Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Fiber layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The retinal nerve fiber layer (RNFL) or nerve fiber layer, stratum opticum, is formed by the expansion of the fibers of the optic nerve; it is thickest near the optic disc, gradually diminishing toward the ora serrata.

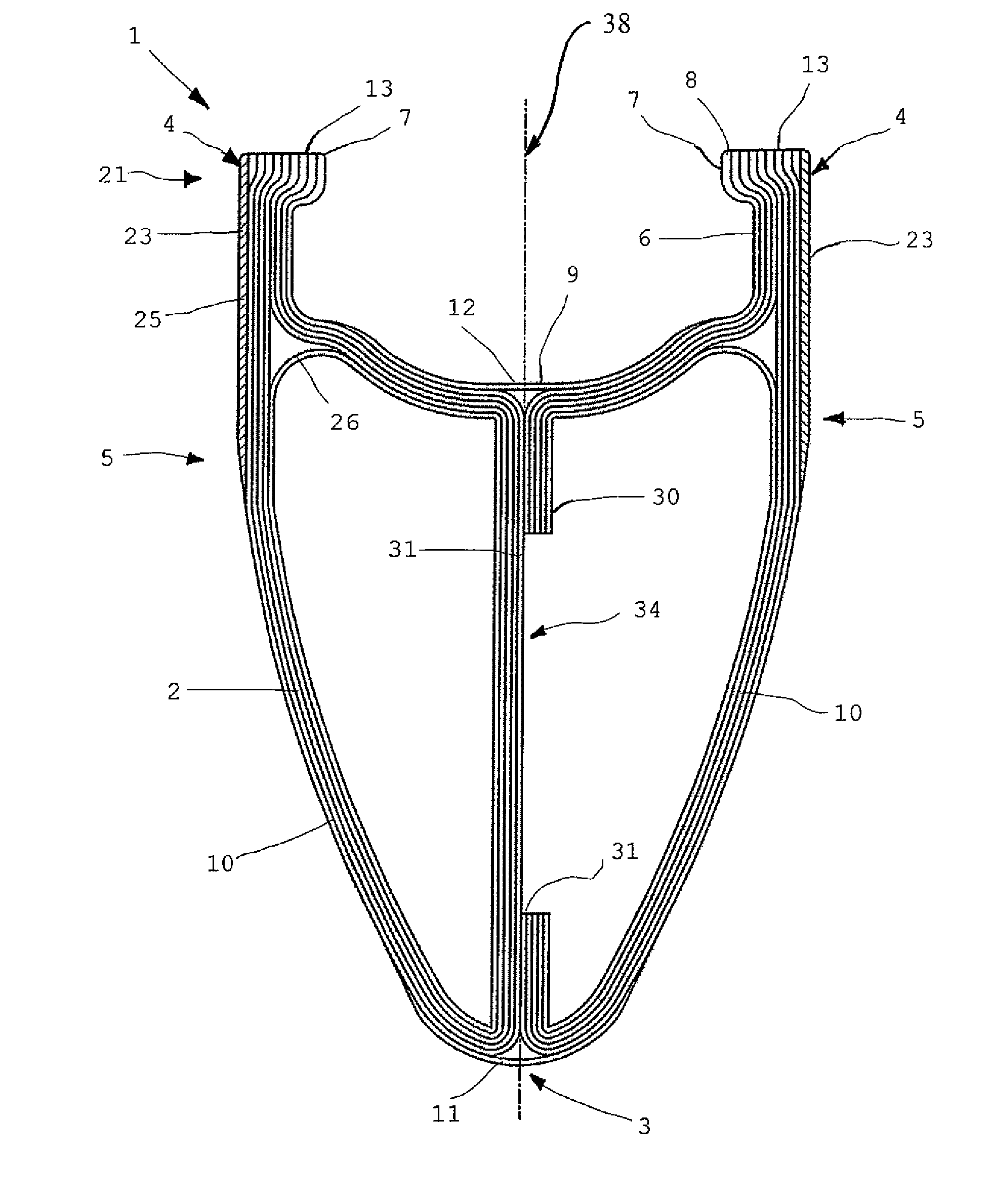

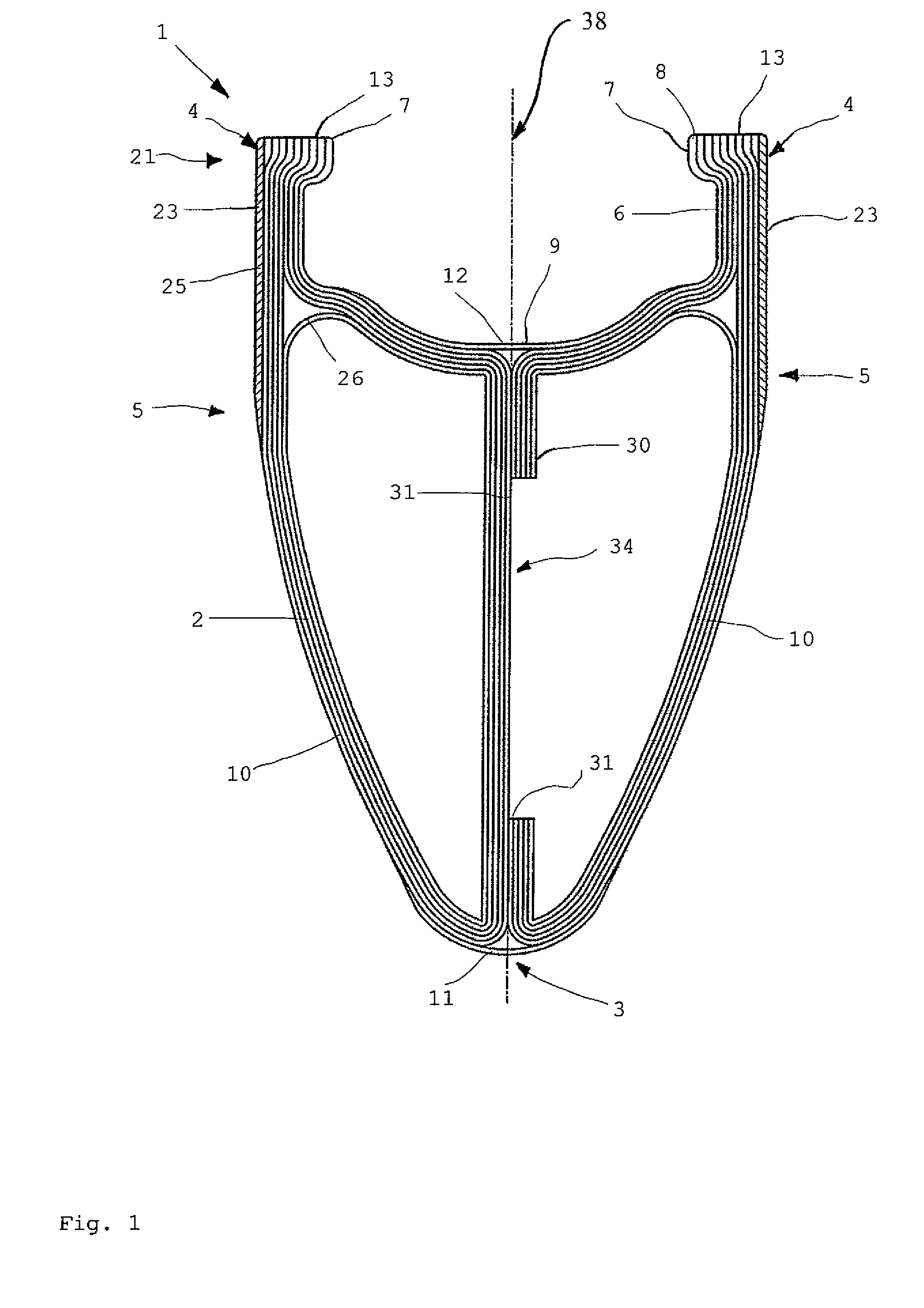

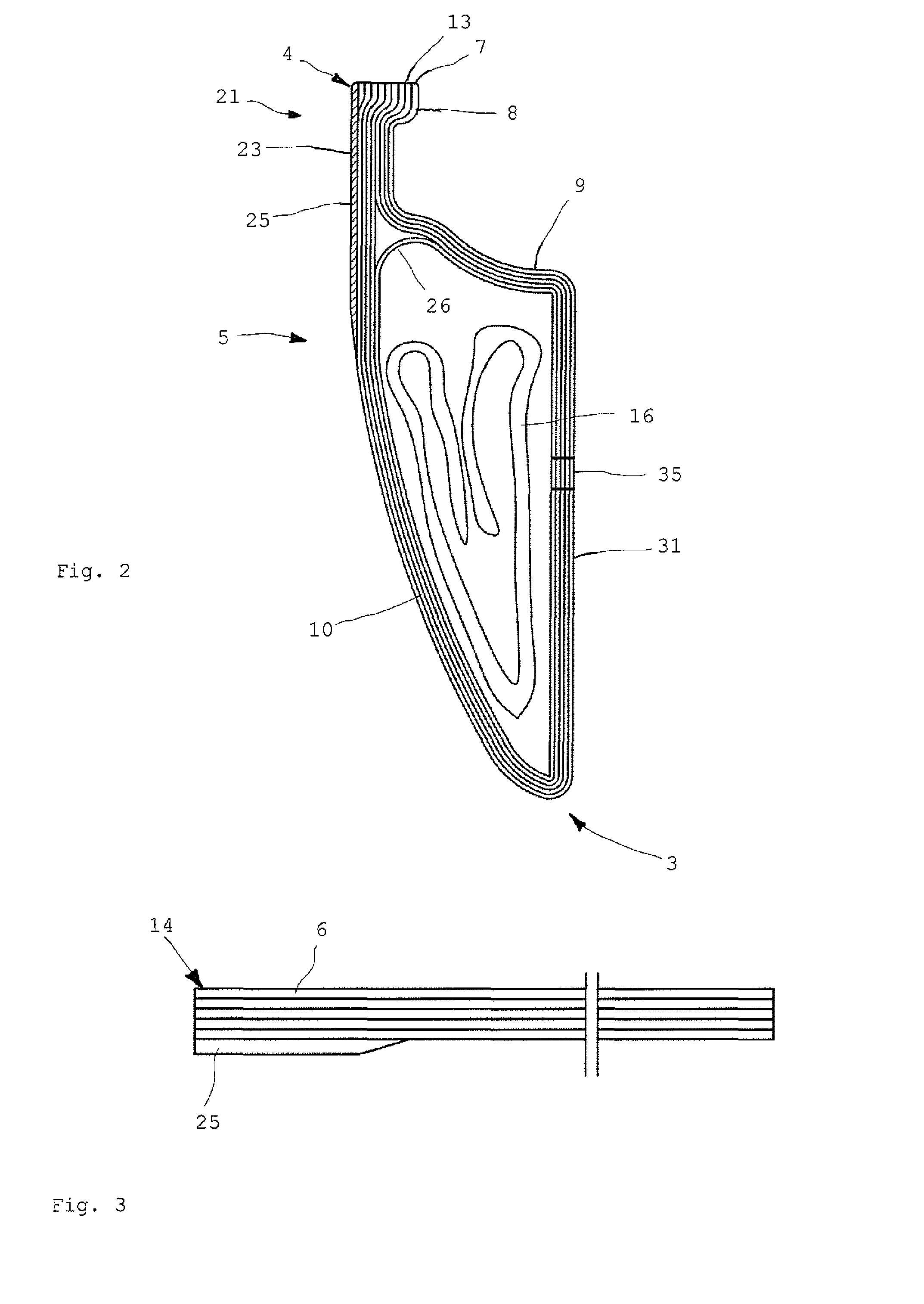

Rim and method for producing a rim

ActiveUS8070235B2Reduce stepsStepRimsNon-metallic wheel bodyFiber layerFibrous composites

Owner:SWISS

High-strength composite fiber non-woven cloth and preparation method thereof

ActiveCN106427147AFirmly connectedClosely connectedProtective equipmentSynthetic resin layered productsEpoxyAlcohol

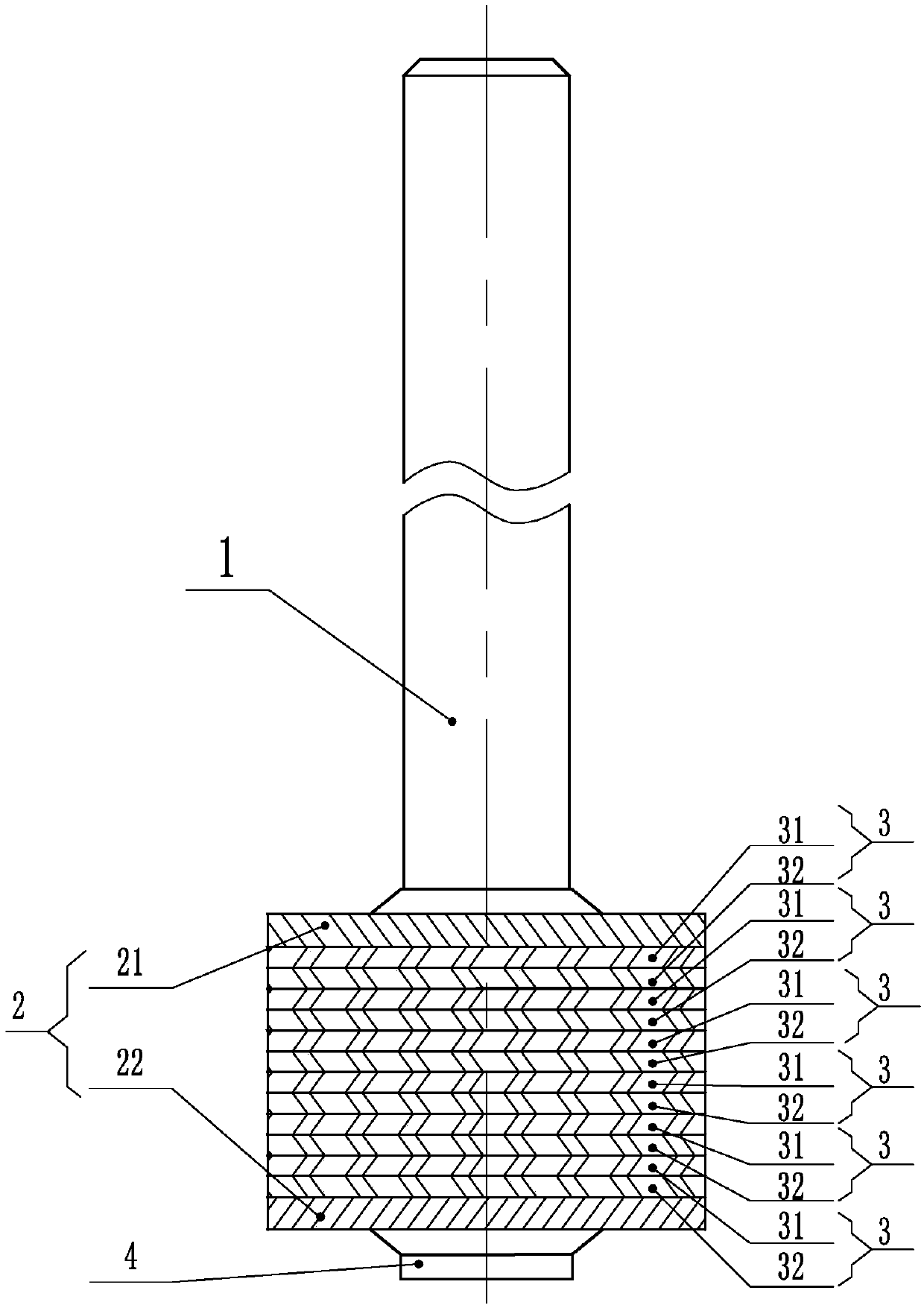

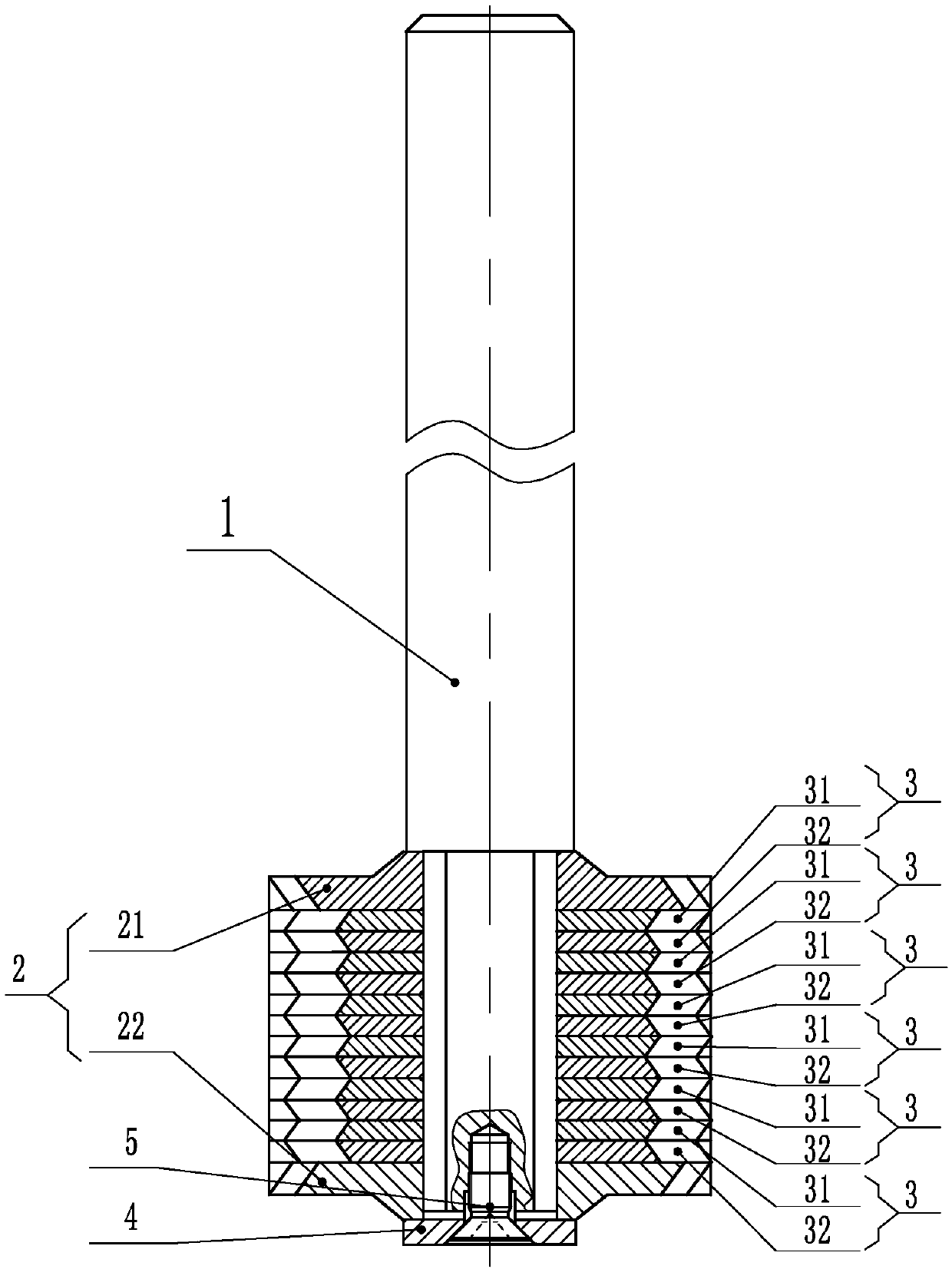

The invention discloses high-strength composite fiber non-woven cloth and a preparation method thereof. Ultrahigh-strength high-modulus polyethylene fibers are used as base materials, the polyethylene fiber obtained after fiber placement is subjected to a series of homogenization, parallelization and straight and upright arrangement and placed in a modified epoxy resin solution for sizing treatment in an environment of 60-80 DEG C, then the formed polyethylene fiber layers are subjected to composite lamination, and the non-woven cloth is prepared, wherein the modified epoxy resin solution is prepared by adding and mixing an adhesion agent, a filling agent, an insulating filler, fire retardant, white carbon black and ethyl alcohol, the mass of hydroxyl chemigum accounts for 8-12% of the mass of the modified epoxy resin solution, and the content of vinyl cyanide accounts for 18-30% of the content of hydroxyl chemigum. The non-woven clothes with different thicknesses are prepared by lamination of the polyethylene fiber layers, an antiknock device can be made from different types of non-woven cloths according to explosion sites and use environment, and the non-woven cloths with different thicknesses are different in anti-explosion range so as to sufficiently withstand the impact of a bullet.

Owner:JIANGSU LINRY NEW MSTAR TECH

High-efficiency filter sheets for air microfiltration membrane filters

InactiveCN108031209AHigh mechanical strengthIncreased mechanical toughnessDispersed particle filtrationFiltration separationPolyvinyl chlorideFilter effect

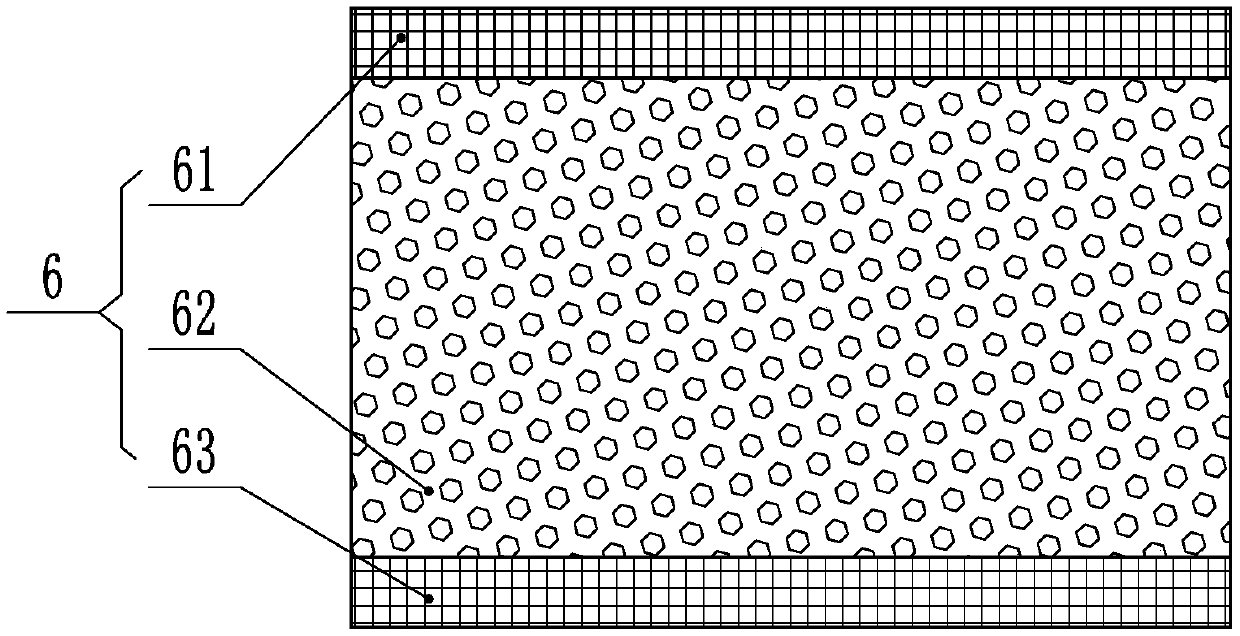

The present invention relates to a high-efficiency filter sheet for air microfiltration membrane filters. The high-efficiency filter sheet comprises a polyvinyl chloride fiber layer and a polytetrafluoroethylene fiber layer, wherein fiber filaments in the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer are respectively in a unidirectional arrangement, and an included angle between the fiber filaments in the polyvinyl chloride fiber layer and the fiber filaments in the polytetrafluoroethylene fiber layer is 60-65 DEG. According to the high-efficiency filter sheet, a double layer combination of the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer is used, and a specific angle between the fiber filaments is set, so that windage resistance and filtering effect of the filter sheet are improved; the introduced polytetrafluoroethylene fiber layer has superhigh mechanical strength and structural toughness, so that vibration caused by strongwind can be effectively suppressed, and airflow in a dust collection chamber of a vacuum cleaner is stabilized; and a filling layer is additively arranged, so that the filtering effect of the filter sheet is further improved.

Owner:SUZHOU QINGRUI AIR SYST

Portable panel construction and method for making the same

ActiveUS20080124501A1Prevent movementFacilitates transportation and assemblyLayered productsSheet joiningEngineeringBuilding construction

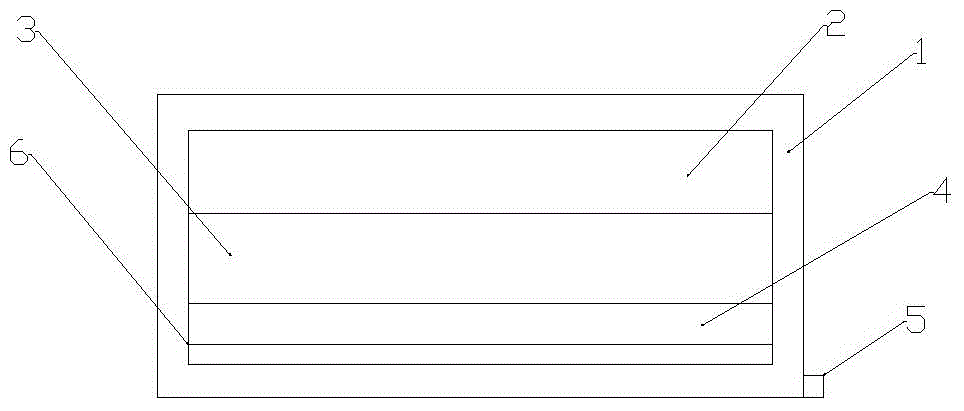

Disclosed herein is a portable panel having numerous favorable characteristics. The panel comprises a core having a length, a width, a first side and a second side. A first fiber layer is attached to the first side while a second fiber layer is attached to the second side. A first polyurethane layer is impregnated in the first fiber layer while a second polyurethane layer is impregnated into the second fiber layer. A first skin is attached to the first polyurethane layer while a second skin is attached to the second polyurethane layer. The panel can be used in the manufacture of tables, flooring, risers, stages, bleachers, and the like.

Owner:PS FURNITURE

Heatable mattress

InactiveCN104665357AWith heating functionWith strengthStuffed mattressesSpring mattressesEngineeringMetal

Owner:董昕悦

Polyester natural color yarn for sewing

The invention discloses a polyester natural color yarn for sewing. The yarn comprises a first polyester silk layer. The first polyester silk layer is connected with a second polyester silk layer through a chemical fiber layer and an antibacterial yarn layer, the first polyester silk layer and the second polyester silk layer penetrate through a wear-resisting layer and a breathable layer, the wear-resisting layer and the breathable layer are in winding connection, the first polyester silk layer and the second polyester silk layer are arranged in parallel, and the first polyester silk layer andthe second polyester silk layer are arranged in an S shape. According to the polyester natural color yarn for sewing, by arranging the wear-resisting layer made of nylon materials, the yarn has the wear-resisting characteristic; by arranging the antibacterial yarn layer, the yarn has the bacteriostatic function; by arranging the breathable layer made of breathing cotton materials, the yarn can solve the problem that an existing polyester yarn product is poor in hygroscopicity, the natural color of the clothes directly sewn by the polyester yarn without printing or dyeing is kept, the yarn conforms to the healthy life idea, and then the polyester yarn is widely applied to production and living.

Owner:HUBEI XINPING TEXTILE CO LTD

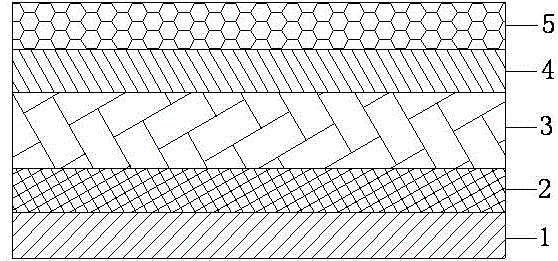

High safety waterproof anti-radiation fabric

InactiveCN106319989ARealize the radiation protection functionGuaranteed wearing comfortLayered productsWoven fabricsPolyurethane membraneEngineering

Owner:杨洪兴

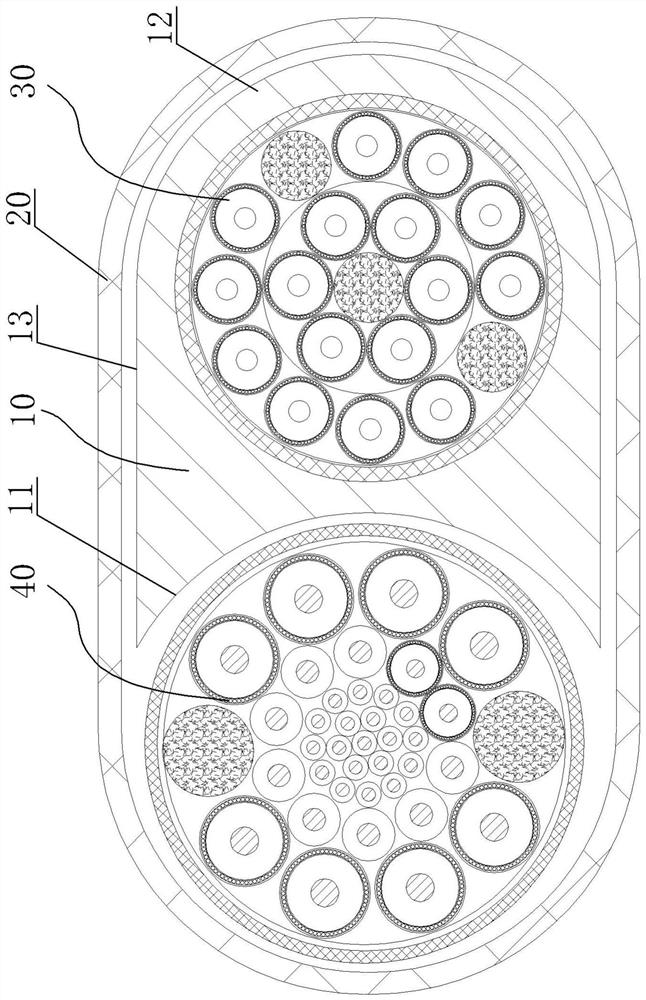

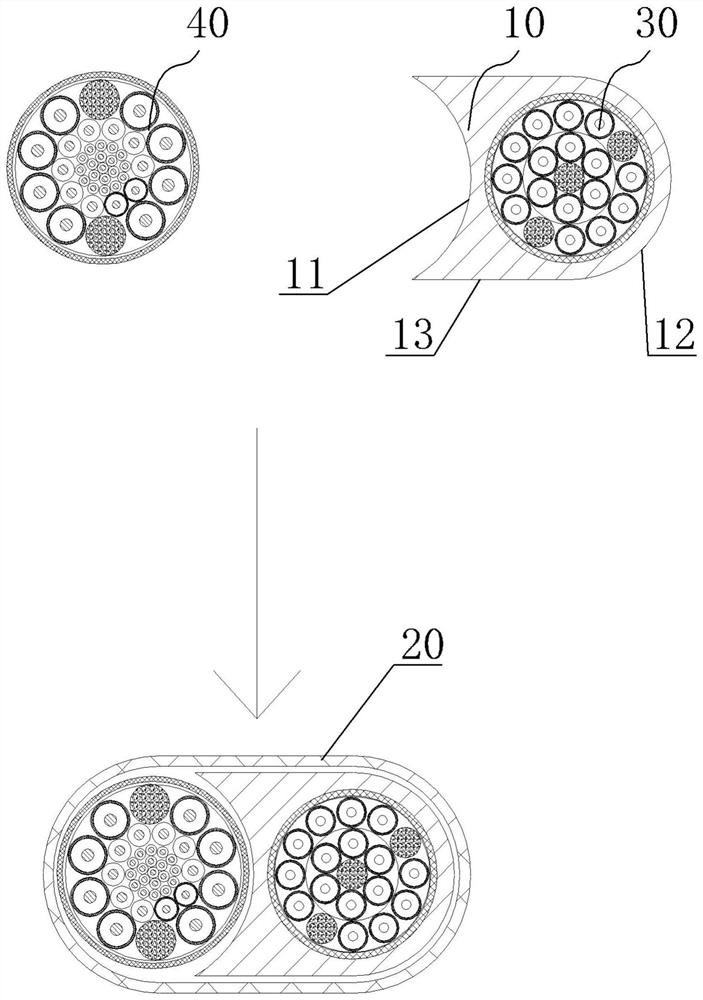

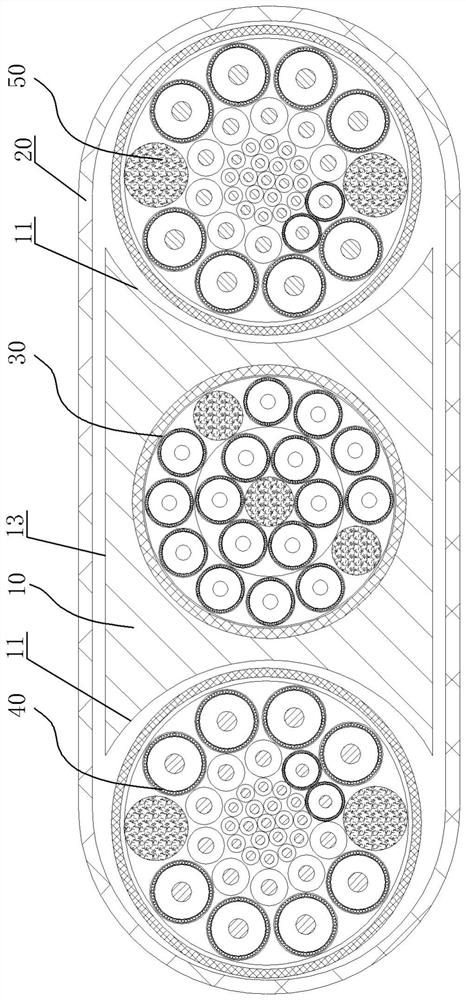

Embedded special-shaped side-by-side cable

Owner:CHANGSHU HONGLIN WIRE & CABLE CO LTD

Electrostatic spinning fiber collecting device for eliminating fiber flying and dynamically adjusting adhesive force between fibers and base material

InactiveCN112695389AEliminate accumulationIncrease electrostatic attractionFilament/thread formingSpinningElectrospinning

The invention relates to the technical field of electrostatic spinning, and discloses an electrostatic spinning fiber collecting device for eliminating fiber flying and dynamically adjusting adhesive force between fibers and a base material. The device can dynamically and automatically adjust the strength of charge elimination in real time according to the charge accumulation amount generated by fiber deposition, prevent the flying filaments and keep the deposition speed of the fibers stable; and the adhesion strength of a fiber layer and the base material is regulated and controlled by controlling the potentials of the surfaces of a collector and a fiber membrane. The novel electrostatic spinning fiber collecting device with dynamic monitoring and feedback compensation functions is designed. Charge accumulated on the collector due to fiber deposition can be timely and effectively eliminated to solve the problem of fiber flying, and the adhesive force between the fibers and the base material is improved by adjusting the deposition speed of the fibers on the surface of the collector, so that, the yield, quality and quality stability of the fibers are improved. The device has important economic and social value for promoting the development of an electrostatic spinning technology and the production and application of nanofibers.

Owner:JIANGSU NANOFIBER NEW MATERIAL TECH CO LTD

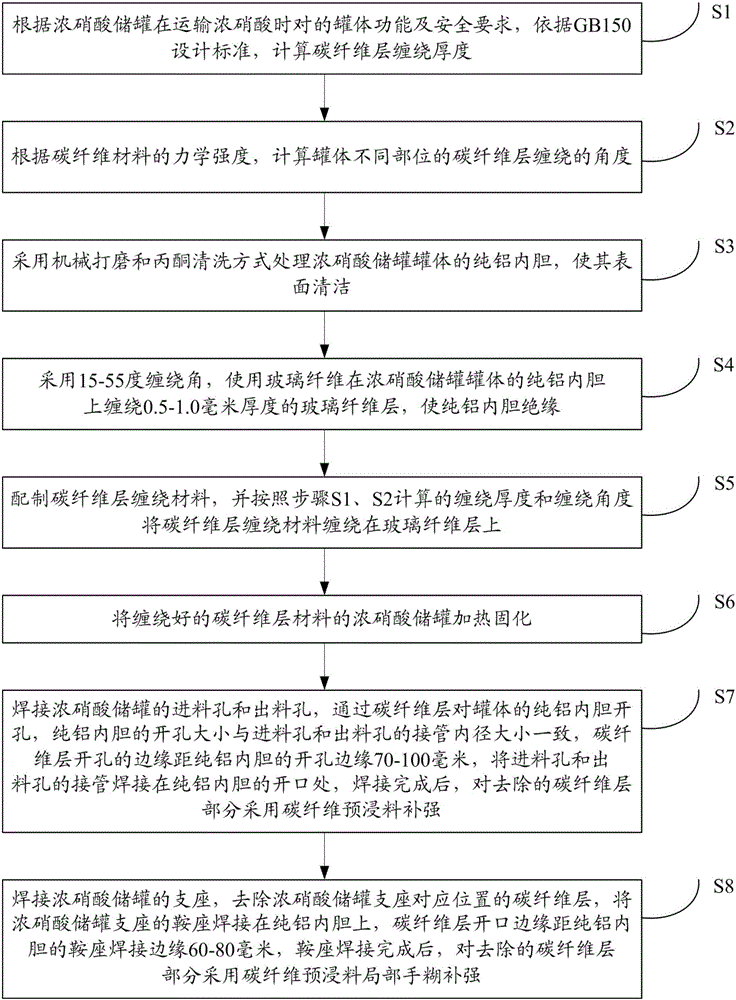

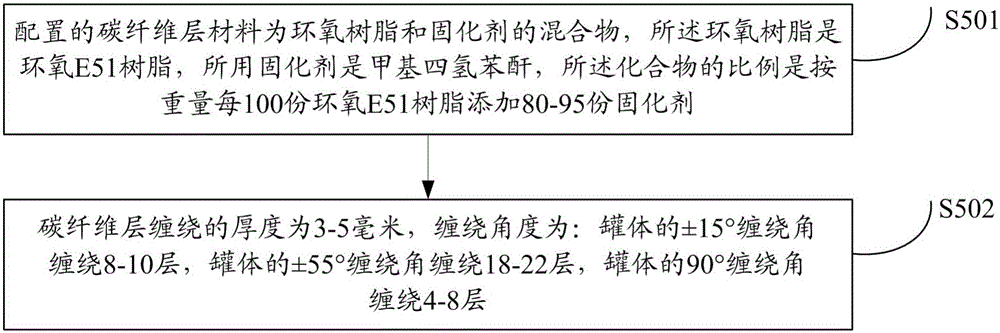

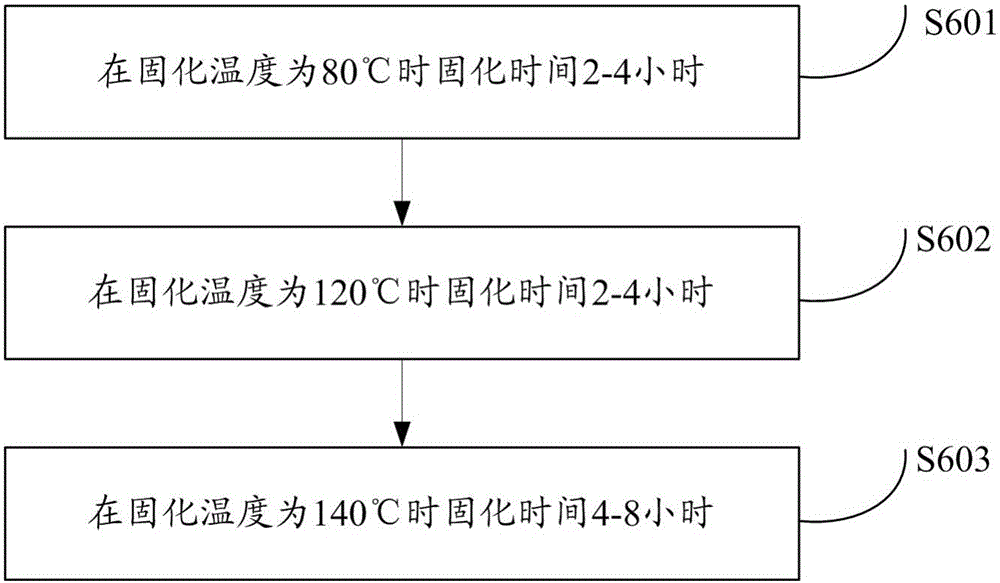

Method for producing concentrated nitric acid storage tank by winding carbon fibers

Owner:中国石油集团东北炼化工程有限公司 +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap