Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20 results about "Surface coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface coating, any mixture of film-forming materials plus pigments, solvents, and other additives, which, when applied to a surface and cured or dried, yields a thin film that is functional and often decorative. Surface coatings include paints, drying oils and varnishes, synthetic clear coatings,...

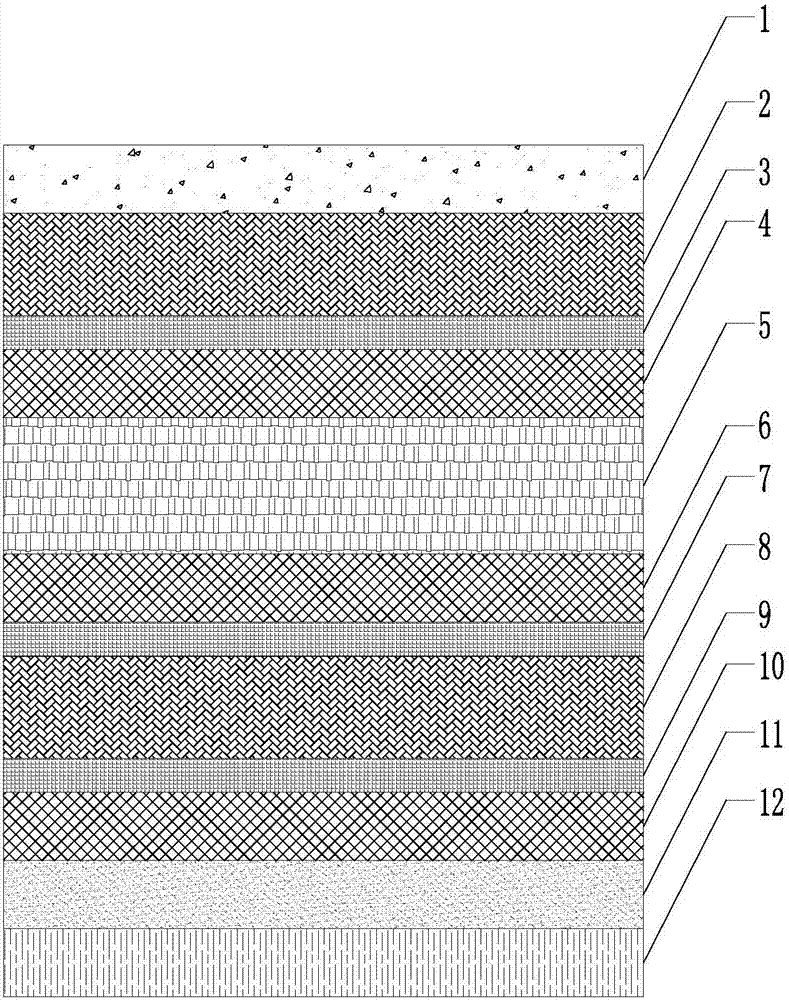

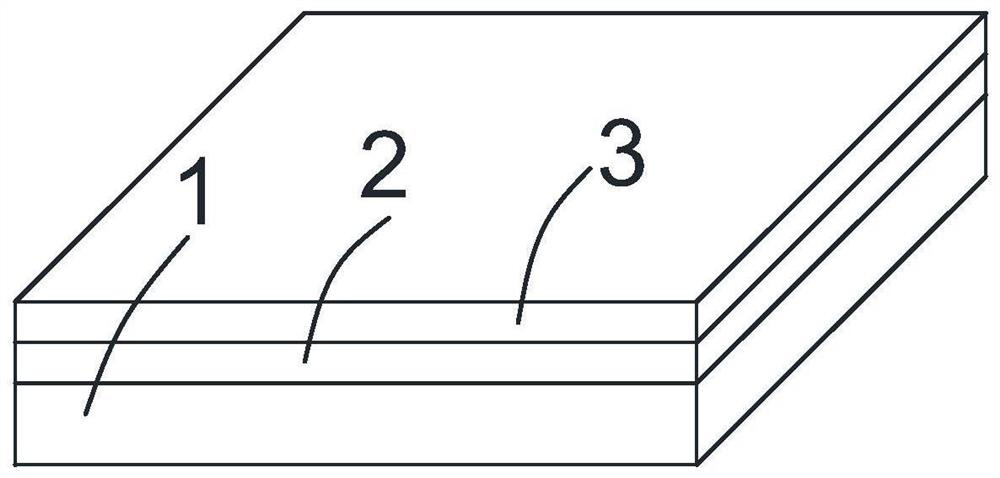

Wood flooring composed of wpl, base and soundproof layer

InactiveUS20060172118A1Improve surface strengthEnhance natural textureCovering/liningsLighting and heating apparatusWood veneerHigh density

Owner:LG CHEM LTD

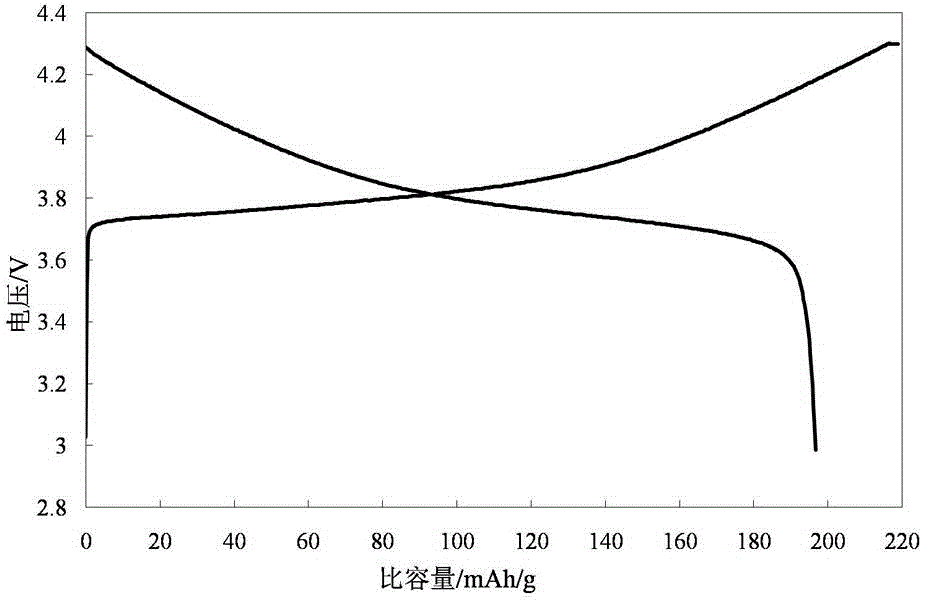

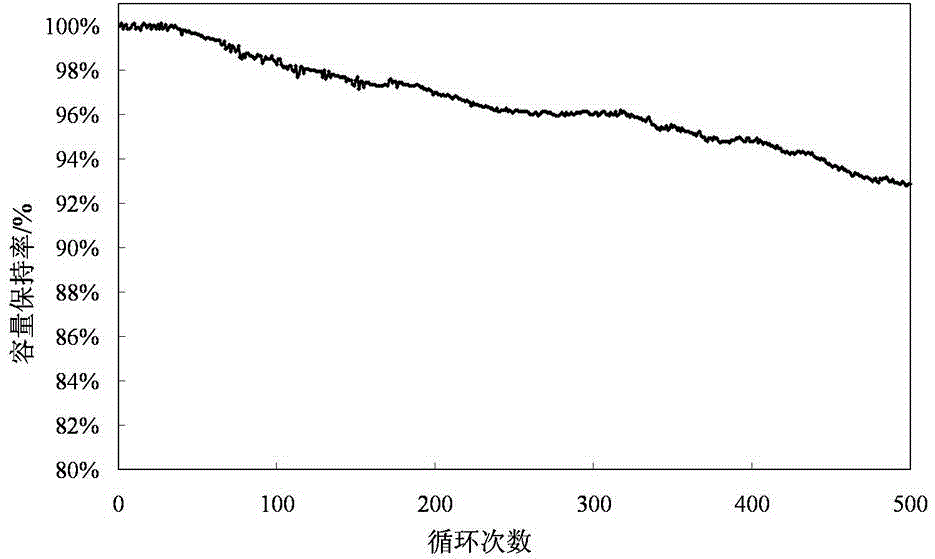

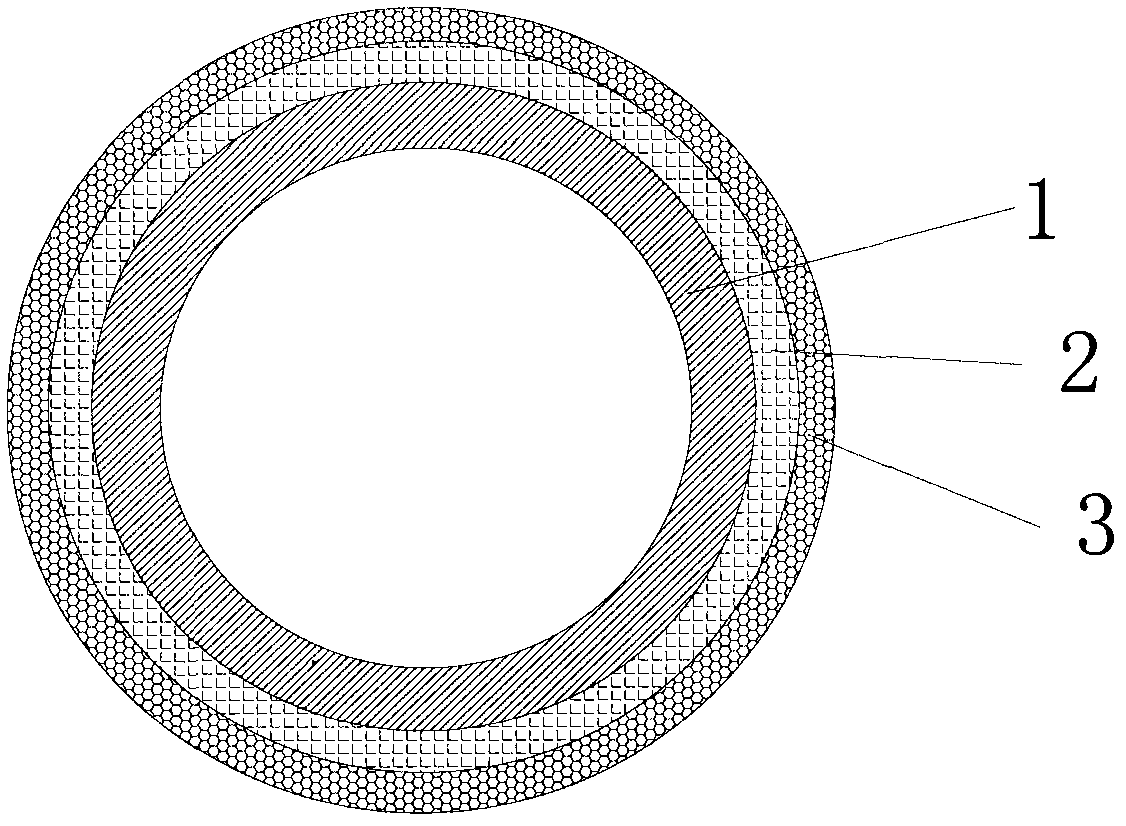

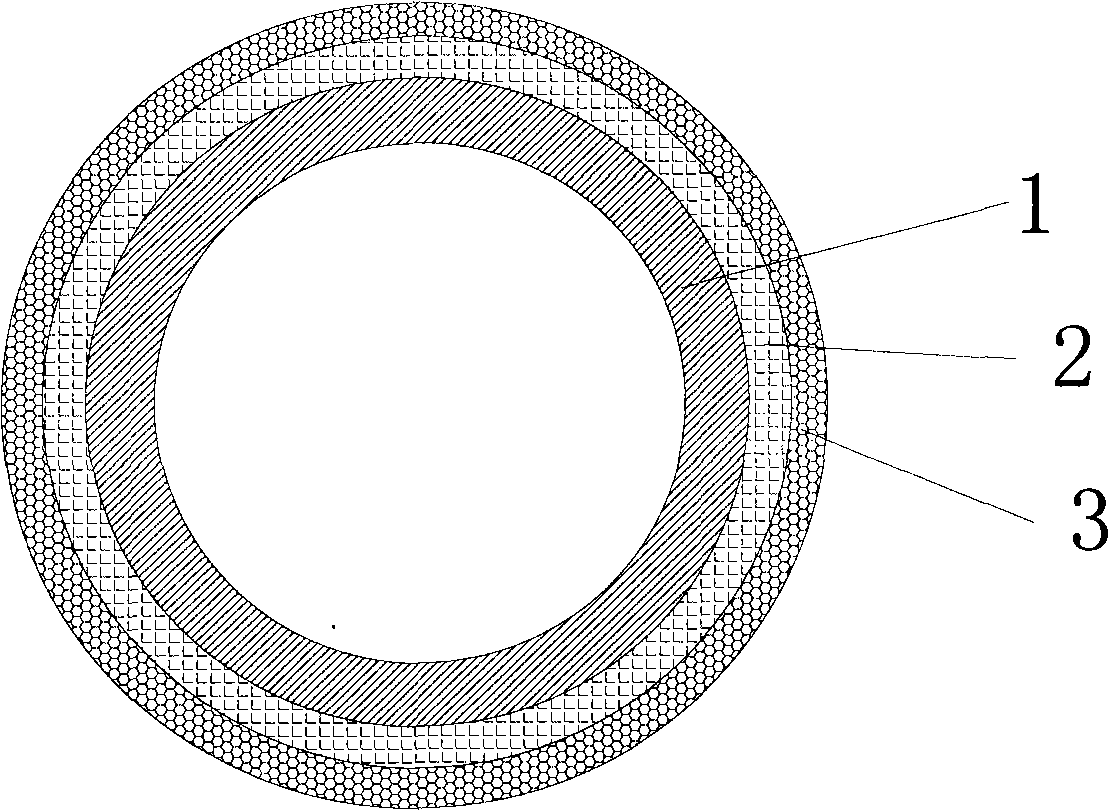

Surface coating modified lithium ion battery cathode material and preparation method thereof

InactiveCN104577093AImprove securityNo significant reduction in specific capacityCell electrodesLithium iron phosphatePhysical chemistry

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

Transparent thermal insulation coating material system for glass substrate

InactiveCN102942841AInstant cureReduce energy consumptionPolyurea/polyurethane coatingsEpoxy resin coatingsThermal insulationUltraviolet lights

The present invention discloses a transparent thermal insulation coating material system for a glass substrate. The coating material system is a double layer coating material system formed by a separately-prepared primary coating and a separately-prepared surface coating, wherein the surface coating is coated on the primary coating, the primary coating comprises the following components, by mass, 0.05-3 parts of a silicane coupling agent or a titanate coupling agent, 0.2-5 parts of a hydrolysis catalyst, and 95-99 parts of a solvent, and the surface coating comprises the following components, by mass, 50-80 parts of a light curable resin, 5-35 parts of an active diluent, 1-8 parts of a photoinitiator, 5-35 parts of an antimony tin oxide nanometer thermal insulation powder slurry or an indium tin oxide nanometer thermal insulation powder slurry, 100-140 parts of an inert diluent, and 0.01-0.15 part of a leveling agent. With the coating material system, a film can be formed through a conventional film forming method, and the film layer can be cured within a few seconds after ultraviolet light irradiation. In addition, the coating material system has characteristics of high hardness, excellent adhesion and excellent water resistance.

Owner:刘志钊 +1

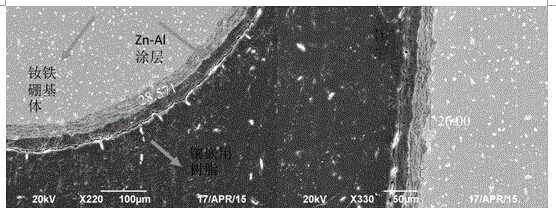

Zinc-aluminum coating enhanced with particles in micro-nano sizes and production method of zinc-aluminum coating

InactiveCN104984889AImprove mechanical propertiesImprove scratch resistancePretreated surfacesSpecial surfacesMicro nanoSilicon oxide

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

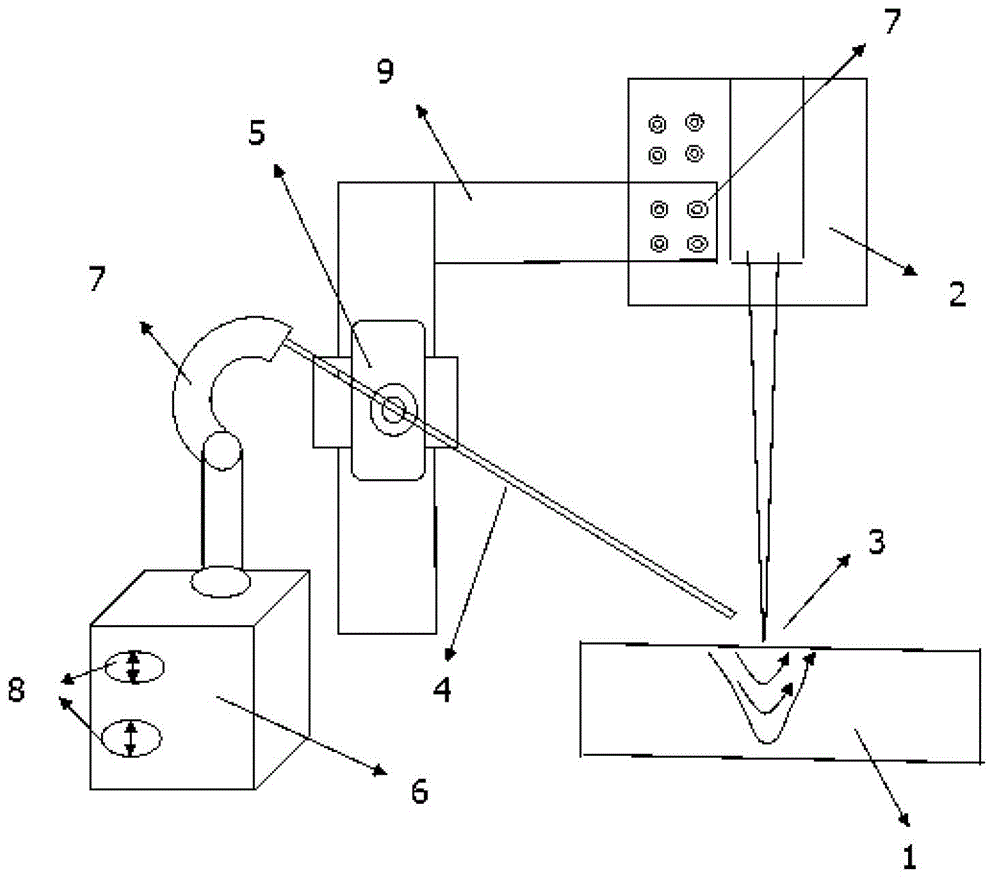

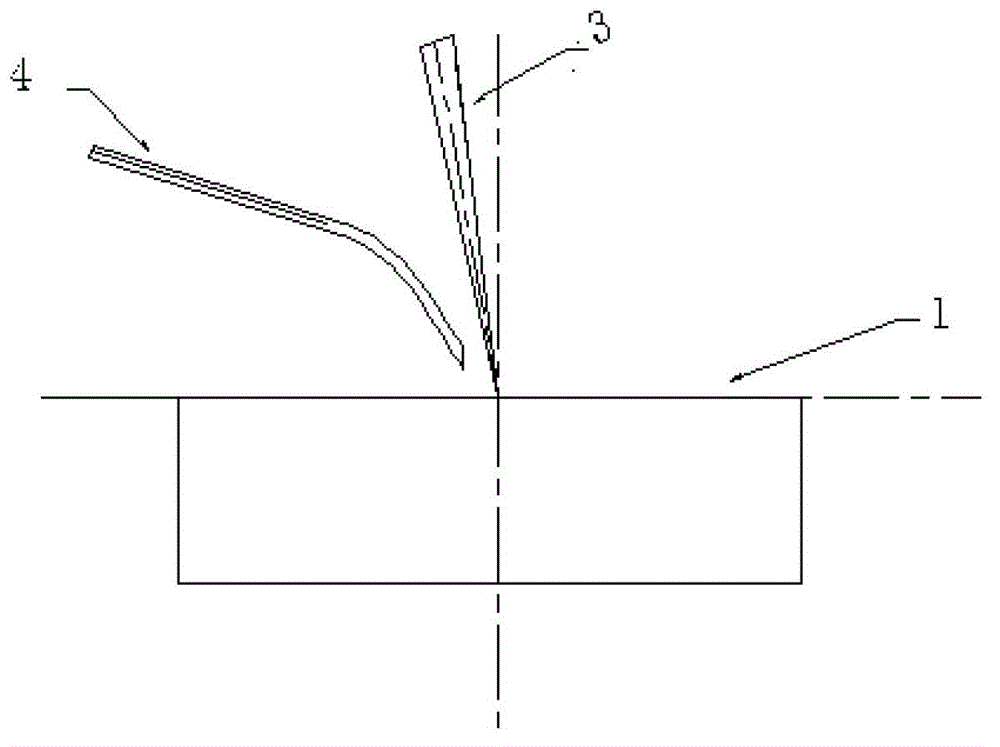

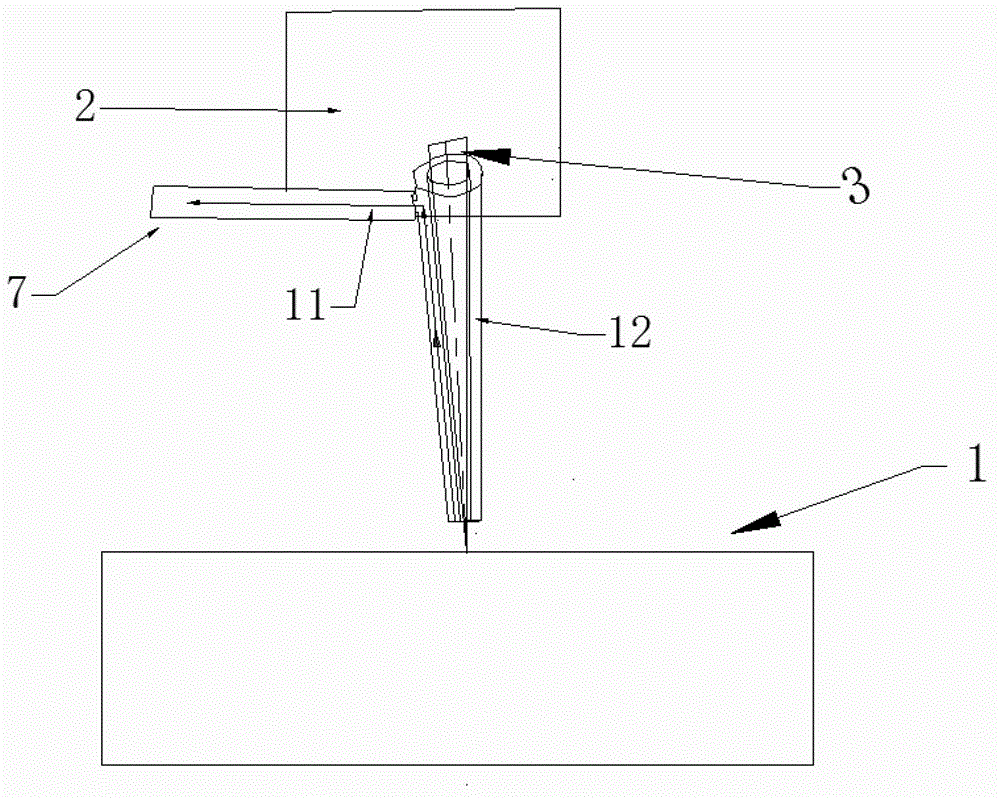

Method and device for controlling laser welding seam holes

InactiveCN102941412AGuaranteed patencyAvoid formingLaser beam welding apparatusThick plateEngineering

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method for durable aluminum and aluminum alloy superhydrophobic surface coating

InactiveCN102527619AExtended service lifeGood antifoulingSpecial surfacesCoatingsSuperhydrophobic coatingPolypropylene

Owner:HUNAN UNIV OF TECH

Reactive surface coating having chemical decontamination and biocidal properties

ActiveUS20140287154A1Reduce and limit amountHigh activityBiocideAntifouling/underwater paintsBiochemical engineeringEnvironmental engineering

Reactive compositions are provided, having biocidal and chemical decontamination / neutralization properties, comprising a hygroscopic polymer and an active, which are useful in a variety of commercial, healthcare and military applications and a wide variety of contaminants, including without limitation chemical and biological warfare agents. The reactive compositions are renewable or rechargeable after use by exposure to an additional application of the active and do not require removal, disposal or replacement of the originally applied composition. Methods for preparing and applying the reactive compositions are disclosed.

Owner:AMERICAN STERILIZER CO +1

Preparation method of special coating resin composition for polyethylene

ActiveCN102863670AImprove melt strengthLow shrinkageNon-macromolecular adhesive additivesFilm/foil adhesivesLow-density polyethylenePeroxide

Owner:PETROCHINA CO LTD

High-weatherability anti-corrosive paint and iron tower assembly

InactiveCN102070986ANot easy to ageNot easy to corrodeLighting support devicesAnti-corrosive paintsUltravioletEngineering

Owner:CHANGSHU FENGFAN POWER EQUIP

Monolithic catalyst with organic waste gas selective adsorption and catalytic oxidation functions as well as preparation method and application thereof

ActiveCN112169827AHigh load rateImprove firmnessGas treatmentMolecular sieve catalystsMolecular sievePtru catalyst

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

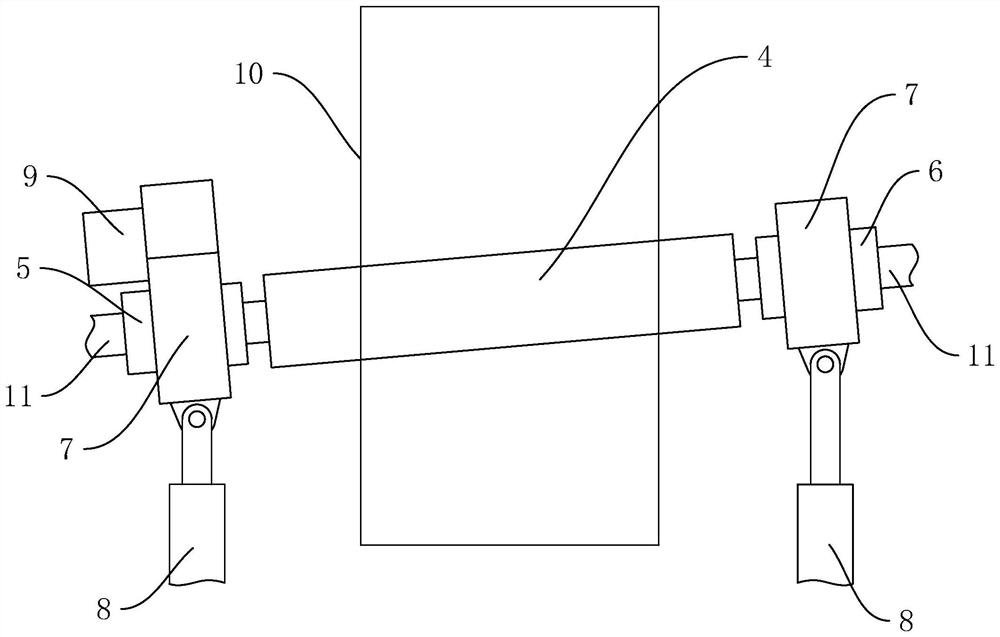

Automatic curved surface coating apparatus

InactiveCN102424162ASufficient athletic abilityAccurate cloaking actionLabelling machinesManipulatorComputer control

The invention belongs to the technical field of curved surface coating, and especially relates to an automatic curved surface coating apparatus which can automatically complete a curved surface coating process. The automatic curved surface coating apparatus comprises a material conveying device and a film paper conveying device which are mounted on a frame; the material conveying device comprises a manipulator for clamping a material, and a manipulator motion mechanism for driving the motion of the manipulator; the film paper conveying device comprises a film paper frame for fixing the film paper, and a film paper horizontal motion mechanism for driving the motion of the film paper; a position measuring device is disposed on the motion tracks of the material conveying device and the film paper conveying device, and is fixed on the frame; the film paper conveying device is disposed in a water tank; the material conveying device, the film paper conveying device, and the measuring device are connected with a computer control device, and are controlled by the computer control device; an activator spraying device is disposed on the frame. The invention provides a curved surface coating apparatus which can perform material curved surface coating in an automatic production mode.

Owner:赖万明

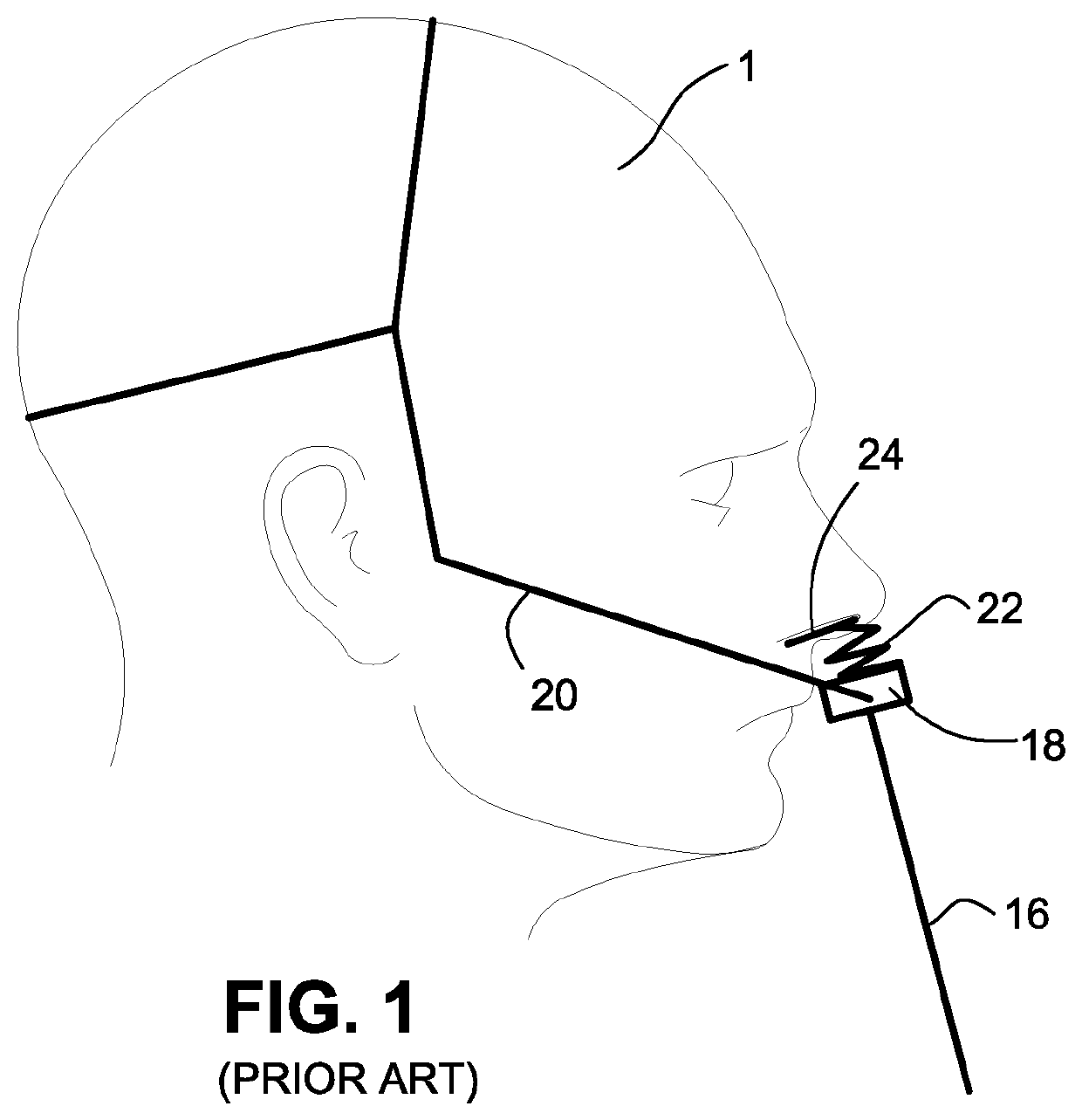

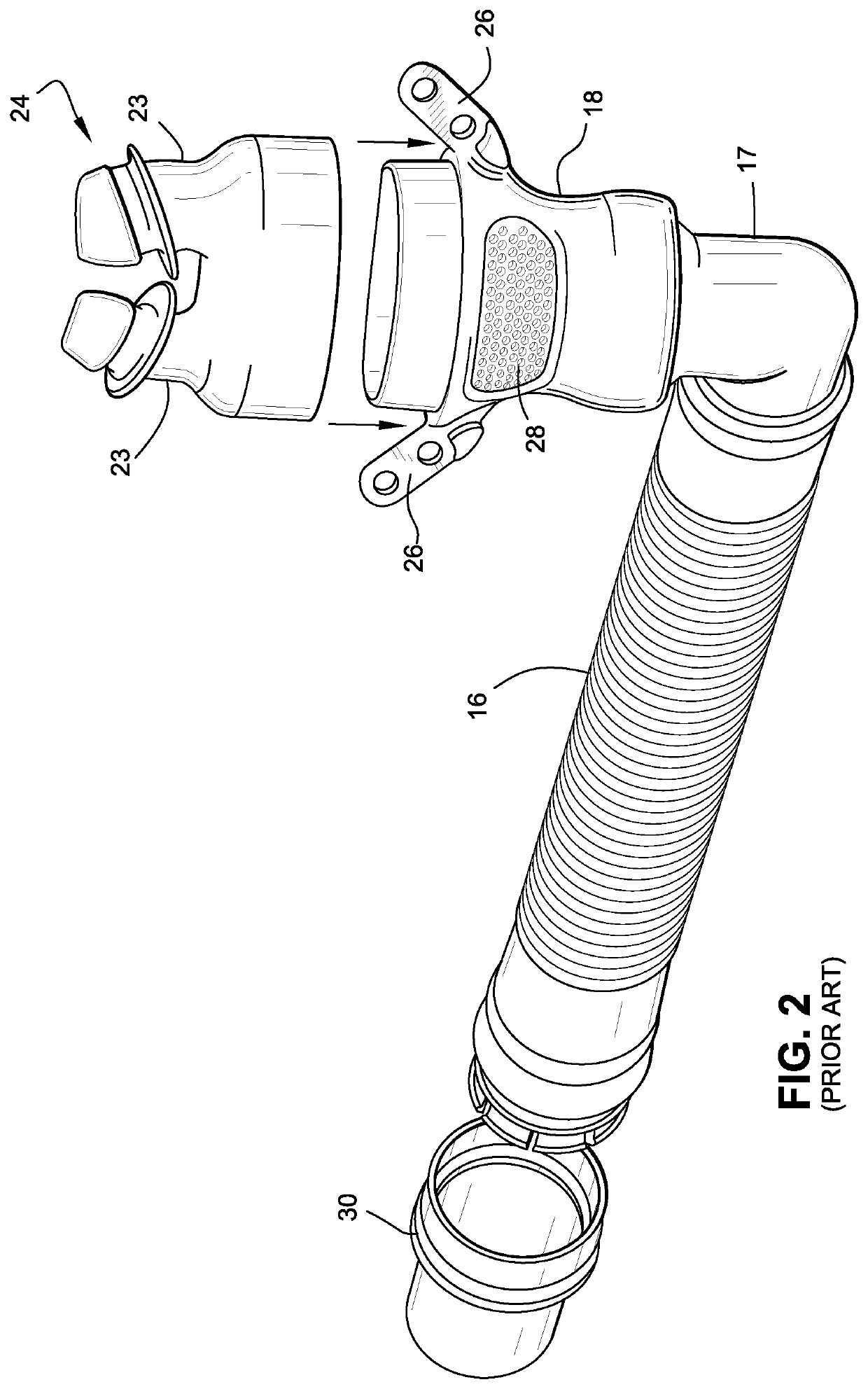

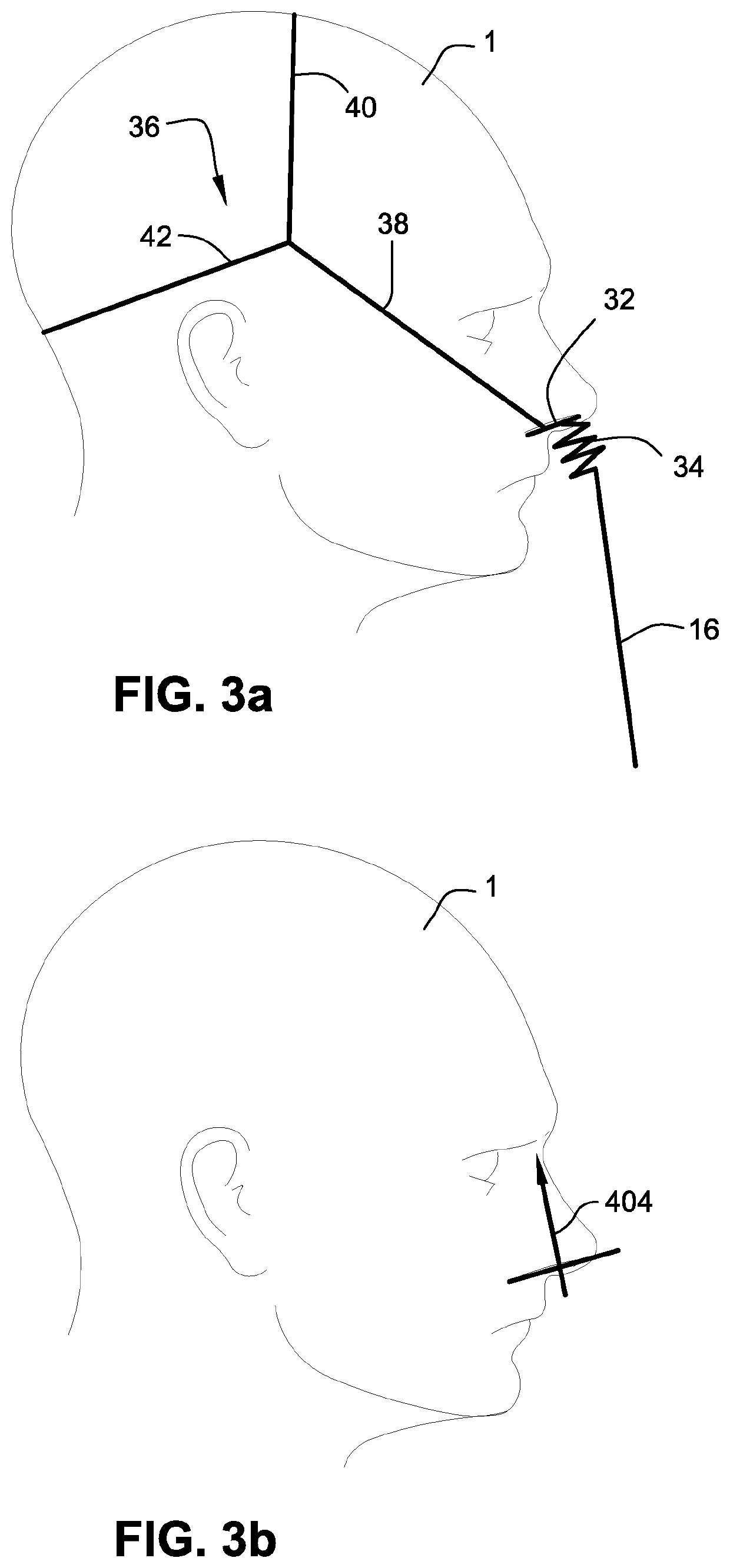

Patient interface systems

PendingUS20200061398A1Easy to useRespiratory masksMedical devicesPhysical medicine and rehabilitationBreathing gas

Owner:RESMED LTD

Coating for high-temperature chlorine corrosion protection and preparation method thereof

ActiveCN111778502ALow melting pointReduce meltingMolten spray coatingChemical compositionSand blasting

Owner:XIAN THERMAL POWER RES INST CO LTD

Ceramic coating for surface of energy-gathering ring of gas stove and preparation method and application method thereof

ActiveCN111040481ADo not decomposeDoes not change colorFireproof paintsPretreated surfacesPtru catalystCeramic coating

The invention discloses a ceramic coating for the surface of an energy gathering ring of a gas stove and a preparation method and an application method of the ceramic coating. The ceramic coating comprises the following components in percentage by mass: a component A, namely, 67.5-69.5% of color paste; a component B, namely, 30.5 to 31.5% of silane; and a component C, namely, 0.7-0.8% of a catalyst. The ceramic coating of the invention solves the problems of poor temperature resistance and easy decomposition and discoloration during combustion of an organosilicon coating on the surface of theenergy-gathering ring of the gas stove, has the characteristics of good high temperature resistance, no decomposition and discoloration at high temperature and no release of smoke, and is very suitable for being used as a surface coating of the energy-gathering ring of the gas stove.

Owner:SHANGHAI MINGJIA NEW MATERIAL TECH CO LTD

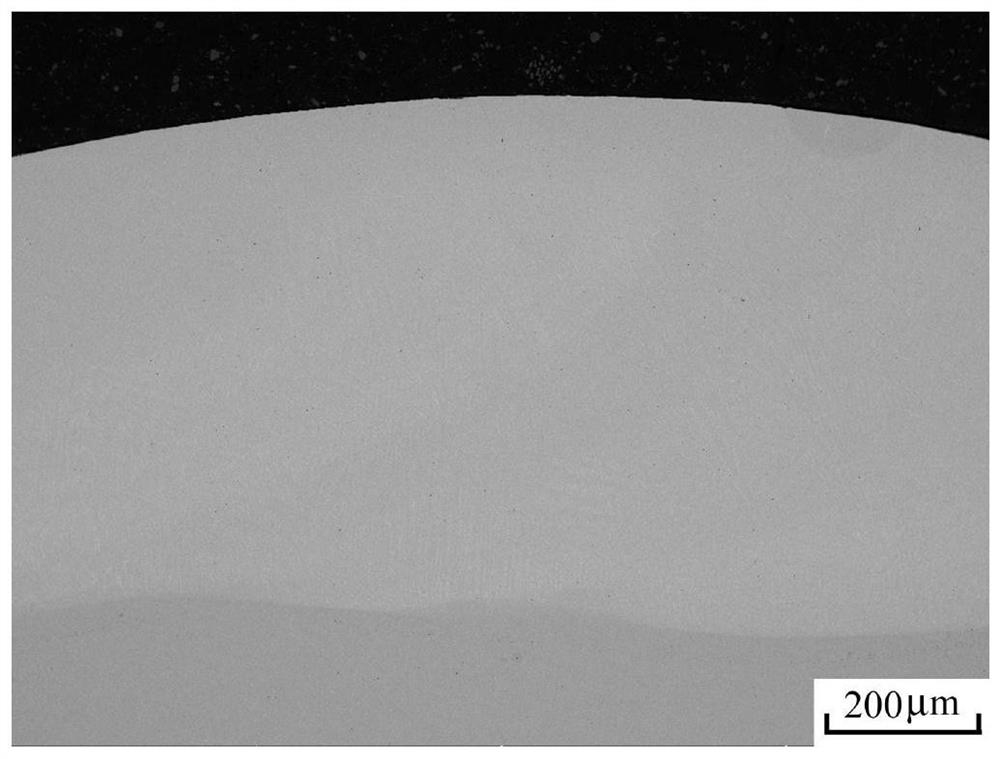

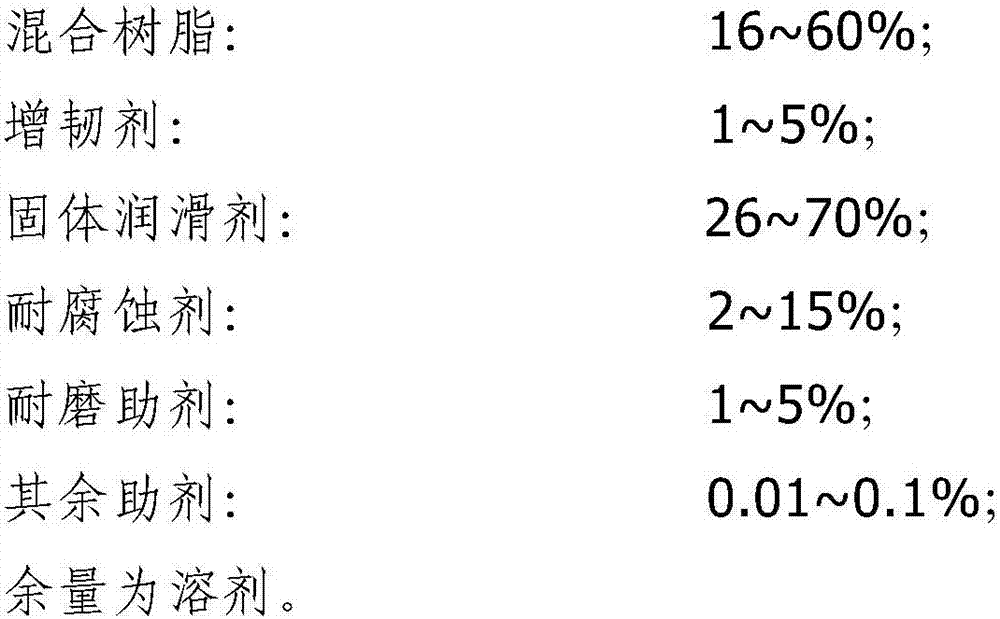

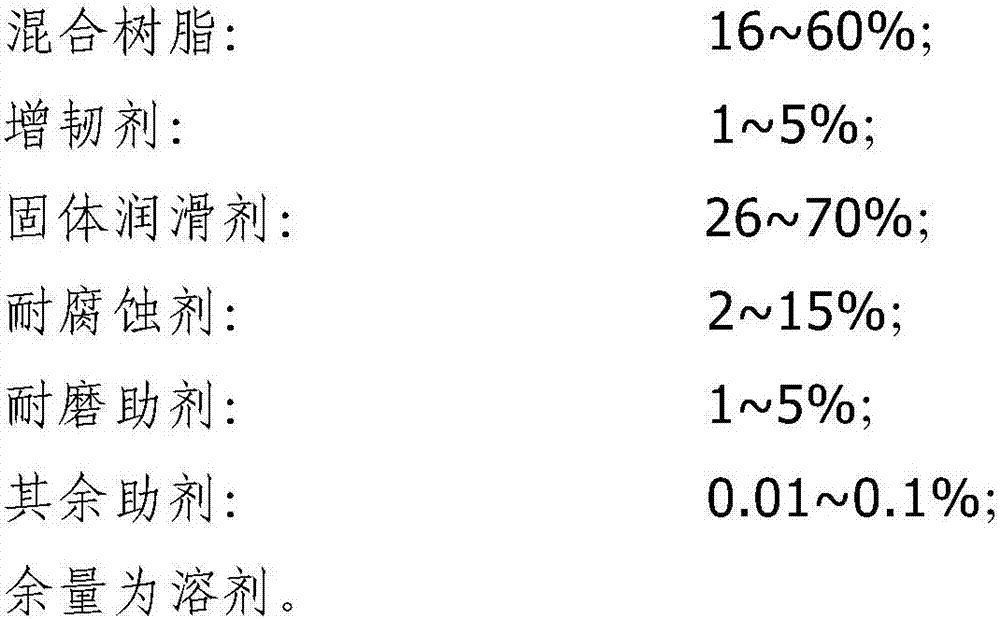

Anti-gluing solid lubricating paint as well as preparation method and applying method thereof

ActiveCN107286839AHigh bonding strengthGood anti-sticking propertiesSpecial surfacesEpoxy resin coatingsSolventToughening

Owner:BAOSHAN IRON & STEEL CO LTD

Aluminum foil tape

Owner:HEFEI SHUSHI IND & TRADE CO LTD

Thermoplastic PVDF fluorocarbon powder coated aluminum veneer

InactiveCN111926957AImprove wear resistanceImprove corrosion resistanceWallsPretreated surfacesThermoplasticWeather resistance

Owner:方大新材料(江西)有限公司

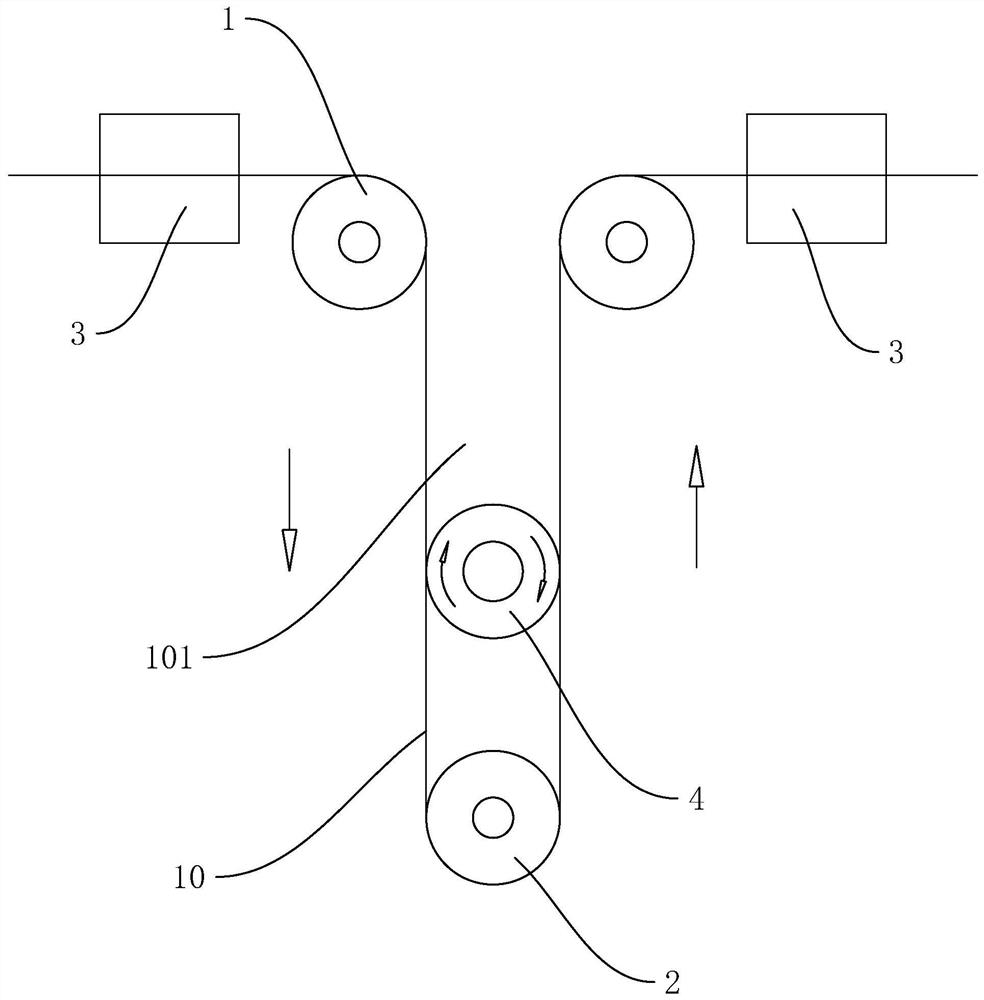

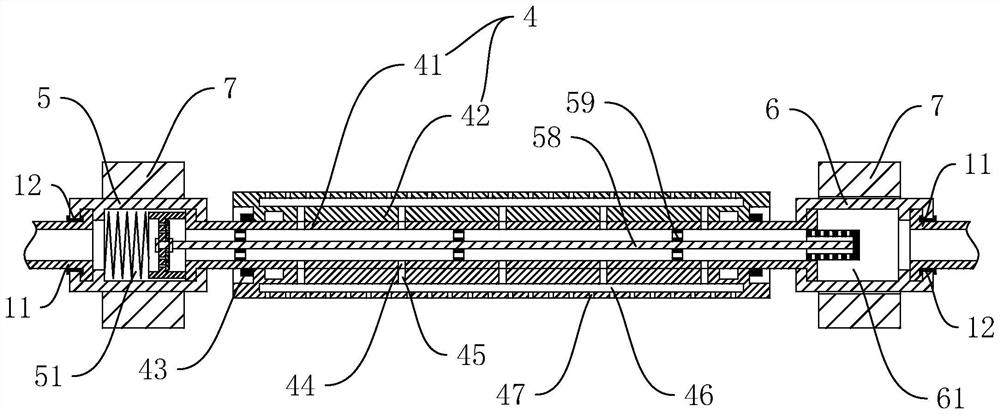

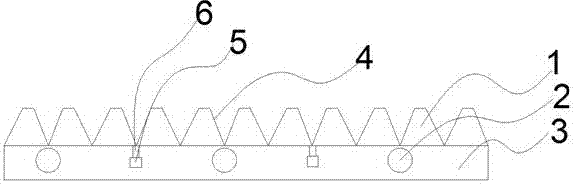

Laser film surface coating system

ActiveCN114713439ARealize double recoatingFull coatingLiquid surface applicatorsCoatingsThin membraneContact position

Owner:绍兴毅龙镭射科技有限公司

Novel rack

InactiveCN107542897AImprove heat resistanceImprove cooling effectPortable liftingGear lubrication/coolingManufacturing cost reductionHeat resistance

Owner:JIANGYIN SHENGYUAN COPPER MATERIAL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap