Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Platinum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Platinum is a chemical element with the symbol Pt and atomic number 78. It is a dense, malleable, ductile, highly unreactive, precious, silverish-white transition metal. Its name is derived from the Spanish term platino, meaning "little silver".

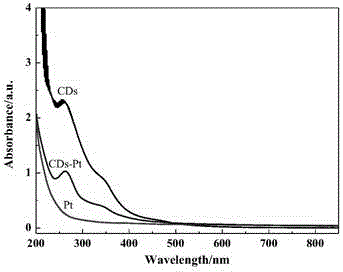

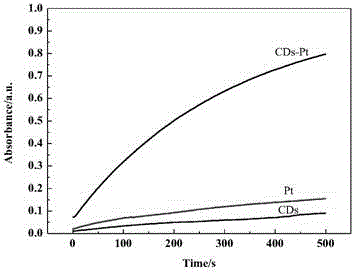

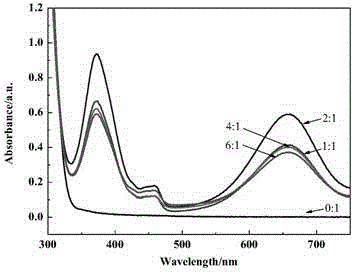

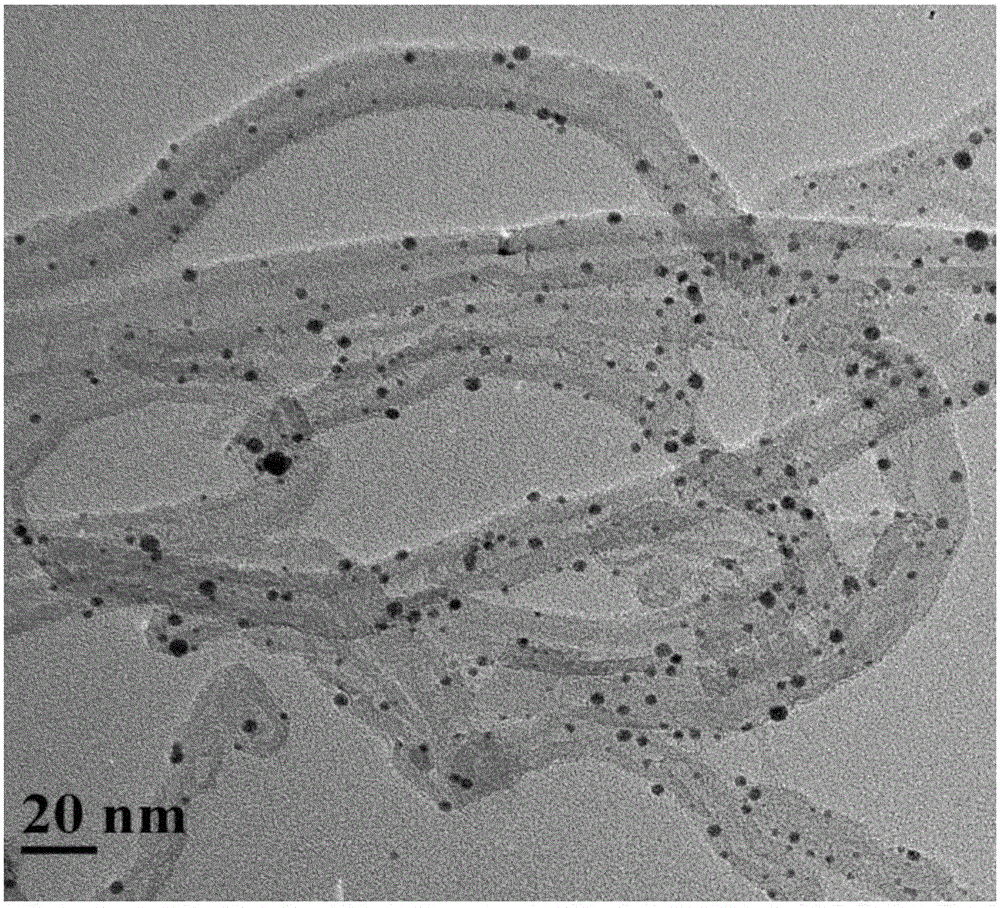

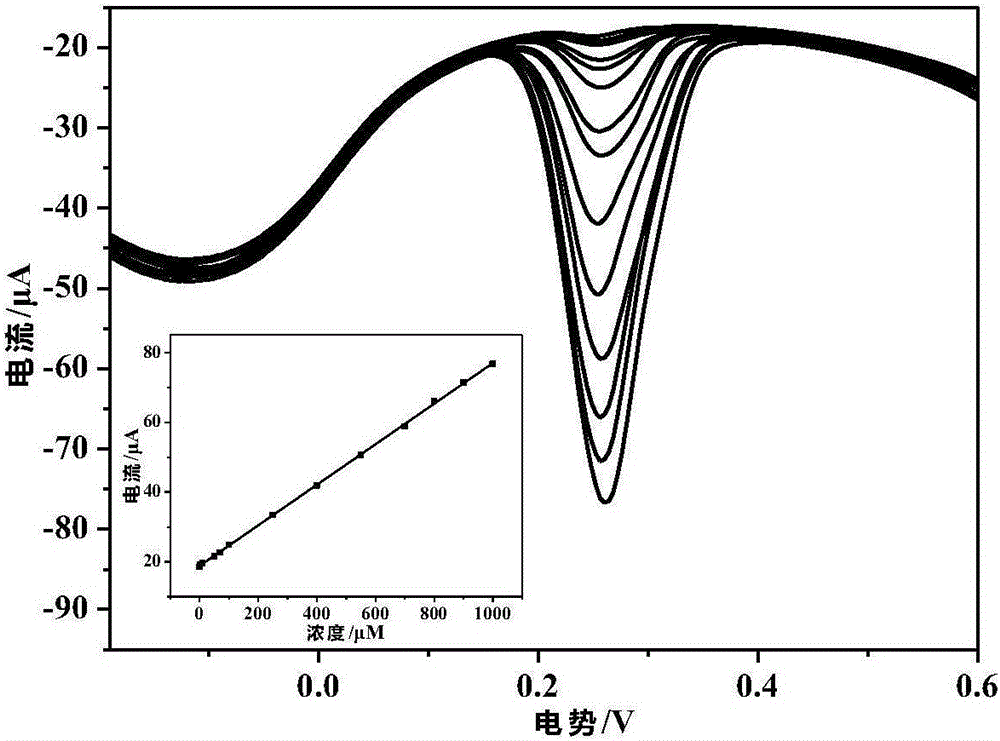

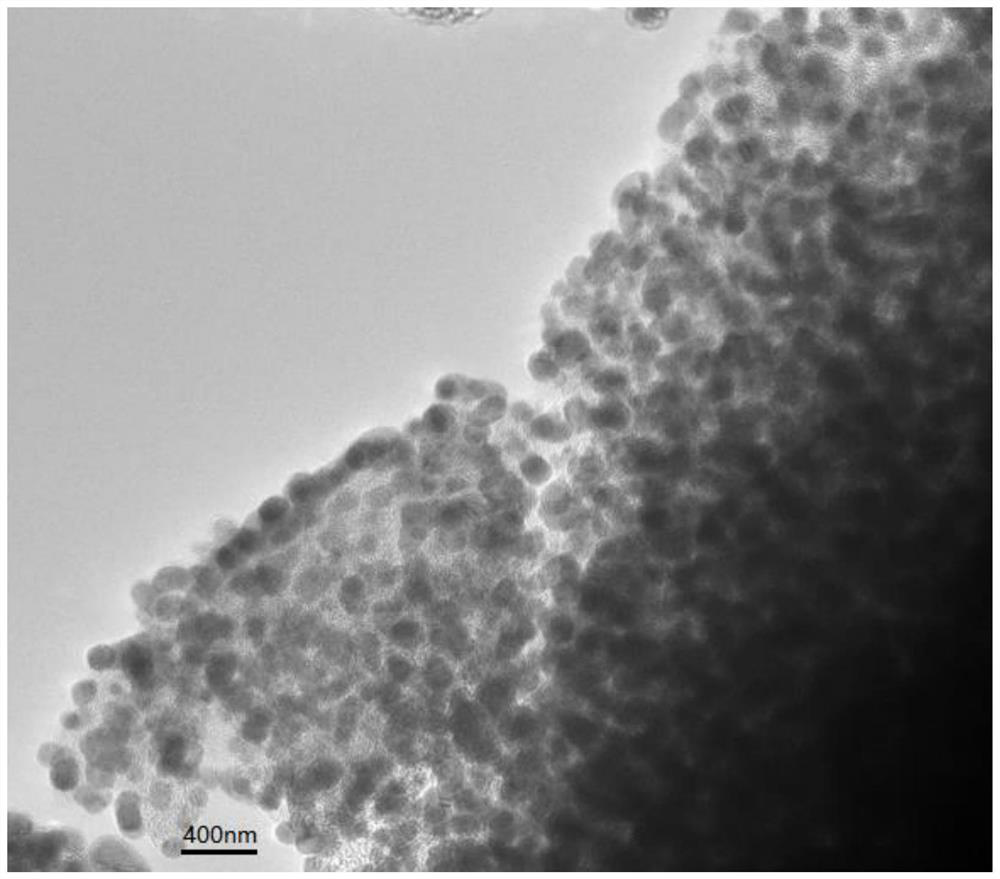

CDs-Pt nanomaterial with catalase catalytic properties

InactiveCN104549234AThe synthesis method is simpleNo pollution in the processMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsPlatinumGlucose detection

Owner:JIANGNAN UNIV

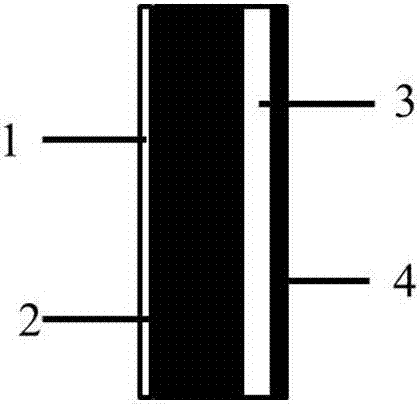

Quantum dot molecular light emitting device

InactiveCN102097564ABroad luminescence spectrumHigh strengthLaser detailsSemiconductor lasersMetal electrodesWaveguide

The invention relates to a quantum dot molecular light emitting device, which sequentially comprises the following structures from bottom to top: a lower gold germanium nickel metal electrode layer (1), a gallium arsenic substrate (2), a gallium arsenic buffer layer (3), a n-type aluminum gallium arsenic lower cladding layer (4), a gallium arsenic lower waveguide limiting layer (5), a quantum dotmolecular active area, a gallium arsenic upper waveguide limiting layer (9), a p-type aluminum gallium arsenic upper cladding layer (10), a p-type gallium arsenic ohmic contact layer (11), a dioxide silicon insulating layer (12) and an upper titanium platinum gold metal electrode layer (13), wherein the quantum dot molecular active area comprises n quantum dot molecular layers each of which comprises quantum dot molecules (6), a stress buffer layer (7) and an isolated layer (8), and n is a natural number not less than 1. According to the invention, the laterally coupled quantum dot molecules are utilized to manufacture an active area structure and corresponding light emitting devices, thereby widening the applicable scope of quantum dot and improving the performance of low dimension semiconductor device.

Owner:HUAZHONG UNIV OF SCI & TECH

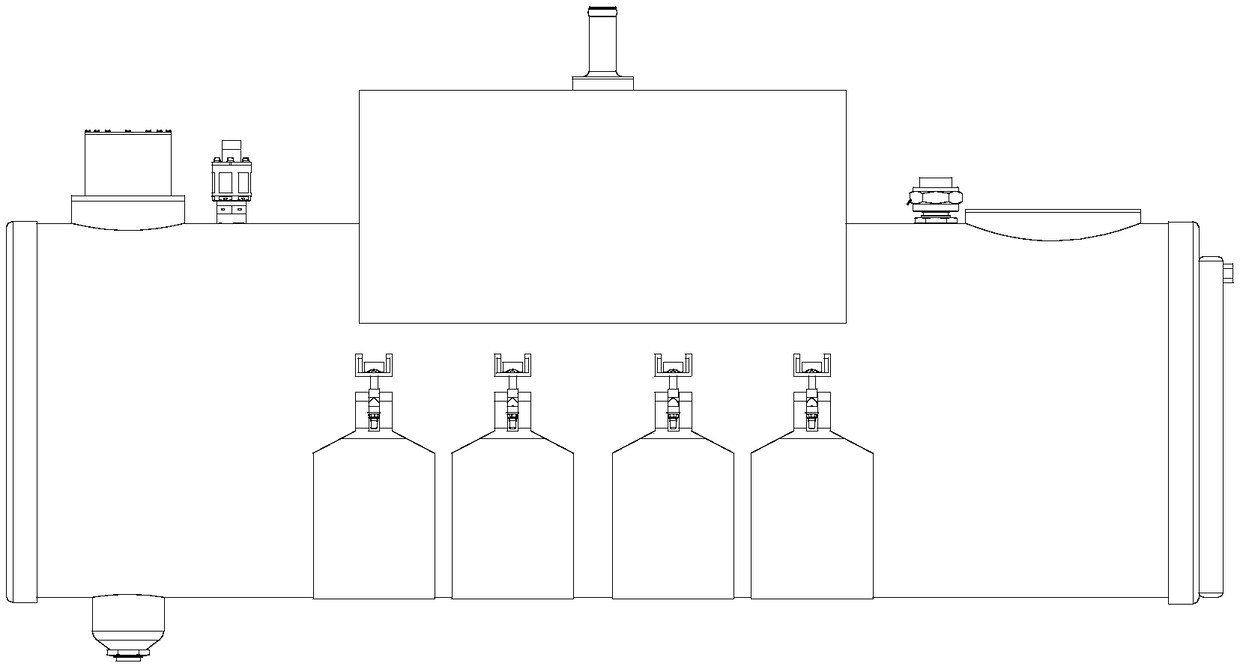

Process and corresponding apparatus for continuously producing gaseous hydrogen to be supplied to micro fuel cells and integrated system for producing electric energy

A process for the production of hydrogen for micro fuel cells, comprises the successive steps of: continuously supplying a catalytic bed with an aqueous solution of sodium borohydride, the catalytic bed being made of at least one metal chosen among cobalt, nickel, platinum, ruthenium with obtainment of hydrogen and of a by-product comprising sodium metaborate, continuously recovering the hydrogen thus obtained and supplying, with said hydrogen as it is as obtained, a micro fuel cell which transforms hydrogen into electric energy. An apparatus provides continuous supply of hydrogen to a micro fuel cell. An integrated system structured for continuously producing and supplying hydrogen to a micro fuel cell and for converting the continuously supplied hydrogen into electric energy.

Owner:STMICROELECTRONICS SRL

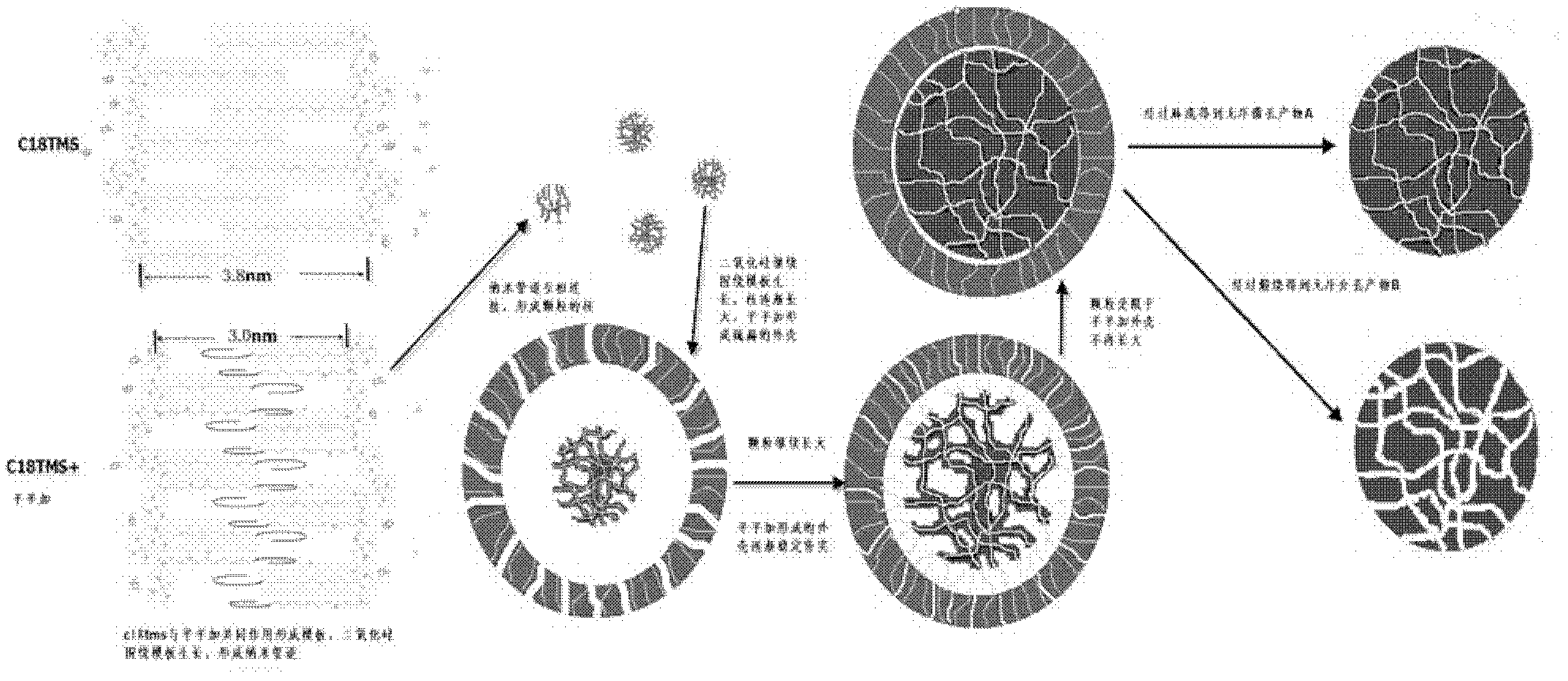

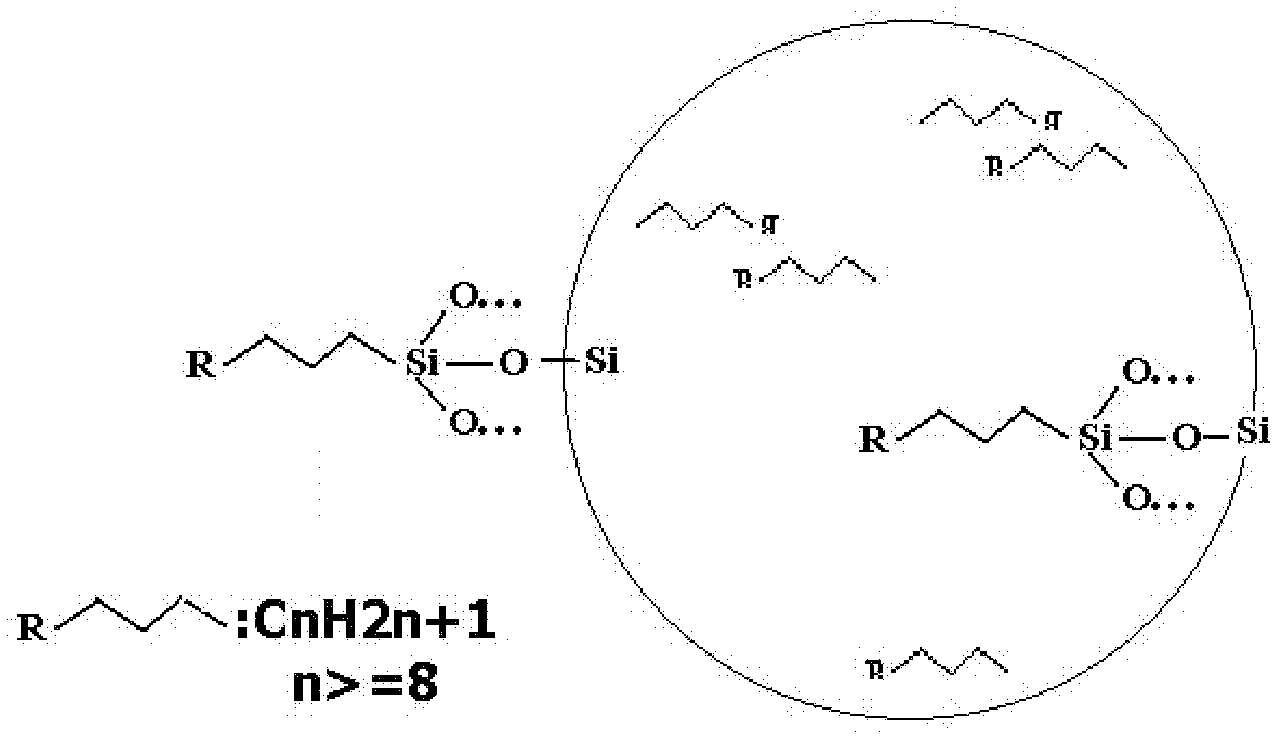

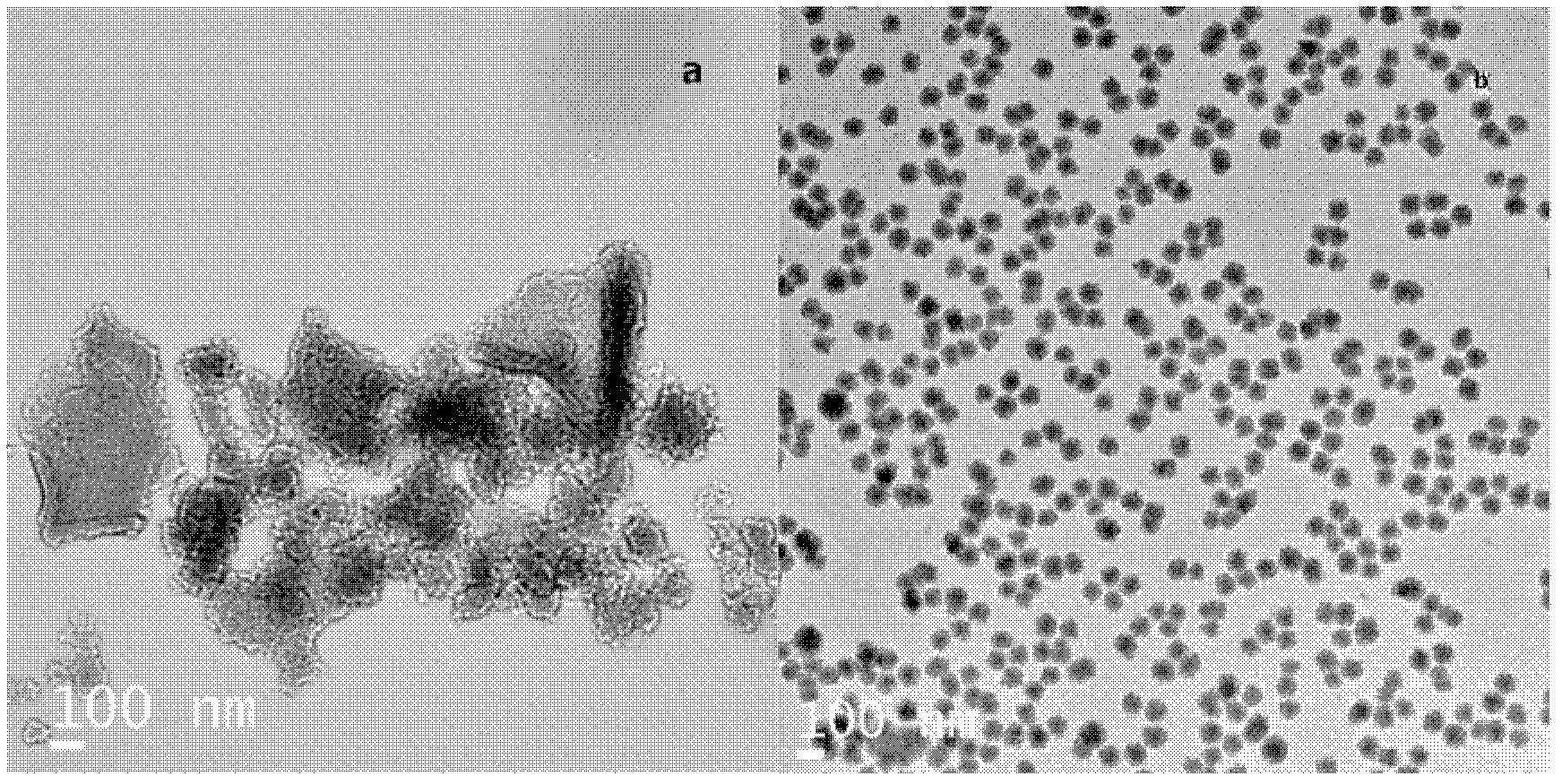

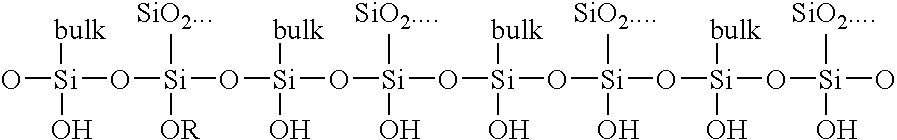

Preparation of disordered porous silicon dioxide material and application of fatty alcohol-polyoxyethylene ether to preparation of disordered porous silicon dioxide material

InactiveCN102807225AGood dispersionStrong level dyeingSilicon organic compoundsSilicaPlatinumPhysical chemistry

Owner:GUANGZHOU NACOMES NEW MATERIAL CORP

Dandelion-shaped iron phosphate microspheres and preparation method thereof through electrochemical anode oxidation

InactiveCN103556169ASynthesis temperature is lowEasy to embedElectrolysis componentsMicrosphereElectrochemical anodization

The invention discloses dandelion-shaped iron phosphate microspheres and a preparation method thereof through electrochemical anode oxidation, relating to dandelion-shaped iron phosphate microspheres and a method for preparing the dandelion-shaped iron phosphate microspheres through electrochemical anode oxidation, and aiming to solve the problems that iron phosphate micro nanoparticles prepared by the prior art are long in synthesis time, high in synthesis temperature and complex in operation step. The method disclosed by the invention comprises the steps of preparing a mixed solution of phosphoric acid and ammonium fluoride of a certain molar concentration to serve as electrolyte for anode oxidation, and generating the dandelion-shaped iron phosphate microspheres on the surface of an iron foil under conditions of certain current by taking a high-purity iron foil as an anode and a platinum sheet as a cathode. The iron phosphate obtained by the invention is used as a precursor when being used for preparing lithium iron phosphate.

Owner:HARBIN INST OF TECH

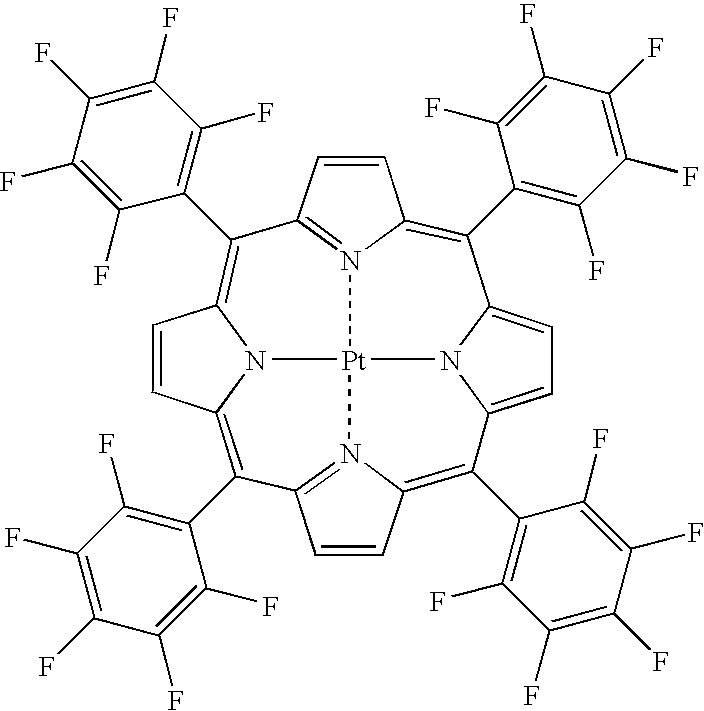

Monitor and a method for measuring oxygen concentration

InactiveUS20100018119A1Minimal spaceComponent safetyInternal combustion piston enginesFuel supply apparatusPlatinumLuminophore

Owner:AIRBUS OPERATIONS LTD

Photosensitive chitosan/precious metal nanoparticle/carbon material composite functional coating layer

InactiveCN105973964AGood biocompatibilityPromote degradationMaterial nanotechnologyMaterial analysis by electric/magnetic meansPlatinumNanoparticle

Owner:JIANGNAN UNIV

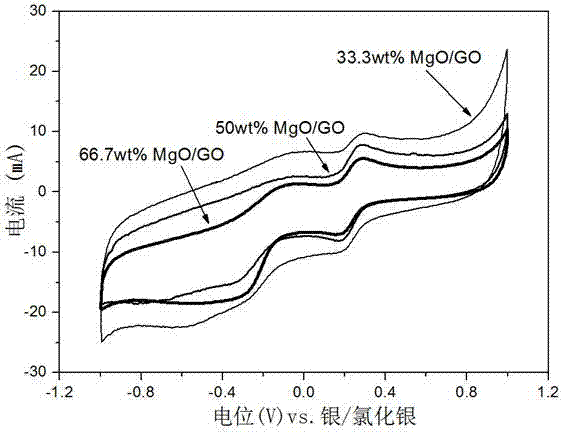

Composite cathode of microbial fuel cell and preparation method and application thereof

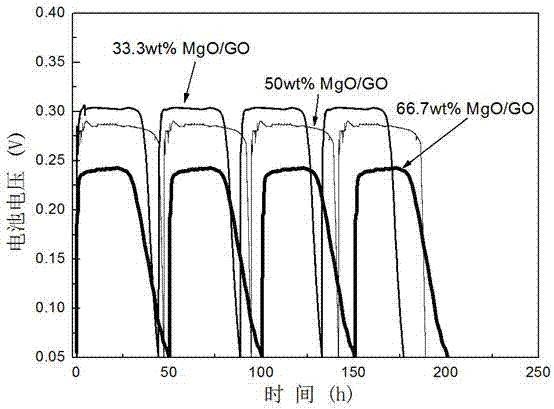

PendingCN107221682AWide variety of sourcesLow priceHybrid capacitor electrodesBiochemical fuel cellsOxide compositeAlloy

Owner:SOUTH CHINA UNIV OF TECH +1

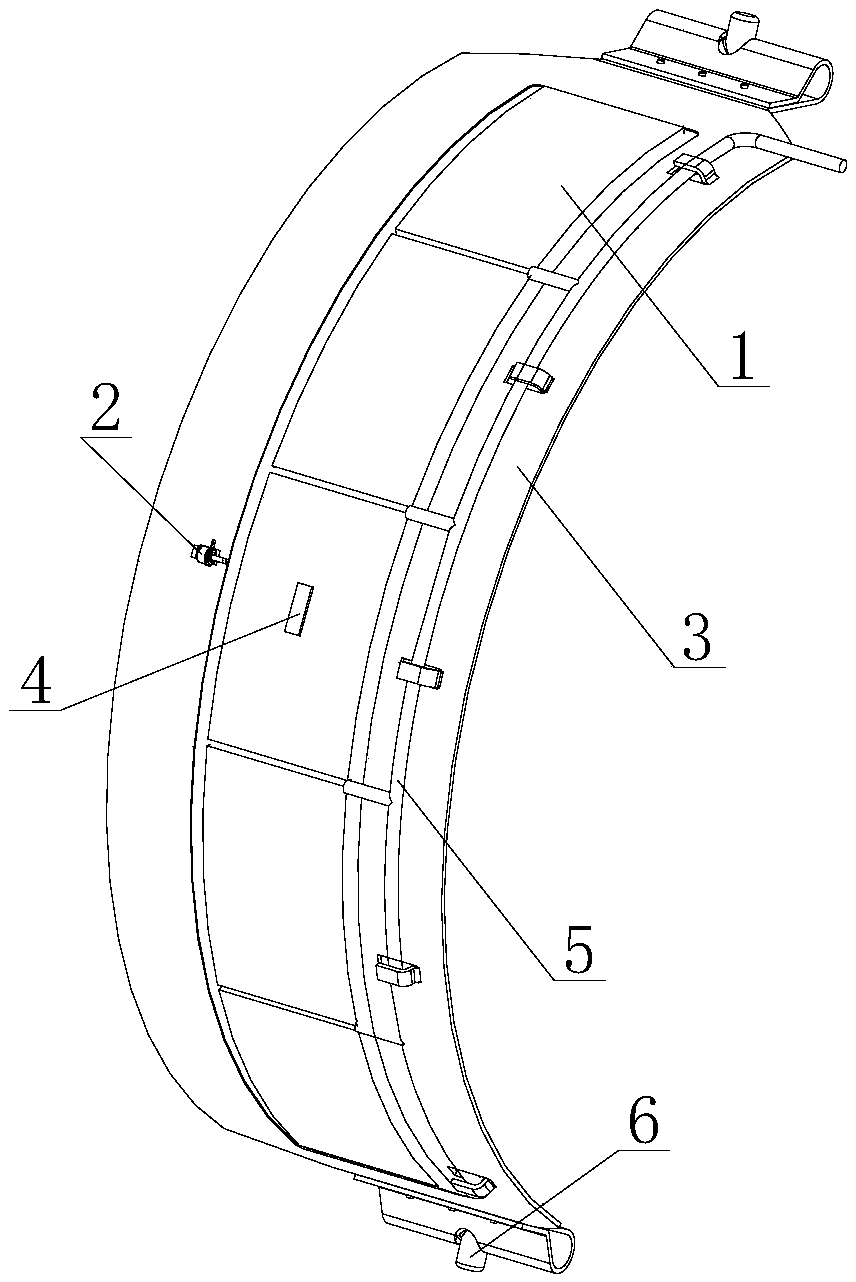

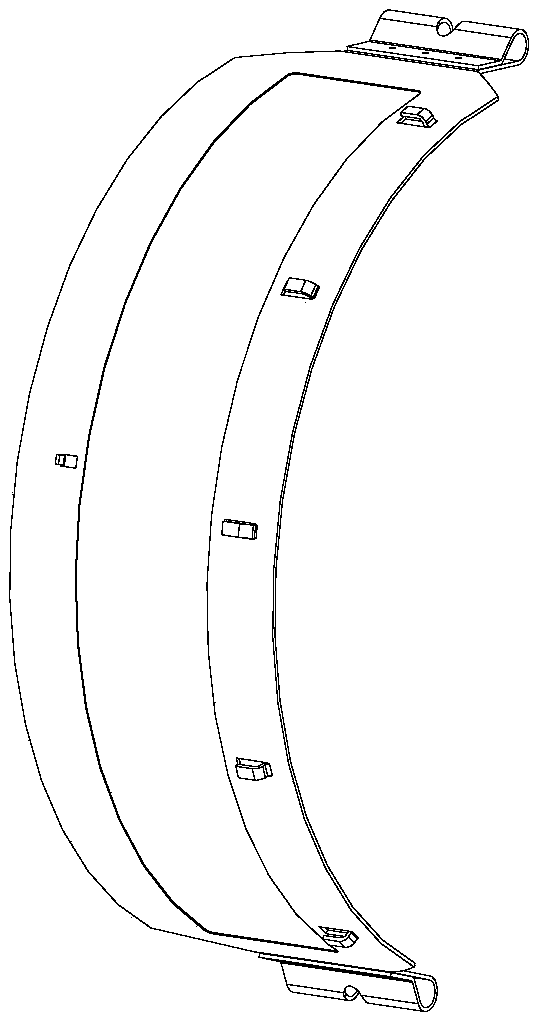

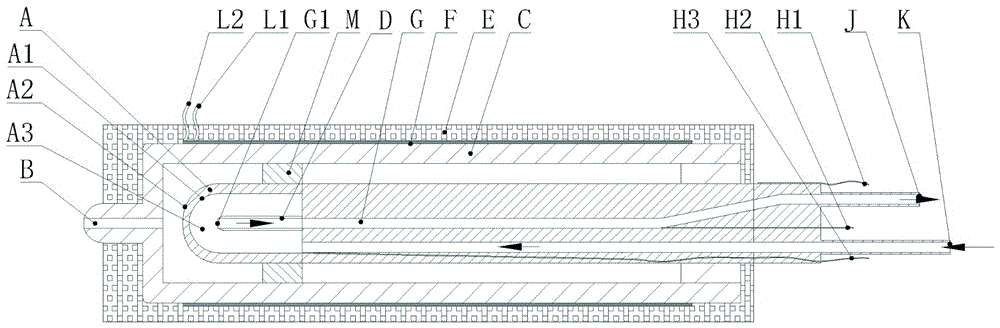

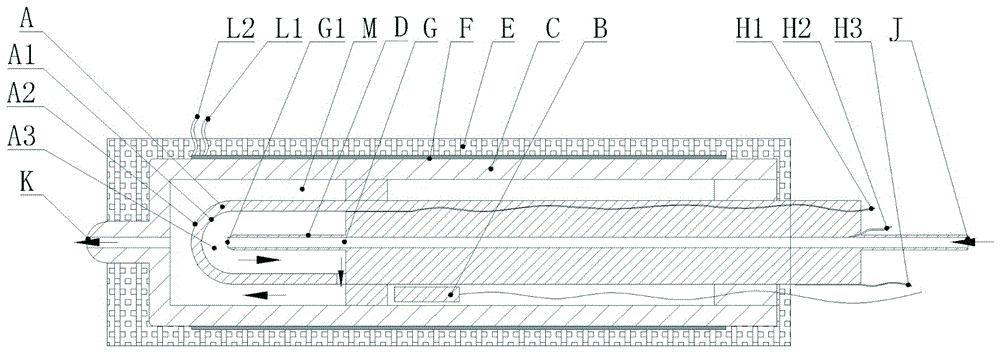

Heating device special for aircraft oil tank

Owner:SHAANXI AIRCRAFT CORPORATION

Method for concentrating platinum and palladium from platinum-palladium flotation concentrates

InactiveCN108722675AHigh precious metal contentHigh enrichment ratioFlotationMass ratioPt element

Owner:GUANGDONG INST OF RARE METALS

Fire ion detector

PendingCN106841445AAvoid safety hazardsSolve the big problem of difficult monitoringComponent separationChemical industryNitrogen gas

Owner:成都凯圣捷科技有限公司

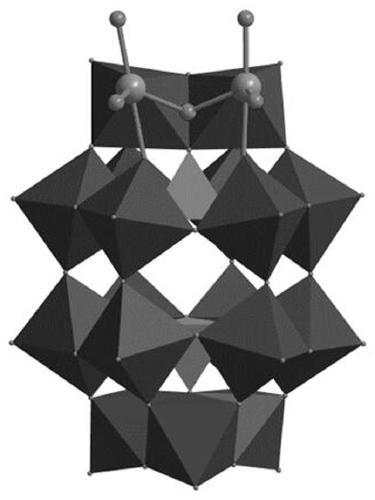

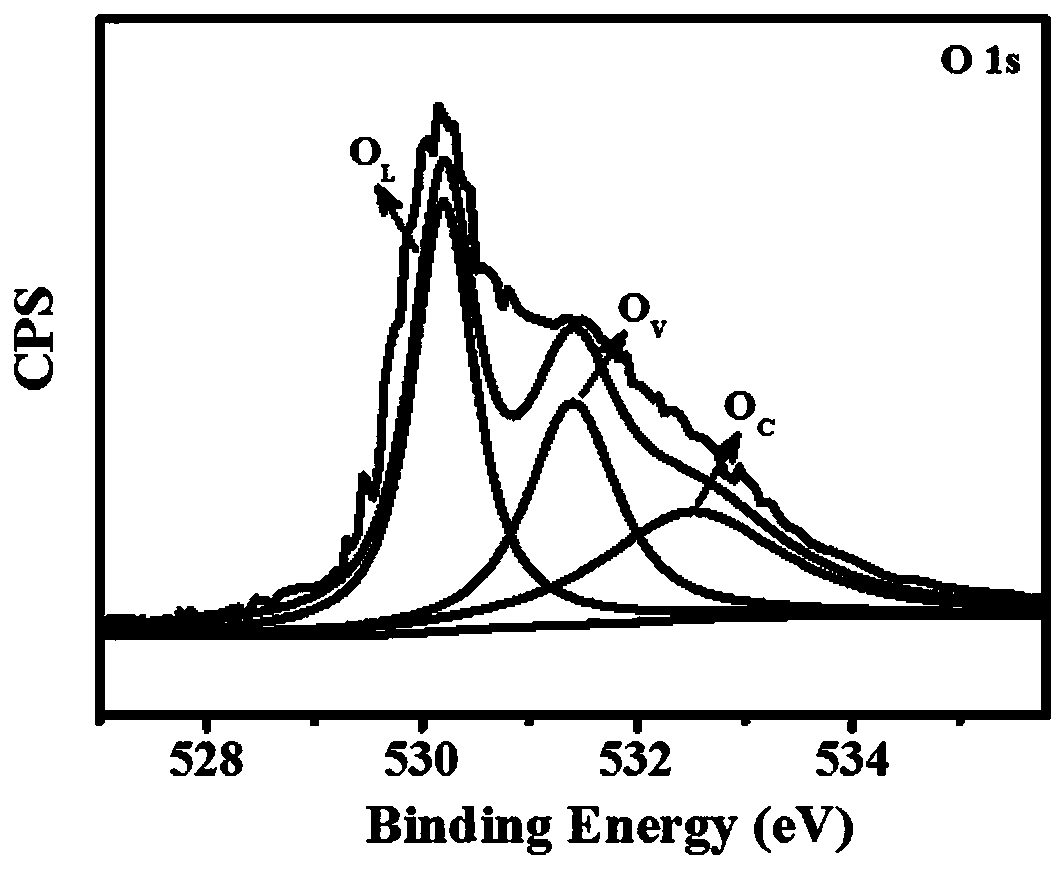

Platinum-doped tungsten oxide catalyst with rich oxygen vacancies and for electrolysis of water, and preparation method thereof

InactiveCN111250083AImprove adsorption capacityRich oxygen vacanciesMetal/metal-oxides/metal-hydroxide catalystsElectrodesPlatinumPtru catalyst

Owner:UNIV OF JINAN

Preparation method of platinum sheet target material

ActiveCN113231467AReduce the probability of crackingReduce thicknessMetal rolling arrangementsPlatinumMetallurgy

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

Fuel cell anode catalyst and preparation method thereof

PendingCN114665111AImprove anti-poisoning performanceExtended service lifeCell electrodesDoped graphenePtru catalyst

Owner:湖南清牛新材料科技有限公司 +1

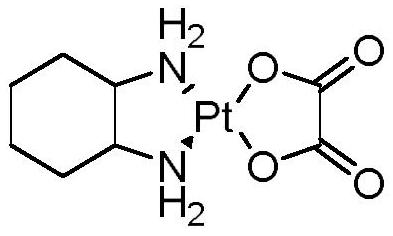

Purification method of oxaliplatin

InactiveCN112209971AReduce usageThe effect of removing silver ions is excellentPlatinum organic compoundsPlatinumPurification methods

Owner:CISEN PHARMA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap