Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

28 results about "Cobalt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt is a chemical element with the symbol Co and atomic number 27. Like nickel, cobalt is found in the Earth's crust only in chemically combined form, save for small deposits found in alloys of natural meteoric iron. The free element, produced by reductive smelting, is a hard, lustrous, silver-gray metal.

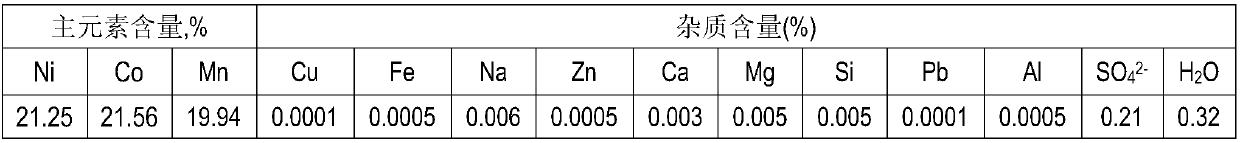

Method for preparing nickel-cobalt-manganese ternary material precursor

ActiveCN103943847ARealize comprehensive utilizationIncrease profitCell electrodesSecondary cellsManganeseCobalt

Owner:北京盟固利新材料科技有限公司

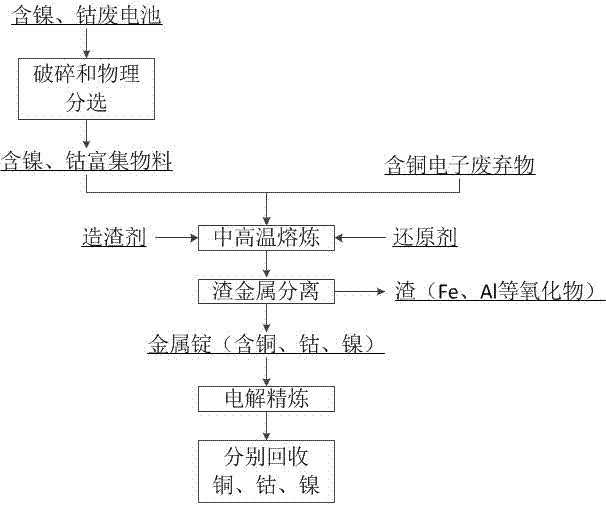

Synergetic metal recycling method for nickel and cobalt containing waste batteries and copper containing electronic waste

InactiveCN107012332AHigh purityAvoid efficiencyPhotography auxillary processesWaste accumulators reclaimingElectrolysisElectrical battery

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

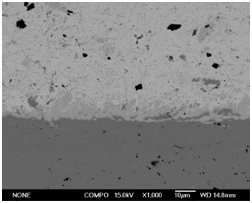

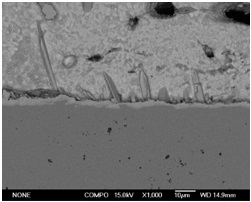

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

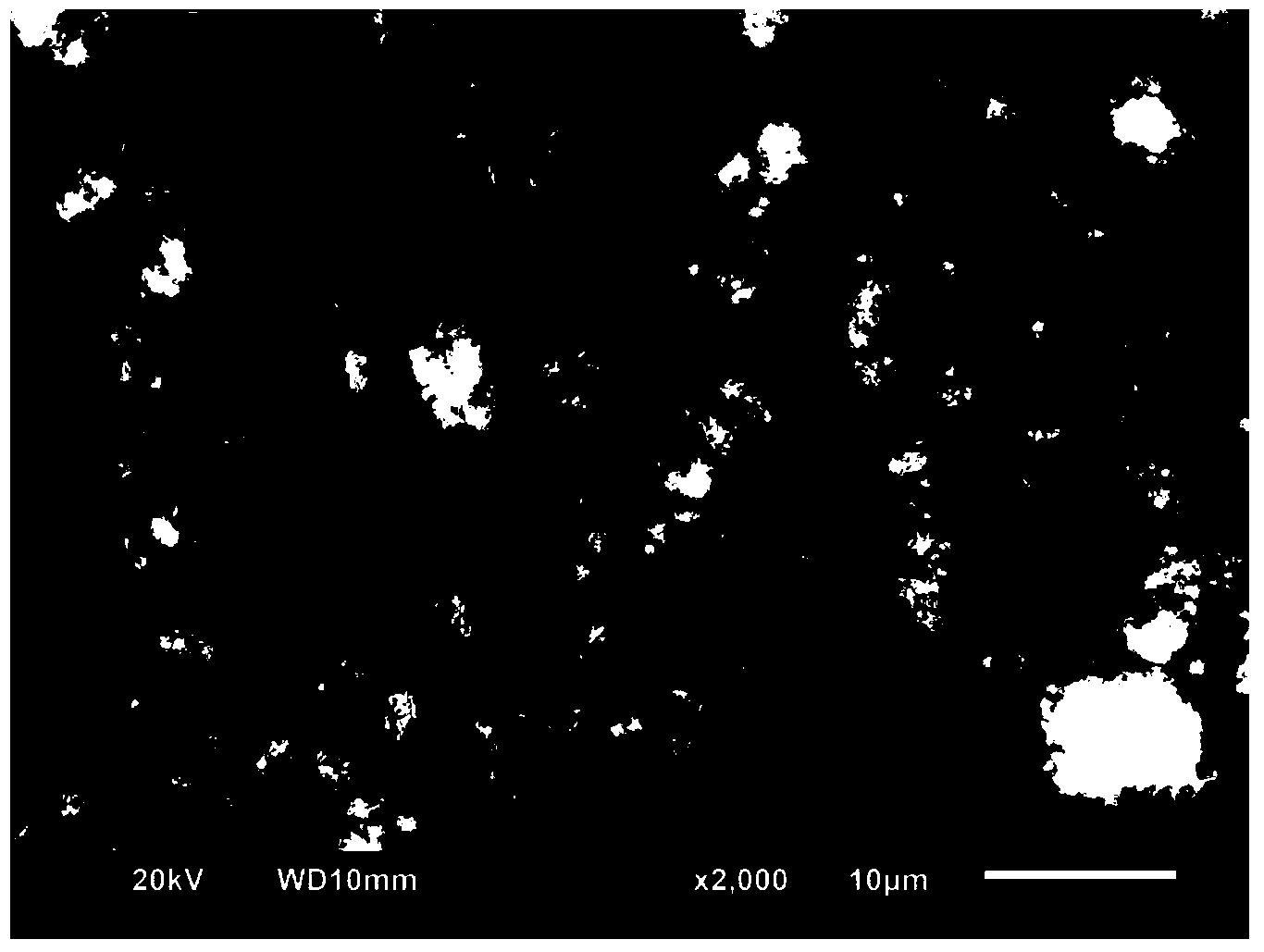

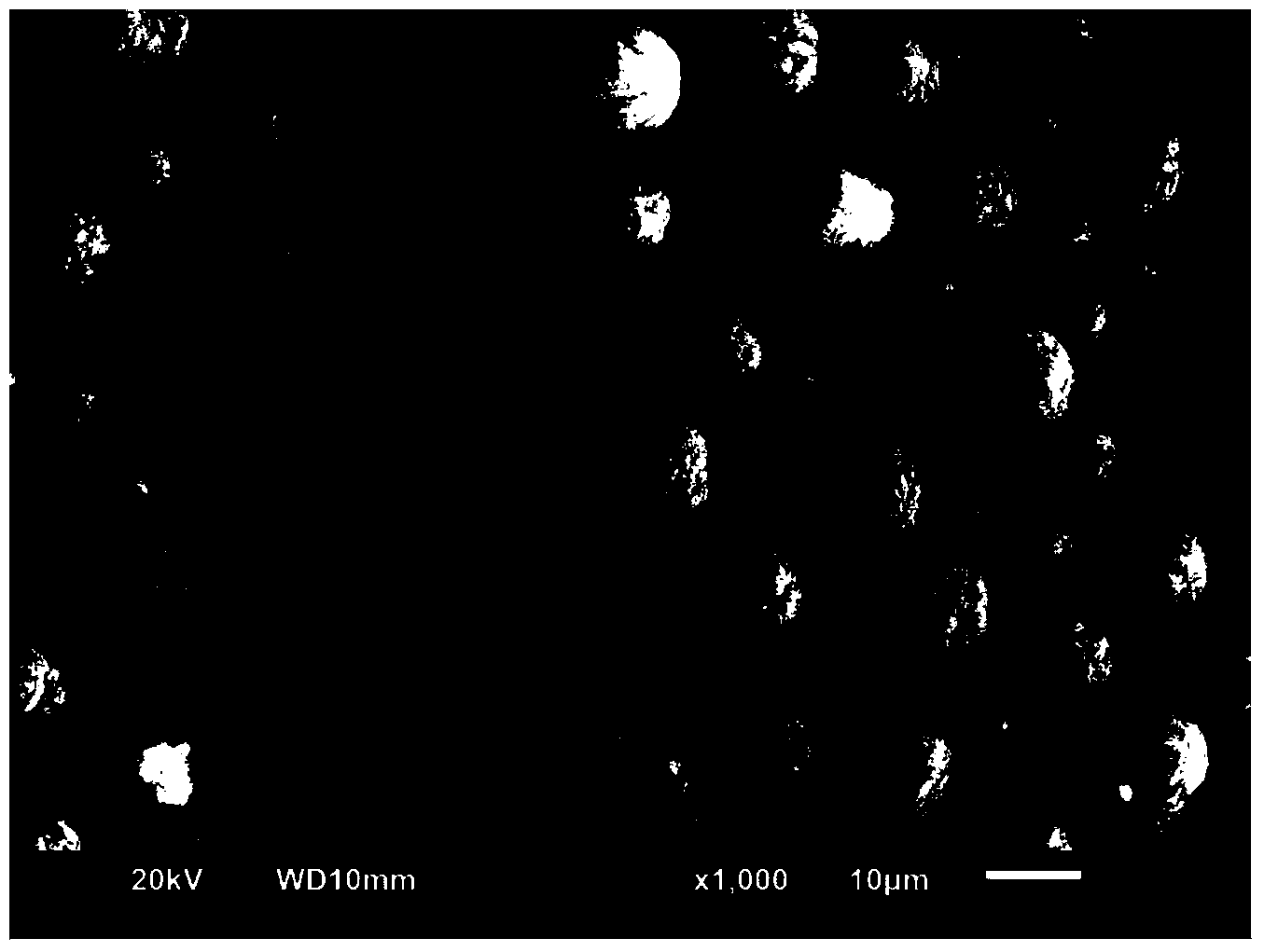

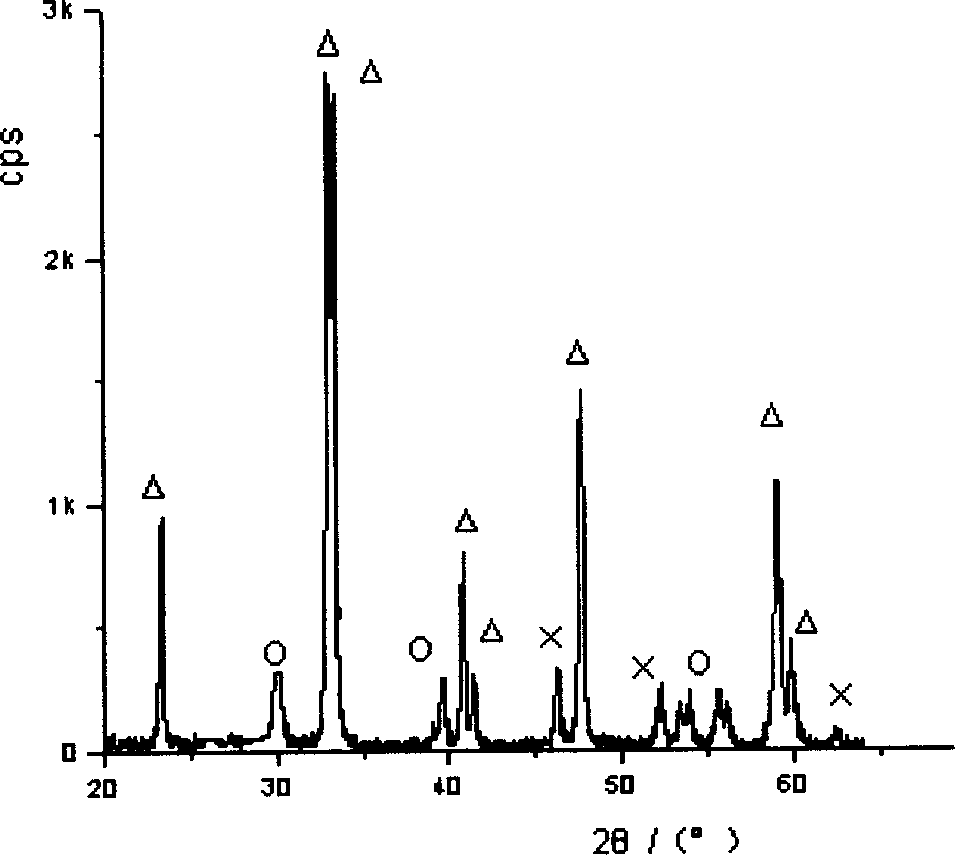

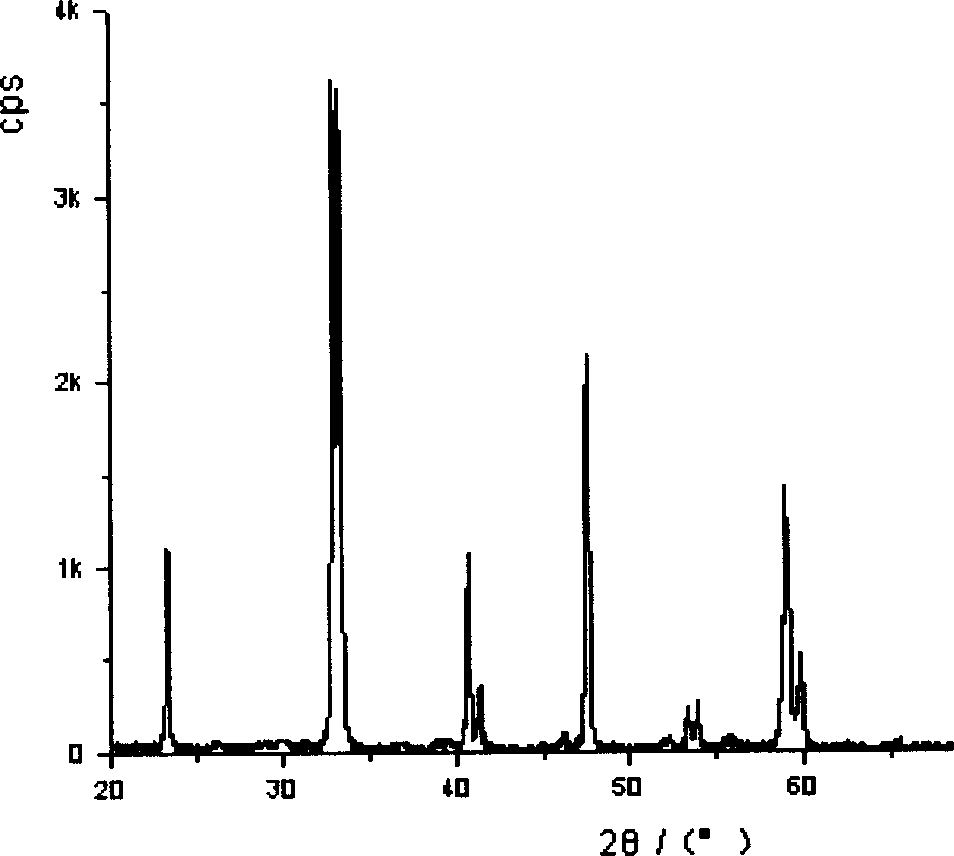

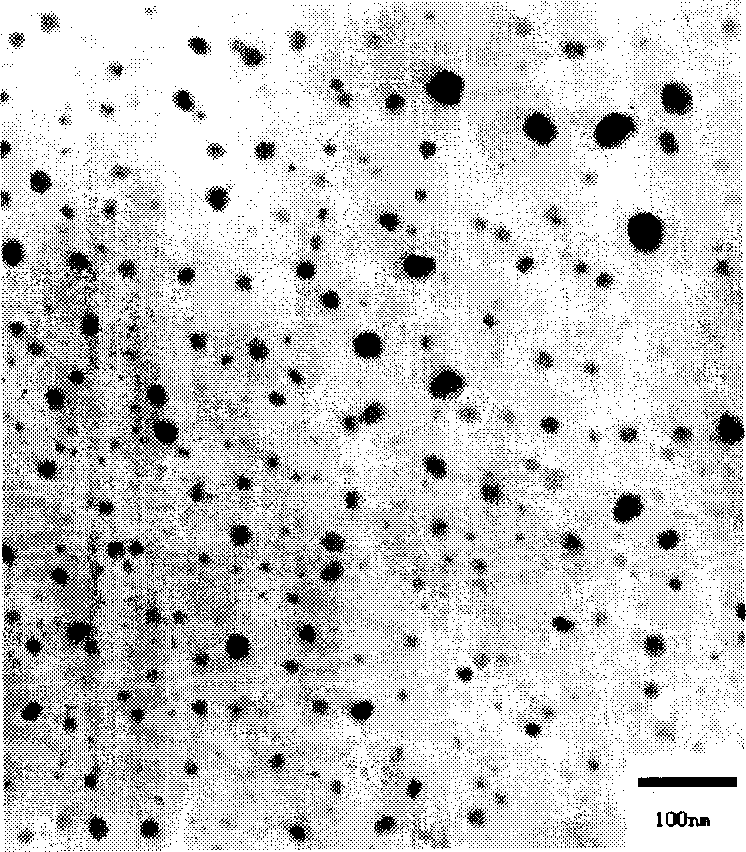

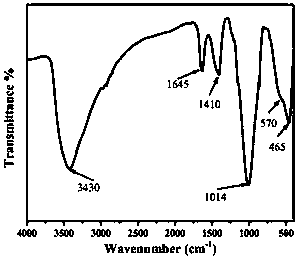

A microwave-absorbing corrosion-resistant powder material and a preparation method thereof

InactiveCN108889939AReduce self-healing abilityMaintain electromagnetic propertiesOther chemical processesTransportation and packagingMesoporous silicaMetal particle

The invention discloses a corrosion-resistant powder material capable of absorbing microwave and a preparation method thereof, wherein the powder material is a core-shell structure, the core-shell structure comprises a shell and a core, the shell is a mesoporous silicon dioxide layer, the core is magnetic metal particles, a corrosion inhibitor is filled between the shell and the core, and the particle size of the magnetic metal particles is 0.6 1 micron, is iron carbonyl and nickel carbonyl, or a composite of iron carbonyl and cobalt carbonyl, the weight ratio of iron carbonyl to nickel or cobalt is 8: 1 4: 1. The invention can effectively solve the problems of insufficient microwave absorption and deterioration of corrosion resistance of conventional coatings.

Owner:SHANDONG GEWU NEW MATERIAL TECH CO LTD

Method of burning gel of stearic acid for preparing Nano LaCo03 in type of perovskite

InactiveCN1915839AOvercome the shortcomings of large particle size and uneven distributionRaw materials are easy to getLithium compoundsCobalt compoundsCombustionNitrate

Owner:ZHONGBEI UNIV

NiCoP nanoparticles grown on surface of g-C3N4 in situ as well as preparation method and application of NiCoP nanoparticles

InactiveCN107617443ASimple and fast manufacturing methodEasy to operatePhysical/chemical process catalystsHydrogen productionHydrogenNanoparticle

The invention provides NiCoP nanoparticles grown on the surface of g-C3N4 in situ as well as a preparation method and application of the NiCoP nanoparticles to production of hydrogen by photocatalytically decomposing water, and belongs to the technical field of photocatalytic decomposition of the water to prepare the hydrogen. The preparation method comprises the following steps: firstly, preparing g-C3N4powder particles; then adding 10mL to 30mL of secondary distilled water into 200mg to 400mg of the g-C3N4 powder particles; after carrying out ultrasonic treatment for 1h to 3h, stirring for 1h to 3h; then adding 10mg to 150mg of a nickel source and 10mg to 150mg of a cobalt source; after carrying out the ultrasonic treatment for 5min to 20min, stirring for 5min to 20min; then adding 50mgto 600mg of a phosphorous source; after carrying out the ultrasonic treatment for 1h to 3h, stirring for 1h to 3h; then drying under the condition that the temperature is 50 DEG C to 80 DEG C; after the water is completely volatilized, sufficiently grinding a product; then calcining for 1h to 3h in a nitrogen atmosphere under the condition that the temperature is 200 DEG C to 400 DEG C; finally, centrifuging and washing by utilizing the secondary distilled water and ethanol; drying a centrifugal product for 10h to 20h under a vacuum condition, so as to obtain the NiCoP nanoparticles grown on the surface of the g-C3N4 in situ.

Owner:JILIN UNIV

Process and corresponding apparatus for continuously producing gaseous hydrogen to be supplied to micro fuel cells and integrated system for producing electric energy

A process for the production of hydrogen for micro fuel cells, comprises the successive steps of: continuously supplying a catalytic bed with an aqueous solution of sodium borohydride, the catalytic bed being made of at least one metal chosen among cobalt, nickel, platinum, ruthenium with obtainment of hydrogen and of a by-product comprising sodium metaborate, continuously recovering the hydrogen thus obtained and supplying, with said hydrogen as it is as obtained, a micro fuel cell which transforms hydrogen into electric energy. An apparatus provides continuous supply of hydrogen to a micro fuel cell. An integrated system structured for continuously producing and supplying hydrogen to a micro fuel cell and for converting the continuously supplied hydrogen into electric energy.

Owner:STMICROELECTRONICS SRL

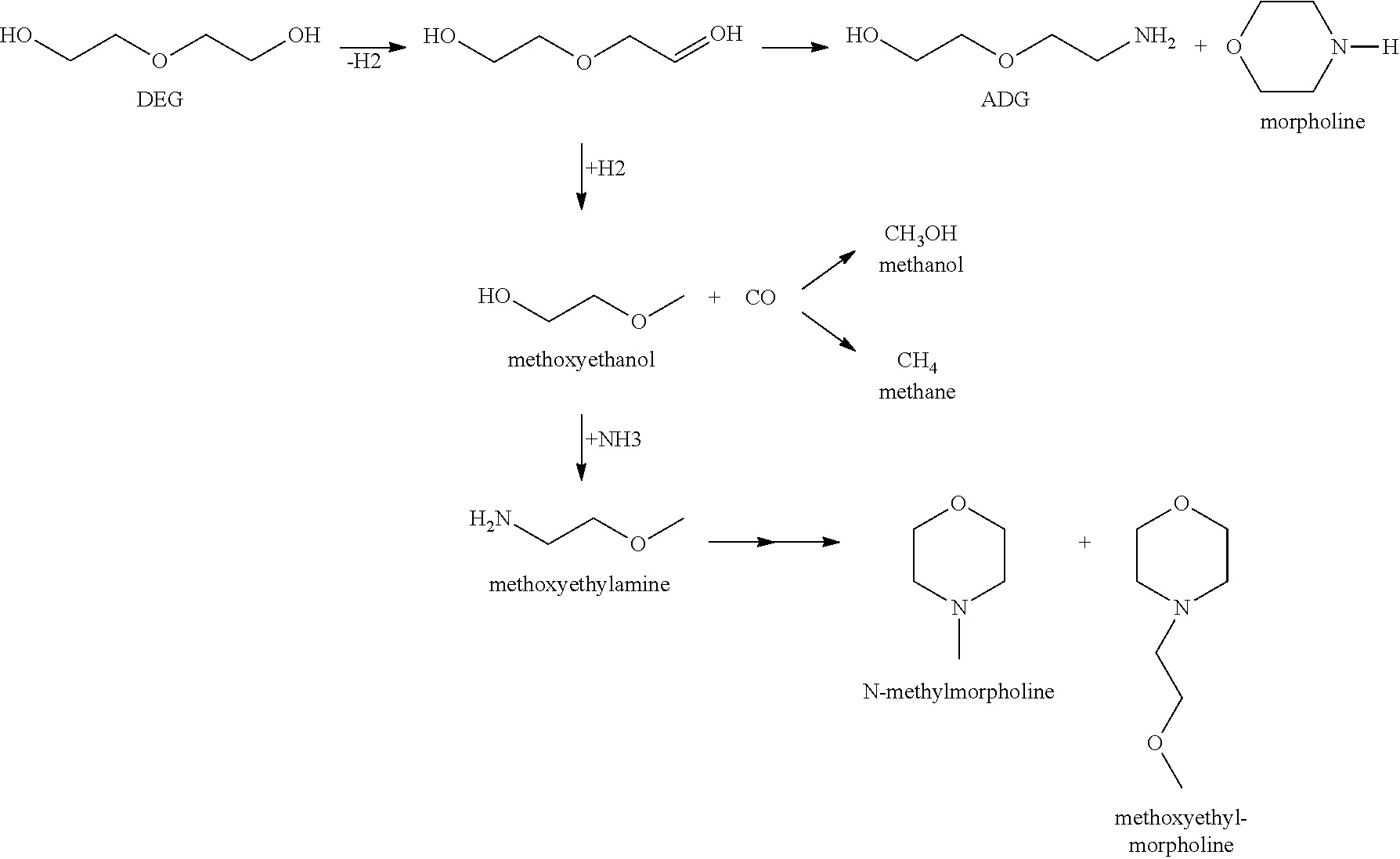

Catalyst and process for preparing an amine

ActiveUS8318982B2Enhances their economic viabilitySpeed up the conversion processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCeriumKetone

Owner:BASF AG

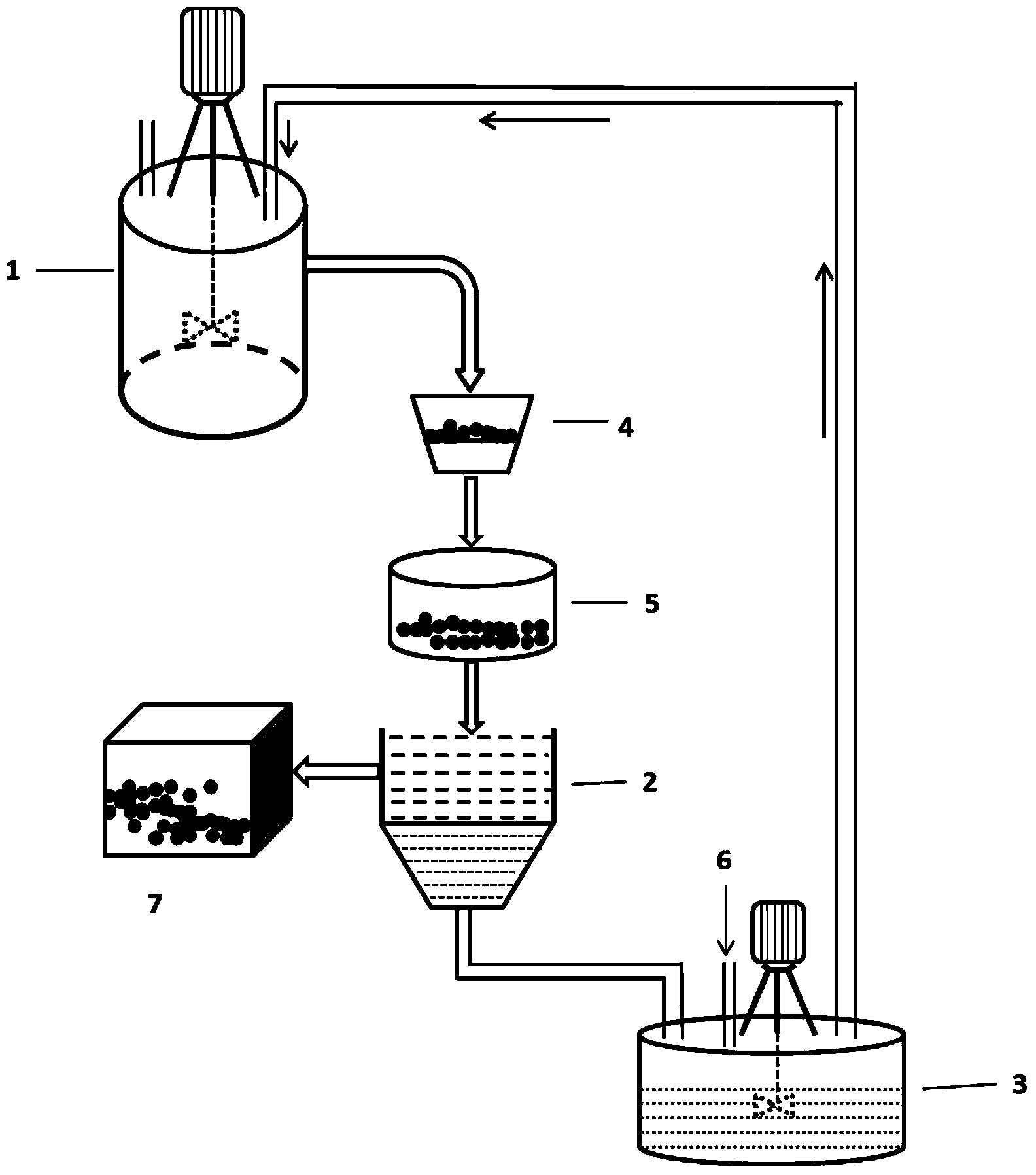

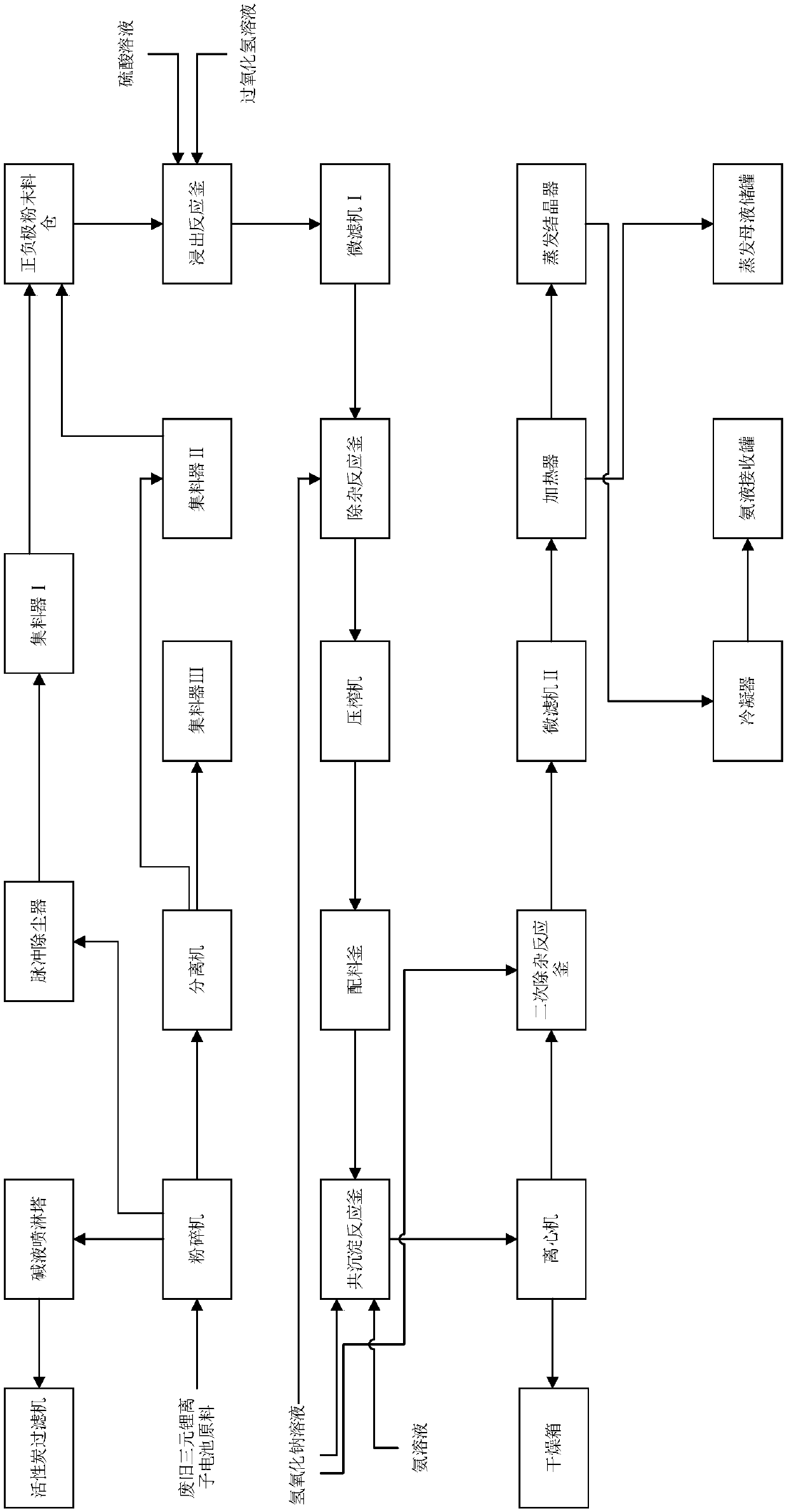

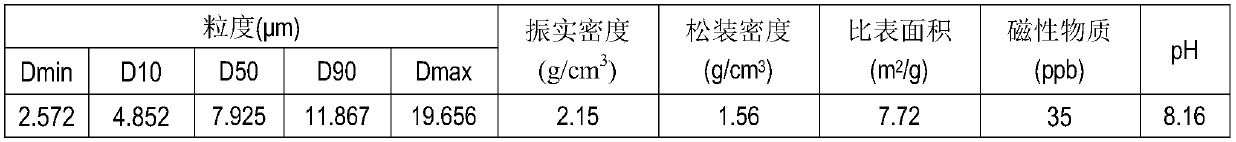

System and technology for continuously recycling waste ternary lithium-ion battery

PendingCN107946687AReduce manufacturing costAchieving continuous operationWaste accumulators reclaimingBattery recyclingManganeseEvaporation

Owner:TIANQI LITHIUM CORP

Compositions and materials for electronic applications

ActiveUS20140346387A1Improve material performancePermeability can be maximizedAntenna supports/mountingsInorganic material magnetismISM bandMagnetic characteristic

Embodiments disclosed herein relate to using cobalt (Co) to fine tune the magnetic properties, such as permeability and magnetic loss, of nickel-zinc ferrites to improve the material performance in electronic applications. The method comprises replacing nickel (Ni) with sufficient Co+2 such that the relaxation peak associated with the Co+2 substitution and the relaxation peak associated with the nickel to zinc (Ni / Zn) ratio are into near coincidence. When the relaxation peaks overlap, the material permeability can be substantially maximized and magnetic loss substantially minimized. The resulting materials are useful and provide superior performance particularly for devices operating at the 13.56 MHz ISM band.

Owner:ALLUMAX TTI LLC

High-rigidity and high-toughness resin material for clothing buttons

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

Preparation method for manganese dioxide@silica nano composite particles with core-shell structures

Owner:UNIV OF SCI & TECH OF CHINA

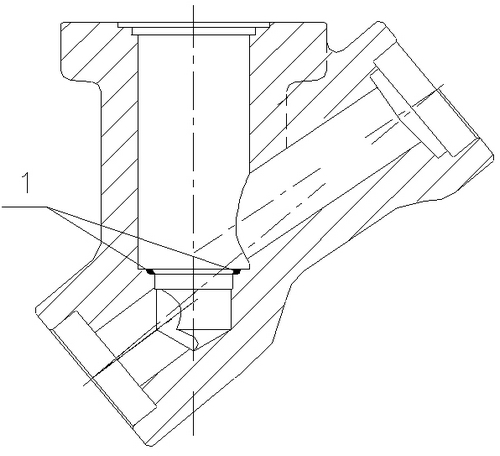

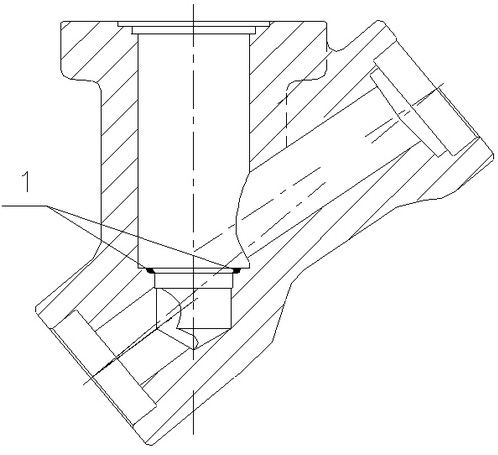

Argon arc welding surfacing process for cobalt-free material ERFeCr-A5

Owner:DALIAN DAGAO VALVE

Fertilizer special for pasture

InactiveCN103553748ANutritional diversitySafe useFertilizer mixturesPhosphoric acidAdditional values

Owner:HENAN UNIV OF ANIMAL HUSBANDRY & ECONOMY

Novel powder metallurgical gear

InactiveCN106041095AUniform densityLarge elongationTransportation and packagingMetal-working apparatusCarbon fibersALUMINUM STEARATES

Owner:黄宇

Preparation method of battery cathode material lithium nickel cobalt aluminum oxide precursor

The invention discloses a preparation method of battery cathode material lithium nickel cobalt aluminum oxide precursor and relates to the technical field of batteries. The preparation method comprises the steps of (1) preparing nickel-cobalt solution; (2) preparing precipitate; (3) purifying the precipitate; (4) preparing a premix; (5) roasting an end product. The lithium nickel cobalt aluminum oxide precursor is prepared by means of aluminum nitrate roasting; the difficulty in forming large particulate precipitate due to high precipitating speed of trivalent aluminum ions is avoided; the lithium nickel cobalt aluminum oxide precursor that is roasted has high true density. In addition, roasting allows fewer acid radicals to be left in the precipitate, and the purity of the lithium nickelcobalt aluminum oxide precursor is further improved accordingly.

Owner:HEFEI CHENGDIAN TECH CO LTD

Novel thermoforming reinforcer and processing method thereof

Owner:JINGJIANG XINCHENG VEHICLE PARTS

Self-lubricating hard alloy wire drawing die and preparation method thereof

InactiveCN109226301AImprove drawing process qualityAchieve self-lubricating effectDrawing diesManufacturing technologyHigh energy

Owner:SOUTHEAST UNIV

Method for producing ytterbium-doped lithium nickel cobalt manganese oxide material used for lithium ion battery

ActiveCN106257715ALoose tube wallAlleviate volume expansionCell electrodesSodium-ion batteryManganese oxide

Owner:ZHEJIANG CHANGXING KISUN POWER SUPPLY

Stable lithium ion battery with high capacitance

InactiveCN103606666AImproved high-magnification performanceImprove power densityCell electrodesSecondary cellsCapacitanceManganese

The invention discloses a stable lithium ion battery with high capacitance. Two poles are respectively prepared from a composite carbon cathode material and a ternary composite anode material. By adopting the stable lithium ion battery, the high magnification performance and the power density of the lithium ion battery can be effectively improved. The stable lithium ion battery has high-magnification charge and discharge properties. Three transition metals such as nickel, manganese and cobalt are evenly mixed, so that a layered structure of the material is stabilized by synergistic effects of the nickel, manganese and cobalt, and the charge and discharge capacities, the cycle performance and the overcharging tolerance of the material are improved.

Owner:JIANGSU TENPOWER LITHIUM

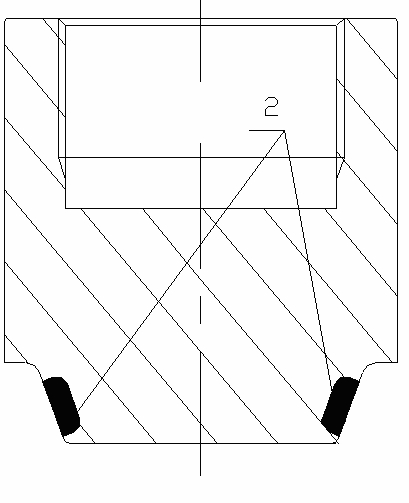

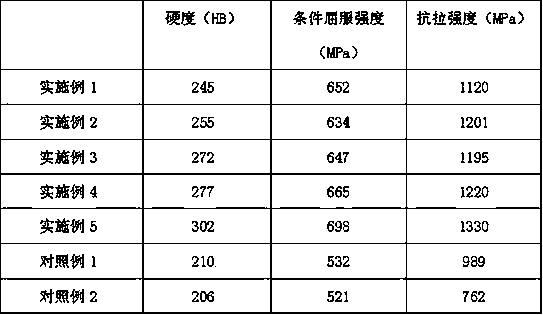

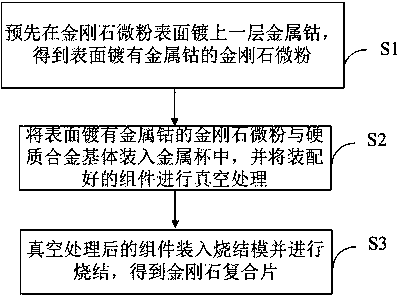

Diamond composite sheet and preparation method thereof

ActiveCN107790710AImprove wear resistanceAvoid abrasionDrill bitsTransportation and packagingAlloy substrateCemented carbide

Owner:SHENZHEN HAIMINGRUN SUPERHARD MATERIALS

Alloy powder for plasma cladding

PendingCN109735842AImprove performanceGood workmanshipMetallic material coating processesWear resistantAlloy

Owner:WEIFANG UNIVERSITY

Method for recovering cobalt and nickel from waste lithium battery

ActiveCN107910612AAchieve separationSimple processWaste accumulators reclaimingBattery recyclingManganeseNitrogen gas

Owner:贵州红星电子材料有限公司

Preparation method of iron-tantalum alloy powder, iron-tantalum alloy powder and application

ActiveCN112059195AHigh purityDense highTransportation and packagingMetal-working apparatusAlloyUltimate tensile strength

The invention relates to a preparation method of iron-tantalum alloy powder, the iron-tantalum alloy powder and application. The preparation method of the iron-tantalum alloy powder comprises the steps: firstly, an iron material and a tantalum material are prepared according to the target atom proportion and mixed; then a mixture is completely molten at the temperature of 1542-1600 DEG C; and thenatomization is conducted under the action of inert gas, and the iron-tantalum alloy powder is obtained. According to the preparation method, the melting temperature of the iron-tantalum mixture is controlled to be 1542-1600 DEG C, the atomization condition is optimized, the purity of the prepared iron-tantalum alloy powder is larger than or equal to 99.95%, the oxygen content is smaller than or equal to 600 ppm, and the iron-tantalum alloy powder with the particle size smaller than 150 meshes is obtained through screening; and an iron-cobalt-tantalum alloy sputtering target material with thehigh purity, high compactness, the high bending strength and the qualified magnetic flux is prepared advantageously, wherein tantalum rim charge of the tantalum target material is used as the tantalummaterial for preparation, so that waste is turned into wealth.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Corrosion-resistant alloy

InactiveCN103265751ACorrosion resistant alloyLithium

The invention relates to a corrosion-resistant alloy, consisting of main components and auxiliary components, wherein the main components consist of the following components in percentage by mass: 32-38% of magnesium, 2-6% of molybdenum, 15-18% of lithium, 2-5% of cobalt, 18-23% of nickel and 2-5% of vanadium; and the auxiliary components consist of the following components in percentage by mass: 15-25% of ethylene-tetrafluoroethylene copolymer, and 1-2% of a lubricant. The corrosion-resistant alloy has good corrosion resistance.

Owner:CHUZHOU HAOYU SLIDING BEARING CO LTD

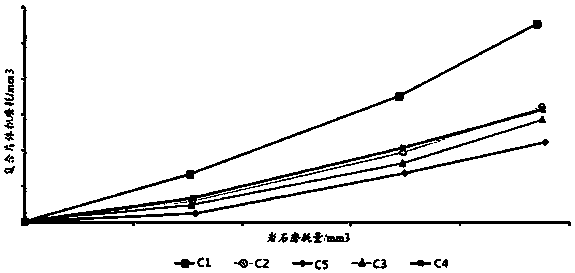

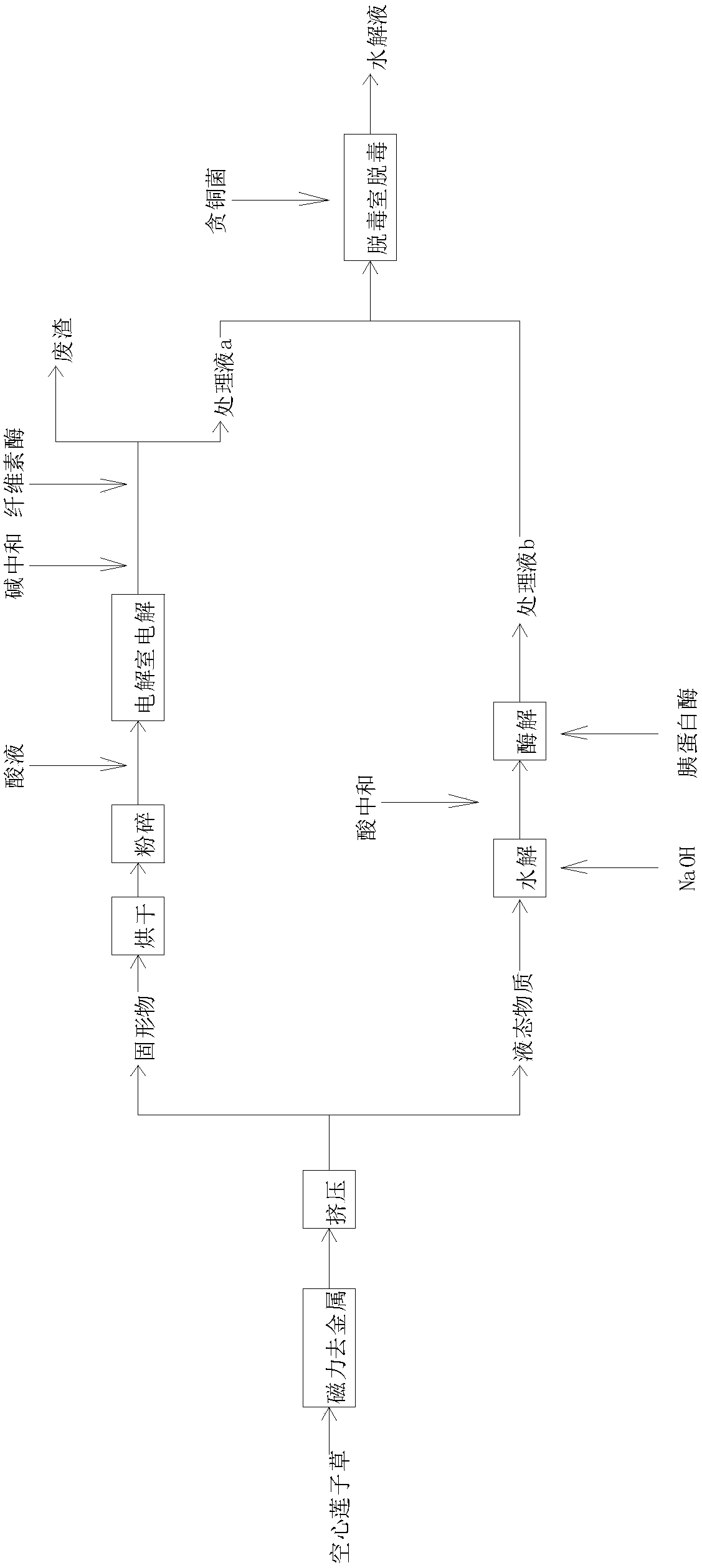

Hydrolysis saccharification process of alternanthera philoxeroides

ActiveCN108315373AReduce the content of metal ionsOptimizing Fermentation ConditionsFermentationCupriavidus speciesCobalt

Owner:JINING UNIV

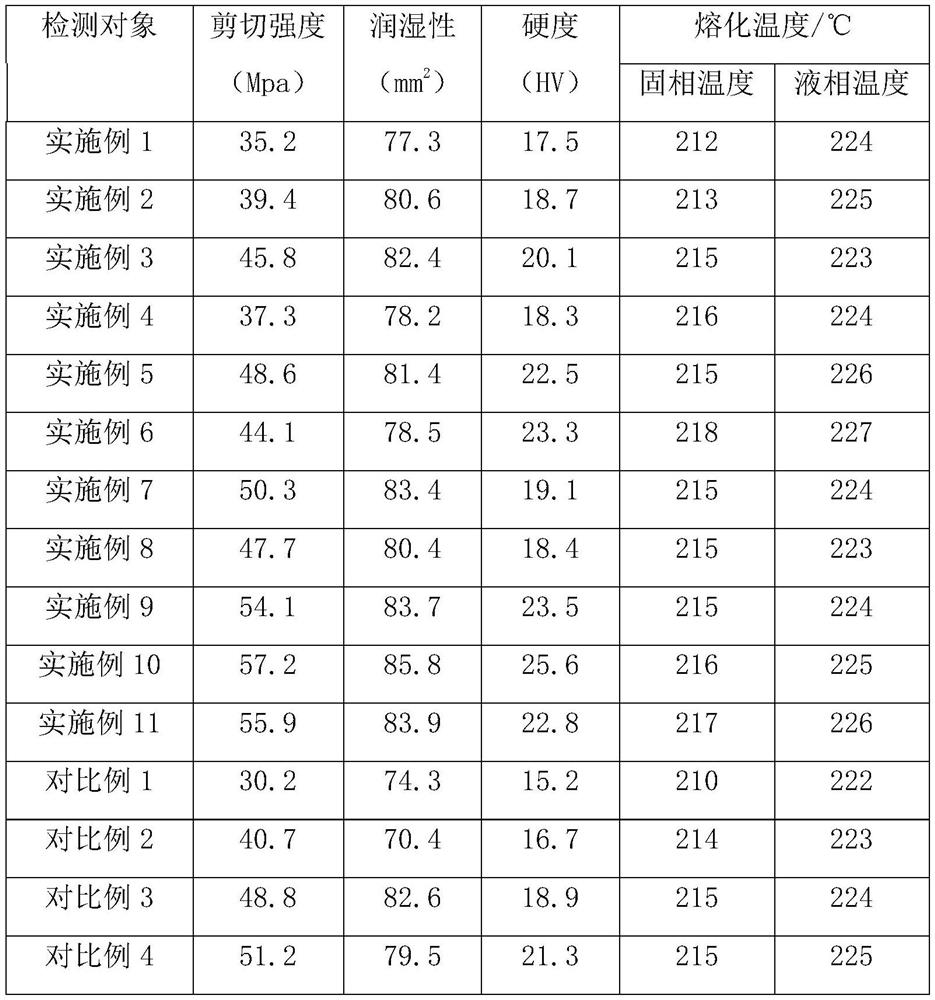

Low-silver high-strength lead-free tin-based brazing filler metal and preparation method thereof

PendingCN114871628AImprove reliabilityReduce pollutionWelding/cutting media/materialsSoldering mediaCeriumCobalt

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

Preparation method of catalyst for catalytic oxidation synthesizing of acrolein through propylene

InactiveCN103285913AHigh catalytic activityMolecular sieve catalystsOrganic compound preparationCatalytic oxidationManganese

Owner:陈和平

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap