Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about "Arc welding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

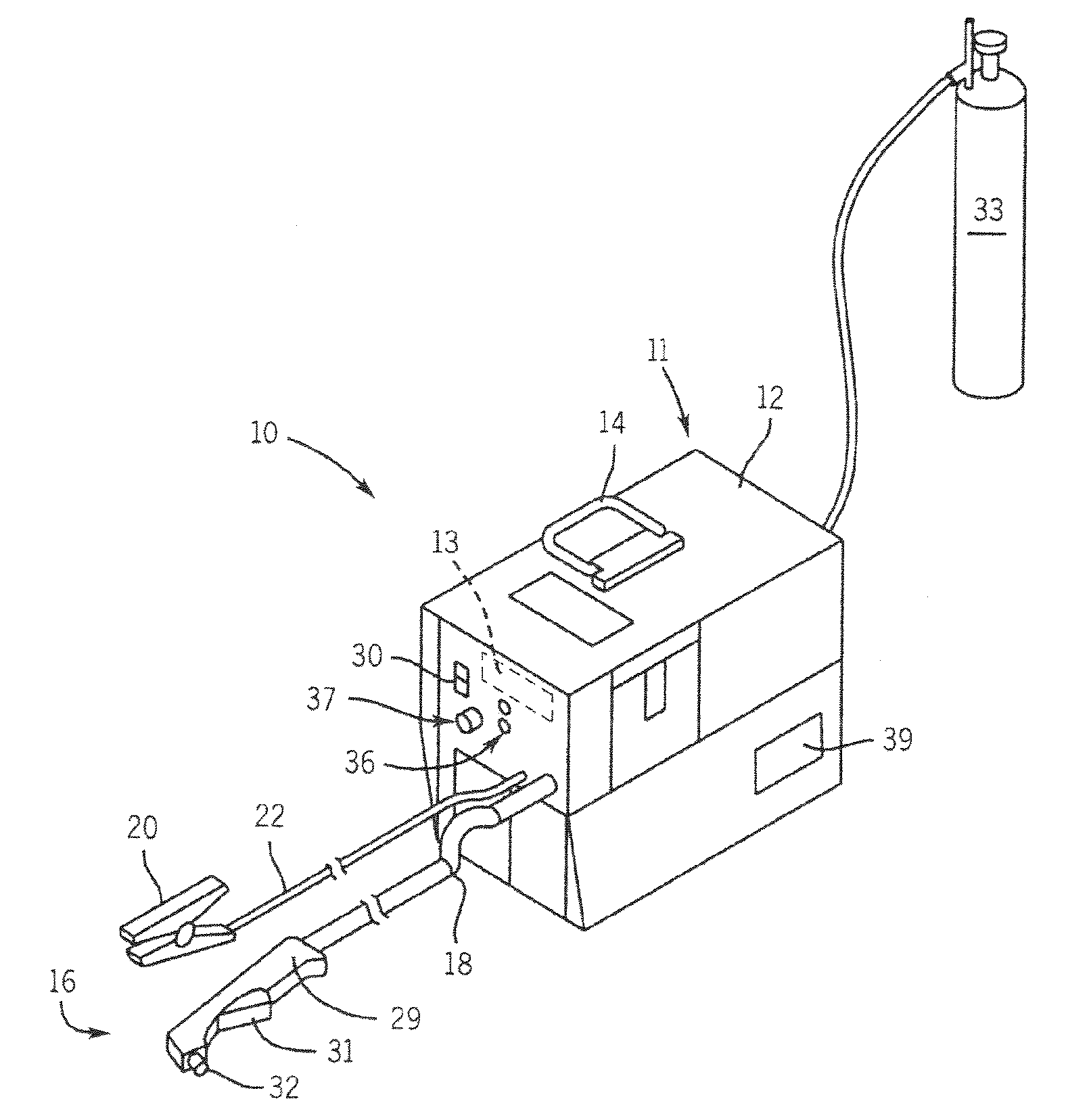

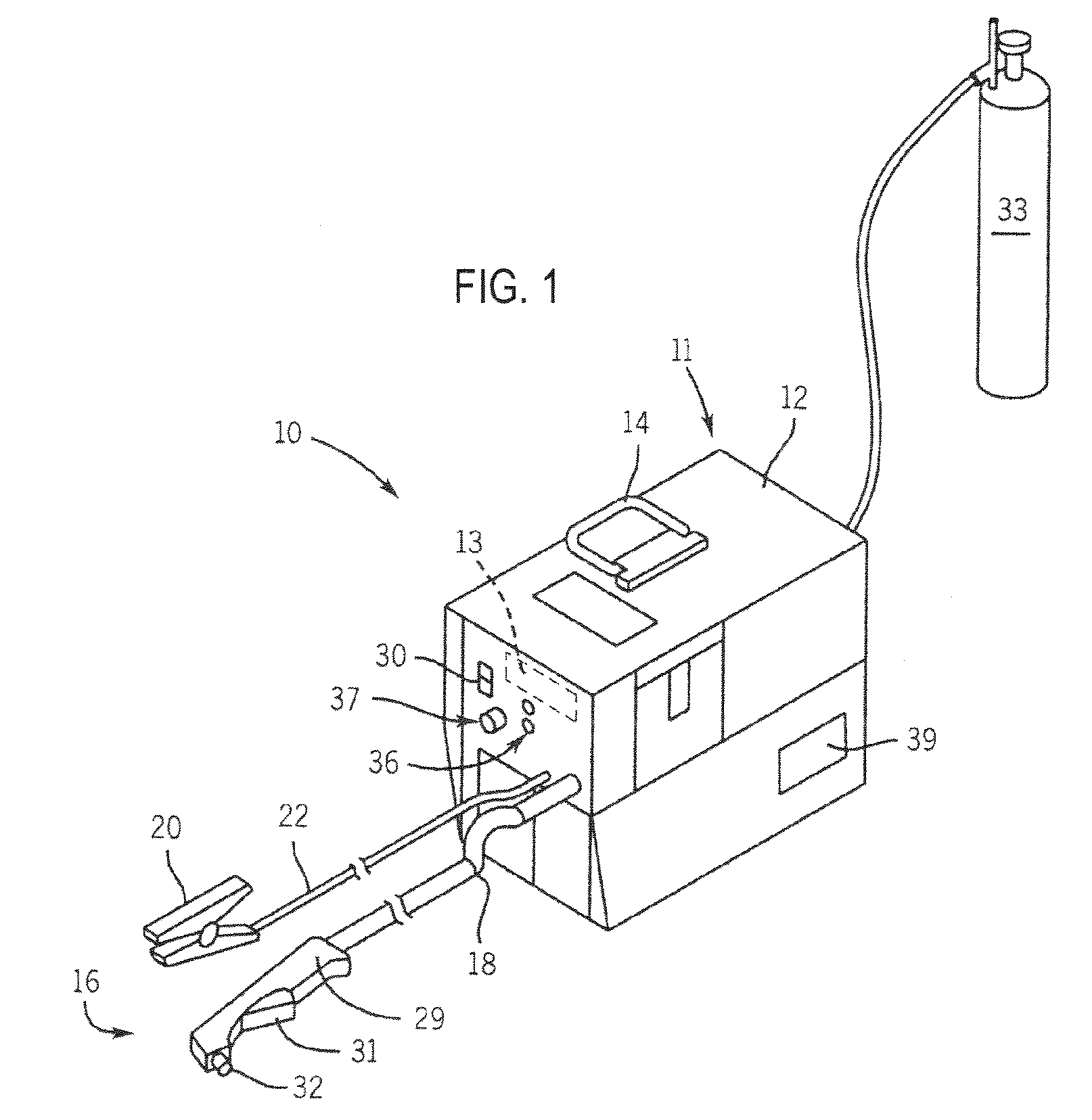

Arc Welder and Related System

ActiveUS20080190900A1Welding/cutting auxillary devicesArc welding apparatusEngineeringMechanical engineering

Owner:ZHANG YU MING

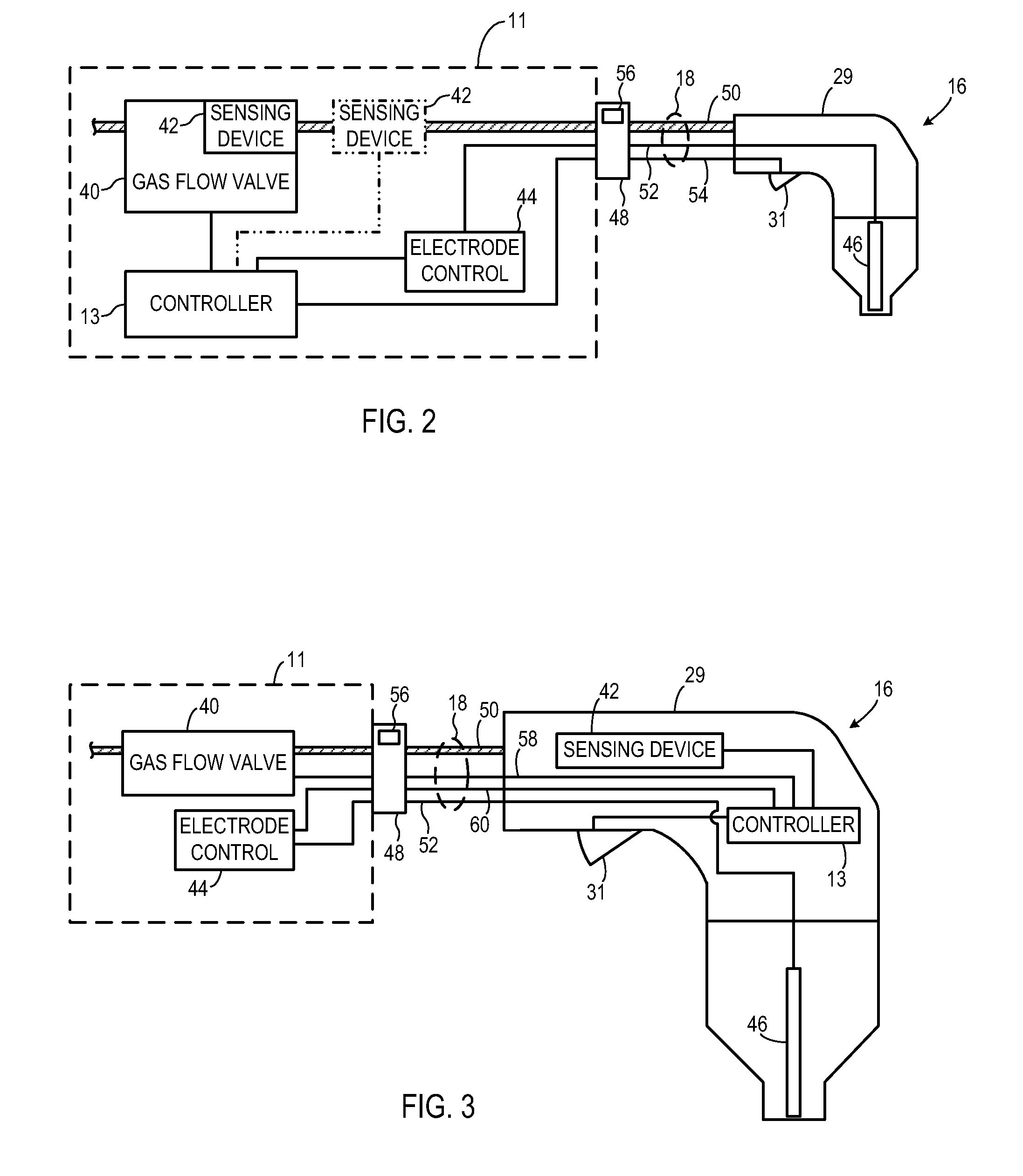

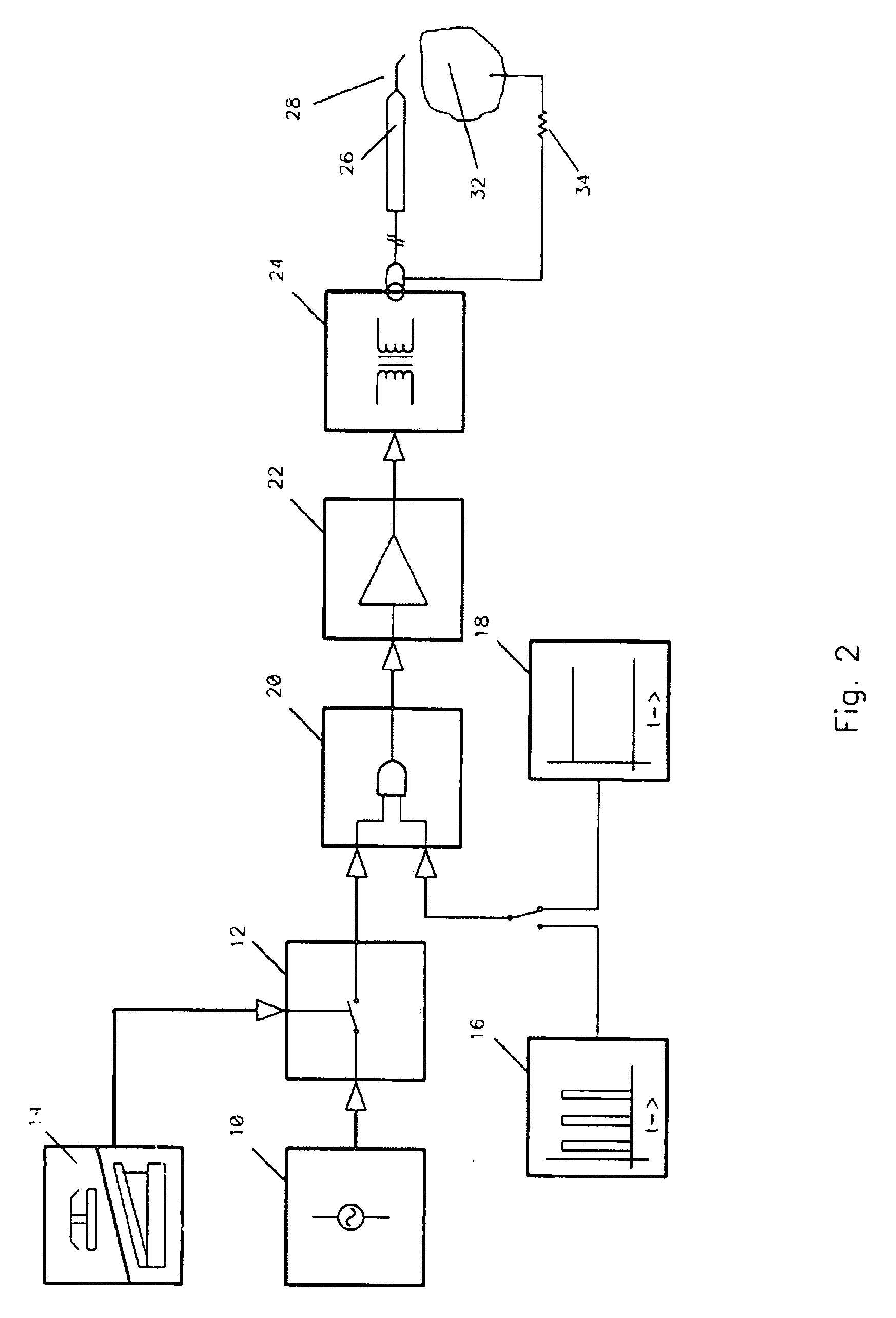

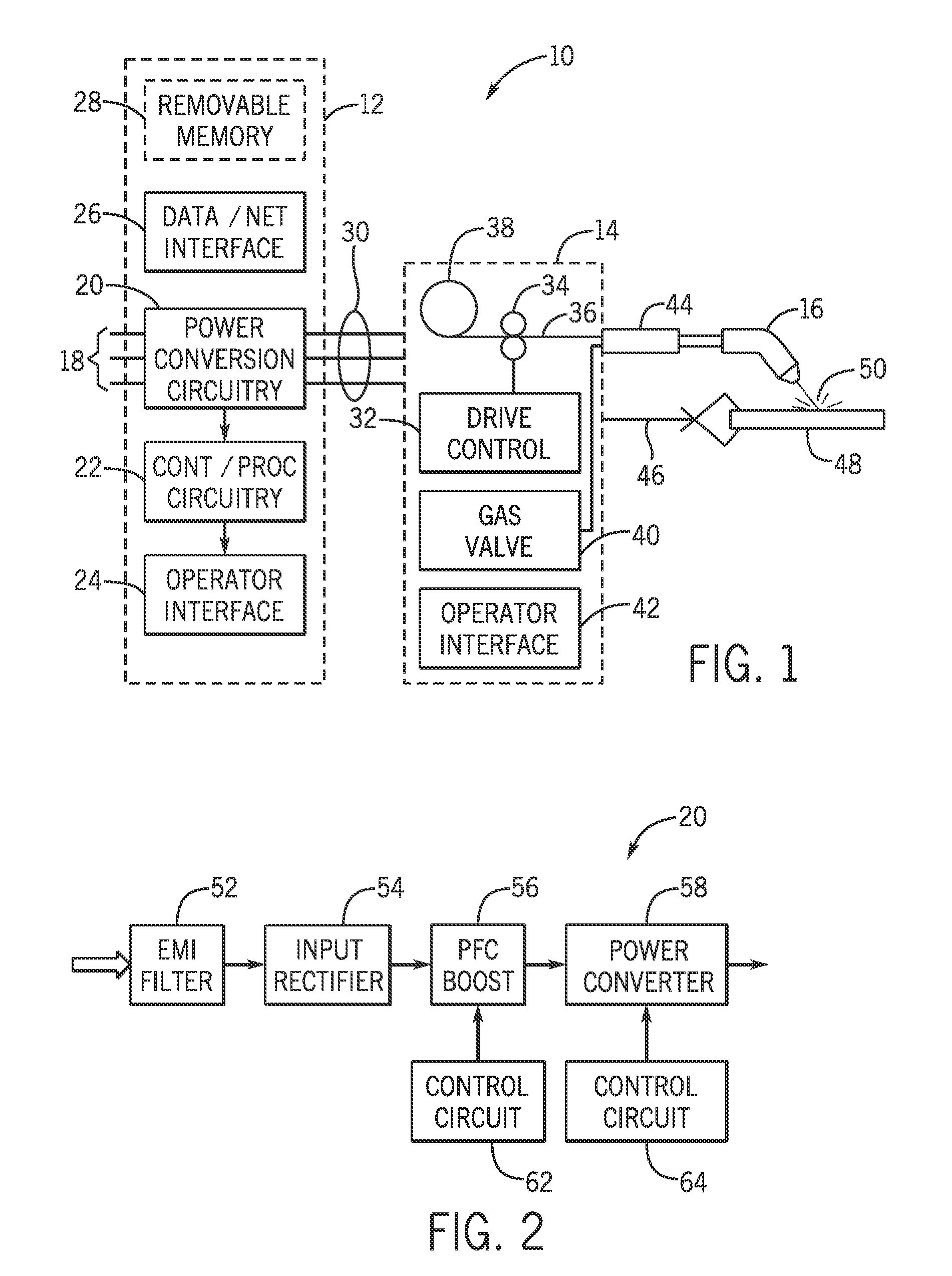

Automatic consumable and torch length detection via pressure decay

Owner:ILLINOIS TOOL WORKS INC

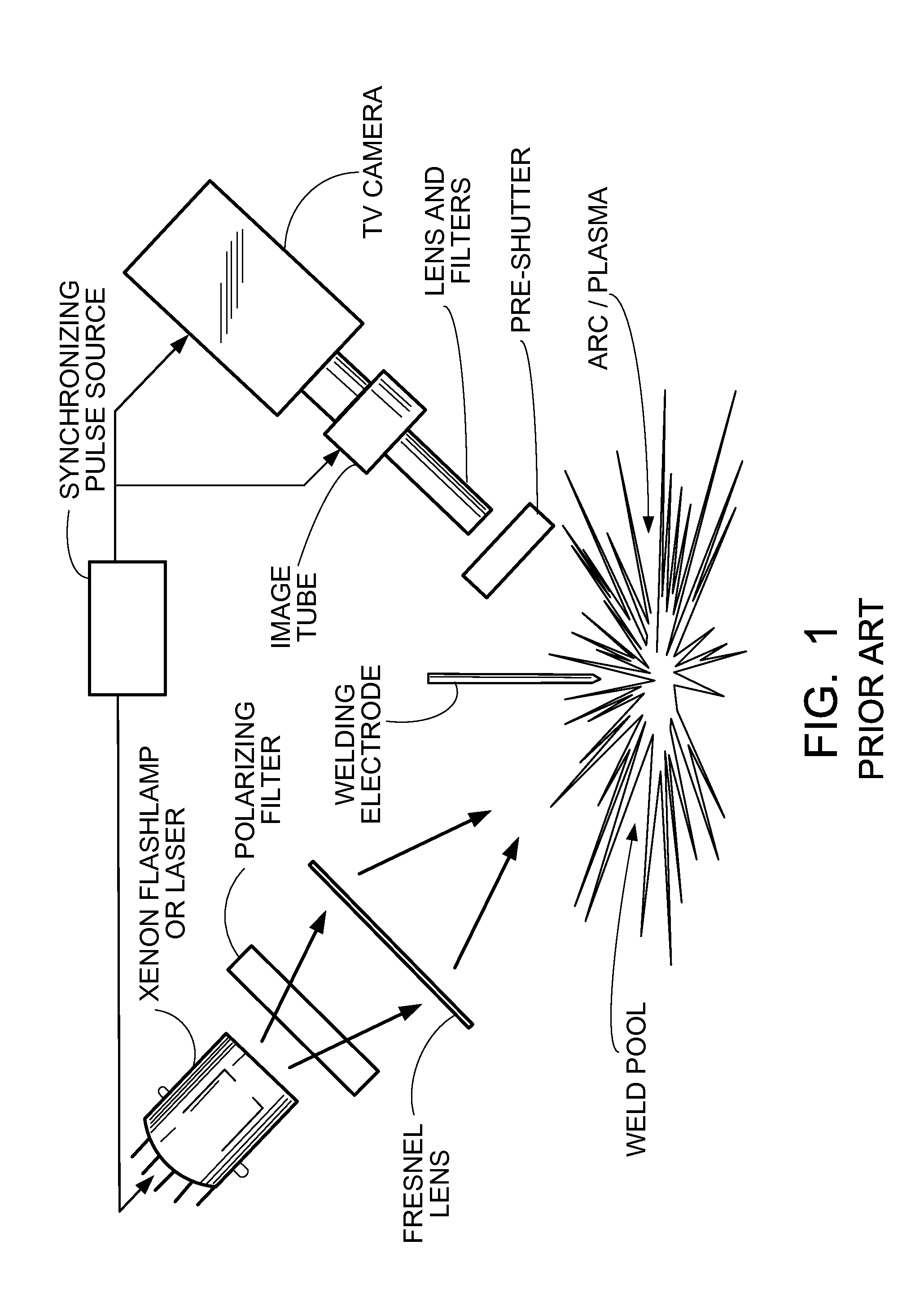

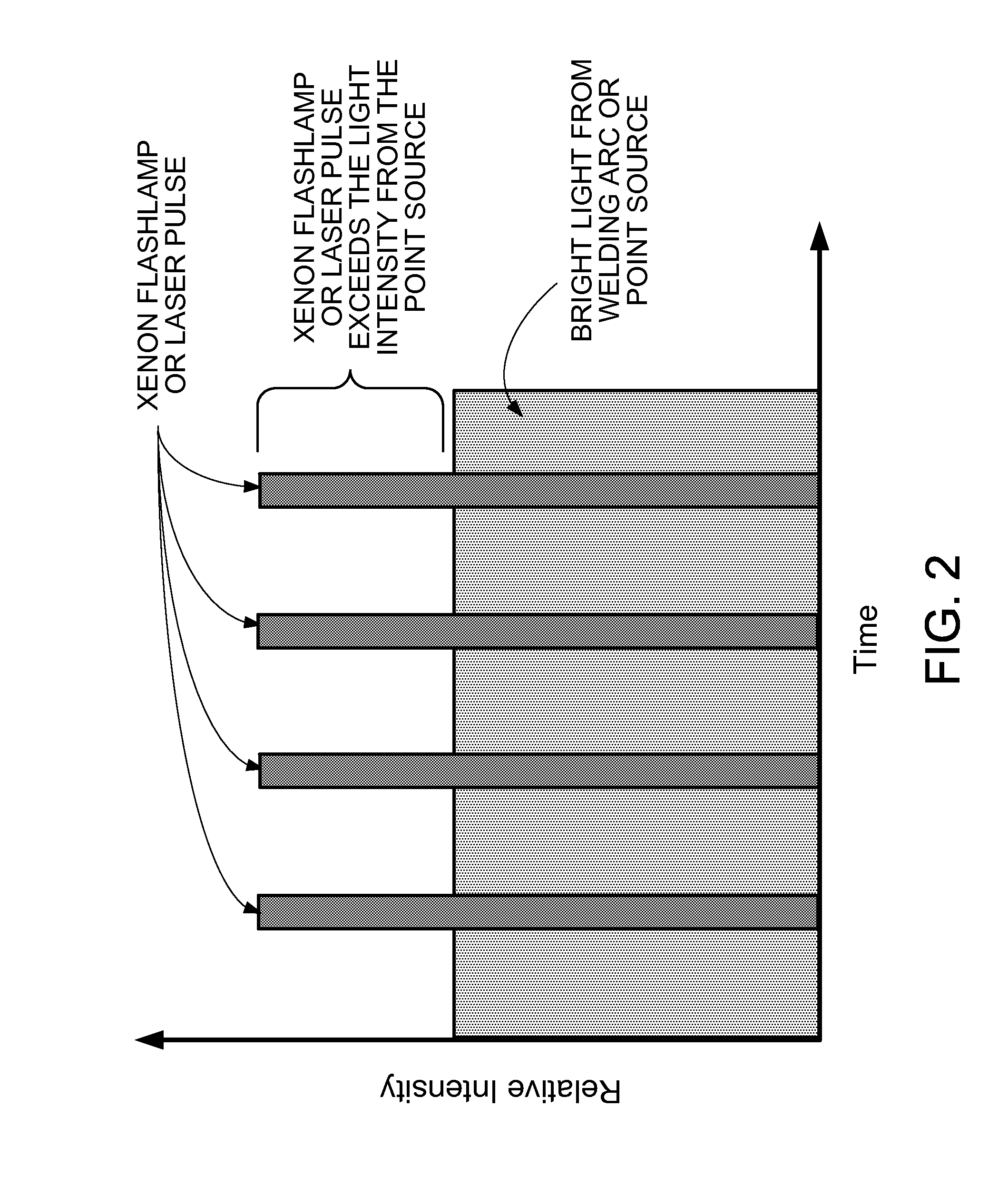

Visual monitoring, or imaging, system and method for using same

Owner:BWXT NUCLEAR OPERATIONS GRP

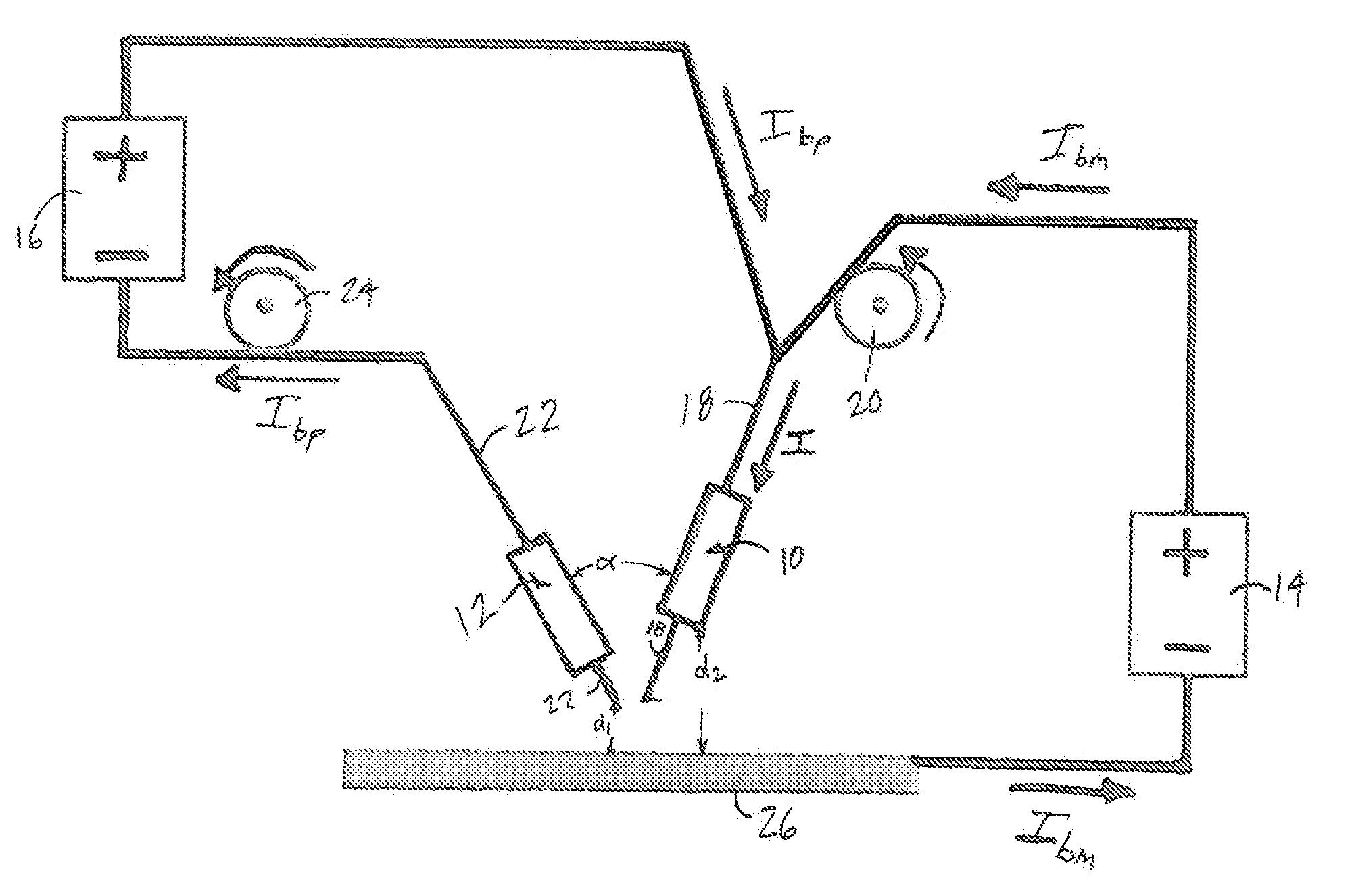

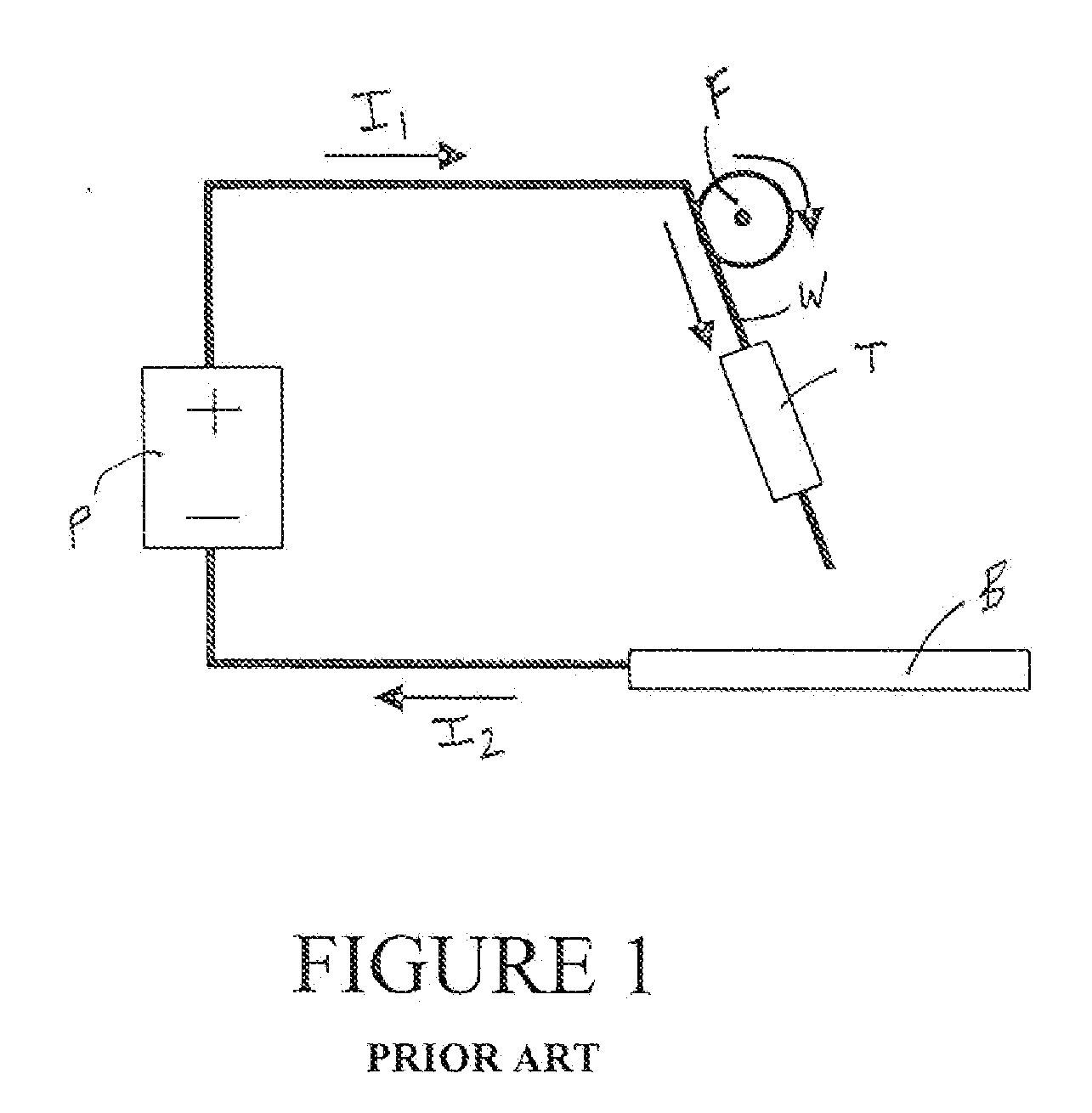

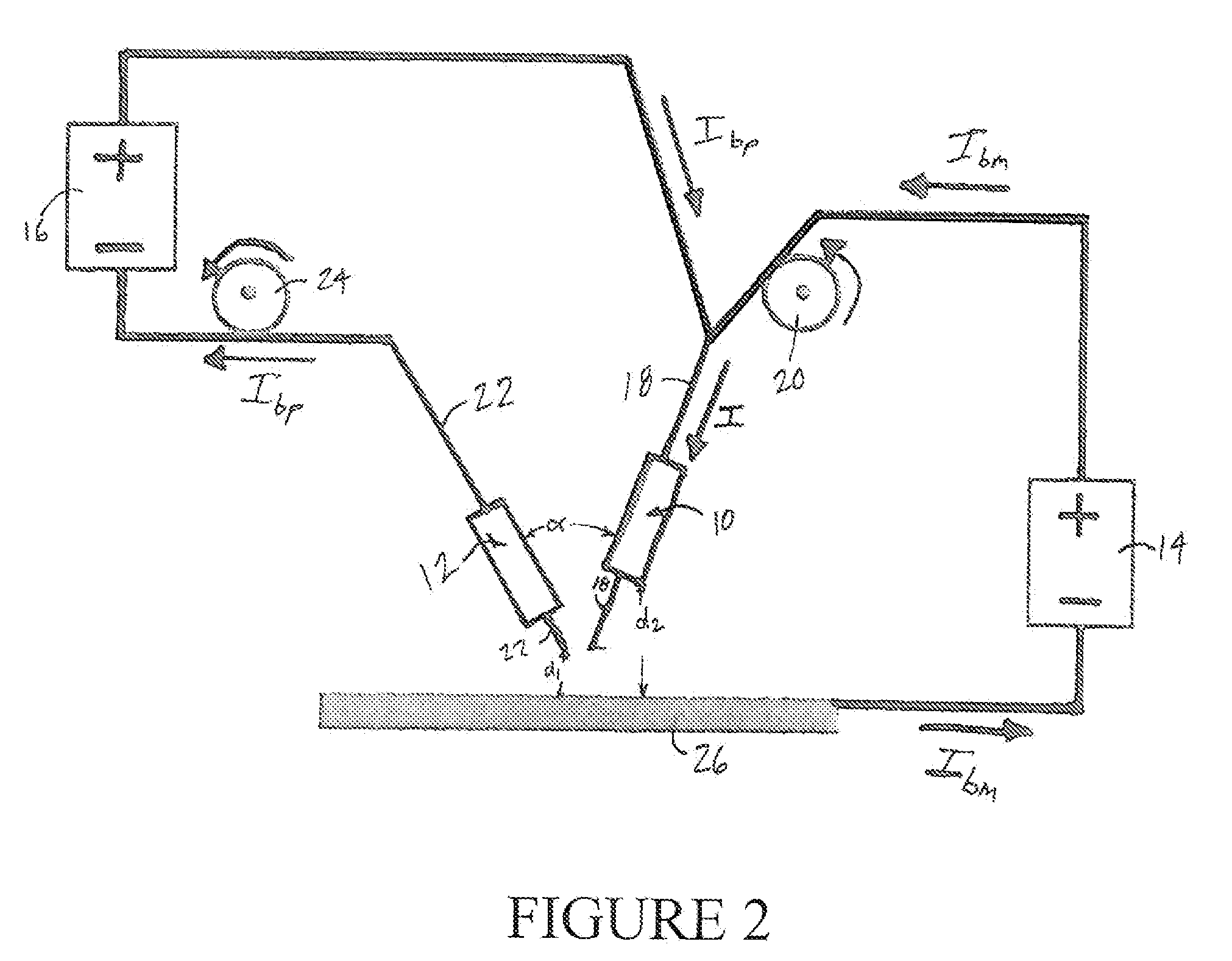

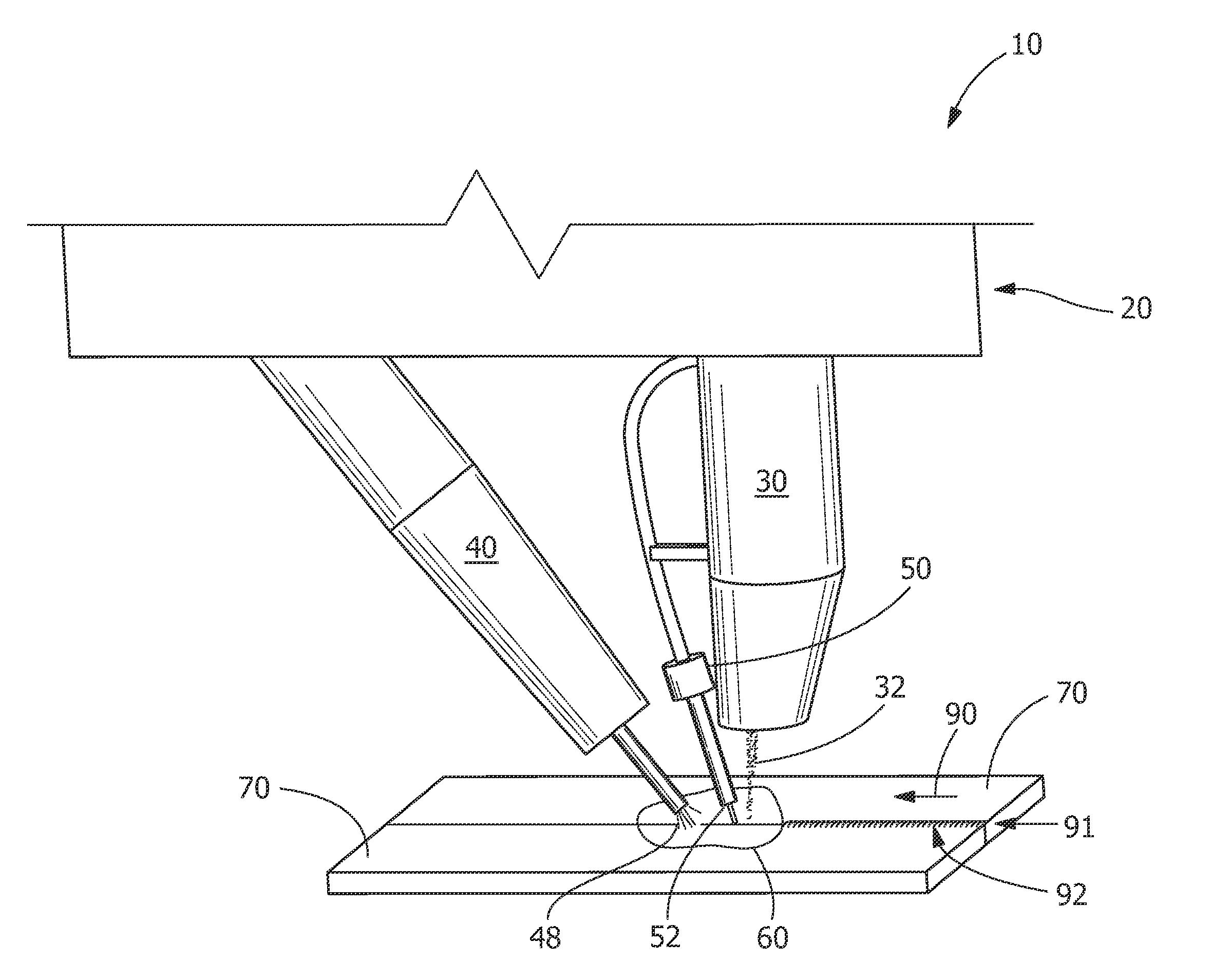

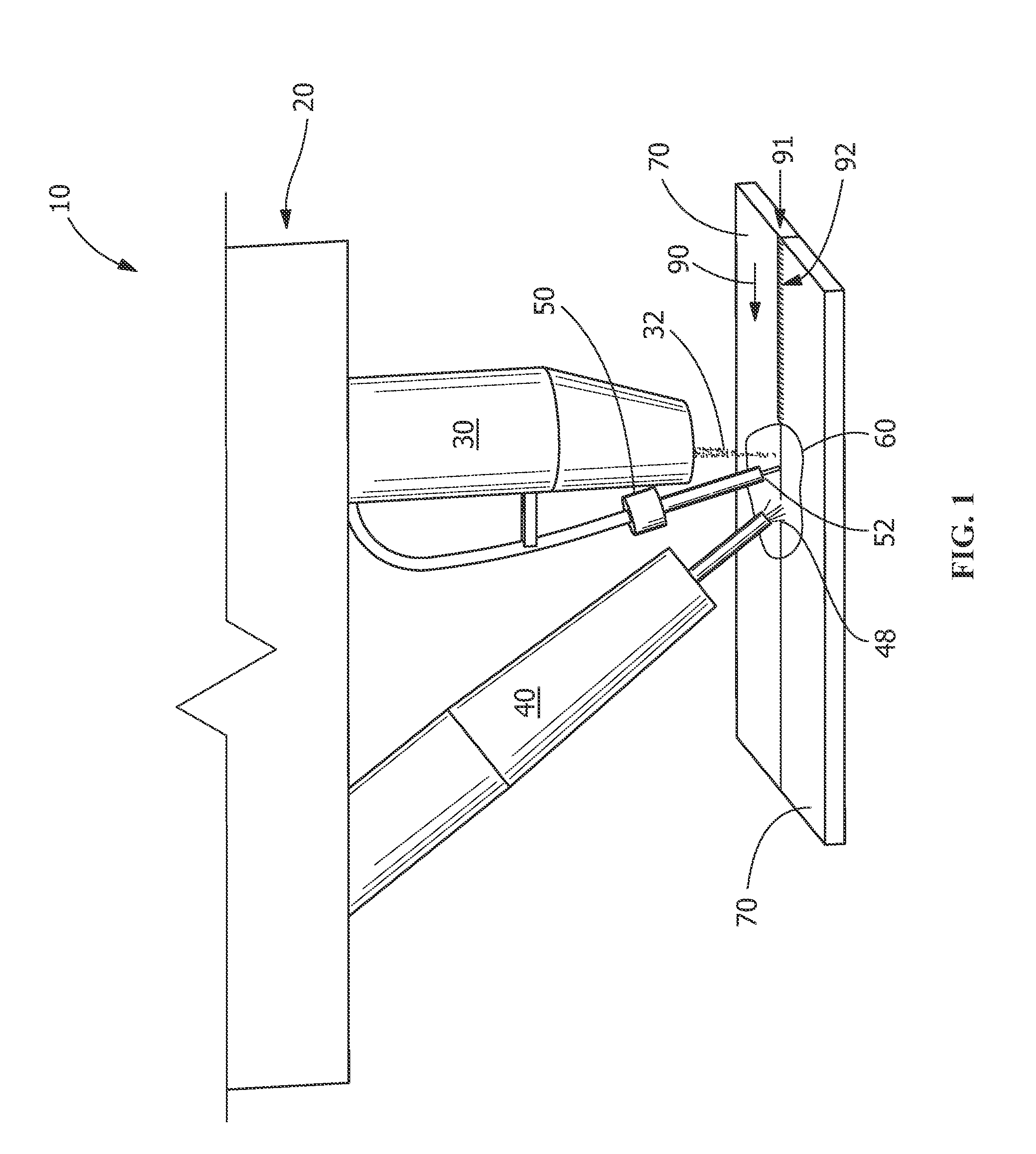

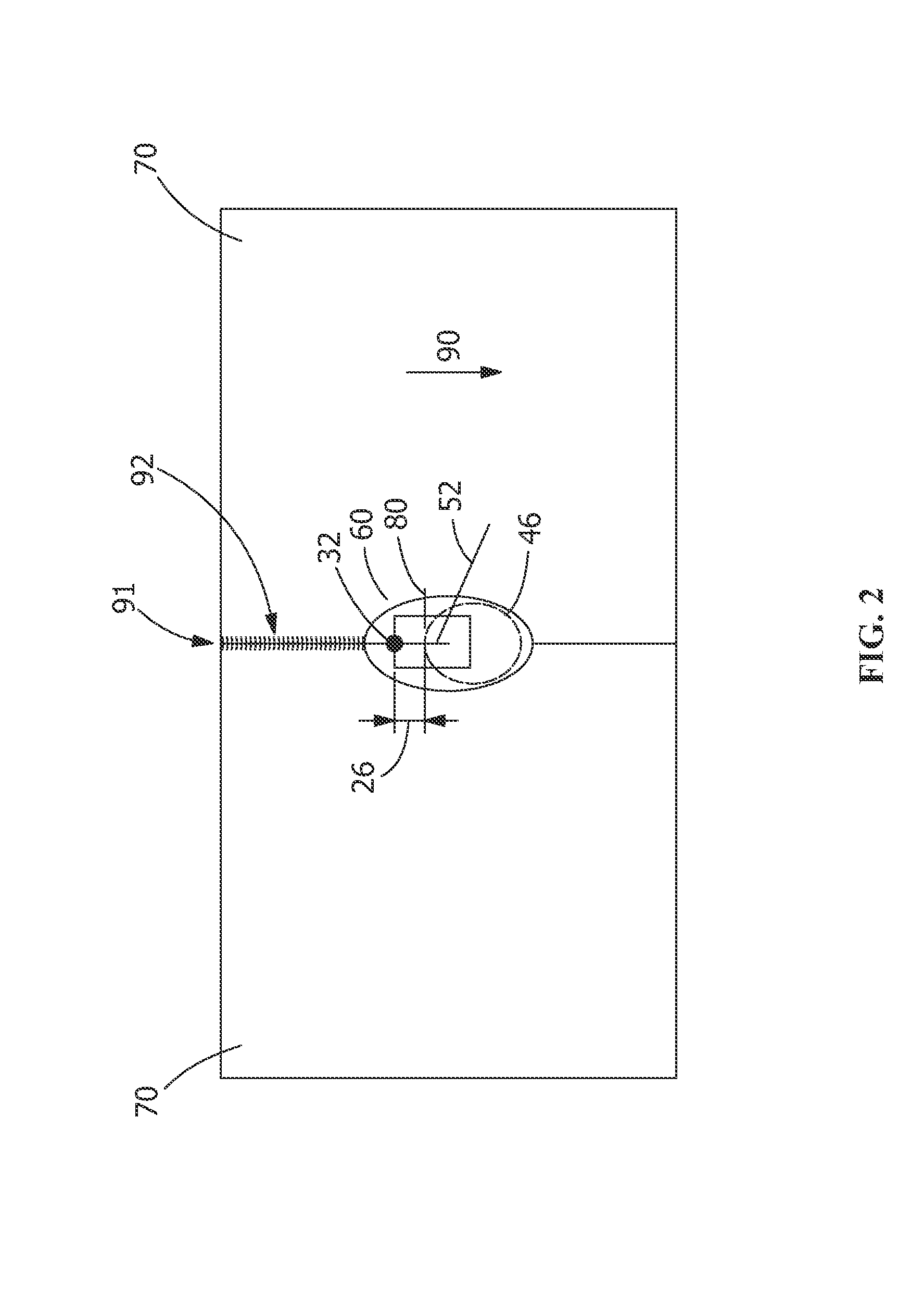

Hybrid welding system and method of welding

InactiveUS20140027414A1High constant weld speedArc welding apparatusLaser beam welding apparatusElectric arcEngineering

Owner:GENERAL ELECTRIC CO

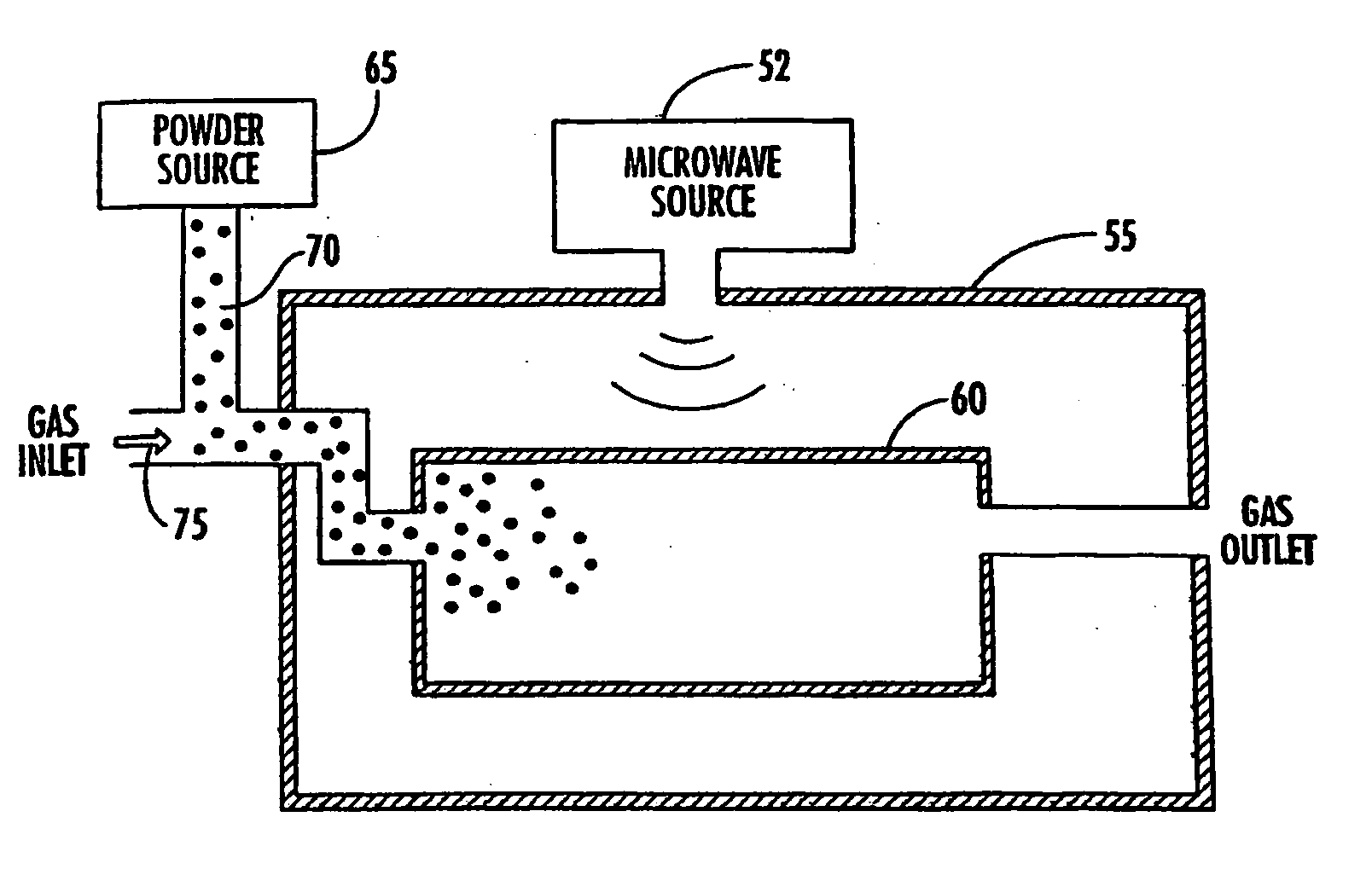

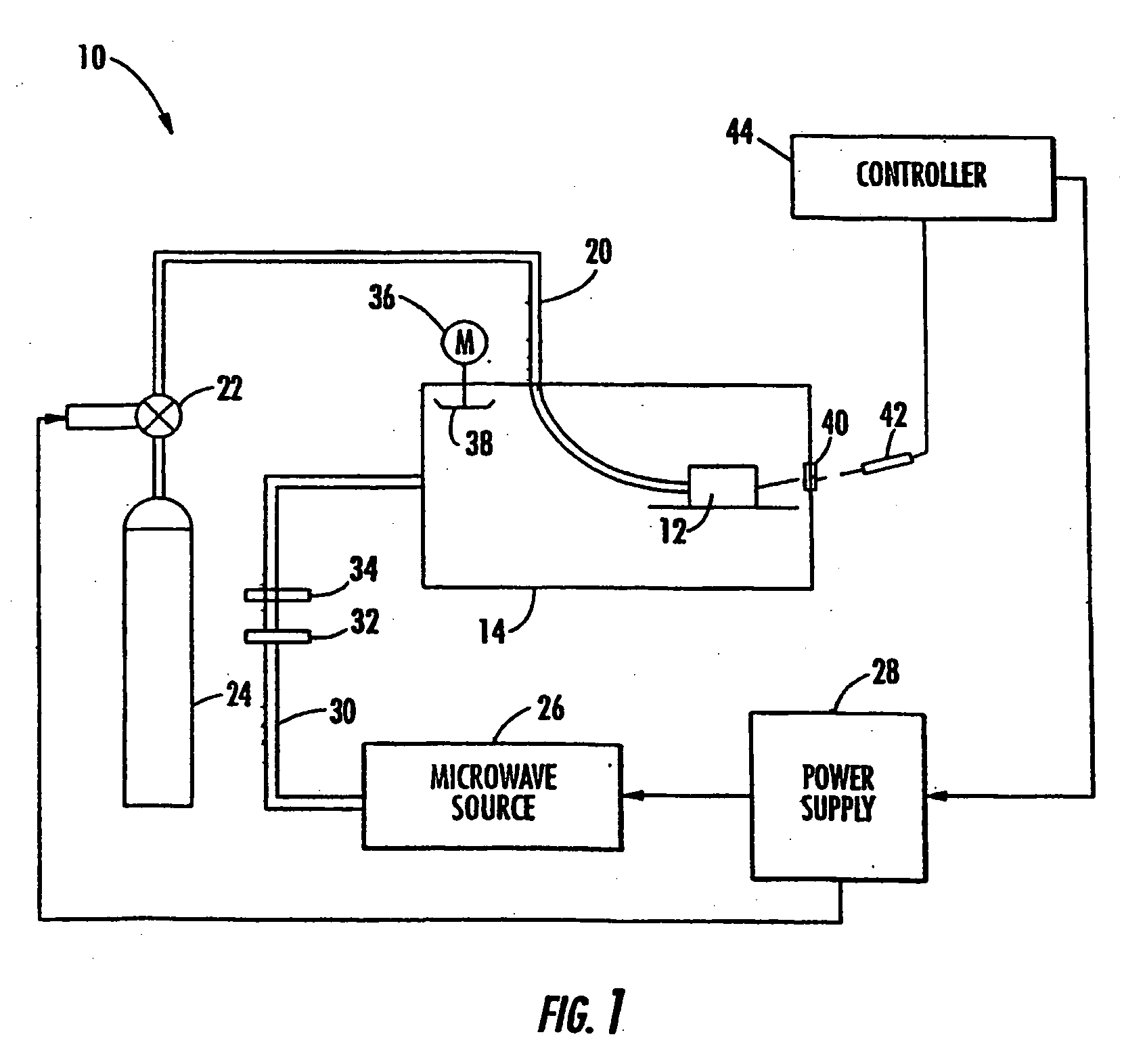

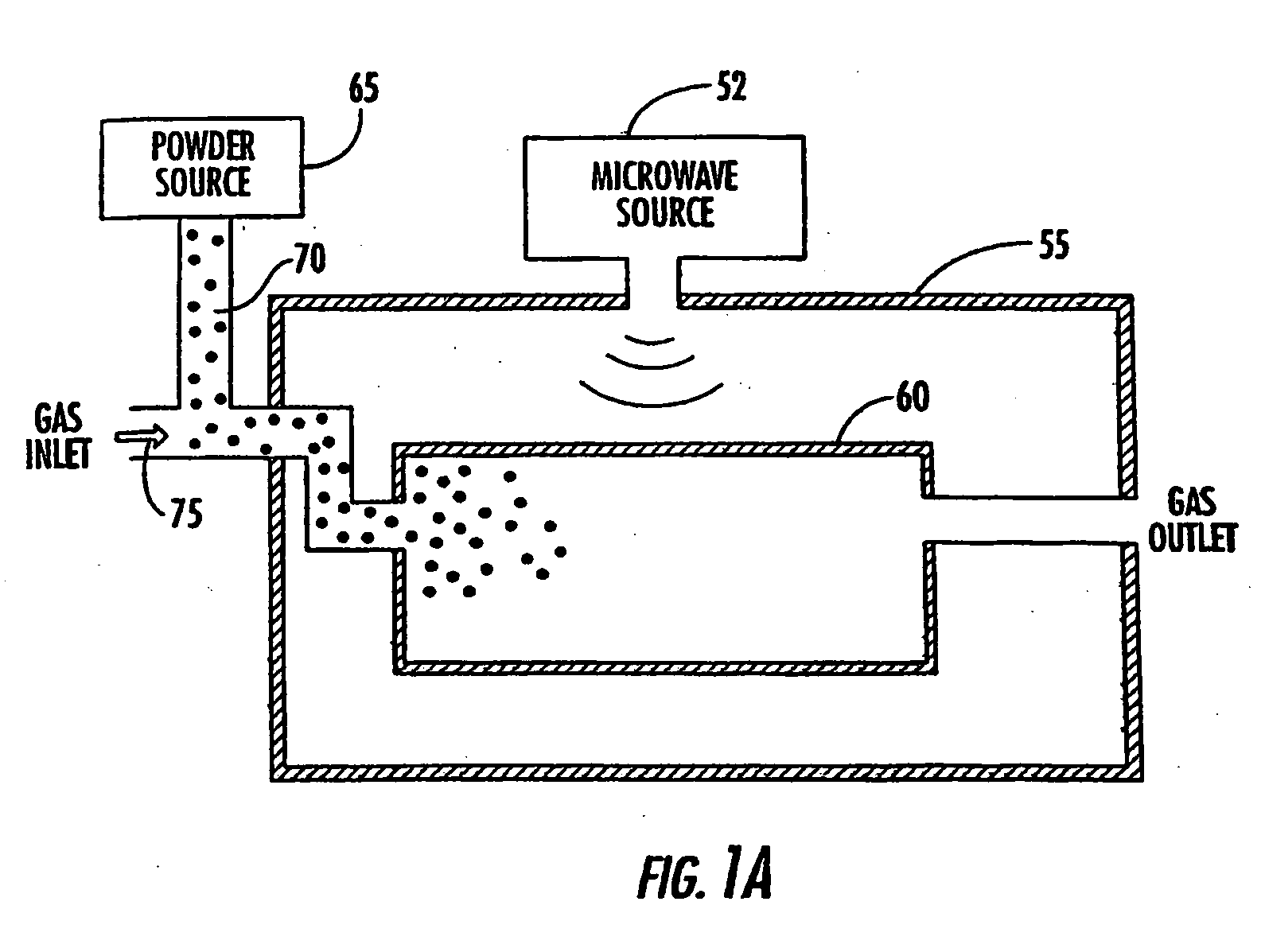

Plasma-assisted processing in a manufacturing line

InactiveUS20060081567A1Arc welding apparatusSemiconductor/solid-state device manufacturingProduct gasManufacturing line

Owner:BTU INTERNATIONAL

Arc welding method and arc welding apparatus

An arc welding method comprising the steps of accelerating a feeding speed of a welding wire to cause shorting between the welding wire and a base metal when a welding end signal is input during a period of arcing, retracting the welding wire backward thereafter until a wire retracting speed reaches a predetermined rate, controlling the wire retracting speed constant at this speed for a predetermined duration of time, then stopping the backward retraction of the welding wire, and then terminating a welding power output after supplying a predetermined amount of welding current for a predetermined duration of time starting from a time when opening of the shorting occurs during the backward retraction of the welding wire.

Owner:PANASONIC INTPROP MANAGEMENT CO LTD

Method and apparatus for plasma incision of cardiovascular tissue

Owner:FUGO RICHARD J

Welded aluminum sheets and process therefore

Owner:NOVELIS INC

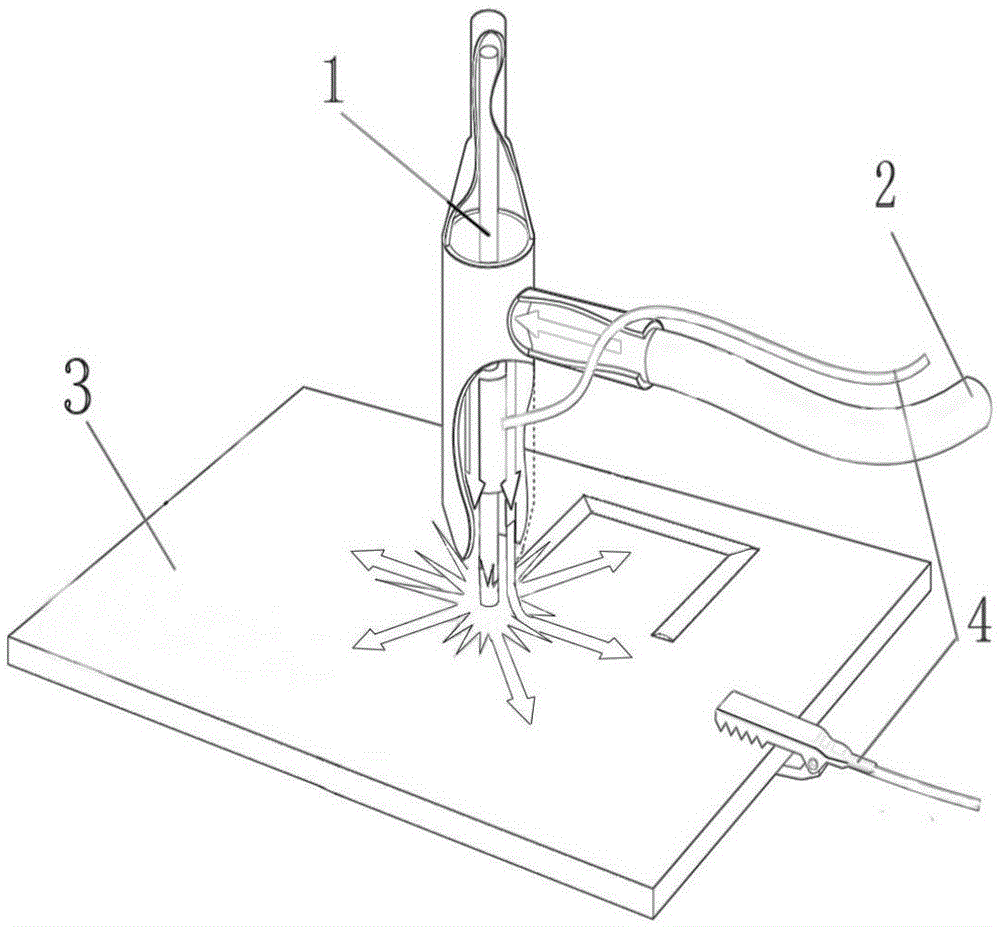

Consumable electrode gas shielded arc deposition three-dimensional printing method

InactiveCN105643053AHigh shape accuracyQuality improvementArc welding apparatusShielding gasEngineering

Owner:GUIZHOU NORMAL UNIVERSITY

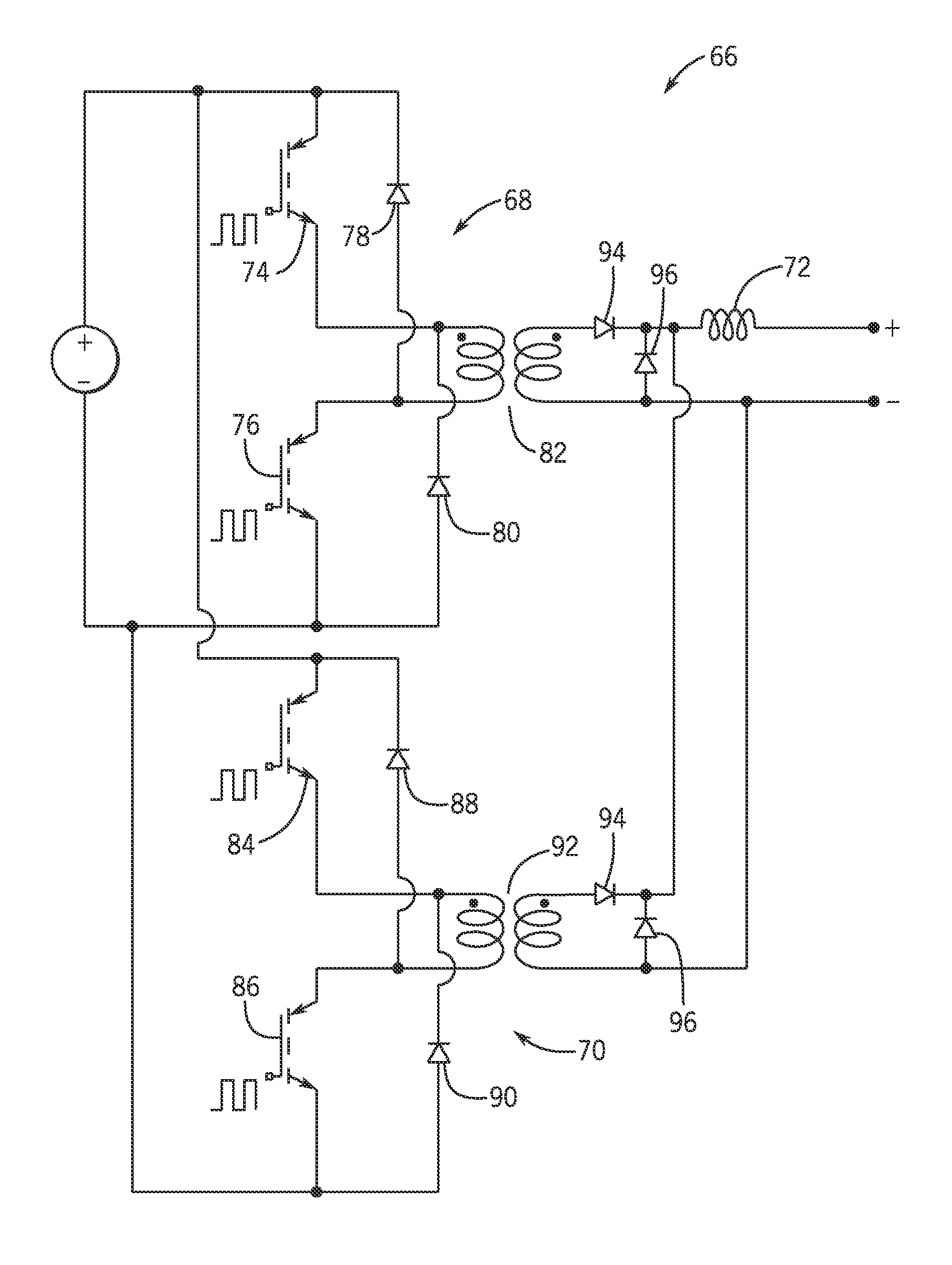

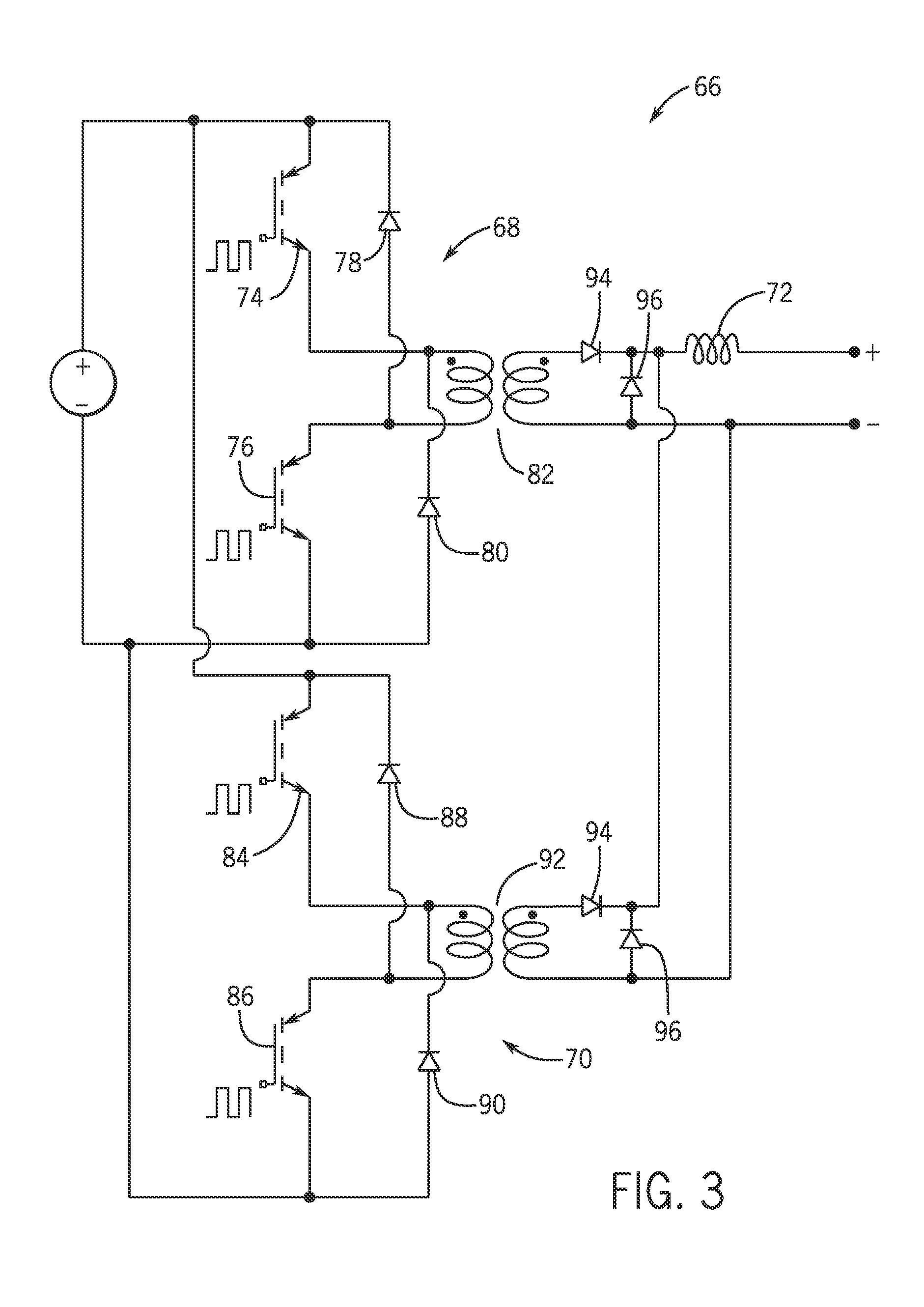

Metal working power supply converter system and method

ActiveUS20140376268A1Arc welding apparatusApparatus with intermediate ac conversionMetal workingPower inverter

Owner:ILLINOIS TOOL WORKS INC

Application of water-soluble paper to argon arc welding of long-distance industrial pipeline intermediate joint collision port

Owner:MCC5 GROUP CORP SHANGHAI

Welding repairing method for tin-based bearing alloy bearing bush

The invention relates to a welding repairing method for a tin-based bearing alloy bearing bush. The welding repairing method comprises the following steps that (1) a welding wire is prepared, specifically, a babbitt material matched with the tin-based bearing alloy bearing bush is selected to be smelted, and the welding wire is prepared; (2) the surface of the tin-based bearing alloy bearing bush is processed; and (3) TIG direct current welding is adopted, argon inert gas protecting is conducted, flat welding is adopted, wire filling welding repairing is conducted through a leftward welding method, the surface of the last layer of welding bead is higher than the original surface of the bearing bush, then protecting nozzle repairing welding is adopted, and the repaired bearing bush is obtained through machining. According to the welding repairing method for the tin-based bearing alloy bearing bush, operation is easy; the repairing result is ideal; the qualified rate is high; the reuse rate of the tin-based bearing alloy bearing bush is increased; and the recasting fund and time are reduced.

Owner:CSSC GUANGZHOU WENCHONG DOCKYARD CO LTD

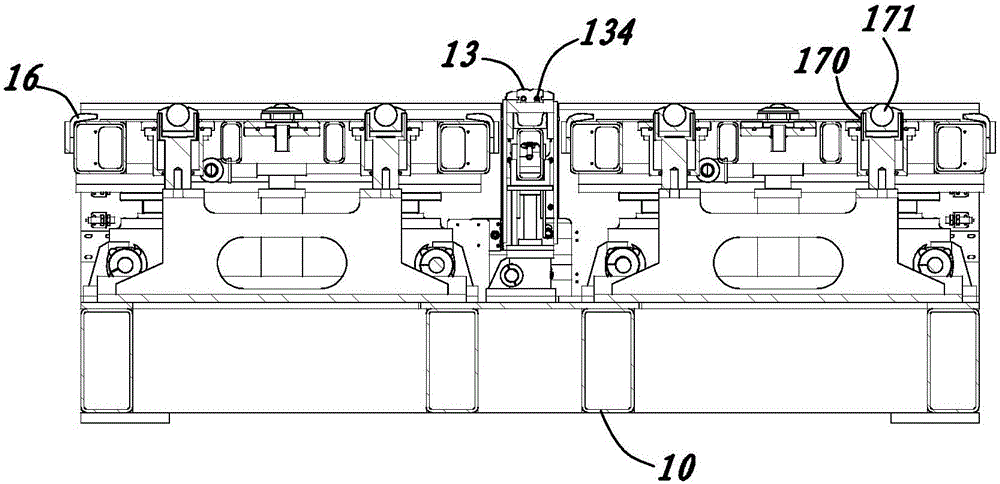

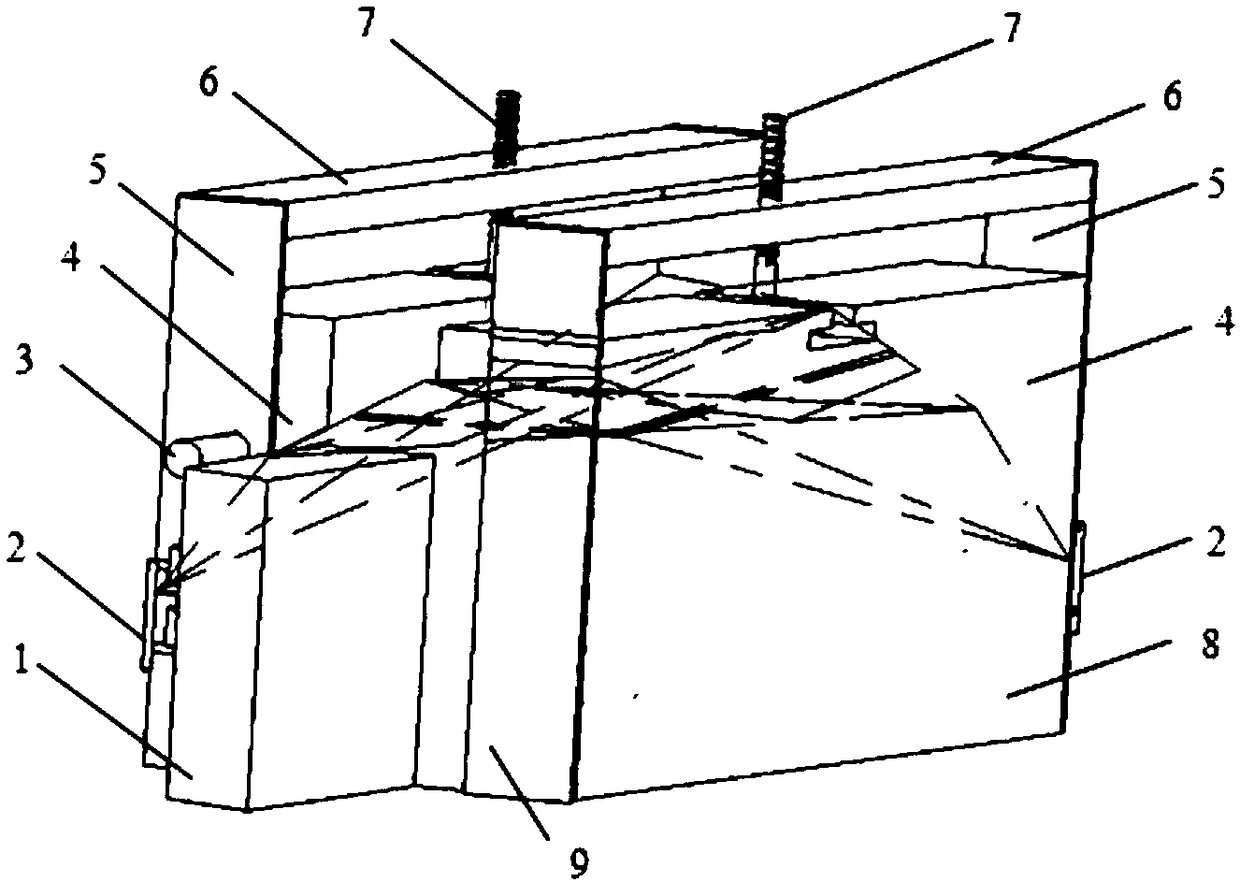

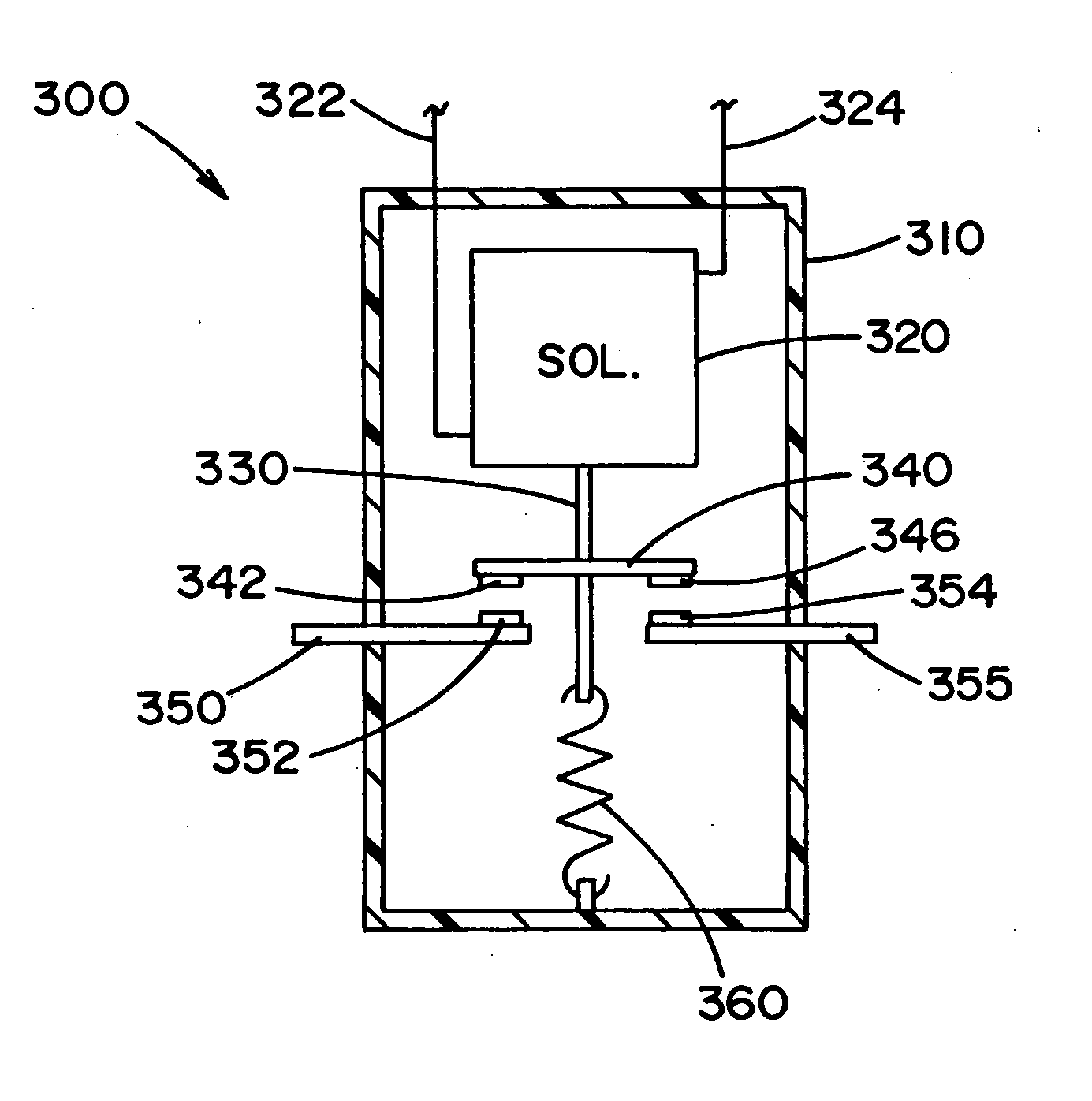

Welding method, welding system and welding jig

InactiveUS20060151572A1Reduce impactAvoid crackingElectric heatingWelding/cutting auxillary devicesFuel tankThermal deformation

A plurality of attachments having springs hold the outer plate of a fuel tank, and an inner jig positions the inner plate. The attachments are attached to clamp arms which are opened / closed by cylinders. When the overlap portion between the outer and inner plates is welded, the thermal deformation caused by welding is accommodated by the springs. The attachments are spaced from the fuel tank in the order in which the welding point is approached.

Owner:HONDA MOTOR CO LTD

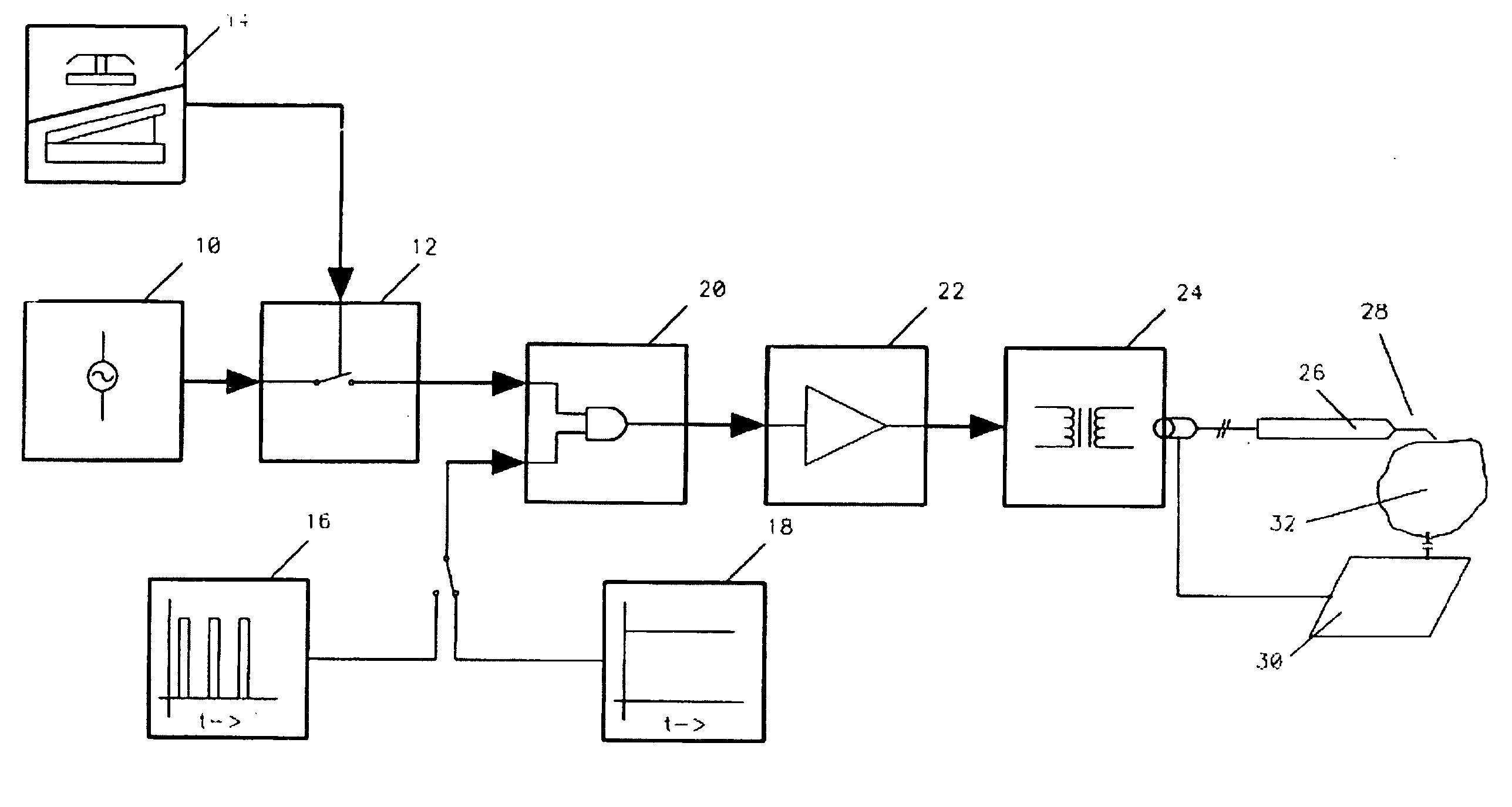

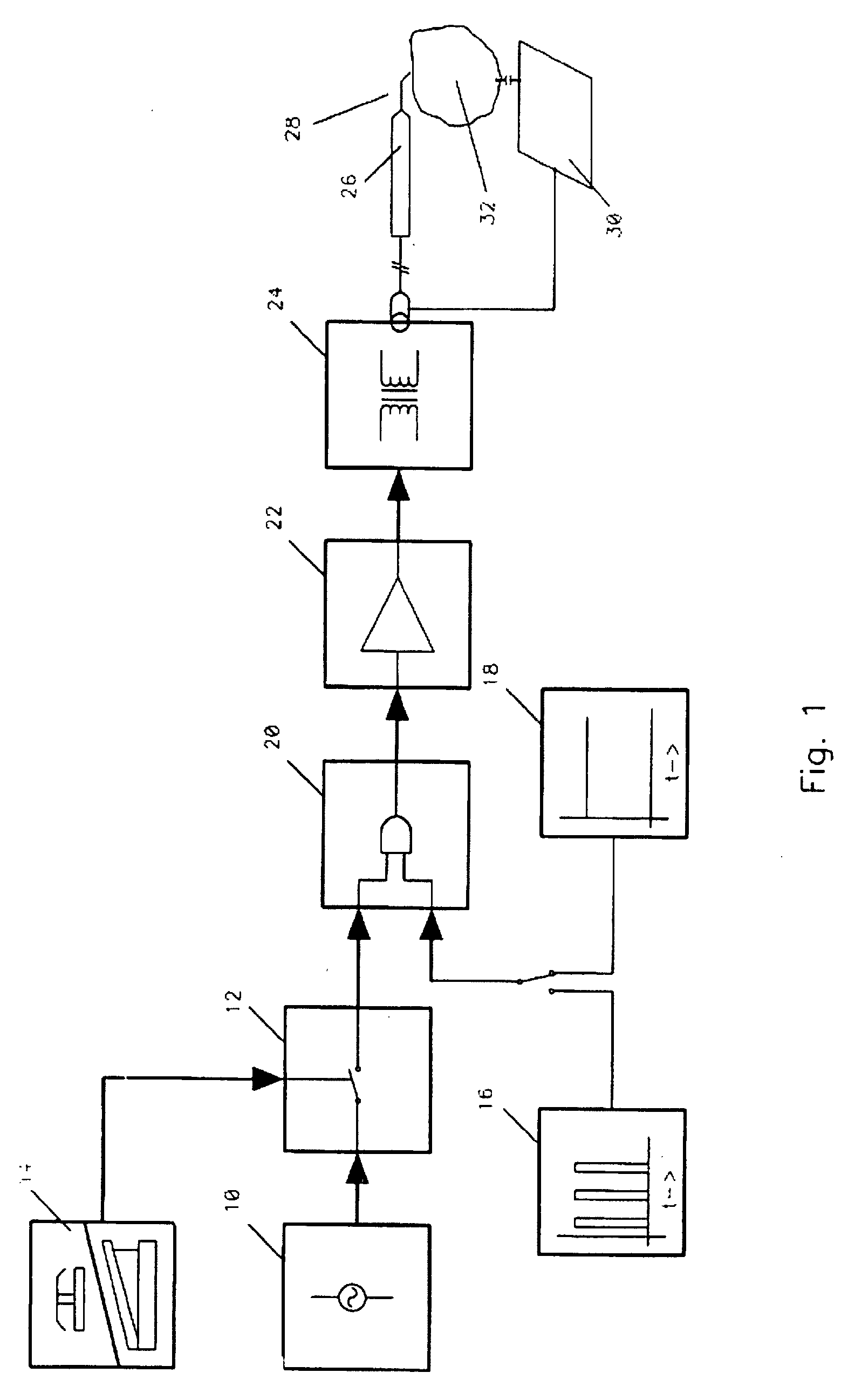

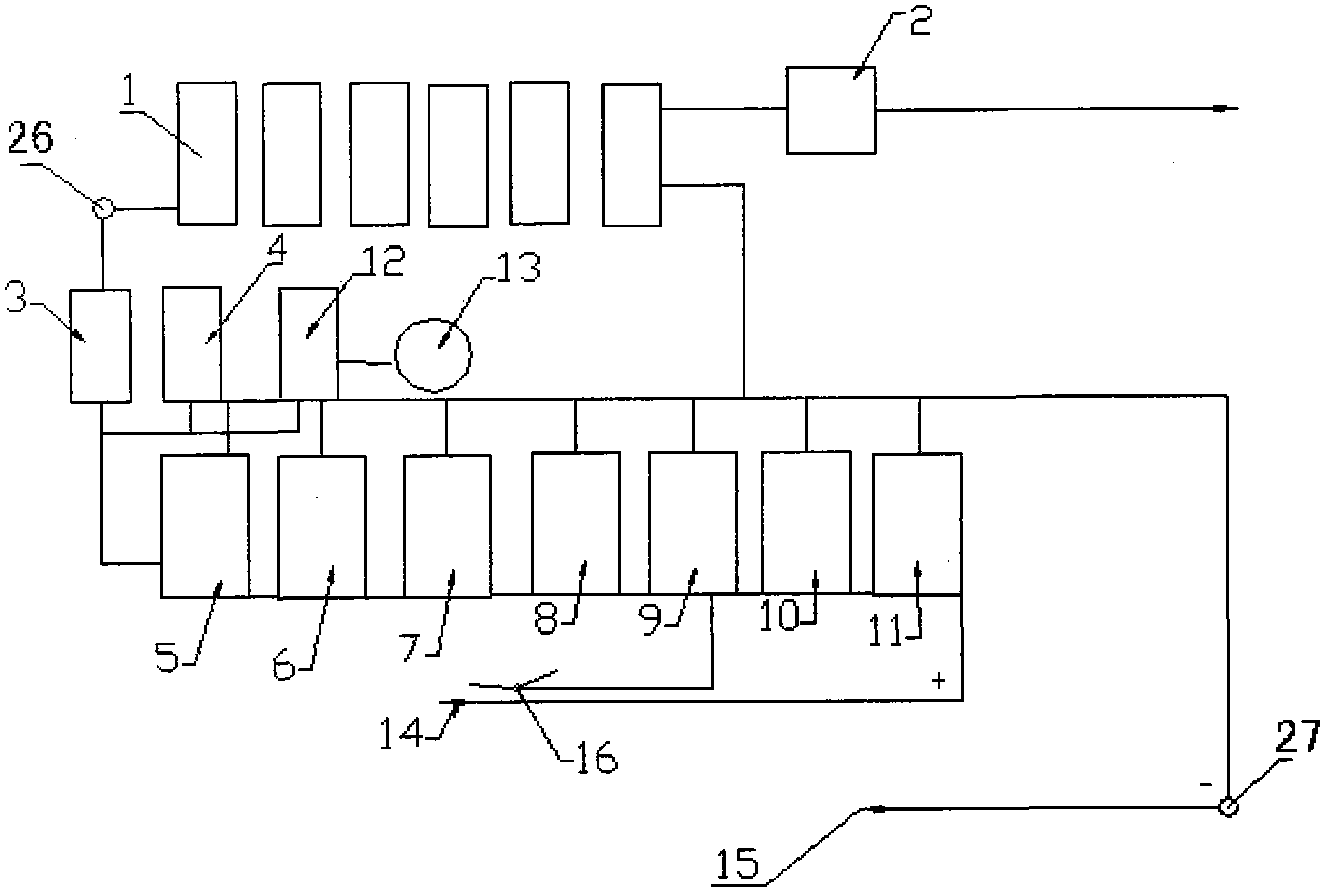

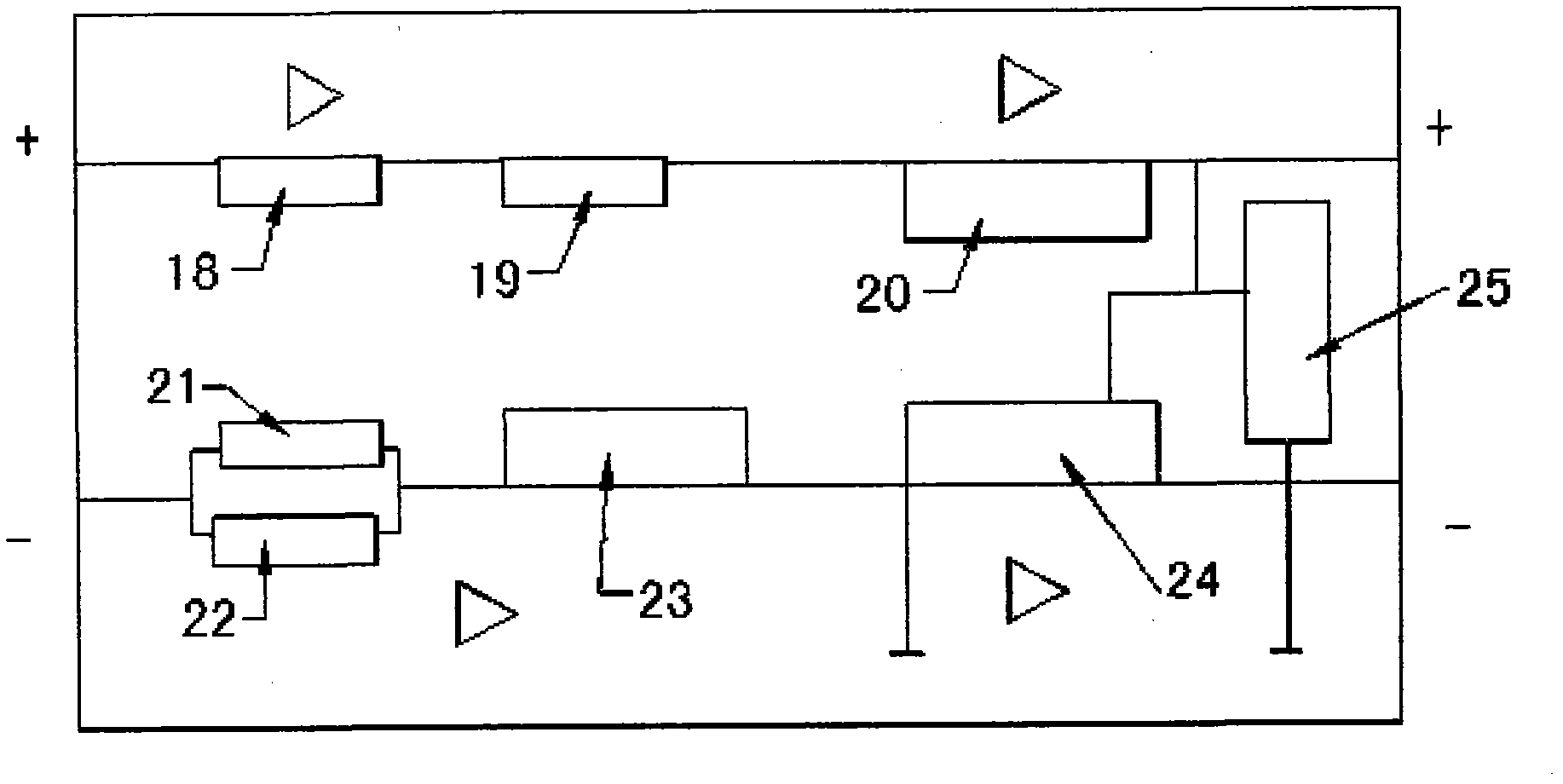

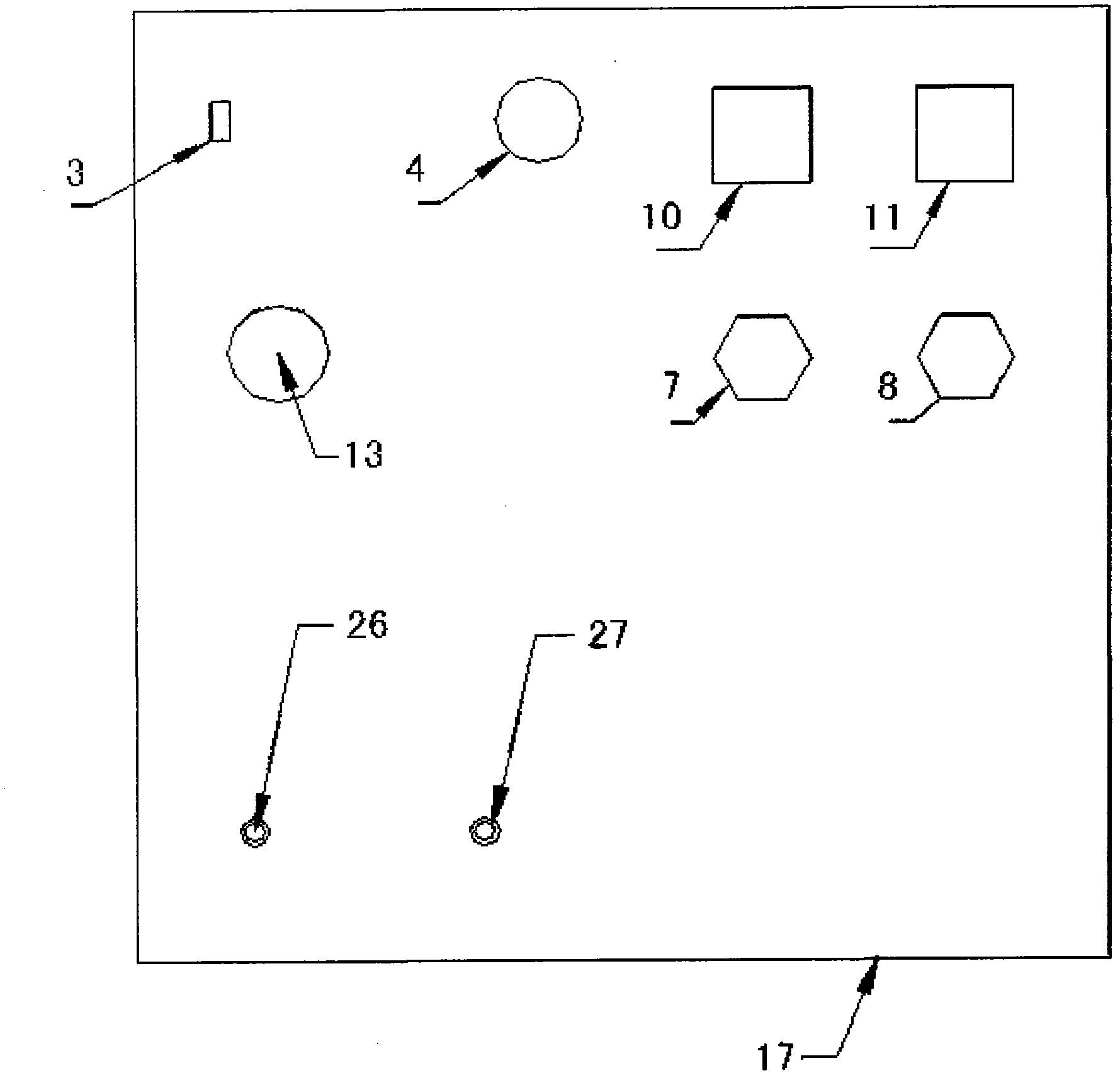

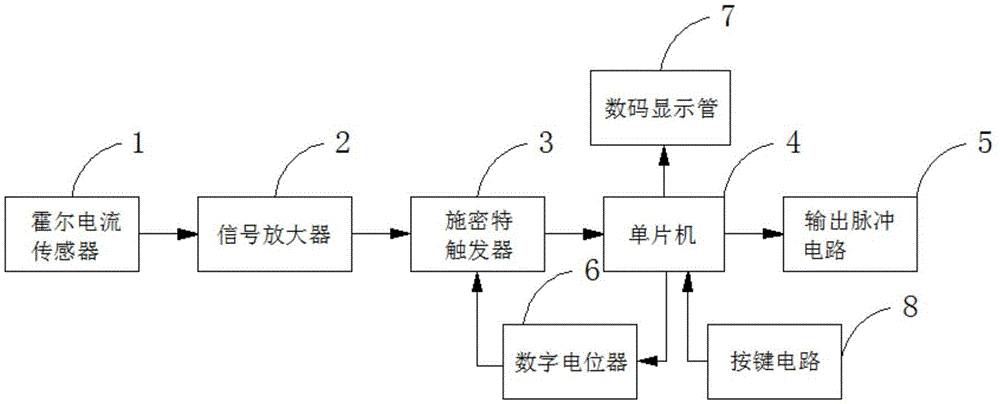

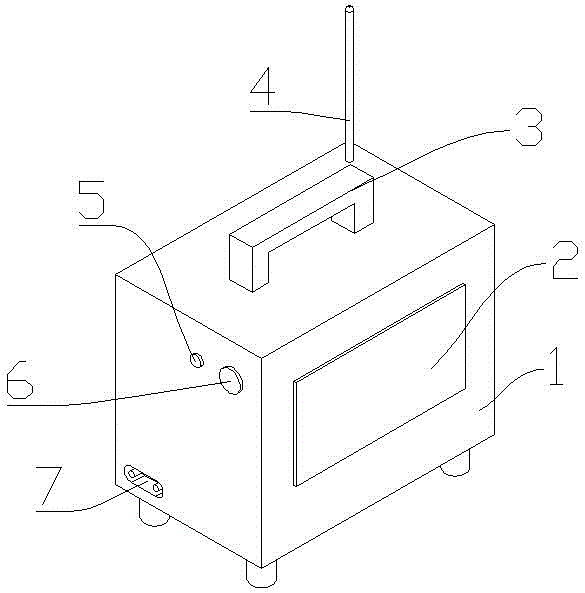

Program controlled trigger and method

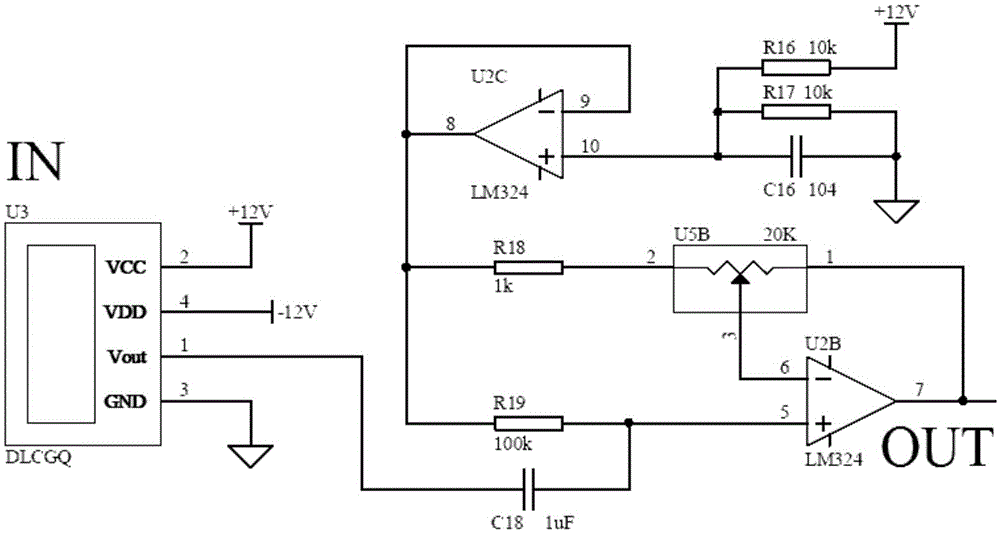

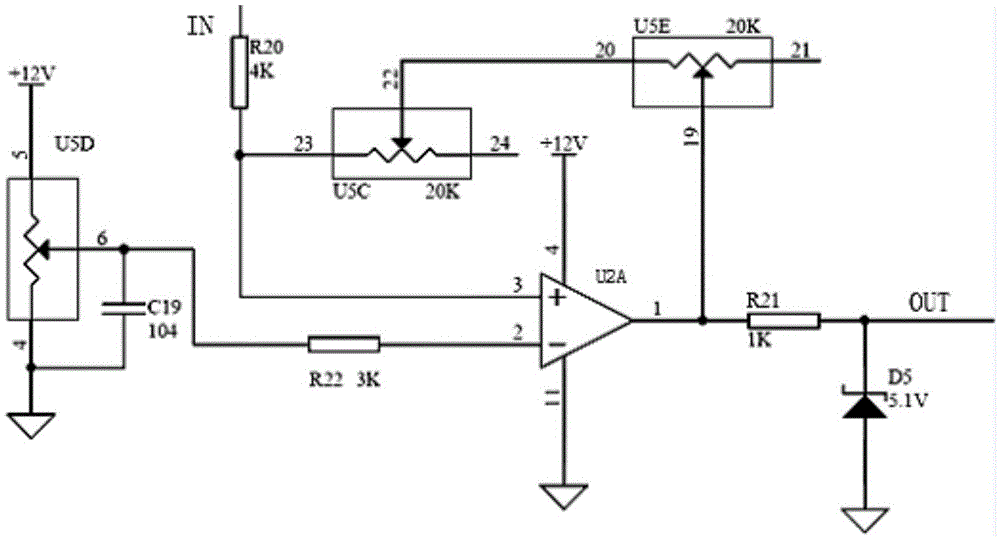

InactiveCN105478965AImprove isolationImprove stabilityArc welding apparatusMicrocontrollerCurrent sensor

Owner:GUILIN UNIV OF AEROSPACE TECH

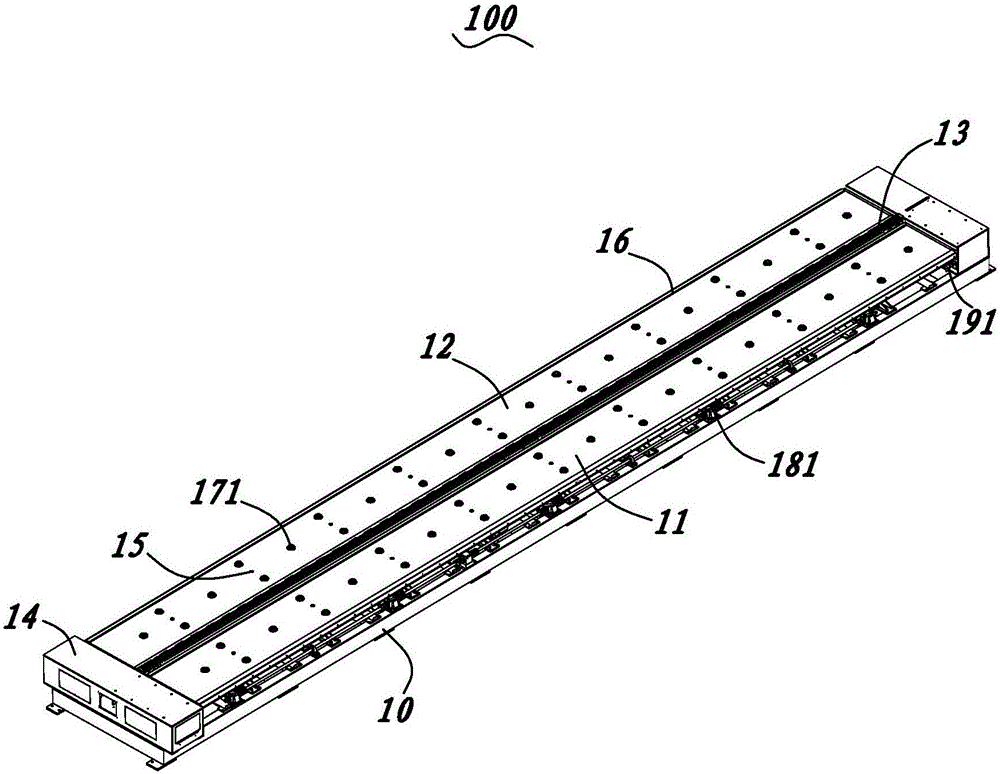

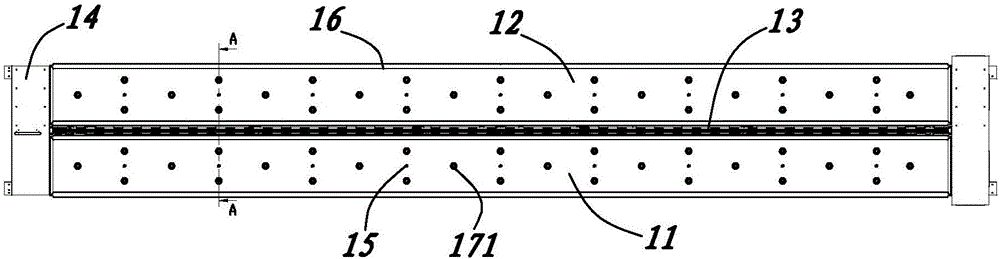

Vacuum adsorption welding device for plate splicing in submerged-arc welding

ActiveCN106077918AFast adsorption fixationEasy to operateWelding/cutting auxillary devicesArc welding apparatusEngineeringPlate fixation

Owner:HUAHENG WELDING

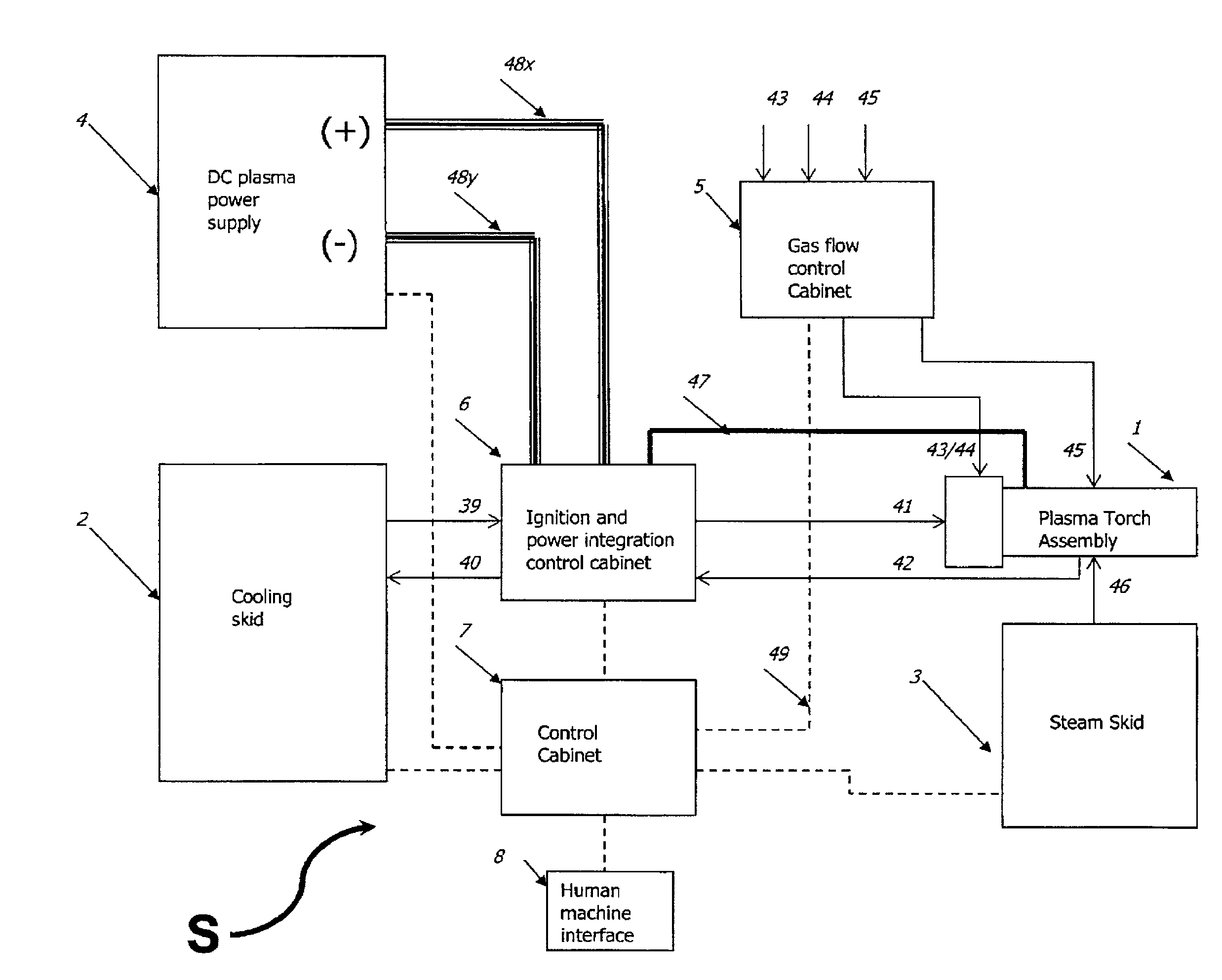

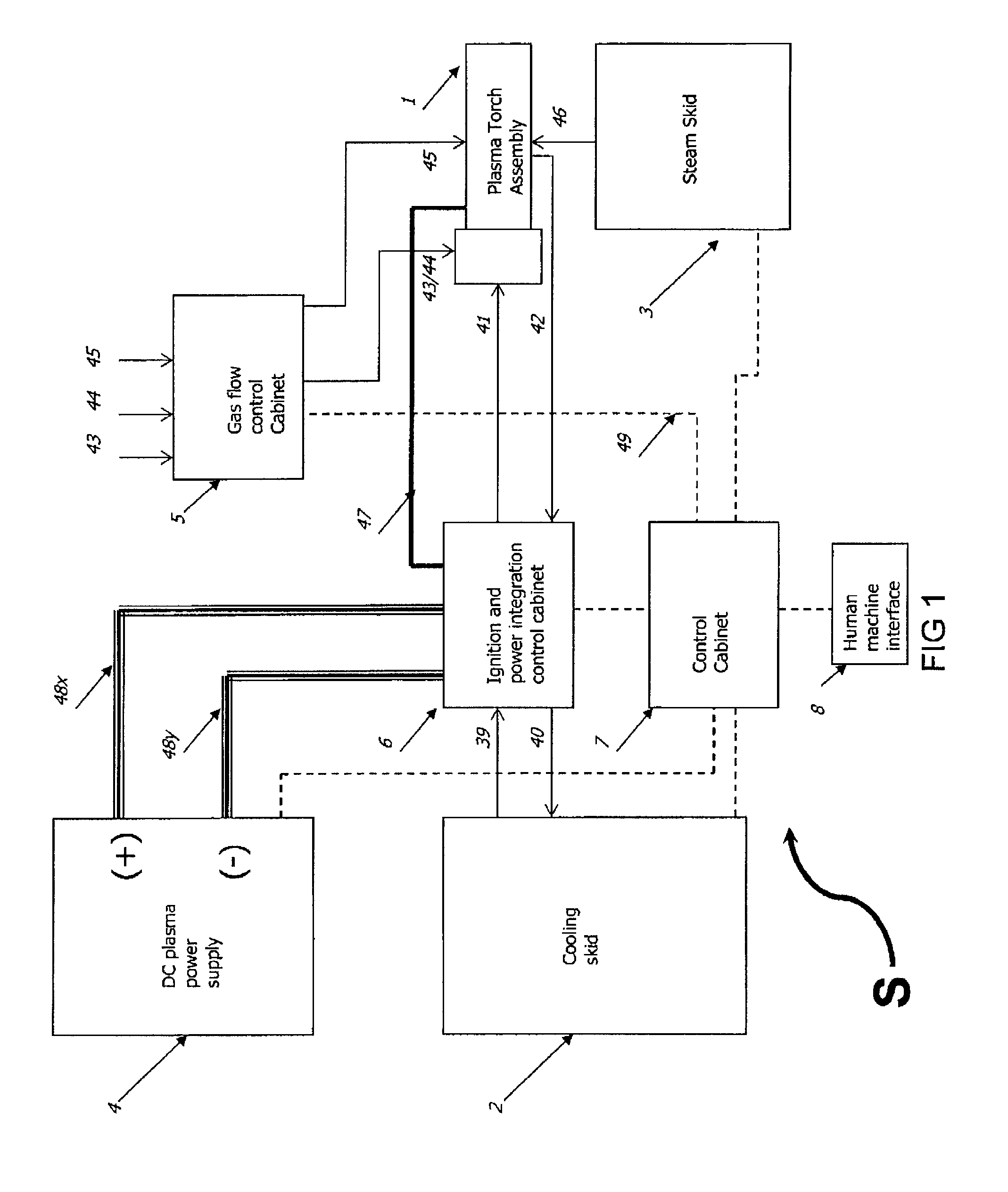

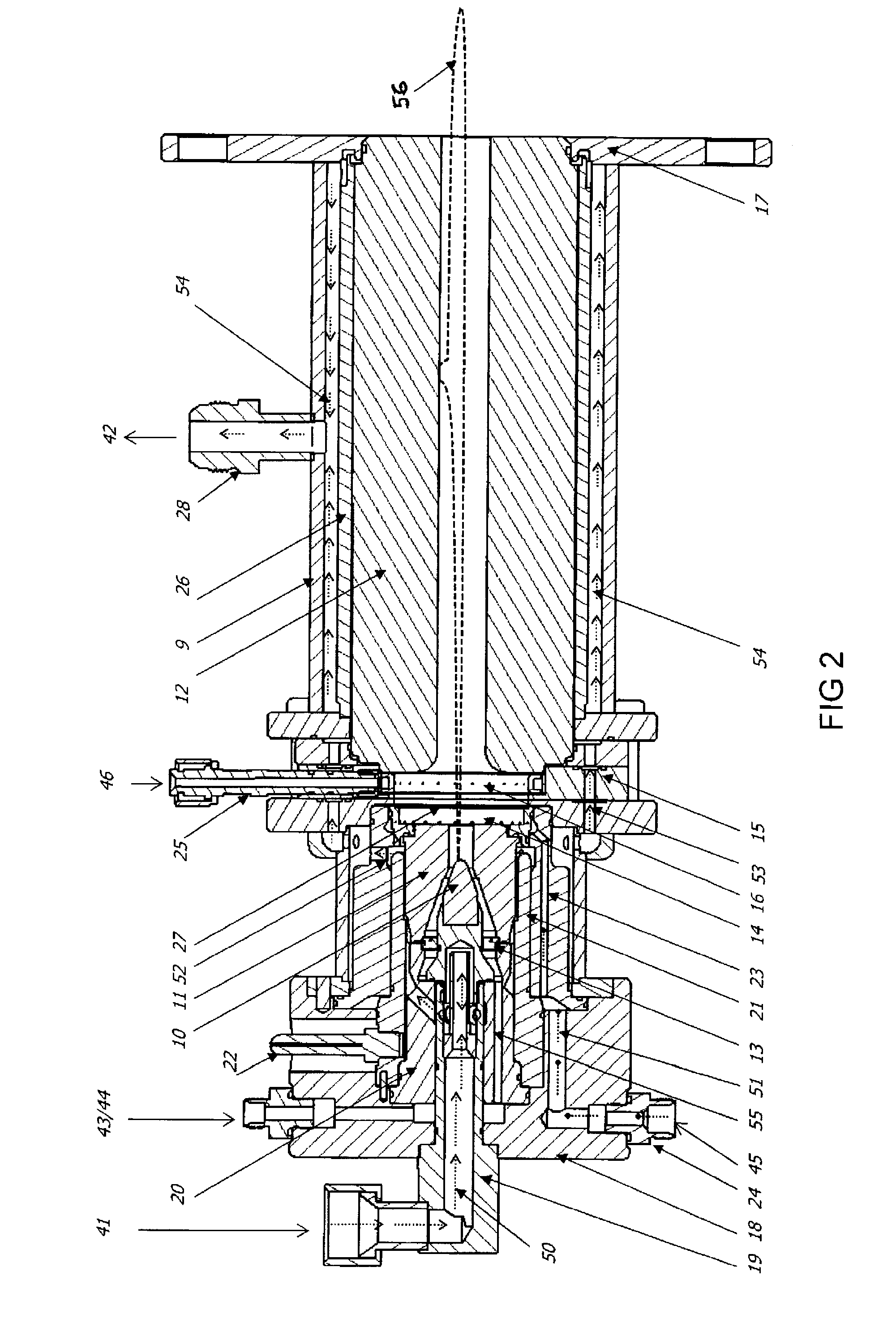

High power DC non transferred steam plasma torch system

Owner:PYROGENESIS CANADA INC

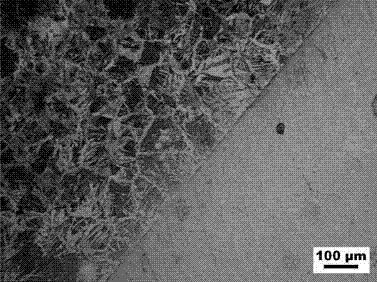

Saw flux system for improved as-cast weld metal toughness

ActiveUS20080078809A1Improve toughnessInhibited and prevented grain growthCooking-vessel materialsArc welding apparatusSlagTitanium

Owner:LINCOLN GLOBAL INC

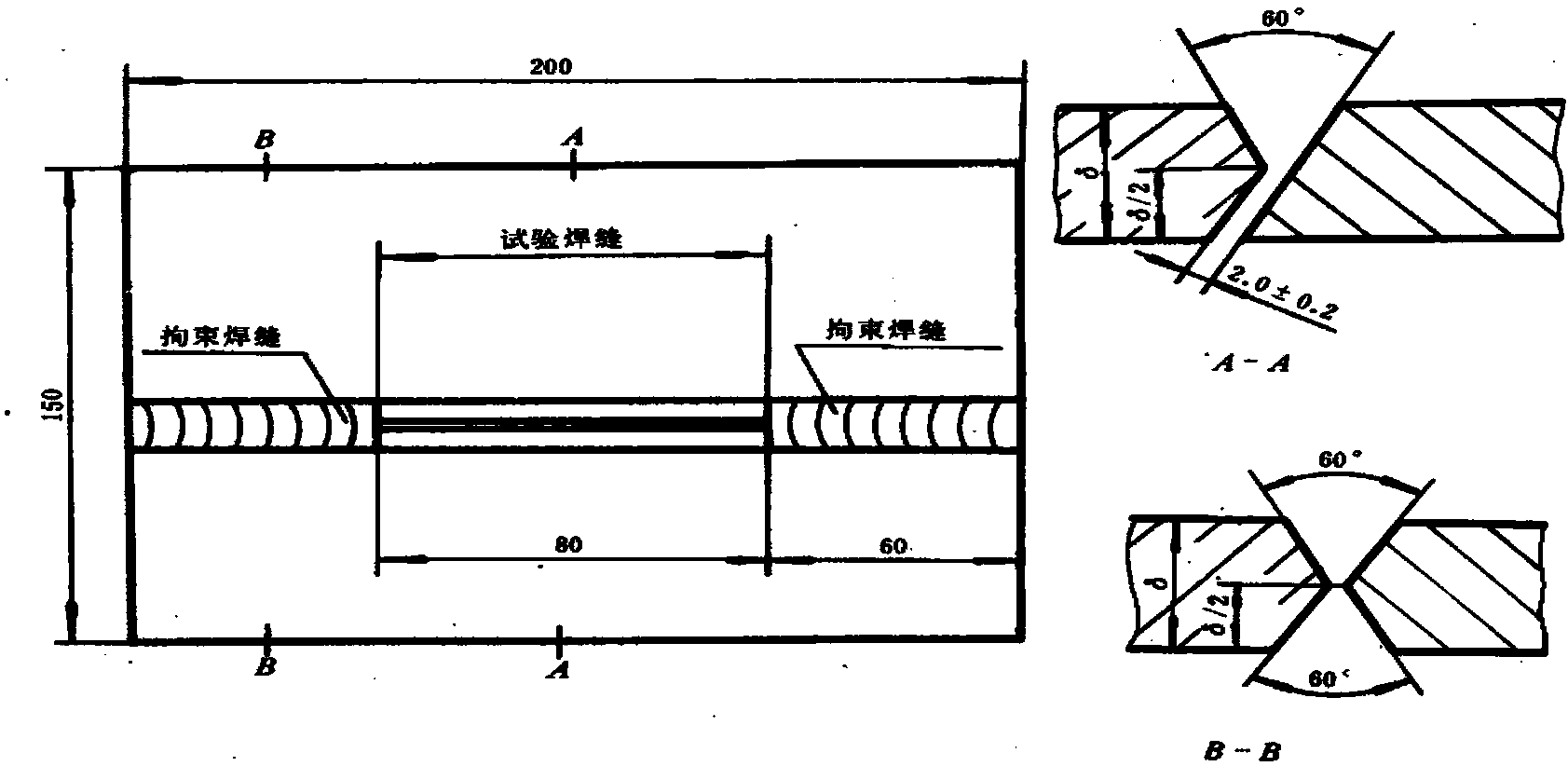

Welding wire of steel-copper dissimilar metal submerged-arc welding and welding method of welding wirethereof

InactiveCN102873467AImprove mechanical propertiesBeautiful shapeArc welding apparatusWelding/cutting media/materialsManganeseSpot welding

Owner:SHENYANG POLYTECHNIC UNIV +1

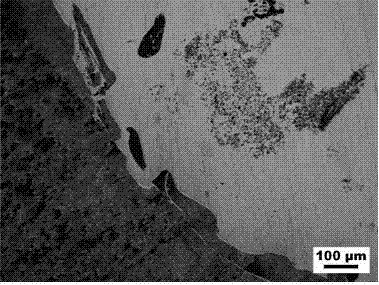

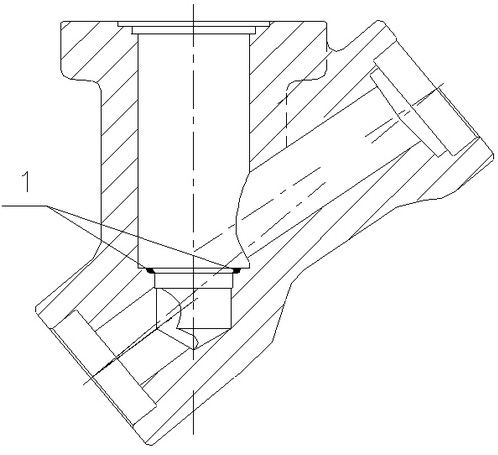

Argon arc welding surfacing process for cobalt-free material ERFeCr-A5

Owner:DALIAN DAGAO VALVE

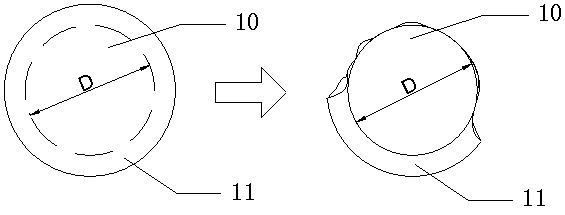

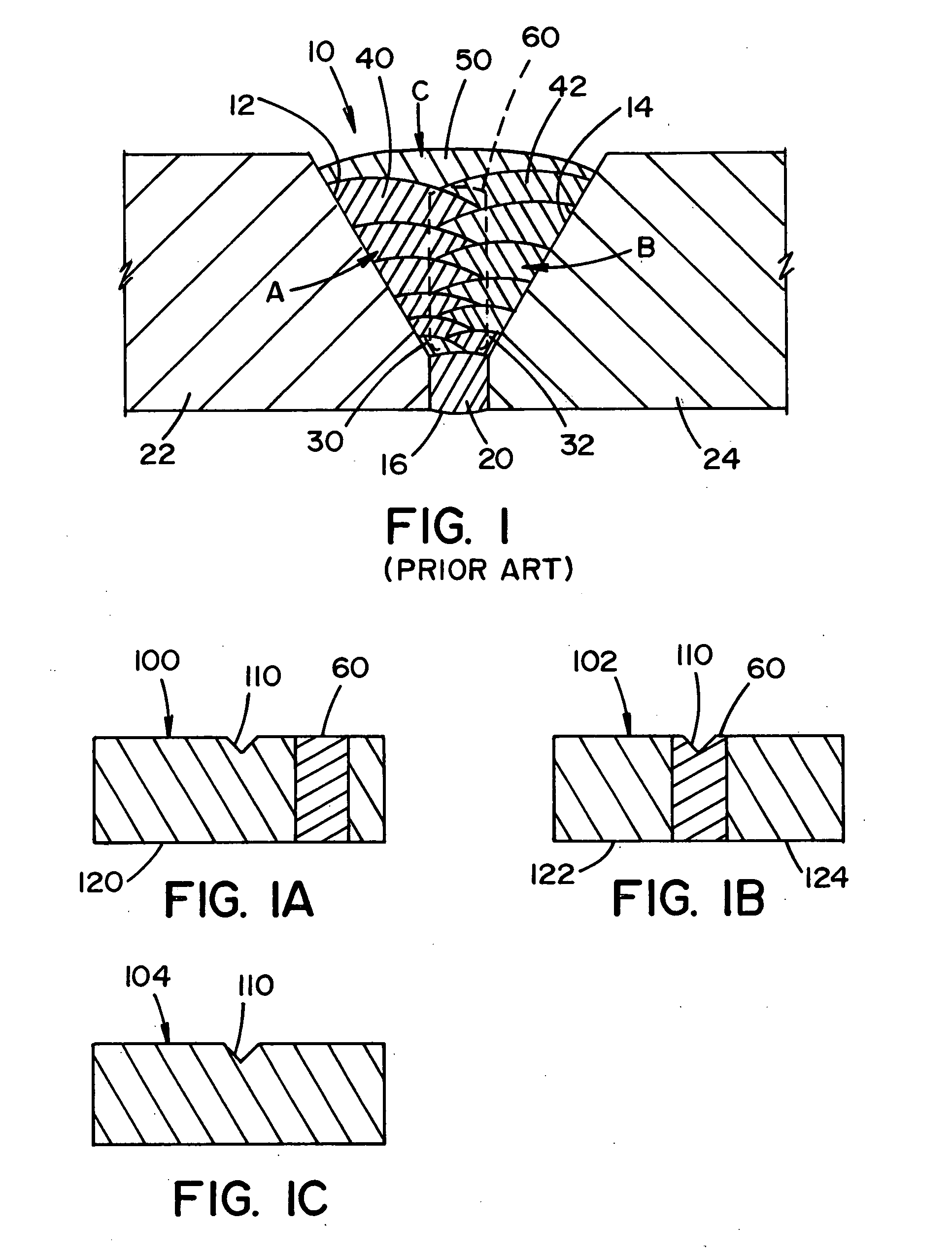

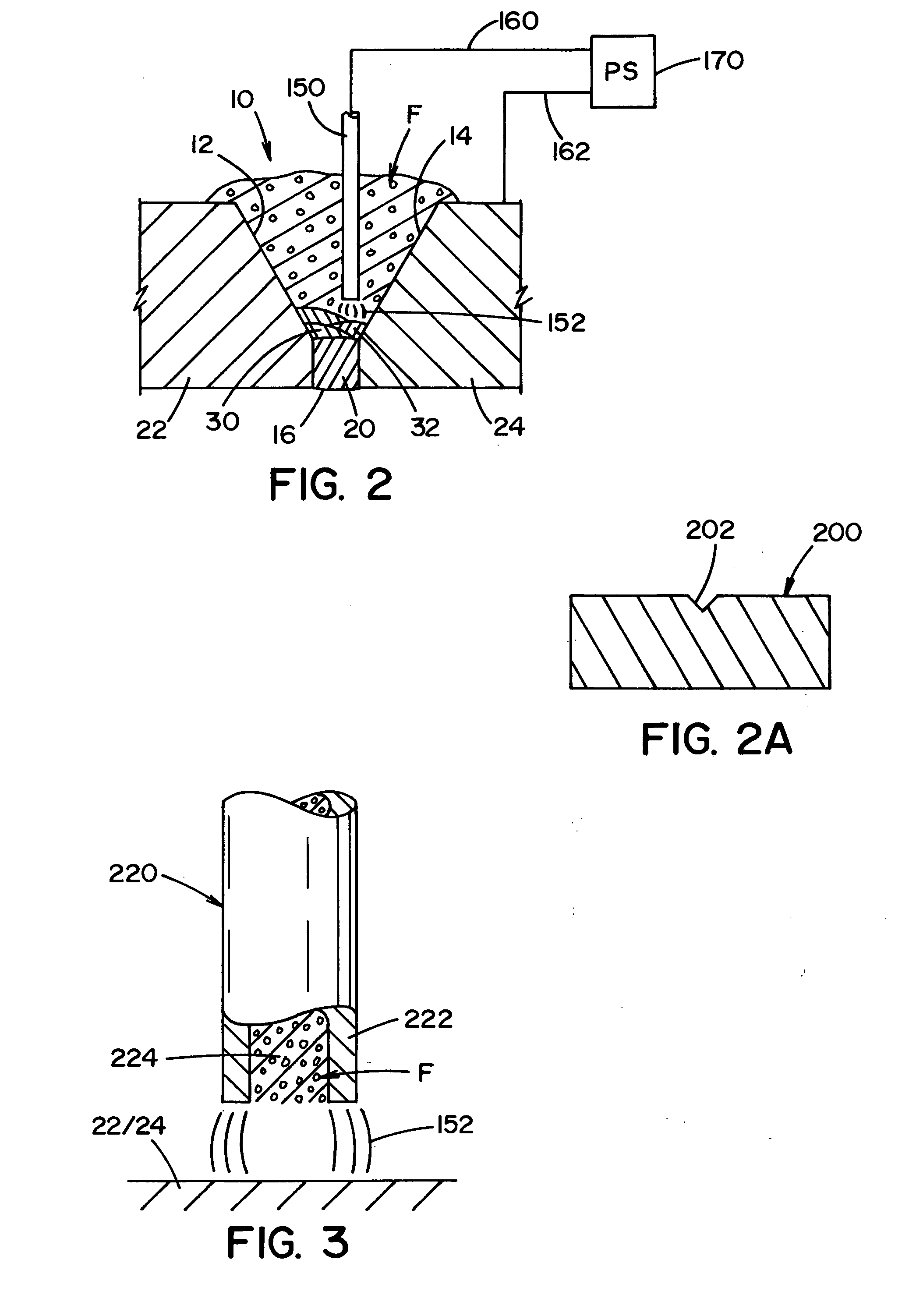

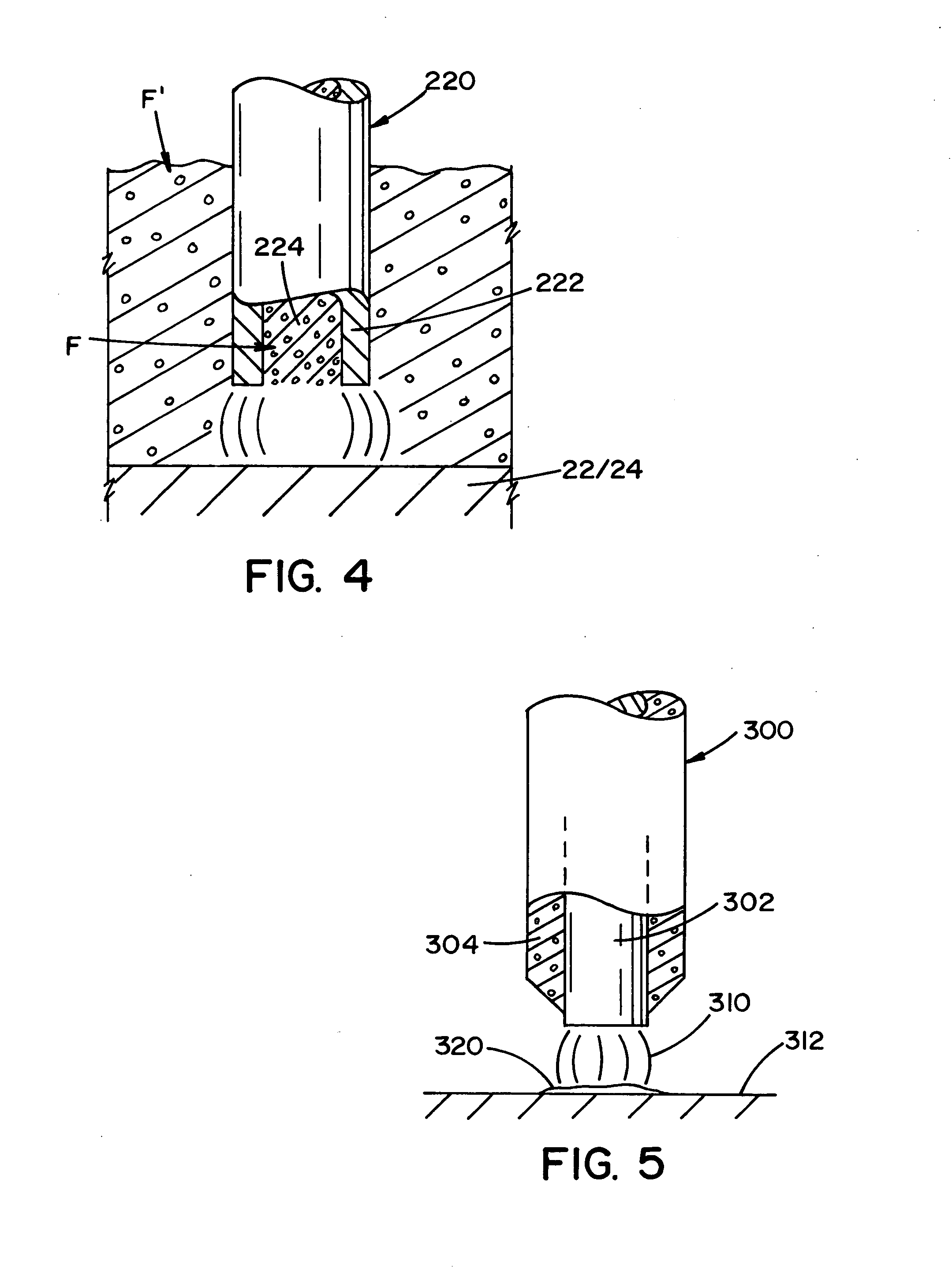

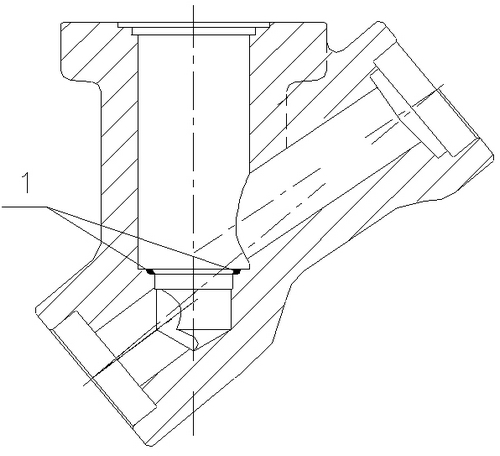

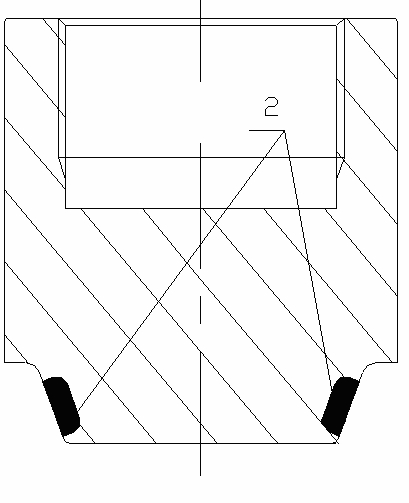

Two-piece compactor wheel tip

A compactor tip (10) assembly for a landfill or soil compactor comprises a base (200) and a tip that are formed from dissimilar materials. The tip (100) may be formed from high carbon steel for wear resistance, while the base (200) may be formed from low carbon steel for easy welding. The compactor tip assembly is attached to the compactor wheel by welding the base to the wheel. The tip and the base each have ground engaging surfaces (101, 201) which may be complementary to one another. A hollow pocket (11) may be formed through the base and in the tip.

Owner:CATERPILLAR INC

Titanium type gas-shielded flux-cored wire

ActiveCN103521949AGood workmanshipImprove crack resistanceArc welding apparatusWelding/cutting media/materialsCrack resistanceManganese

Owner:TIANJIN YONGCHANG WELDING WIRES

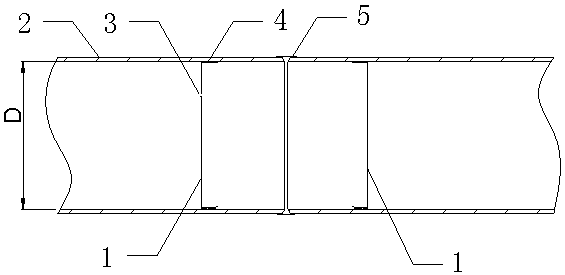

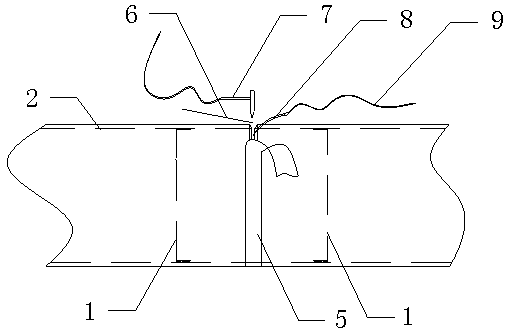

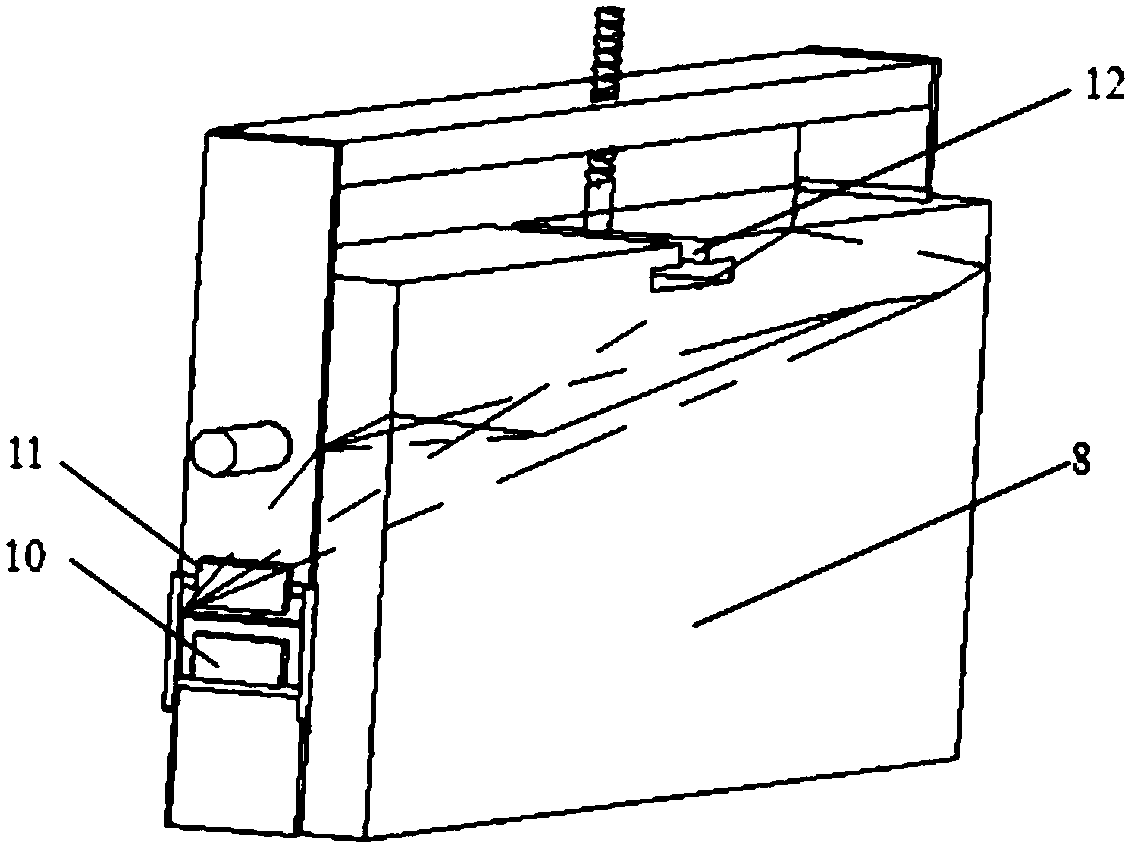

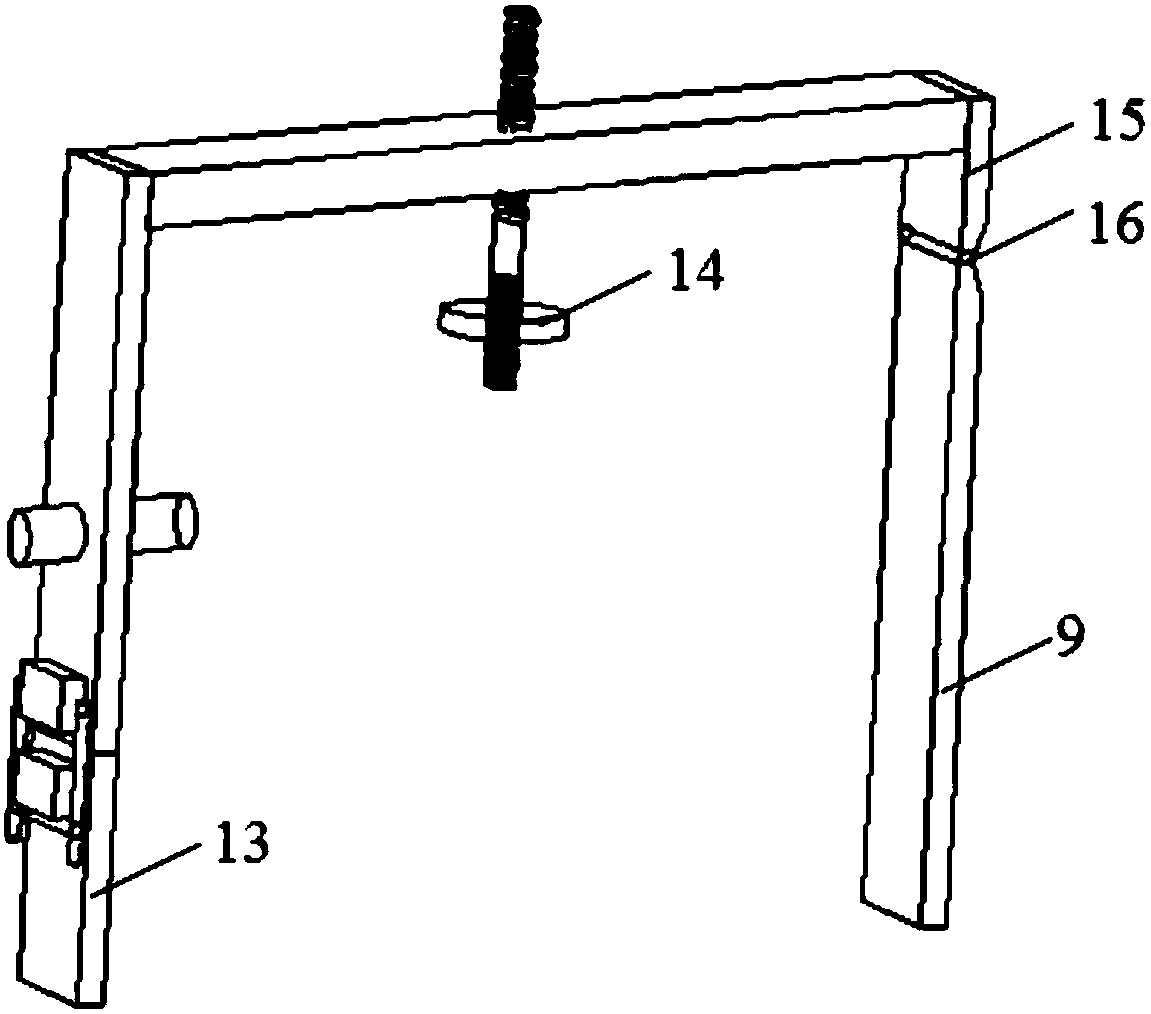

Lateral joint welding and fixing device of deformable ultra-thin metal structure and method for welding lateral structure using same

InactiveCN108381103AReliable weldingGuarantee welding qualityWelding/cutting auxillary devicesArc welding apparatusThin metalPetroleum engineering

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

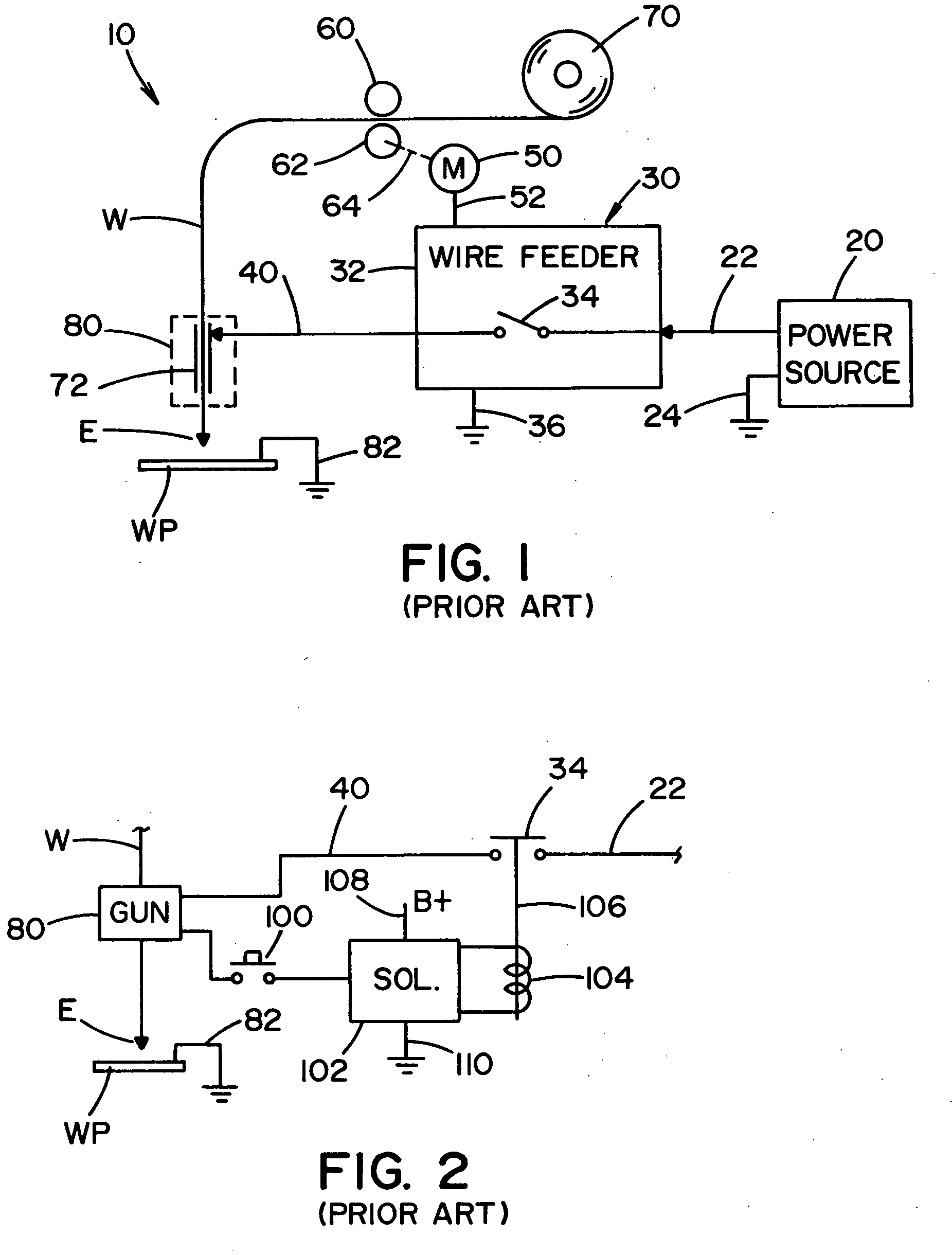

Contactor material for welding wire feeder

InactiveUS20060193098A1Avoid problemsCircuit-breaking switches for excess currentsArc welding apparatusElectricityAlloy

Owner:LINCOLN GLOBAL INC

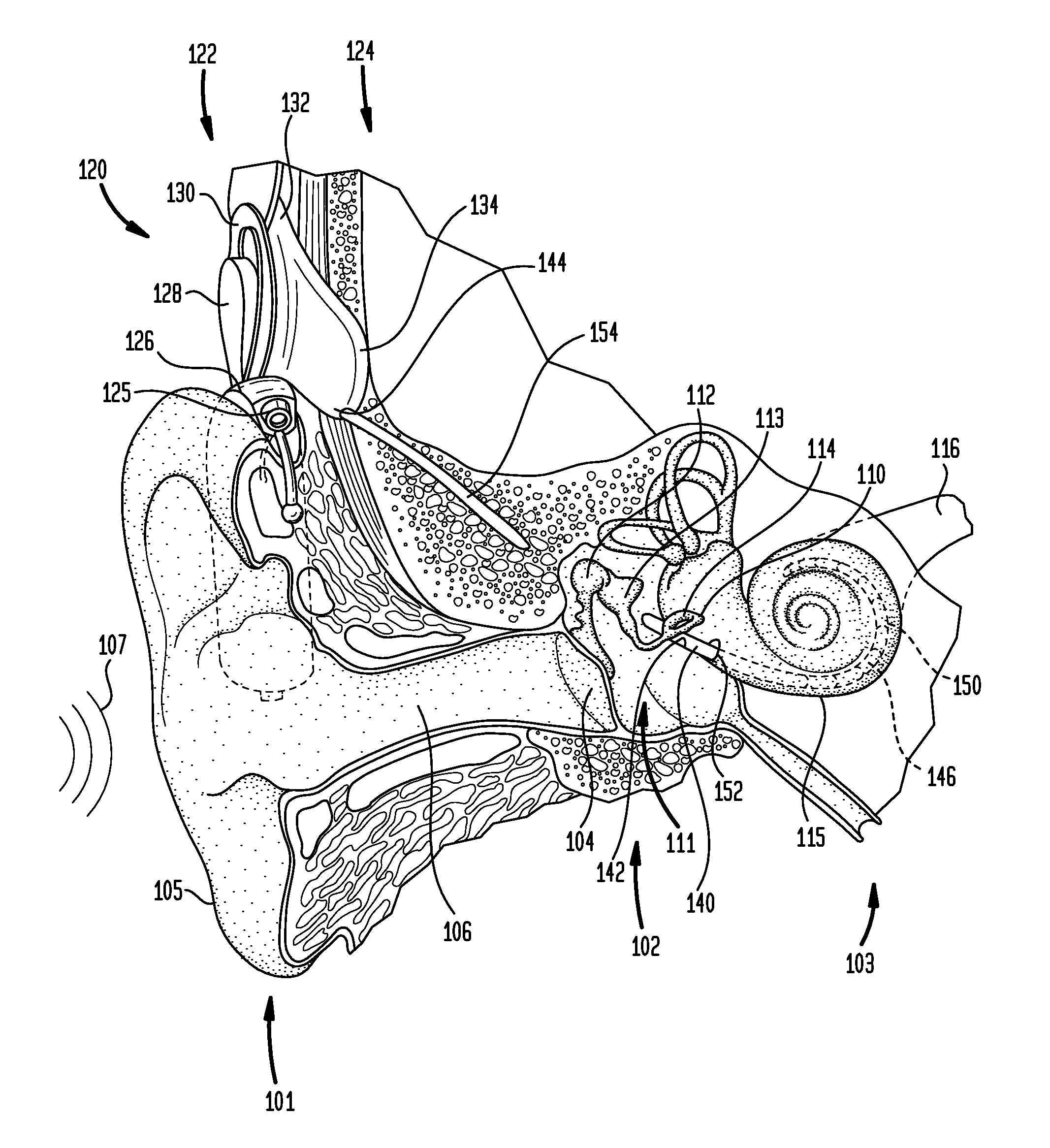

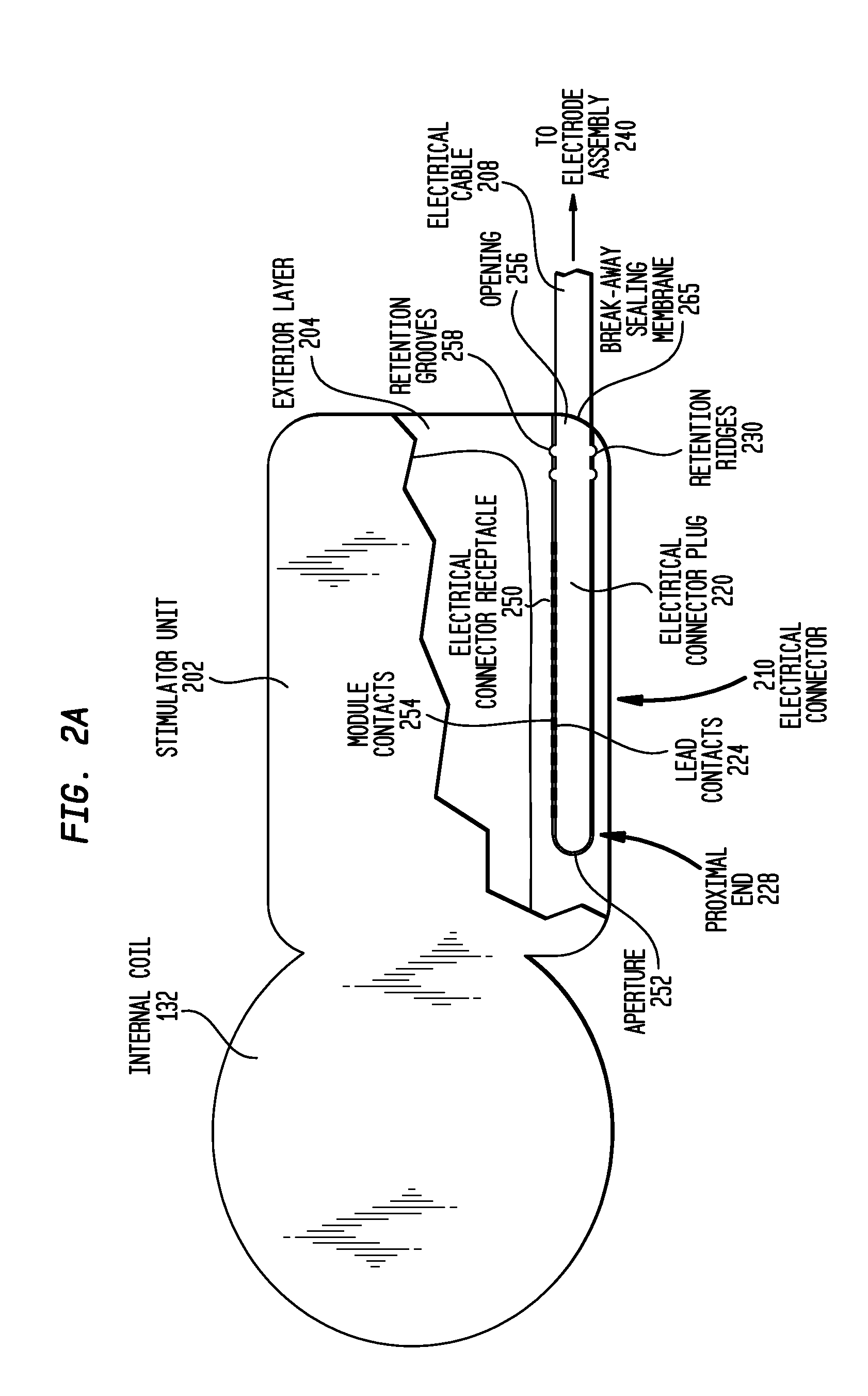

In situ adjustment of implantable components connected by an implantable electrical connector

Owner:COCHLEAR LIMITED

Welding method for angle iron tower clad steel

Owner:HENAN DINGLI POLE TOWER

Co-Mn-Si-Fe nanometer welding layer for welding and preparation method

InactiveCN104889597AImprove performanceExtended service lifeArc welding apparatusWelding/cutting media/materialsUltimate tensile strengthWear resistance

The invention relates to a Co-Mn-Si-Fe nanometer welding layer for welding and a preparation method. The Co-Mn-Si-Fe nanometer welding layer for welding comprises the following components in percentage by mass: 46-63% of Co, 29-37% of Mn, 7-9% of Si, 7-9% of Fe, 2-3% of Al2O3, and 0.5-1.5% of additive. The additive is Ni60A. The method comprises the following steps: Co, Mn, Si, Fe and Al2O3 are prepared to nanometer balls by an atomization method; the nanometer balls are uniformly mixed with grinded Ni60A to prepare nanometer welding rods; and finally, the nanometer welding rods are welded on the surface of a part to form the nanometer welding layer. The prepared nanometer welding layer has such advantages as high bonding strength, wear resistance and good corrosion resistance, realizes the repairing of the part, improves the service performance of the part, and prolongs the service life of the part.

Owner:WUHU DINGHAN REMFR TECH

Welding material for ZG40Cr25Ni20Si2

InactiveCN108453409AImprove corrosion resistanceImprove mechanical propertiesArc welding apparatusWelding/cutting media/materialsChemical compositionMechanical property

Owner:李泳澎

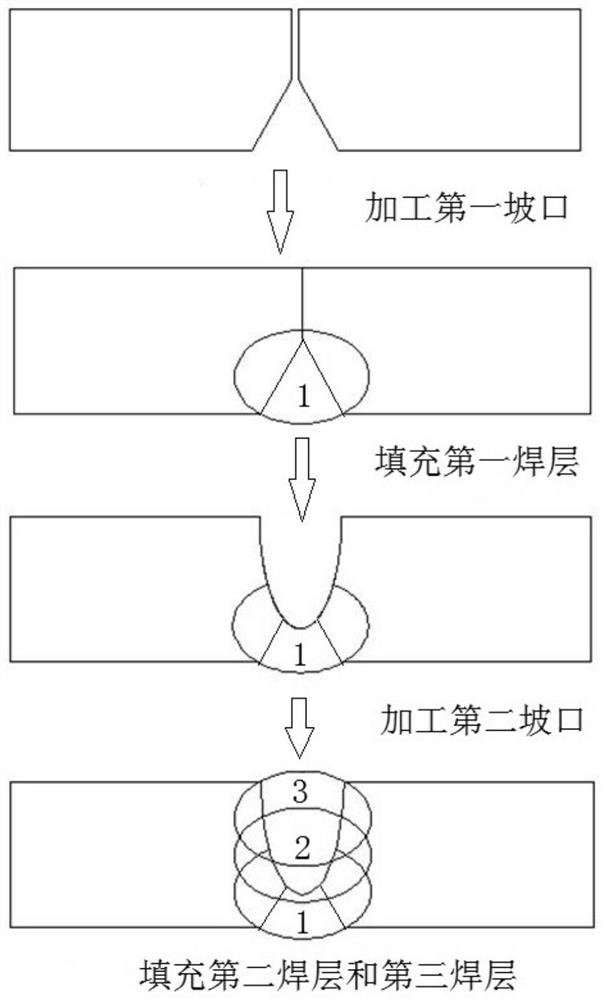

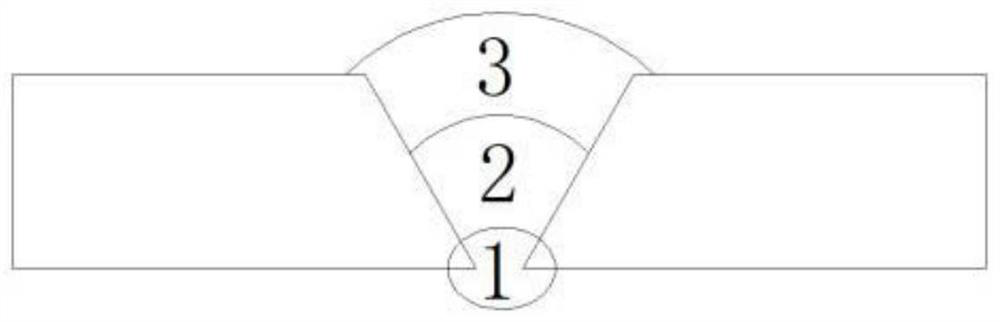

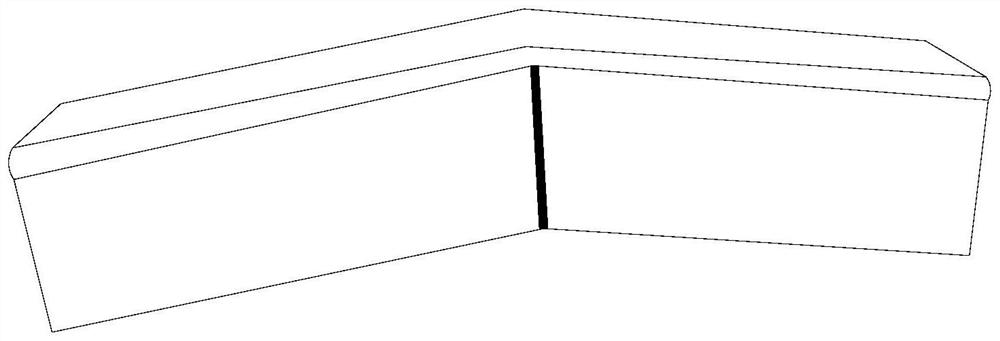

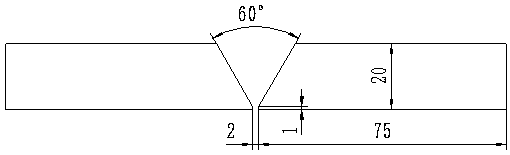

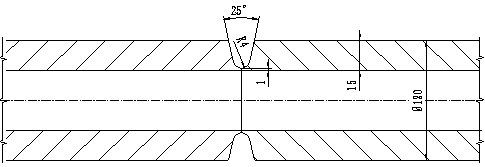

Submerged arc welding method for BB503 steel plate welded joint of 100mm thick blast furnace shell

InactiveCN109352145AArc welding apparatusWelding/soldering/cutting articlesSteel platesSubmerged arc welding

Owner:NANJING IRON & STEEL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap