Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

29 results about "Pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyrolysis is the thermal decomposition of materials at elevated temperatures in an inert atmosphere. It involves a change of chemical composition and is irreversible. The word is coined from the Greek-derived elements pyro "fire" and lysis "separating".

Method for preparing hetero-atom doped porous carbon material through carbonation of biomass under assistance of molten salt

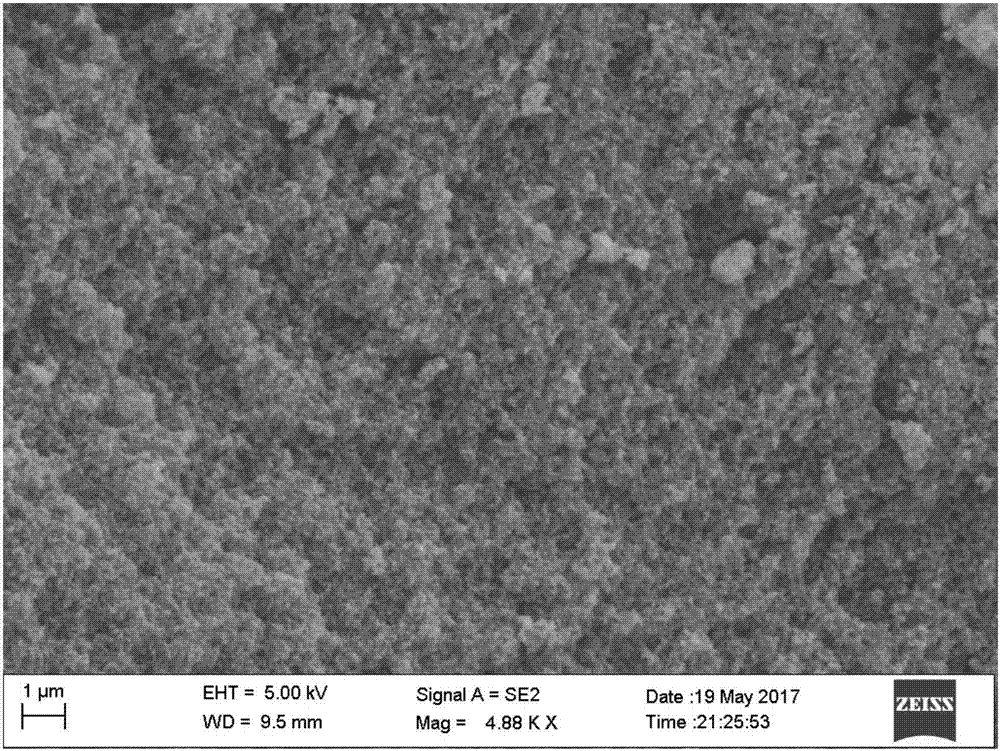

The invention provides a method for preparing a hetero-atom doped porous carbon material through carbonation of biomass under the assistance of molten salt. The method comprises the following steps: uniformly mixing biomass powder, the molten salt and a hetero-atom doped compound to obtain a product A, wherein the molten salt contains LiCl and KCl, the mass of LiCl accounts for 59 percent of that of the molten salt, and the mass of KCl accounts for 59 percent of that of the molten salt; putting the product A in a pipe furnace; carrying out high-temperature calcination; cleaning with distilled water to remove the molten salt and obtain the final product, namely the hetero-atom doped porous carbon material. The method has the advantages that the biomass is taken as a raw material, and the molten salt containing hetero-atoms is taken as a carbonization medium, so that the hetero-atoms can be introduced into the skeleton of the carbon material during the pyrolysis and carbonization process of the biomass synchronously and controllably, and the hetero-atom in-situ doped porous carbon material is obtained finally. Compared with the conventional doping method, the method provided by the invention have the advantages that the steps are simple; the cost is low; the operation is easy; the reactant purity is high; the application prospect is relatively good.

Owner:HARBIN ENG UNIV

Three-dimensionalgraphene composite aerogel and preparation method thereof

ActiveCN106890605ASimple methodGood lookingOther chemical processesWater contaminantsFiberChemical reaction

The invention discloses three-dimensionalgraphene composite aerogel. High-molecular material nano fiber with a biomass polysaccharide structure is compounded with oxidized graphene through a surface electrostatic-force effect, and then the composite aerogelis prepared by utilizing hydrazine hydrate reduction and a method for high-temperature pyrolysis in an inert atmosphere. The invention further discloses a preparation method of the three-dimensionalgraphene composite aerogel. The method for preparing the three-dimensionalgraphene composite aerogel is simple, easy to operate, large in specific surface area, uniform in pore size distribution and good in electrical conductivity, and the chemical reactivity is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

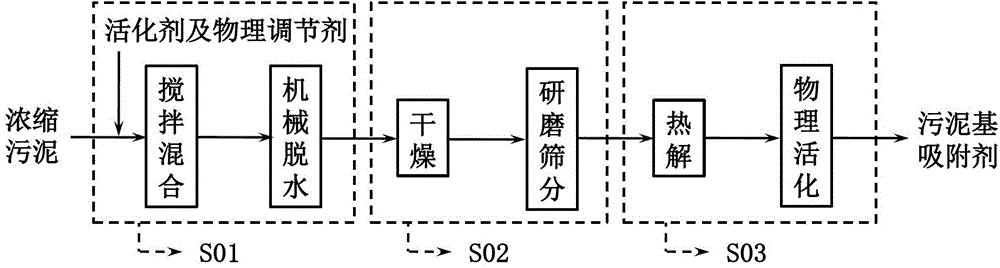

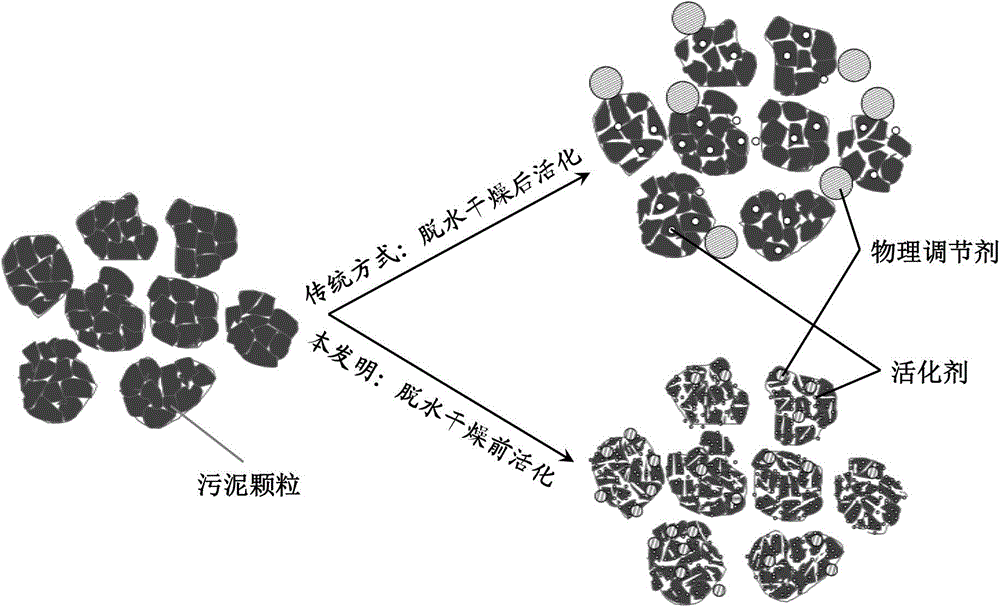

Sludge-based adsorbent used for desulfurization and demercuration of flue-gas and preparation method thereof

ActiveCN102745879AHigh porosityHigh adsorption activitySludge treatment by de-watering/drying/thickeningOther chemical processesSludge cakePhysical conditioning

Owner:HUAZHONG UNIV OF SCI & TECH

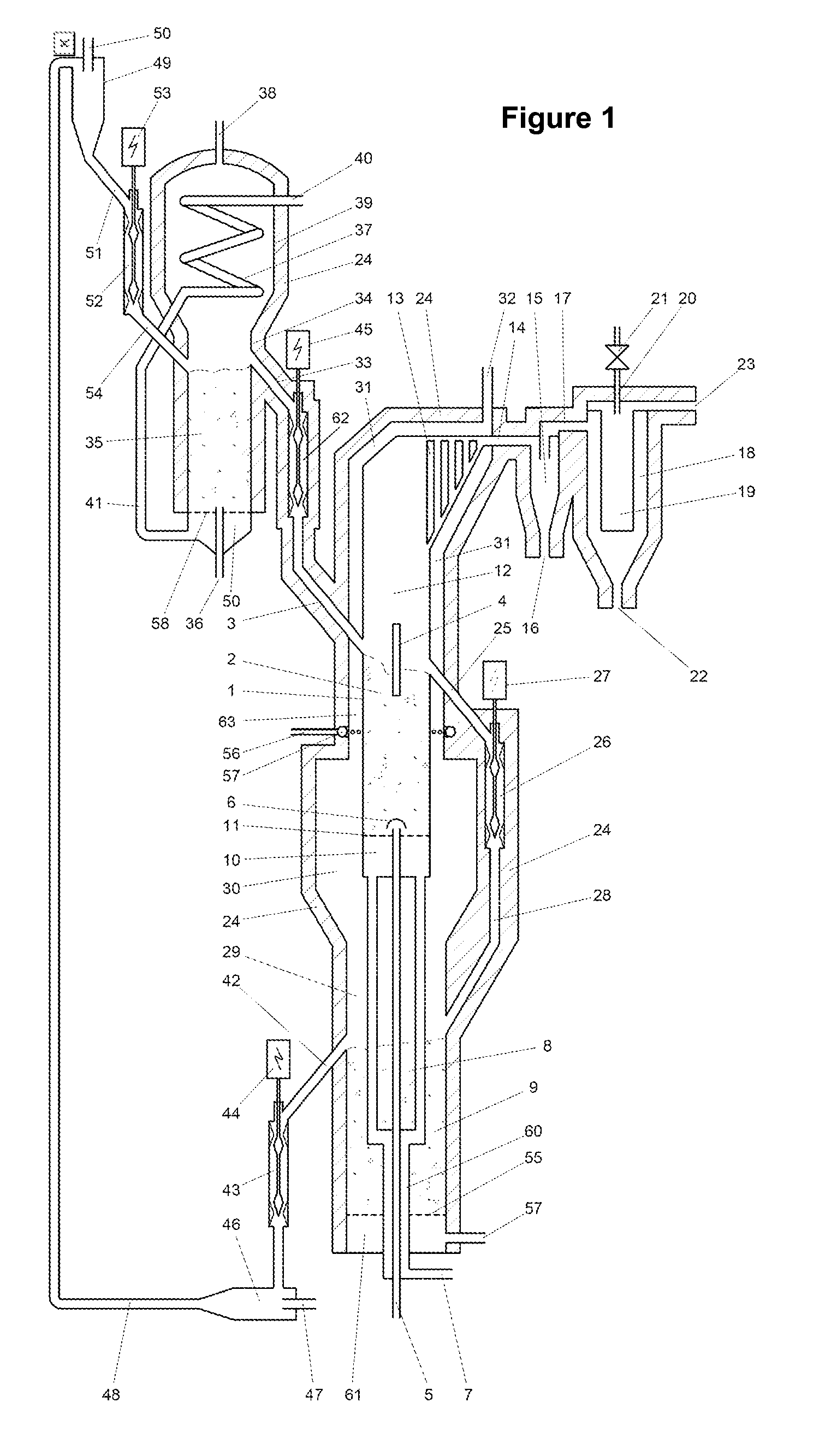

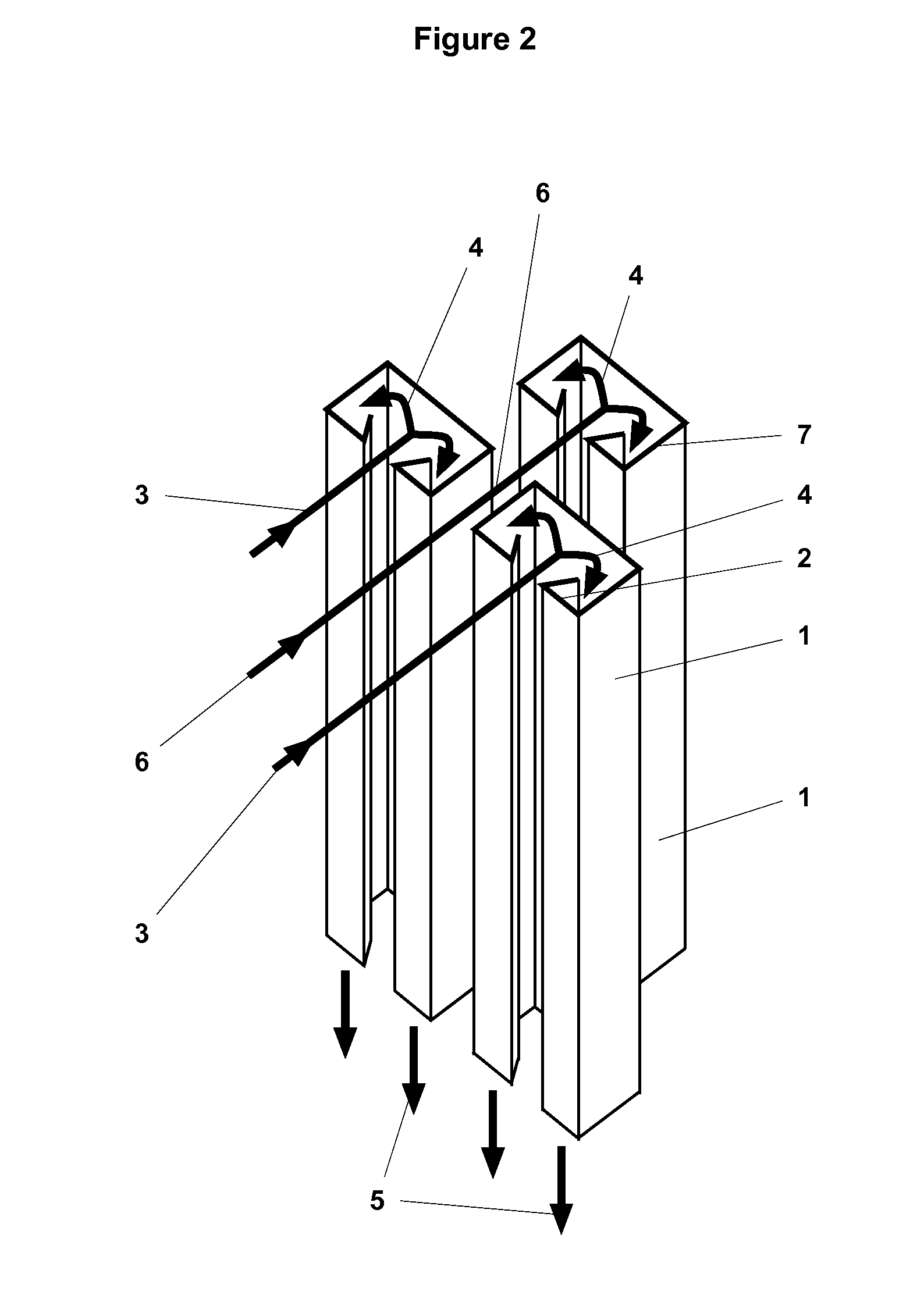

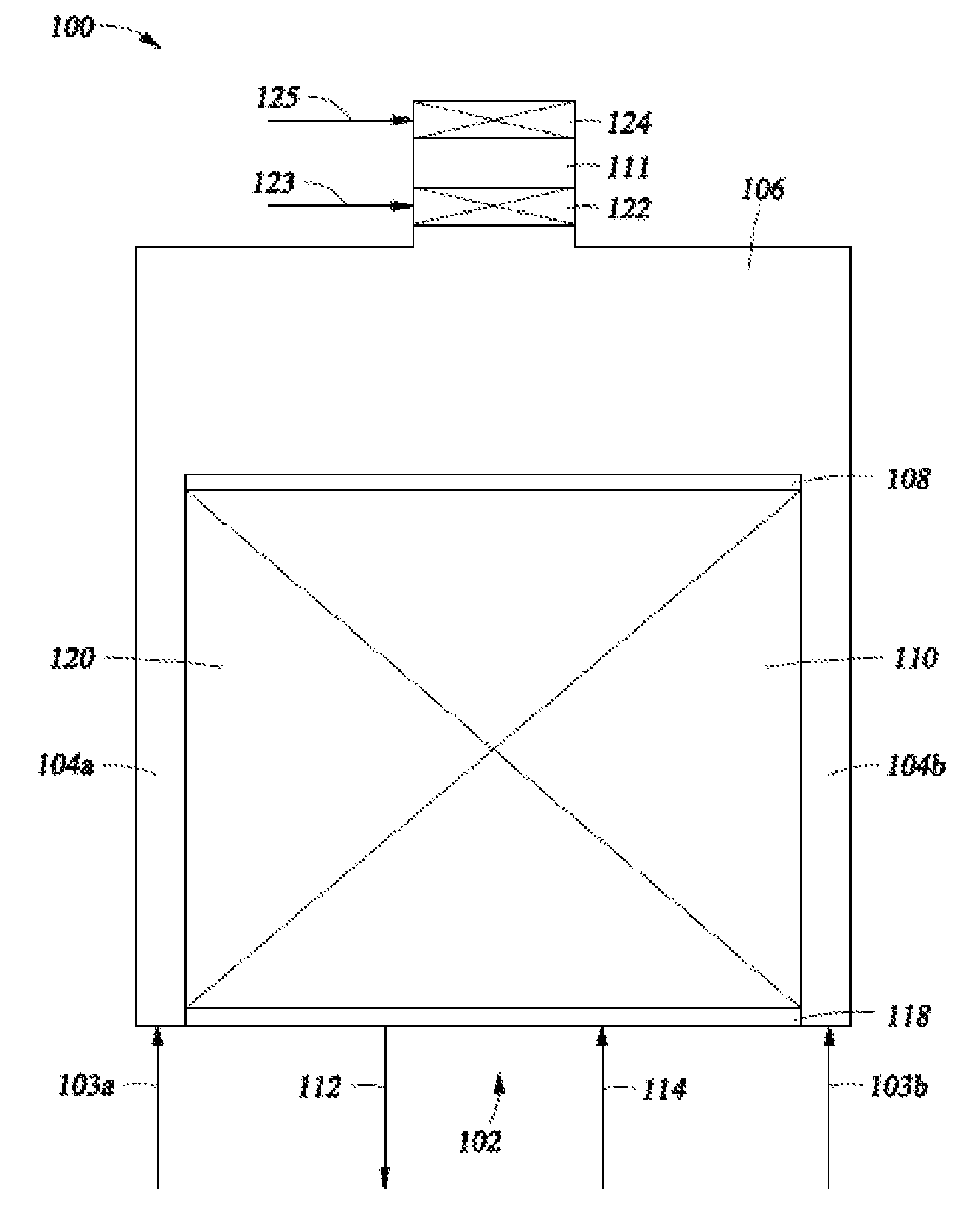

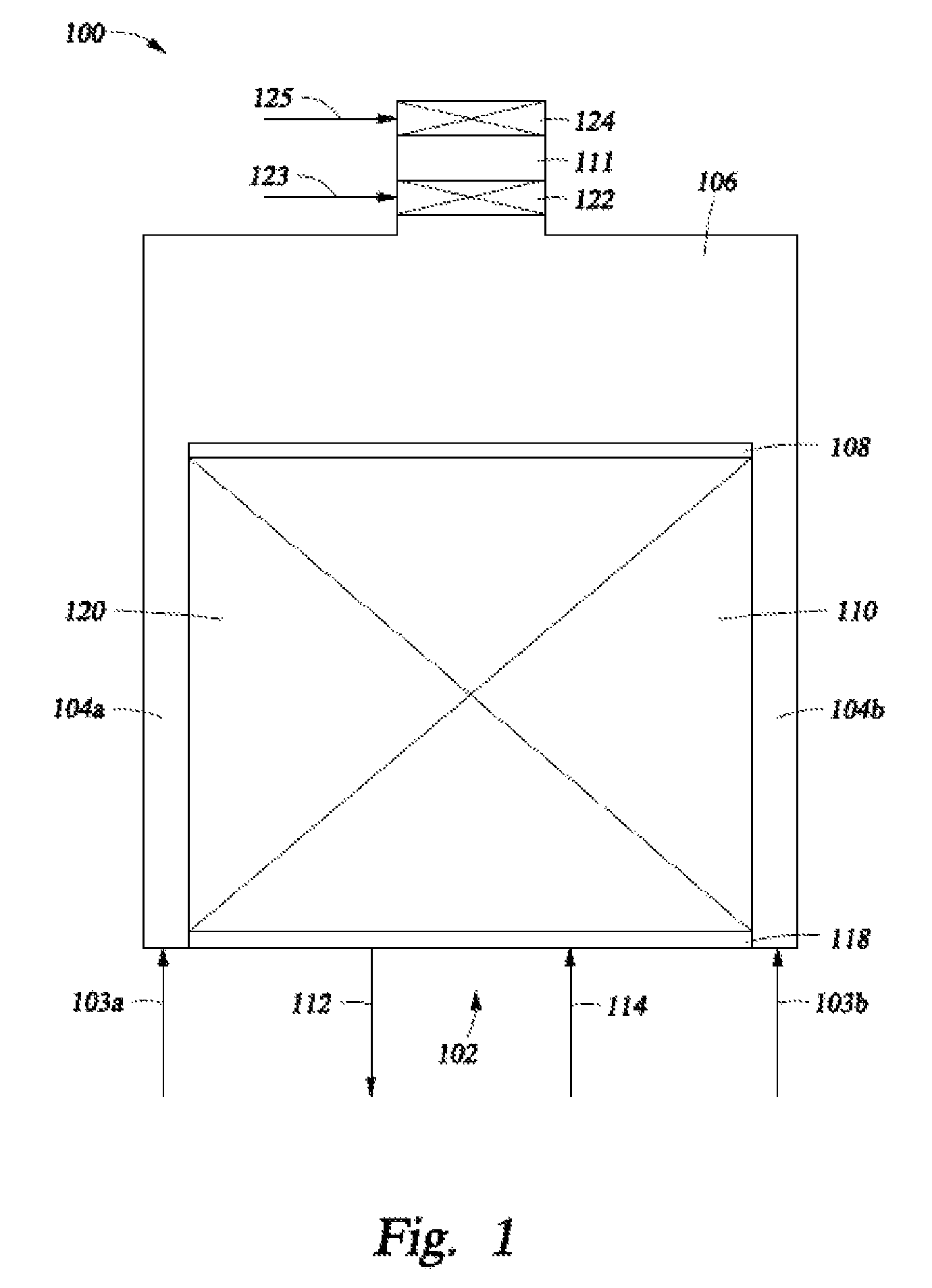

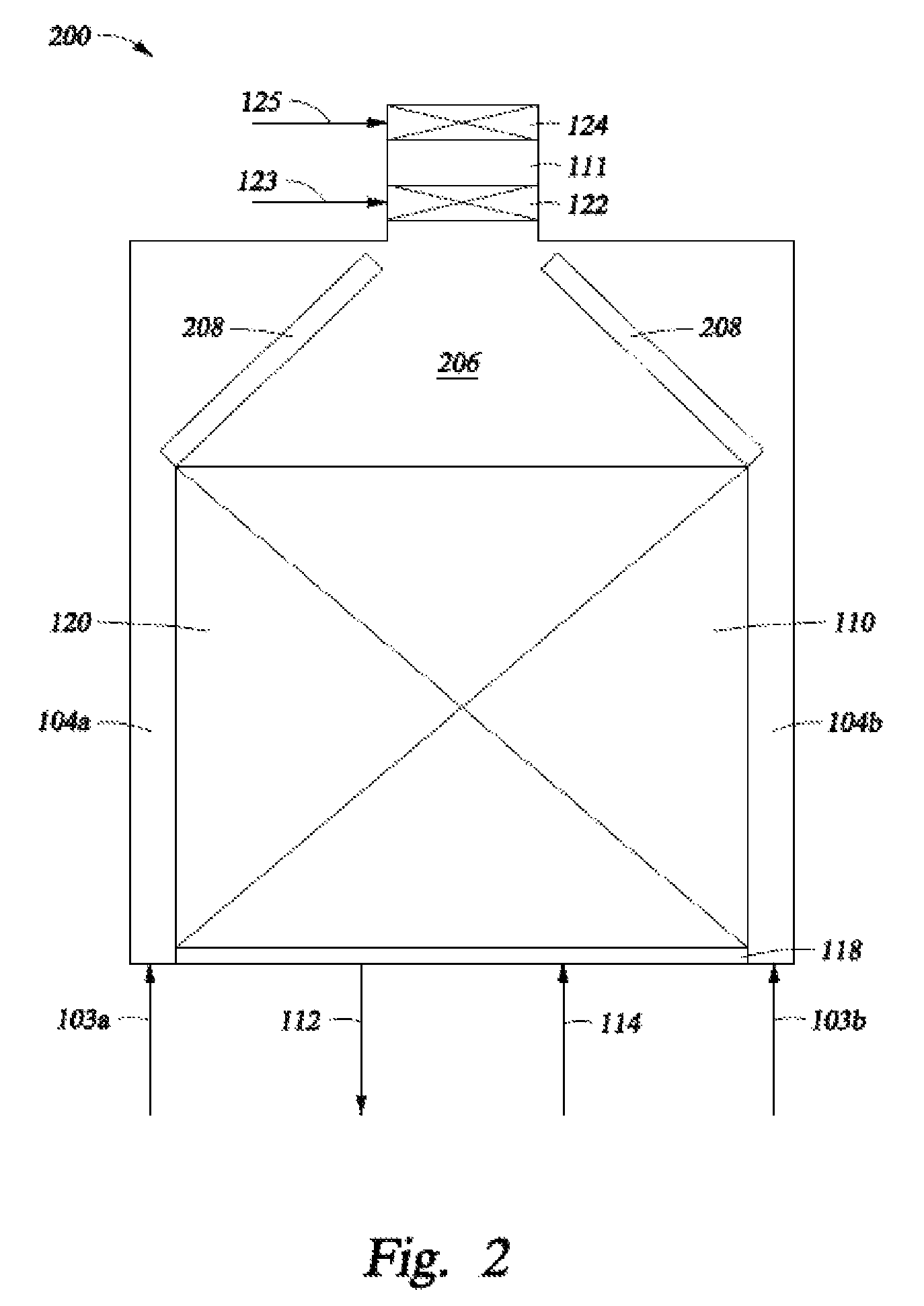

Equipment and a method for generating biofuel based on rapid pyrolysis of biomass

Owner:UNIV DE CONCEPCION

Biomass pyrolysis gasification multifunctional iron-based catalyst and preparation method thereof

ActiveCN103394356AGas purification with selectively adsorptive solidsMetal/metal-oxides/metal-hydroxide catalystsMuffle furnacePyrolysis

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

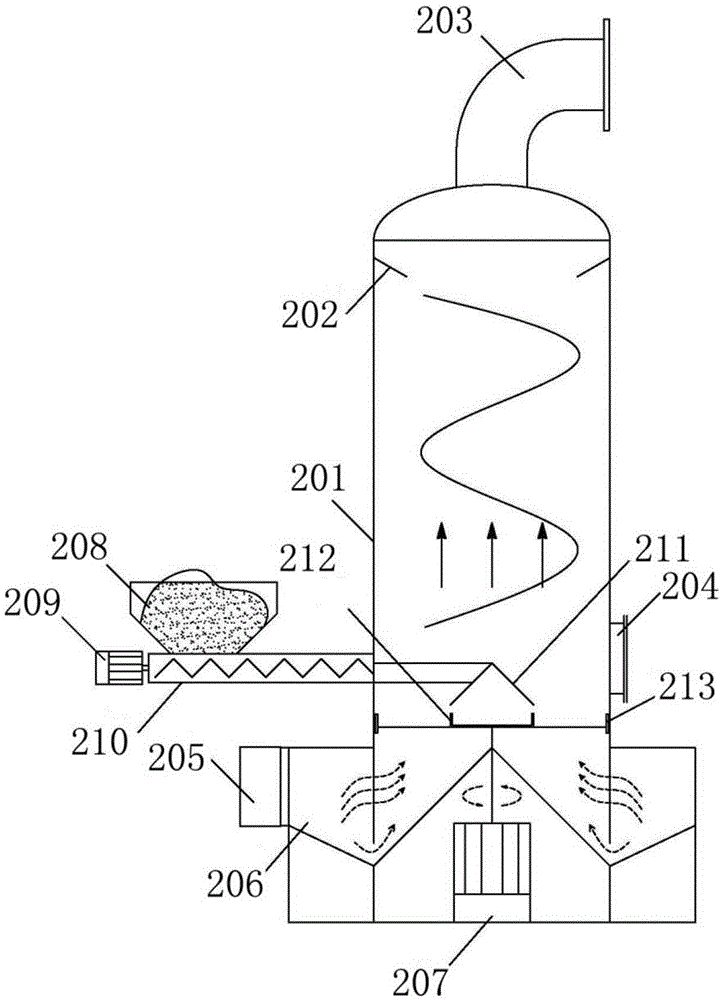

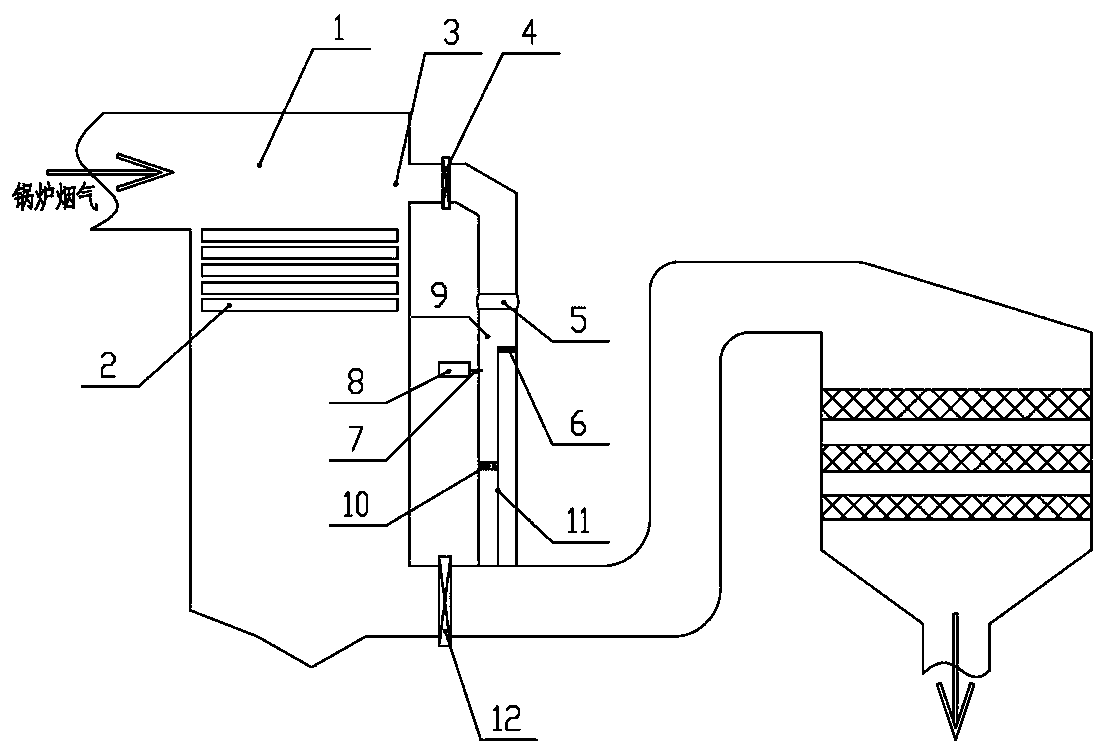

System for urban sludge flue gas drying middle-temperature pyrolysis carbonization

InactiveCN105602586AAvoid cokingAvoid blockingSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesEnergy gradientSludge

Owner:HUBEI JIADE TECH

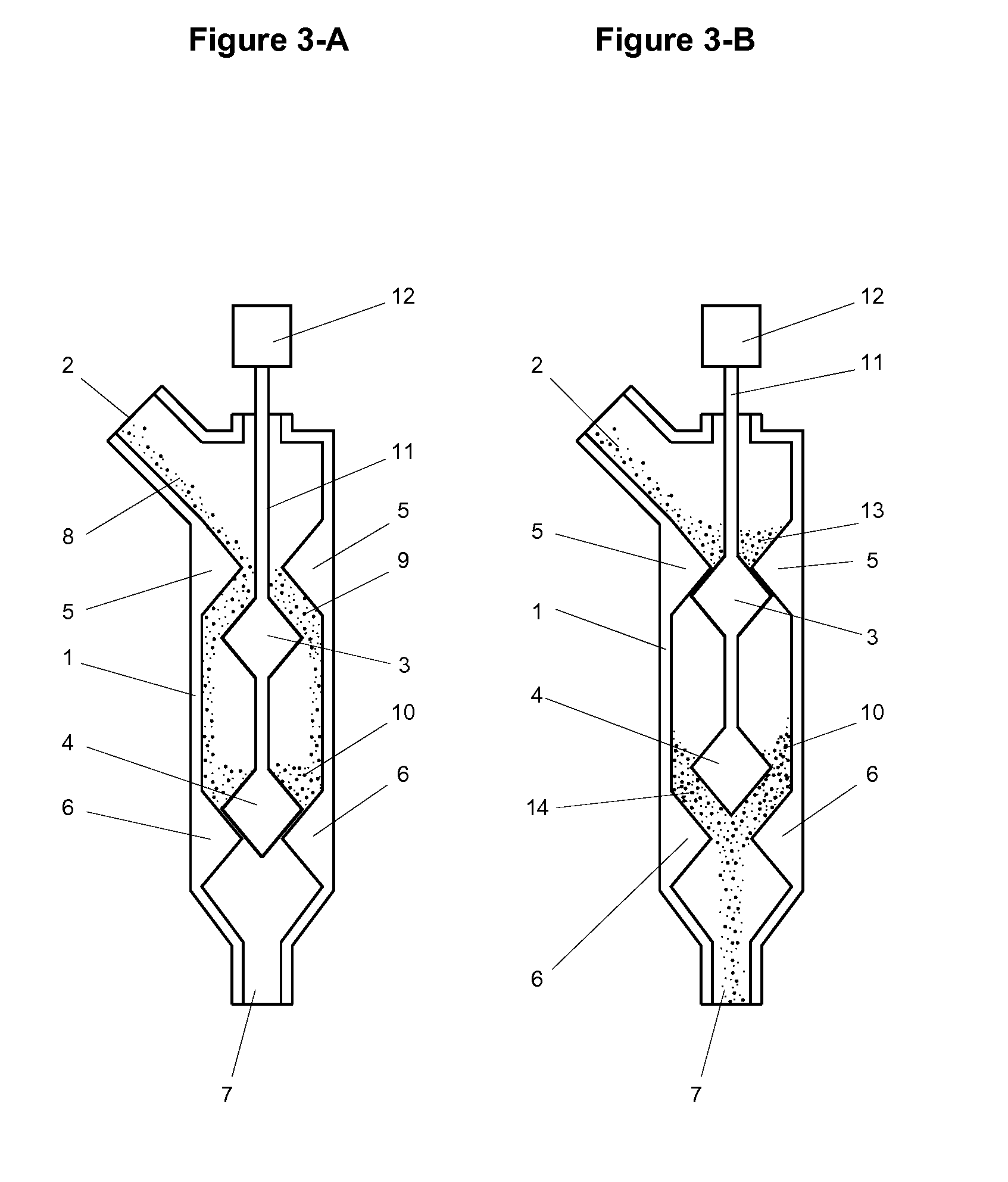

Hydrocarbon pyrolysis method

ActiveUS9126882B2Enhanced pyrolysis reaction processIncrease ethylene productionPhysical/chemical process catalystsHydrocarbonsChemistryPyrolysis

Owner:EXXONMOBIL CHEM PAT INC

Method for preparing active carbon from biomass, and prepared active carbon

InactiveCN107337206AReduce pollutionRecycling reducesZinc halidesCarbon compoundsActivated carbonAcid washing

Owner:HEFEI UNIV OF TECH

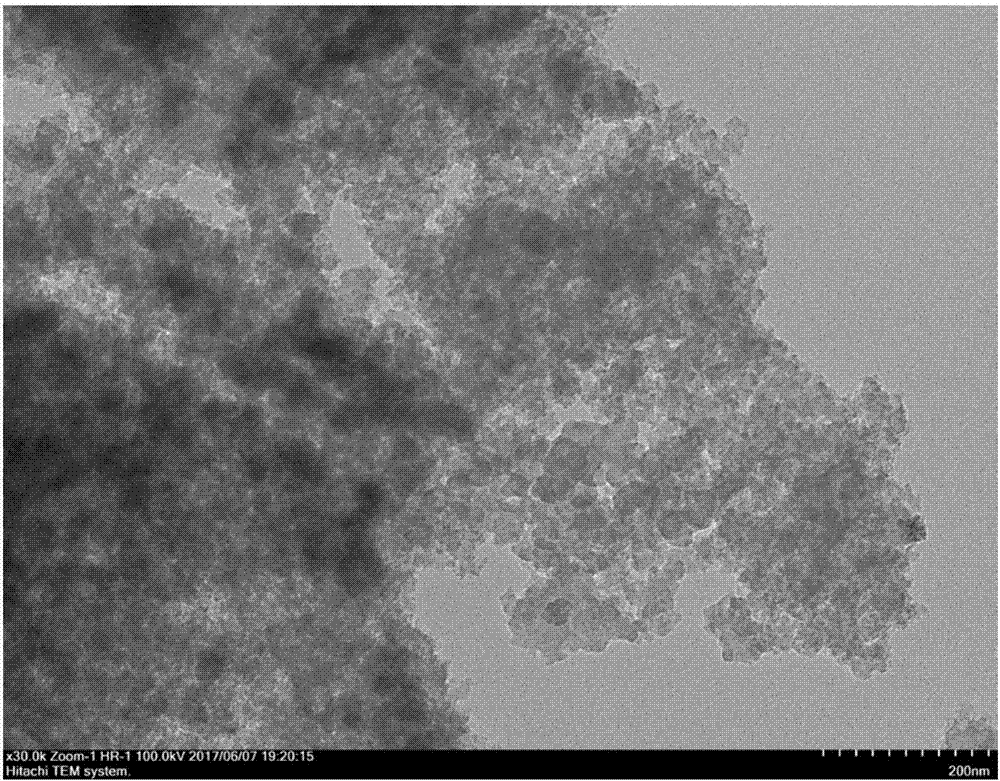

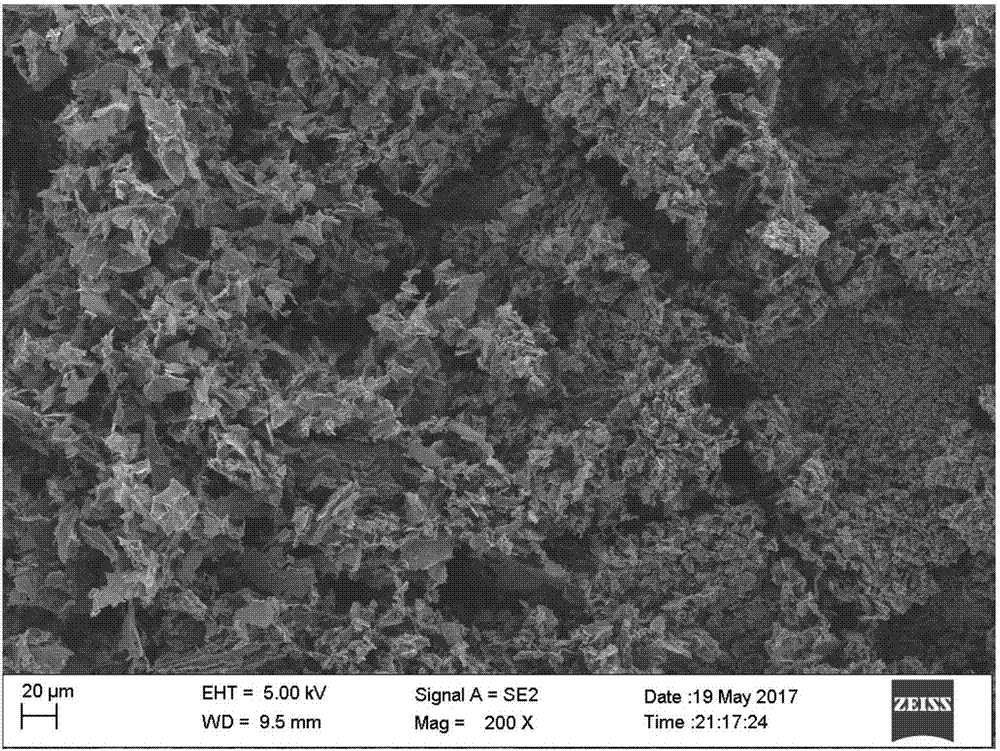

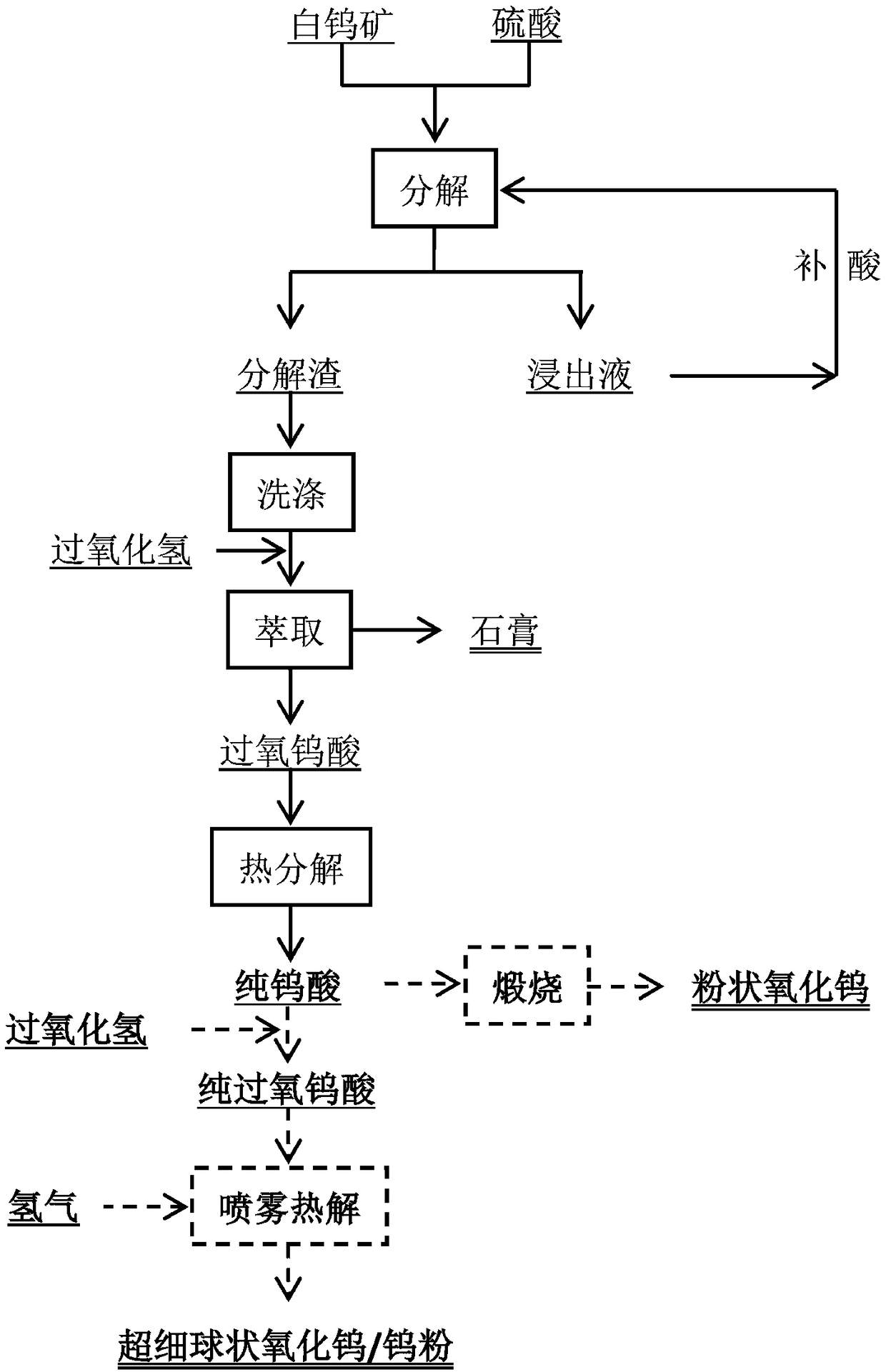

Method for preparing tungsten oxide and tungsten powder from scheelite

ActiveCN108640156AReduce break down costReduce manufacturing costTungsten oxides/hydroxidesProcess efficiency improvementDecompositionCalcination

Owner:CENT SOUTH UNIV

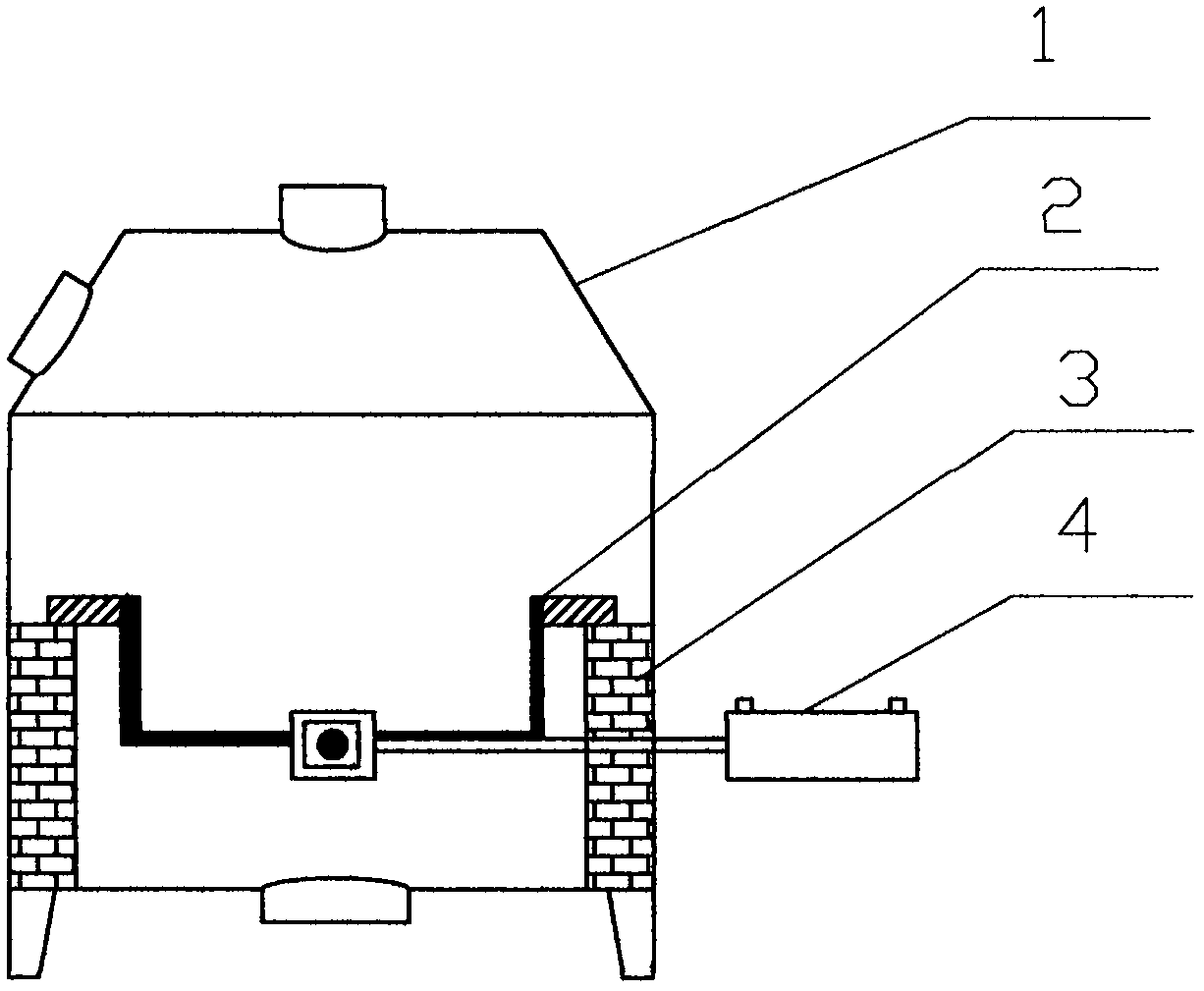

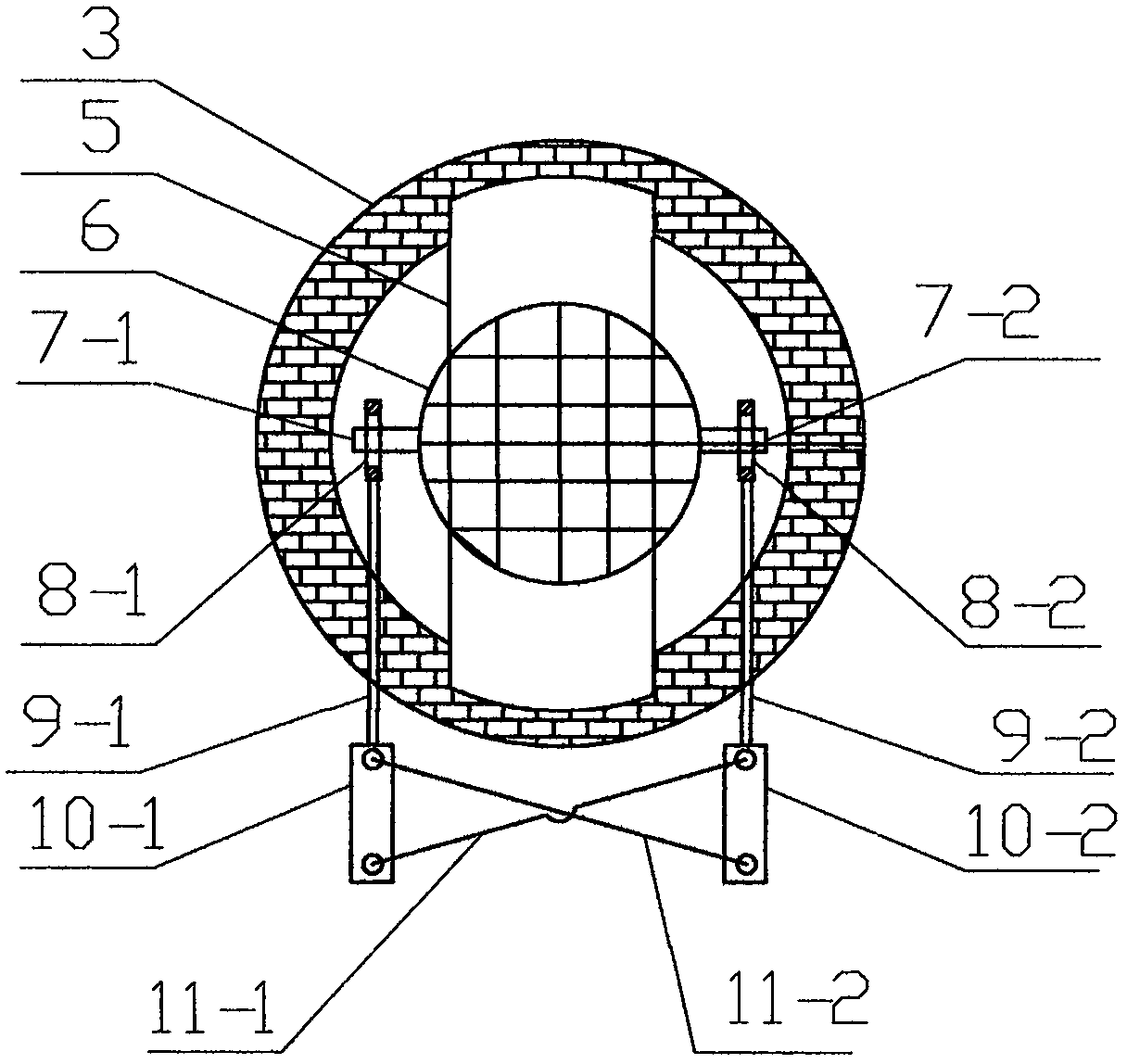

Slag removal machine of waste pyrolysis gasifier

The invention discloses a slag removal machine of a waste pyrolysis gasifier. The slag removal machine structurally comprises a furnace body, a material conveying pipe, a pushing machine, a feeding hopper, a fuel gas outlet, a hot air inlet and a slag removing mechanism, wherein the material conveying pipe is arranged at the top end of the left side of the furnace body, the pushing machine is arranged at the left end of the conveying pipe, the upper surface of the conveying pipe is connected with the feeding hopper, the fuel gas outlet is formed in the right side of the upper portion of the furnace body, and the hot air inlet is formed in the right side of the lower portion of the furnace body. The gasifier has the beneficial effects that a wiper and a scraper are arranged on the two sides of a rotating column, a motor drives the rotating column to rotate, a cutter is installed on the scraper so as to to scrape slag on the inner wall, the slag can fall into a material receiving disc, the inner wall is wiped through a cleaning brush on the wiper after the slag is scrapped, a ball pushing device and a stirring device are arranged inside the rotating column, a stirring rod can control balls in a rolling way, and the scraper and the wiper can be controlled to be stretched by changing the movement of the balls so as to adapt to furnace bodies with different sizes.

Owner:QUANZHOU TONGTONG ELECTRONIC EQUIP CO LTD

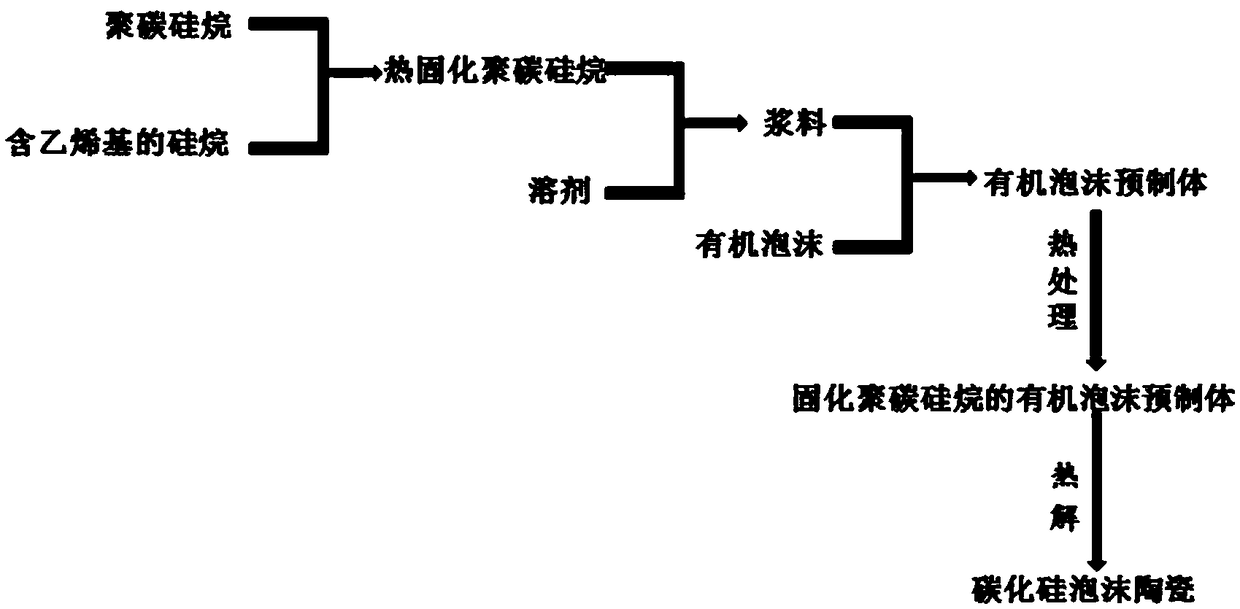

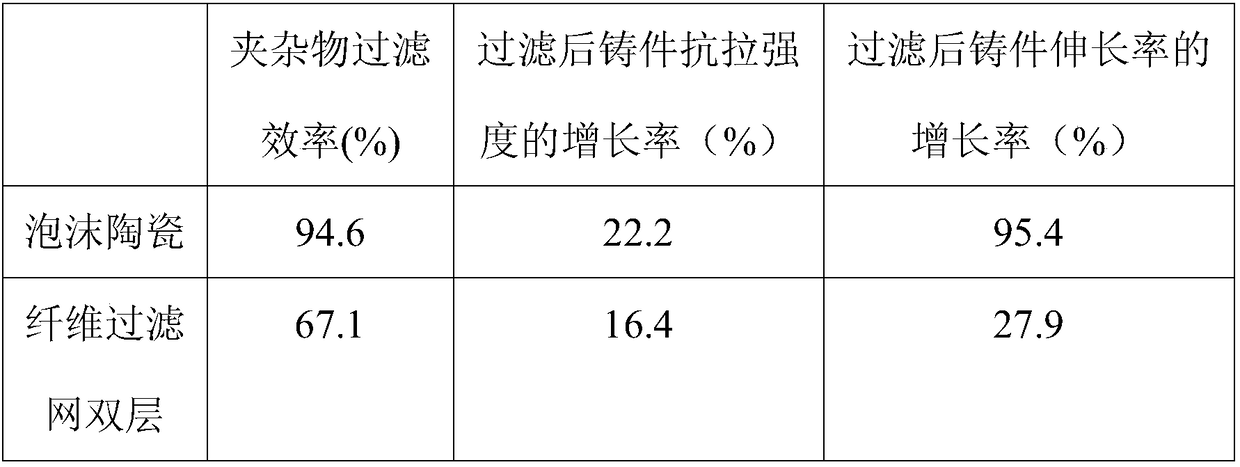

Silicon carbide foamed ceramic, and liquid metal filter produced therefrom

InactiveCN108558409ANo foamingControl pore structureCeramicwareStationary filtering element filtersFiltrationHydrosilylation

Owner:俞雪利

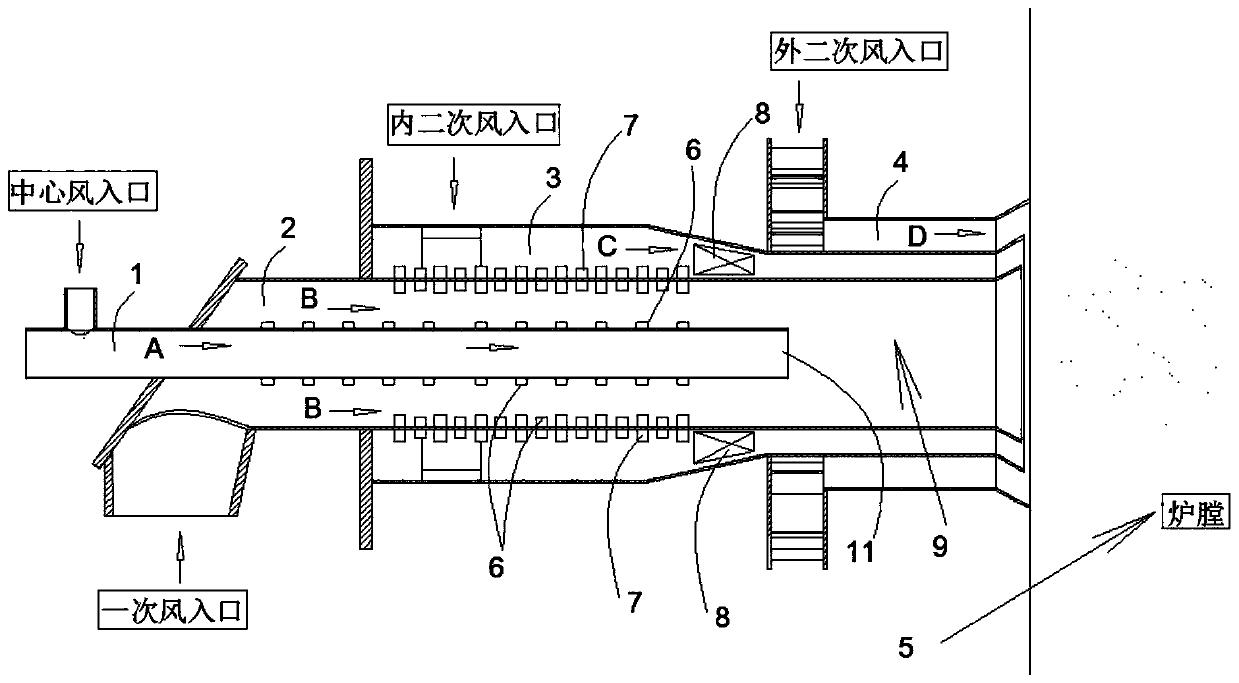

Swirl pulverized coal burner based on in-advance pyrolysis

PendingCN110186037AReduce incomplete combustion lossesIncrease temperaturePulverulent fuel combustion burnersNon-combustible gases/liquids supplyEngineeringCoal fired

Owner:GUODIAN LONGYUAN ENERGY SAVING TECH

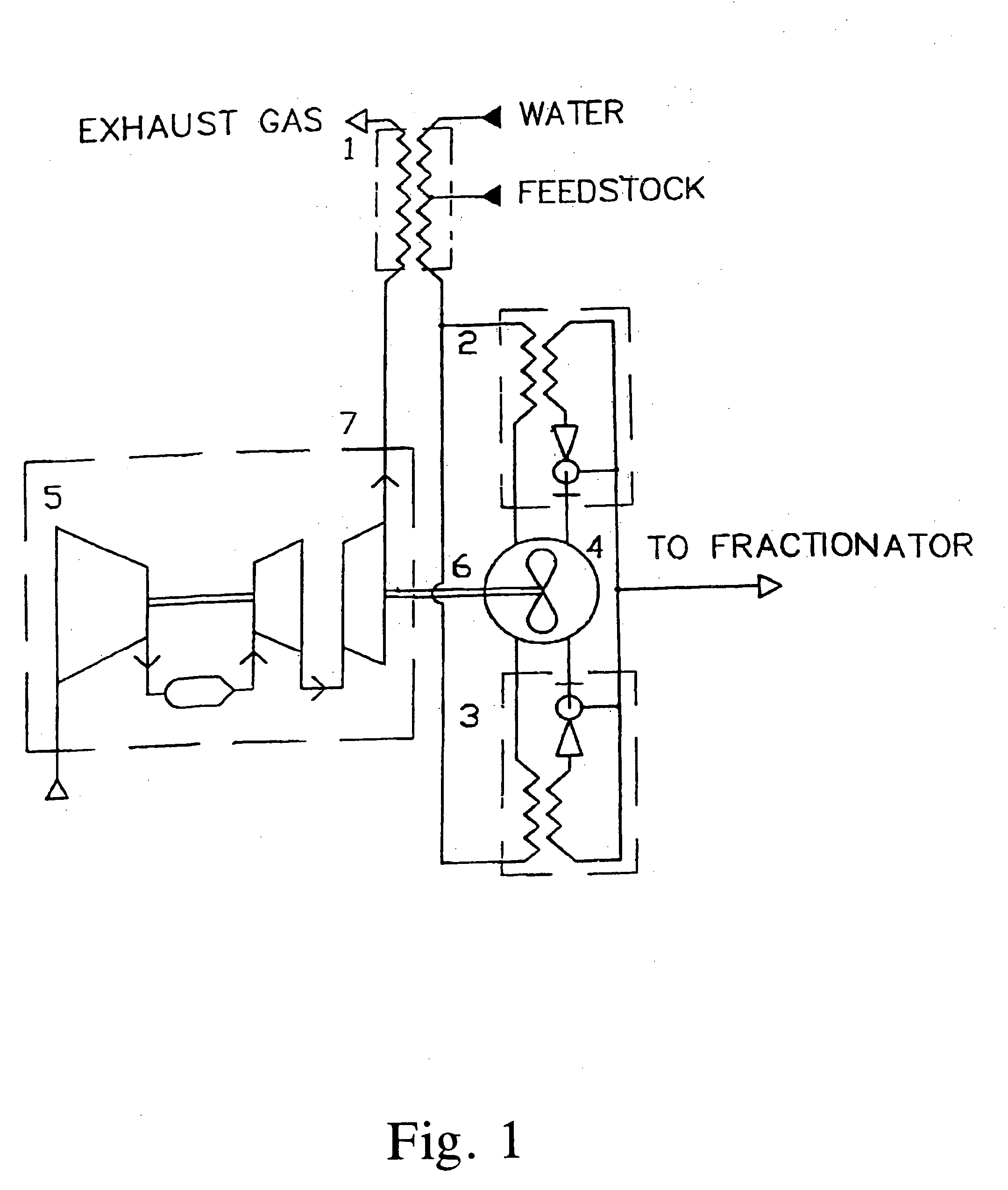

Process for producing low-molecular olefins by pyrolysis of hydrocarbons

InactiveUS20050137440A1Reduce energy consumptionEfficient use ofThermal non-catalytic crackingFlow mixersFractionationDiluent

Owner:COOLBROOK

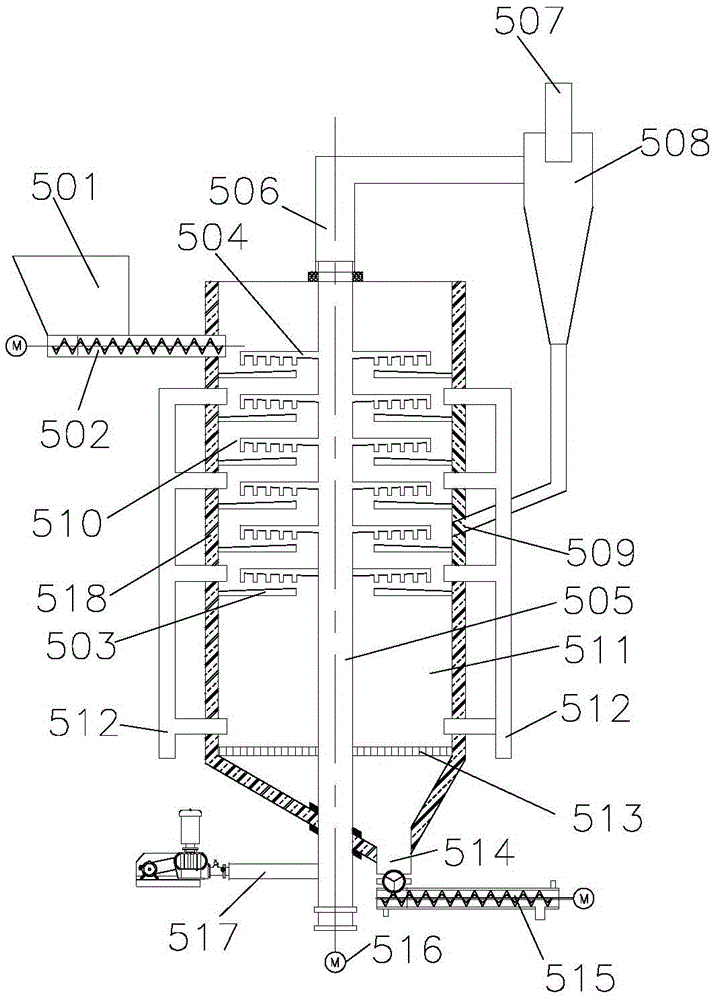

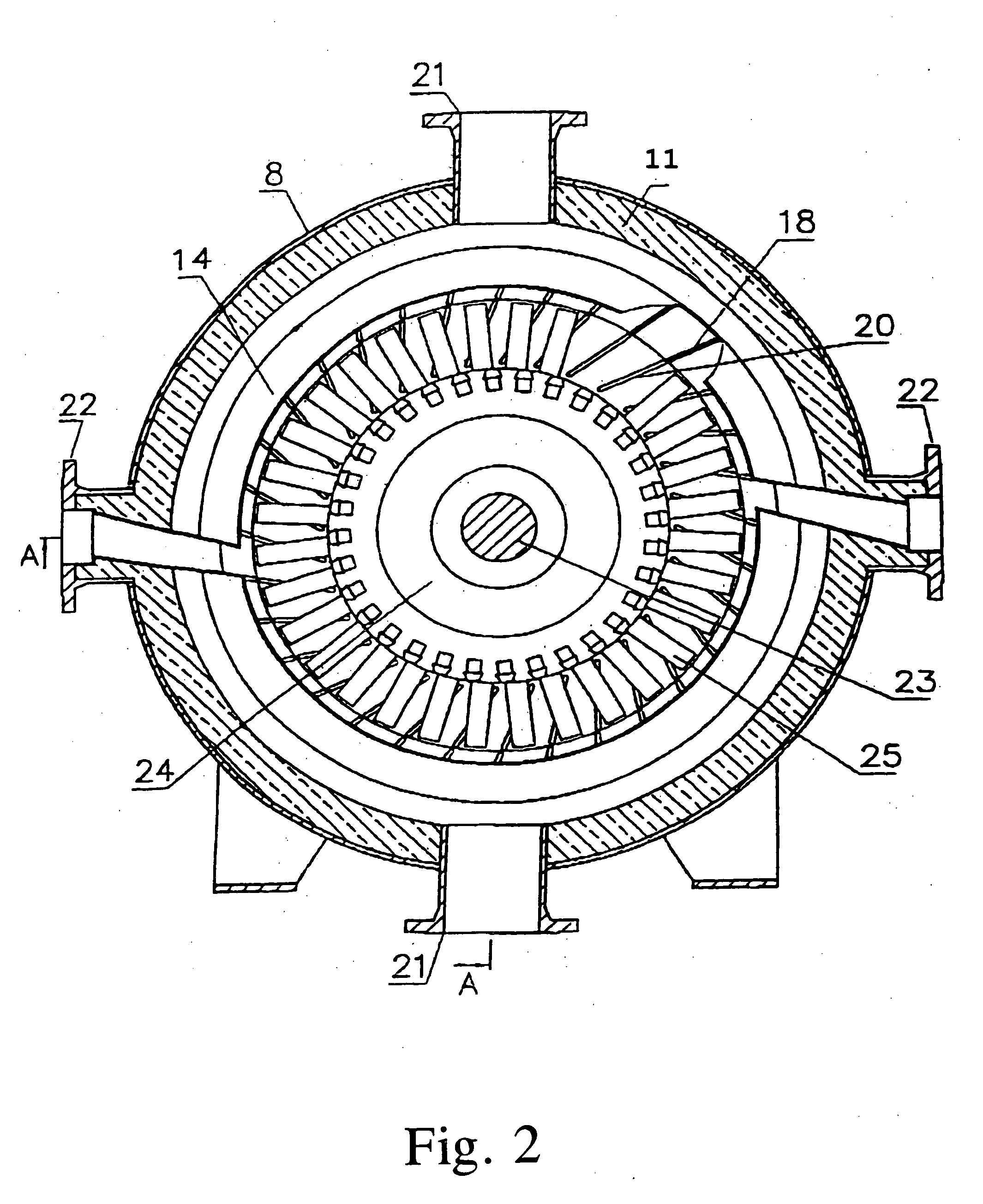

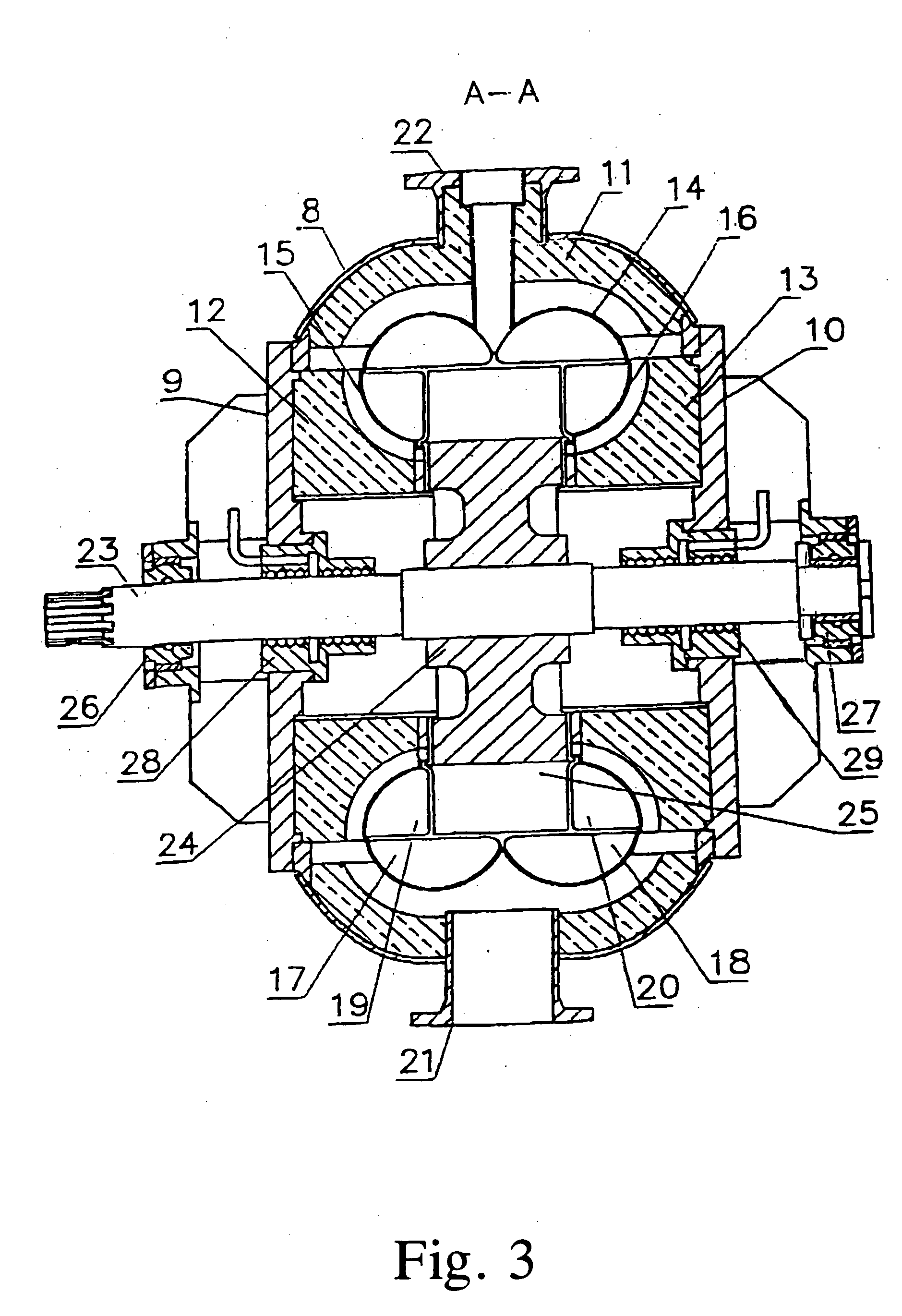

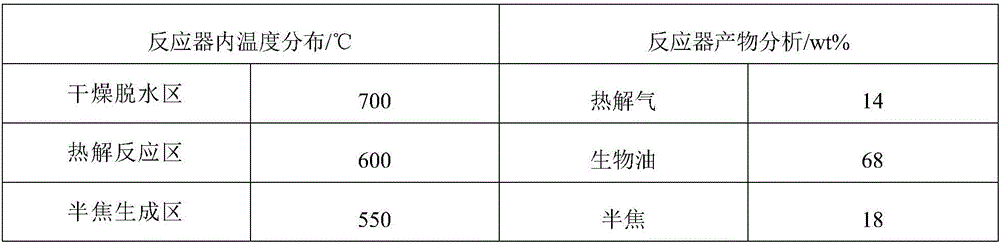

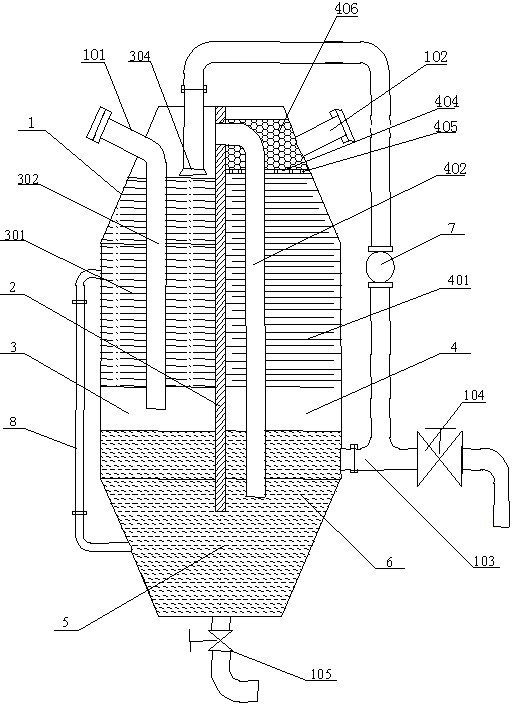

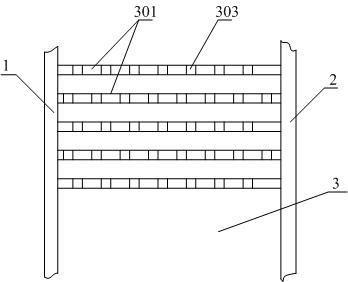

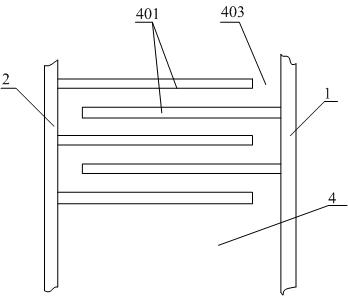

Fast pyrolysis reactor

PendingCN106520155AEffective pyrolysisSimple structureDirect heating destructive distillationBiofuelsVertical projectionNuclear engineering

Owner:SHENWU TECH GRP CO LTD

Purification device in waste biomass resource pyrolysis and gasification system

InactiveCN102504884ACompact structureSmall footprintGas purification by liquid washingSolventBiomass

Owner:LUOYANG JUNTENG ENERGY TECH +1

Method for determining carbon black content of PE reclaimed material by using combustion method

InactiveCN108445144AReduce the chance of being oxidized by airReduce the chance of oxidationWeighing by removing componentChemical analysis using combustionCombustionNitrogen atmosphere

The invention relates to the testing technical field of black polyethylene plastics for wires and cables, and discloses a method for determining carbon black content of a PE reclaimed material by using a combustion method, the method includes initial weighing of a PE sample, pyrolysis, weighing after the pyrolysis, combustion, weighing after the combustion, and other steps. In the process ofweighing after the pyrolysis, after cooling in a nitrogen atmosphere to 400 DEG C-450DEG C, the opening of a combustion tube is opened, a combustion boat is dragged to the opening for cooling for 5 min, andthe combustion boat is taken out of the combustion tube. The accuracy of detection of the carbon black content in the PE reclaimed material can be improved by changing of temperature of oxygen introduction in the combustion method or heat insulating time of nitrogen gas introduction at 600DEG C or changing of the temperature of oxygen introduction in the combustion method from 600 DEG C to 850 DEG C, so that the result of the method is substantially consistent with the result of a thermogravimetric analysis method.

Owner:JIANGYIN ECOSENBOTTOM POLYMER CO LTD

5G-based high-performance electromagnetic shielding material and preparation method thereof

InactiveCN111875921AImprove absorbing performanceLight in massMagnetic/electric field screeningCarbide siliconNanowire

The invention discloses a 5G-based high-performance electromagnetic shielding material, of which the volume density is less than 2.5 g / cm3 and the electromagnetic shielding efficiency is greater than85dB; the high-performance electromagnetic shielding material is composed of foamy carbon, silicon carbide nanowires, graphene and phenolic resin. The preparation method comprises the following steps:taking organic foam as a raw material, carrying out pyrolysis at high temperature to prepare foam carbon, then carrying out in-situ growth of silicon carbide nanowires in the foam carbon by adoptinga chemical vapor deposition (CVI) method and Ni catalysis to obtain a silicon carbide nanowire reinforced foam carbon matrix, and then carrying out vacuum pressure impregnation with graphene modifiedresin, thereby finally obtaining the silicon carbide nanowire reinforced foam carbon material of the graphene modified resin. The material has a good shielding effect on high-frequency electromagneticwaves, the shielding bandwidth is large, the heat dissipation performance is good, and meanwhile structure and function integration is achieved.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

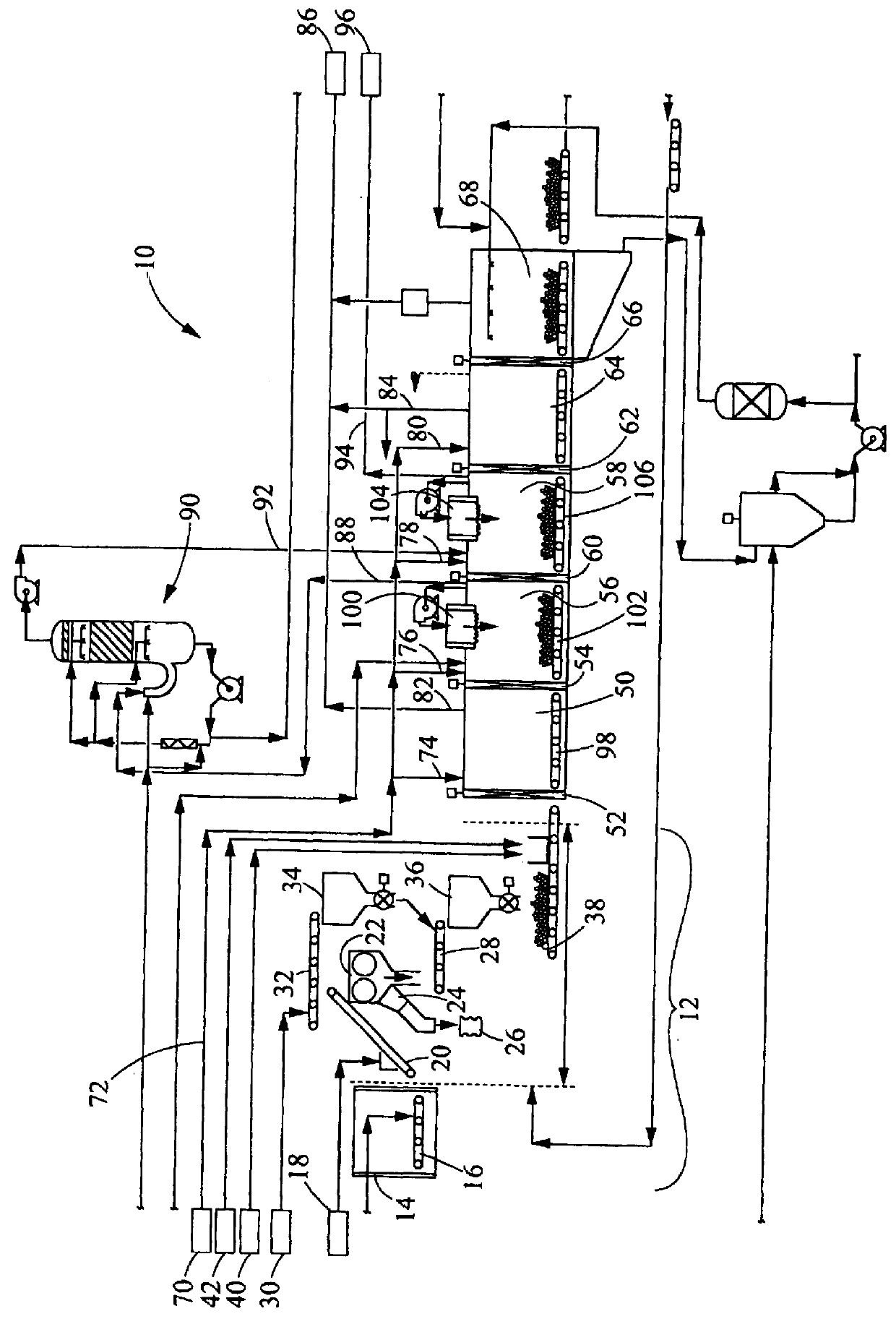

Multi-stage pyrolysis systems for treating chlorine contaminated wastes

InactiveUSH2198H1Minimize the possibilityMinimizes dioxinUsing liquid separation agentIncinerator apparatusFuranOxygen

Owner:CH2M HILL

Full-load denitration device with urea fume pyrolysis function

PendingCN108607358AAvoid pyrolysisReduced pyrolysis energy requirementsGas treatmentDispersed particle separationSuperheaterFuel oil

Owner:HUNAN DATANG ENERGY SAVING SCI & TECH CO LTD

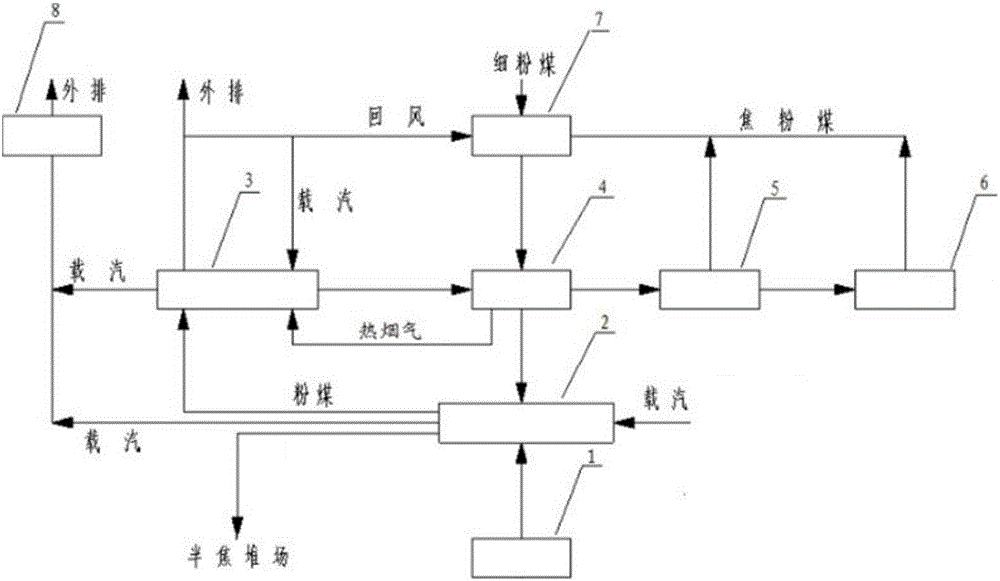

Pyrolytic process method for directly drying pulverized coal through semicoke

InactiveCN106190205AReduced risk of cloggingSimple processEnergy inputSpecial form destructive distillationProcess engineeringHeat energy

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

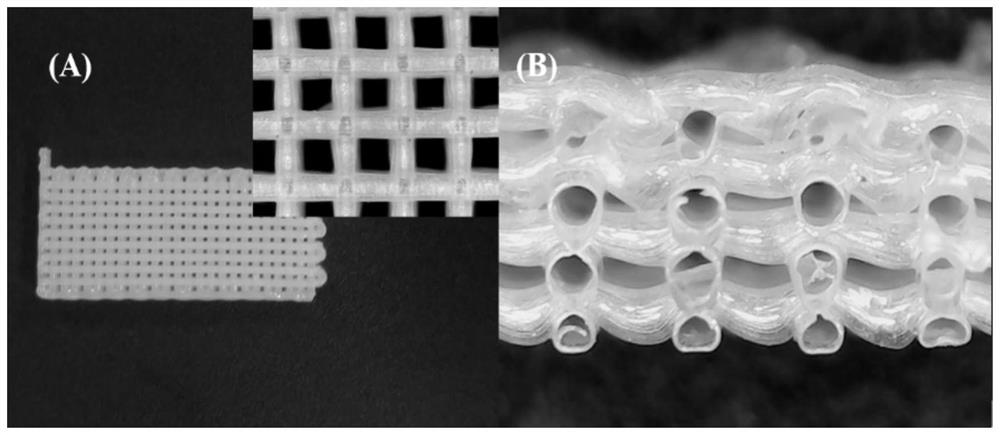

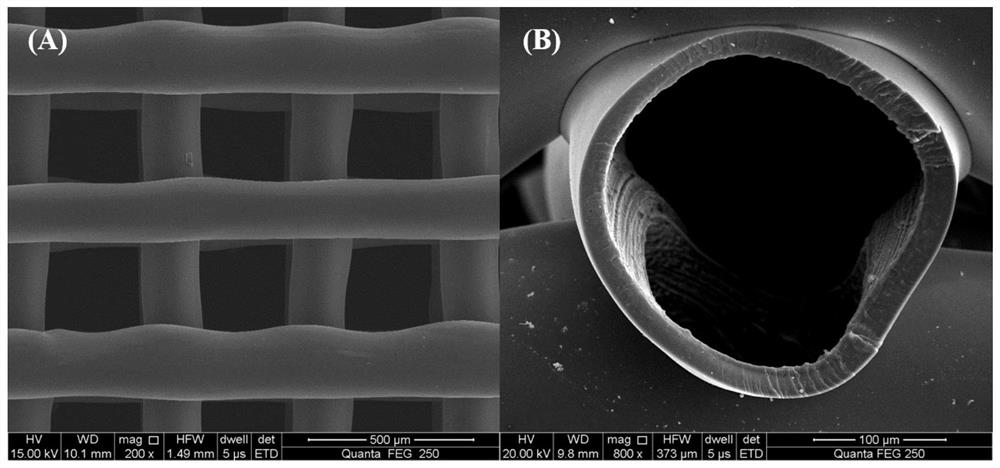

Preparation method of hollow tube micro-lattice structure ceramic material

ActiveCN111646804AReduce adverse effectsEasy to controlAdditive manufacturing apparatusAdditive manufacturing with liquidsMolten stateManufacturing technology

Owner:CENT SOUTH UNIV

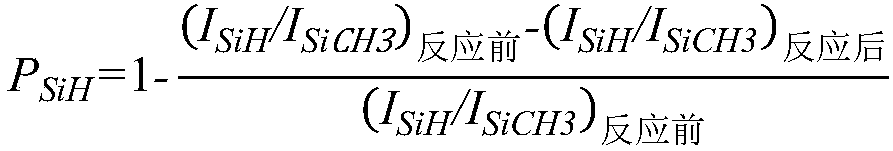

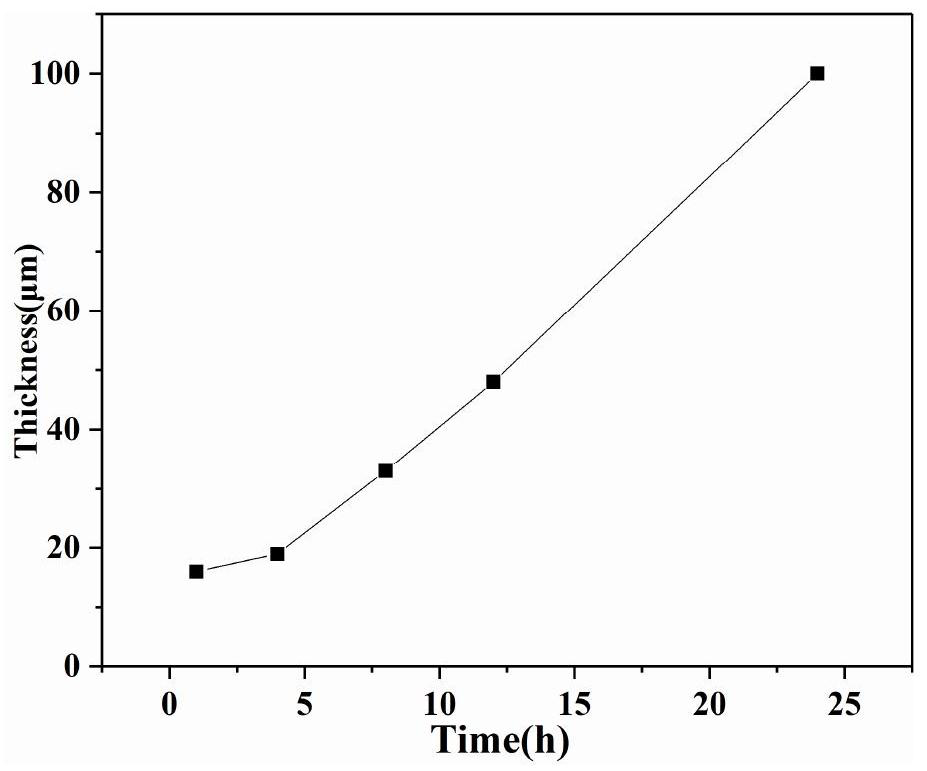

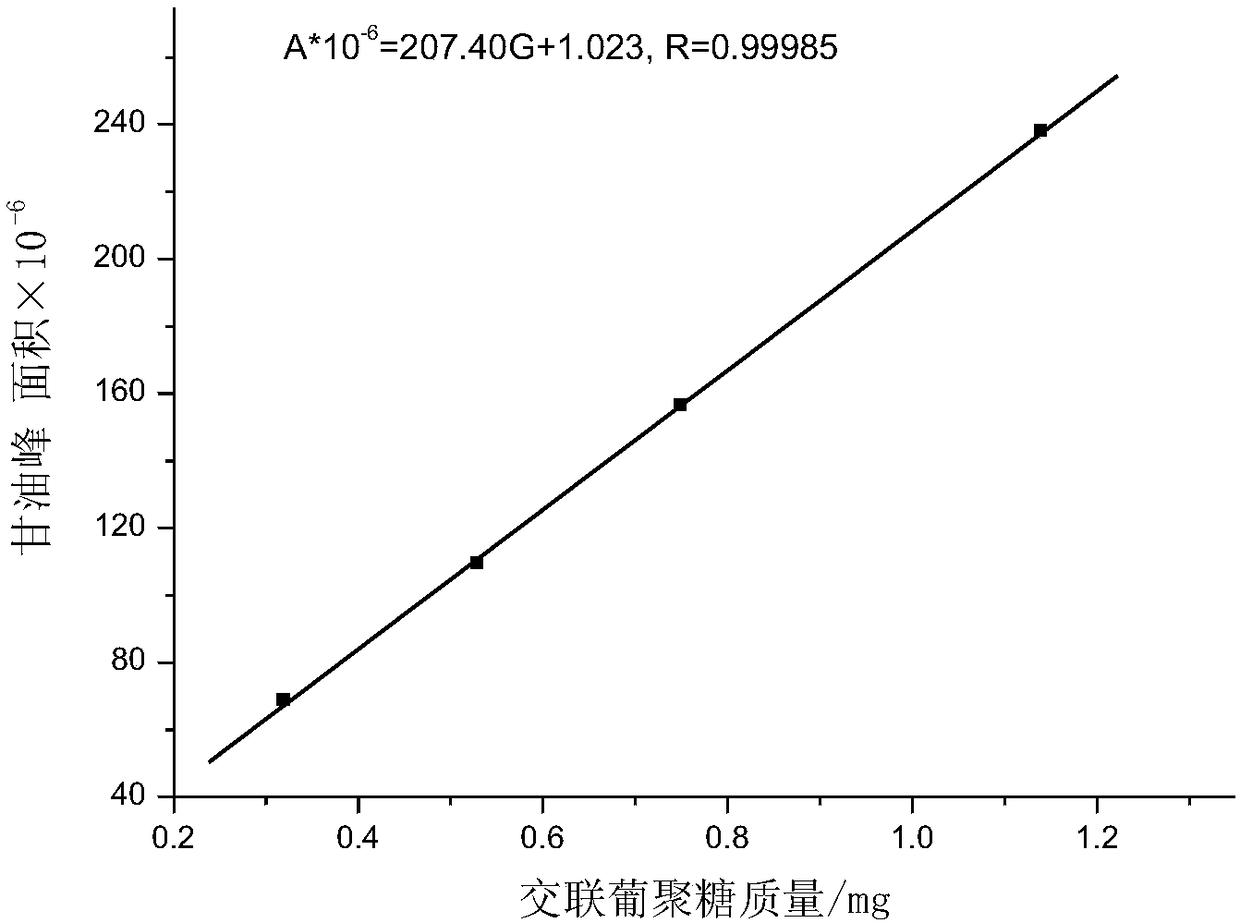

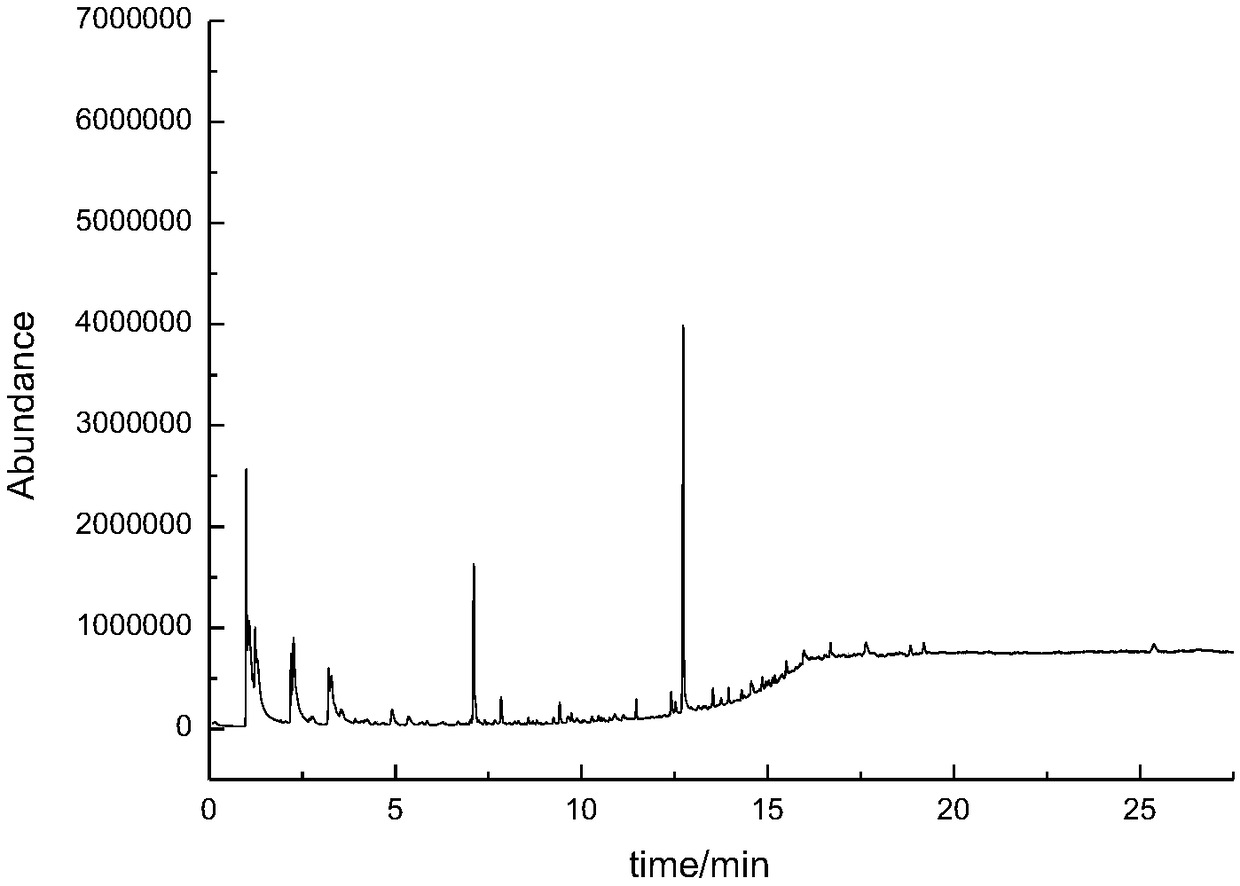

Method for determining content of crosslinked glucan filled in sodium hyaluronate gel

ActiveCN108254456AReliable resultsSimple and fast operationComponent separationGlycerolLinear relationship

Owner:浙江理工大学桐乡研究院有限公司

Cylinder swinging type slag falling device adopted during waste pyrolysis

Owner:湖南奔骥环保能源科技有限责任公司

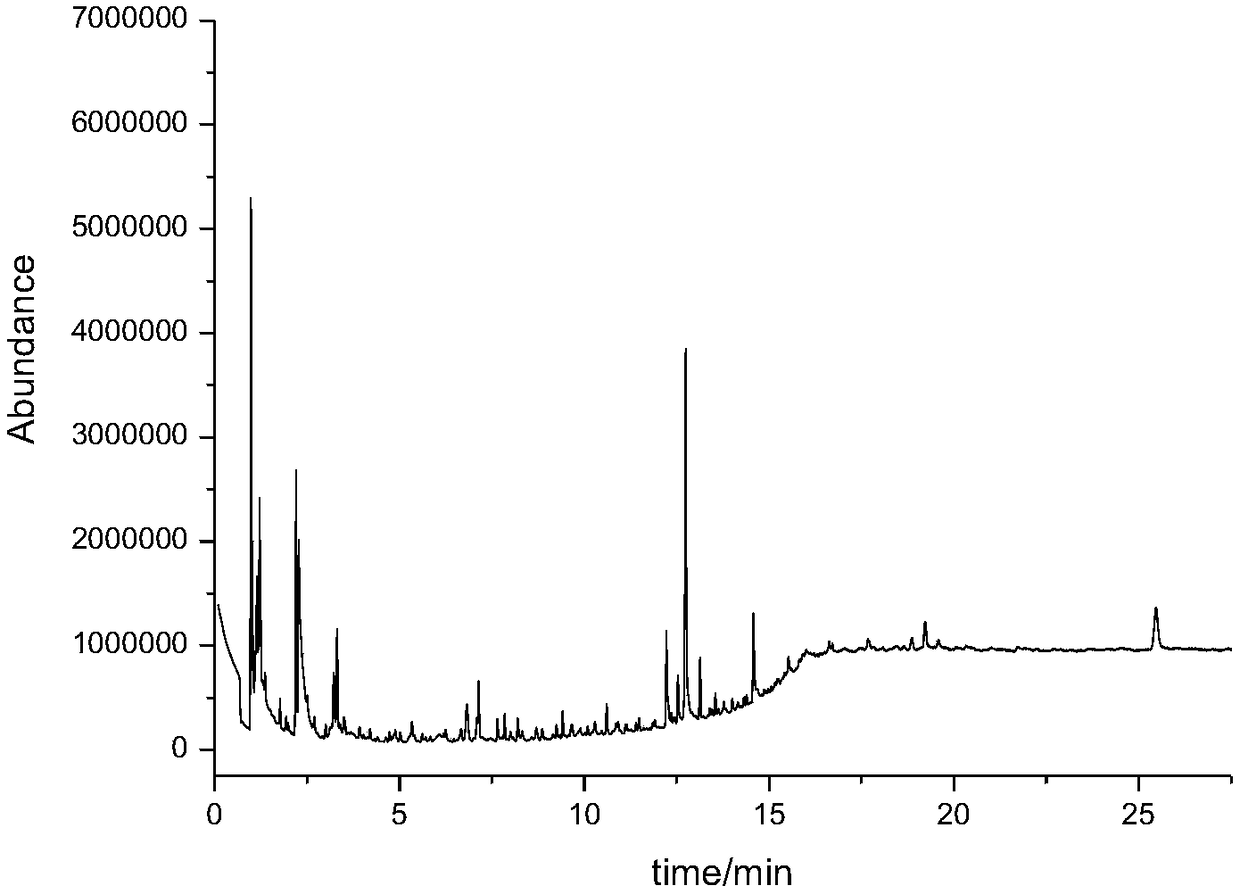

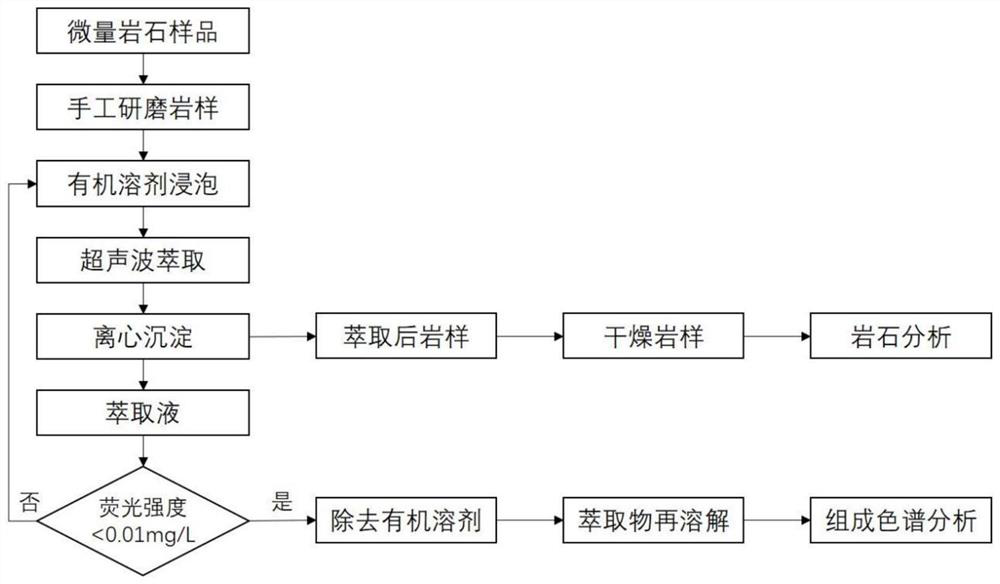

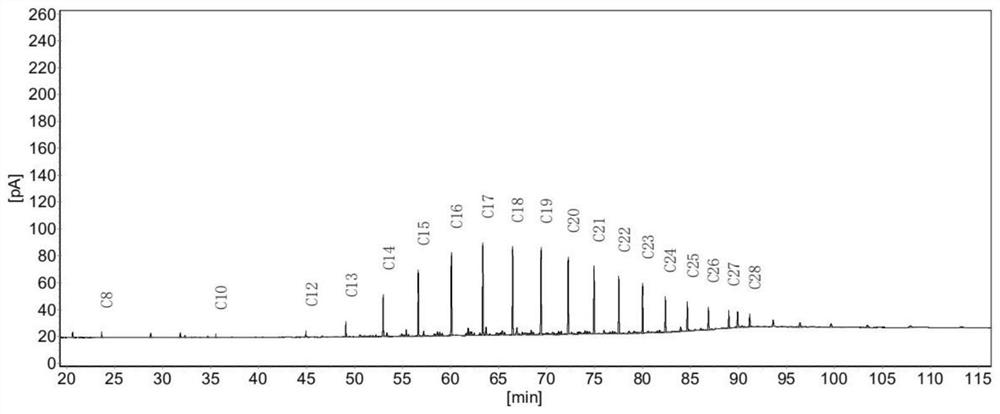

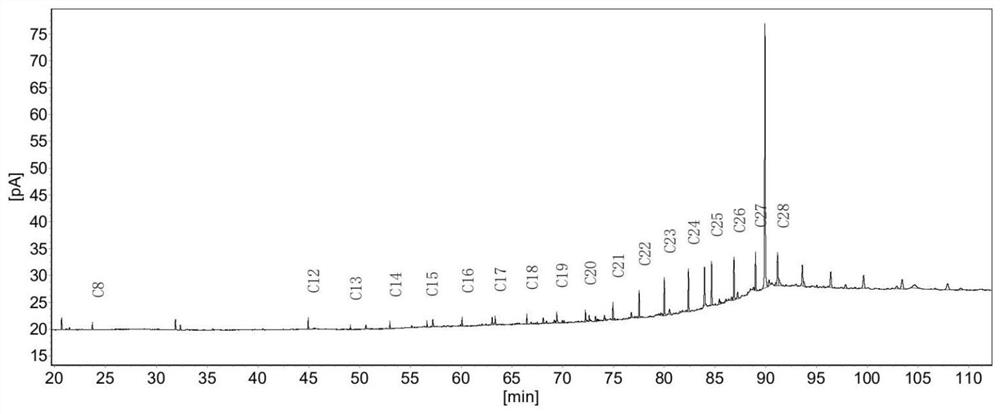

Solvent extraction method for hydrocarbon substances in trace rock sample

PendingCN113945444AAvoid cleavageAvoid generatingComponent separationPreparing sample for investigationPhysical chemistryOrganosolv

Owner:科正检测(苏州)有限公司

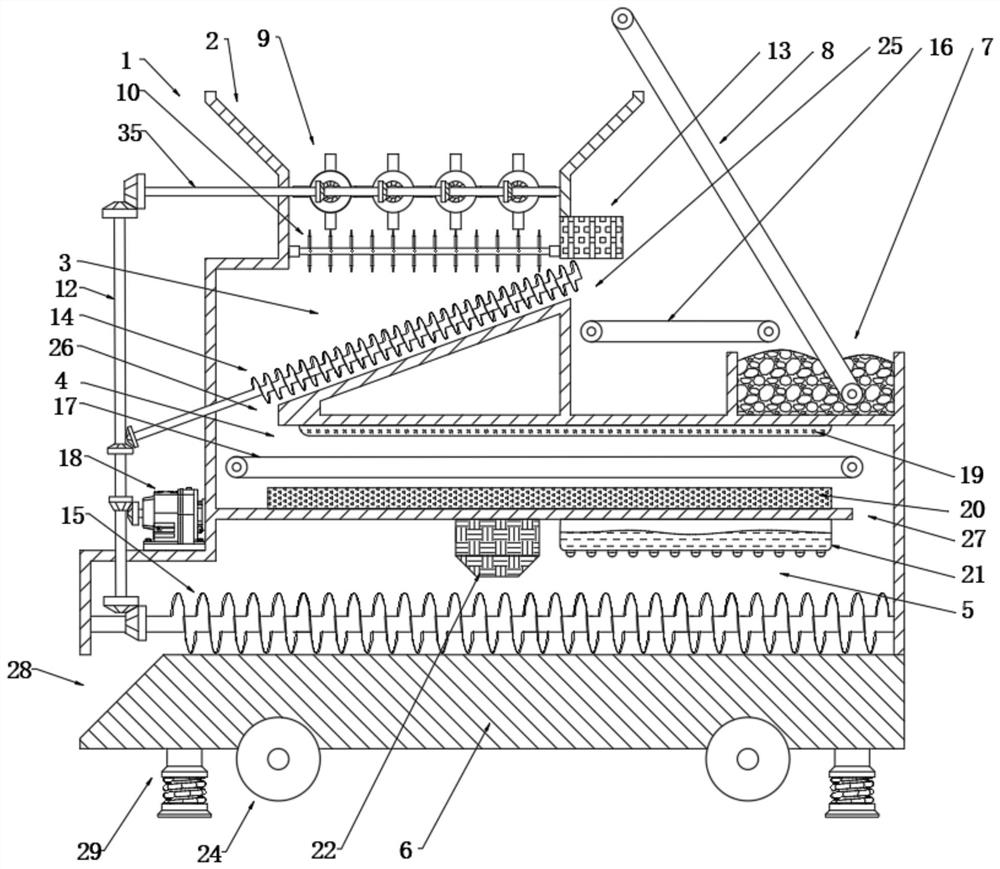

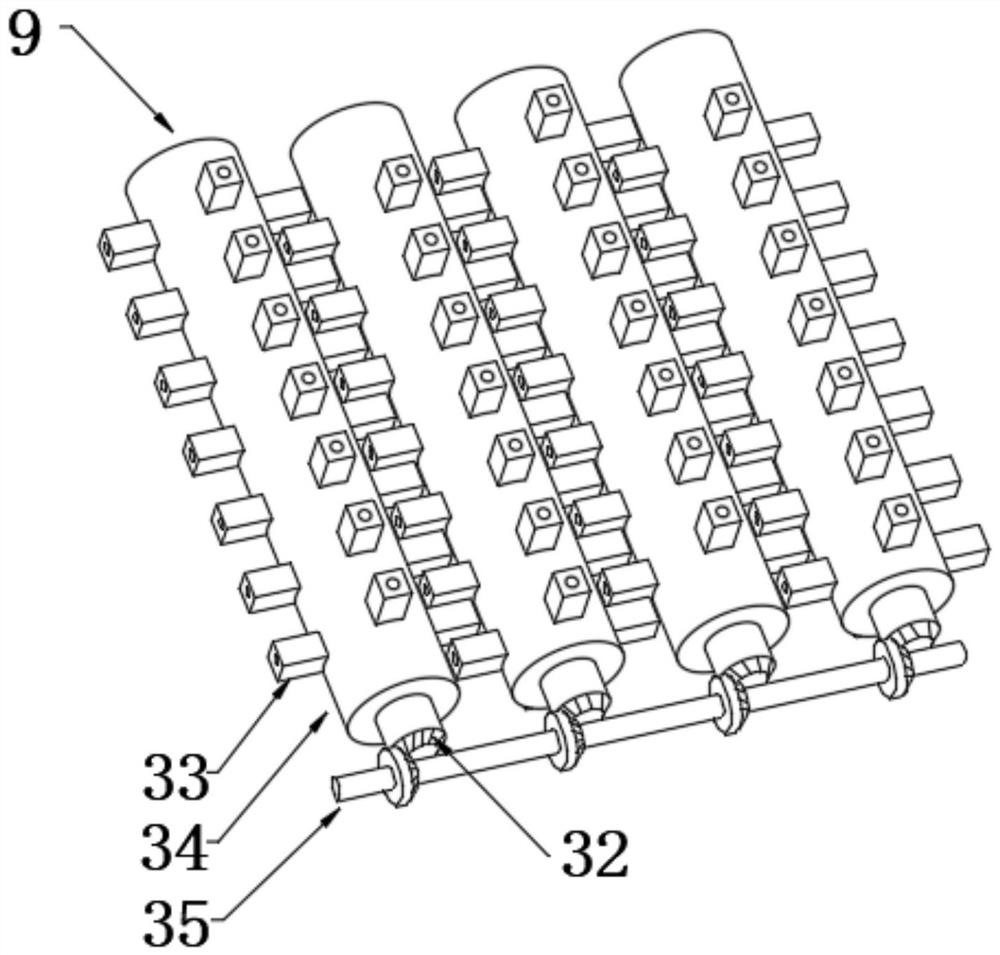

Soil pollution remediation device

InactiveCN112058888AEfficient repairImprove crushing effectContaminated soil reclamationGrain treatmentsSoil sciencePollution soil

Owner:卢超

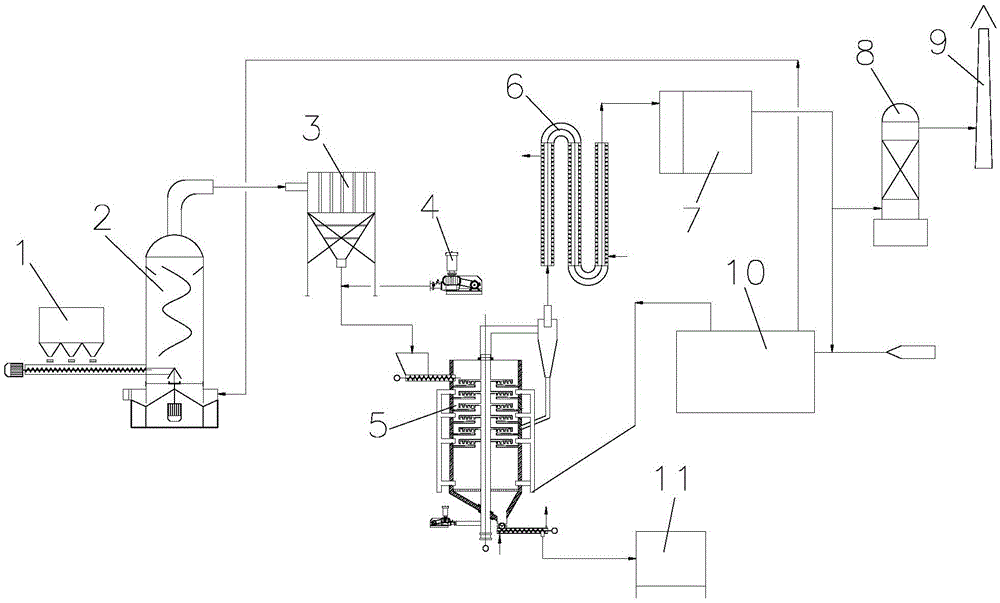

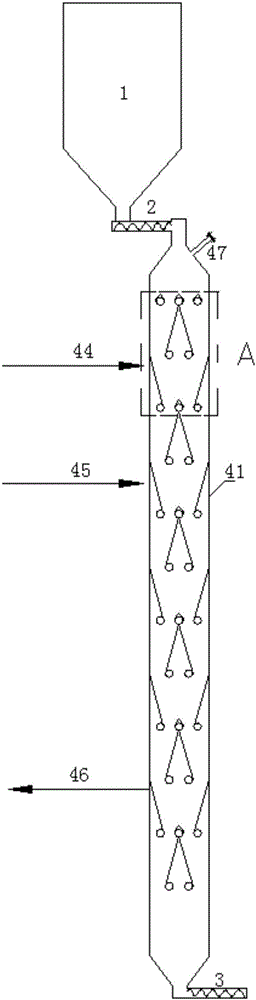

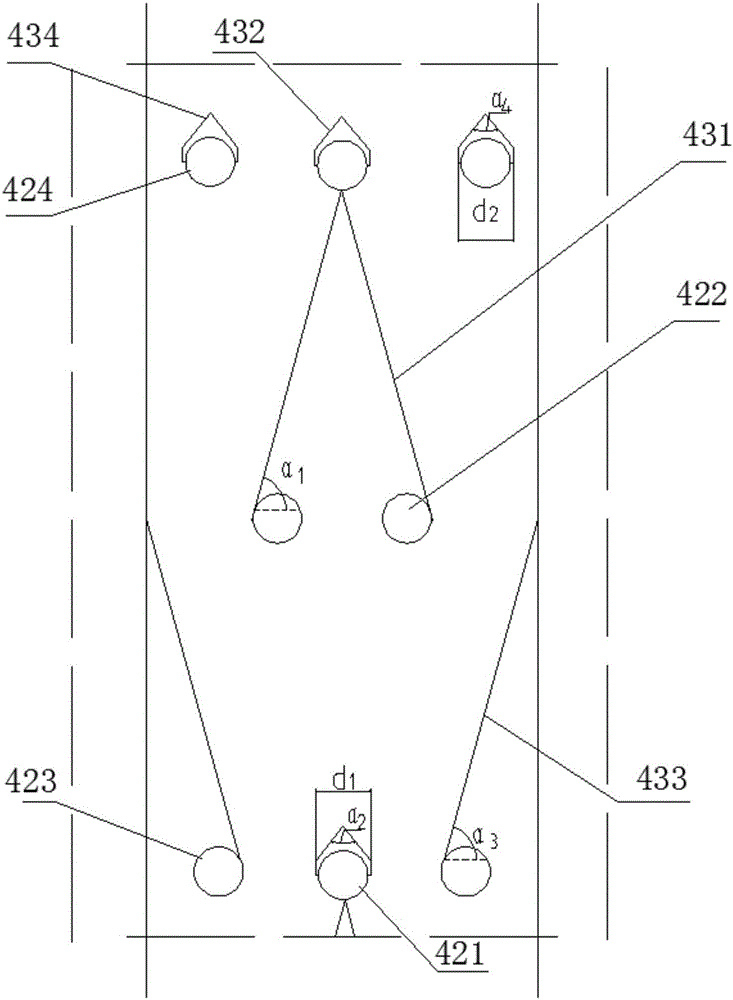

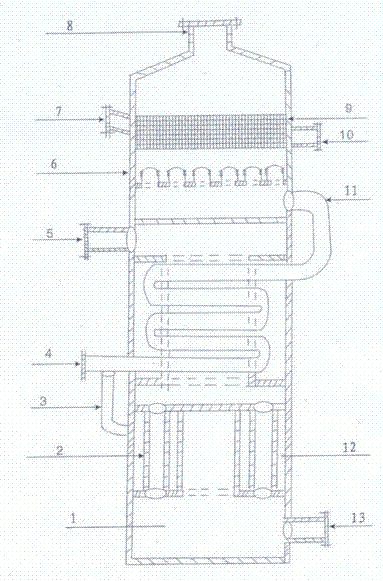

Small and medium sized fuel gas production device based on household refuse grading and flash pyrolysis and gasification

ActiveCN105907428AGasification processes detailsGranular/pulverulent flues gasificationFluidized bedIron removal

The invention provides a small and medium sized fuel gas production device based on household refuse grading and flash pyrolysis and gasification. The small and medium sized fuel gas production device comprises an iron-removal pulverizer, a riser, a circulating fluidized bed, a gas distributor, an ash discharging pipe, a gas inlet pipe, a feed inlet, a first-stage gas and solid separator, a coarse ash circulating pipe, a back feeder, a second-stage gas and solid separator, a fine ash circulating pipe, an entrained-flow bed, a fuel gas outlet, an air heat-exchanger and the like. The iron-removal pulverizer and the riser are arranged at the front end of the circulating fluidized bed sequentially; the gas distributor and the ash discharging pipe are arranged at the bottom of the circulating fluidized bed; the entrained-flow bed is arranged at the position which is 1000-2000 mm away from the bottom of the circulating fluidized bed; an oil gas inlet is arranged at the position which is 500-3000 mm away from the entrained-flow bed; the second-stage gas and solid separator is arranged at the top of the circulating fluidized bed; a coarse-particle ash circulating pipe of the first-stage gas and solid separator is connected to the bottom of the circulating fluidized bed, and a fine-particle ash circulating pipe of the first-stage gas and solid separator is connected to the entrained-flow bed through the back feeder; and a gas outlet is connected with the fuel gas outlet through the air heat exchanger.

Owner:田原宇

Furnace wall of contaminated soil pyrolysis or incineration furnace

Owner:深圳深态环境科技有限公司

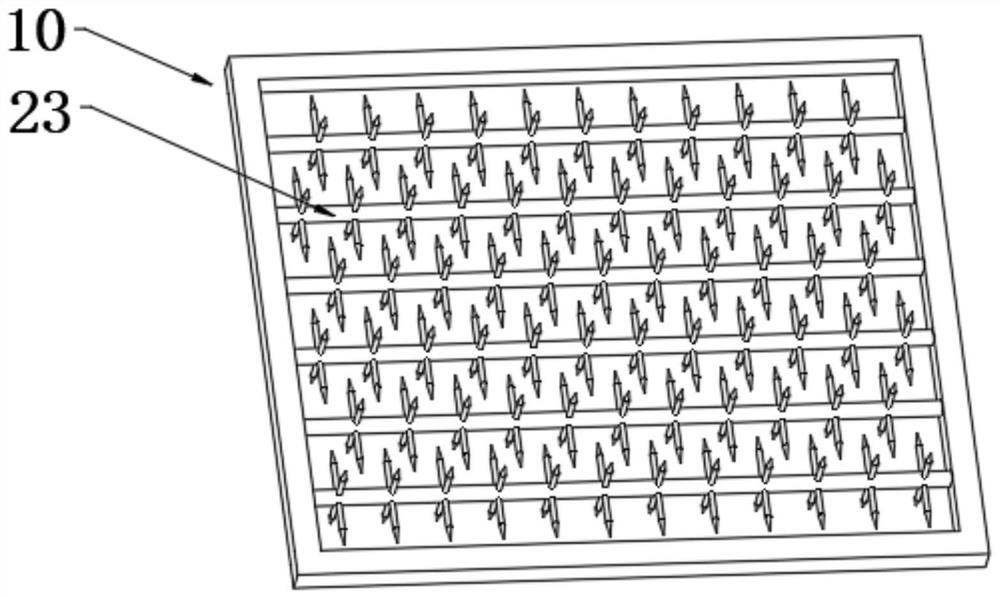

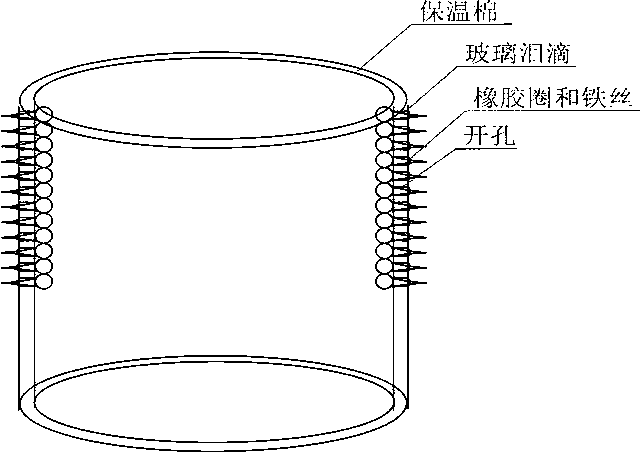

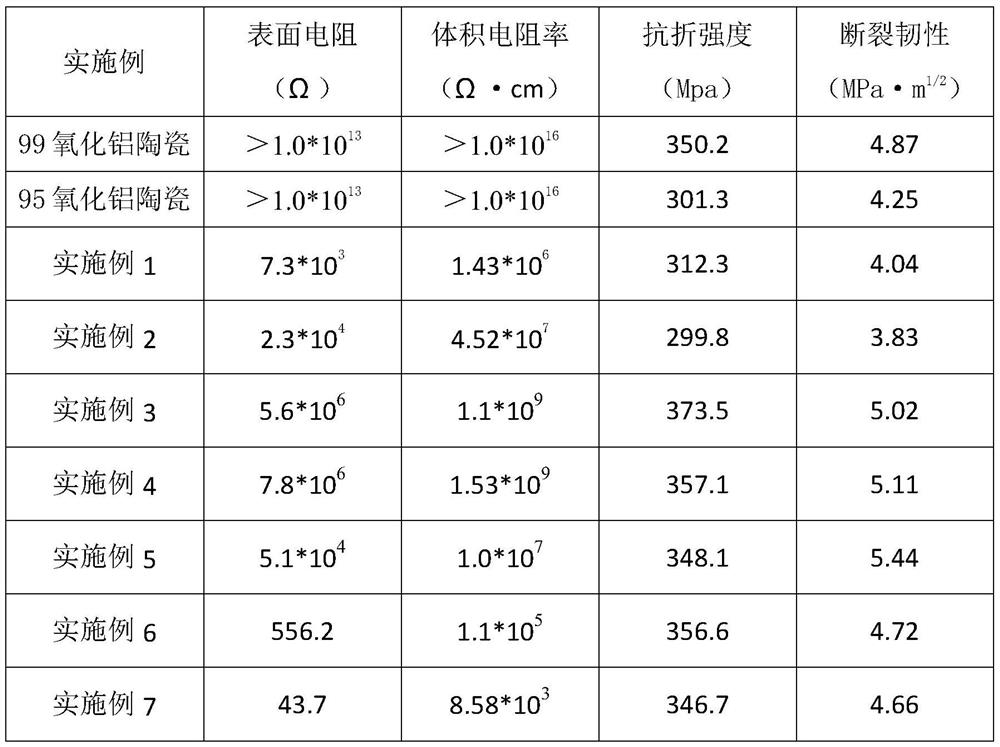

A kind of preparation method of graphene conductive alumina ceramics

ActiveCN110511001BFunctional compositePyrolysis

Owner:SHANGHAI LEVSON ENTERPRISE GRP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap