Thermoplastic PVDF fluorocarbon powder coated aluminum veneer

A technology of powder coating and aluminum veneer, which is applied in the field of building decoration materials, can solve the problems of high environmental protection pressure, lack of anti-ultraviolet ability of fluorocarbon paint, color difference of building appearance, etc., and achieve the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

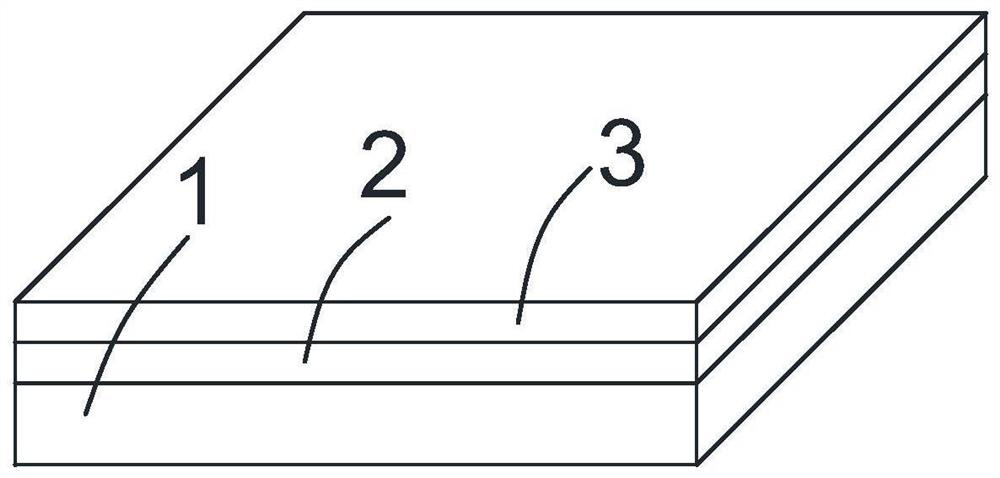

[0015] Such as figure 1 As shown, a PVDF fluorocarbon-coated aluminum veneer for architectural decoration includes an aluminum alloy base plate 1, a passivation film 2 and a PVDF fluorocarbon powder layer 3, and the thickness of the aluminum alloy base layer 1 is 2.5 mm or 3.0 mm. It is 3003 series aluminum alloy, through the sheet metal processing technology to make it reach the required shape, and the surface to be sprayed is polished with 80 mesh sandpaper to deal with the scratches, pits, indentations and other defects on the surface of the plate to increase the roughness of the surface to be sprayed. Increase the adhesion of the paint film; the passivation film 2 is a dense silver-white protective film with a thickness of about 2-3 μm formed by spraying the aluminum alloy base plate with a passivation agent in the passivation process of the pre-t

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap