Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

163results about "Conveyors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

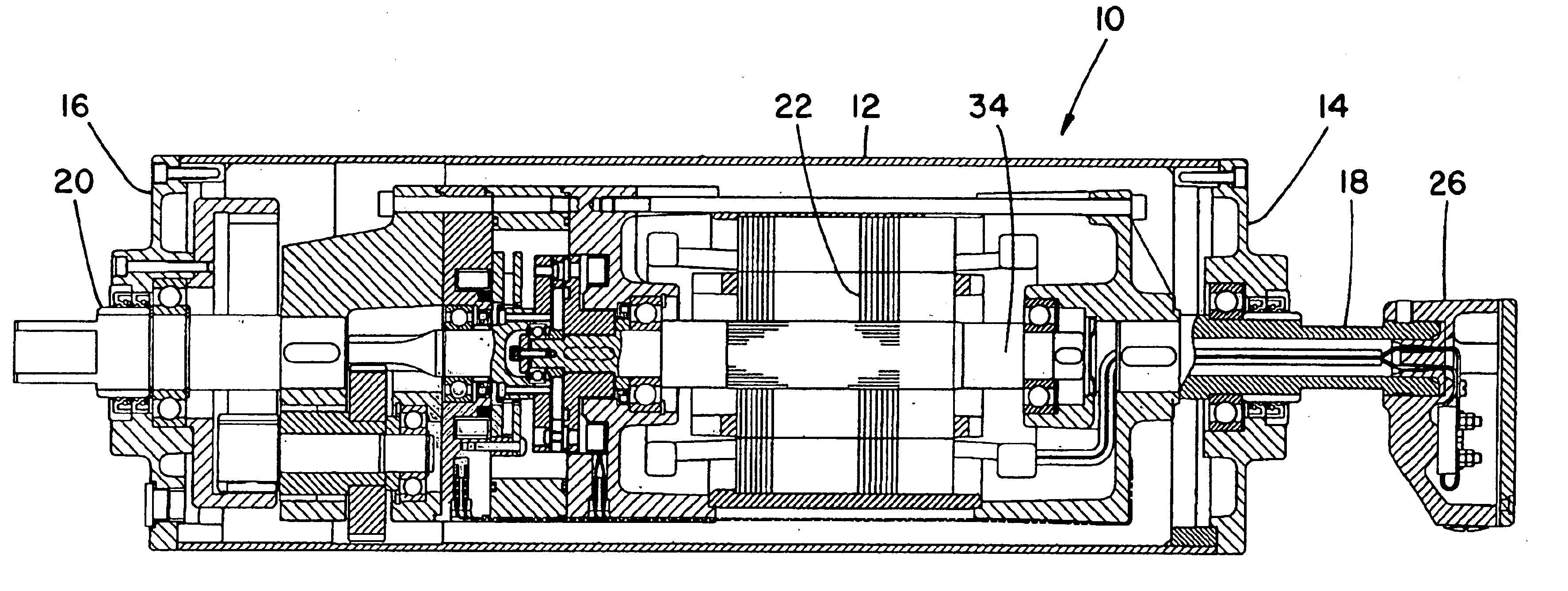

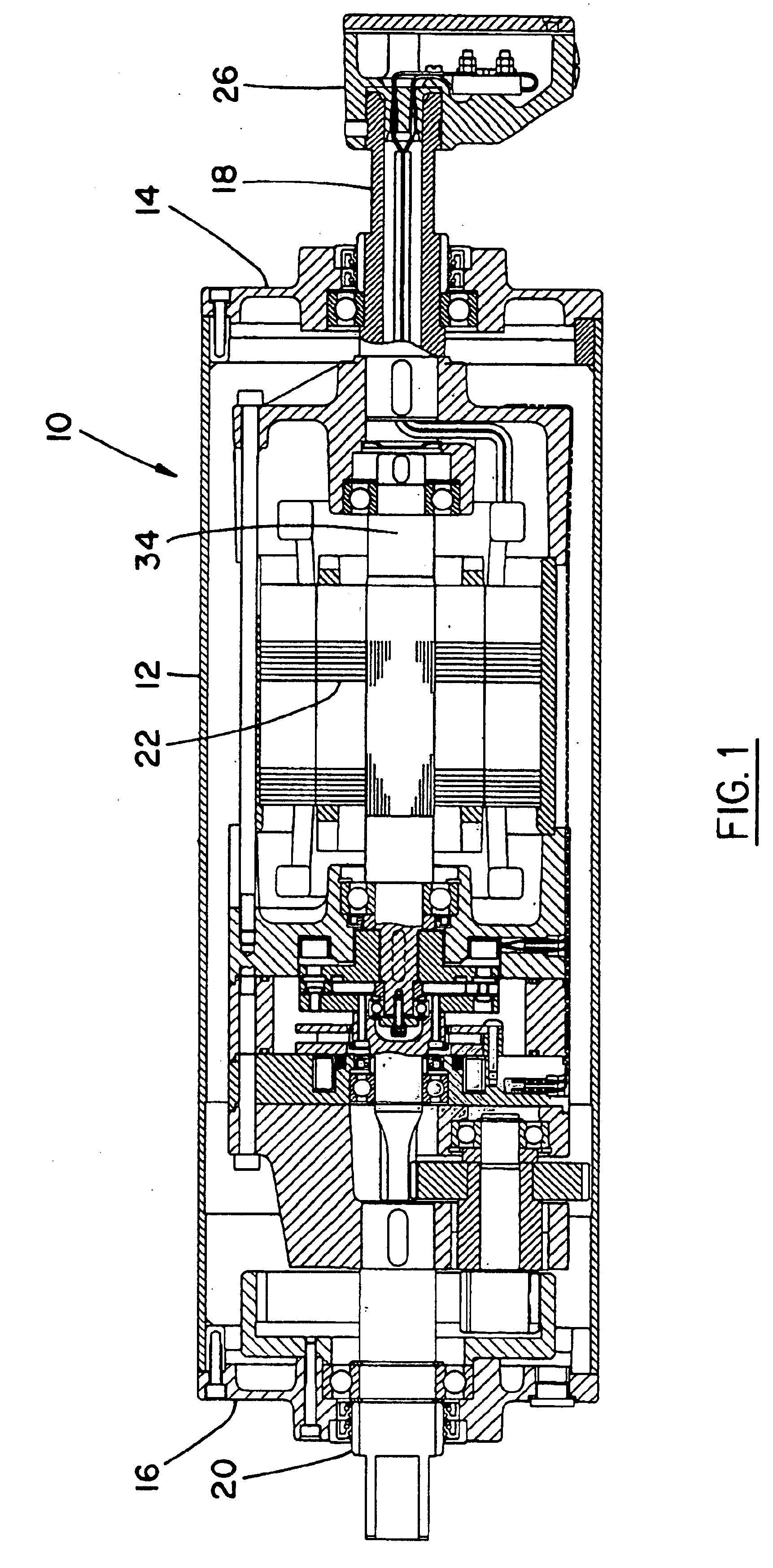

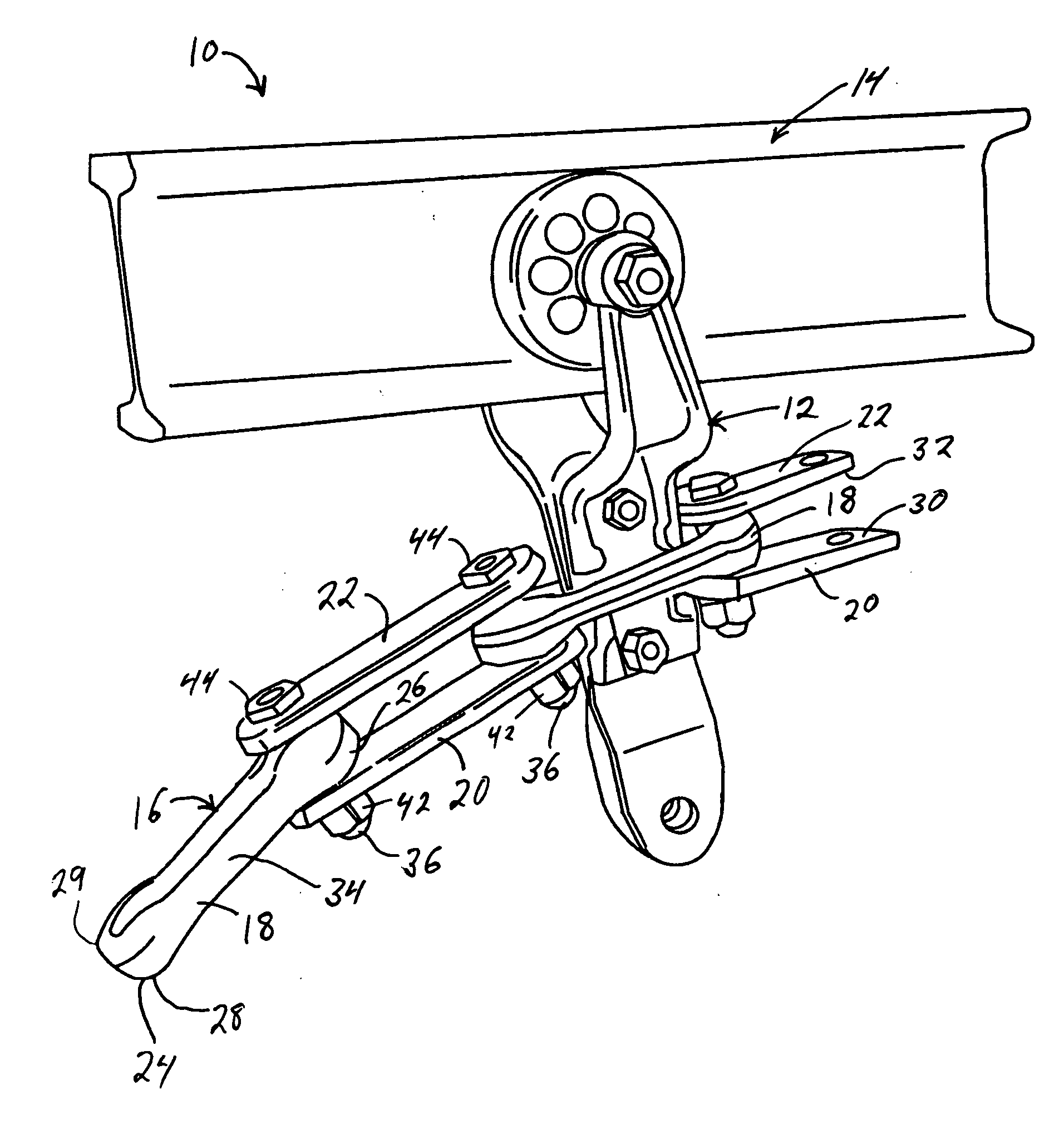

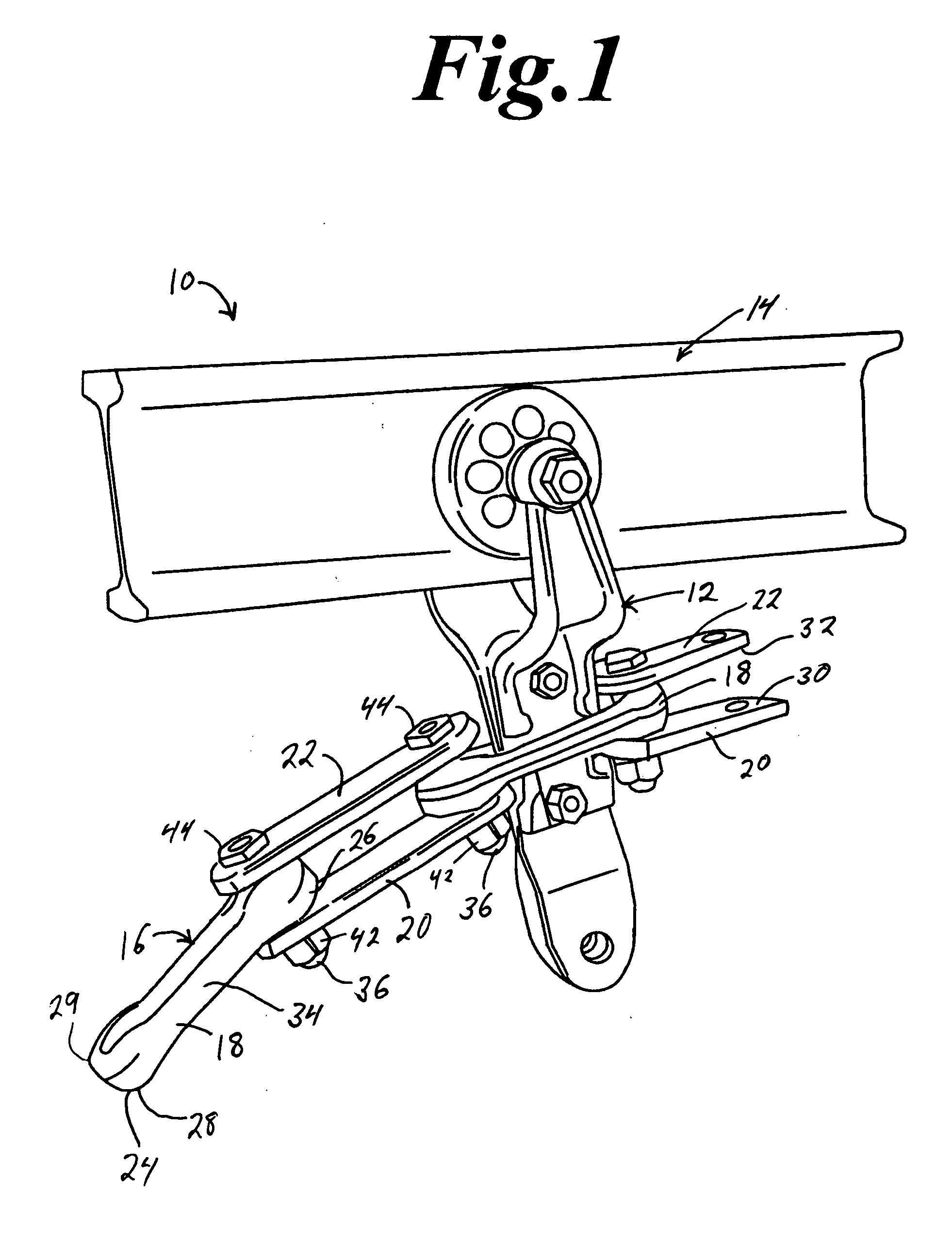

Clutch and brake for a conveyor drive roll

Owner:VAN DER GRAAF

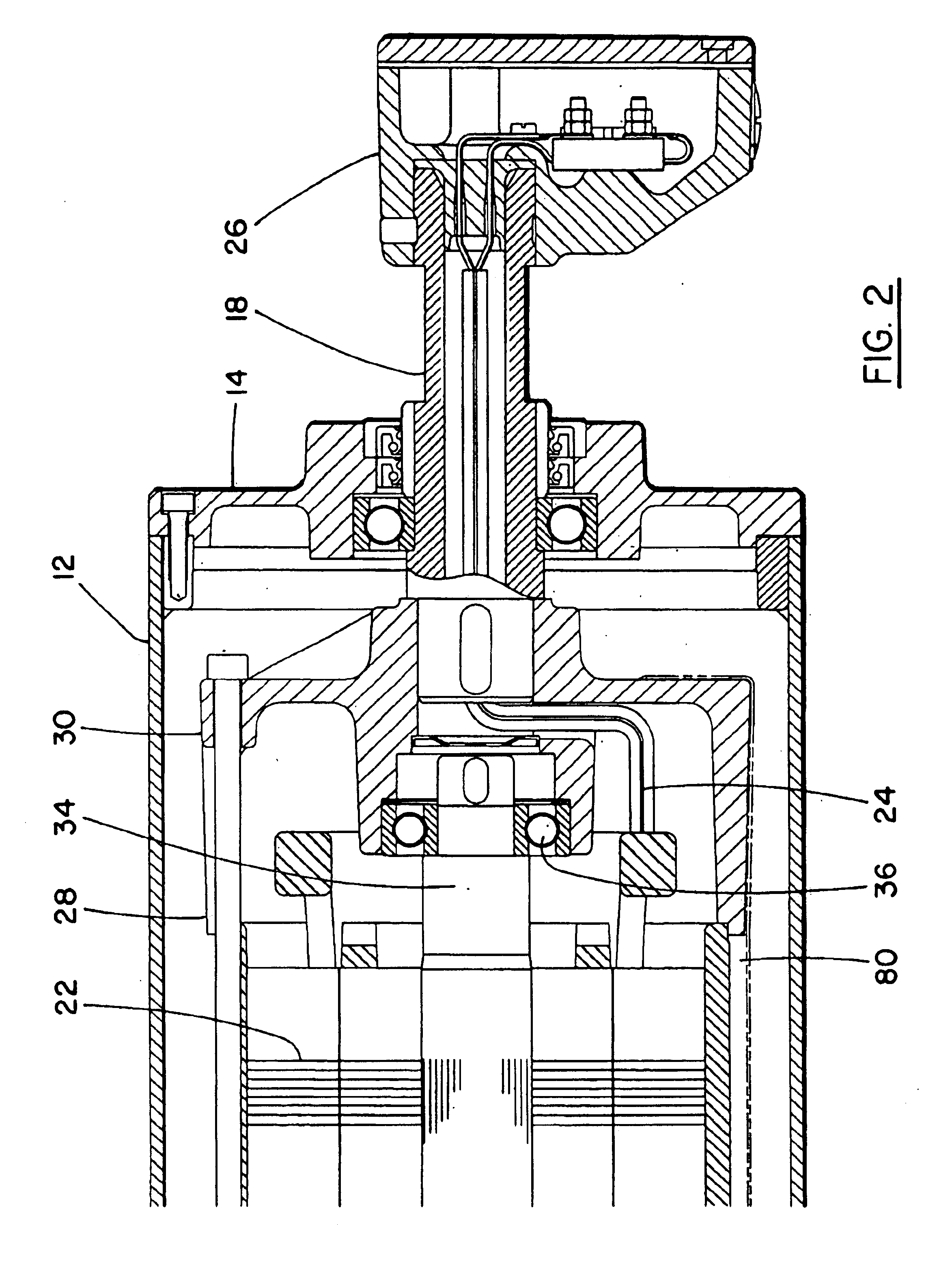

Heavy power and free overhead conveyer

Owner:SHANXI ORIENTAL MATERIAL HANDLING

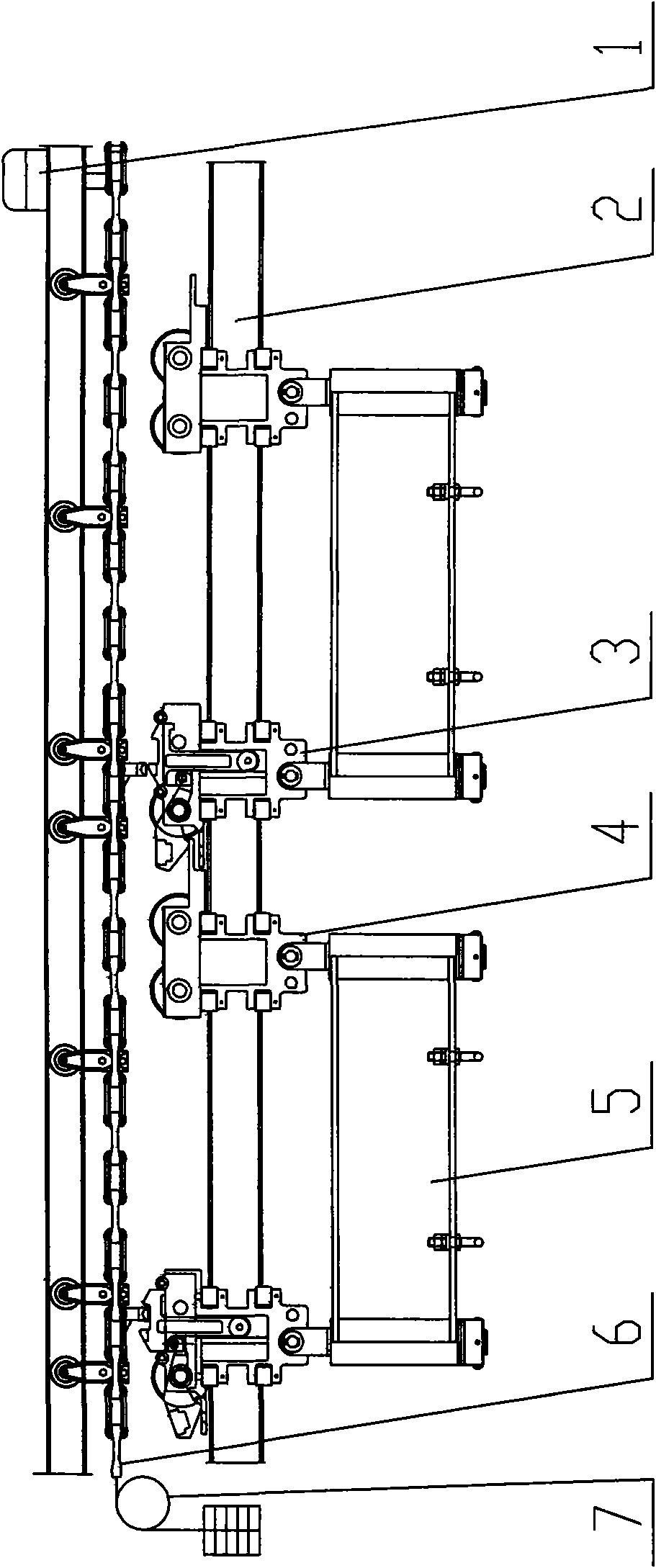

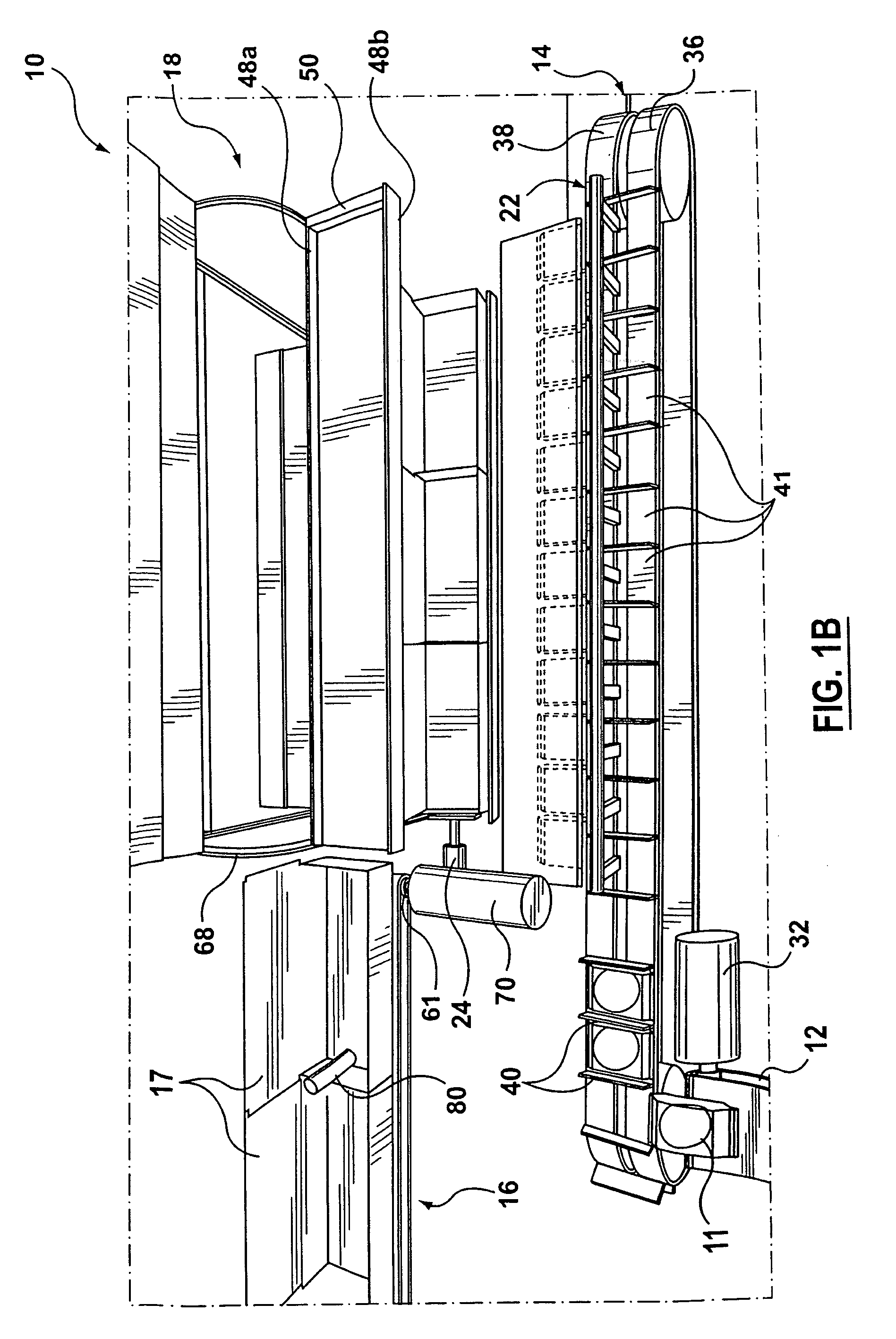

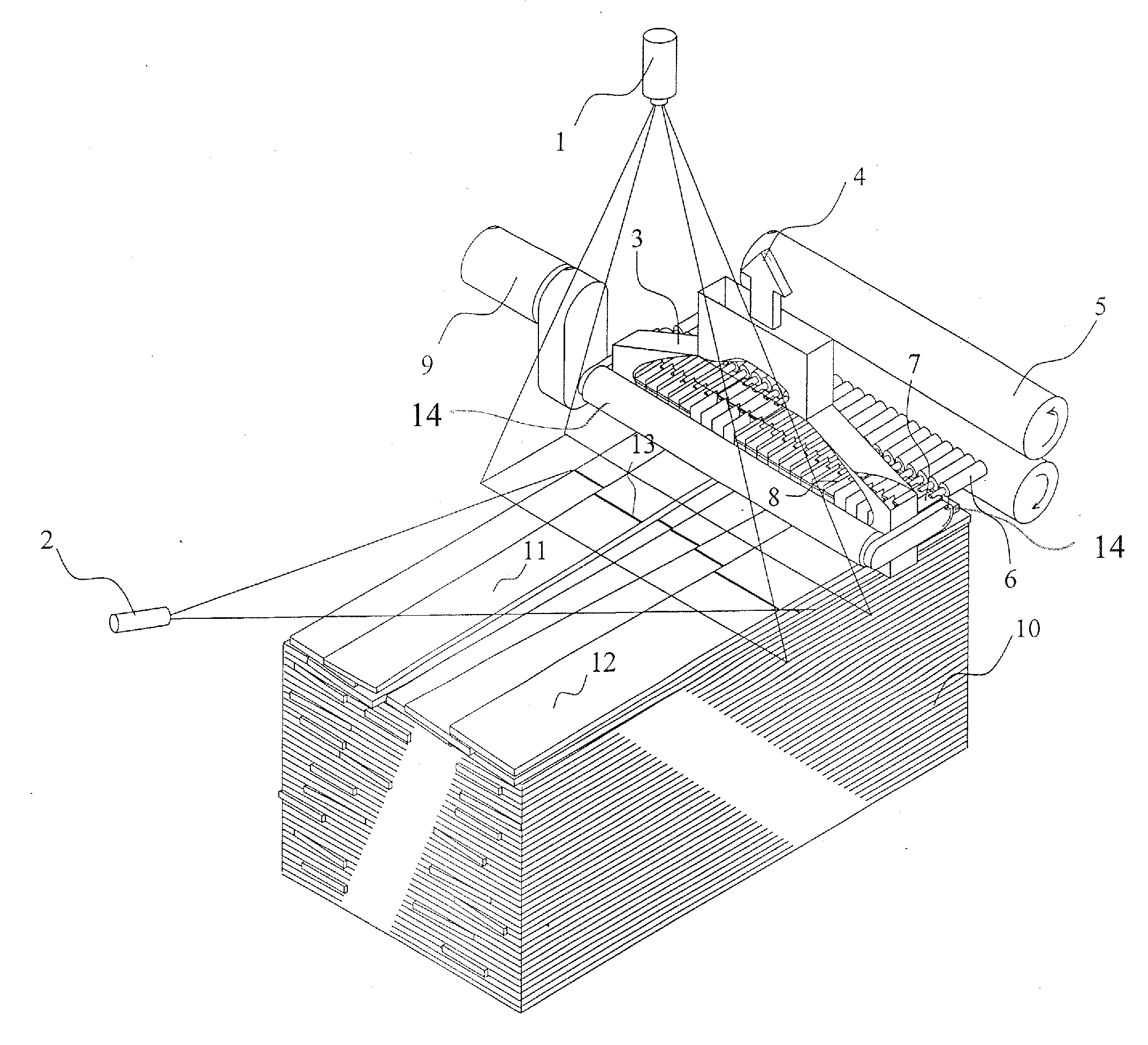

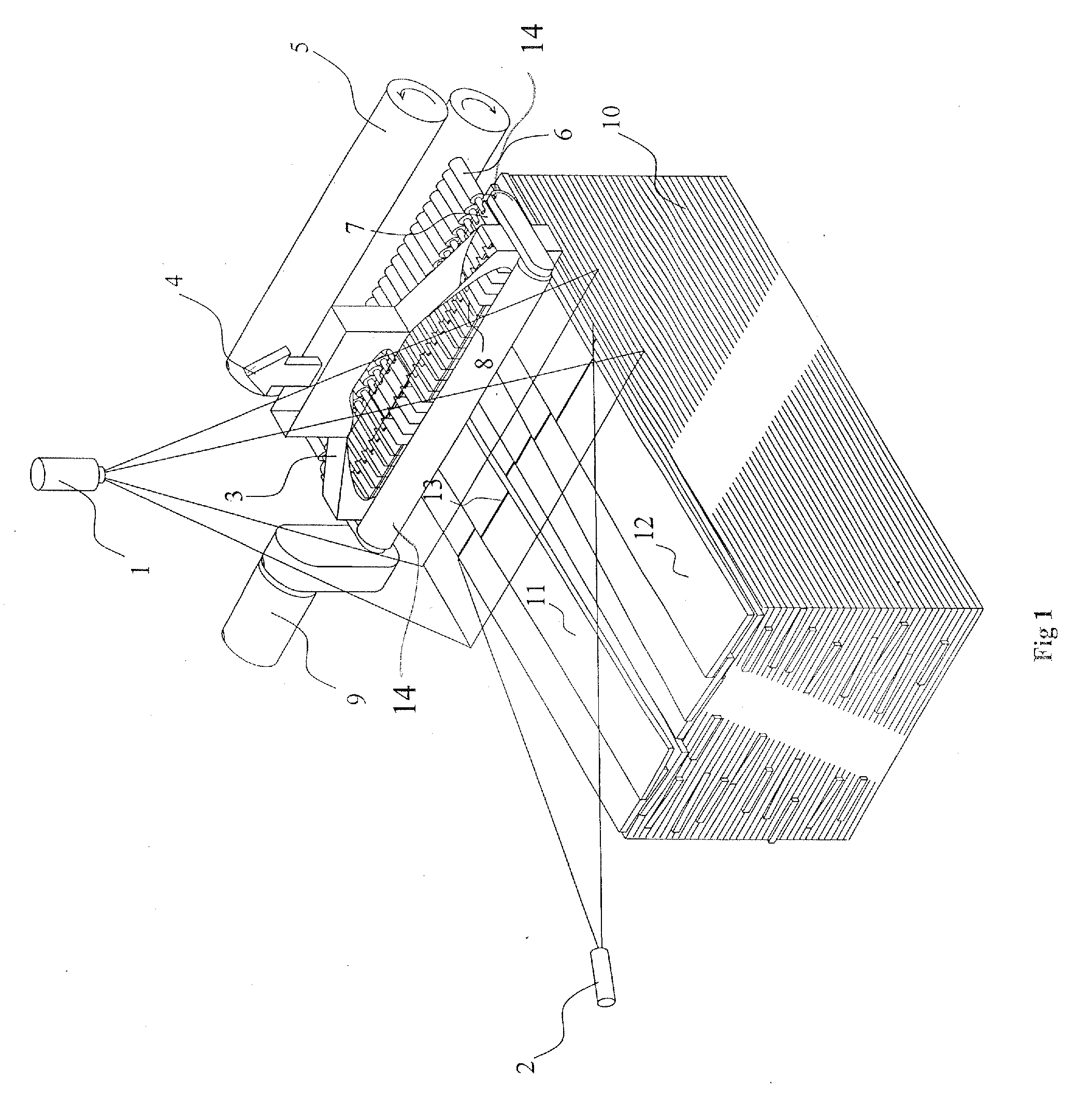

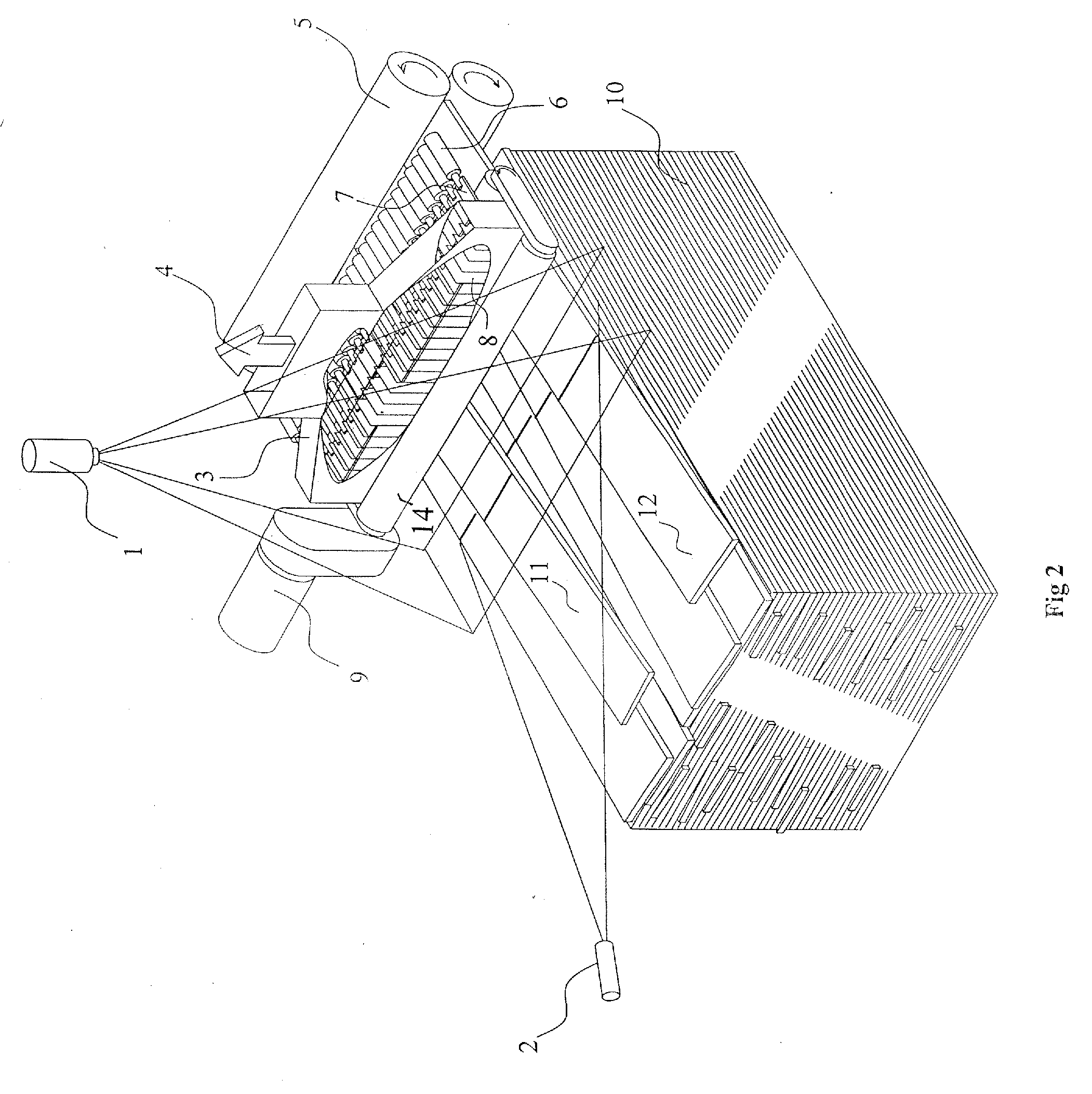

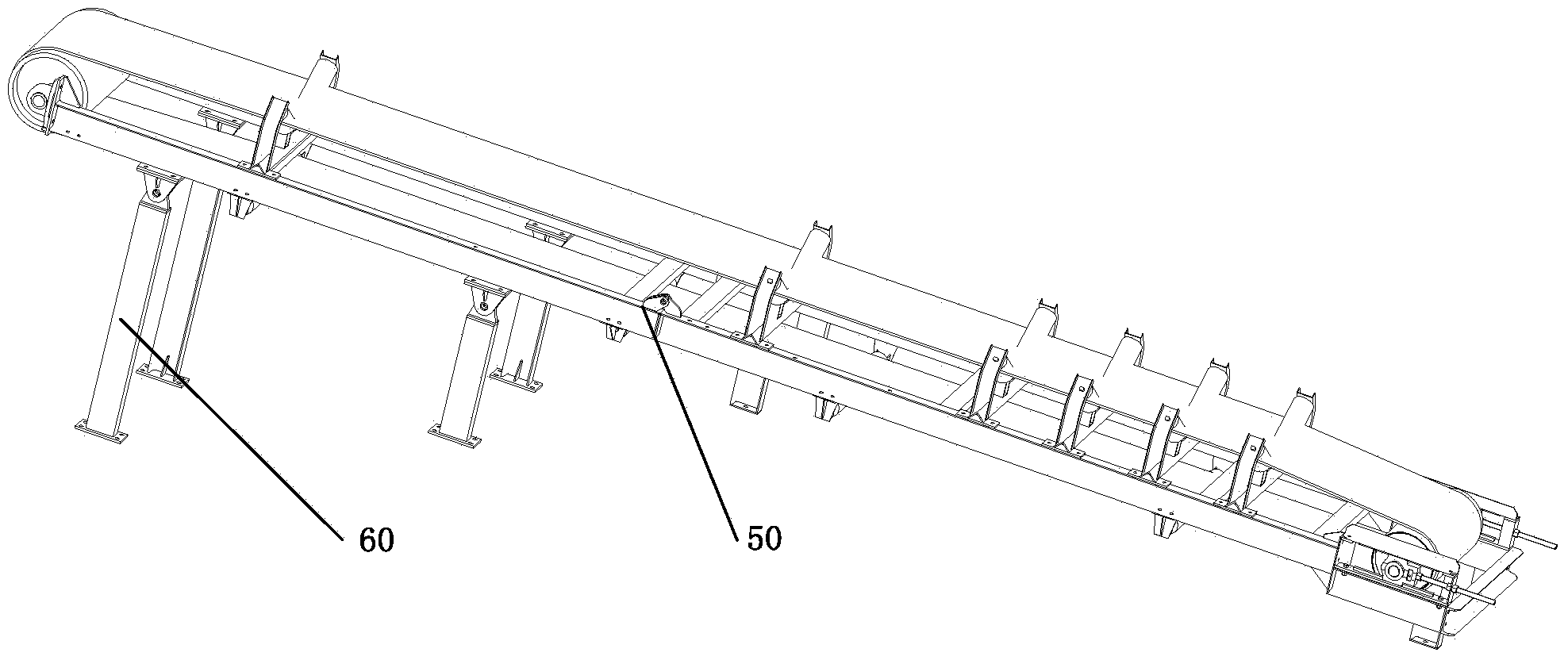

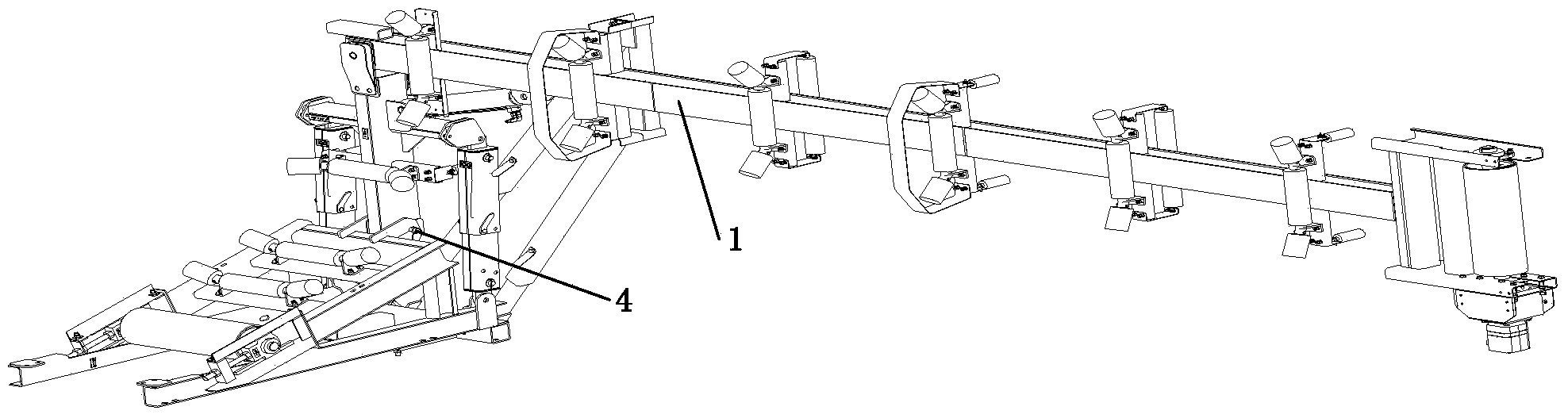

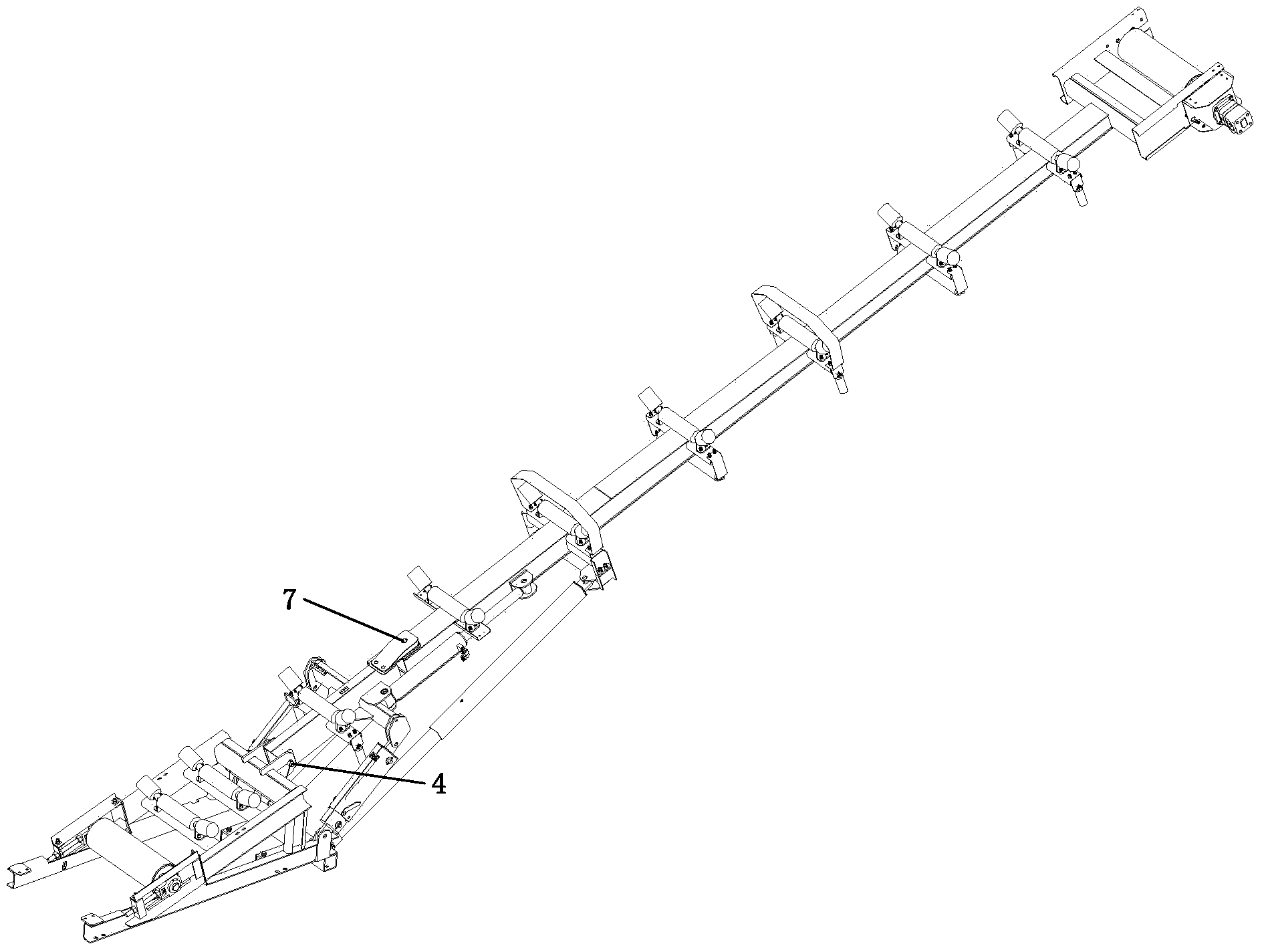

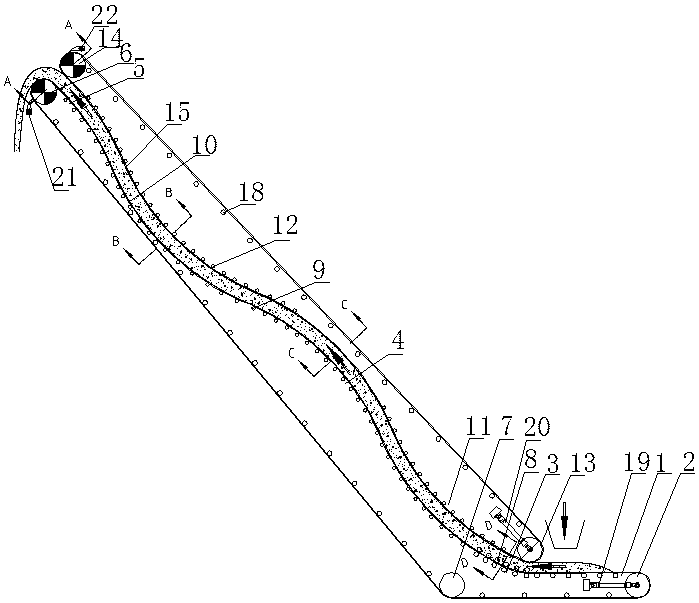

Telescopic belt conveyor changeable in amplitude and direction

ActiveCN106966116AFunction increaseExtended working hoursConveyorsLogistics managementClassical mechanics

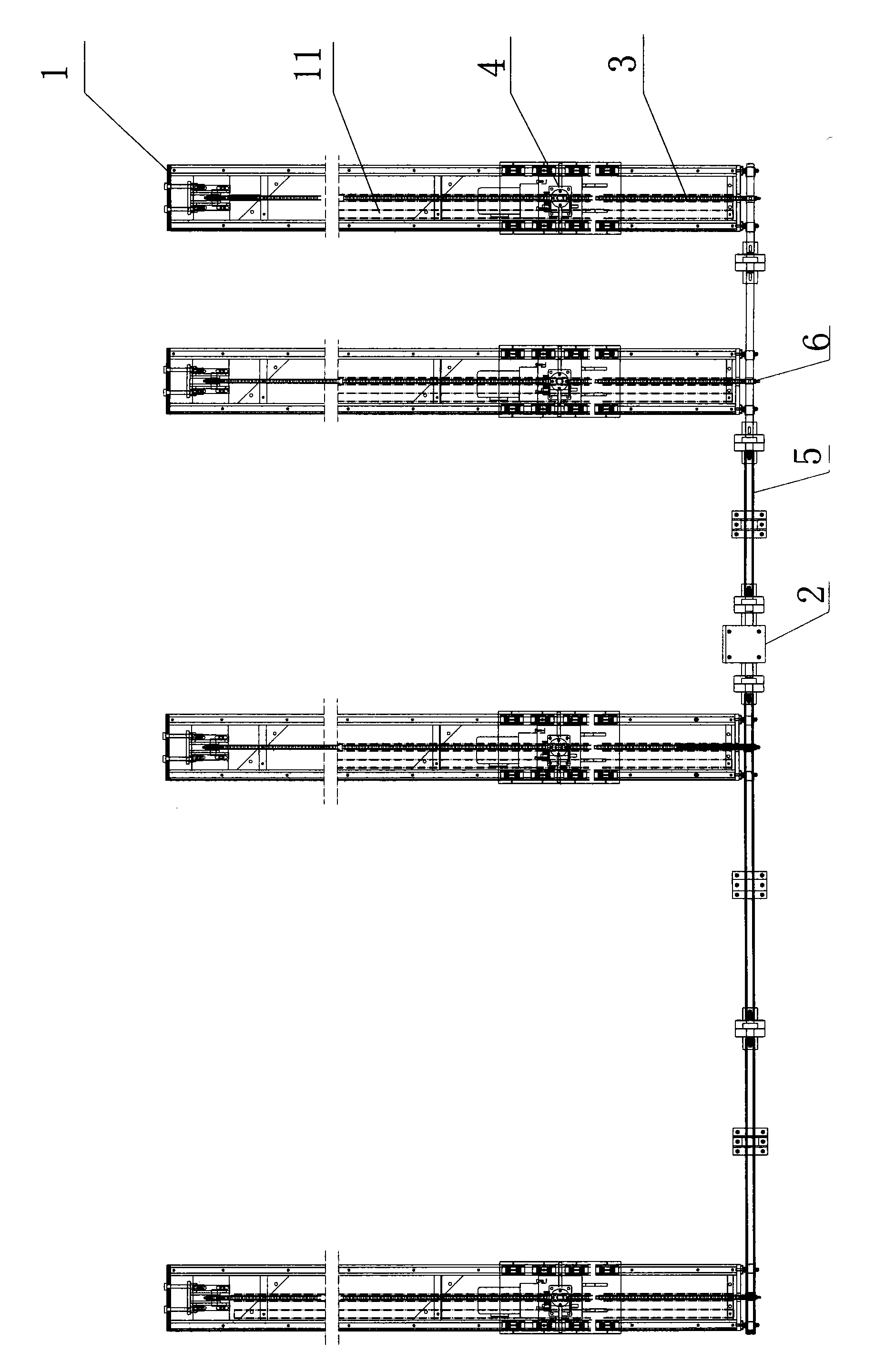

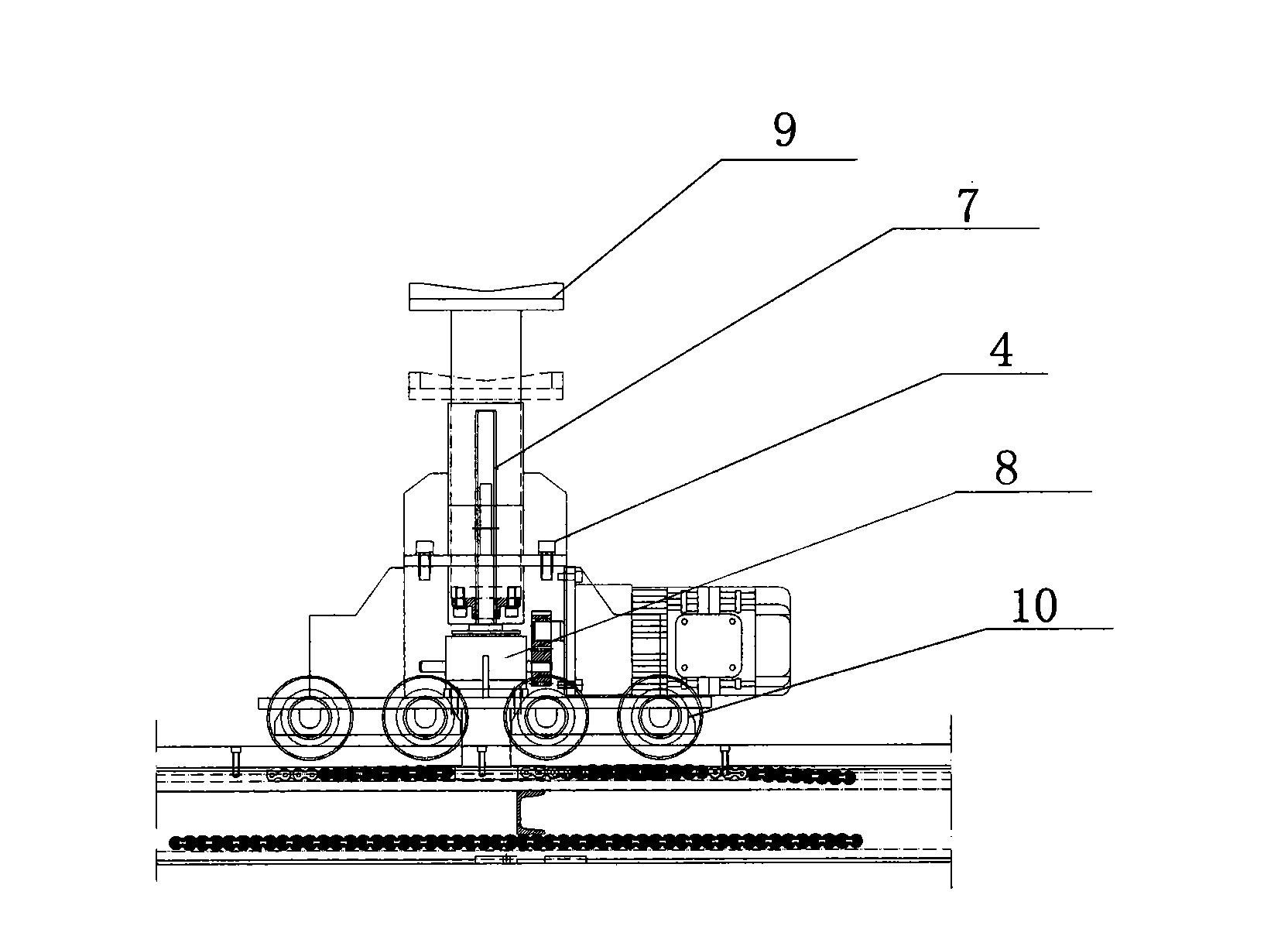

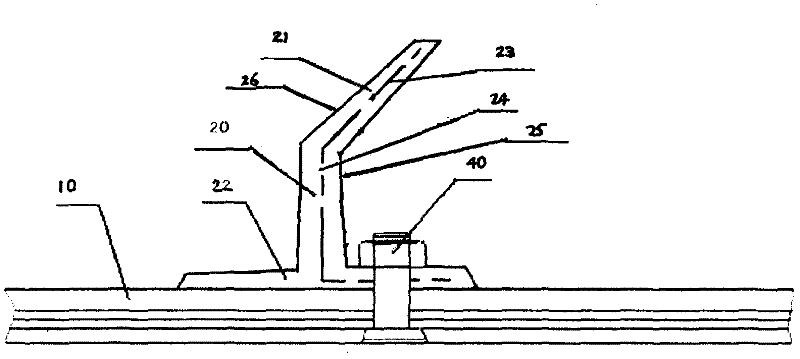

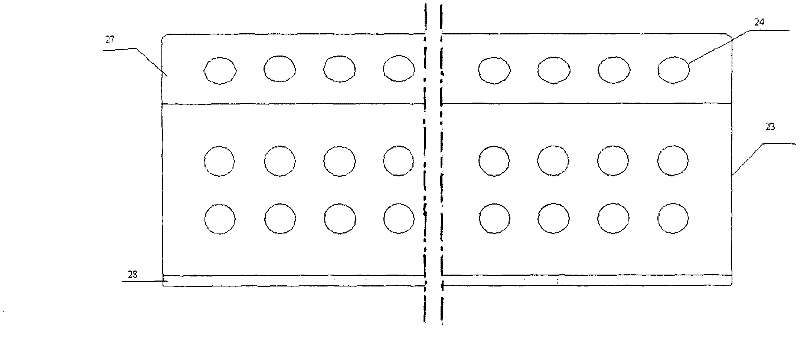

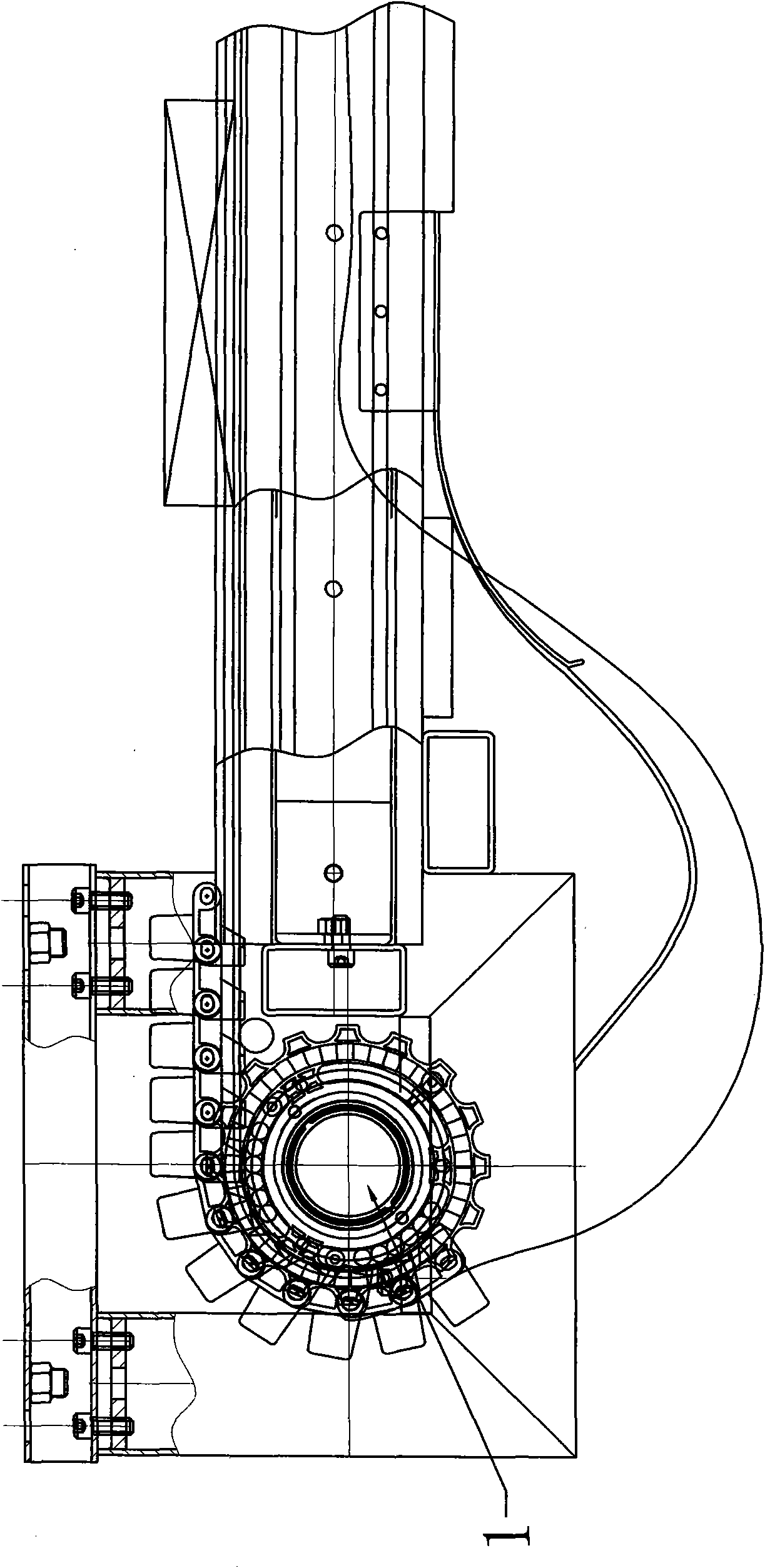

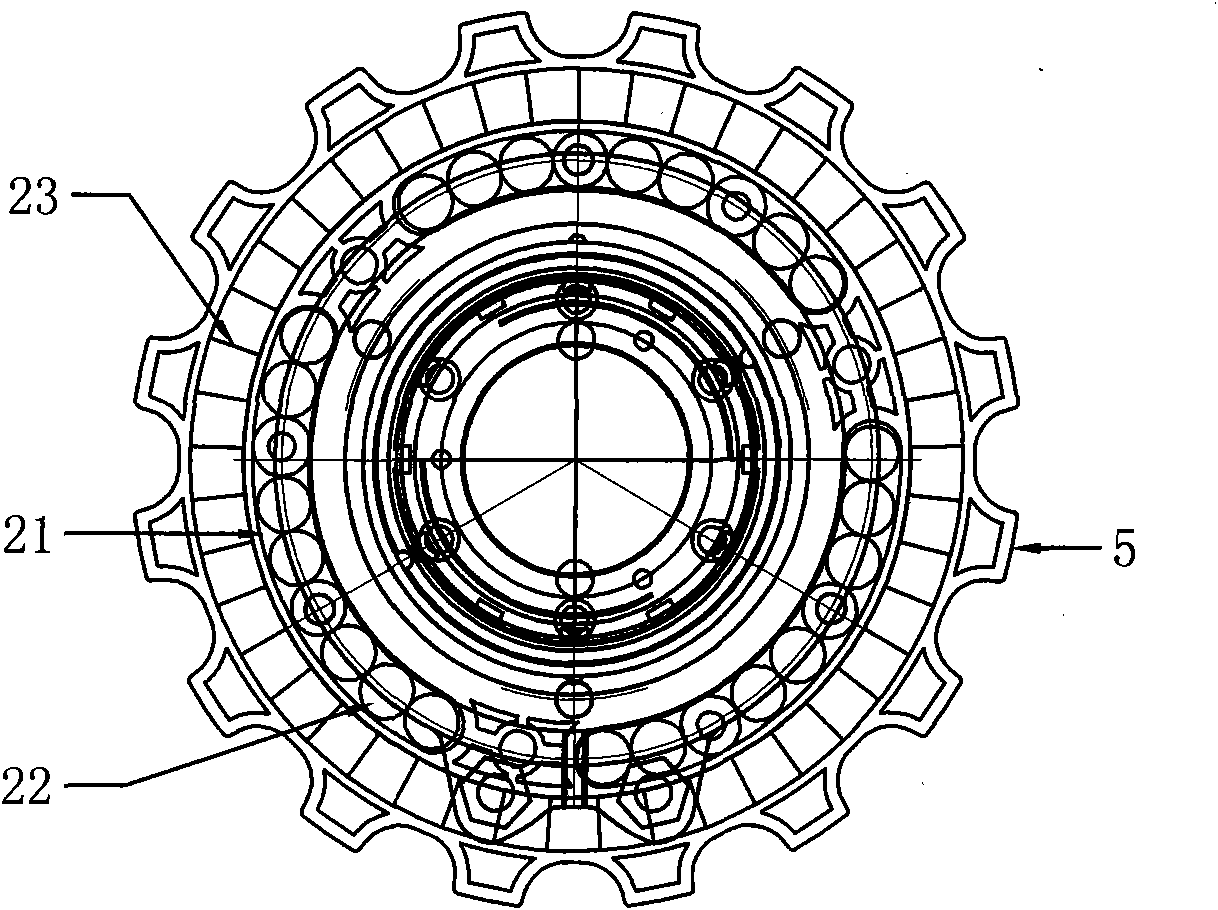

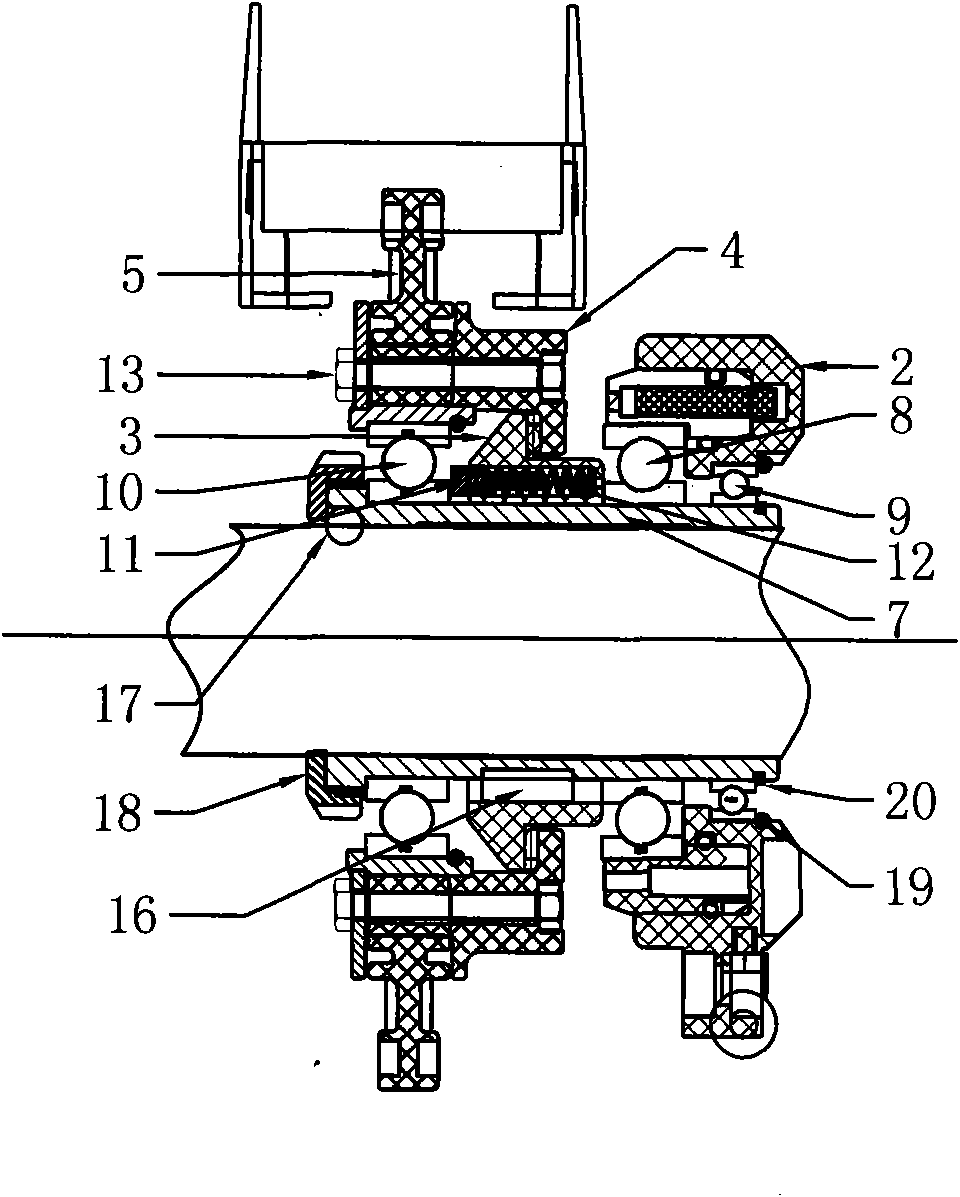

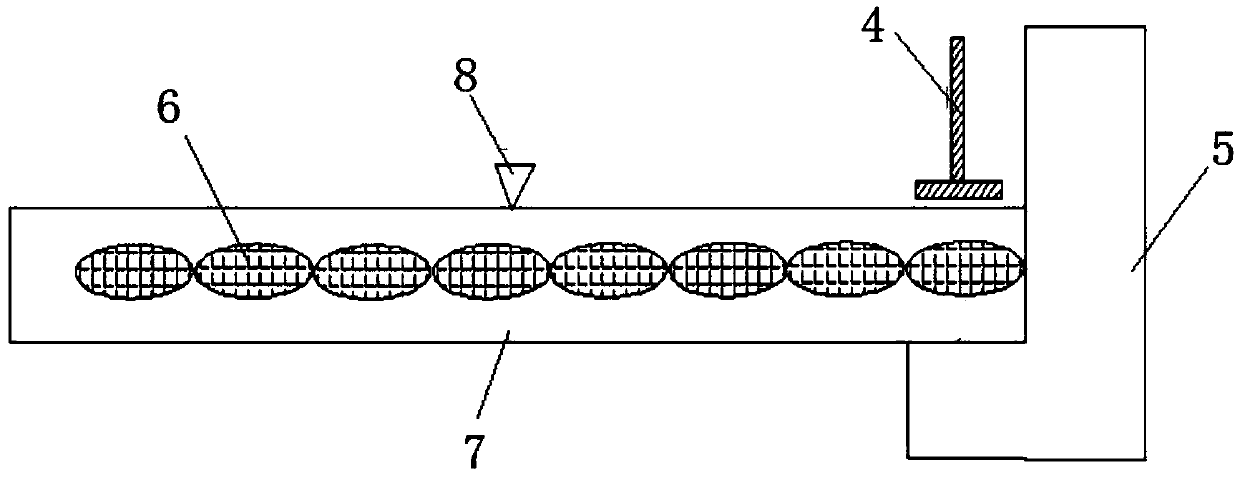

The invention discloses a telescopic belt conveyor changeable in amplitude and direction, and relates to the field of logistics transportation cargo handling mechanical equipment. The telescopic belt conveyor is composed of a three-section two-stage telescopic belt conveyor body with a telescopic function, an amplitude change mechanism with tilting and amplitude change functions, and a swing rotating mechanism with swing rotating and direction change functions. According to the telescopic belt conveyor changeable in amplitude and direction, a sleeved telescopic machine frame structure is adopted, and the elongation and shortening function, the tilting and amplitude change functions and the swing rotating and direction change functions of the belt conveyor are added by additionally arranging the amplitude change mechanism and the swing rotating mechanism; the conveying range is widened, along with conducting of the loading, unloading and conveying processes, under the condition that loading and unloading places of materials are changed, the conveying distance, height and direction are adjusted by driving and controlling a telescopic mechanism, the amplitude change mechanism and a direction change mechanism, and thus, the telescopic belt conveyor can adapt to change of the loading and unloading places; cargoes are directly delivered to the destination through only one time of loading and unloading, manual auxiliary carrying is reduced, the labor intensity is relieved, the operation time is shortened, the loading and unloading efficiency is improved, and the loading and unloading carrying cost is reduced; and the working environment and the labor condition are effectively improved, and the effect that loading and unloading transport is economical, rapid, convenient and safe is ensured.

Owner:XIANGYANG ZHONGLIANG ENG MASCH CO LTD

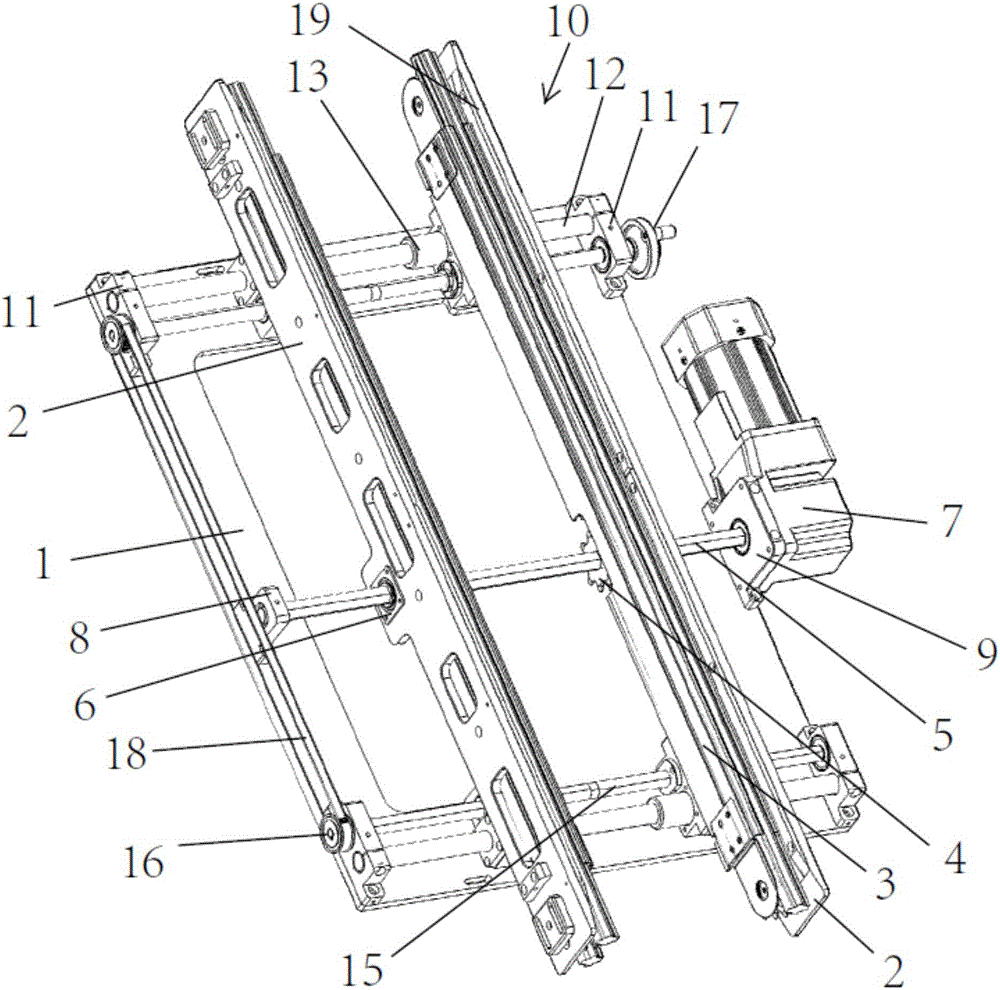

Width-adjustable transmission device

Owner:SUZHOU LANGKUN AUTOMATION EQUIP CO LTD

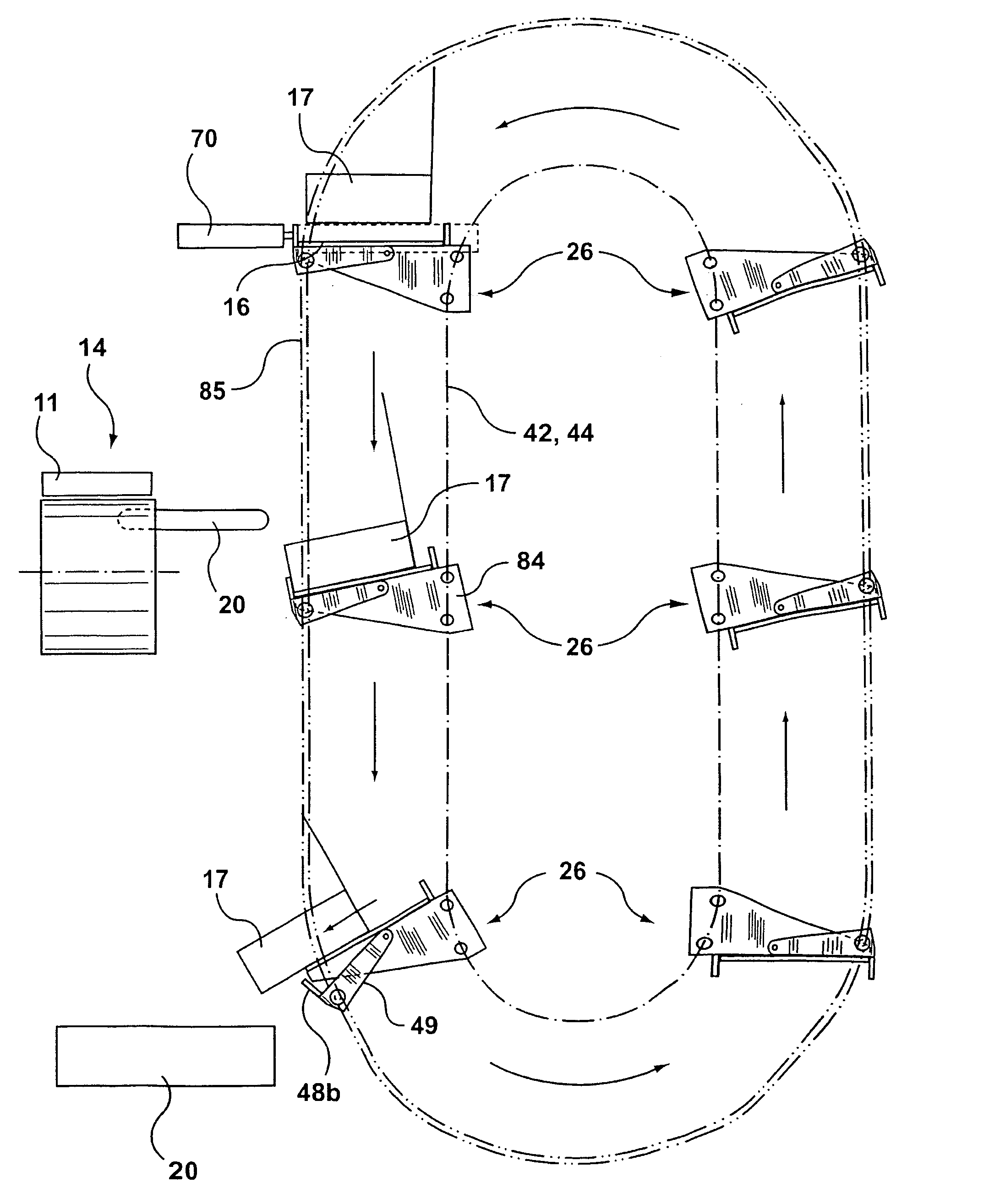

Tray loader

Owner:LANGEN PACKAGING

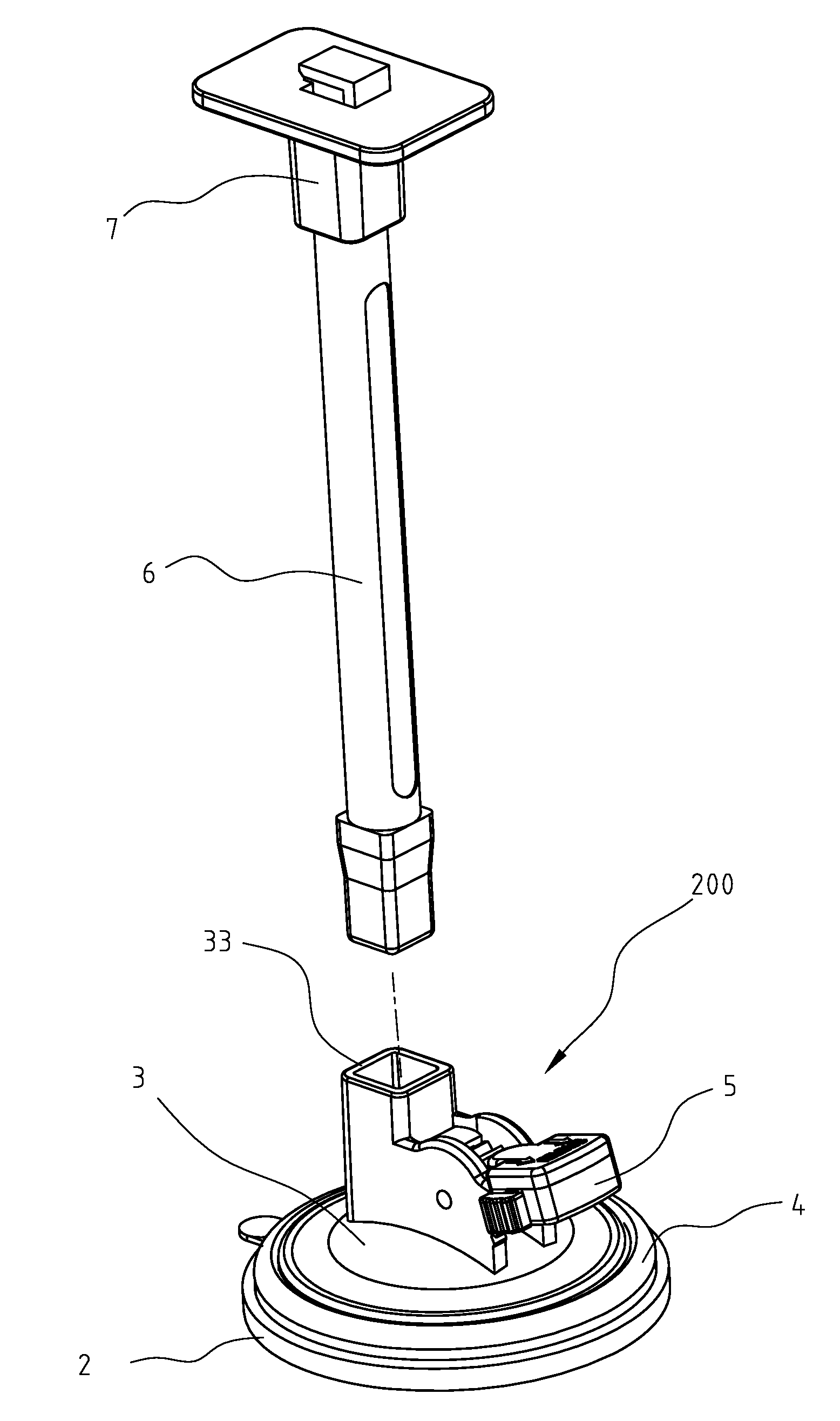

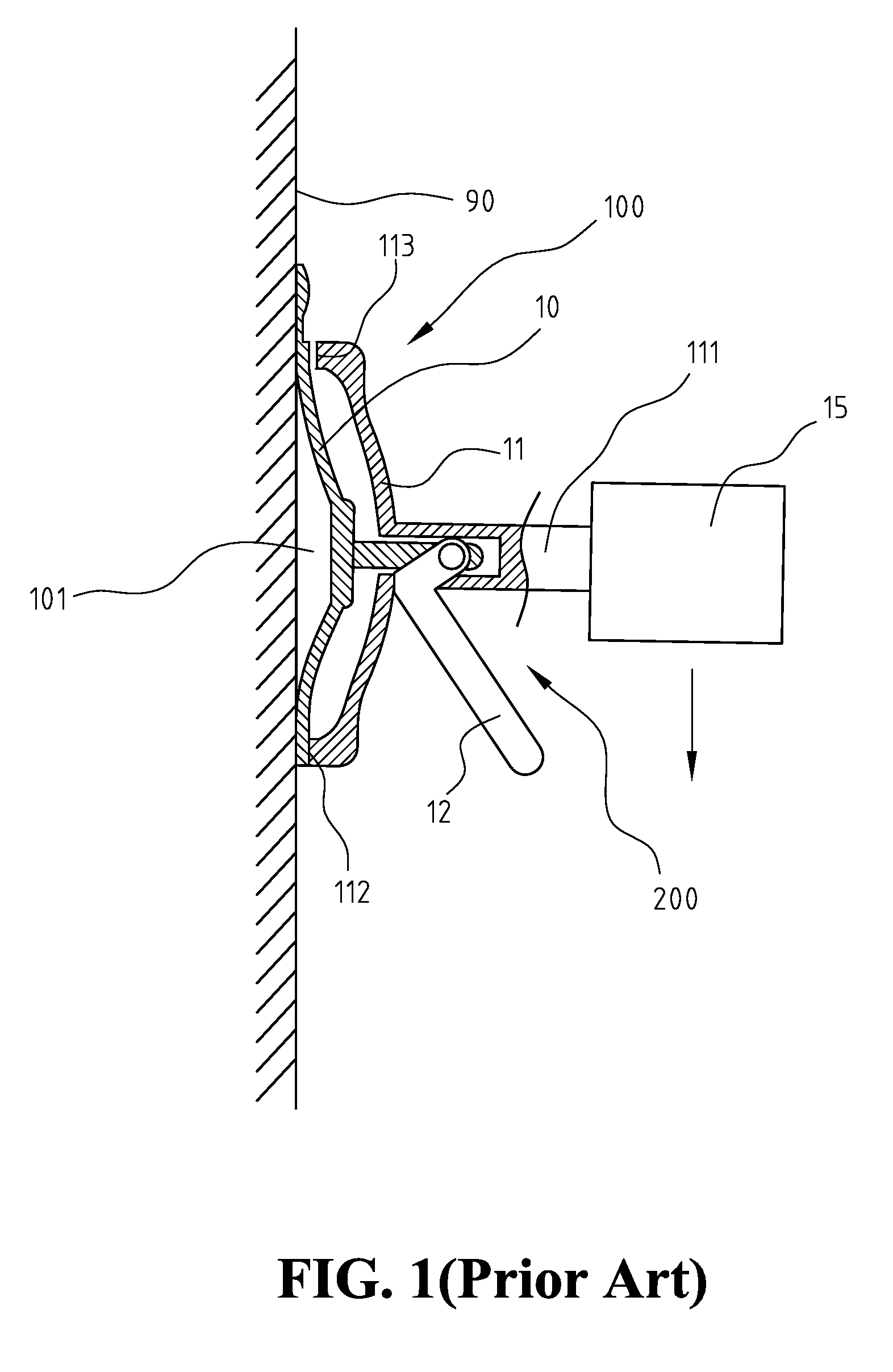

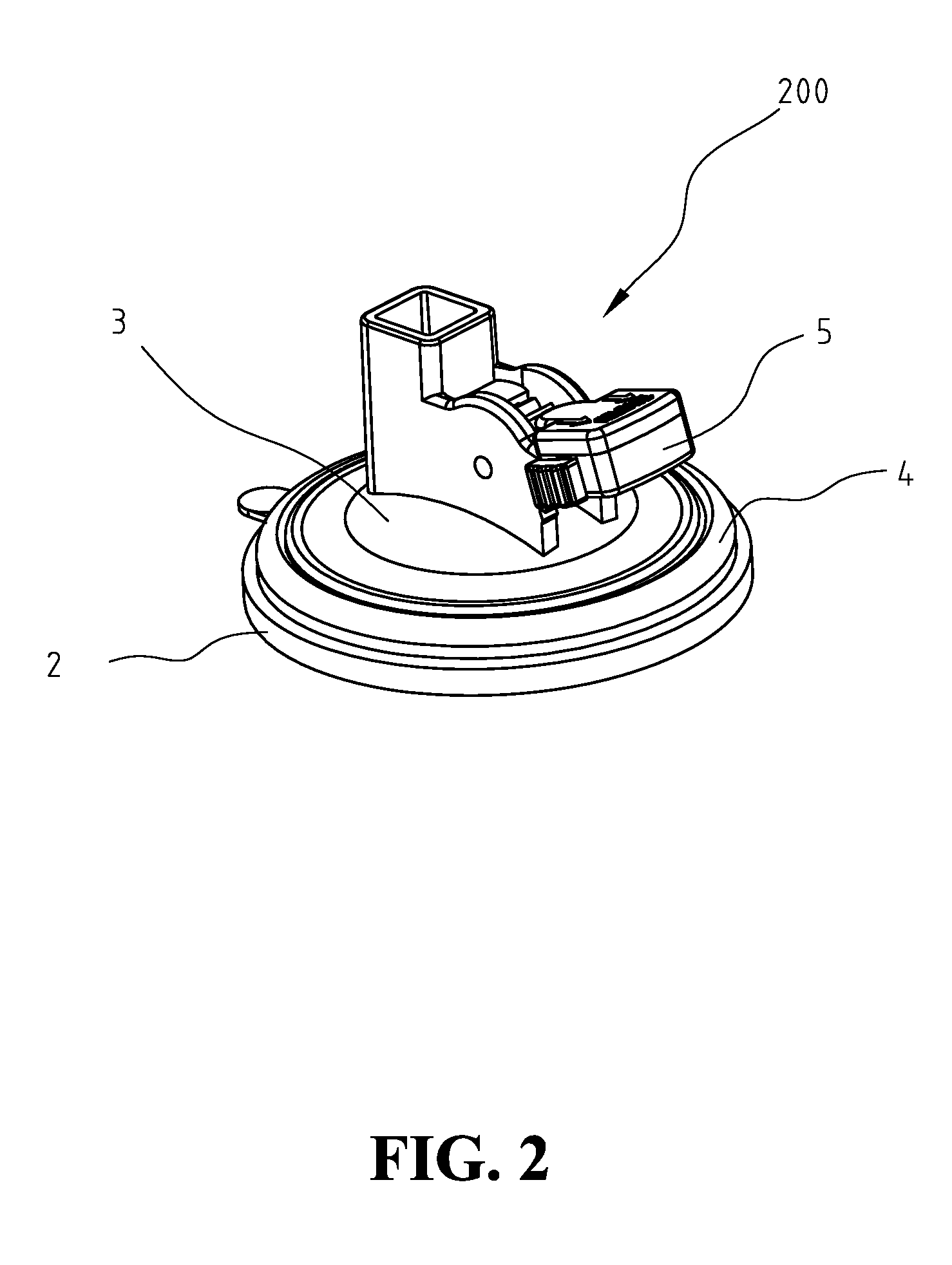

Structure For A Suction Device

Owner:FAN EAGLE

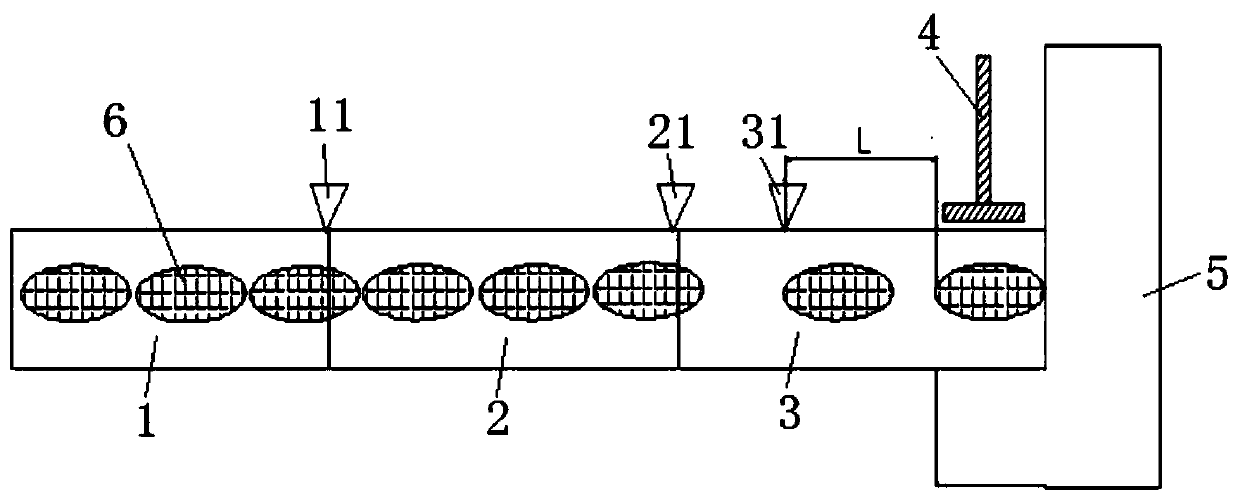

Box body conveying, pushing and clamping system for instrument glass sheet assembly

InactiveCN107380967ASmooth feedingShorten the timeConveyorsControl devices for conveyorsEngineeringMechanical engineering

Owner:新朗思(新沂)智能科技有限公司

Container yard management mode on cloud

ActiveCN110510314ASolve the contradiction of tight land supplySolve the contradiction of the whole process informatization and transparency requirementsConveyorsLogisticsInformatizationLogistics management

The invention discloses a container yard management mode on cloud, and belongs to the technical field of container logistics. The container yard management mode on cloud involves a port information center, a container operator, a container yard, a CFS warehouse, a consolidated company and a consolidated truck driver. According to the container yard management mode on cloud, the contradiction between ground demands of the container yard and land tension of surroundings around the port, the contradiction between the empty-load transportation of devanning service empty container returning and theempty-load transportation of encasement service container despatching and the contradiction between traditional yard informatization island and logistics informatization demands are comprehensively solved. After containers are devanned, the containers are directly matched with the nearest container user, and when the container amount is insufficient, the containers are supplemented by the imported to-be-lightered containers, and then linkage supplemented by the container yard if insufficiency still exists. In the process, a cloud container yard platform realizes intelligent scheduling of thecontainers through big data cloud computing, and each qualified to-be-returned container is used as an inventory of the cloud container yard platform; meanwhile, the yard dispatching mode is transformed into a cloud container yard platform mode combining a distributed type, micro-inventory, direct-matching with fast-circulation; and finally, a traditional container yard is reserved and is used asan inventory and maintenance container.

Owner:SHANGHAI BOX CLOUD LOGISTICS TECH CO LTD

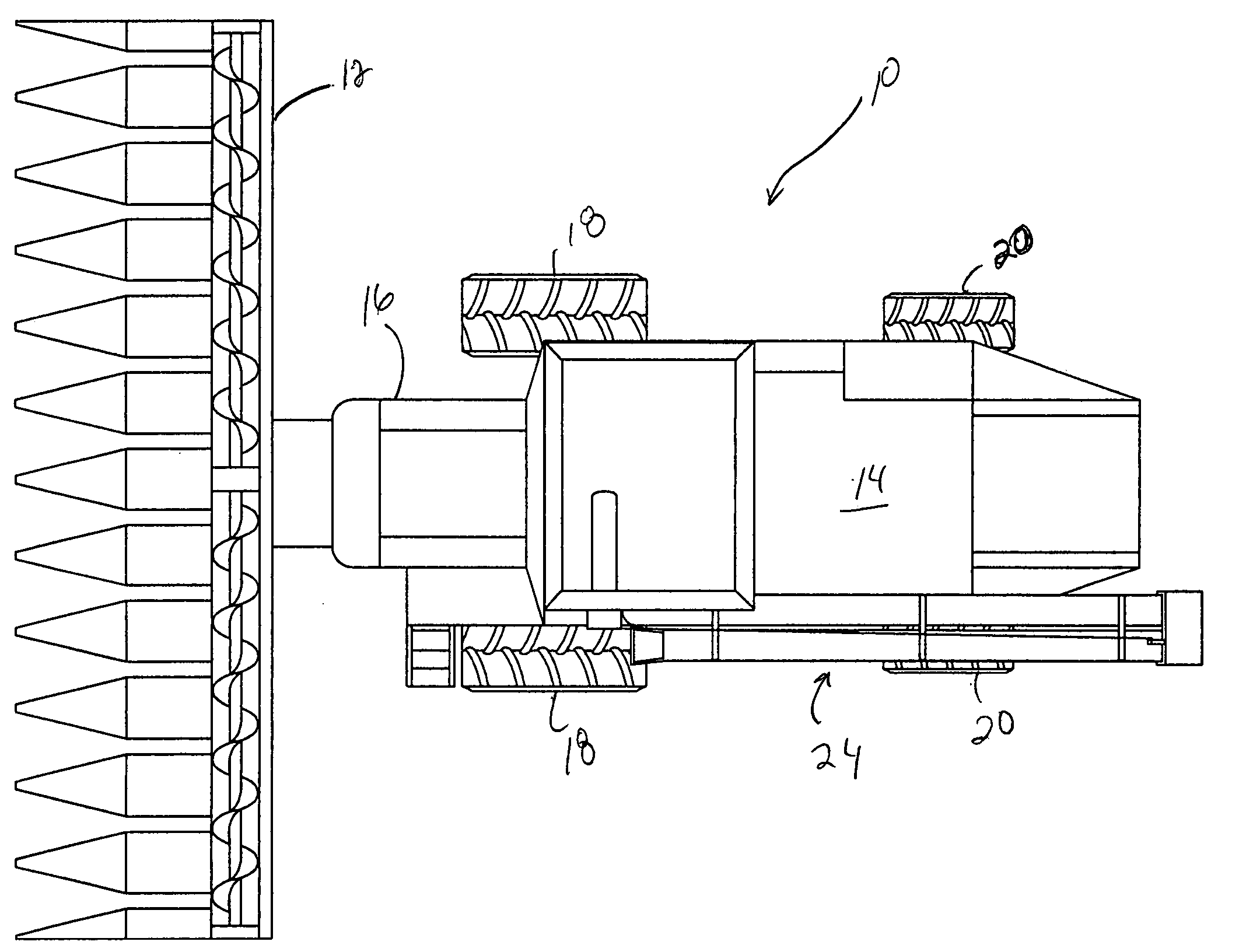

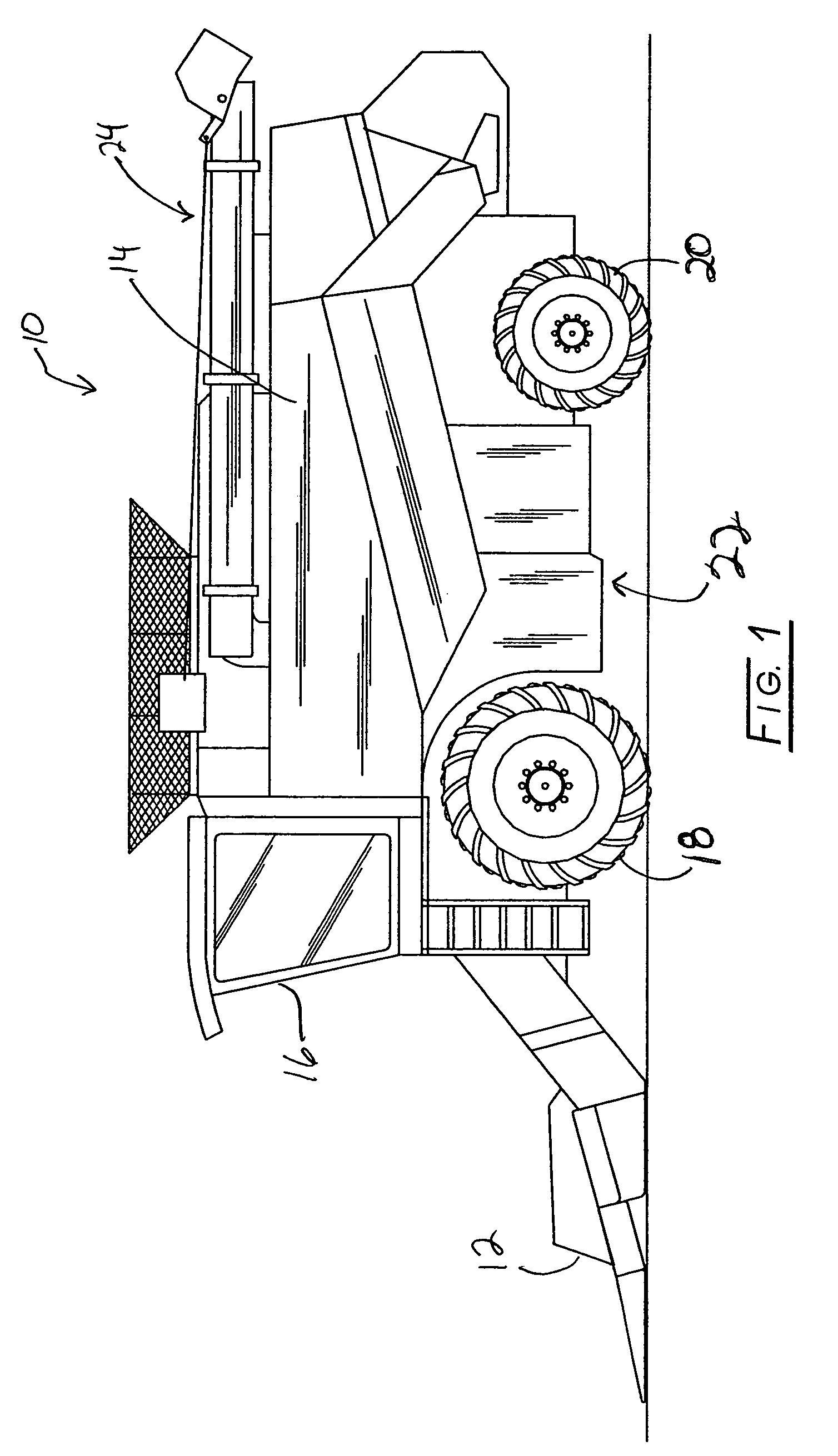

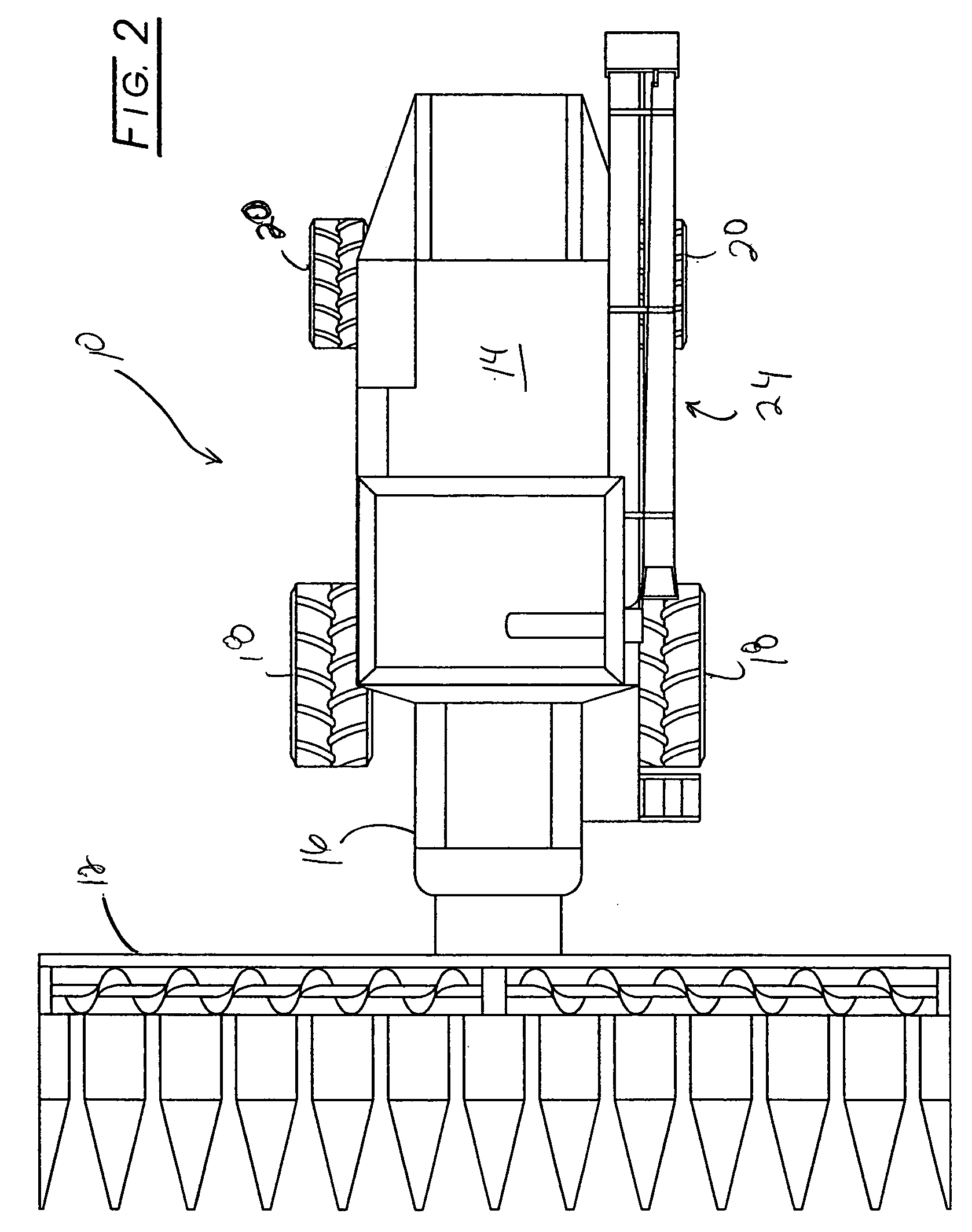

Combine dual auger unloader

ActiveUS20060045701A1Improve unloading abilityEasy to transformConveyorsMowersEngineeringCombine harvester

Owner:TRIBINE IND

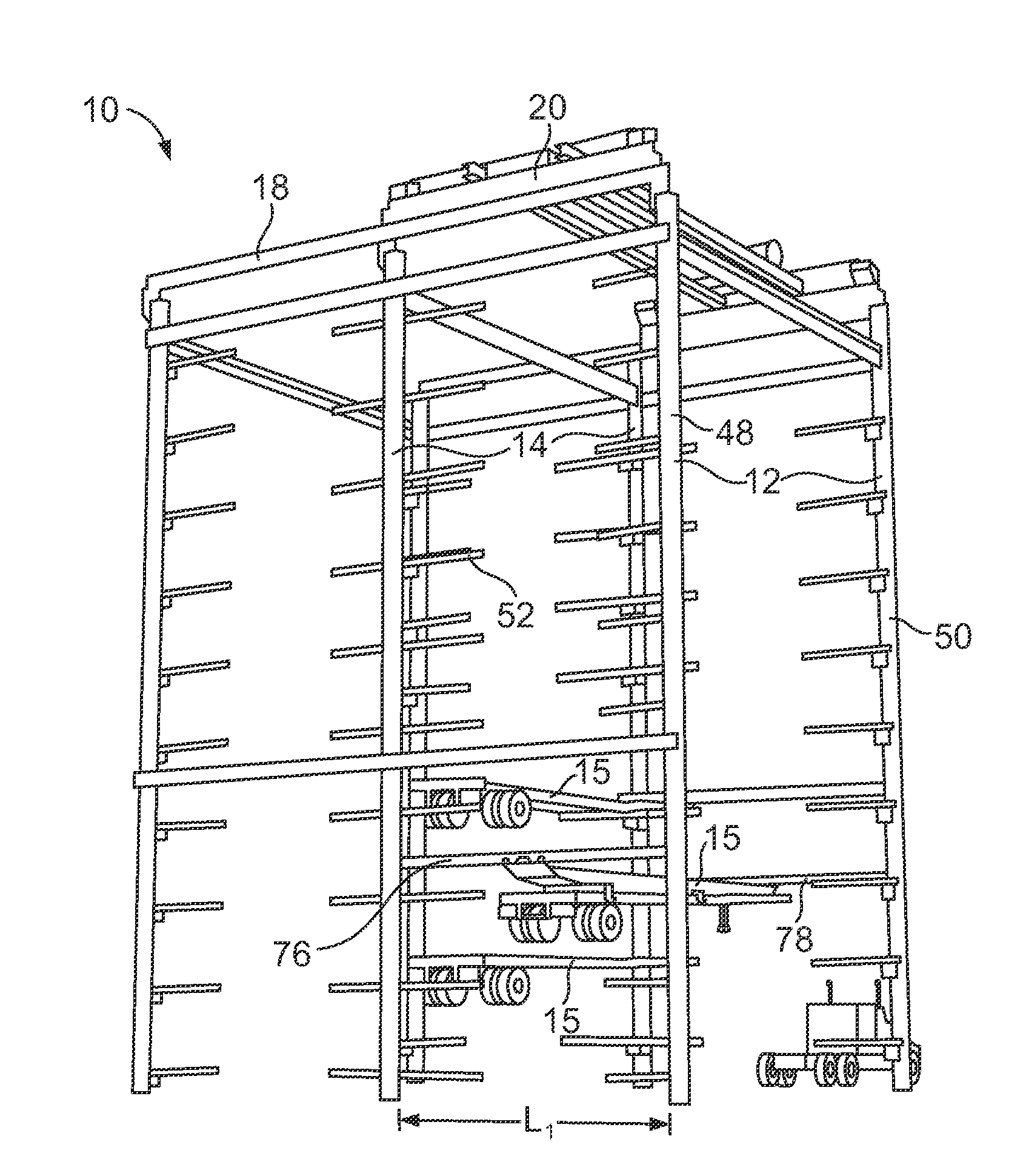

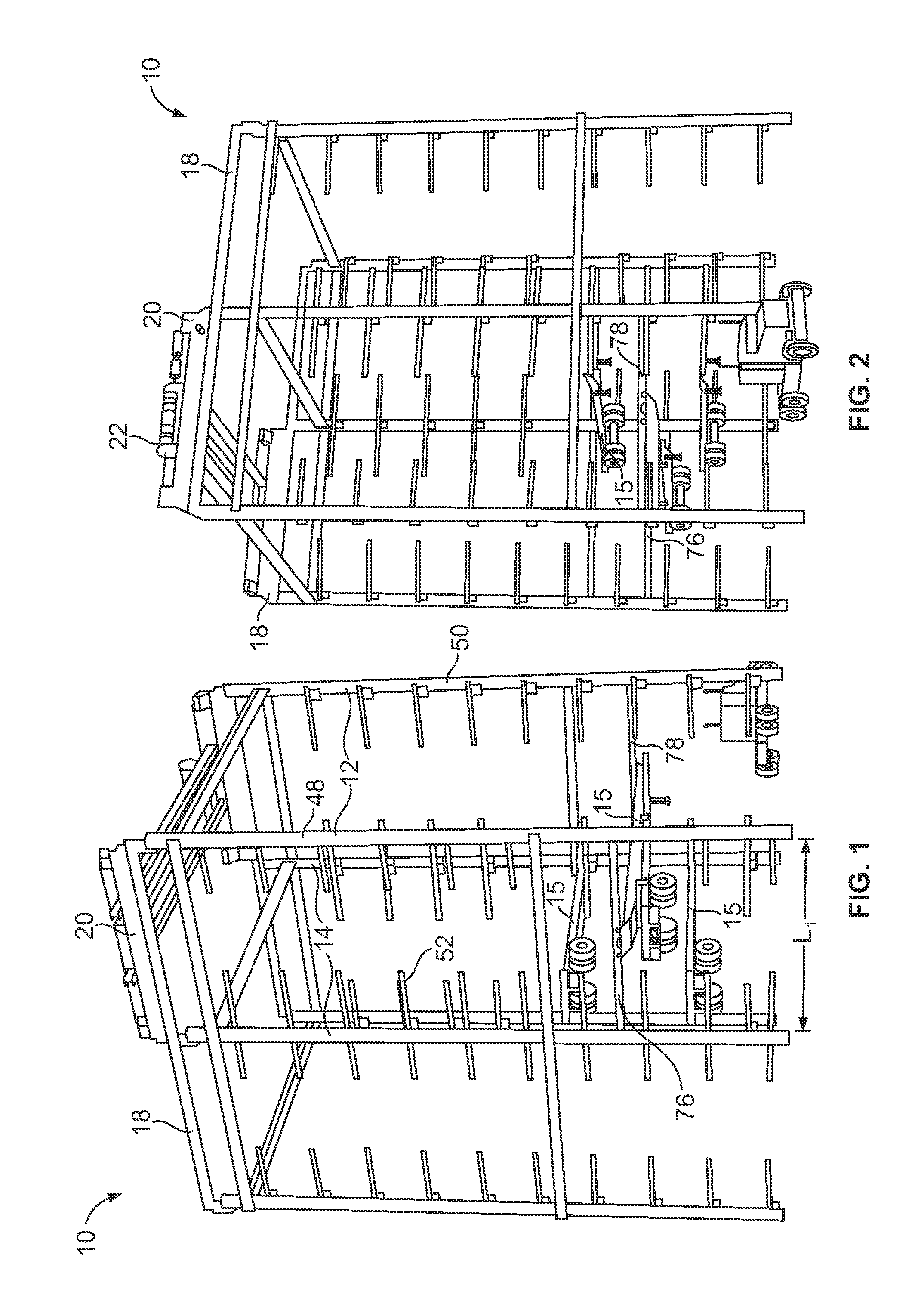

Chassis Stacker

Owner:MI JACK PRODS

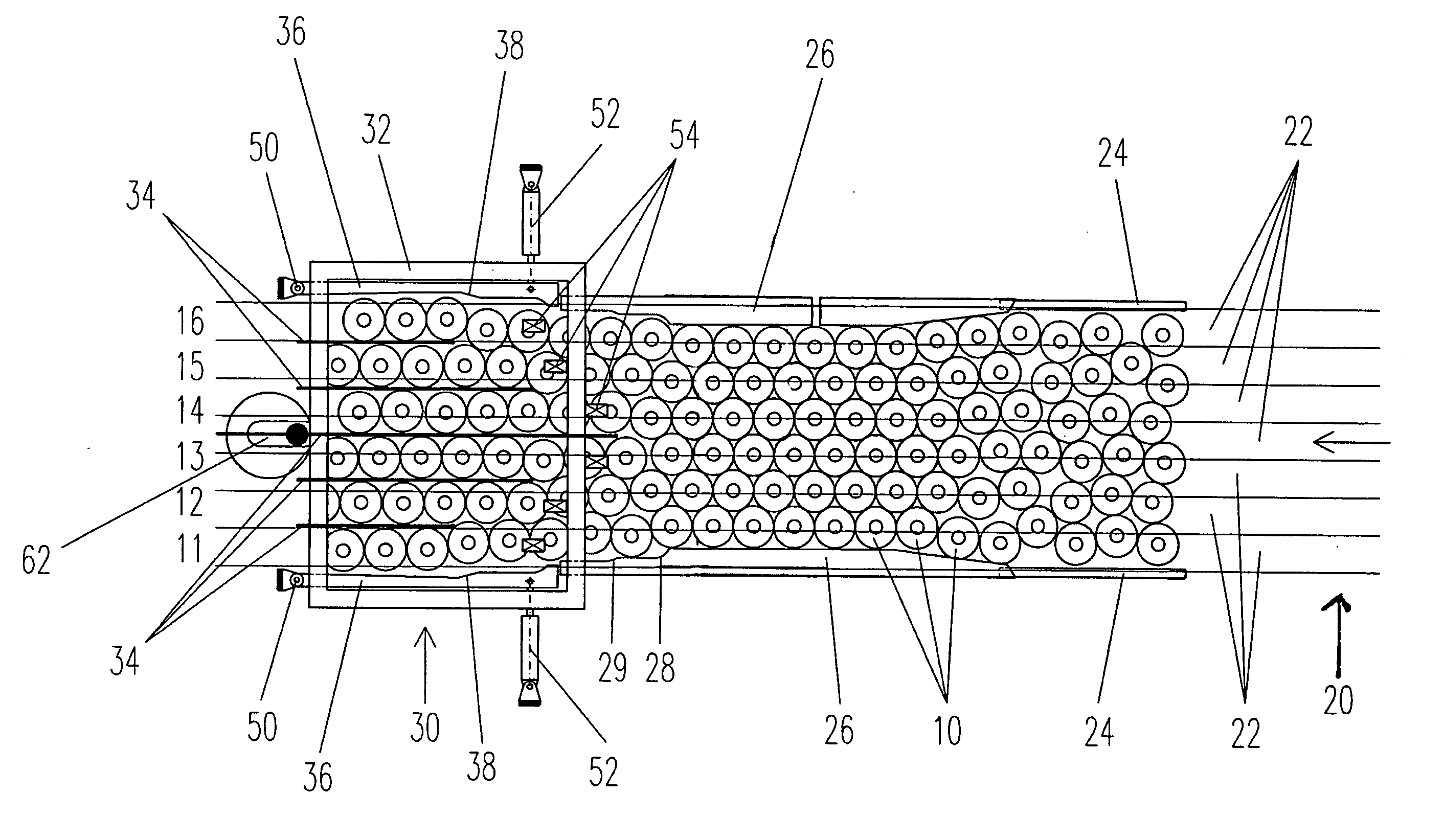

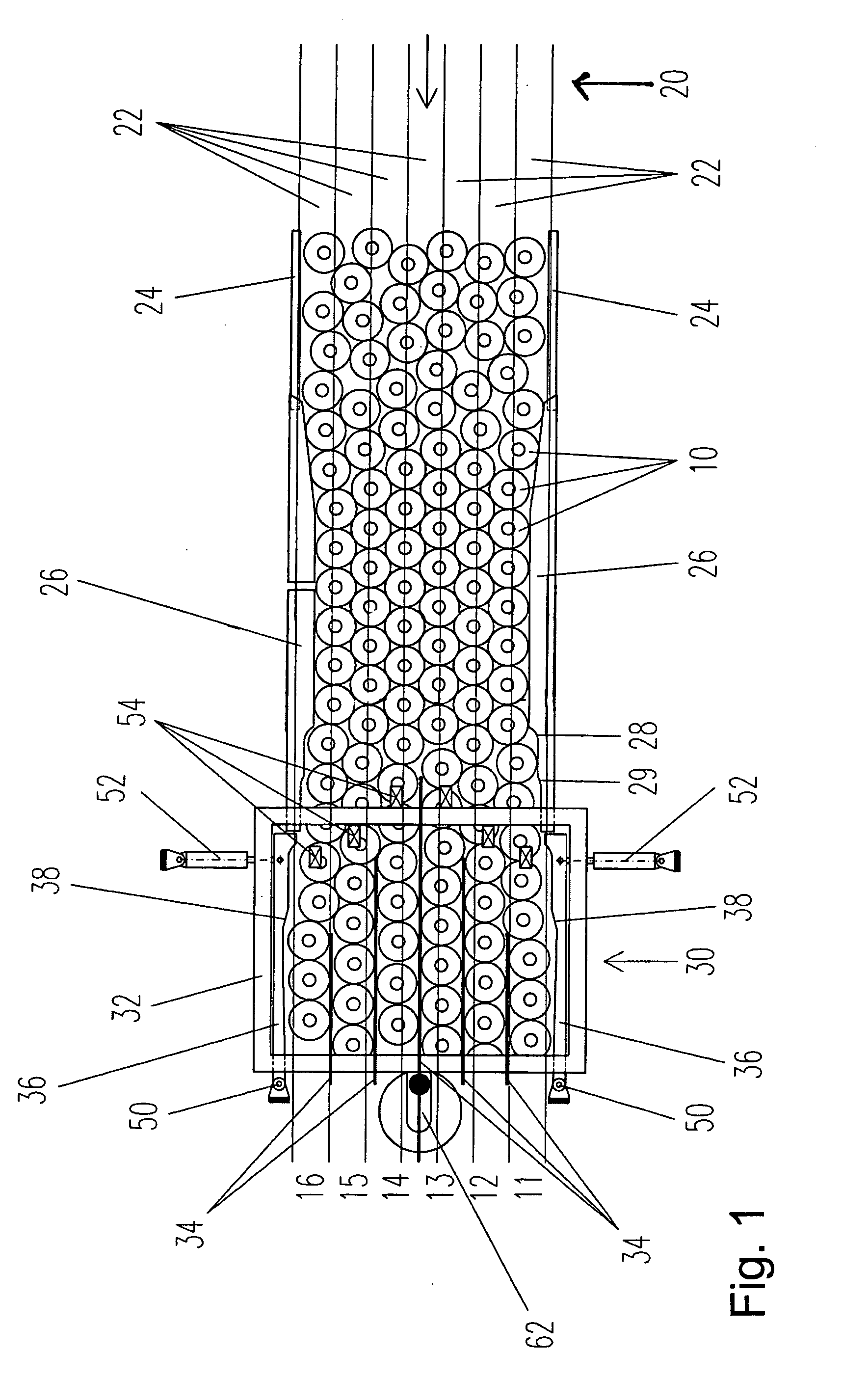

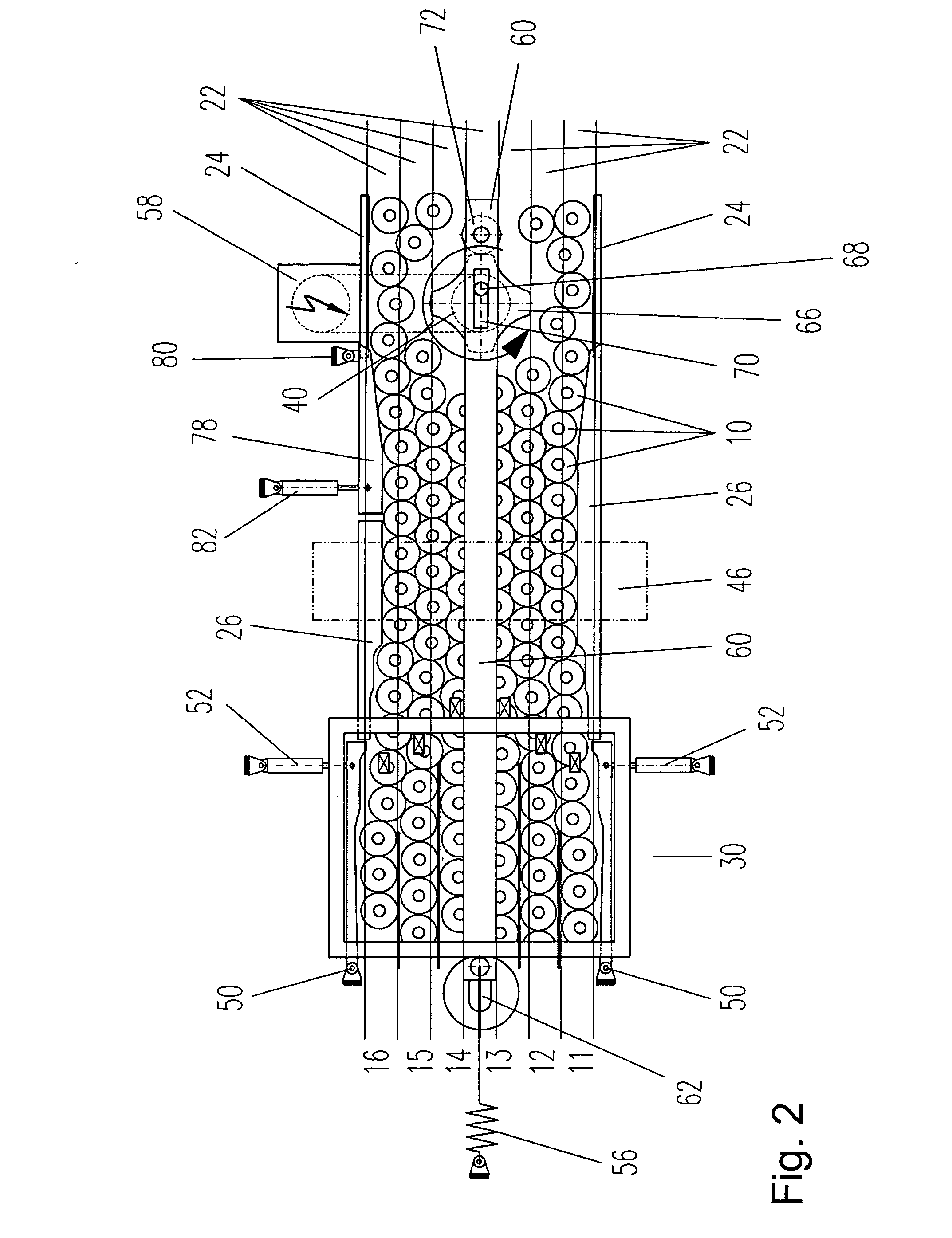

Apparatus for the Distribution of a Random Stream of Cylindrical Items, for Example Drinks Bottles, into Several Lanes

Owner:HEUFT SYSTTECHN GMBH

Steel seal stamping machine with automatic feeding and discharging functions

InactiveCN105035638AProcess stabilitySimple structureConveyorsConveyor partsDrive wheelElectric machine

The invention provides a steel seal stamping machine with automatic feeding and discharging functions. The steel seal stamping machine comprises a working table, a supporting plate, a motor, a controller, a driving wheel, a driven wheel, a plurality of conveying plates, a chain and a steel seal stamping device. The working table further comprises a table top, table legs, a rocking handle, a rotating disc, a slide rod and track grooves, the rocking handle is fixedly connected with the rotating disc, the rotating disc and the slide rod are fixedly connected, the driving wheel is arranged above the table top, a motor shaft penetrates through the table top and is connected with the driving wheel, and the driven wheel is located above the table top. The steel seal stamping machine is simple in structure; as the chain is used for transmission, it is ensured that the transmission ratio is accurate, the transfer power is large, force exerted on the shaft is small, and the transmission efficiency is high; the steel seal stamping machine can work in an atrocious environment, the rotating speed can be controlled by the controller, the automation degree is high, the rotating speed is appropriate, steel seals can be replaced, and the steel seal stamping machine is wide in application range, high in the steel seal stamping quality, capable of automatically feeding and discharging materials and high in working efficiency.

Owner:ZHEJIANG YATAI FORGING MFG CO LTD

Powerless pile separation device

ActiveCN109160273AGuaranteed uptimeSimple structureConveyorsDe-stacking articlesProduction lineEngineering

The invention discloses a powerless pile separation device. The powerless pile separation device comprises a machine body, a pile separation module, a conveying module and a connecting rod module, wherein the machine body is provided with a first slide way and a second slide way arranged at intervals; the first slide way and the second slide way are used for conveying goods containers; the pile separation module is connected with the machine body, is arranged above the first slide way, and is used for separating the goods containers on the first slide way; the conveying module is arranged between the first slide way and the second slide way, and is used for conveying the goods containers to the second slide way after separation by the pile separation module; the connecting rod module is rotationally arranged on the machine body; one end of the connecting rod module is connected with the pile separation module, and the other end of the connecting rod module is connected with the conveying module; the connecting rod module is provided with a handle; and when the handle pulls the connecting rod module to move, the connecting rod module drives the pile separation module to separate thegoods containers on the first slide way, and the connecting rod modules drives the conveying module to convey the goods containers, separated on the first slide way, to the second slide way. The powerless pile separation device is simple and small in structure and convenient for operation and application to a small production line.

Owner:GAC TOYOTA MOTOR

Sheet feeder

Owner:RAUTE OY

Pipe prefabrication transverse automatic conveying system

Owner:上海前山管道技术有限公司

High-temperature resisting conveyor belt with diaphragm plates and retaining sides

Owner:QINGDAO RUBBER SIX CONVEYER BELT

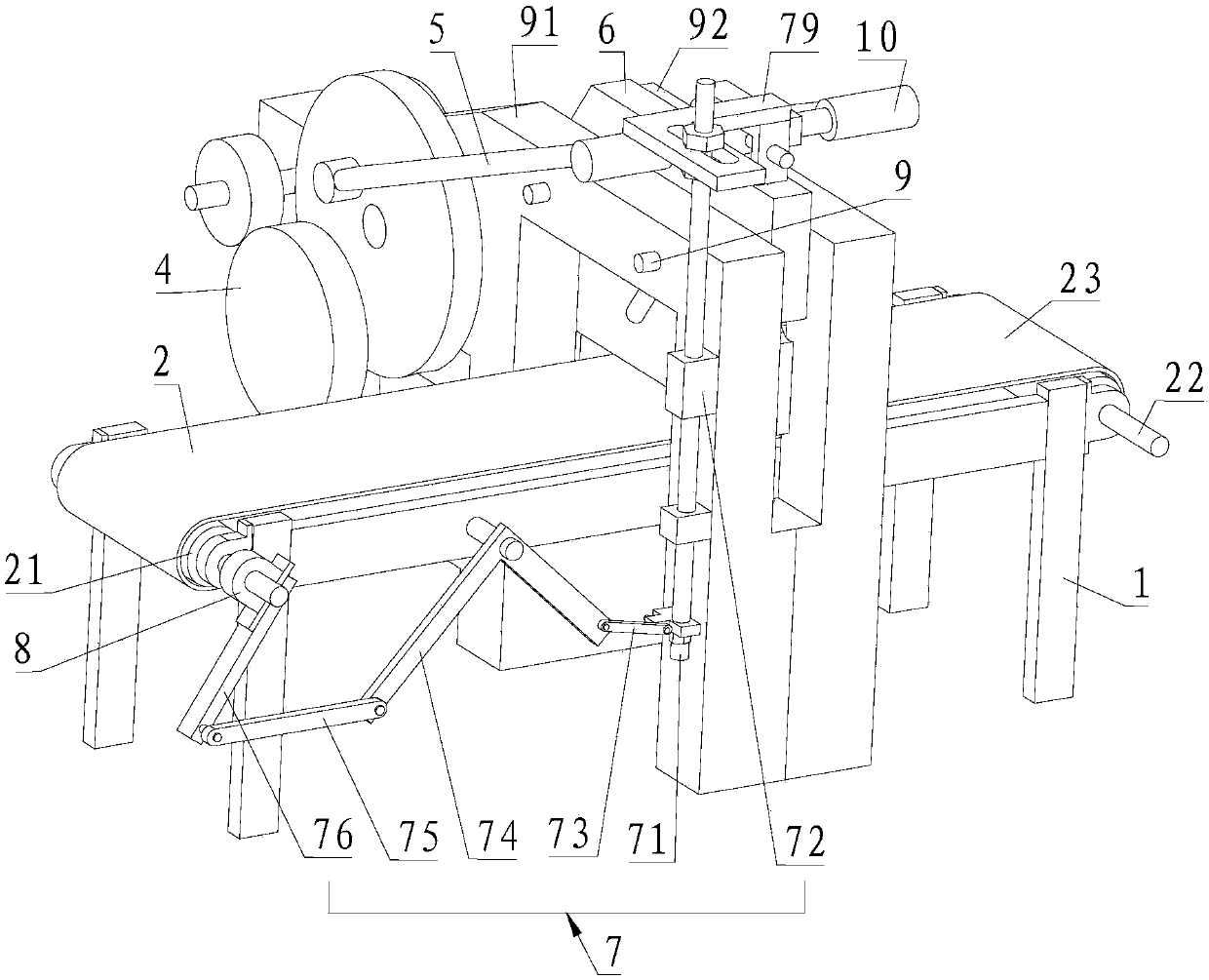

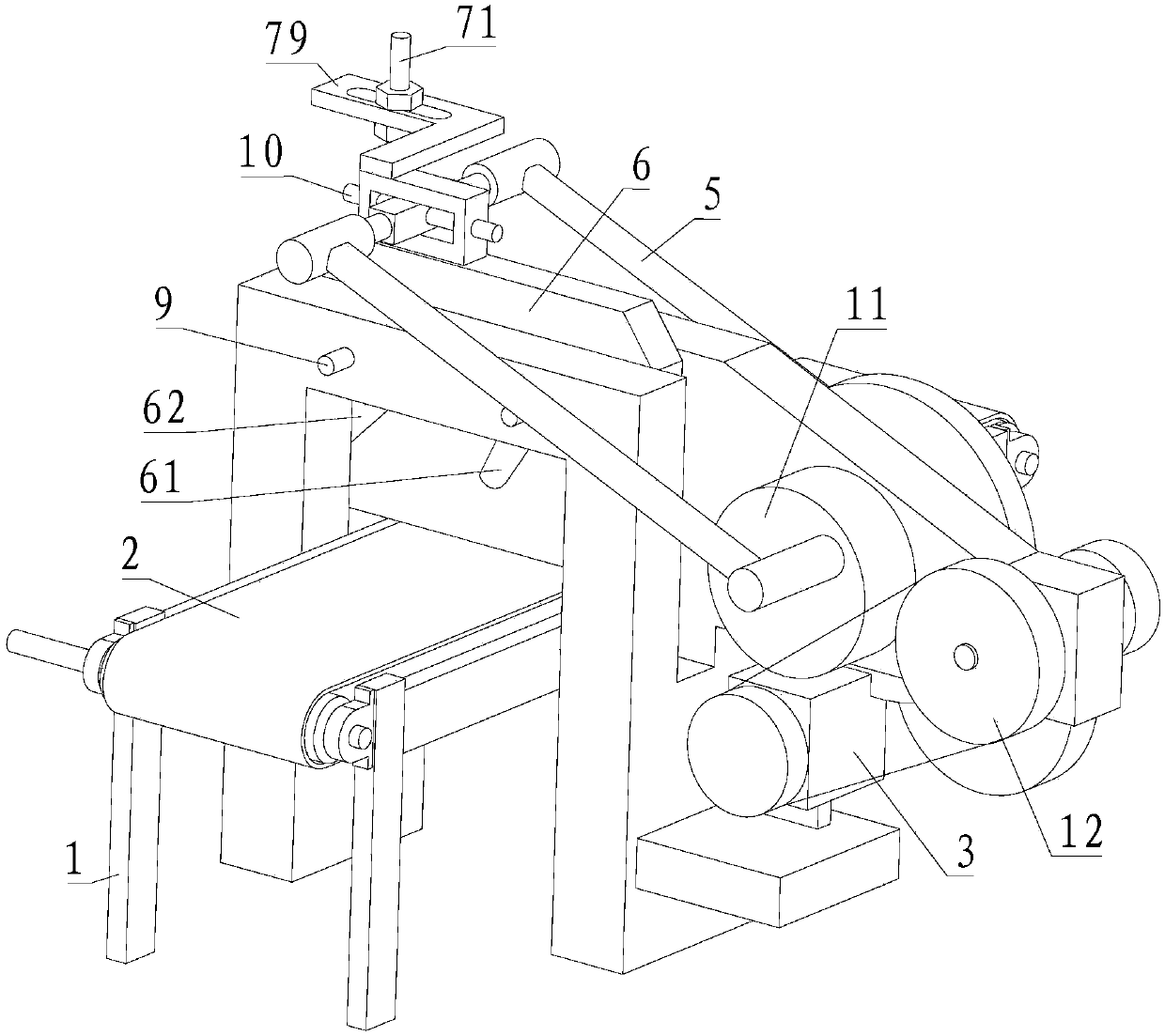

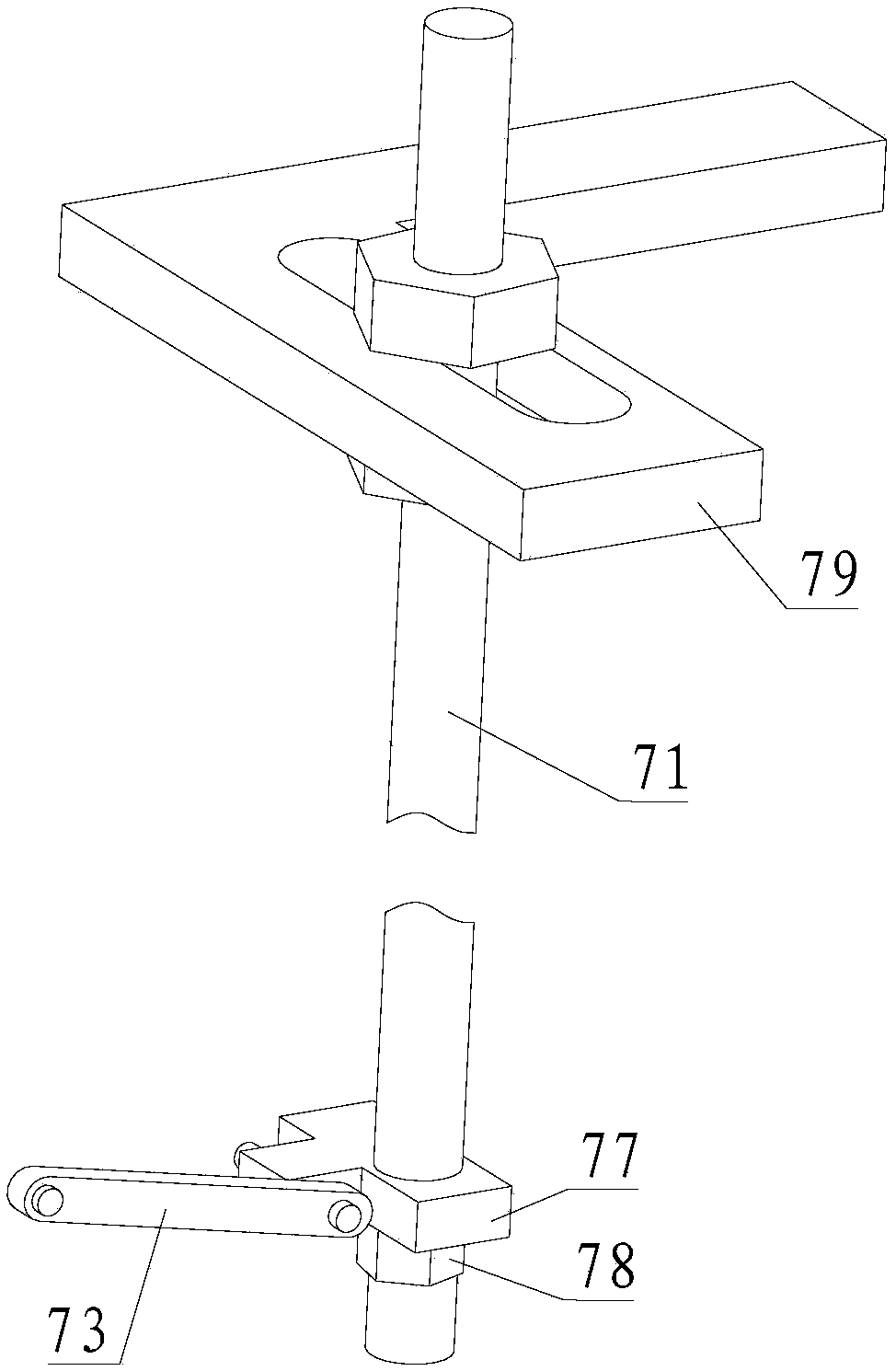

Film cutting device

PendingCN107792707AReasonable and stable structureSimple system structureConveyorsArticle deliveryEngineeringGear drive

The invention provides a film cutting device comprising a machine frame and a conveyer belt assembly. The conveyer belt assembly comprises a first rolling shaft, a second rolling shaft and a conveyerbelt. The conveyer belt is connected to the first rolling shaft and the second rolling shaft in a sleeving manner. The film cutting device further comprises a motor, a gear transmission assembly, pullrods, a cutter, a connection rod mechanism and a one-way bearing. An output shaft of the motor is connected with the input end of the gear transmission assembly. One end of each pull rod is rotationally connected with the gear transmission assembly in an eccentric manner. The other end of each pull rod is rotationally connected with the upper end of the cutter. The cutter is located above the conveyer belt. The input end of the connection rod mechanism is connected with the upper end of the cutter. The output end is connected with the first rolling shaft through the one-way bearing. The motoris fixed to the machine frame. The motor drives the cutter to move up and down through the gear transmission assembly and the pull rods, the first rolling shaft is driven to conduct intermittent rotation through the connection rod mechanism and the one-way bearing, and the two actions of film cutting and feeding are achieved. The film cutting device is simple in system and saves energy.

Owner:王友炎

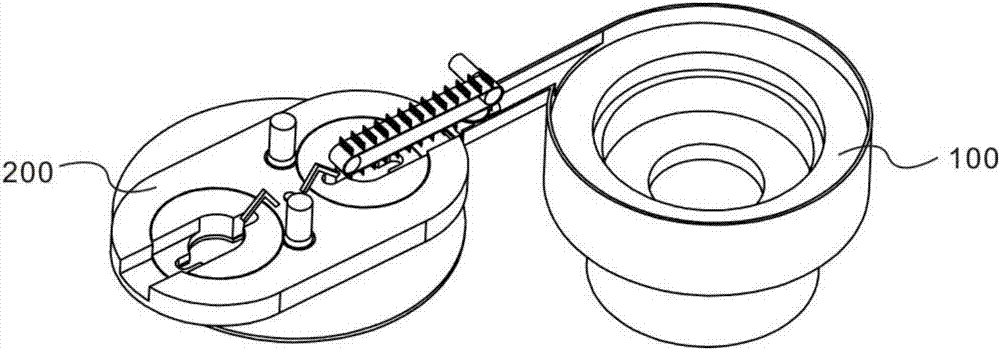

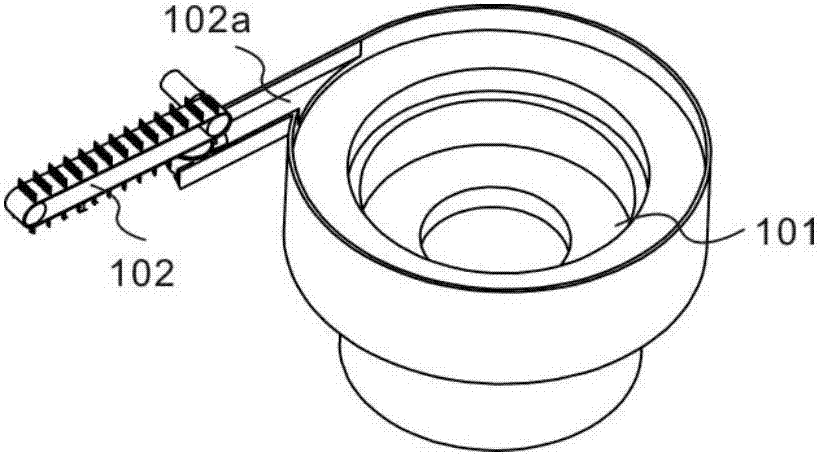

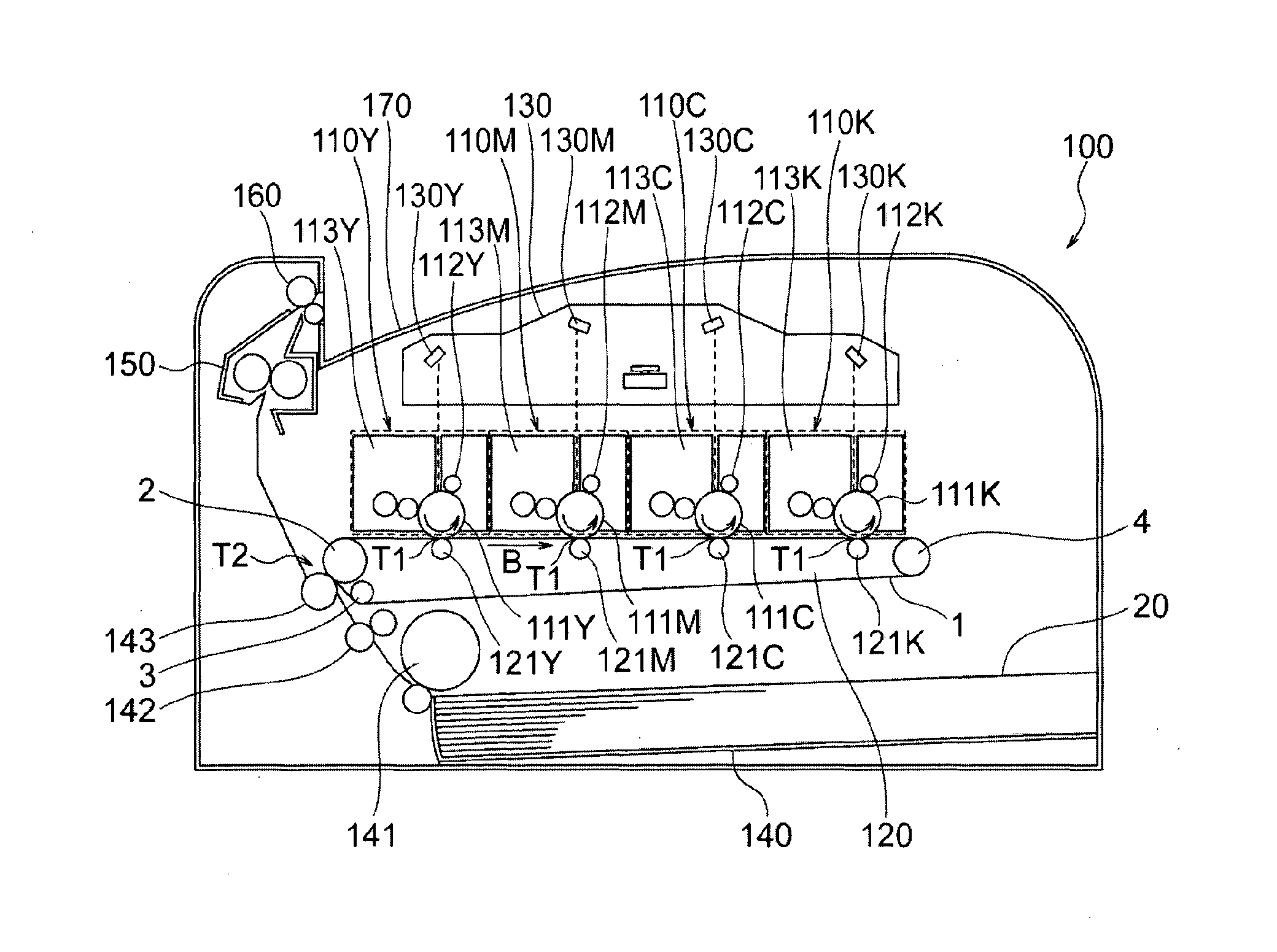

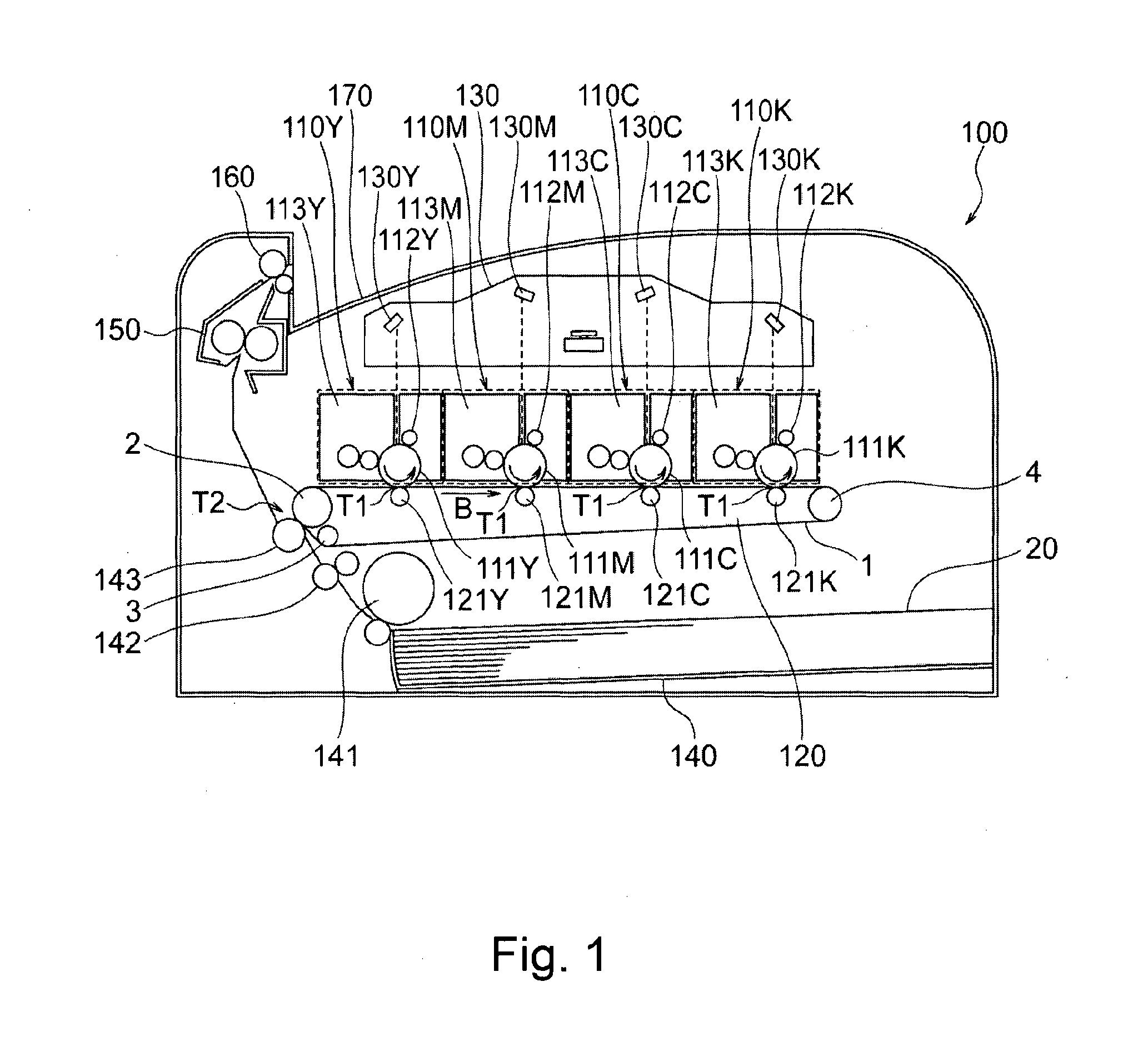

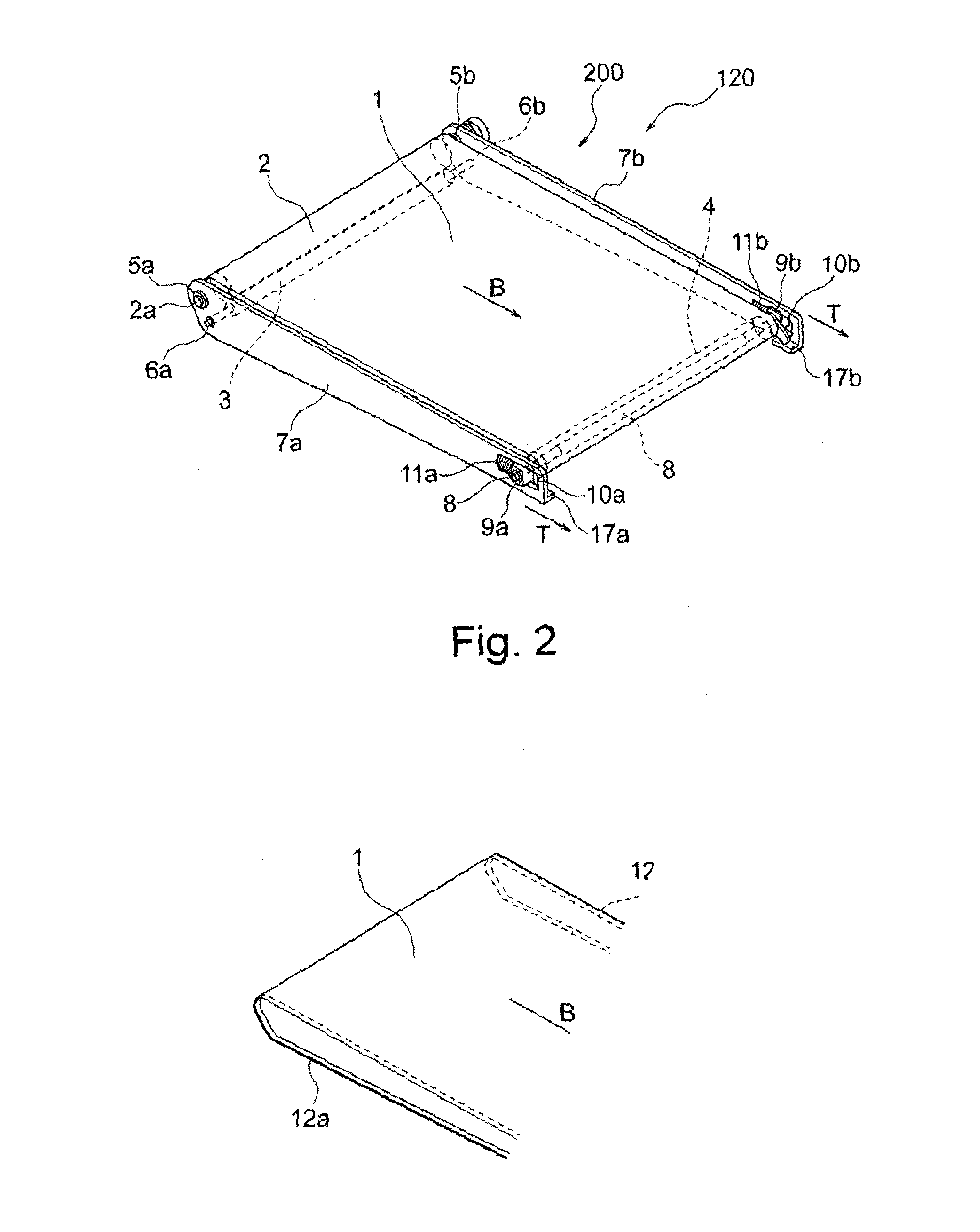

Belt driving apparatus and image forming apparatus

ActiveUS20140054139A1Precise positioningConveyorsElectrographic process apparatusRotational axisEngineering

Owner:CANON KK

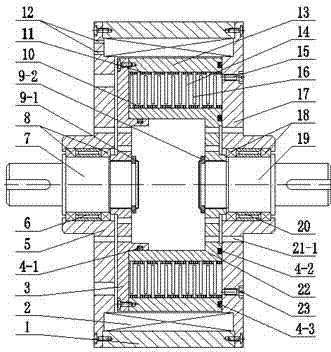

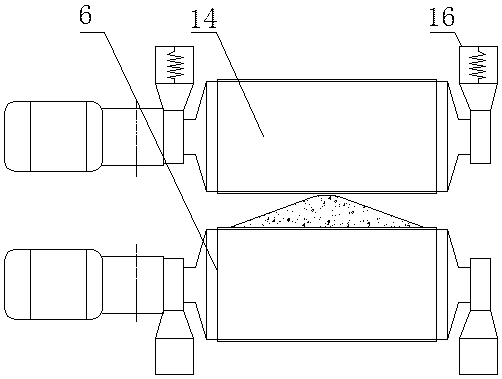

A multi-chip magneto-rheological soft start device

ActiveCN102297213AEasy to change sizeSimple structureConveyorsFluid clutchesMagnetorheological fluidEngineering

Owner:苏州方德锐精密机电科技有限公司

Handling mechanism

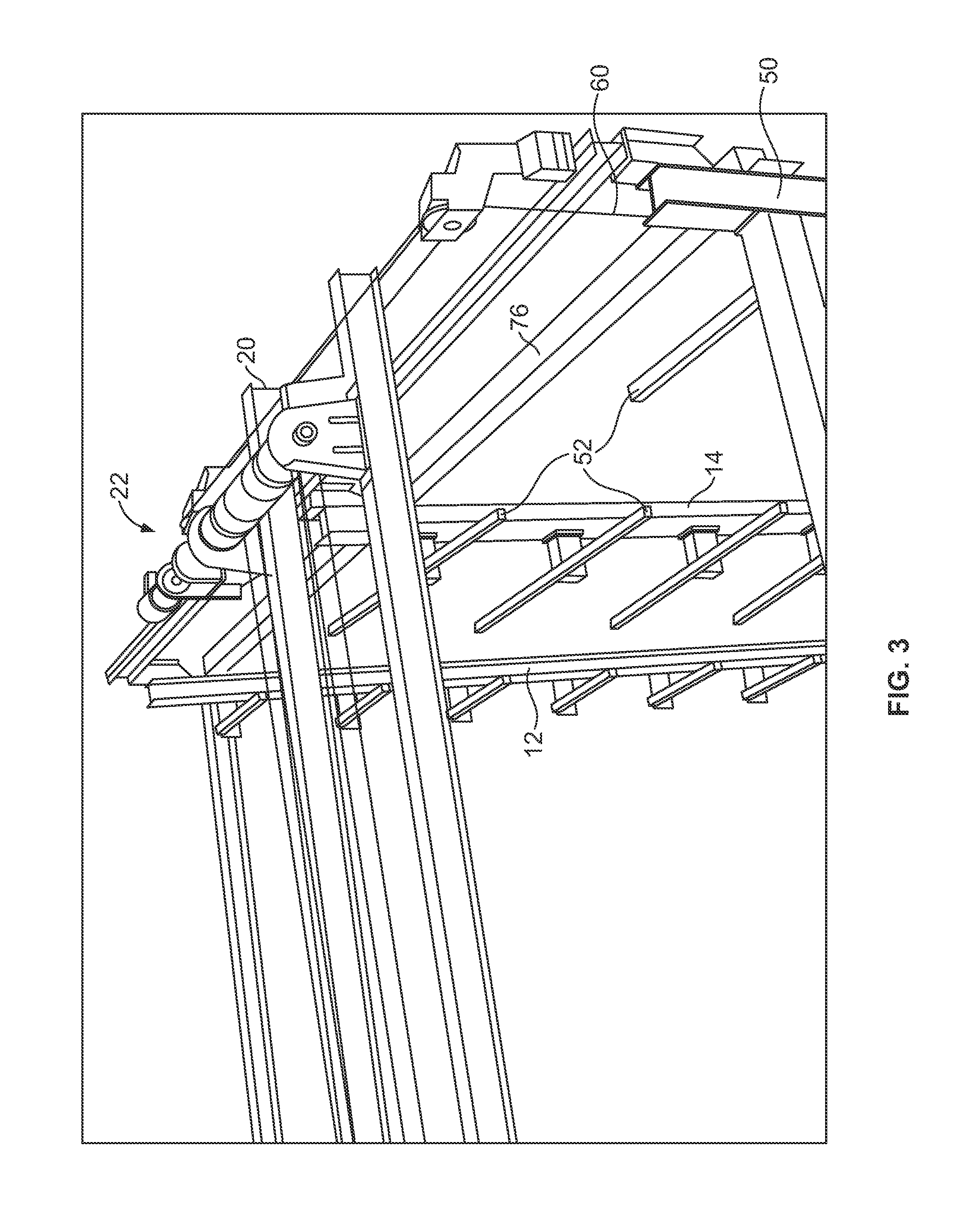

InactiveUS20130136568A1Easily distorted and even destroyedProgramme-controlled manipulatorConveyorsEngineeringMechanical engineering

A handling mechanism comprises a mounting seat, a driving assembly, a sliding member, an extending mechanism and a clamping assembly. The driving assembly is mounted on the mounting seat. The sliding member is slidably mounted on the mounting seat and driven by the driving assembly. The extending mechanism comprises an extending member and a strength member. The extending member is positioned on the sliding member being capable of moving along a direction perpendicular to a direction of the movement of the mounting seat. The strength member is slidably positioned on the sliding member and connects with the extending member. The clamping assembly is fixed to the strength member for clamping very heavy workpieces.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

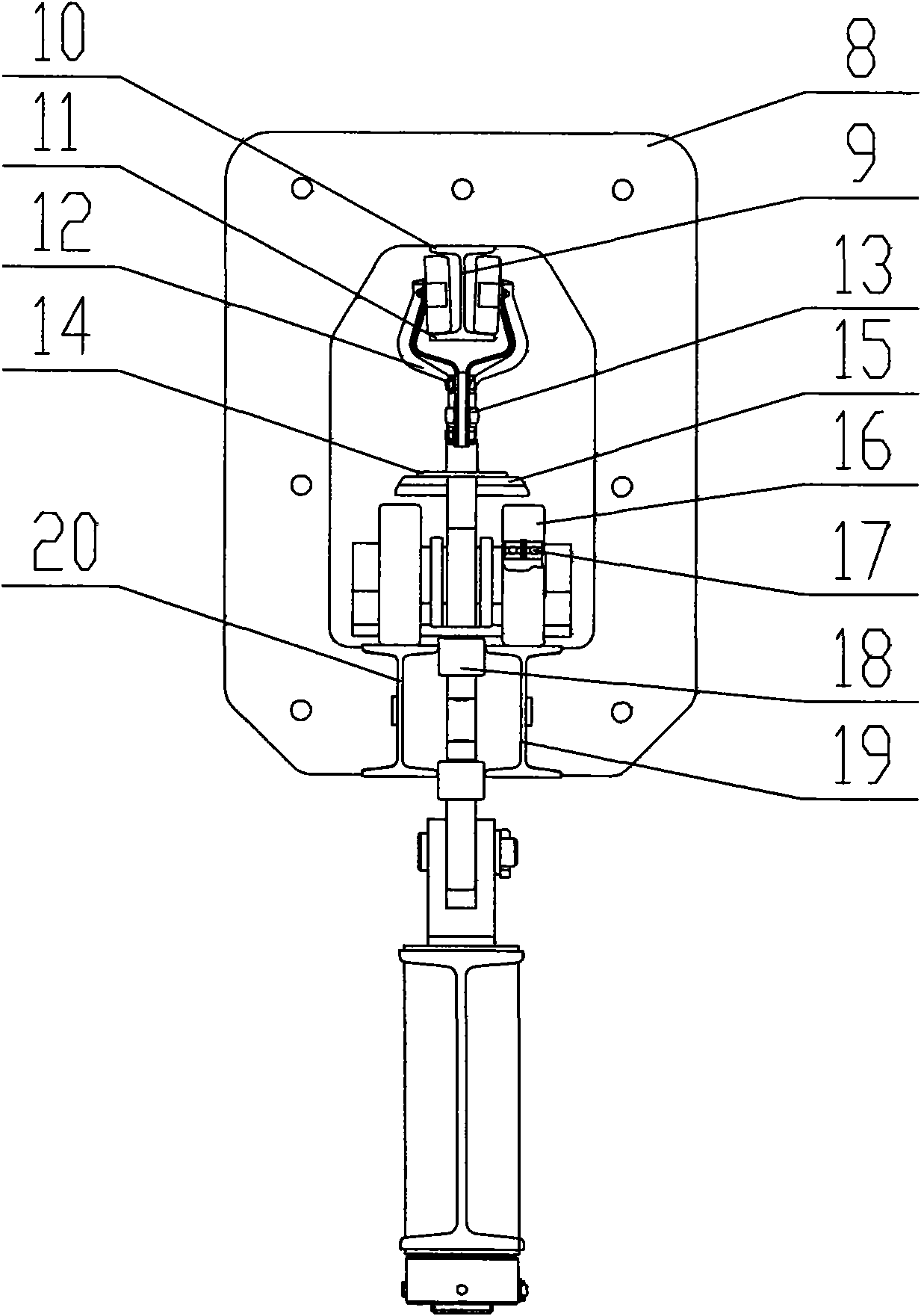

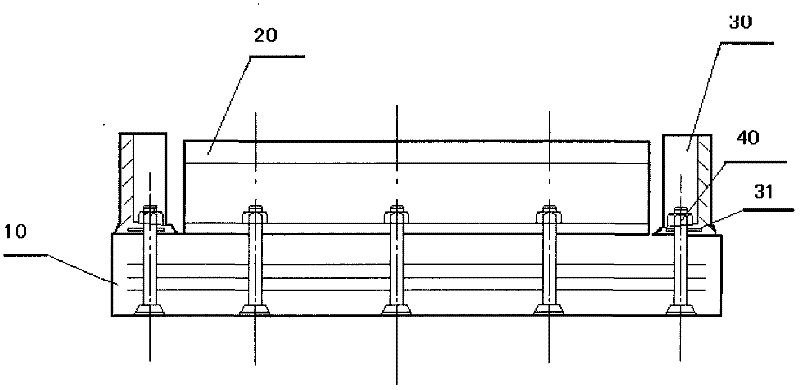

Clamping device of photovoltaic junction box body

PendingCN107826742ANot easy to damageImprove efficiencyConveyorsConveyor partsEngineeringMaterials science

The invention discloses a clamping device of a photovoltaic junction box body, which mainly solves the technical problems of easiness in damage and lower efficiency during movement of the photovoltaicjunction box body. The clamping and conveying device of the photovoltaic junction box body comprises a fixed side plate, wherein a clamping device is arranged on the top of the side plate, a channelis formed in the side plate below the clamping device, and a push device is arranged at the bottom of the channel, so that the problem is preferably solved. The clamping and conveying device can be used for clamping and conveying photovoltaic junction boxes.

Owner:SUZHOU SUOLIWANG NEW ENERGY TECH CO LTD

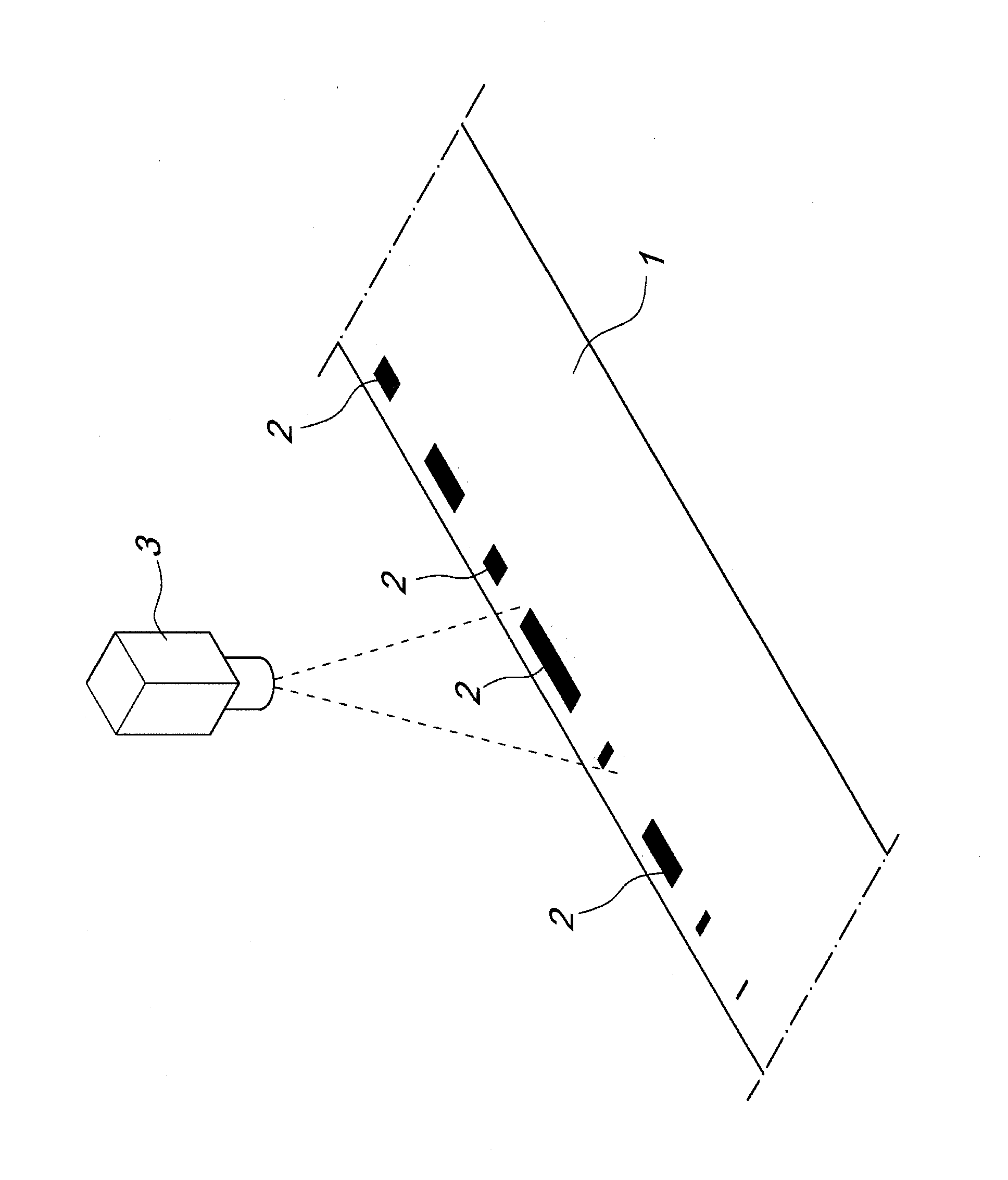

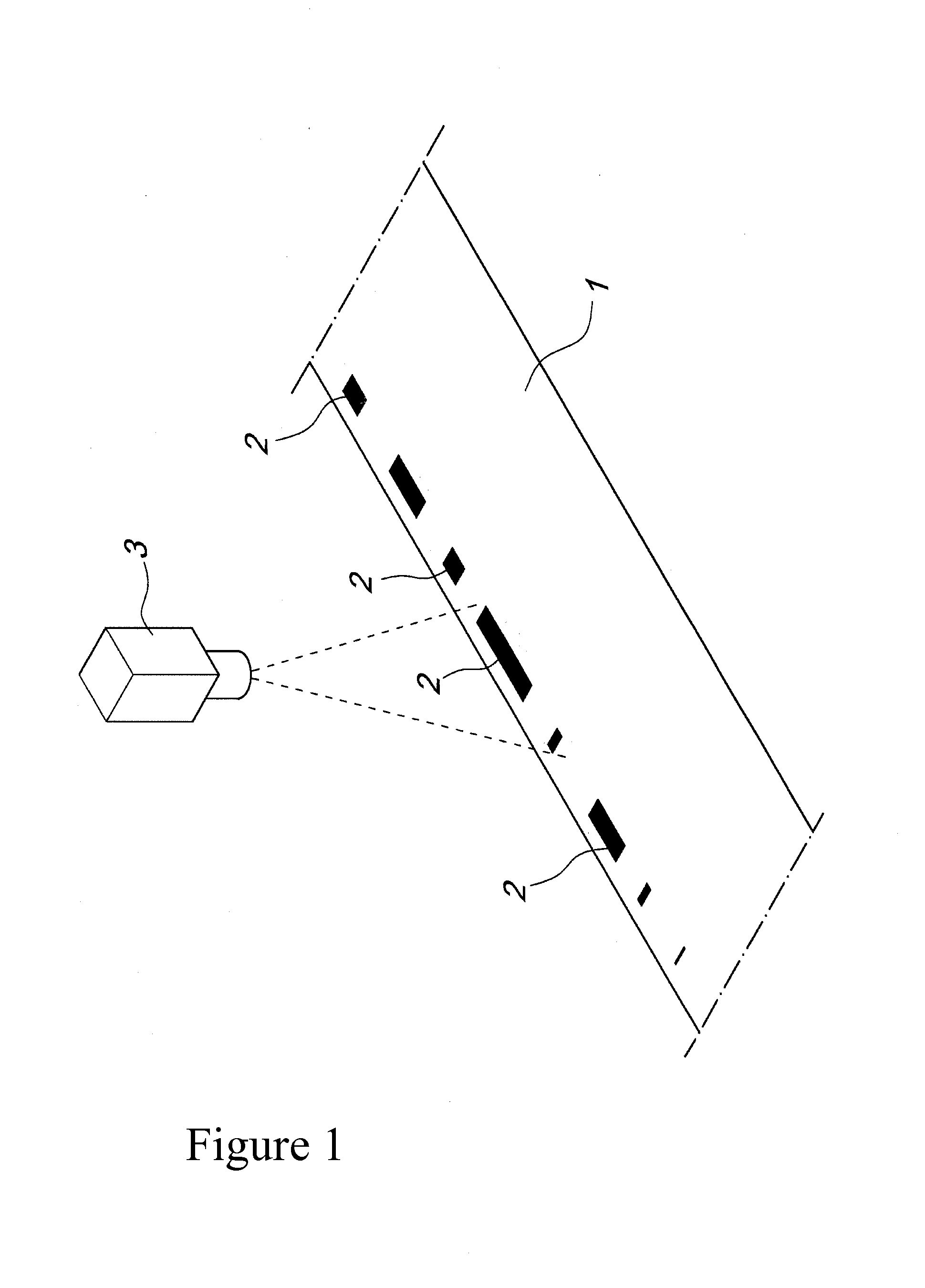

Method and device for detecting the position of a conveyor

ActiveUS20140022562A1Keep full controlConveyorsControl devices for conveyorsEngineeringConveyor belt

Owner:COMELZ SPA

Chicken chain

Owner:WILKIE BROS

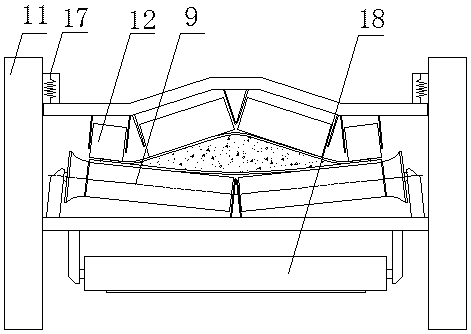

Belt conveyer and mobile crushing and sieving equipment

The invention discloses a belt conveyer and mobile crushing and sieving equipment, relates to the field of engineering machinery, and is used for improving the transport convenience of the mobile crushing and sieving equipment. The belt conveyer comprises a conveyer body and a first angle adjusting device, wherein the conveyer body comprises a conveyer section I and a conveyer section II which are rotationally connected; one end of the first angle adjusting device is connected with the conveyer section I, and the other end of the first angle adjusting device is connected with the conveyer section II; the first angle adjusting device can drive the conveyer section I to rotate relative to the conveyer section II. The belt conveyer can be folded, so that the whole conveyer is convenient to transport.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

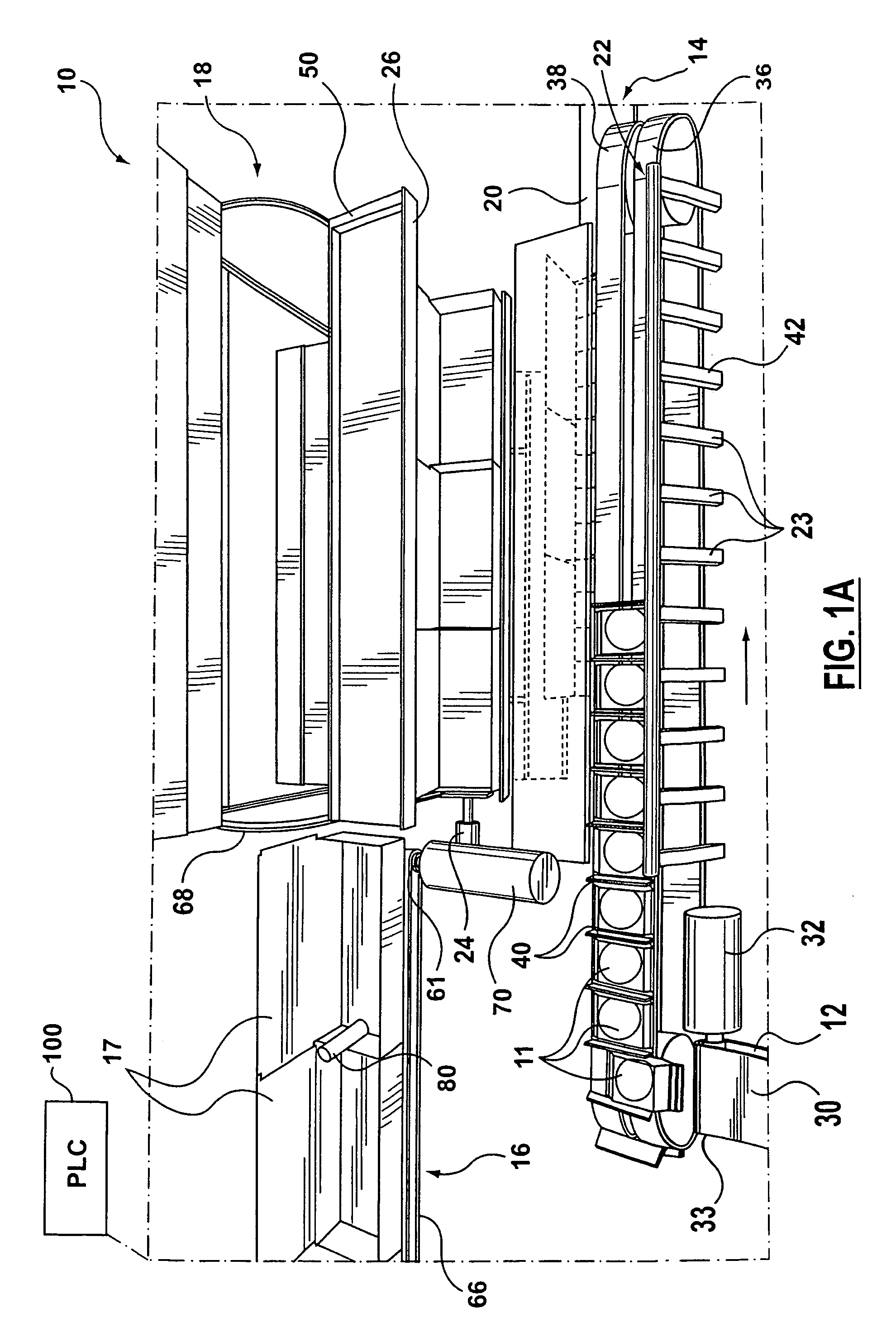

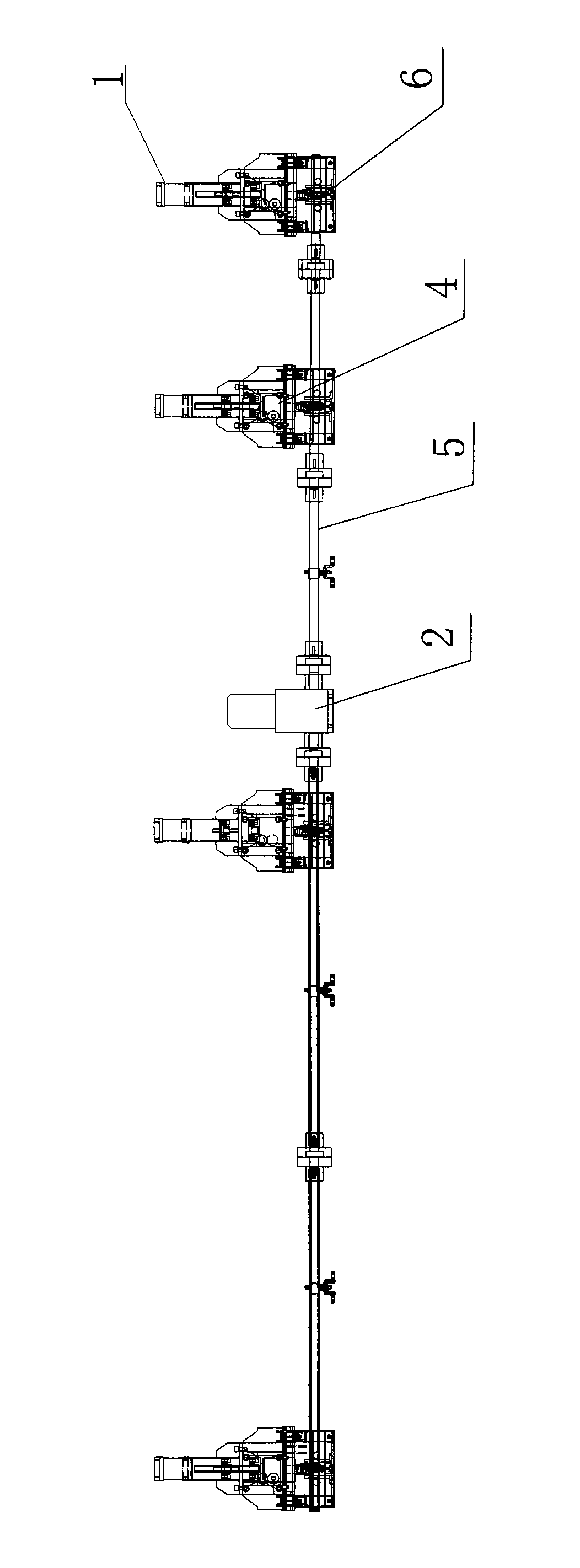

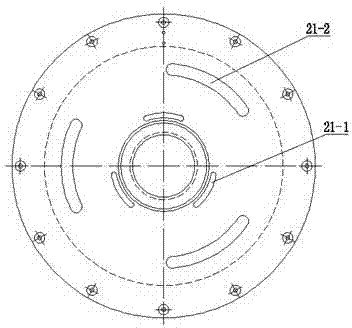

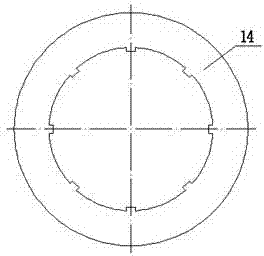

Ceramic forming mold automatic exchange machine

InactiveCN108724449APositioning synchronizationPrecise positioningConveyorsAuxillary shaping apparatusProduction lineCeramic molding

The invention relates to the field of ceramic forming production equipment, in particular to a ceramic forming mold automatic exchange machine. The ceramic forming mold automatic exchange machine is characterized by comprising a longitudinal moving mechanism, an exchange mechanism and a clamping mechanism; the longitudinal moving mechanism comprises a mold clamping rack, a longitudinal slide railfixedly arranged on the mold clamping rack, a longitudinal moving rack slidably arranged on the longitudinal slide rail and a longitudinal driving unit driving the longitudinal moving rack to move; the exchange mechanism comprises an exchange servo motor fixedly arranged on the longitudinal moving rack and a rotary frame driven by the exchange servo motor to rotate. According to the ceramic forming mold automatic exchange machine provided by the invention, rising, dropping, position exchange and clamping of plaster molds can be implemented through the longitudinal moving mechanism, the exchange mechanism and the clamping mechanism; unformed plaster molds on a production line and formed plaster mold on an automatic forming machine can be exchanged; the automation degree is high, manual carrying of molds is omitted; the production efficiency is improved; and the labor cost is lowered.

Owner:FUJIAN DEHUA BOLONG CERAMICS CO LTD

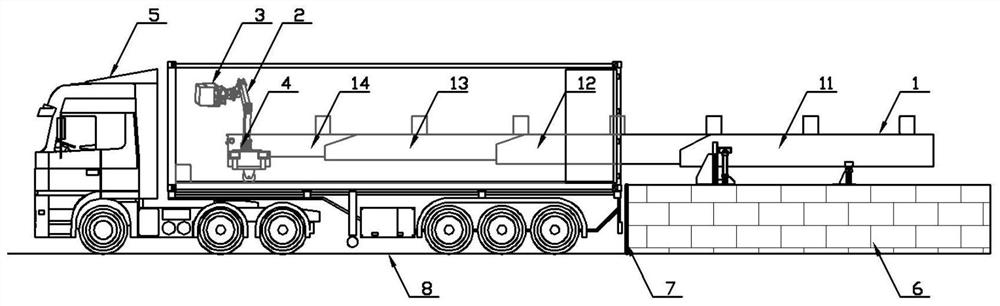

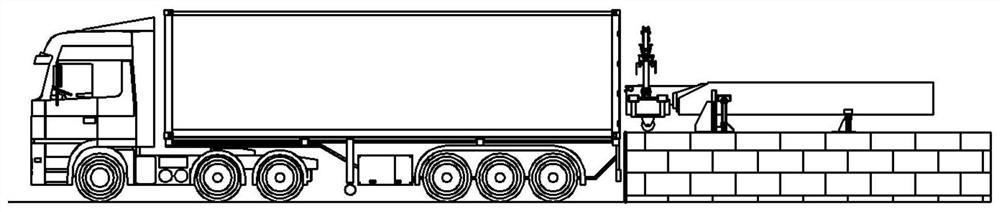

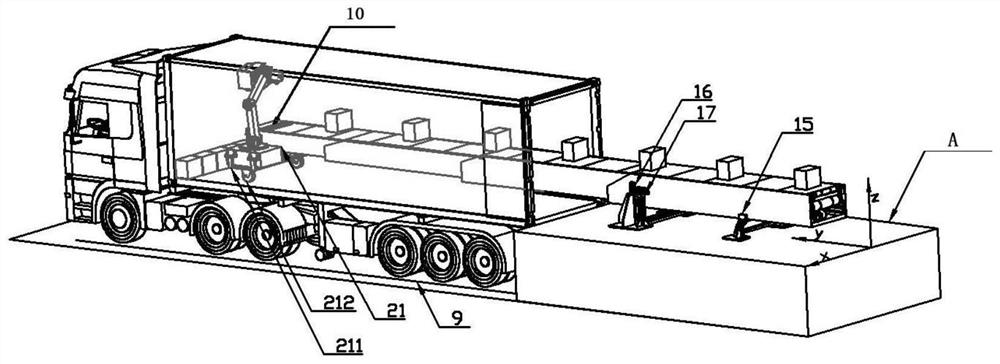

Device for van to automatically load and unload cargoes packaged in cartons

Owner:WUHAN YANCHENG TECH CO LTD

Large-dip-angle belt conveyor

Owner:TIDFORE HEAVY IND

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap