Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Fire retardant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fire retardant is a substance that is used to slow or stop the spread of fire or reduce its intensity. This is commonly accomplished by chemical reactions that reduce the flammability of fuels or delay their combustion. Fire retardants may also cool the fuel through physical action or endothermic chemical reactions. Fire retardants are available as powder, to be mixed with water, as fire-fighting foams and fire-retardant gels. Fire retardants are also available as coatings or sprays to be applied to an object.

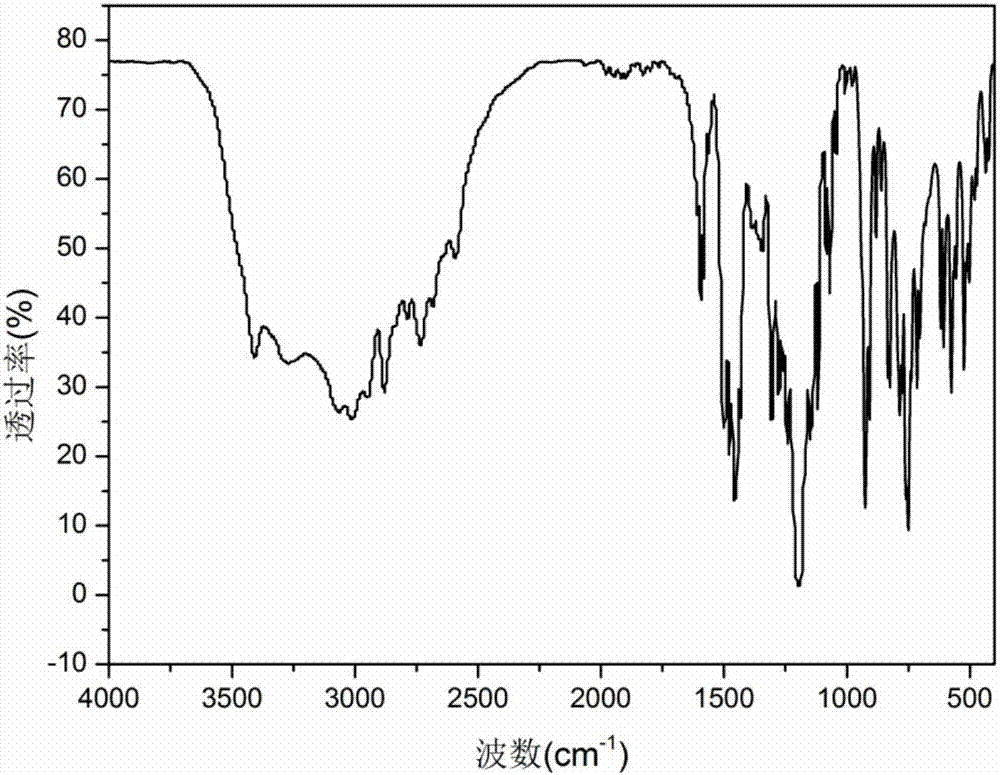

Phosphor-silicon-containing aggregated flame retardant and preparation method thereof

ActiveCN107266685AOvercome the disadvantage of easy precipitationHigh flame retardant efficiencyGroup 5/15 element organic compoundsEpoxyPolymer science

Owner:宁波塑之华塑化有限公司

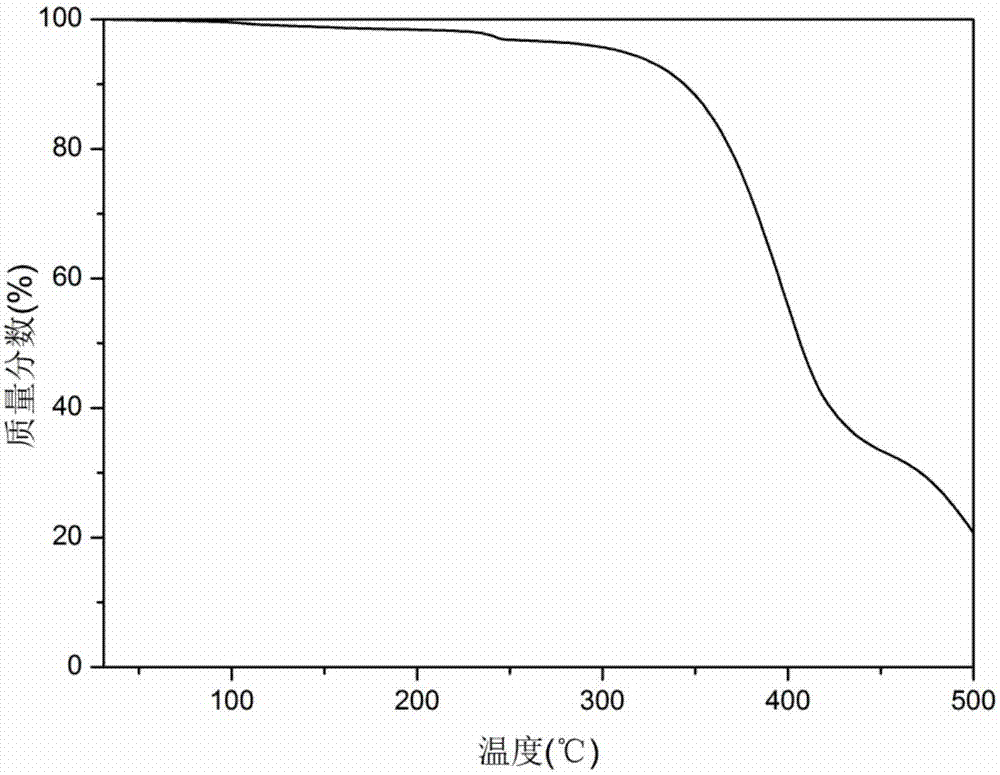

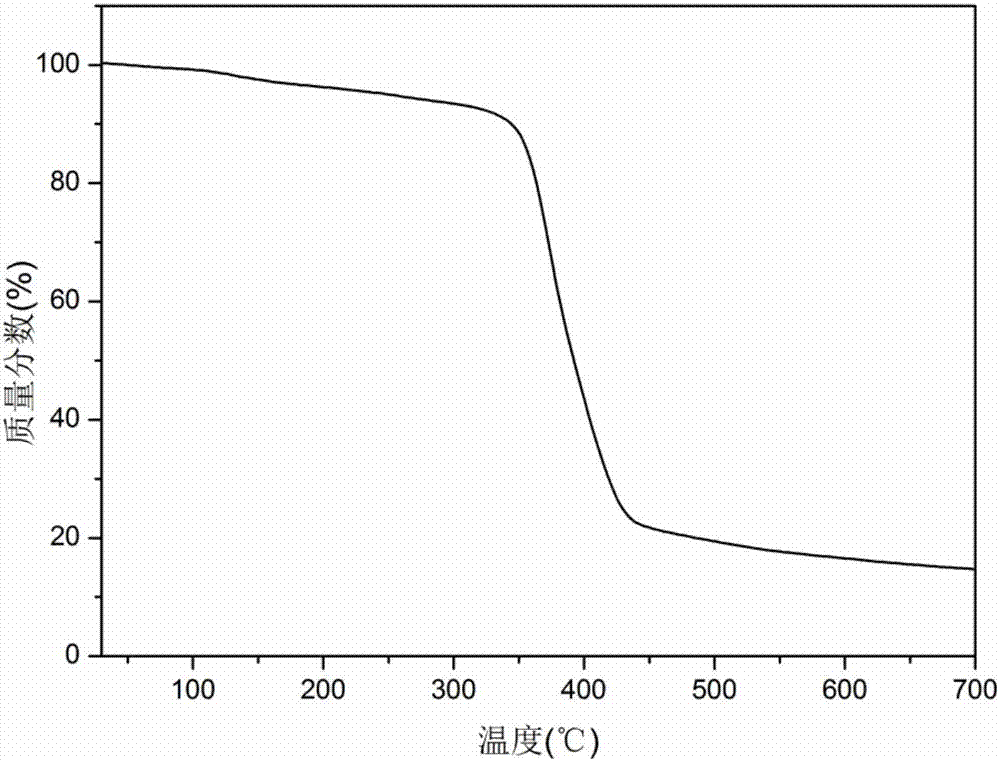

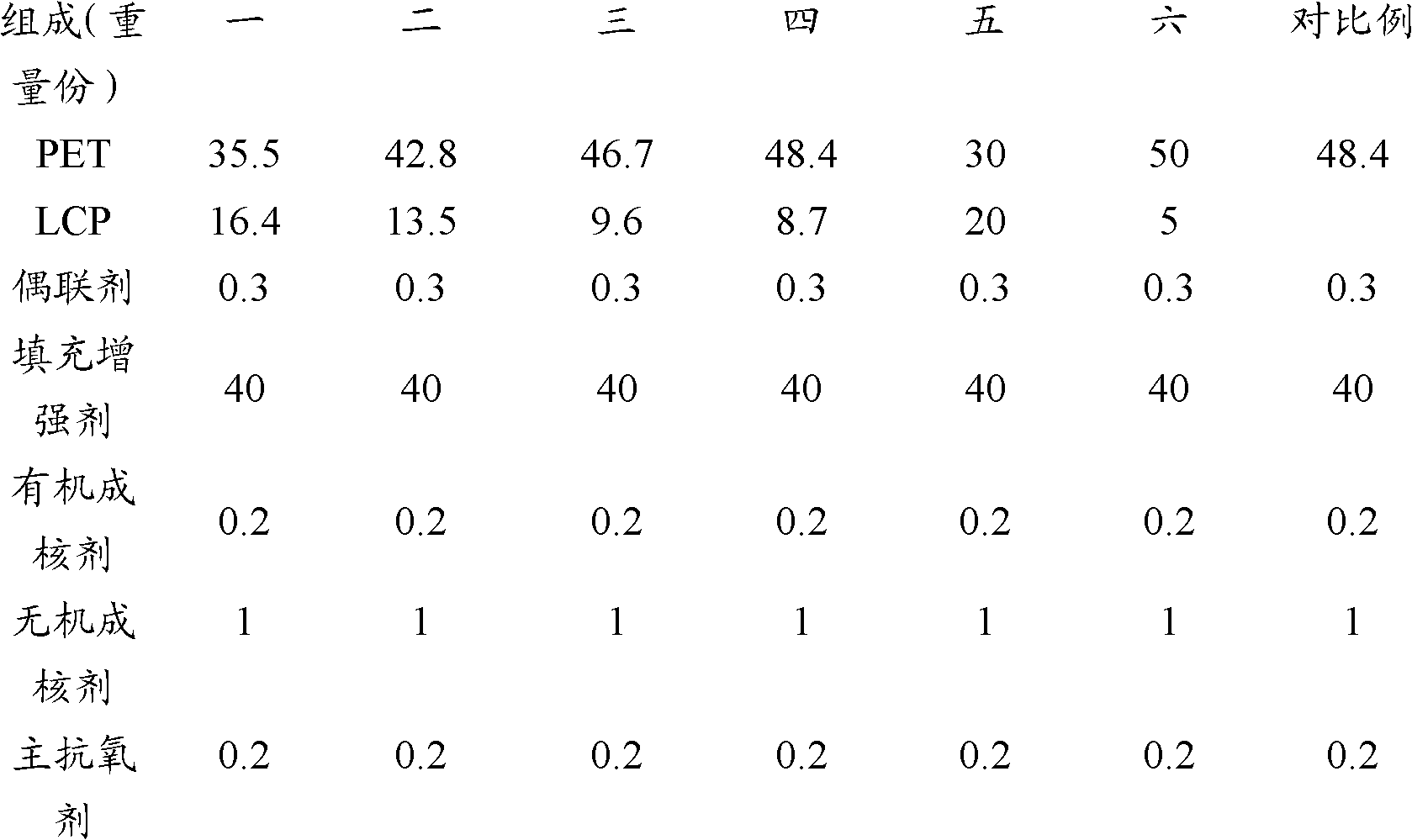

Polyethylene terephthalate (PET)/liquid crystal polymer (LCP) engineering plastics as well as preparation method and application thereof

InactiveCN102040812AImprove performanceHigh crystallinityPolyethylene terephthalate glycolAntioxidant

Owner:SHENZHEN KEJU NEW MATERIAL

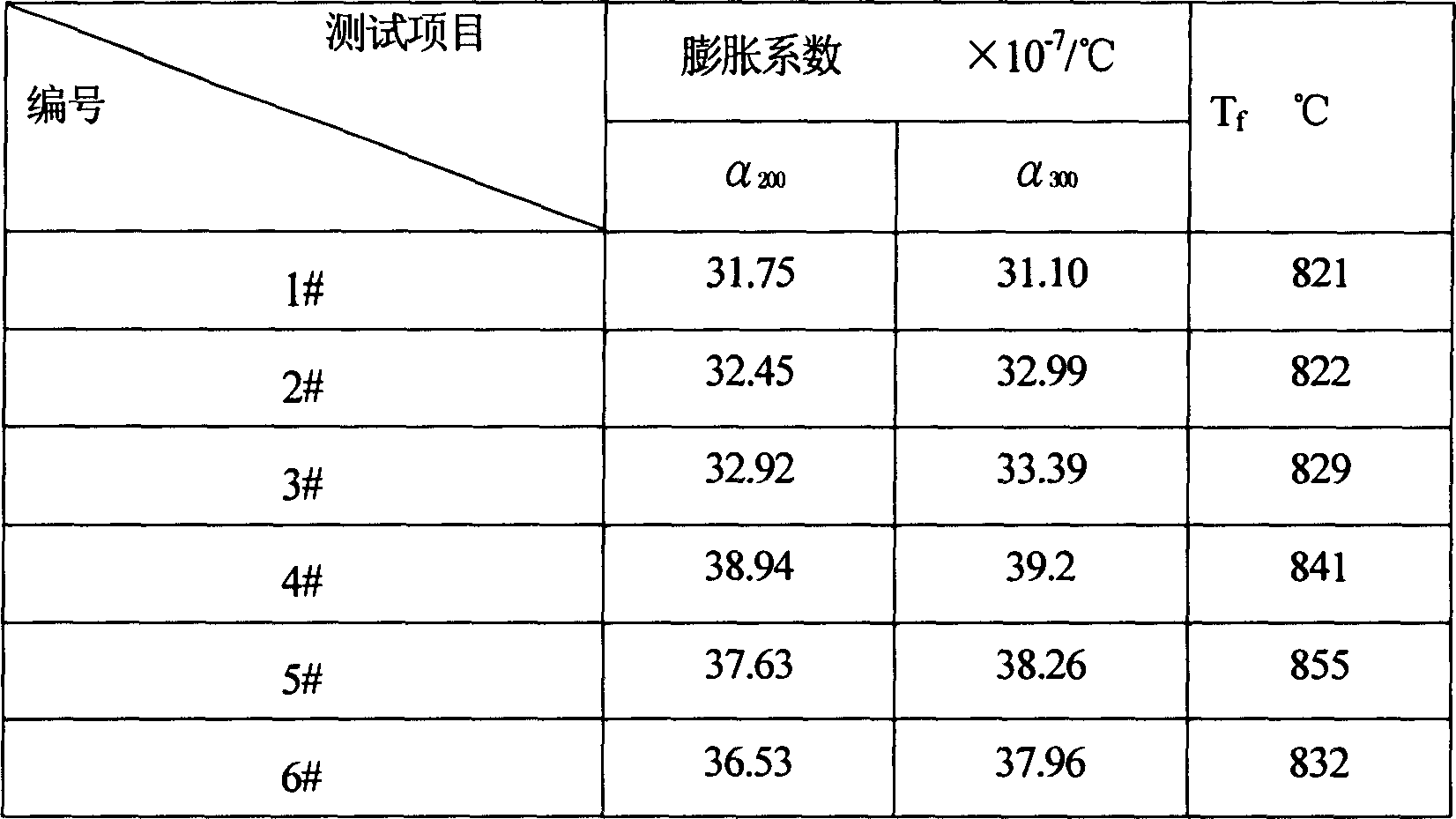

Low-expansion heat-resisting fire-retardant glass

Owner:CHINA LUOYANG FLOAT GLASS GROUP

Aluminum plastic plate flame-retardant core layer and aluminum-plastic plate

ActiveCN109111617AReduce corrosionExtended service lifeSynthetic resin layered productsMetal layered productsLow-density polyethyleneAntioxidant

Owner:台州市佳信新材料科技有限公司

Antistatic anti-flaming PC/ABS compound material and preparation method thereof

The invention discloses an antistatic and flame-resistant PC / ABS composite material and a preparation method thereof. The composite material comprises 60-80 parts of PC resin; 8-15 parts of ABS resin; 8-12 parts of flame retardant; toughening agent 1-5 parts; antistatic agent 8-25 parts; antioxidant 0.01-2 parts; other additives 0.4-0.8 parts. The present invention selects the preferred antistatic agent, which minimizes the impact on PC performance, and the use of the antistatic agent in conjunction with the emulsion method ABS is beneficial to the antistatic effect of the antistatic agent and can last.

Owner:SHANGHAI KINGFA SCI & TECH +2

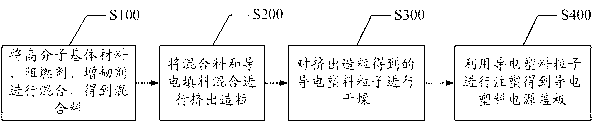

Conductive plastic for processing power supply cover plate, and fabrication method of power supply cover plate

InactiveCN103214718AStrong acid and alkali corrosion resistanceResistivity adjustableConductive polymerEngineering

Owner:SHENZHEN FRD SCI & TECH

Thermoplastic Polymer Blends Comprising Crosslinked Polar Olefin Polymers in a Thermoplastic Polyurethane Matrix

InactiveUS20120238664A1Insulated cablesInsulated conductorsThermoplastic polyurethaneOlefin polymerization

Polymer blends comprising a first phase comprising a thermoplastic polyurethane matrix and a second phase comprising a crosslinked polar olefin polymer are provided. The first phase is a continuous phase and the second phase can be co-continuous with the first phase, or dispersed as a non-continuous phase in the first phase. The first phase further comprises a metal hydroxide flame retardant and an organic flame retardant. The second phase further includes a metal hydroxide which is coupled to the olefin polymer via a silane coupling agent.

Owner:YAN WILSON XIAO WEI +6

Flexible protective coating

Owner:ICP CONSTR INC

Acrylate damping coating and preparation method thereof

The invention discloses an acrylate damping coating and a preparation method thereof. The acrylate damping coating comprises, by weight, 20-35 parts of water, 1-3 parts of an aqueous disperser, 10-18 parts of calcium carbonate, 20-35 parts of talcum powder, 7-11 parts of a fire retardant, 0.5-2 parts of an aqueous antifoaming agent, 50-110 parts of a propionate emulsion, 0.1-1.5 parts of a thickener, 0.1-3.3 parts of a damping pigment filler and 0.5-1.8 parts of a film forming assistant. The propionate emulsion is adopted in the preparation process of the acrylate damping coating, so the damping performance of the coating in high and low temperature state is improved, and the coating also has the advantages of good noise reduction effect, non-toxicity, no peculiar smell, hard film, good gloss retention, good durability and good pollution resistance.

Owner:郭小曼

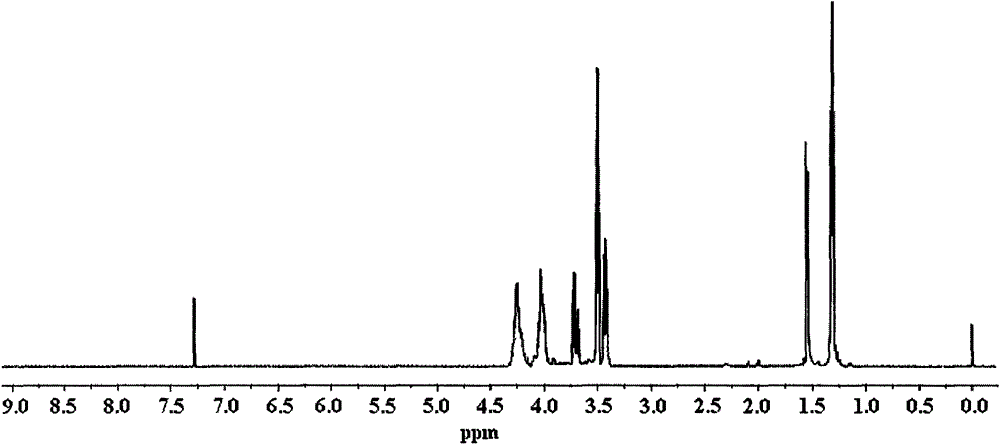

Novel fire retardant microencapsulated red phosphorus and preparation method thereof

The invention discloses a novel fire retardant microencapsulated red phosphorus which is formed by wrapping phenol-formaldehyde prepolymer (PFP) on the surface of superfine red phosphorus powder. Due to addition of a high-efficient catalyst in the preparation process, the surface activity of the red phosphorus is improved, the surface of the red phosphorus is tightly wrapped with a PFP layer, and meanwhile as methanol is added to prevent formaldehyde auto-agglutination and the pH value of a reaction solution in the wrapping process is controlled to be 1-6, the stability and the resistivity of the red phosphorus are improved, the machining property is improved, and meanwhile the moisture absorption rate and the PH3 release amount are greatly reduced.

Owner:NANJING UNIV OF SCI & TECH

Nano-modified PET engineering plastic and preparation method thereof

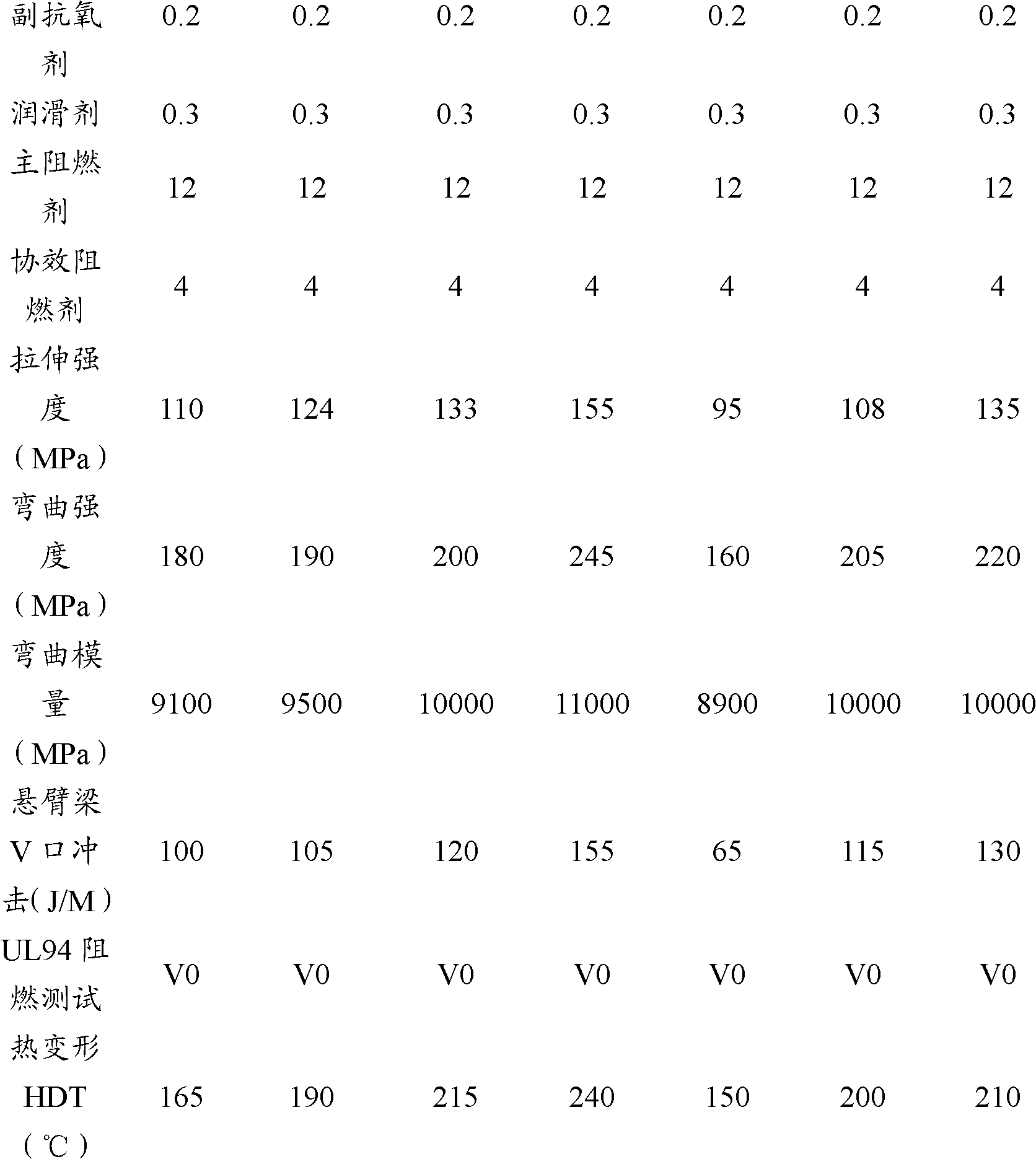

The invention discloses a nano-modified PET engineering plastic and a preparation method thereof. The nano-modified PET engineering plastic comprises 40%-60% of polyester (PET), 20%-40% of glass fibers, 0.4% of lubricant, 0.6% of antioxidant, 2.5% of flexibilizer, 13% of fire retardant, 2.5% of synergistic-effect fire retardant, and 1% of nano-nucleating agent; according to the proportions of the materials, the nano-modified PET engineering plastic has the advantages of good tenacity, good mechanical properties and good fire resistance, is greatly improved in the aspects of tenacity, wear resistance, high temperature resistance and ageing resistance, and is capable of well satisfying the use requirements and the use environments. In addition, the preparation method comprises the step of weighing materials, the step of mixing and stirring and the step of extruding and granulating by use of a twin-screw extruder; and due to the design of the process steps, the preparation method of the nano-modified PET engineering plastic is simple and low in cost.

Owner:广东壹豪新材料科技股份有限公司

High-strength composite fiber non-woven cloth and preparation method thereof

ActiveCN106427147AFirmly connectedClosely connectedProtective equipmentSynthetic resin layered productsEpoxyAlcohol

The invention discloses high-strength composite fiber non-woven cloth and a preparation method thereof. Ultrahigh-strength high-modulus polyethylene fibers are used as base materials, the polyethylene fiber obtained after fiber placement is subjected to a series of homogenization, parallelization and straight and upright arrangement and placed in a modified epoxy resin solution for sizing treatment in an environment of 60-80 DEG C, then the formed polyethylene fiber layers are subjected to composite lamination, and the non-woven cloth is prepared, wherein the modified epoxy resin solution is prepared by adding and mixing an adhesion agent, a filling agent, an insulating filler, fire retardant, white carbon black and ethyl alcohol, the mass of hydroxyl chemigum accounts for 8-12% of the mass of the modified epoxy resin solution, and the content of vinyl cyanide accounts for 18-30% of the content of hydroxyl chemigum. The non-woven clothes with different thicknesses are prepared by lamination of the polyethylene fiber layers, an antiknock device can be made from different types of non-woven cloths according to explosion sites and use environment, and the non-woven cloths with different thicknesses are different in anti-explosion range so as to sufficiently withstand the impact of a bullet.

Owner:JIANGSU LINRY NEW MSTAR TECH

BMC material for molding decorative plate and preparation method thereof

The invention discloses a BMC material for a molding decorative plate. The BMC material comprises the following components: unsaturated polyester resin, calcium carbonate, aluminium hydroxide, zine stearate, potato starch, a low shrinkage agent, a curing agent, chopped glass fiber and stone toner. A preparation method of the BMC material comprises the following steps: (1) calcium carbonate, aluminium hydroxide, zine stearate and potato starch are added into a kneader to be mixed; (2) unsaturated polyester resin, the low shrinkage agent and the curing agent are mixed by a high-speed mixer; (3) a resin solution from the step (2) is added into the powder from the step (1) to be kneaded; (4) the stone toner is added into the mixture from the step (3) to be mixed and kneaded; and (5) chopped glass fiber is added into the pellet material from the step (4) to be kneaded, and discharging is carried out after kneading. The prepared BMC material for the decorative plate is fire retardant, has high plasticity, is easy to process, has good dimensional stability and has bright and lasting color.

Owner:GAOGANG DISTRICT DEYI NEW MATERIALS FACTORY

Fungicidal and Parasiticidal Fire-Retardant Powder

InactiveUS20130274347A1Improve air qualityMinimizes fume emissionBiocideSolid waste managementNatural fiberFire retardant

Owner:SOLVAY SA

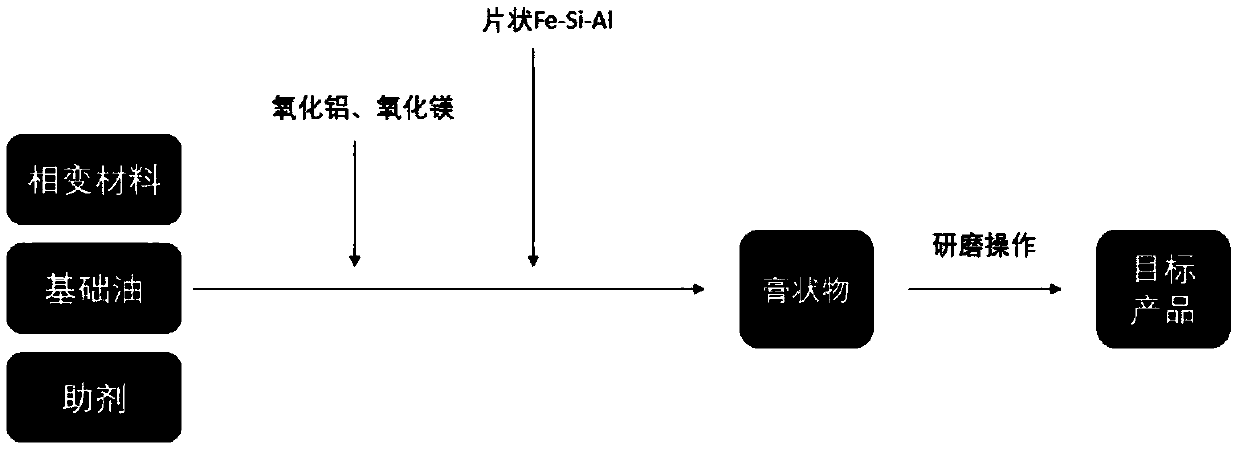

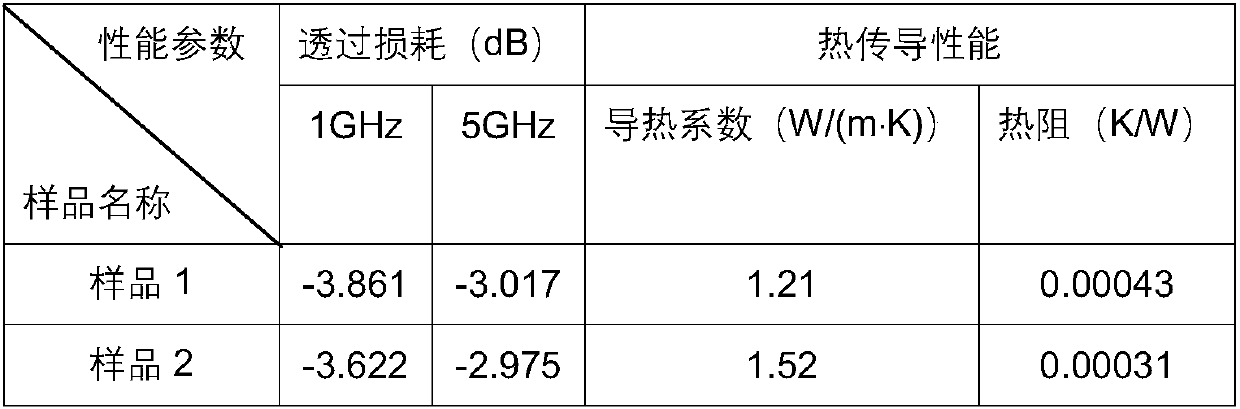

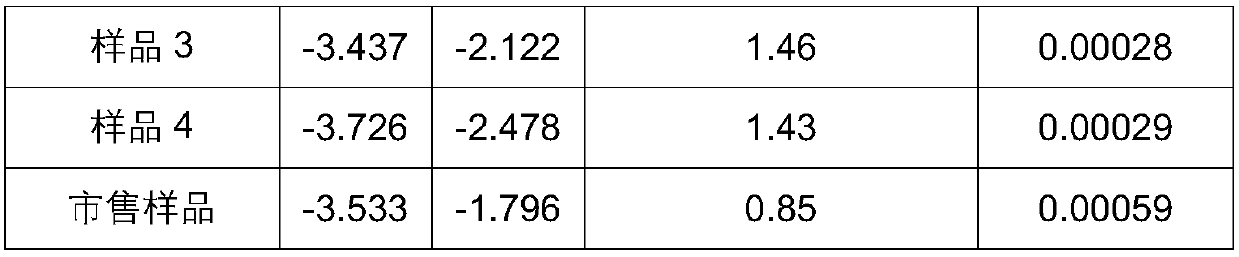

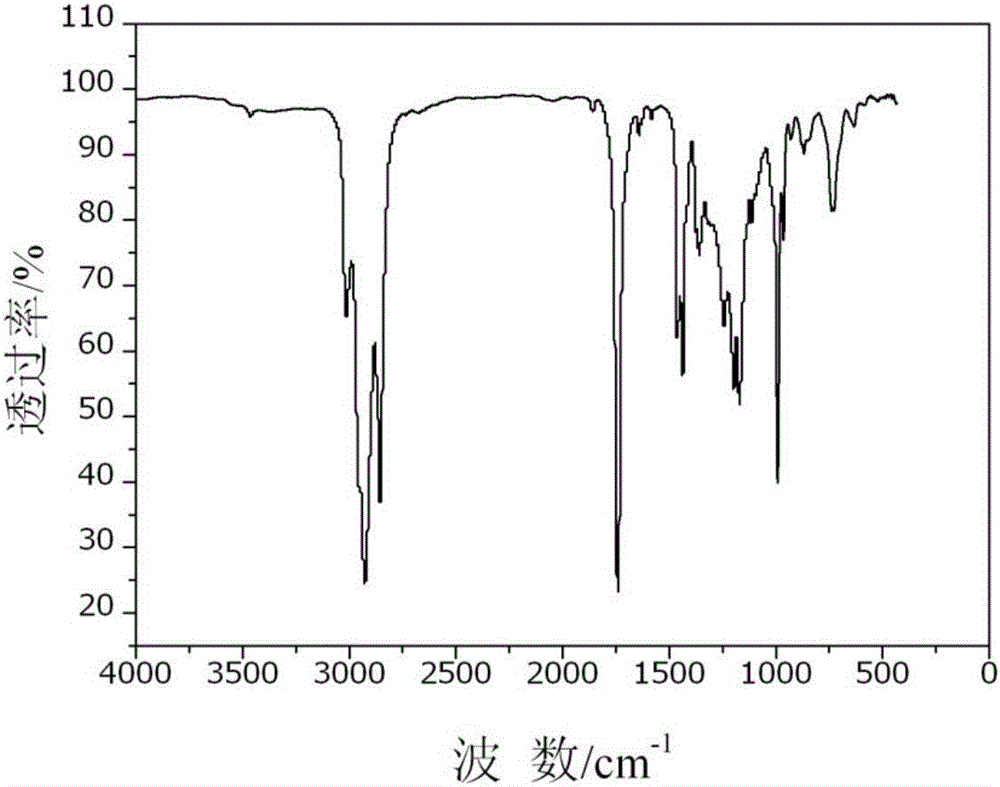

Paste-like phase-change wave-absorbing heat-conducting material and preparation method thereof

Owner:苏州铂韬新材料科技有限公司

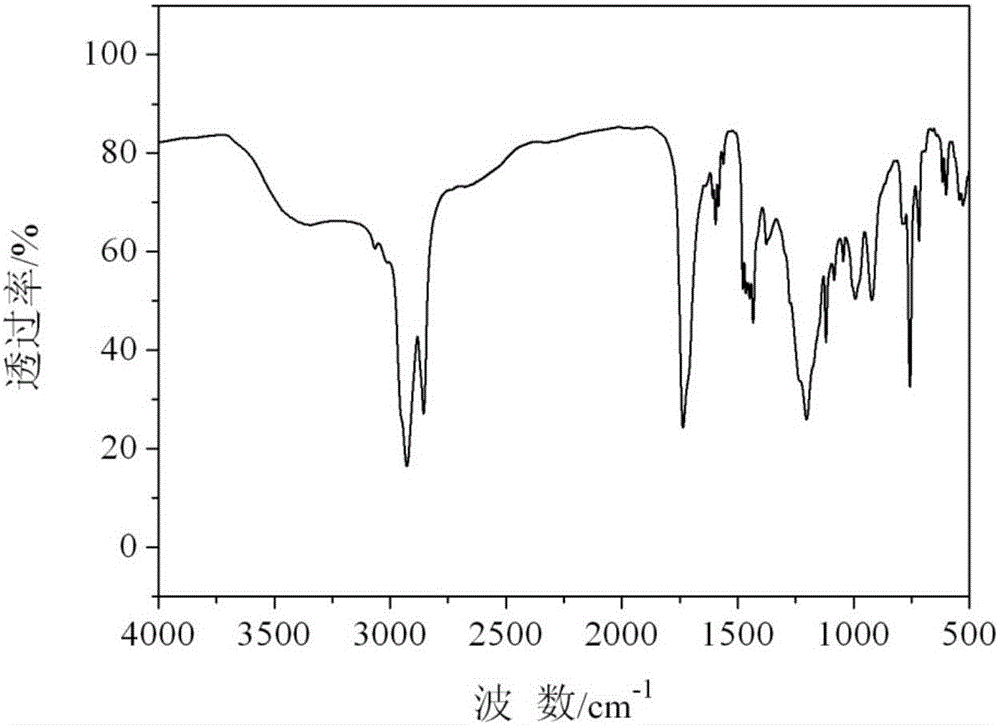

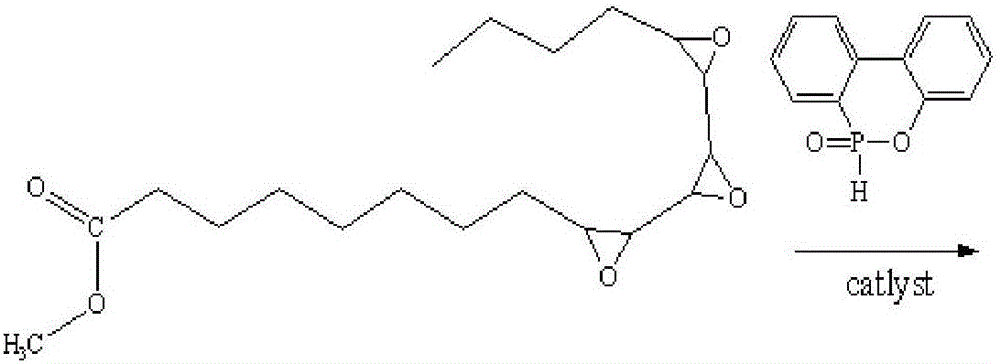

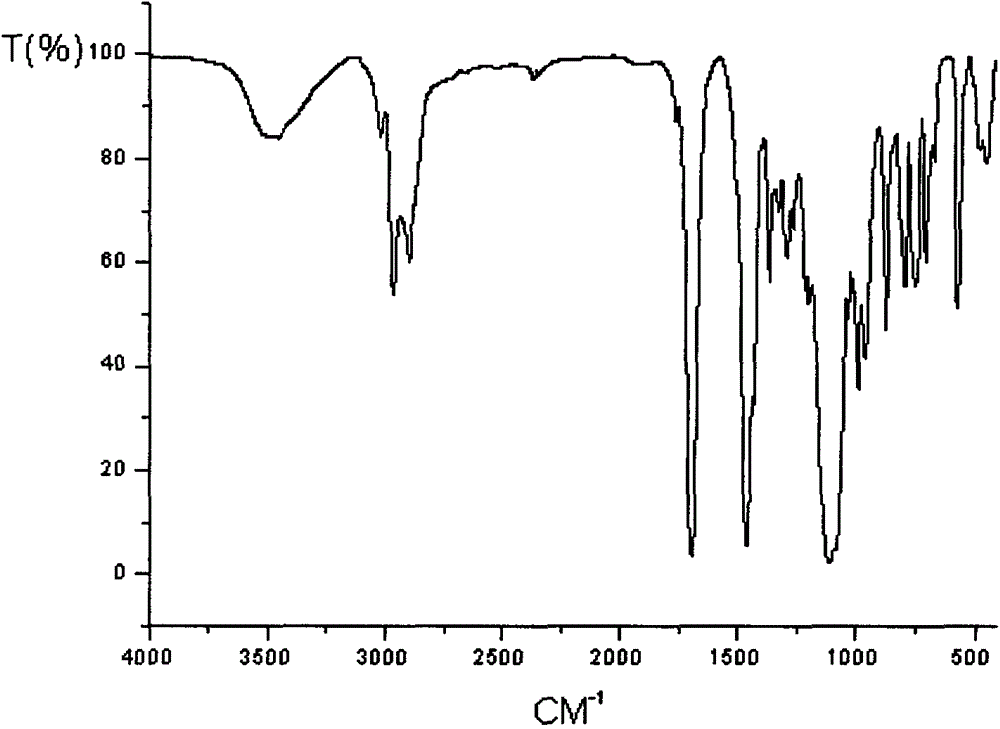

Phosphorus-containing vegetable oil based flame-retardant polyol and preparation method and application thereof

ActiveCN106349290AGood storage stabilityGood compatibilityGroup 5/15 element organic compoundsVegetable oilPhosphate

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

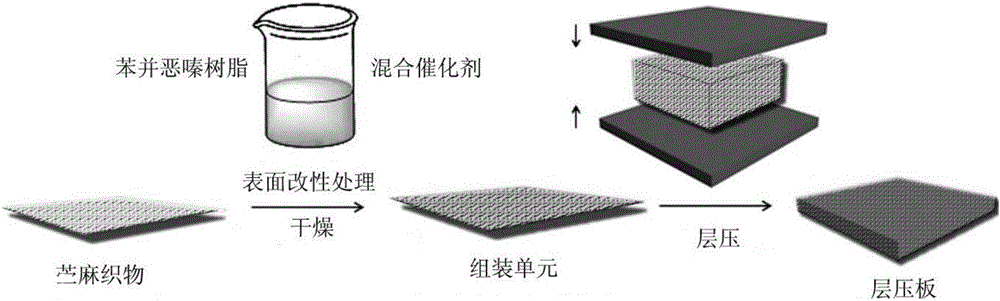

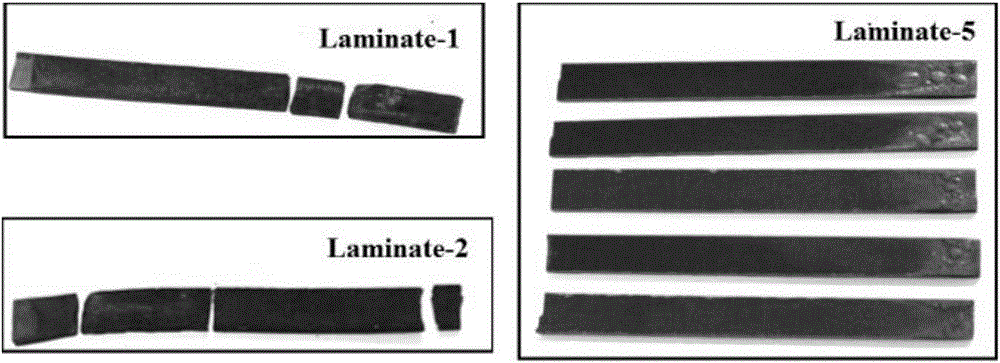

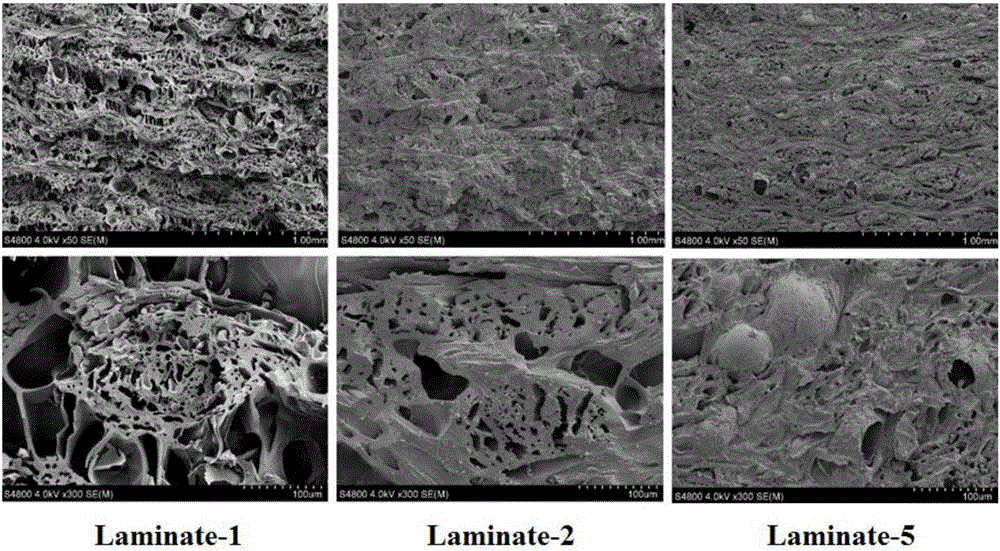

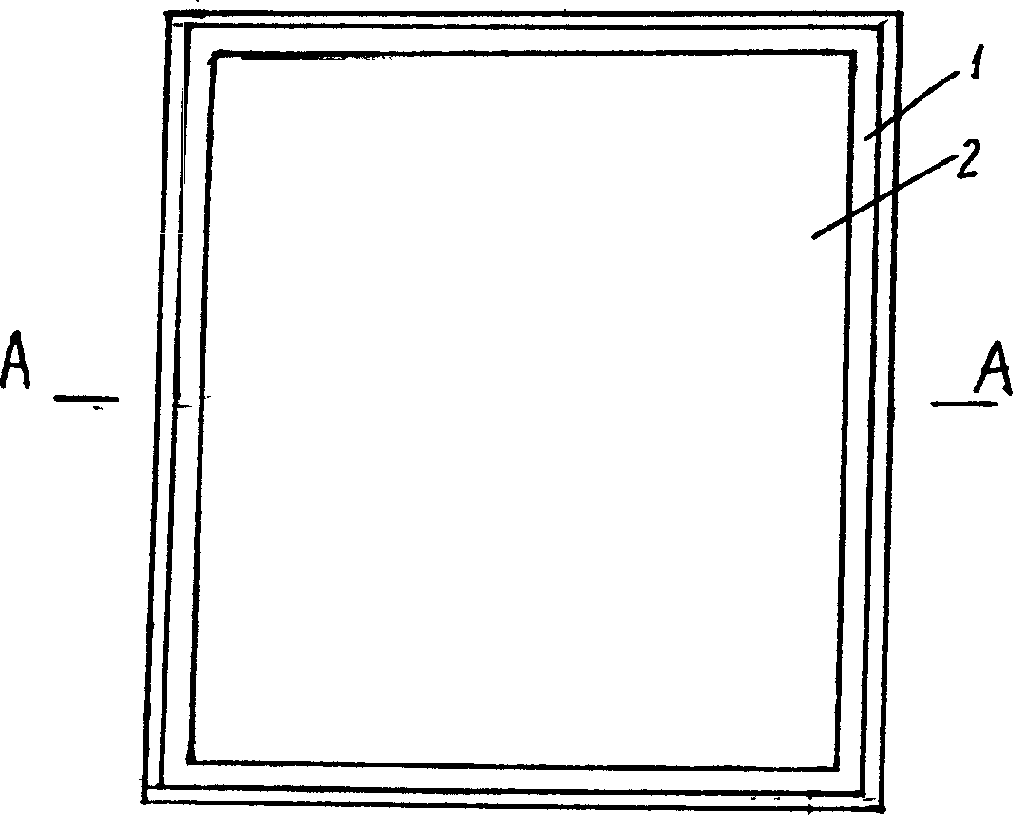

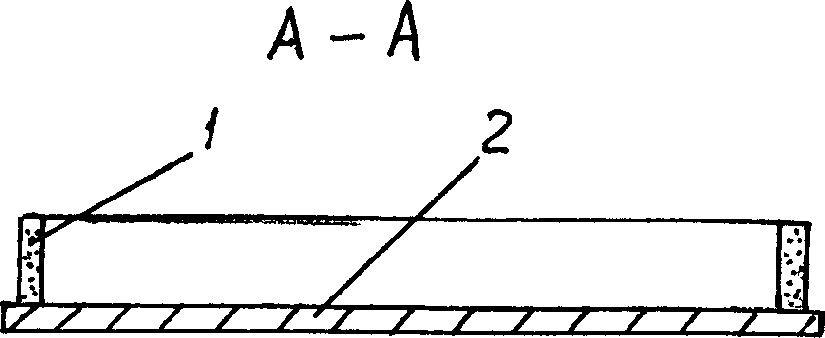

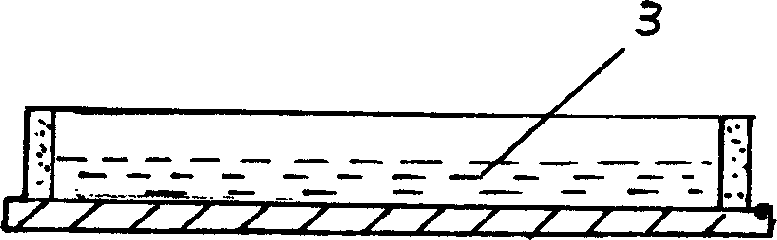

Flame-retardant modified ramie fabric/benzoxazine resin laminated board and preparation method thereof

ActiveCN106079723AImprove flame retardant performanceImprove performanceLamination ancillary operationsLayered product treatmentEngineeringFire retardant

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

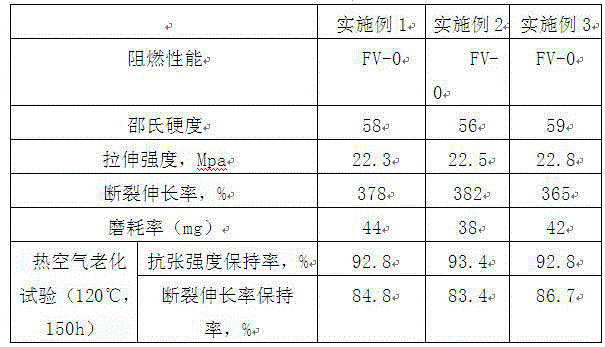

Flame-retardant and wear-resisting rubber material for borehole cable sheath and preparation method of flame-retardant and wear-resisting rubber material

InactiveCN105175824AImprove high temperature resistanceImprove wear resistanceRubber insulatorsPolymer scienceDibenzoyl Peroxide

Owner:华泓喆

Environment-friendly high-flame-retardance foaming material for automobile instrument trim and preparing method of environment-friendly high-flame-retardance foaming material

Owner:YANGZHONG TIANZHENG SYNTHETIC MATERIAL RES CENT

Preparation process of fire and corrosion prevention wooden door

Owner:江苏兄弟智能家居有限公司

Olefin halogen-free flame retardant and preparation method thereof

InactiveCN103360655AGood compatibilityHigh content of active ingredientsPolymer scienceOlefin polymerization

Owner:CHENGDU SOLVER TECH

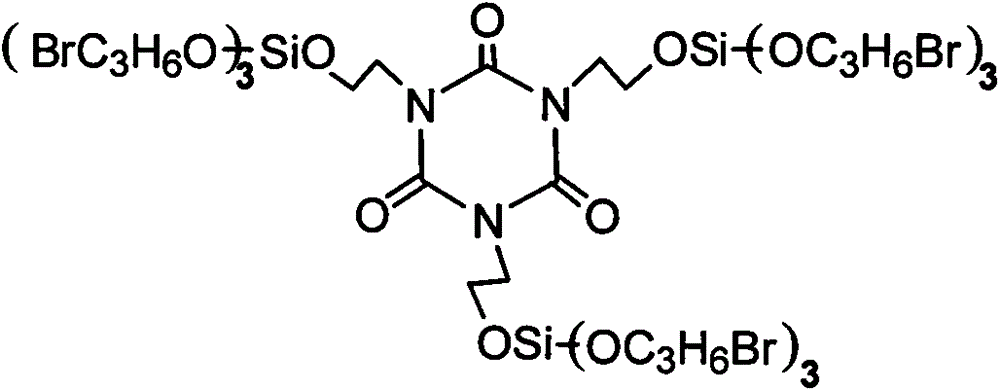

Flame retardant tris(hydroxyethyl) isocyanurate trisilicate propyl bromide compound and preparation method thereof

ActiveCN103554147APrevent secondary combustionHigh synergistic flame retardant performanceSilicon organic compoundsEpoxyPropyl bromide

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Artificial stone and processing method thereof

InactiveCN1541972AReduce manufacturing costImprove fire performanceSynthetic resin layered productsCeramic shaping apparatusHardnessArtificial stone

Owner:赵英春

PC/ABS composite with low-temperature impact resistance and product thereof

The invention specifically relates to a PC / ABS composite with low-temperature impact resistance and a product thereof, belonging to the technical field of high polymer materials. The PC / ABS compositewith low-temperature impact resistance comprises organosilicon-copolymerized PC resin, ABS resin, a flexibilizer, a fire retardant and an inorganic filling material. The product is prepared by moldingthe PC / ABS composite with low-temperature impact resistance. According to the invention, the organosilicon-copolymerized PC resin and the compound flexibilizer with low-temperature impact resistanceare used for the PC / ABS composite, so the PC / ABS composite has excellent notch impact strength at a low temperature after addition of the inorganic filling material.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Preparation method of functional magnesium hydroxide flame retardant and flame retardant prepared through method

Owner:FOSHAN JUCHENG BIOCHEM TECH RES & DEV CO LTD

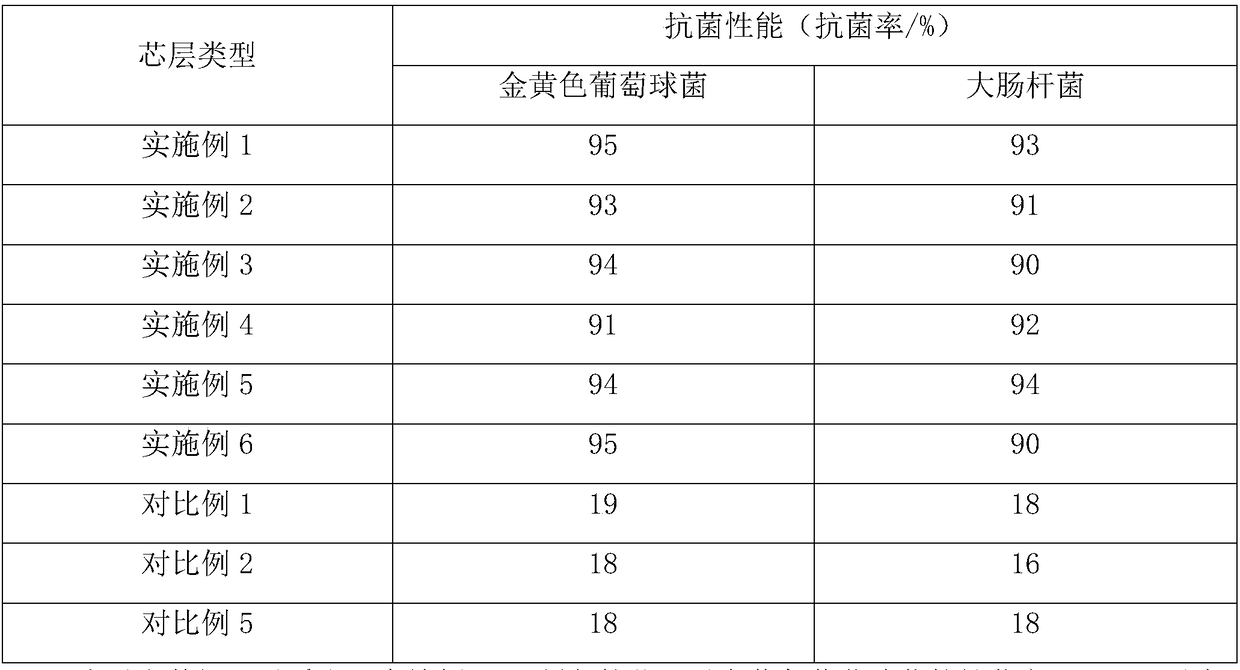

Preparation method of sterilizing PET (Polyethylene Terephthalate) plastic

Owner:东莞市金顺包装材料有限公司

High-thermal-filament ignition polyphenyl ether composition as well as preparation method and application thereof

The invention discloses a high-thermal-filament ignition polyphenyl ether composition. The polyphenyl ether composition comprises the following components in parts by weight: 40-90 parts of polyphenylether, 2-40 parts of styrene resin, 1-10 parts of a toughening agent, 5-18 parts of a flame retardant, 0.1-3 parts of polyformaldehyde resin and 0.1-1 part of metal oxide. According to the heat-resistant wire ignition polyphenyl ether material, the quality of a carbon layer is greatly enhanced through the catalytic charring effect of metal oxide and POM in the early stage of ignition, the HWI performance of the material is obviously improved, a good effect on flame retardance is achieved, and the flame-retardant PPE material with the 0-grade HWI can be prepared through the method.

Owner:KINGFA SCI & TECH CO LTD

Sponge abrasive material and preparation method thereof

InactiveCN108000377AAvoid indistinguishableRealization of long-term continuous productionAbrasion apparatusFire retardantUltimate tensile strength

The invention discloses a sponge abrasive material and a preparation method thereof, and relates to the field of abrasive materials. The sponge abrasive material comprises the following components of,by weight, 0.999-1 part of a polyurethane elastic material, 0.001-0.01 part of color paste, 1-20 parts of hard abrasive materials and 0.02-0.08 part of a flame retardant, the hard abrasive materialsare evenly distributed between foam formed by the polyurethane elastic material and the flame retardant, the color paste has different colors, and the hard abrasive materials are one or several of steel sand, brown corundum, garnet and the like. The sponge abrasive material and the preparation method thereof have the beneficial effects that the problem that the type of the hard abrasive materialsis difficult to distinguish after the hard abrasive materials are wrapped with polyurethane sponge is avoided, according to the preparation method of the sponge abrasive material, the wrapping strength of the sponge abrasive material is improved, the service life is prolonged, meanwhile, the problem of continuous production of the sponge abrasive material is solved, the efficiency is improved, theyield is increased,, and consumption is reduced.

Owner:SHANDONG TAA CLOUD IND ENG TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap