Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45 results about "Aluminium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium oxide (IUPAC name) or aluminum oxide (American English) is a chemical compound of aluminium and oxygen with the chemical formula Al₂O₃. It is the most commonly occurring of several aluminium oxides, and specifically identified as aluminium(III) oxide. It is commonly called alumina and may also be called aloxide, aloxite, or alundum depending on particular forms or applications. It occurs naturally in its crystalline polymorphic phase α-Al₂O₃ as the mineral corundum, varieties of which form the precious gemstones ruby and sapphire. Al₂O₃ is significant in its use to produce aluminium metal, as an abrasive owing to its hardness, and as a refractory material owing to its high melting point.

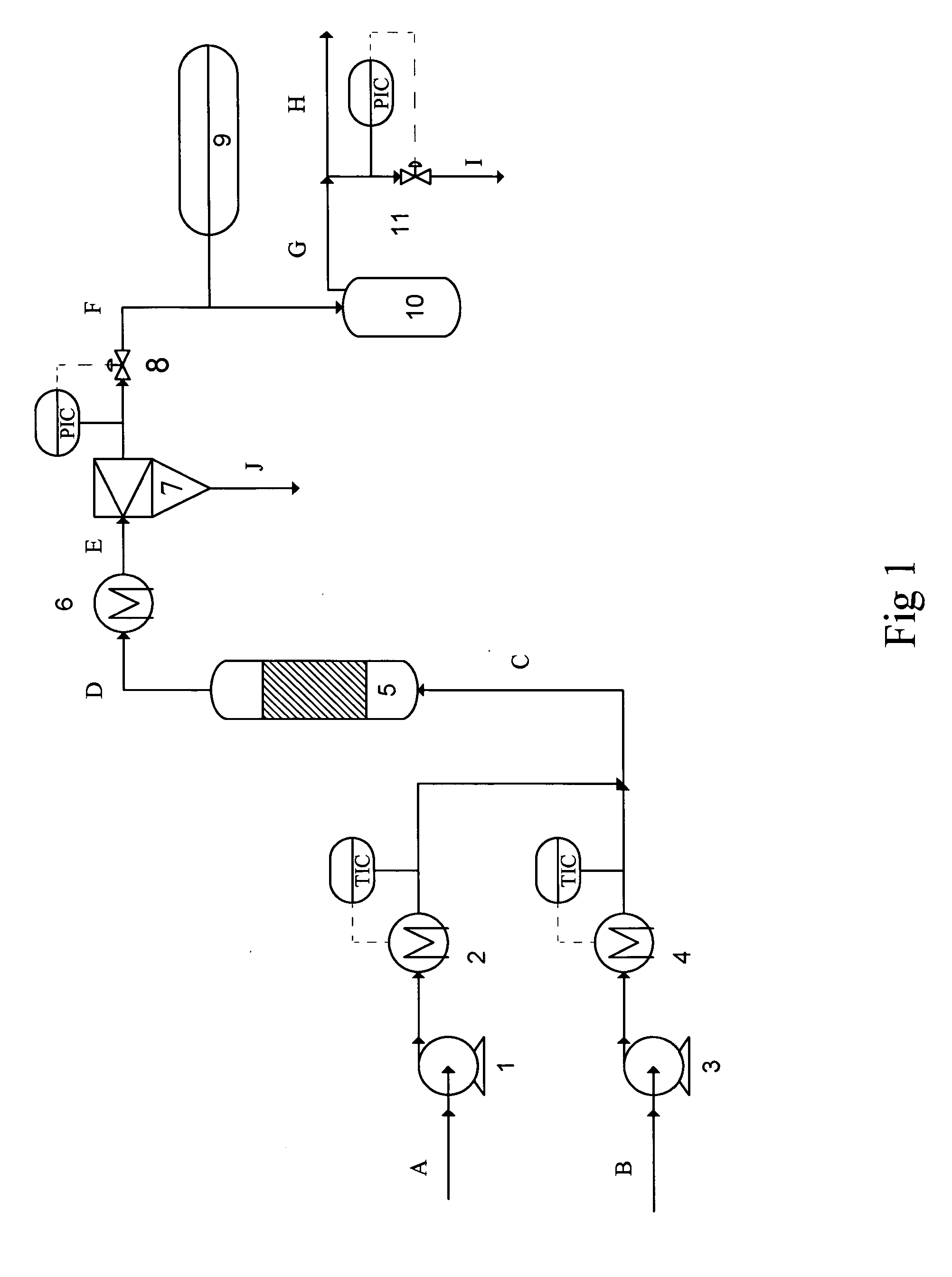

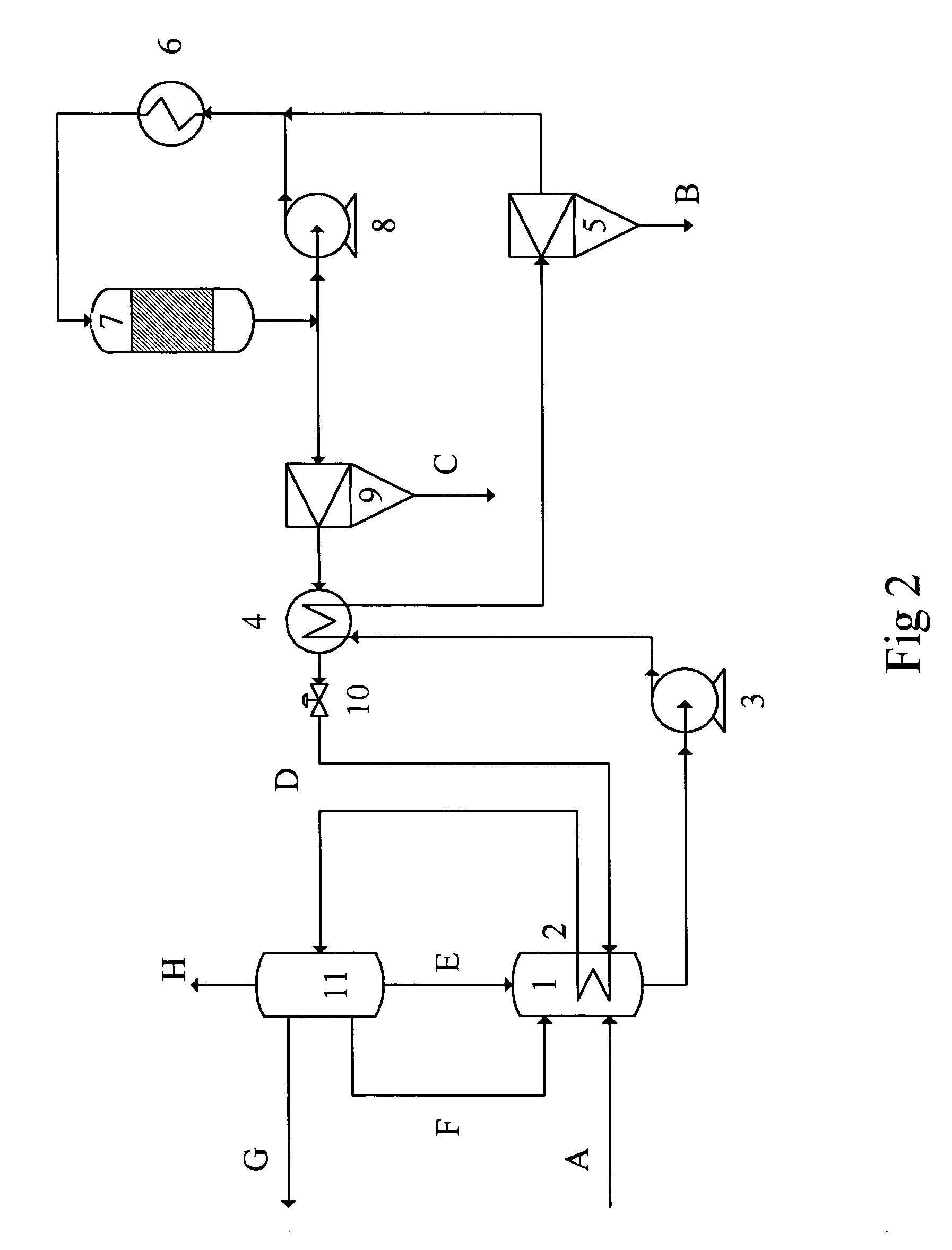

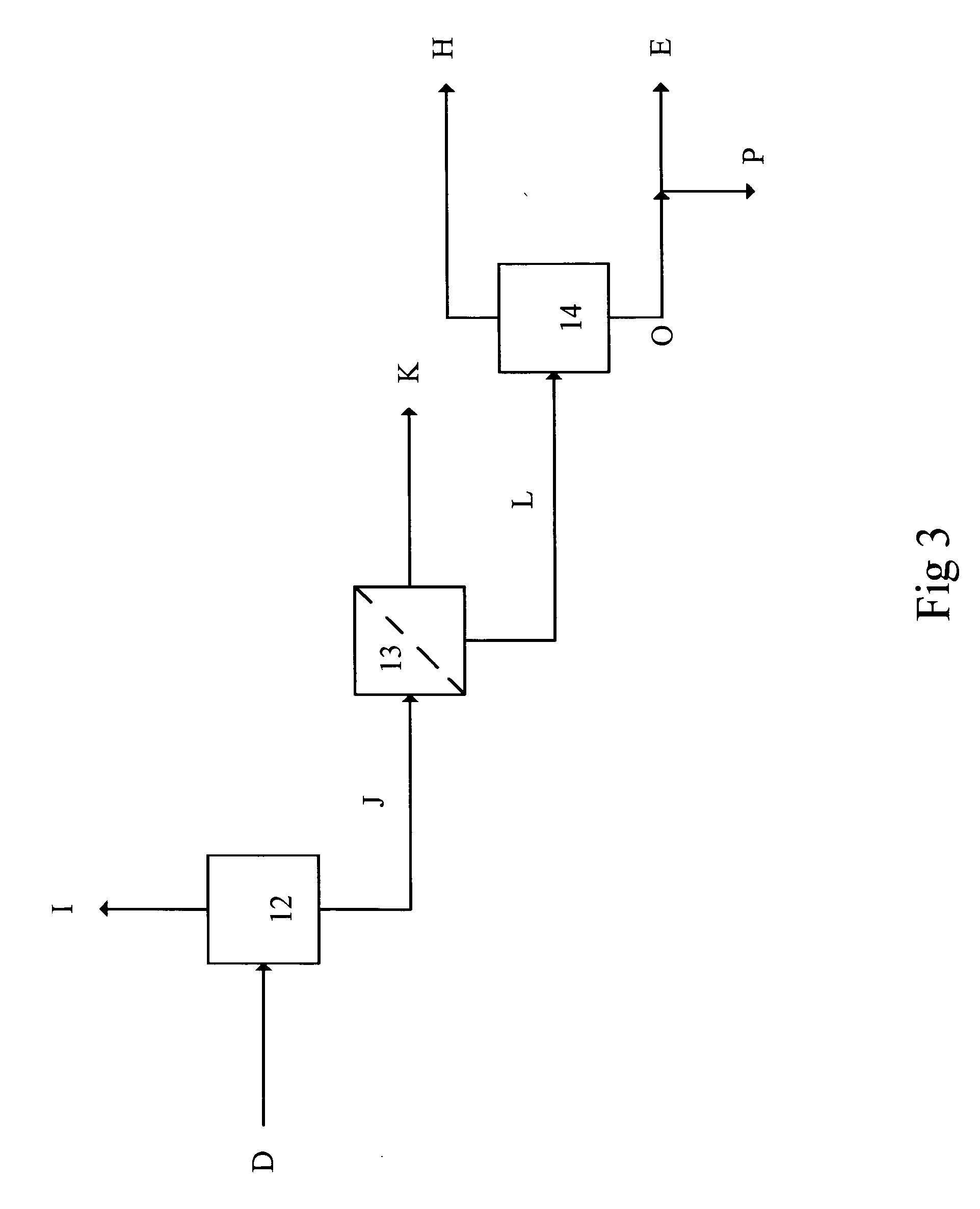

Method and apparatus for converting organic material

ActiveUS20060260186A1Apparatus is enlargedCatalytic crackingByproduct vaporizationHomogeneous catalysisHydrocarbon

Owner:SCF TECH AS

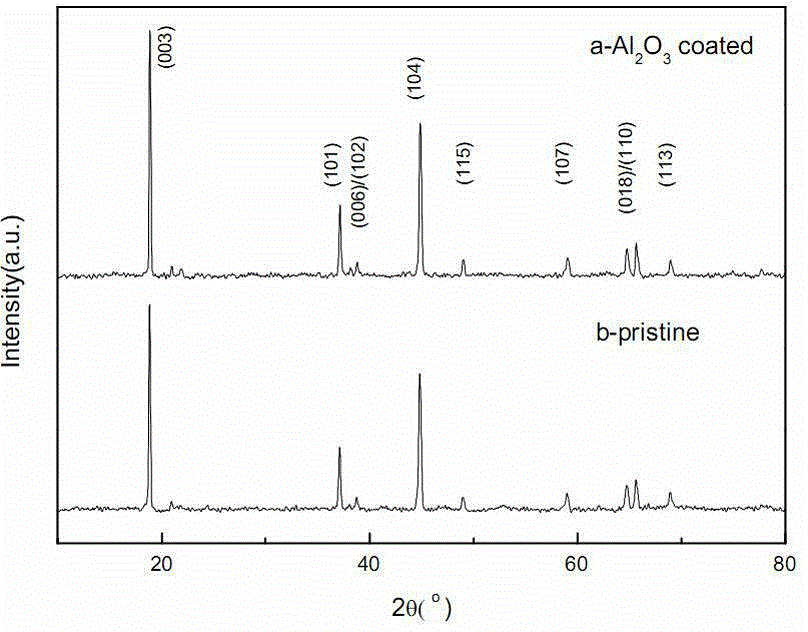

Alumina coating method of lithium ion battery positive electrode material

InactiveCN104577128AImprove cycle stabilitySmall capacity attenuationCell electrodesSecondary cellsAir atmosphereLithium-ion battery

Owner:WUXI XINGBO ENERGY TECH

Method for desulphurizing, denitrating and decoking fire coal

The invention discloses a method for desulphurizing, denitrating and decoking fire coal. In the method, in a raw coal burning stage, a synergist is added in an amount of 0.2 to 0.3 weight percent based on the total weight of the raw coal into the fire coal, and a catalytic active agent is added in an amount of 0.002 to 0.008 weight percent based on the total weight of the raw coal into a slurry boax in a desulphurizing system at the same time. The synergist comprises 8 to 25 mass percent of calcium carbona, 5 to 15 mass percent of magnesium oxide, 5 to 10 mass percent of silicon dioxide, 5 to10 mass percent of zinc oxide, 8 to 10 mass percent of manganese dioxide, 15 to 40 mass percent of calcium oxide, 5 to 10 mass percent of barium hydroxide, 3 to 8 mass percent of aluminum oxide and 8to 15 mass percent of potassium permanganate; and the catalytic active agent comprises 0 to 40 mass percent of active calcium oxide, 20 to 30 mass percent of active carbon, 10 to 15 mass percent of calcium ammonium nitrate, 5 to 20 mass percent of ferric oxide and 2 to 10 percent of zinc oxide. Under the condition of not changing the conventional boiler equipment and process, the method can realize fire coal combustion-supporting and coal-saving functions at one time so as to perform desulphurization, denitration and decoking.

Owner:GUANGZHOU ZHONGKE GAOCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Castable for blast-furnace tapping channel and preparation method thereof

Owner:JIANGSU REFUTA NEW MATERIALS CO LTD

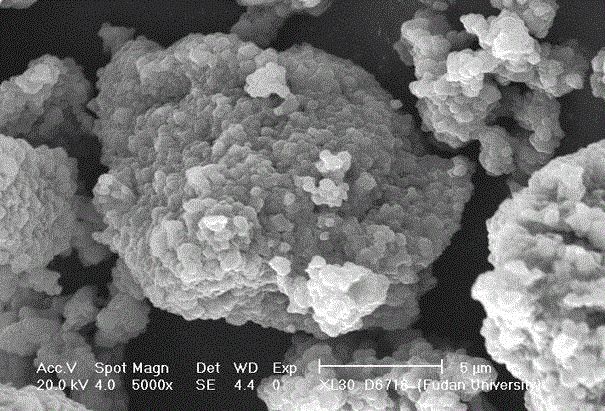

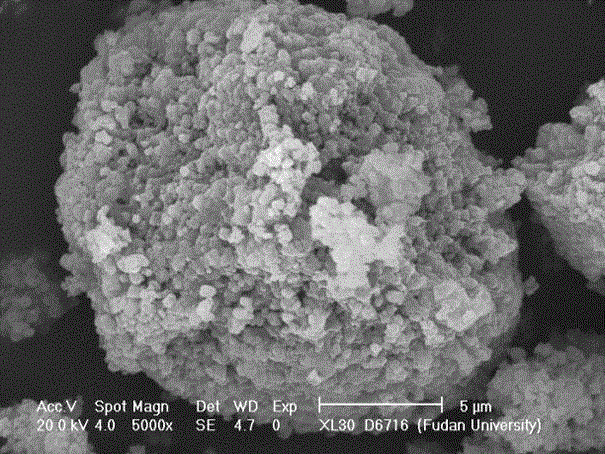

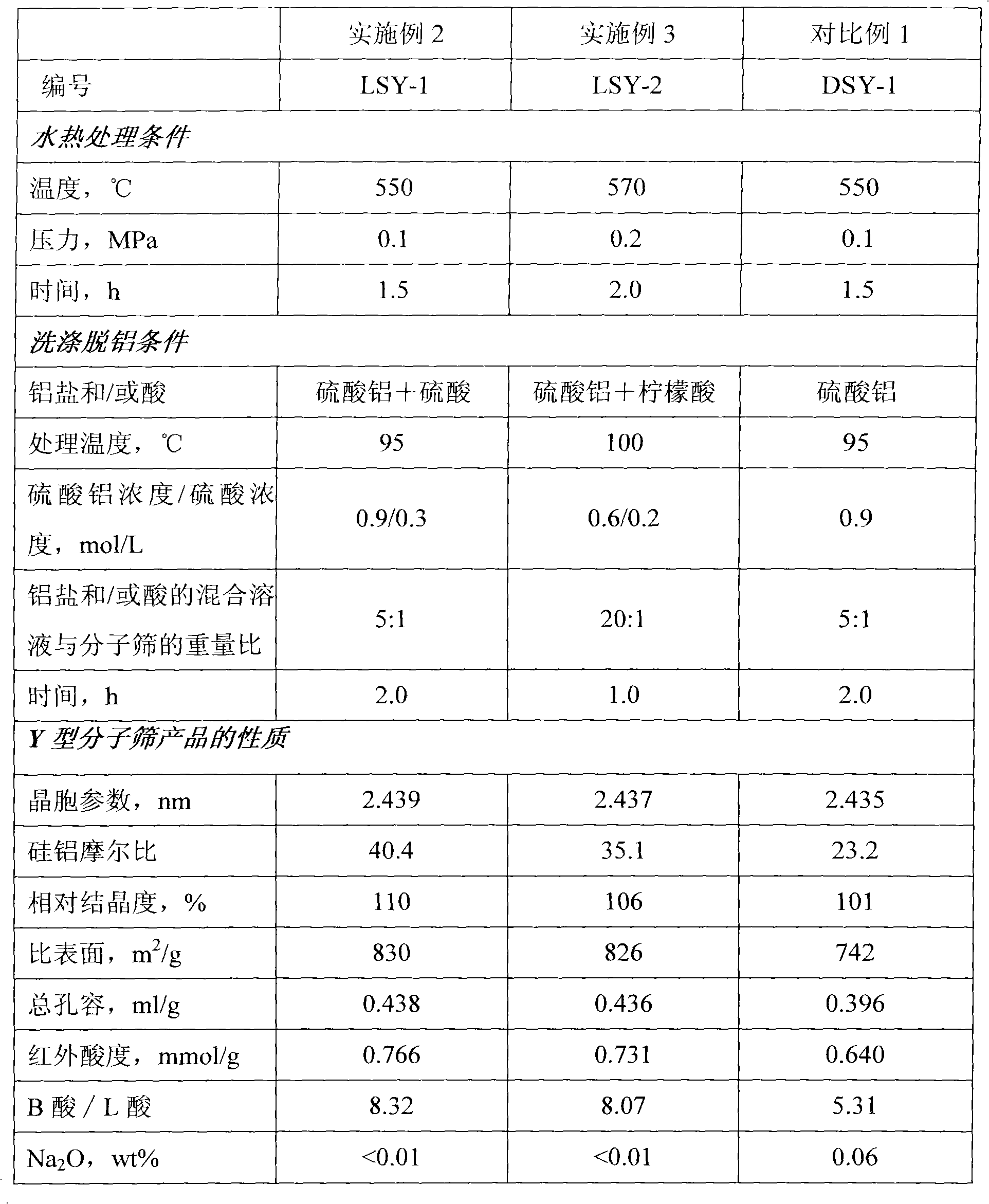

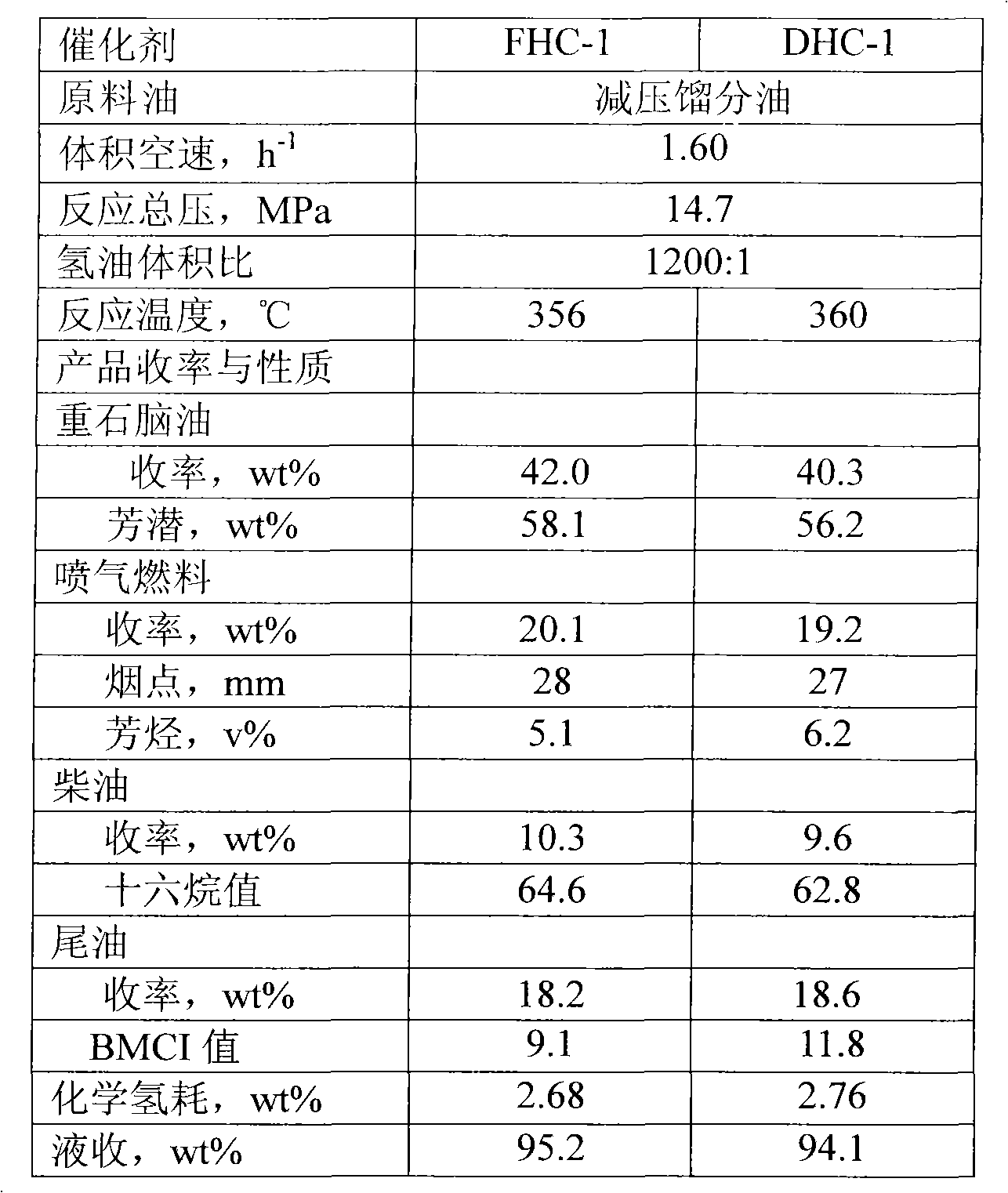

Y-type molecular sieve-containing hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618347AHigh ratio of silicon to aluminumLarger than surfaceCatalyst carriersMolecular sieve catalystsCrystallinityCell parameter

Owner:CHINA PETROLEUM & CHEM CORP +1

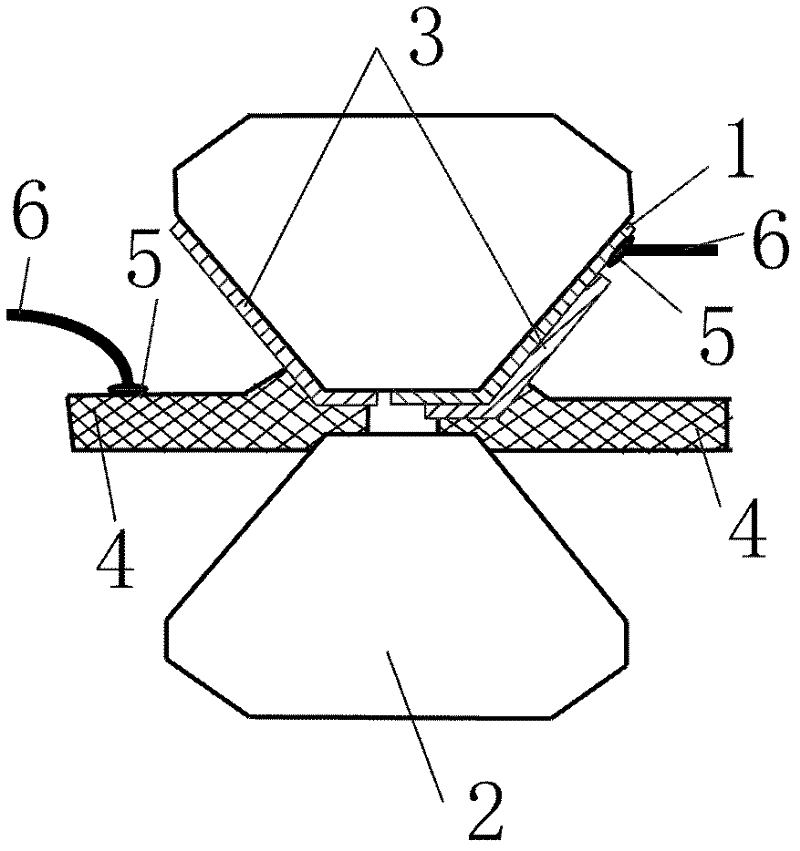

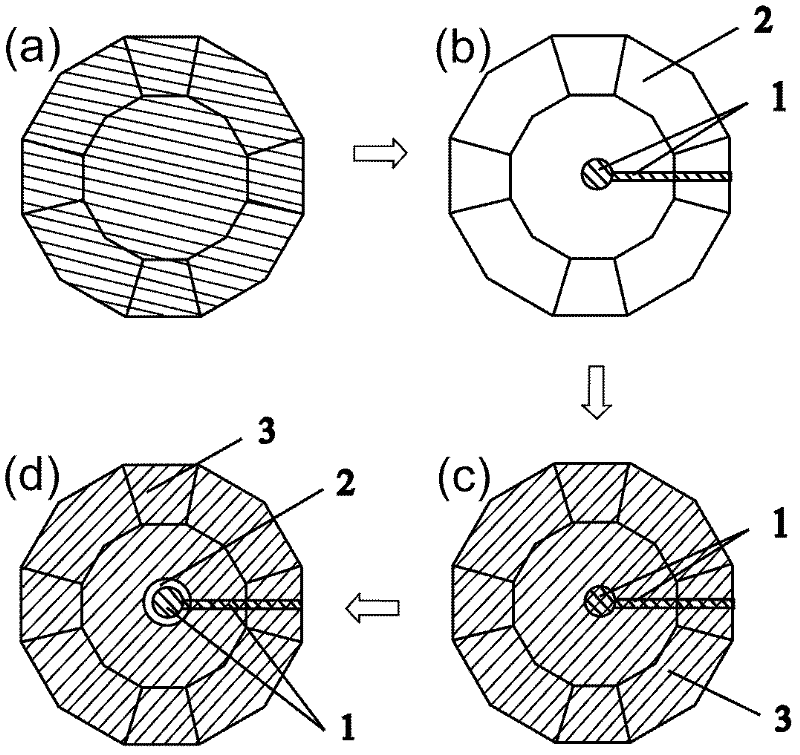

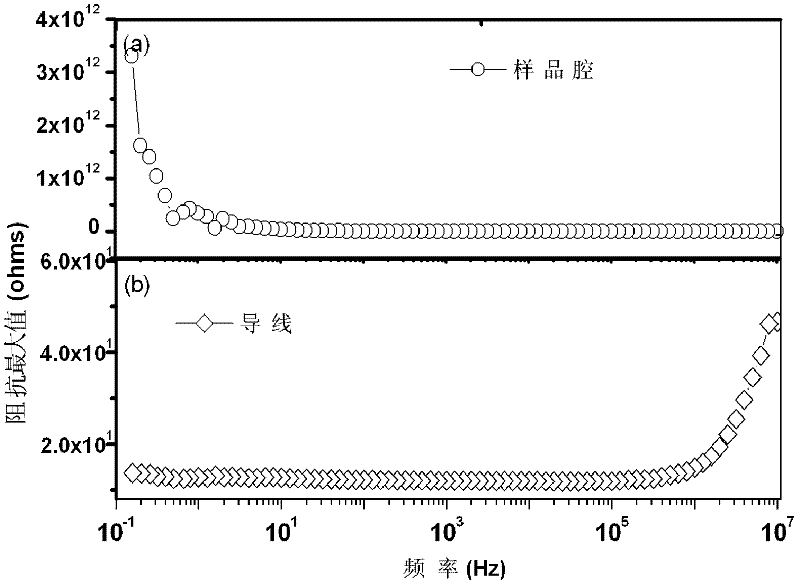

Electrode for high-voltage in-situ impedance spectroscopy measurement and its preparation method and application

InactiveCN102288824AFix fixitySolve insulation problemsResistance/reactance/impedenceEtchingInsulation Problem

Owner:JILIN UNIV

Methods for purifying and stabilizing hydrofluoroolefins and hydrochlorofluoroolefins

Owner:ARKEMA INC

Catalyst for oxidative dehydrogenation of raw materials containing CO (carbon monoxide) gas

InactiveCN102649055ACarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsLoss rateAdditive ingredient

The invention relates to a catalyst for oxidative dehydrogenation of raw materials containing CO (carbon monoxide) gas, which mainly solves the technical problems in the prior art that the hydrogen removal rate is low, and the loss rate of CO is high. The catalyst comprises a carrier, an active component and an accessory ingredient in percentage by weight: (a) the active component which is selected from at least one of platinum metals, and has the dosage being 0.003-2 percent of the weight of the catalyst in a metering manner of a simple substance; (b) the accessory ingredient which is selected from at least one of Pr, Nd, Cs and Ba, and has the dosage being 0.005-15 percent of the weight of the catalyst in a metering manner of a simple substance; and (c) 84-99.5 percent of carrier, wherein the carrier is selected from a compound type carrier of aluminum oxide and silicon oxide, and the weight ratio of the aluminum oxide to the silicon oxide is 0.01-100:1. According to the technical scheme, the problems are better solved, and the catalyst can be applied in industrial production of oxidative dehydrogenation of raw materials containing the CO gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Comprehensive recycling treatment method of waste rare-earth fluorescent lamp

ActiveCN103627906AShort processReduce recycling costsProcess efficiency improvementLiquid wasteEconomic benefits

The invention discloses a comprehensive recycling treatment method of a waste rare-earth fluorescent lamp, which comprises the steps that S1, waste fluorescent powder, a waste glass tube and mercury-containing waste liquid are separated and recycled from the waste rare-earth fluorescent lamp; S2, the waste fluorescent powder is roasted; an obtained roasted ore is leached; a leaching solution and a leaching residue are obtained; S3, the leaching solution is subjected to extraction, reverse extraction and separation; alumina and rare-earth oxide are obtained; and S4, the leaching residue is subjected to digestion, extraction and purification; and a strontium-containing product is obtained. The waste rare-earth fluorescent lamp is separated, the obtained waste fluorescent powder and the obtained mercury-containing waste liquid are comprehensively recycled respectively by technologies of roasting, leaching, extraction, reverse extraction and the like, and then secondary valuable resources such as alumina, various rare-earth oxide and the strontium-containing product are comprehensively recycled from the waste fluorescent powder. The method is short in technological process and low in recycling cost, solves the problems of stockpiling, environmental pollution and the like caused by the industrial waste rare-earth fluorescent lamp, and has certain economic benefits and industrial significance.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

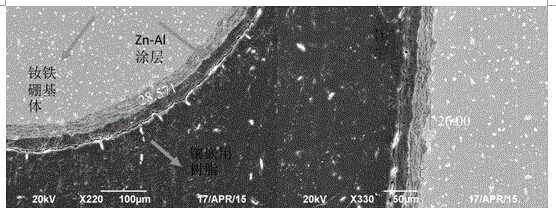

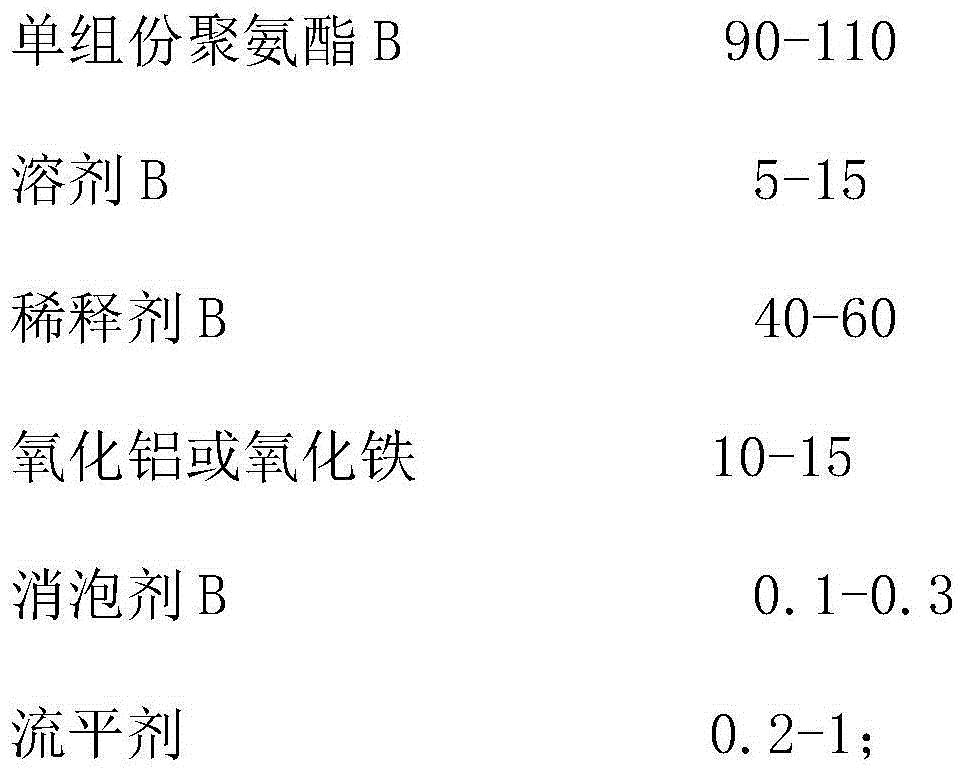

Zinc-aluminum coating enhanced with particles in micro-nano sizes and production method of zinc-aluminum coating

InactiveCN104984889AImprove mechanical propertiesImprove scratch resistancePretreated surfacesSpecial surfacesMicro nanoSilicon oxide

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Ceramic floor tile with diatom mud and method for manufacturing ceramic floor tile

InactiveCN105298081AReduce processing difficultyNice appearanceCeramic shaping apparatusFlooringSurface layerEthylic acid

Owner:佛山市高明区生产力促进中心

Method for manufacturing plugged honeycomb structure, and plugged honeycomb structure

A method for manufacturing a plugged honeycomb structure, includes: a forming raw material preparation step of mixing and kneading a partition wall base material raw material at least including cordierite powder and binder with water to obtain a partition wall base material forming raw material; a forming / drying step of forming the partition wall base material forming raw material to obtain a honeycomb formed body, and drying the honeycomb formed body to obtain a honeycomb dried body; a slurry application step of applying trapping layer forming slurry including a cordierite forming raw material or alumina to a surface of a not-fired partition wall base material of the obtained honeycomb dried body; a firing step of firing the slurry-applied honeycomb dried body; and a plugging step of disposing a plugging portion at open ends of predetermined cells of the slurry-applied honeycomb dried body or of the honeycomb fired body.

Owner:NGK INSULATORS LTD

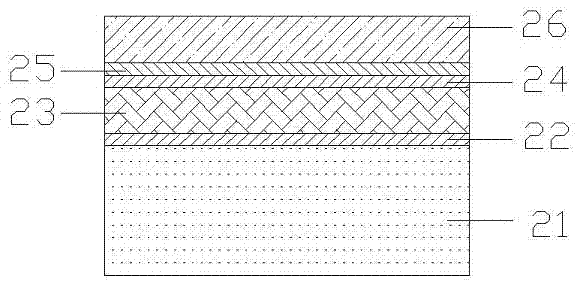

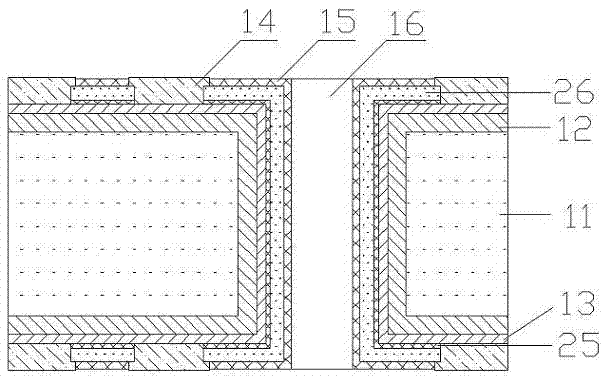

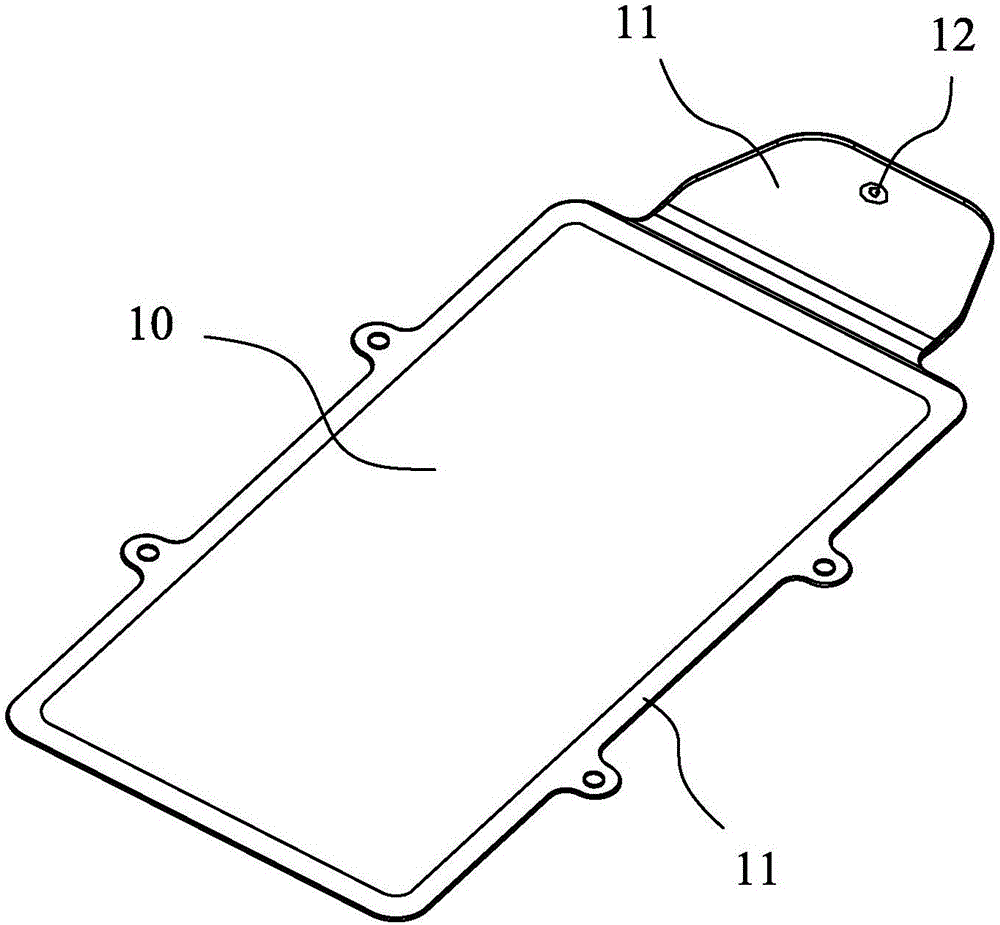

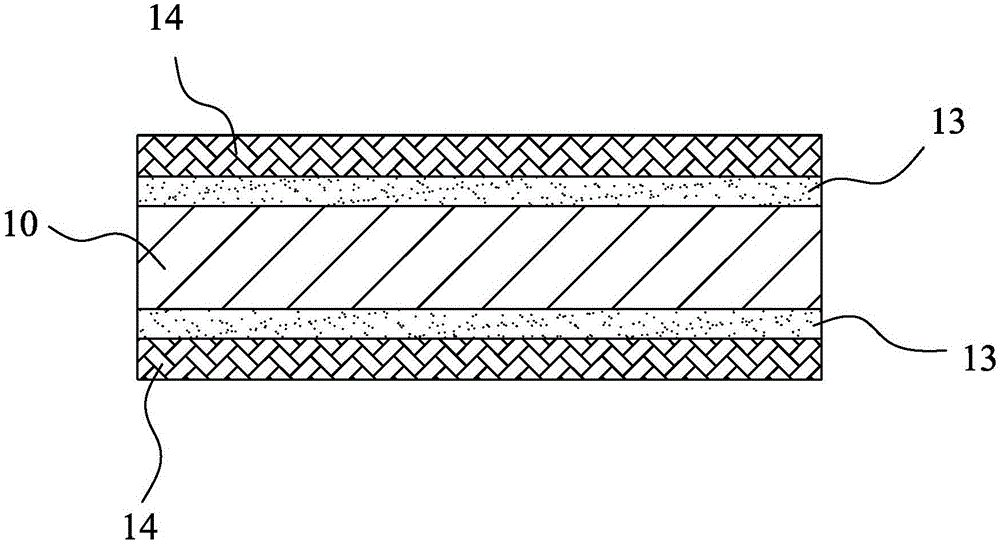

Double-sided aluminum base circuit board with super-high thermal conductivity and preparation method thereof

InactiveCN102740591ASimple processImprove yieldPrinted circuit detailsPrinted element electric connection formationDlc coatingInsulation layer

Owner:苏州热驰光电科技有限公司

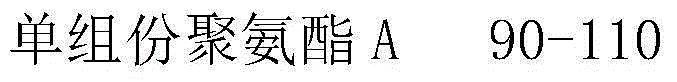

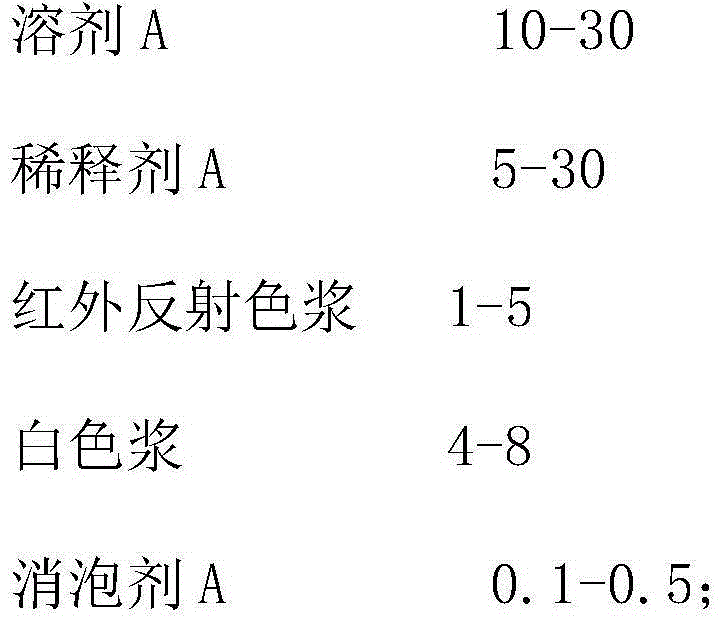

Infrared stealth textile coating fabric

ActiveCN105034523ALow infrared reflectanceImprove stealth performanceSynthetic resin layered productsCross-linkPolymer science

Owner:CTA HI TECH TEXTILES

Manufacturing method of high-hardness plastic screen and housing of mobile phone and mobile phone screen and housing manufactured thereby

ActiveCN105922525AHigh hardnessReduce use costSynthetic resin layered productsTelephone set constructionsRainbowAdhesive

Owner:DONGGUAN JIAOJIN ELECTRONICS TECH CO LTD

Glass ceramics made from high silicon iron tailings and manufacturing method thereof

The invention relates to the technical field of solid waste resource utilization, in particular to glass ceramics made from high silicon iron tailings, which is characterized by comprising the raw materials in parts by weight: 30-70 parts of the iron tailings, 15-40 parts of quartz, 5-20 parts of calcium carbonate, 3.5-6.5 parts of aluminum oxide, 8.5-9.5 parts of sodium carbonate, 4-5 parts of zinc oxide, 3-6 parts of barium carbonate and 1-3 parts of borax. The manufacturing method of the glass ceramics comprises the following steps: putting the glass ceramics blended materials in a kiln for melting into molten glass; allowing the molten glass to directly flow into water for water quenching to form glass particles; and paving the glass particles in a refractory die, crystallizing the paved particles in a tunnel kiln, a shuttle kiln or a chamber electric furnace, and grinding and cutting the crystallized glass ceramics to finally obtain the finished product of the glass ceramics. The invention can reduce stockpile of the tailings, alleviate environmental pollution, realize comprehensive resource utilization, improve product performances and lower production cost, thus having good social benefit and good economic benefit.

Owner:ANSTEEL GRP MINING CO LTD

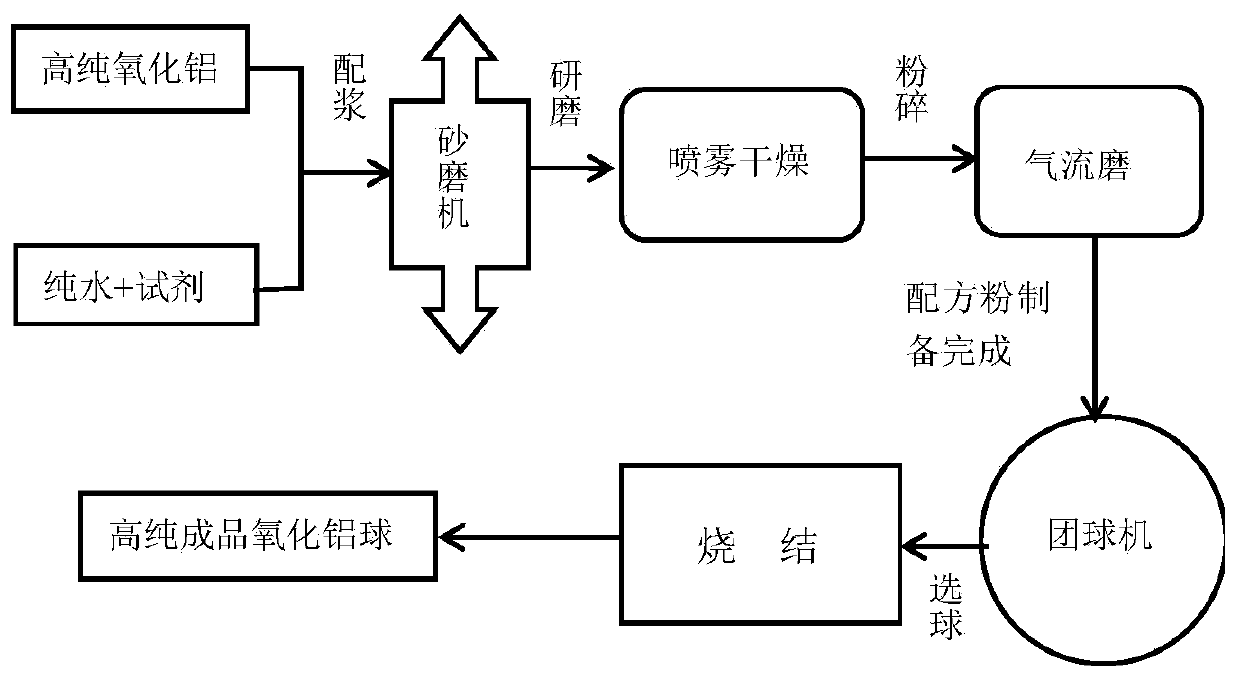

Alumina grinding ball preparation method

Owner:青海万加环保新材料有限公司

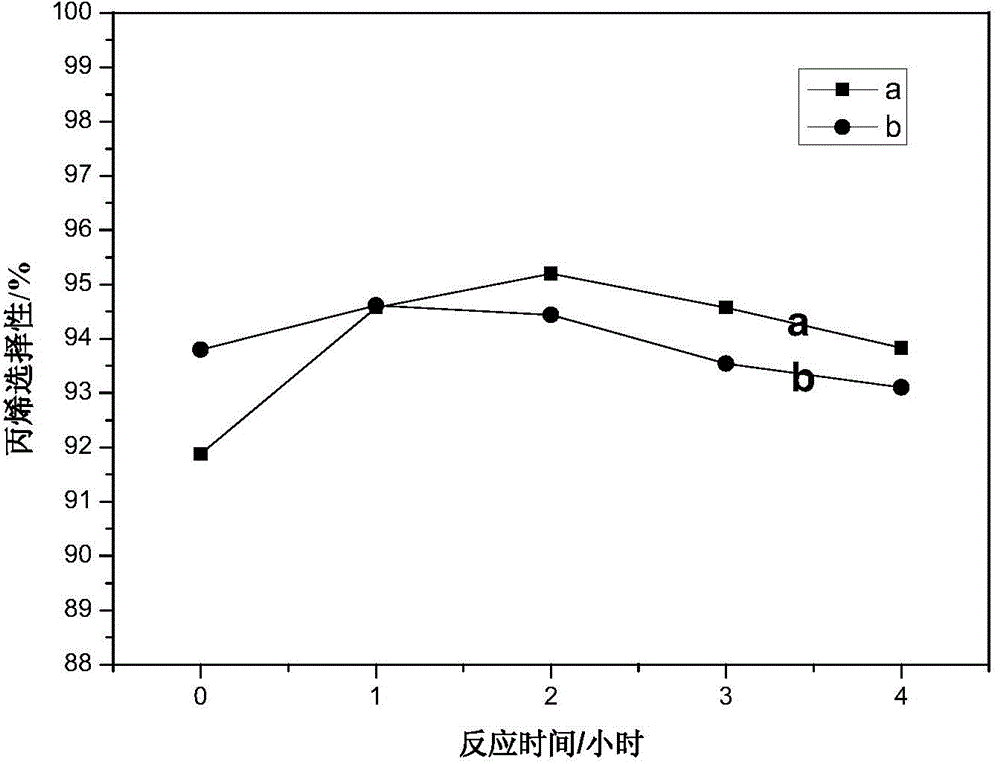

Catalyst for production of propylene through catalytic dehydrogenation of propane, and preparation method thereof

InactiveCN104941640AHigh selectivitySimple processHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActive componentDehydrogenation

Owner:NANKAI UNIV

Epoxy resin curing agent

Owner:南通市福来特化工有限公司

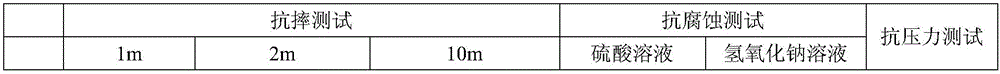

Anti-smashing glass bottle and production method thereof

InactiveCN106587605AGood chemical stabilityIncrease surface tensionGlass blowing apparatusGlass tempering apparatusManufacturing technologyBreak the glass

Owner:柳州市昌泉贸易有限公司

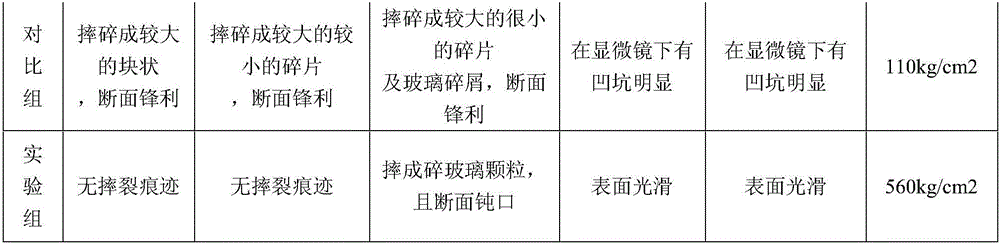

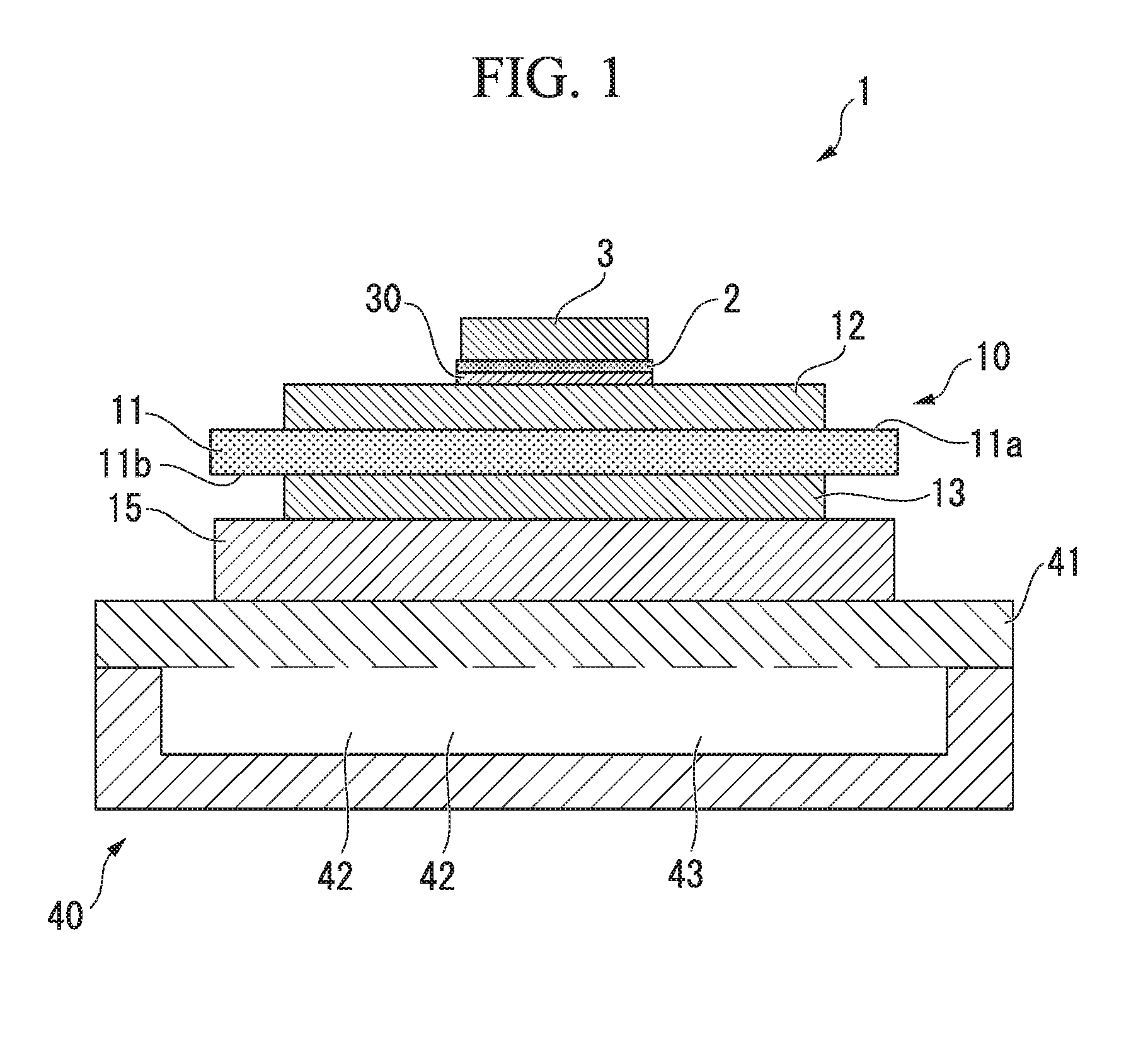

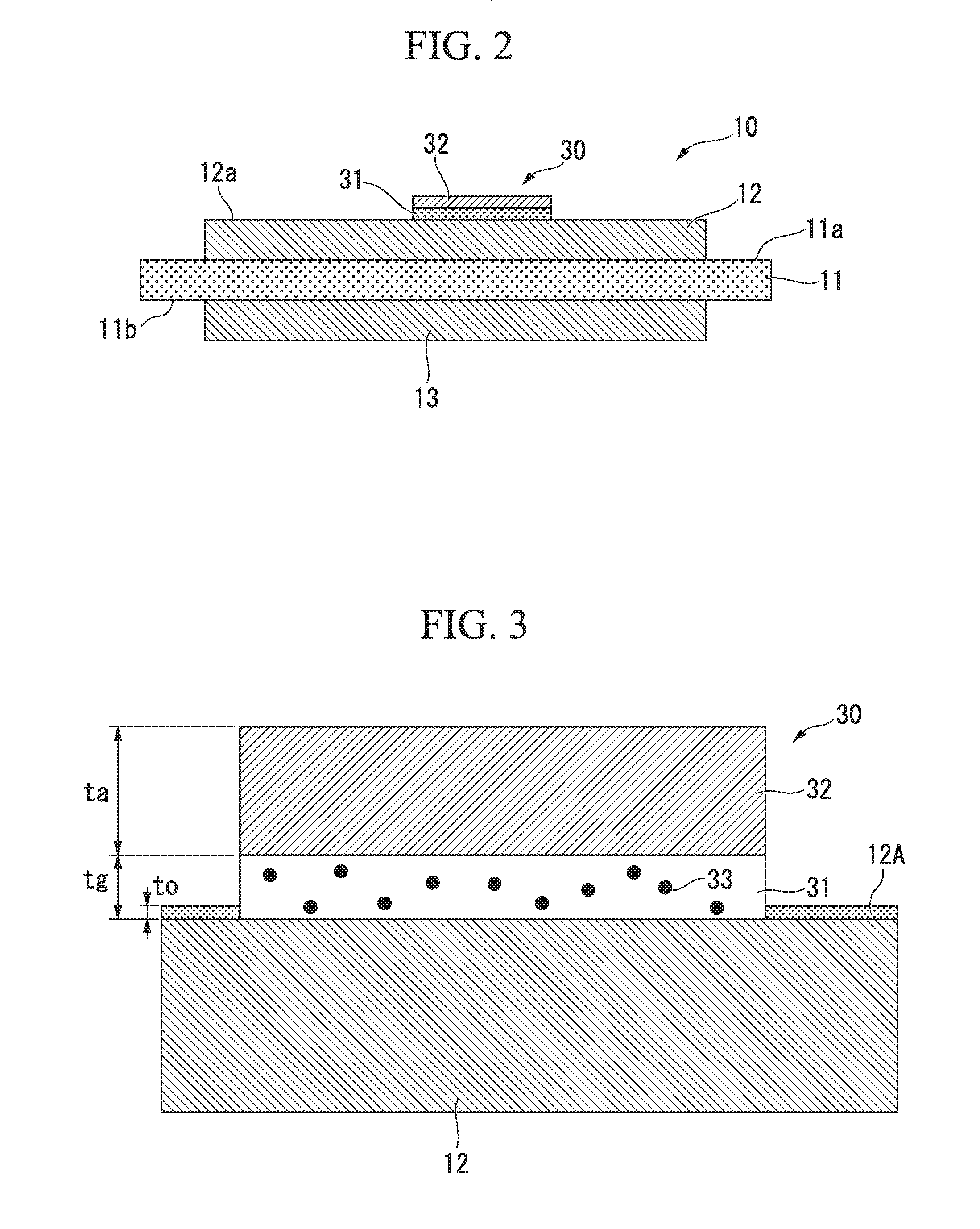

Power module substrate, method of producing same, and power module

ActiveUS20160293562A1Lower the resistance valueSemiconductor/solid-state device detailsSolid-state devicesComputer moduleEngineering

Owner:MITSUBISHI MATERIALS CORP

Manufacturing method for attenuation sheet

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

Stainless steel welding rod improving vertical welding process performance

ActiveCN112975199AIncrease the solidification rateImprove vertical welding operabilityWelding/cutting media/materialsSoldering mediaElectrolysisSS - Stainless steel

The invention provides a stainless steel welding rod improving vertical welding process performance. The stainless steel welding rod comprises a stainless steel core wire and a coating wrapping the surface of the stainless steel core wire, the coating is prepared from the following raw materials, in parts by weight, 30-40 parts of rutile, 3-8 parts of zircon quartz, 5-10 parts of feldspar, 10-18 parts of marble, 2-6 parts of fluorite, 2-8 parts of dolomite, 1-5 parts of magnesia, 1-5 parts of aluminum oxide, 5-10 parts of electrolytic manganese metal, 5-10 parts of chromium metal, 3-6 parts of ferrotitanium, 2-7 parts of iron powder, 1-2 parts of sodium alginate and 1-2 parts of microcrystalline cellulose. According to the stainless steel welding rod improving the vertical welding process performance, the excellent flat welding process performance of an acid coating stainless steel welding rod is reserved, meanwhile, by designing the coating of the welding rod, the welding rod melting rate is reduced, the slag forming number in unit time is reduced, the slag solidification rate is improved, vertical welding slag is stably solidified and does not flow downwards, and the vertical welding operability of the stainless steel welding rod is improved.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

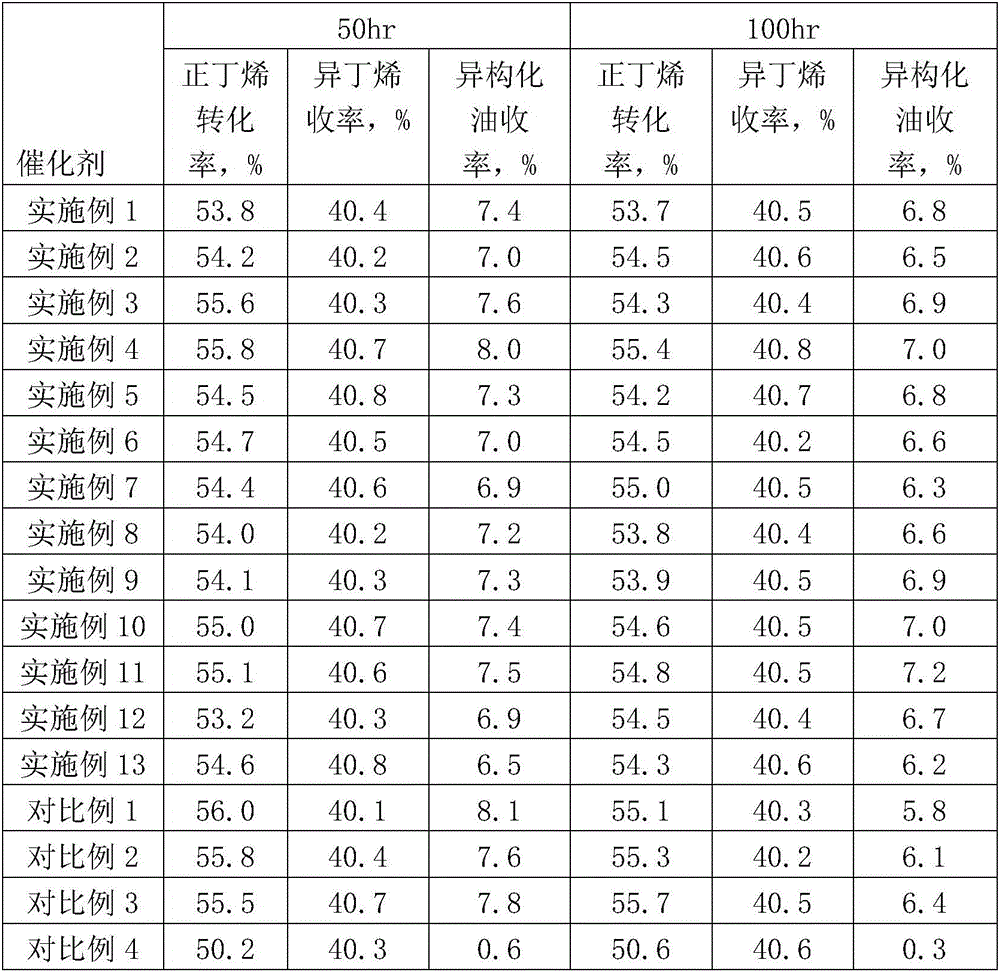

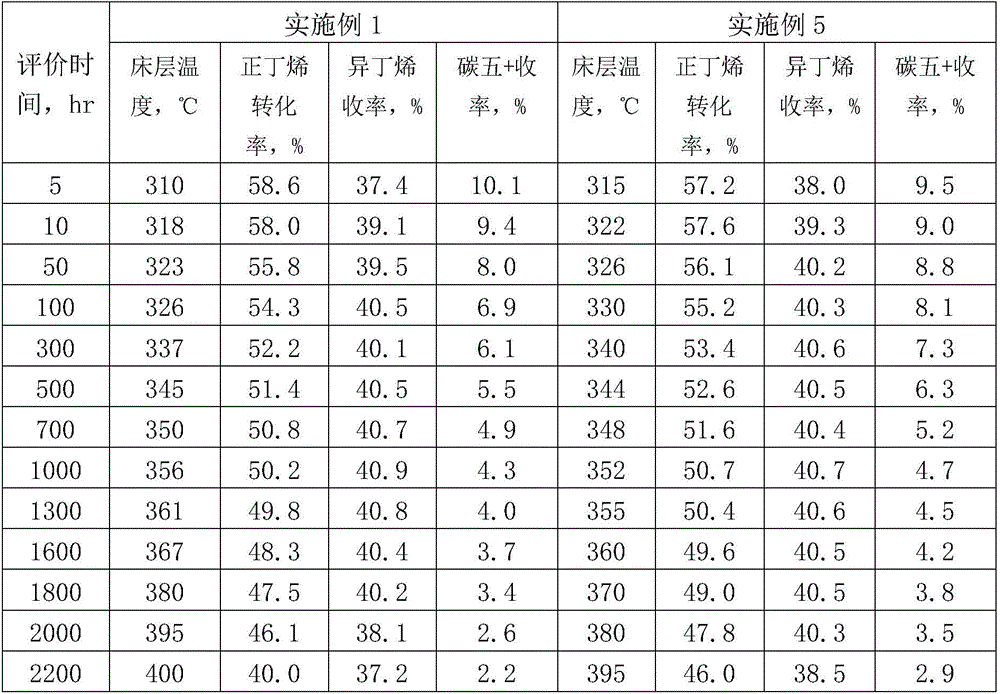

N-alkene isomerization catalyst and preparation method and application thereof

ActiveCN106076408AReduce in quantityReduce cokingHydrocarbon by isomerisationMolecular sieve catalystsButeneIsomerization

Owner:山东迅达化工集团有限公司

Environment-friendly ceramic coating material for water faucet

InactiveCN106189561ACorrosion resistantWear-resistantAnti-corrosive paintsCarbon fibersPolybutylene terephthalate

Owner:朱燕华

Preparation method of battery cathode material lithium nickel cobalt aluminum oxide precursor

The invention discloses a preparation method of battery cathode material lithium nickel cobalt aluminum oxide precursor and relates to the technical field of batteries. The preparation method comprises the steps of (1) preparing nickel-cobalt solution; (2) preparing precipitate; (3) purifying the precipitate; (4) preparing a premix; (5) roasting an end product. The lithium nickel cobalt aluminum oxide precursor is prepared by means of aluminum nitrate roasting; the difficulty in forming large particulate precipitate due to high precipitating speed of trivalent aluminum ions is avoided; the lithium nickel cobalt aluminum oxide precursor that is roasted has high true density. In addition, roasting allows fewer acid radicals to be left in the precipitate, and the purity of the lithium nickelcobalt aluminum oxide precursor is further improved accordingly.

Owner:HEFEI CHENGDIAN TECH CO LTD

Insulated fireproof coating for optical cables

InactiveCN105567024AExcellent physical and chemical propertiesDry fastFireproof paintsEpoxy resin coatingsFiberEpoxy

Owner:FUXIN POWER SUPPLY COMPANY STATE GRID LIAONING ELECTRIC POWER +1

Al2O3-TiC/Al2O3-TiC-CaF2 self-lubricating laminated ceramic drawing die and preparation method thereof

The invention relates to a drawing die and particularly relates to an Al2O3-TiC / Al2O3-TiC-CaF2 self-lubricating laminated ceramic drawing die and also relates to a preparation method of the laminated ceramic drawing die. The technical scheme is as follows: the Al2O3-TiC / Al2O3-TiC-CaF2 self-lubricating laminated ceramic drawing die mainly comprises an Al2O3-TiC layer ceramic material and an Al2O3-TiC-CaF2 layer ceramic material, wherein the Al2O3-TiC layer ceramic material comprises the following components according to the volume ratio: 45% of aluminum oxide, 50% of titanium carbide, 0.5% of molybdenum, 4.5% of nickel and trace magnesium oxide and yttrium oxide; the Al2O3-TiC-CaF2 layer ceramic material comprises the following components according to the volume ratio: 30% of aluminum oxide, 60% of titanium carbide and 10% of calcium fluoride. The Al2O3-TiC layer ceramic material and the Al2O3-TiC-CaF2 layer ceramic material are laminated according to the design requirements of different wire processing sizes for the ceramic drawing die, and the ceramic die obtained after sintering retains higher hardness and strength, meanwhile, the toughness of the die is improved, and in addition, the whole die has a self-lubricating characteristic in the drawing process, so that the wear reducing and resisting effects are remarkable.

Owner:UNIV OF JINAN

Blue-in-green rice-pattern glaze and application method thereof

ActiveCN107473589ABreak through the decorative effectNo side effectsClaywaresSilicon dioxideNatural mineral

The invention discloses a blue-in-green rice-pattern glaze and an application method thereof. The blue-in-green rice-pattern glaze is prepared from the following natural mineral raw materials and industrial chemical engineering raw materials in percentage by mass: 72.25 to 72.39% of SiO2 (silicon dioxide), 15.13 to 15.50% of Al2O3 (aluminum oxide), 0.71 to 0.73% of Fe2O3 (ferric oxide), 2.61 to 2.93% of K2O (potassium oxide), 1.23 to 2.22% of Na2O (sodium oxide), 6.64 to 6.93% of CaO (calcium oxide), and 0.28 to 0.45% of MgO (magnesium oxide) through proportioning, ball milling and screening. The blue-in-green rice-pattern glaze has the advantages that the blue-in-green decoration effect is realized without adding of oxide coloring agent, the decoration effect of the traditional rice-pattern porcelain in Jingdezhen is broken, most of raw materials are natural mineral raw materials, the sources are rich, the cost is low, any side effect to a human body is avoided, and the market space is broad.

Owner:JINGDEZHEN CERAMIC UNIV

Baking-free long water gap for large-plate-blank continuous casing low-carbon and low-silicon steel and preparation process of baking-free long water gap

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap