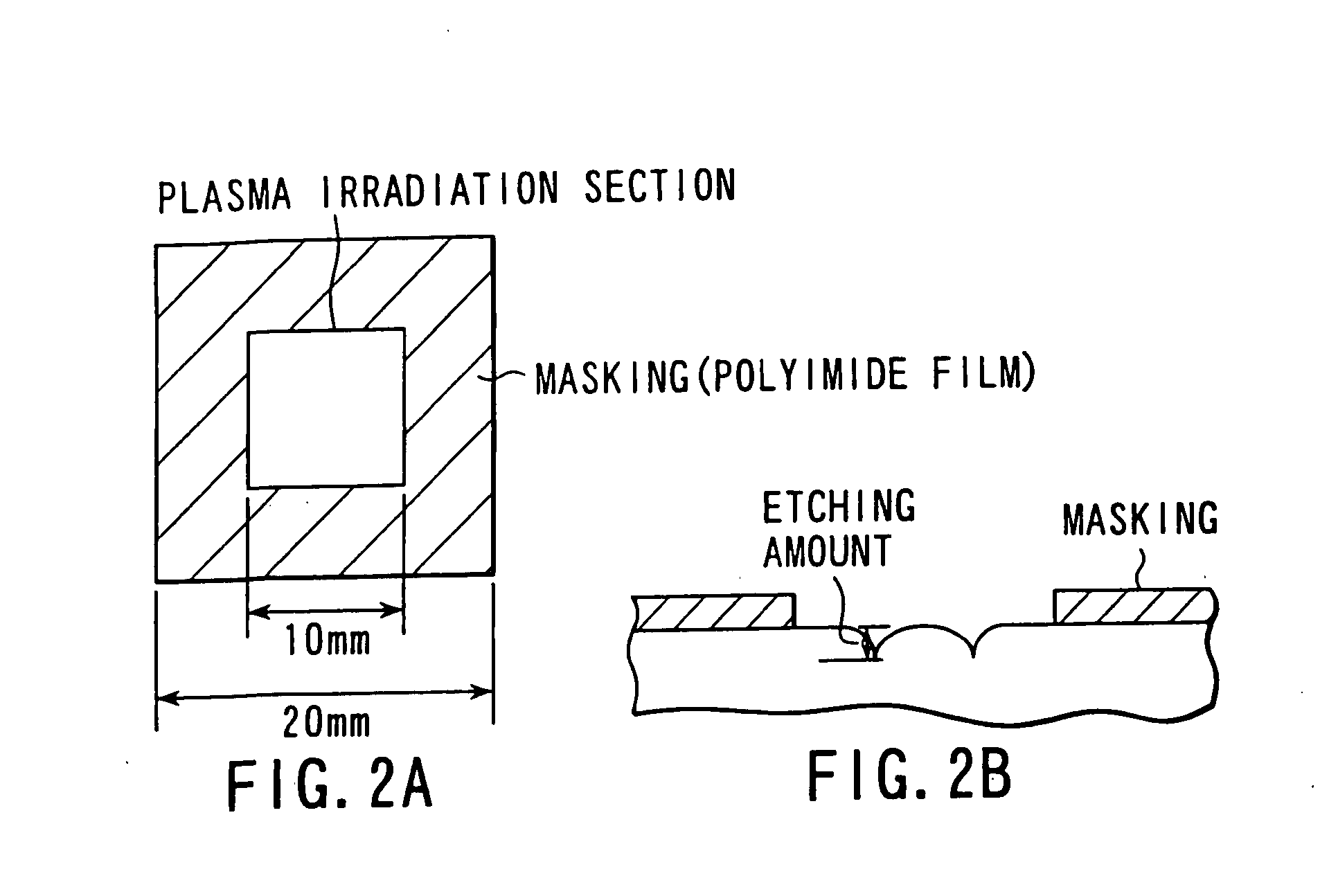

Processing apparatus with a chamber having therein a high-corrosion-resistant sprayed film

InactiveUS20080070032A1High-corrosion-resistant propertyLess depositionLiquid surface applicatorsMolten spray coatingCorrosion resistantEngineering

A processing apparatus of the present invention has a mounted chamber holding a semiconductor wafer and having members for work-processing the substrate under any of heating, plasma and process gas or a combination of them, in which a film of Al2O3 and Y2O3 is formed on an inner wall surface of the chamber and on those exposed surface of the members within the chamber and has a high-corrosion resistance and insulating property and, when the process gas is introduced onto a processing surface of a semiconductor wafer and diffused into it, any product is less liable to be deposited on a plasma generation area and on those members held within the chamber.

Owner:TOKYO ELECTRON LTD

Coating compositions having improved "direct to metal" adhesion and method therefore

InactiveUS20040071887A1Good adhesionImprove corrosion resistanceMetallic material coating processesPolyester coatingsCorrosionMetallic substrate

Owner:BASF CORP

Material and method used for TA2/0Cr18Ni9Ti welded by high-entropy effect

InactiveCN102676904AImprove performanceSimple preparation stepsWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceAlloy

The invention discloses a high-entropy interlayer alloy, which comprises the following components in atomic percentage: 5-10% of Ti, 5-10% of Fe, 25-30% of Al, 15-20% of Ni, 30-35% of Cu and 5-10% of Cr. The invention also discloses a method for welding TA2 / 0Cr18Ni9Ti by the high-entropy effect, which comprises the following steps that: high-entropy interlayer alloy is placed between the two plates to be welded, the high-entropy interlayer alloy is in a foil folding structure, and the high-entropy interlayer alloy and local parent metal are subjected to heat fusing by an interface resistor ina resistance spot welding mode, so that the high performance welding of TA2 / 0Cr18Ni9Ti can be realized. According to the method and the high-entropy interlayer alloy of the method, which are disclosed by the invention, the high-entropy interlayer alloy has the advantages of favorable strength, toughness and corrosion resistance, is easy to process and form and is convenient to weld and assembly. The preparation method has the advantages of simple step and low manufacture cost and is convenient to popularize.

Owner:XIAN UNIV OF TECH

Magnesium alloy surface zinc-calcium series phosphating solution and conversion treatment process thereof

InactiveCN101671824AImprove corrosion resistanceStrong adhesionMetallic material coating processesMg alloysPhosphate

The invention discloses magnesium alloy surface zinc-calcium series phosphating solution and a conversion treatment process thereof; the magnesium alloy surface phosphating solution is aqueous solution formed by the following constituents, namely, every liter solution contains: 10-30g of disodium hydrogen phosphate, 4-6g of zinc nitrate, 2-4g of sodium nitrite, s0.5-2g of sodium fluoride, and 0.-2g of calcium nitrate; the process for carrying out surface conversion treatment to the phosphating solution comprises the following process flows: alkaline washing and degreasing->rinsing->acidity activation->rinsing->surface activation->rinsing->phosphating->rinsing->drying; the working temperature is 40-70 DEG C, and the time is 5-60 minutes. The conversion treatment process can obtain phosphateconversion coating on the surface of the magnesium alloy, wherein the conversion coating has good protectiveness, is fine and uniform and stable, and has strong adhesive force, and can improve the corrosion-resisting property of magnesium alloy parts; the conversion treatment process is stable and easy to control, and has low cost.

Owner:CHONGQING UNIV OF TECH

Ceramics particle strengthened composite material lining metal tube and manufacturing method thereof

InactiveCN101900227AExtended service lifeImprove wear resistanceCorrosion preventionPipe protection against corrosion/incrustationPolyesterManufacturing technology

The invention discloses a ceramics particle strengthened composite material lining metal tube and a manufacturing method thereof, belonging to the field of composite wear-resistant tubes. 4,4-Diphenylmethane diisocyanate (MDI), polyester glycol, 1,4-butanediol (BD), ceramics particles and the like serve as raw materials to prepare composite material liquid castables, and a centrifugal casting technology is adopted to cast polyurethane base ceramics particle strengthened composite material lining layers on the inner wall of an outer thimble. The invention has the beneficial effect that the prepared ceramics particle strengthened composite material lining metal tube has excellent abrasive resistance and corrosion-resistance and greatly improves service life. The raw materials of the invention are easy to be obtained, manufacturing technology is simple, cost is low and economic benefit is obvious and practical application and mass production are beneficial for factories.

Owner:XUZHOU SHENGHAI MACHINERY MFG TECH

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

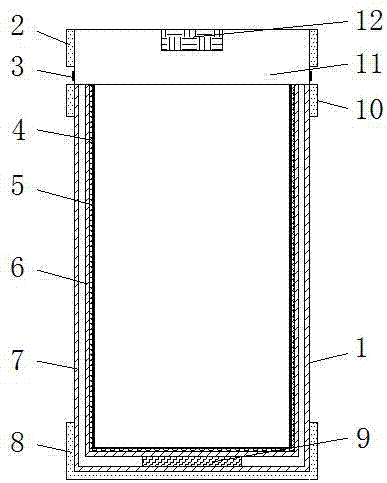

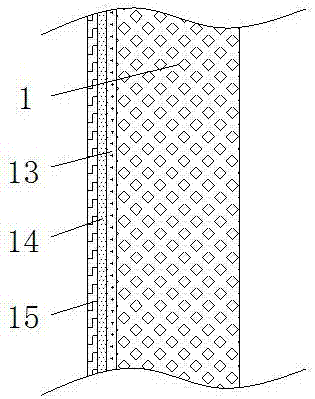

Solar photoelectric photo-thermal integrated assembly and solar combined heat and power generation system thereof

InactiveCN103594538AEliminates the effects of thermal contact resistanceEliminate the effects ofPV power plantsEnergy industryCells panelMetal sheet

The invention relates to a solar photoelectric photo-thermal integrated assembly and a solar combined heat and power generation system of the solar photoelectric photo-thermal integrated assembly. The solar photoelectric photo-thermal integrated assembly is characterized by comprising a photovoltaic cell panel provided with a metal outer frame, a metal sheet type heat exchanger and a heat-preservation material layer, wherein the metal sheet type heat exchanger and the heat-preservation material layer are sequentially arranged on the back surface of the photovoltaic cell panel in parallel and in an overlapped mode, and are rapidly fixed in the metal outer frame of the photovoltaic cell panel through a metal fixing clamp, and the standard photovoltaic cell panel can be rapidly modified into the photoelectric photo-thermal integrated assembly. The photoelectric photo-thermal integrated assembly has the advantages of being compact in structure, high in efficiency, small in pressure loss, light in weight, flexible to install, high in pressure bearing performance, resistant to corrosion, low in cost and the like, further reduces the initial investment and installation space of a medium and low temperature solar thermoelectric system, lowers the operation expenses of the system, and is suitable for civil and industrial occasions requiring for both heat and power.

Owner:SHANGHAI LVJIAN ENERGY TECH

Copper/cerium-containing antimicrobial stainless steel and preparation method thereof

The invention discloses a copper / cerium-containing antimicrobial stainless steel and a preparation method thereof. The copper / cerium-containing antimicrobial stainless steel comprises the following chemical components in percentage by weight: at most 0.08% of C, at most 1% of Si, at most 2.00% of Mn, less than 0.045% of P, less than 0.030% of S, 17.5-20.0% of Cr, 8-11% of Ni, 0.5-2.8% of Cu, 0.01-0.45% of Ce, and the balance of Fe and inevitable impurities. The stainless steel is molten in an induction furnace after smelting, and is subjected to aging high-temperature diffusion heat treatment composed of 20-minute 1180 DEG C solid solution and 1-hour 685 DEG C thermal insulation so as to precipitate the antimicrobial phase epsilon-Cu and Ce, thereby endowing the stainless steel with antimicrobial property. The steel grade has stainless steel performance and broad-spectrum antibacterial property; the corrosion resistance, wear resistance, strength, toughness, oxidation resistance and other comprehensive properties of the stainless steel are improved; and the production technique is simple, has great utilization value in industry, and is suitable for industrial production.

Owner:SHANGHAI UNIV

A microwave-absorbing corrosion-resistant powder material and a preparation method thereof

InactiveCN108889939AReduce self-healing abilityMaintain electromagnetic propertiesOther chemical processesTransportation and packagingMesoporous silicaMetal particle

The invention discloses a corrosion-resistant powder material capable of absorbing microwave and a preparation method thereof, wherein the powder material is a core-shell structure, the core-shell structure comprises a shell and a core, the shell is a mesoporous silicon dioxide layer, the core is magnetic metal particles, a corrosion inhibitor is filled between the shell and the core, and the particle size of the magnetic metal particles is 0.6 1 micron, is iron carbonyl and nickel carbonyl, or a composite of iron carbonyl and cobalt carbonyl, the weight ratio of iron carbonyl to nickel or cobalt is 8: 1 4: 1. The invention can effectively solve the problems of insufficient microwave absorption and deterioration of corrosion resistance of conventional coatings.

Owner:SHANDONG GEWU NEW MATERIAL TECH CO LTD

Ultra-low carbon martensitic stainless steel seamless tube and manufacturing method thereof

InactiveCN108277438AHigh tensile strengthHigh yield strengthFurnace typesHeat treatment furnacesMartensitic stainless steelHigh pressure

The invention discloses an ultra-low carbon martensitic stainless steel seamless tube. The ultra-low carbon martensitic stainless steel seamless tube is prepared from ultra-low carbon martensitic stainless steel. The ultra-low carbon martensitic stainless steel is prepared from the following components in percentage by mass: less than or equal to 0.03% of C, 0.1-0.5% of Si, 0.2-0.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.002% of S, 12.2-13.2% of Cr, 5.2-5.7% of Ni, 1.9-2.1% of Mo, 0.1-1.6% of Cu and the balance of Fe and other impurities. The seamless tube can be suitable for oil and gas fields. The invention also provides a manufacturing method of the seamless tube. The manufacturing method comprises the following steps: smelting; tube blank thermal processing;steel tube thermal processing; and thermal treatment, wherein the heating temperature of tube blank thermal processing is 1200-1280 DEG C, the heating temperature of tube manufacturing by means of anextruding method is 1150-1250 DEG C, the heating temperature of tube manufacturing by means of a perforating cold rolling method is 1200-1280 DEG C, and the temperatures for thermal treatment are as follows: quenching at 900-1050 DEG C and tempering at 550-680 DEG C. The seamless tube provided by the invention has excellent strength and corrosion resistance in a CO2 and Cl<-> coexisting corrosionenvironment and in high-temperature and high pressure conditions.

Owner:TAIYUAN IRON & STEEL (GRP) CO LTD

Glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and preparation method thereof

The invention provides glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and a preparation method thereof. The glass ceramics use the tailings obtained by nickel-molybdenum ore dressing and smelting as main raw materials and silica or quartz sand (SiO2), limestone or calcite (CaCO3), sodium carbonate (Na2CO3), alumina (Al2O3), potassium carbonate (K2CO3), magnesium oxide (MgO) and calcium fluoride (CaF2) as auxiliary raw materials. The preparation method comprises the steps of grinding the tailings obtained by nickel-molybdenum ore dressing and smelting and the auxiliary raw materials, sieving the powder with a 20-mesh sieve, and mixing the powder uniformly in a mixer to obtain a base batch; melting the base batch at the temperature of 1450-1550 DEG C, homogenizing and clarifying the melt to obtain qualified molten glass, and then forming a base glass plate or granules through moulding by casting or water quenching of the molten glass; finally filling the base glass plate or the granules into a mould, and then carrying out crystallization thermal treatment, thus obtaining the glass ceramics prepared from the tailings obtained by nickel-molybdenum ore dressing and smelting. The preparation process is simple in operation course and has the effects of not only expanding the way of resource comprehensive utilization of the tailings obtained by nickel-molybdenum ore dressing and smelting but also reducing the environmental pollution of the tailings.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Fuel cell separator

PendingCN109962255AImprove corrosion resistanceSuppression of increase in contact resistanceCollectors/separatorsFinal product manufactureCarbon filmChemistry

Owner:TOYOTA JIDOSHA KK

Multi-runner aluminum flat pipe for heat radiation

InactiveCN102829665AImprove corrosion resistanceImprove heat transfer efficiencyTubular elementsAluminiumCorrosion

Owner:范良凯

Surfacing AlCrCuFe2.5NiTix corrosion-resistant high-entropy alloy and preparation method thereof

PendingCN113996970AImprove corrosion resistanceLow costSoldering mediaWelding/cutting media/materialsAl elementCorrosion resistant

Owner:SHENYANG POLYTECHNIC UNIV

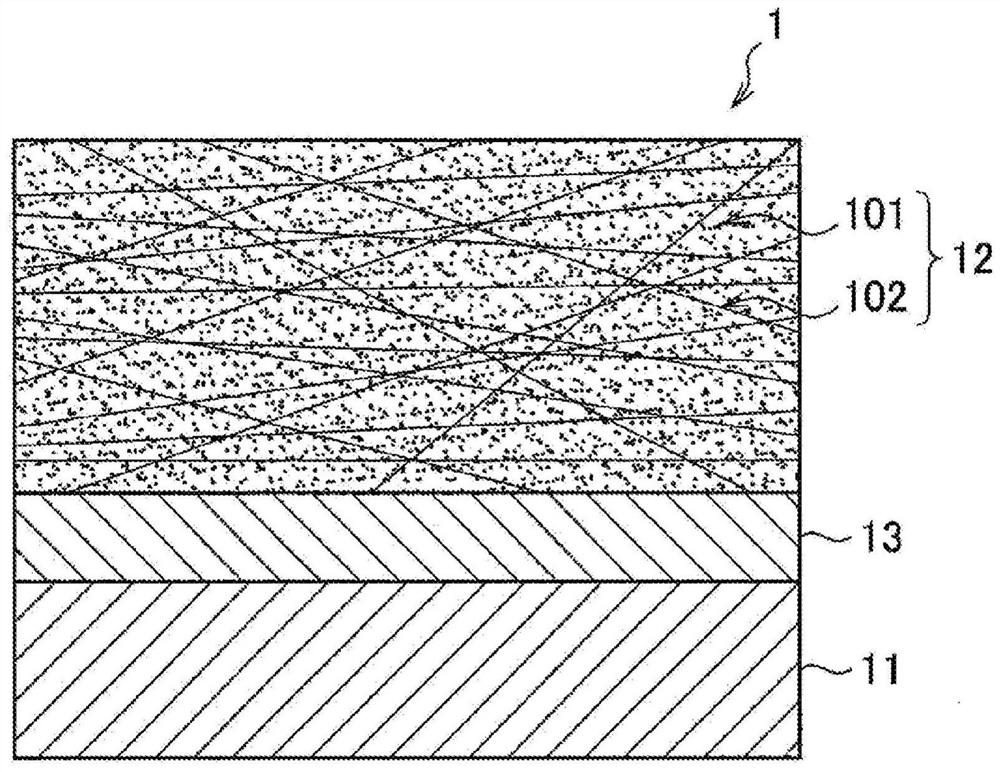

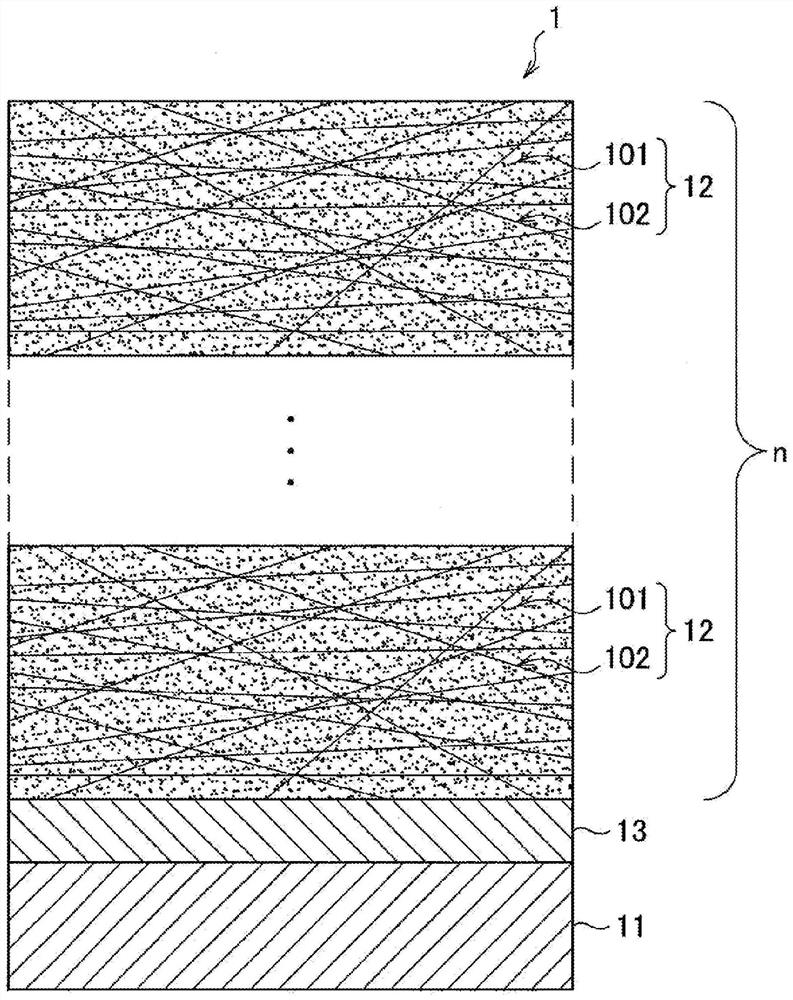

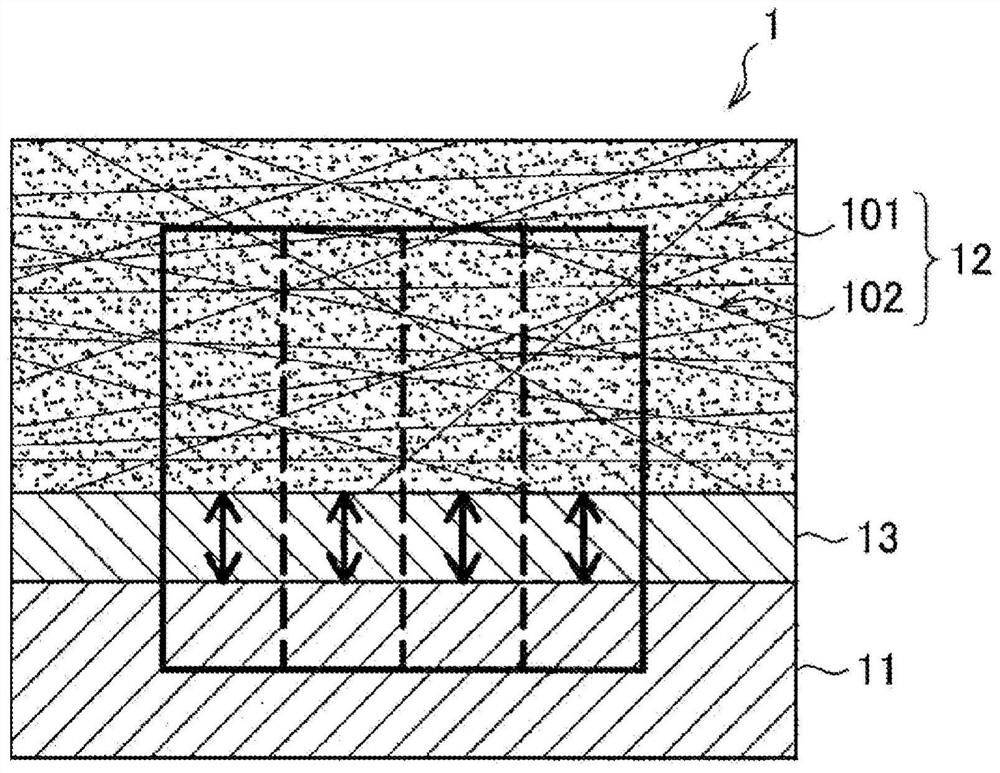

Metal-carbon fiber reinforced resin material composite and production method for metal-carbon fiber reinforced resin material composite

ActiveCN111655475AImprove corrosion resistanceSynthetic resin layered productsLaminationFiberChloride sodium

Owner:NIPPON STEEL CORP

High-strength concrete formula and preparation method of high-strength concrete formula

InactiveCN102690126AHigh strengthImprove penetration resistanceCeramicwareHigh strength concreteLevel structure

The invention discloses a high-strength concrete formula. The high-strength concrete formula is characterized by comprising the following constituents by weight: 20-40% of cement, 3-5% of pulverized coal ash, 30-50% of fine aggregate, 20-40% of coarse aggregate, 3-5% of plant protein foaming agent, 1-10% of water reducer and 1-10% of water. Above materials are mixed and uniformly stirred to obtain the concrete. The concrete disclosed by the invention has the advantages of fewer holes in interior of the concrete, compact microstructure and meso-level structure and excellent anti-permeability performance by mutual interaction of various ingredients, so that the high-performance concrete is good in durability, and the strength can be up to over 280MPa.

Owner:LANGFANG RONGSHENG CONCRETE

Shatter-resistant glass vacuum cup

InactiveCN107126040AImprove corrosion resistanceExtended service lifeNon-pressured vesselsDrinking vesselsEngineeringAluminium oxide

Owner:耒阳凌宝水晶玻璃工艺有限公司

Pilot control hydraulic one-way valve

InactiveCN106641351AEasy to controlSimple structureOperating means/releasing devices for valvesCheck valvesEngineeringPilot valve

The invention provides a pilot control hydraulic one-way valve. The pilot control hydraulic one-way valve comprises a valve sleeve, a main valve core and a main spring; a radial hole is formed in the main valve core; a water outlet is formed in the valve sleeve; a cover plate is arranged at the top end of the valve sleeve; the main spring is fixed to the bottom surface of the cover plate; a plurality of through holes of which the upper ends are plugged are formed in the cover plate; an annular groove is formed in the centre of the cover plate to communicate the through holes to form an accommodating cavity; a draining hole is formed in the cover plate; the top of the cover plate is connected with a pilot valve body; a pilot valve core is arranged in the pilot valve body; a pilot spring is arranged on the pilot valve core in a sleeving manner; the bottom end of the pilot valve core extends into the accommodating cavity; an electromagnetic coil is arranged at the top end of the pilot valve body; a pole shoe is arranged between the pilot valve body and the electromagnetic coil; an armature is arranged in the electromagnetic coil; the end part of the armature penetrates through the pole shoe to be in contact with the top end point of the pilot valve core. The pilot control hydraulic one-way valve is simple in structure; the pilot valve core is closed or opened by controlling the on-off state of the power of the electromagnetic coil, so that the on-off state among a water inlet, the water outlet and a draining hole is controlled; therefore, combination control of liquid flowing directions and control of automatic flow distributing protecting function are realized.

Owner:HANYUSEN TECH (WUHAN) CO LTD

Double metal alloy barrel material and producing technology thereof

InactiveCN107312962AModerate hardnessImprove high temperature performanceChromium carbideMetal alloy

The invention discloses a double metal alloy barrel material. Raw material powder of the double metal alloy barrel material comprises, by mass, 25-50% of molybdenum, 2-10% of boron, 5-15% of chromium, 2-10% of nickel, 1-5 %of manganese, 0.1-1% of carbon, 0.8-3% of chromium carbide and the balance ferrum. The producing technology of the double metal alloy barrel material comprises the following steps of 1), raw powder ball-milling, 2), powder mixing and drying, 3), powder pressing for forming a green body, 4) green body machining and shaping, 5), vacuum degreasing and sintering, 6) semi-finished product shaping and machining, 7) green body heat covering treatment, and 8), inner hole machining treatment. A double metal alloy barrel produced by the above materials is moderate in rigidity, excellent in high temperature performance, good in bending strength, close to density of steel substrate, high in breaking tenacity, excellent in wear-resisting property and excellent in decay resistance, plastic molding can be more stable by using the producing technology, and the service life of the alloy barrel is greatly improved.

Owner:DONGGUAN JIEYU MASCH CO

Nickel-based alloy powder material for repairing crystallizer foot roller and repairing method

ActiveCN112680634AImprove antioxidant capacityImprove thermal shock resistanceIncreasing energy efficiencyMetallic material coating processesOxidation resistantWear resistance

The invention discloses a nickel-based alloy powder material for repairing a crystallizer foot roller. The nickel-based alloy powder material comprises the following chemical components in percentage by mass of 22-28% of Cr, 8-12% of Mo, 3-4% of Nb, 1.0-2.5% of Si, 0.8-1.6% of B, 0.8-2% of V, 0.05-0.08% of C and the balance of Ni. The invention further discloses a repairing method of the crystallizer foot roller. The method comprises the following steps of 1, rough turning; 2, pre-flaw detection; 3, laser cladding, wherein a cladding layer comprises two layers, a base coat is iron-based alloy powder, a functional layer is cladded on the base coat, and the functional layer is made of nickel-based alloy powder; 4, finish turning; 5, grinding; and 6, post-flaw detection. The crystallizer foot roller repaired by using the material and the method provided by the invention has the advantages that the properties such as high-temperature oxidation resistance, cold and hot fatigue resistance and wear resistance are obviously improved, and the corresponding service life is also greatly prolonged.

Owner:TAIER (ANHUI) IND TECH SERVICE CO LTD

Forging method of nickel base alloy containing copper and nickel base alloy containing copper

ActiveCN104741494AImprove plasticityAvoid defects such as cracking and scrappingMetal-working apparatusIngotHeating furnace

The invention provides a forging method of nickel base alloy containing copper and the nickel base alloy containing copper and belongs to the technical field of forging technologies. The forging method overcomes the defects that because copper is added to the nickel base alloy, the hot working character is poor, and forge cracking is caused, and the yield can be effectively improved. The forging method comprises the steps of conducting billet forging, wherein preprocessed nickel base alloy ingots containing copper are placed in a heating furnace, the nickel base alloy ingots containing copper are heated to the temperature T1, the temperature T1 is kept, forging is conducted according to the forging ratio y1, so that forging stocks are obtained, the temperature T1 is 1120+ / -10 DEG C, and y1 is smaller than or equal to 1.4; conducting initial forming, wherein the forging stocks are arranged in the heating furnace to be heated, the temperature is kept, and forged pieces which are initially formed are obtained through forging; conducting final forging, wherein the initially formed forged pieces are arranged in the heating furnace to be heated to the temperature T3, the temperature T3 is kept, forging is conducted according to the forging ratio y3, so that finished forged pieces are obtained, the temperature T3 is higher than 1000 DEG C and lower than 1080+ / -10 DEG C, and y3 is larger than 1.5 and smaller than 2. The forging method can be used for forging of the nickel base alloy containing copper.

Owner:ENN ENVIROTECH CO LTD

Antibiotic corrosion resistant heat exchanger aluminum pipe

InactiveCN102330000AGood antibacterial propertiesImprove corrosion resistanceHeat exchange apparatusAluminium alloyAnti bacterial

Owner:SUZHOU FANGJIYUAN ENERGY SAVING TECH

Production process of movable iron core of electromagnetic valve

ActiveCN110284075AImprove corrosion resistanceImprove magnetic propertiesIncreasing energy efficiencyAlloyElectromagnetic valve

Owner:HENGYANG JINZELI SPECIAL ALLOY CO LTD

High-temperature firing-free gasket for welding and manufacturing method of gasket

InactiveCN110076484AEnergy savingImprove corrosion resistanceAuxillary welding devicesClaywaresAlloy elementCorrosion

Owner:NORTHEAST GASOLINEEUM UNIV

Environment-friendly aluminum alloy chemical oxidation liquid and chemical oxidation method

ActiveCN113106434AStable structureGood protectionMetallic material coating processesChromic saltOrganic acid

The invention relates to an environment-friendly aluminum alloy chemical oxidation liquid and a chemical oxidation method. The chemical oxidation liquid is composed of zirconium salt, trivalent chromium salt, organic acid and a surfactant, the concentration of the trivalent chromium salt is 0.3-3 g / L, the concentration of the zirconium salt is 2-20 g / L, the concentration of the organic acid is 0.1-1 g / L, and the concentration of the surfactant is 0.005-0.1 g / L. The chemical oxidation method comprises the steps of oil removal, deoxidation treatment and chemical oxidation. The chemical oxidation liquid does not contain hexavalent chromium and is beneficial to the health of operators and the environment, and a conversion film subjected to chemical oxidation treatment is excellent in corrosion resistance and is firmly combined with a paint film.

Owner:NANCHANG UNIV +1

Aqueous graphene heavy-anticorrosive coating and preparation method thereof

InactiveCN109517482AImprove adhesionImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsGrapheneHigh adhesion

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

Water pump

ActiveCN106246603AImprove wear resistanceImprove corrosion resistancePump componentsEngine fuctionsEngineeringCorrosion

The invention discloses a water pump. The water pump comprises a volute, a pump shell and a bearing seat, wherein the volute, the pump shell and the bearing seat are sequentially connected. A wear-proof pump shaft and a mechanical seal cavity of a reasonable structure are applied to the water pump, and a reasonable locating structure and a reasonable jackscrew structure are designed. In this way, the wear resisting capacity and the corrosion resisting capacity of the water pump are improved; and besides, detachment is convenient, installation and detachment can be simplified, the production cost and the installation cost can be reduced, and the production efficiency and the maintenance efficiency can be improved.

Owner:QINGMUCHUAN ENVIRONMENTAL PROTECTION TECH (GUANGZHOU) CO LTD

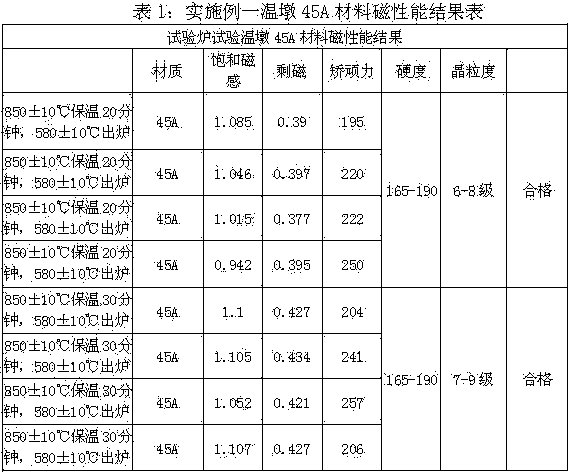

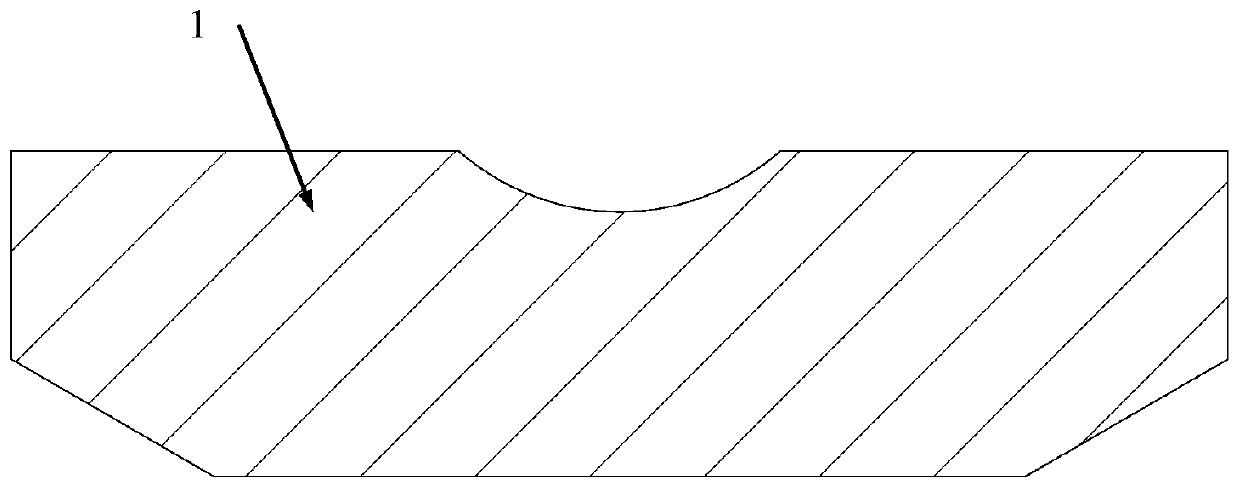

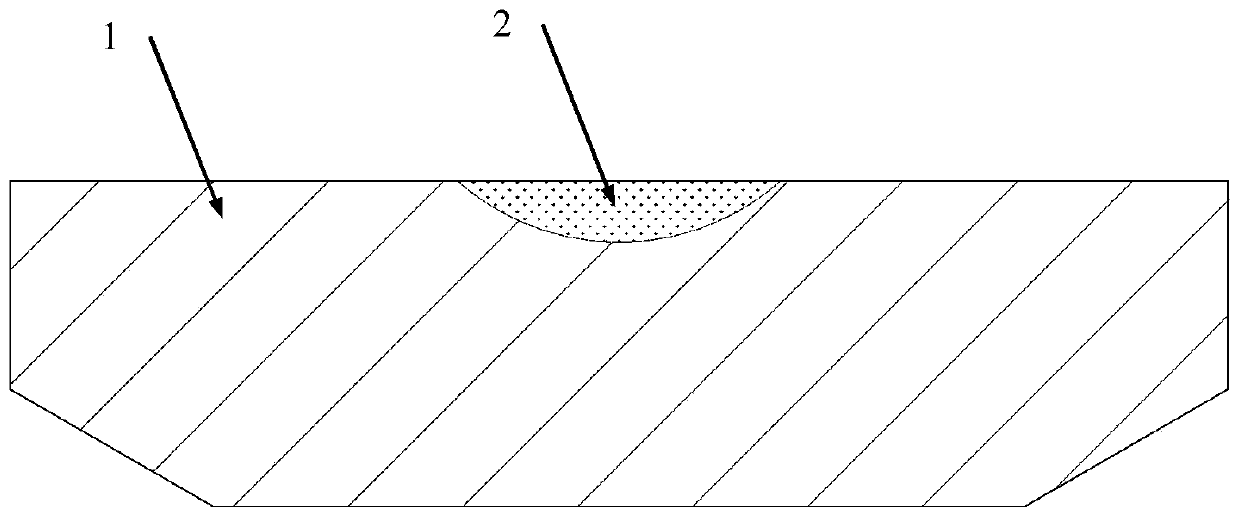

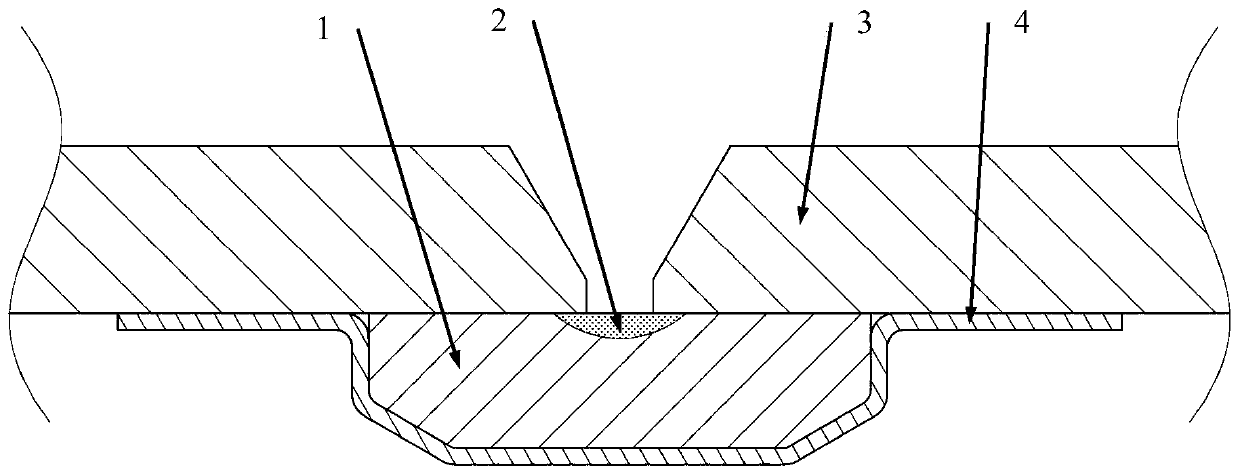

Rare-earth alloy permanent magnet material preparation device and technique

InactiveCN104308160ASolve segregationImprove coercive forceMagnetic materialsMaterials preparationRare earth

A rare-earth alloy permanent magnet material preparation device comprises a raw material treatment portion, a precipitation tank, an electrolytic furnace, a grinding mechanism, a stamping mechanism and a vacuum sintering furnace. The raw material treatment portion comprises a rare-earth metal treatment tank and a blending tank, a delivery pipe connected with the blending tank is arranged on the rear-earth metal treatment tank, the blending tank is connected with the precipitation tank through a complexing solution delivery pipe, the precipitation tank is connected with the electrolytic furnace, a feed inlet is arranged on one side of the electrolytic furnace, a casting chamber is arranged at the tail end of the electrolytic furnace and connected with a cooling chamber, the cooling chamber is connected with the grinding mechanism through a discharge pipe, and the grinding mechanism is connected with the stamping mechanism which is connected with the vacuum sintering furnace. The problem of segregation of alloy ingots is solved effectively, high temperature strength, structural stability, welding performance and corrosion resistance of the alloy ingots are improved beneficially due to addition of Sc, and the common electrolytic furnace can be used for smelting the alloy ingots by adopting mixture after Nd, Pr, Dy and Sc complexing.

Owner:NANJING SABER IND DESIGN & RES INST CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap