Arc Welder and Related System

a technology of arc welding and related systems, which is applied in the field of welding, can solve the problems of increased residual stress and distortion of the base metal being welded, increased welding penetration, and increased heat input of the base metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

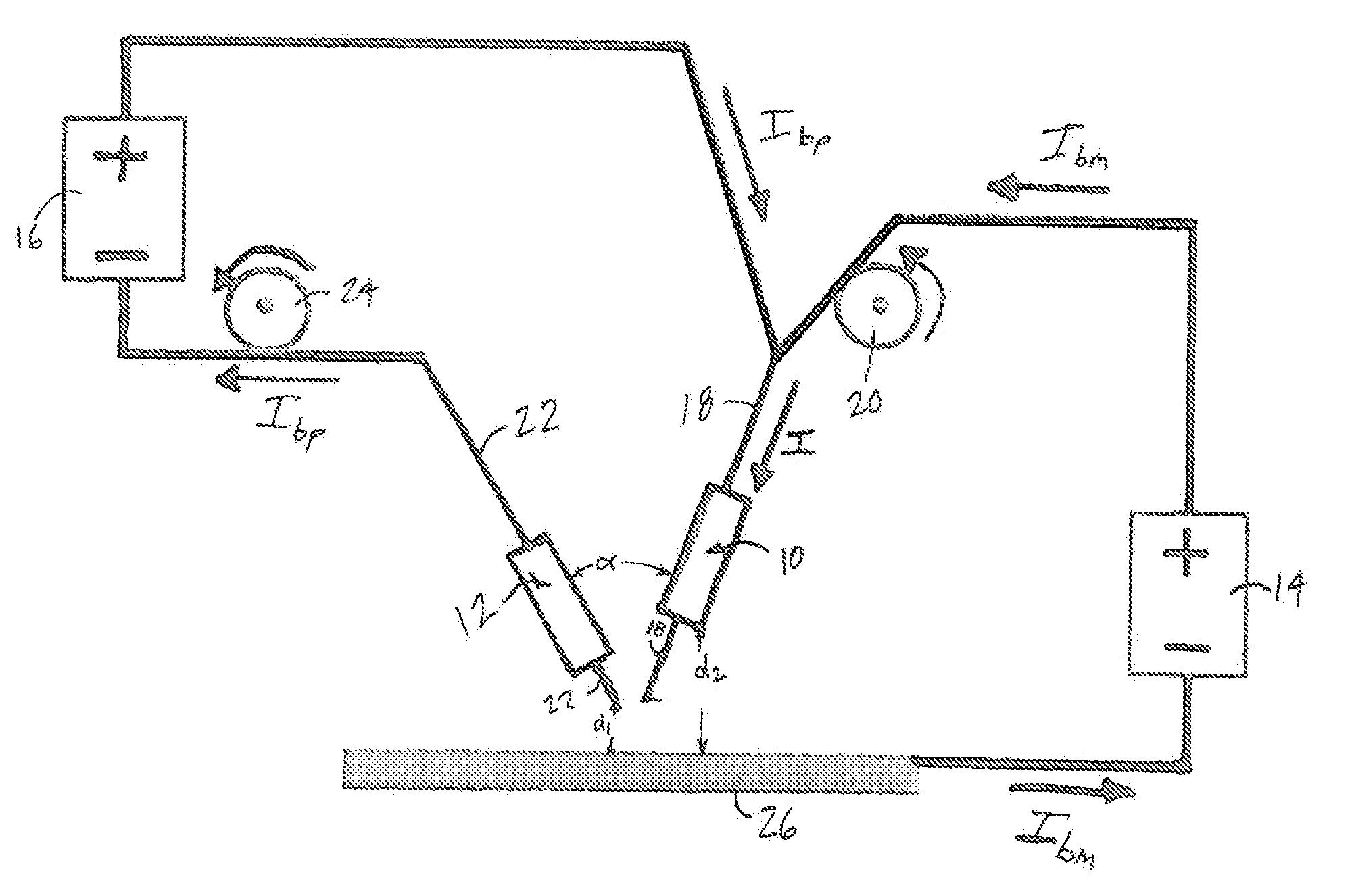

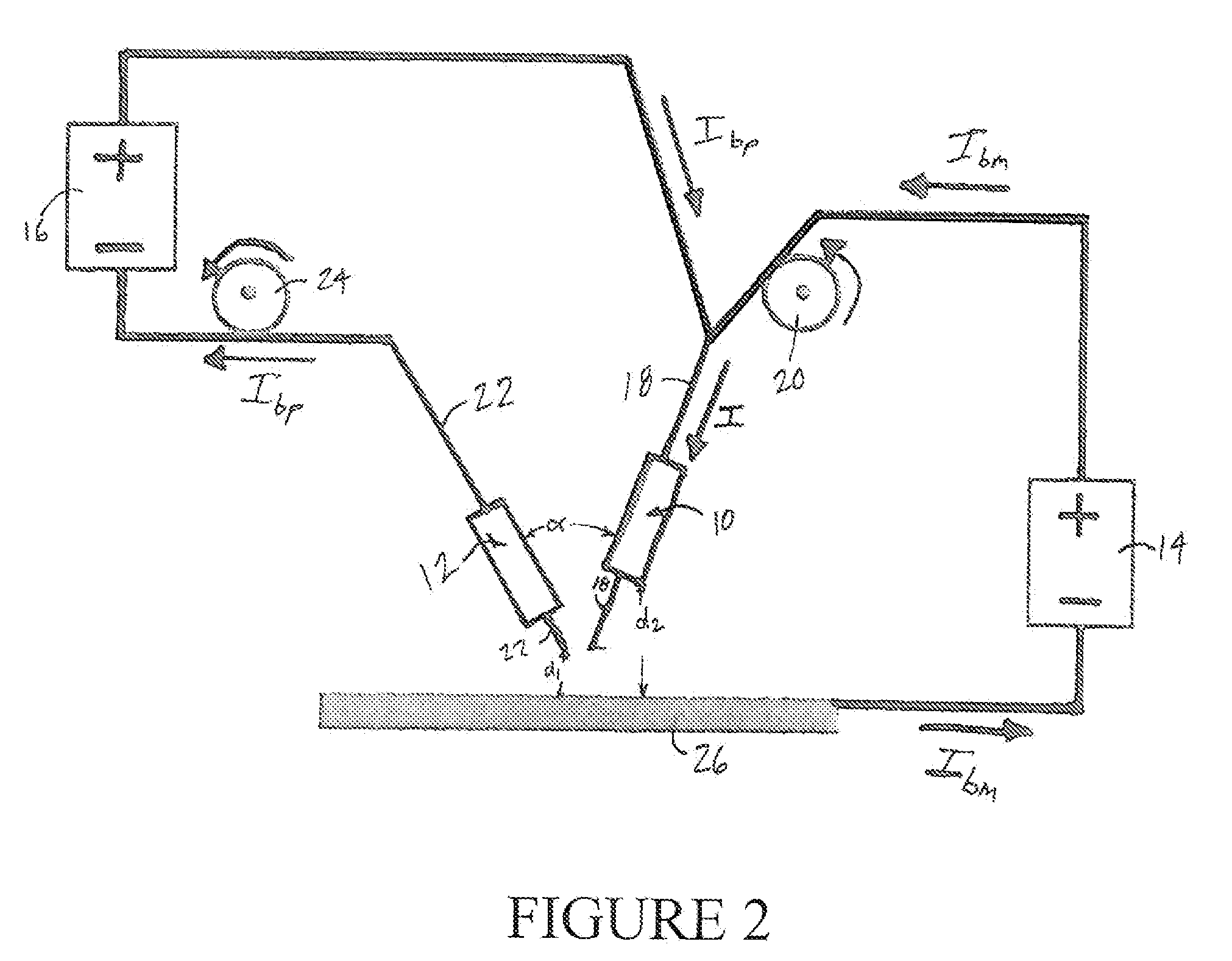

[0048]A welding system was setup with a CV power supply, a GMAW gun, a water-cooled GTAW torch, and four 0.1 ohm power resistors controlled by four IGBTs. The tungsten electrode, protected by a water cooling system, had a diameter of 3.2 mm. Pure argon was used to shield the GMAW gun and GTAW torch. The gas flow rates for the GMAW gun and GTAW torch were 16.5 L / min and 7.1 L / min, respectively. The following parameters were used to determine the geometrical relationship between the GMAW gun, GTAW torch, and base metal: the distance from the GMAW contact tube to the base metal was set to 20 mm; the distance from the bypass electrode to the base metal was set to 5 mm; the distance between the bypass electrode and the electrode wire was set to 4mm; and the angle between the electrode wire and the tungsten electrode was set to 60°. The base metal was a mild steel plate measuring 50×120×2 mm. A low-carbon welding wire (ER70S-6) with a diameter of 1.2 mm was used. The welding voltage was

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric potential / voltage | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap