Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118 results about "Impeller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An impeller (also written as impellor or impellar) is a rotor used to increase (or decrease in case of turbines) the pressure and flow of a fluid.

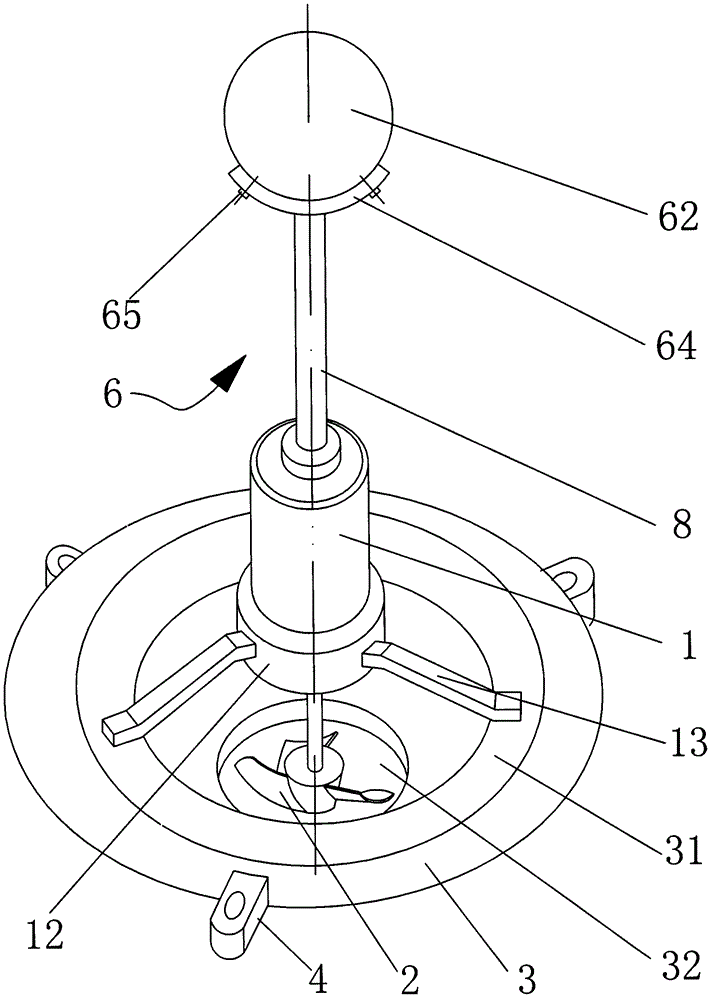

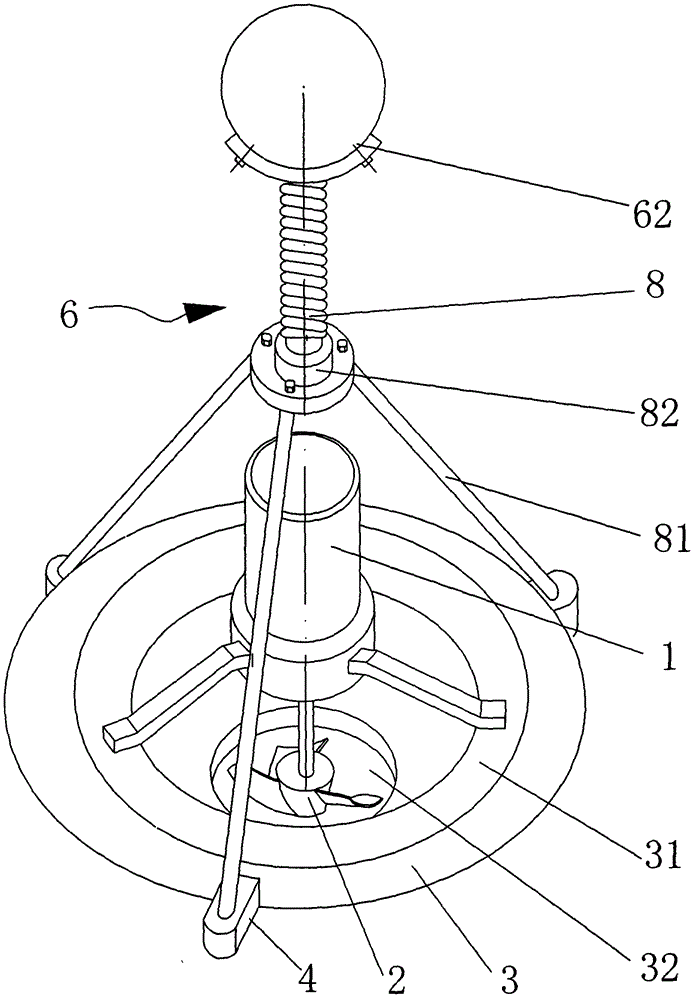

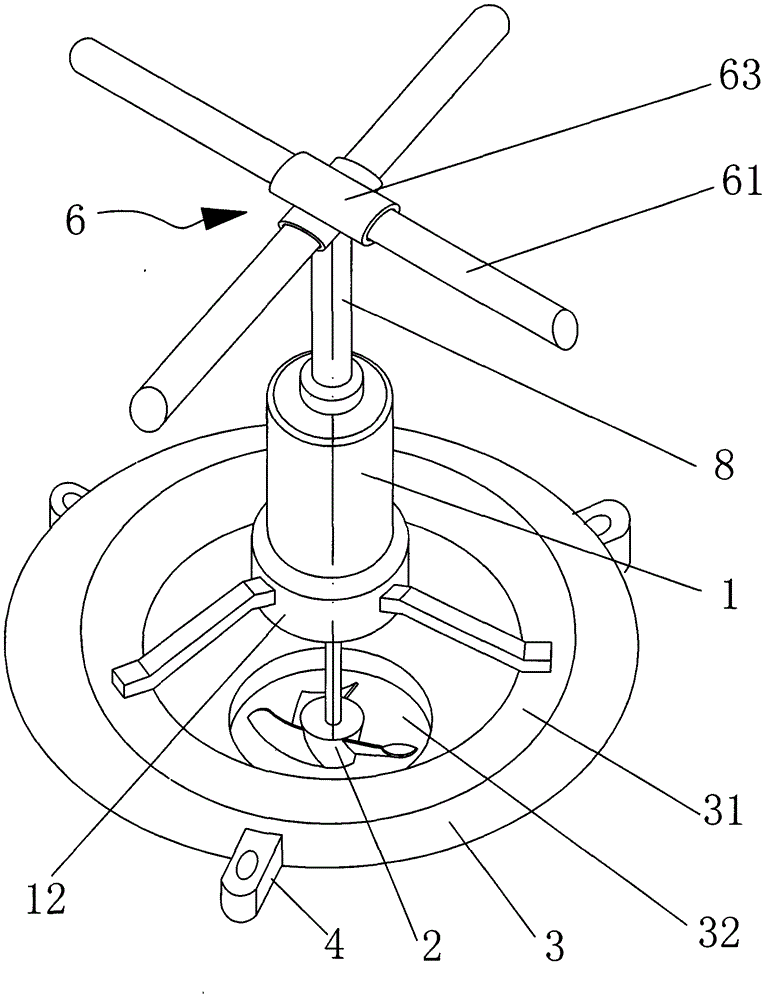

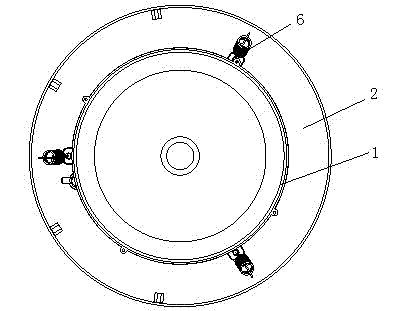

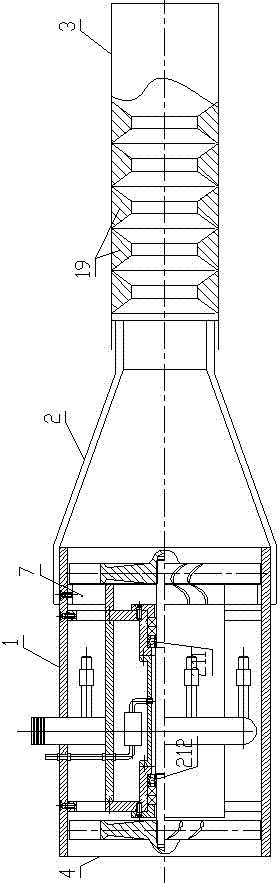

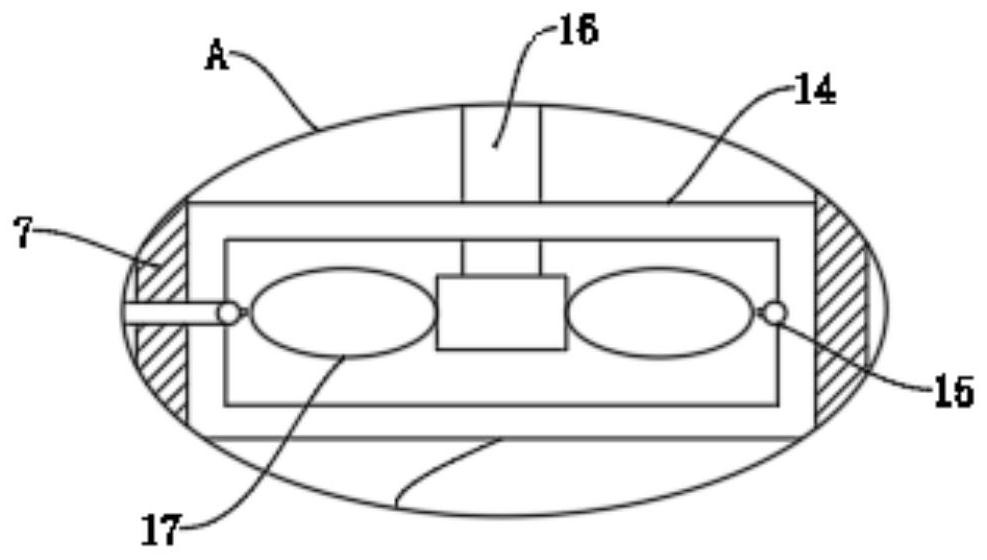

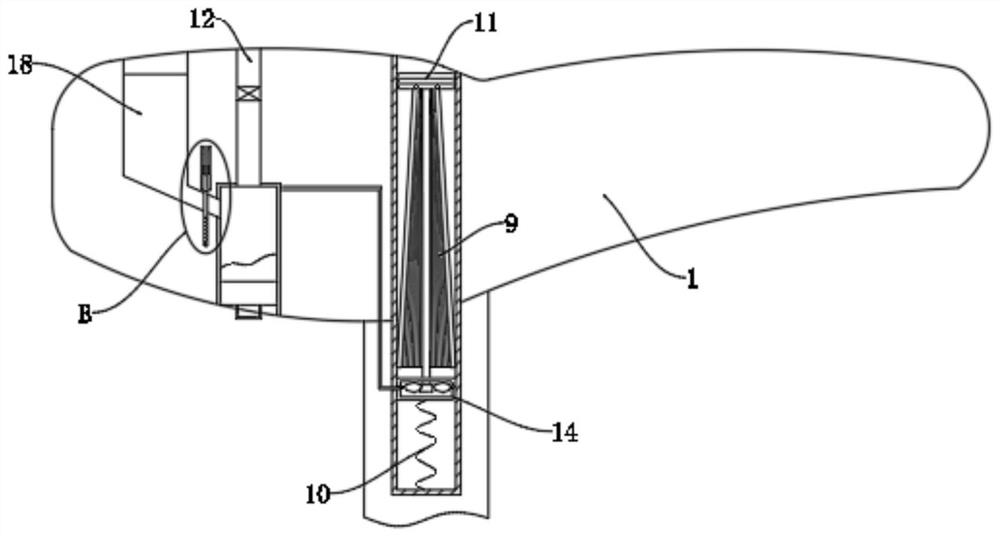

Multifunctional sprinkler structure

ActiveUS7255291B1Accurate operationEqually distributedMovable spraying apparatusSpray nozzlesImpellerWater discharge

A multifunctional sprinkler structure comprises a water motor having an outlet seat and a top cover mounted to a top-end side, and two adjusting seats and a water supply seat assembled onto a bottom-end side. The bottom-end side of the water motor has a guide groove with a restrictive hole for the extension of a switch shaft there-through. The outlet seat has a water-discharge chamber with multiple barriers extending thereon corresponding to an impeller of the water motor, and an oblique-extending central guide port matching to a spray nozzle having multiple water-guiding ribs obliquely extending towards the same direction therein. Therefore, the barriers of the outlet seat and the water-guiding ribs of the spray nozzle are utilized to correspond to the direction of the water flow so that the water discharge can be easily switched to eject either in more direct and forceful column-like spray or in more expanding spray.

Owner:YUAN MEI CORP

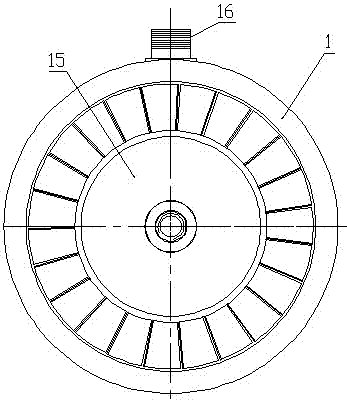

Open type water pump and application thereof

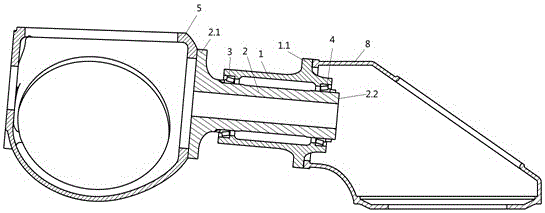

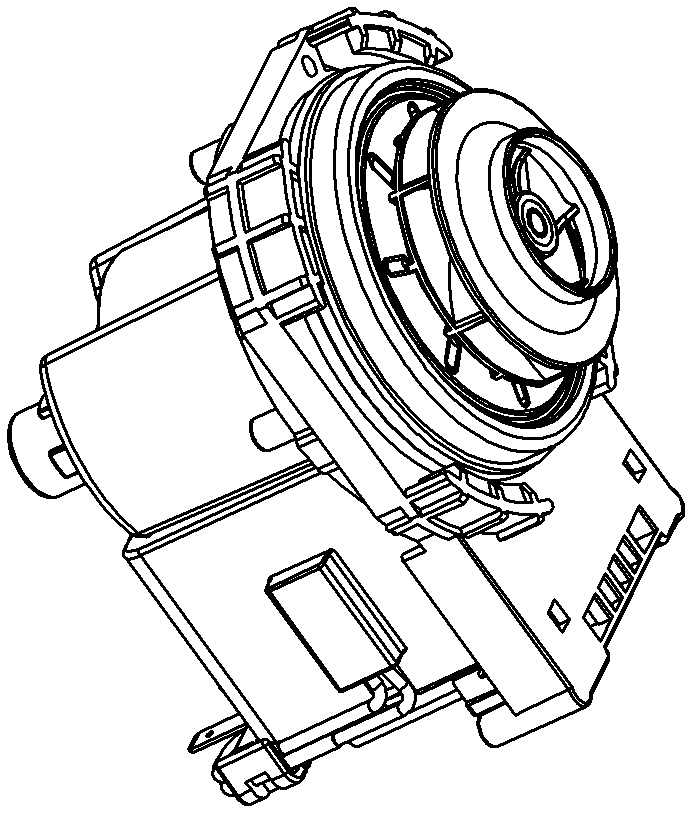

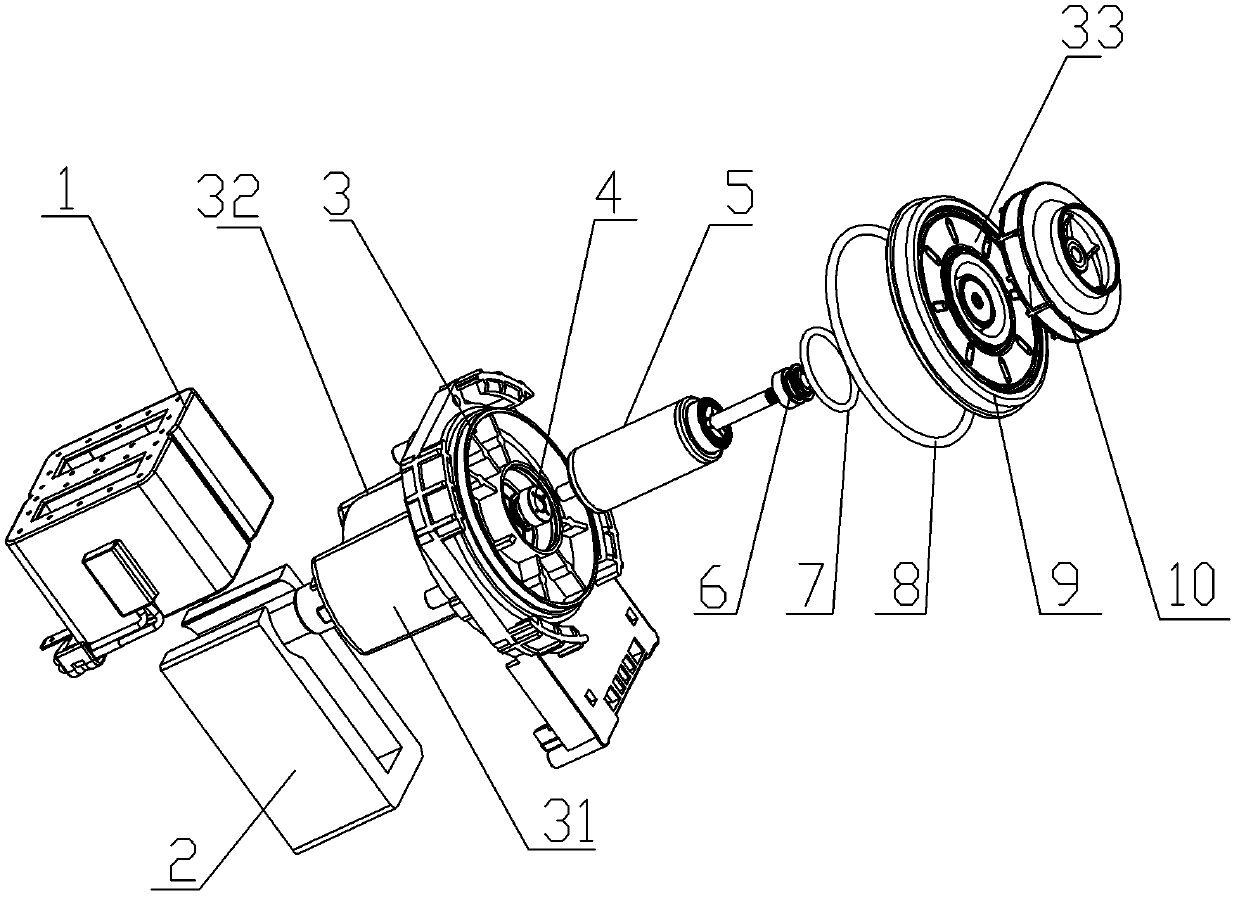

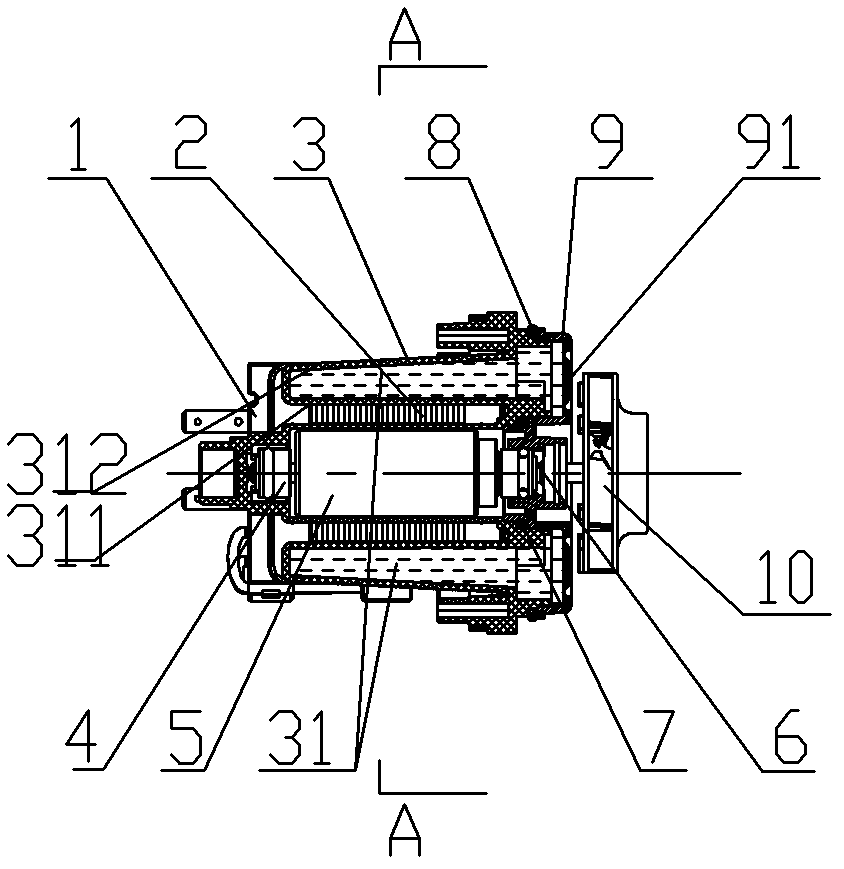

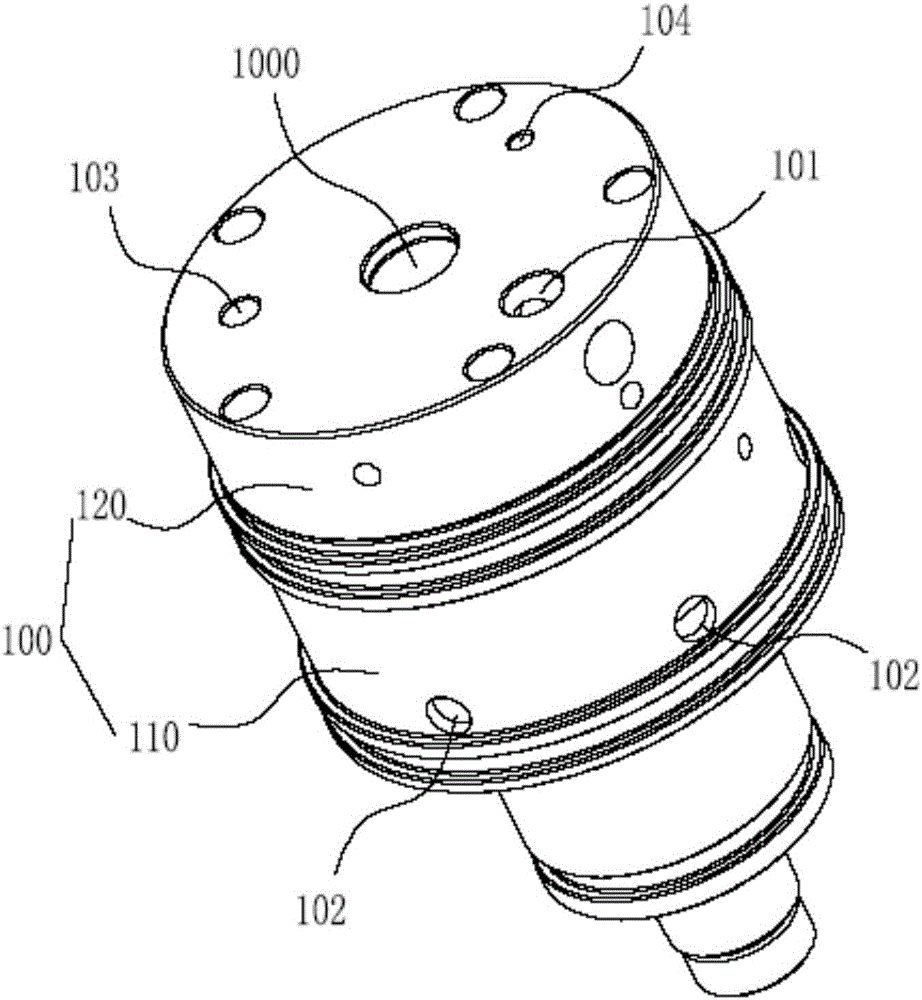

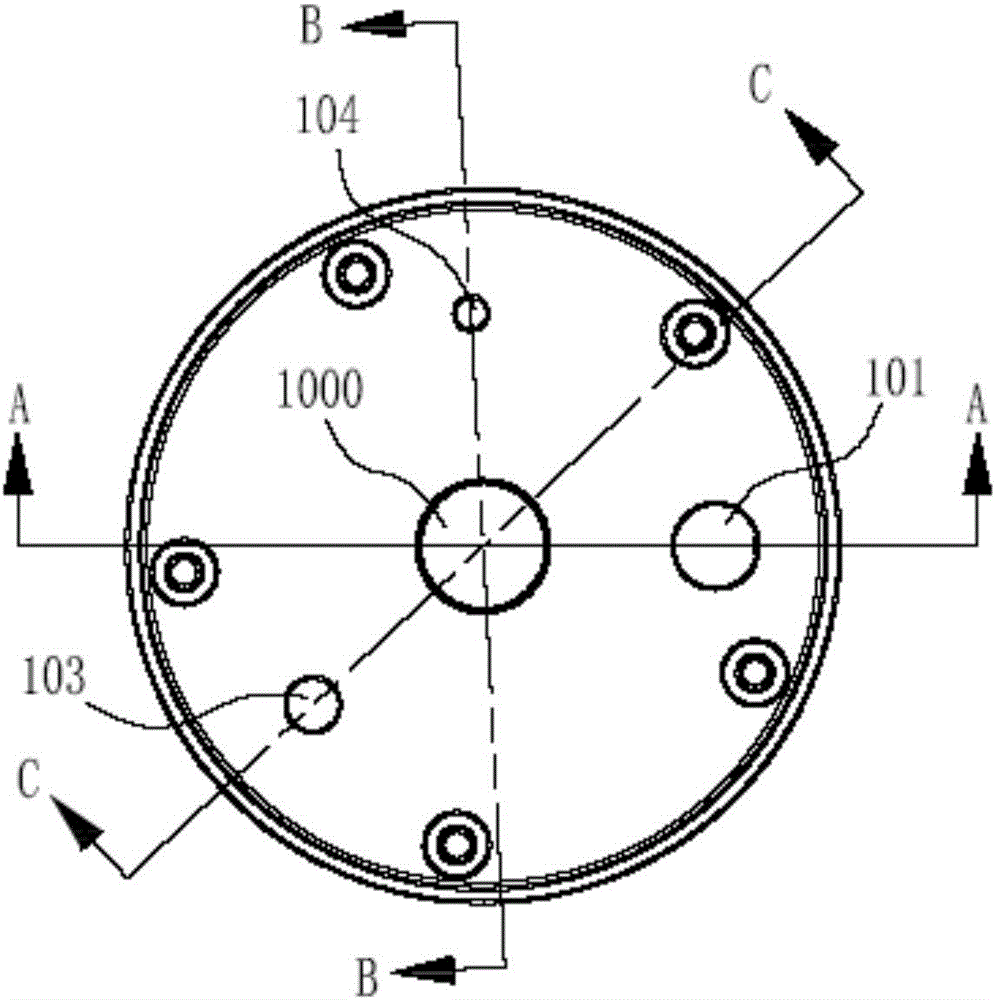

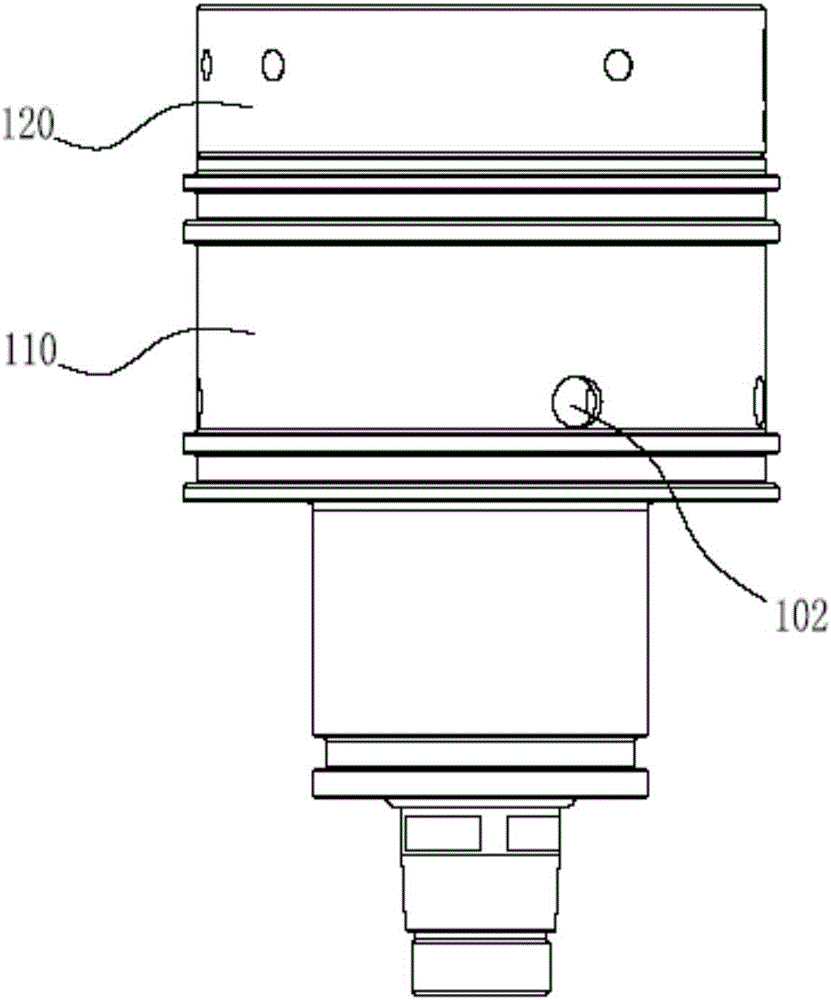

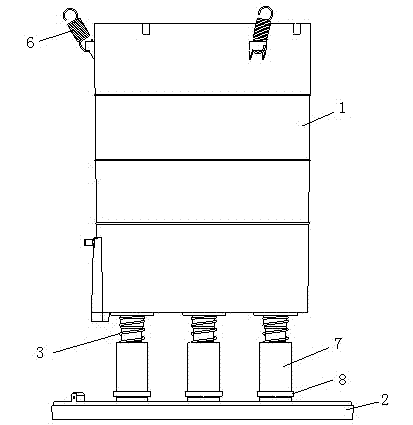

ActiveCN104564838AImprove water extraction efficiencyImprove balanceTableware washing/rinsing machine detailsPump componentsImpellerUpper segment

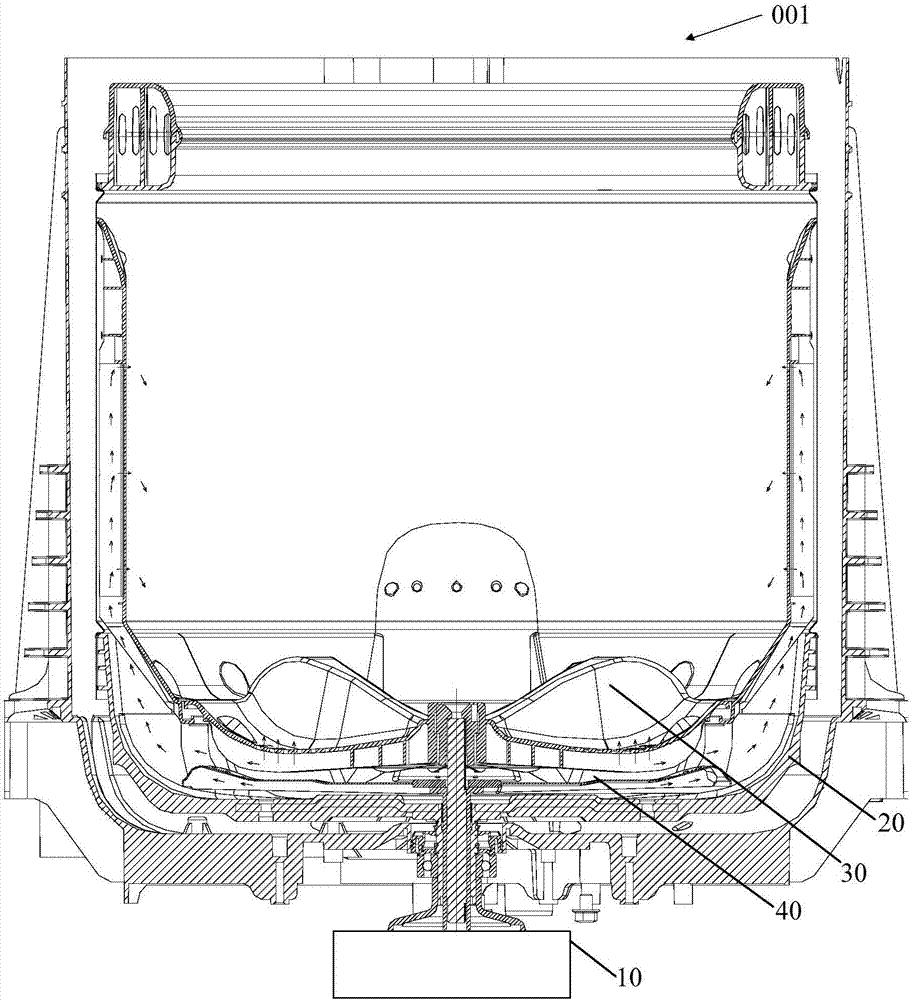

The invention discloses an open type water pump. The open type water pump comprises an upper housing, a lower housing and an impeller; the impeller comprises a shaft which is positioned in the center, and a plurality of axially-extended blades which are circumferentially and uniformly distributed on the circumferential surface of the shaft; the blade is axially divided into an upper section and a lower section which are interconnected; an upper storing cavity for storing the upper section of the blade is formed in the upper housing; a lower storing cavity for storing the lower section of the blade is formed in the lower housing. The open type water pump is characterized in that the upper housing and the lower housing synchronously rotate; a bottom ring for mounting and positioning the lower housing is arranged below the lower housing. The invention also discloses a water tank type cleaner using the open type water pump.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

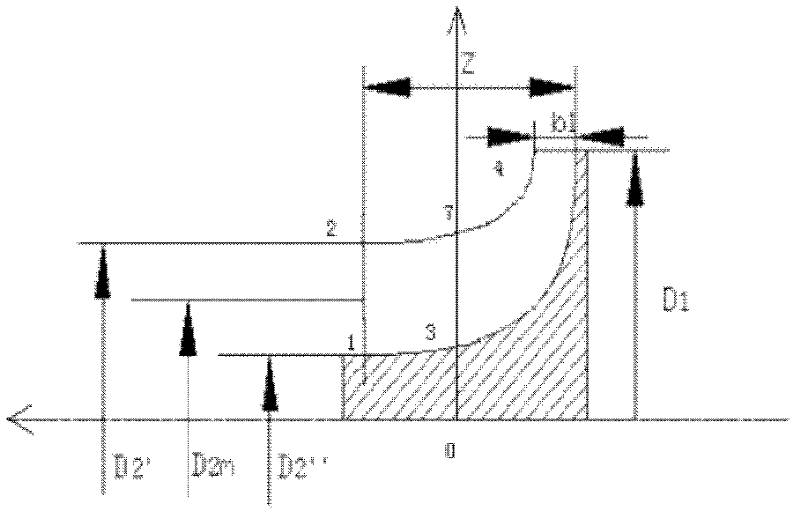

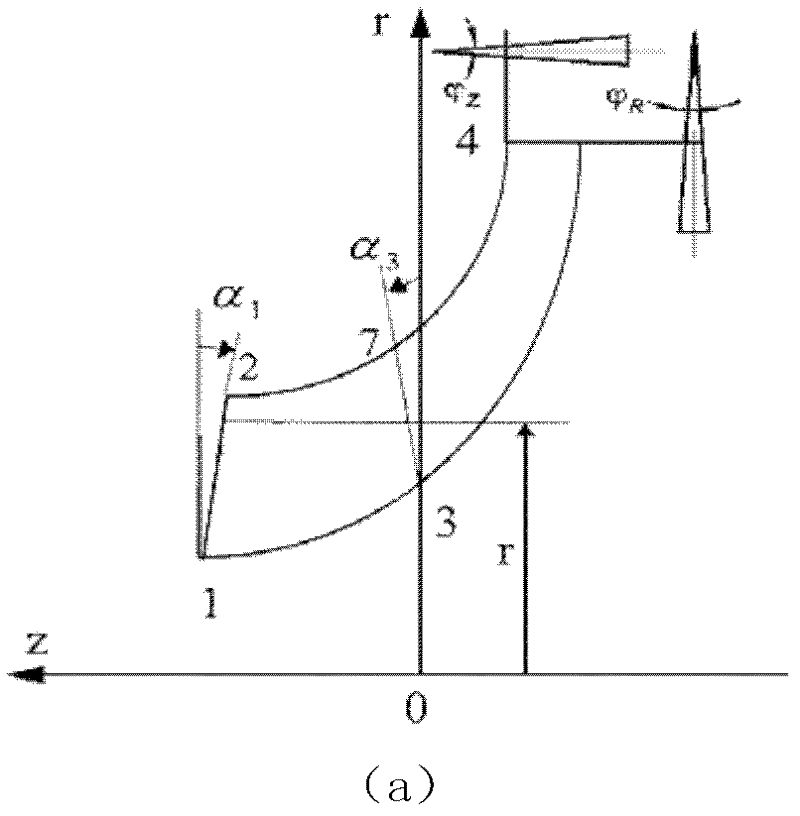

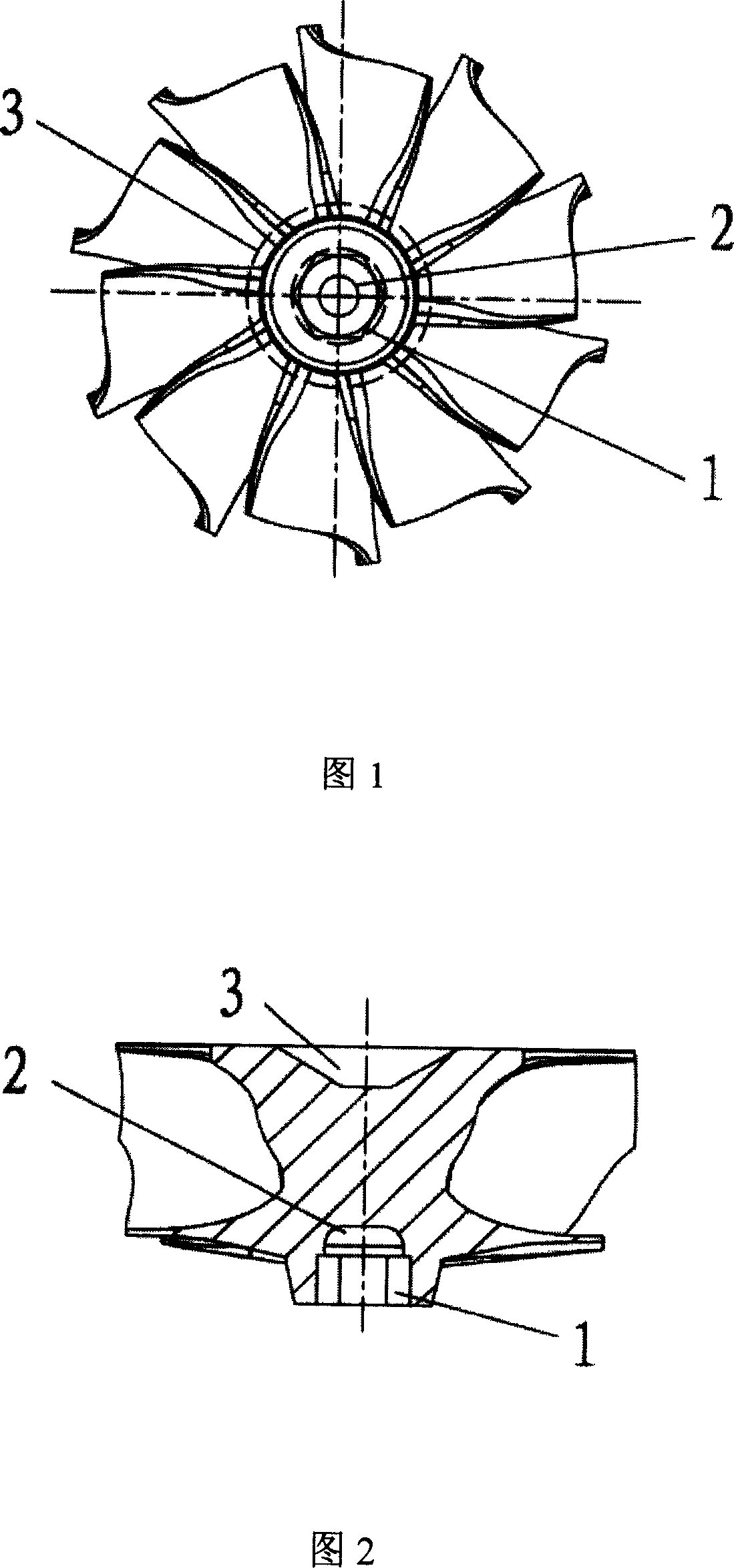

Optimization design method of radial-flow-type hydraulic turbine

ActiveCN102608914ASmall amount of calculationHigh precisionAdaptive controlImpellerMultivariable optimization

Owner:开山(西安)透平机械有限公司

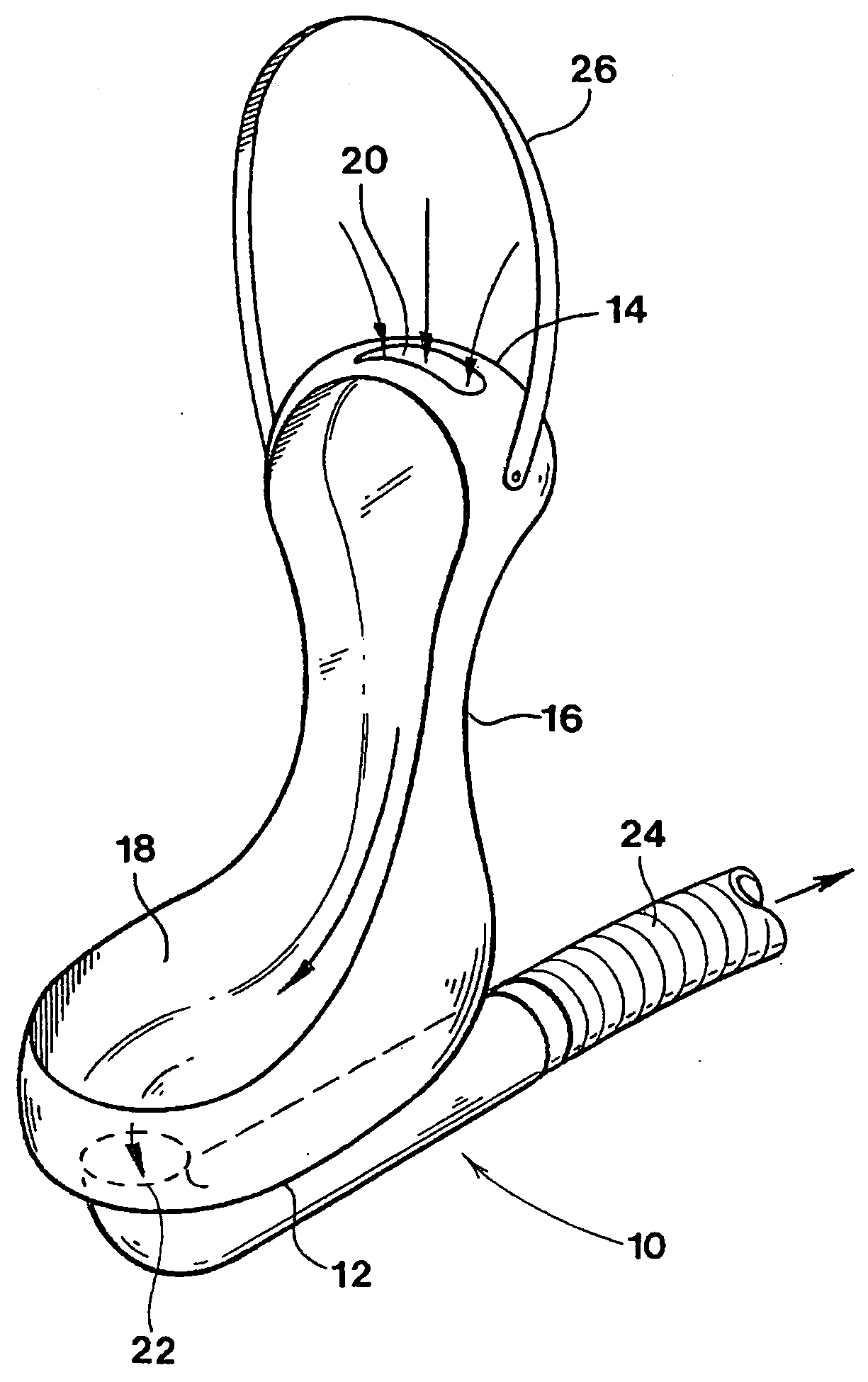

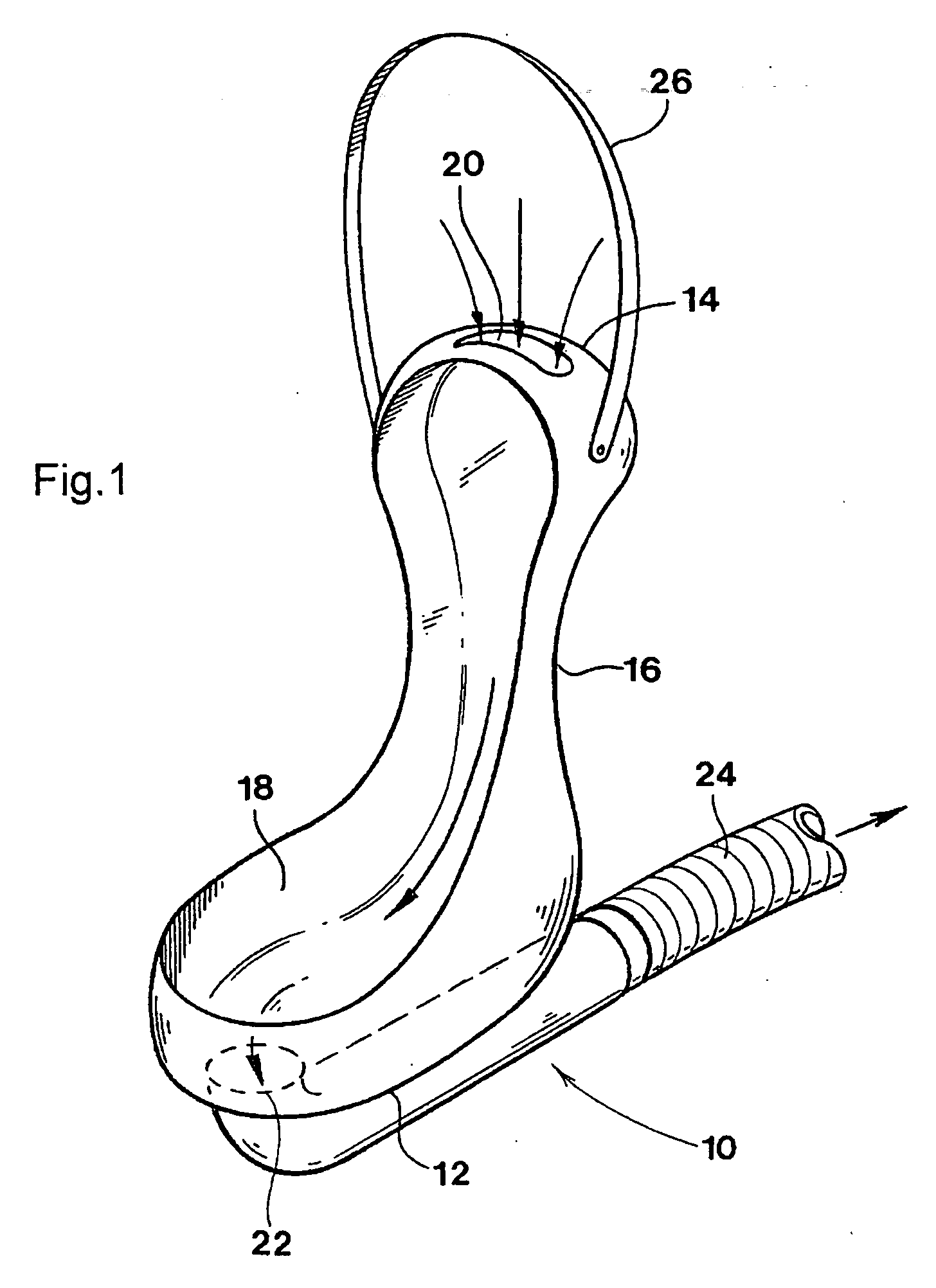

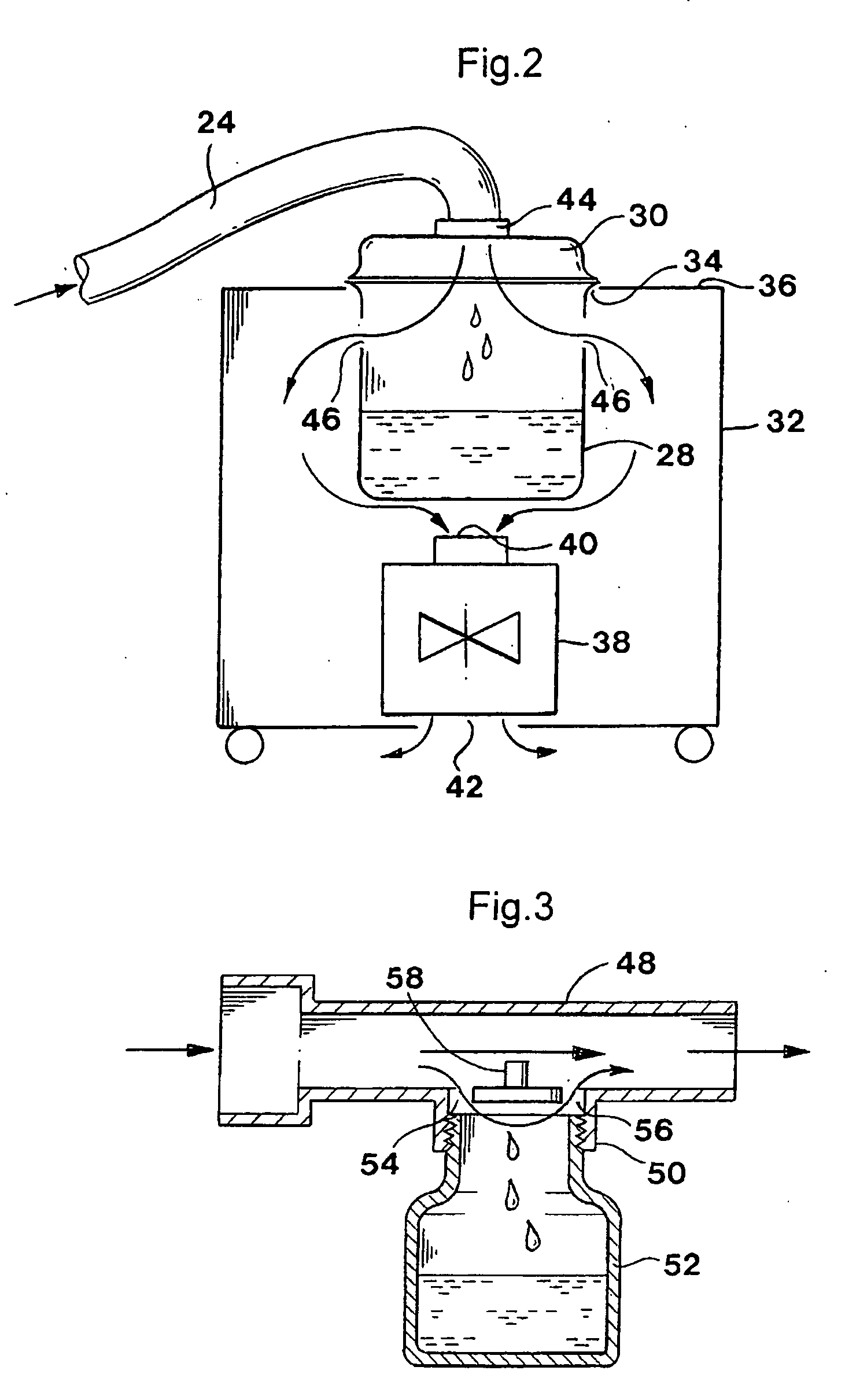

Urine collection apparatus

Owner:ONKOLOGIE INTERNASIONALE BELEGGINGS

Decelerator and washing machine with same

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

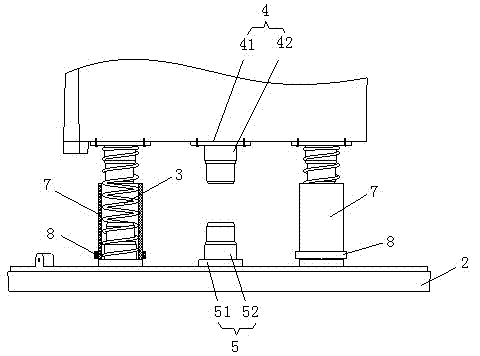

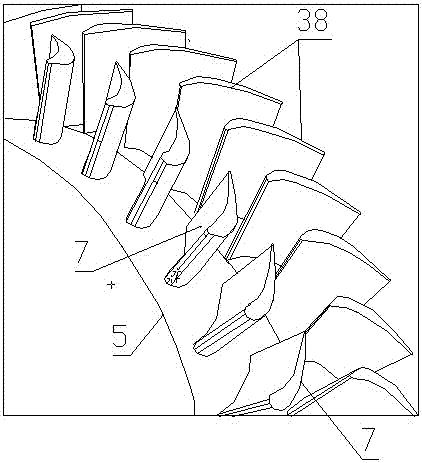

Load-dependent vibration reduction experimental system with damping structure blade

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

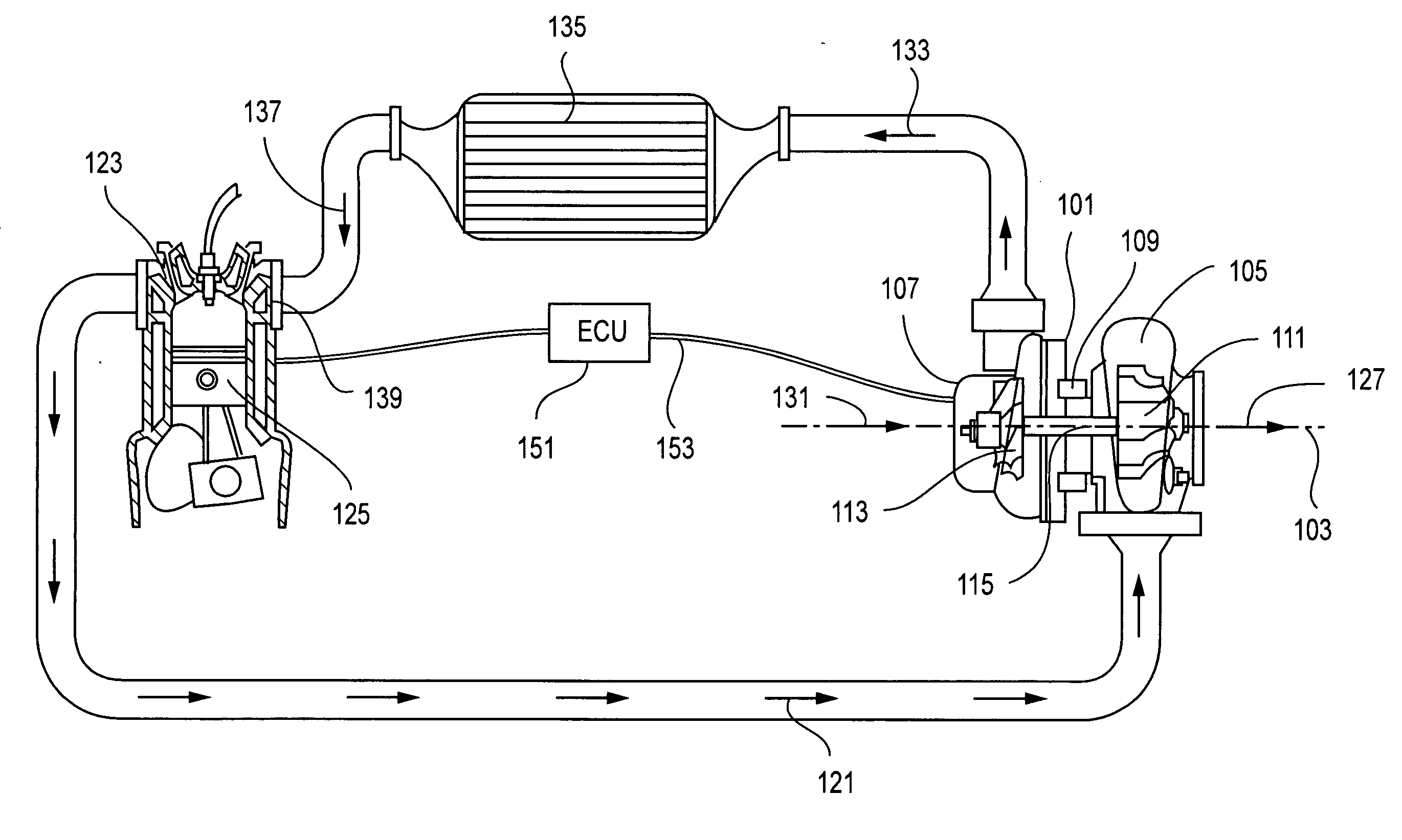

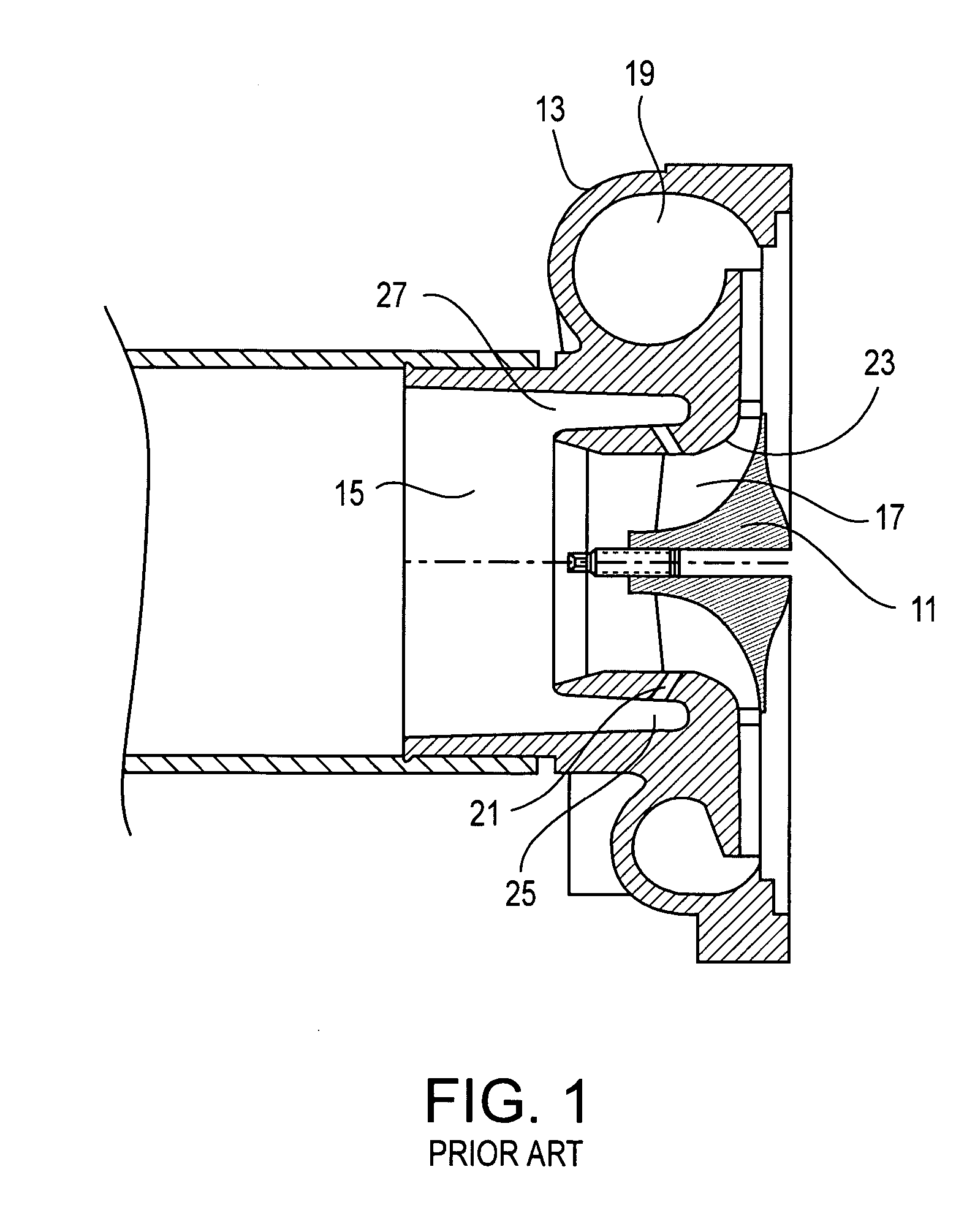

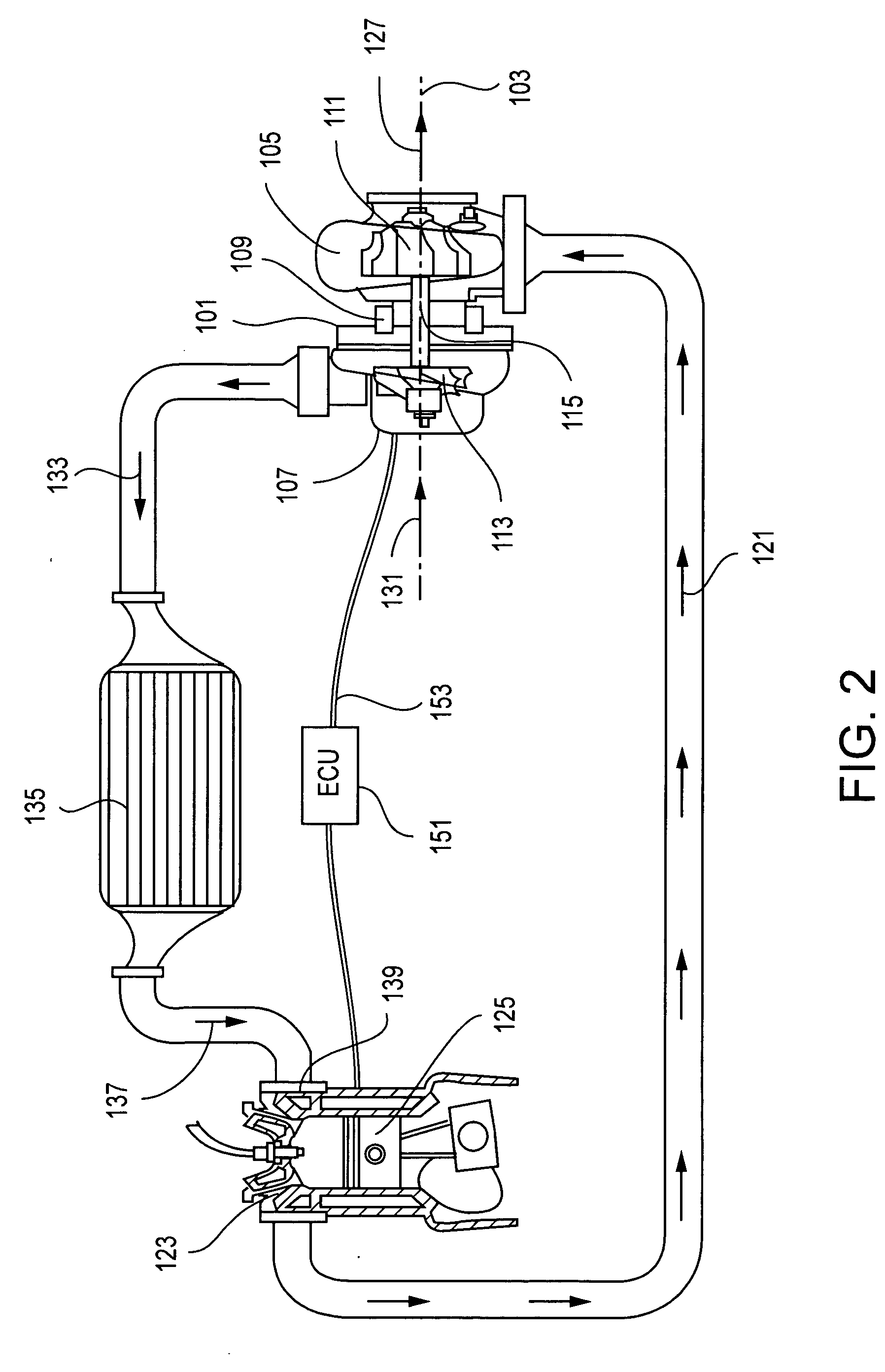

Ported shroud with filtered external ventilation

Owner:GARRETT TRANSPORATION I INC

Rainwater collection device for garden irrigation

InactiveCN107366328AEasy to irrigatePrevent waterloggingGeneral water supply conservationWatering devicesImpellerRainwater harvesting

Owner:SOUTHWEST FORESTRY UNIVERSITY

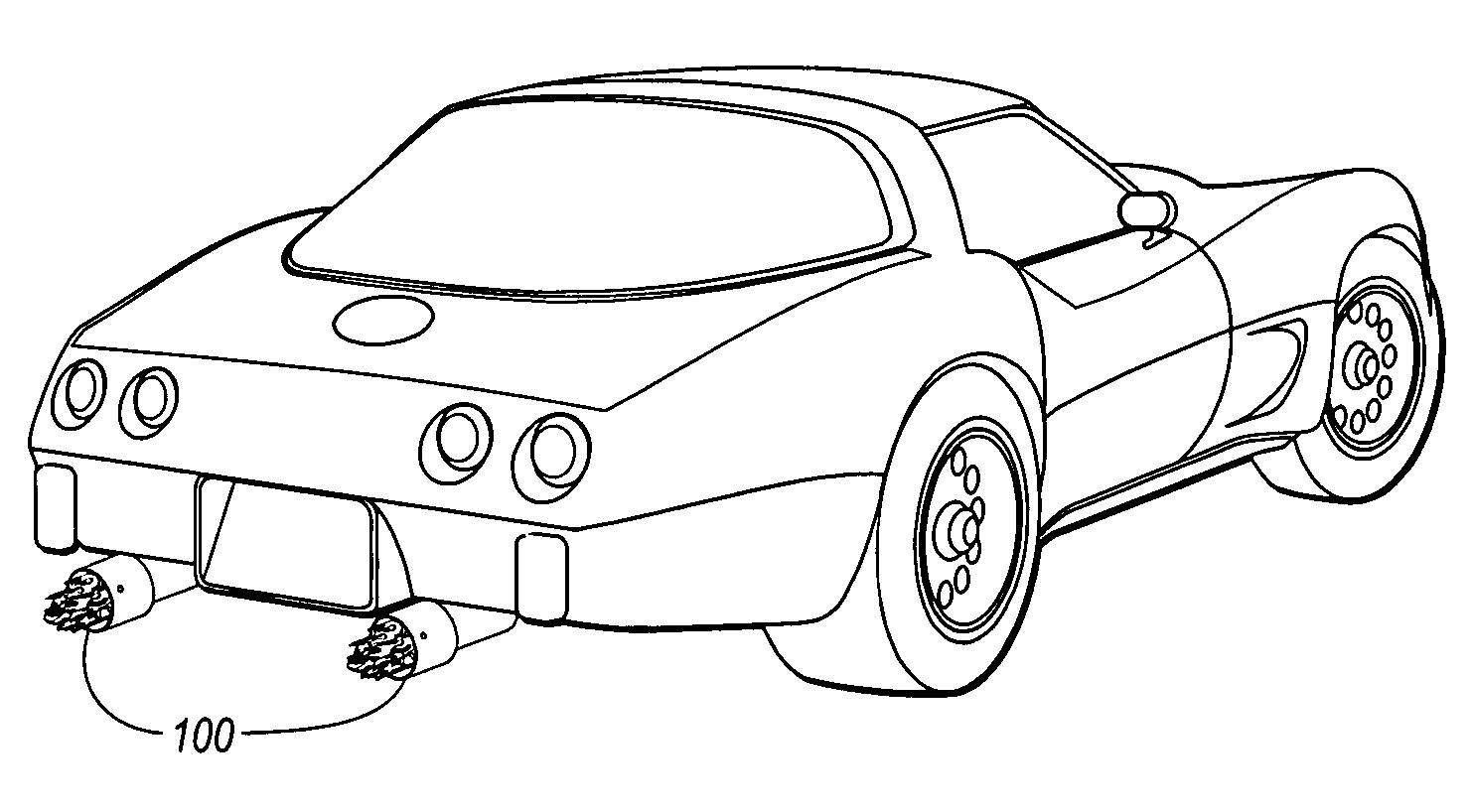

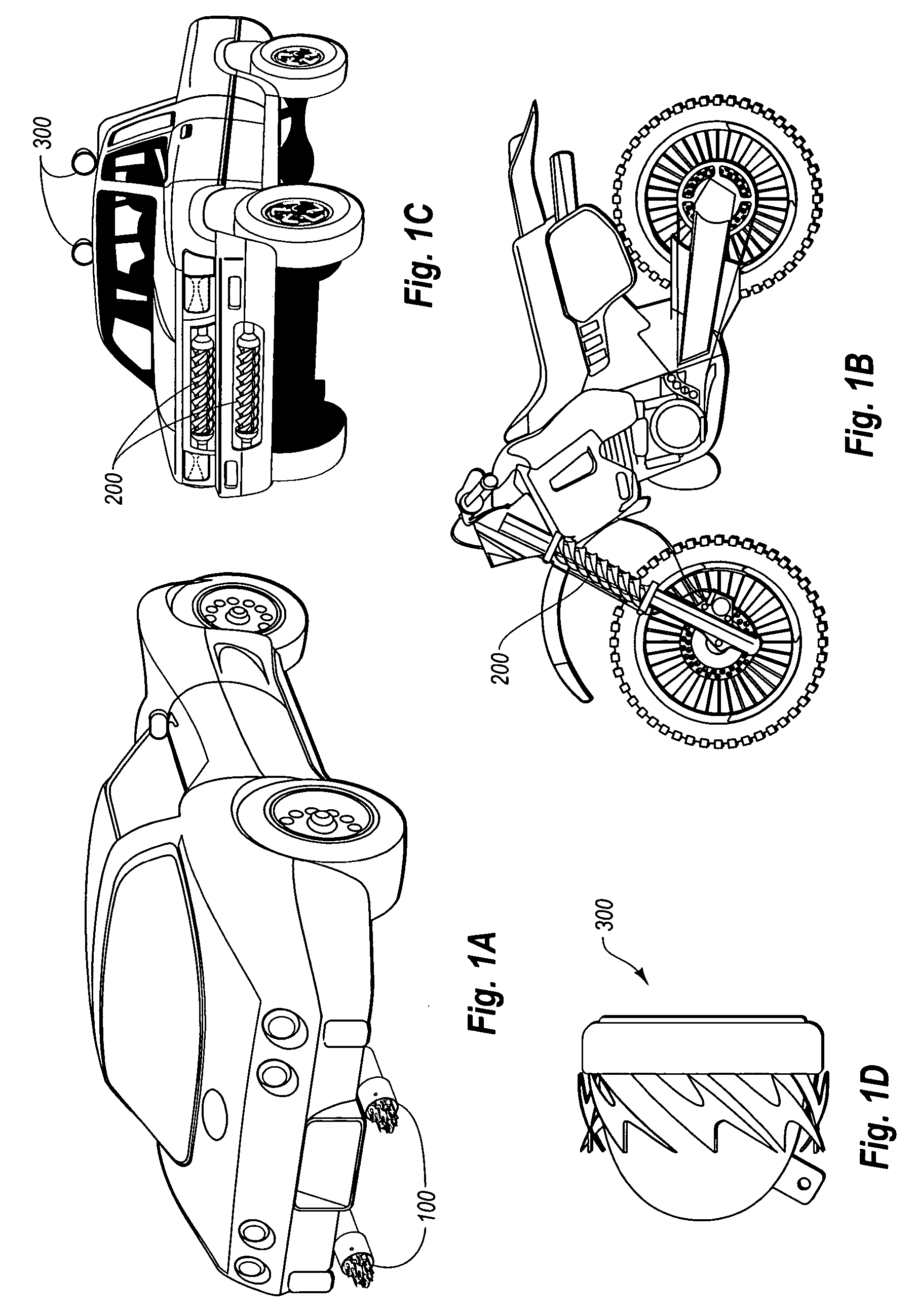

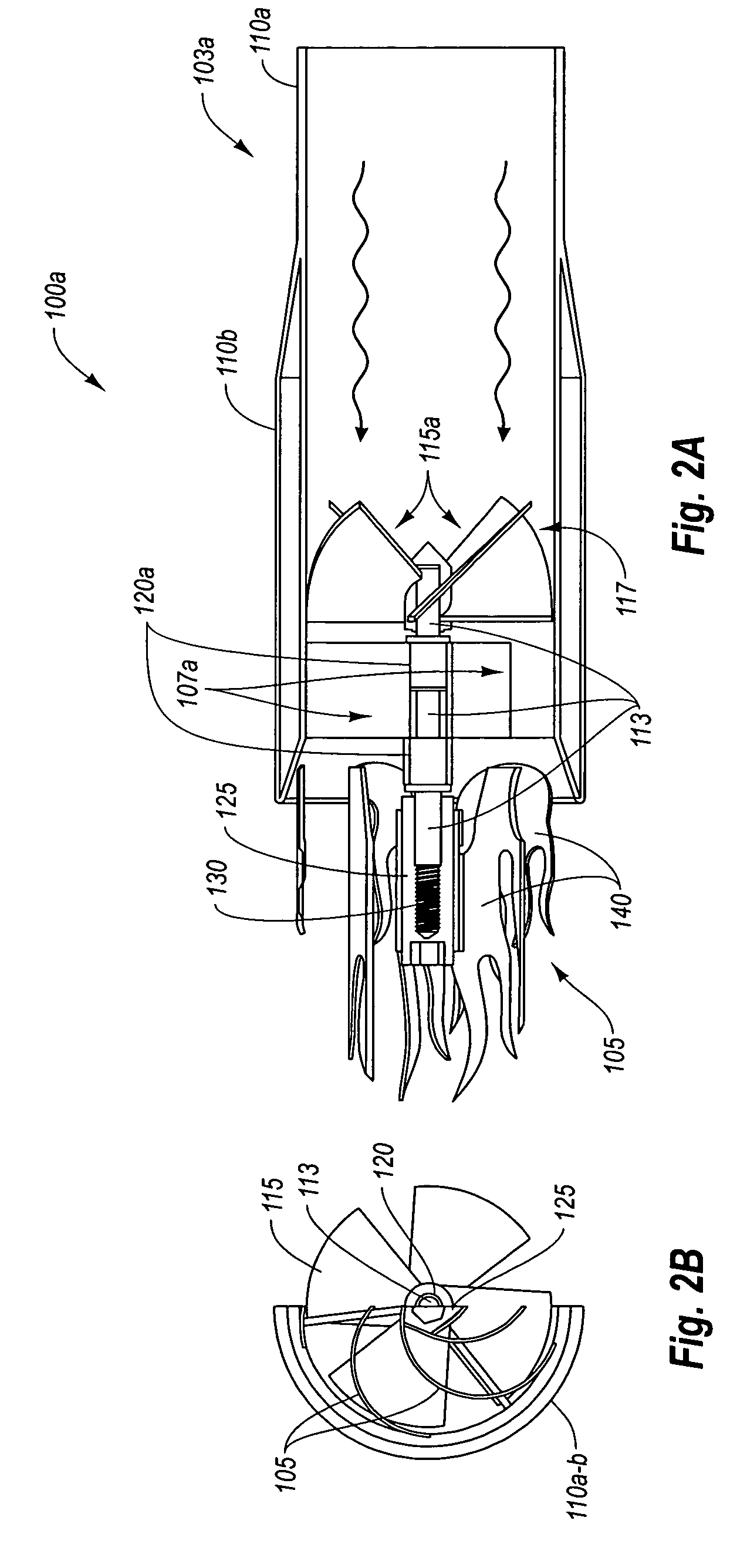

Rotatable vehicle accessory

InactiveUS20060070789A1Unique decorative effectExhaust apparatusSilencing apparatusImpellerAutomotive engineering

Owner:DIRKSON JOHN C

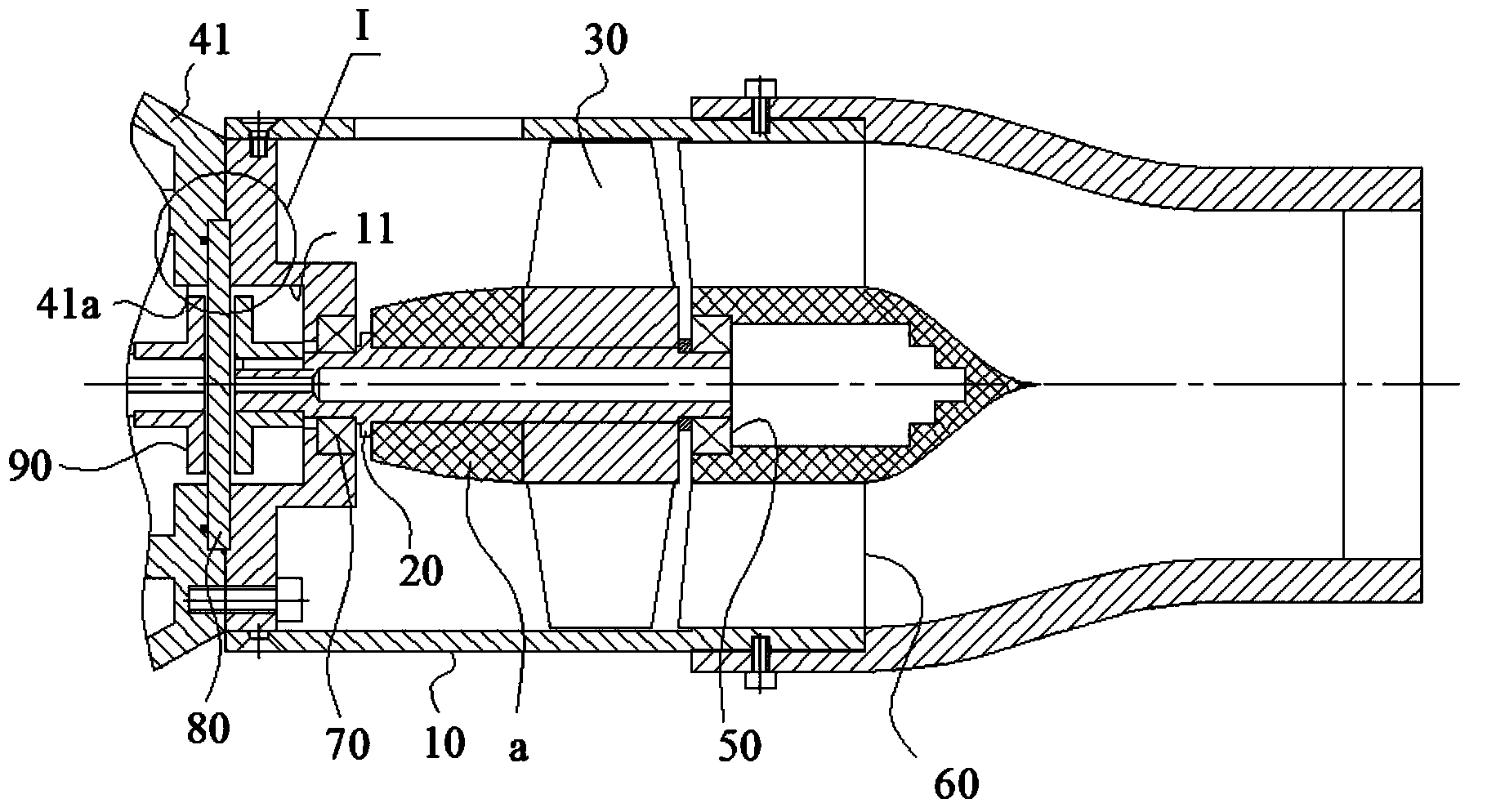

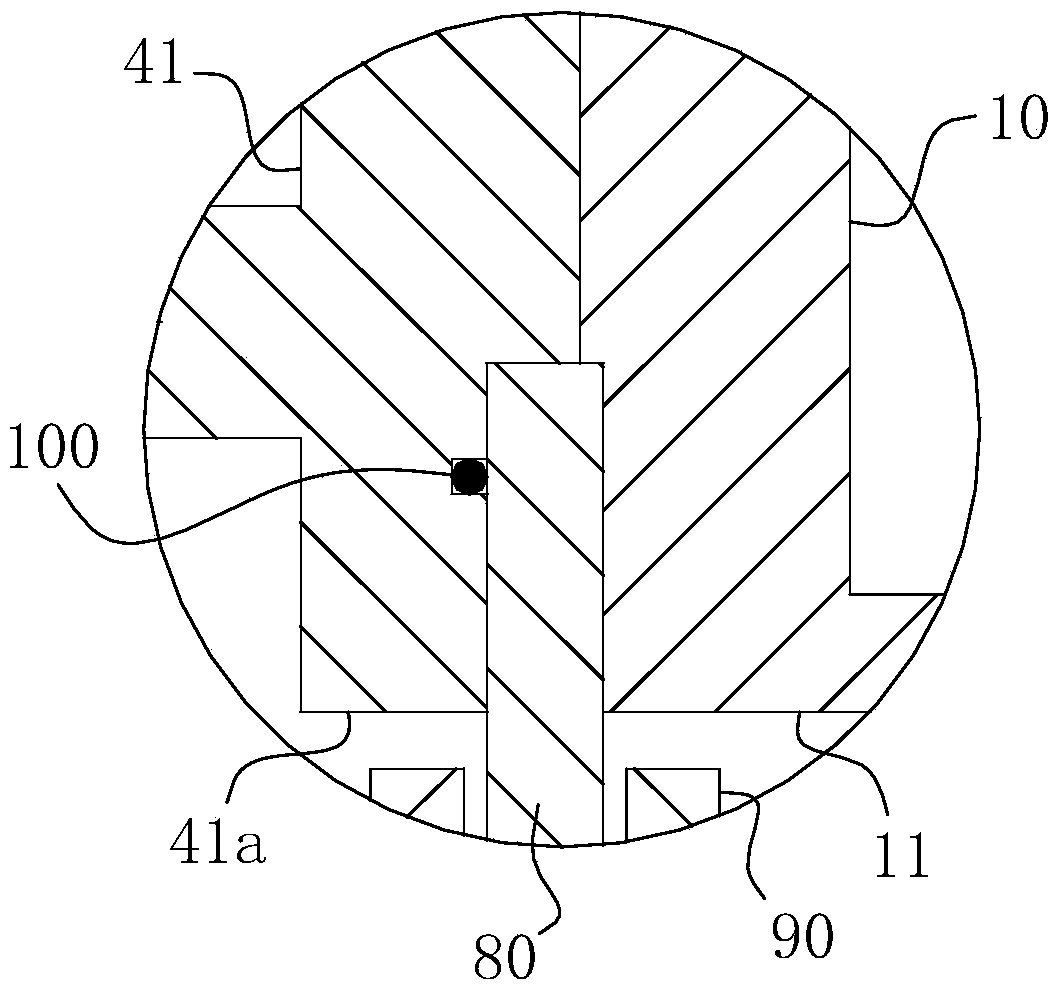

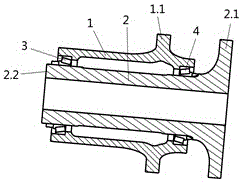

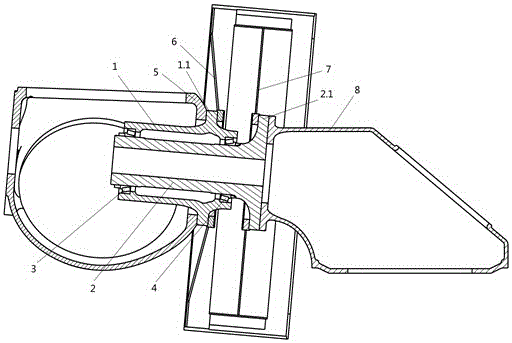

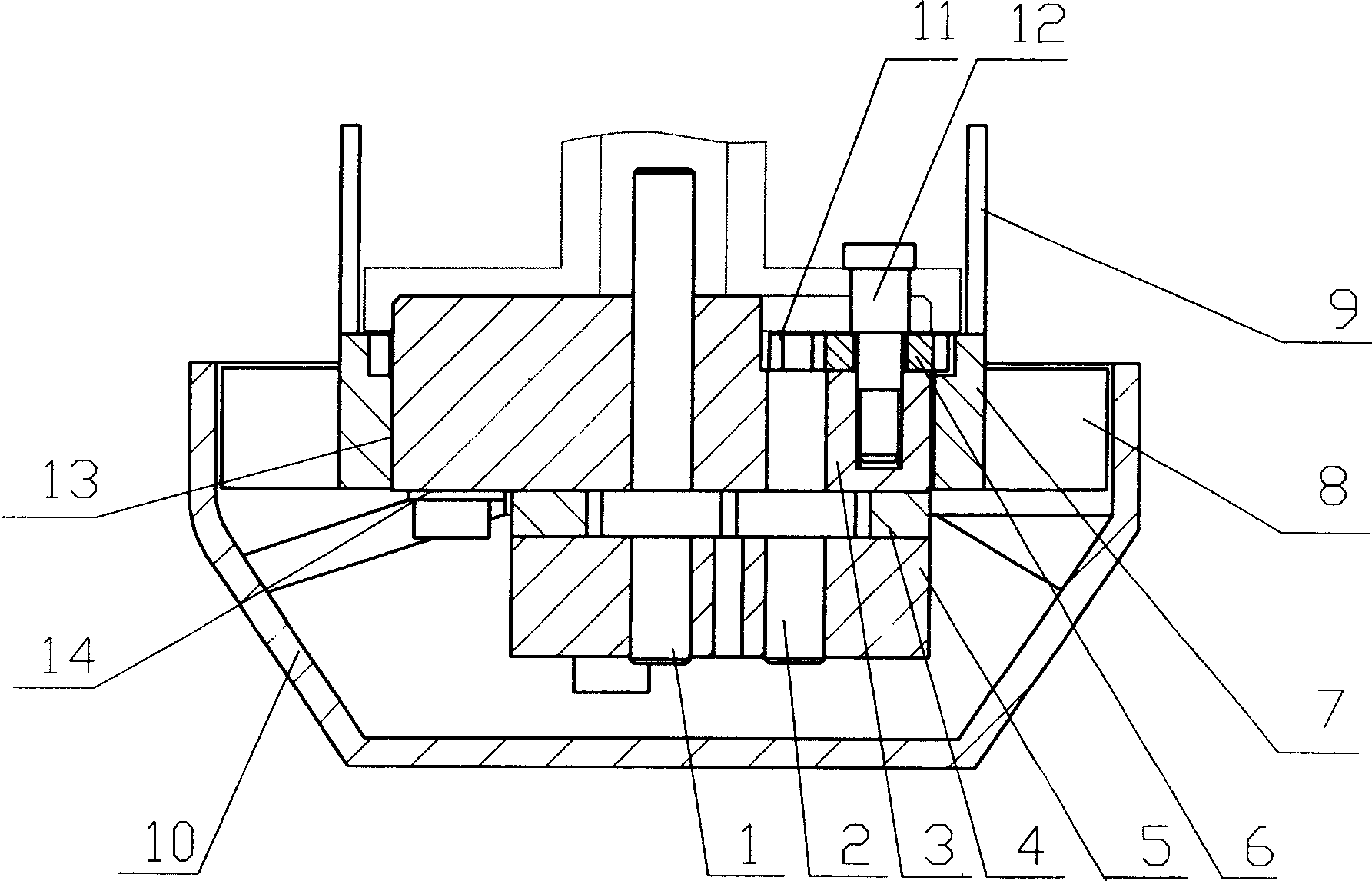

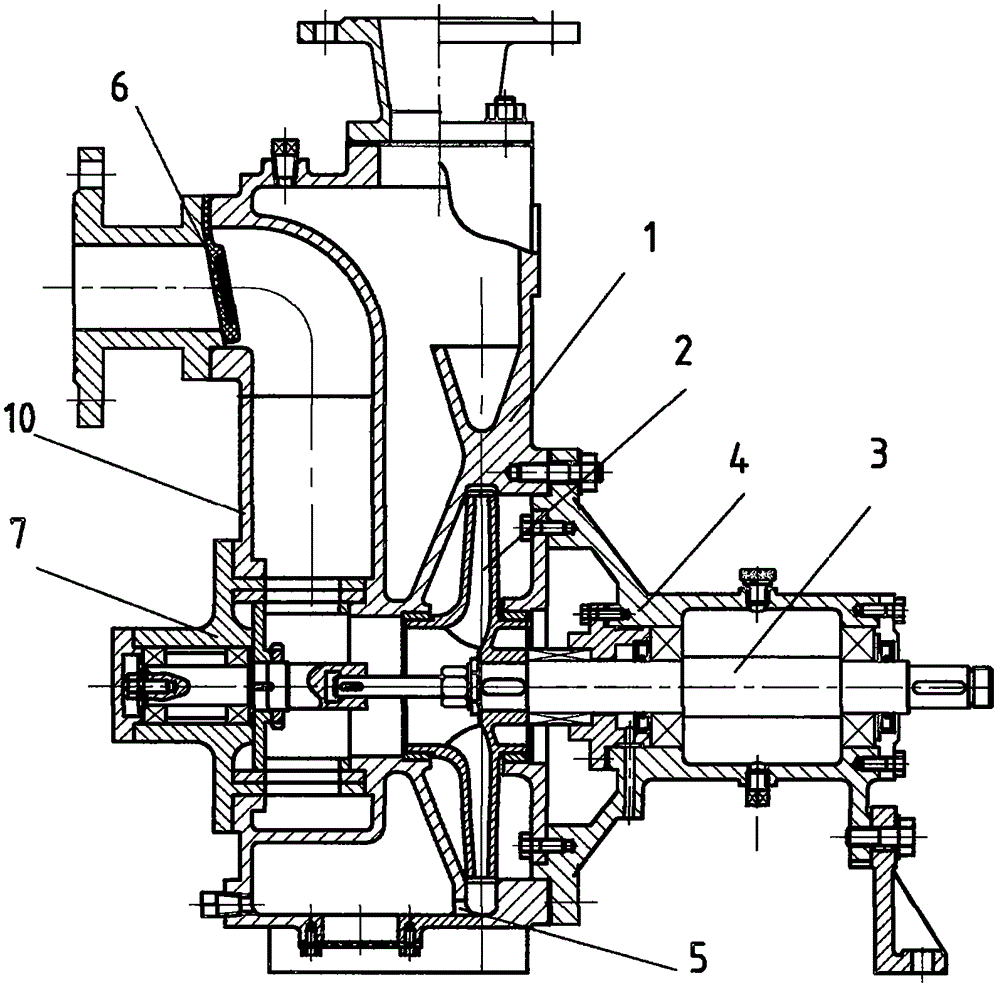

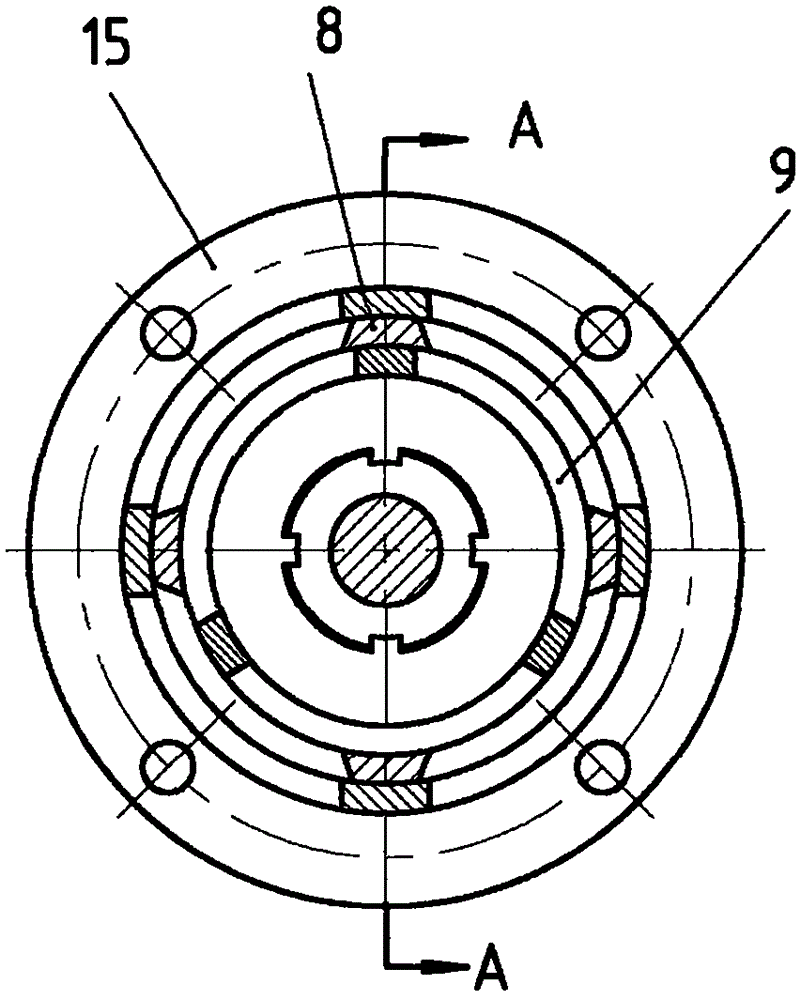

Water jet propulsion pump

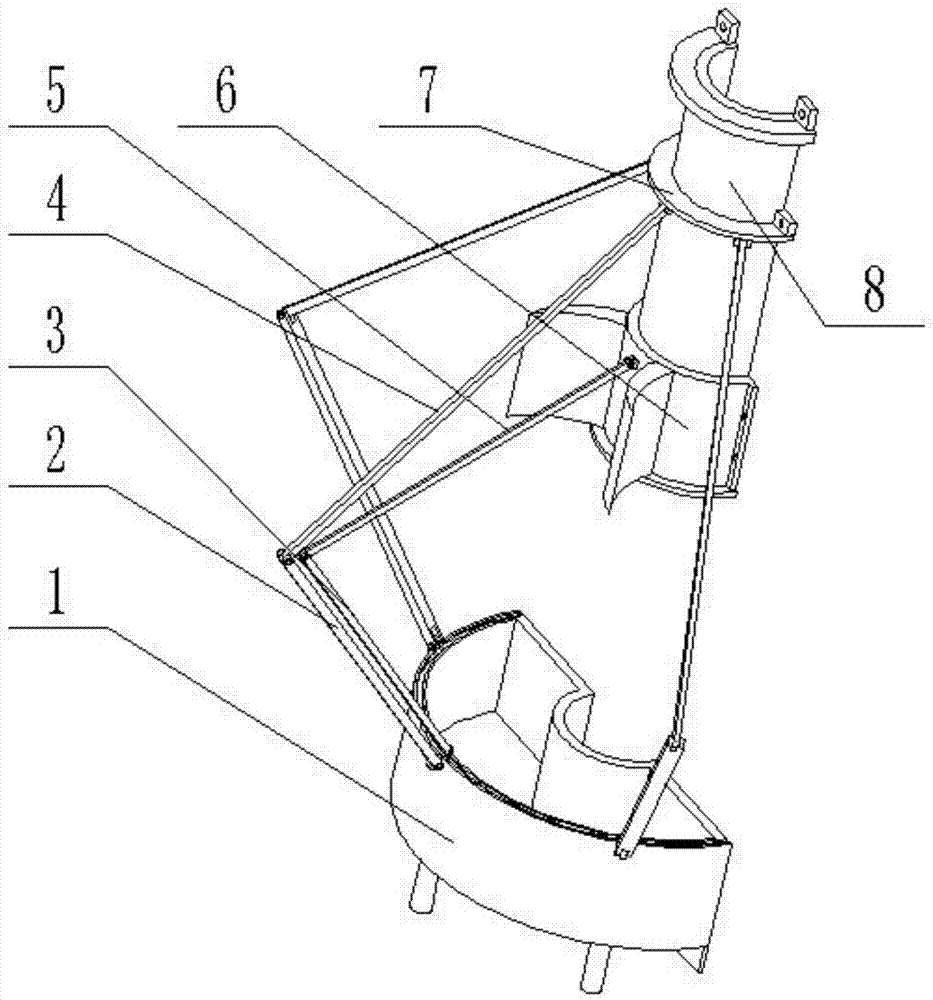

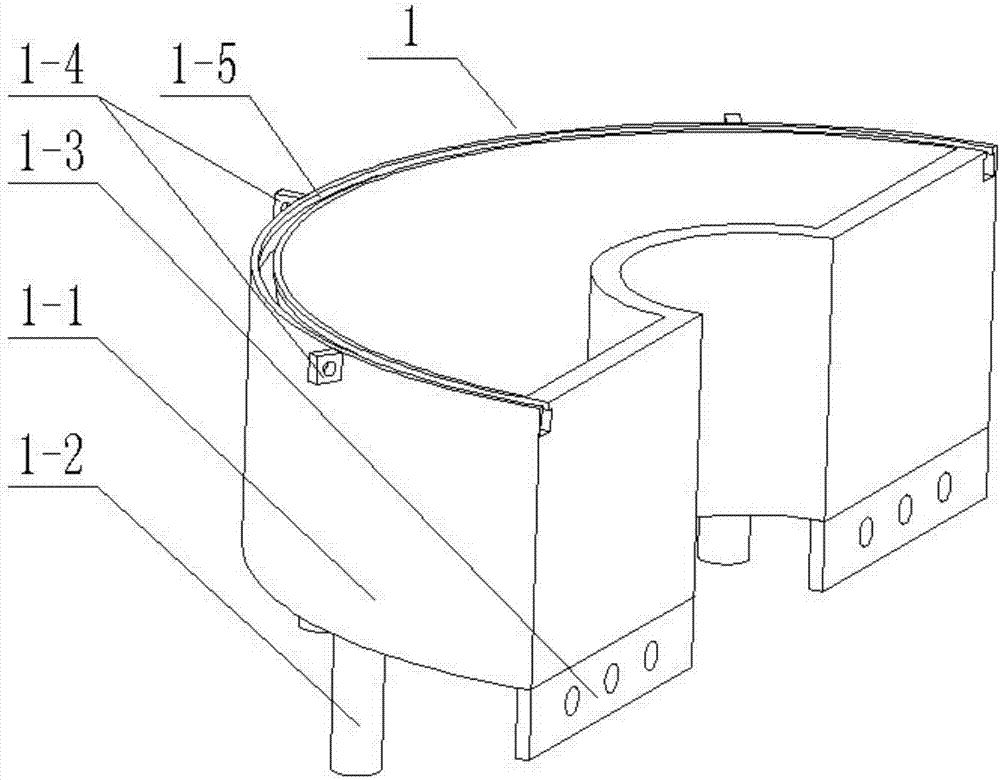

InactiveCN103527521AGuaranteed working noiseGuaranteed high performance and long lifePump componentsPropulsive elementsImpellerWater jet

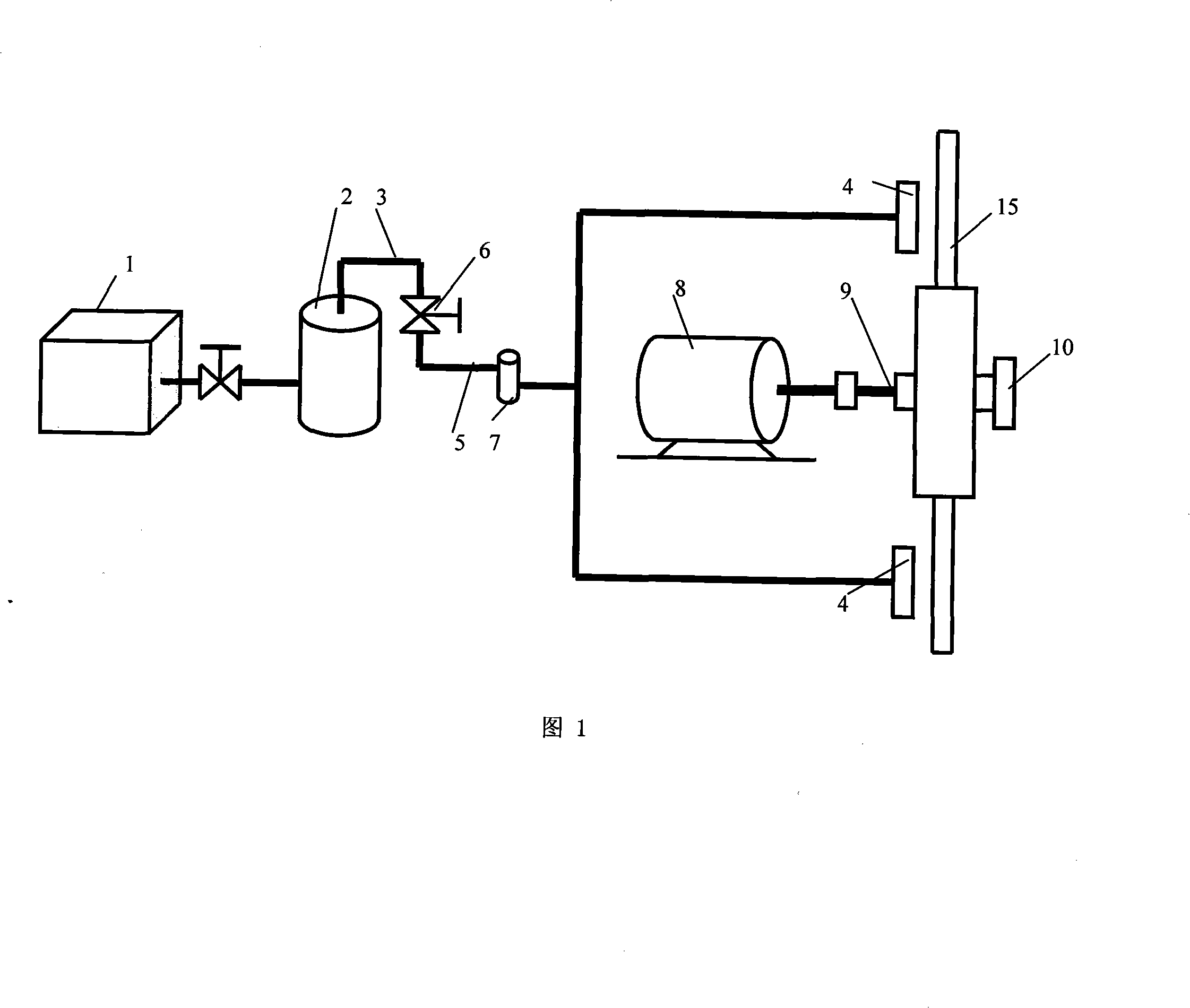

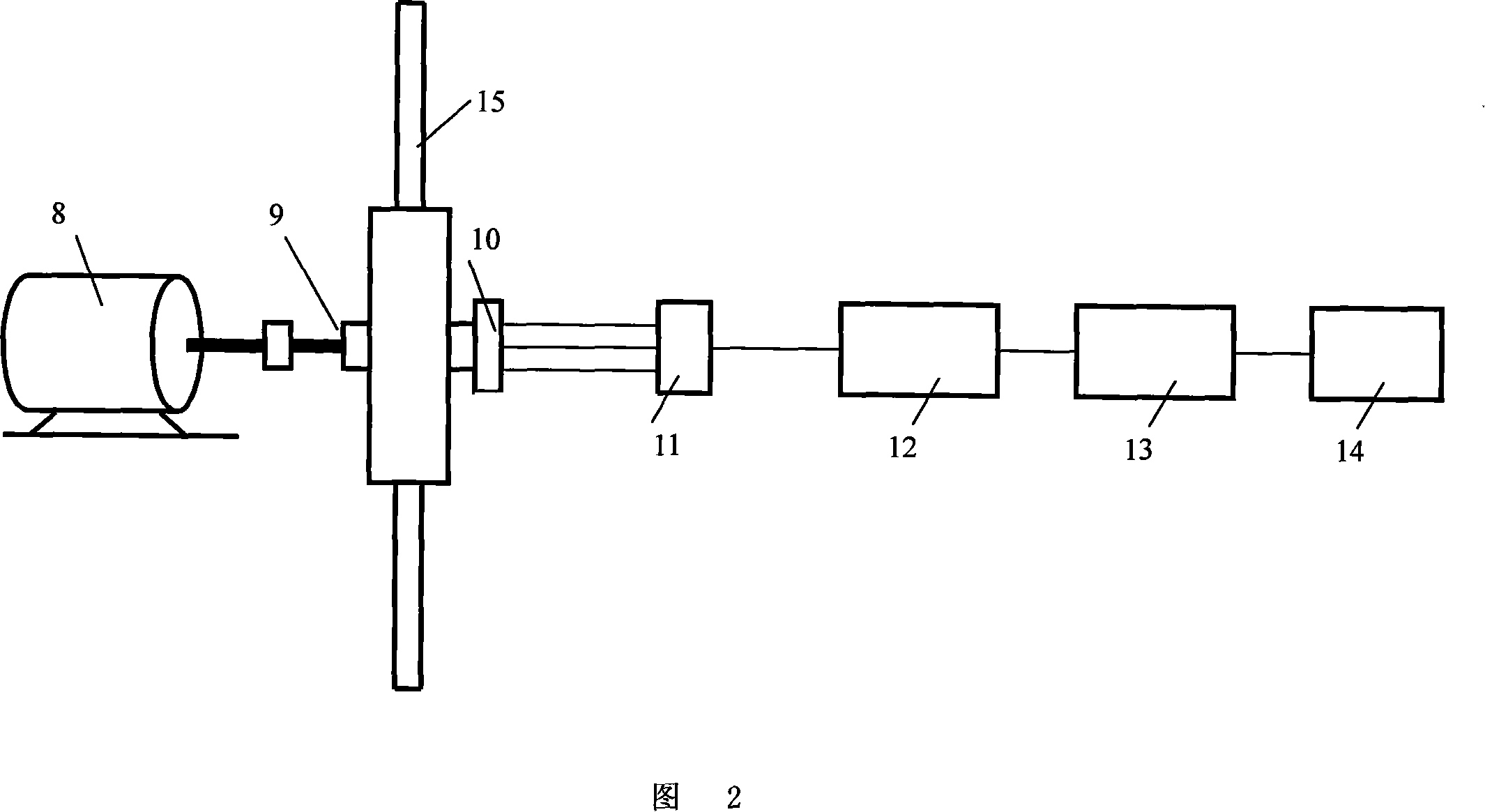

The invention belongs to the field of pumps and particularly relates to a water jet propulsion pump which comprises a pump body and a pump shaft assembly arranged at a pump cavity of the pump body. The pump shaft assembly at least comprises a pump shaft and an impeller wheel arranged on the pump shaft; the pump shaft is of a simply supported beam structure with bearings at the two ends of the pump shaft fixedly connected, the tail end of the pump shaft and a power source of the water jet propulsion pump are in normal-running fit, and the head end of the pump shaft extends in the axial direction and is in bearing fit with a bearing assembly arranged on the pump body; bounded by an impeller wheel body, the water jet propulsion pump is divided into a water inlet area and a water outlet area, wherein the water inlet area is communicated with a liquid inlet of the pump body, and the water outlet area is used for discharging water; a reflux passageway used for reducing the hydraulic thrust at the bearing assembly is arranged between the water inlet area and the water outlet area, and the water inlet area of the pump body, the water outlet area of the pump body, gaps to be lubricated of the bearing assembly and the reflux passageway are sequentially communicated and form a circular flow channel. The water jet propulsion pump is reasonable and practical in structure, wide in working usage range and long in service life, and high-efficiency work of components within the whole water outlet area of the pump body can be effectively guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH +2

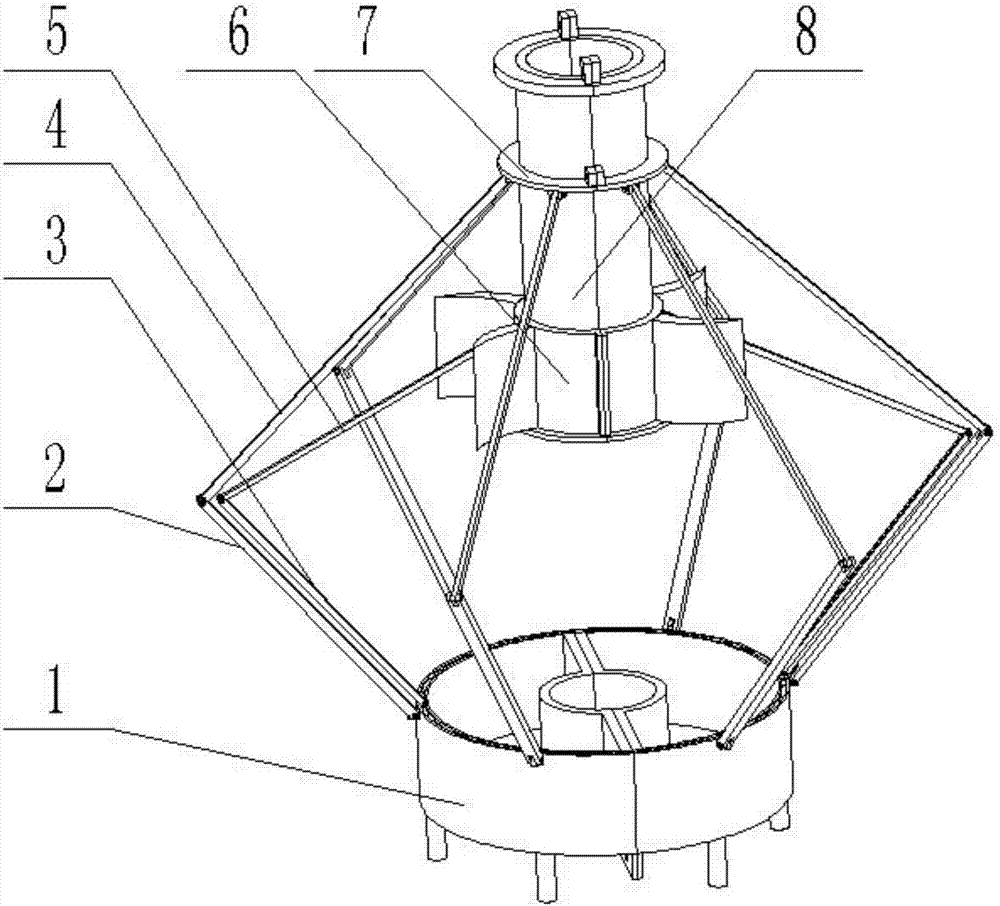

Wave-making oxygen increasing machine

ActiveCN104621039AIncrease dissolved oxygenLarge amplitudePisciculture and aquariaReduction driveEngineering

Owner:靖江市金标空调设备厂

Main bearing assembly of wind generating set

Owner:BEIJING SANLI XINNENG SCI & TECH

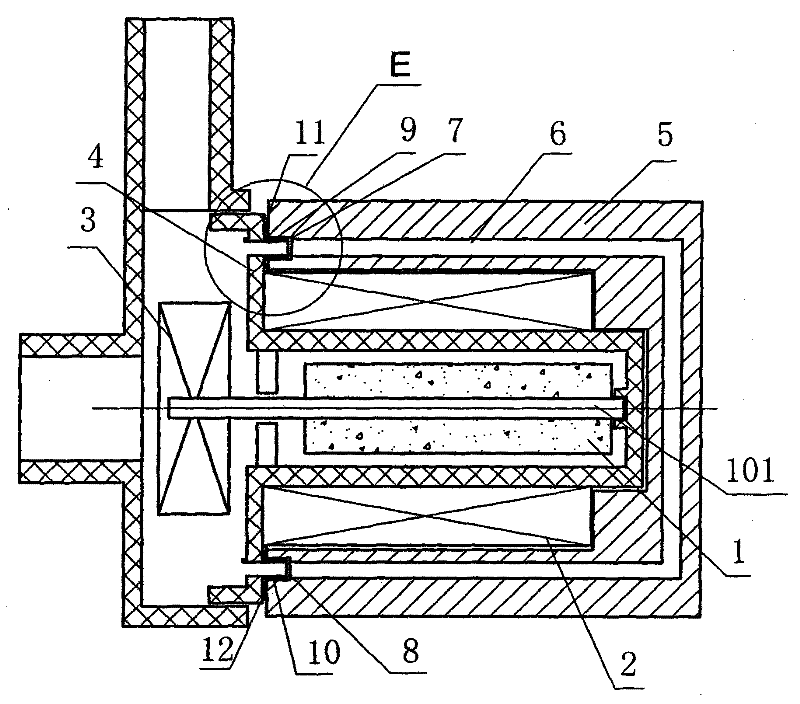

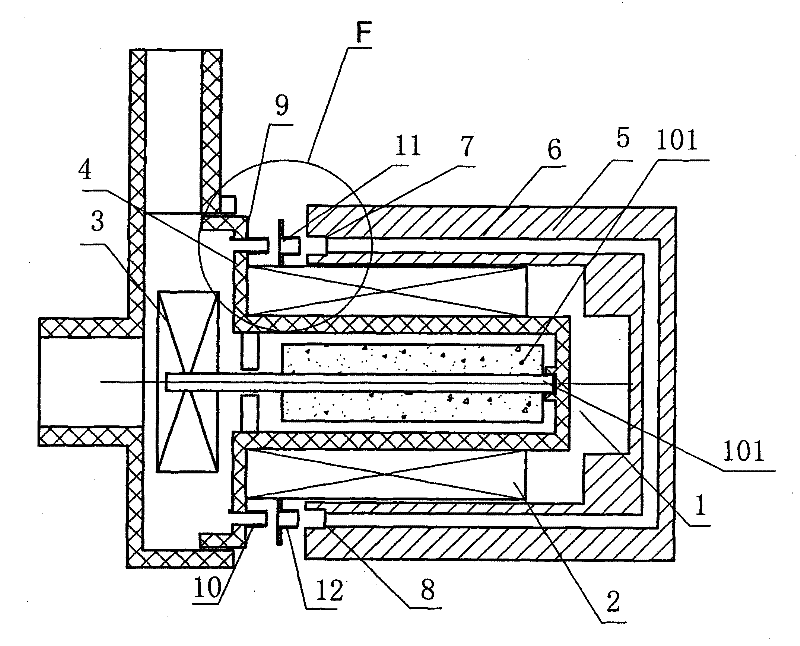

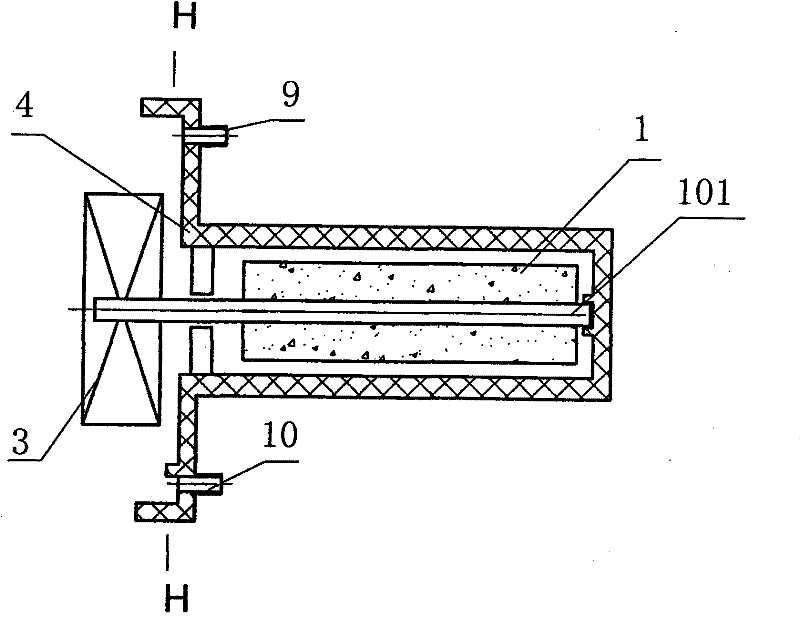

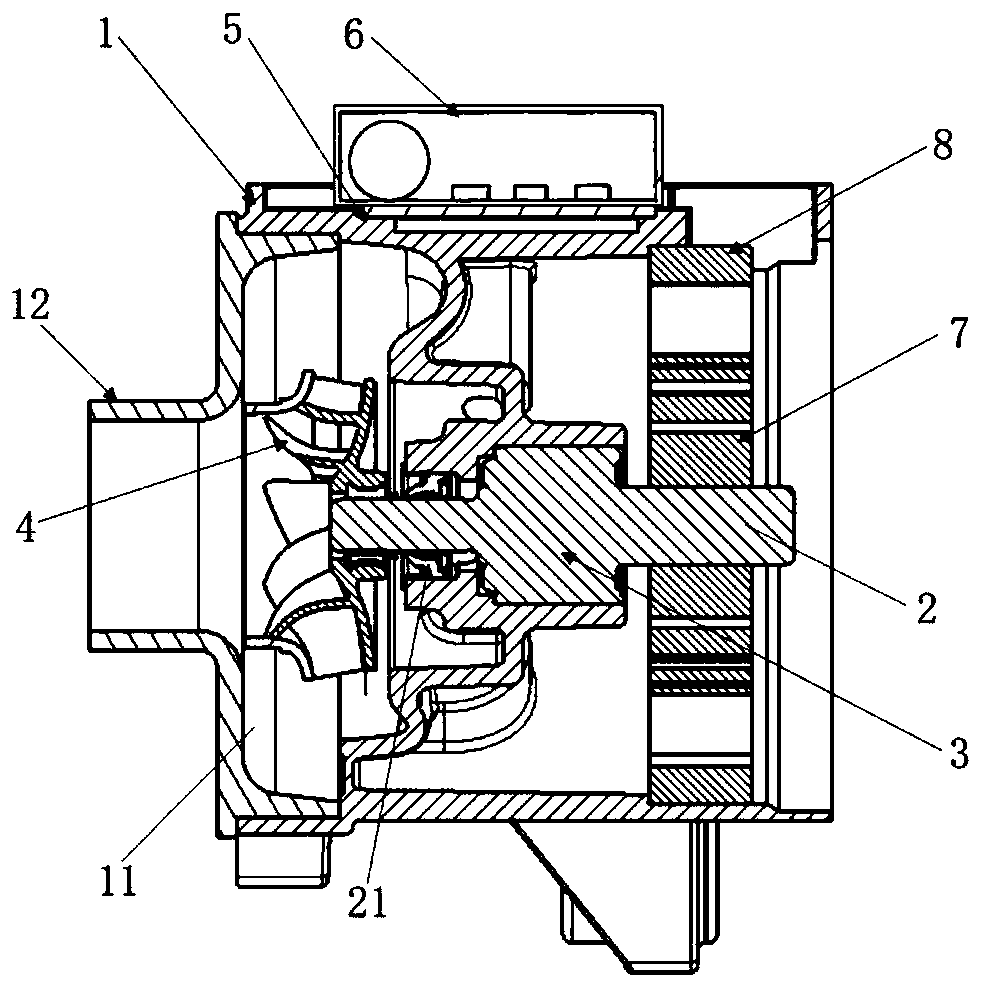

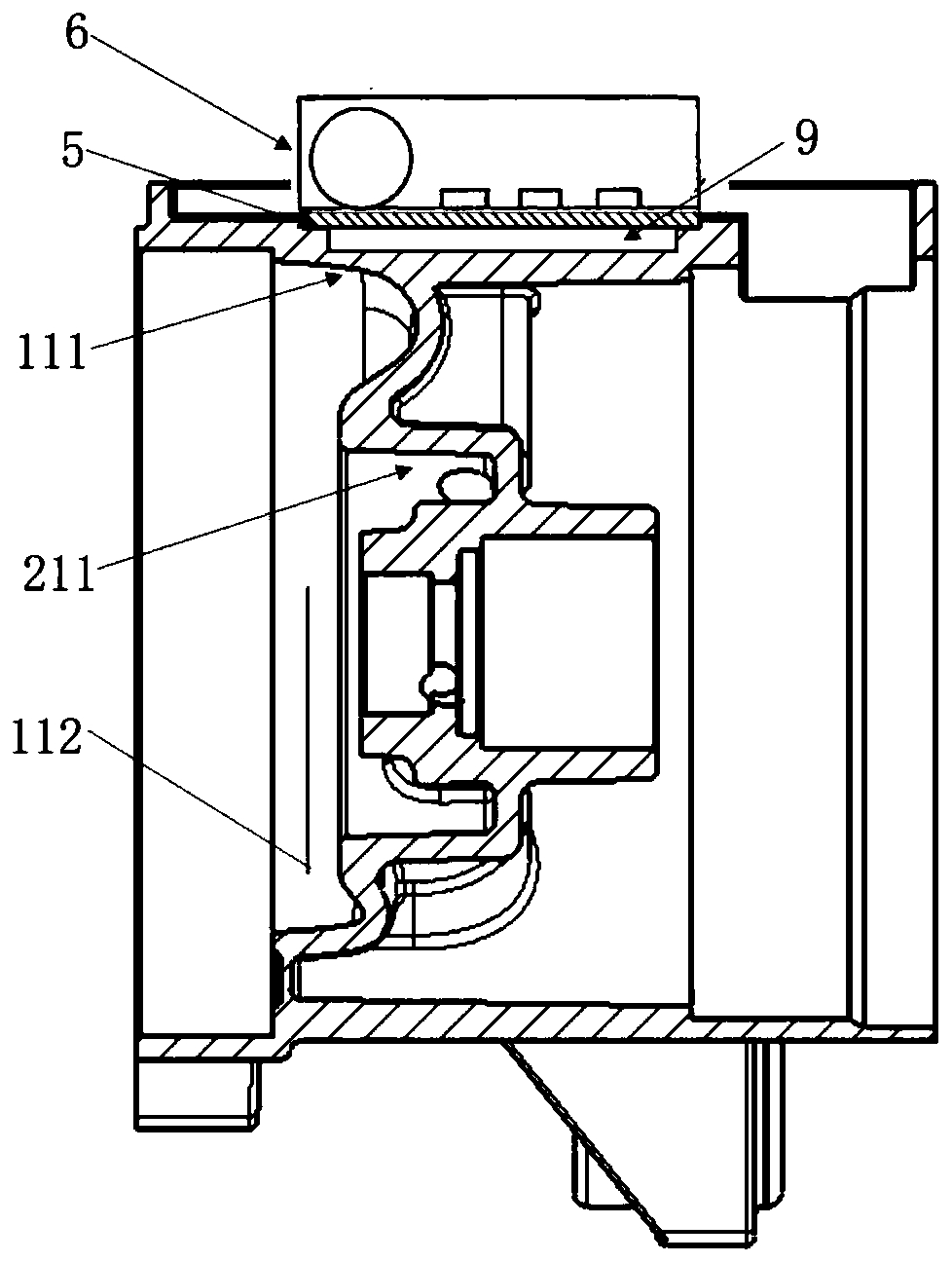

Alternating-current permanent magnet synchronous drainage pump with built-in closed cooling water tank

InactiveCN102182711ATo achieve the purpose of heat dissipation and coolingReduce temperature risePump componentsPumpsPermanent magnet rotorImpeller

Owner:HANYU GRP CO LTD

Pneumatic motor

Owner:SICHUAN SHENGXIANGSHENG INTELLIGENT TECH CO LTD

Full-automatic impeller washing machine

InactiveCN102817211AAchieve riseAchieve sinkingOther washing machinesTextiles and paperImpellerStructural reliability

Owner:WHIRLPOOL CHINA

Structure of turbine blade wheel weight reducing for pressurizer

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for machining submerged pump impeller

The invention discloses a method for machining a submerged pump impeller. The method comprises the steps that firstly, a three jaw chuck clamps a large outer circle of the impeller, and rough turning is performed on an impeller opening ring, a plane A and a front cover board after calibration; secondly, surfacing adjusting is performed, the three jaw chuck clamps the opening ring, rough turning is performed on a plane B after calibration, drilling is performed, rough turning is performed on a rear cover board and a sealing surface, and rough turning is performed on the large outer circle; thirdly, rough turning is performed on the plane B, boring is performed, the rear end cover and the sealing surface undergo finish turning so as to meet the requirements of a drawing, and chamfering is performed; fourthly, turning is performed on a core rod, the impeller is sleeved in the core rod and screwed through a nut, finish turning is performed on the plane A (1), the overall length is controlled according to the requirements of the drawing, the opening ring and the front end cover (3) undergo turning so as to meet the requirements of the drawing, the large outer circle undergoes finish turning so as to meet the requirements of the drawing, and chamfering is performed; fifthly, checkout is performed; sixthly, a static equilibrium test is performed as the requirements; seventhly, a keyway is inserted; eighthly, checkout is performed; ninth, cleaning, burring, oiling and stockroom entering are performed. The method for machining the submerged pump impeller facilitates machining, ensures machining precision and improves production efficiency, and is suitable for machining of industrial pump impellers.

Owner:JIANGSU YAMEI PUMP IND GRP

Lubricating gearing pump with high oil-absorbing performance

InactiveCN1818385AReduce viscosityImprove liquidityRotary piston pumpsLubricating pumpsImpellerOil and grease

Owner:赵冬章 +1

A small centrifugal pump with an inner rotor motor directly driving the impeller

Owner:HANYU GRP CO LTD

Turbo chiller and chiller system including the same

ActiveUS20150338160A1Increase capacityImprove convenienceCompression machines with non-reversible cycleFluid circulation arrangementImpellerEngineering

A turbo chiller and a chiller system are disclosed. The turbo chiller includes a compressor including an impeller for compressing a refrigerant and a motor for driving the impeller, a condenser configured to perform heat exchange between condensed water and the refrigerant introduced from the compressor, an evaporator configured to perform heat exchange between chilled water and the refrigerant discharged from the condenser, and an expansion valve disposed between the condenser and the evaporator. The compressor, the evaporator and the condenser are arranged to be stacked in a predetermined direction.

Owner:LG ELECTRONICS INC

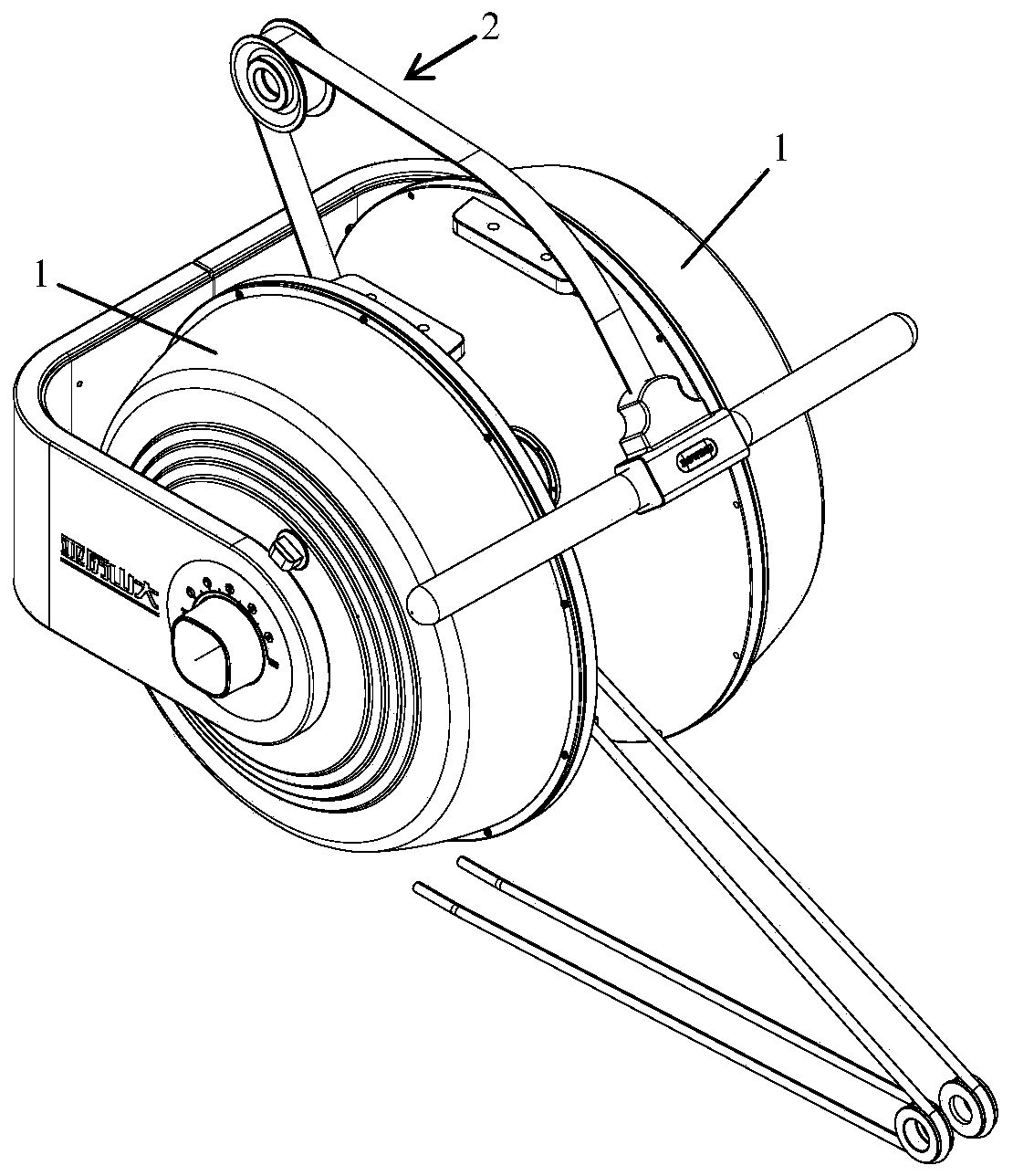

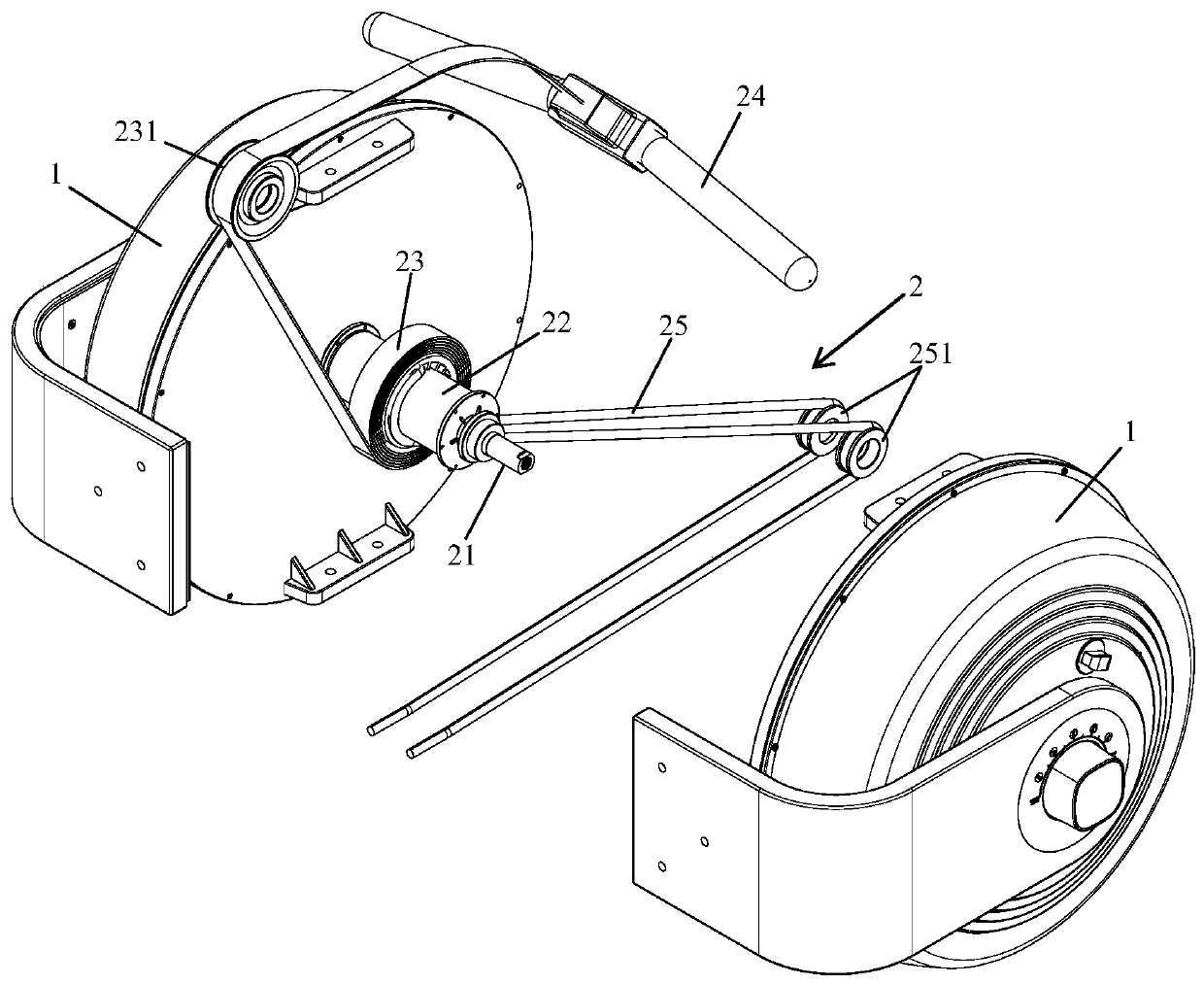

Vacuum cleaner and suction piece assembly thereof

InactiveCN1138500CReduce structural weightImprove maneuverabilitySuction nozzlesImpellerSpray nozzle

A suction piece and a vacuum cleaner using the same where in the suction piece is provided with impeller adapted to be rotated by a sunction force, brushes or scrapers spirally mounted to the whole or part of the impeller and adapted to come into contact with a surface being cleaned, a rotary brush coaxial with the impeller and adapted to rotate together therewith, and there is not provided any partition or the like between the impeller and the rotary brush where by the suction piece is made small-sized, lightweight and quiet.

Owner:HITACHI LTD

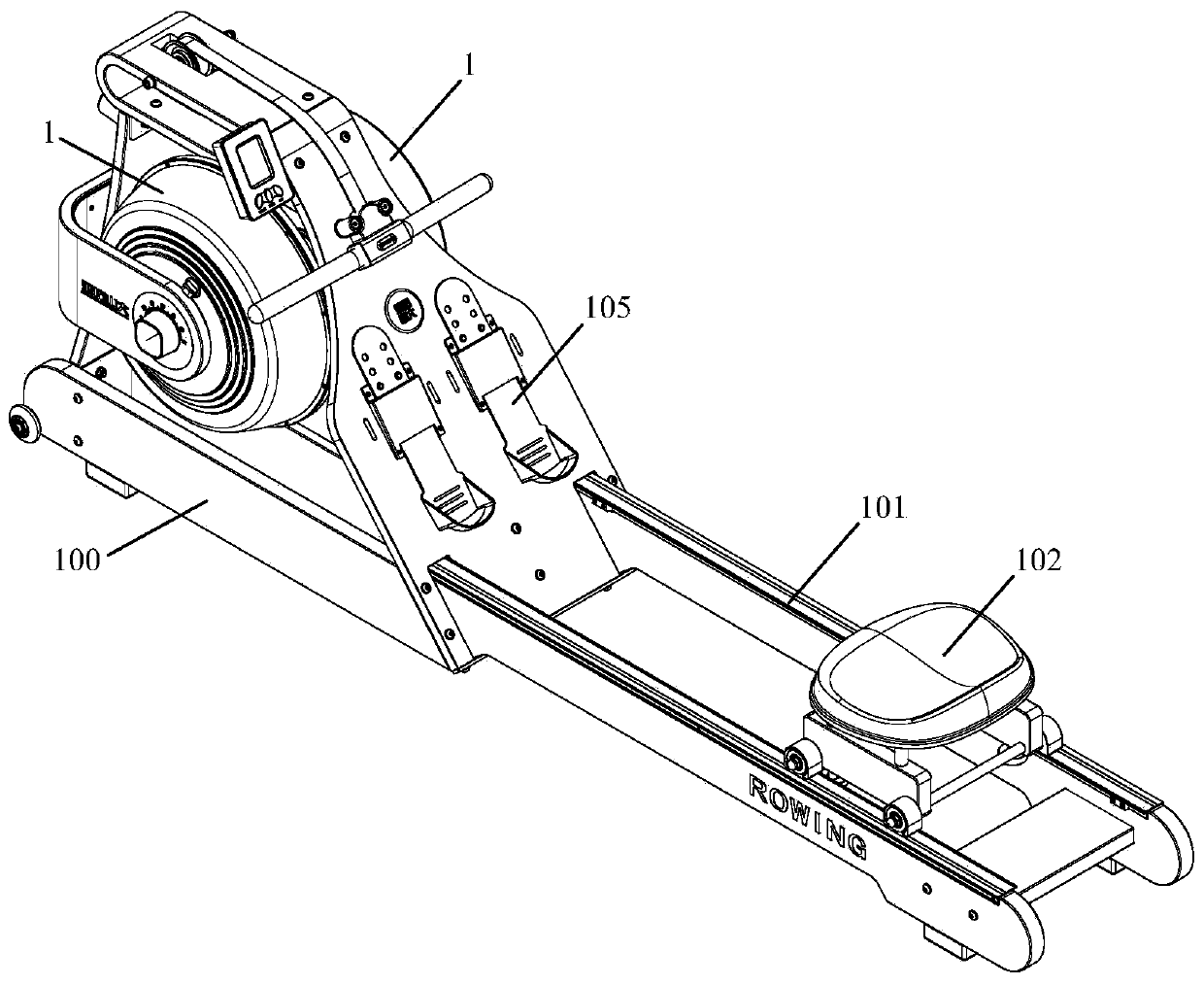

A water resistance rowing fitness machine

Owner:LEIYUN SHANGHAI IND CO LTD

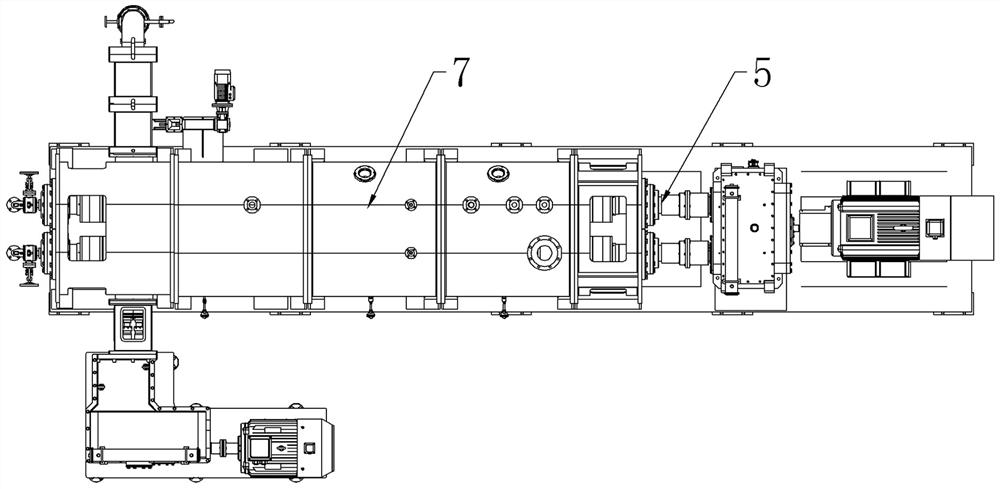

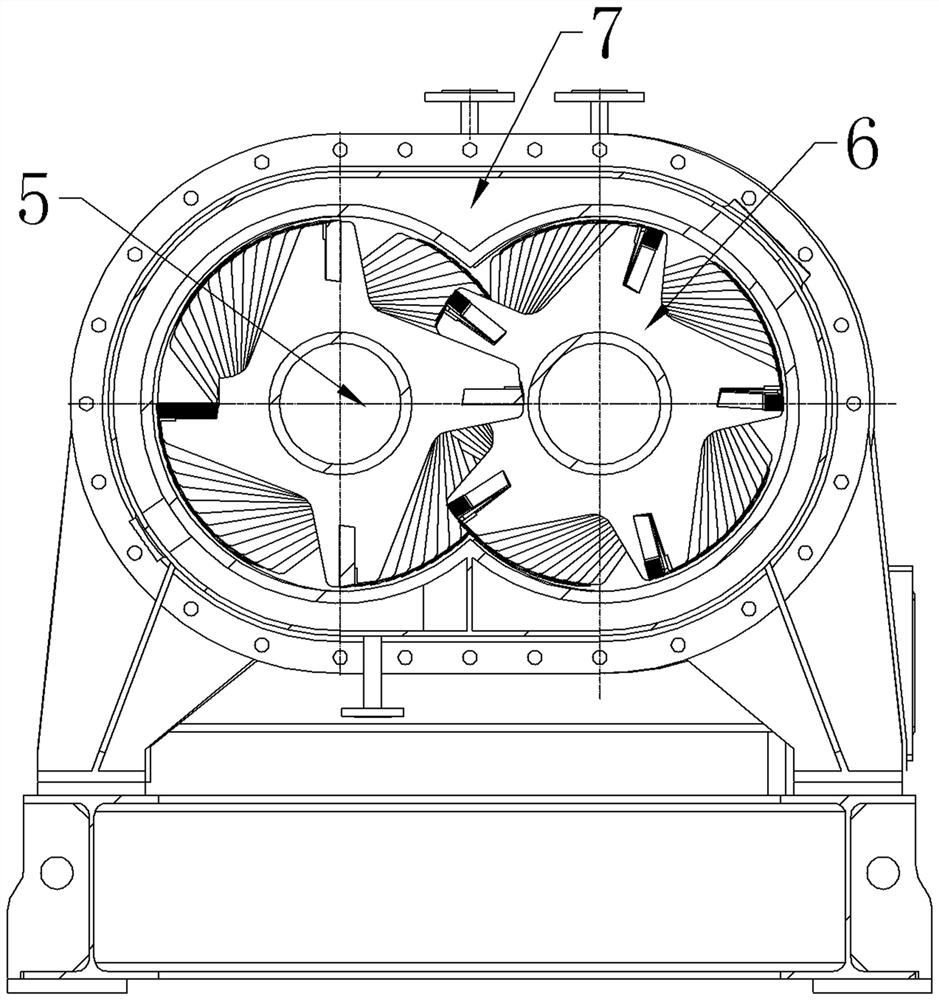

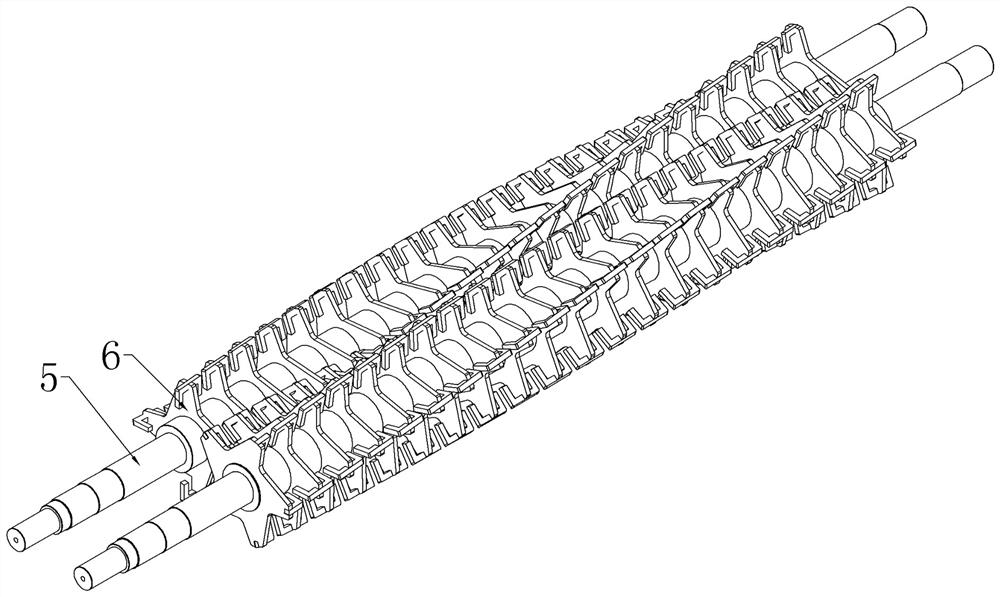

Self-cleaning kneading reactor

PendingCN113318692AAvoid stickingImprove mixing efficiencyChemical/physical/physico-chemical stationary reactorsImpellerEngineering

Owner:江苏胜开尔工业技术有限公司

Vane-type pneumatic mineralizing equipment and pneumatic flotation cell using same

Owner:ZHENGZHOU GOYOD RESOURCES NEW TECH CO LTD

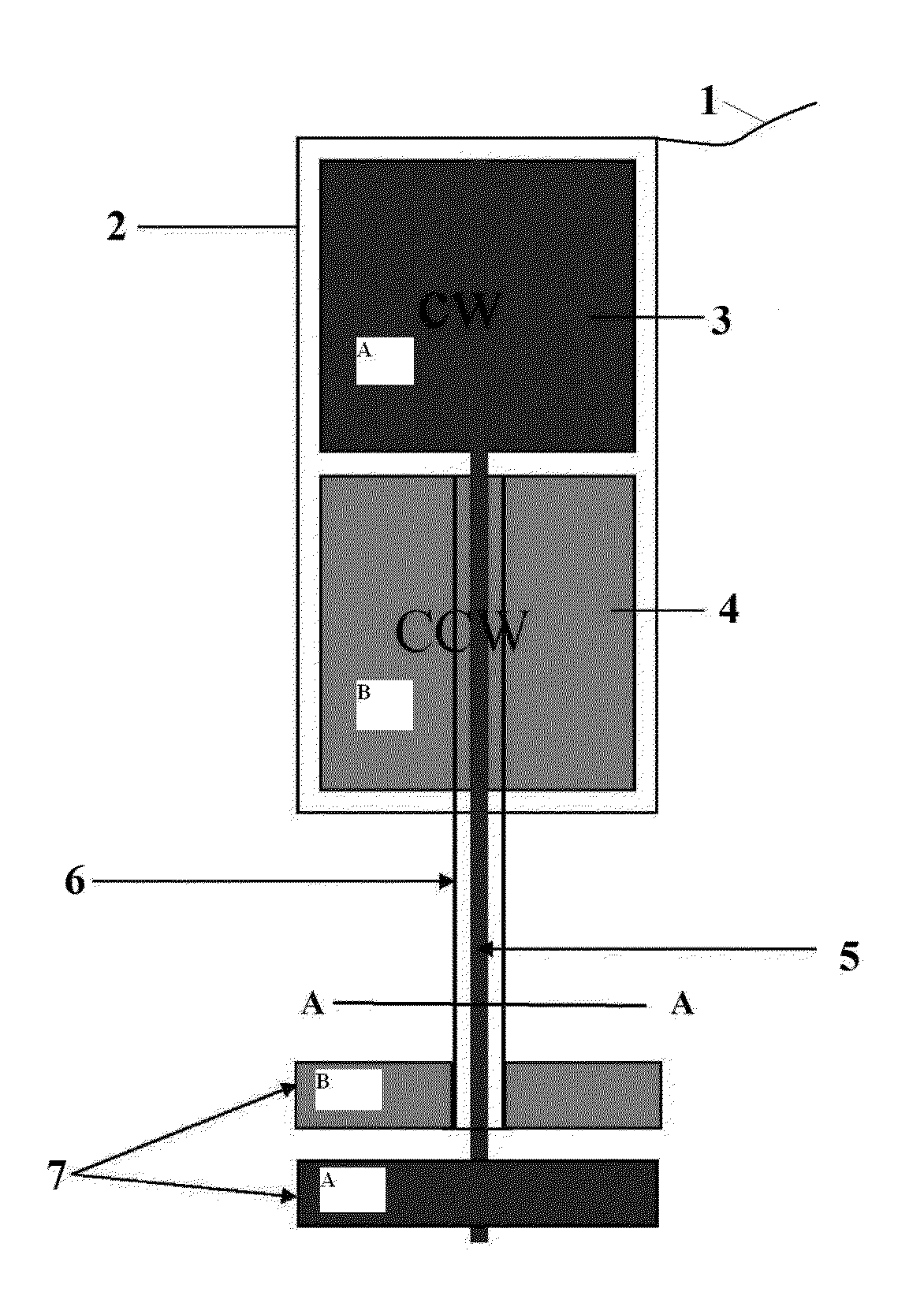

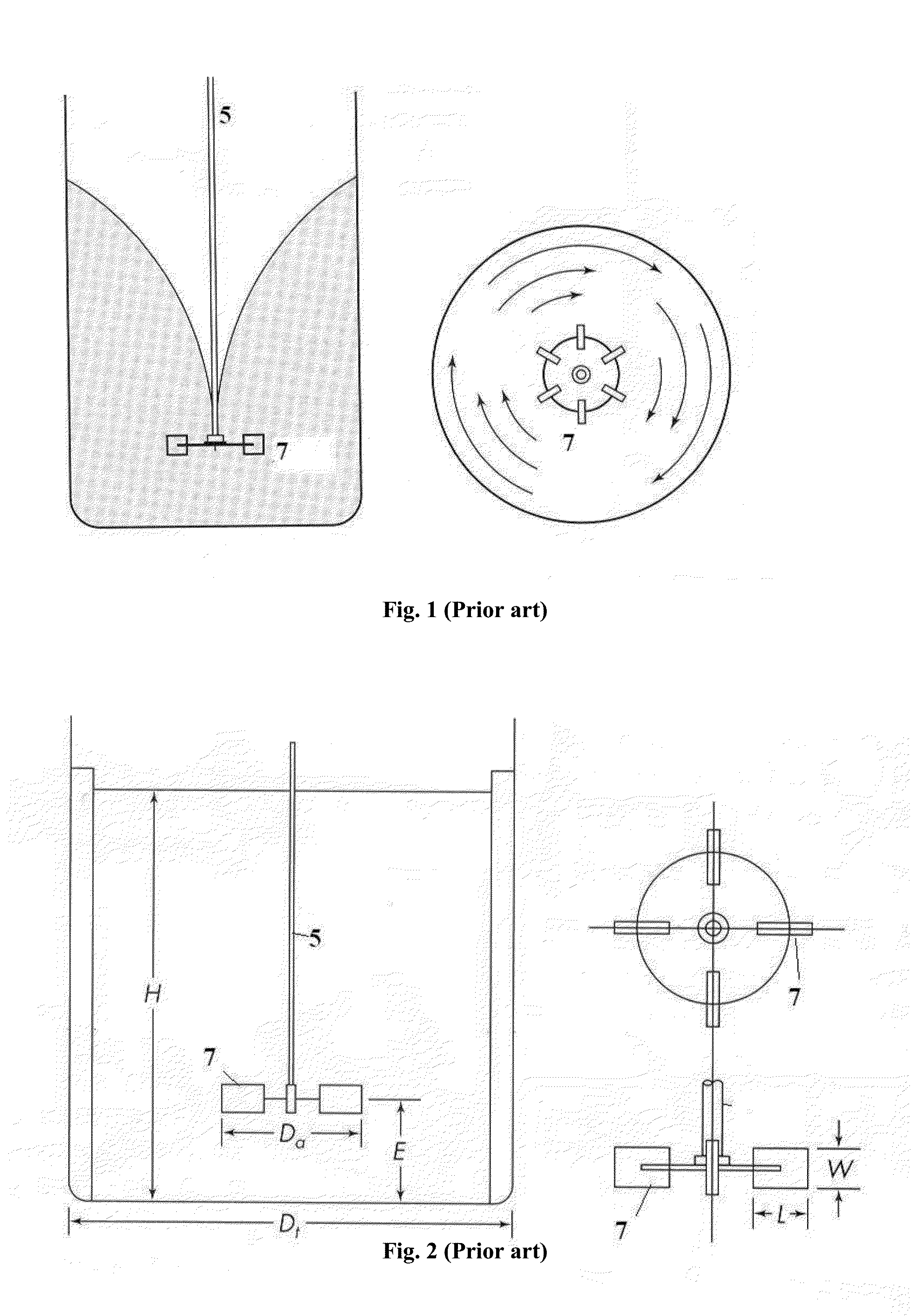

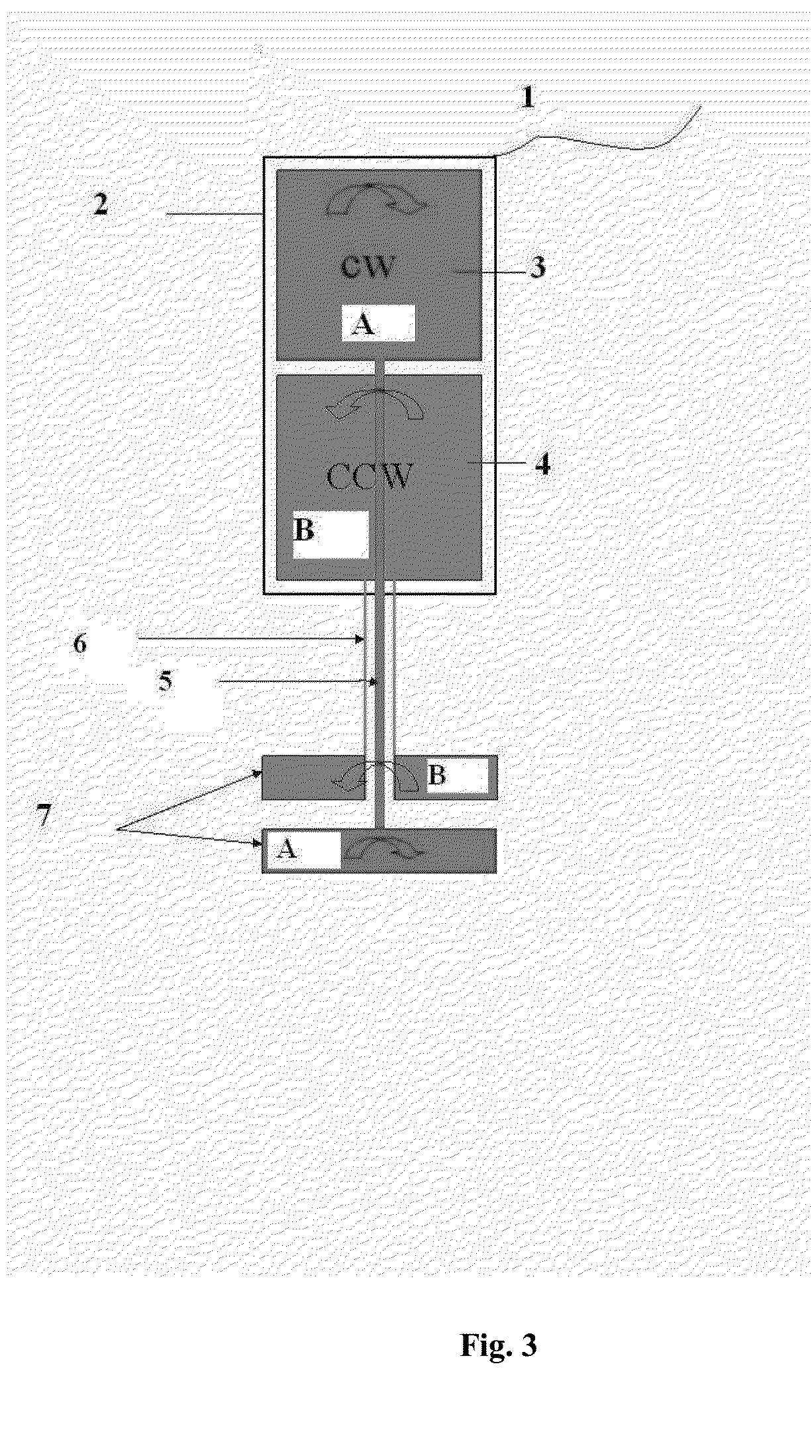

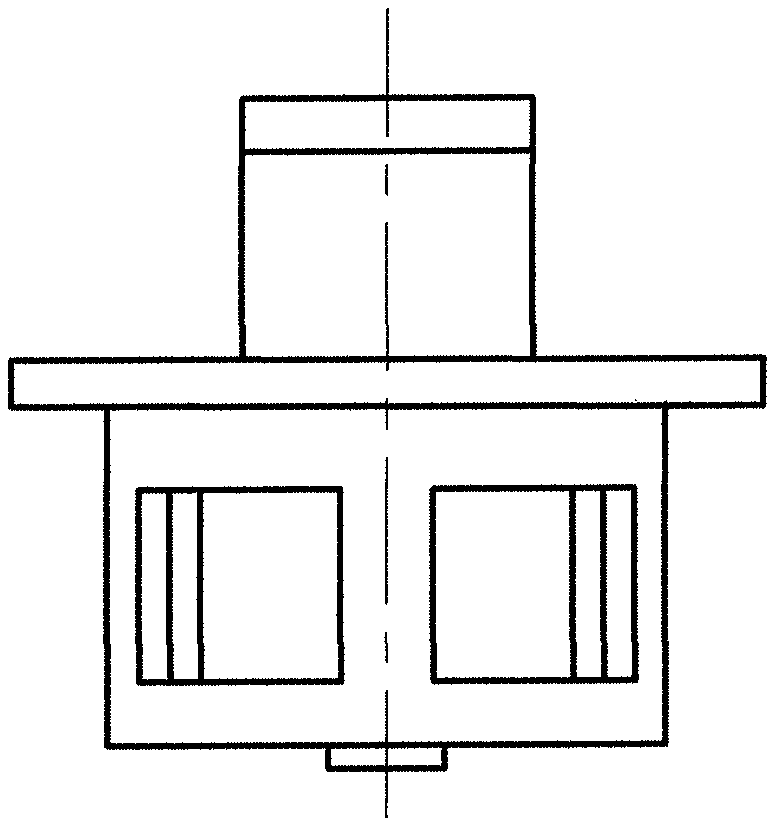

Enhancement of agitation by an innovative blender

InactiveUS20160038892A1Less energyQuick combinationRotary stirring mixersTransportation and packagingImpellerChemical compound

Owner:KORAI GASHTASEB MARDANI +2

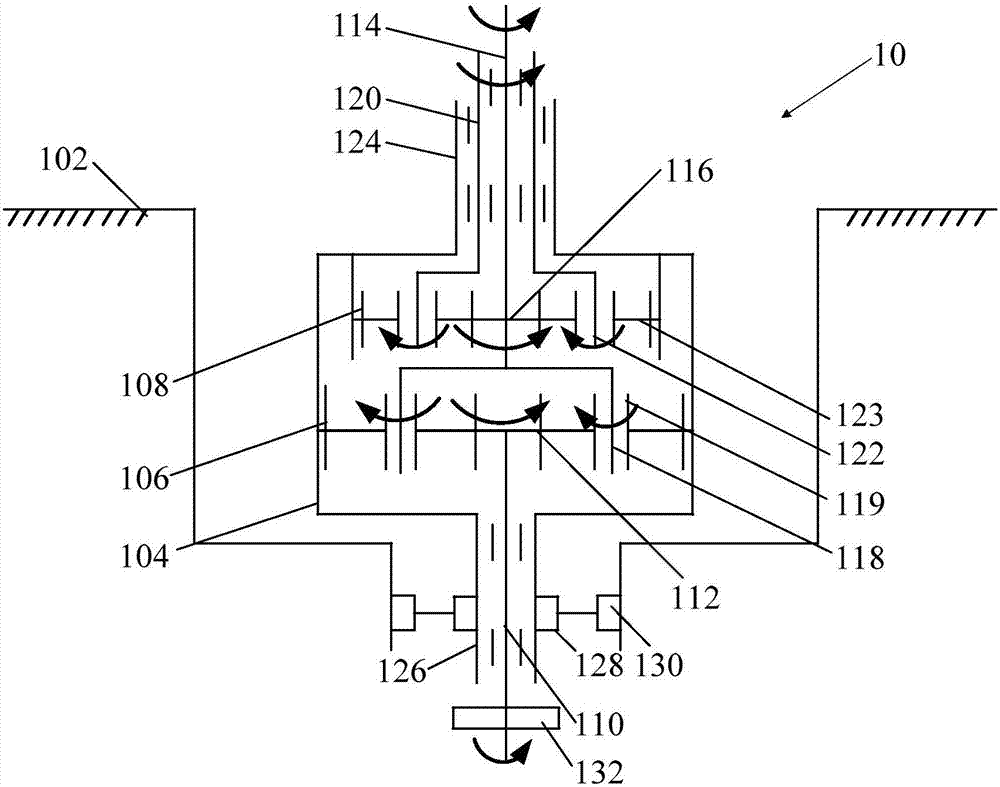

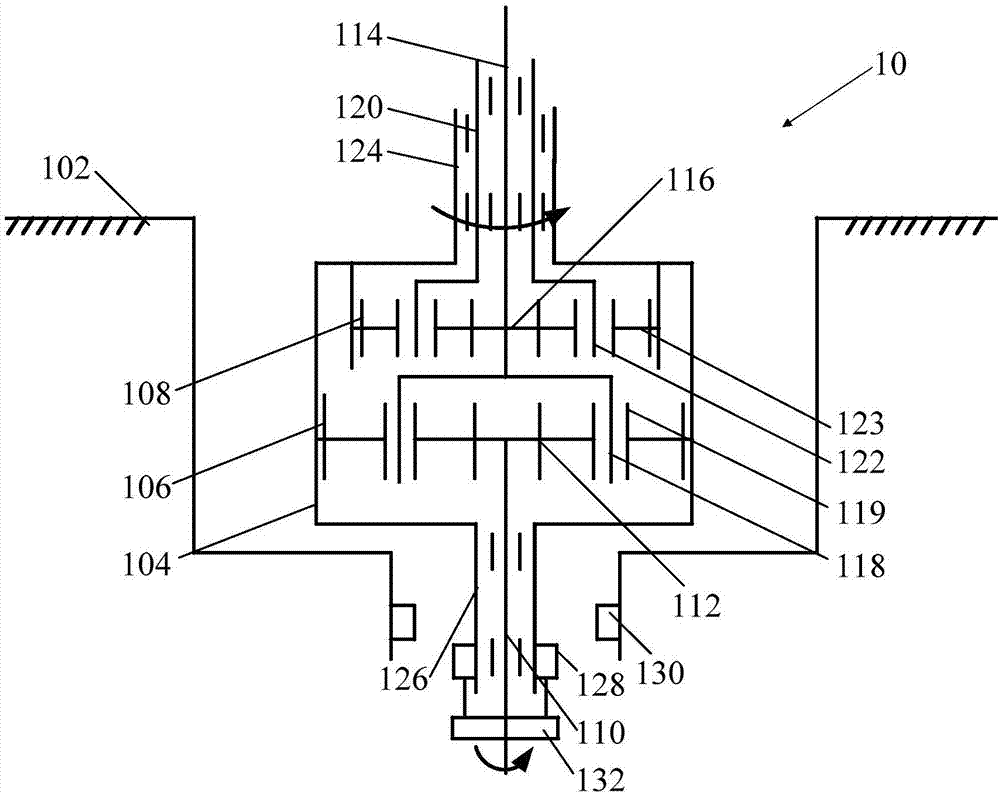

Multifunctional washing machine with super-strong detergency

PendingCN111270476ARealize the function of tapping deep cleaningOther washing machinesWashing machine with receptaclesImpellerLaundry washing machine

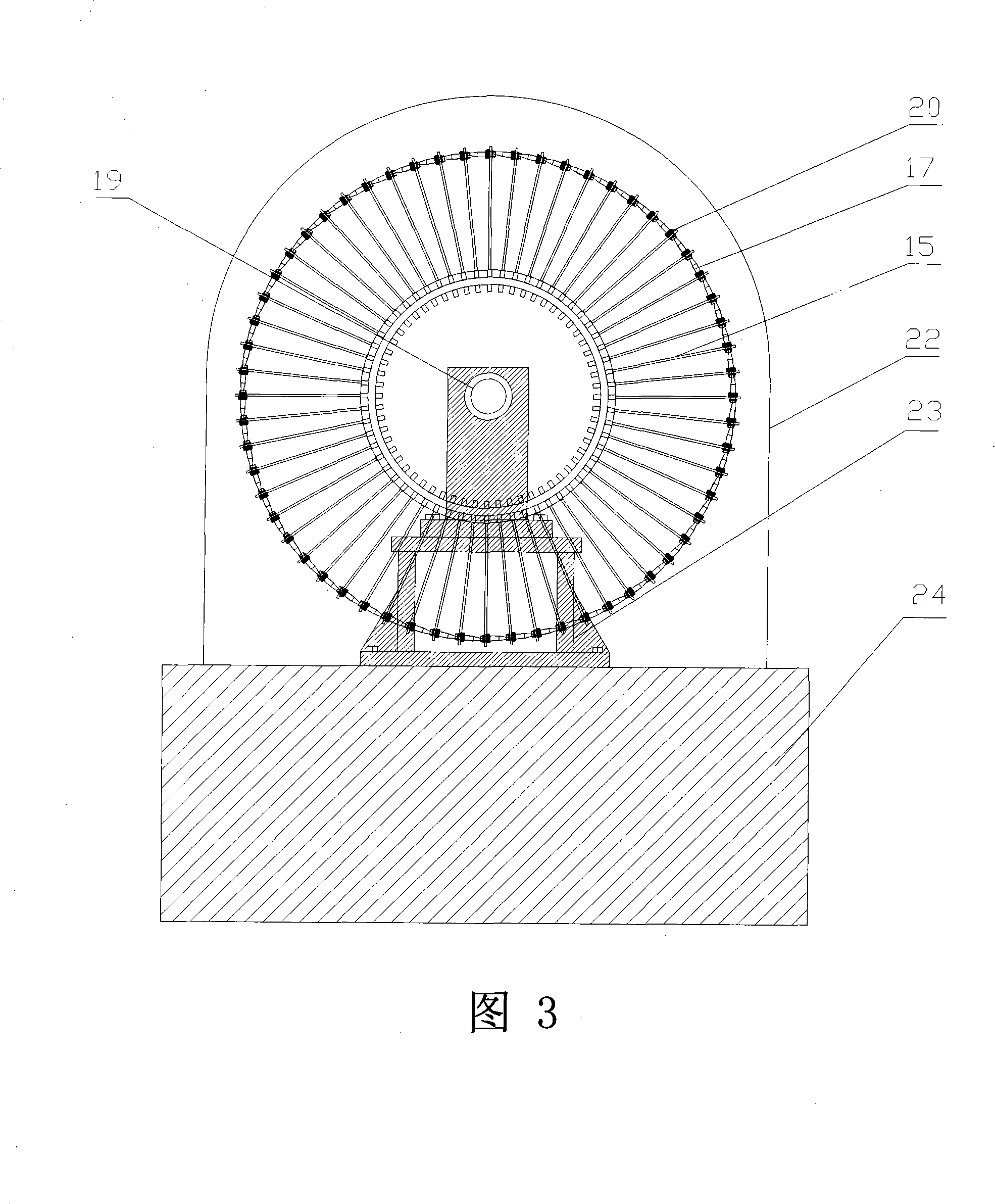

The invention discloses a multifunctional washing machine with super-strong detergency and belongs to the field of household appliances. A motor shaft assembly transmits driving force to a middle gear-shifting transmission assembly through belt transmission; the middle gear-shifting transmission assembly can realize two-gear power transmission, a main transmission mechanism assembly can realize two-gear power transmission of synchronous rotation and asynchronous rotation of a central pinion and a main transmission shaft, the main transmission mechanism assembly is in flat key connection and synchronous rotation with an inner impeller assembly, a sun wheel is fixedly connected and synchronously rotates with an outer impeller, and an inner impeller single-rotation washing mode, an outer impeller single-rotation washing mode and an inner and outer impeller synchronous rotation washing mode can be realized based on gear cooperation of the middle gear-shifting transmission assembly, the main transmission mechanism assembly and a planet wheel assembly; a waterway may cooperate with various washing modes to realize inner barrel independent inflow, outer barrel independent inflow and innerand outer barrel synchronous inflow; and a deep cleaning mechanism assembly is designed between the inner barrel and the outer barrel and is only started when the outer impeller works, so that the flapping type deep cleaning function can be realized.

Owner:CHANGCHUN INST OF TECH

Automobile electronic water pump with side-mounted controller and attached with cooling flow channel and automobile

Owner:苏州玲珑汽车科技有限公司

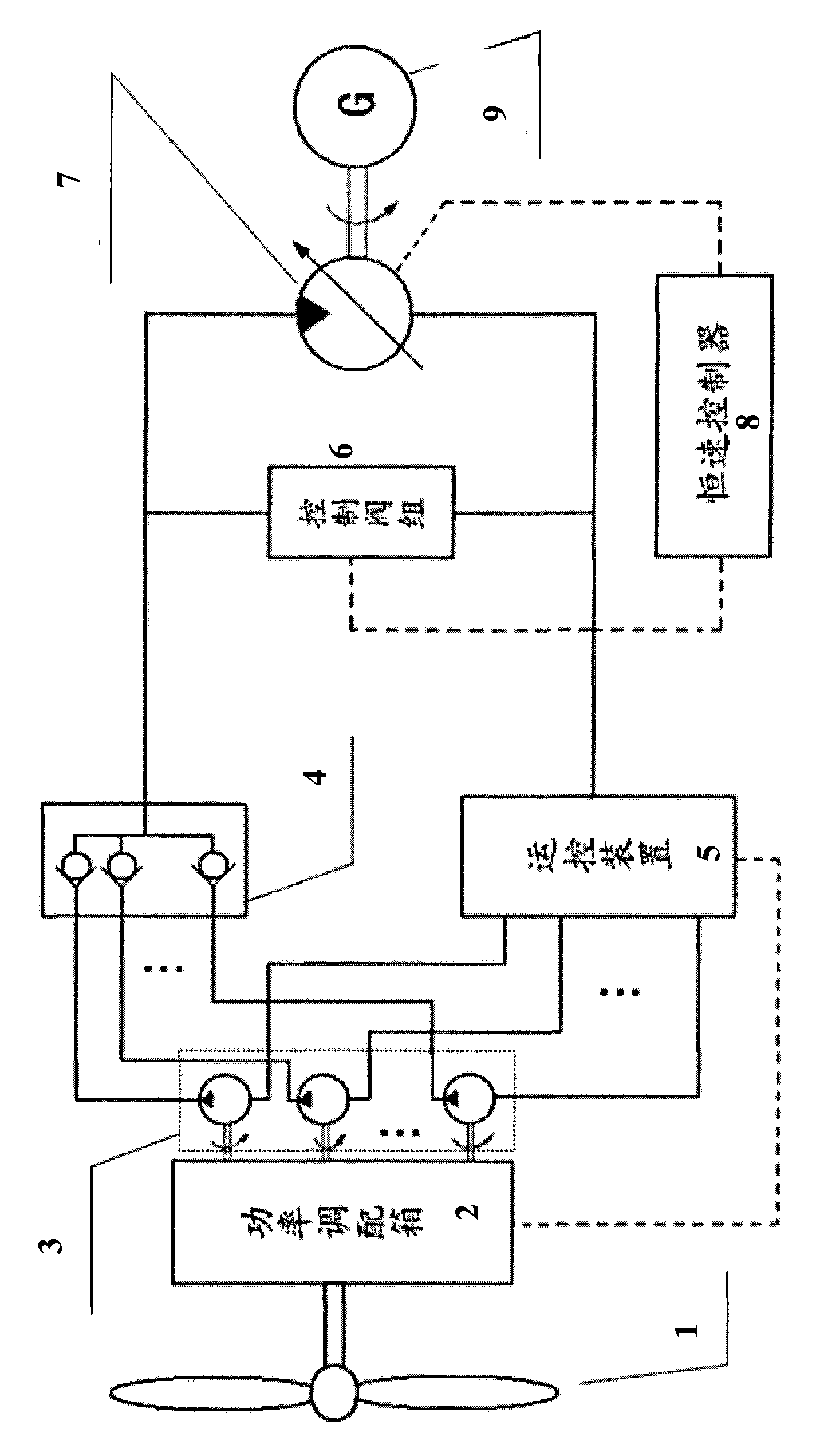

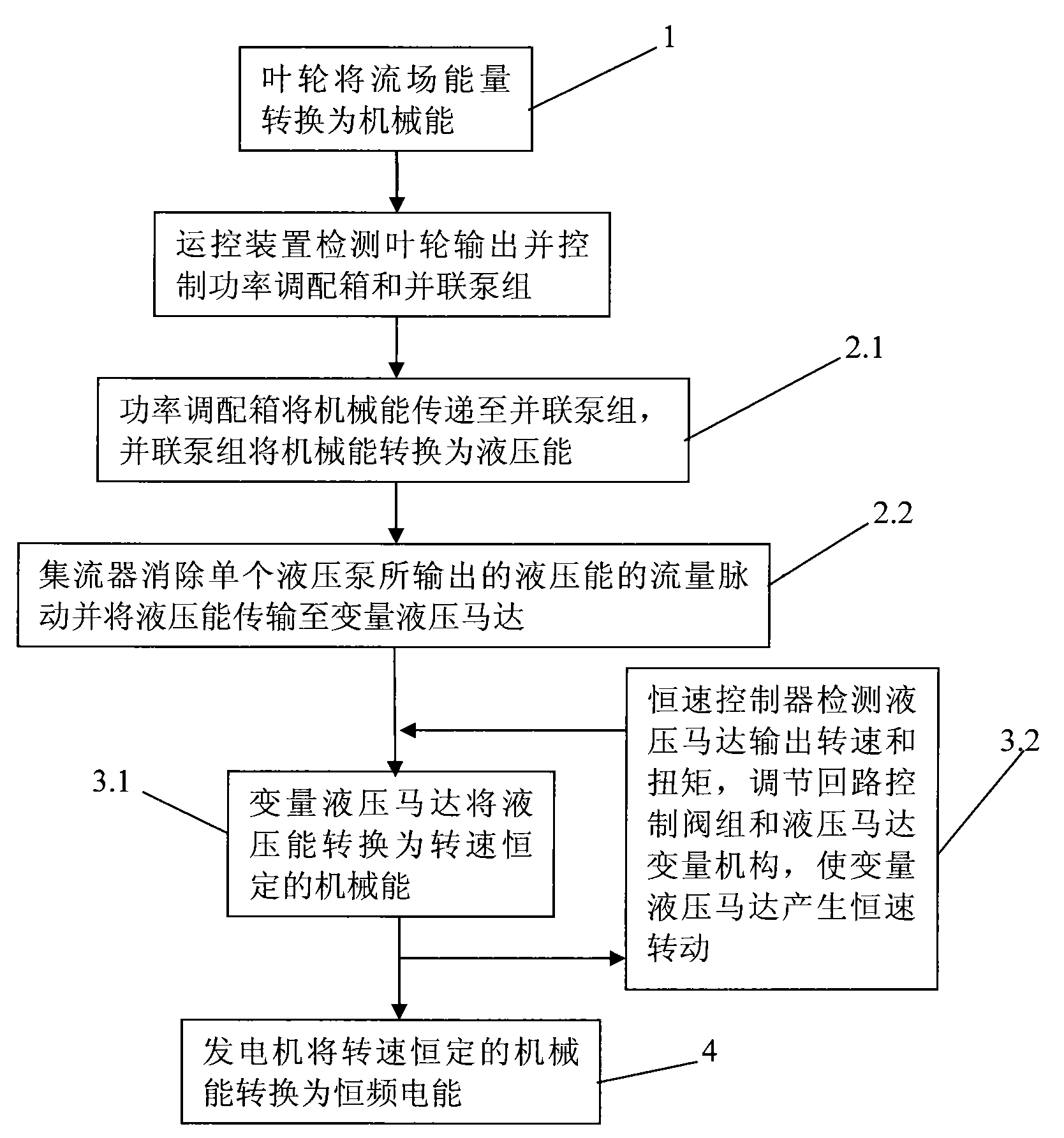

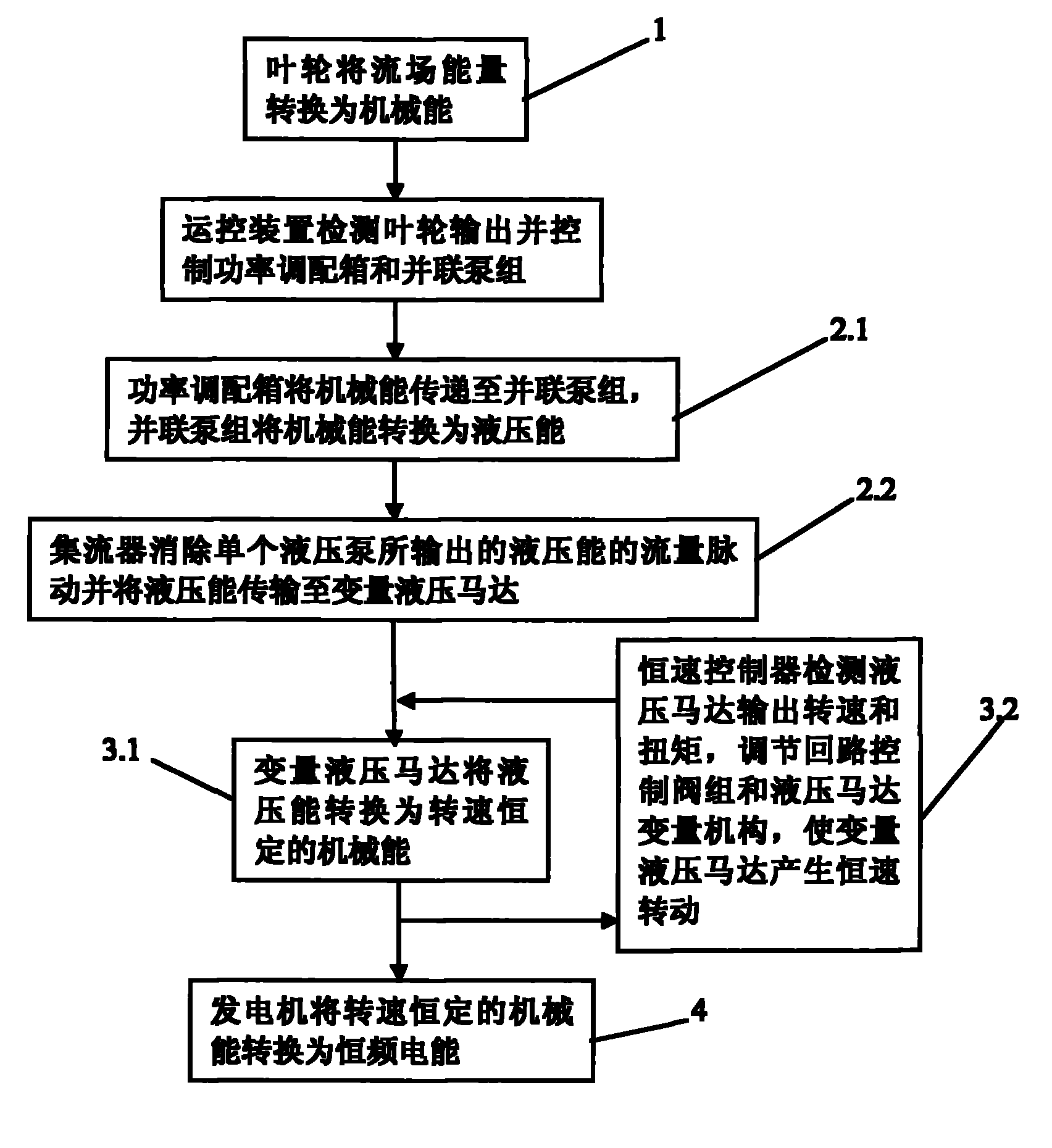

Hydraulically controlled frequency stabilization power generating method

ActiveCN101793232AImprove qualityReduce manufacturing difficultyWind motor controlEnergy industryFrequency stabilizationConstant frequency

Owner:SHANGHAI XISHUNLAI MACHINERY & ELECTRIC EQUIP MFG CO LTD

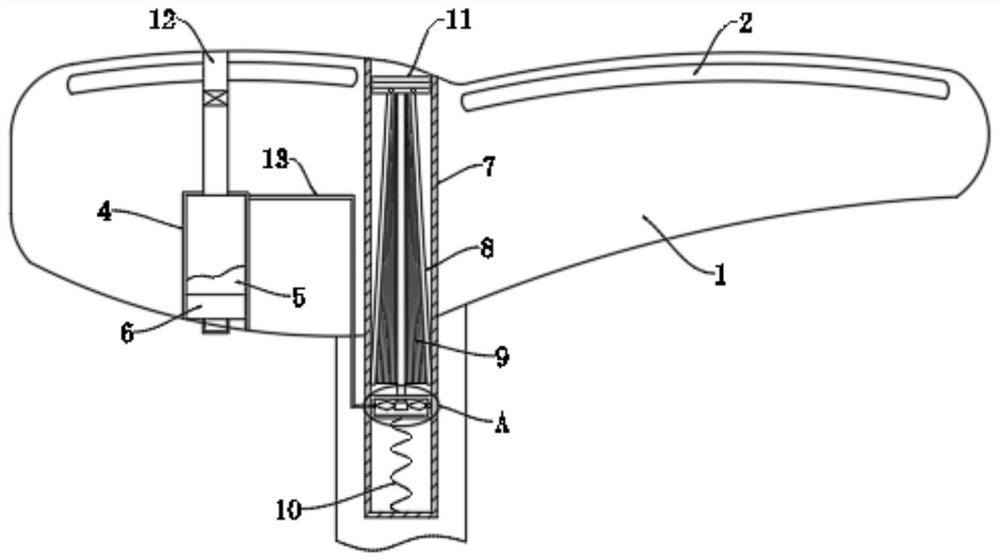

Rainproof seat of shared bicycle

Owner:邳州市景鹏创业投资有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap