Combined tool for carbon fiber aramid paper honeycomb sandwich composite board

A technology of honeycomb interlayer and combined tool, which is applied in metal processing and other directions to achieve the effect of reducing tool cost, eliminating delamination and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

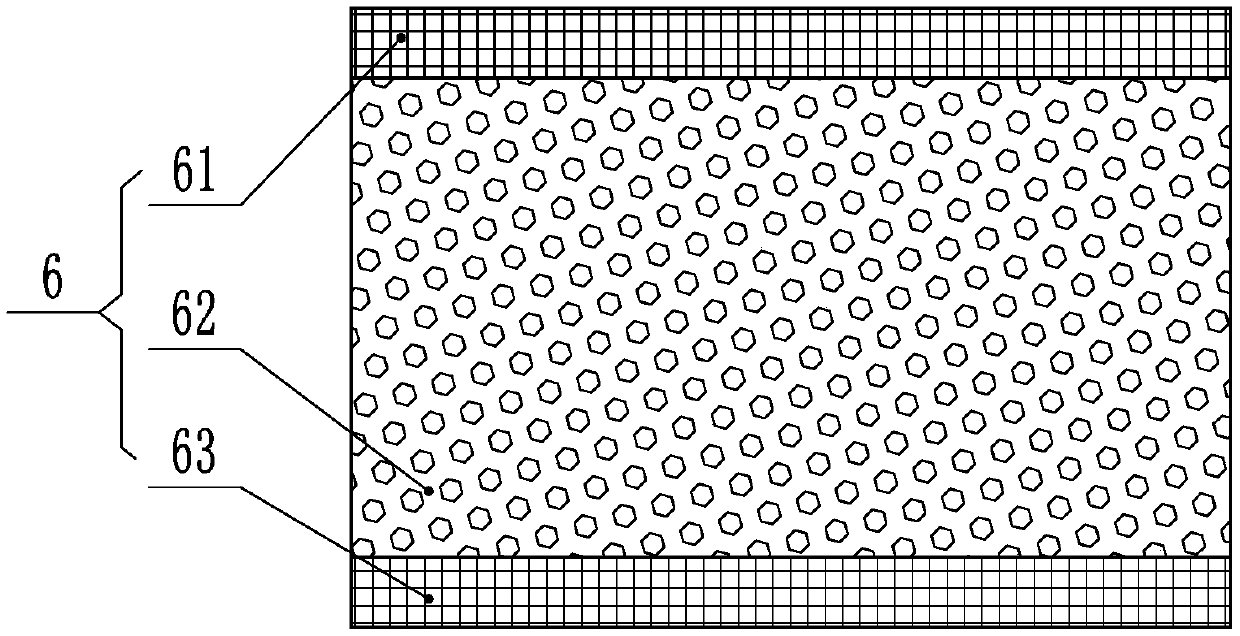

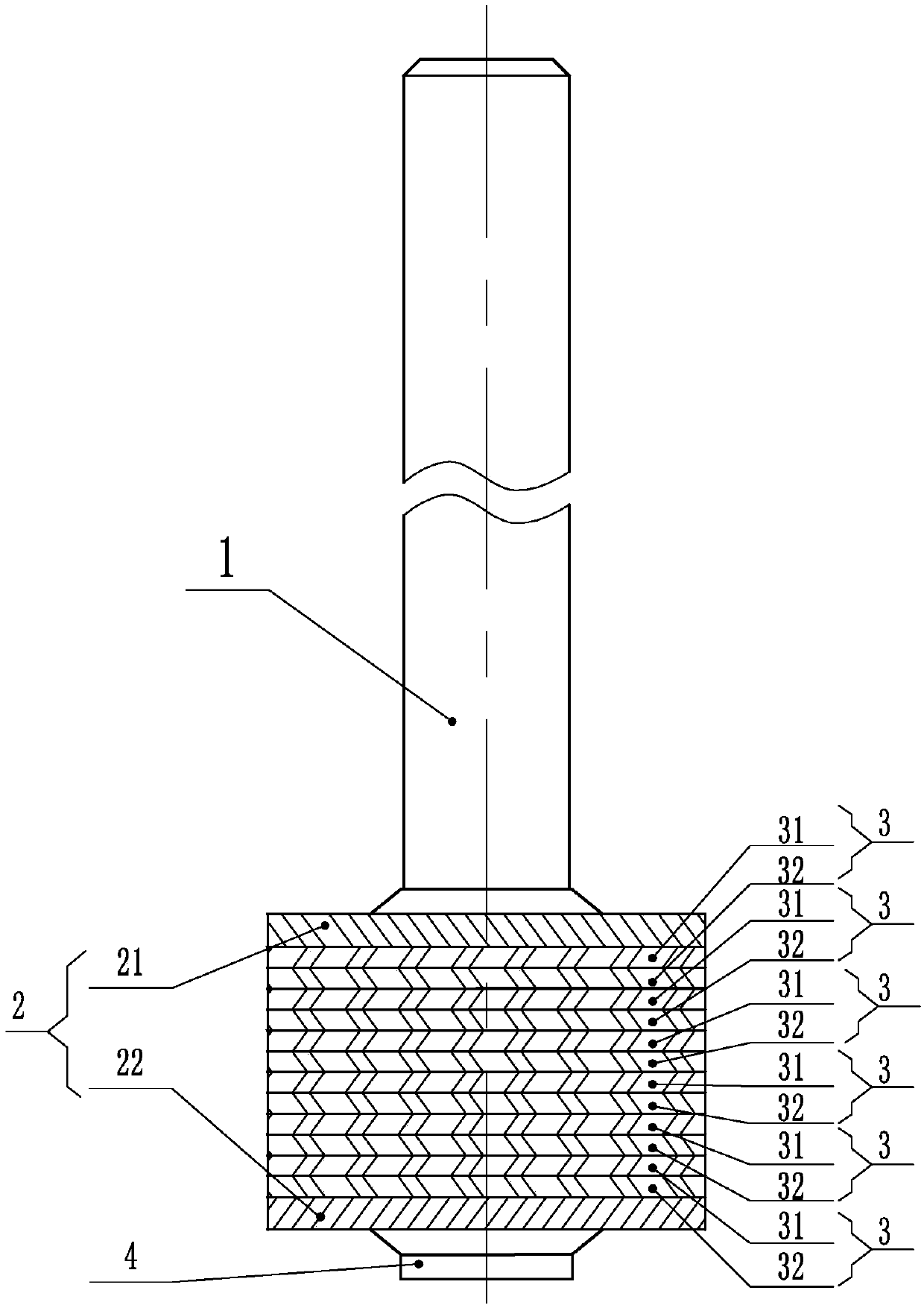

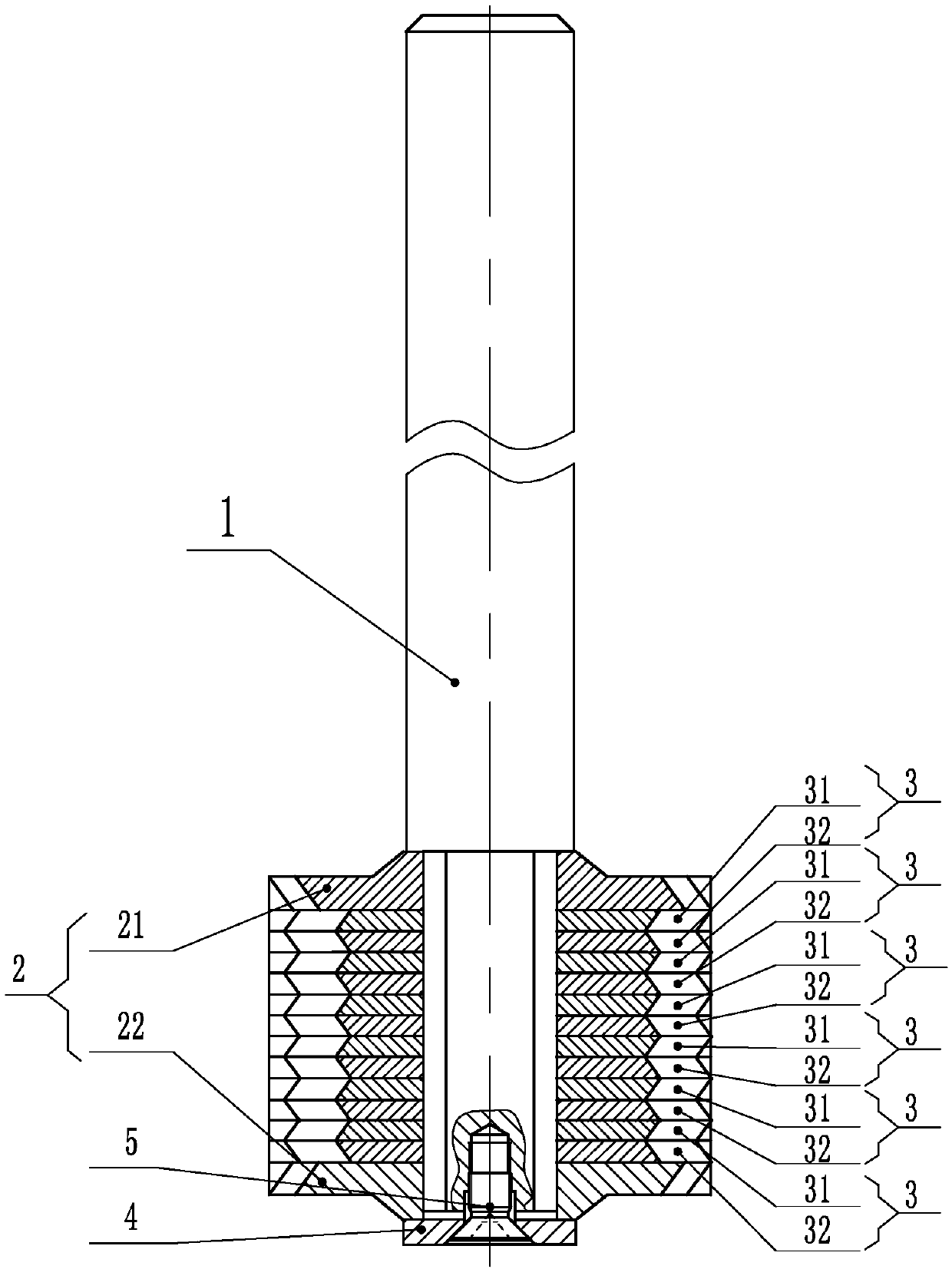

[0037] Examples, see Figure 1-Figure 9 As shown, a combined cutter for carbon fiber aramid paper honeycomb sandwich composite board of the present invention includes a cutter bar 1 and a cutter head, and the cutter head is arranged on the cutter bar 1 . The structure of the carbon fiber aramid paper honeycomb sandwich composite board is as follows figure 1 As shown, the carbon fiber aramid paper honeycomb sandwich composite panel 6 includes two carbon fiber layers 61, 63 and an aramid paper honeycomb interlayer 62 between the two carbon fiber layers 61, 63, each carbon fiber layer is made of carbon fiber composite material , Aramid paper honeycomb interlayer is made of aramid paper honeycomb core material. The cutter head includes:

[0038] A first cutting assembly 2 is used to process the upper and lower carbon fiber layers 61, 63 of the carbon fiber aramid paper honeycomb sandwich composite board. a first helical groove 212 / 222, the first knife teeth 211 / 221 of the cutt

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap