Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95 results about "Hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hardness is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion. Some materials (e.g. metals) are harder than others (e.g. plastics, wood). Macroscopic hardness is generally characterized by strong intermolecular bonds, but the behavior of solid materials under force is complex; therefore, there are different measurements of hardness: scratch hardness, indentation hardness, and rebound hardness.

Method for enhancing surface of magnesium aluminium alloy by laser remelting

InactiveCN101532134AHigh strengthImprove corrosion resistanceMolten spray coatingSuperimposed coating processOxygenLaser beams

The invention relates to a method for enhancing the surface of magnesium aluminium alloy by laser remelting, aiming at enhancement processing of the surfaces of magnesium aluminium alloy plates and magnesium aluminium alloy rods by the methods of flame spraying of alloyed powder and laser remelting. The method is characterized by cleansing the surface of the magnesium aluminium alloy, carrying out oxy-acetylene flame spraying on the alloyed powder, namely aluminium nickel alloy powder, nickel-chromium-boron-silicon-iron master alloy powder and neodymium powder, carrying out remelting and curing on the surface of the magnesium aluminium alloy on a laser processor, carrying out omnibearing radiation by laser beams according to trace curves set by computer programs so that a nickel base alloy layer is melted and cured on the surface of the magnesium aluminium alloy to form the alloy layer, therefore, the hardness of the surface of magnesium aluminium alloy is greatly improved by 8-10 times as high as that before processing, the wearing resistance and corrosion resistance of the surface of magnesium aluminium alloy are greatly improved respectively by 56% and 56.4%. The method has short process flow, easy realization, safety, stability and reliability and firm solid melting layer, is not easy to fall off and can enhance the surfaces of the magnesium aluminium alloys with various profiles.

Owner:TAIYUAN UNIV OF TECH

Boron-containing semi-high speed steel cold roller and manufacturing method thereof

InactiveCN101407891AReduce manufacturing costReduce the amount addedProcess efficiency improvementElectric furnaceIngotMolten steel

The invention relates to a boron-containing semi high-speed steel cold roller and a manufacturing method thereof and belongs to the field of steel rolling technology. The existing cold rollers have the problems of poor wear-resistance, high production cost and the like. The invention obtains the boron-containing semi high-speed steel cold roller by pouring the molten steel with the compositions of the following weight percentages of 0.30 to 0.45 of C, 3.8 to 4.2 of Cr, 0.2 to 0.6 of Si, 0.2 to 0.6 of Mn, 0.5 to 0.8 of Mo, 0.2 to 0.4 of Ni, 0.3 to 0.6 of Cu, 0.6 to 1.0 of B, 0.3 to 0.7 of V, 0.6 to 0.8 of Ti, 0.1 to 0.3 of Nb, 0.03 to 0.10 of N, 0.25 to 0.45 of Al, less than 0.03 of S, less than 0.04 of P and the residual quantity of Fe into an outer layer of the cold roller and adopting ductile cast iron as a core part or directly pouring the molten steel into ingots. The roller has the advantages of high hardness and intensity, good toughness and wear-resistance, simple production process, low cost, etc.

Owner:BEIJING UNIV OF TECH

Antistatic teflon film and preparation thereof

InactiveCN101481483ADoes not affect electrical insulationImprove mechanical propertiesOther chemical processesTetrafluoroethyleneAntistatic agent

Owner:广州市东泓氟塑料股份有限公司

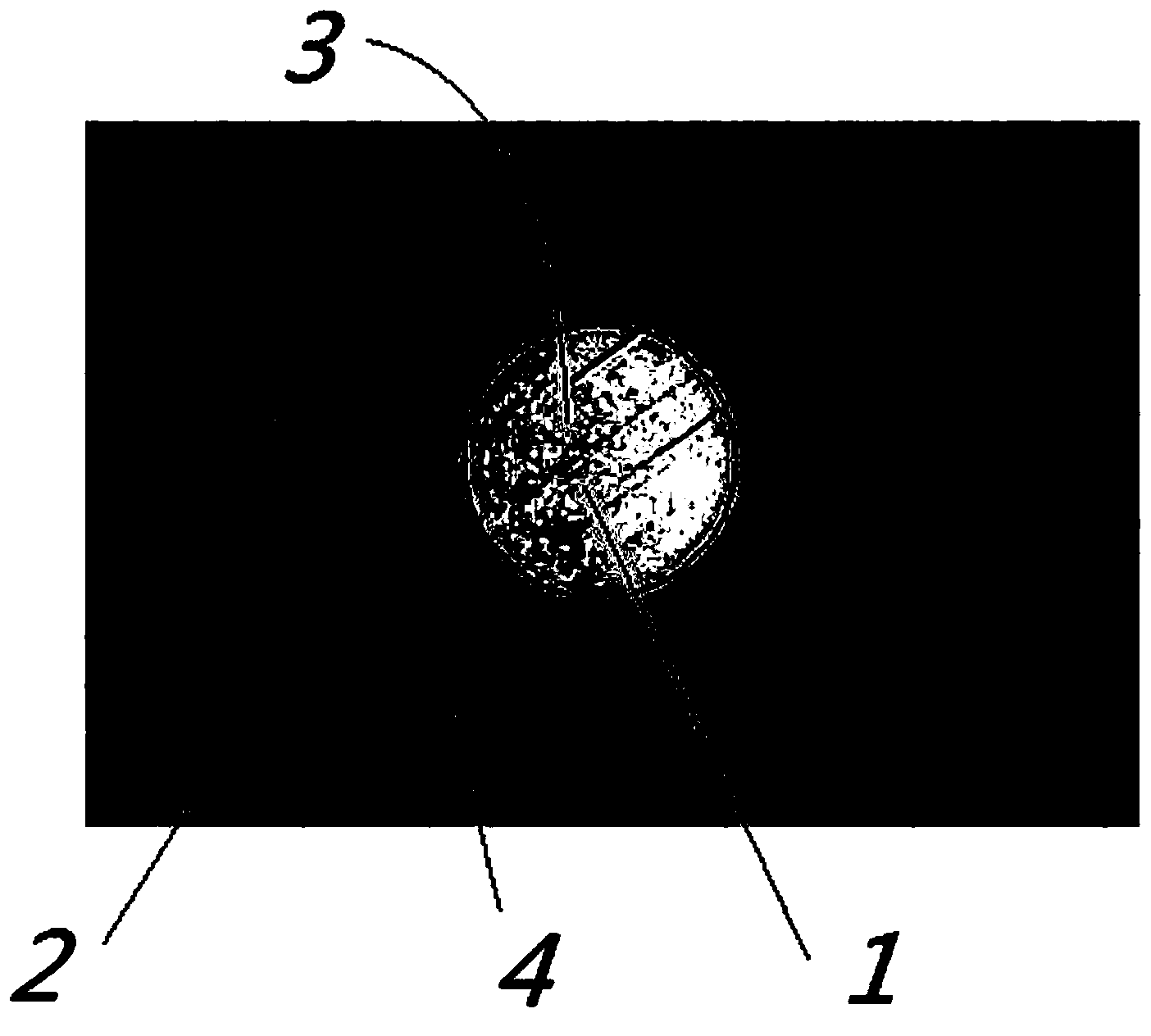

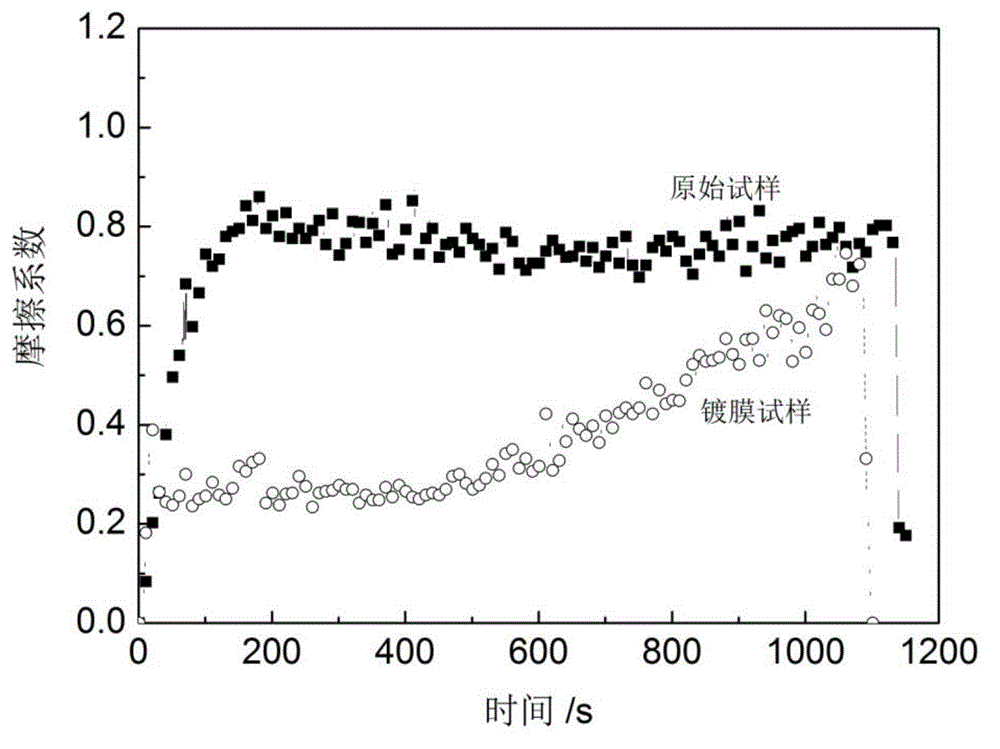

Method for preparing diamond-like composite coating on surface of piston ring

InactiveCN101665940AImprove wear resistanceImprove the lubrication effectVacuum evaporation coatingSputtering coatingLow temperature plasmaMagnetic filtration

The invention relates to a method for preparing a diamond-like composite coating with high hardness and good abrasion proof and self lubricating properties on the surface of a piston ring. In the method, a nitriding layer with high bonding strength, high hardness and good abrasion resistance is formed on the surface of the piston ring by the low-temperature plasma nitriding treatment, a non-hydrogen diamond-like surface layer with solid lubricating property is deposited by the combination of magnetic filtration cathode arc and magnetic control sputtering, and finally the nitriding / diamond-likecomposite coating, which is dense and smooth and possesses excellent abrasion proof and self-lubricating properties, is obtained on the surface of the piston ring. Compared with the durionising piston ring or CrN plating piston ring, the coating of the piston ring of the invention has higher comprehensive performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Transparent thermal insulation coating material system for glass substrate

InactiveCN102942841AInstant cureReduce energy consumptionPolyurea/polyurethane coatingsEpoxy resin coatingsThermal insulationUltraviolet lights

The present invention discloses a transparent thermal insulation coating material system for a glass substrate. The coating material system is a double layer coating material system formed by a separately-prepared primary coating and a separately-prepared surface coating, wherein the surface coating is coated on the primary coating, the primary coating comprises the following components, by mass, 0.05-3 parts of a silicane coupling agent or a titanate coupling agent, 0.2-5 parts of a hydrolysis catalyst, and 95-99 parts of a solvent, and the surface coating comprises the following components, by mass, 50-80 parts of a light curable resin, 5-35 parts of an active diluent, 1-8 parts of a photoinitiator, 5-35 parts of an antimony tin oxide nanometer thermal insulation powder slurry or an indium tin oxide nanometer thermal insulation powder slurry, 100-140 parts of an inert diluent, and 0.01-0.15 part of a leveling agent. With the coating material system, a film can be formed through a conventional film forming method, and the film layer can be cured within a few seconds after ultraviolet light irradiation. In addition, the coating material system has characteristics of high hardness, excellent adhesion and excellent water resistance.

Owner:刘志钊 +1

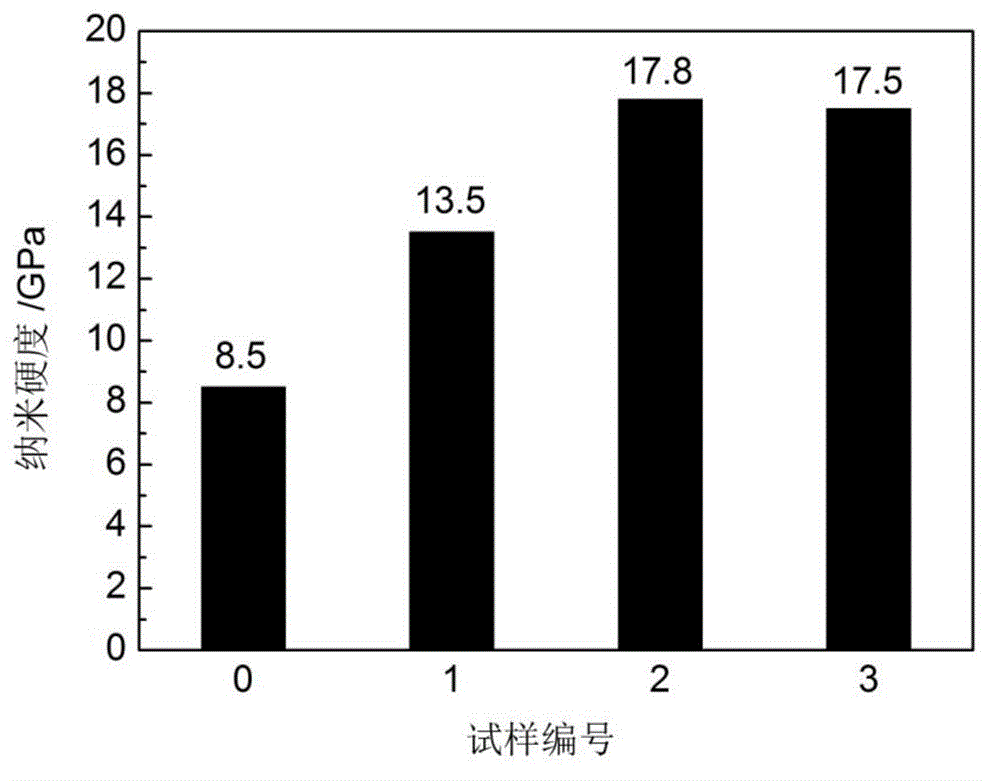

High-hardness and high-elasticity-modulus multi-component nitride coating and preparation method thereof

InactiveCN106835037AIngredient ControlHigh hardnessVacuum evaporation coatingSputtering coatingSputteringAlcohol

The present invention is a multi-component nitride coating with high hardness and high elastic modulus. Its chemical formula is AlCrTiZrNbN, and the atomic ratios of Al, Cr, Ti, Zr, Nb and N are respectively 8-12%: 8-12 %: 8~12%: 8~12%: 8~12%: 48~52%, the thickness of the coating is 2~5μm. The present invention also provides a method for preparing the above-mentioned nitride coating. Firstly, the surface of the substrate is subjected to mirror polishing, then ultrasonically cleaned with acetone and alcohol, and after vacuum ion cleaning, the AlCrTiZrNbN layer is deposited by radio frequency reactive sputtering, wherein AlCrTiZrNbN is mostly The component nitride coating is composed of AlCrTiZrNb alloy target with equiatomic molar ratio in (Ar+N 2 ) atmosphere prepared. The coating of the invention has high hardness and high modulus of elasticity, and can be used as a novel protective coating for various service occasions such as cutting tools and molds.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

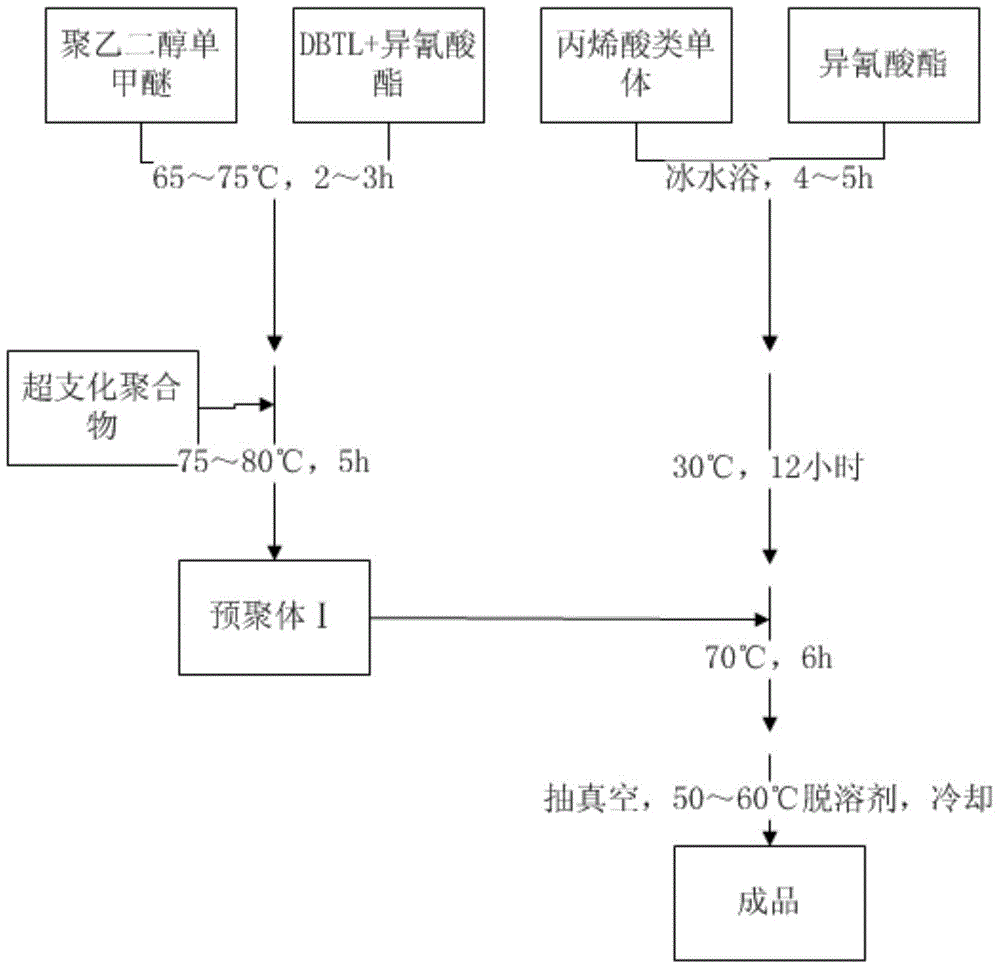

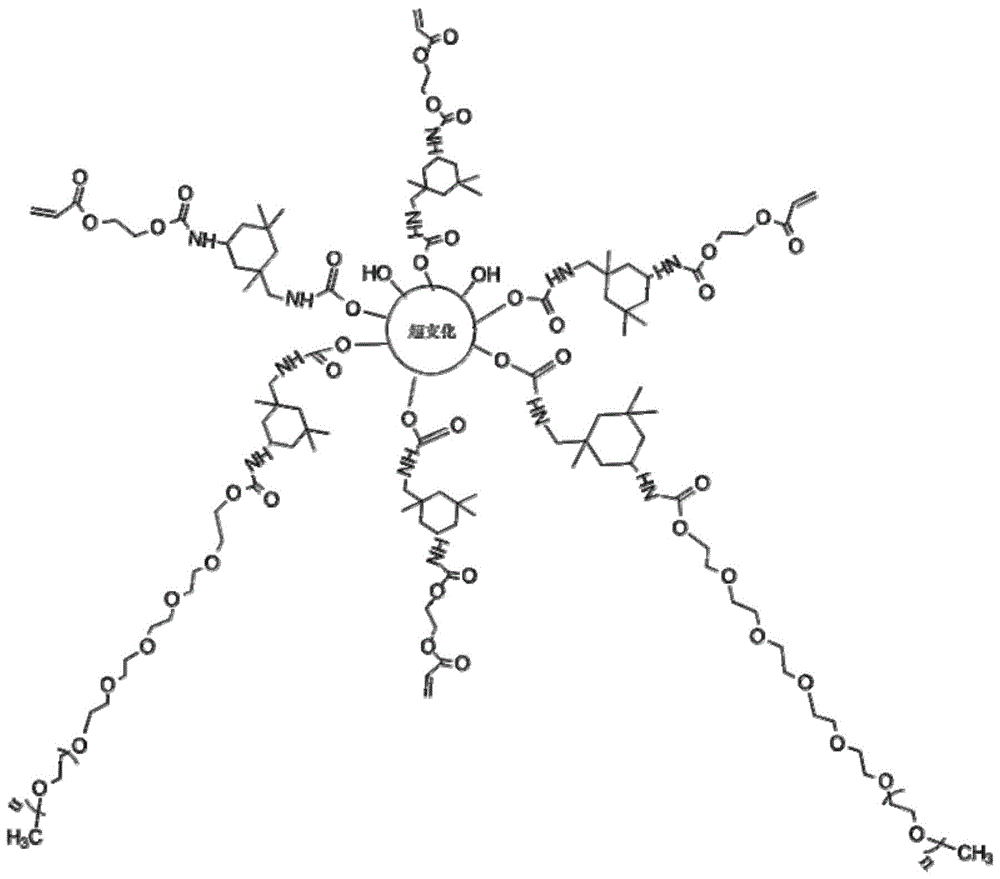

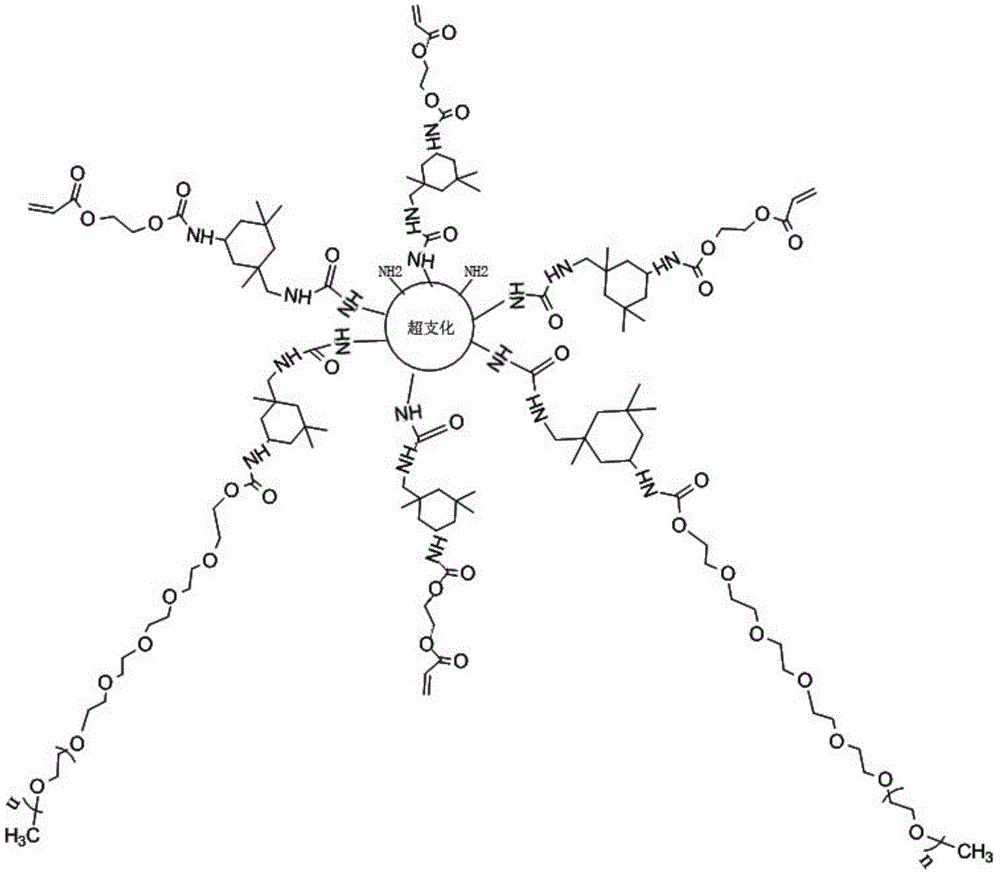

Hydrophilic UV (Ultraviolet) coating hardness assistant and preparation method thereof

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

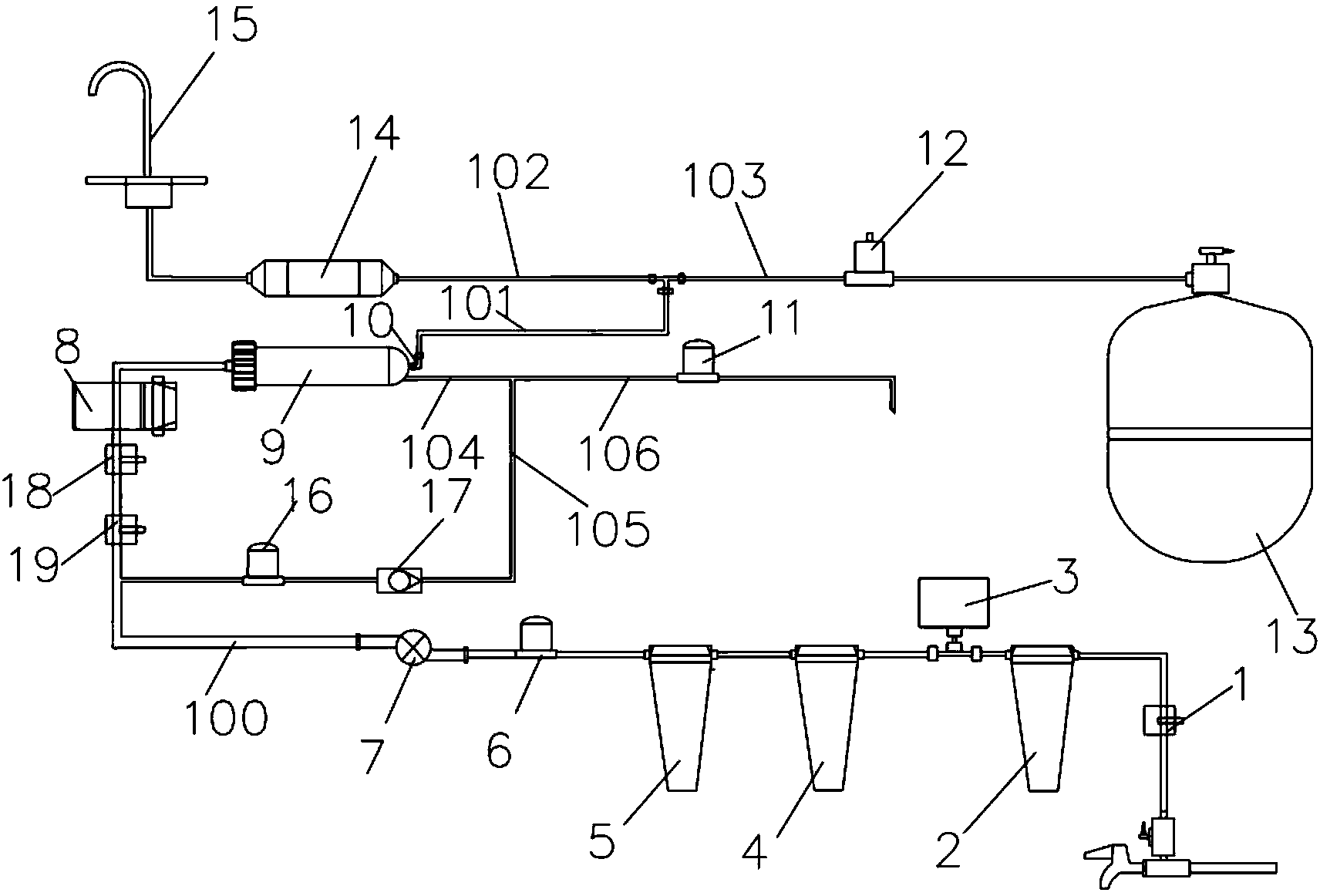

Reverse osmosis water purification system, reverse osmosis water purifier and control method

Owner:LEAYUN TECH CO LTD OF ZHUHAI

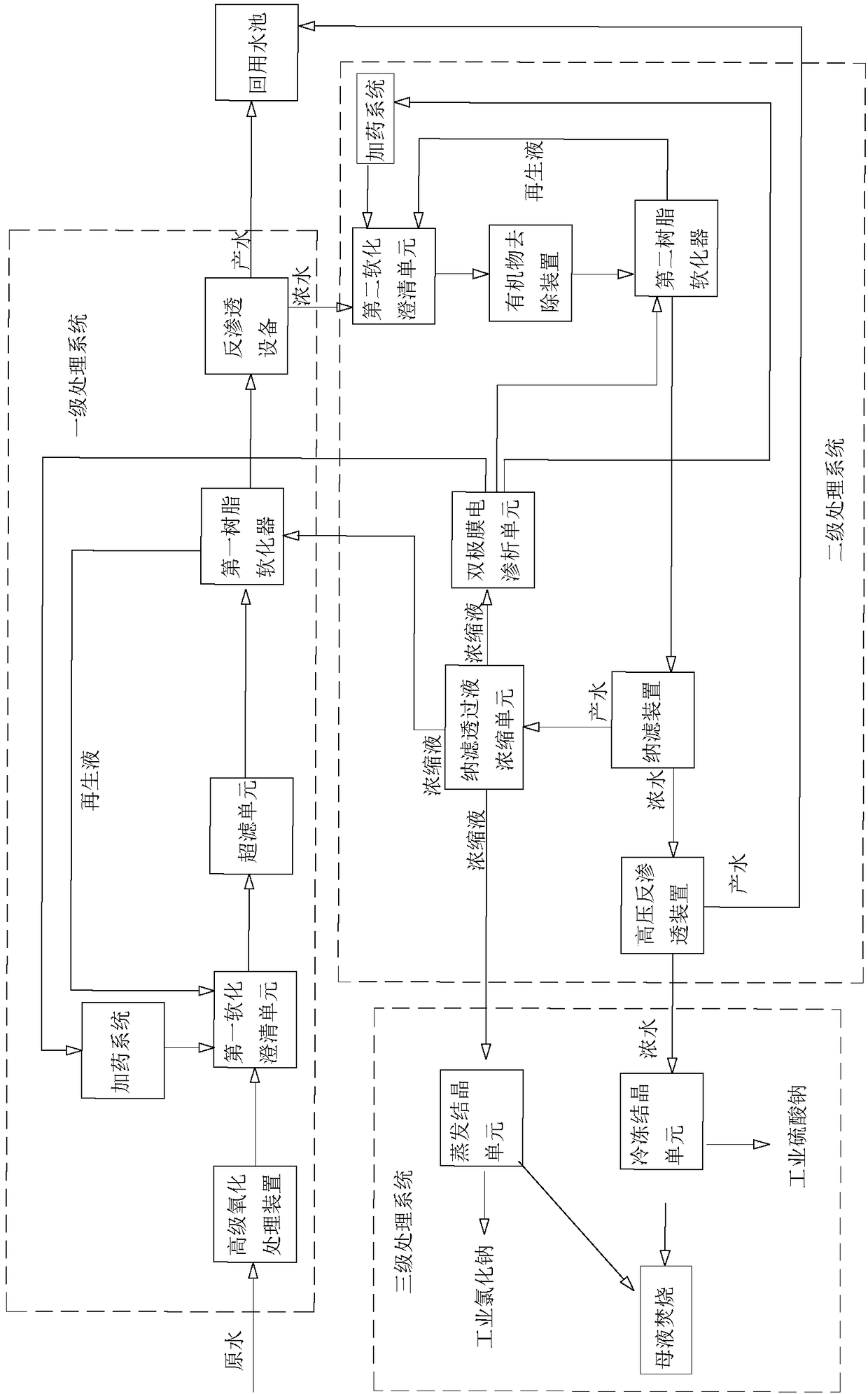

Treatment method for recycling high-hardness and high-salinity waste water

InactiveCN108275817ATake advantage ofRealize internal consumptionWater/sewage treatment by irradiationGeneral water supply conservationChemical treatmentTreatment effect

Owner:ZHEJIANG CREATION ENVIRONMENT TECH

Fluorine-containing aqueous coating composition

InactiveCN1738878AGood chemical resistanceImprove water resistancePolyurea/polyurethane coatingsWater dispersibleSolvent

A fluorine-containing aqueous coating composition composed of (A) an aqueous emulsion of a functional group-containing fluororesin obtained by dispersing, in water, a fluoroolefin copolymer having a functional group that is obtained through solution polymerization and (B) a water-dispersible unblocked isocyanate compound is disclosed. The fluororesin aqueous coating composition can be cured at ordinary temperature, and a coating formed therefrom is excellent in chemical resistance, water resistance, solvent resistance, contamination resistance, hardness, weathering resistance and durability.

Owner:DAIKIN IND LTD

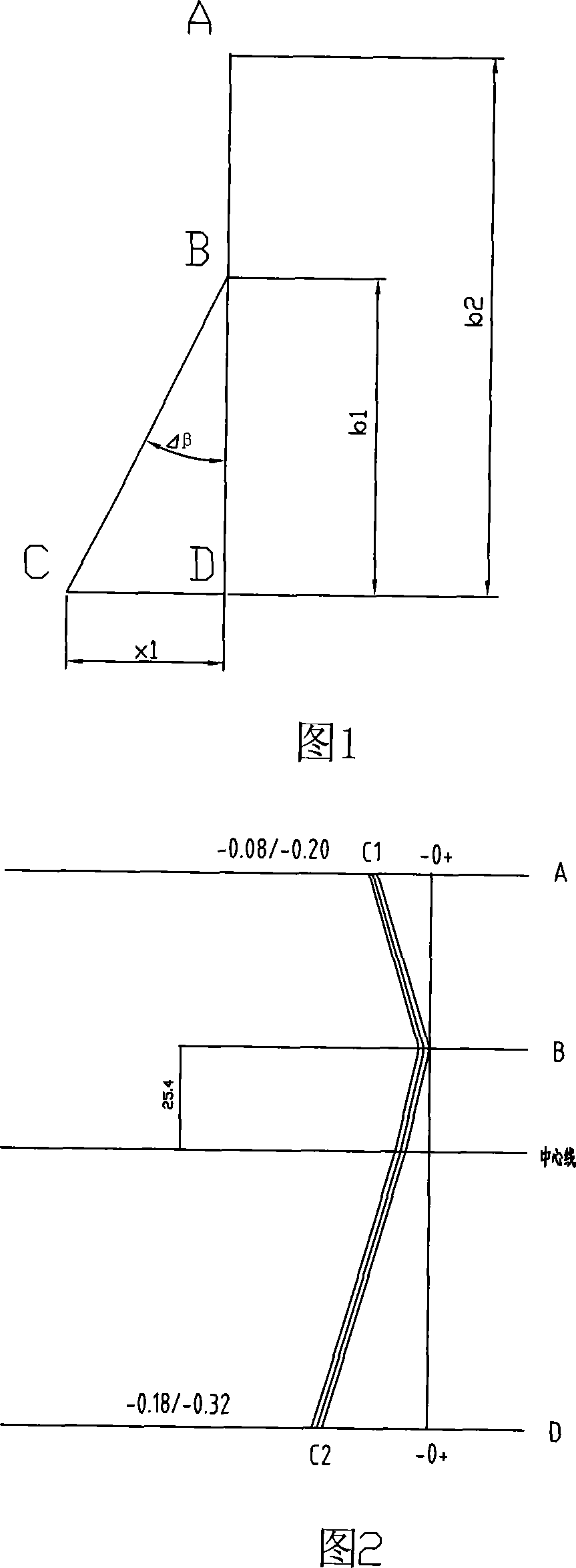

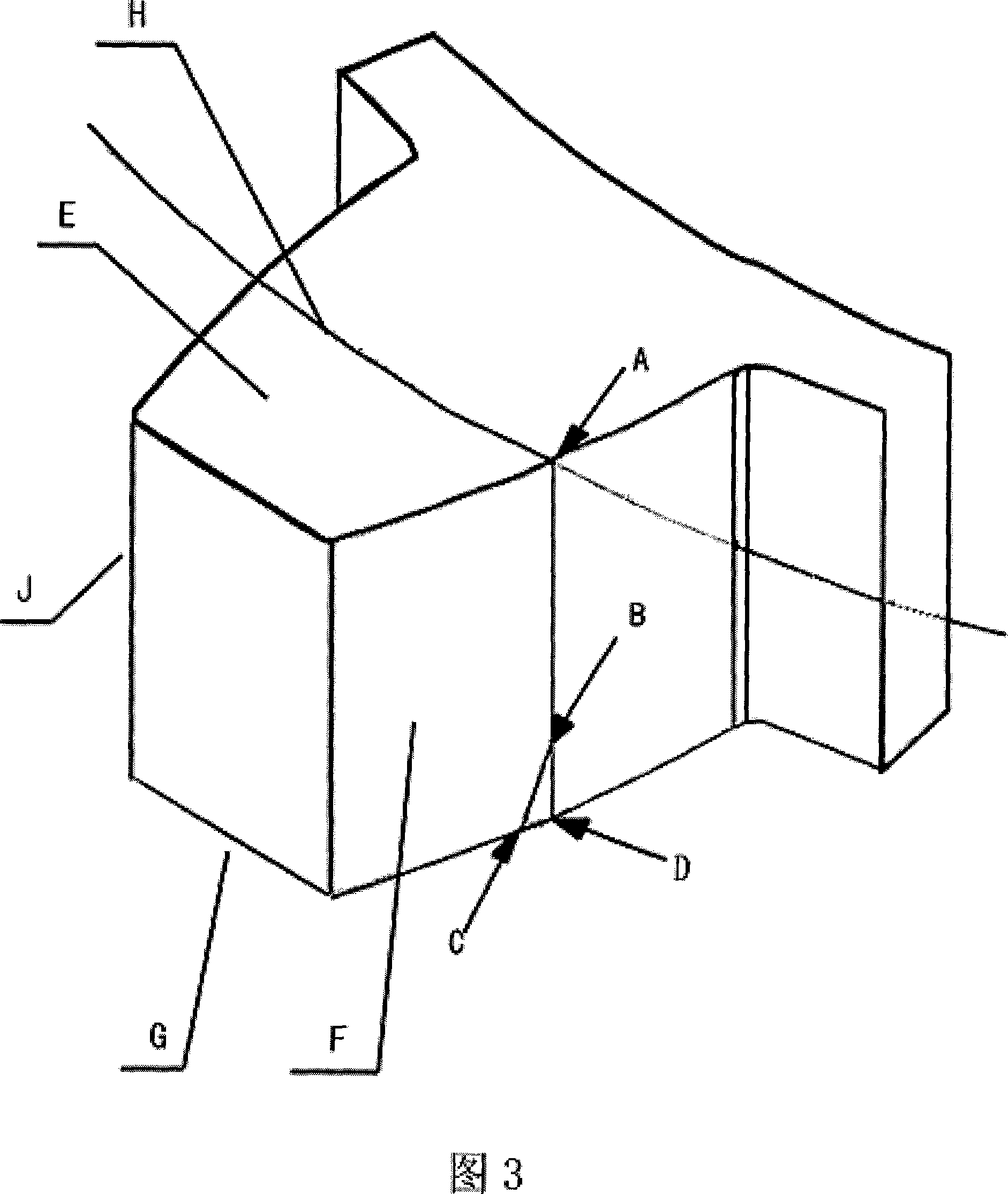

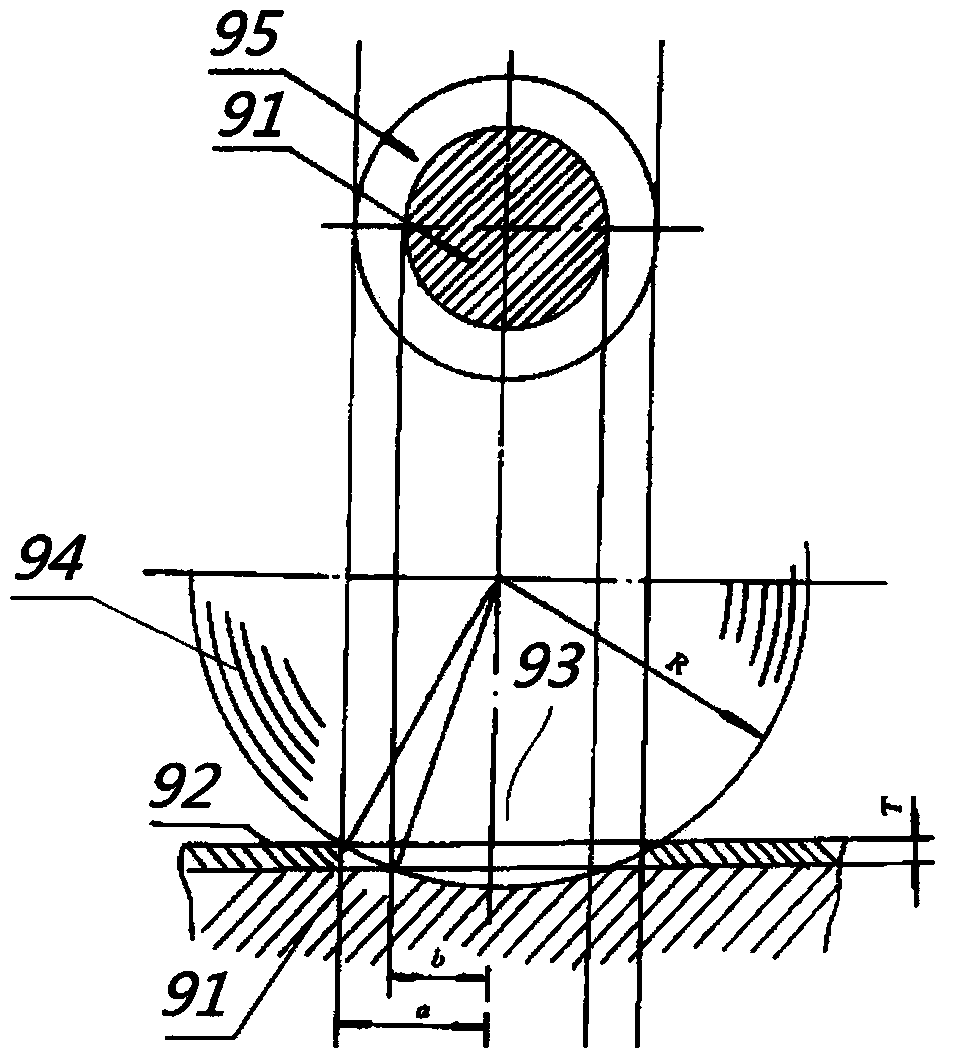

Tooth direction shaping gear hobbing processing technique

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Working roll for rolling medium-thickness plate with high grade and high strength and manufacture method thereof

ActiveCN101954378AImprove wear resistanceImproved roll shape retentionRollsMetal rolling arrangementsChemical compositionWork roll

The invention discloses a working roll for rolling a medium-thickness plate with high grade and high strength and a manufacture method thereof. The working roll is applied to a medium-thickness plate rolling mill of a rolling steel industry. A working layer comprises the following alloy components in percentage by weight: 3.00-3.50 percent of C, 0.40-1.20 percent of Si, 0.50-1.20 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 1.30-2.50 percent of Cr, 3.20-4.50 percent of Ni, 0.20-1.00 percent of Mo, 0.20-2.00 percent of W and 1.00-1.50 percent of V. A roll core comprises the following chemical components in percentage by weight: 2.80-3.50 percent of C, 2.00-2.50 percent of Si, 0.50-1.00 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 0.20-0.50 percent of Cr, 0.20-0.60 percent of Ni, not more than 0.20 percent of Mo and not more than 0.30 percent of Re. The working roll manufactured by adopting a centrifugal composite casting process and two-section tempering production at 400-550 DEG C for 25-30 hours is the working roll for rolling the medium-thickness plate with high grade and high strength, which has the advantages of high abrasion resistance and less hardness reduction.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Weather-resistant type coating material of acrylic acid-polyester powder modified by inorganic nano composite material, and its prepn. method

InactiveCN1462784AImprove anti-aging propertiesIncreased weather resistance indexPowdery paintsPolyester coatingsAcrylic resinAdhesive

Owner:SICHUAN UNIV +1

Composite shaping technique method of iron pattern coated sand and iron type core assembly

InactiveCN102921902AClotting rate inhibition and slowing downUniform hardnessMoulding machinesHardnessSpare part

Owner:LIUZHOU QINYOU TRADE

Spherical Composite particles and cosmetics with the particles blended therein

Owner:CATALYSTS & CHEM

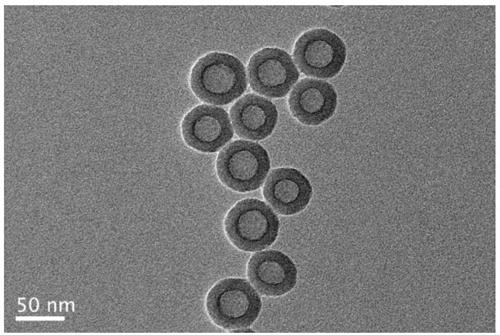

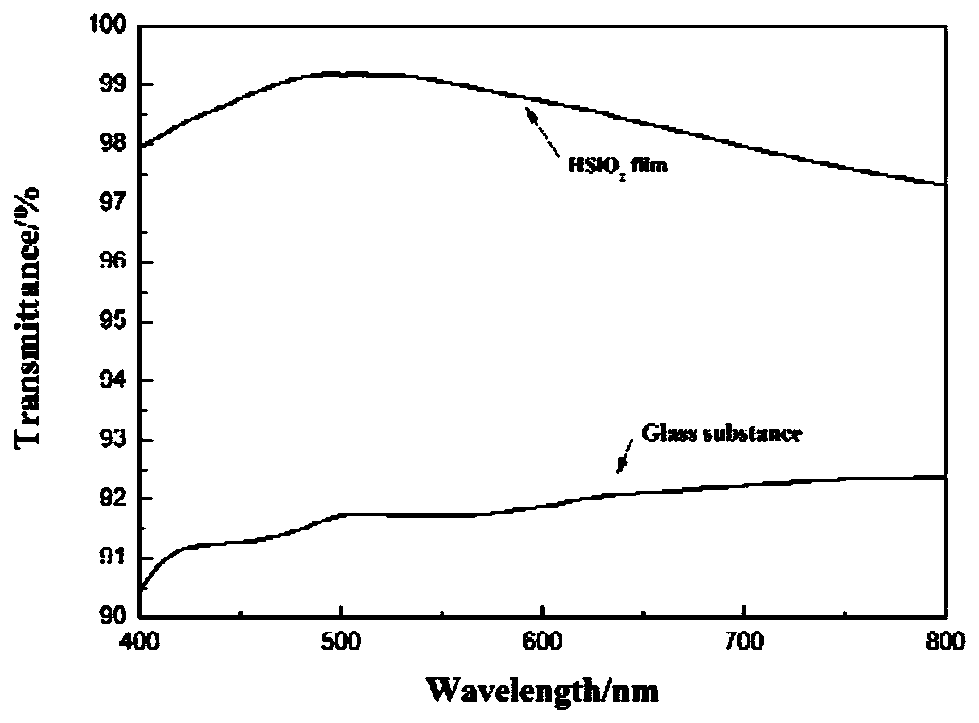

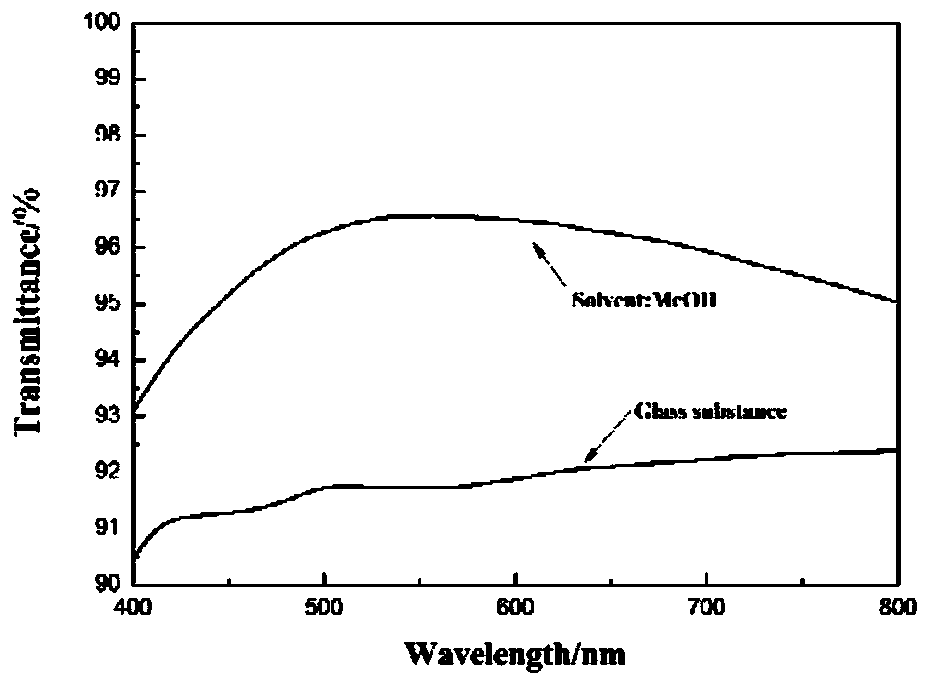

Method for preparing high-hardness antireflection film on basis of hollow silicon dioxide

ActiveCN109502987AUniform sizeHigh light transmittanceCoatingsSilicon compoundsOptical thin filmSolvent

Owner:CHANGZHOU UNIV

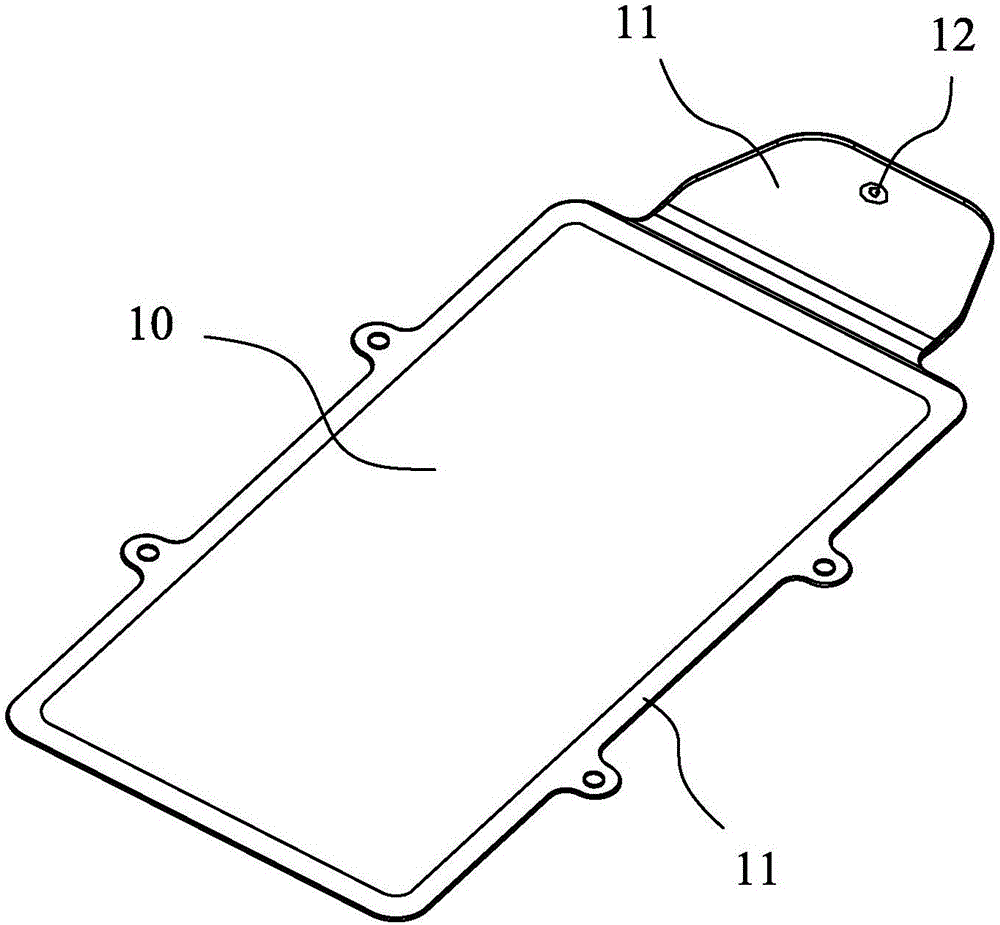

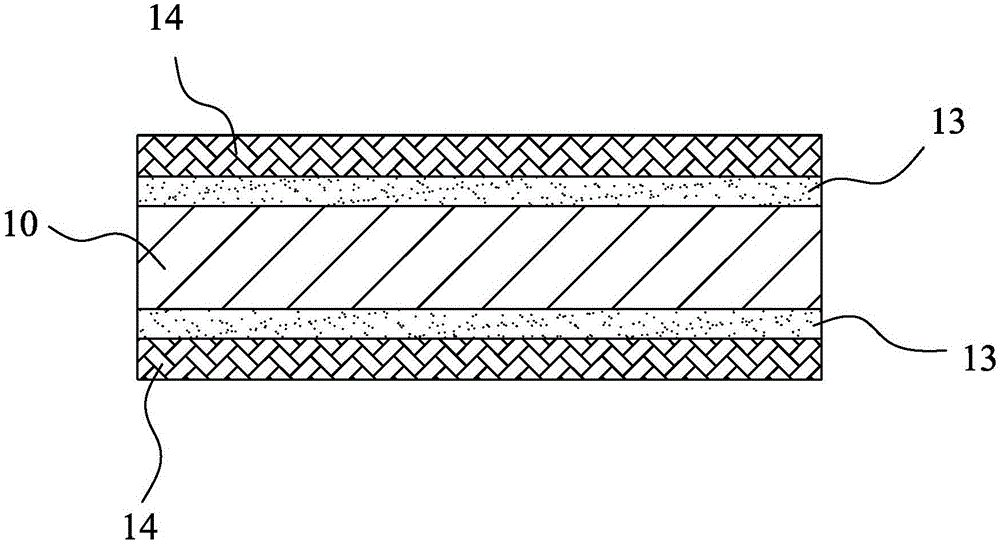

Combined fatigue resistant pad and manufacturing method thereof

InactiveCN101292833AReduce manufacturing costEffective protectionLayered productsDomestic articlesFoaming agentPolyvinyl chloride

Owner:TAICANG ALL MATS PLASTIC IND

Superhard non-stick silicon cooker coating prepared by sol-gel hybridization technique

InactiveCN102002268ALower sintering temperatureIncreased durabilityCoatingsSilicic acidCeramic coating

The invention discloses a superhard non-stick silicon cooker coating prepared by a sol-gel hybridization technique. The coating comprises the following components: 30-50% of nanometer silica, 20-40% of silicic acid compound, 5-10% of magnesium-calcium compound, 3-5% of ammonium chloride, 0.5-2.0% of catalyst, 1-4% of accessory ingredient, 0.5-2.0% of silane coupling agent, 15-25% of multielement organosilicon material, 5-10% of absolute ethyl alcohol and 10-20% of distilled water. The preparation method of the coating comprises the following steps: using a sol-gel method to synthesize nano CaO-SiO2 power; replacing Ca by Mg to develop a (Ca, Mg)SiO3 nano power material; introducing low-temperature sintered assistant precursors into sol to reduce the sintering temperature of ceramics; and adding a defined amount of organosilicon material to adjust the hardening temperature of the ceramics to obtain the low-temperature sintering nano ceramic coating at the temperature below 250 DEG C. The superhard non-stick silicon cooker coating has strong adhesive force, high hardness, small possibility of scratch, and impact resistance, is non-toxic and environment-friendly, and can completely replace Teflon non-stick coatings.

Owner:DONGGUAN EONTEC CO LTD

Photo-cured acrylate-layered double hydroxide nano composite material and preparation method thereof

InactiveCN101555304AImprove efficiencyFast curingPigment treatment with non-polymer organic compoundsIon exchangeUltraviolet lights

Owner:广州市番禺广信丝印材料有限公司 +1

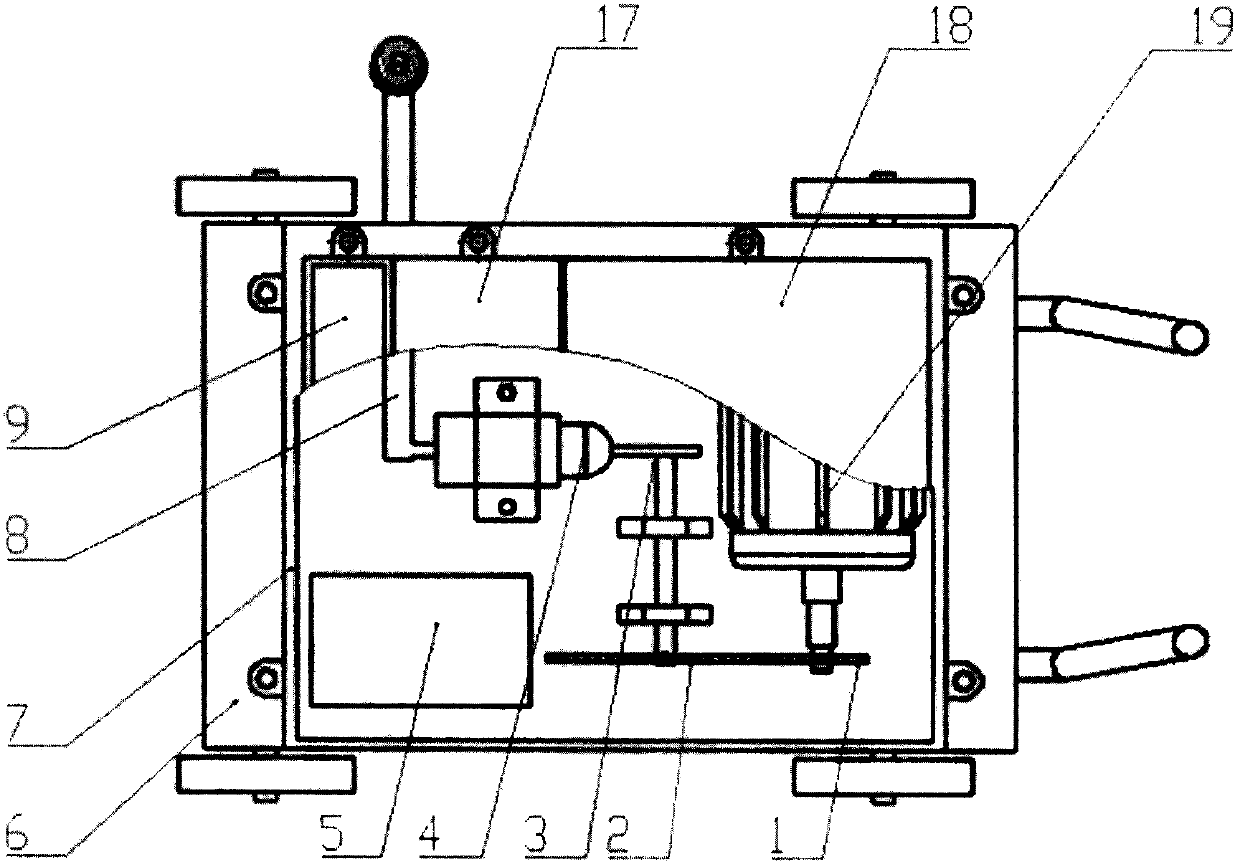

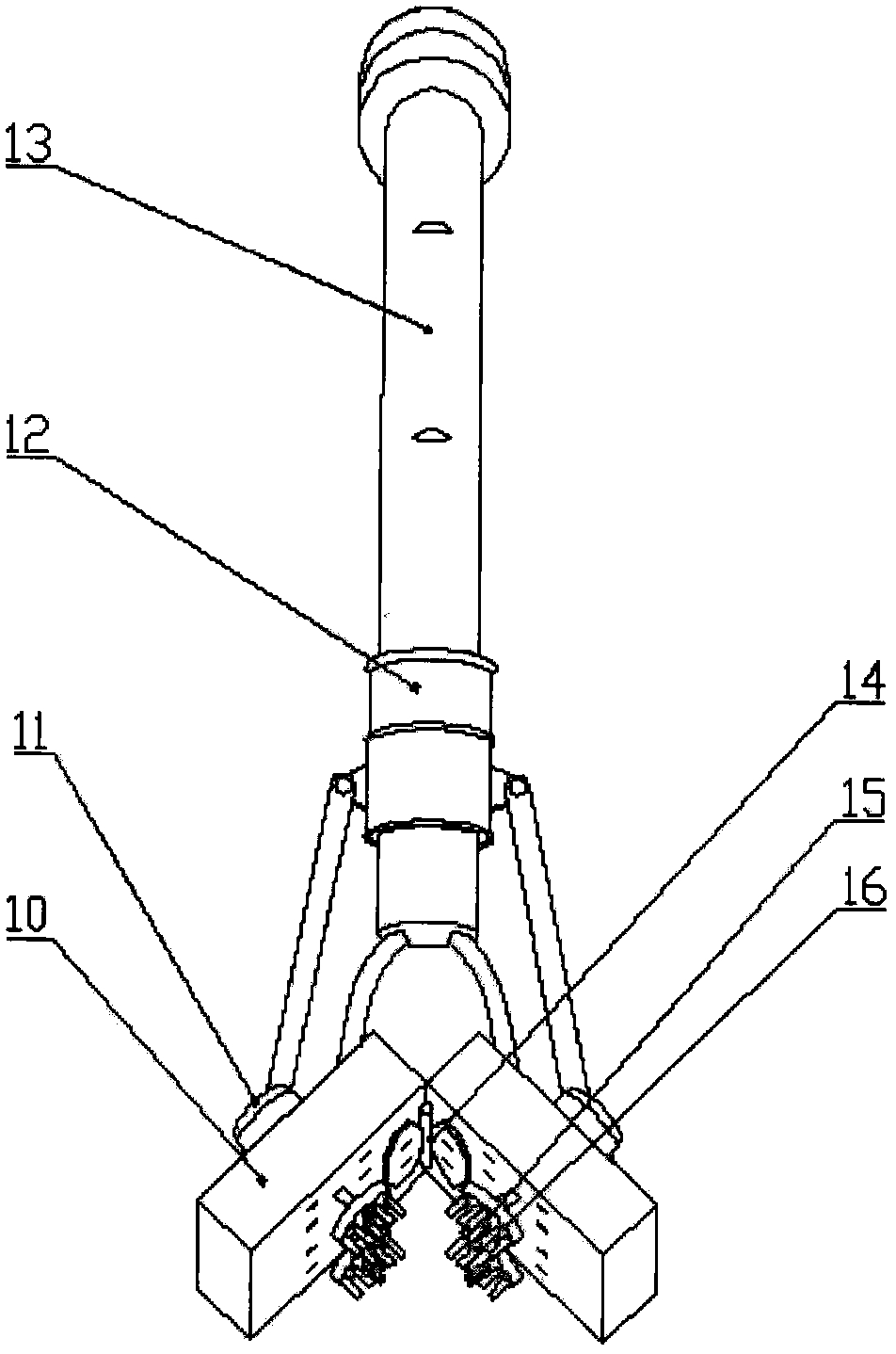

Portable rubbish advertisement cleaning machine

InactiveCN103990626AChange cleanup rangeCleaning using toolsCleaning using liquidsMotor driveHardness

Owner:NANJING AGRICULTURAL UNIVERSITY

Additive and method for producing 6 micron high-hardness electrolytic copper foil by using additive

The invention relates to an additive. The additive comprises a hardness agent and a brightening agent; the hardness agent is an aqueous solution A containing 1,3-thiazolidin-2-one, DPS and MESS, wherein in the aqueous solution A, the concentration of 1,3-thiazolidin-2-one is 0.5-10 ppm, the concentration of DPS is 10-50 ppm, and the concentration of MESS is 1-20 ppm; and the brightening agent is an aqueous solution B containing SPS and Cl-, wherein in the aqueous solution B, the concentration of SPS is 10-50 ppm, and the concentration of Cl- is 10-30 ppm. According to 6 micron electrolytic copper foil made through the method, a HVS-1000 desktop hardness meter is adopted for detecting a hardness value, hardness is remarkably improved (can reach 120-150 HV), water ripples are greatly relieved, and the added technical value is remarkably improved.

Owner:LINGBAO WASON COPPER FOIL

Ionic nitriding heat treatment technique of 35CrMoV toothed sleeve or toothed ring for centrifugal compressor

ActiveCN106893822AHigh strengthHigh hardnessFurnace typesSolid state diffusion coatingHardnessUltimate tensile strength

The invention discloses an ionic nitriding heat treatment technique of a 35CrMoV toothed sleeve or toothed ring for a centrifugal compressor and belongs to the technical field of heat treatment techniques. The ionic nitriding heat treatment technique comprises the following steps that (1) normalizing treatment is conducted, specifically, the normalizing temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then air cooling is conducted; (2) quenching treatment is conducted, specifically, the quenching temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then oil cooling is conducted; (3) tempering treatment is conducted, specifically, the tempering temperature is 600 DEG C, the heat preservation time with the unit being hour is 1.5 times the quenching heat preservation time, and then air cooling is conducted; and (4) ionic nitriding treatment is conducted, specifically, ionic nitriding is conducted at the temperature of 520 DEG C for 18.0-25.0 h, furnace cooling is conducted till the temperature is lowered to be 200 DEG C, and then a product is moved out of a furnace and subjected to air cooling. The contact-fatigue strength of a workpiece treated through ionic nitriding heat treatment can be greatly improved owing to the fact that the core strength and hardness are improved.

Owner:SHENYANG TURBO MASCH CORP

Manufacturing method of high-hardness plastic screen and housing of mobile phone and mobile phone screen and housing manufactured thereby

ActiveCN105922525AHigh hardnessReduce use costSynthetic resin layered productsTelephone set constructionsRainbowAdhesive

Owner:DONGGUAN JIAOJIN ELECTRONICS TECH CO LTD

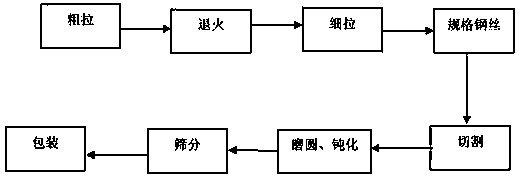

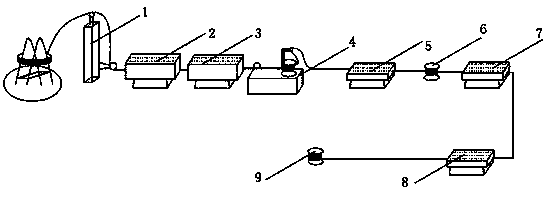

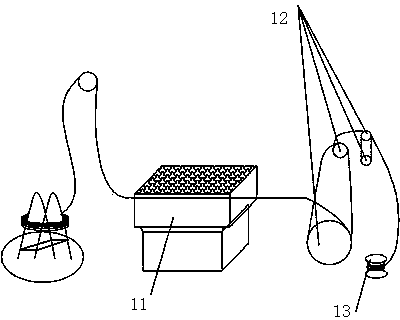

High-hardness and long-service-life steel wire cut shot producing method and production line

Owner:山东开泰工业科技有限公司

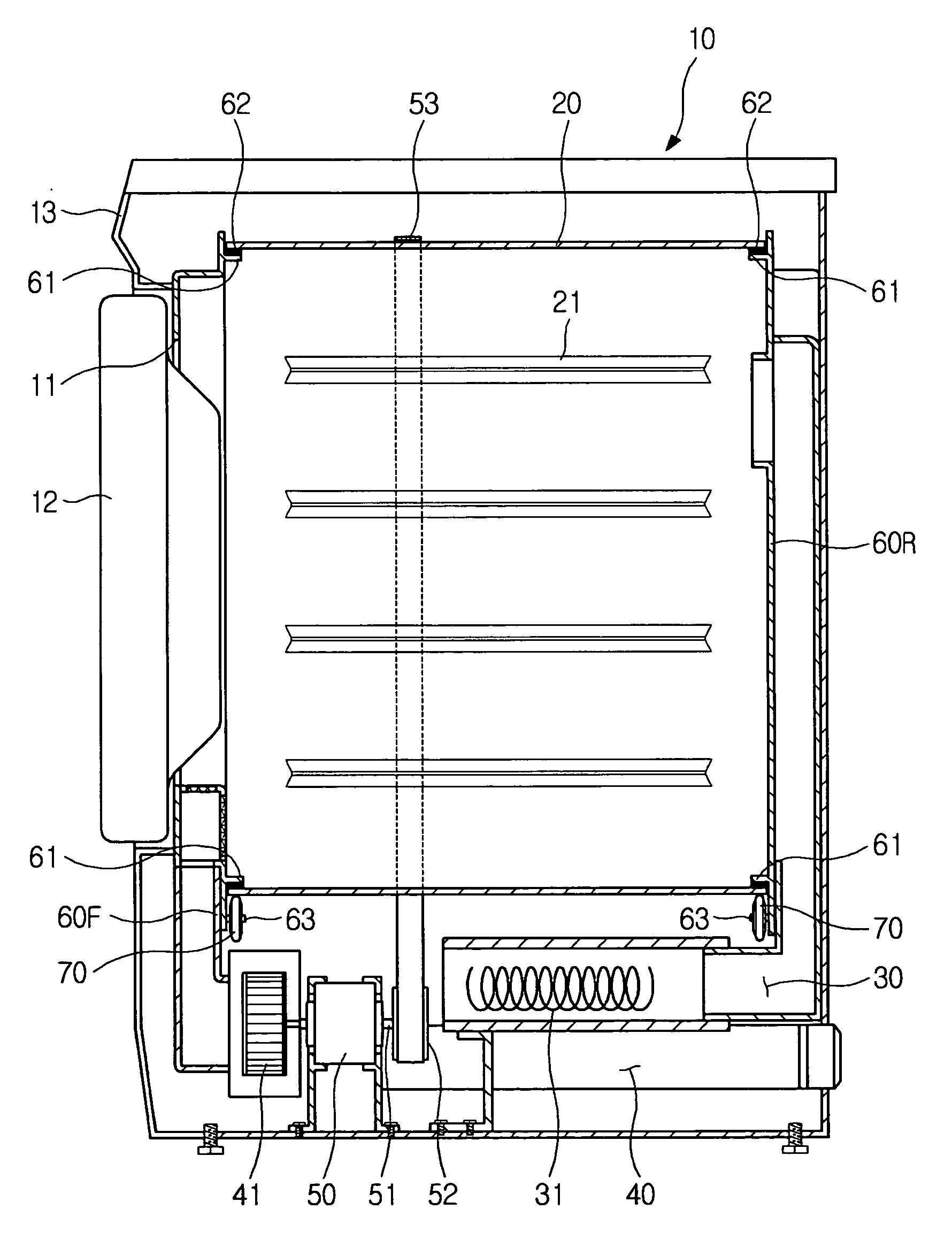

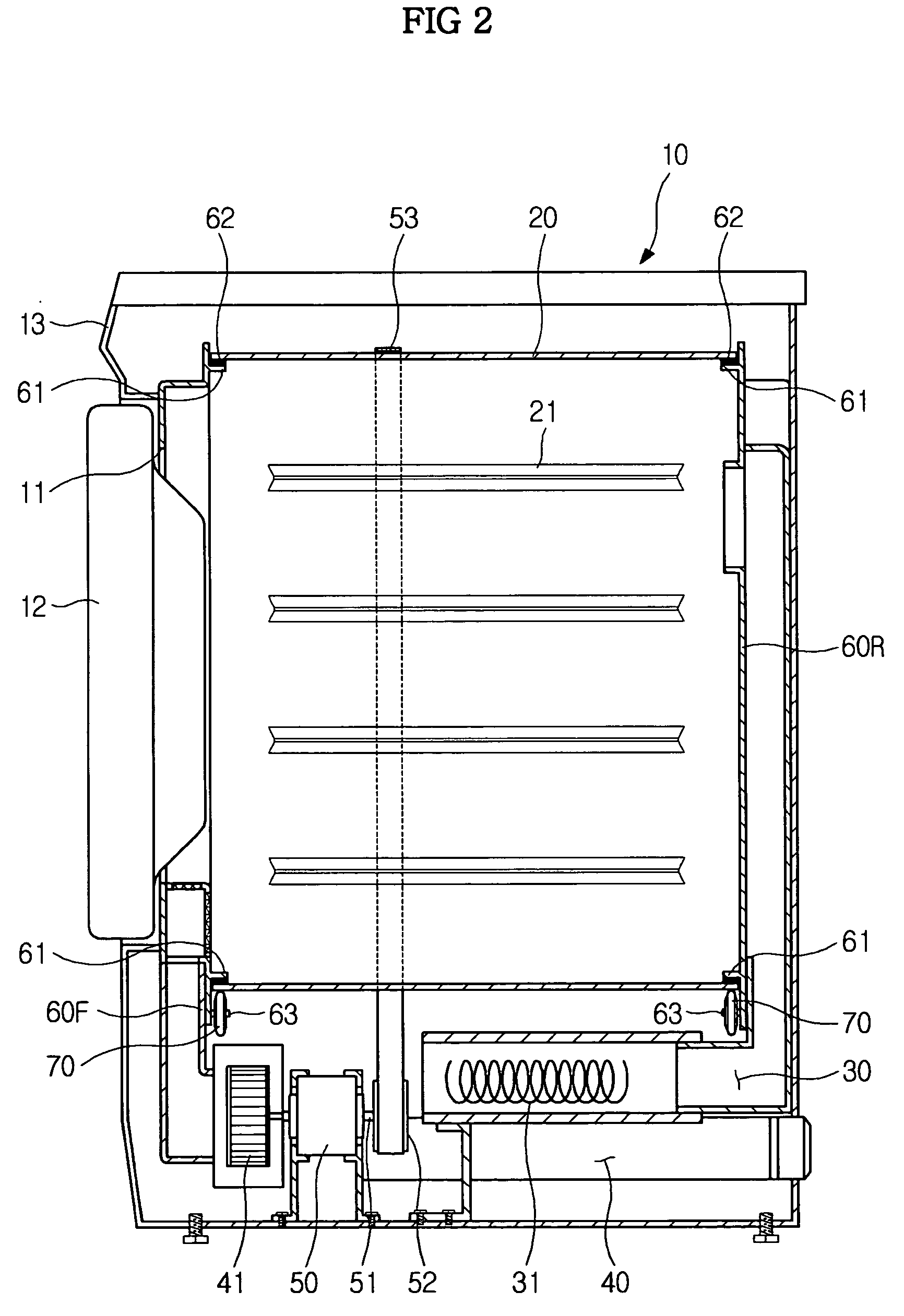

Roller and clothes drying apparatus provided with the same

InactiveUS20050097772A1Improve impact absorption performanceTextile treatmentShaftsEngineeringHardness

Owner:SAMSUNG ELECTRONICS CO LTD

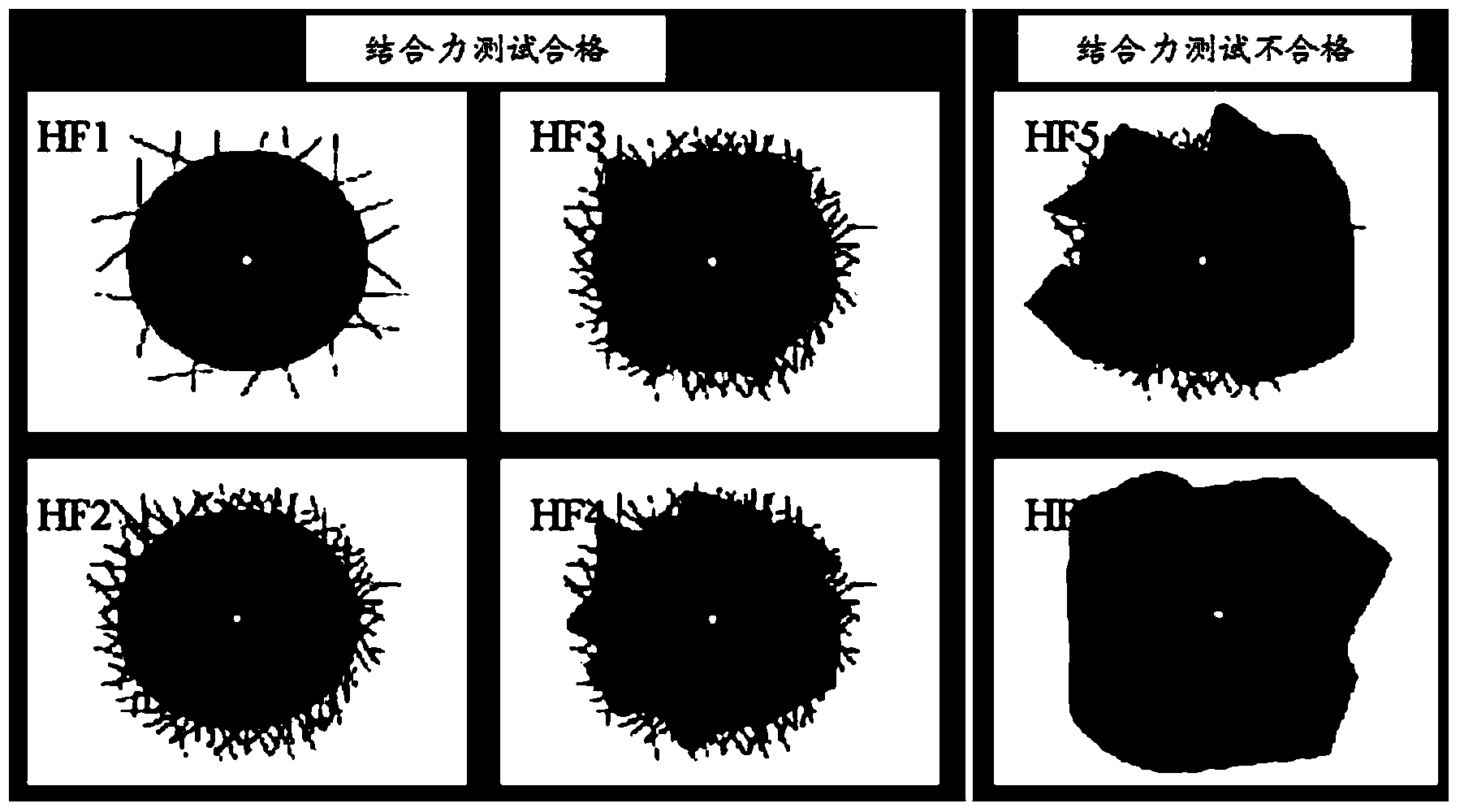

Method for detecting hard coating quality

ActiveCN104142280AAvoid damageAvoid problems with polished coated surfacesUsing optical meansInvestigating material hardnessHardnessGreat circle

Owner:FUNIK ULTRAHARD MATERIAL

Preparation method of Ta (Tantalum) film on bearing steel surface

Owner:SHANGHAI UNIV OF ENG SCI

Constant temperature curing high-bearing and anti-adhering wear resistant lubricating paint

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

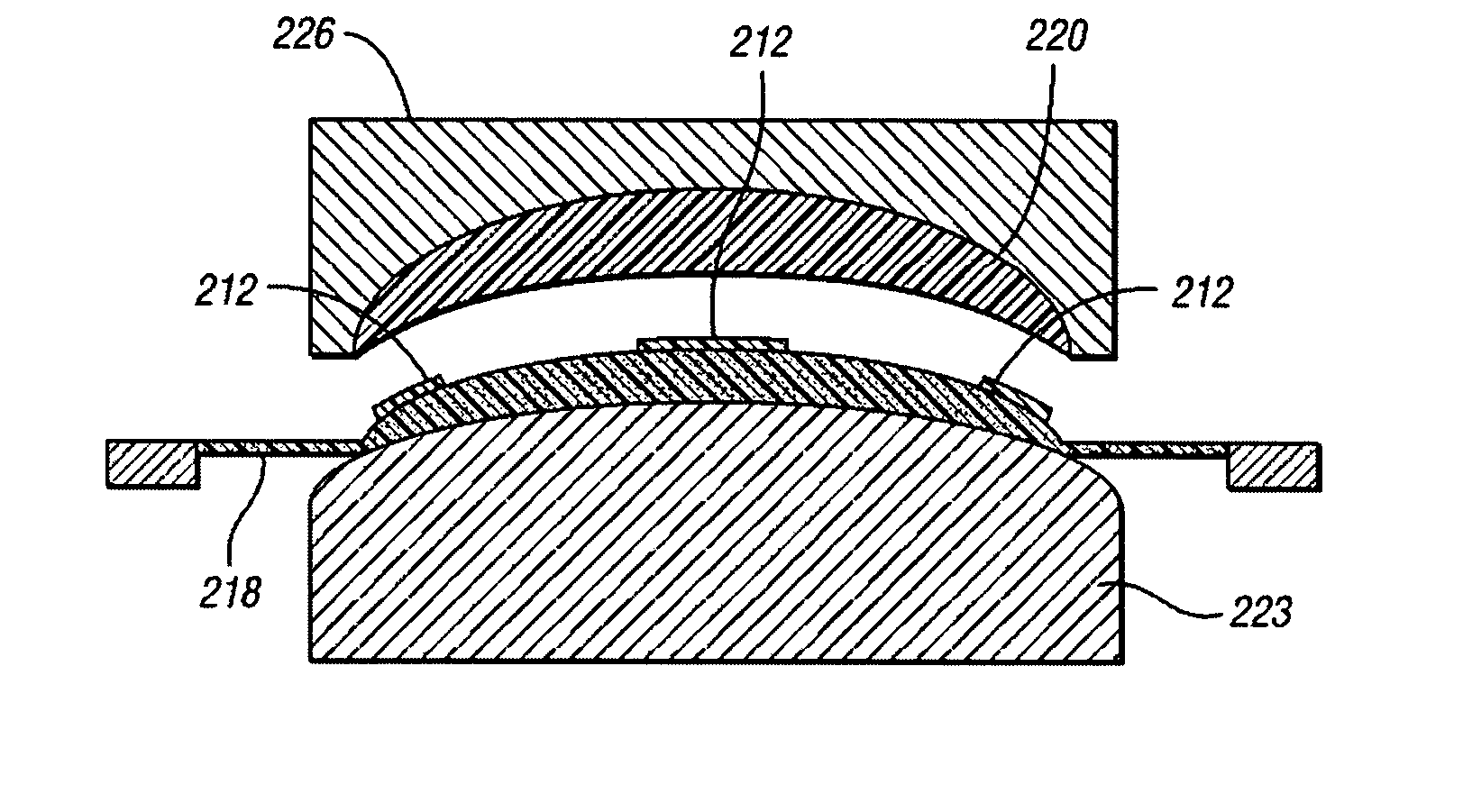

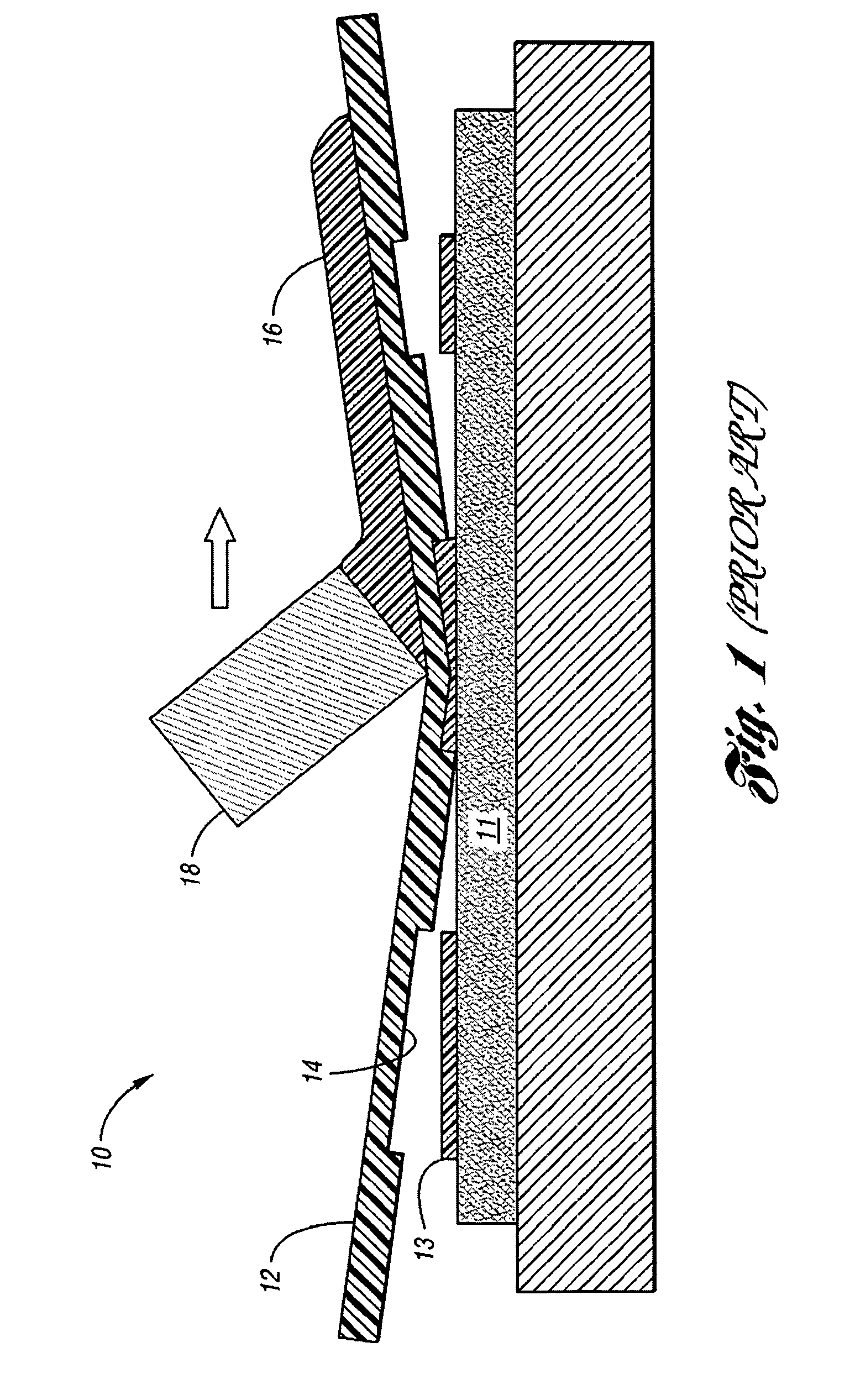

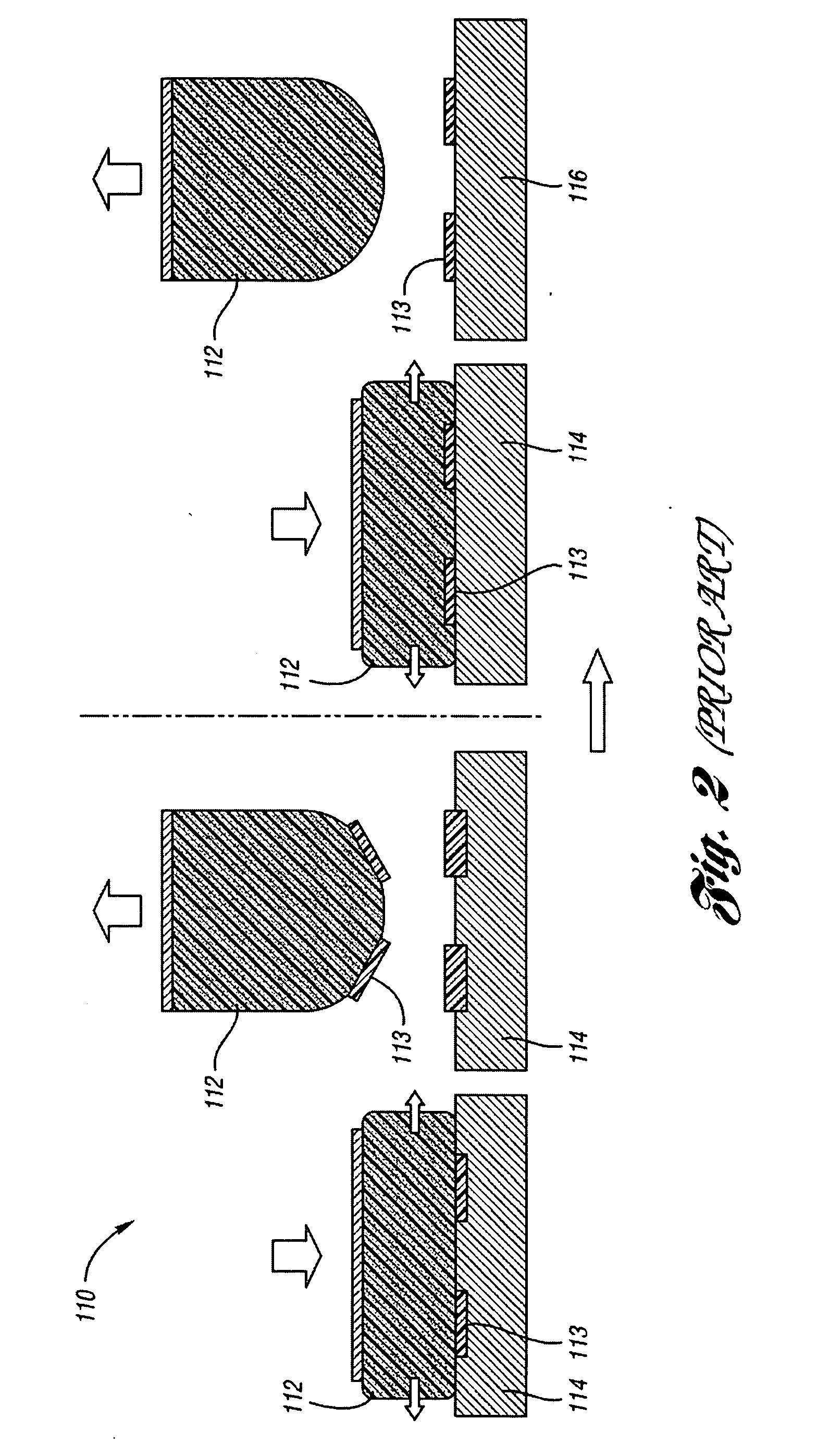

Method of transferring a membrane image to an article in a membrane image transfer printing process

ActiveUS20050193905A1Improve performanceLiquid surface applicatorsStencilling apparatusImage transferHardness

Owner:EXATEC LLC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap