Main bearing assembly of wind generating set

A technology for wind turbines and main bearings, applied to wind turbine components, wind engines, engines, etc., can solve the problems of increasing machining costs and not being able to be used in generator direct drive units, and achieve low cost, light weight, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

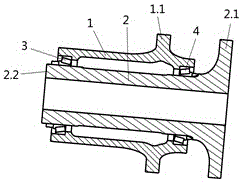

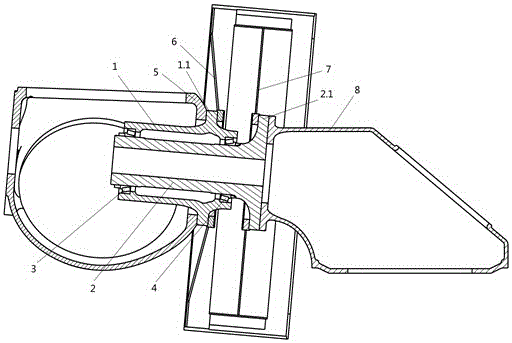

[0019] Attached figure 1 , 2 It is an embodiment of the present invention. The invention provides a main bearing assembly of a wind turbine generator set, comprising an outer shaft, an inner shaft, a front bearing and a rear bearing. The outer shaft is provided with an inner shaft, and a front bearing is provided between one end of the outer shaft and one end of the inner shaft. A rear bearing is arranged between the other end of the shaft and the other end of the inner shaft, one end of the inner shaft is provided with flange one, the other end is provided with flange two, and the outer shaft wall is provided with a connecting flange.

[0020] Further, the outer shaft is located between the outer shaft and the inner shaft, and one end with a rear bearing is provided with a connecting flange.

[0021] Further, the inner shaft is located between the outer shaft and the inner shaft, and one end of the rear bearing is provided with flange one, and the other end is provided with fl...

Embodiment 2

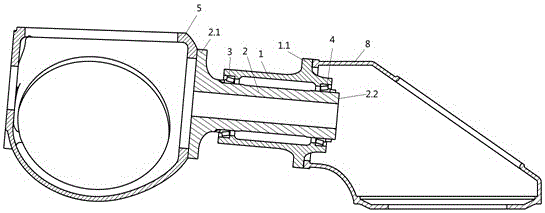

[0026] Attached image 3 In an embodiment of the present invention, a main bearing assembly of a wind turbine generator set of the present invention includes an outer shaft, an inner shaft, a front bearing and a rear bearing. The outer shaft is provided with an inner shaft, and one end of the outer shaft is connected to the inner shaft. A front bearing is provided between one end, and a rear bearing is provided between the other end of the outer shaft and the other end of the inner shaft. One end of the inner shaft is provided with flange one, the other end is provided with flange two, and the outer shaft wall is provided with a connection Flange.

[0027] Further, the outer shaft is located between the outer shaft and the inner shaft, and one end with a rear bearing is provided with a connecting flange.

[0028] Further, the inner shaft is located between the outer shaft and the inner shaft, and one end of the front bearing is provided with flange one, and the other end is provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap