Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Base metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A base metal is a common and inexpensive metal, as opposed to a precious metal such as gold or silver. A long-time goal of alchemists was the transmutation of a base (low grade) metal into a precious metal. In numismatics, coins often derived their value from the precious metal content; however, base metals have also been used in coins in the past and today.

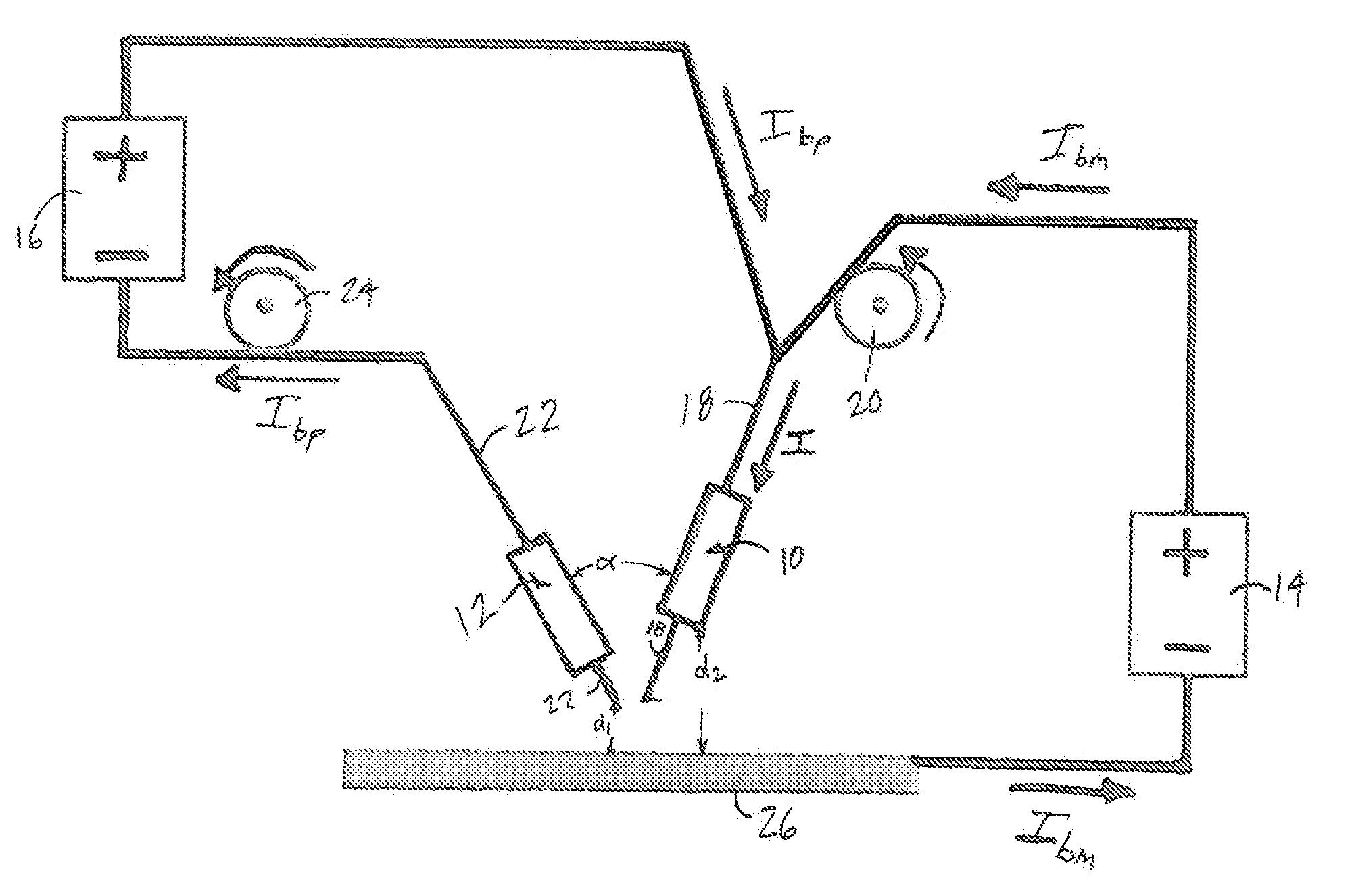

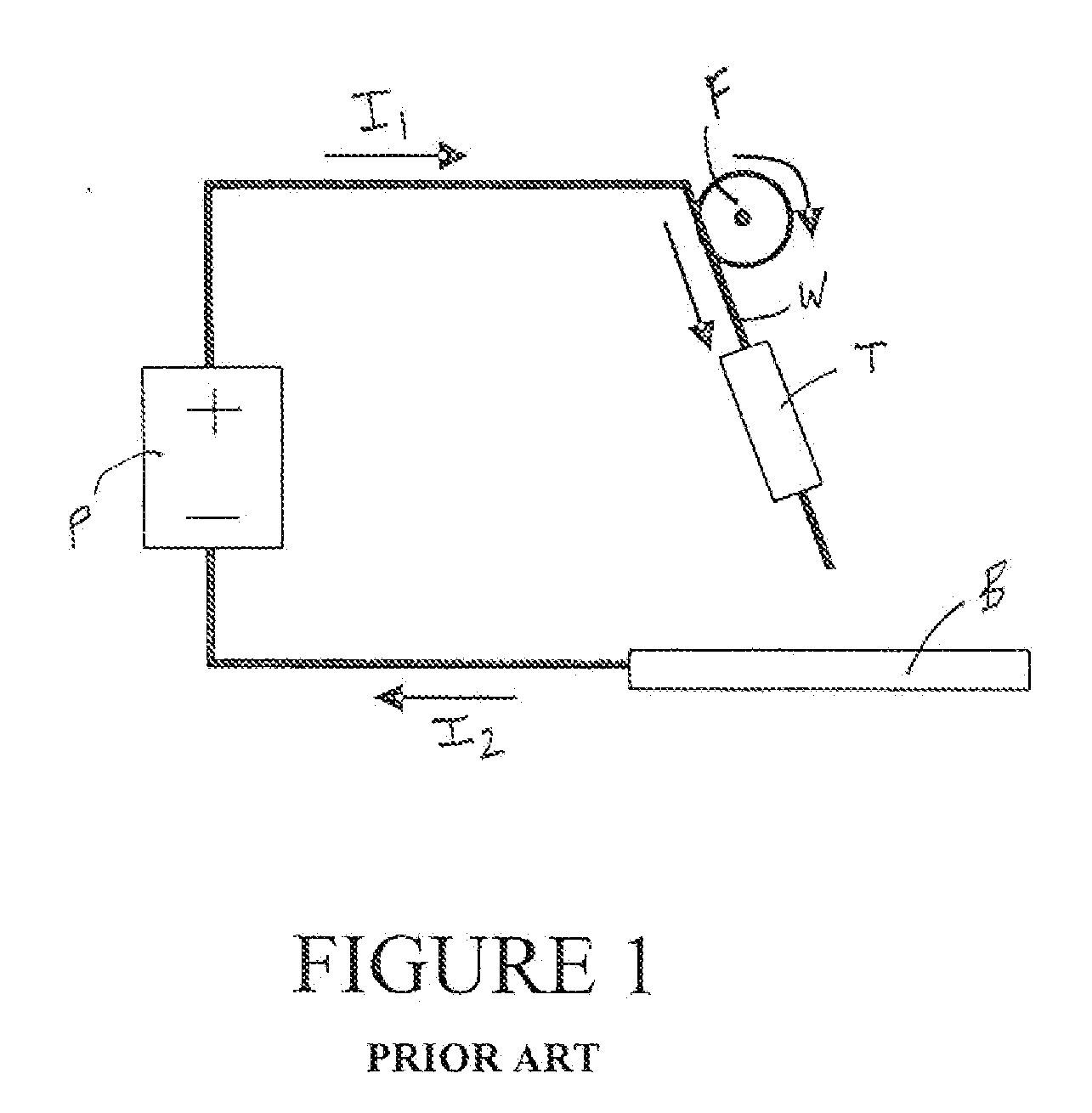

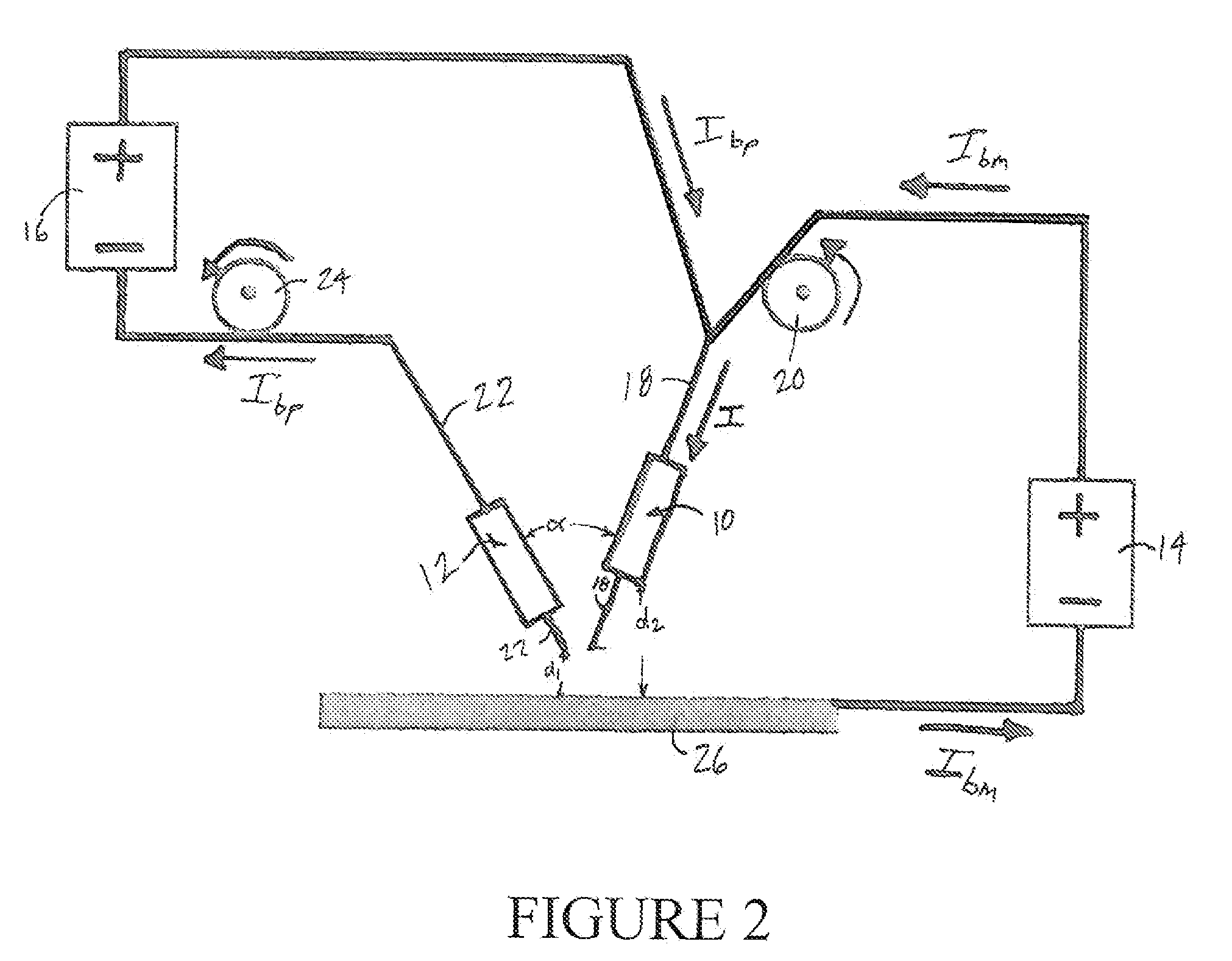

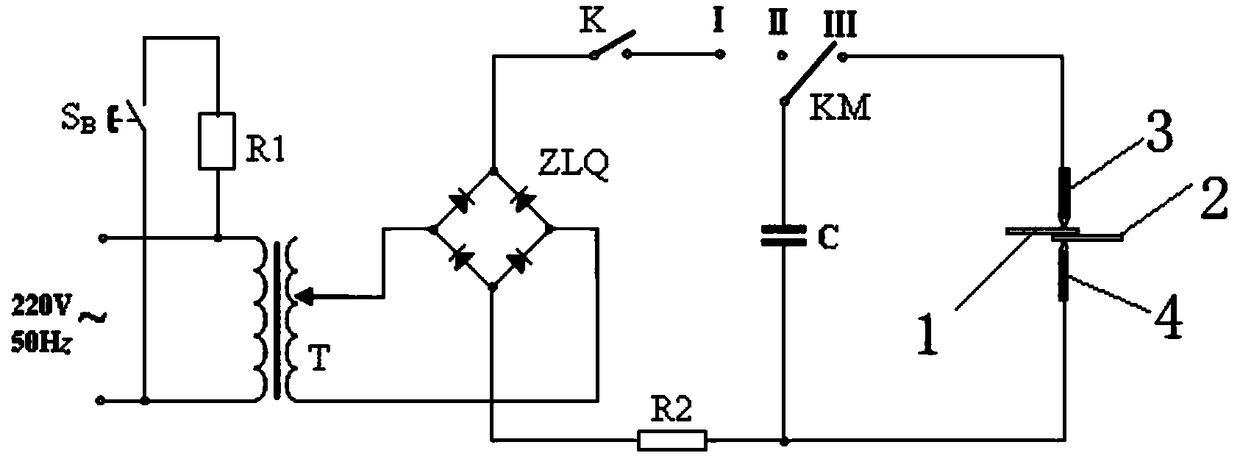

Arc Welder and Related System

ActiveUS20080190900A1Welding/cutting auxillary devicesArc welding apparatusEngineeringMechanical engineering

Owner:ZHANG YU MING

Arc welding method and arc welding apparatus

An arc welding method comprising the steps of accelerating a feeding speed of a welding wire to cause shorting between the welding wire and a base metal when a welding end signal is input during a period of arcing, retracting the welding wire backward thereafter until a wire retracting speed reaches a predetermined rate, controlling the wire retracting speed constant at this speed for a predetermined duration of time, then stopping the backward retraction of the welding wire, and then terminating a welding power output after supplying a predetermined amount of welding current for a predetermined duration of time starting from a time when opening of the shorting occurs during the backward retraction of the welding wire.

Owner:PANASONIC INTPROP MANAGEMENT CO LTD

Welding wire material for austenitic stainless steel

InactiveCN102303196AReduce sensitivityHigh deposition rateWelding/cutting media/materialsSoldering mediaRare-earth elementAustenite

Owner:JIANGSU XINGHAI SPECIAL STEEL

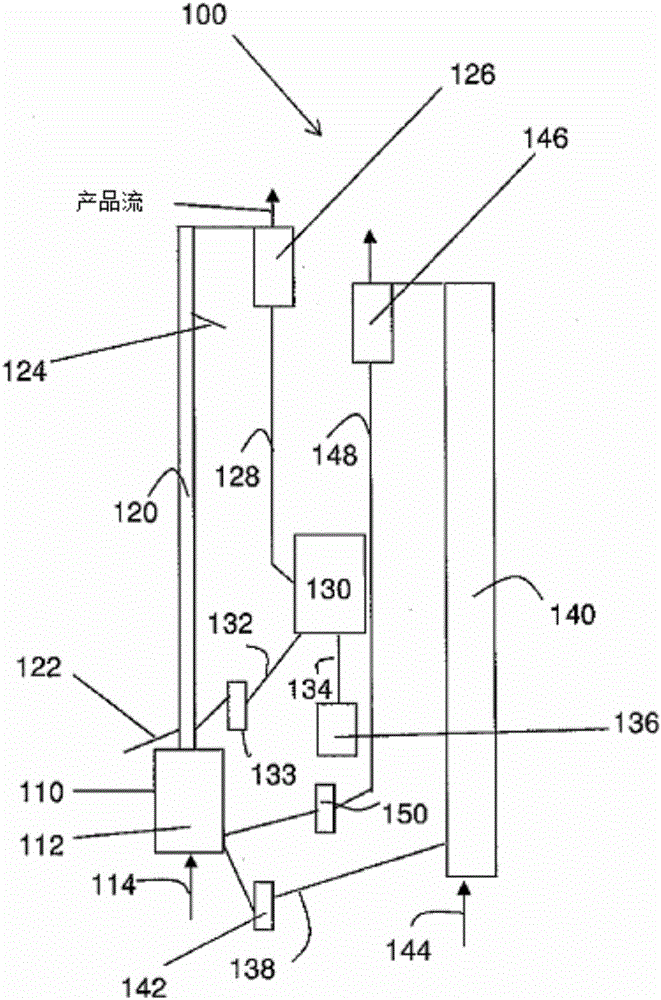

Sour gas combustion using in-situ oxygen production and chemical looping combustion

InactiveCN106029559AAchieve conversionAvoid direct contactFluidized bed combustionCalcium/strontium/barium sulfatesSorbentSulfur

Owner:SAUDI ARABIAN OIL CO

Method for concentrating platinum and palladium from platinum-palladium flotation concentrates

InactiveCN108722675AHigh precious metal contentHigh enrichment ratioFlotationMass ratioPt element

Owner:GUANGDONG INST OF RARE METALS

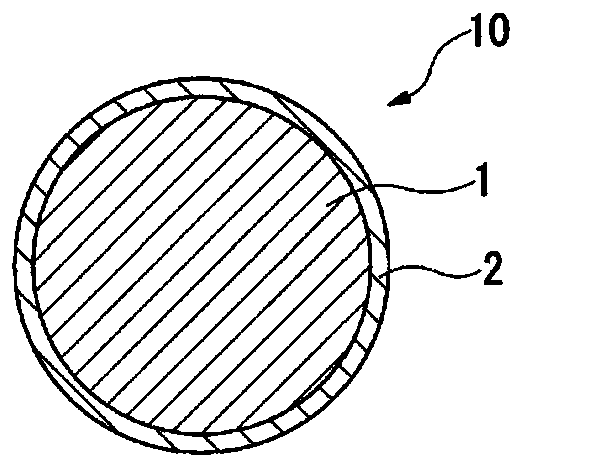

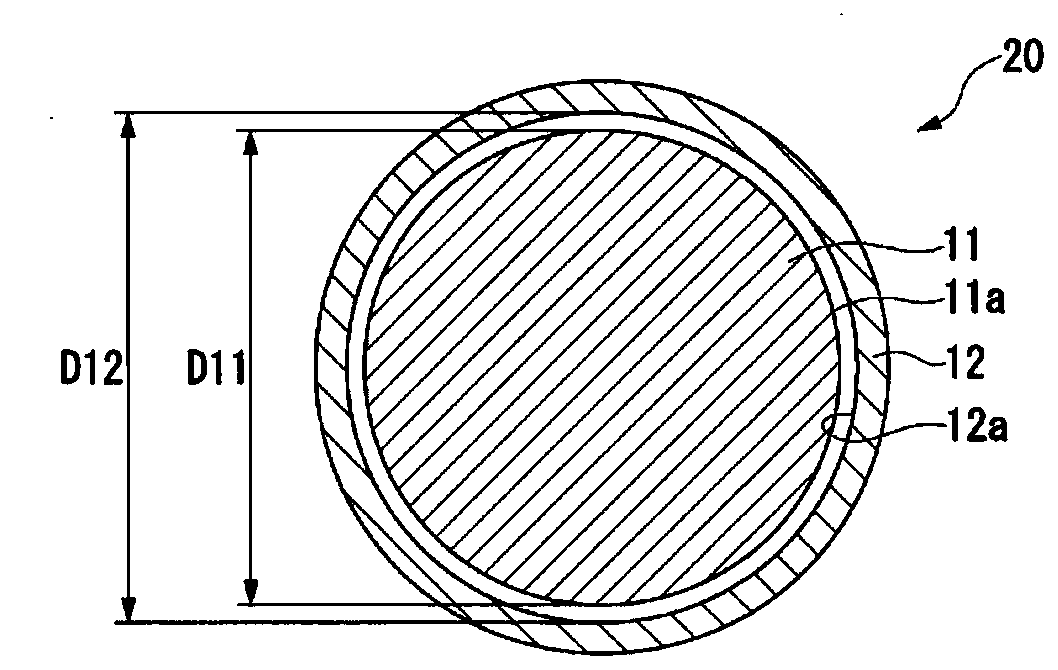

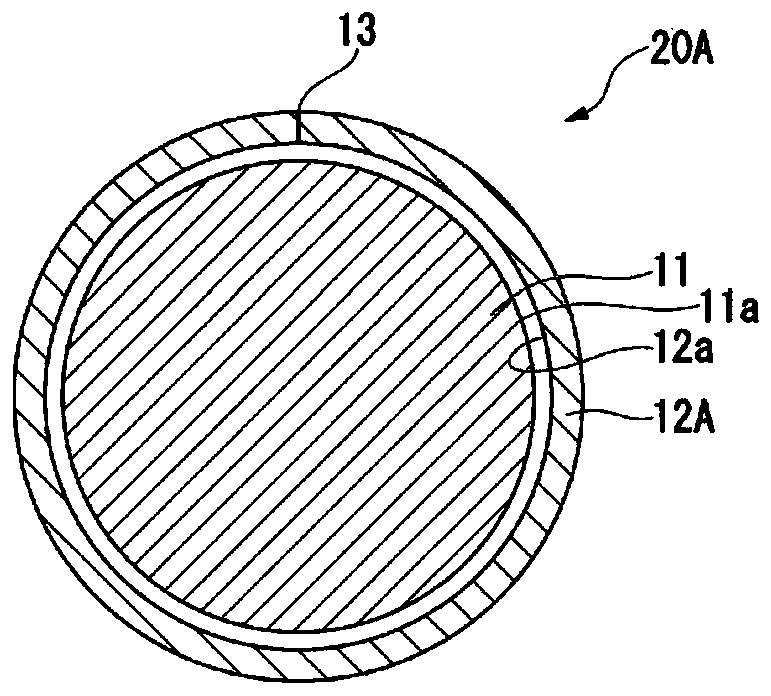

Wire and method for manufacturing same

InactiveCN110382128AReduce hardnessNot easy to breakSingle bars/rods/wires/strips conductorsInsulated cablesElectrical conductorMaterials science

Owner:THE FUJIKURA CABLE WORKS LTD

Alkali-resistant anticorrosive paint

Owner:QINGYANG ZHOUYANG MACHINERY MFG

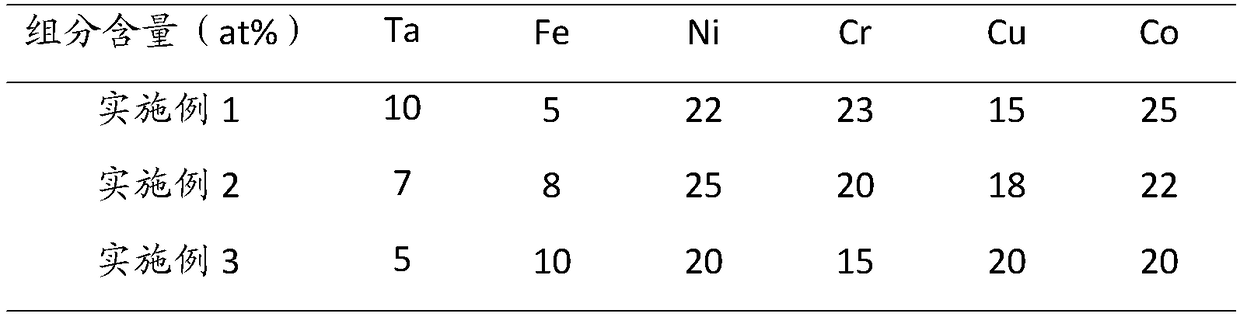

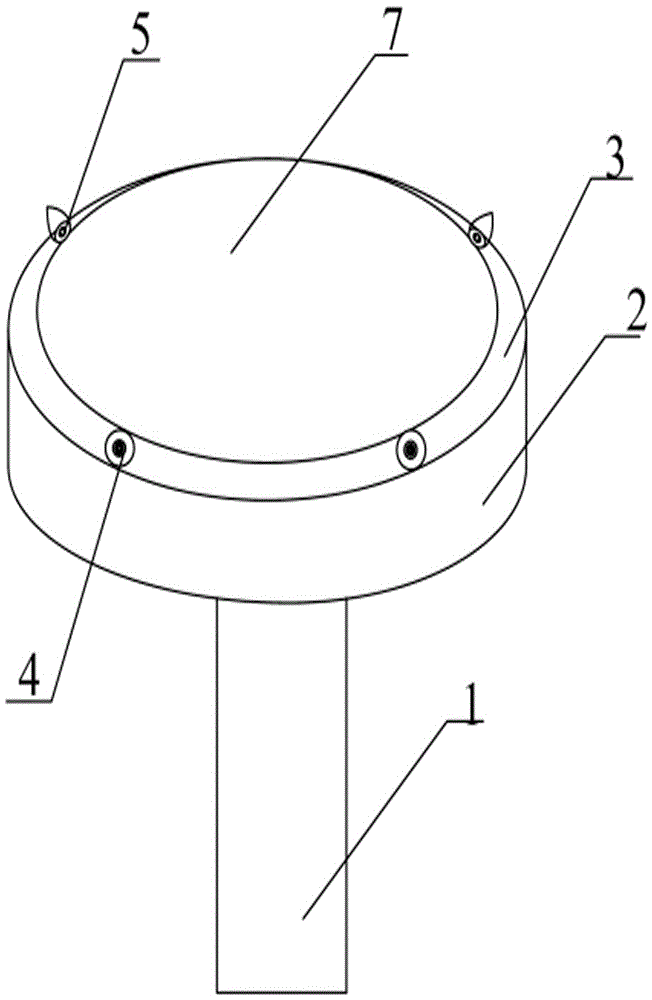

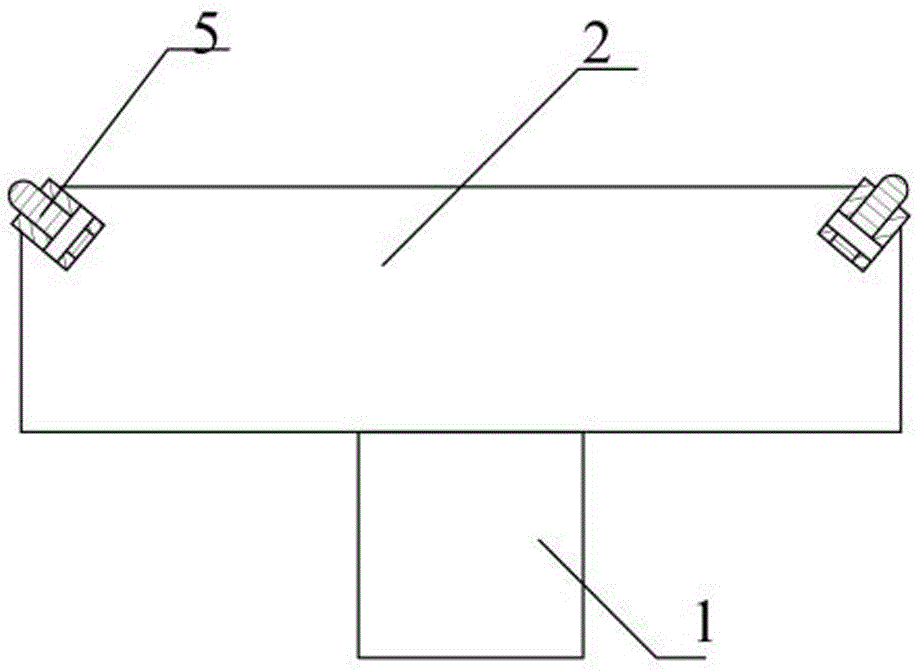

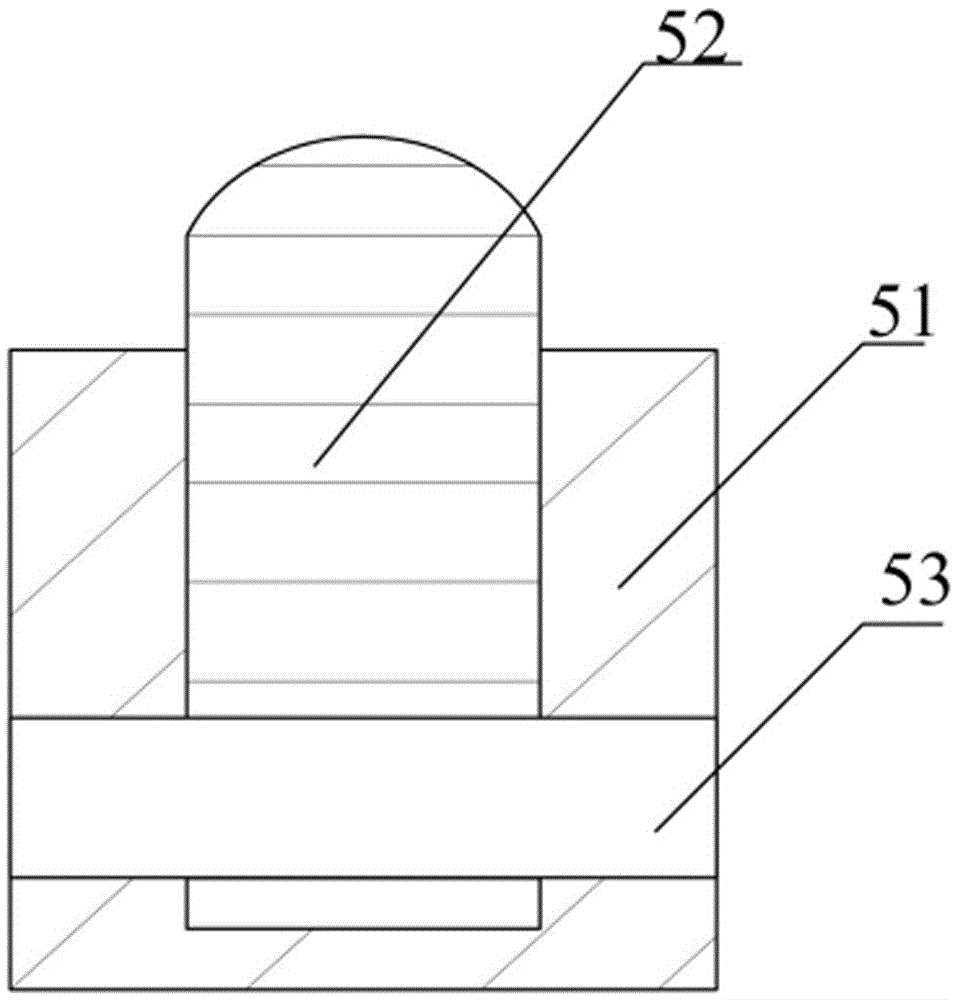

Intermediate layer alloy applied to resistance spot-welding of tantalum Ta1 and Q235 and preparation method thereof

ActiveCN109202244AImprove matchImproved comprehensive mechanical properties of jointsWelding/cutting media/materialsWelding/soldering/cutting articlesElectrical resistance and conductanceSpot welding

Owner:XIAN UNIV OF TECH

Separating preventing hard alloy maintenance tool

ActiveCN106403610AReduce pressure coefficientImprove protectionMaintainance of heating chambersThermal expansionAlloy

Owner:南通盟鼎新材料有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap