Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Polycarbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a unique resin identification code (RIC) and are identified as "Other", 7 on the RIC list.

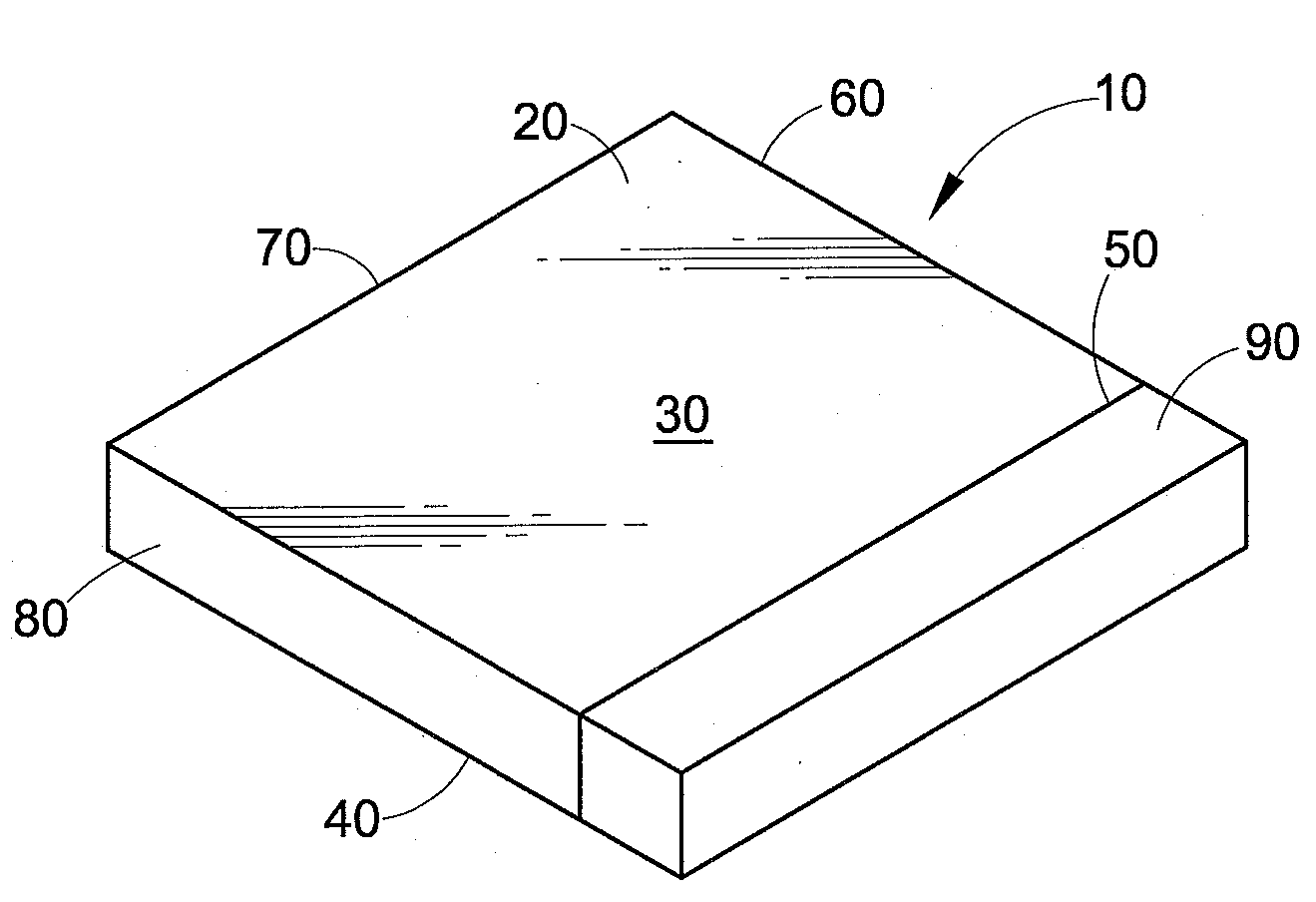

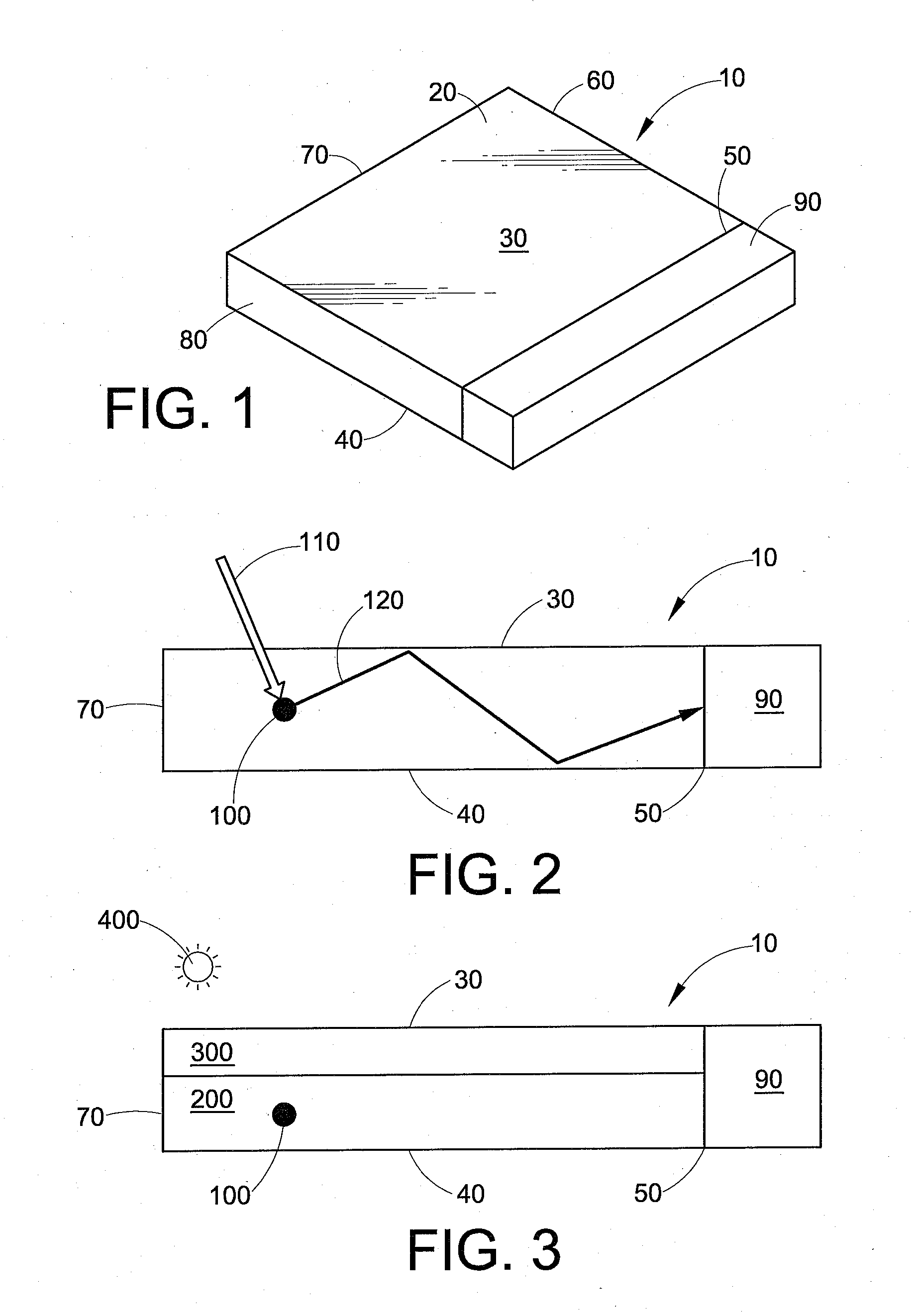

Luminescent solar collector

Owner:SABIC GLOBAL TECH BV

Cleaning member, image forming apparatus provided with a cleaning blade member, and process cartridge detachably attachable on the image forming apparatus

A cartridge detachably attachable on an image forming apparatus a photosensitive member as an image bearing member and a cleaning blade member polycarbonate resin having a viscosity average molecular weight of 1.5x104 or less is blended with the surface layer of the image bearing member, and the peak value of tan delta of the dynamic viscoelastic characteristic of the cleaning blade member appears at 12 DEG C. or less.

Owner:CANON KK

Modified weatherable polyester molding composition

Owner:GENERAL ELECTRIC CO

Scratch-resistant Layered Composite and Articles

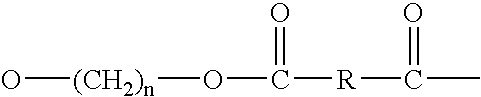

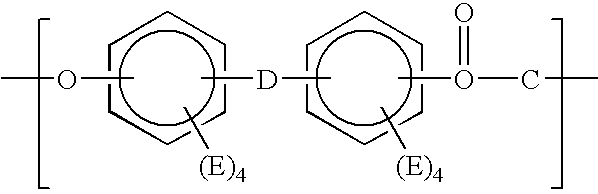

InactiveUS20080254299A1Synthetic resin layered productsCellulosic plastic layered productsPolycarbonateRepeat unit

Owner:SABIC INNOVATIVE PLASTICS IP BV

Method for preparing polycarbonate with continuous two-phase interface phosgene method

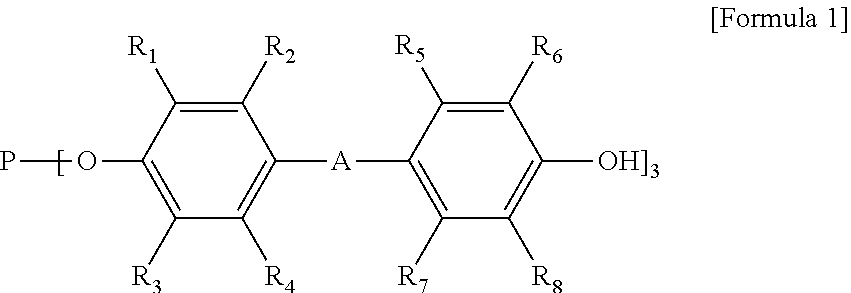

The invention relates to a novel method for preparing polycarbonate with a continuous two-phase interface phosgene method, comprising the following steps: carrying out photochemical reaction on alkali metal hydroxide solution and organic phase to prepare polycarbonate oligomer emulsion, wherein bisphenol or polyphenol or mixture of the bisphenol and the polyphenol is dissolved in the alkali metal hydroxide solution, the alkali metal hydroxide solution accounts for 95-99.5 percent of the weight in the formula, and the organic phase contains phosgene; and carrying out coupling reaction on the polycarbonate oligomer emulsion and the residual alkali metal hydroxide solution to finally prepare polycarbonate resin. The method for preparing the polycarbonate with the continuous two-phase interface phosgene method is simpler in process than the existing method for preparing the polycarbonate, and the loss of the phosgene and the alkali liquor is reduced effectively.

Owner:WANHUA CHEM GRP CO LTD +1

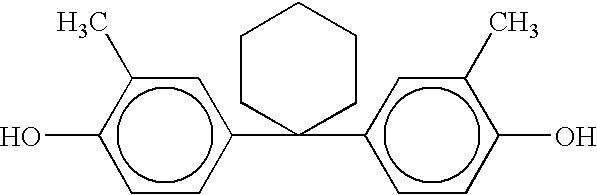

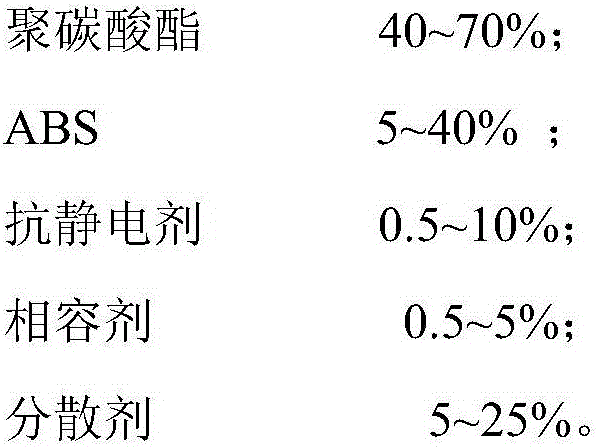

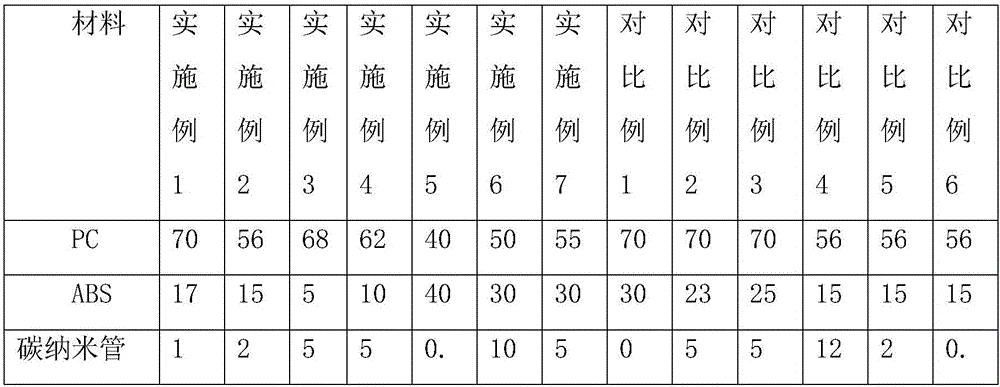

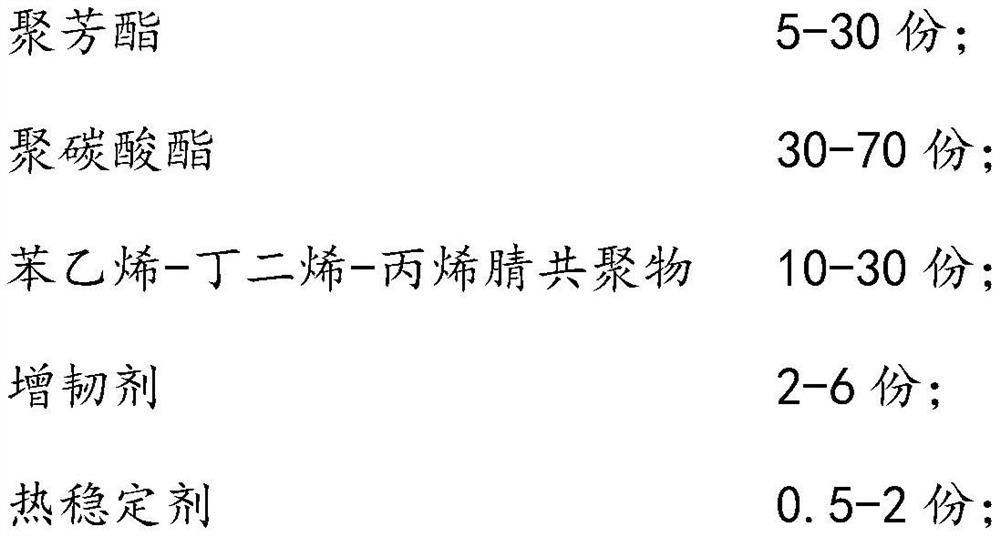

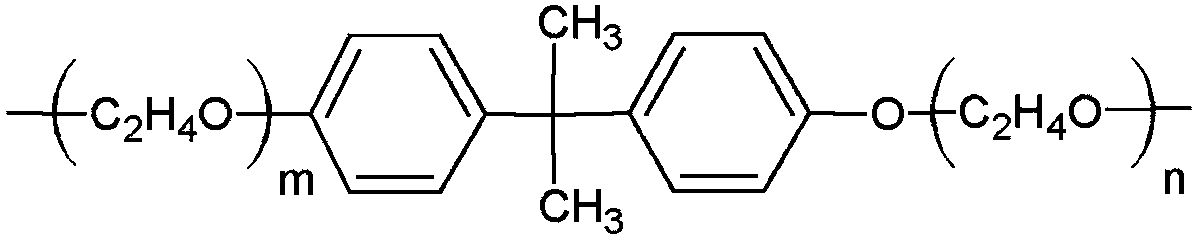

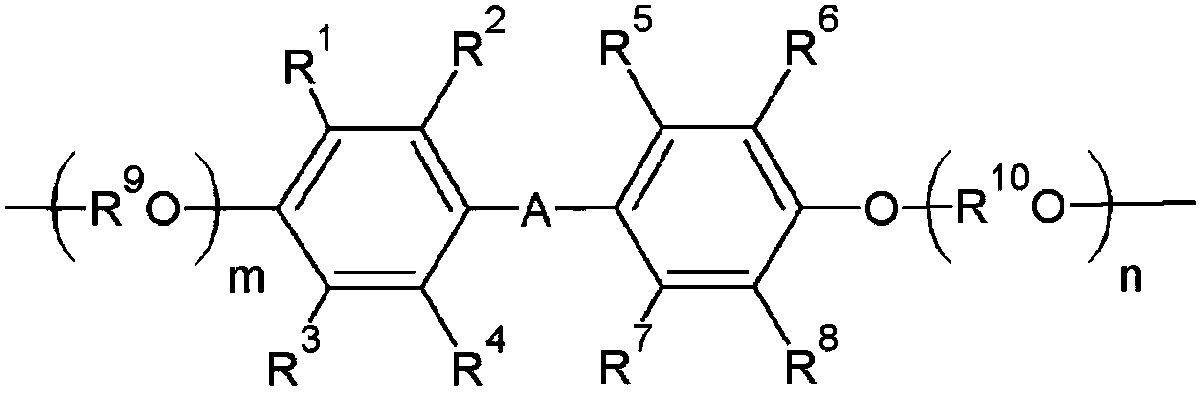

Efficient anti-static PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) composite material and preparation method thereof

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

Carbon nanotube filled polycarbonate Anti-curl back coating with improved electrical and mechanical properties

Transparent or semi-transparent, electrically conductive anti-curl back coating composite for electrophotographic imaging member comprising a carbon nanotube complex and a polycarbonate binder are described along with processes for preparing them.

Owner:XEROX CORP

Preparation method of waterborne polyurethane emulsion and waterborne polyurethane emulsion prepared by preparation method

InactiveCN104211902AImprove waterproof performanceGood solvent resistanceHydroxybutyric acidPolymer science

Owner:内蒙古源创绿能节能环保产业创业投资合伙企业(有限合伙)

Anti-bacterial and mouldproof plastic

The invention discloses anti-bacterial and mouldproof plastic. The anti-bacterial and mouldproof plastic comprises the following substances by weight: 14-18 parts of cinnamyl aldehyde, 18-28 parts of POE, 2-5 parts of copper, 2-3 parts of glycerol triglycerate, 4-7 parts of polyvinyl ester, 3-7 parts of magnesium sulfate, 3-12 parts of polypropylene, 6-10 parts of a bisphenol A type polycarbonate, 5-8 parts of an active resin binder, 6-12 parts of triethanolamine, 2-6 parts of vinyl triethoxysilane and 8-16 parts of a drier. With the above technical solution, raw materials are easily available, and cost is low. By adding the drier, the surface of the plastic can be maintained relatively dry; an environment for microbial growth is broken; propagation of microbes is effectively suppressed; and mouldiness can be prevented.

Owner:JIANGSU XINRUN PLASTIC CO LTD

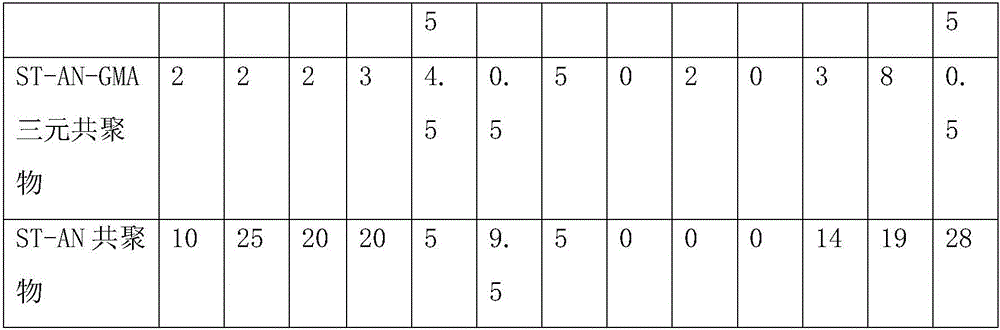

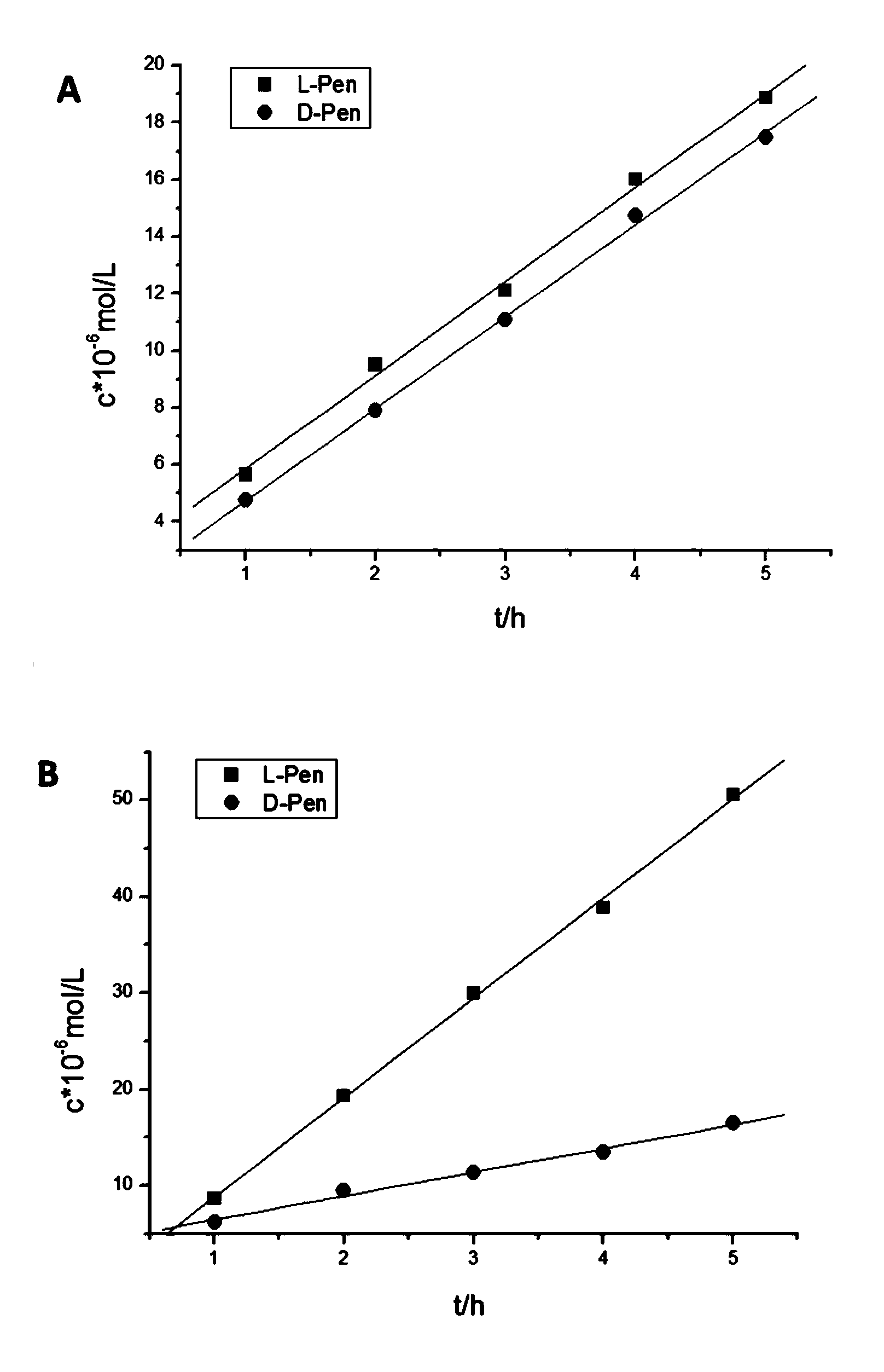

Method of separating chiral drug penicillamine enantiomer based on functional gold nanochannel

Owner:SHANGHAI NORMAL UNIVERSITY

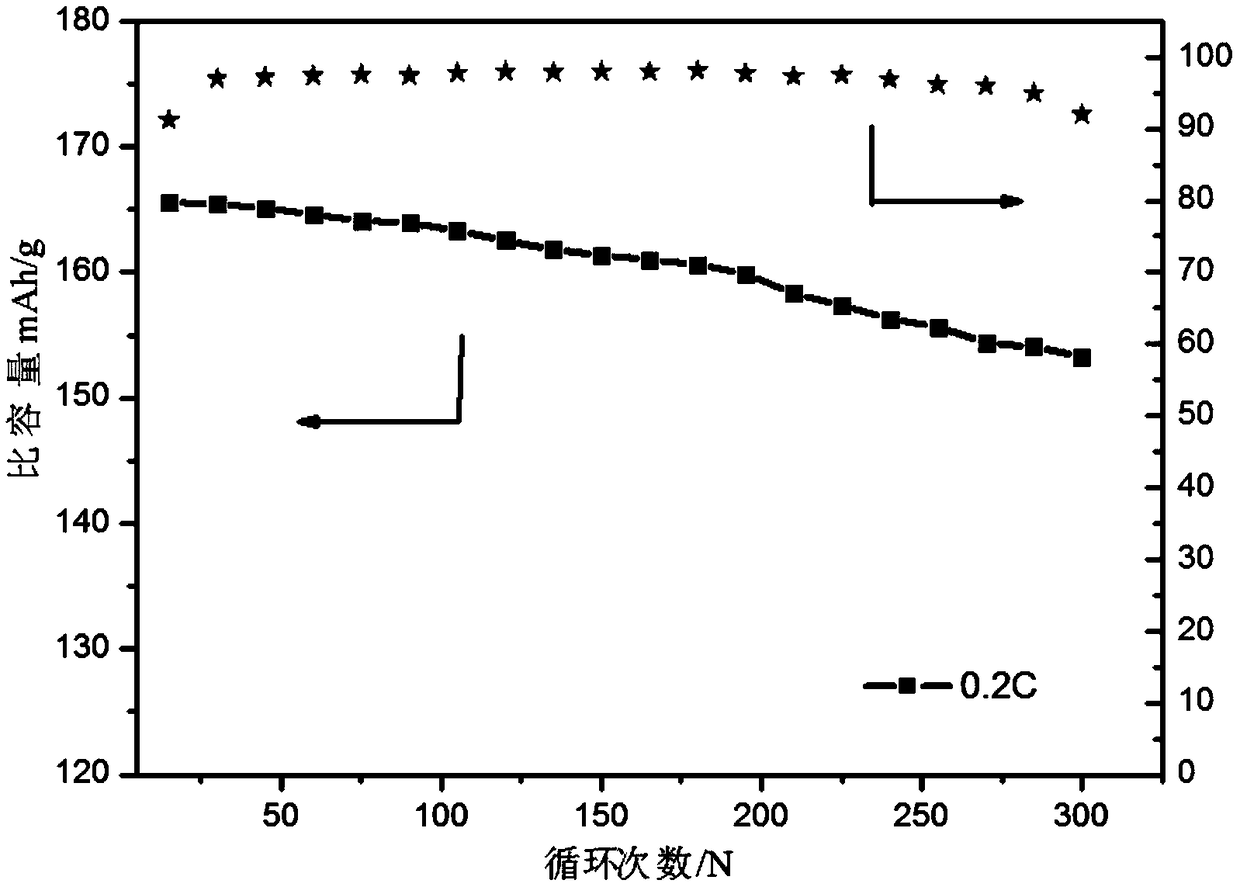

Surface treatment process of lithium metal anode and application thereof

ActiveCN108711609AImprove stabilityAvoid reactionSecondary cellsImpregnation manufacturingPolyethylene oxideElectrical conductor

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

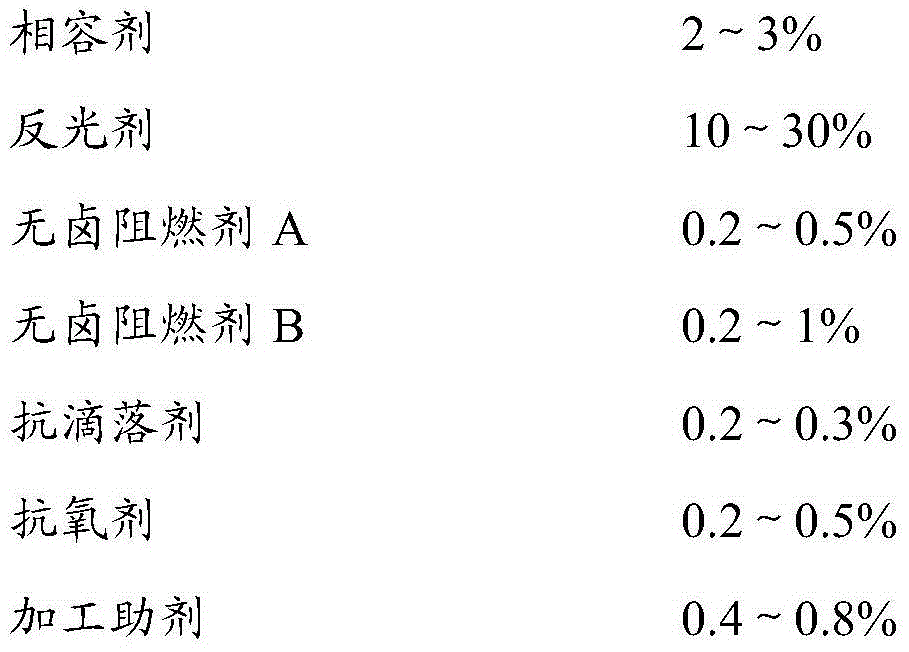

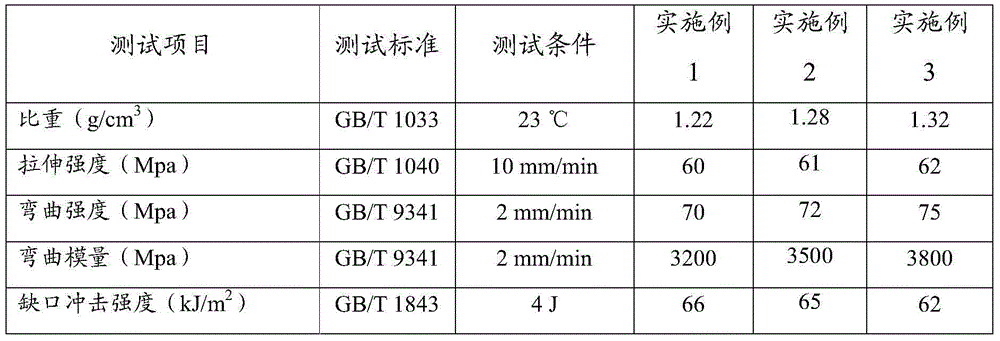

High-toughness halogen-free flame-retardant PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) alloy reflecting material and preparation method thereof

Owner:GUANGDONG WAYLAM ENG PLASTICS

Impact-resistant composite insulating material and preparing method thereof

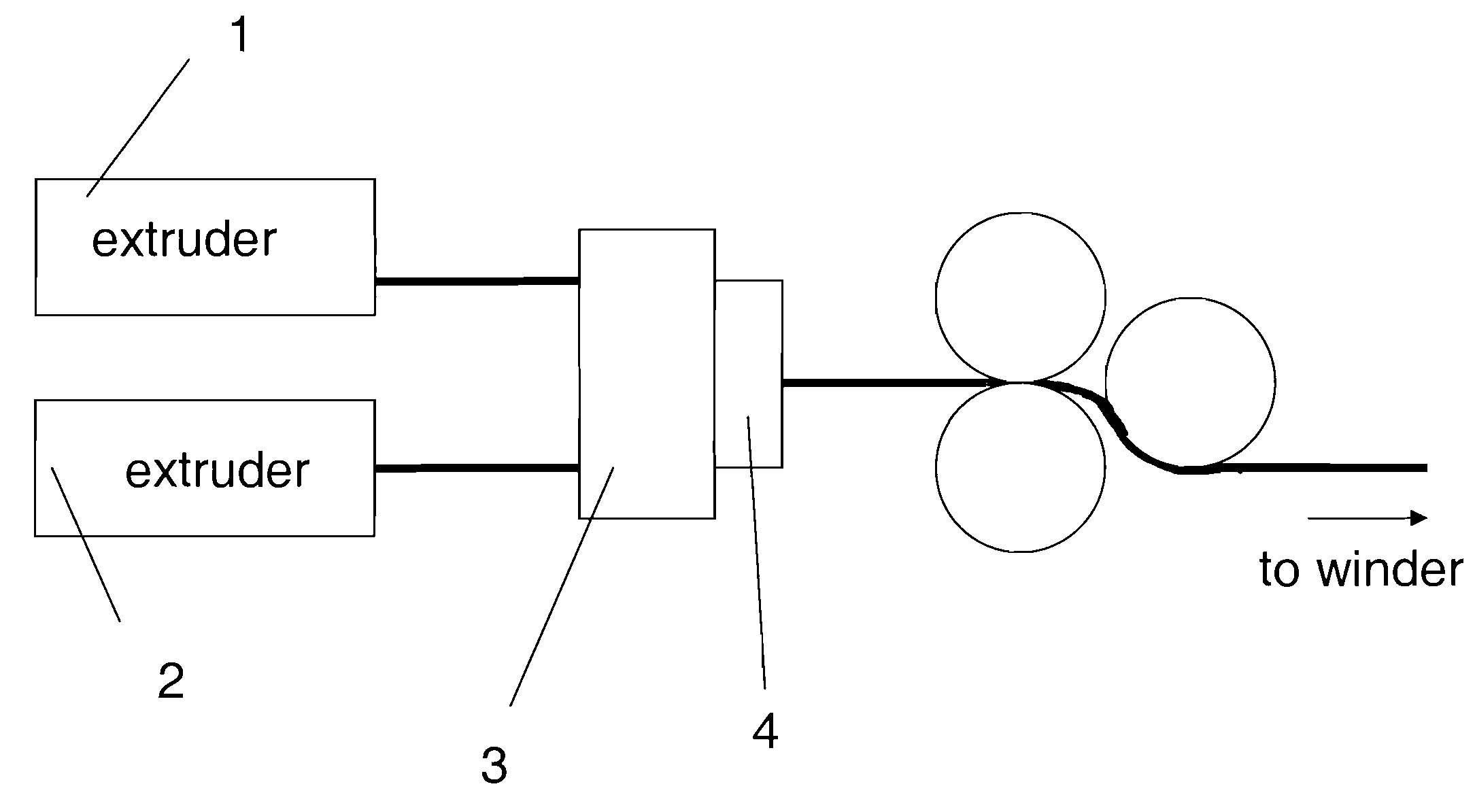

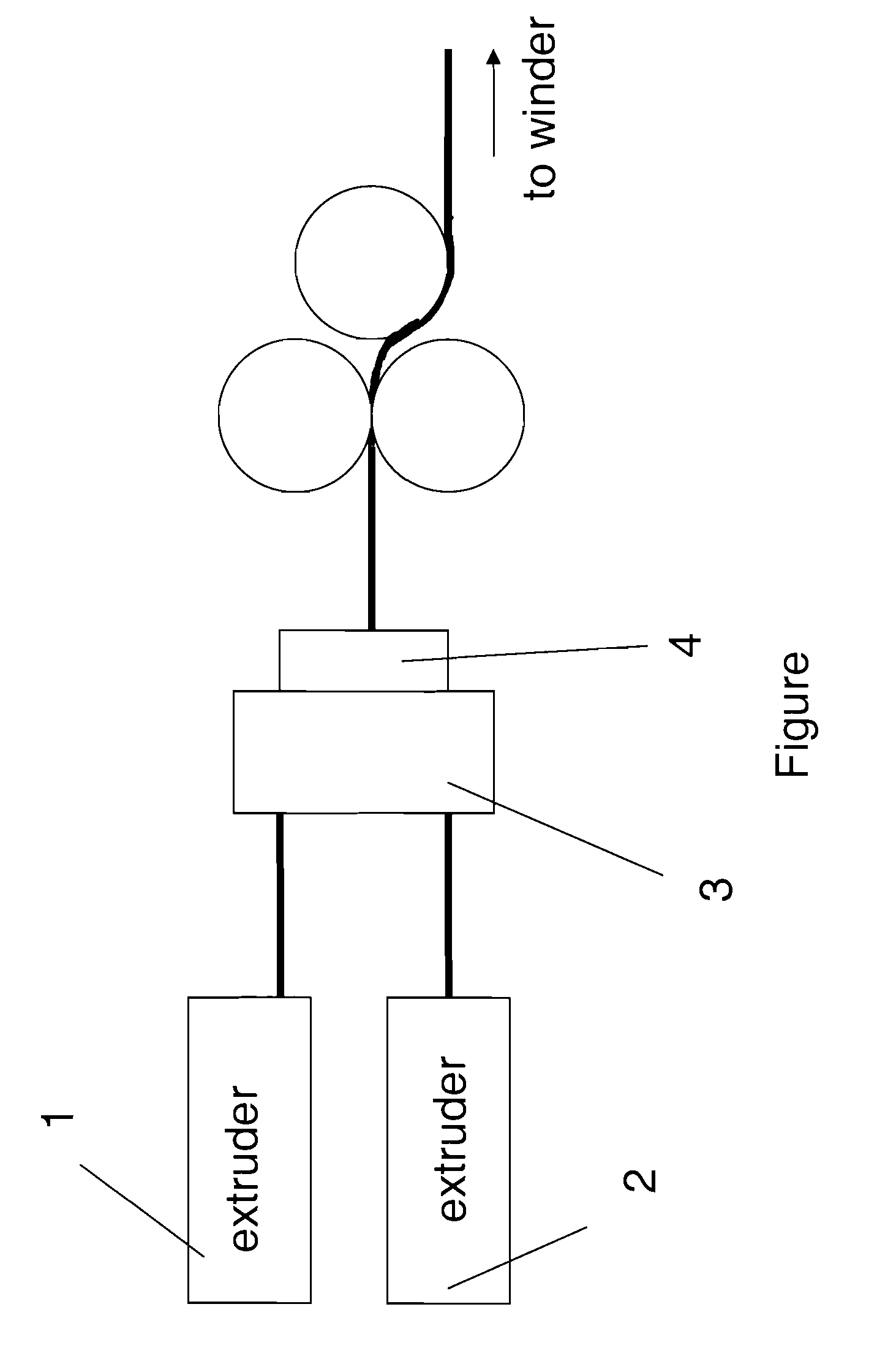

The invention discloses an impact-resistant composite insulating material and a preparing method thereof. The insulating material is prepared from 4-10 parts of polyimide resin, 3-6 parts of glass fibers, 5-12 parts of bisphenol-S epoxy resin, 5-15 parts of polycarbonate, 4-8 parts of dodecyl acrylate, 3-7 parts of dodecanol polyethenoxy ether, 2-5 parts of ethylene bis-oleamide, 3-6 parts of styrylphenol polyoxyethylene ether, 4-10 parts of phenolic epoxy vinyl ester resin and 2-5 parts of polyvinyl cinnamate. The preparing method includes the following steps that 1, the components are thrown into a high-speed mixer to be mixed; 2, the insulating material mixture mixed evenly is taken out of the high-speed mixer and extruded through a double-screw extruder; 3, the material extruded in the step 2 is granulated, and the impact-resistant composite insulating material is obtained after the granulated material is cooled to normal temperature.

Owner:SUZHOU YIXINYUAN PHOTOELECTRIC TECH

High-impact flame-retardant reinforced PC/ABS alloy material and preparation method thereof

Owner:四川鑫达企业集团有限公司

Environment-friendly plastic material and preparation method thereof

The invention discloses an environment-friendly plastic material and a preparation method thereof. The preparation method comprises the following steps that 1, ball milling is performed on calcium sulfate and magnesium oxide through a ball mill, the ball milling time is 3-5 h, and the ratio of grinding media to the materials is 20:1-30:1; 2, 12-20 parts of polyamide-1010, 5-10 parts of polycarbonate, 4-9 parts of alkyd resin, 4-8 parts of polyvinyl alcohol, 3-8 parts of calcium sulfate, 4-10 parts of magnesium oxide, 2-6 parts of polytrimethylene terephthalate, 3-8 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 2-6 parts of polybutyl methacrylate and 4-10 parts of polyparahydroxybenzoic acid are weighed by weight, all the components are extruded inside a double-screw extruder, and the extruded components are the environment-friendly plastic material. The obtained plastic material effectively overcomes the defects that the tensile strength and the elongation at break of the conventional plastic material are low, and the mechanical performance of the plastic material is improved.

Owner:SUZHOU SHURUI ENVIRONMENTAL PROTECTION TECH CO LTD

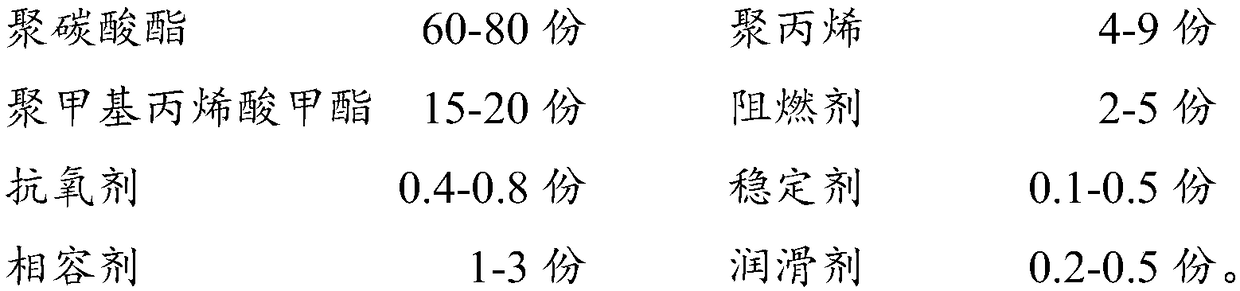

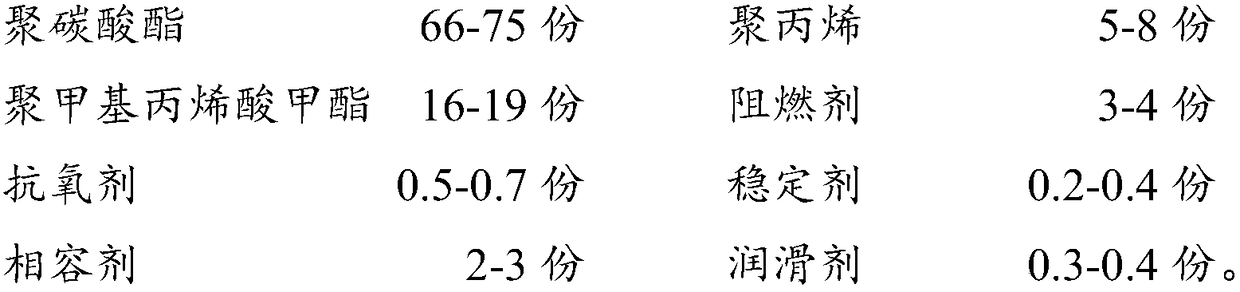

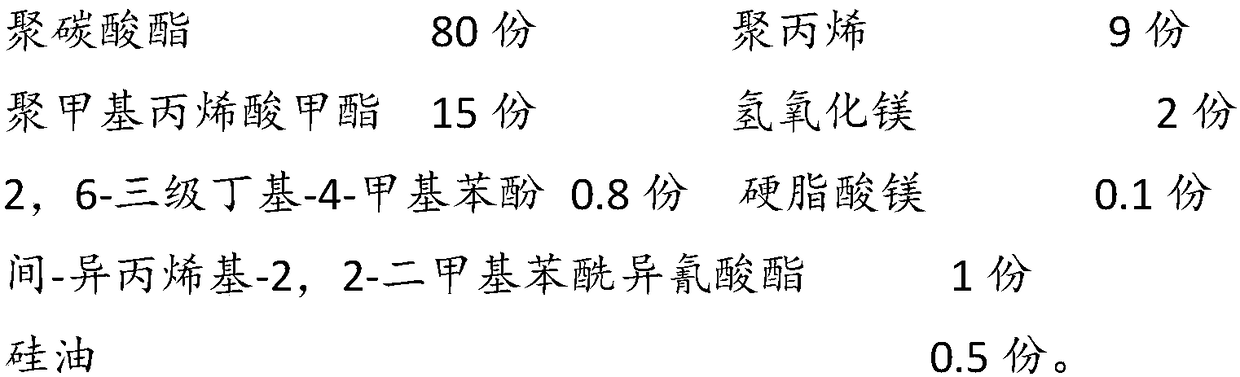

Shell plastic for computer display screens and preparation method of shell plastic

InactiveCN107163494AGood acid and alkali resistanceGood high temperature resistancePolyvinyl chlorideEngineering

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

Polyester alloy composition for improving high-temperature welding performance and application thereof

Owner:安庆会通新材料有限公司

PMMA/PC-based high-performance polaroid

InactiveCN113093323AReduce manufacturing costImprove performancePolarising elementsCoatingsGlass fiberPolymer science

Owner:SOUTHWEAT UNIV OF SCI & TECH

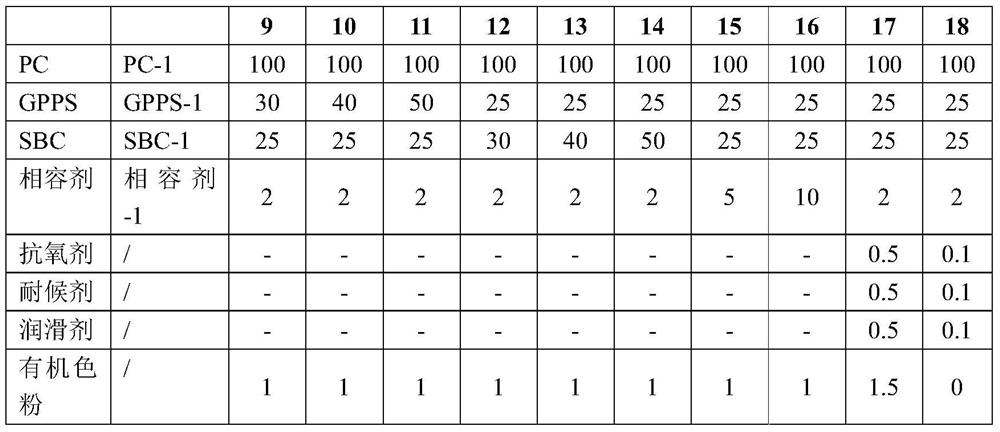

Injection-molded foam of resin composition with satisfactory surface property and capable of weight reduction and rib design

Owner:KANEKA CORP

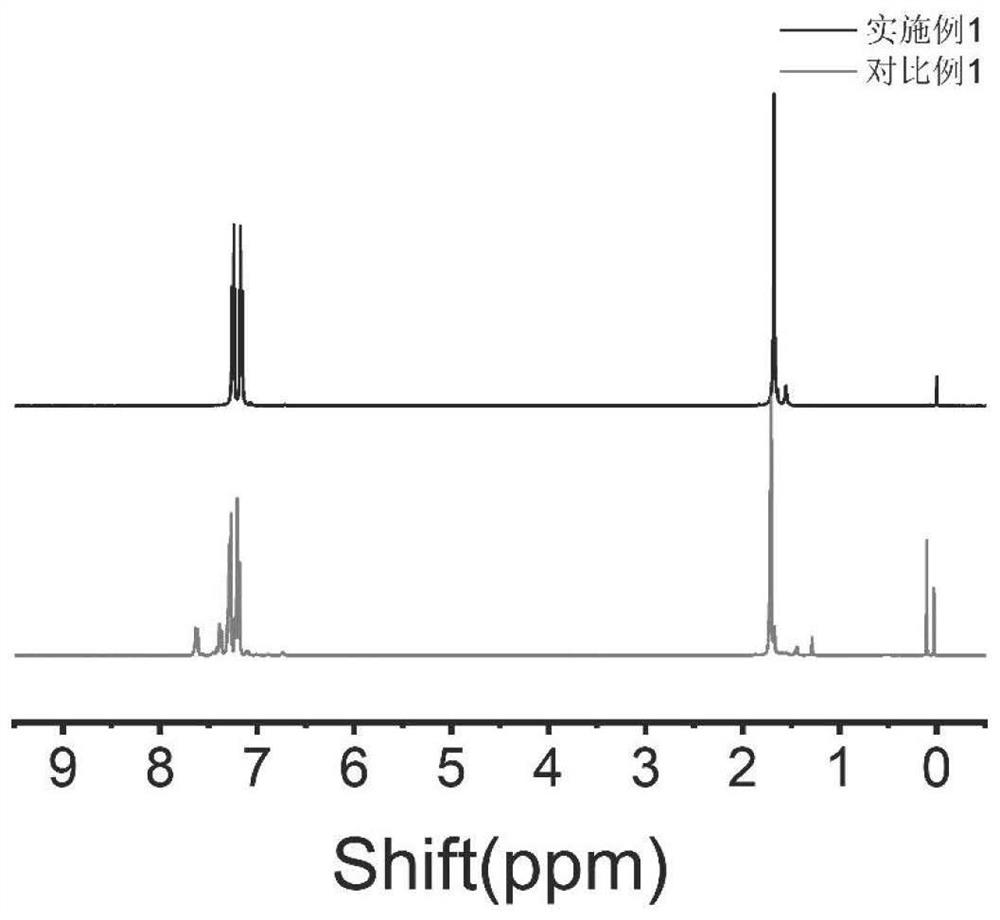

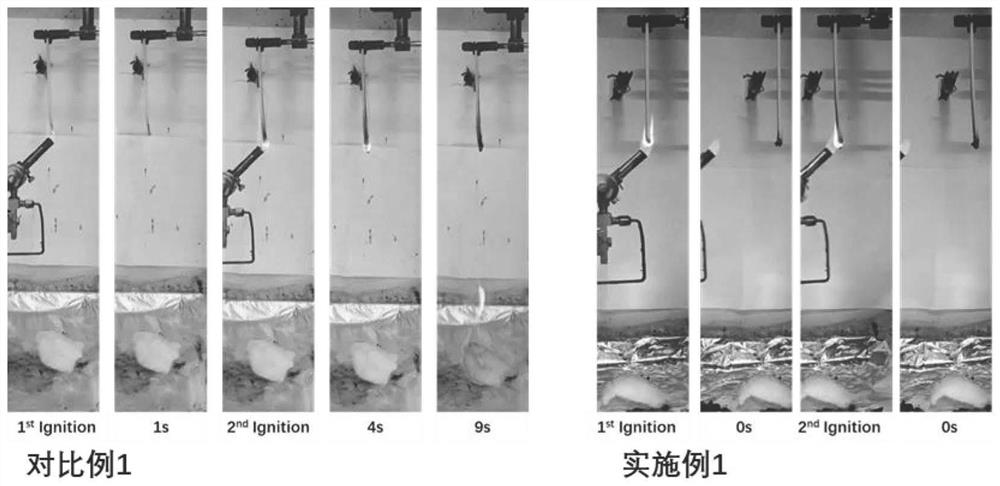

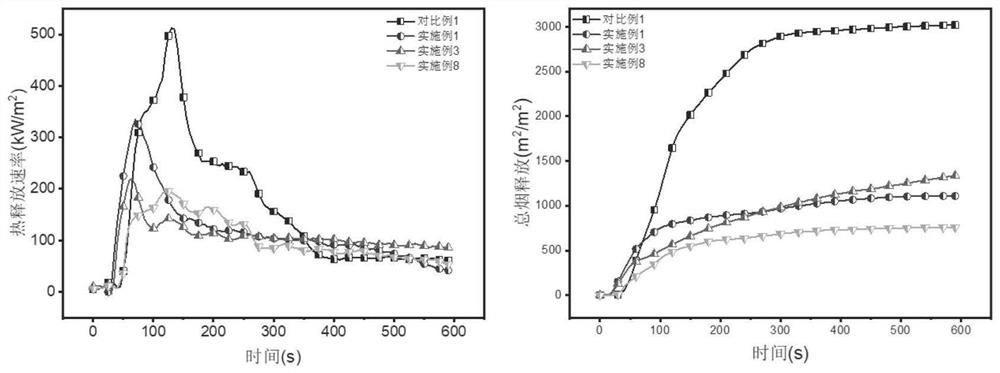

Low-smoke low-heat intrinsic flame-retardant copolycarbonate as well as preparation method and application thereof

Owner:SICHUAN UNIV

High-strength durable polylactic acid and preparation method thereof

The invention relates to high-strength durable polylactic acid and a preparation method thereof, belongs to the technical field of composite materials, and aims to solve the technical problems of lowmechanical strength and poor durability of polylactic acid in the prior art. The high-strength durable polylactic acid is prepared from 100 parts by weight of polylactic acid, 5 to 8 parts by weight of poly(butylene adipate-co-terephthalate) resin, 3 to 5 parts by weight of 2-(3,4-dihydroxyphenyl)ethylamine, 4.5 to 7.5 parts by weight of polycarbonate, 1 to 2 parts by weight of wood flour, 2 to 4parts by weight of silane coupling agent, 1 to 3 parts by weight of antioxidant, 1.5 to 3 parts by weight of polyethylene wax, 2.5 to 3 parts by weight of ethylene-vinyl acetate copolymer, 1 to 2 parts by weight of wollastonite powder, 0.5 to 1.5 parts by weight of ultraviolet light absorber, 1 to 3 parts by weight of sodium phosphite and 0.5 to 1 part by weight of heat stabilizer. The high-strength durable polylactic acid has high mechanical performance and high durability.

Owner:CHANGCHUN YUNCHUANG SPACE TECH CO LTD

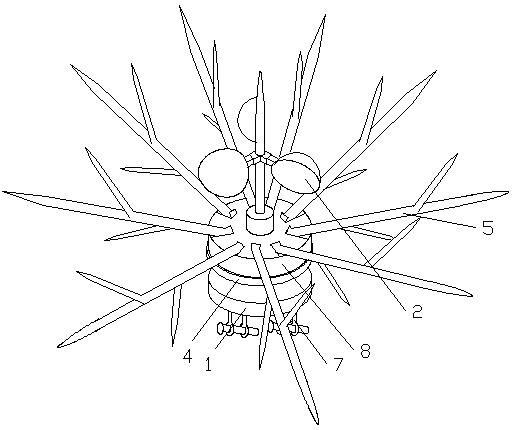

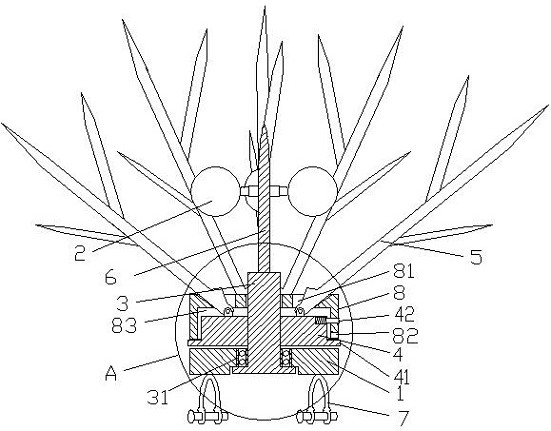

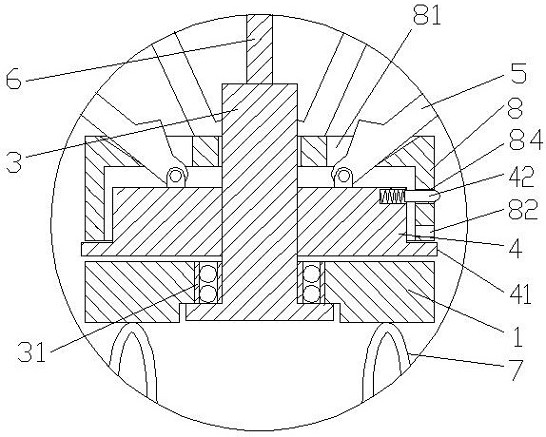

Insulated rotary anti-bird device and use method thereof

Owner:PUYANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER +1

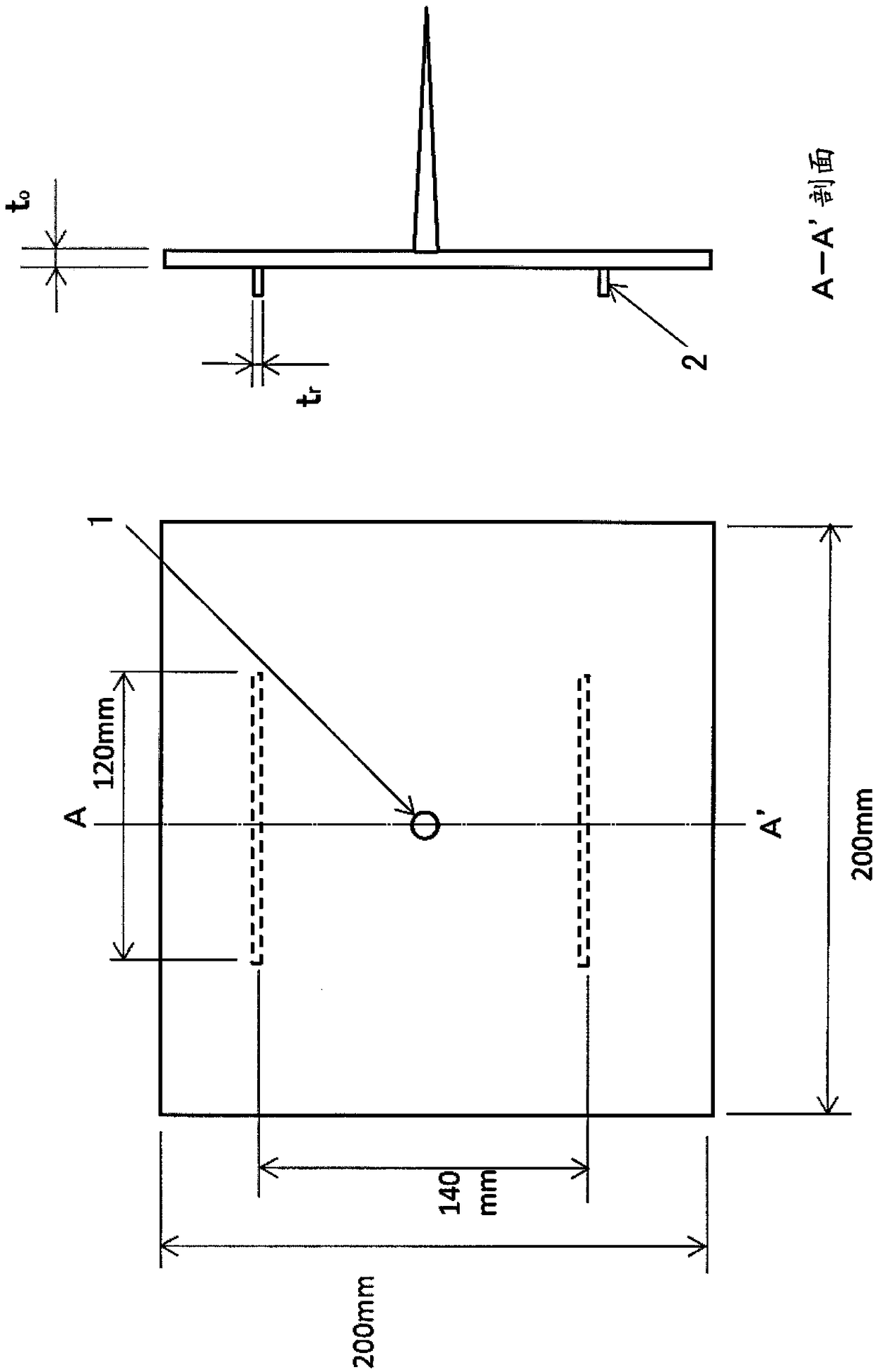

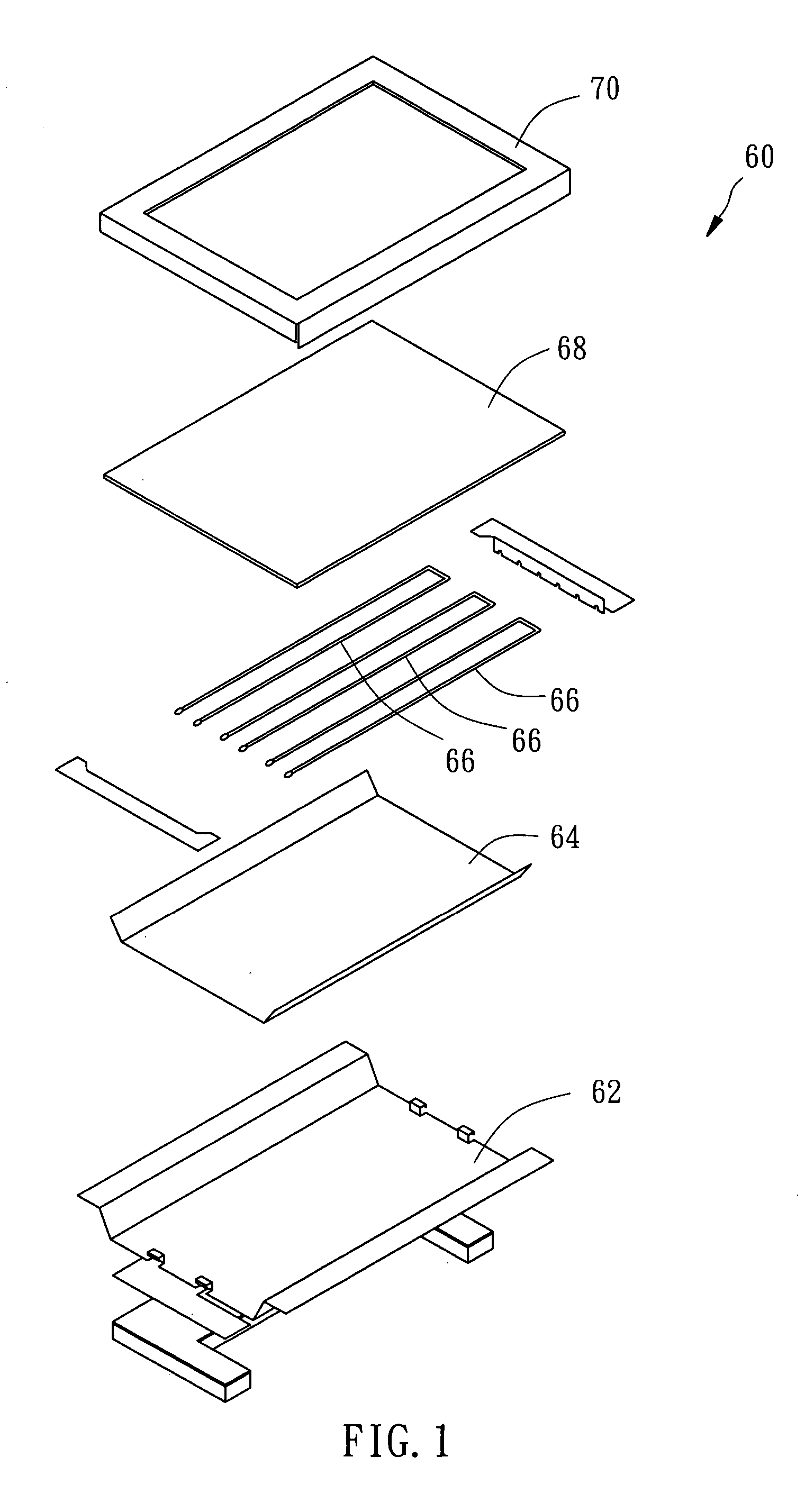

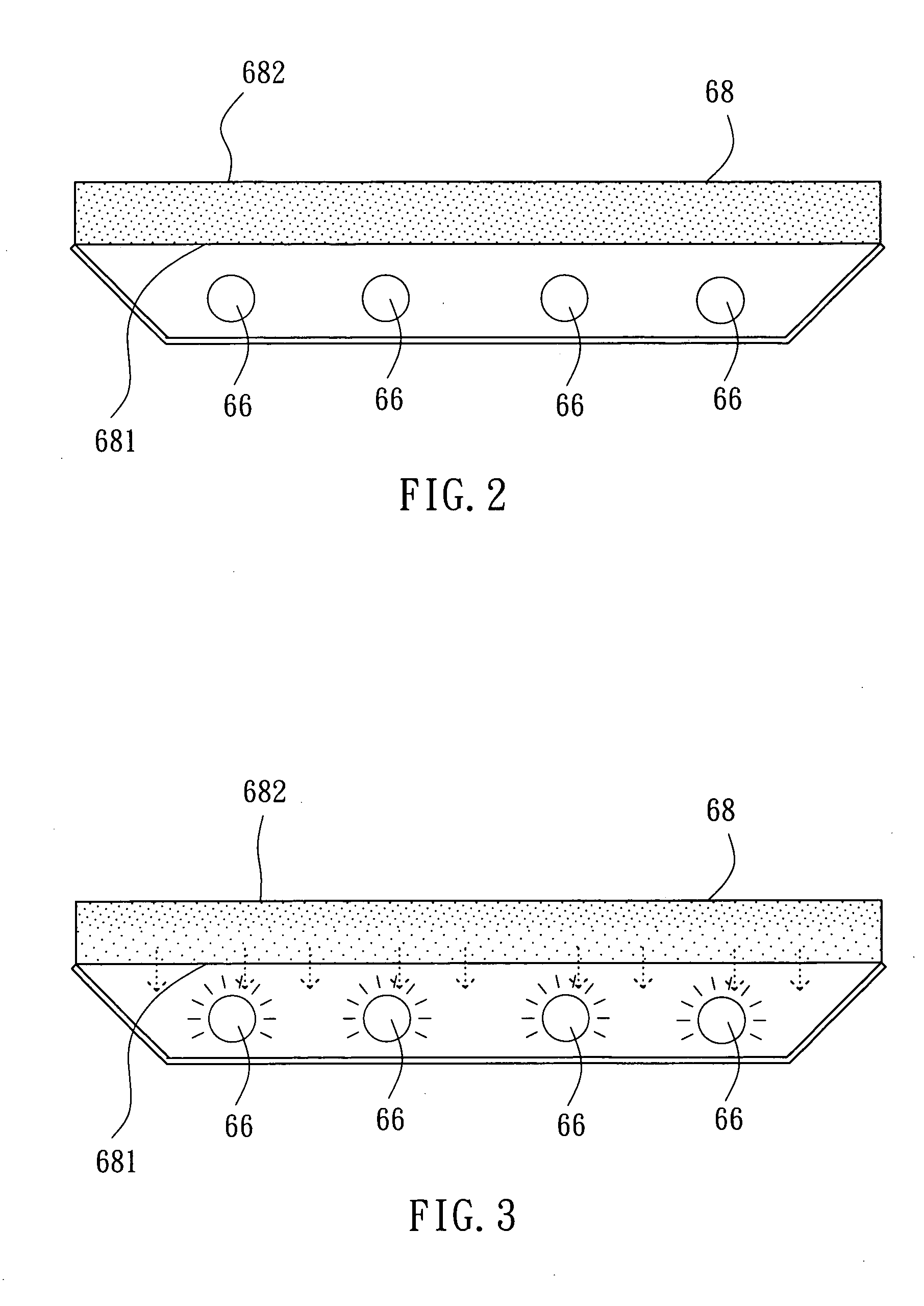

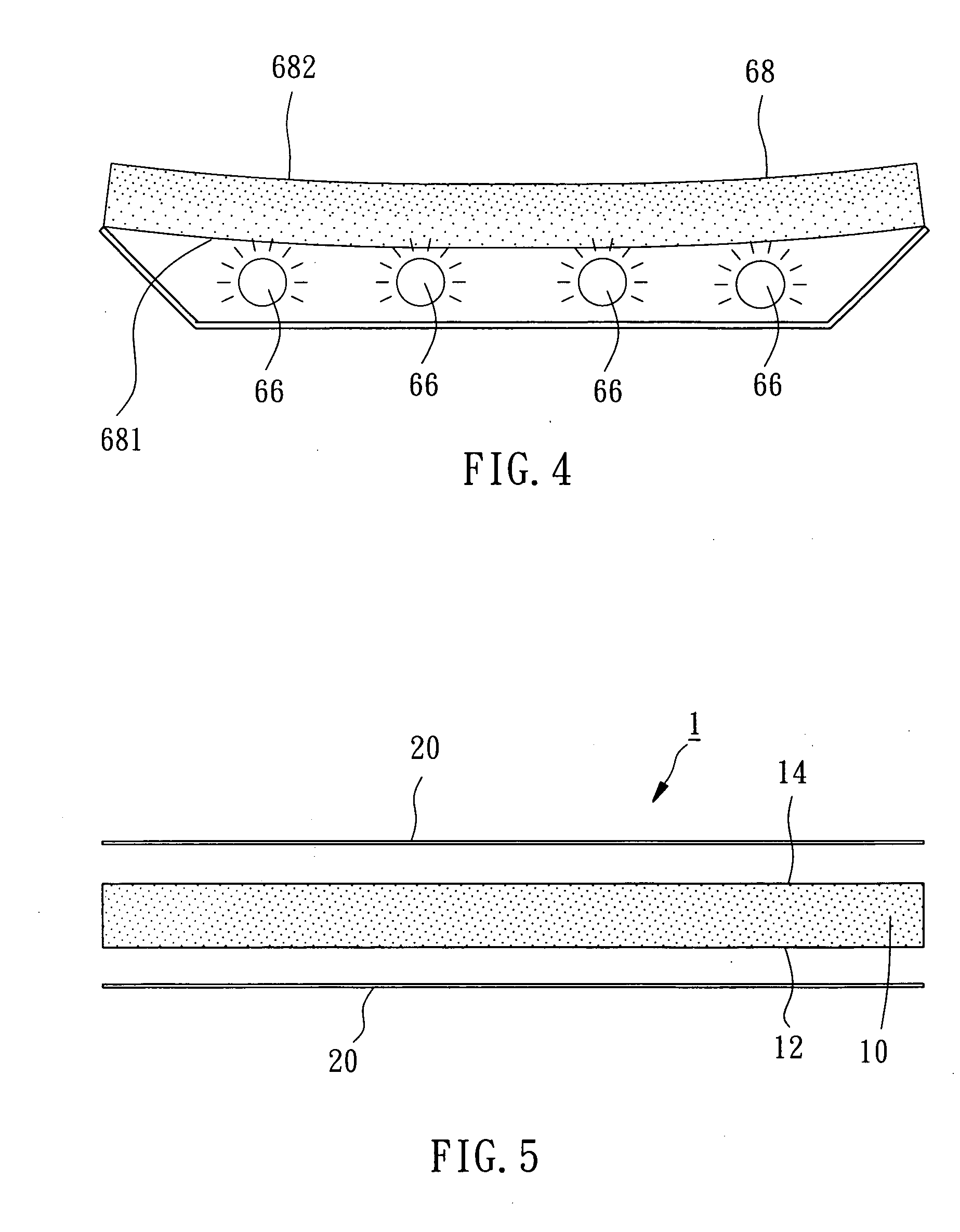

Substrate having insulating layers to prevent it from warping

Owner:FORHOUSE CORPORATION

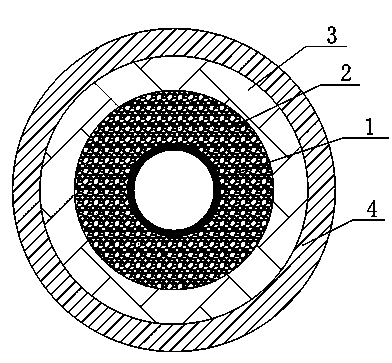

Pipeline with noise reduction and thermal insulation

InactiveCN104110535AImprove sealingHigh strengthThermal insulationPipe protection by thermal insulationThermal insulationEngineering

Owner:JIANGYIN HAILU HIGH PRESSURE PIPE

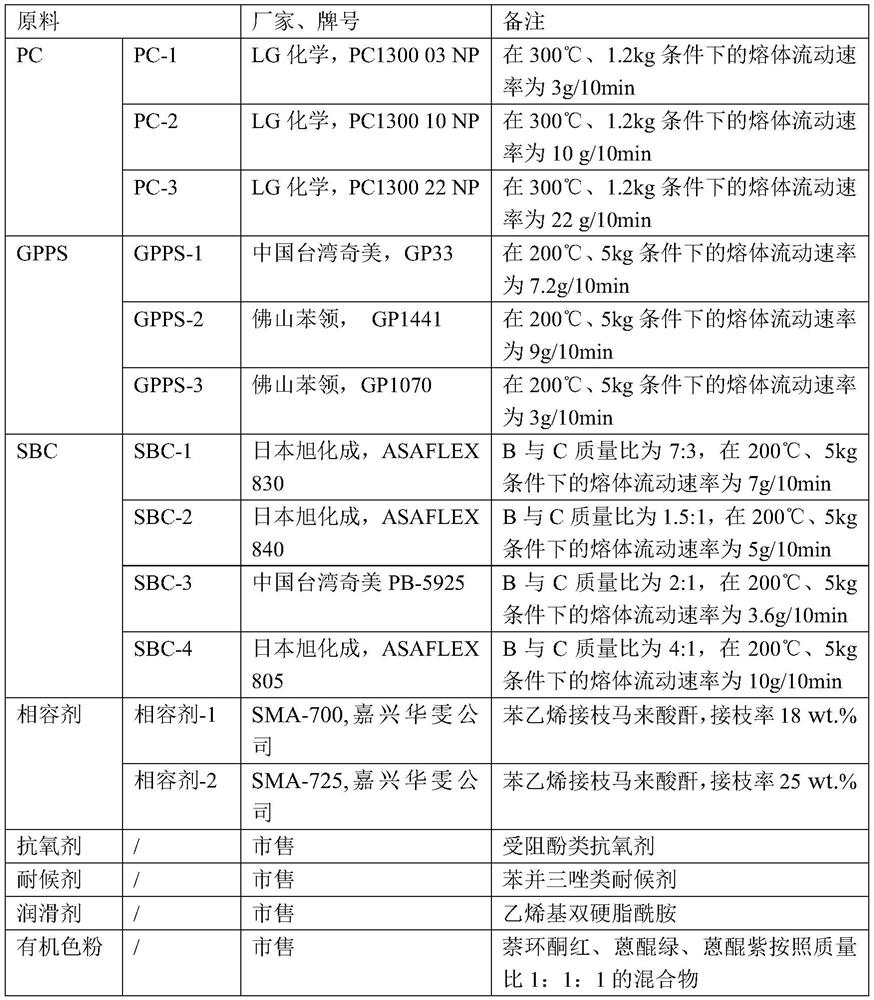

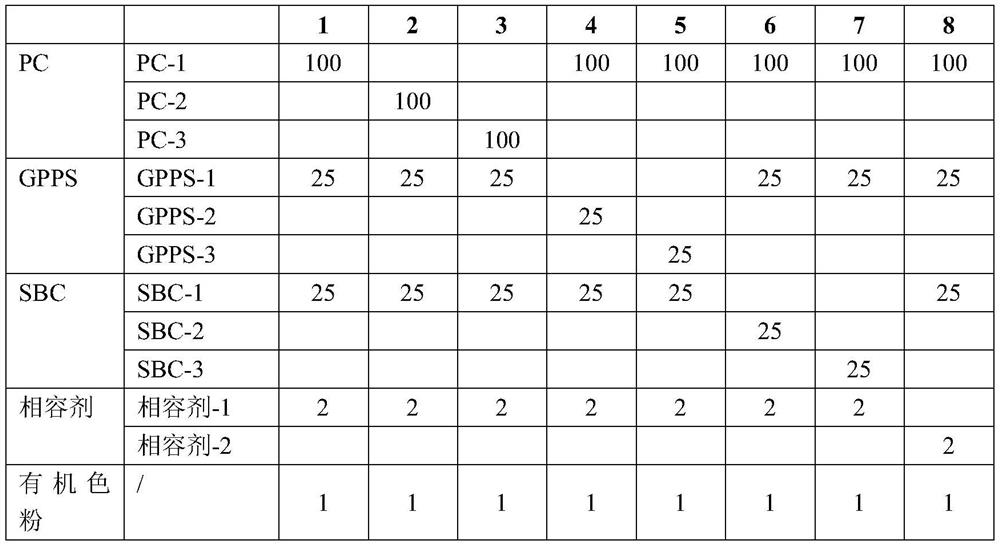

High-toughness and high-fluidity PC (polycarbonate) composition as well as preparation method and application thereof

Owner:KINGFA SCI & TECH CO LTD

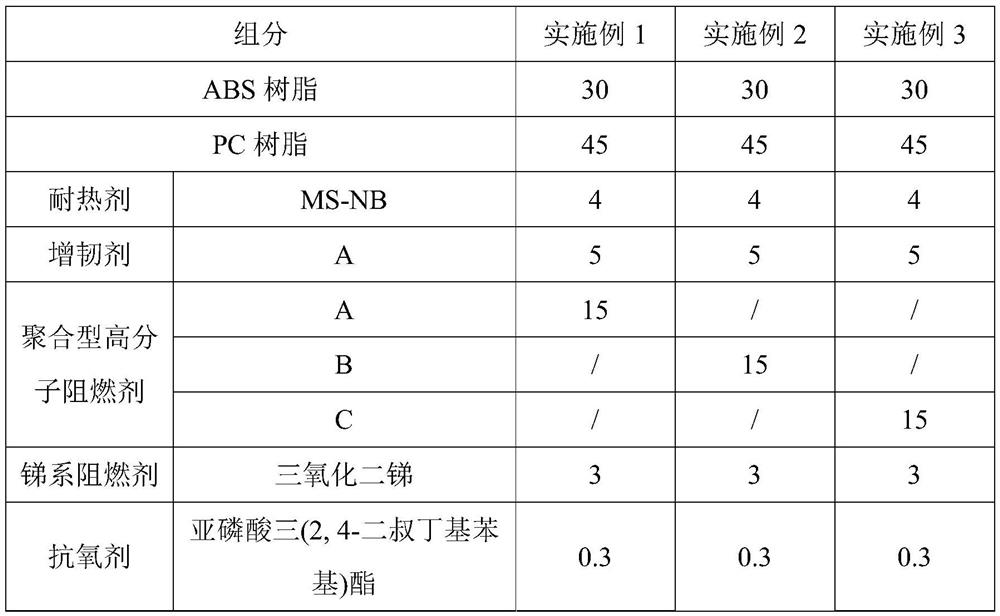

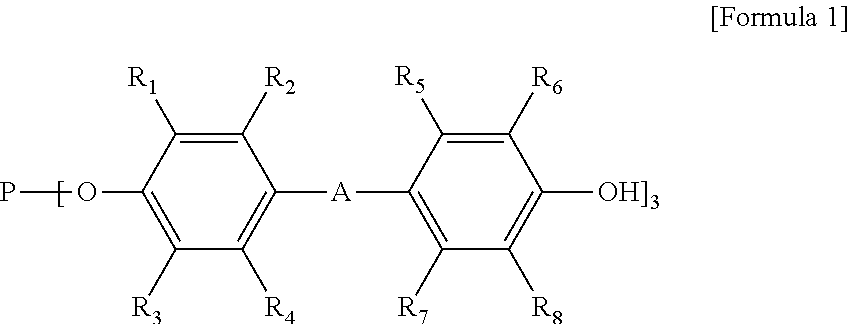

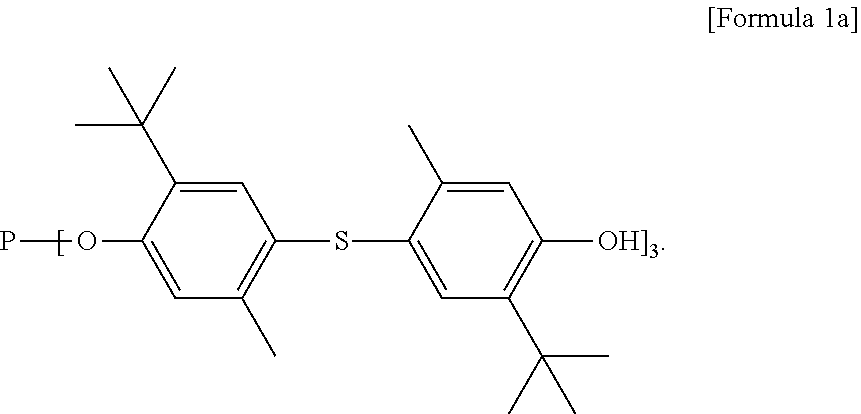

High-ball-pressure flame-retardant PC/ABS material as well as preparation method and application thereof

PendingCN114316554AIncrease high ball pressure temperatureGuaranteed flame retardancy and mechanical propertiesPolycarbonateOrganosilicon

The invention belongs to the technical field of modified plastics, and particularly relates to a high-ball-pressure flame-retardant PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) material as well as a preparation method and application thereof. The material is mainly prepared from the components such as the polymeric high-molecular flame retardant, the antimony flame retardant, the heat-resistant agent and the organic silicon / acrylic acid composite rubber flexibilizer, all the components have a synergistic effect, the polymeric high-molecular flame retardant and the heat-resistant agent can jointly increase the ball pressure temperature of the ABS material, the toughness of the ABS material can be improved by combining with the flexibilizer, and the toughness of the ABS material is improved. The high ball pressure temperature of the flame-retardant PC / ABS material is remarkably improved, meanwhile, the flame retardance and the mechanical property of the flame-retardant PC / ABS material can be guaranteed, and the flame-retardant PC / ABS material is very suitable for manufacturing high-temperature-resistant products.

Owner:KINGFA SCI & TECH CO LTD

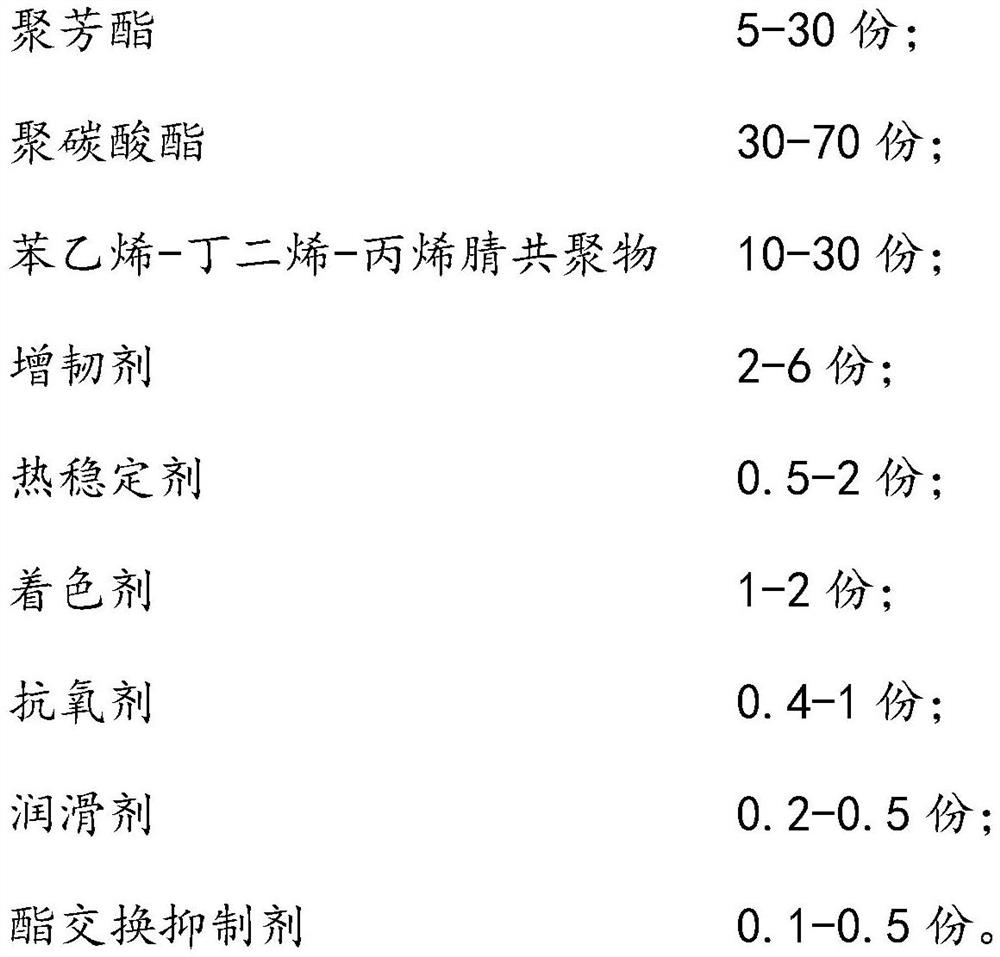

Thermoplastic Resin Composition and Article Produced Therefrom

Owner:LOTTE ADVANCED MATERIALS CO LTD

Production process of wear-resistant PC (polycarbonate) board

Owner:江苏迪迈新材料有限公司

High-strength impeller

Owner:WUXI YANGGONG MACHINERY MFG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap