Rim and method for producing a rim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

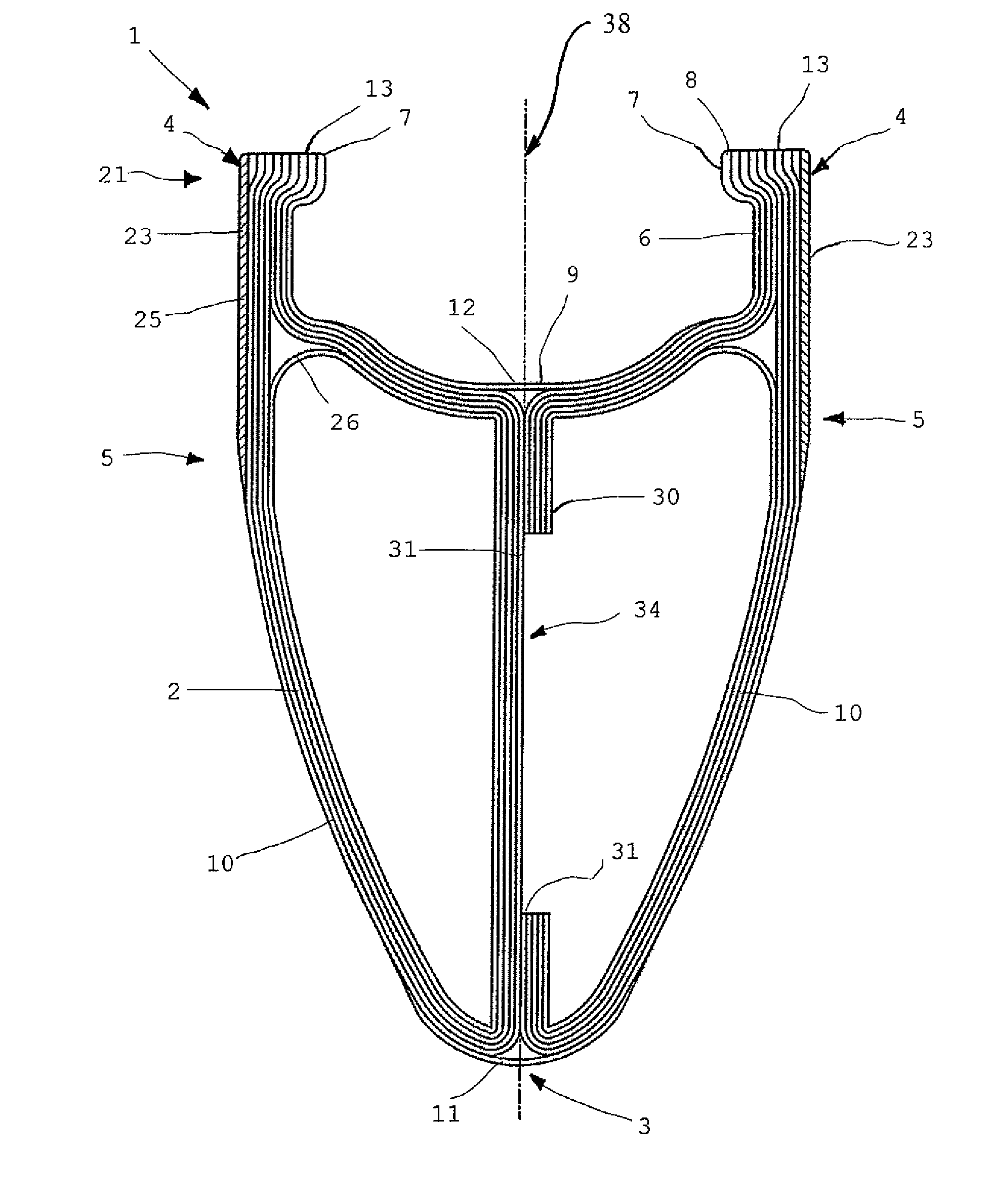

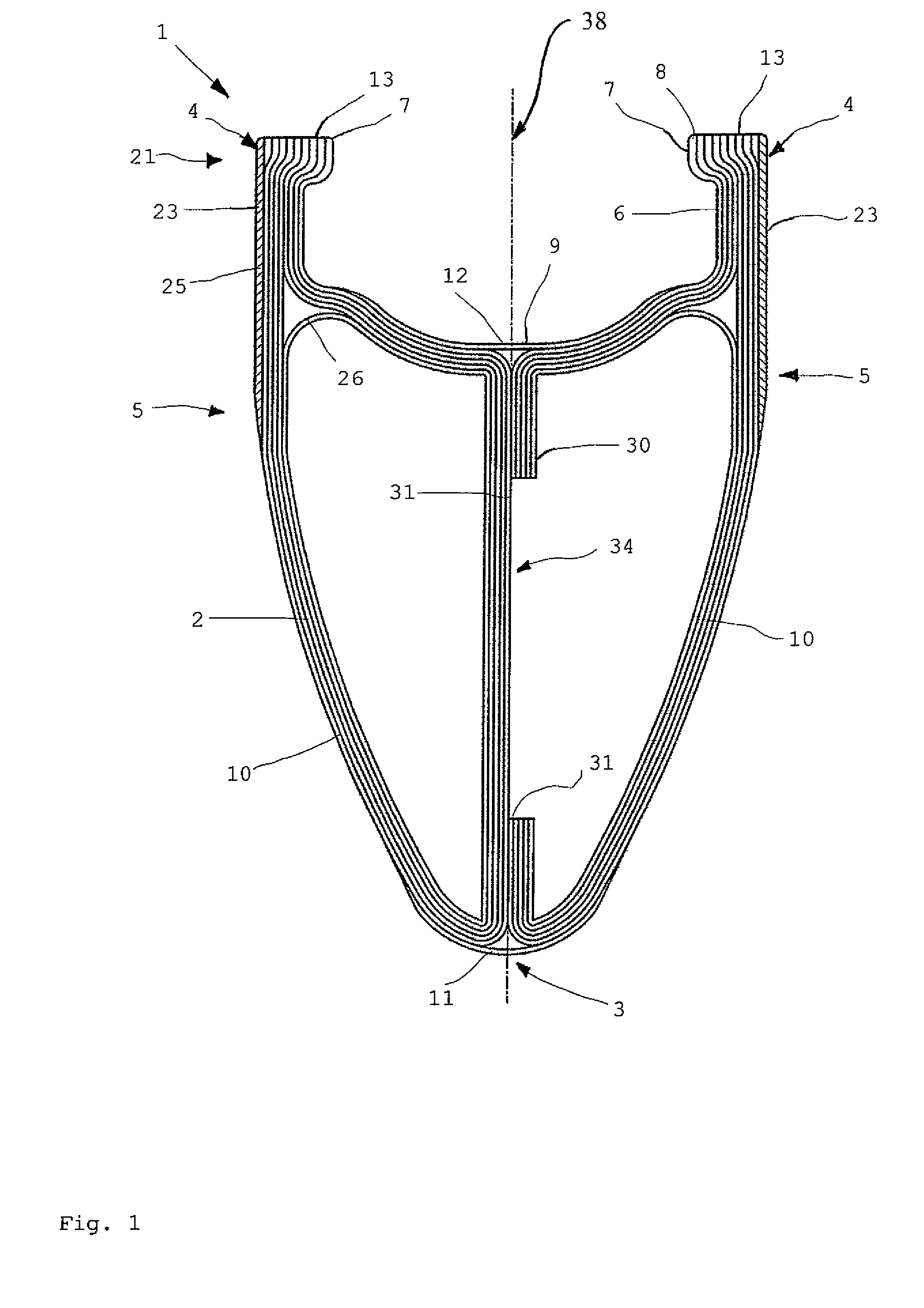

FIG. 1 illustrates a first embodiment of a rim 1 according to the invention in cross-section. The rim 1, entirely produced of a fibrous composite material, substantially consists of two halves or rim parts 10 which in the present embodiment are configured to be symmetrical and identical relative to a radial plane 38.

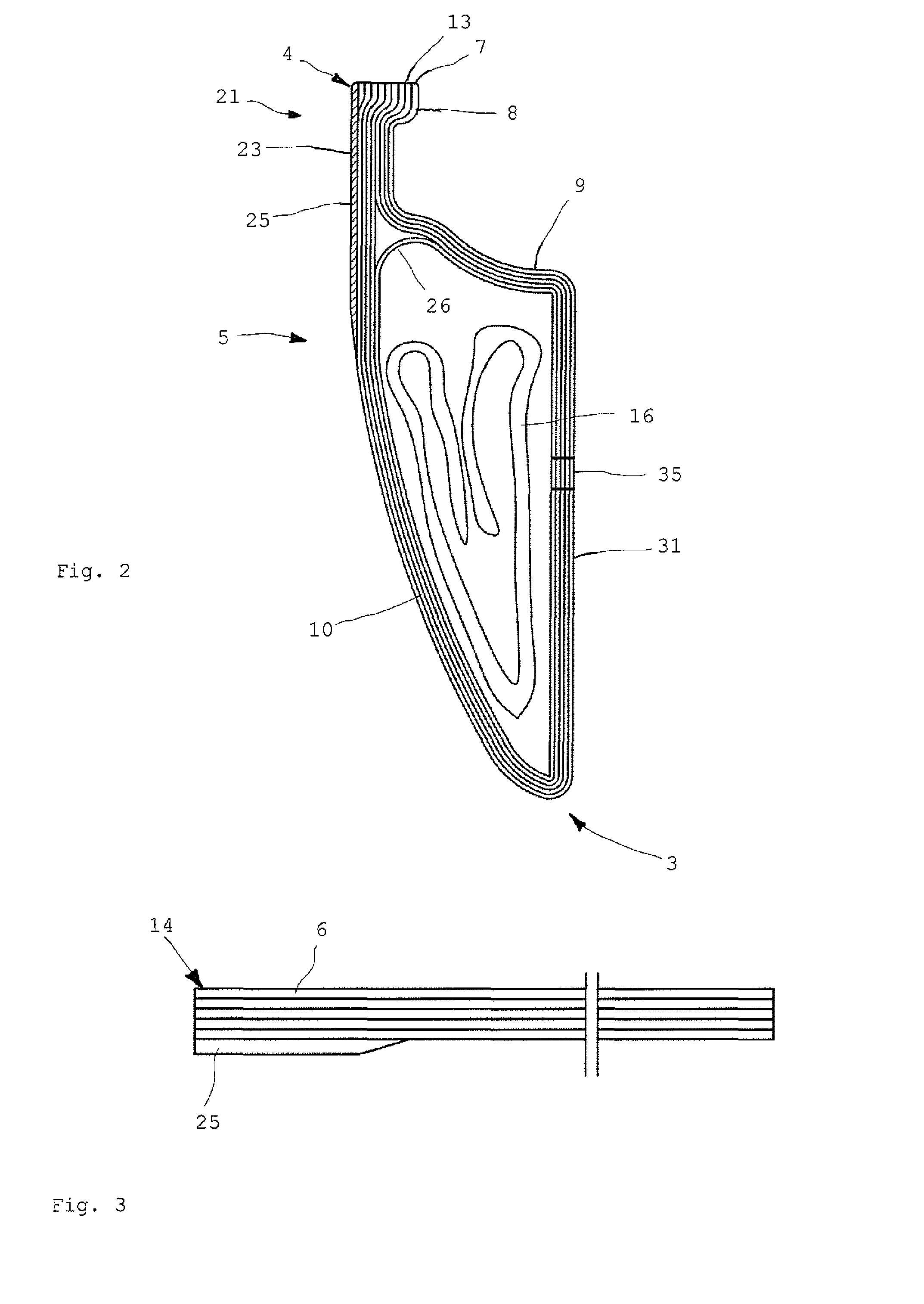

Each rim part 10 comprises a rim flank 5 with the rim flange 4 provided on it, part of the rim well9 and, in the radially inwardly region of the rim flank 5, part of the rim base 3.

Each rim part 10 is produced separately wherein in the present embodiment includes identical molds that are employed for producing the rim. Each rim part 10 is formed as an at least substantially closed annular body and to complete the rim, the two rim parts 10 are bonded to one another wherein a web 30 forms from the walls 31 in contact with one another.

To reduce the weight of the entire rim, openings or recesses 34 may be made in the walls 31 before joining the two rim parts 10, by routing or t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap