Cylinder swinging type slag falling device adopted during waste pyrolysis

A swinging, pyrolysis technology, applied in the direction of lighting and heating equipment, combustion methods, combustion types, etc., can solve the problems of cumbersome operation, laborious, dust flying and unhygienic, and achieve the improvement of automation, sanitation conditions and labor intensity. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described in conjunction with the following examples.

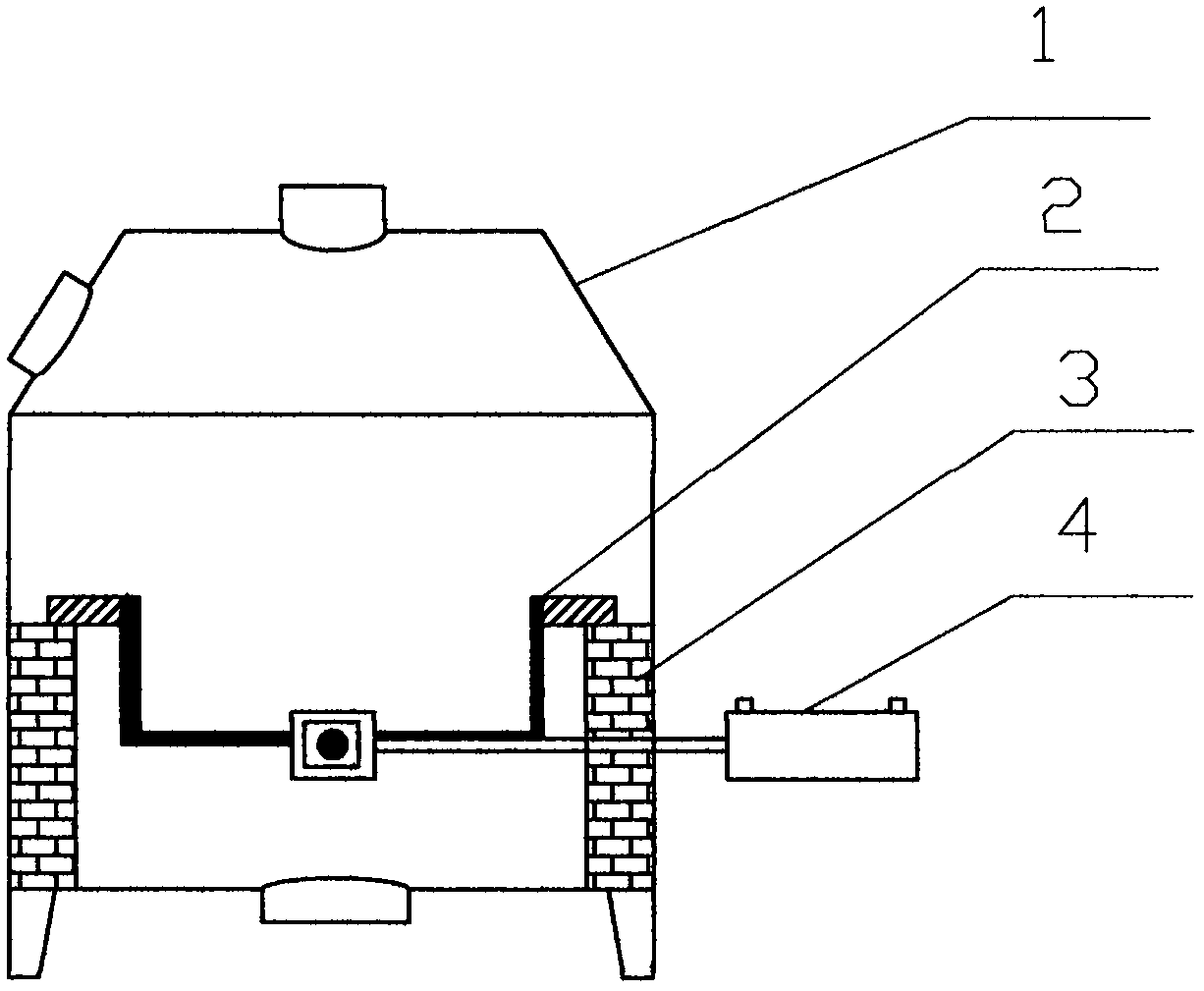

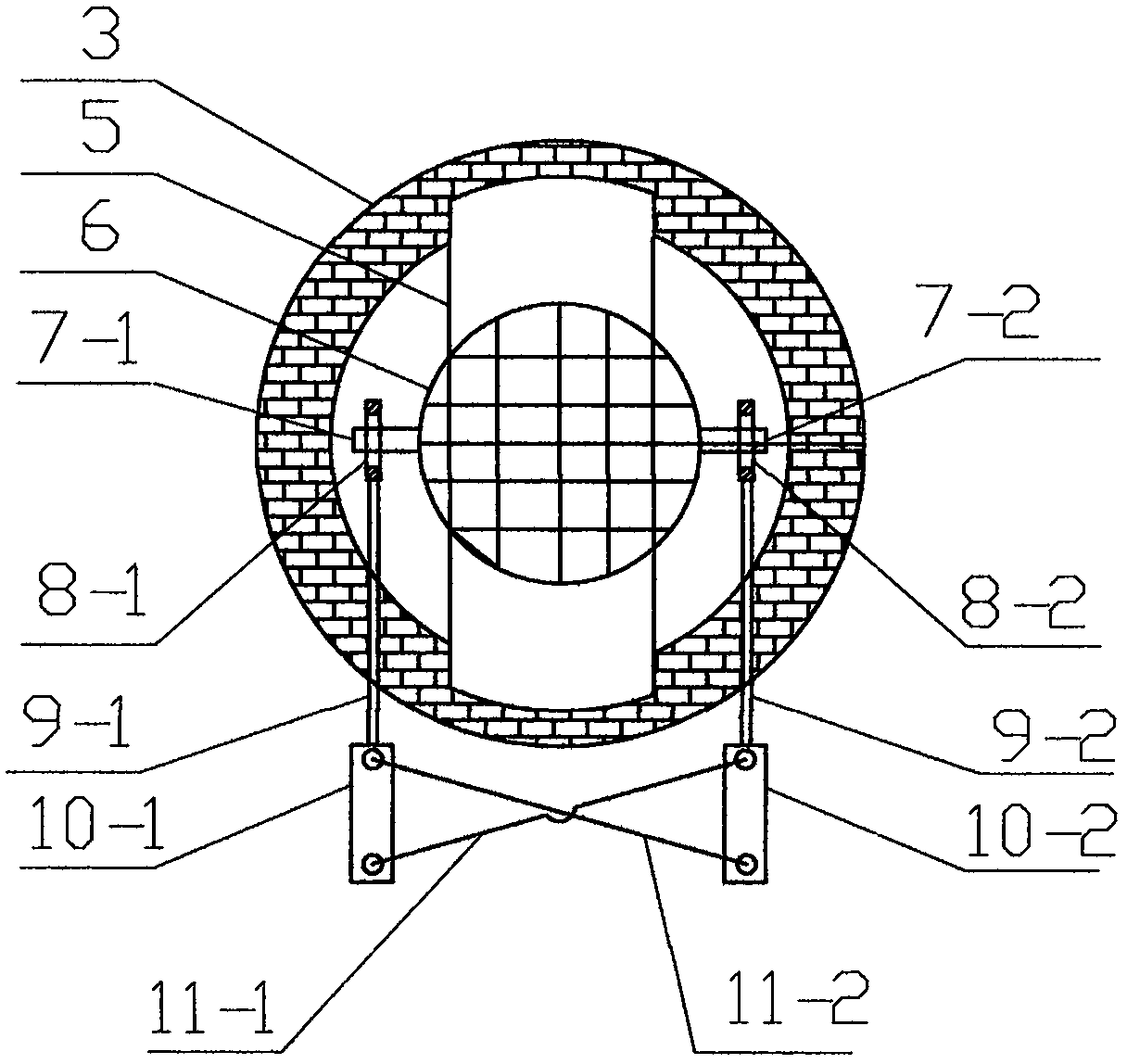

[0017] A cylinder swing type slag removal device is used in the pyrolysis of garbage in this embodiment. The present invention consists of a pyrolysis upper furnace body (1), a grid-type pyrolysis frame (2), a pyrolysis lower furnace body (3), and a cylinder swing The slag remover (4) consists of: the pyrolysis upper furnace body (1) is connected with the pyrolysis lower furnace body (3); on the step of the pyrolysis lower furnace body (3), a grid-shaped pyrolysis frame (2 ); on both sides of the grid-type pyrolysis frame (2), a cylinder swinging slag remover (4) is arranged, and the both sides of the grid-type pyrolysis frame (2) are provided with support ear one (7-1) and support Ear two (7-2) is matched with cylinder swing slag remover (4).

[0018] A cylinder swing type slag removal device is used for the pyrolysis of garbage, and the grid-shaped pyrolysis frame (2) consists of lu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap