Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

170 results about "Pulp and paper industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The pulp and paper industry comprises companies that use wood as raw material and produce pulp, paper, paperboard and other cellulose-based products. The pulp is fed to a paper machine where it is formed as a paper web and the water is removed from it by pressing and drying.

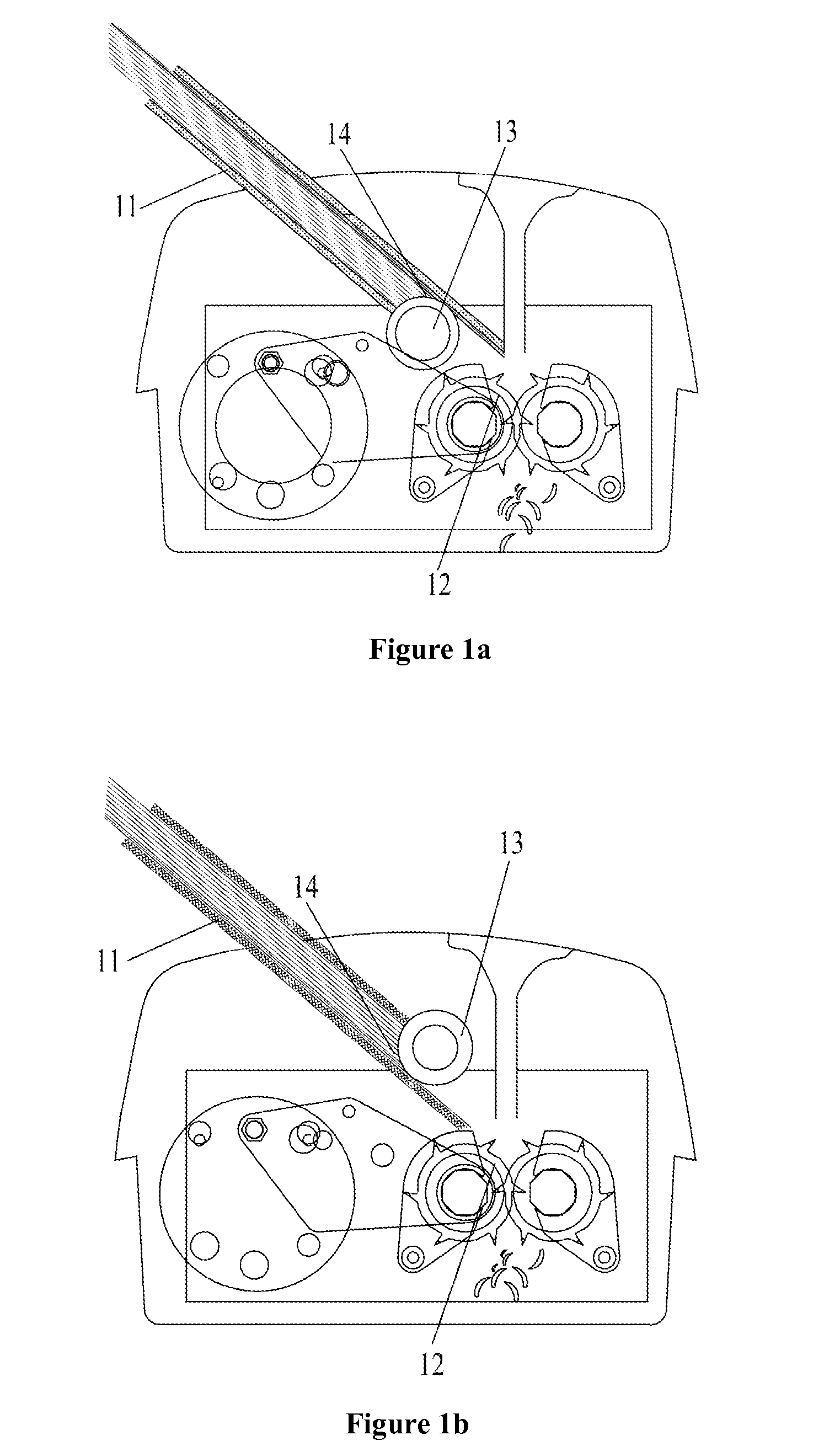

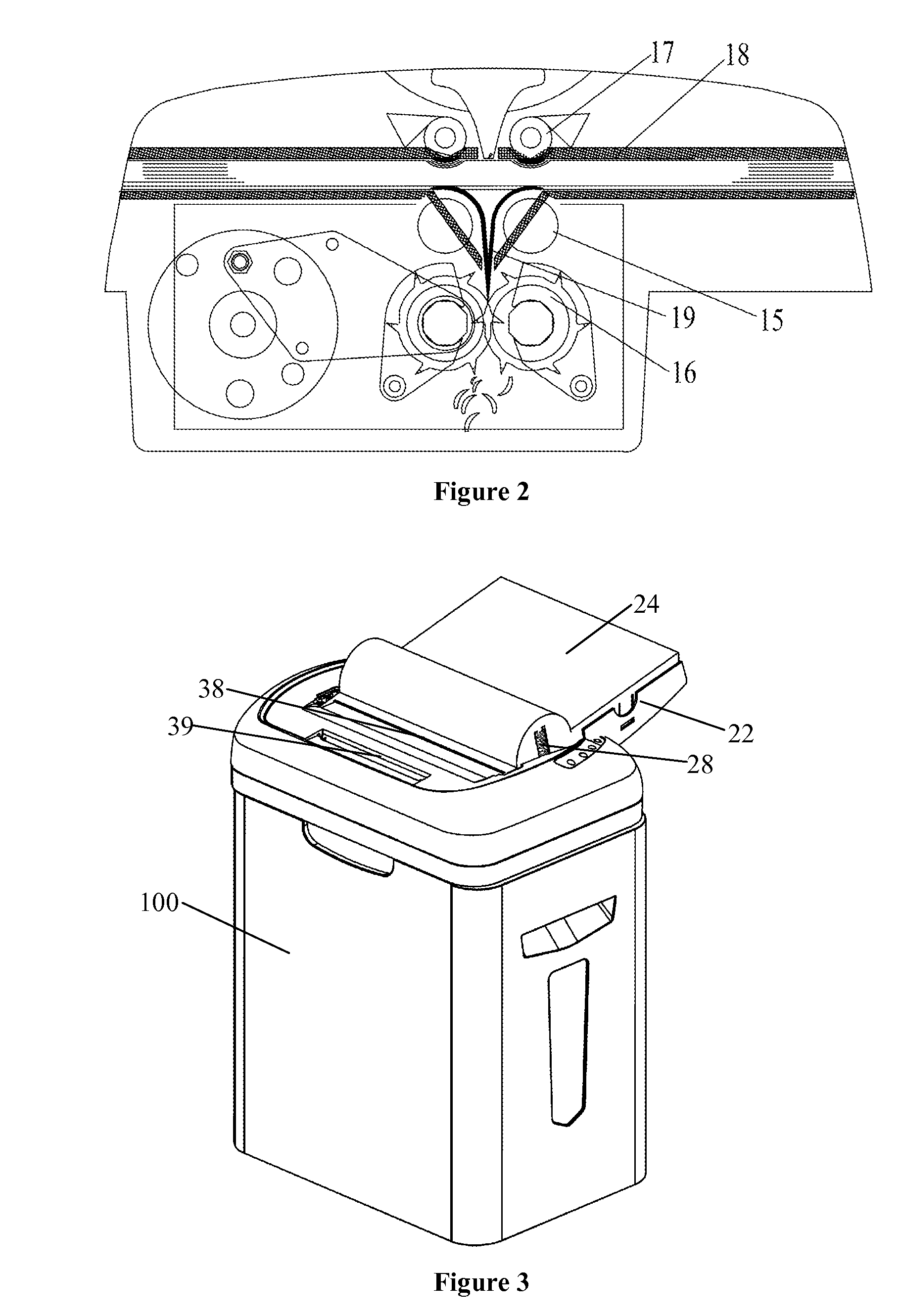

Automatic shredder without choosing the number of paper to be shredded

Owner:AURORA OFFICE EQUIP

Full-automatic urine analyzer and test paper plate used for same

InactiveCN101887065APrevent cardPrevent deformation and other phenomenaMaterial analysisPulp and paper industryTest strips

Owner:龙桂忠 +1

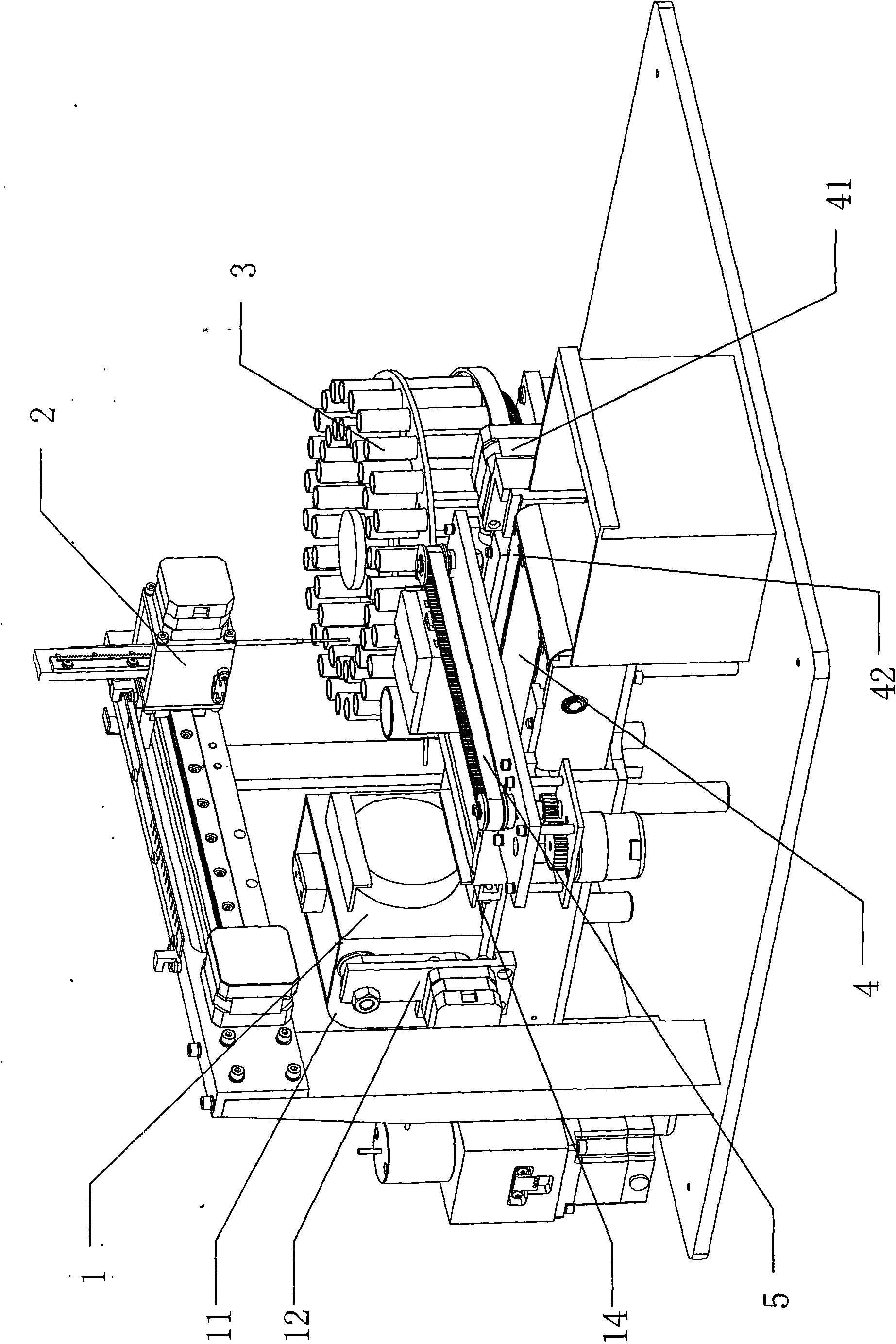

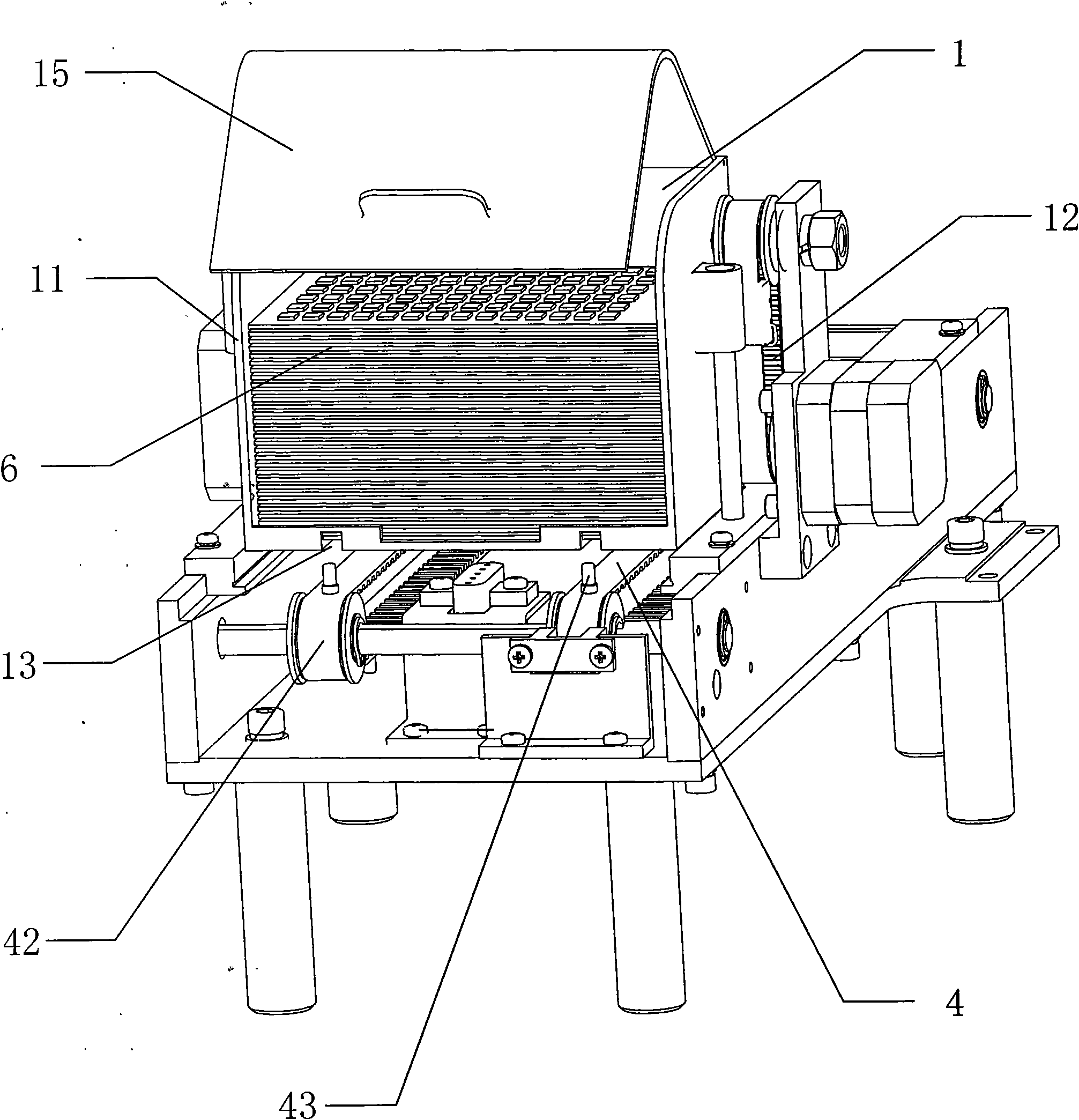

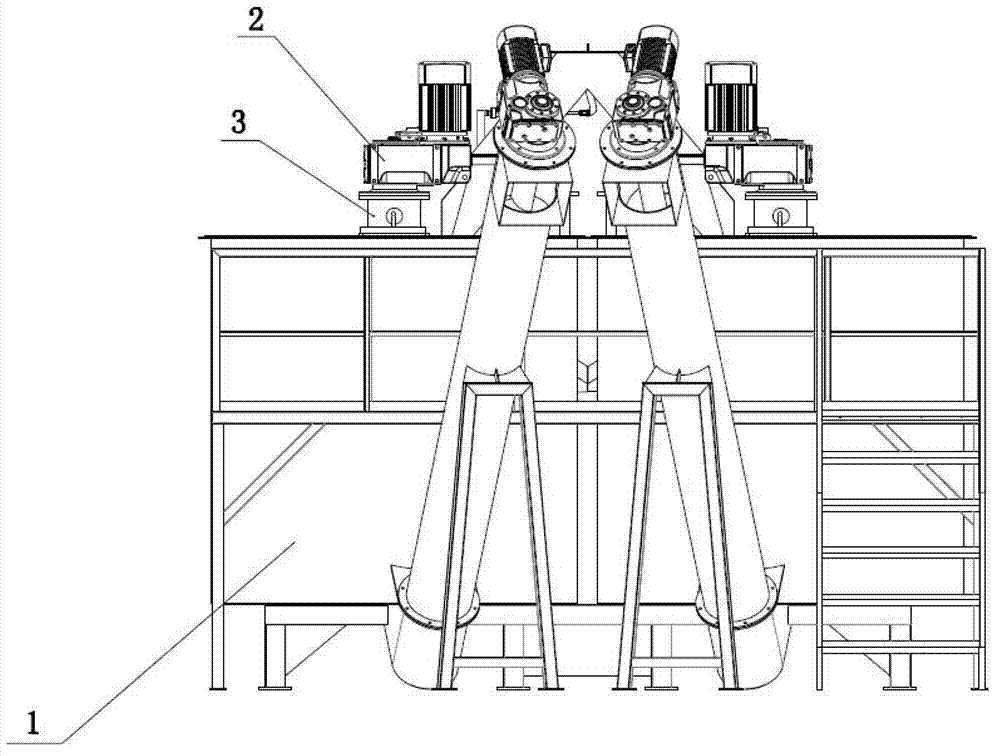

Asphalt mixture regenerating heating stirring roller

The invention discloses an asphalt mixture regenerative heating rod and mixing roller, and belongs to the concrete stirring technical field. The invention has a tilted roller supporting frame, a rolling ring, a roller and a roller driving device, wherein, the rolling ring is sleeved on the roller and supported by a rolling wheel arranged on the roller supporting frame, a burner is arranged at the lower end of the roller, a material outlet is arranged on the roller at the lower part of the burner, a material inlet is arranged at the other end of the roller, and a smoke outlet is arranged on the roller; wherein, an inner screening tube is sleeved inside the roller positioned at the material inlet end, and the inner screening tube is connected with the roller, the outer peripheral wall of the inner screening tube is composed of a screening mesh, a circular filtering mesh is sealed at the end part on the inner side of the inner screening tube, the material inlet is communicated with the inner screening tube, and an asphalt nozzle is arranged inside the roller positioned below the burner at the outlet end. The invention has compact and rational structure and high heat exchange efficiency, does not require secondary breakup of the waste asphalt mixture, can directly heat the block shape waste asphalt mixture for recycling; and the regenerated asphalt mixture can be directly utilized.

Owner:HENAN ROADY ROAD MACHINERY

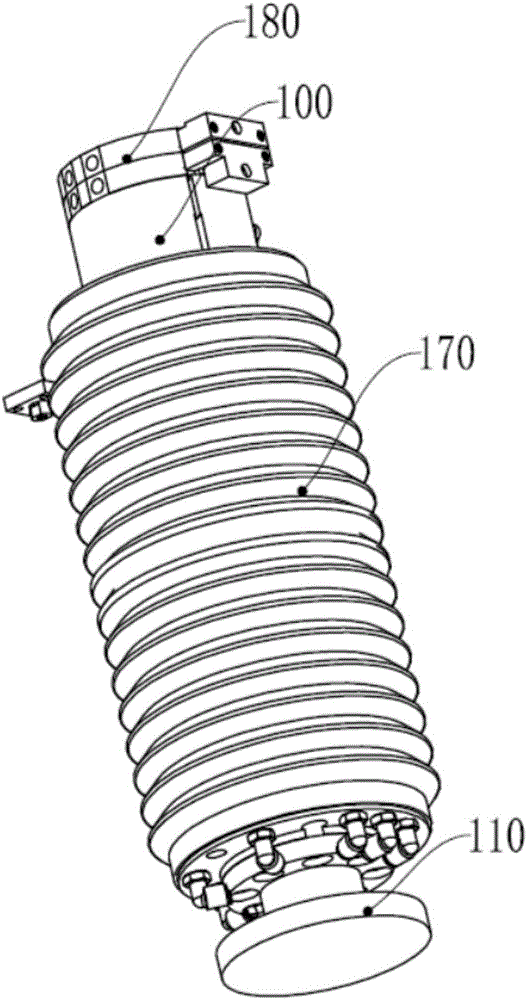

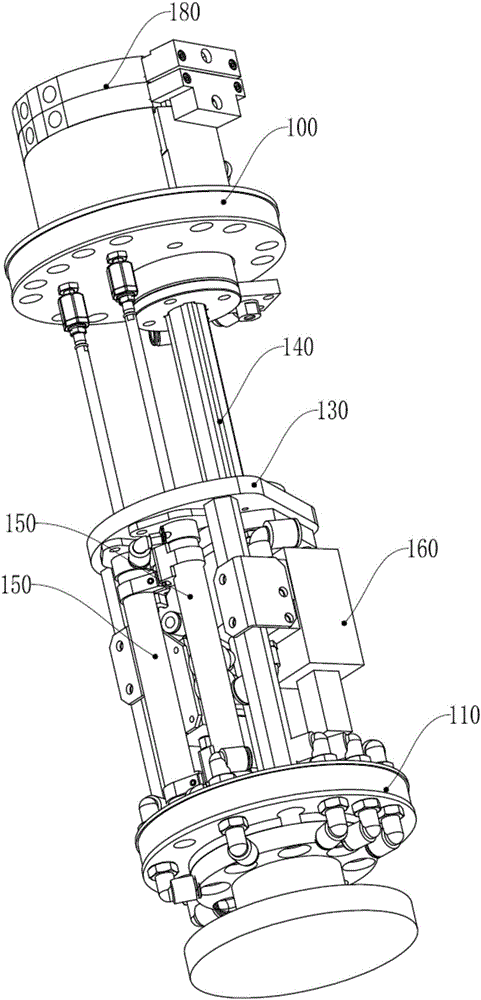

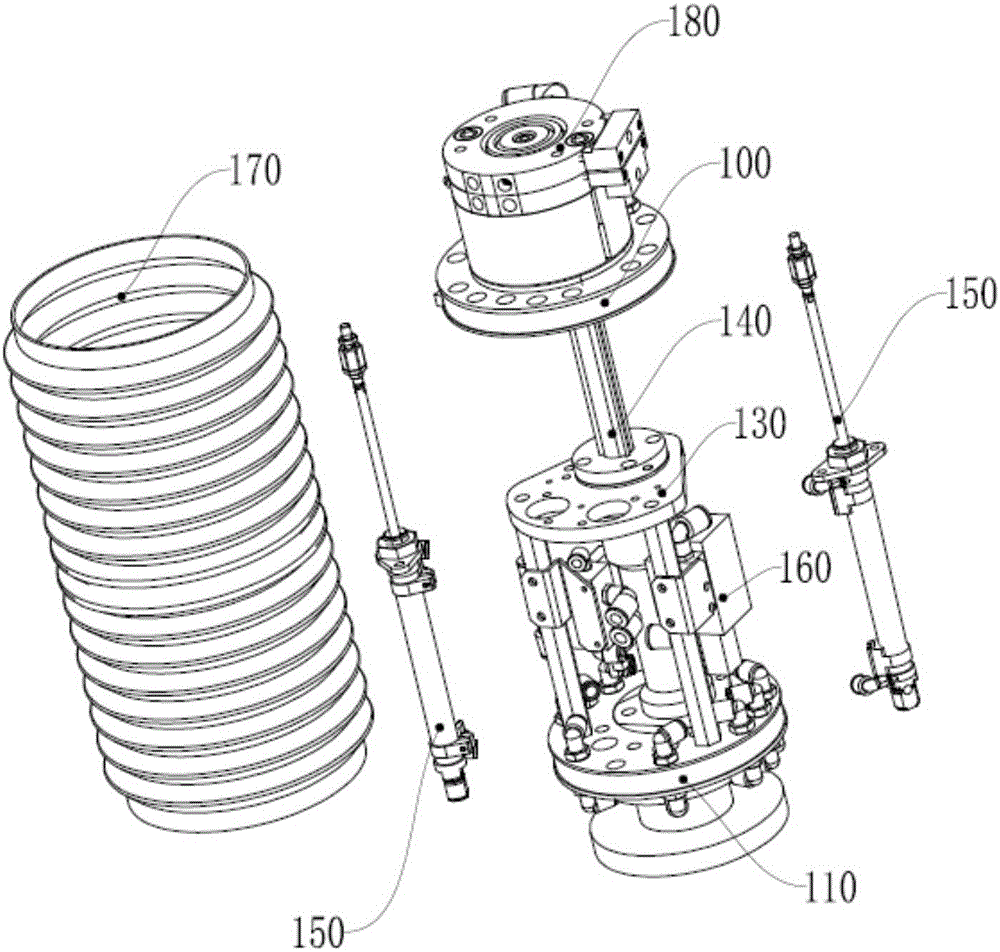

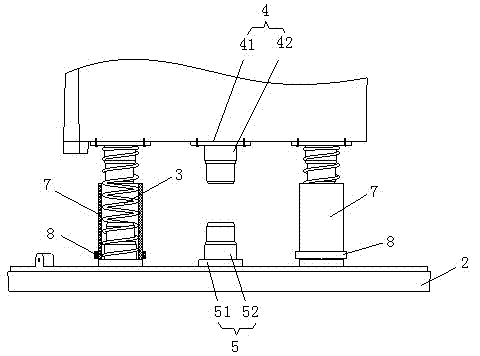

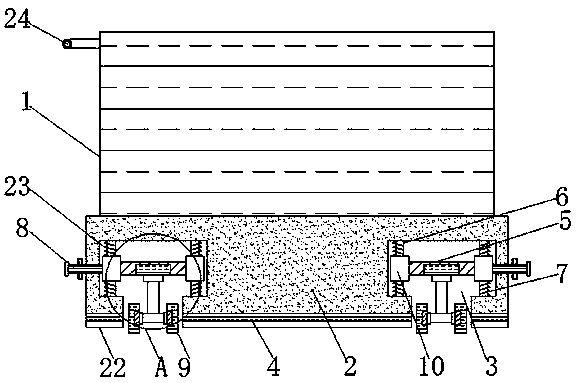

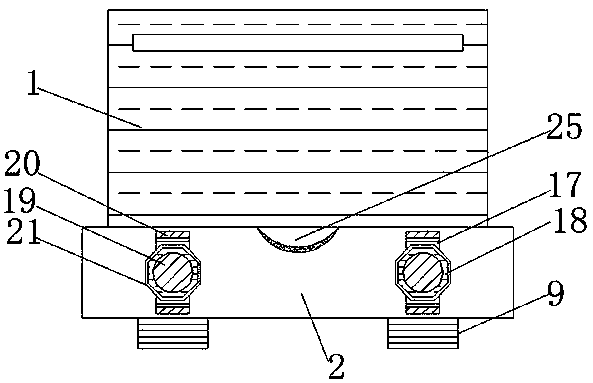

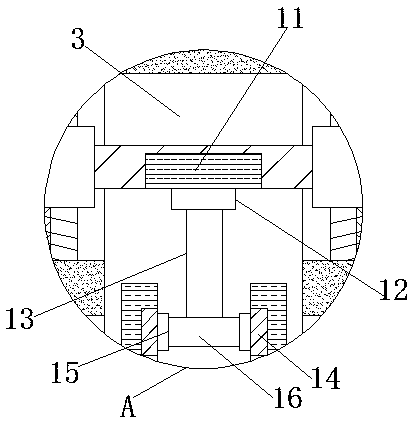

Supporting device and supporting method for machining propeller blade

InactiveCN102886699AIncrease stiffnessStable supportPositioning apparatusMetal-working holdersHydraulic cylinderPropeller

Owner:JIANGSU UNIV OF SCI & TECH

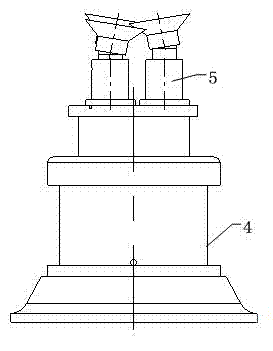

Method for continuously cooking grass raw materials and equipment used in same

ActiveCN101906729ASmooth dischargeFinely-divided material pretreatmentBlack liquorPulp and paper industry

The invention provides a method for continuously cooking grass raw materials, comprising the following steps: (1) preparing the grass raw materials before dipping to obtain the prepared grass raw materials before dipping; (2) transferring the prepared fibrous raw materials into an impregnator through a screw feeder, adding impregnation liquid for dipping treatment, putting the prepared grass raw materials in a digester and adding impregnation liquid to the digester at the same time, and then adding hot black liquor for primary cooking to obtain the primarily cooked grass raw materials; and (3) adding cooking liquor to the primarily cooked grass raw materials for secondary cooking to obtain pulp of the grass raw materials. The method of the invention achieves the purpose of continuously cooking the grass raw materials with large liquor ratio, shortens cooking time, reduces energy consumption and improves uniformity of the pulp. The invention further provides cooking equipment used in the method.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

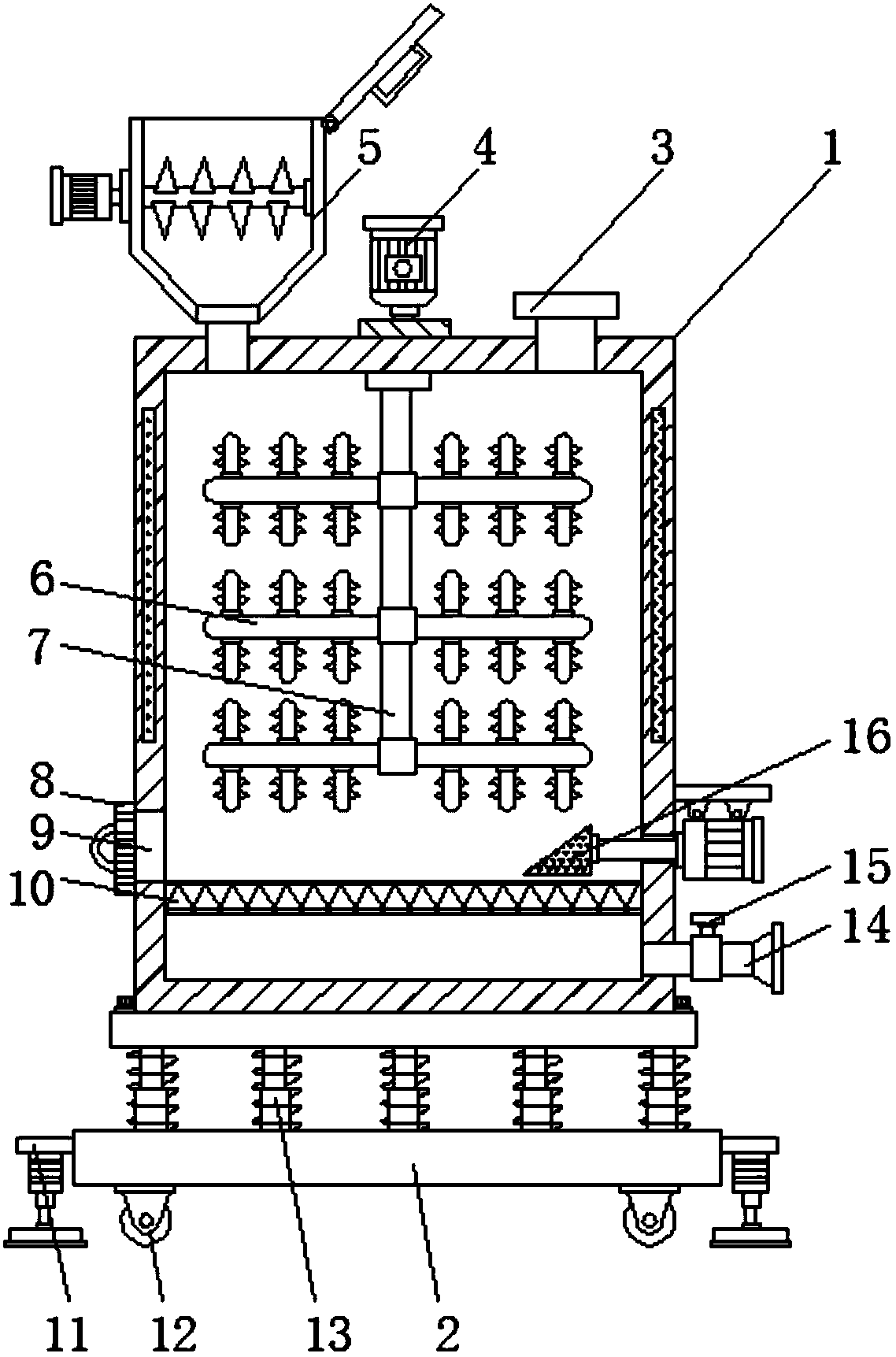

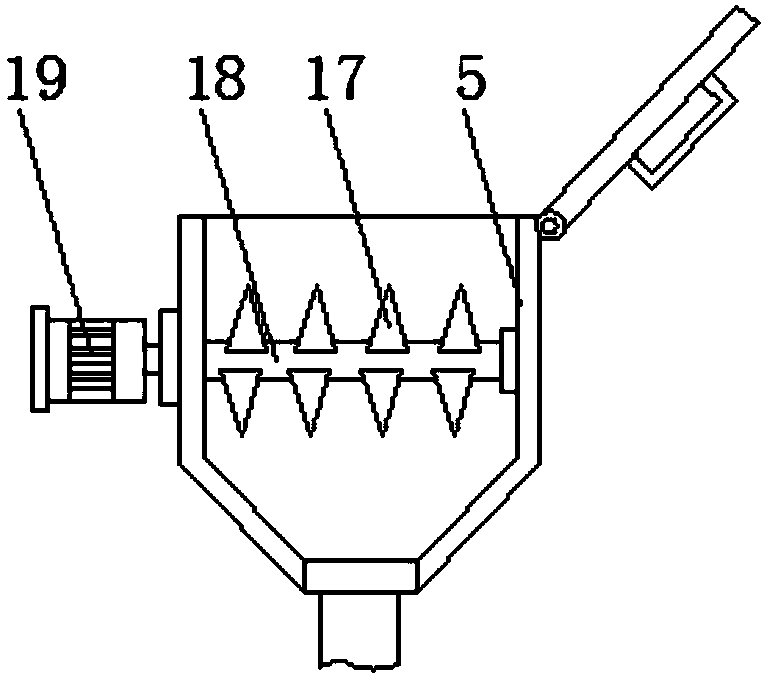

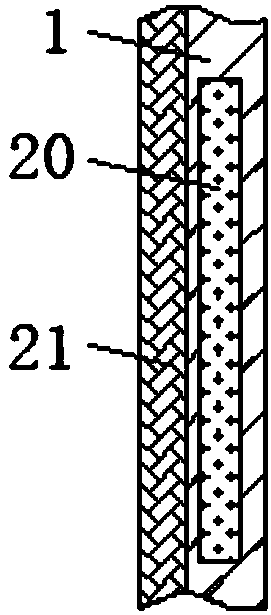

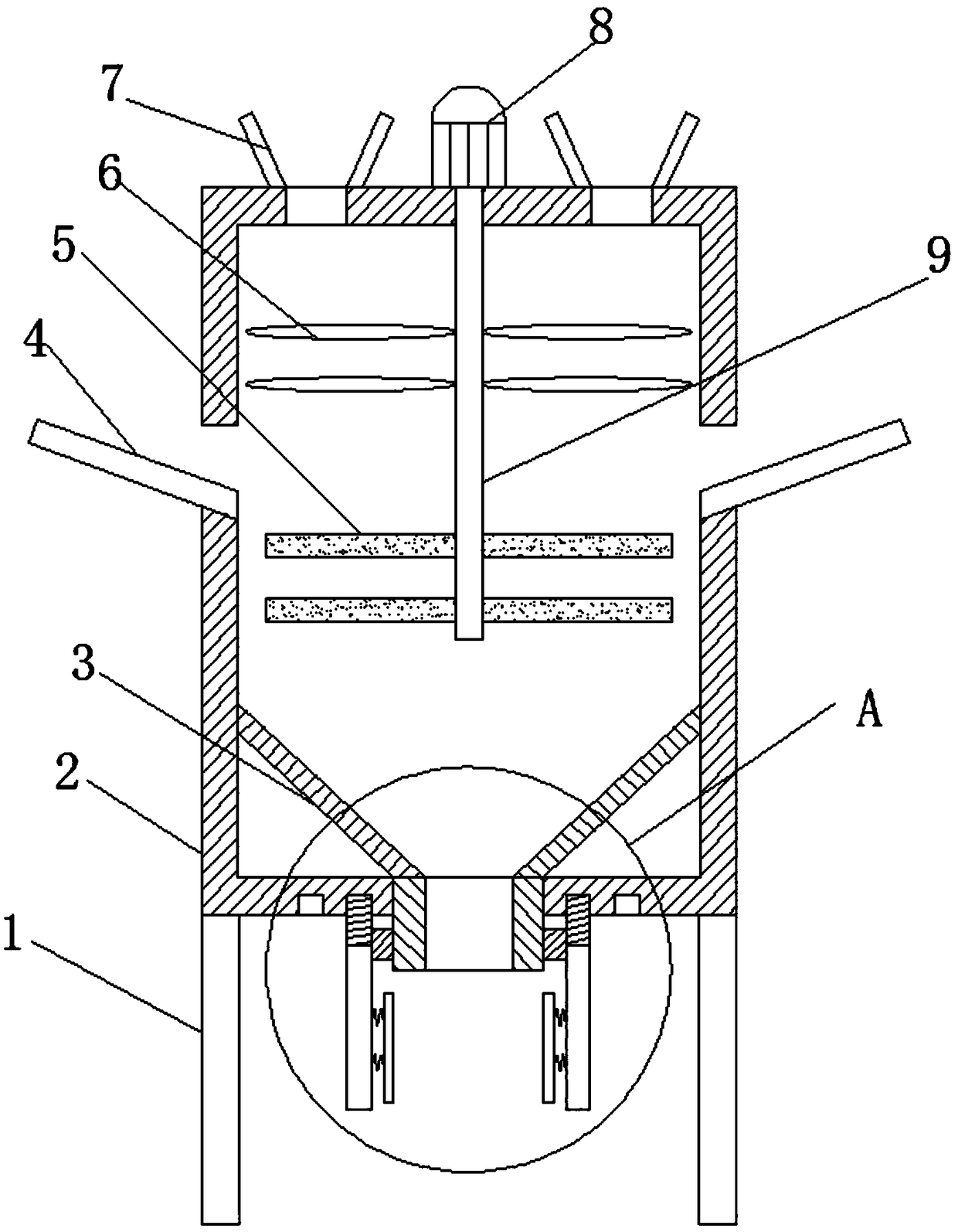

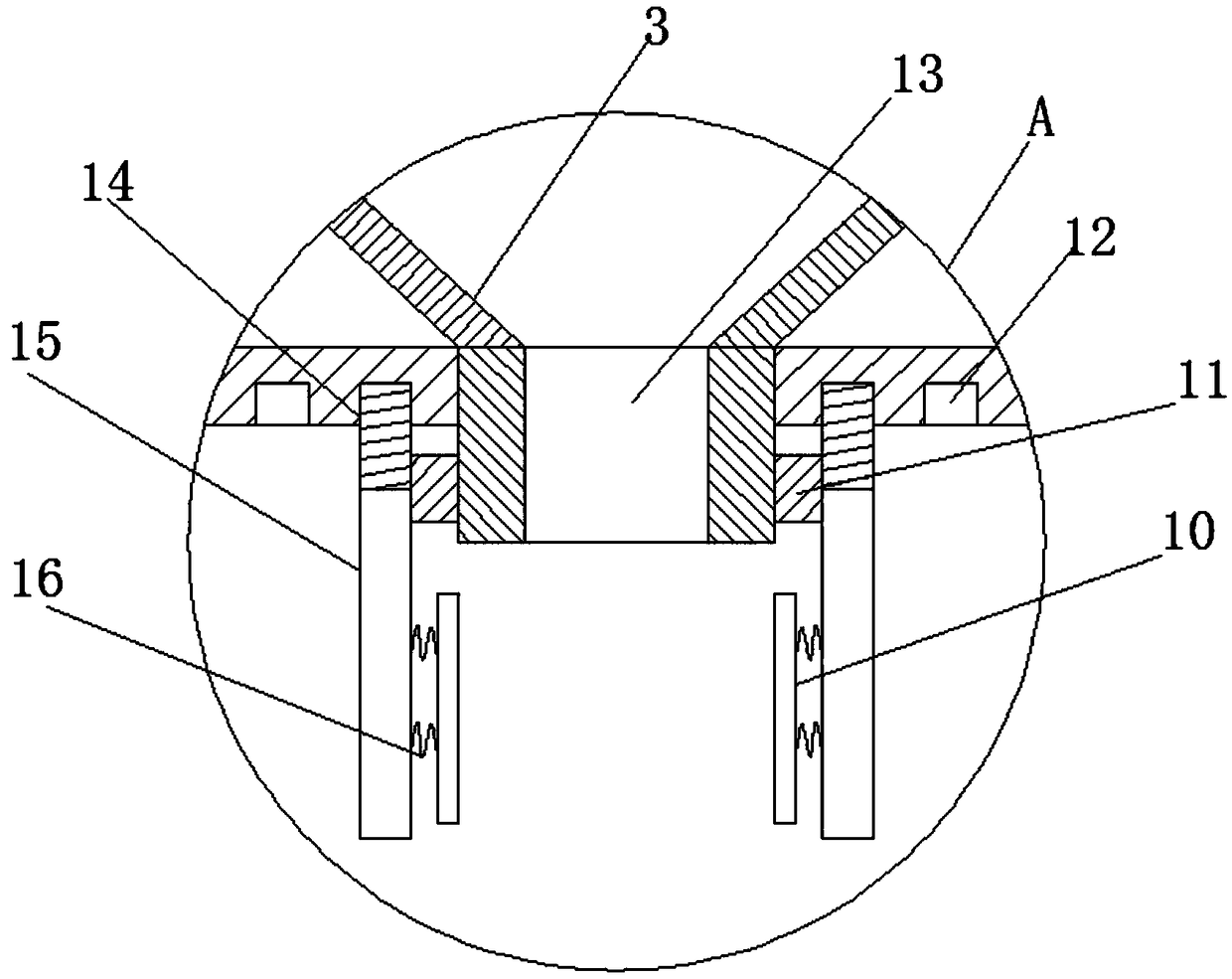

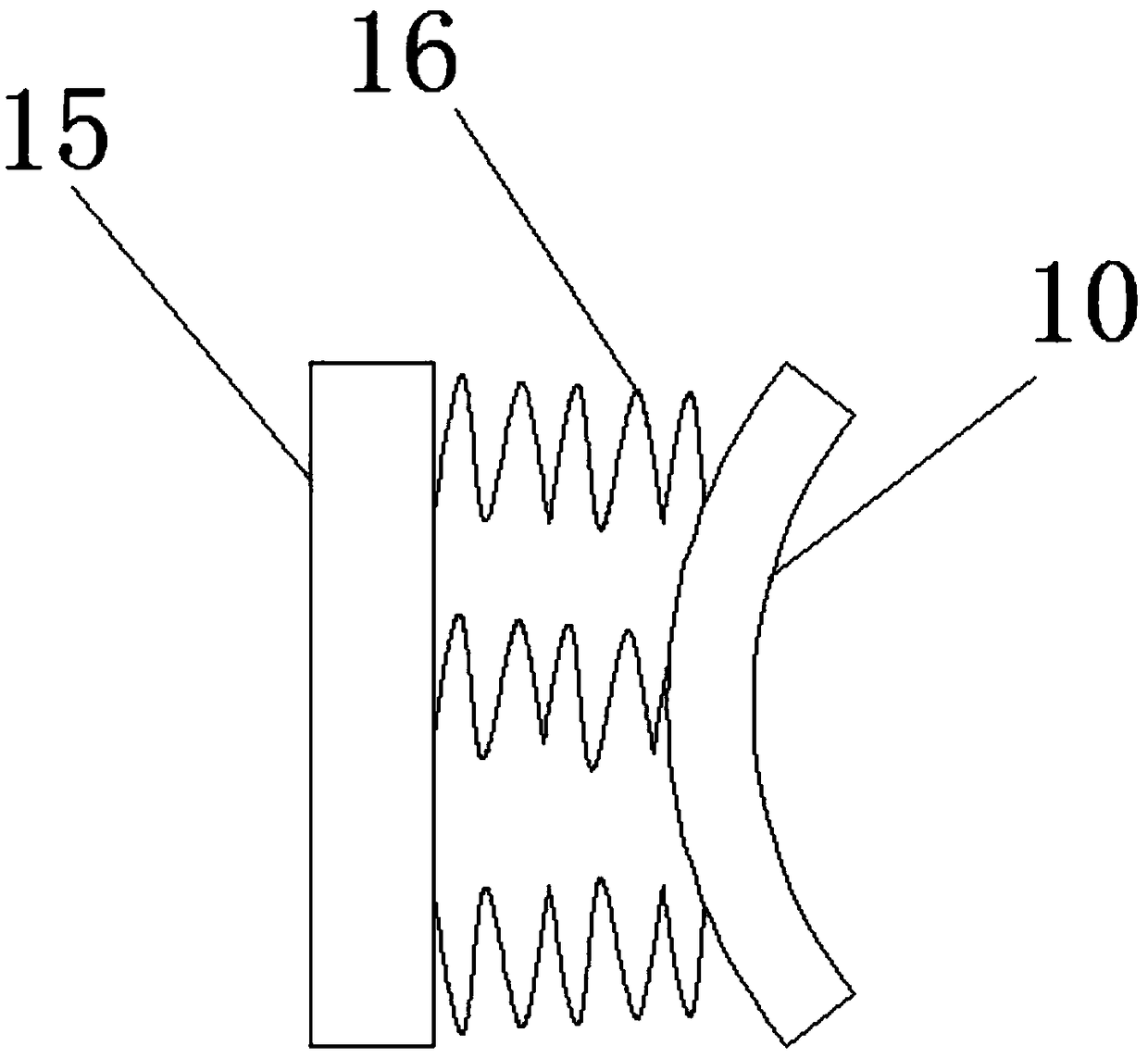

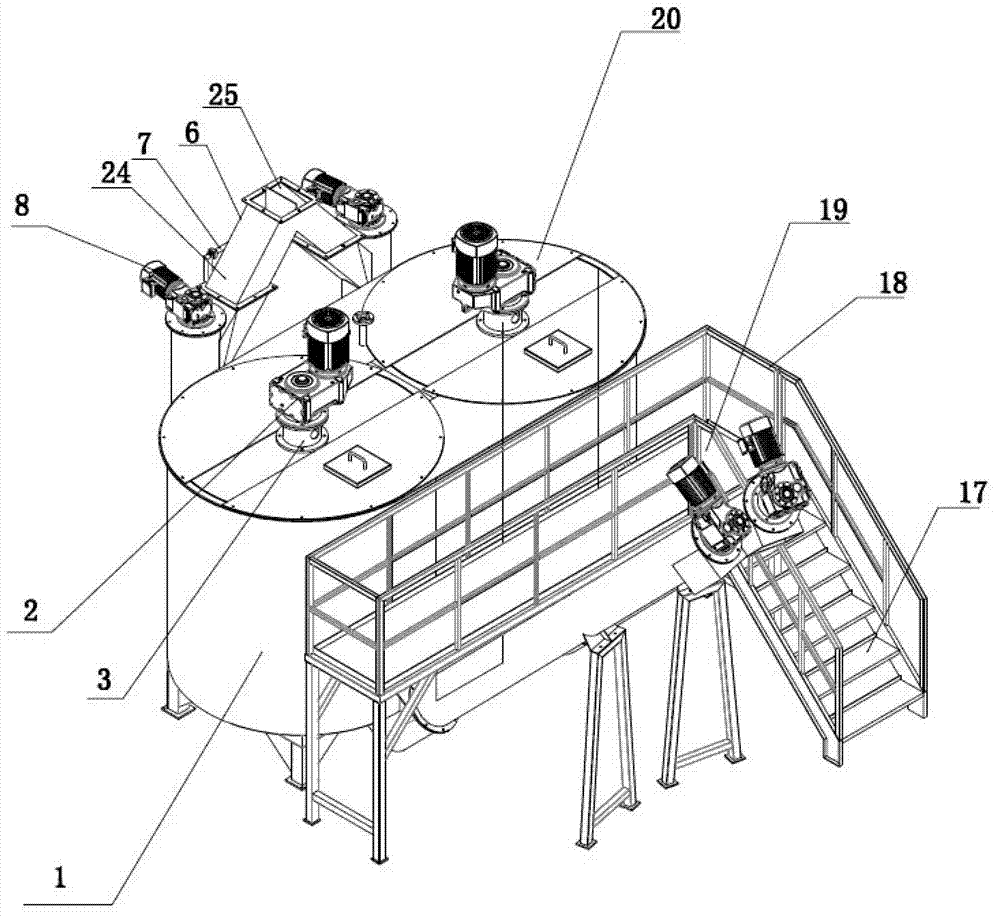

Slurry stirring device for coated fabric production

PendingCN108607463AStir wellEffective crushing and refiningRotary stirring mixersTransportation and packagingPulp and paper industryReducer

Owner:浙江唐艺织物整理有限公司

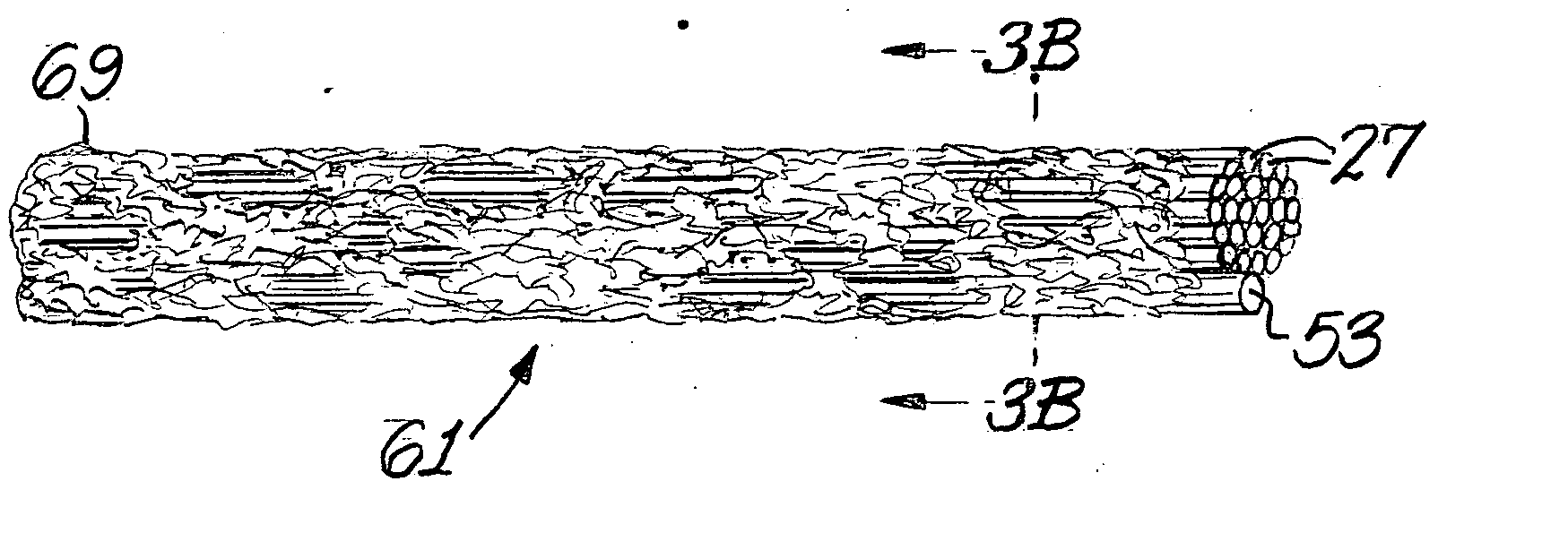

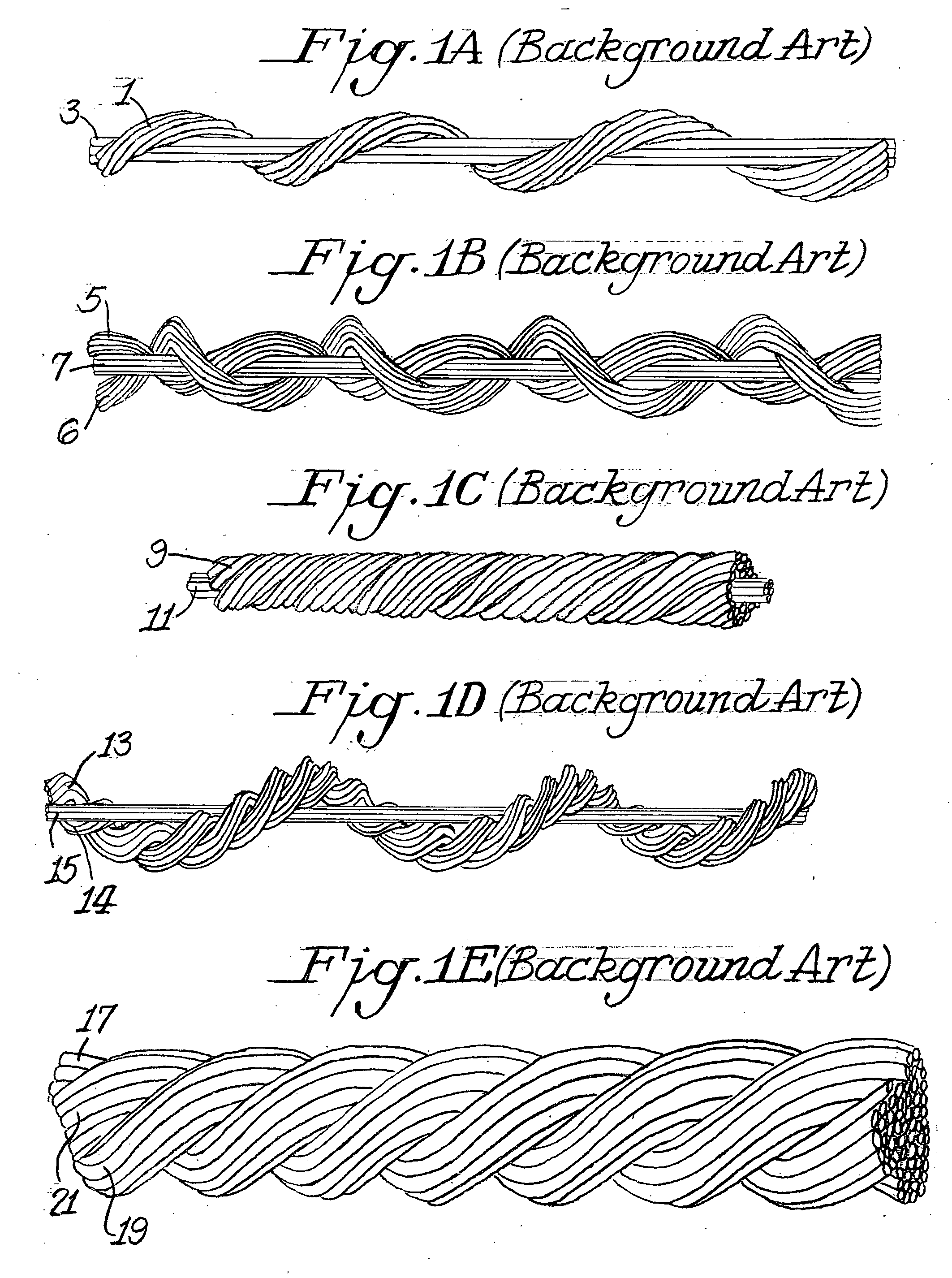

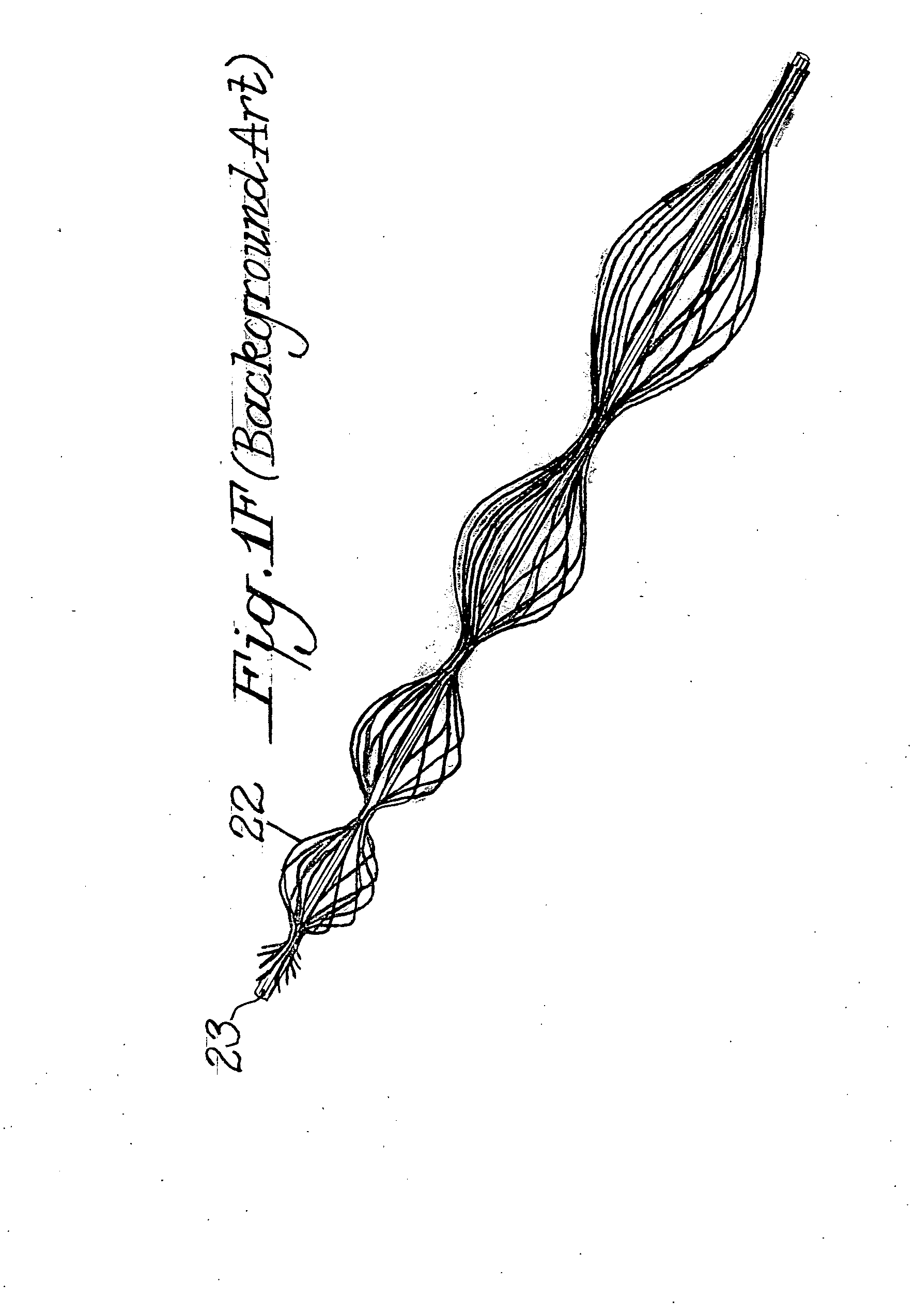

Size-covered composite yarns and method for making same

InactiveUS20050124245A1Appealing tactile propertyIncrease speedWarp knittingSynthetic resin layered productsYarnFiber

Owner:INVISTA NORTH AMERICA R L

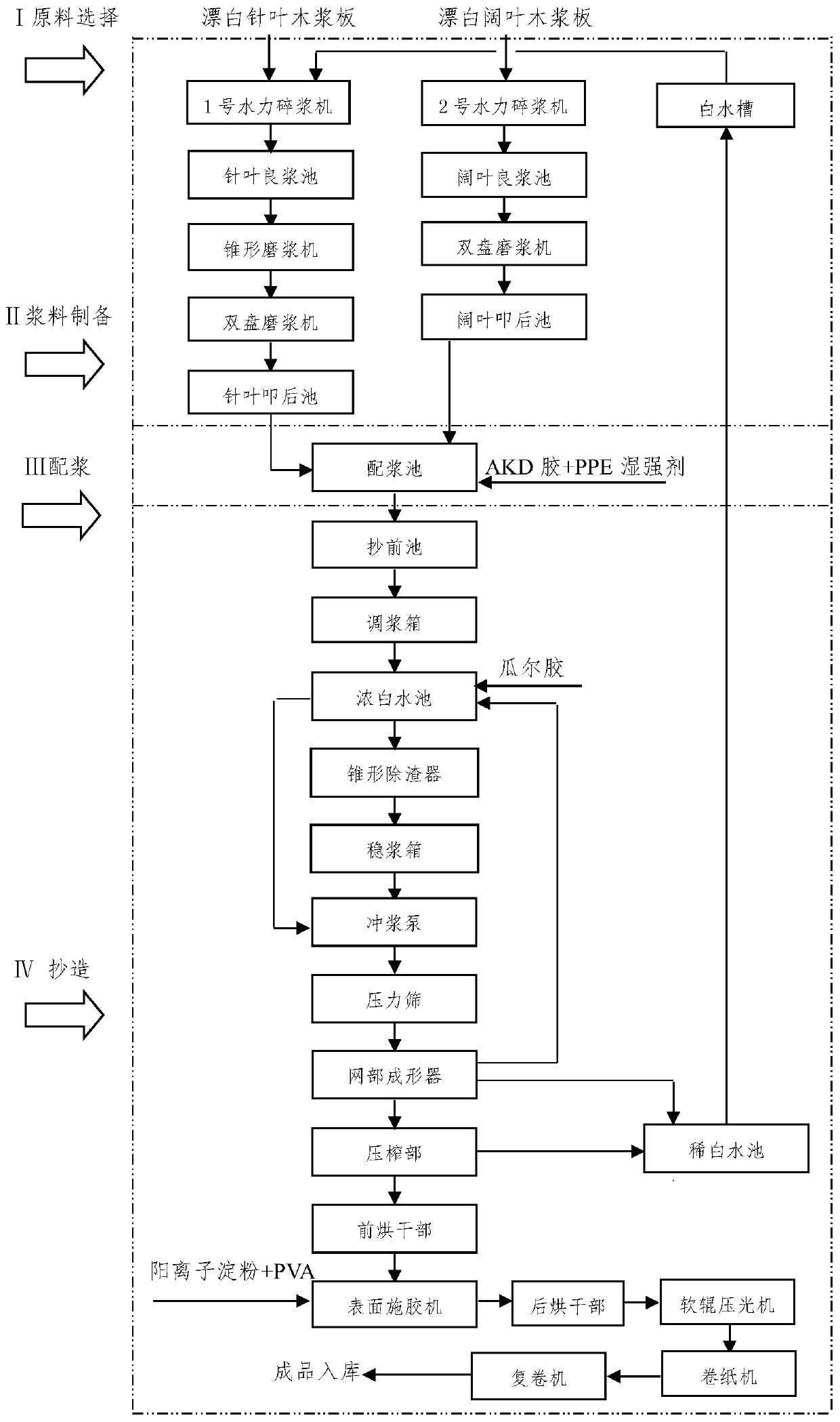

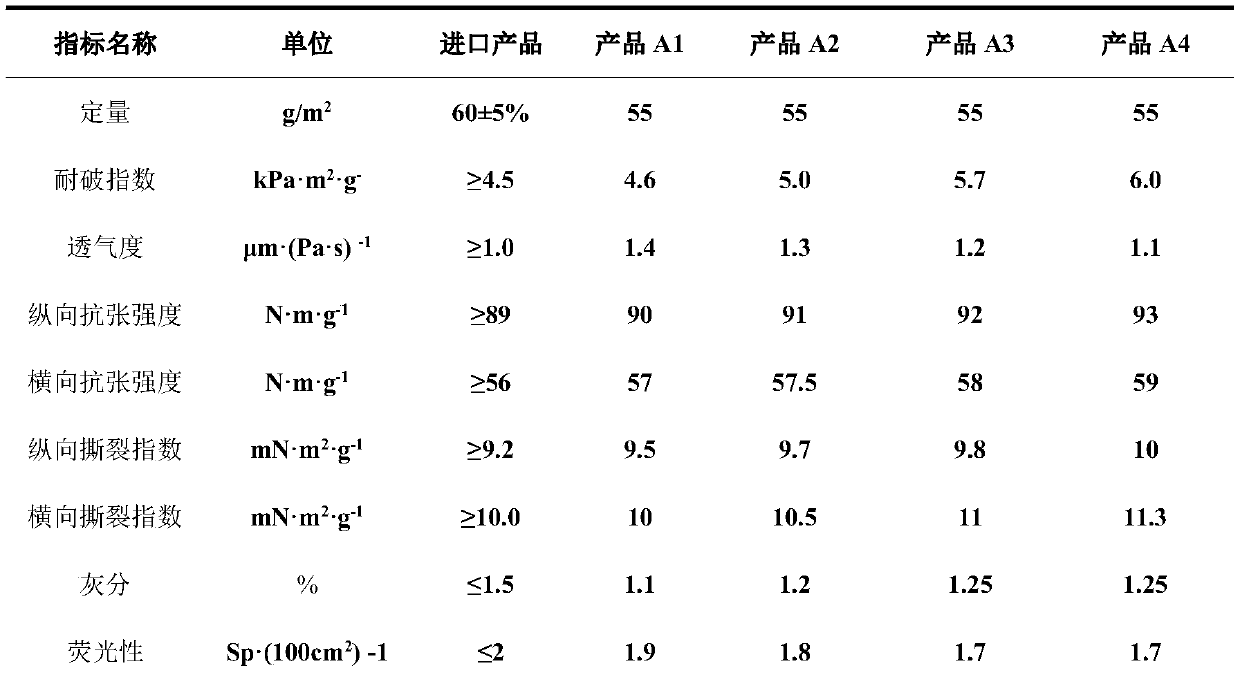

Medical dialysis body paper and production method thereof

InactiveCN109853297AHigh strengthImprove breathabilityWater-repelling agents additionSpecial paperWinding machinePulp and paper industry

Owner:NANJING FORESTRY UNIV

Method for manufacturing holographic aluminized paper material

InactiveCN101725077AWith molded holographic propertiesShort stayCoated paper substrateCoatingsWater basedPaper based

Owner:GUANGDONG MAGNOLIA PACKING MACHINERY

Environment friendly pulping process

Owner:刘长如

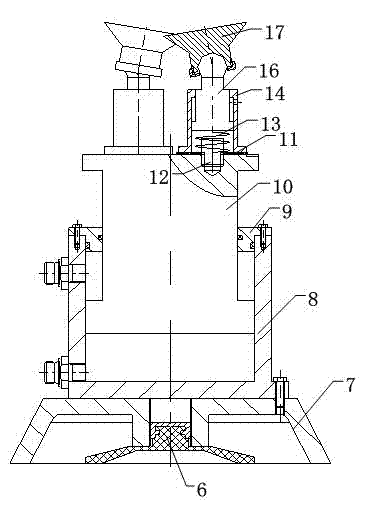

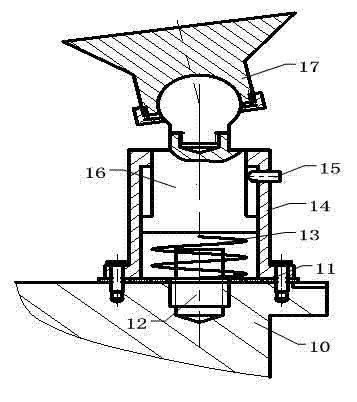

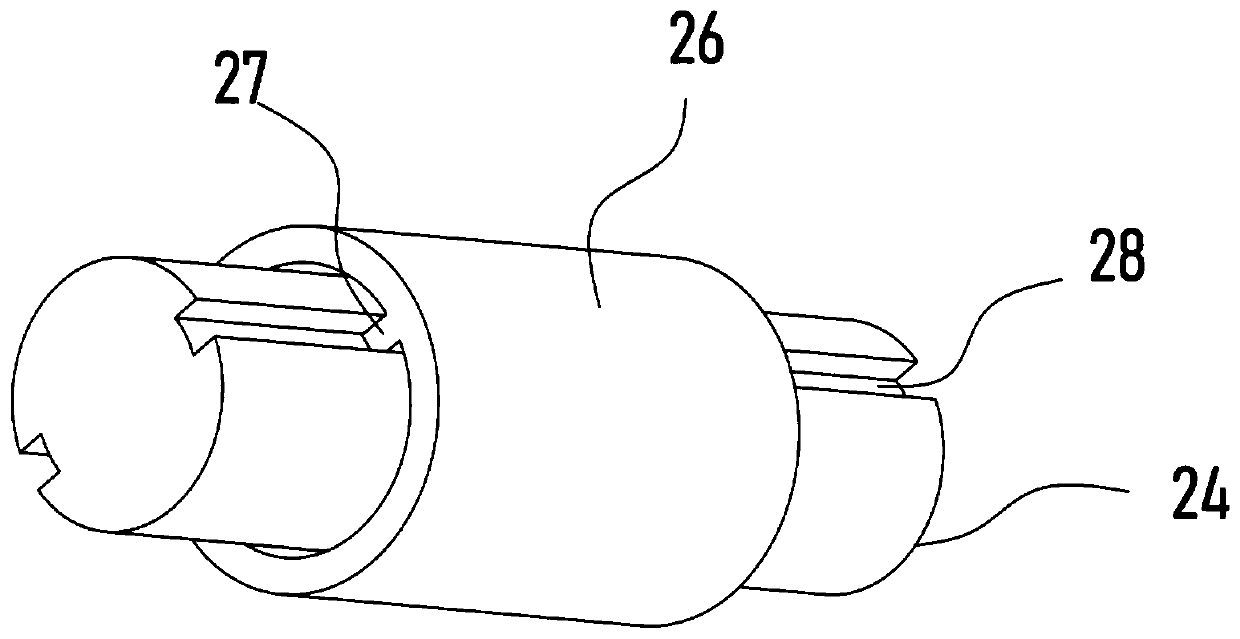

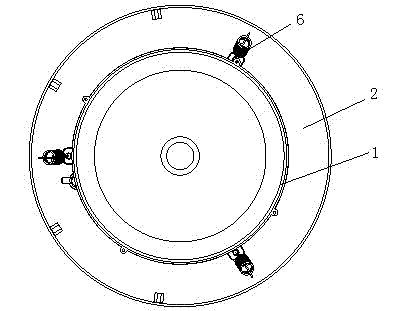

Regulable eccentric chuck

The invention discloses a regulable eccentric chuck. The regulable eccentric chuck comprises a fixing chuck, a clamping chuck and a positioning flange plate, wherein the positioning flange plate is fixedly clamped on the fixing chuck, and a plurality of mounting holes are formed in the positioning flange plate; the clamping chuck is fixedly mounted on the positioning flange plate through the mounting holes, the mounting holes adopt a bar-shaped groove structure, the mounting holes are mutually in parallel in the lengthwise direction, a threaded hole is formed in one jack catch on the clamping chuck, and a positioning bolt is mounted in the threaded hole. The regulable eccentric chuck disclosed by the invention is reformed from a general three-jaw chuck, can be used for production of eccentric parts in batches, and has high production efficiency; the processing accuracy can be effectively controlled through rough regulation and fine regulation in the process of using the regulable eccentric chuck, and the regulable eccentric chuck has the characteristics of high efficiency, high accuracy and low cost.

Owner:CHENGDU KOWLOON CABINET IND CO LTD

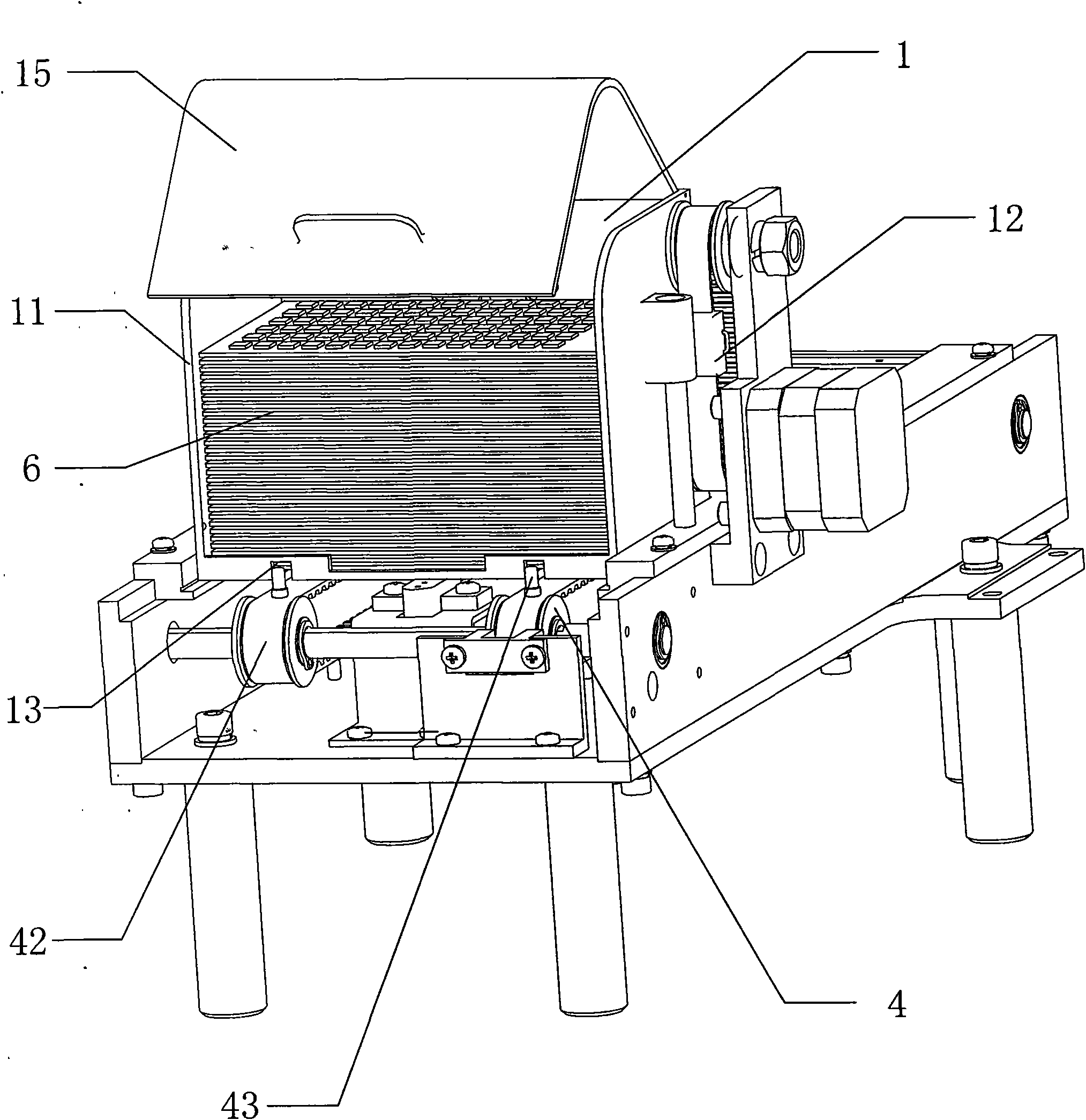

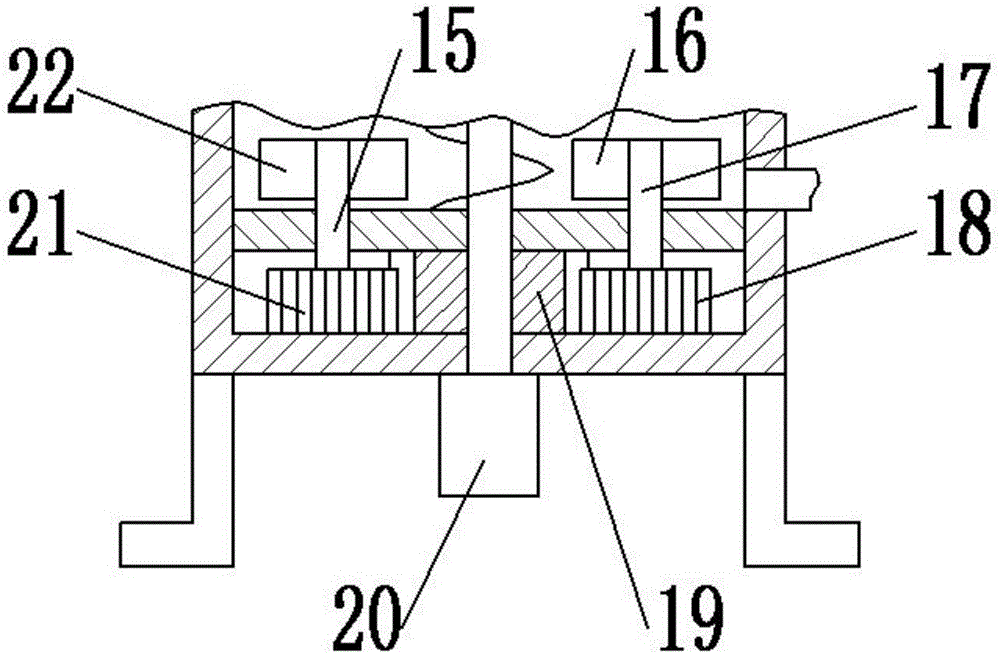

Direct current dual-edge trimmer

InactiveCN102630506AWide range of workImprove work efficiencyCuttersCutting implementsPulp and paper industryDirect current

The invention discloses a direct current dual-edge trimmer. The trimmer comprises a motor, a reducing mechanism, a blade support, an upper blade, a lower blade, a first connecting rod, a second connecting rod and a main shaft, wherein the blade support is elongated; at least two mounting holes are arranged at the middle part of the blade support; main bodies of the upper and lower blades are elongated; a plurality of toothed edges are respectively arranged on the two sides of the main bodies of the blades; at least two elongated holes are arranged at the middle parts of the main body of each blade along the length direction; bolts passing through the elongated holes and the mounting holes fix the upper and lower blades on the blade support; the motor drives the main shaft via the reducing mechanism; a first eccentric wheel and a second eccentric wheel are fixed on the main shaft; one end of the first connecting rod is sleeved on the first eccentric wheel and the other end of the first connecting rod is hinged with the end of the upper blade; and one end of the second connecting rod is sleeved on the second eccentric wheel and the other end of the second connecting rod is hinged with the end of the lower blade. The trimmer has the following beneficial effects: the working range of the product is wider, thus the working efficiency is effectively improved; and the product achieves the effects of saving energy and protecting environment as the battery can be recycled repeatedly.

Owner:ZHEJIANG GRACE IND CO LTD

Heat recycling type efficient medicinal material drying device

ActiveCN106382808ADrying gas arrangementsDrying chambers/containersPulp and paper industryAir blower

Owner:深圳市惠普生科技发展有限公司

Automatic residue crushing device for dish-washing machine

PendingCN109758087ASimple structureSave spaceTableware washing/rinsing machine detailsPulp and paper industrySewage

The invention provides an automatic residue crushing device for a dish-washing machine. The automatic residue crushing device comprises a water containing groove, a water cup and a residue crushing component, wherein the water containing groove is formed in a bottom plate of the dish-washing machine, and a water through hole is formed in the bottom of the water containing groove; the water cup isarranged at the bottom of the water containing groove, and an opening is formed in the top of the water cup; the opening is in liquid seal connection with the water through hole; the residue crushingcomponent is arranged on the lower part of the water cup to be used for crushing residues flowing into the bottom of the water cup along with water; a drain outlet is formed in the lower part of the water cup to be used for draining the crushed residues and sewage. With the adoption of the structure, the residues produced by cleaning tableware or foods flow into the water containing groove along with water and drop into the bottom of the water cup by virtue of the water through hole and the opening, the dropping residues are crushed by the residue crushing component, and the crushed residues are drained from the drain outlet along with the sewage, so that the pipeline is effectively prevented from being blocked. Meanwhile, the structure is directly arranged at the bottom of the dish-washing machine, the pipeline space is not occupied, and the automatic residue crushing device is low in manufacturing cost and long in service life.

Owner:ZHONGSHAN INSE GROUP

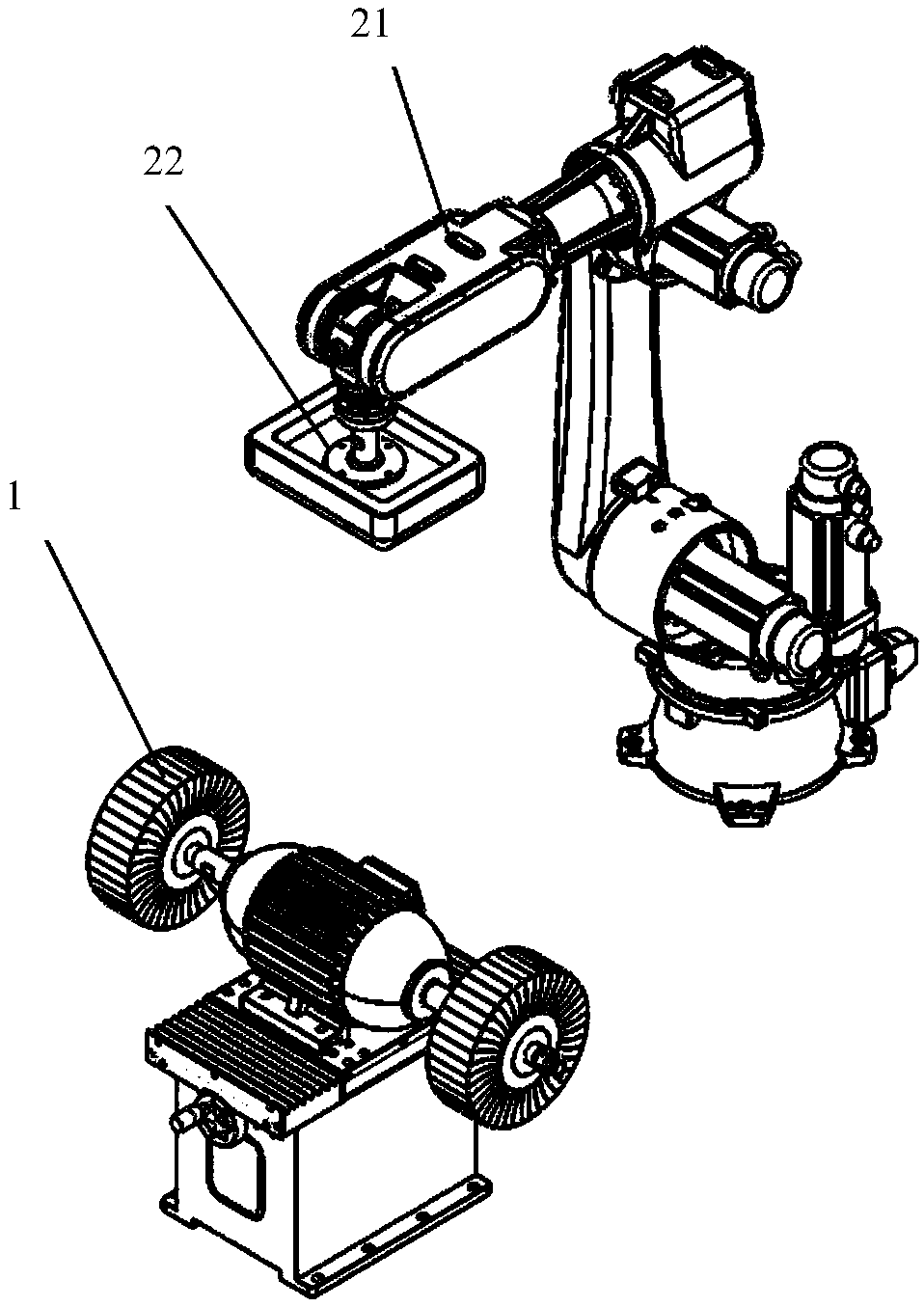

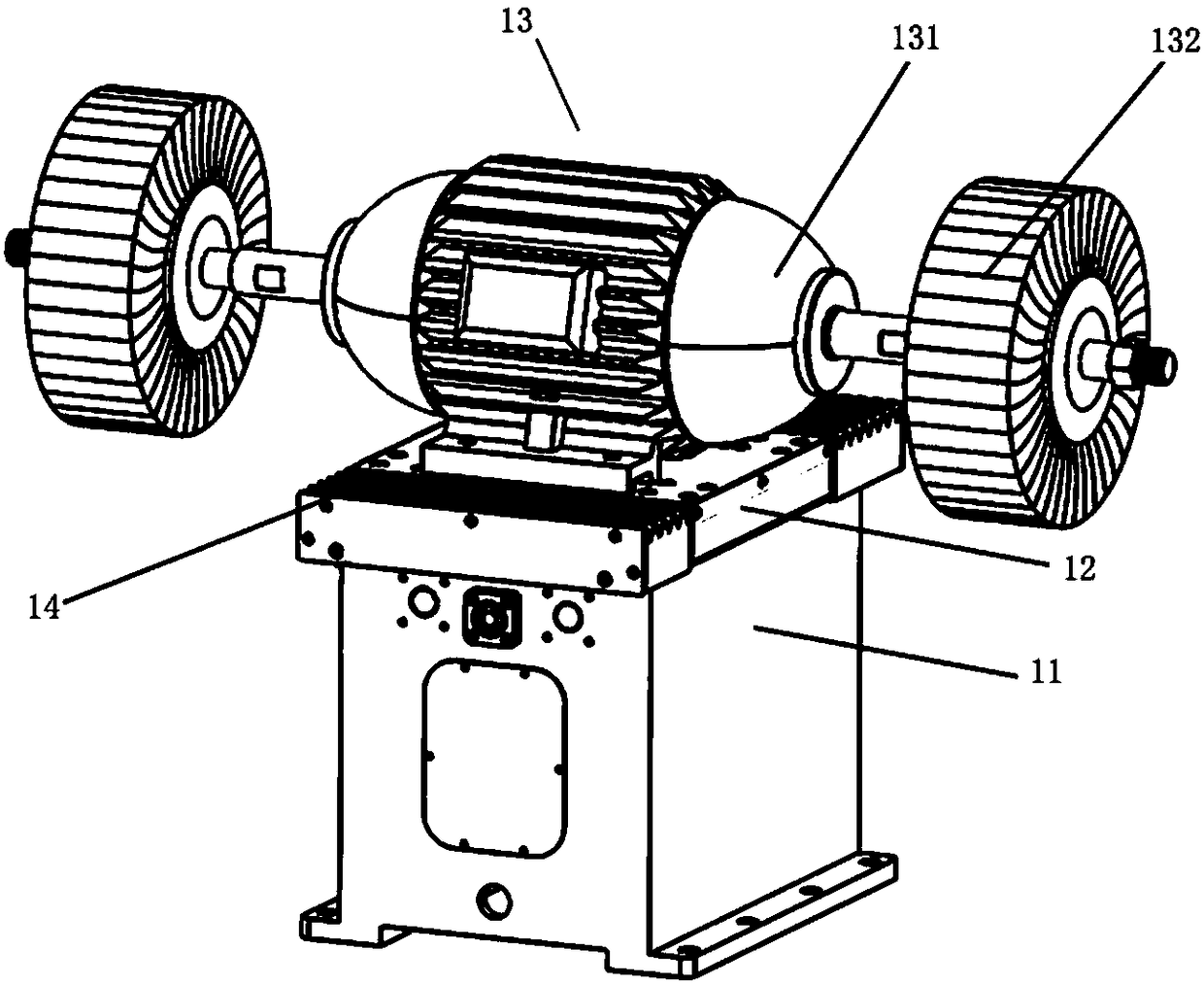

Force-controlled polishing device and polishing robot applying force-controlled polishing device

Owner:GUANGDONG LXD ROBOTICS CO LTD

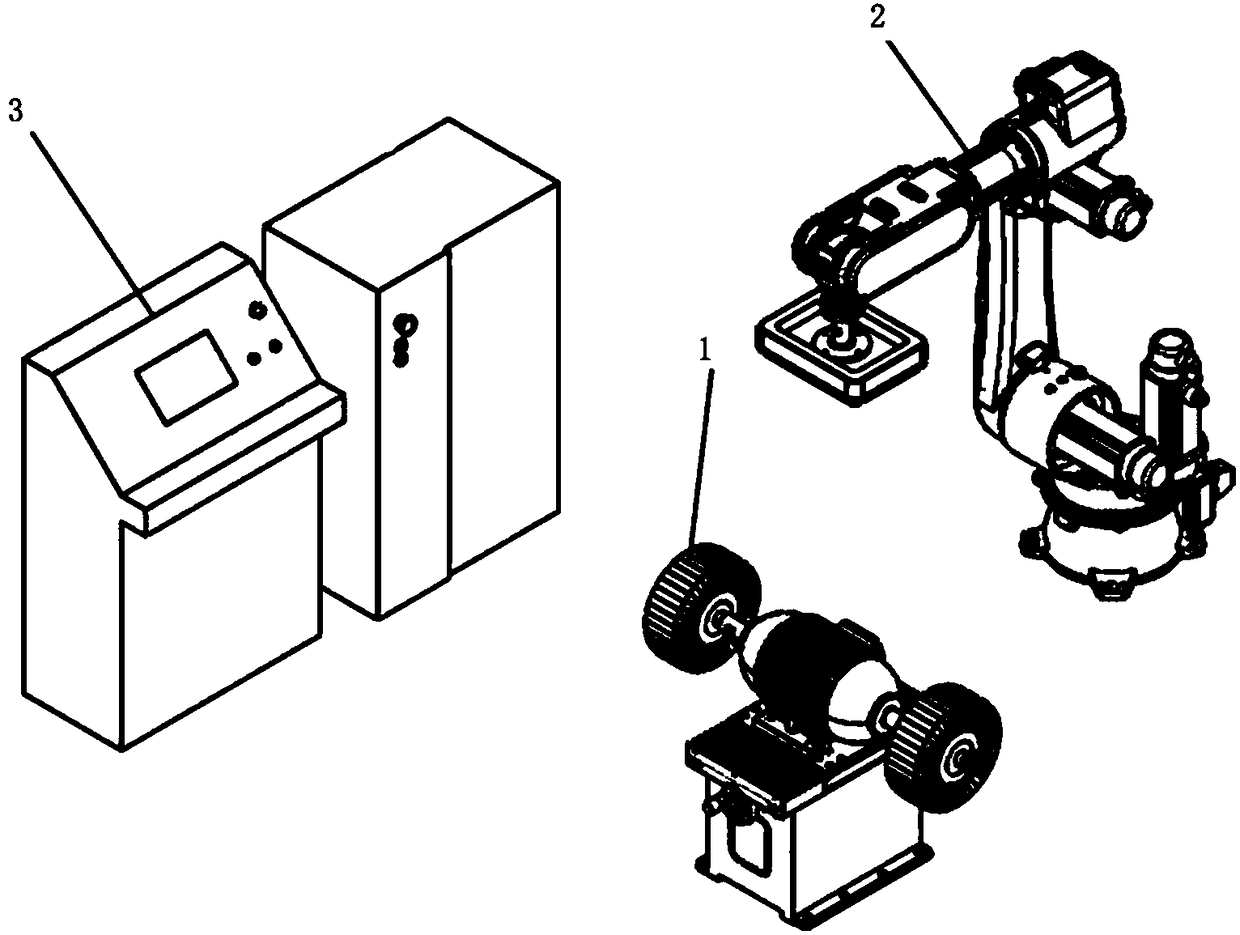

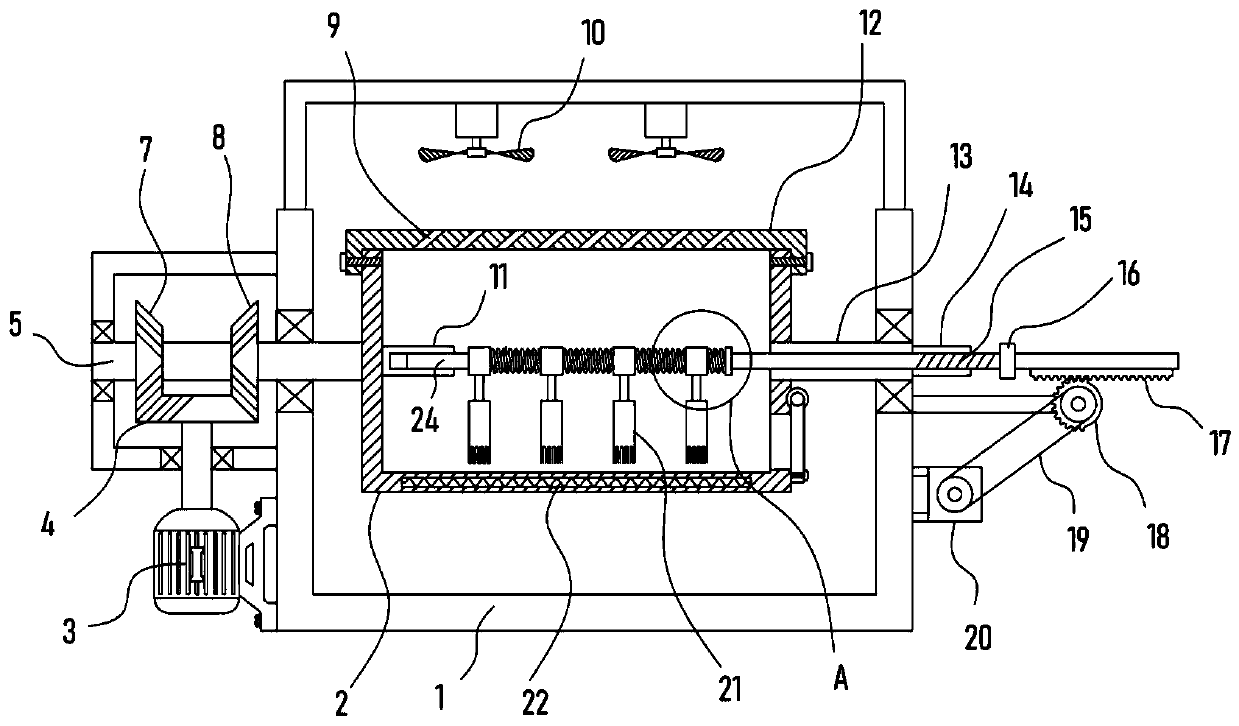

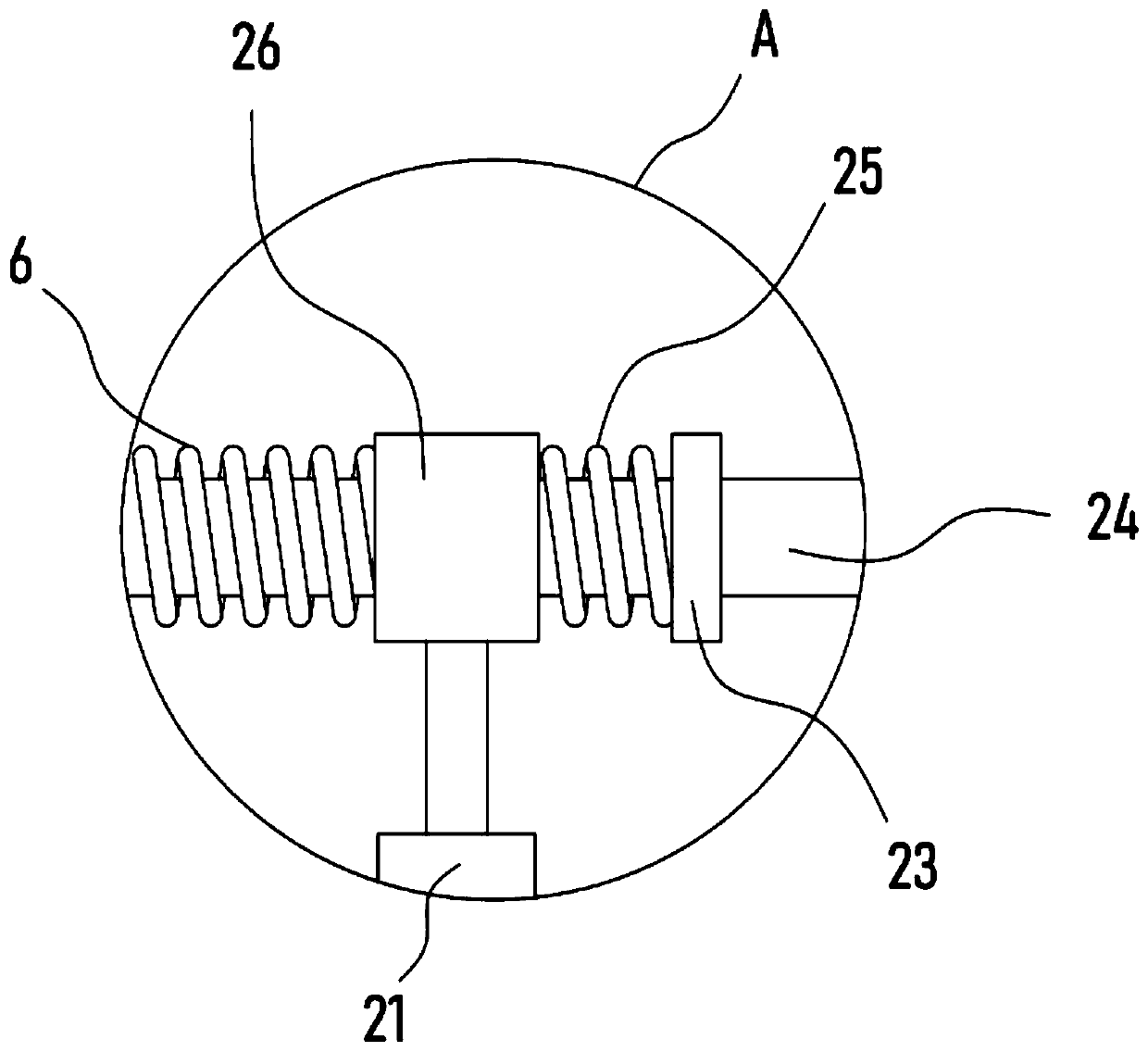

Pressure-controllable industrial robot grinding and polishing system and grinding and polishing method

PendingCN108296962AImprove grinding and polishing effectImprove production efficiency and product qualityPolishing machinesGrinding drivesPulp and paper industryIndustrial robot

The invention provides a pressure-controllable industrial robot grinding and polishing system. The pressure-controllable industrial robot grinding and polishing system is characterized by comprising apolishing device, a feeding device and a controller, and the polishing device comprises a fixed base, a mounting seat, a polishing mechanism, first slide rails, a position adjusting mechanism and a cylinder. The cylinder is connected with the mounting seat, and the mounting seat is slidably connected with the first slide rails to realize that the cylinder pushes the mounting seat to move in the length direction of the first slide rails to drive the polishing mechanism to move. The cylinder is connected with the controller to enable the controller to control the cylinder to control grinding pressure between the polishing mechanism and a workpiece. The cylinder is disposed on the fixed base through the position adjusting mechanism. The pressure-controllable industrial robot grinding and polishing system can improve grinding and polishing effects and improve production efficiency and product quality. The invention further provides an industrial robot grinding and polishing method which is capable of realizing constant grinding pressure between the polishing mechanism and the workpiece, effectively improving the grinding and polishing effects and improving the production efficiency and the product quality.

Owner:FOSHAN INST OF INTELLIGENT EQUIP TECH +1

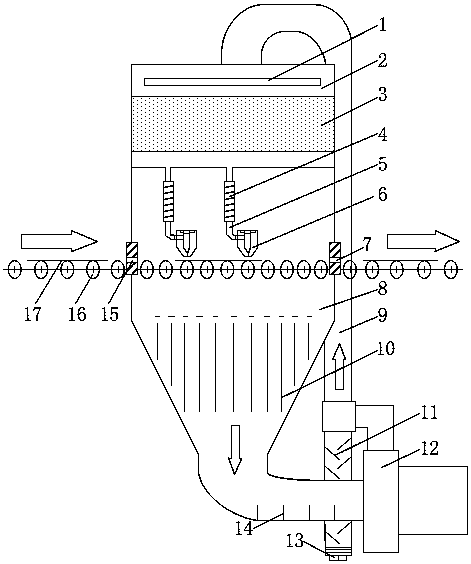

Ceramic glaze drying device

ActiveCN110044137APromote shakingFull heating effectDrying solid materials with heatDrying gas arrangementsWater vaporDrive shaft

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

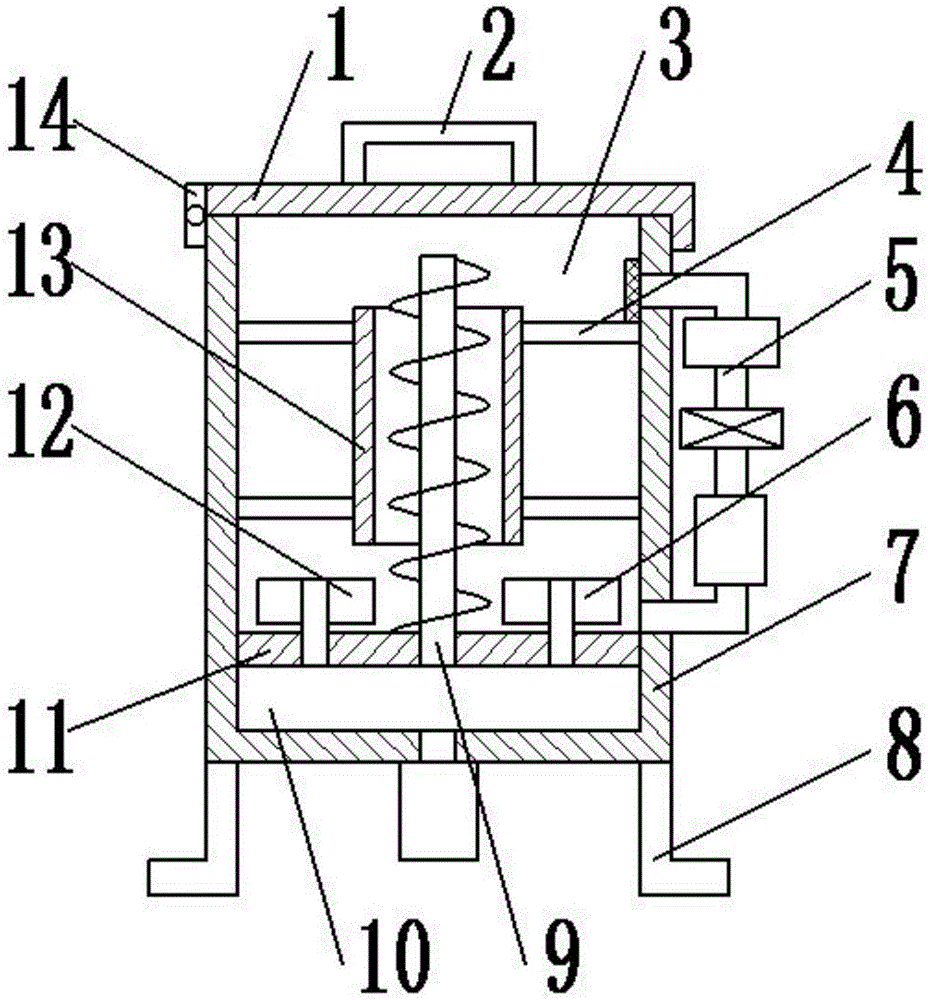

Double-crushing type civil paper shredder

InactiveCN108654779AReduce the number of installationsImprove confidentialityGrain treatmentsGear wheelPulp and paper industry

The invention discloses a double-crushing type civil paper shredder. The double-crushing type civil paper shredder comprises a paper shredder body, a paper inlet is formed in the top end of the papershredder body, two rubber roller shafts are movably arranged in the positions, located at the lower end of the paper inlet, in the paper shredder body, two paper shredding hobs are movably arranged atthe lower ends of the two rubber roller shafts correspondingly, a center shaft of one paper shredding hob is fixedly connected with the driving end of a motor, a driving gear is fixedly arranged on the outer side of the driving end of the motor, and a transmission gear is movably meshed on the driving gear. According to the double-crushing type civil paper shredder, waste paper is preliminarily crushed by the two paper shredding hobs which roll oppositely, one paper shredding hob is driven by the motor, the other paper shredding hob can freely rotate, furthermore, one rubber roller shaft is driven to rotate through a gear transmission structure, and the other rubber roller shaft can freely rotate, so that the number of the motors to be installed is reduced; and when the waste paper crushed by the paper shredding hobs enters a secondary crushing box, secondary crushing is carried out on preliminarily crushed paper strips by a high-speed rotating crushing device.

Owner:MINNAN INST OF SCI & TECH

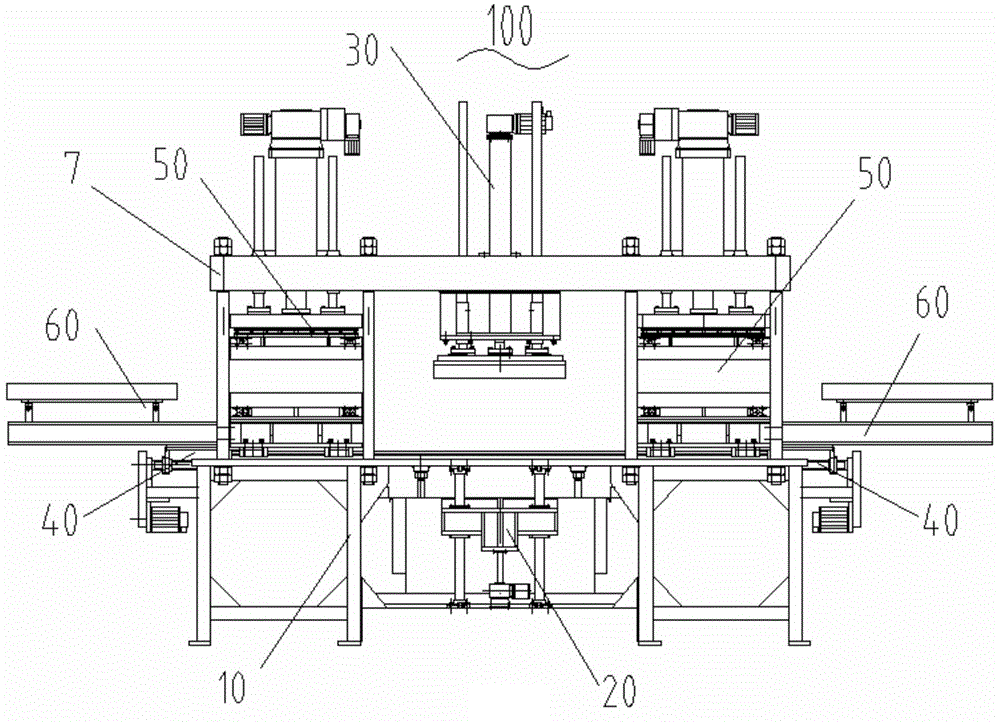

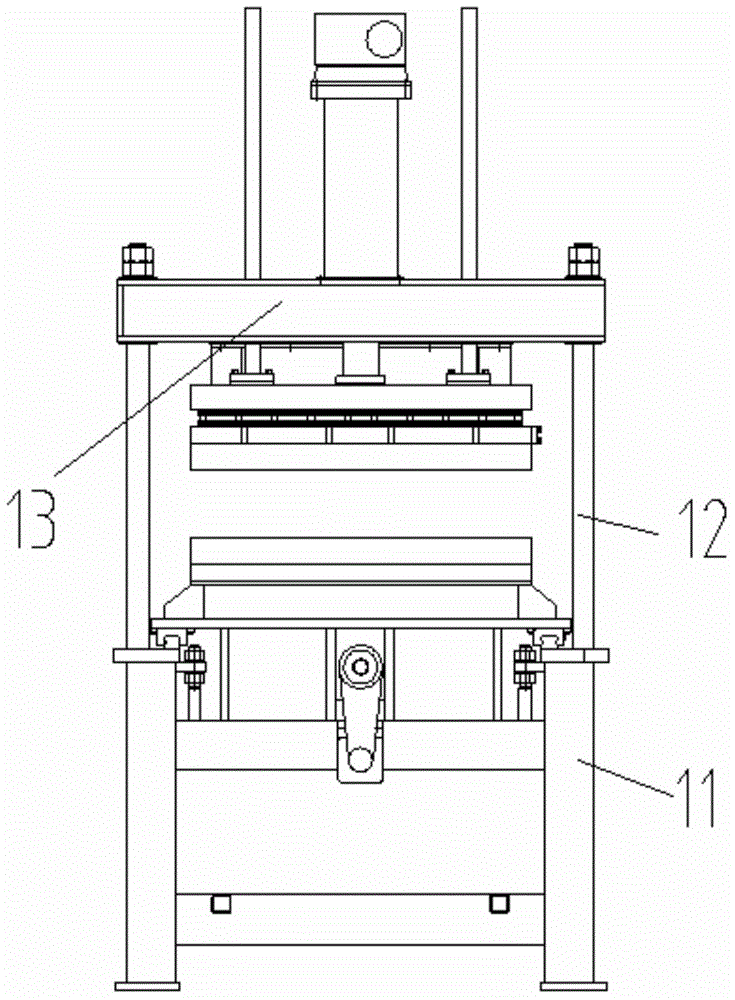

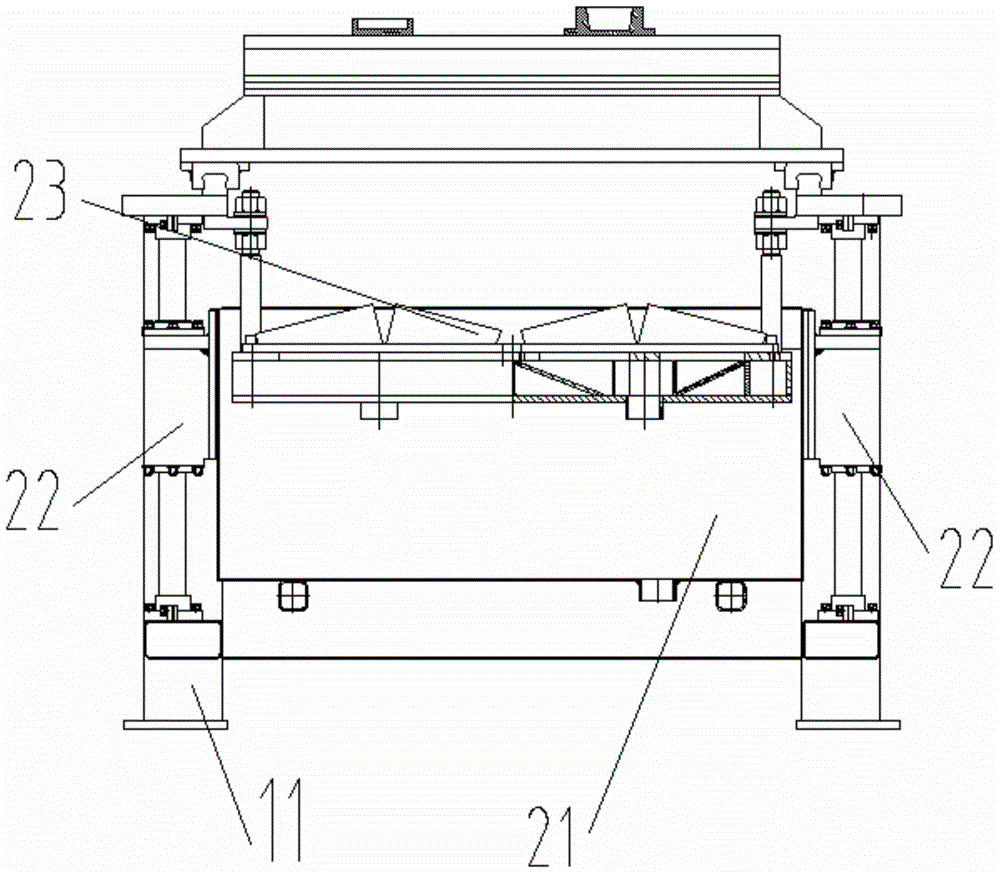

Paper pulp molding forming machine

Owner:ZHEJIANG SHURCON MFG

Multi-functional meat processing equipment

InactiveCN108703193AAvoid breakingSimple structureSausage filling/stuffing machinesMeat mixing apparatusAdditive ingredientPulp and paper industry

Owner:ANHUI HAOZAILAI FOOD

Fan blade type bottle flake washing equipment

Owner:无锡绿科环保科技有限公司

Straw carbonization and separation technique and separating device used thereby

InactiveCN101735836AAchieve refinementBiofuelsDispersed particle separationCombustible gasCarbonization

The invention discloses a straw carbonization and separation technique and a separating device used thereby to realize the carbonization of the straw and extract various useful substances, such as wood tar oil, wood vinegar, mixed combustible gas and the like in a carbonization process. The technique comprises the following steps of: processing the straw into segmented straw, sending the segmented straw into a furnace kiln and igniting to heat the segmented straw at a high temperature to produce smoke gas and placing the treated straw into a sharp quenching multi-pipe separating device to extract wood tar oil; extracting mixture of wood tar oil and wood vinegar liquid in a multi-layer staggered separating device; extracting wood vinegar liquid in an internal rotation centrifugal separating device; and sending remaining gas into a purification tower to purify and controlling the temperature to be between 60 and 80 DEG C. The invention has the advantages that: a new straw carbonization and separation technique is developed and the extraction of various useful substances, such as wood tar oil, wood vinegar and mixed combustible gas, is realized when bio-carbon is produced.

Owner:崔宝玲

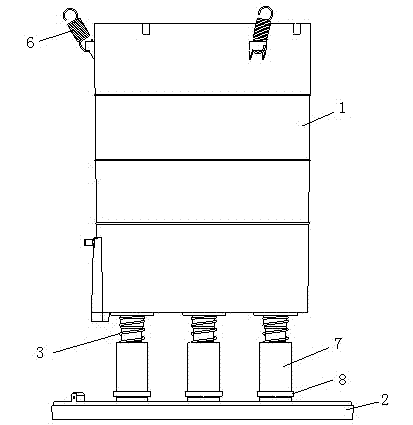

Water-saving potato high-efficiency washing device

InactiveCN108378389AEasy to cleanSave waterClimate change adaptationFood treatmentWater savingWater resources

The invention discloses a water-saving potato high-efficiency washing device. The water-saving potato high-efficiency washing device comprises a bracket, a washing bucket, a rotating motor, a cylinderbody, a water tank and a washing roller, wherein the washing bucket is fixedly connected with the bracket; the washing roller is arranged in the washing bucket; a threaded sleeve penetrates through the upper end of the cylinder body and is rotatably connected with the cylinder body; the lower end of a threaded rod is fixedly connected with a piston; a pushing rod is fixedly mounted at the lower end of the piston; the lower end of the pushing rod is hinged to a sleeve; a propping and pressing rod penetrates through the bottom of the washing bucket and is rotatably connected with a disk; and moving rods are fixedly mounted on the disk, and penetrate through the lower end of the side wall of the washing roller to extend to a cavity of the side wall. According to the water-saving potato high-efficiency washing device disclosed by the invention, intermittent water supply is performed through pumping of clean water by the arranged cylinder body to wash potatoes, so that the washing effect is good, and water resources are saved; and the potatoes are washed through the rotating of the arranged washing roller, and brushes on the washing roller can also perform washing in an up-and-down brushing manner, so that the multi-direction washing is realized, and the water-saving potato high-efficiency washing device is high in washing efficiency, high in practicality and high in automation degree.

Owner:孙灵科

Ionic wind surface treatment machine

PendingCN108787625AReduce filter loadExtended service lifeFlexible article cleaningCleaning using gasesPulp and paper industryHigh pressure

Owner:CHENZHOU HAILI MICROELECTRONICS TECH

Air cleaning equipment

InactiveCN102671508AAdequate responseEfficient removalDispersed particle separationComing outAir cleaning

The invention relates to air cleaning equipment which comprises an adsorption tank and a condenser. An exhaust gas inlet is arranged on the side face of the middle part of the absorption tank, adsorbent is filled in the cavities of an upper absorption tank and a lower absorption tank, an upper exhaust port is arranged at the top of the absorption tank, a lower exhaust port is arranged on one side surface of the bottom of the absorption tank, the upper exhaust port and the lower exhaust port are connected with an air reservoir through a pipeline, the air reservoir is connected with a ventilator, the air reservoir is connected with one end of a sound eliminator through the pipeline, and the other end of the sound eliminator is connected with a clean air outlet pipe, a cooling water feed pipe is connected at the bottom of the condenser, the cooling water feed pipe is communicated with a side wall at the top of the absorption tank, a condensate pipe is connected on the side surface at the bottom of the condenser, the condensate pipe is communicated with a separator, and the separator is communicated with a solvent recovery liquid reservoir through the pipeline. The air cleaning equipment has the advantages that the exhaust gas enters through the exhaust gas inlet at the middle part of the absorption tank, the adsorbent is located the cavities of the upper absorption tank and the lower absorption tank, and the exhaust gas fully reacts with the adsorbent, so that the air coming out from the clean air outlet pipe is cleaner.

Owner:陈娟

Full-automatic impeller washing machine

InactiveCN102817211AAchieve riseAchieve sinkingOther washing machinesTextiles and paperImpellerStructural reliability

Owner:WHIRLPOOL CHINA

Slag removal machine of waste pyrolysis gasifier

The invention discloses a slag removal machine of a waste pyrolysis gasifier. The slag removal machine structurally comprises a furnace body, a material conveying pipe, a pushing machine, a feeding hopper, a fuel gas outlet, a hot air inlet and a slag removing mechanism, wherein the material conveying pipe is arranged at the top end of the left side of the furnace body, the pushing machine is arranged at the left end of the conveying pipe, the upper surface of the conveying pipe is connected with the feeding hopper, the fuel gas outlet is formed in the right side of the upper portion of the furnace body, and the hot air inlet is formed in the right side of the lower portion of the furnace body. The gasifier has the beneficial effects that a wiper and a scraper are arranged on the two sides of a rotating column, a motor drives the rotating column to rotate, a cutter is installed on the scraper so as to to scrape slag on the inner wall, the slag can fall into a material receiving disc, the inner wall is wiped through a cleaning brush on the wiper after the slag is scrapped, a ball pushing device and a stirring device are arranged inside the rotating column, a stirring rod can control balls in a rolling way, and the scraper and the wiper can be controlled to be stretched by changing the movement of the balls so as to adapt to furnace bodies with different sizes.

Owner:QUANZHOU TONGTONG ELECTRONIC EQUIP CO LTD

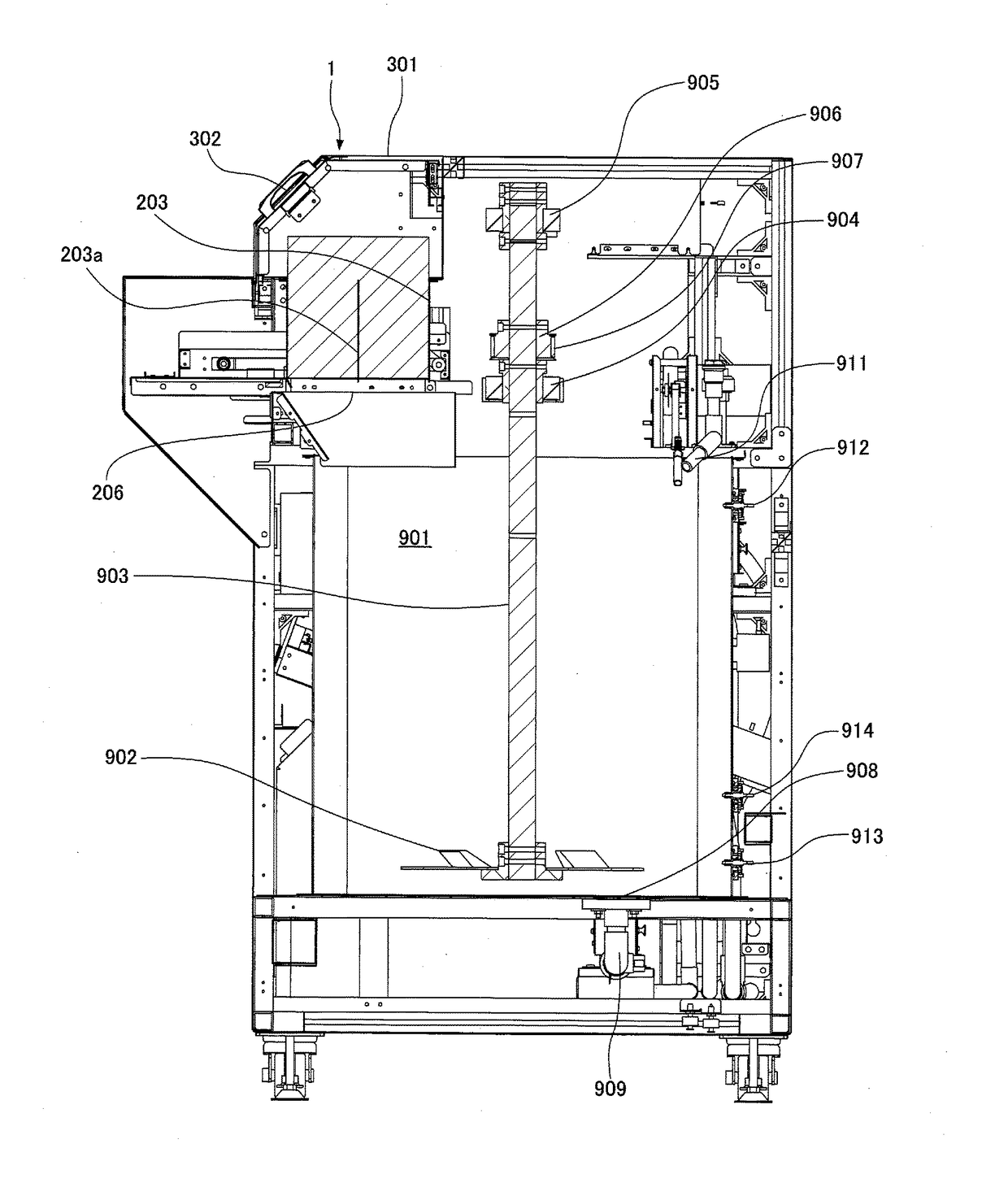

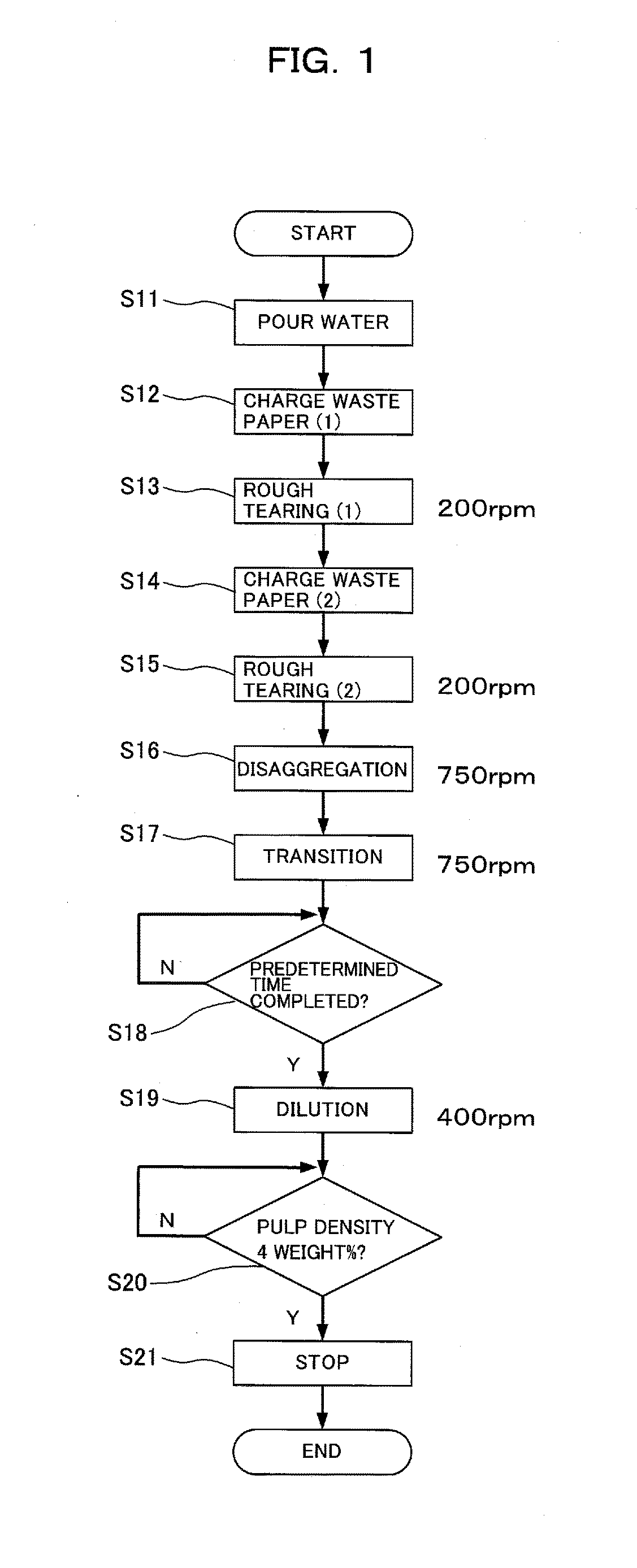

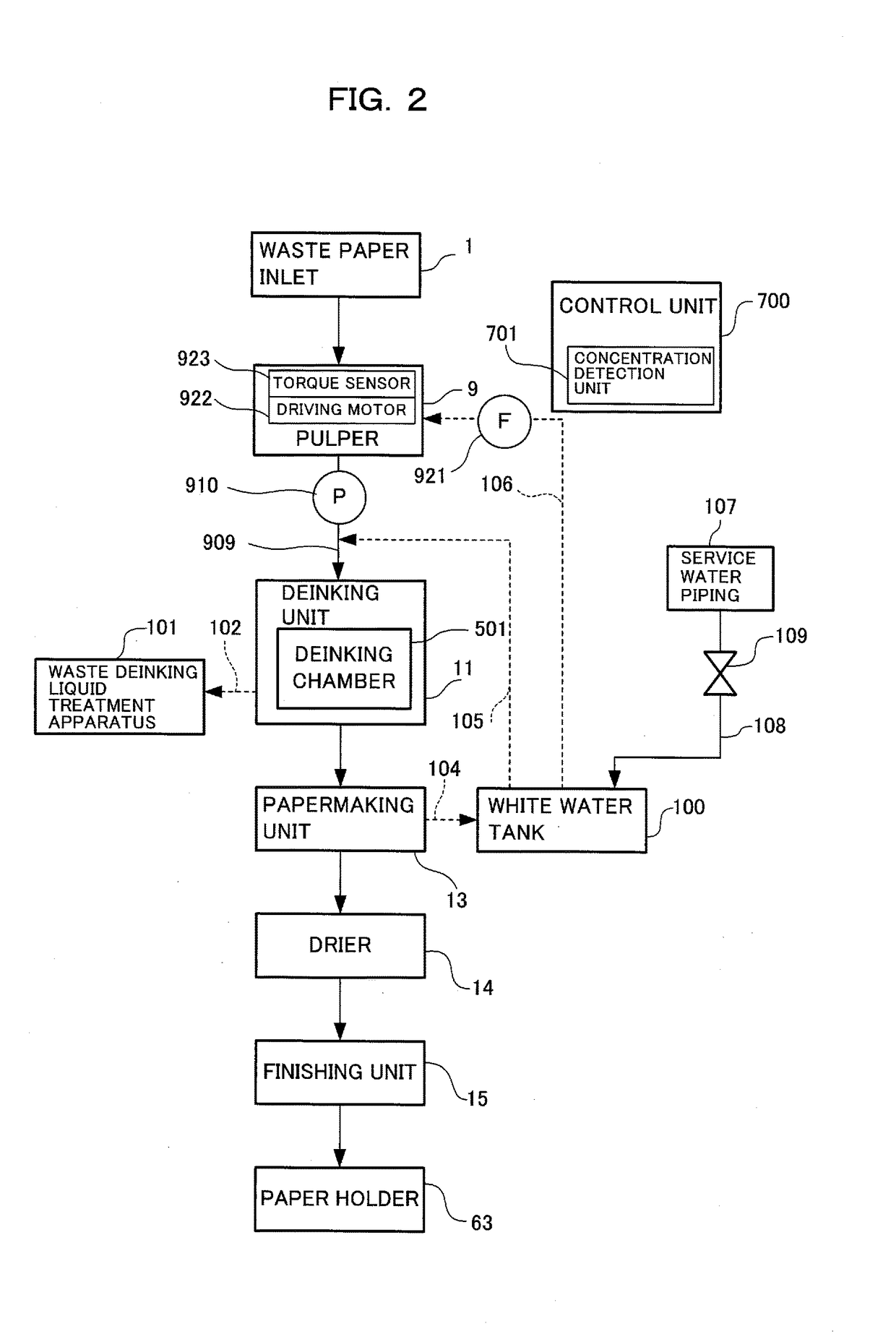

Waste paper recycling apparatus

Owner:DUPLO SEIKO CORP

Easy-to-move washing machine

Owner:高峰

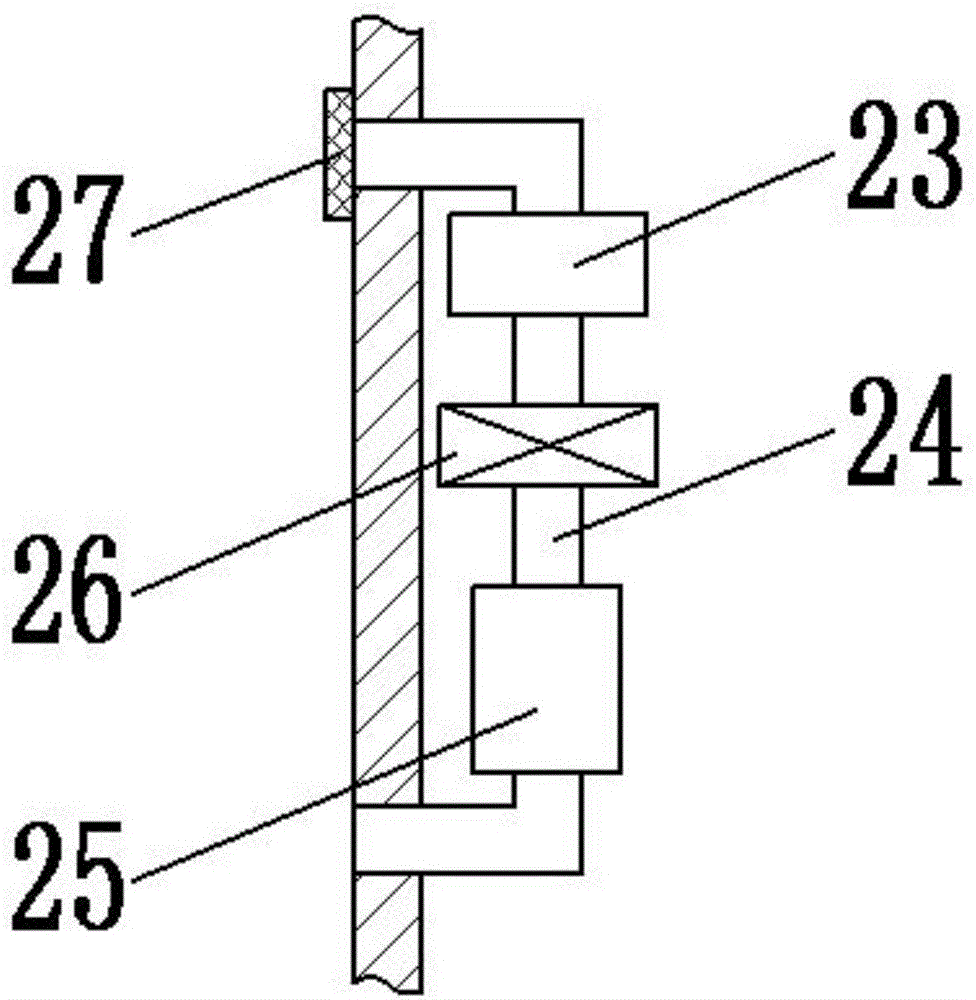

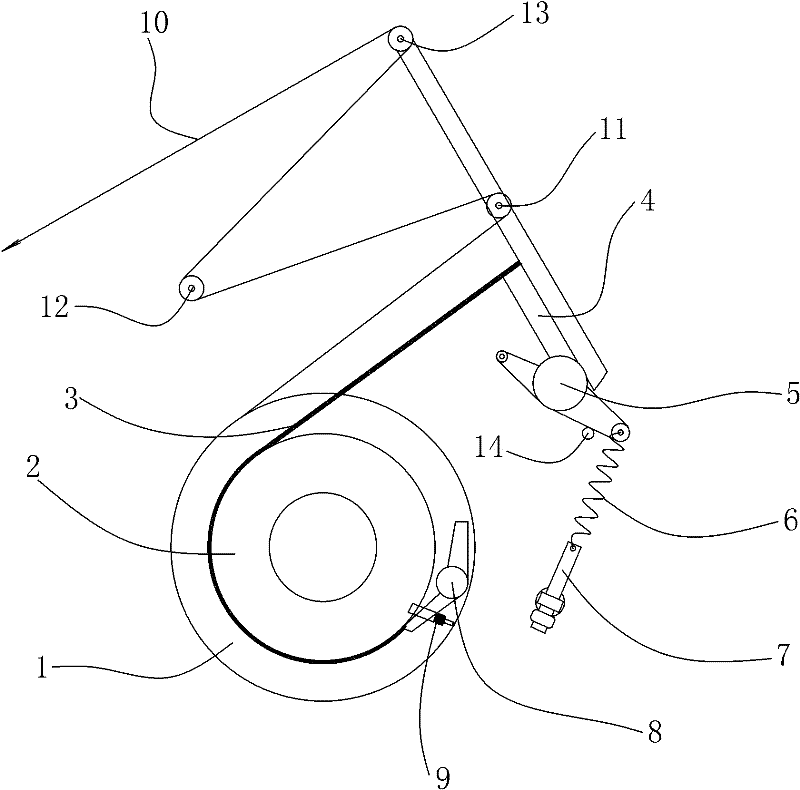

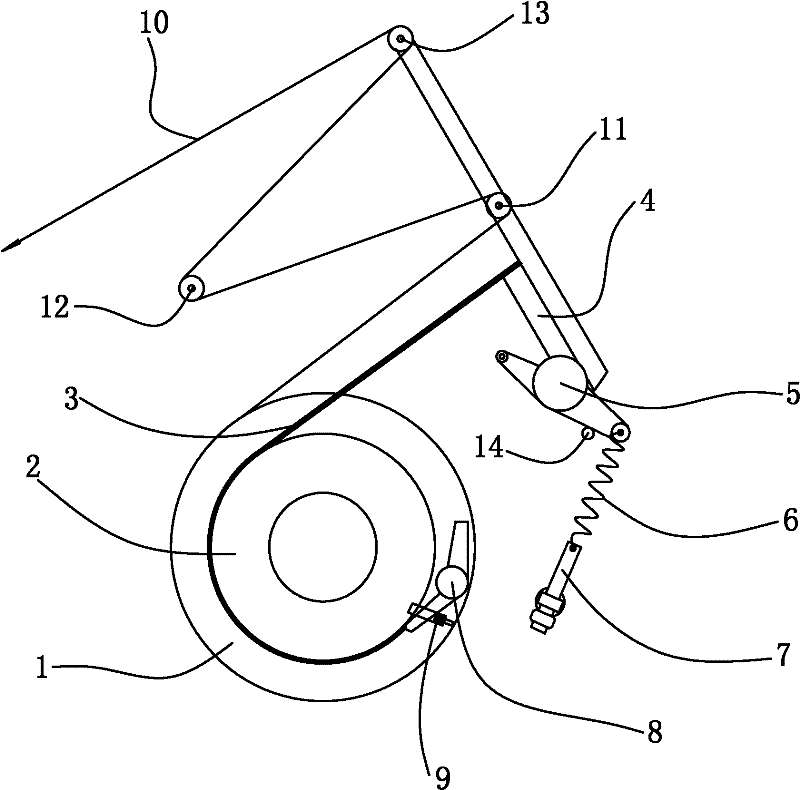

Braking device with transparent paper brake disc of cigarette packing machine

InactiveCN102530314AWrapping material feeding apparatusDrum brakesCigarette packPulp and paper industry

Owner:CHINA TOBACCO GUIZHOU IND

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap