Substrate having insulating layers to prevent it from warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

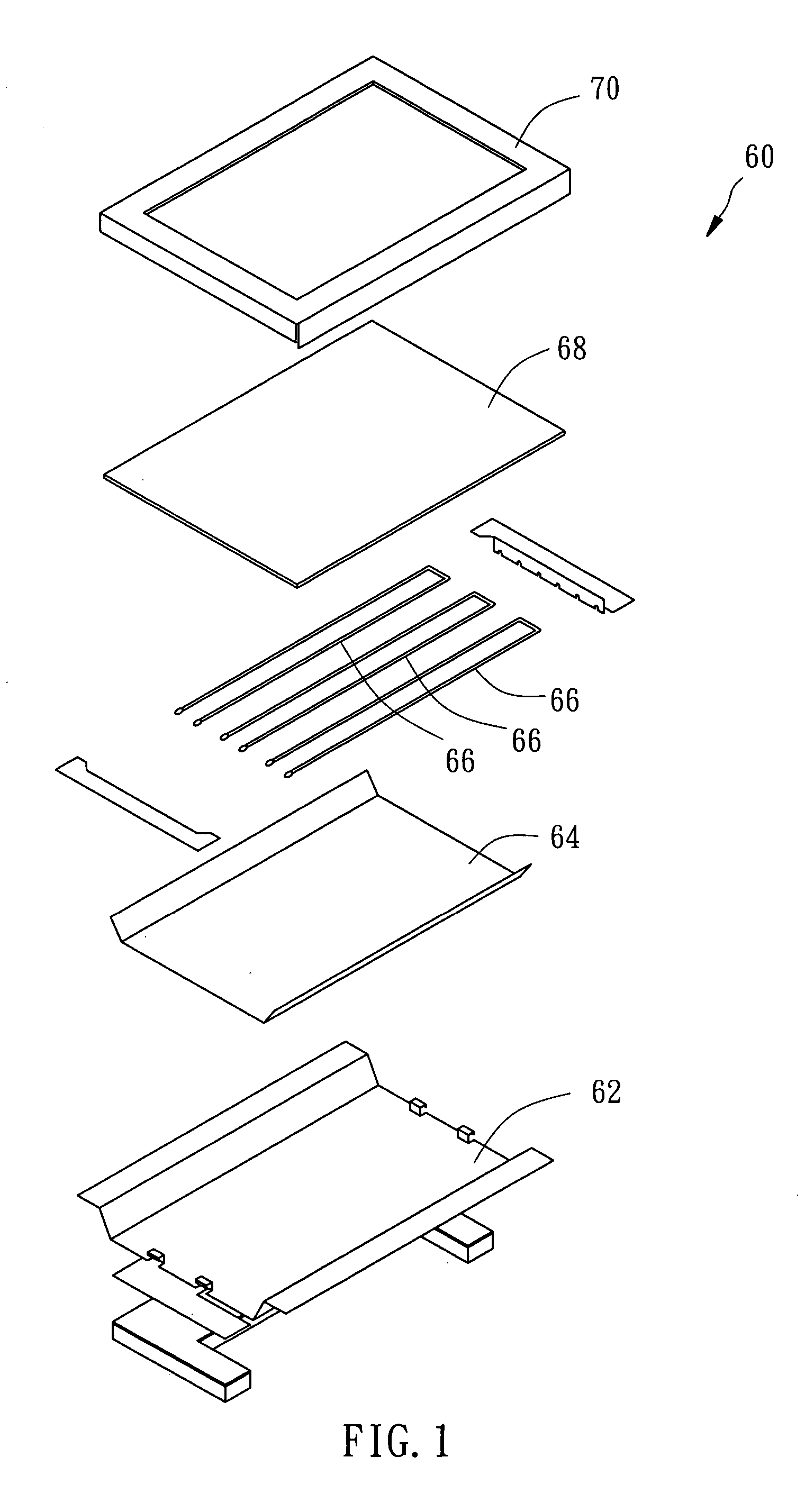

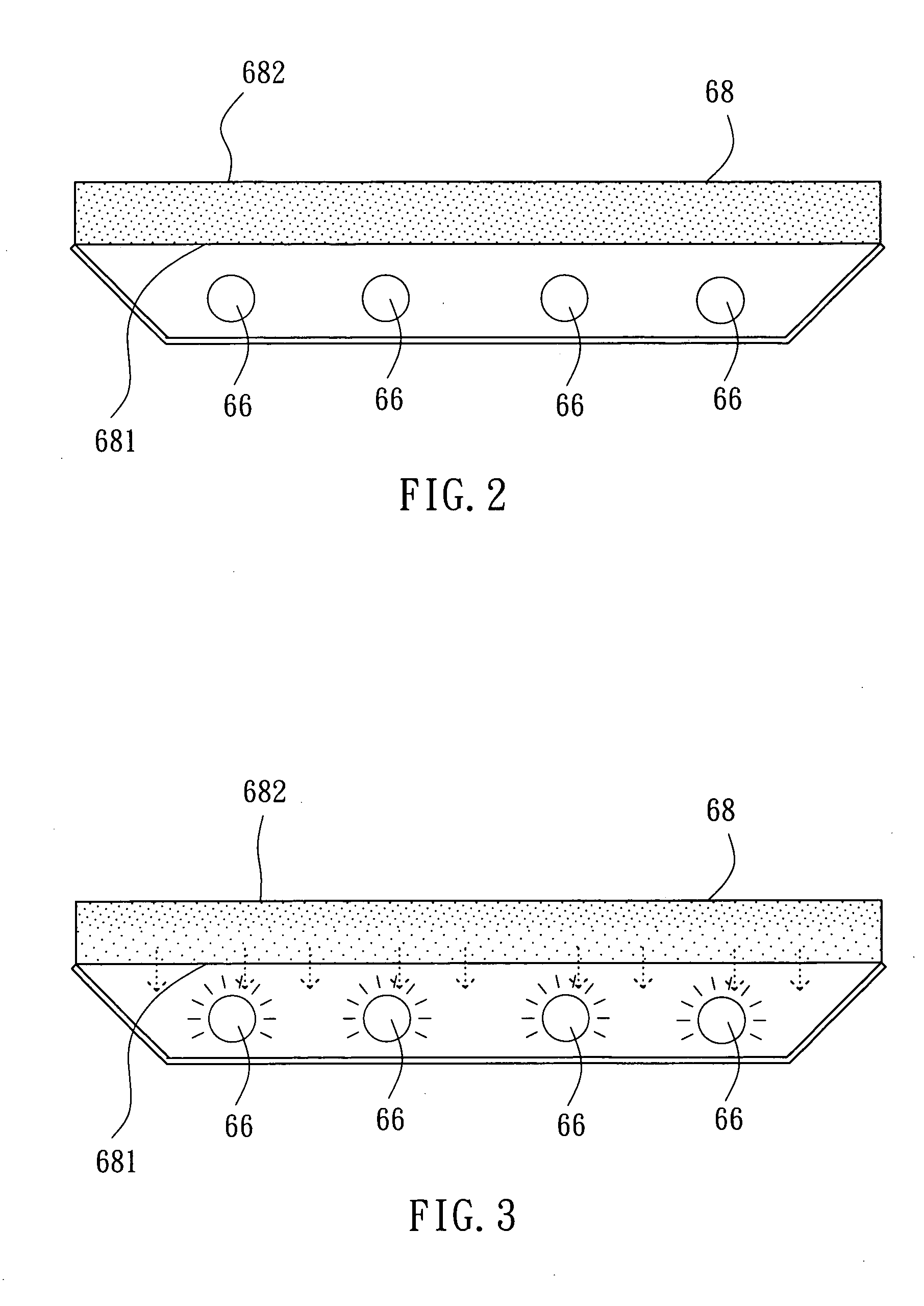

Image

Examples

Embodiment Construction

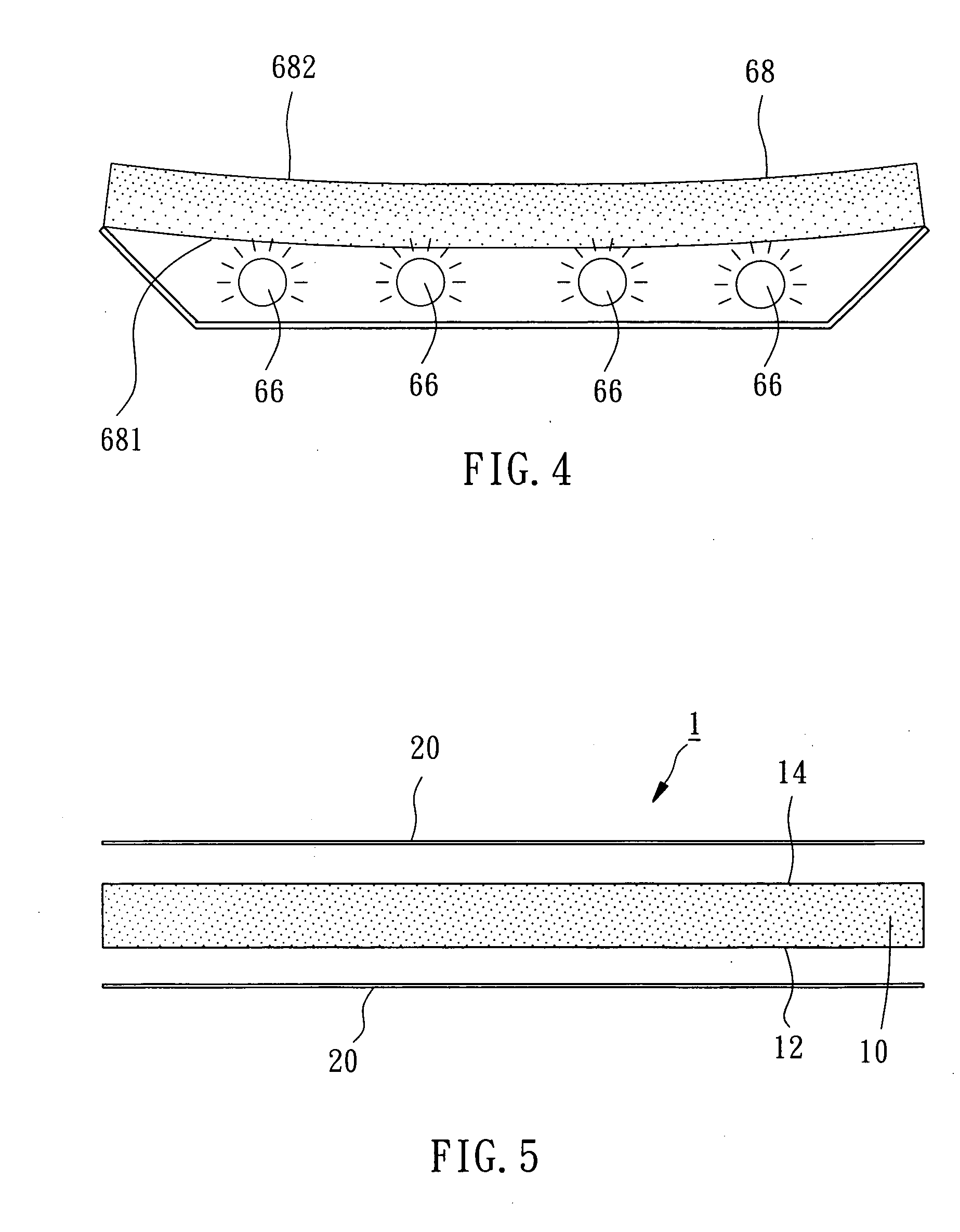

[0019] As shown in FIG. 5, the first preferred embodiment of the present invention provides a substrate 1 comprises a substrate member 10 having a first side 12 and a second side 14 and two insulating layers 20 provided on the fist and the second sides 12 and 14 of the substrate member 10 respectively.

[0020] The substrate member 10 is made of Polymethyl methacrylate (PMMA) or Polycarbonate (PC). PMMA is broadly applied to modern life because that it is superior in optical property thereof and is cheap. PC has superior properties in strength and in high transparent. Both of PMMA and PC are broadly applied to conventional automobile industry and architecture, furthermore, they are applied to compact discs, optical fibers, light guild plates or diffusers in the backlight units and other optical devices.

[0021] The insulating layers 20 are made of Cyclic Olefins Polymer (COP), and more particularly, the insulating layers 20 are made of Cyclic Olefins Copolymer (COC).

[0022] COC is synthes

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap