Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

22 results about "Vacuum cleaner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

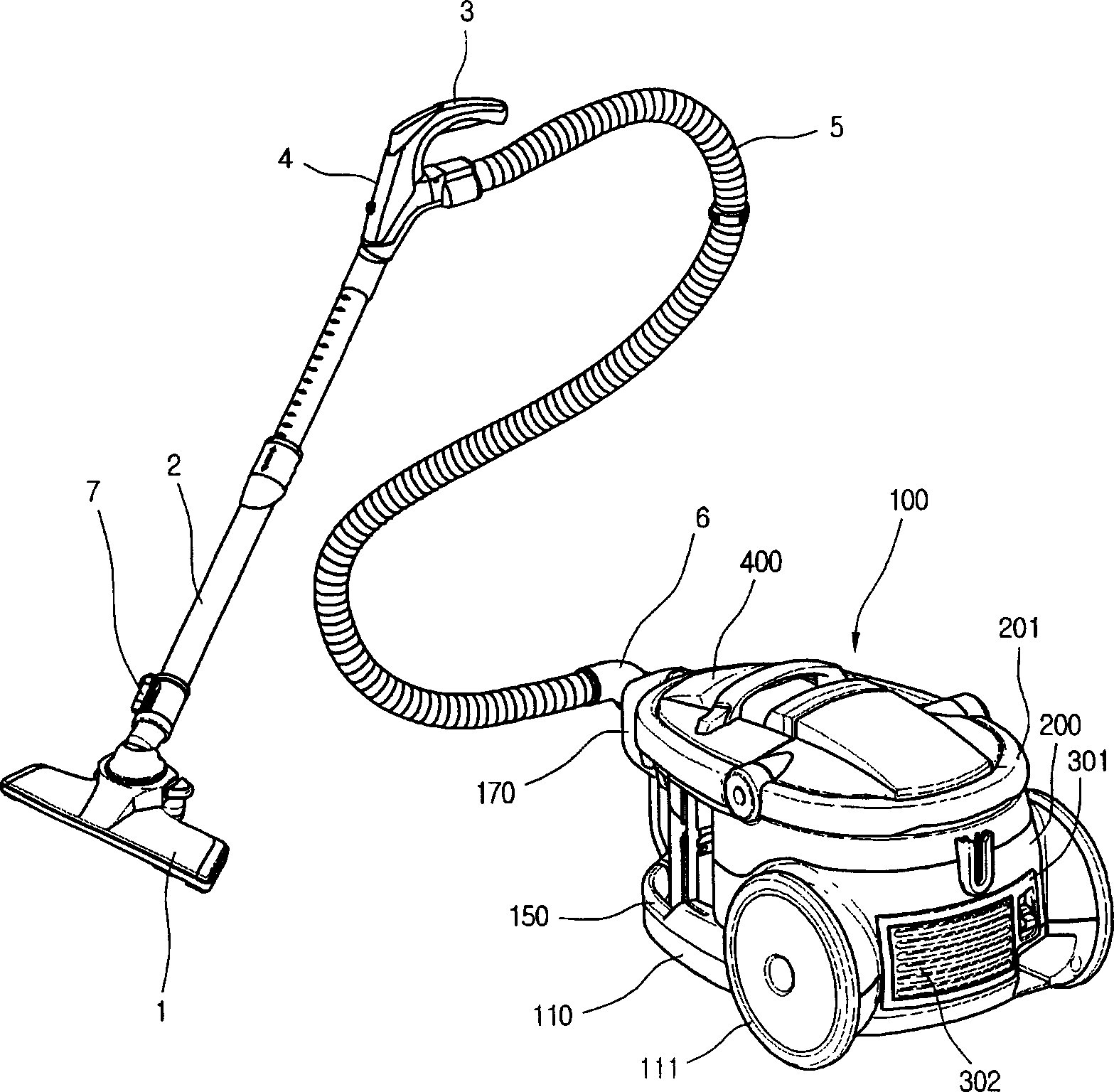

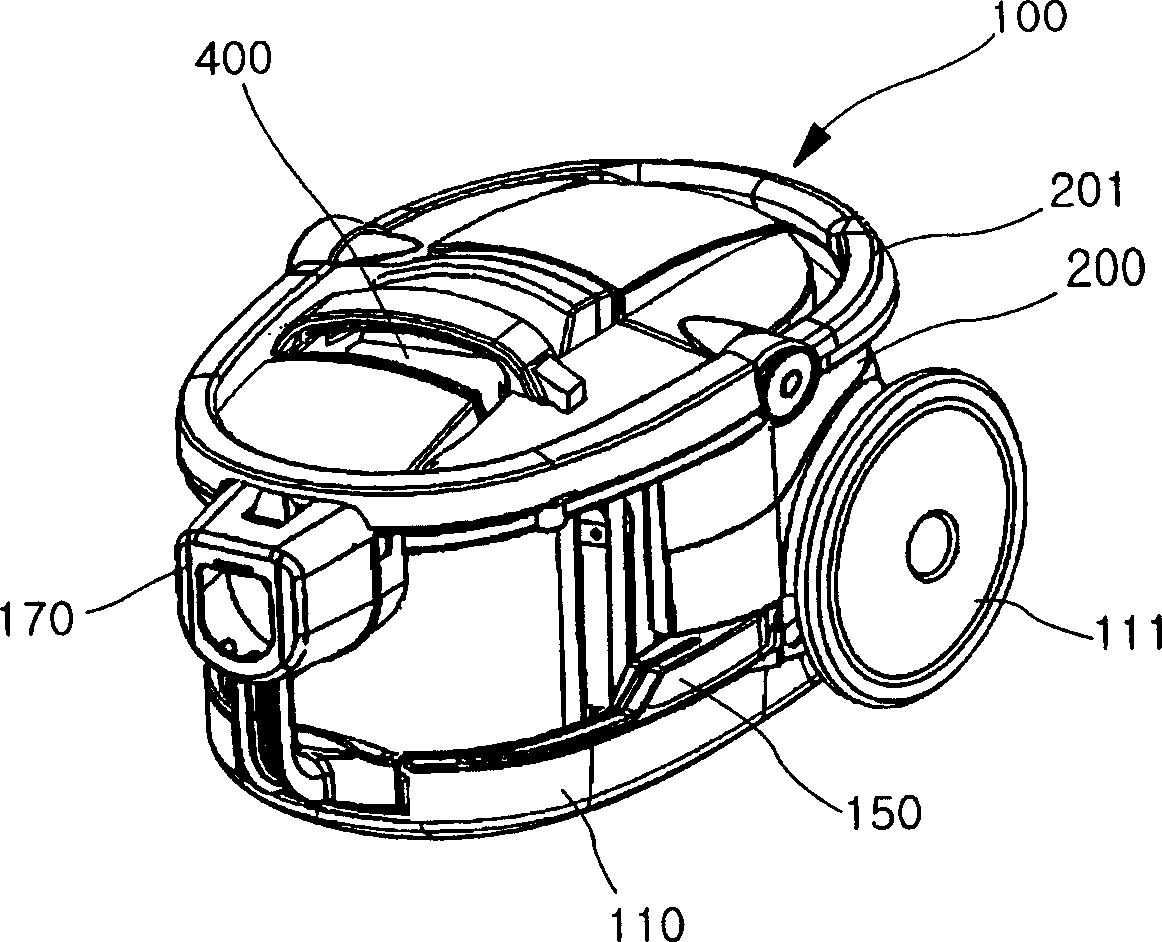

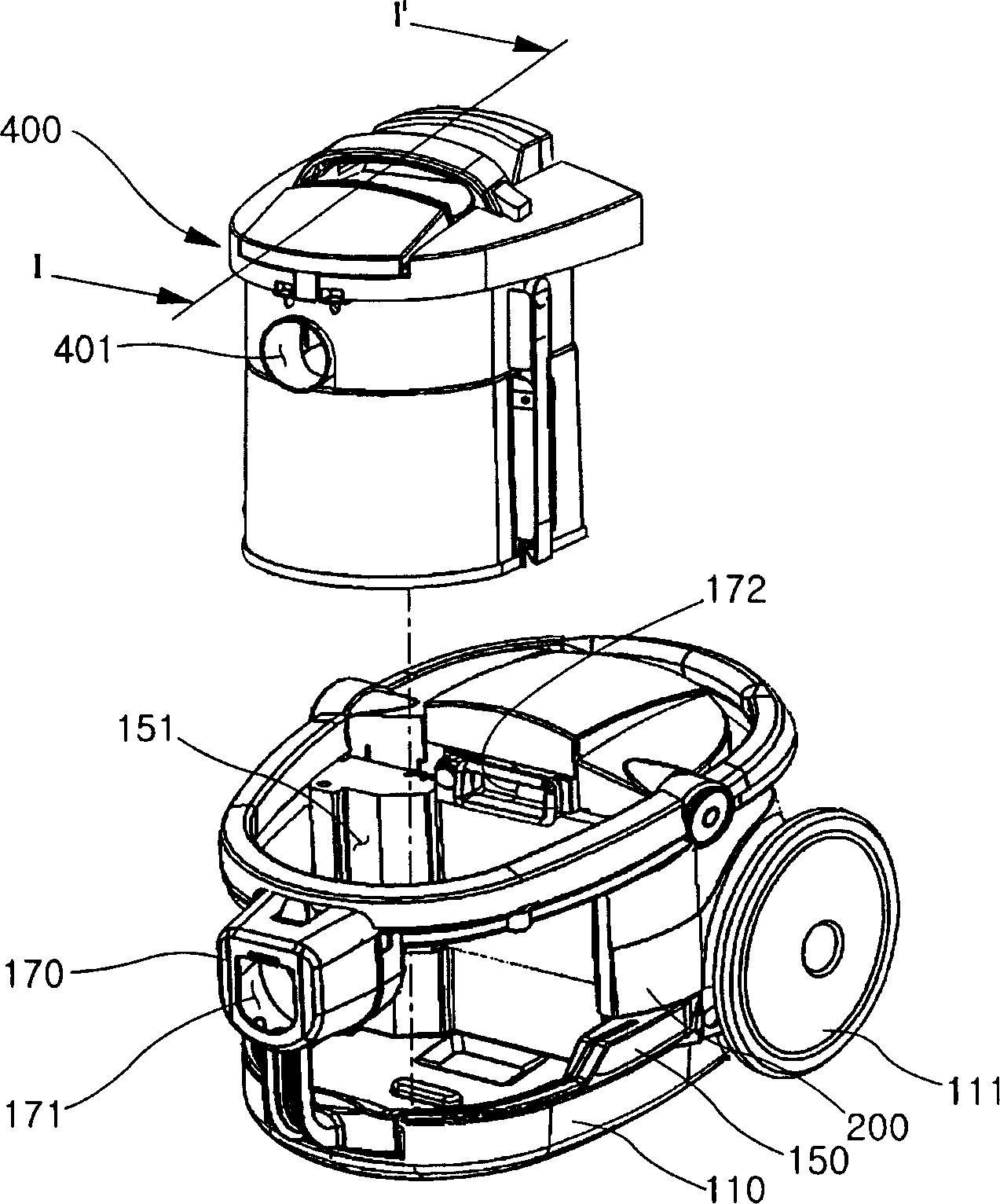

Inventor

A vacuum cleaner, also known simply as a vacuum, is a device that causes suction in order to remove debris from floors, upholstery, draperies and other surfaces. It is generally electrically driven. The dirt is collected by either a dustbag or a cyclone for later disposal. Vacuum cleaners, which are used in homes as well as in industry, exist in a variety of sizes and models—small battery-powered hand-held devices, wheeled canister models for home use, domestic central vacuum cleaners, huge stationary industrial appliances that can handle several hundred litres of dust before being emptied, and self-propelled vacuum trucks for recovery of large spills or removal of contaminated soil. Specialized shop vacuums can be used to suck up both dust and liquids.

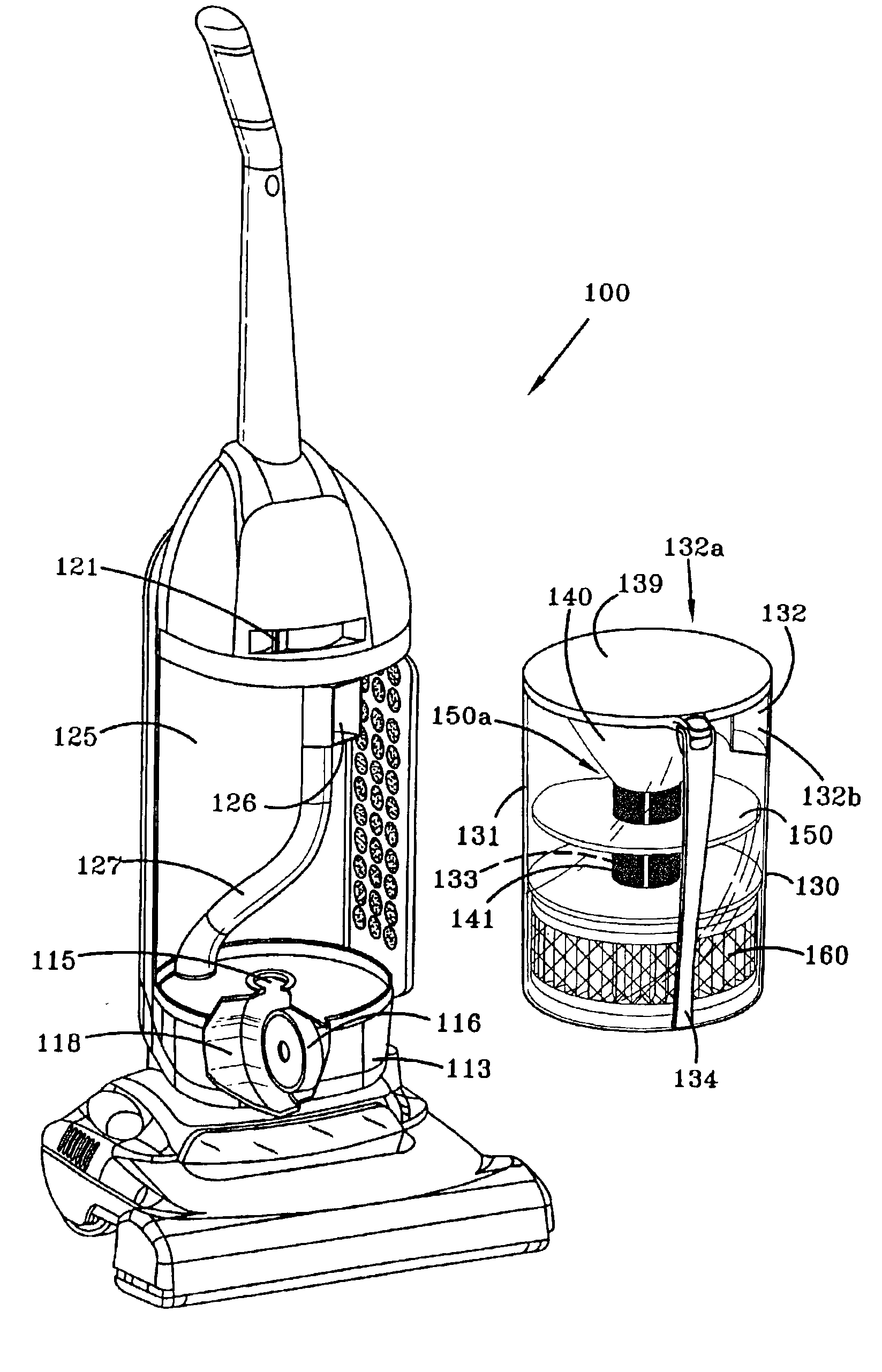

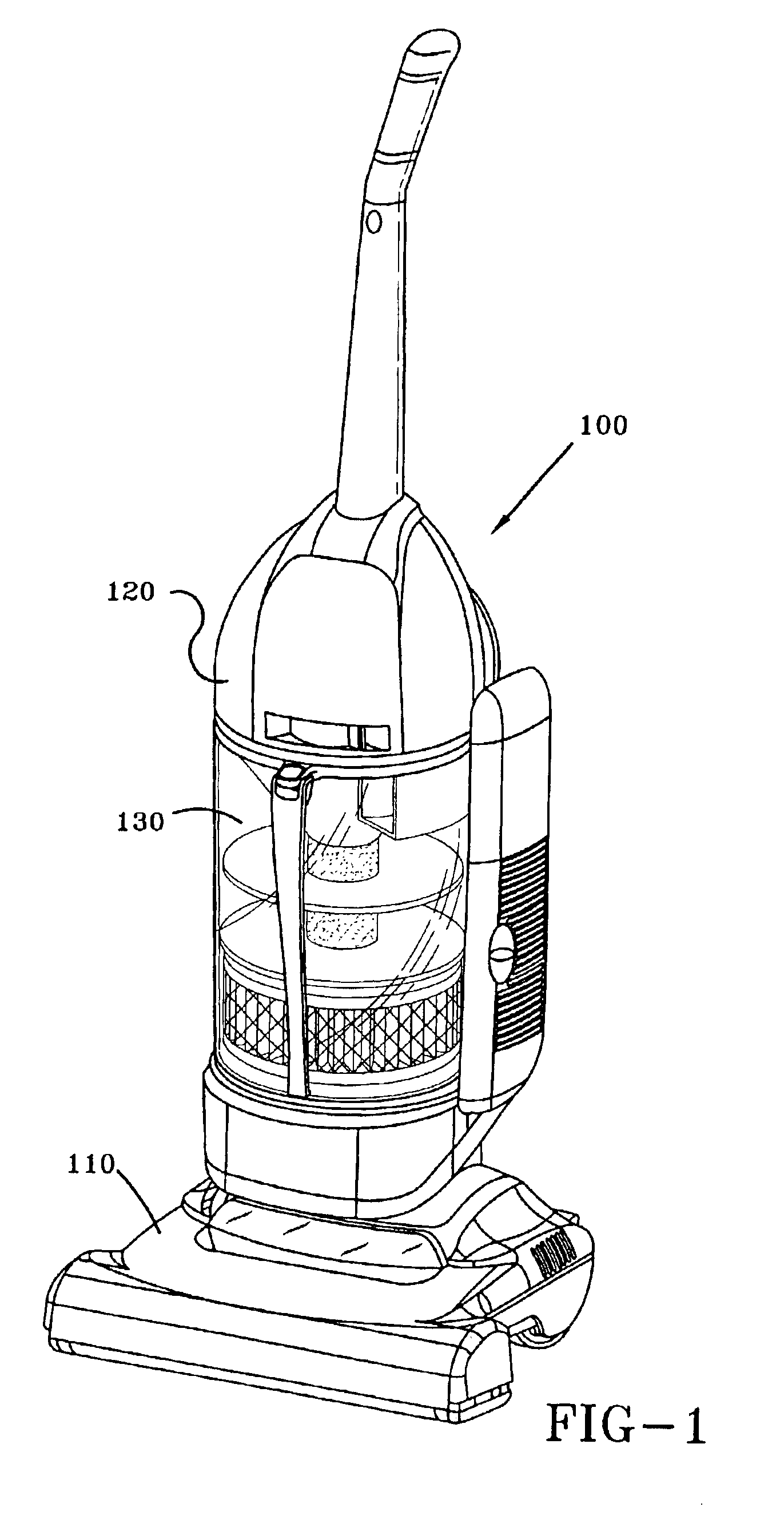

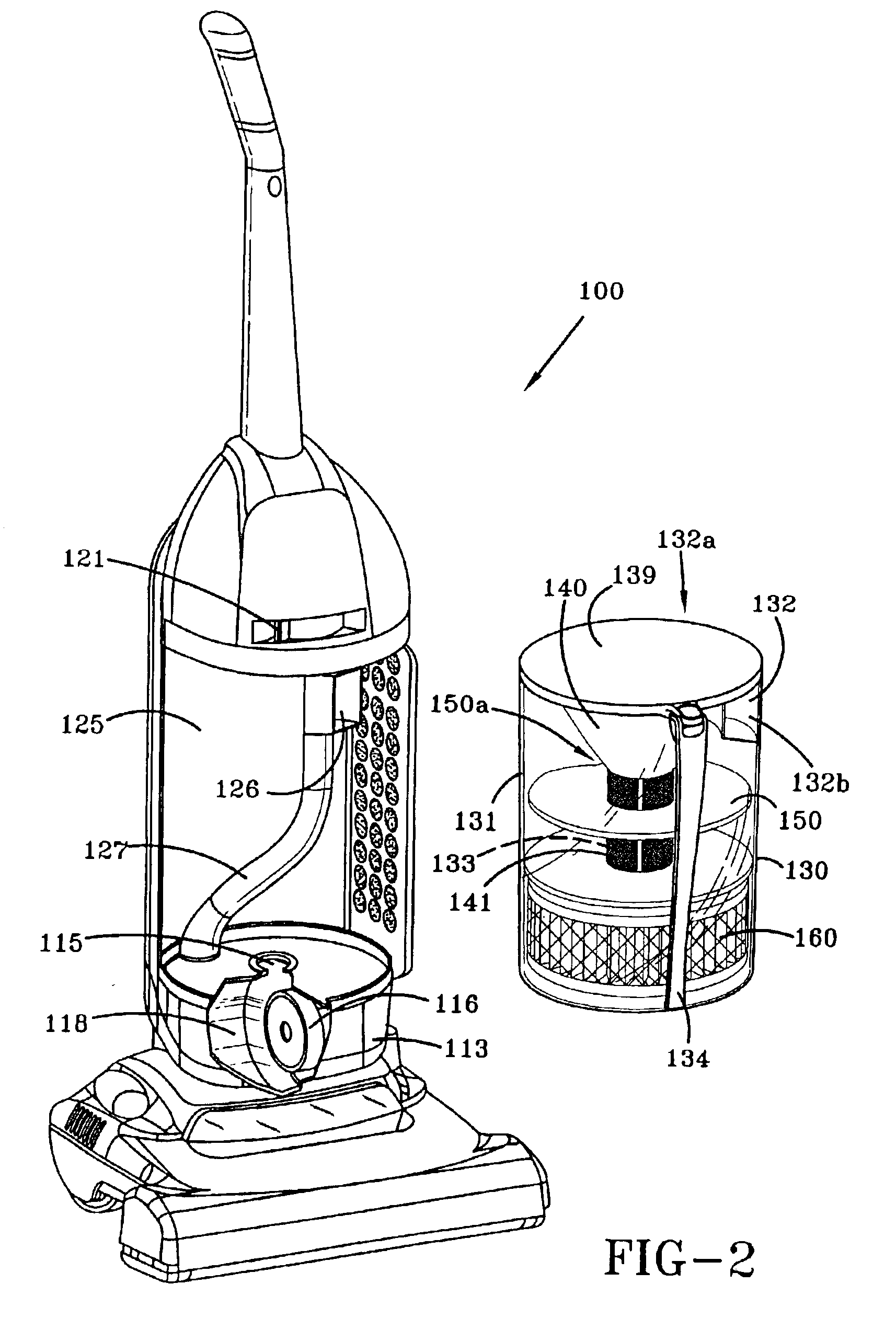

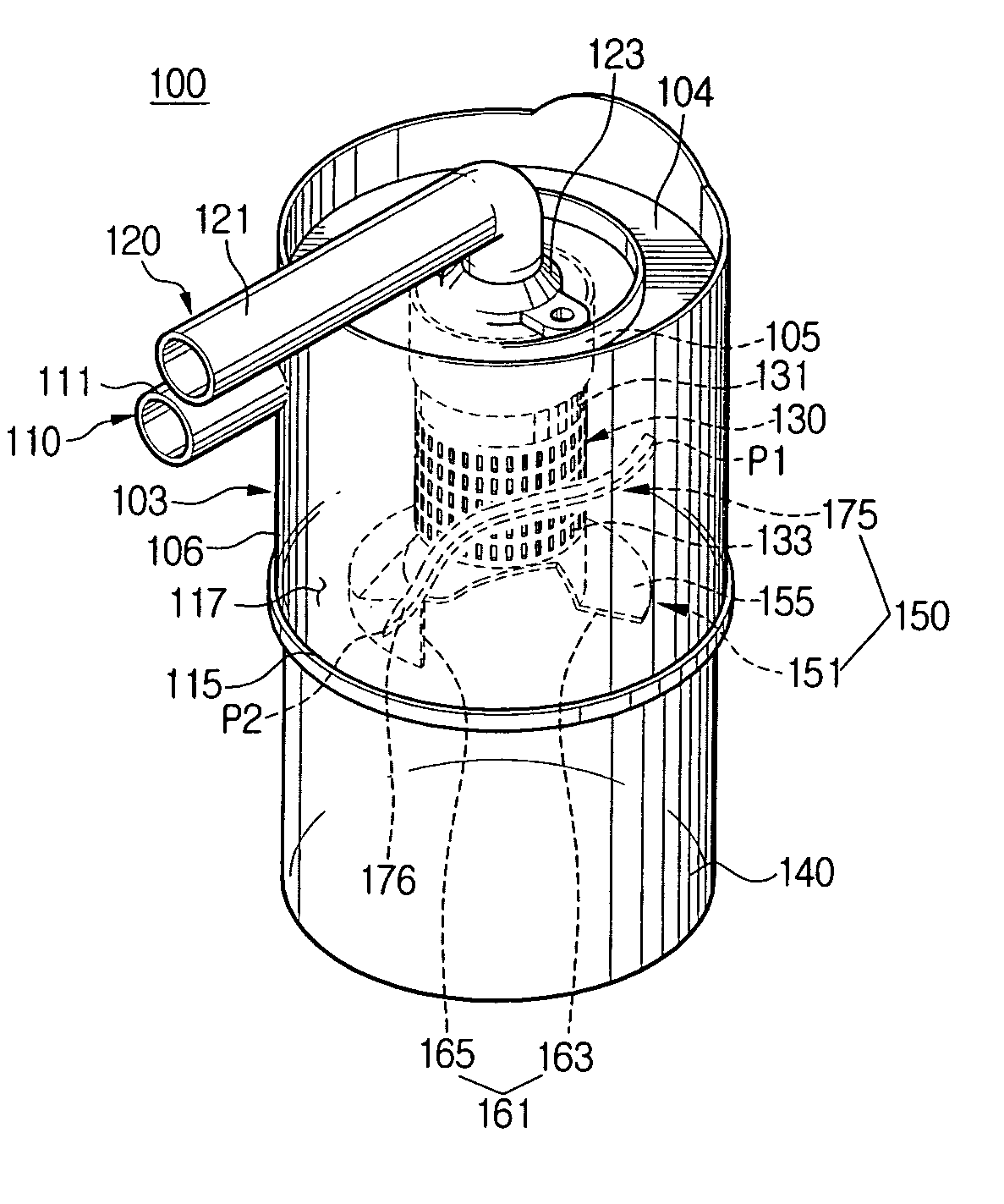

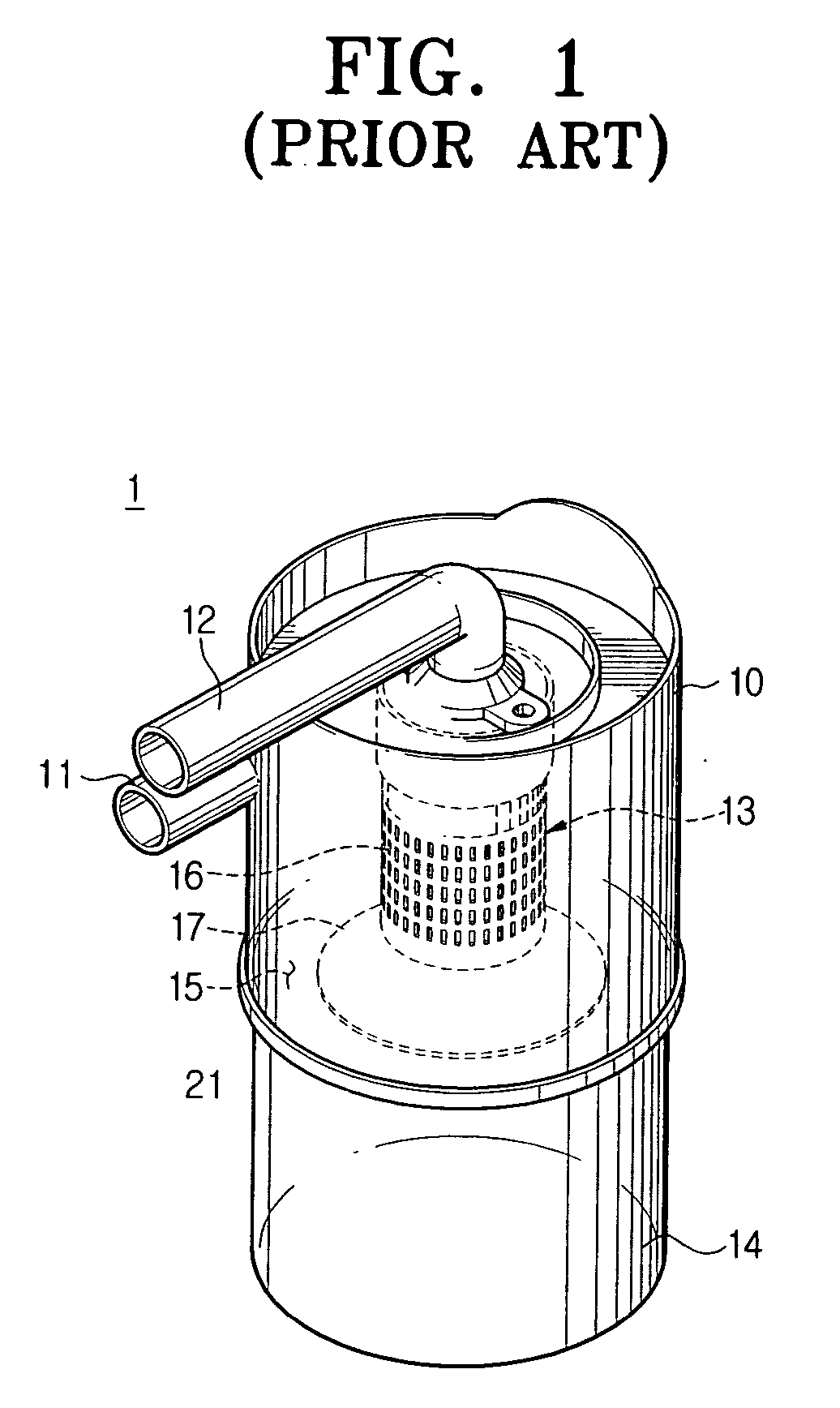

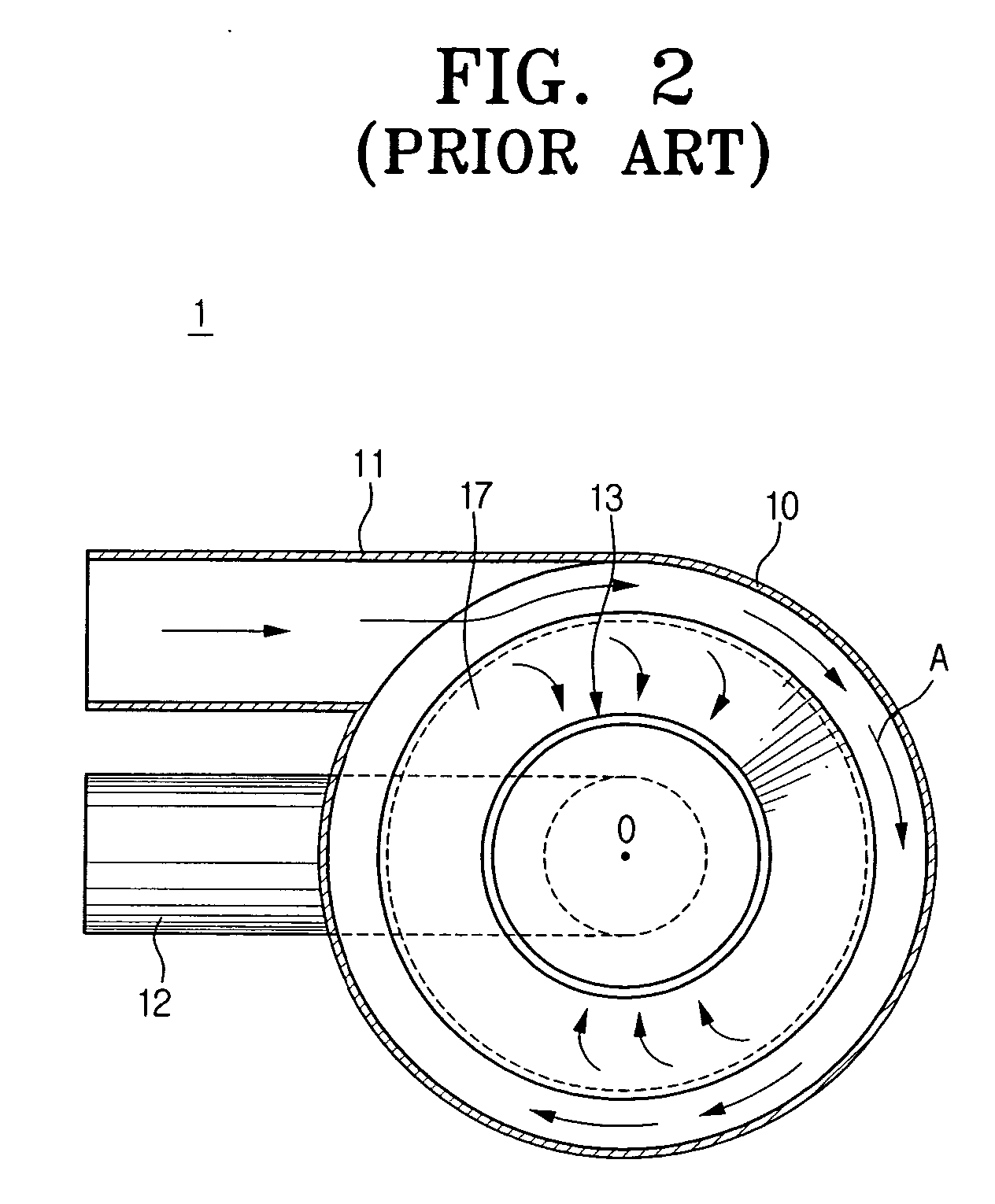

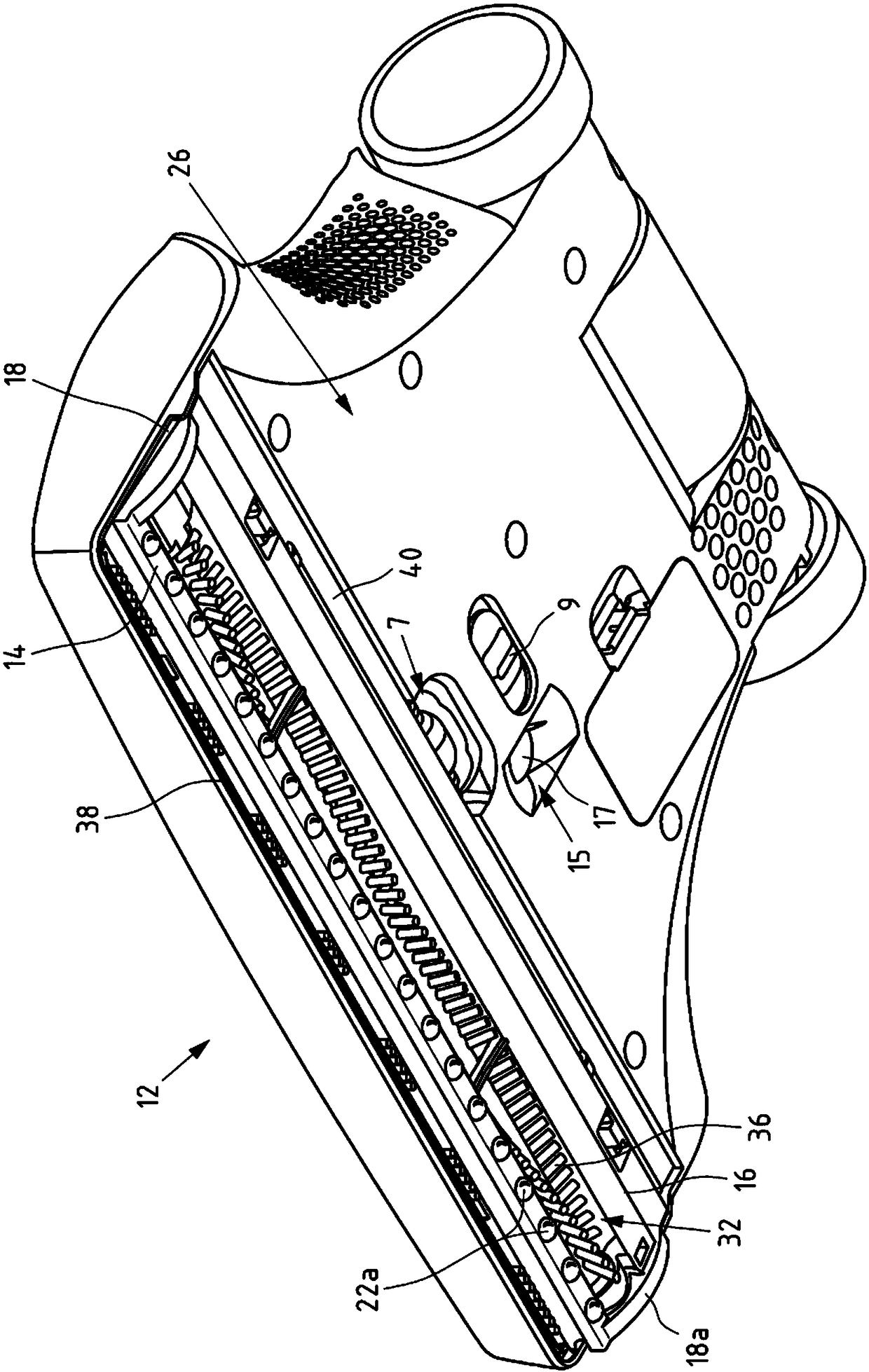

Dirt collecting system for a floor care appliance

InactiveUS6896719B2Improve filtering effectEasy to emptyCleaning filter meansCombination devicesEngineeringGuide tube

Owner:HEALTHY GAIN INVESTMENTS

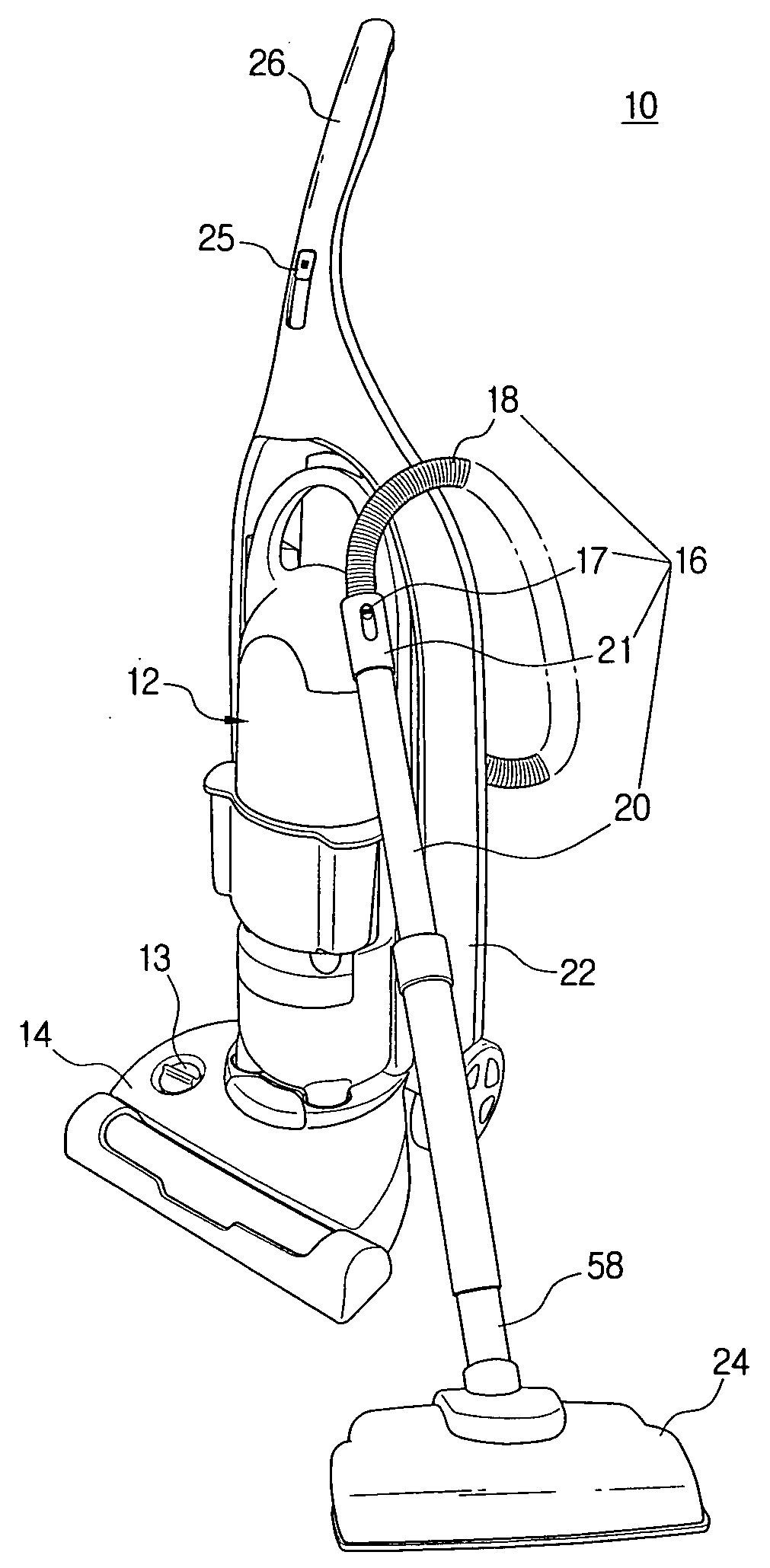

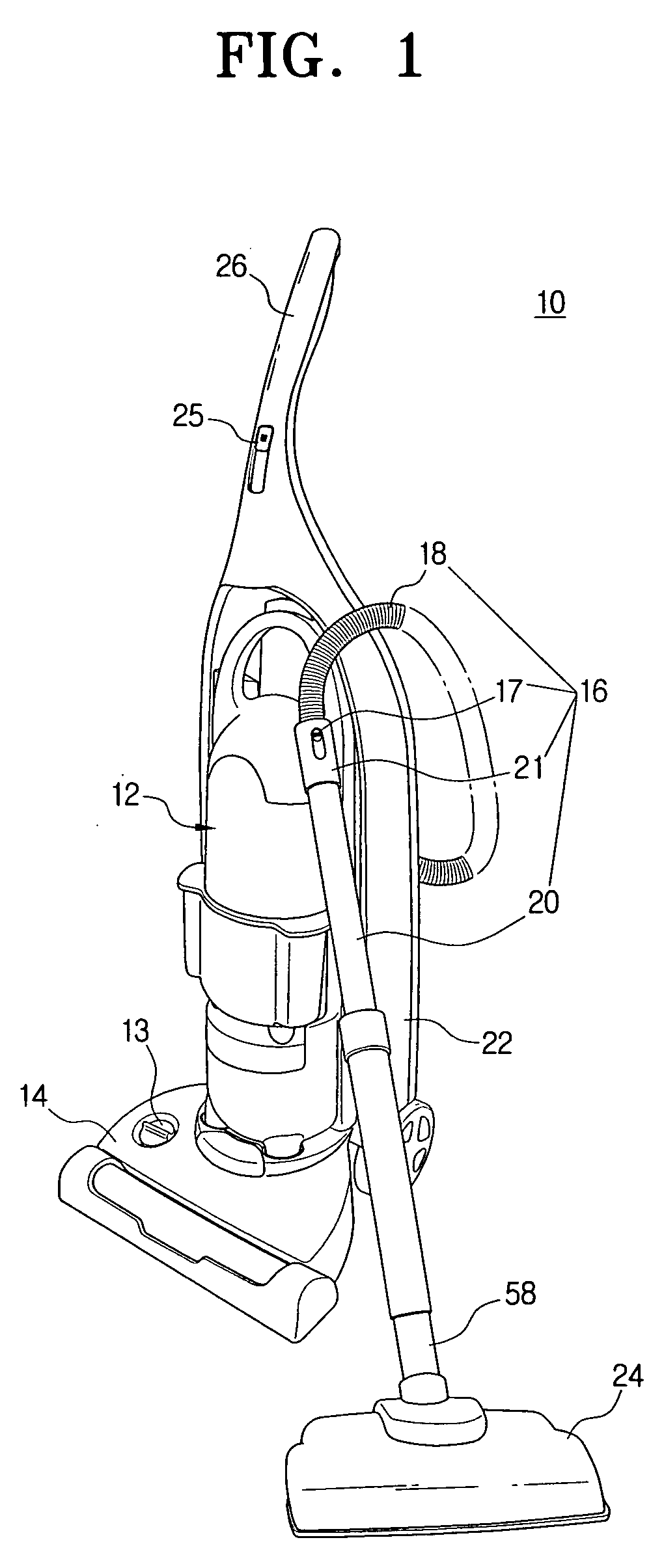

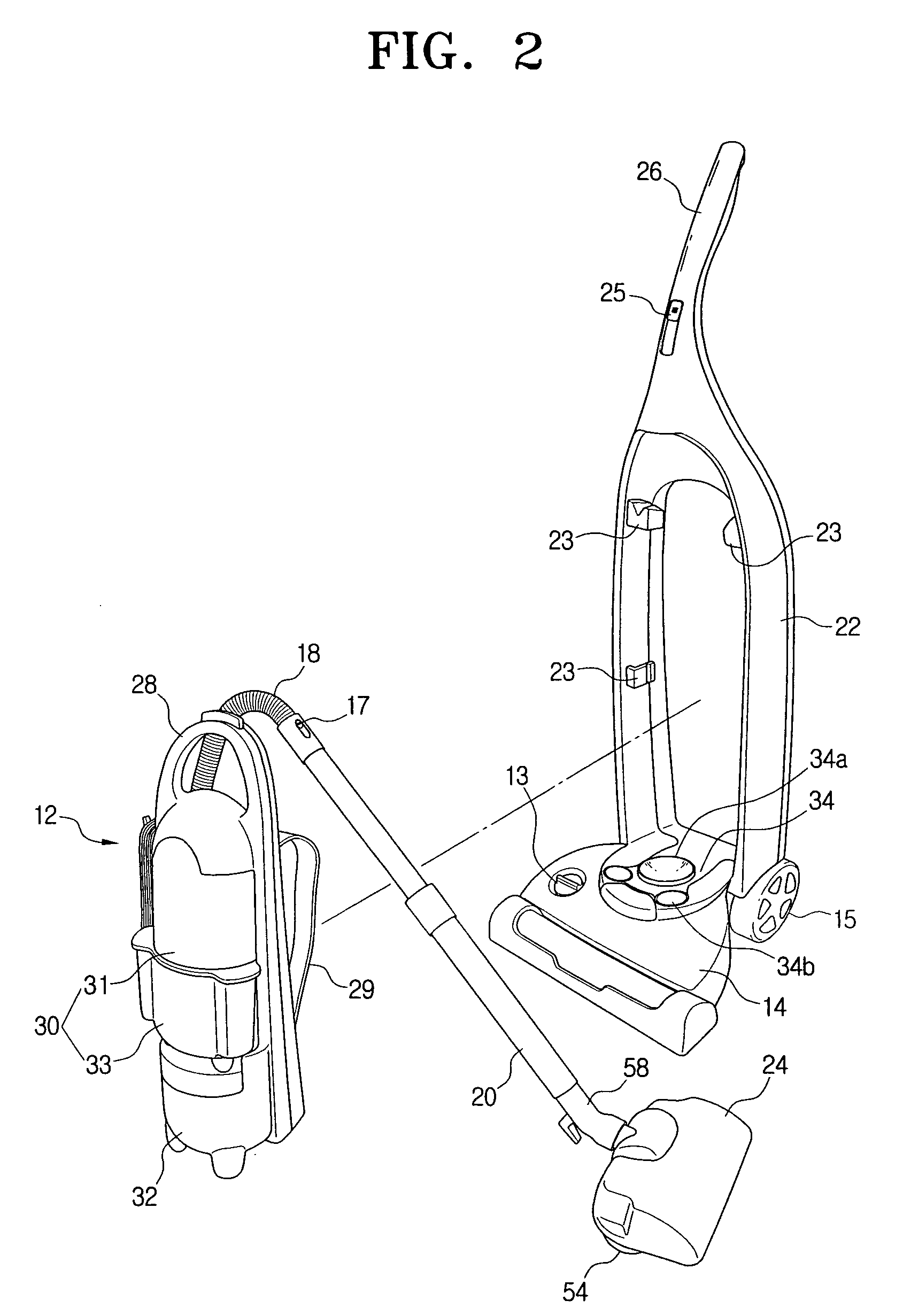

Upright vacuum cleaner having wet cleaning function

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Grille for a cyclone vacuum

InactiveUS20060130441A1Simple structureAvoid problemsCleaning filter meansCombination devicesEngineeringVacuum cleaner

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

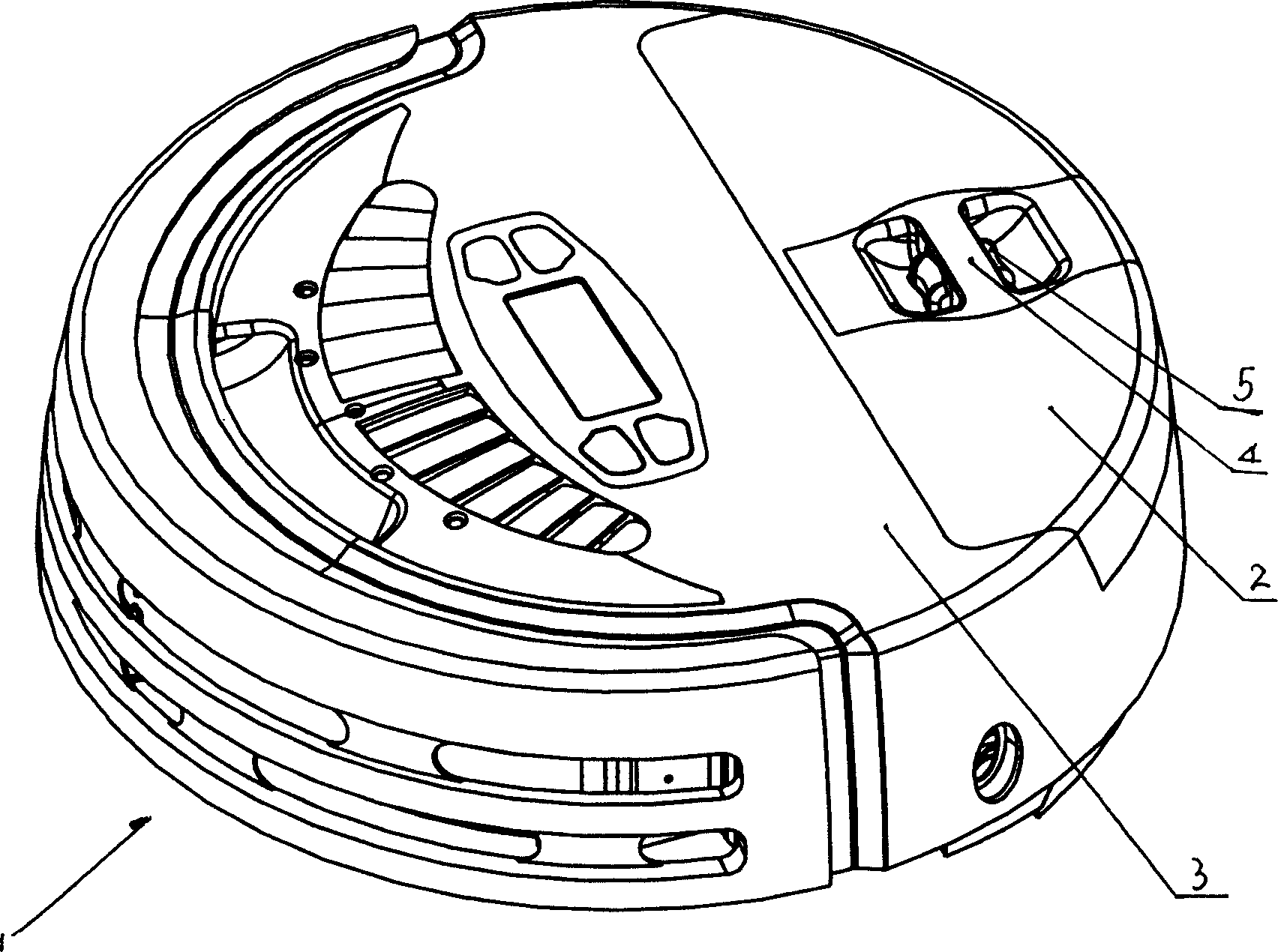

Automatic suction cleaner

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

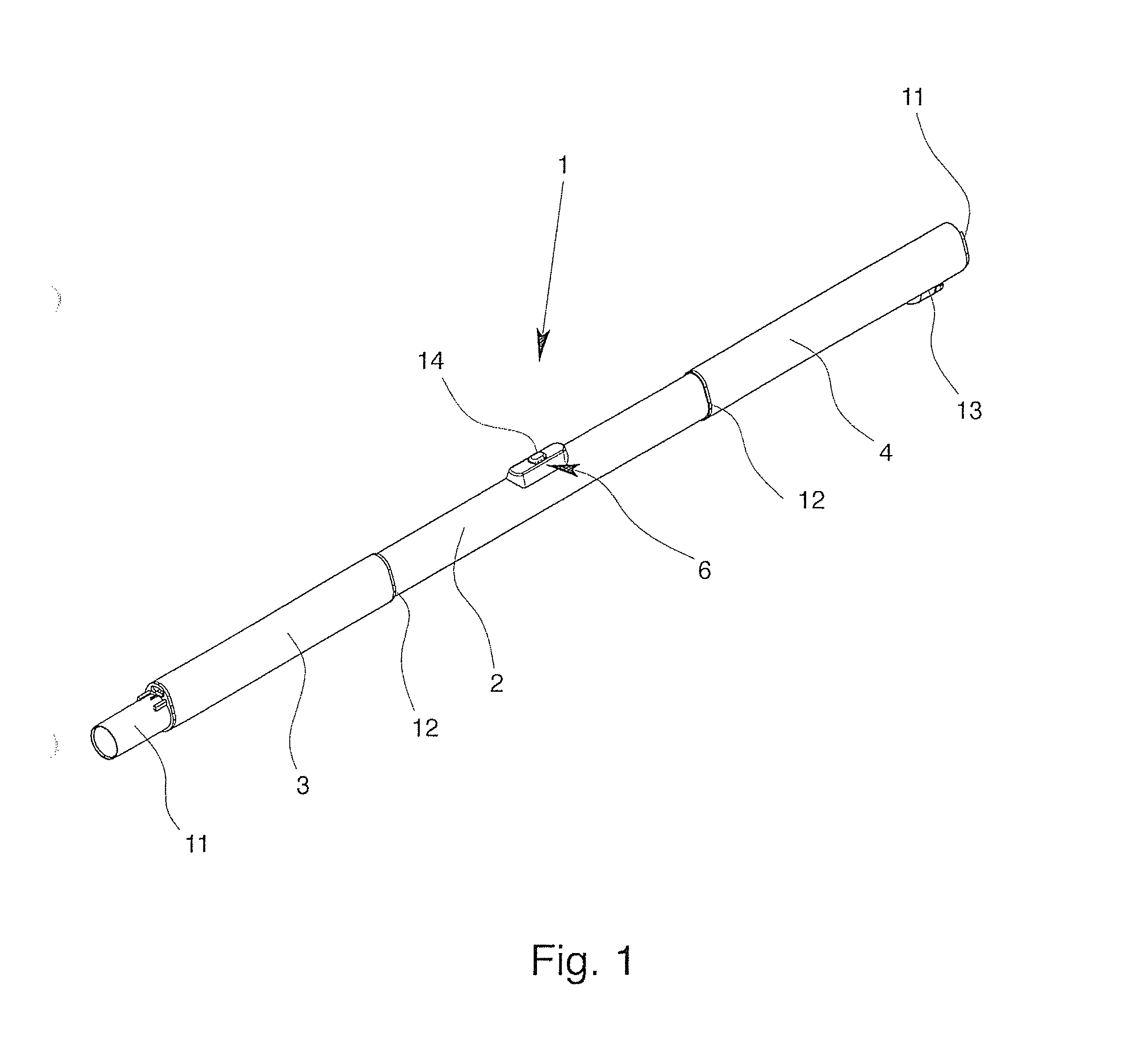

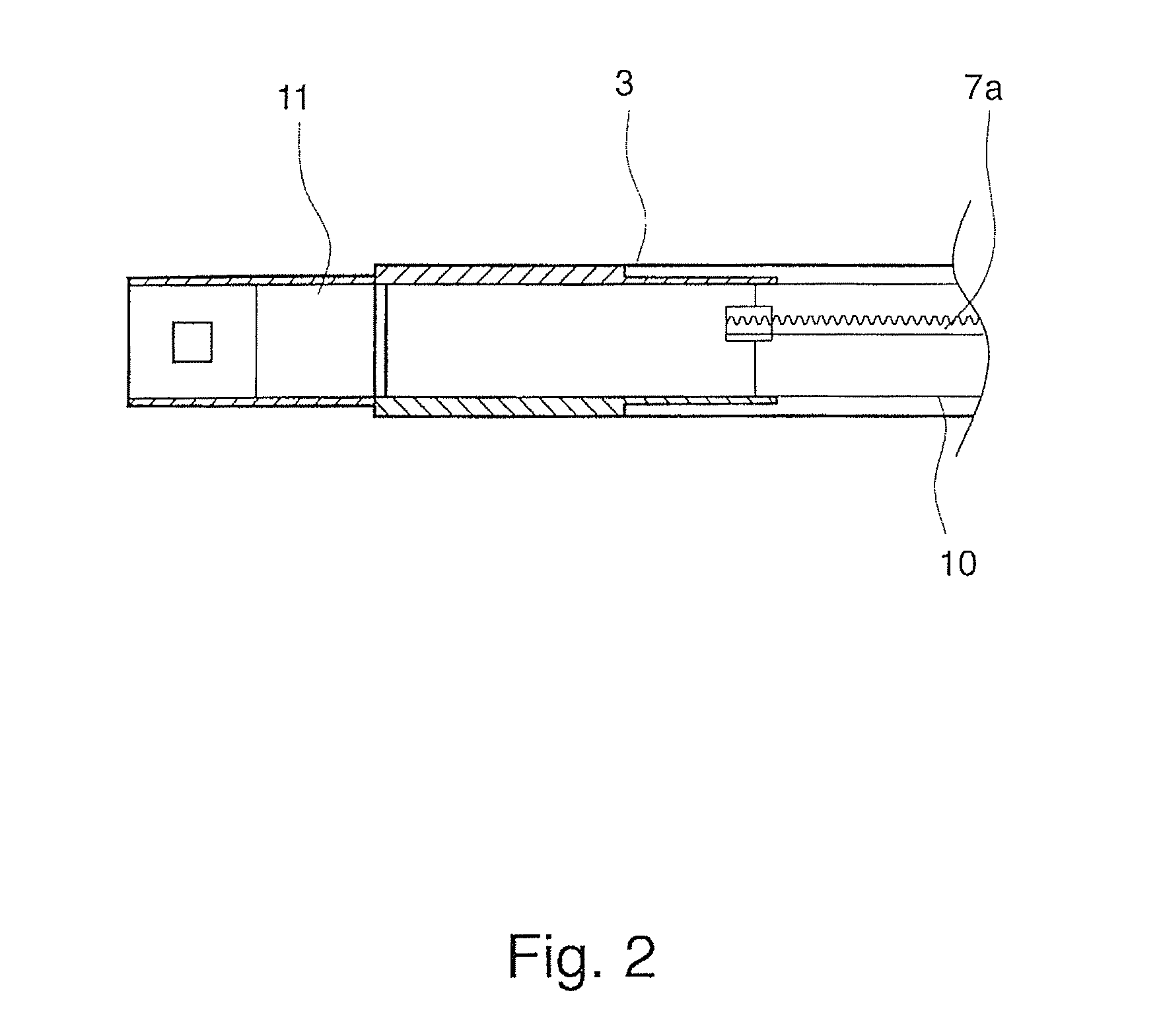

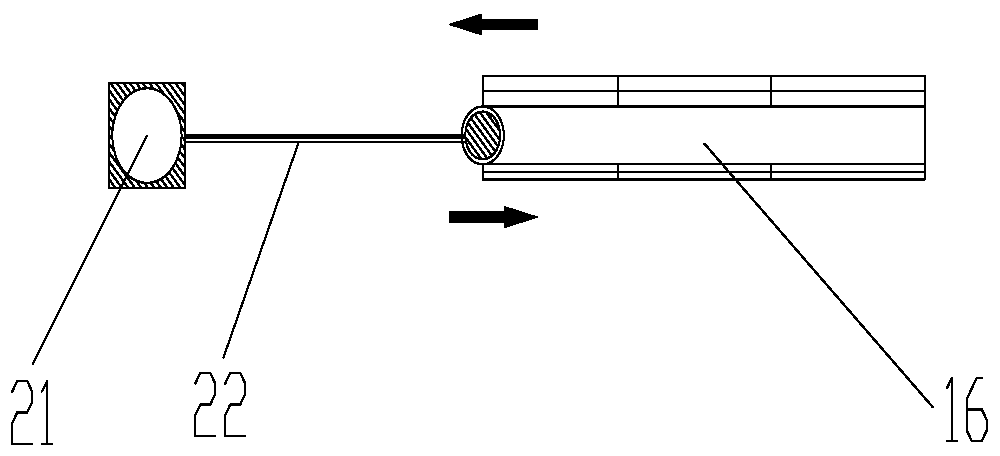

Vacuum cleaner suction pipe

Owner:FISCHER ROHRTECHN

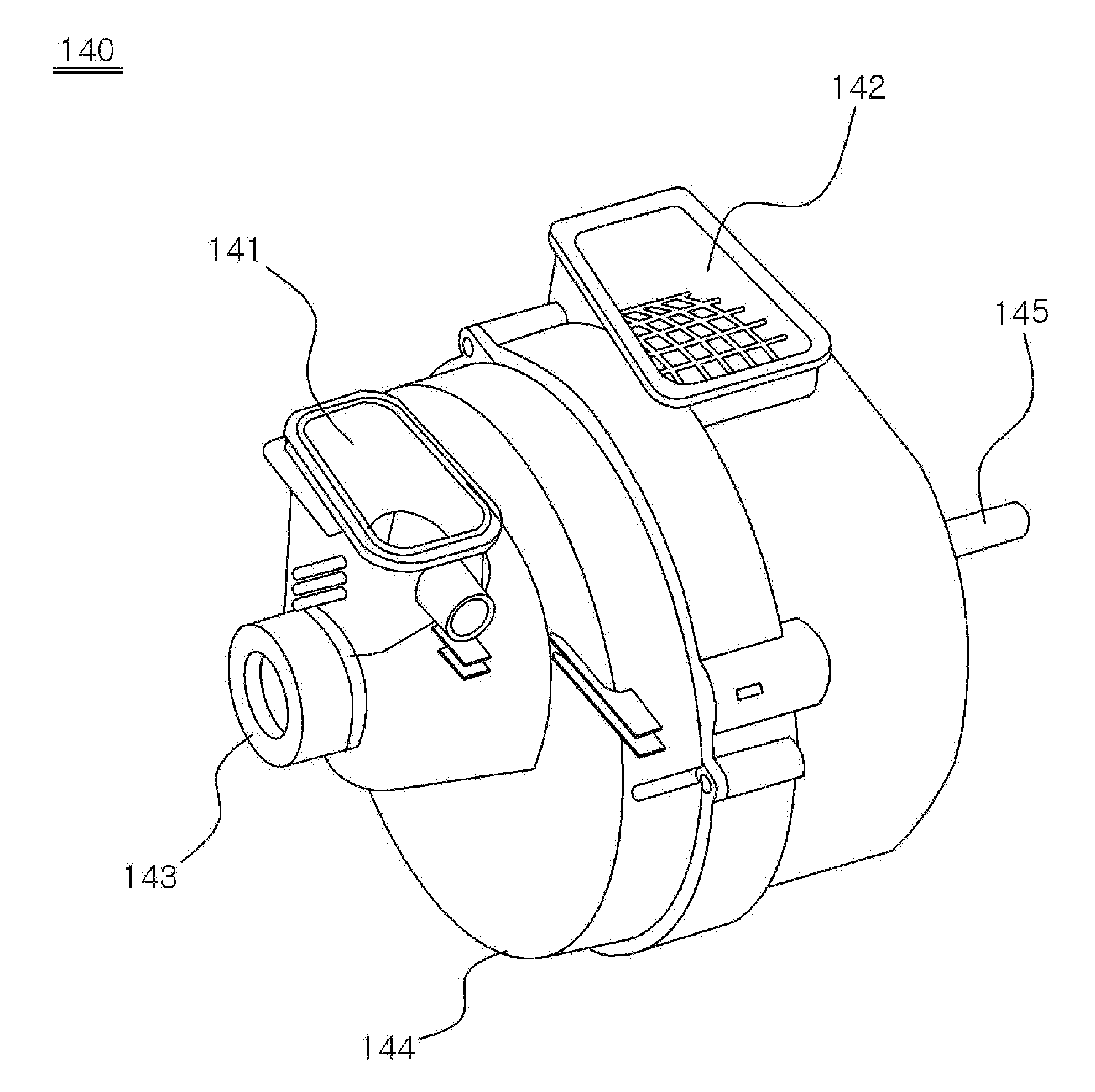

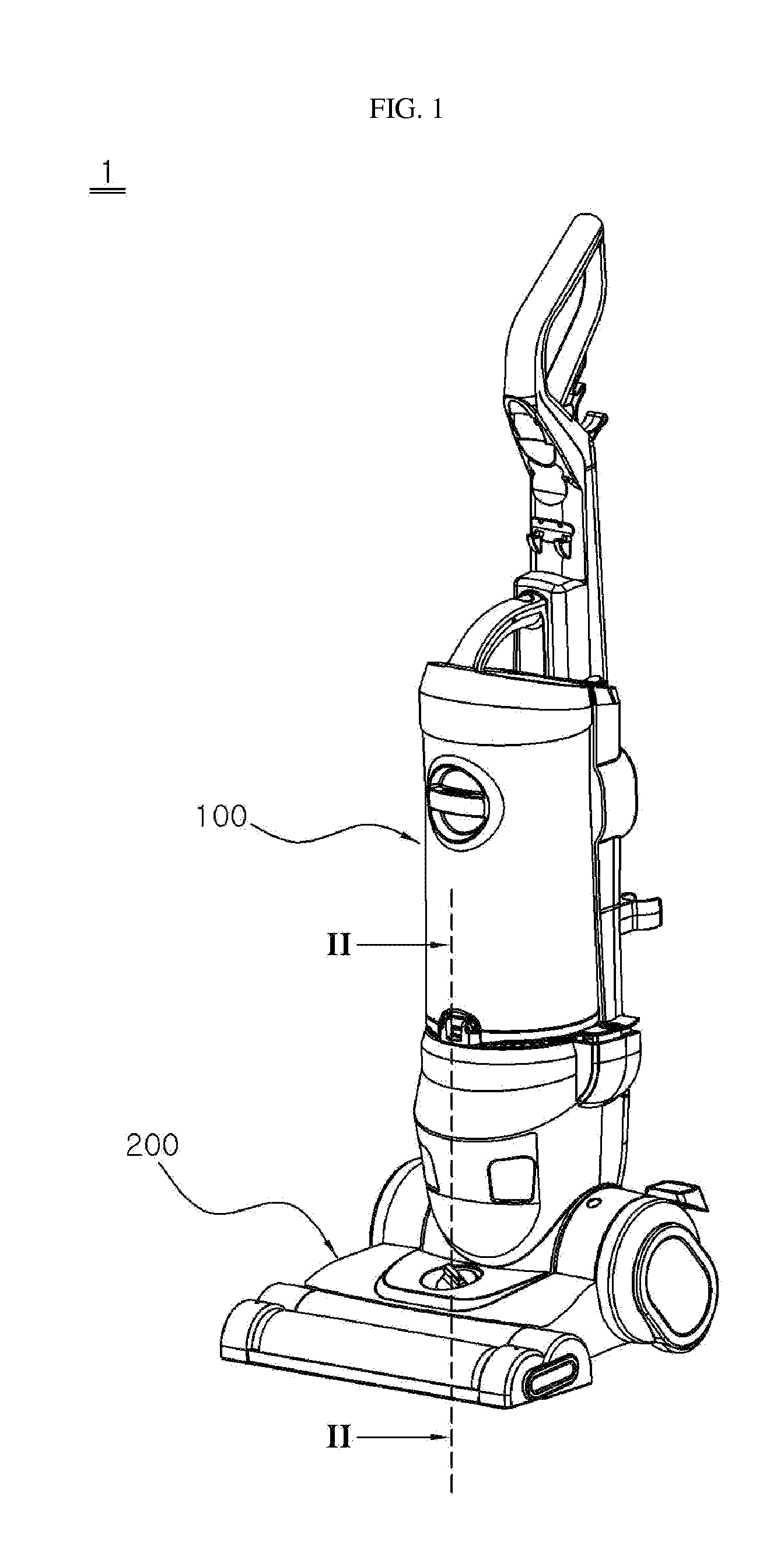

Upright type vacuum cleaner

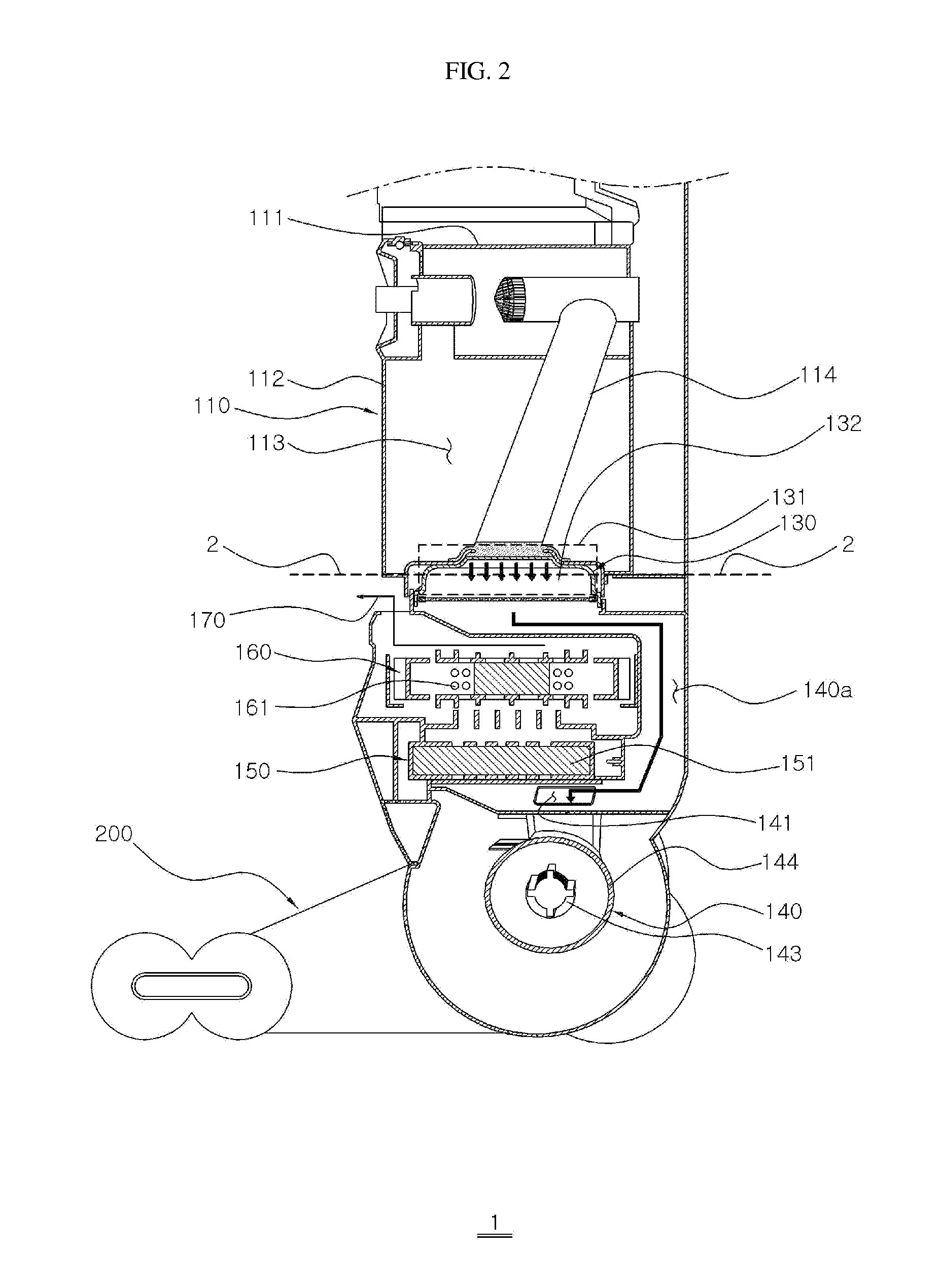

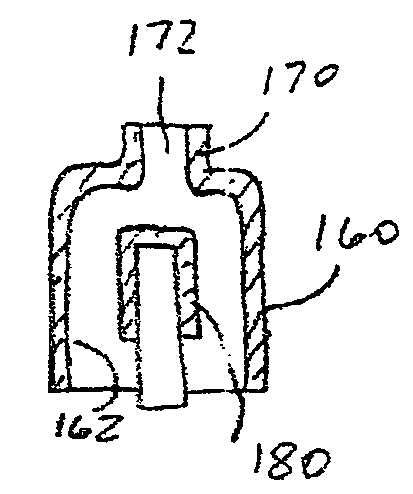

InactiveUS20100269288A1Increase vacuum pressureCleaning filter meansSuction filtersVacuum cleanerMotor unit

Owner:SAMSUNG ELECTRONICS CO LTD

Vacuum cleaner and suction piece assembly thereof

InactiveCN1138500CReduce structural weightImprove maneuverabilitySuction nozzlesImpellerSpray nozzle

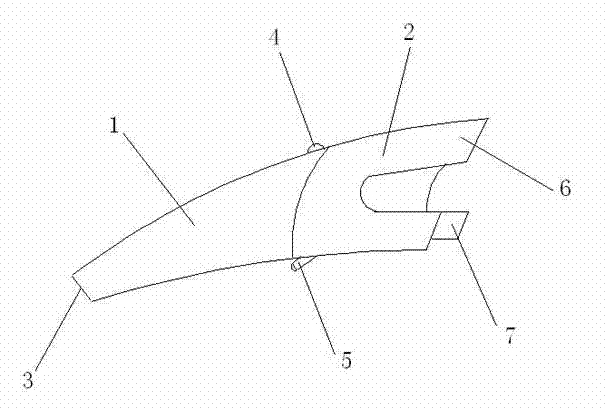

A suction piece and a vacuum cleaner using the same where in the suction piece is provided with impeller adapted to be rotated by a sunction force, brushes or scrapers spirally mounted to the whole or part of the impeller and adapted to come into contact with a surface being cleaned, a rotary brush coaxial with the impeller and adapted to rotate together therewith, and there is not provided any partition or the like between the impeller and the rotary brush where by the suction piece is made small-sized, lightweight and quiet.

Owner:HITACHI LTD

High-efficiency filter sheets for air microfiltration membrane filters

InactiveCN108031209AHigh mechanical strengthIncreased mechanical toughnessDispersed particle filtrationFiltration separationPolyvinyl chlorideFilter effect

The present invention relates to a high-efficiency filter sheet for air microfiltration membrane filters. The high-efficiency filter sheet comprises a polyvinyl chloride fiber layer and a polytetrafluoroethylene fiber layer, wherein fiber filaments in the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer are respectively in a unidirectional arrangement, and an included angle between the fiber filaments in the polyvinyl chloride fiber layer and the fiber filaments in the polytetrafluoroethylene fiber layer is 60-65 DEG. According to the high-efficiency filter sheet, a double layer combination of the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer is used, and a specific angle between the fiber filaments is set, so that windage resistance and filtering effect of the filter sheet are improved; the introduced polytetrafluoroethylene fiber layer has superhigh mechanical strength and structural toughness, so that vibration caused by strongwind can be effectively suppressed, and airflow in a dust collection chamber of a vacuum cleaner is stabilized; and a filling layer is additively arranged, so that the filtering effect of the filter sheet is further improved.

Owner:SUZHOU QINGRUI AIR SYST

Device for removing loose pet hair strands and method thereof

Owner:STRAUB KELLY C +1

Demoulding structure used for producing brush strip of dust collector

A demoulding structure used for producing a brush strip of a dust collector comprises a fixing board, a bearing pedestal and a sliding block which are sequentially arranged from front to back; a bearing is installed inside the bearing pedestal; a cylindrical cavity is arranged in the bearing in a penetrating mode; the front end of the cavity extends out of the fixing board; the rear end of the cavity is fixedly connected with the sliding block; an ejection block is arranged behind the sliding block and forwards provided with an ejection rod used for ejecting the brush strip of the dust collector; the front end of the ejection rod extends into the cavity; the cavity is sleeved with a roller; the roller is provided with a spiral groove matched with the brush strip of the dust collector; the fixing board is provided with a guide block matched with the spiral groove; and the sliding block is moved backwards, the roller drives the cavity to move backwards spirally, and the ejection rod ejects the brush strip of the dust collector out of the cavity. Through cooperation of the spiral groove in the roller and the guide block, the spiral demoulding structure is formed, the brush strip of the dust collector is rapidly and completely released from a mould, the mold manufacturing cost is lower, the demoulding speed is higher, and the production efficiency is higher.

Owner:NINGBO HENGHE PRECISION INDUSTRY CO LTD

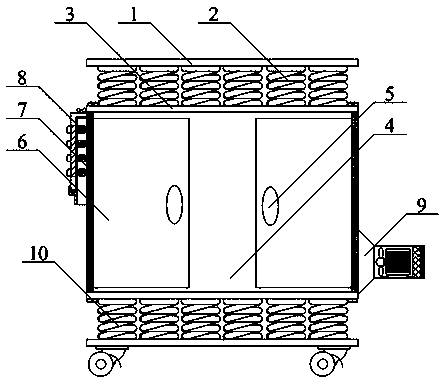

Low-voltage metal clad switch safety cabinet

InactiveCN107769031ASubstation/switching arrangement casingsAnti-seismic devicesEngineeringVacuum cleaner

Owner:TIANJIN LNER ELECTRIC

Handle structure of vacuum cleaner

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Handheld dust collector for vehicle

InactiveCN102765370AEasy to cleanEasy to useCleaning apparatus for vehicle exteriorsEngineeringMechanical engineering

Owner:SUZHOU ORIGIN IND DESIGN

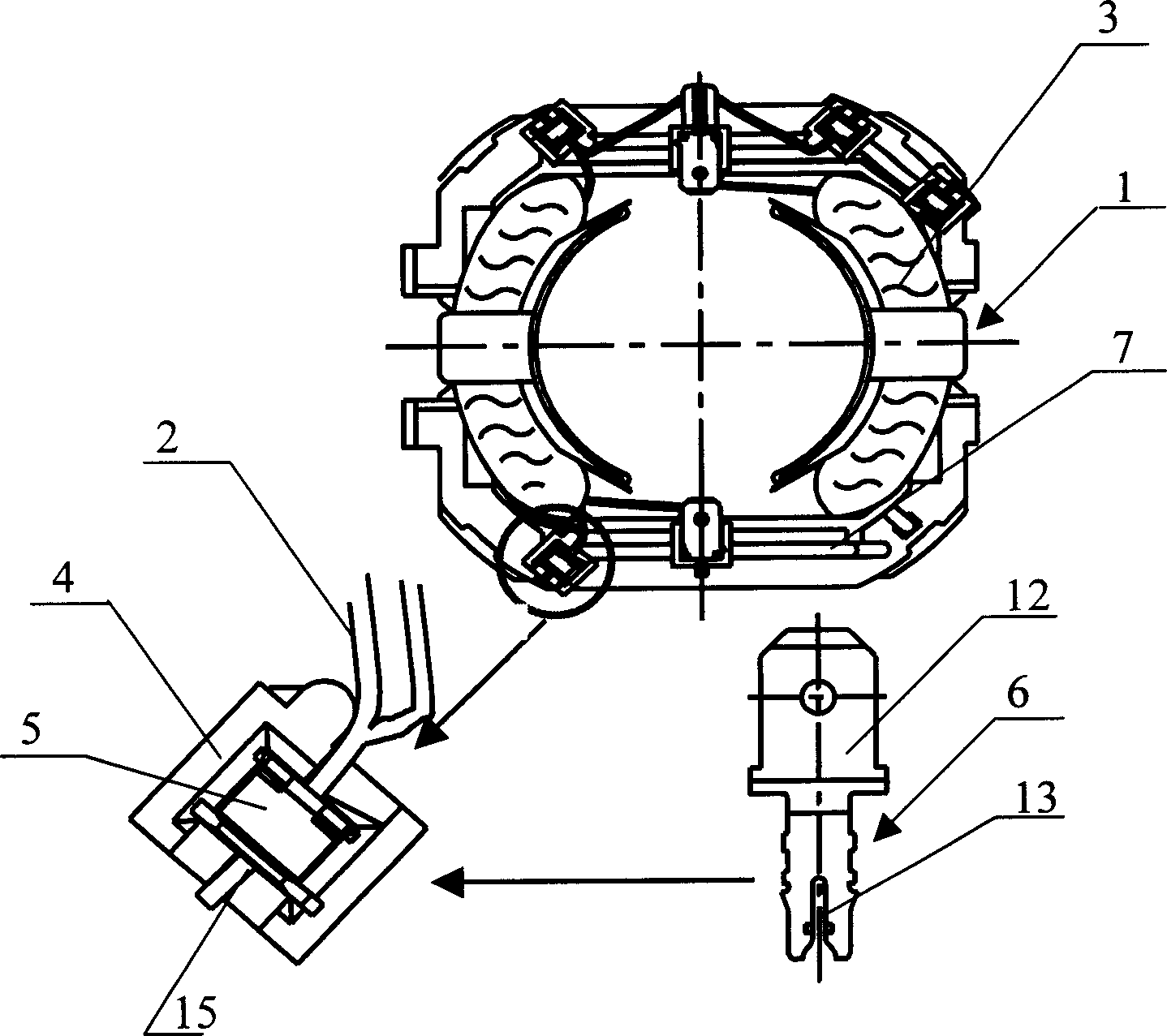

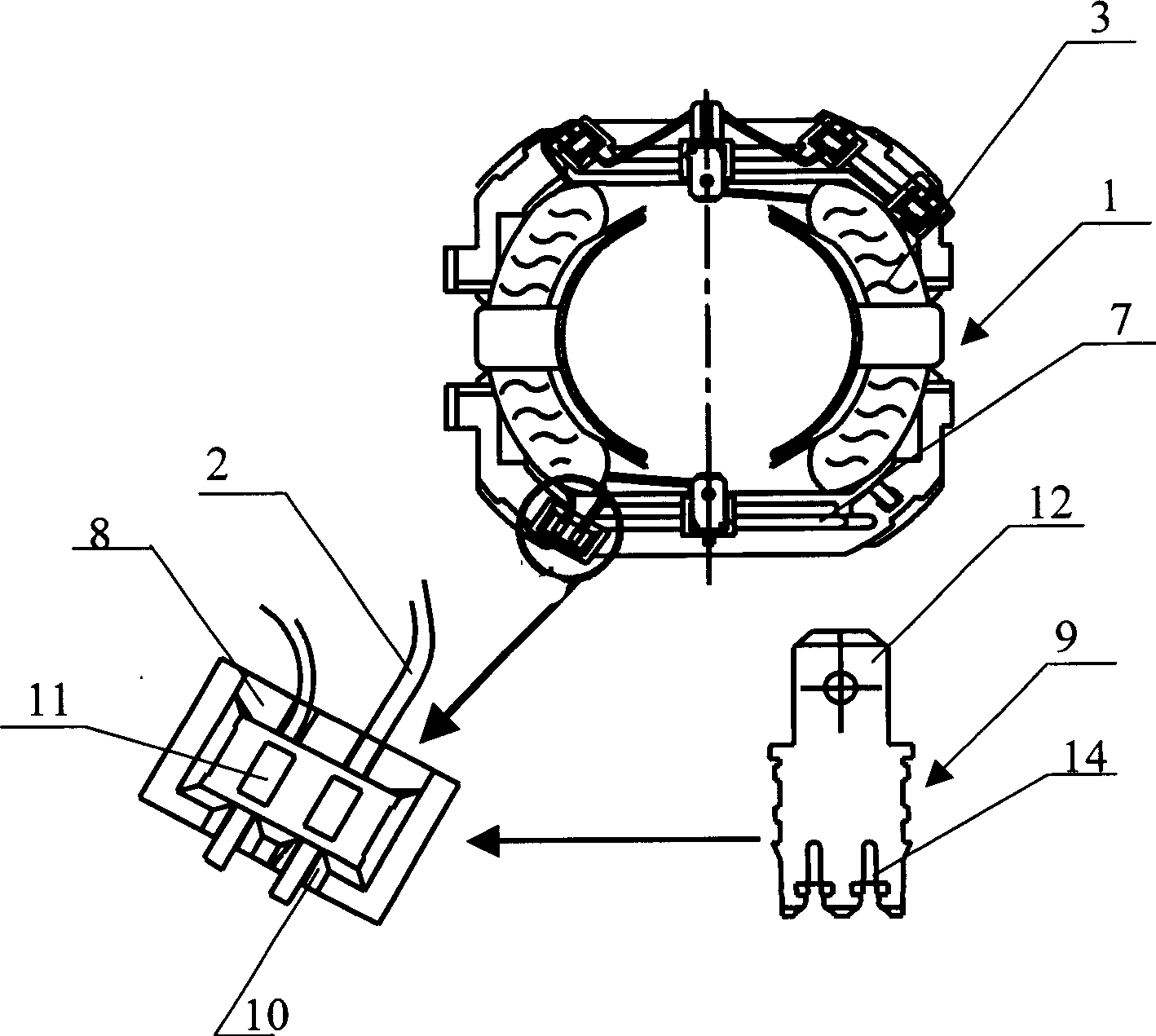

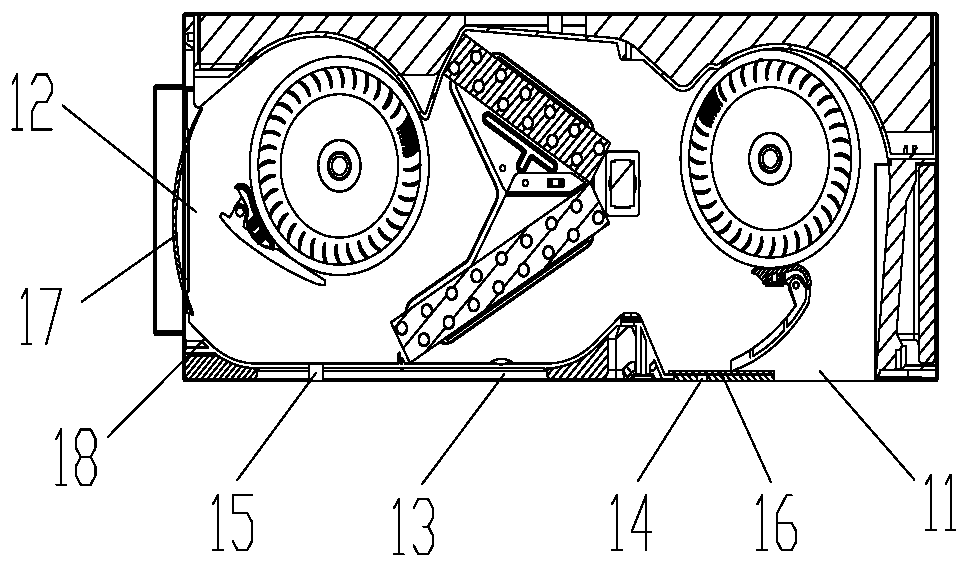

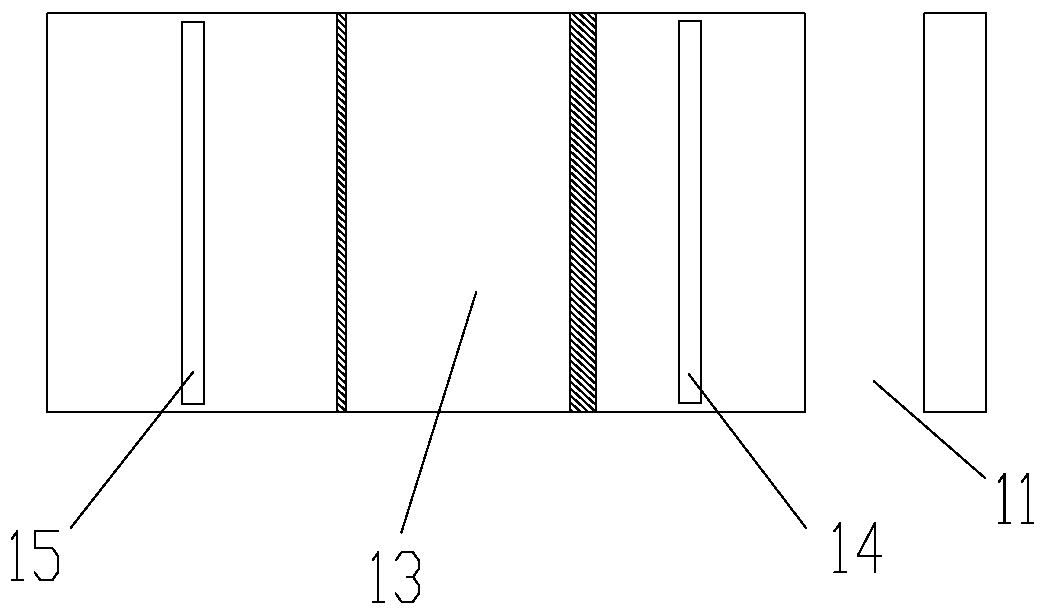

Connection structure between vacuum cleaner motor stator enamelled wire connection end and connection terminal

InactiveCN1783584ADynamo-electric machinesContact members penetrating/cutting insulation/cable strandsEngineeringVacuum cleaner

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Electric vacuum cleaner

ActiveCN103096773AEasy to installImprove ease of useSuction filtersMechanical engineeringVacuum cleaner

The electric vacuum cleaner is provided with a vacuum cleaner body, a dust-collecting device and a handle. Catches are provided on the ends of the handle. On the upper part of the dust-collecting device are provided first engaging parts that engage with the catches and hold the handle in a tilted state. On the vacuum cleaner body are provided second engaging parts that engage with the catches and hold the dust-collecting device on the vacuum cleaner body. When the dust-collecting device is mounted on the vacuum cleaner body with the handle in a tilted state, the engagement of the catches with the first engaging parts is released and the catches are engaged with the second engaging parts.

Owner:PANASONIC CORP

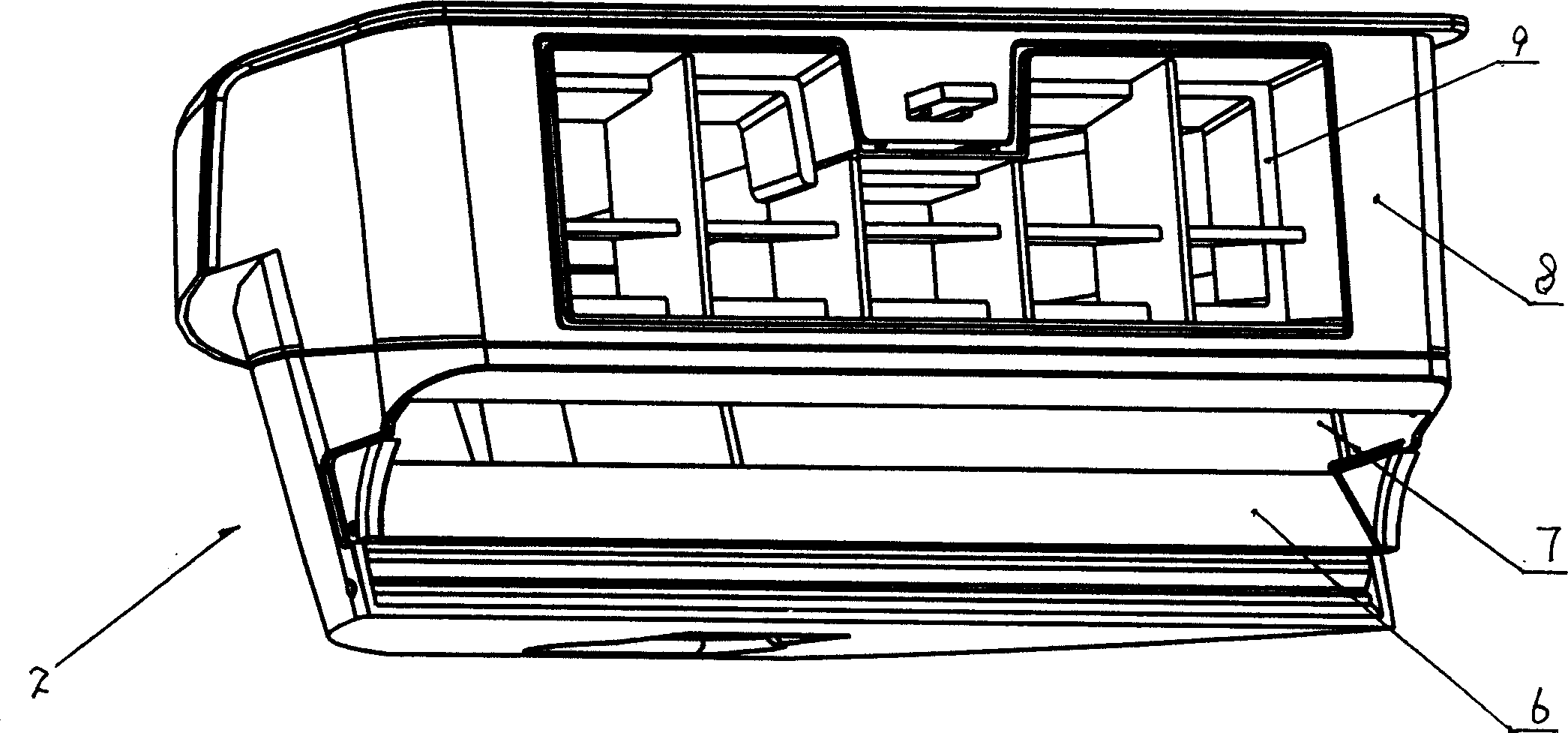

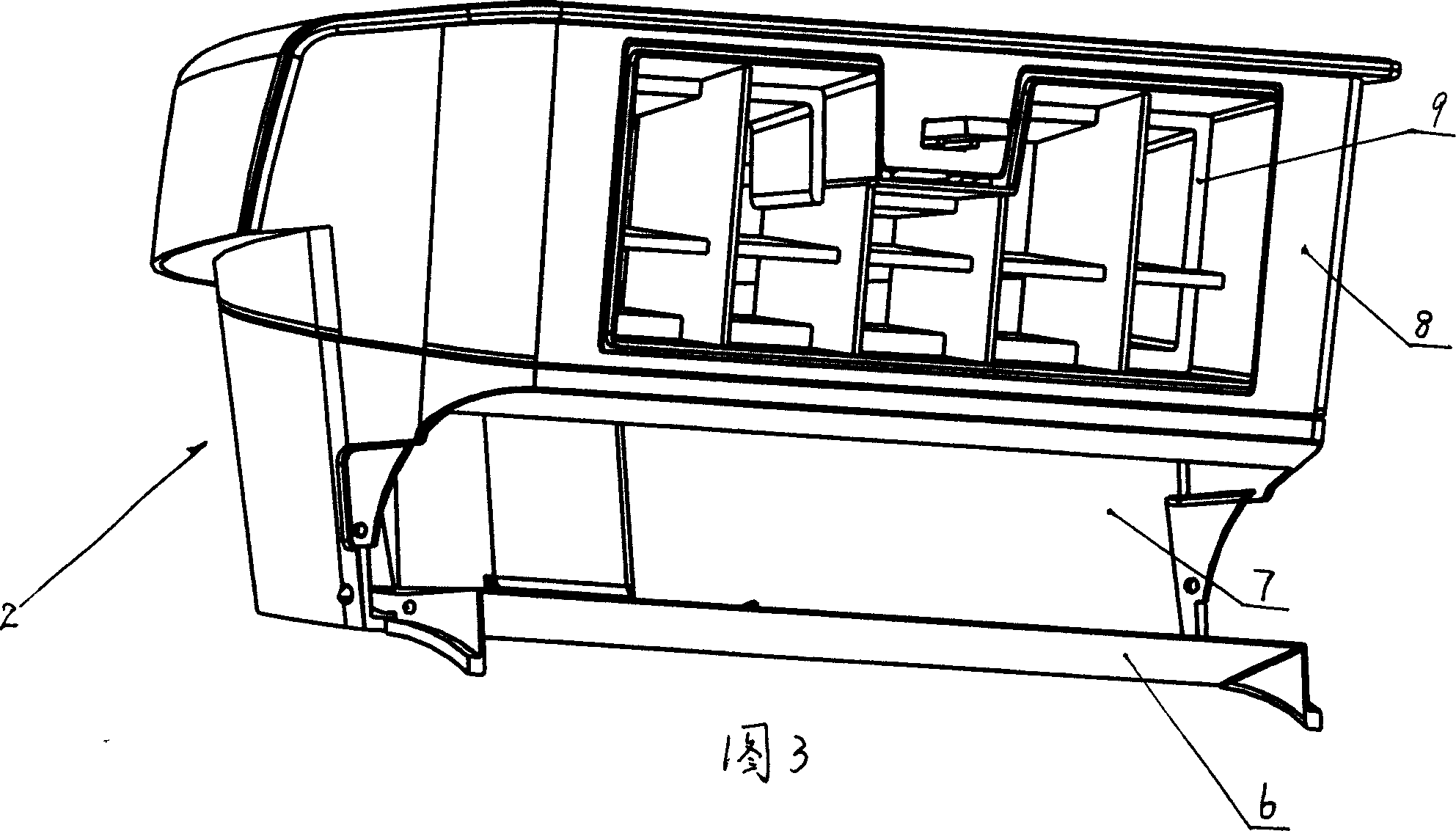

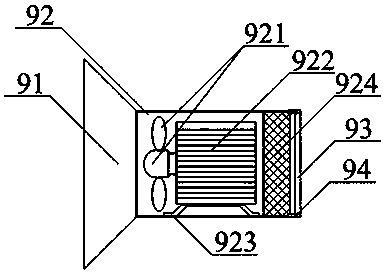

Dust removal structure of air conditioner and dust removal method thereof

Owner:GREE ELECTRIC APPLIANCES INC

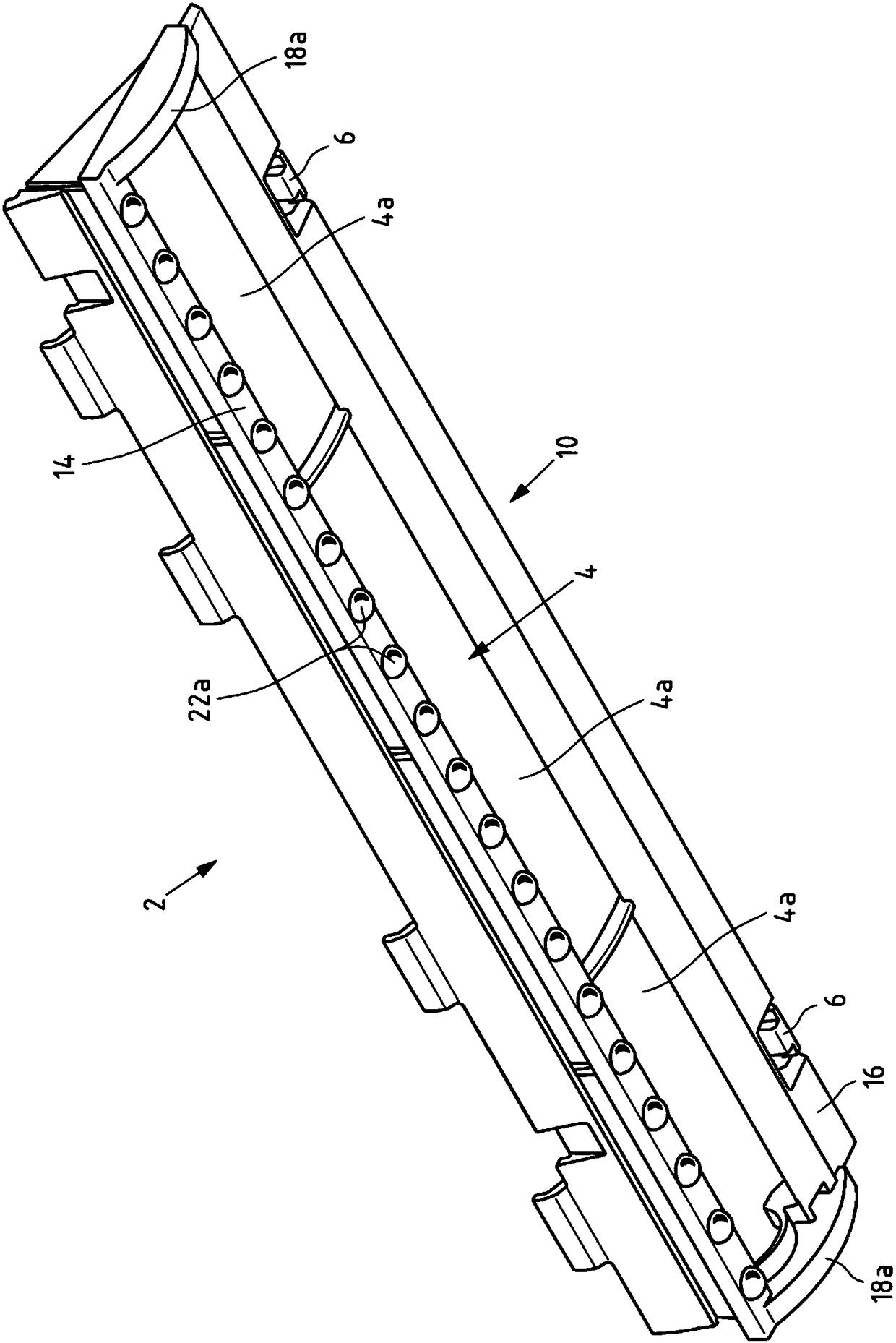

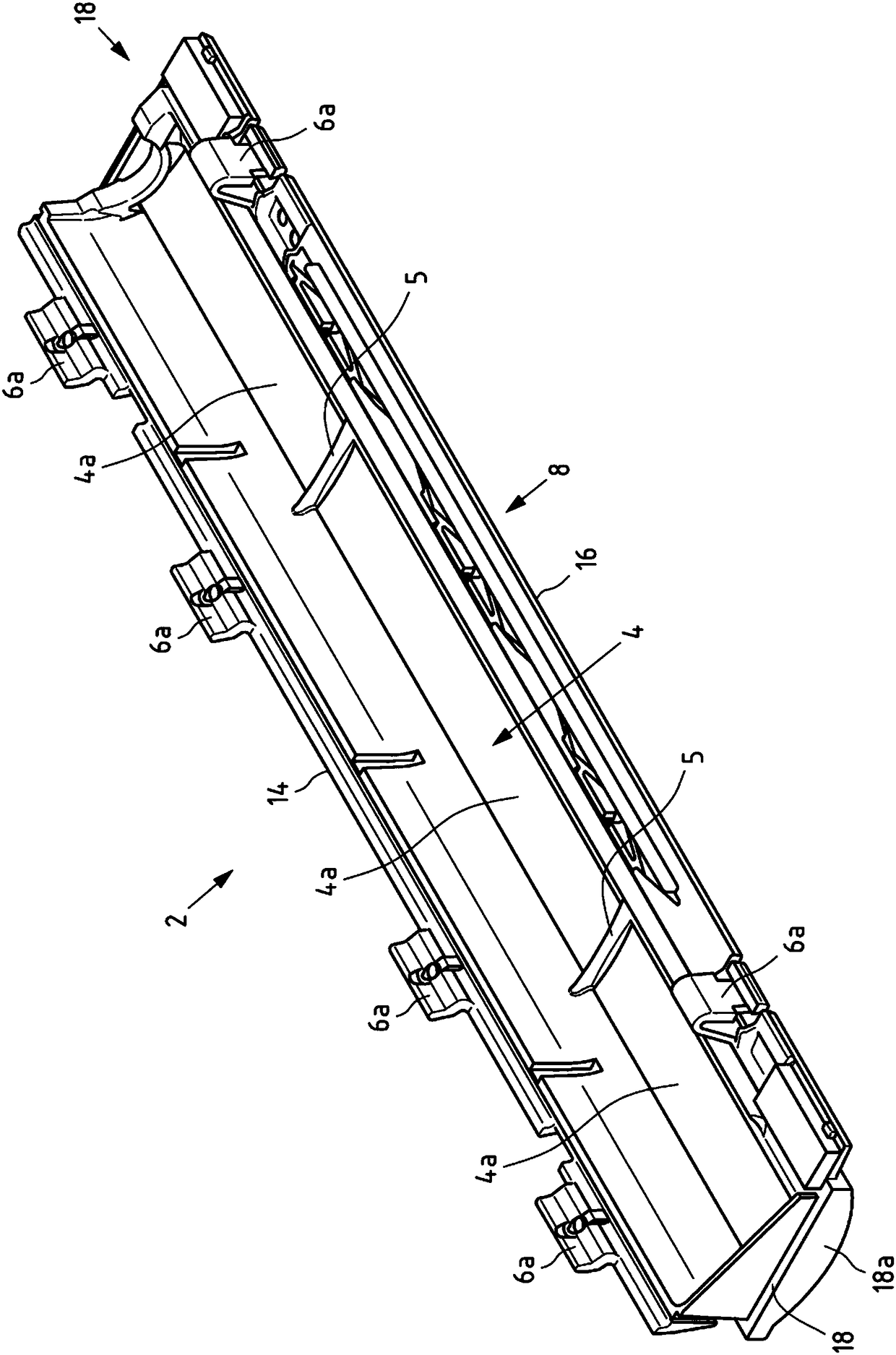

Chassis for nozzle with air guiding element

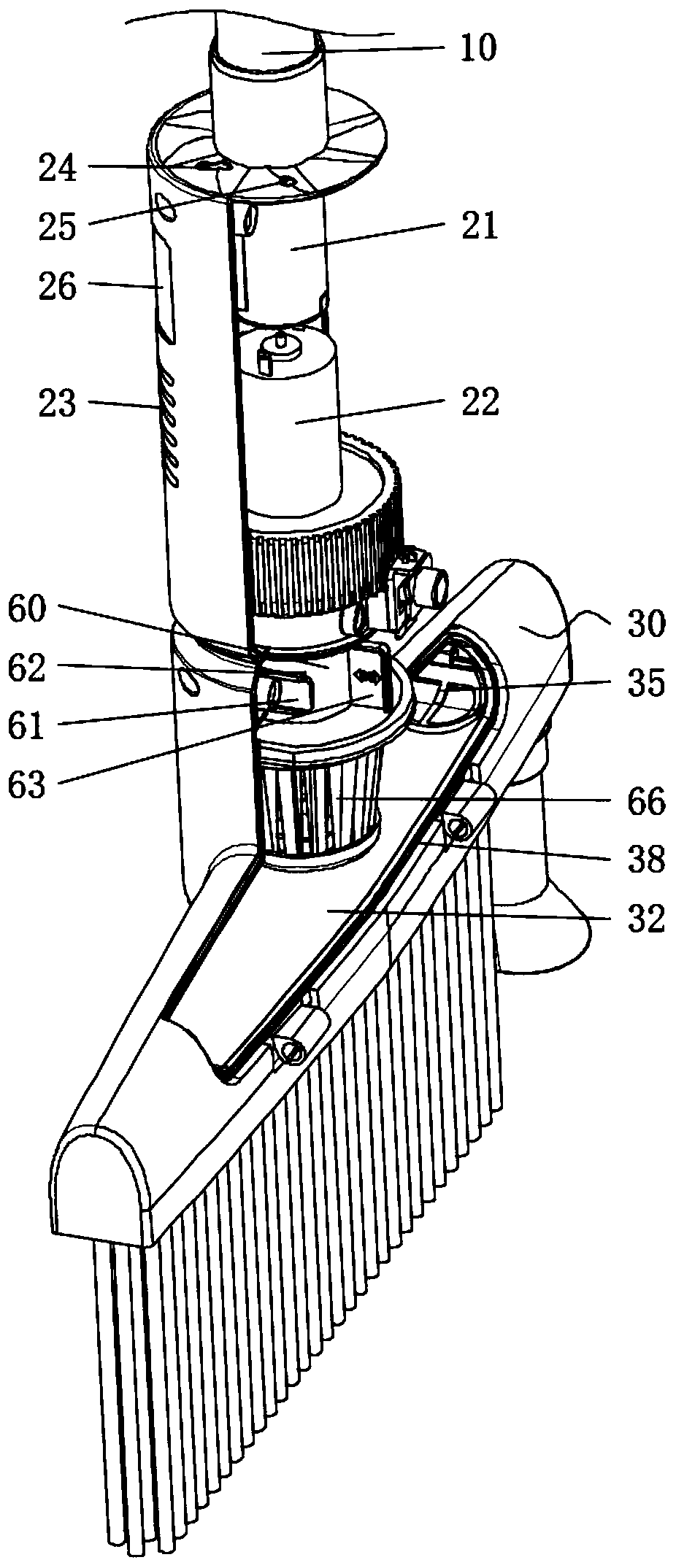

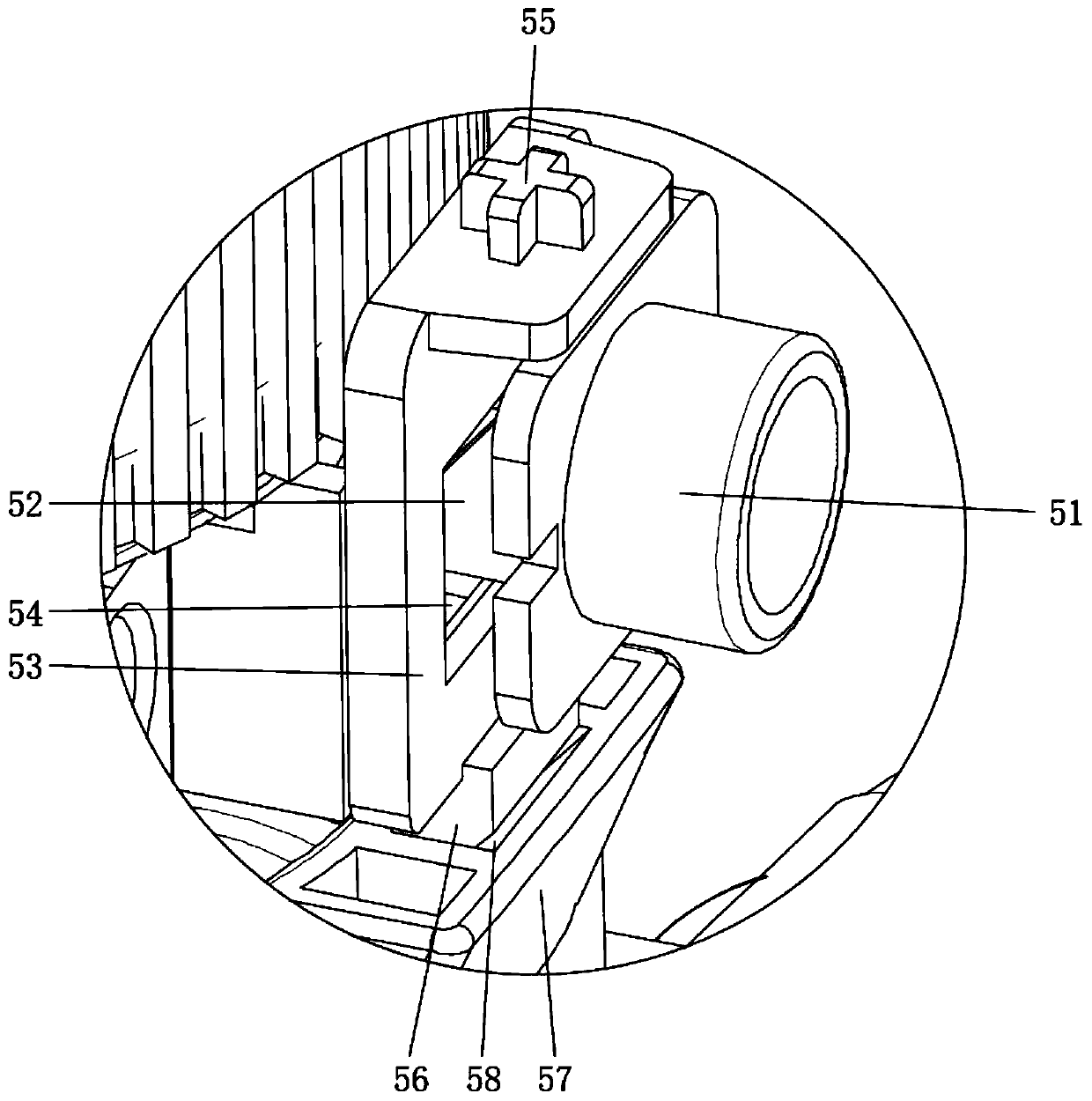

ActiveCN108294685AComfortable runningAvoid stickingSuction nozzlesFront edgeVacuum cleaner

Owner:VORWERK & CO INTERHOLDING GMBH

Handheld hair washing machine capable of being used for wiping body

InactiveCN112971310AFlexible operationSmall structureSuction cleanersBathroom accessoriesHand heldSoft materials

The invention discloses a handheld hair washing machine capable of being used for wiping body. The hair washing machine at least comprises a machine body, a washing device, a water supply device, a water absorption device and a cleaning wiper, the machine body is of a box-shaped structure with a cavity, a containing frame is arranged above a shell of the machine body, the washing device is a handheld device, the handheld part of the washing device is placed on the containing frame, the water supply device at least comprises a water supply tank and a water supply pipe, the water supply tank is mounted on the machine body, one end of the water supply pipe is arranged in the water supply tank, and the other end is connected with the washing device; the water absorption device at least comprises a water suction pipe and a dust collector, one end of the water suction pipe is connected with the dust collector, and the other end of the water suction pipe is connected with the machine body; a drainage box is arranged at the bottom of the machine body; the cleaning piper is made of soft materials and installed at the front end of the washing device. The handheld hair washing machine is small in size, small in occupied space and suitable for cleaning all parts of the body.

Owner:SHANGHAI HOMAGE TECH CO LTD

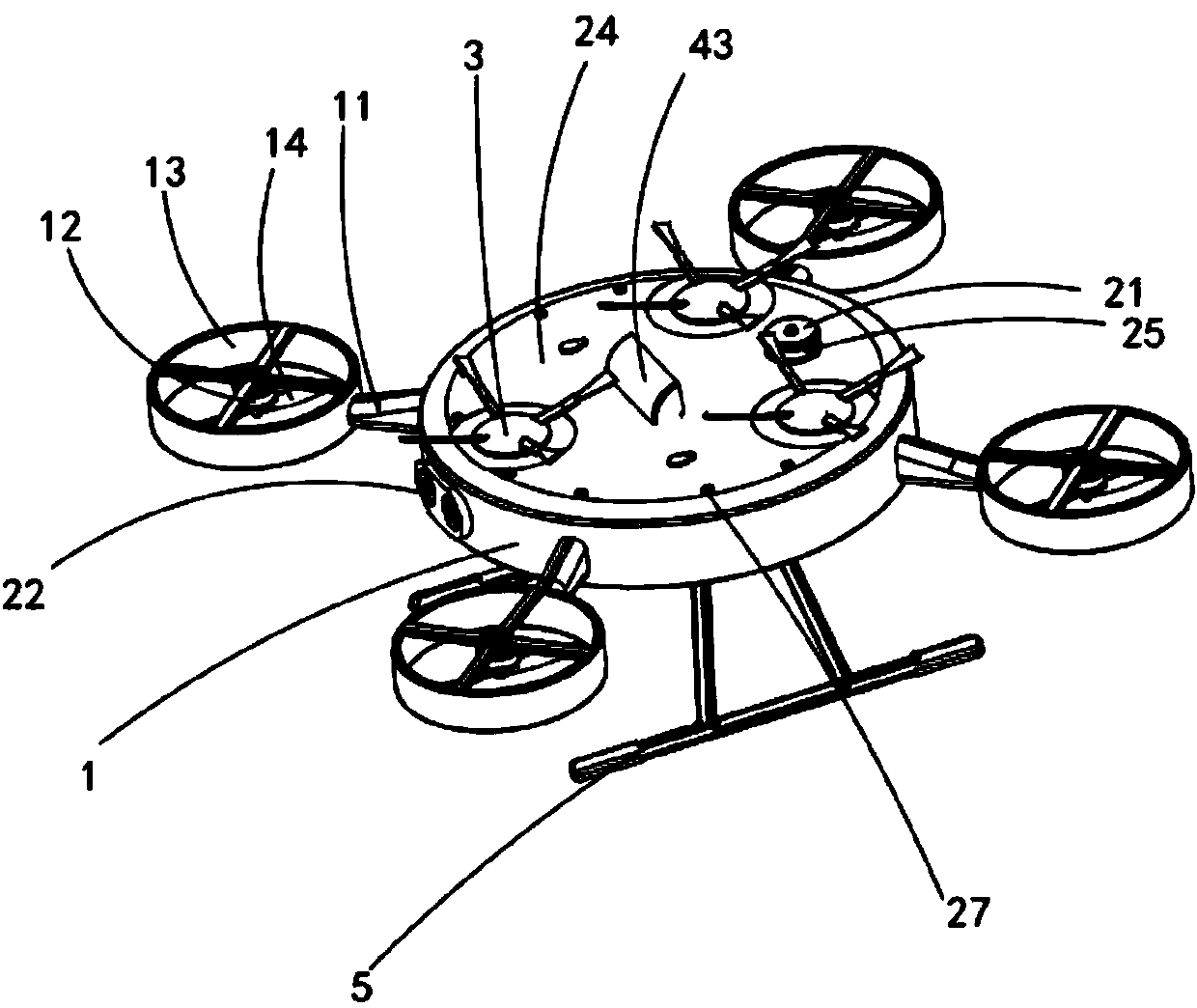

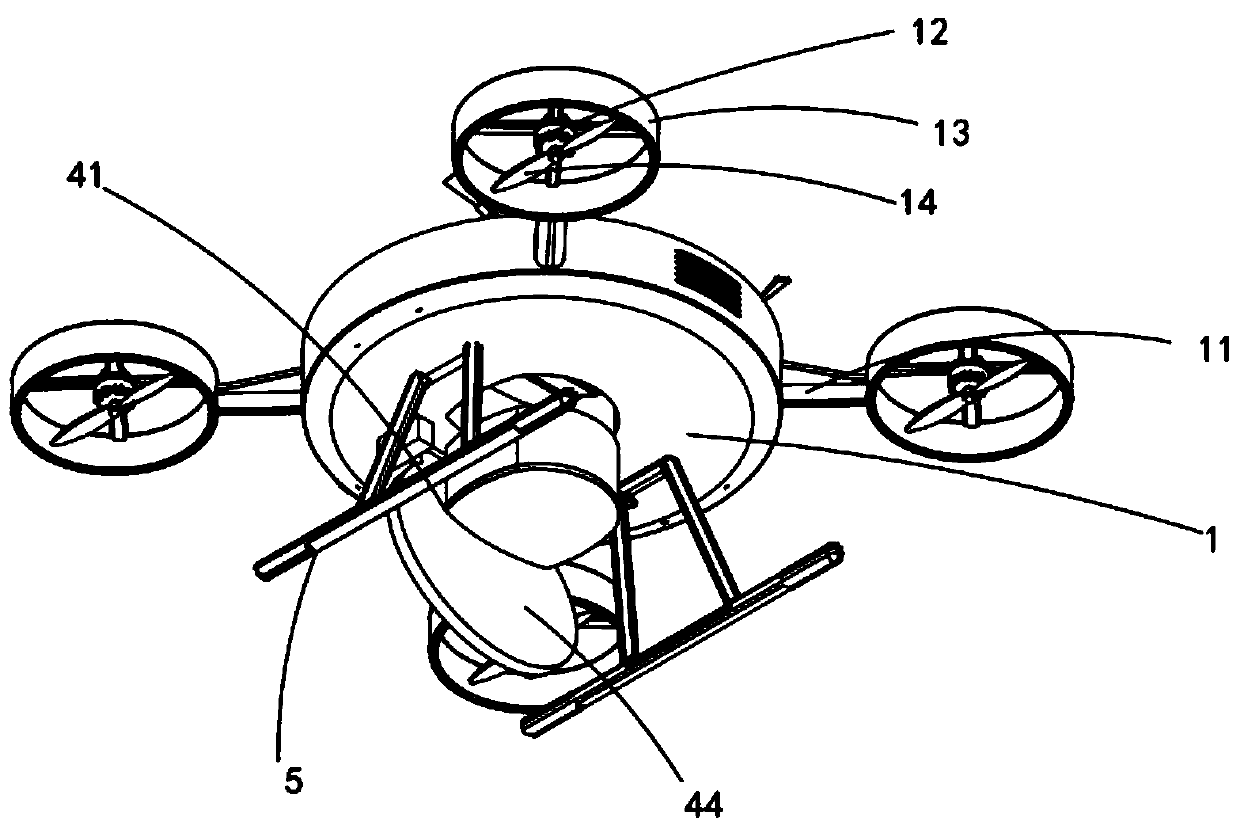

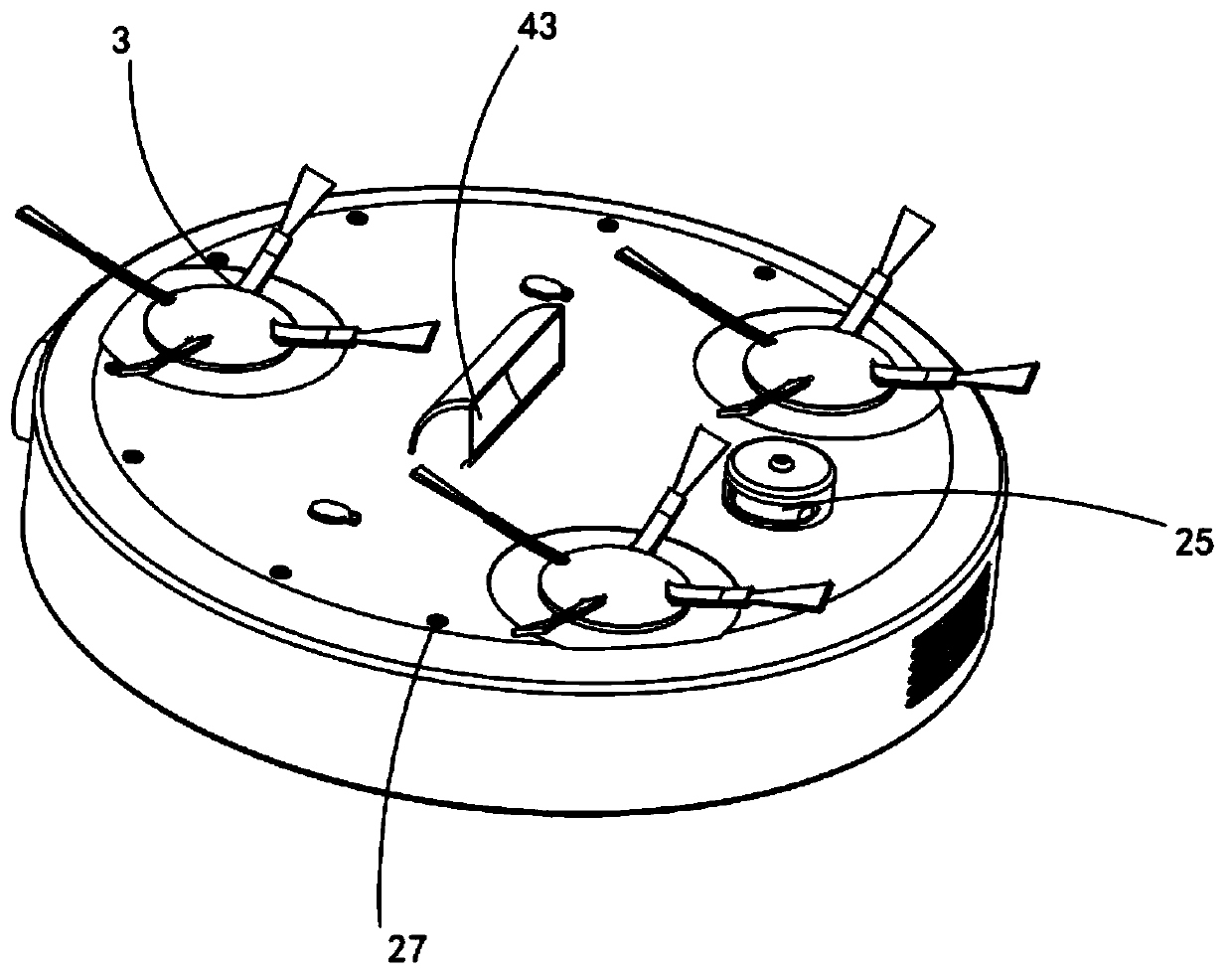

Unmanned aerial vehicle ceiling cleaning device

PendingCN110946527AImprove efficiencyExpand the cleanable areaCarpet cleanersFloor cleanersBrushless motorsUncrewed vehicle

Owner:GUANGXI UNIV

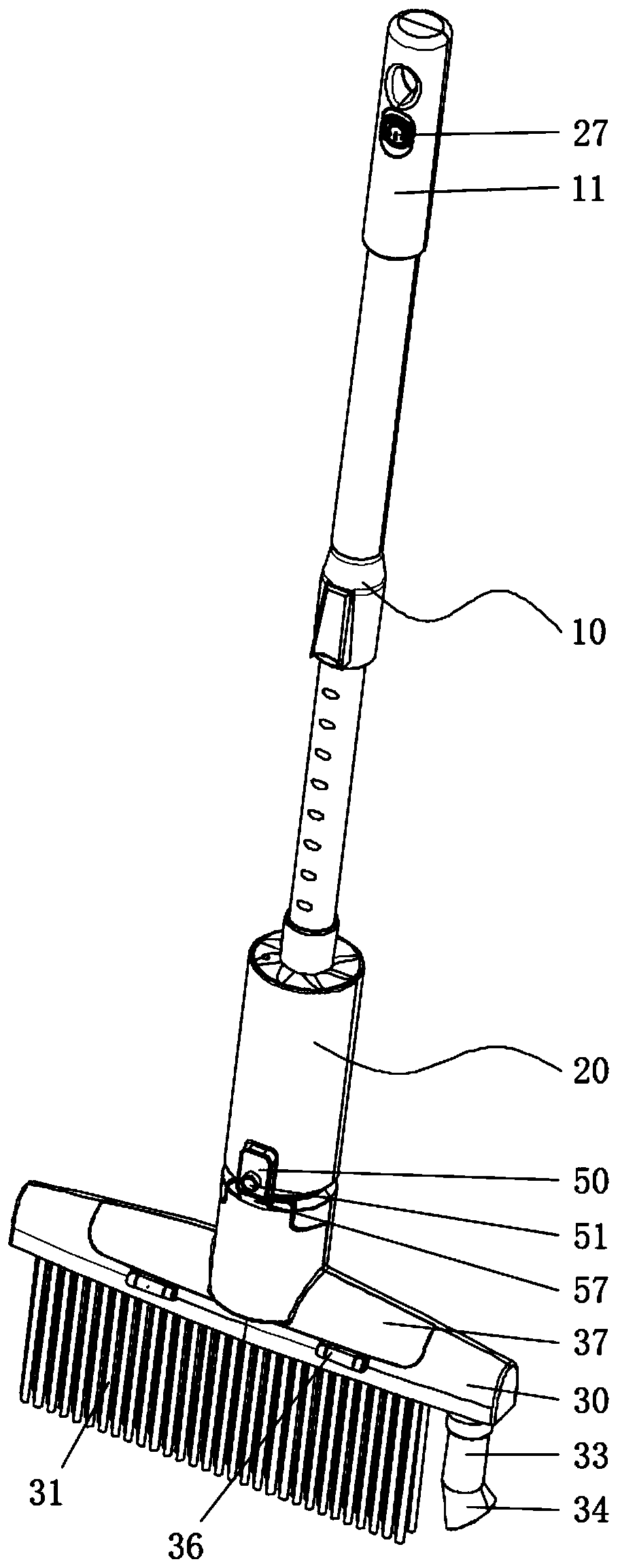

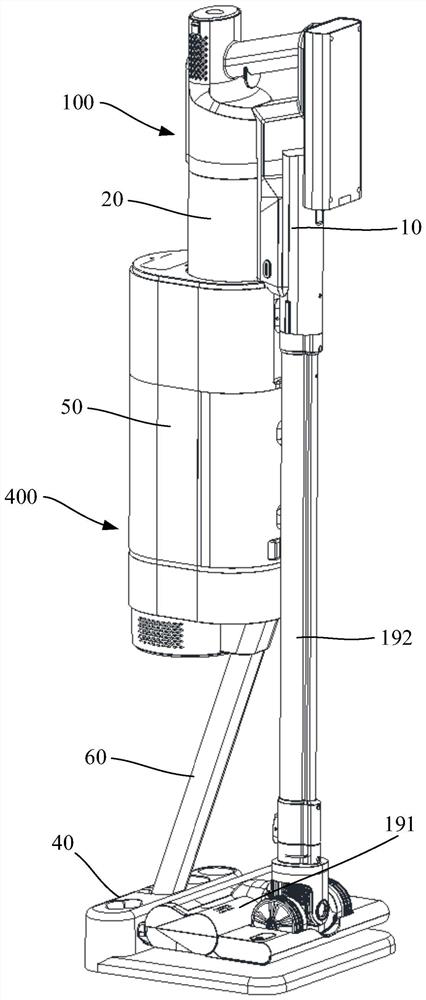

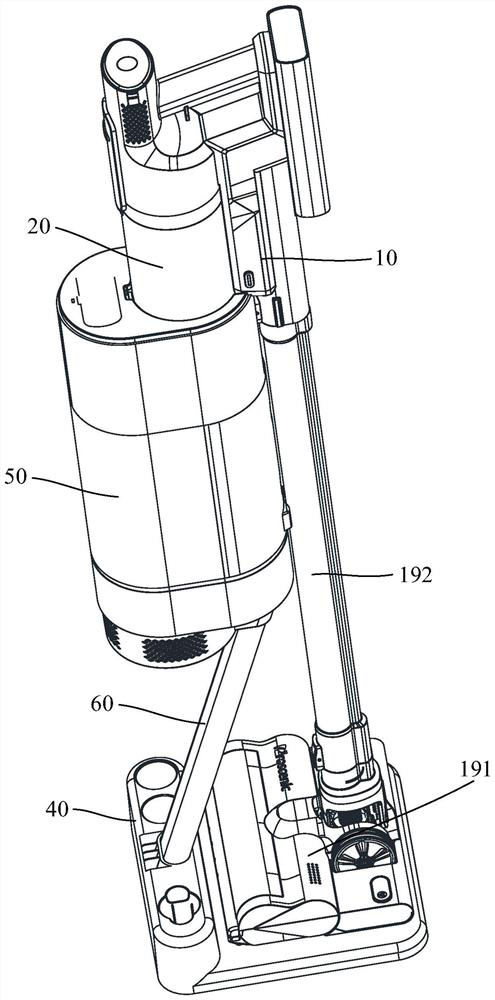

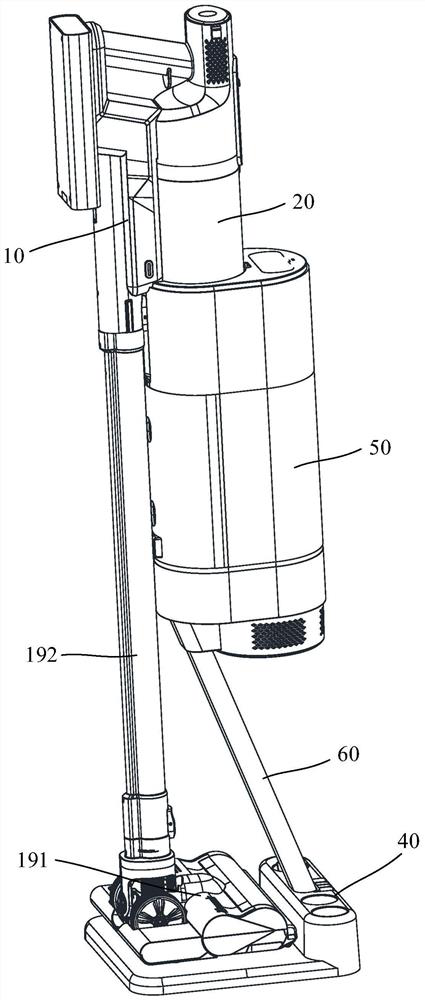

Electric broom

PendingCN110638375AReduce weightReduce the burden onCarpet cleanersFloor cleanersSuction forceEngineering

Owner:苏州锐科兰电器有限公司

Cleaning device

PendingCN114403745ALarge capacityEasy to useSuction filtersEnvironmental engineeringMechanical engineering

Owner:SHENZHEN PROSCENIC TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap