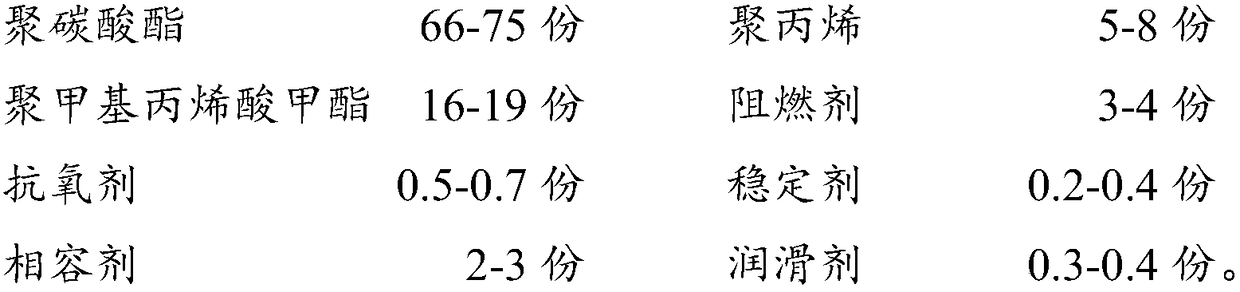

High-temperature-resisting and high-strength lamp cover material composition

A material composition and a technology of the composition are applied in the field of high-strength lampshade material composition and high temperature resistance, which can solve the problems of being ignited, hidden dangers, low strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

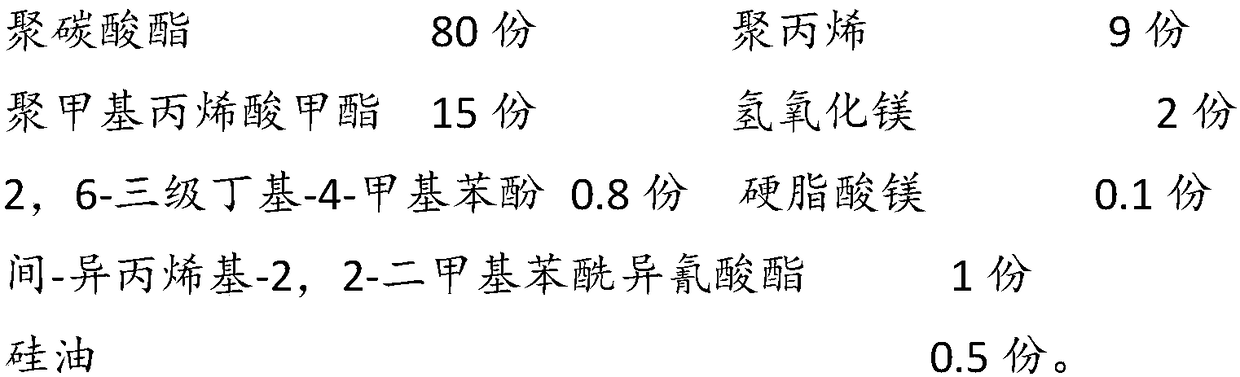

Embodiment 1

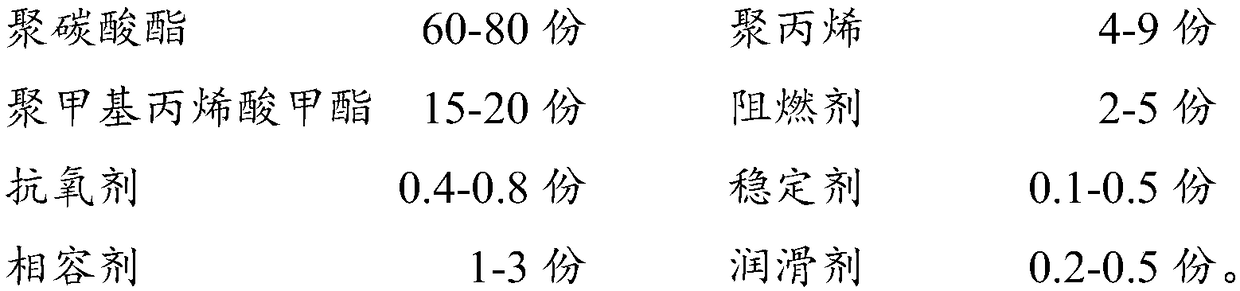

[0023] High-temperature-resistant, high-strength lampshade material composition, the composition is in parts by mass:

[0024]

[0025] The preparation method is:

[0026] Weighing components of polycarbonate, polypropylene, polymethylmethacrylate, magnesium hydroxide, 2,6‐tertiary butyl‐4‐methylphenol, magnesium stearate, m‐isopropenyl‐2 , 2‐Dimethylbenzoyl isocyanate and silicone oil;

[0027] Mixing polycarbonate, polypropylene and polymethyl methacrylate into a pulverizer, pulverizing to 20 mesh, to obtain a mixture a, set aside;

[0028] Add magnesium hydroxide, 2,6-tertiary butyl-4-methylphenol, magnesium stearate, m-isopropenyl-2,2-dimethylbenzoyl isocyanate and silicone oil into a high-speed mixer, and stir Speed is 320r / min, and stirring time is 4min, obtains mixture b;

[0029] Add the mixture a and the mixture b into the low-speed mixer, the stirring speed is 80r / min, the stirring time is 20min, and the mixture c is obtained;

[0030] Add the compound c to

Embodiment 2

[0033] High-temperature-resistant, high-strength lampshade material composition, the composition is in parts by mass:

[0034]

[0035] The preparation method is:

[0036] Weighing components of polycarbonate, polypropylene, polymethyl methacrylate, monoammonium phosphate, bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide, aluminum stearate, m- Isopropenyl-2,2-dimethylbenzoyl isocyanate and silicates;

[0037] Mix polycarbonate, polypropylene and polymethyl methacrylate into a pulverizer, pulverize to 25 mesh to obtain a mixture a, set aside;

[0038] Monoammonium phosphate, bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide, aluminum stearate, m-isopropenyl-2,2-dimethylbenzoyl isocyanate and silicate Add it into a high-speed mixer, the stirring speed is 310r / min, and the stirring time is 4min to obtain the mixture b;

[0039] Add the mixture a and the mixture b into the low-speed mixer, the stirring speed is 70r / min, the stirring time is 22min, and the mixture c is obtained

Embodiment 3

[0043] High-temperature-resistant, high-strength lampshade material composition, the composition is in parts by mass:

[0044]

[0045]

[0046] The preparation method is:

[0047] Weighing components of polycarbonate, polypropylene, polymethyl methacrylate, ammonium chloride and boric acid, 2,6-tertiary butyl-4-methylphenol, potassium stearate, m-isopropenyl ‐2,2‐Dimethylbenzoyl isocyanate and fluorine oil;

[0048] Mix polycarbonate, polypropylene and polymethyl methacrylate into a pulverizer, pulverize to 40 mesh to obtain a mixture a, set aside;

[0049] Add ammonium chloride and boric acid, 2,6-tertiary butyl-4-methylphenol, potassium stearate, m-isopropenyl-2,2-dimethylbenzoyl isocyanate and fluorine oil to a high-speed mixer In, stirring speed is 240r / min, and stirring time is 8min, obtains mixture b;

[0050] Add mixture a and mixture b into a low-speed mixer with a stirring speed of 40 r / min and a stirring time of 30 minutes to obtain mixture c;

[0051] Ad

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap