Wire and method for manufacturing same

A manufacturing method and wire technology, applied in cable/conductor manufacturing, coils, circuits, etc., can solve problems such as reduced power transmission efficiency, heat generation, and easy breakage of enameled wires, and achieve the effect of superior operability

Inactive Publication Date: 2019-10-25

THE FUJIKURA CABLE WORKS LTD

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

The technical effect of this patented process allows for improved durability against damage caused by winding electrical conductors with high-strength materials such as aluminum or steel wire without requiring expensive equipment like electroplated coatings on their surface.

Problems solved by technology

The technical problem addressed in this patented technology relates to improving the performance of electrical wires with layers containing magnetism metals such as iron oxide or nickel alloy deposited onto them without decreasing their effectiveness at transmitting signals through certain frequencies. This can lead to reduced energy transfer efficacy and increased temperature generated within devices caused by impedance mismatches between different parts connected together.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Magnetic field | aaaaa | aaaaa |

Login to view more

Abstract

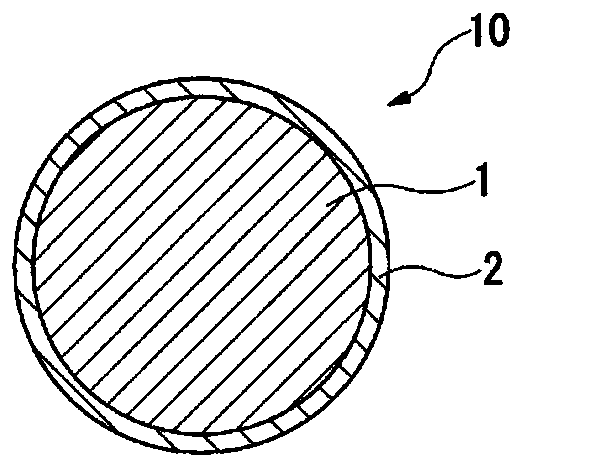

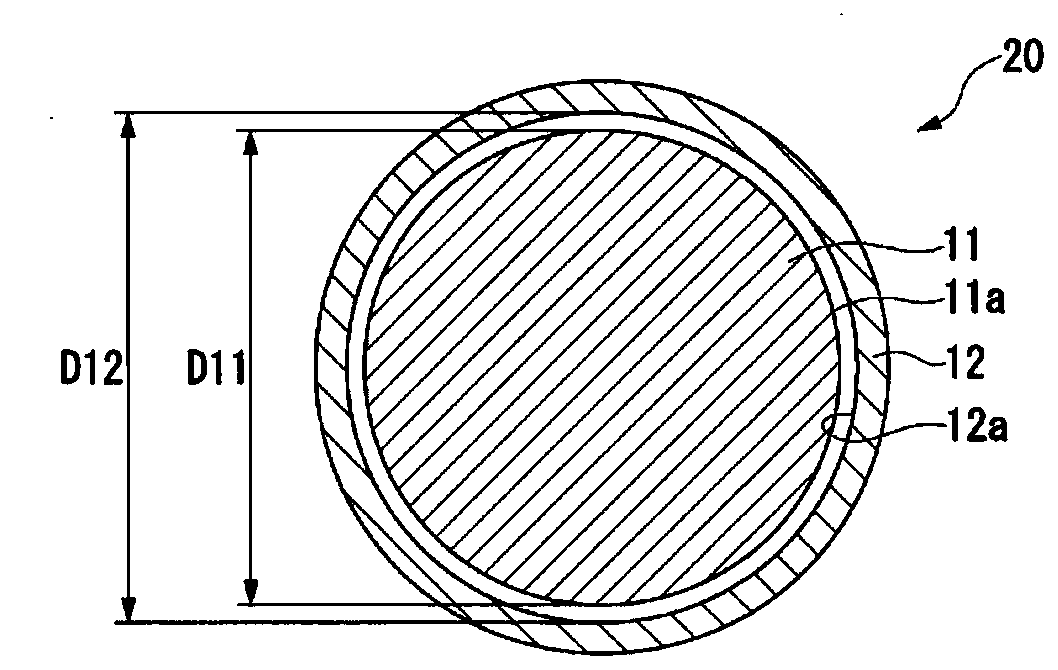

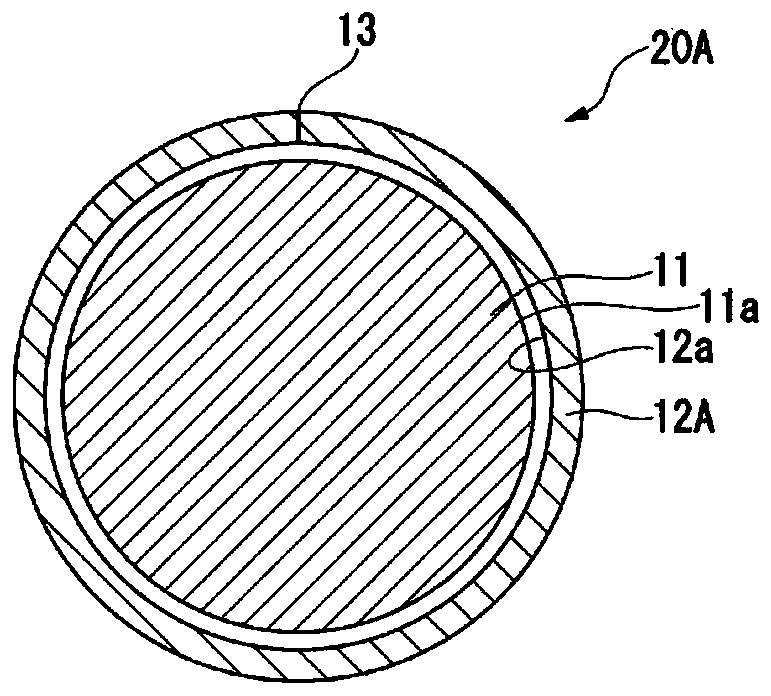

Provided is a method for manufacturing wire wherein a cylindrical outer layer body constituted of a magnetic metal containing iron and a core body having an outside diameter with a ratio to the insidediameter of the outer layer body of 85.1-99.4% are prepared, the inside surface of the outer layer body and the outside surface of the core body are mechanically polished, at least one of the insidesurface of the outer layer body and the outside surface of the core body is treated with hydrochloric acid, a base metal is obtained by disposing the core body inside the outer layer body, and the base metal is passed through a wire drawing die, thereby obtaining a wire having a core conductor that is formed by the core body and an outer layer that is formed by the outer layer body and covers thecore conductor.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Owner THE FUJIKURA CABLE WORKS LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap