Planting paper and preparation method thereof

A paper layer and plant seed technology, applied to the preparation of the planting paper and the field of planting paper, can solve the problems of serious consumption of human and material resources, cumbersome planting procedures, loss of seeds, etc., and achieve good economic benefits, reduce costs, and methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

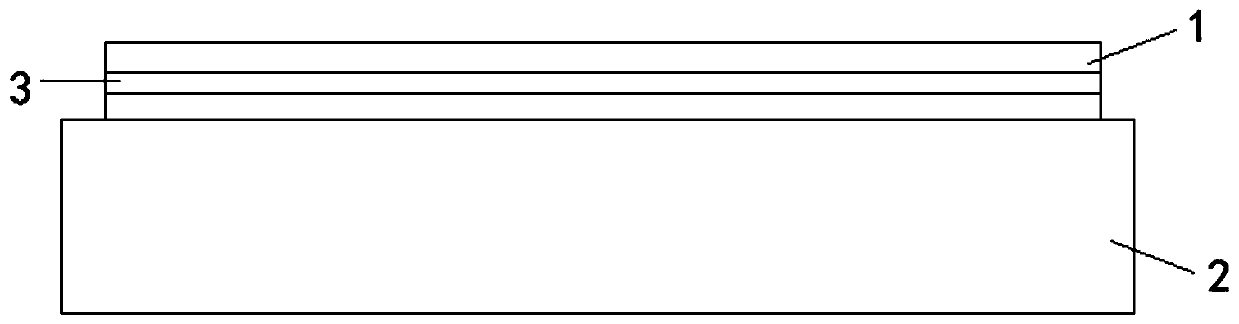

Image

Examples

preparation example Construction

[0037] A kind of preparation method of planting paper, concretely carries out according to the following steps

[0038] Step 1, the mass concentration is 0.5%~0.7% 1 # Pomace fiber slurry and plant fiber slurry with a mass concentration of 0.5% to 0.7% are mixed to form a mixed slurry, and 0.4 to 0.6% of inorganic fertilizer relative to the dry mass of the mixed slurry is added to the mixed slurry. A plant growth agent with an absolute dry mass of slurry of 0.1-0.2%, with a weight of 60g / m obtained by papermaking2 ~80g / m 2 seed paper,

[0039] 2 with a mass concentration of 0.5% to 0.7% # Pomace fiber slurry and waste paper fiber slurry with a mass concentration of 0.5% to 0.7% are mixed to form a matrix mixed slurry, and 1.0% to 4.0% of the dry weight of the matrix mixed slurry is added to the matrix mixed slurry. 0.01% to 0.05% of the dry mass of the insecticide mixed with the slurry relative to the matrix, and then made to obtain the base sheet;

[0040] Specifically f

Embodiment 1

[0057] A kind of preparation method of planting paper, concretely carries out according to the following steps

[0058] Step 1, the mass concentration is 0.5% of 1 # The pomace fiber slurry and the plant fiber slurry with a mass concentration of 0.5% are mixed to form a mixed slurry, and 0.4 of the inorganic fertilizer relative to the dry mass of the mixed slurry and 0.1% of the dry mass of the mixed slurry are added to the mixed slurry. % plant growth agent, the quantitative obtained by copying is 60g / m 2 seed paper,

[0059] The mass concentration is 0.5% of 2 # The pomace fiber slurry and the waste paper fiber slurry with a mass concentration of 0.5% are mixed to form a matrix mixed slurry, and 1.0% antifungal agent relative to the dry mass of the matrix mixed slurry is added to the matrix mixed slurry and mixed with the matrix Slurry dry weight 0.01% of the insecticide after the paper to obtain the substrate;

[0060] Specifically follow the steps below:

[0061] Step

Embodiment 2

[0076] A kind of preparation method of planting paper, concretely carries out according to the following steps

[0077] Step 1, the mass concentration is 0.7% of 1 # The pomace fiber slurry and the plant fiber slurry with a mass concentration of 0.7% are mixed to form a mixed slurry, and 0.6% of the inorganic fertilizer relative to the dry mass of the mixed slurry and 0.6% relative to the dry mass of the mixed slurry are added to the mixed slurry. 0.2% plant growth agent, the quantification obtained by copying is 80g / m 2 seed paper,

[0078] The mass concentration is 0.7% of 2 # The pomace fiber slurry and the waste paper fiber slurry with a mass concentration of 0.7% are mixed to form a matrix mixed slurry, and 4.0% antifungal agent relative to the dry mass of the matrix mixed slurry is added to the matrix mixed slurry and mixed with the matrix. Slurry with 0.05% insecticide in absolute dry mass is copied to obtain the substrate;

[0079] Specifically follow the steps belo

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap