Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Paper sheet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

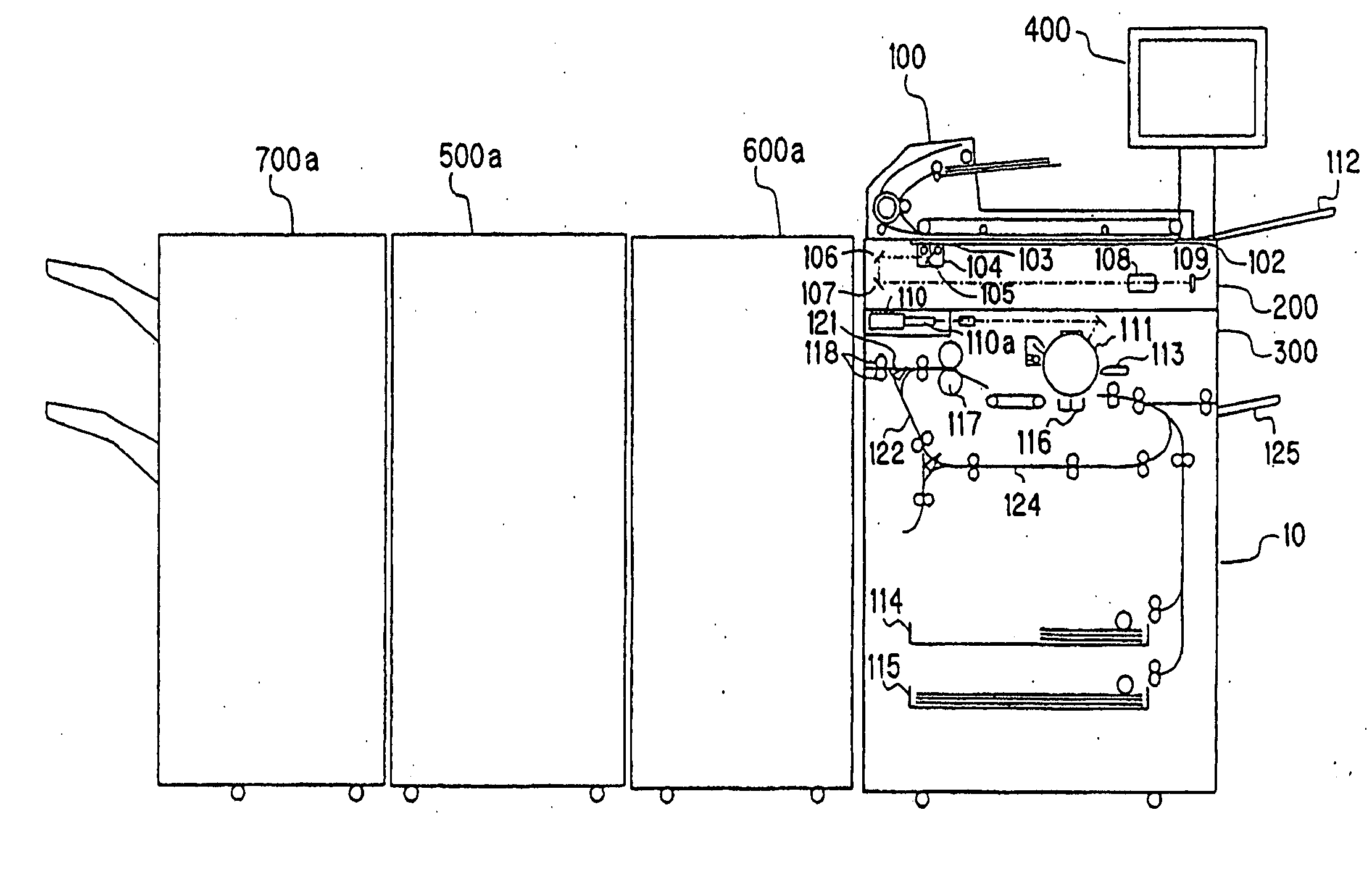

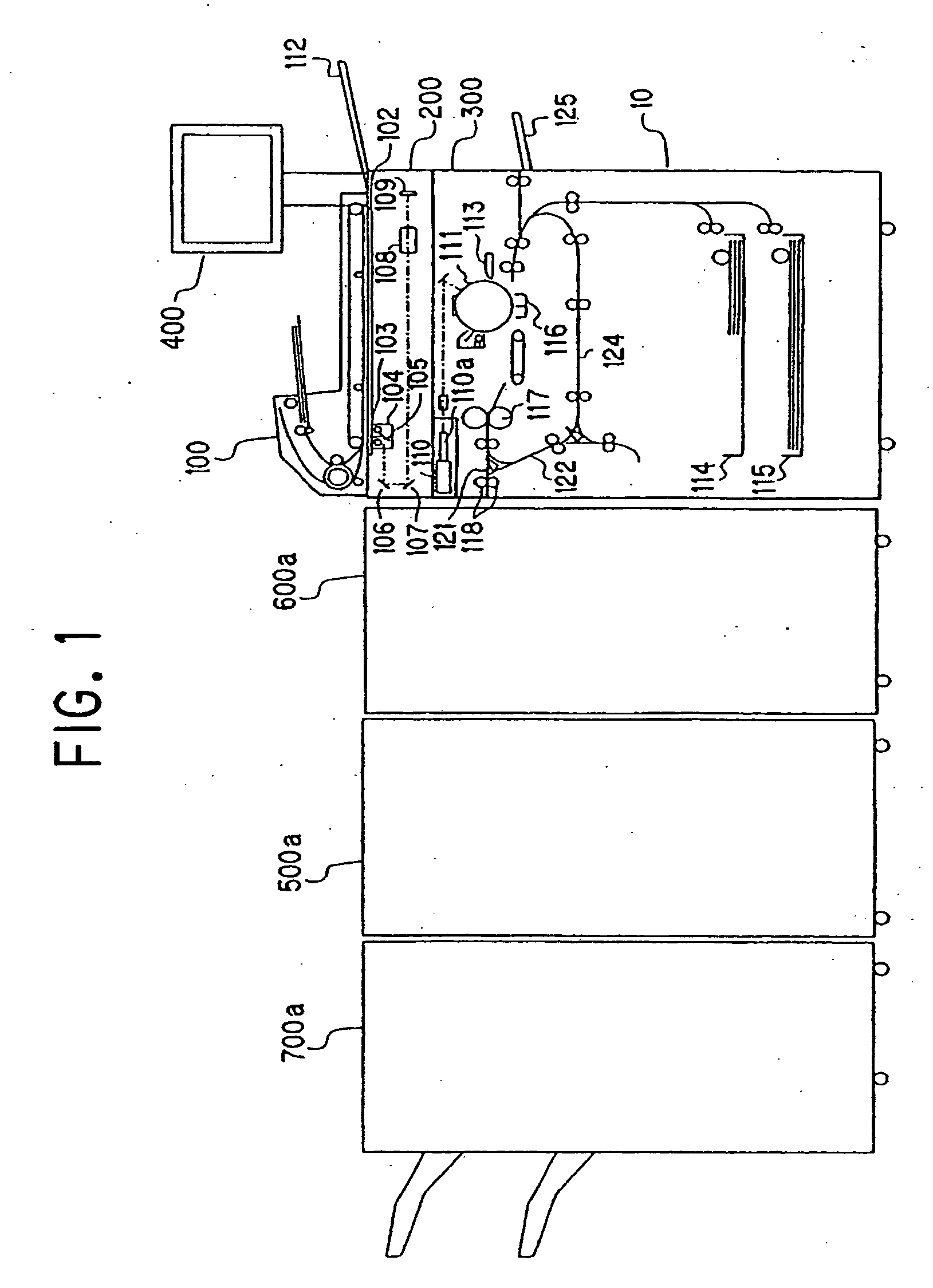

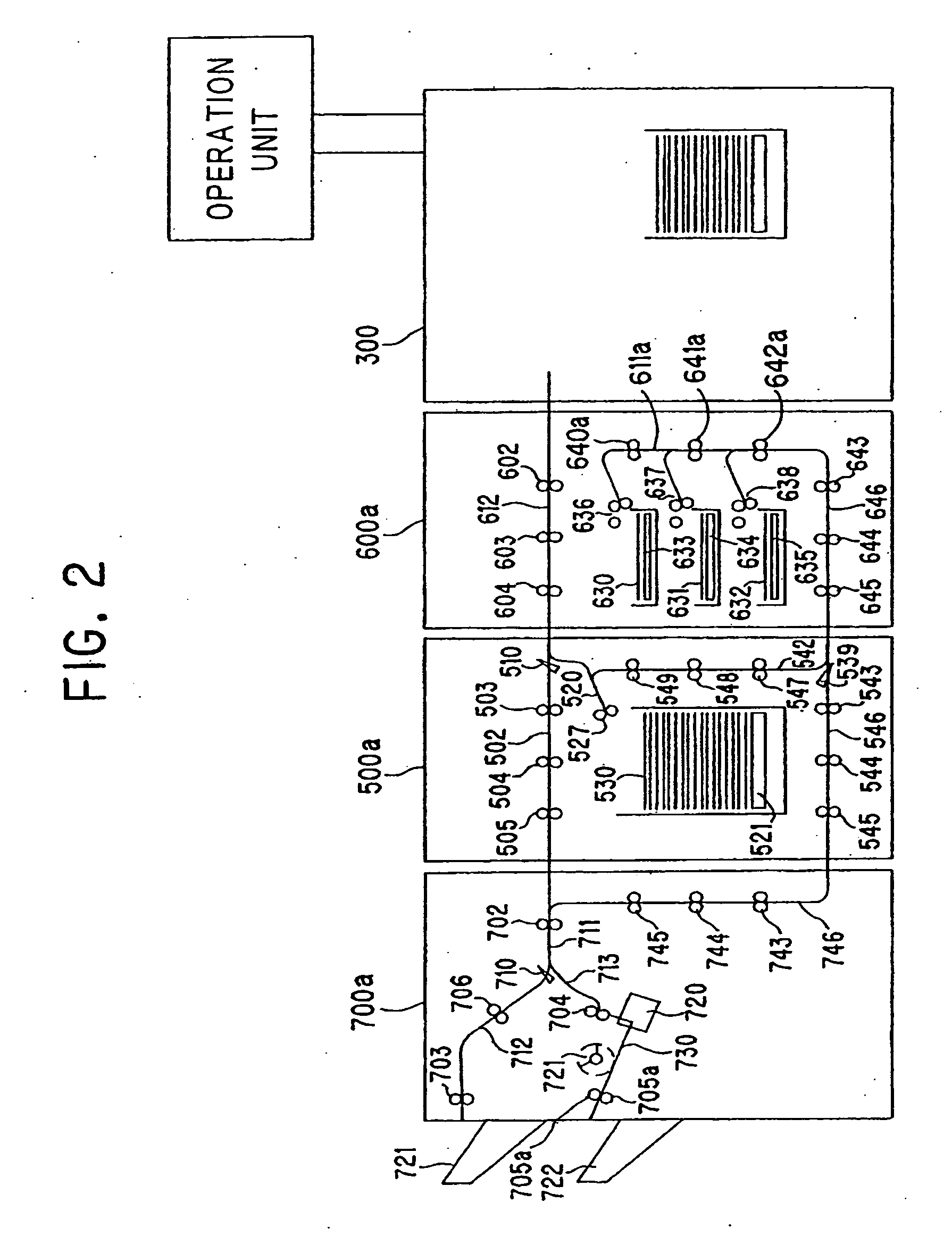

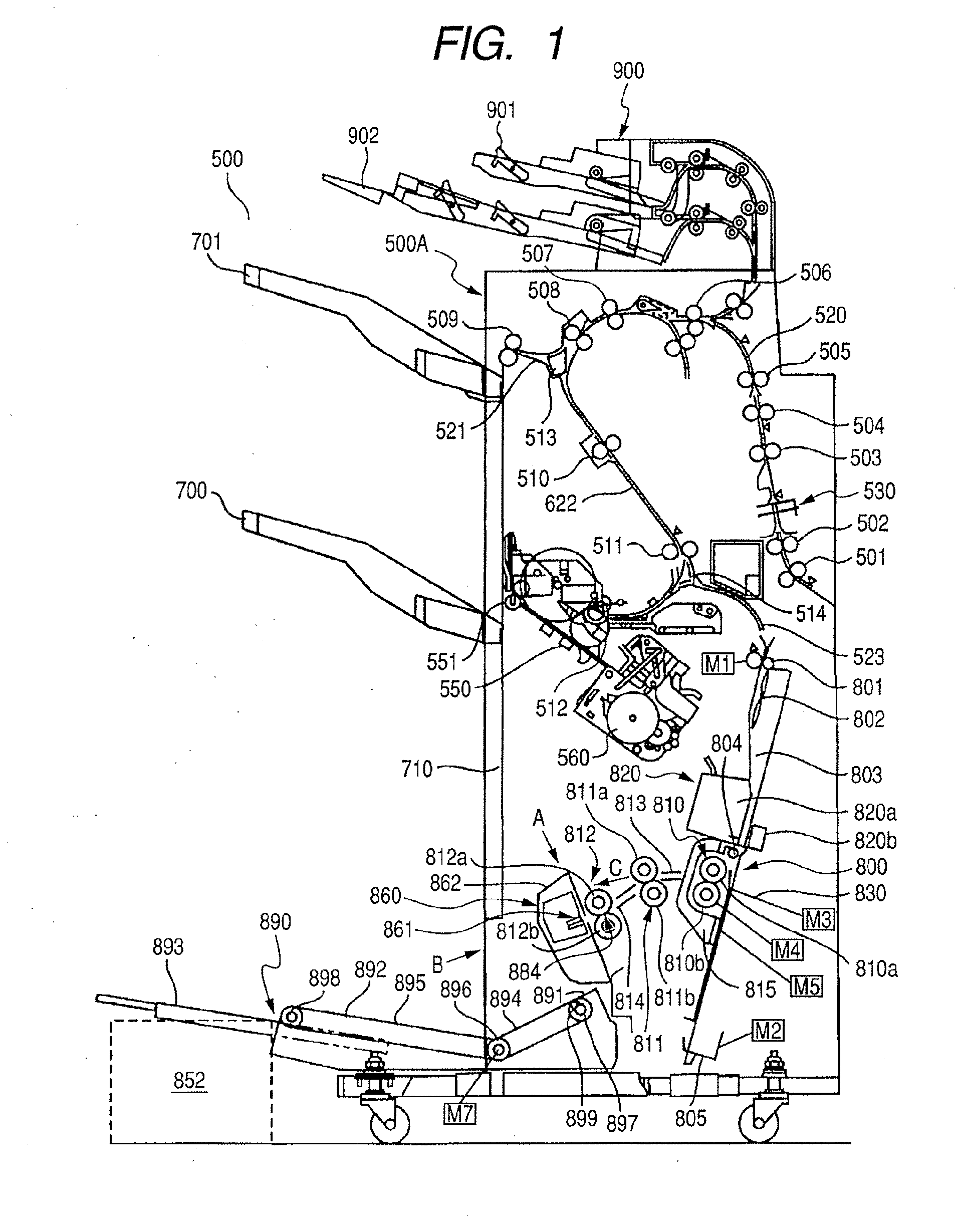

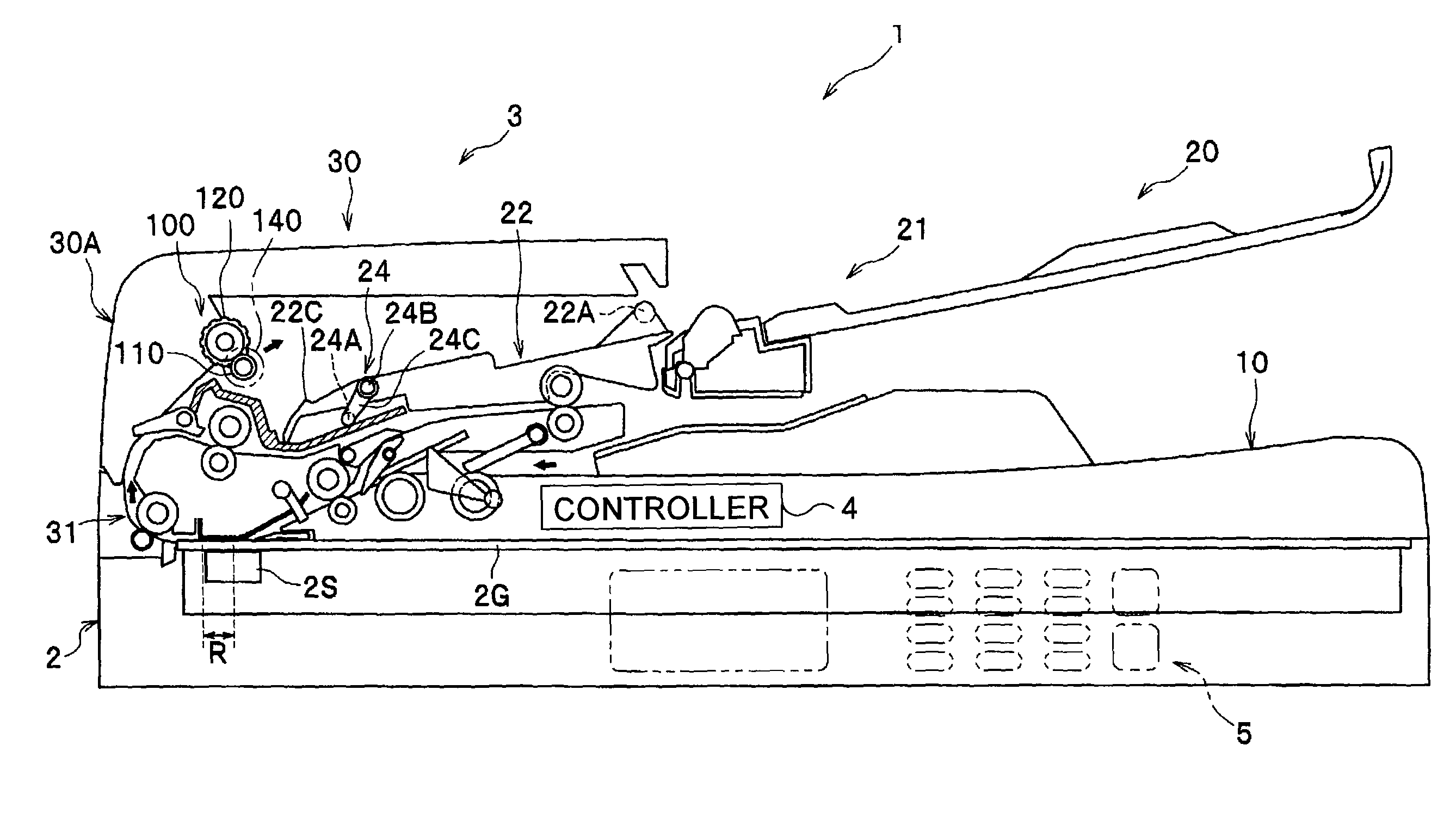

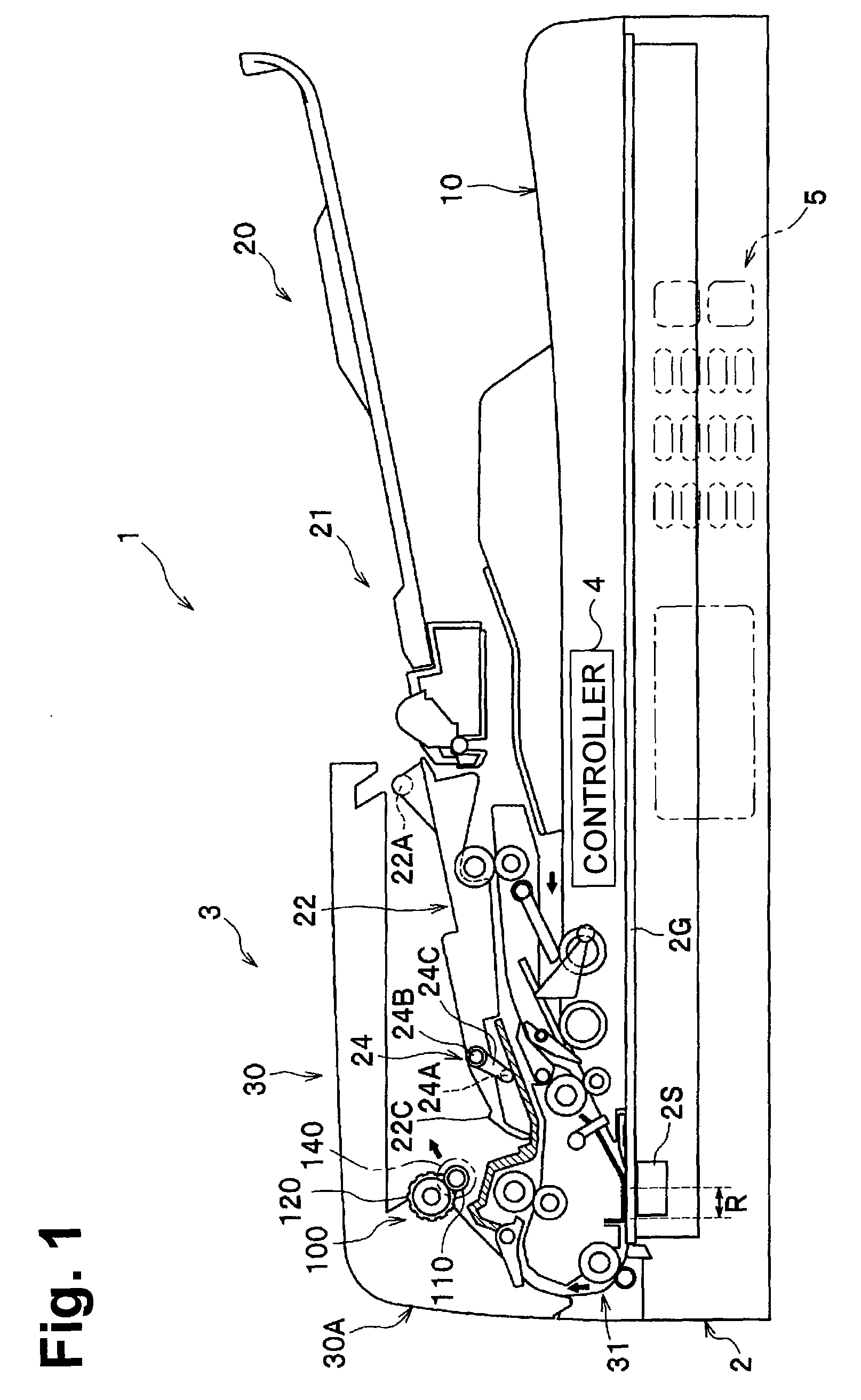

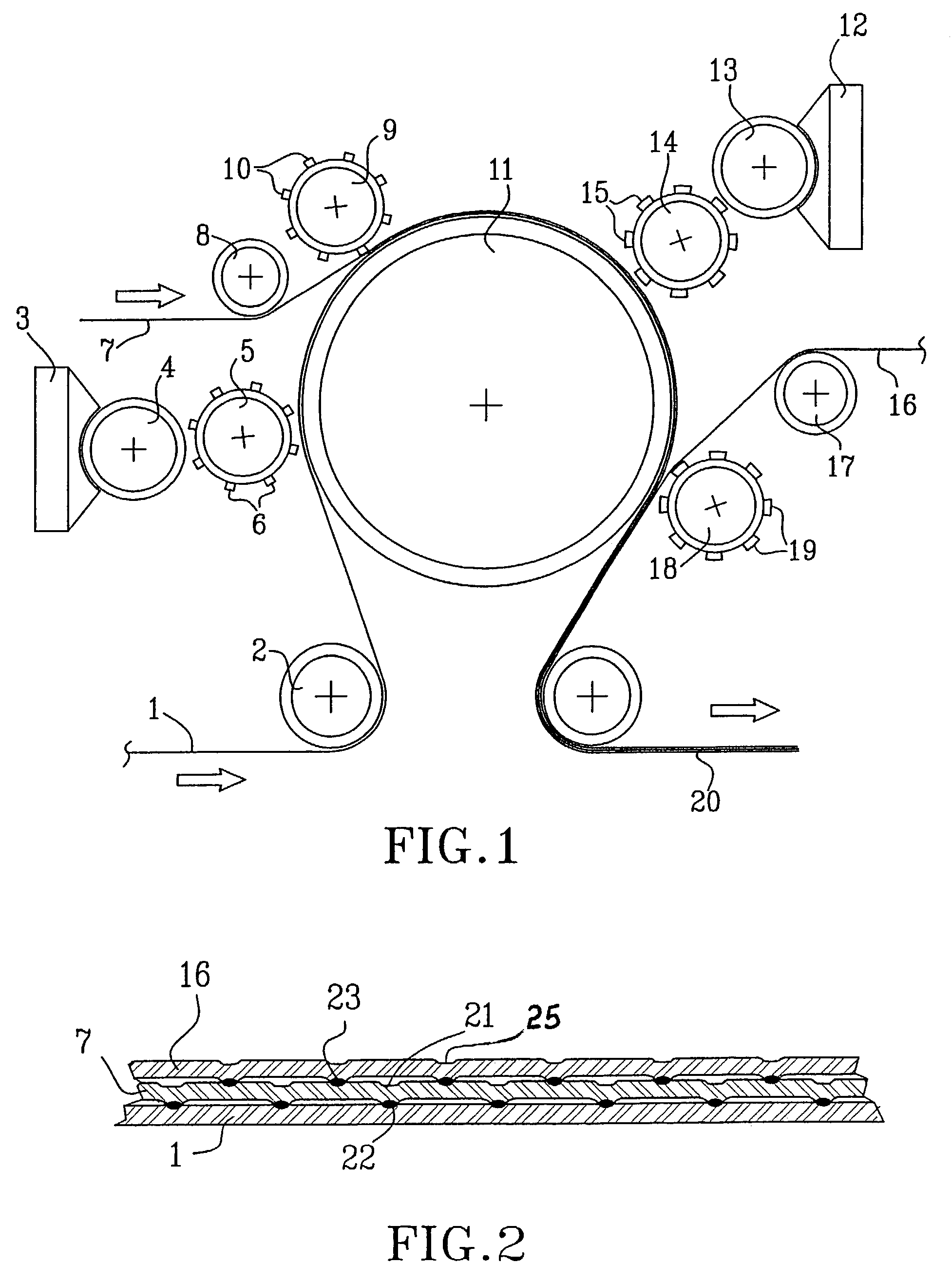

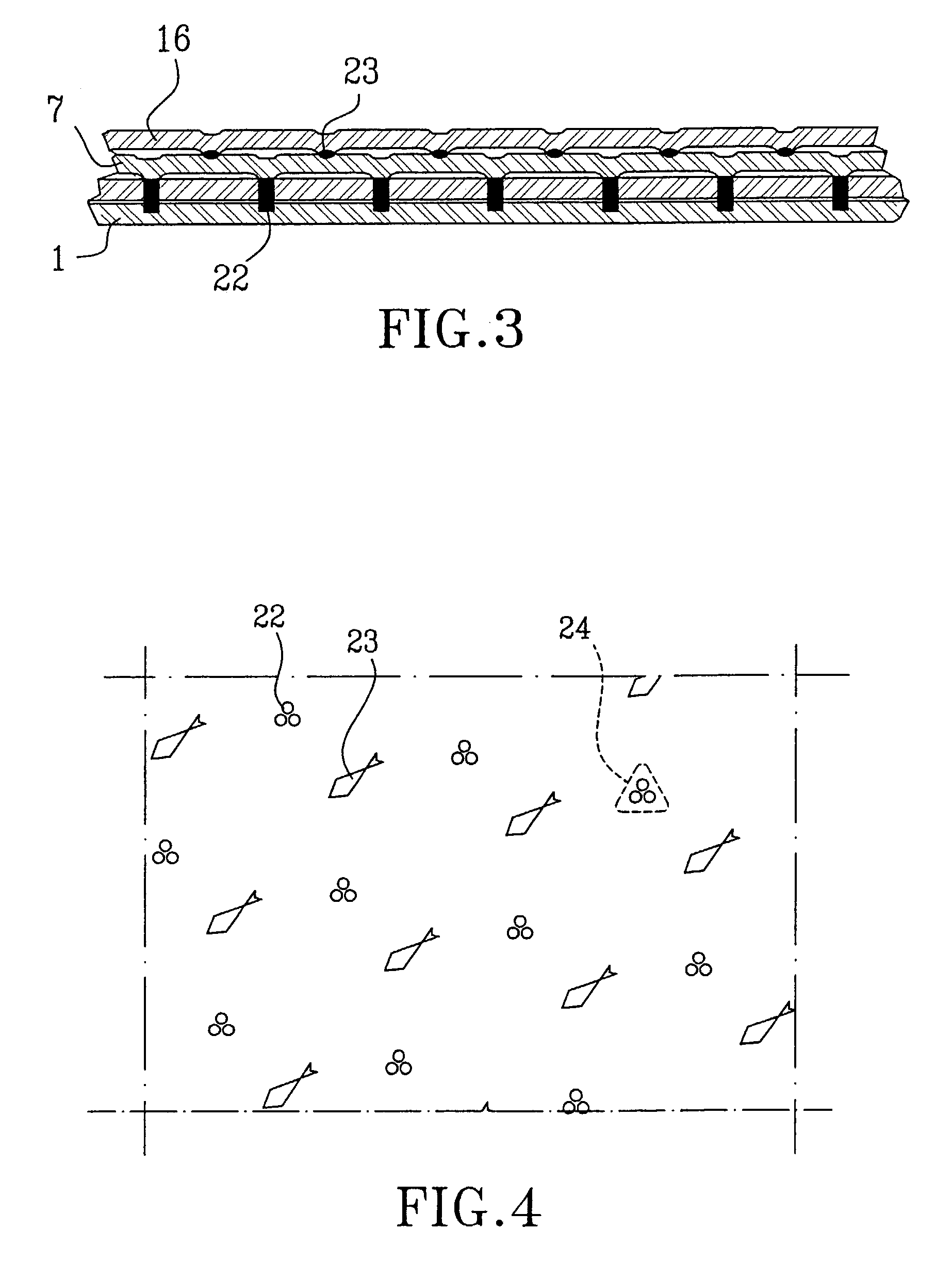

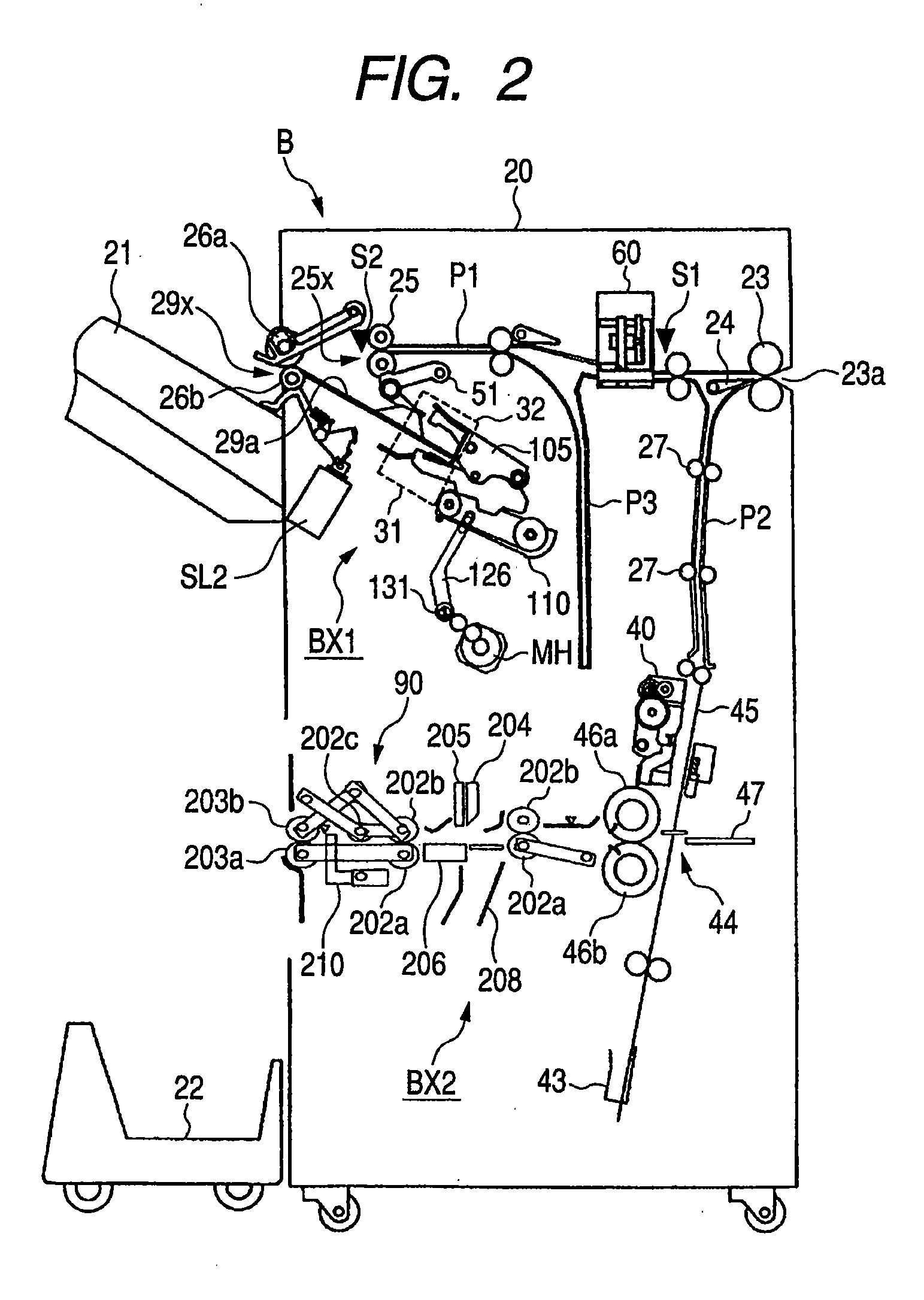

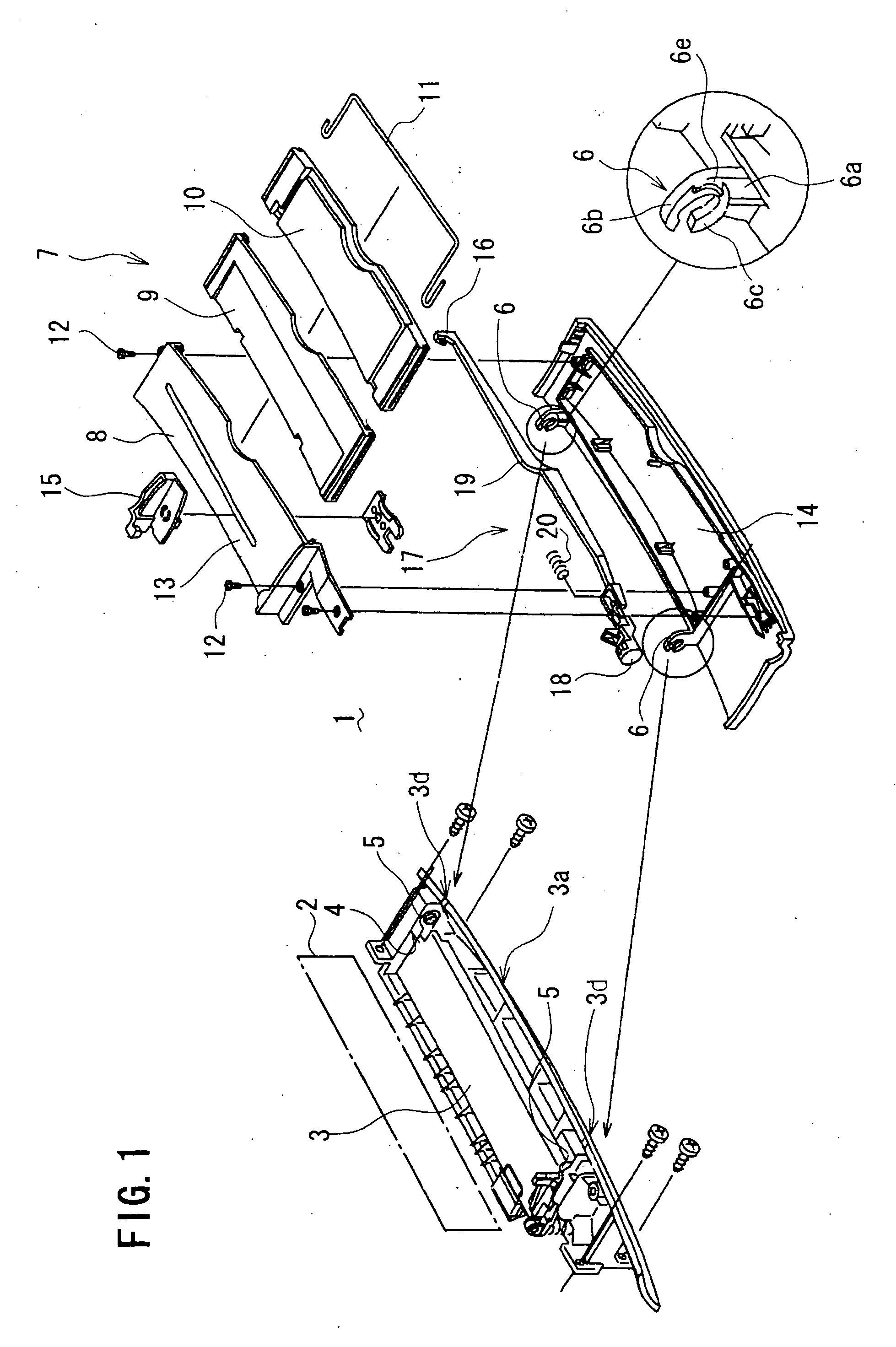

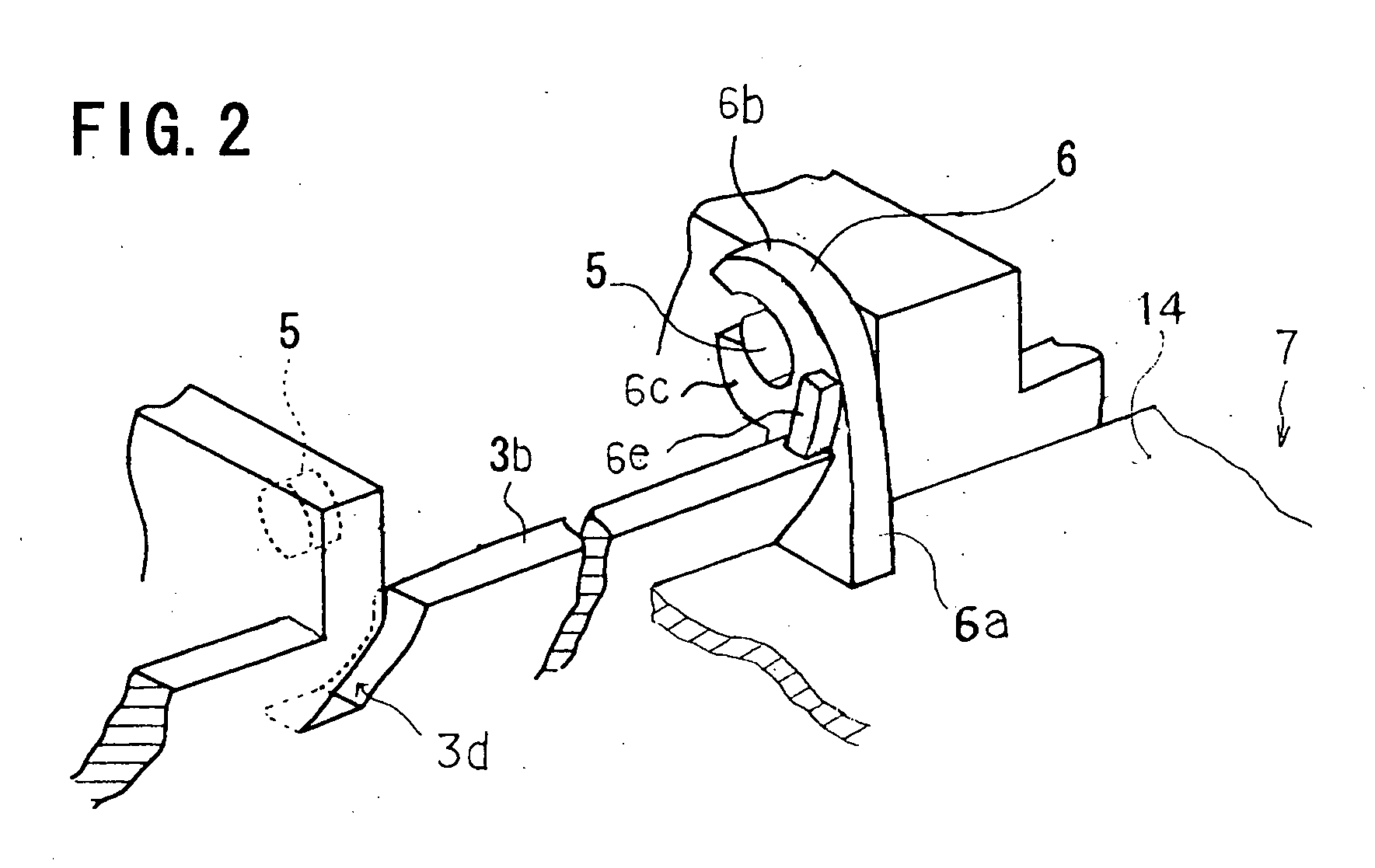

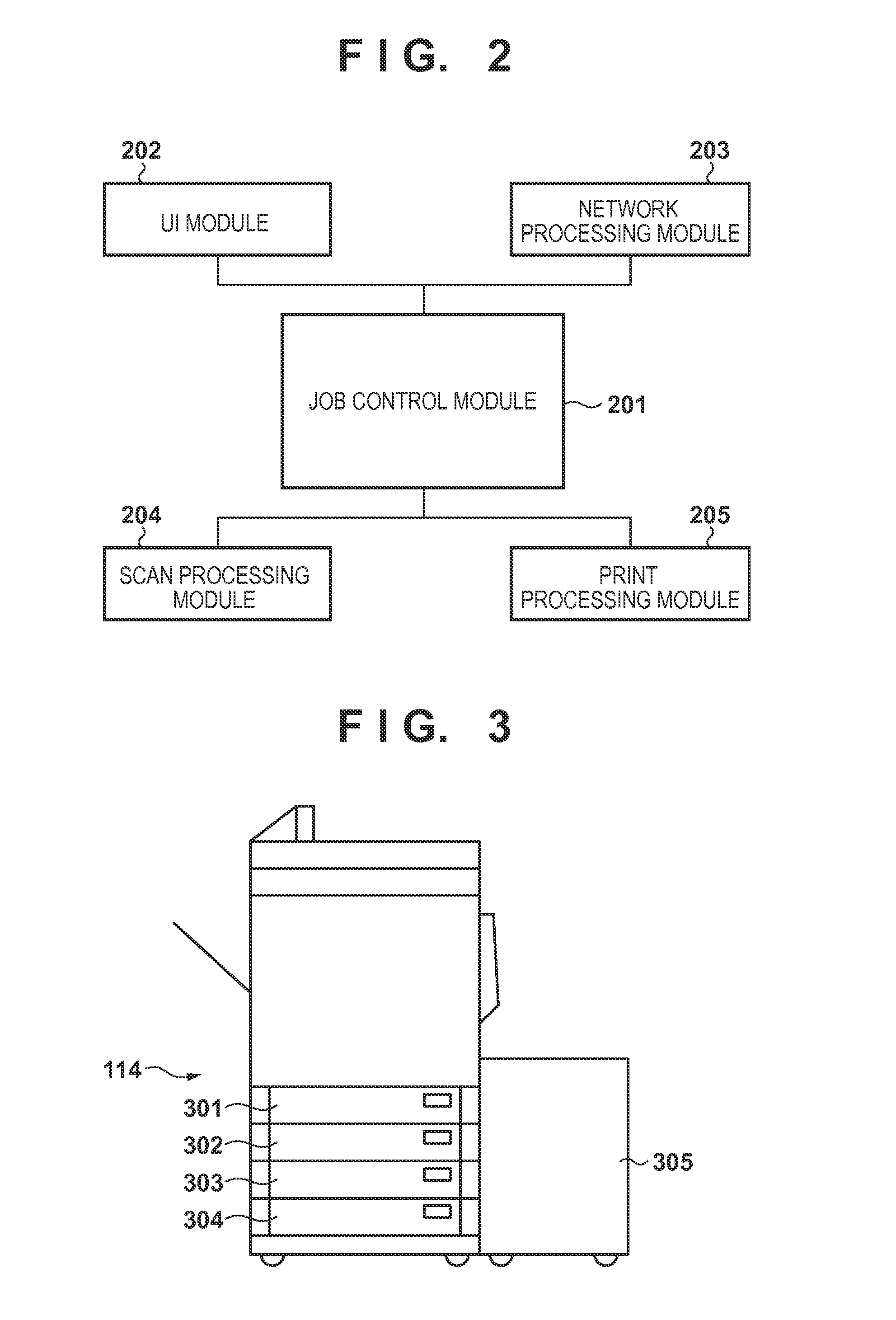

Sheet processing system

InactiveUS20050082735A1Improve productivityFunction indicatorsElectrographic process apparatusEngineeringPaper sheet

Owner:CANON KK

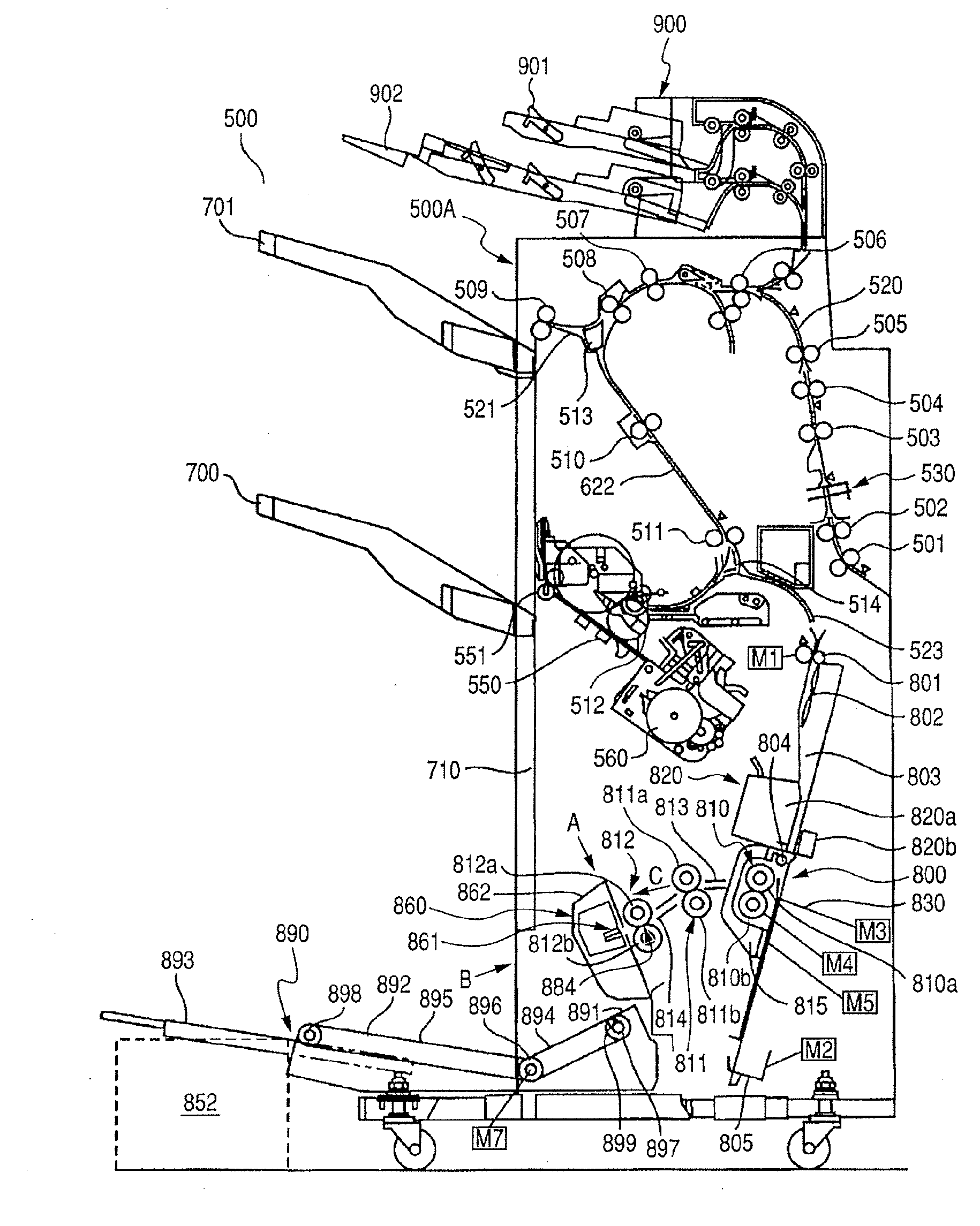

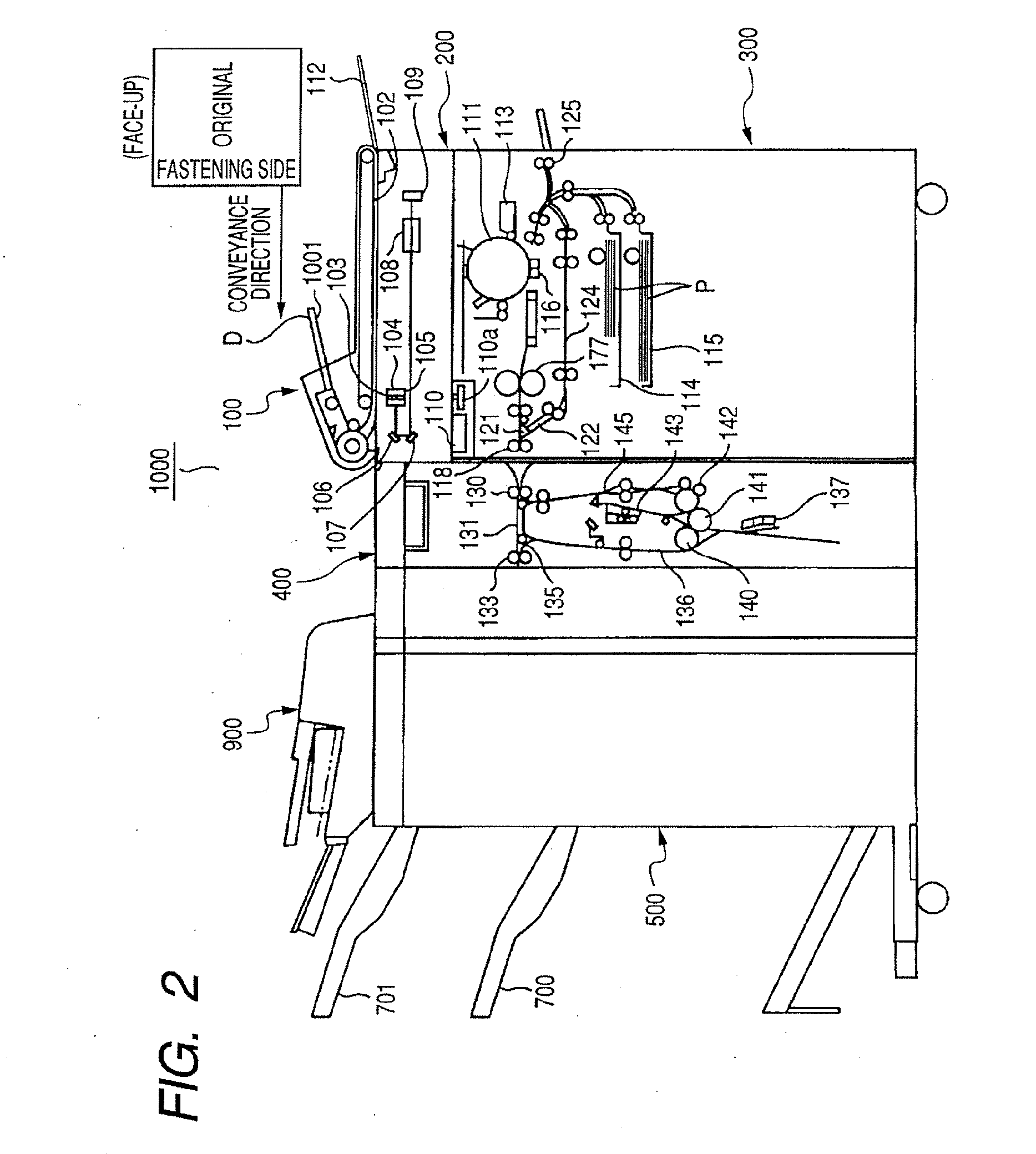

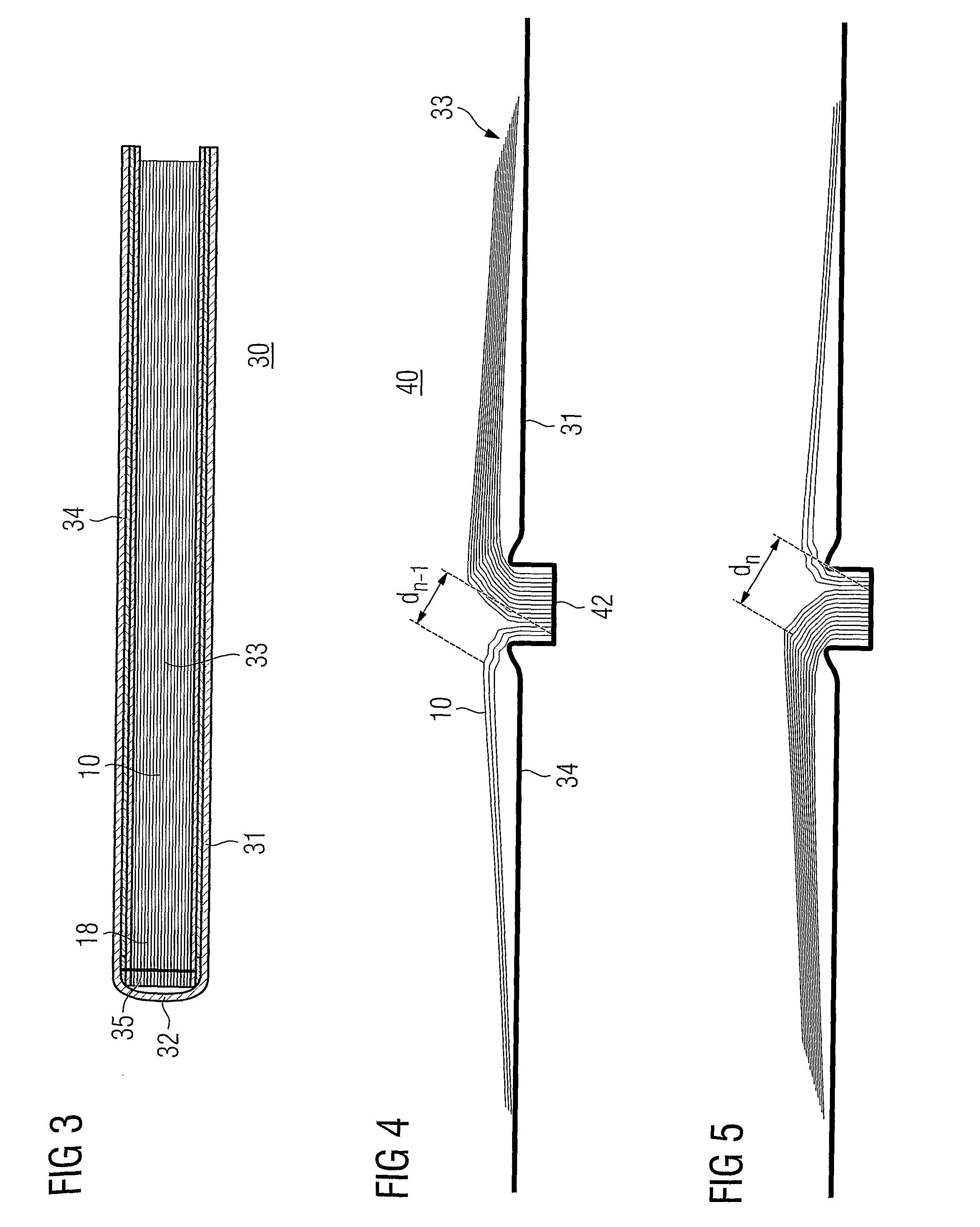

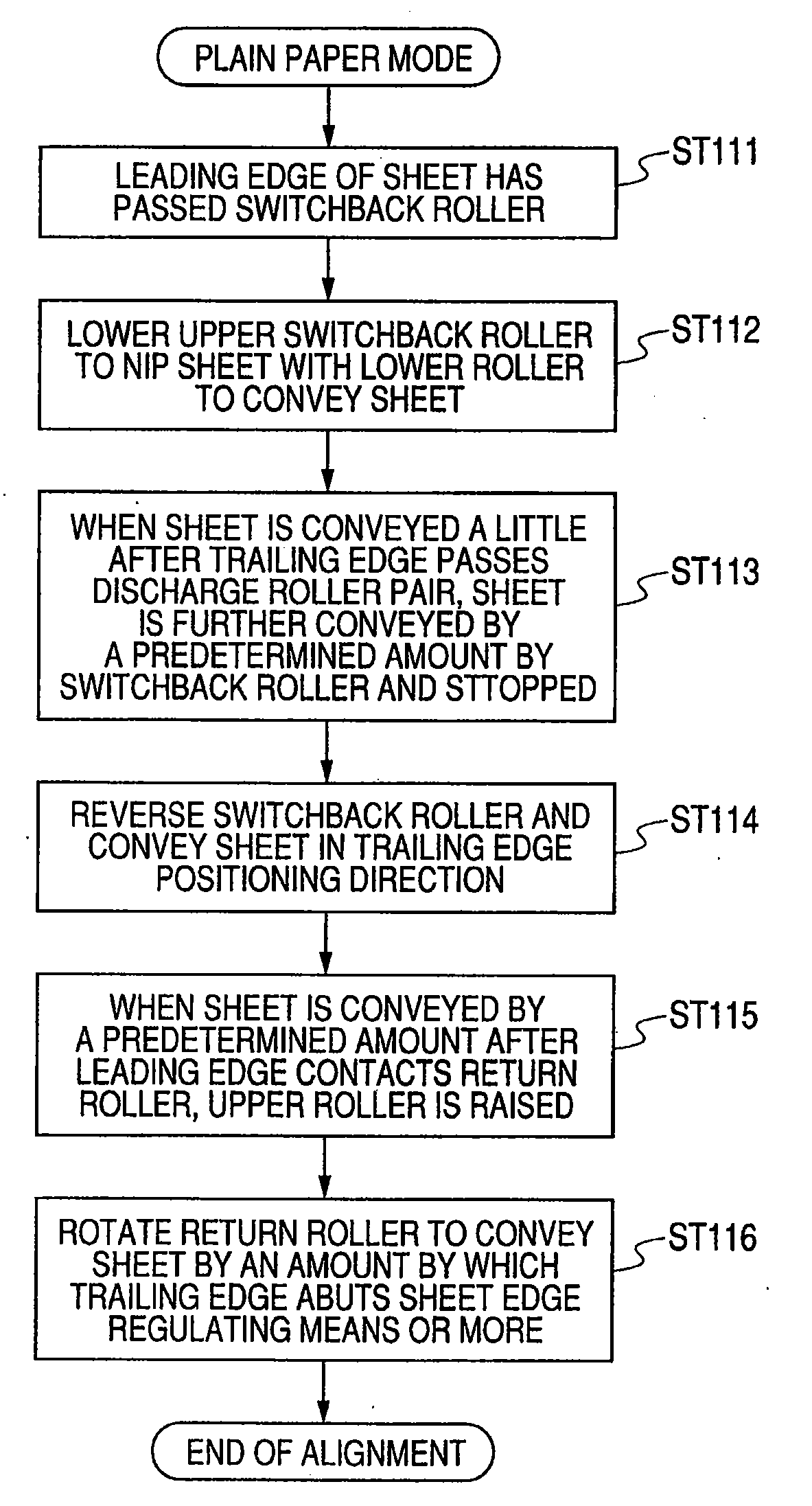

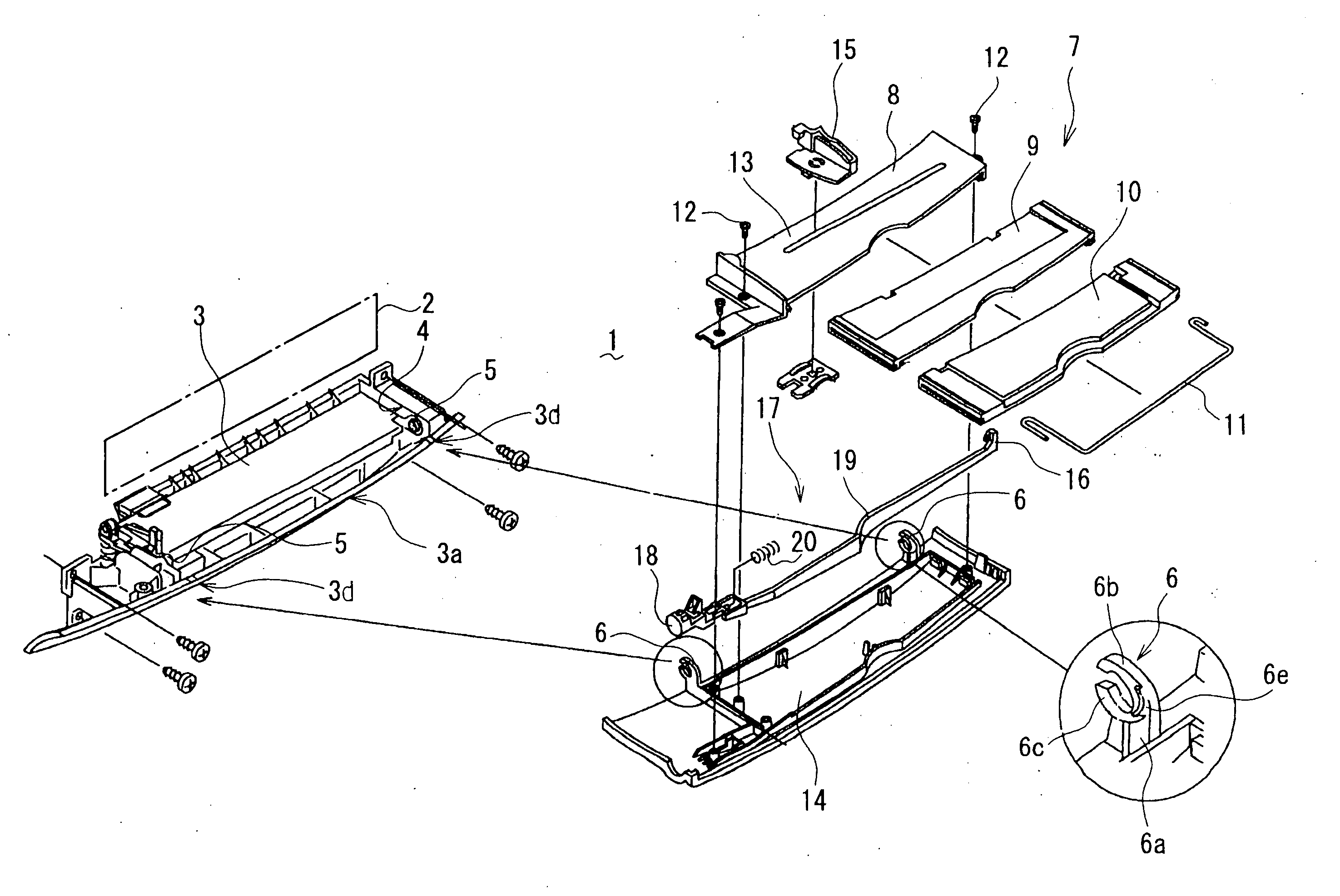

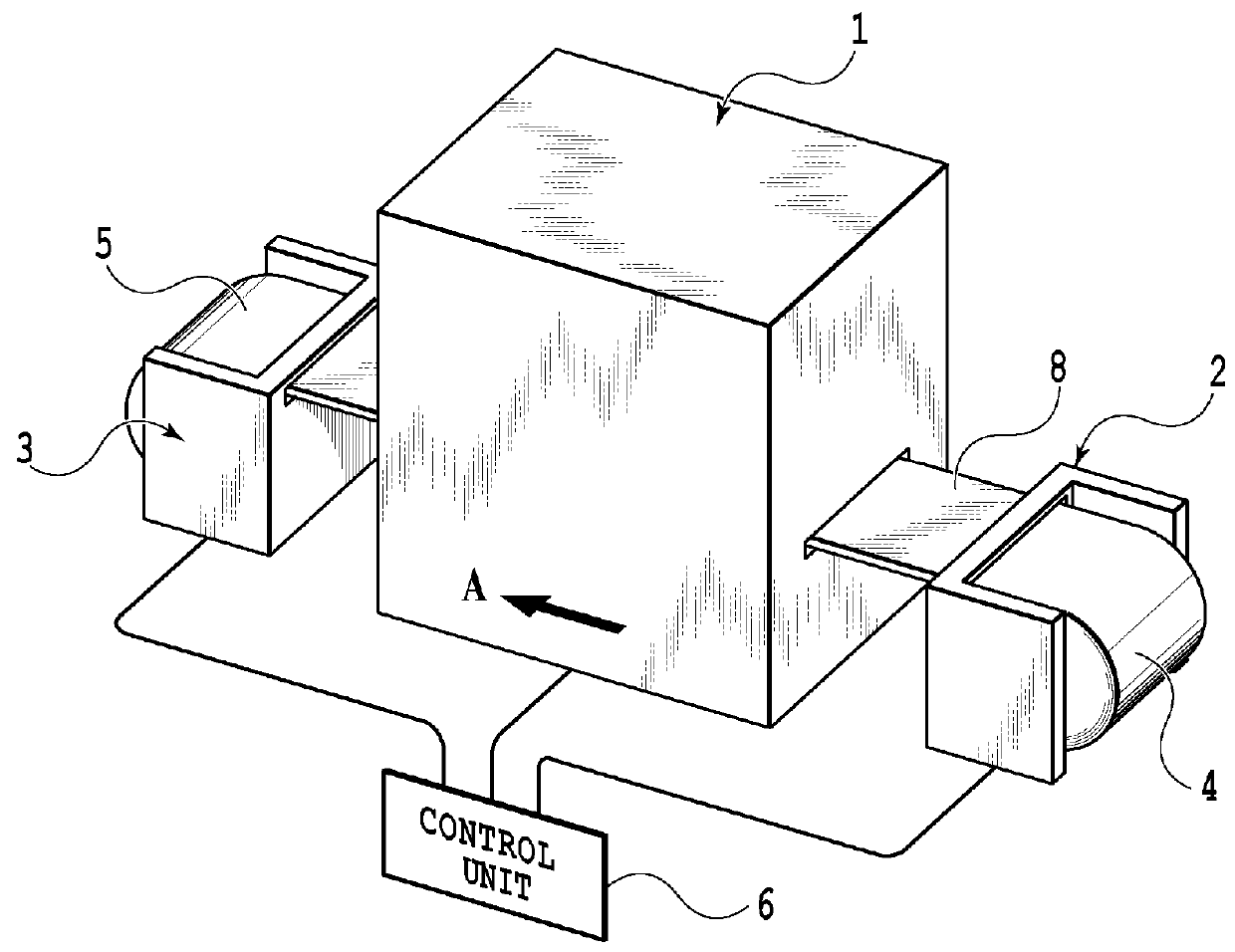

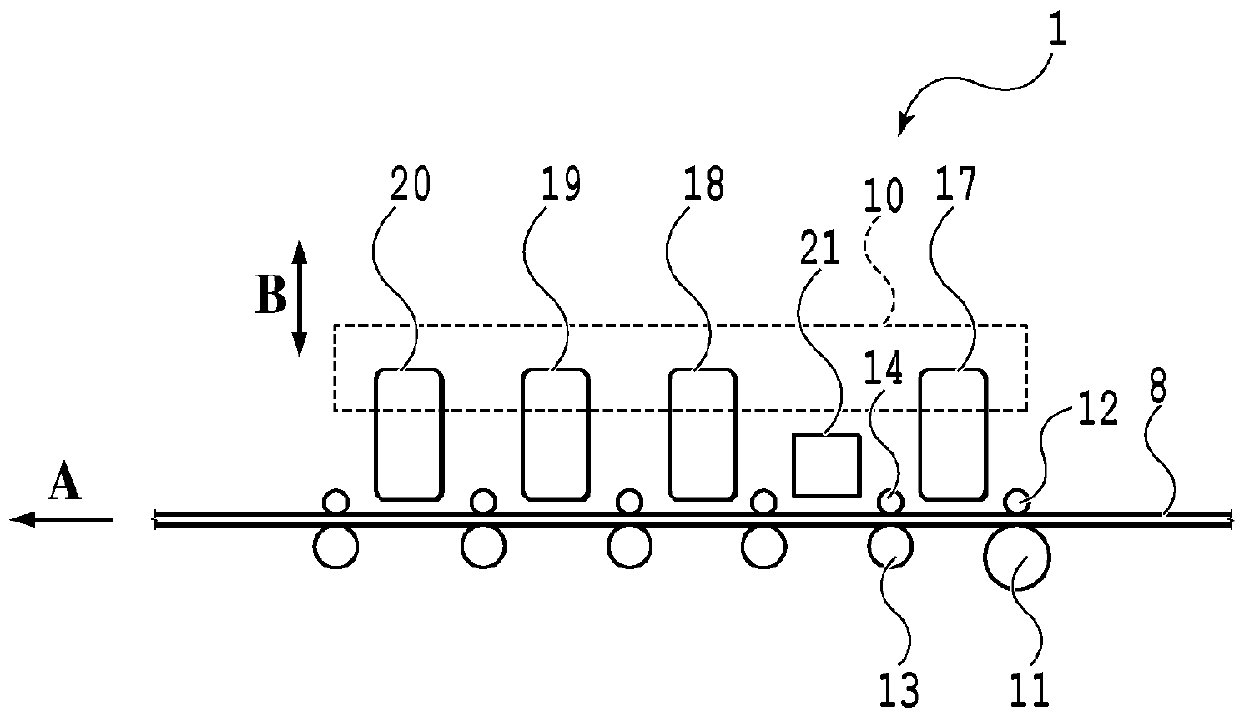

Sheet processing apparatus and image forming apparatus

ActiveUS20070045919A1Folding thin materialsElectrographic process apparatusLeading edgeImage formation

Owner:CANON KK

AKD emulsion and preparation method thereof

ActiveCN104499363AThe emulsification process is streamlinedLow impurity contentWater-repelling agents additionWaxStarch gelatinization

The invention discloses an AKD emulsion and a preparation method thereof. According to the preparation method of the AKD emulsion, as the process of starch gelatinization is saved, and AKD waxes and other raw materials are simultaneously added in the emulsification process, the operation is simple, and the consumed time is obviously shortened. According to the preparation method, equipment and manpower inputs are reduced, and the inventory of the raw materials are also reduced; in addition, as the prepared emulsified product can be used while being produced, the aging rate of paper leaving the machine is high, the hydrolysis degree of the AKD is greatly lowered, the sizing effect is ensured, and the economical benefit is obvious.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

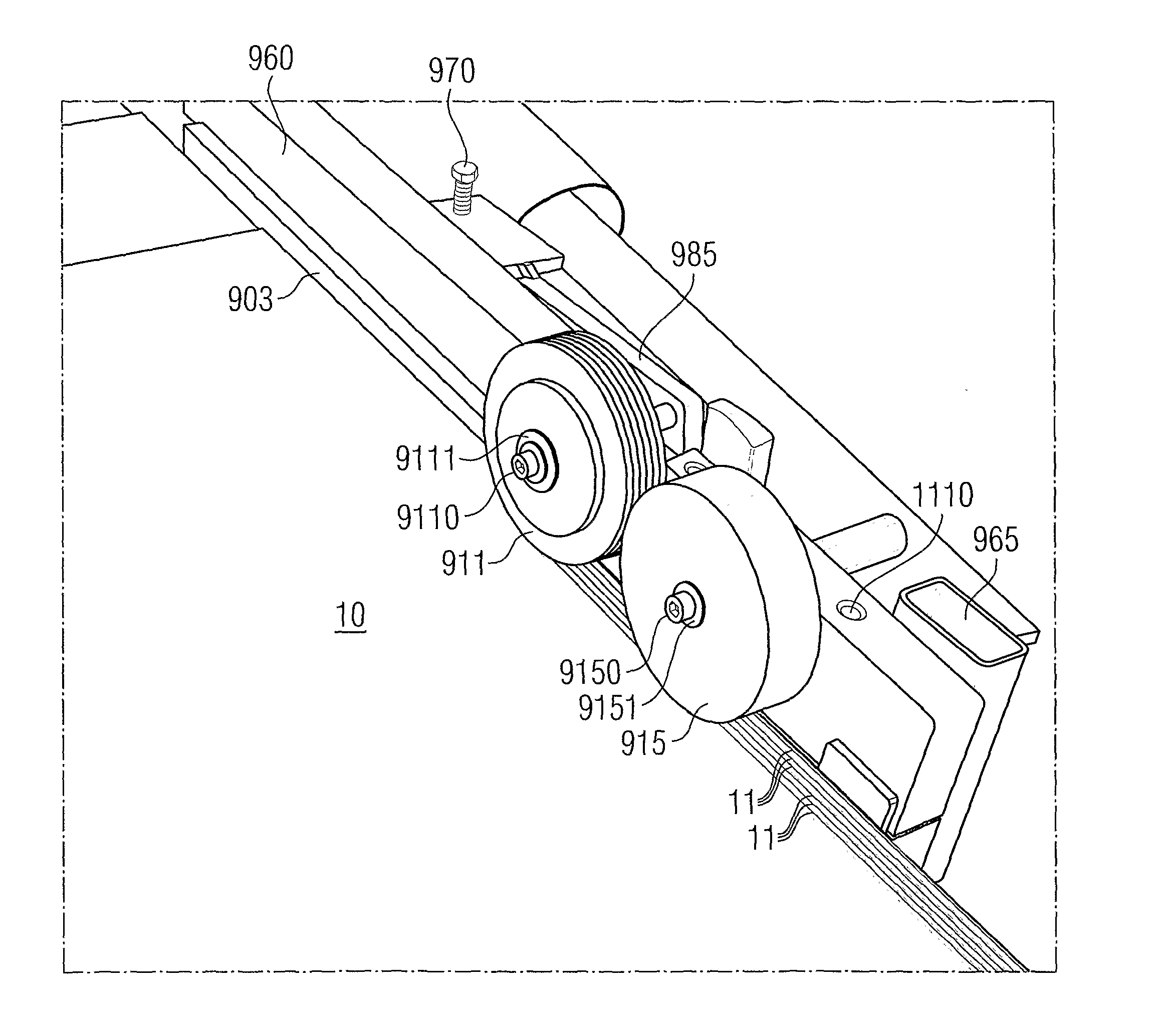

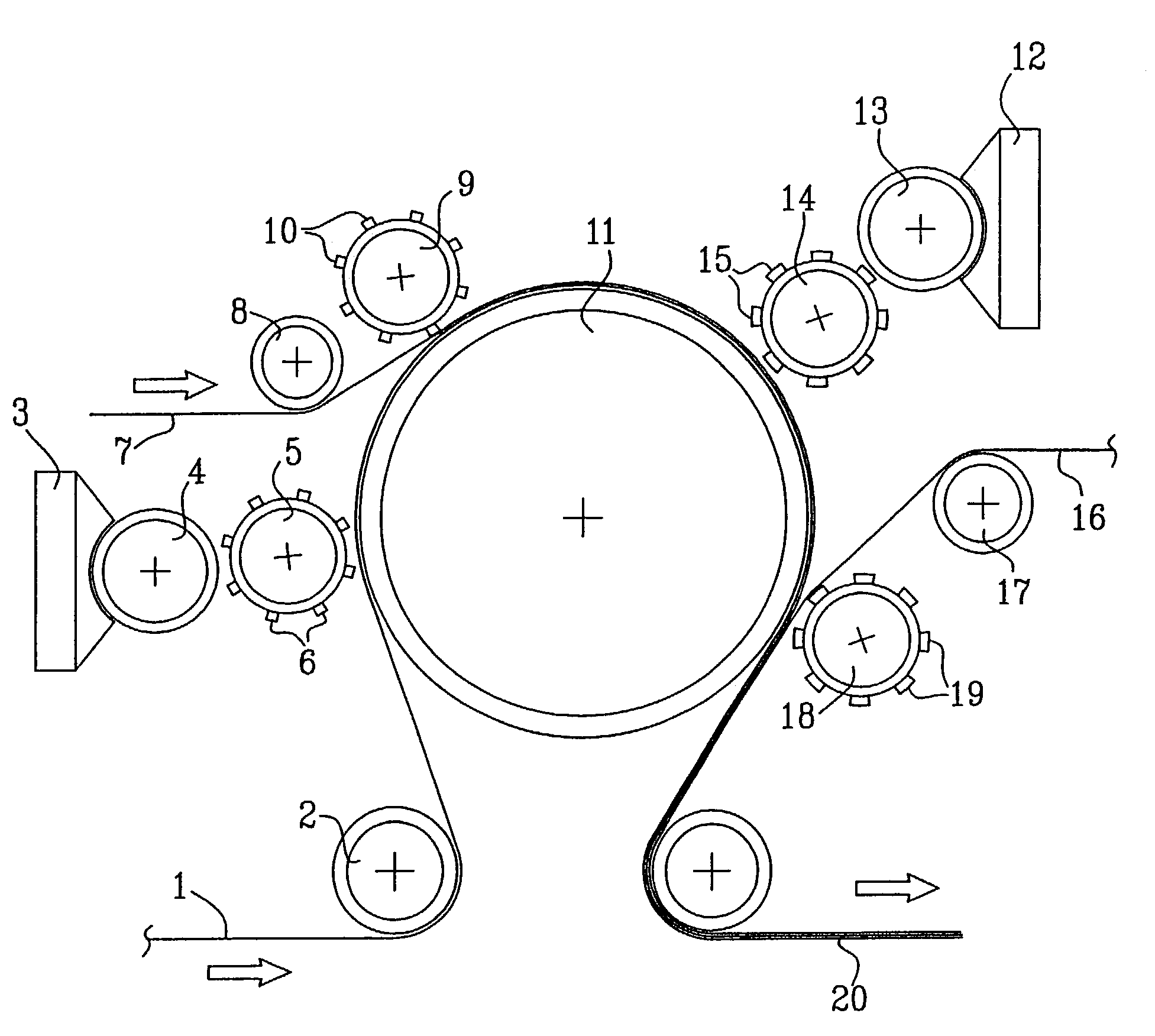

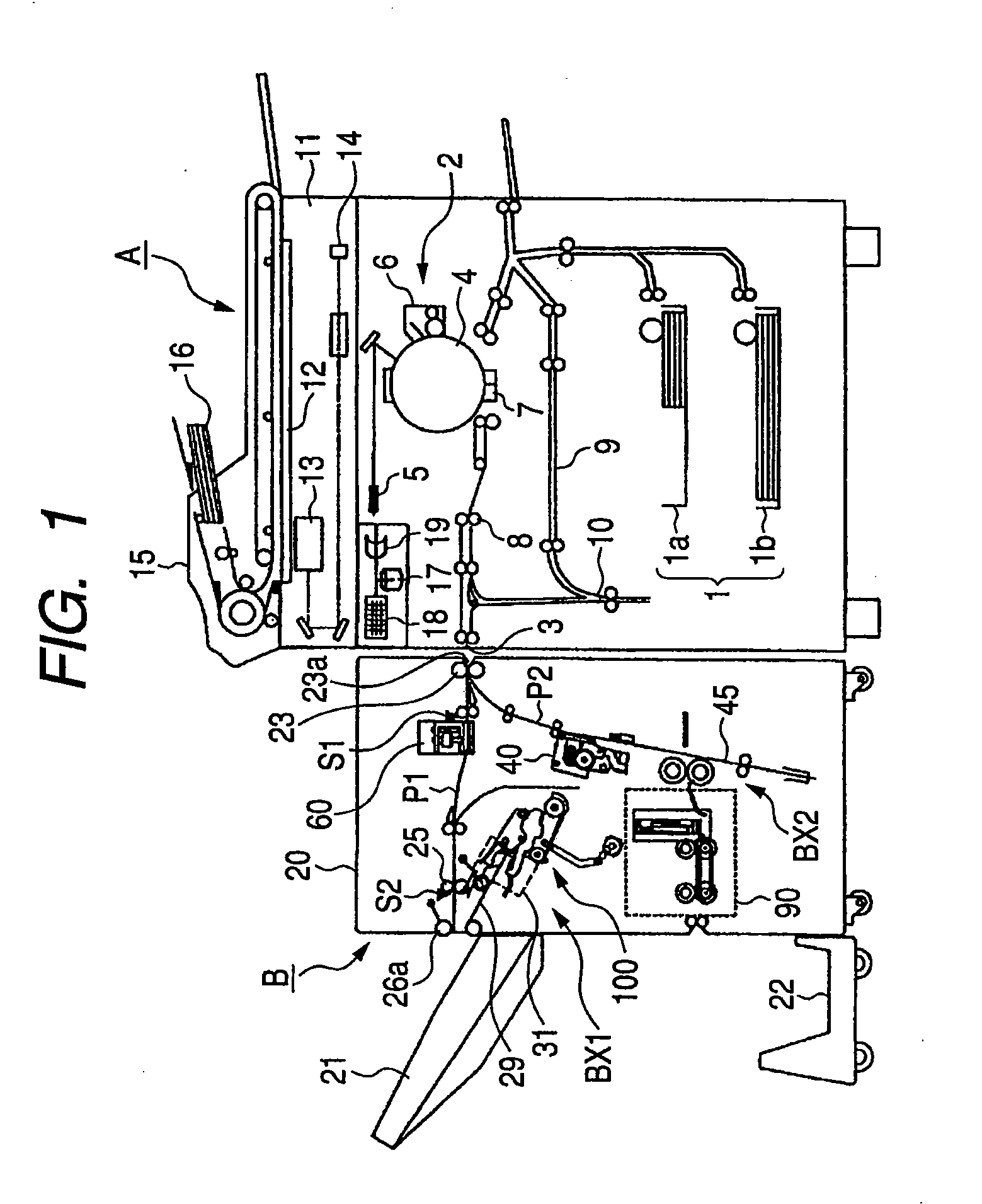

Sheet Output Device and Original Sheet Transporting Device

ActiveUS20100244357A1Improve performanceElectrographic process apparatusPile receiversPaper sheetEngineering

Owner:BROTHER KOGYO KK

Corrugating linerboard, corrugated board, and methods of making the same

A method of making a corrugating linerboard includes supplying a web of coated linerboard having a first side, a second side and a thickness defined by a distance between the first side and the second side, the first side being coated with a moisture-repellant material; and impregnating the coated linerboard with a hydrophobic material from the second side such that the hydrophobic material penetrates into the thickness of the coated linerboard.

Owner:GEORGIA PACIFIC CORRUGATED

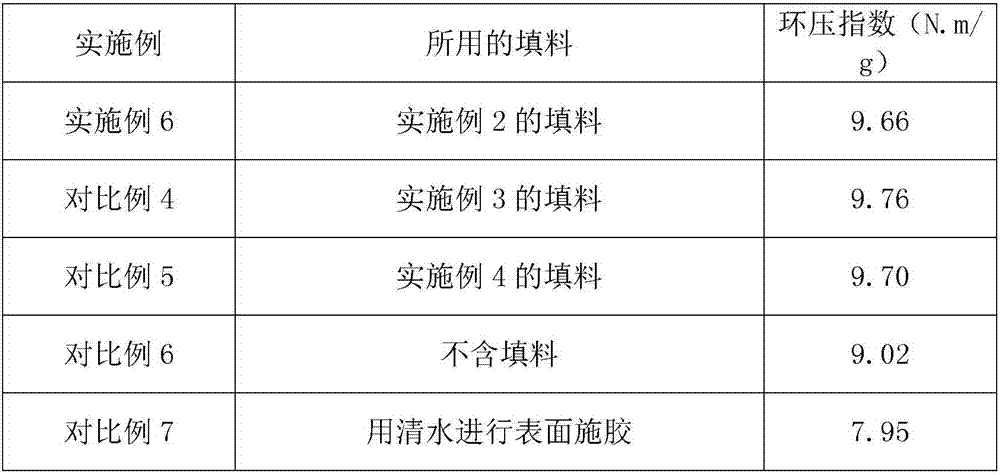

Paper making method with pulp and product of high-surface-intensity offset printing paper

ActiveCN103526630AImprove retentionHigh strengthWater-repelling agents additionInorganic compound additionCalcium silicateFiber

The invention discloses a paper making method with pulp and a product of high-surface-intensity offset printing paper. The paper making method with the pulp comprises the steps that (1) multi-hole calcium silicate and mixed wood pulp fibers are subjected to mixing pulping, mixed pulp is obtained; (2) retention and drainage agents A, sizing agents and retention and drainage agents B are added into the mixed pulp in sequence, even stirring is carried out, papermaking pulp is obtained; (3) the papermaking pulp is subjected to papermaking, squeezing and drying, body paper is obtained; (4) surface sizing agents are used for carrying out surface sizing on the body paper, and the offset printing paper is obtained. The multi-hole calcium silicate is used as the papermaking padding, during a papermaking process, paper pulp / padding medium-high-concentration mixing pulping, CS / CPAM double-element retention and surface sizing agent formula improving and other measures are used, the padding retention rate is improved, paper intensity is effectively improved, and the waterproof performance, the oil resistance, the paper surface intensity, the tensile strength and other performance indexes of paper are obviously improved.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Method for manufacturing holographic aluminized paper material

InactiveCN101725077AWith molded holographic propertiesShort stayCoated paper substrateCoatingsWater basedPaper based

Owner:GUANGDONG MAGNOLIA PACKING MACHINERY

Method for producing a multi-ply web of flexible material, such as paper and nonwoven, and multi-ply material produced by the method

Owner:SCA HYGIENE PROD AB

Sheet processing apparatus

Owner:COPYER

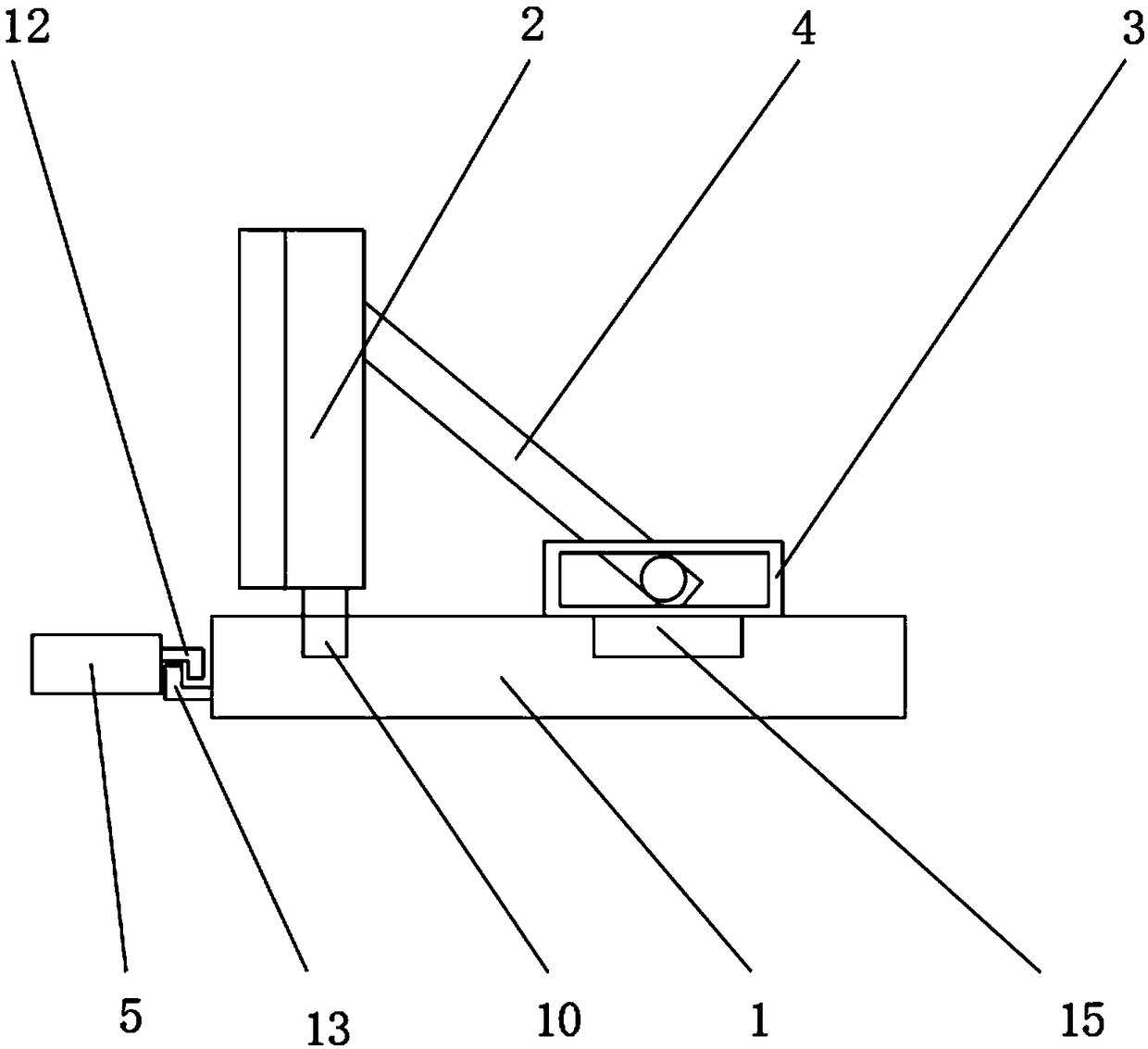

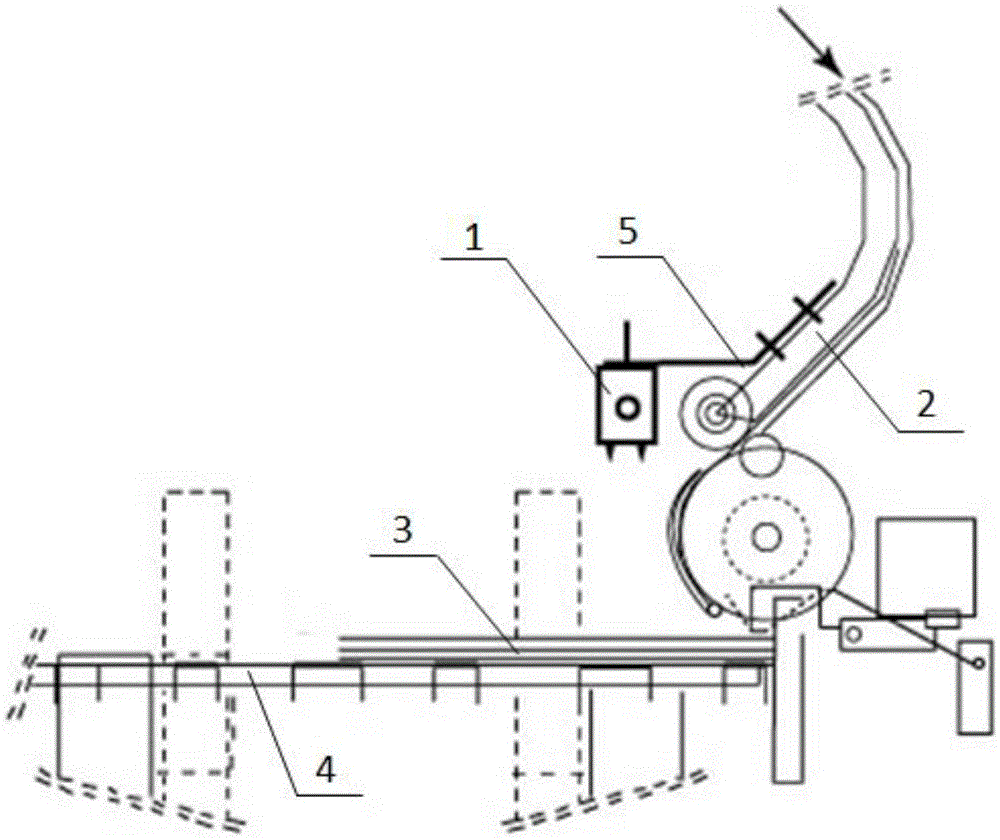

Heat transfer printing printer

ActiveCN106926588AAvoid wastingReduce printing costsOther printing apparatusSeparated statePaper tape

A heat transfer printing printer comprises a machine base, a printing rubber roller, a printing head bracket, a printing head, a thermal transfer ribbon mechanism, a paper supplying trough, a paper dividing mechanism and a paper feeding mechanism. A lifting mechanism is additionally arranged, first fastening pieces are directly mounted on the power output end of the lifting mechanism, and the lifting mechanism drives the first fastening pieces to lift and drop, so that the printing head and the printing rubber roller are in a closed state or a separation state; meanwhile, a take-up gear and a drive gear are in a meshing state or a separation state; and in the separation state, winding of a thermal transfer ribbon is suspended, so that thermal transfer ribbon waste caused by thermal transfer ribbon empty winding at the time of printing blank data is avoided, the thermal transfer ribbon is saved by a large margin, and printing cost is reduced. Limit partition boards and limit adjustment mechanisms are arranged on the two sides of a paper feeding belt and paper feeding pinch rollers, when the printing head is locally damaged and needs to change the printing position, the positions of the limit partition boards are changed by adjusting the limit adjustment mechanisms of the corresponding limit partition boards, so that the printing head can still print normally under the condition of local damage, and the printing cost is reduced.

Owner:SHANTOU HIGH TECH ZONE JUSHENG TECH CO LTD

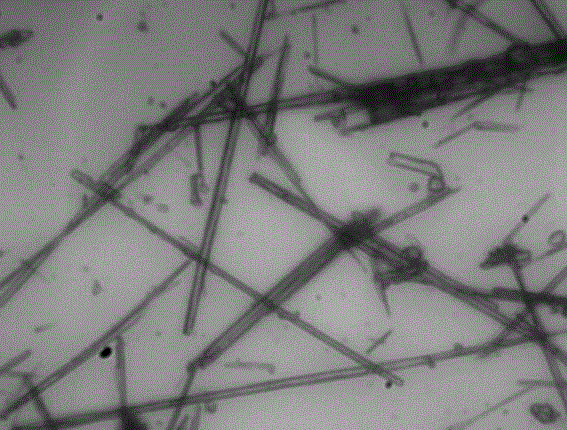

Method for modifying calcium sulphate whisker surface

InactiveCN104651945AExcellent physical and chemical propertiesLow costAfter-treatment detailsInorganic compound additionPaper sheetSodium aluminate

The invention discloses a method for modifying a calcium sulphate whisker surface. The method comprises the following steps: (1) adding a calcium sulphate whisker into deionized water, stirring, pouring the obtained calcium sulphate whisker solution into an ultrasonic dispersing instrument and oscillating, wherein the mass rate of the calcium sulphate whisker to the deionized water is 1:9; (2) adding sodium aluminate into the oscillated calcium sulphate whisker solution, and performing chemical coating reaction, wherein the mass rate of the sodium aluminate to the calcium sulphate whisker is 1:(10-100). The calcium sulphate whisker surface is subjected to modification treatment, and the modified calcium sulphate whisker is used as a stuffing in a paper-making process, so that the retention rate in the paper reaches the level of calcium carbonate stuffing, the physical and chemical performances of the obtained paper are excellent, and the influence on popularization and application of the calcium sulfate whisker in the paper-making industry can be avoided.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD +1

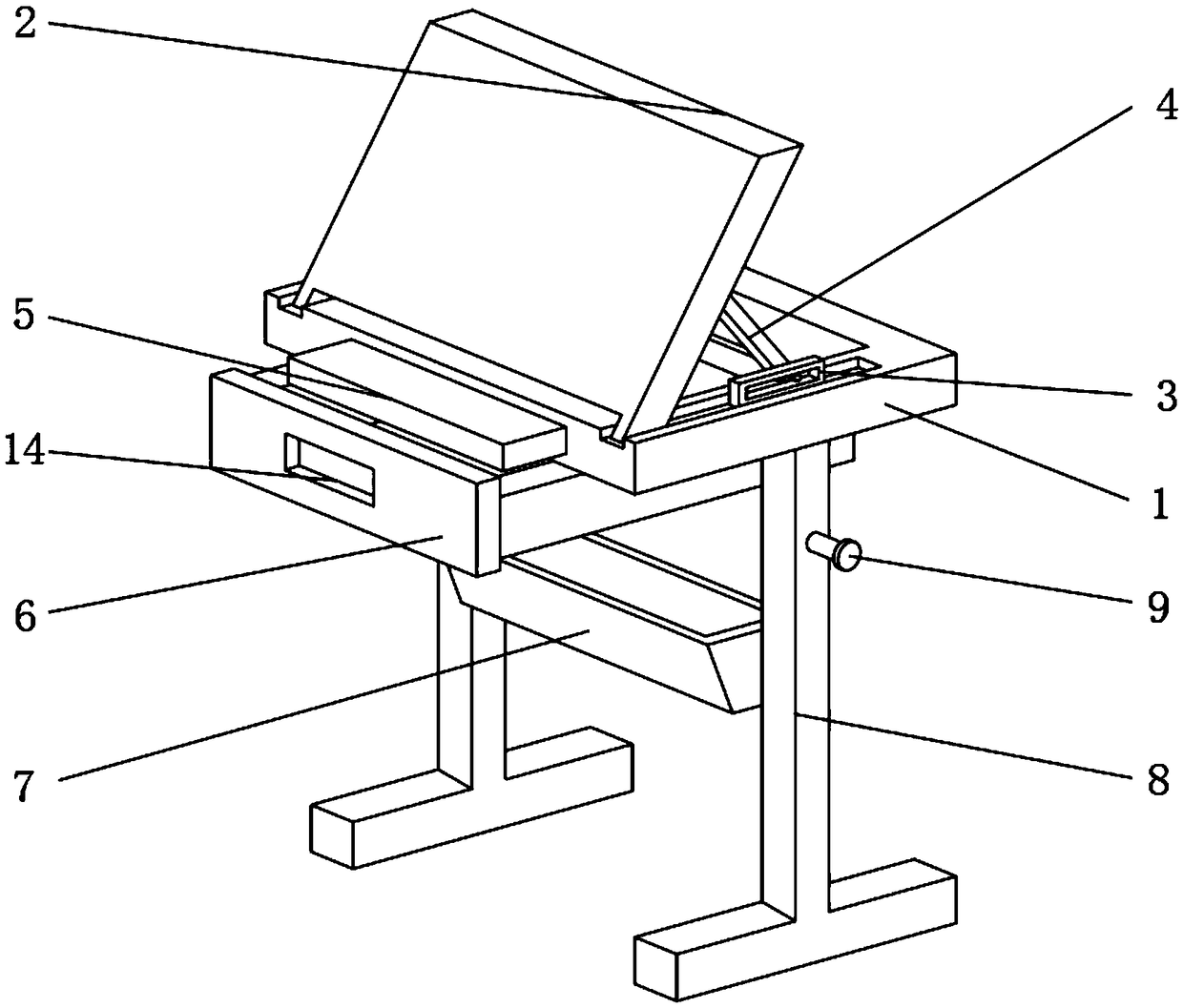

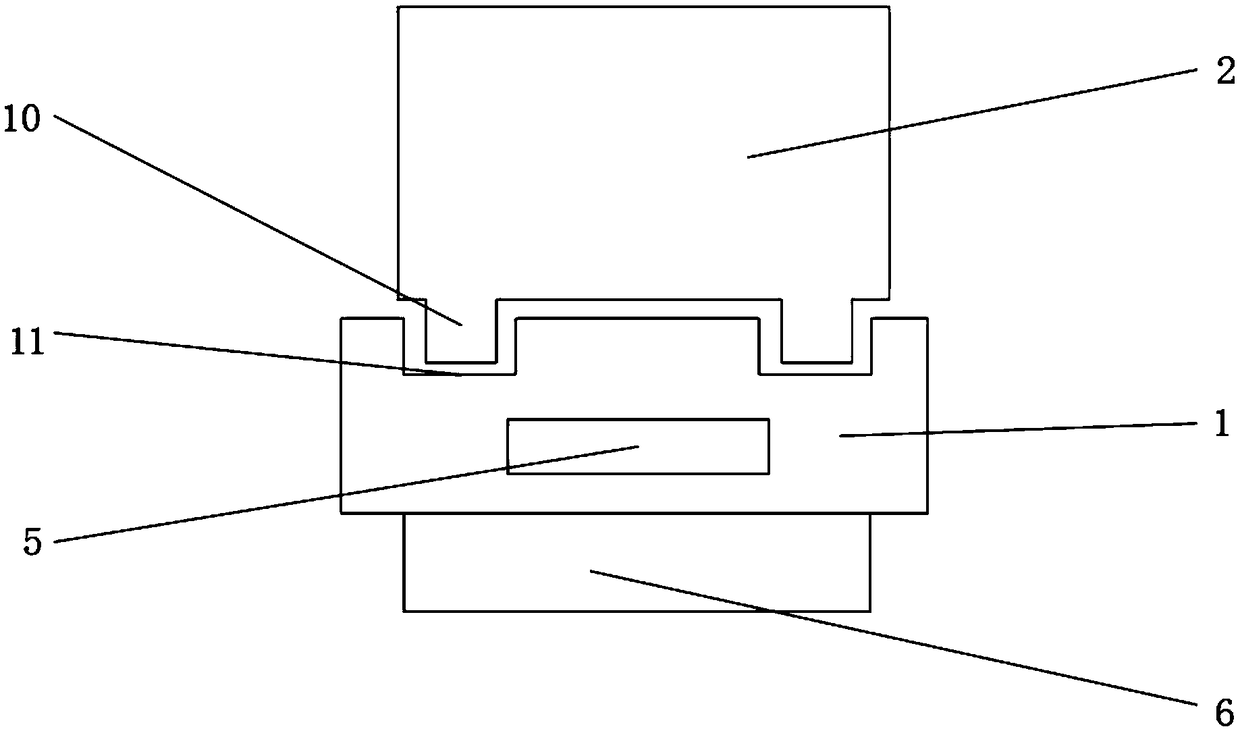

Drawing table facilitating drawing placement for engineering drawing

Owner:平湖市超越时空图文设计有限公司

Sheet feeder

Owner:RAUTE OY

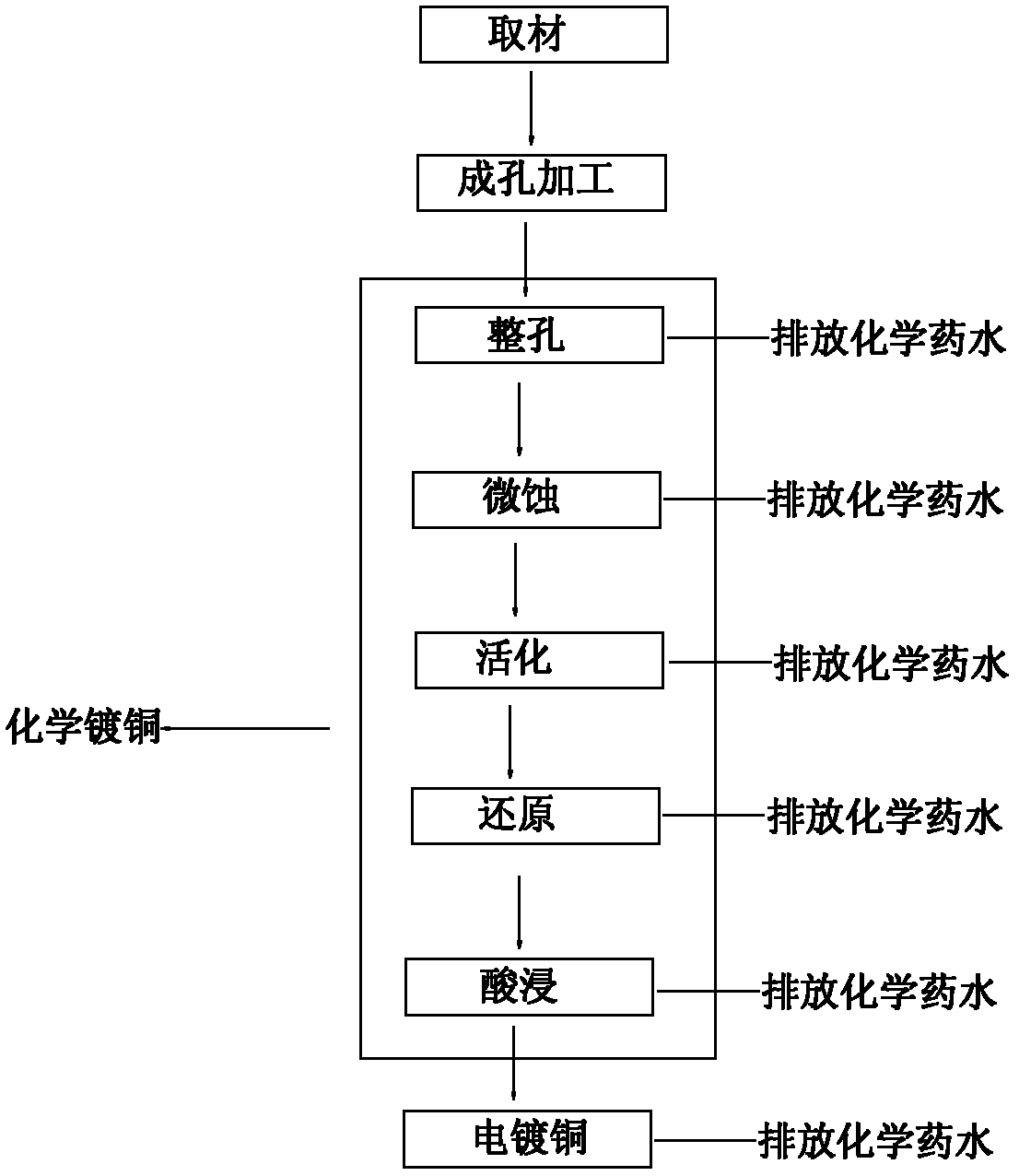

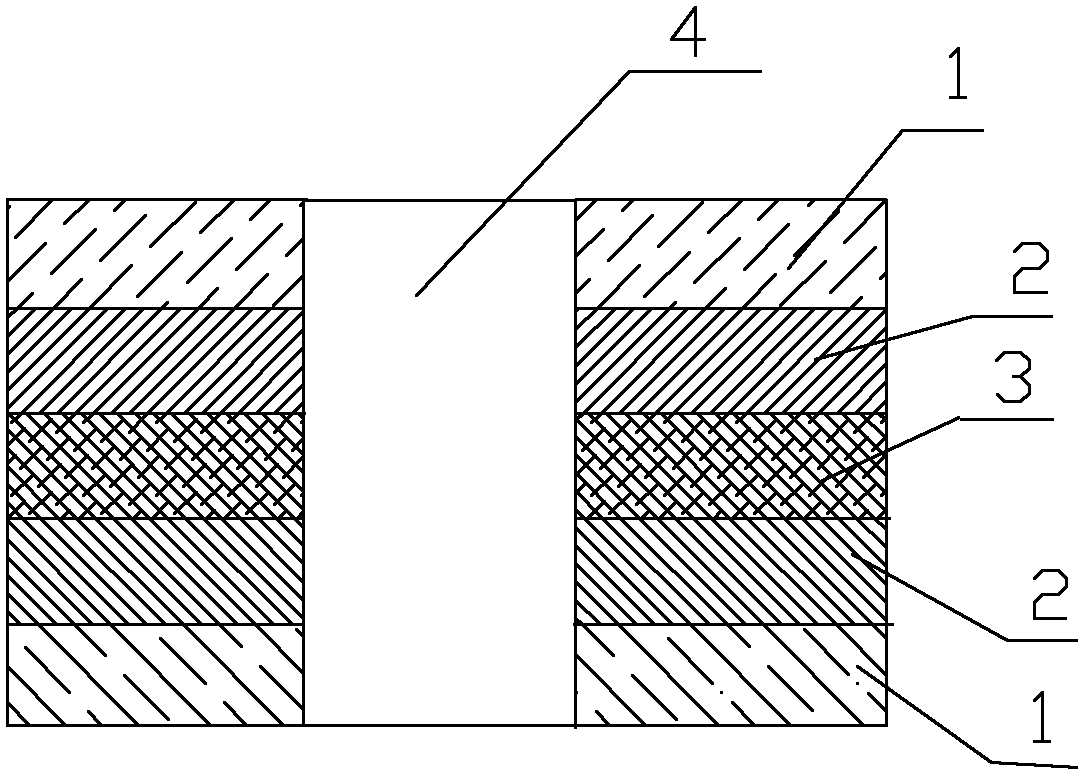

Manufacturing process of interlayer copper connector of printed circuit board

InactiveCN102638946AReduce investmentReduce investment riskPrinted element electric connection formationScreen printingInsulation layer

Owner:SHENZHEN HONGHAI ELECTRON MATERIAL TECH CO LTD

Expandable high-bonding and high-sound-absorption paper honeycomb composite board and manufacturing method thereof

Owner:浙江华江科技股份有限公司

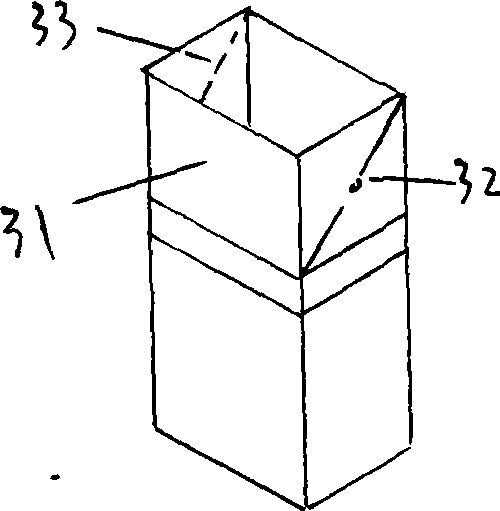

Rectangle paper box

Owner:李平

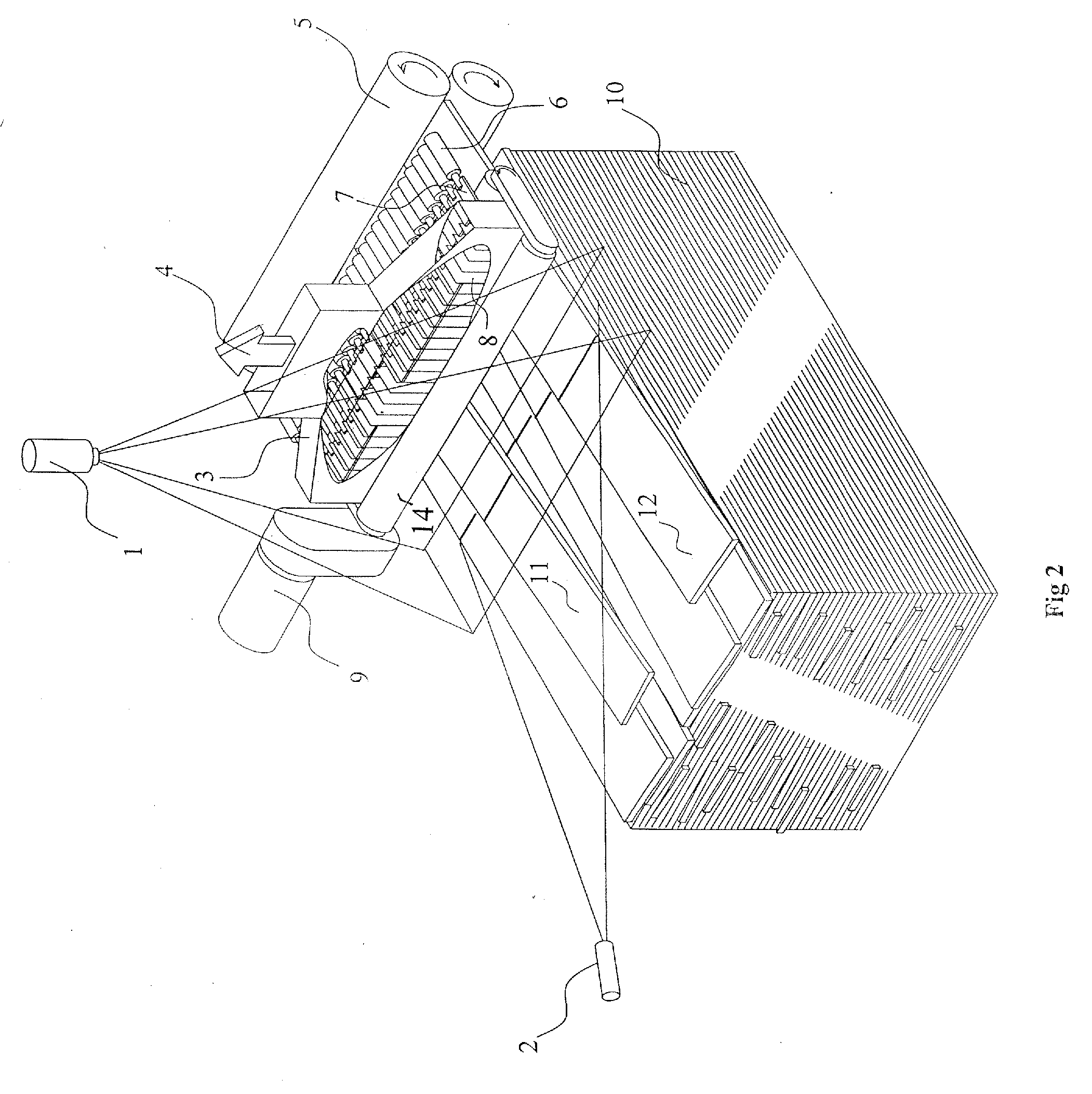

Classification device

ActiveCN104382375AAccurate classificationImprove classification efficiencyBook cabinetsEngineeringPaper sheet

A classification device comprises a base, two supporting plates, a fixing shaft, a fixing disc and a rotating part. The two supporting plates are parallelly arranged on the base. Two ends of the fixing shaft are respectively and fixedly arranged on the two supporting plates. The fixing disc is fixedly arranged on the fixing shaft and provided with a paper inlet. The rotating part comprises a rotating wheel, a rotating ring, a plurality of partition plates and a plurality of doorway pages, wherein the rotating wheel is rotatably arranged on the fixing shaft, the partition plates are radially and fixedly arranged on the rotating wheel, the rotating ring is fixedly connected with the sides away from the rotating wheel, of the partition plates, and the doorway pages are rotatably arranged on the partition plates. Each pair of adjacent partition plates, the fixing disc and the rotating ring define an accommodating cavity. The rotating part of the classification device is rotatably matched with the fixing disc through the rotating wheel, the rotating ring and the partition plates, accordingly printing paper can be accurately classified in time sequence, and the classification efficiency is also high.

Owner:XUZHOU BO GEN CONSTR DEV GRP CO LTD

Traceless screw

The invention discloses a traceless screw. The traceless screw comprises a screw head and a screw rod, wherein the screw head is embedded into a base and forms a whole with the base, the screw rod is perpendicular to the surface of the base and is exposed out of the base, and the bottom surface of the base is connected to the upper surface of a base plate; and the lower surface of the base plate is coated with an adhesive layer, and release paper covers outside the adhesive layer. According to the traceless screw provided by the invention, the screw can be used on a smooth or coarse wall surface without drilling a hole in a wall body, the screw can be instantly used after mounted, and the screw can be used for a long time as well as be repeatedly used.

Owner:王天允

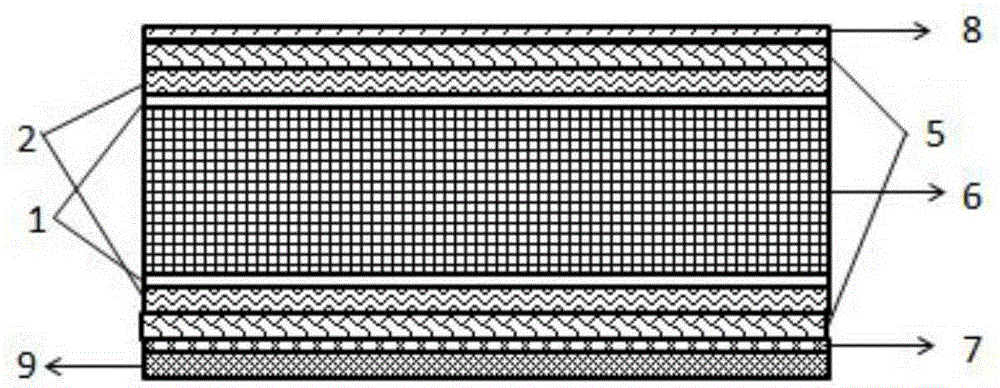

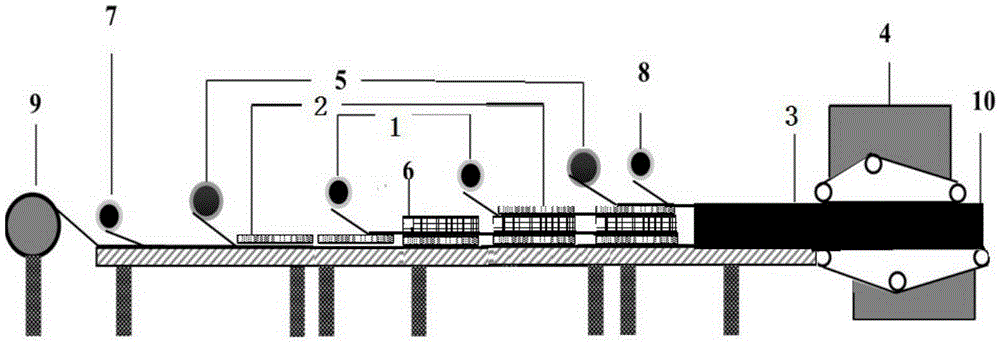

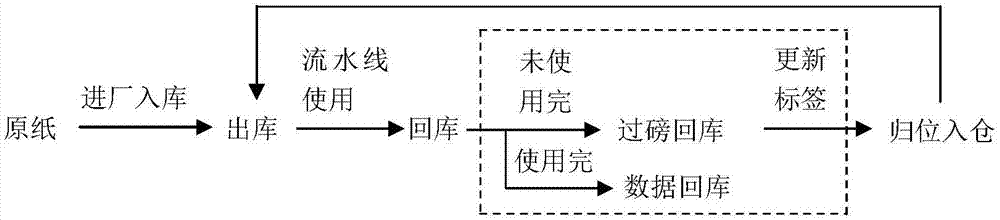

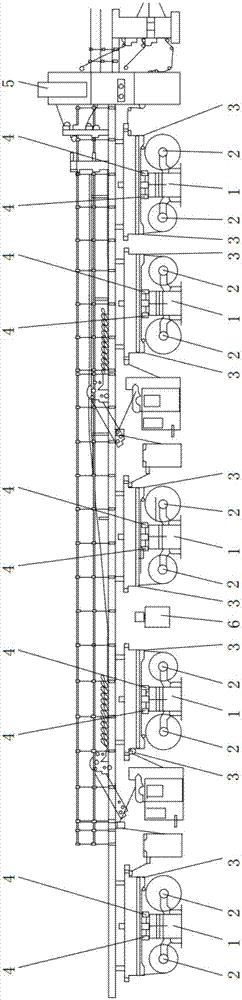

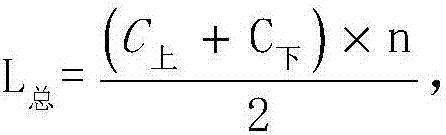

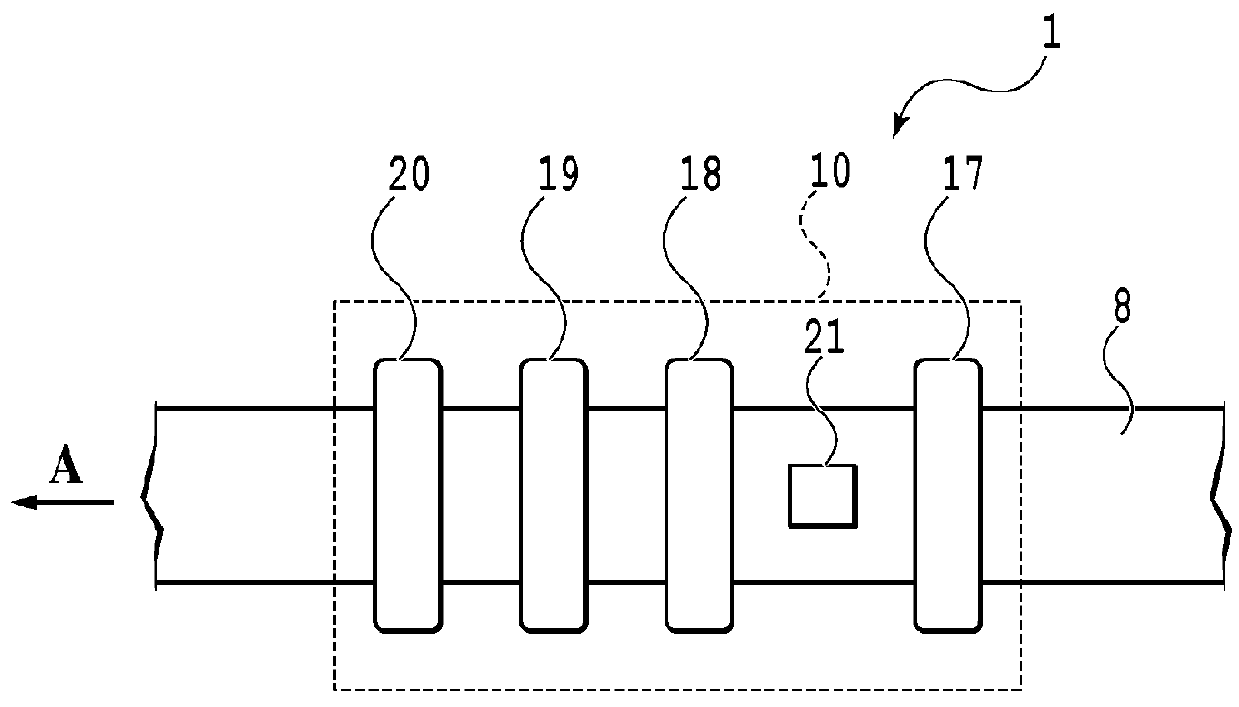

Intelligent metering method for remnant base paper rolls of corrugated paper board assembly line

ActiveCN107478652AReduce operating costsIncrease profitMaterial analysis by optical meansPaper sheetOperational costs

The invention relates to the technical field of packaging, in particular to an intelligent metering method for remnant base paper rolls of a corrugated paper board assembly line. The intelligent metering method for the remnant base paper rolls of the corrugated paper board assembly line comprises steps as follows: a plurality of base paper feeding positions are arranged in the conveying direction of the assembly line at intervals, a base paper feeding frame is arranged in each base paper feeding position, and two base paper feeding rolls located on two sides of each base paper feeding frame are arranged on the base paper feeding frame; each base paper feeding roll is provided with lap recording sensors and incremental encoders, the lap recording sensors are used for monitoring the number of paper feeding laps of base paper clamped on the corresponding base paper feeding roll, the incremental encoders are used for monitoring the length of each lap after the base paper on the base paper feeding roll passes by one lap, and the lap recording sensors and the incremental encoders are connected with a controller. Intelligent metering can be realized, the operation cost of an enterprise is reduced, labor is saved, and the utilization rate of enterprise resources is increased.

Owner:DACHENG PACKAGING PROD SUZHOU

Scrapbook having scented pages

InactiveUS20060202466A1High transparencyTough and long-lastingToysFiling appliancesPolymer thin filmsDiffusion barrier

A scrapbook, in which multiple fragrances associated with memorable events can be stored for extended periods of time, includes scented pages enclosed in perforated see-through protector sleeves, diffusion barrier sheets bound between adjacent pages having dissimilar fragrances, a diffusion barrier sheet bound between a front cover of the scrapbook and the first scented page, and a diffusion barrier sheet bound between a back cover of the scrapbook and the last scented page. The protector sleeves, which control the release of fragrance from paper sheets to which a fragrance has been applied, are fabricated from polymeric films, such as polypropylene, which have excellent resistance to oils and gases. Barrier sheets may be metalized for enhancement of diffusion barrier qualities. Fragrances may be applied to scrapbook paper by spraying, rolling, painting, stamping, printing or immersion.

Owner:HIRONAKA ROBIN S

Paper tray for printer

InactiveUS20060210346A1Simple structureLittle strengthOther printing apparatusArticle separationComputer printingStructural engineering

Owner:FUNAI ELECTRIC CO LTD

Printing apparatus and printing method

Owner:CANON KK

Straw-based composite filler and preparation method of straw-based composite filler as well as paper sheet containing straw-based composite filler

InactiveCN106866897AHydrophilicCationicReinforcing agents additionPaper/cardboardCore shellToughening

Owner:GUANGDONG IND TECHN COLLEGE

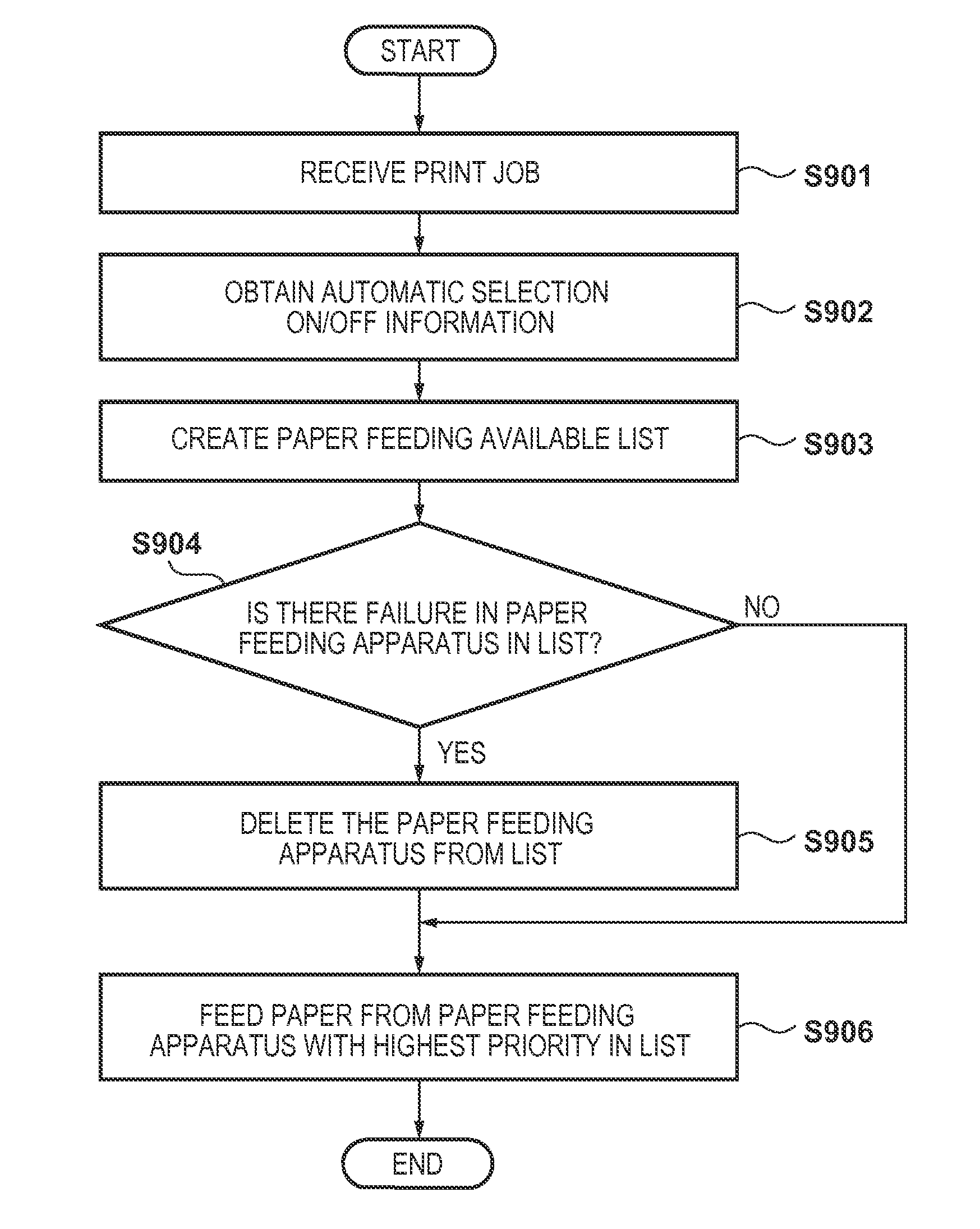

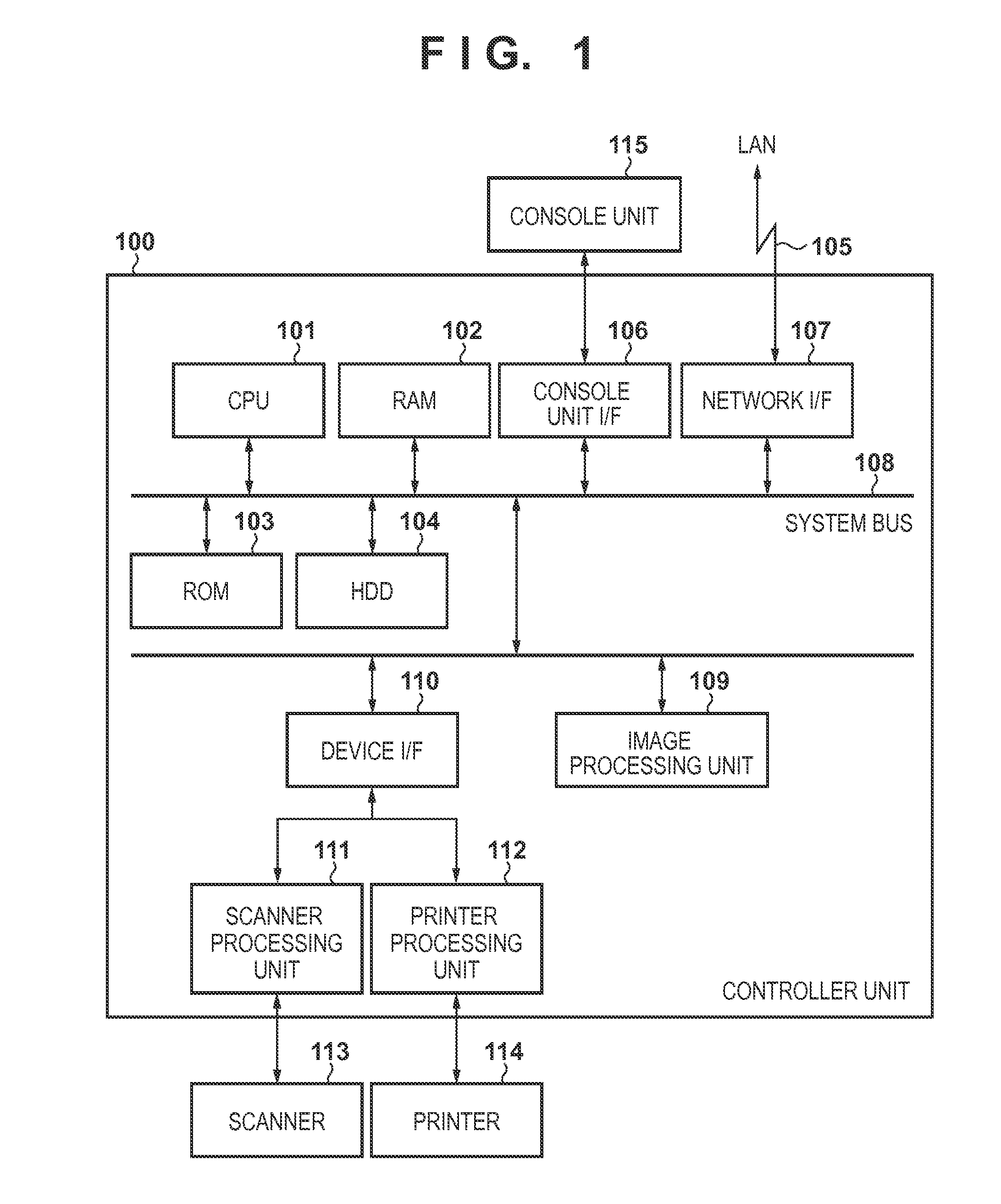

Image forming apparatus, method of controlling the same, and computer-readable storage medium

Owner:CANON KK

Electrostatic elimination device used for high-speed digital printer

Owner:众联易通(北京)科技有限公司

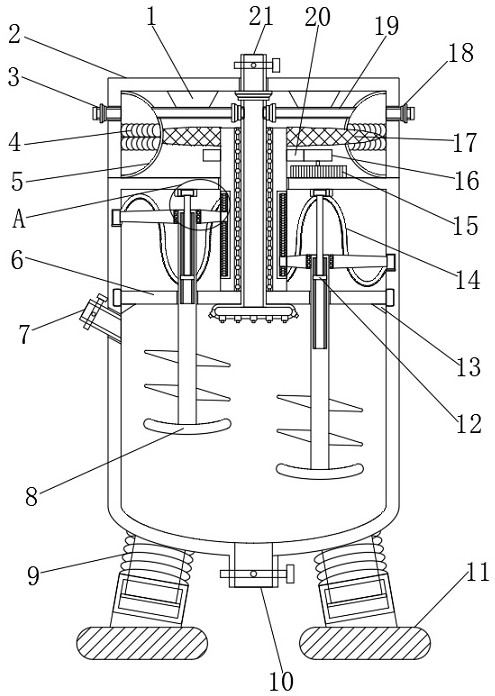

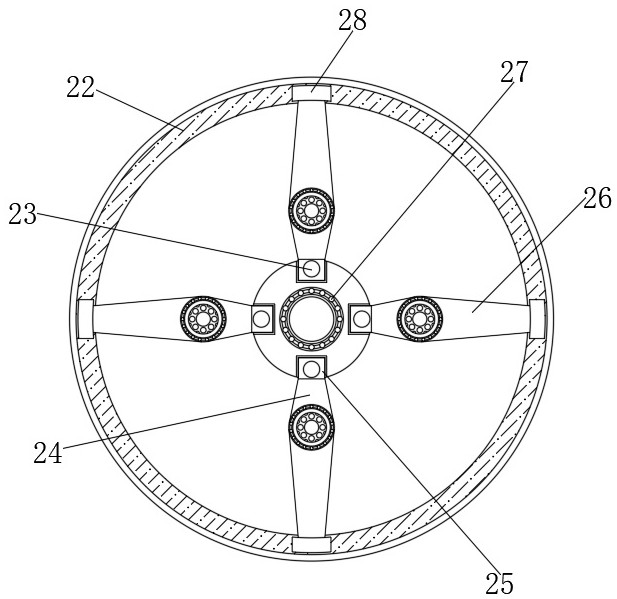

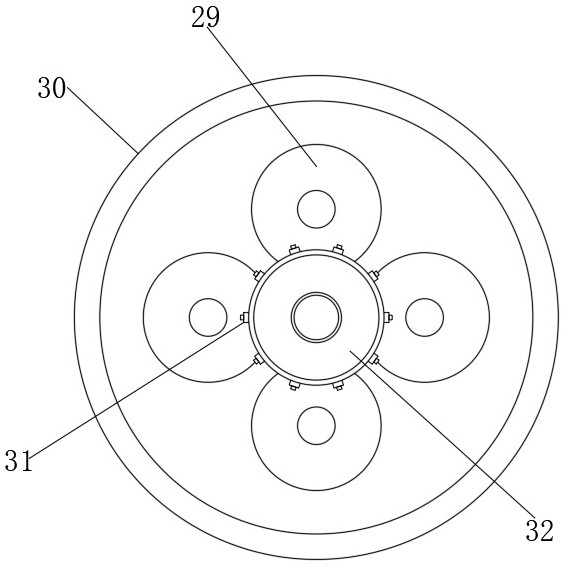

Papermaking additive uniform dilution device for papermaking

PendingCN112796163AFully dilutedQuality assuranceRotary stirring mixersTransportation and packagingCircular discElectric machine

Owner:王永利

Planting paper and preparation method thereof

Owner:SHAANXI UNIV OF SCI & TECH

Amorphous alpha-olefin copolymer improved paper-based friction material and preparation method thereof

ActiveCN112855811AEasy to processImprove high temperature stabilityOther chemical processesFriction liningFiberPolymer science

Owner:NORTHWESTERN POLYTECHNICAL UNIV

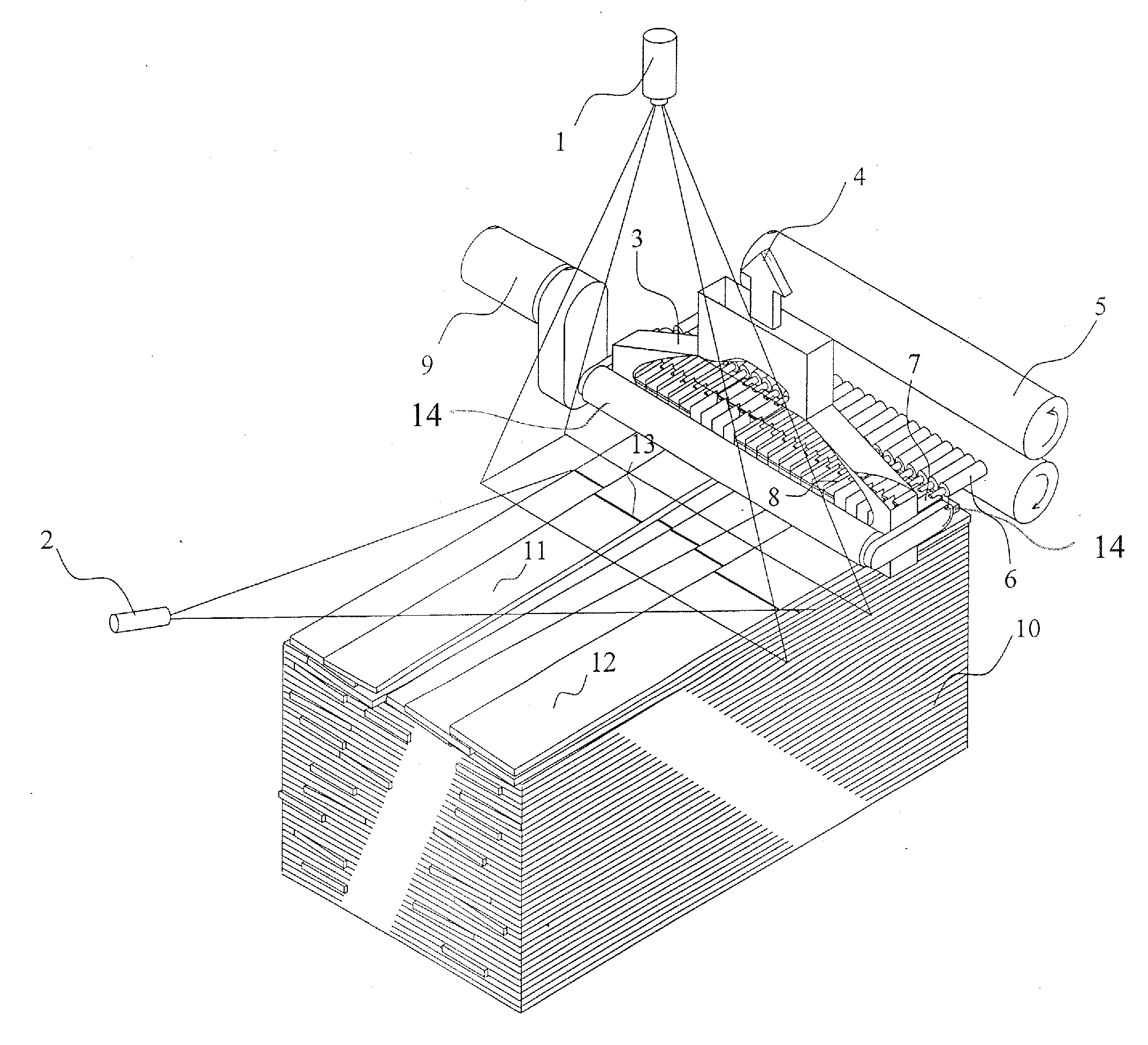

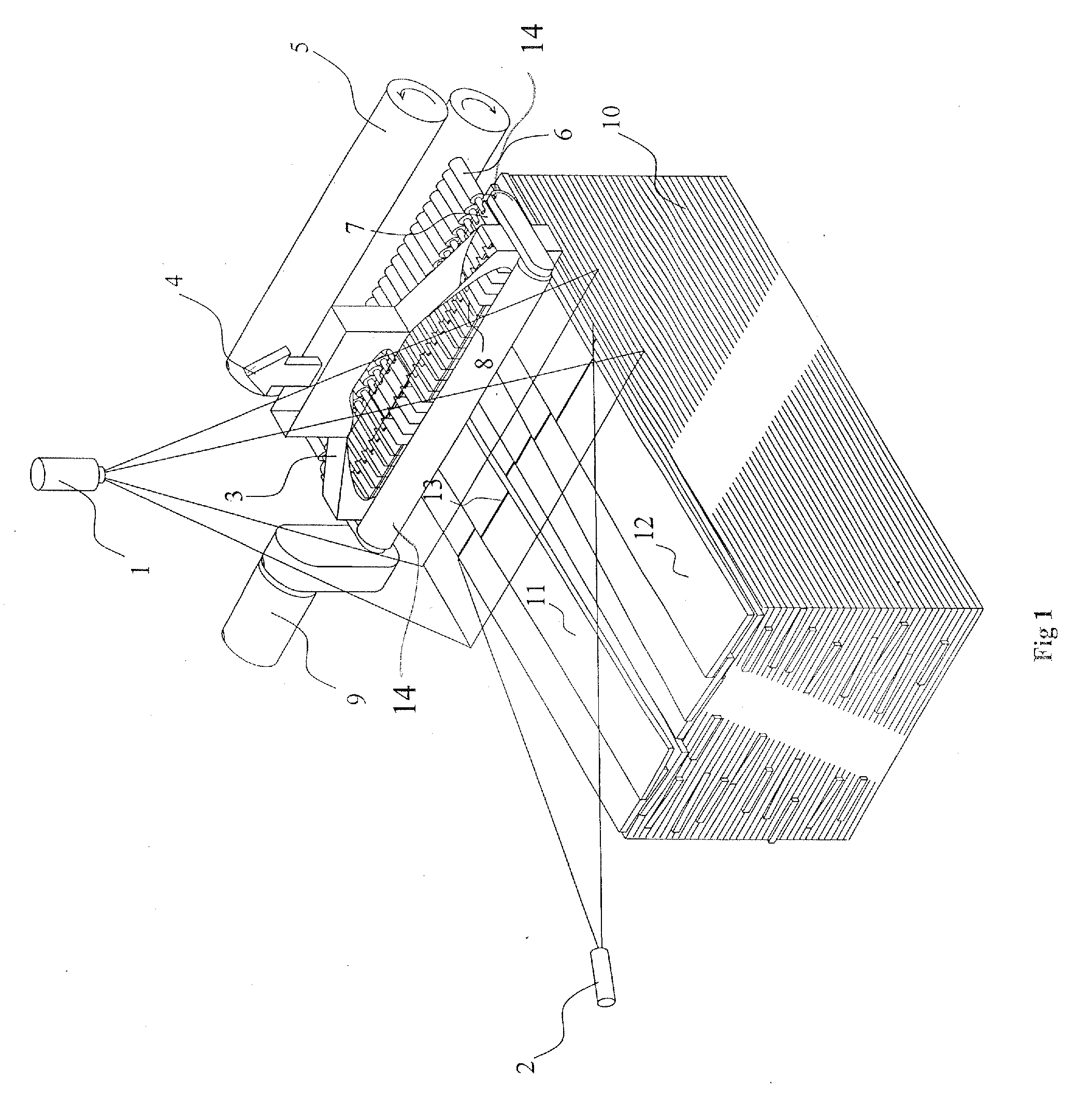

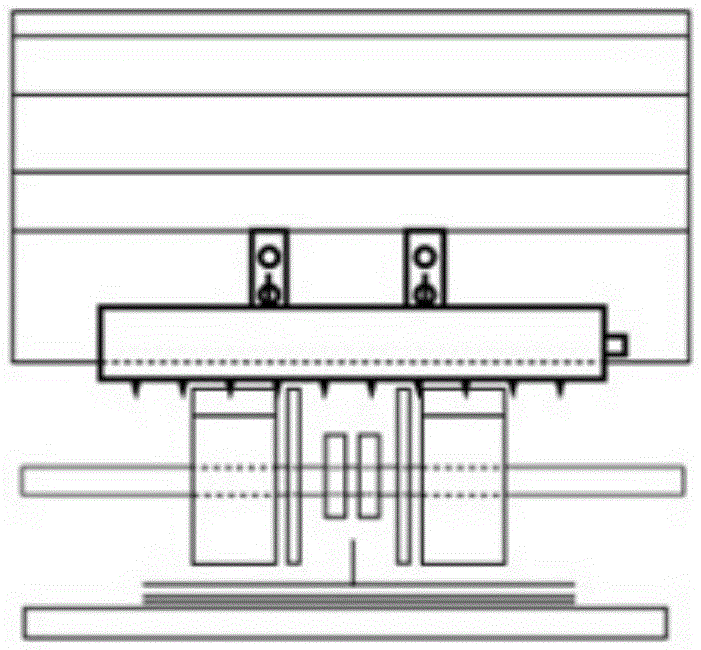

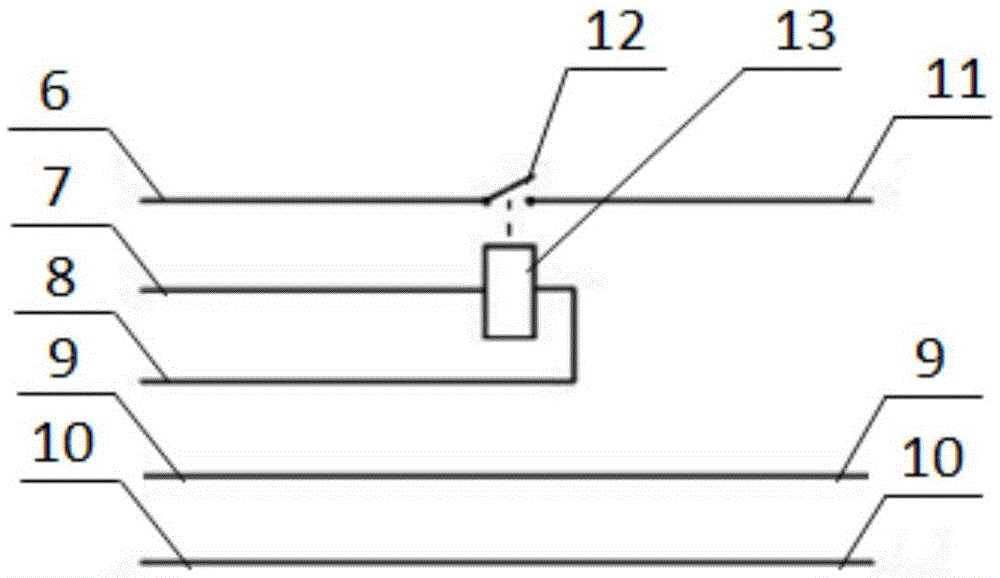

Method and system for aligning upper window and lower window of paper detection scanning frame moving trolley

ActiveCN112798046AImprove stabilityGood repeatabilityMeasurement apparatus componentsProduction lineReciprocating motion

The invention discloses a method and system for aligning an upper window and a lower window of a paper detection scanning frame moving trolley. The method comprises the steps: firstly setting a motion range of a moving trolley, and carrying out initialization setting on the moving trolley; keeping one window of the moving trolley static, collecting the characteristic parameters of the reciprocating motion of the other window of the moving trolley in the motion range, inputting the characteristic parameters into a trained model, calculating and recording the alignment positions of the moving trolley in the forward and backward motion directions to obtain a final alignment position; and aligning the upper window and the lower window of the moving trolley at the final alignment position. According to the invention, in the window alignment process, the AD value of the sensor is directly used as a judgment basis, so that system errors caused by sensor assembly and trolley installation are avoided; and the acquisition speed is faster and more sensitive, the alignment process is not affected by a production line, no additional auxiliary equipment facility is needed, manual regular maintenance is not needed, and the equipment cost and the labor cost are further saved.

Owner:MIANYANG MUTUAL SUCCESS INTELLIGENT EQUIP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap