Method for producing a multi-ply web of flexible material, such as paper and nonwoven, and multi-ply material produced by the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

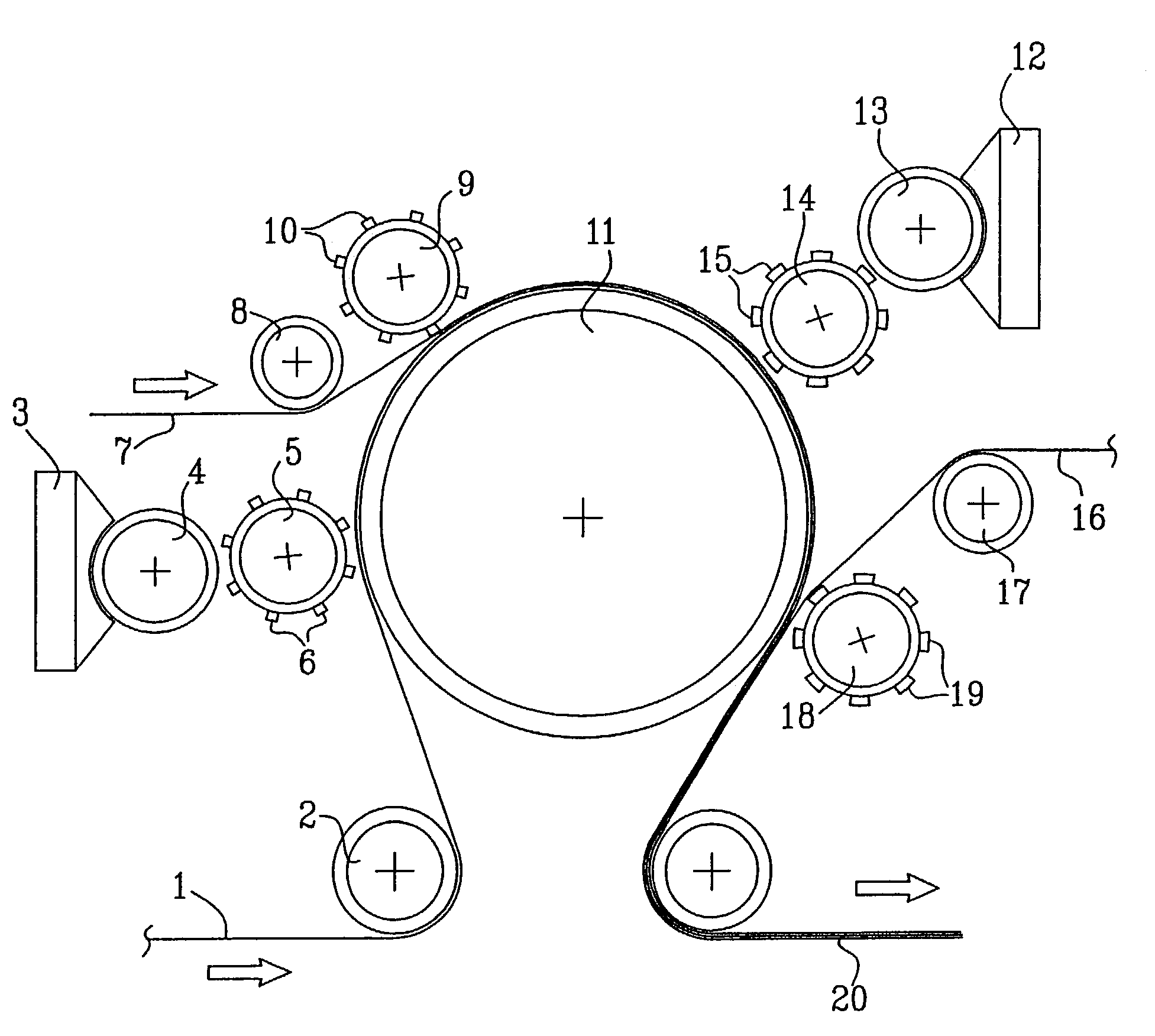

[0029]FIG. 1 shows a device for producing a three-ply material, e.g. paper, especially tissue paper. A first paper web 1 is fed over a roll 2 towards a glue application station. This comprises a glue chamber 3 from which glue is applied on a glue roll 4. The glue roll 4 is in contact with a first patterned glue transfer roll 5, which along its periphery is provided with a pattern of protuberances 6. The glue roll 4 is only contacting the tops of the protuberances 6, so that glue is only applied thereon. The paper web 1 is passed into a press nip between the first glue transfer roll 5 and a centrally placed impression roll 11. Glue will thus be applied to the first paper web 1 in a first glue pattern corresponding to the configuration of the tops of the protuberances 6. The pressure in the press nip between the pattern roll 5 and the impression roll 11 is only sufficiently high to accomplish a transfer of glue to the paper web 1. However there should preferably be no deformation of the

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap