Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about "Incinerator apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt-aluminum composite oxide catalyst and preparation method and application thereof

PendingCN110433806ALarge specific surface areaLarge transport channelIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCatalytic transformationPtru catalyst

The invention relates to the technical field of catalyst preparation, and discloses a cobalt-aluminum composite oxide catalyst and a preparation method and application thereof. The preparation methodcomprises the steps that metal salt solutions of cobalt and aluminum are taken as precursors correspondingly, polymer microspheres are taken as a template agent, templates are soaked in the precursorsolutions, then impregnation and roasting are conducted, and thus the cobalt-aluminum composite oxide catalyst is obtained. A three-dimensional ordered hierarchical pore structure with a mesoporous and macroporous structure is created through the polymer microspheres, thus the specific surface area of the catalyst is increased, the prepared catalyst has a large transmission pore channel, reactantmodules enter the pore channel from all directions advantageously, the diffusion resistance is lowered, thus the convective mass transfer efficiency between gases is improved, and the catalytic activity of the cobalt-aluminum composite oxide catalyst is facilitated; and meanwhile, through the large transmission channel, the situation that the modules are blocked when reacting on the pore wall or the pore channel of the transmission channel, and consequently, the reaction progress is influenced can further be effectively avoided, and the catalytic conversion efficiency of the catalyst is improved.

Owner:FUZHOU UNIV

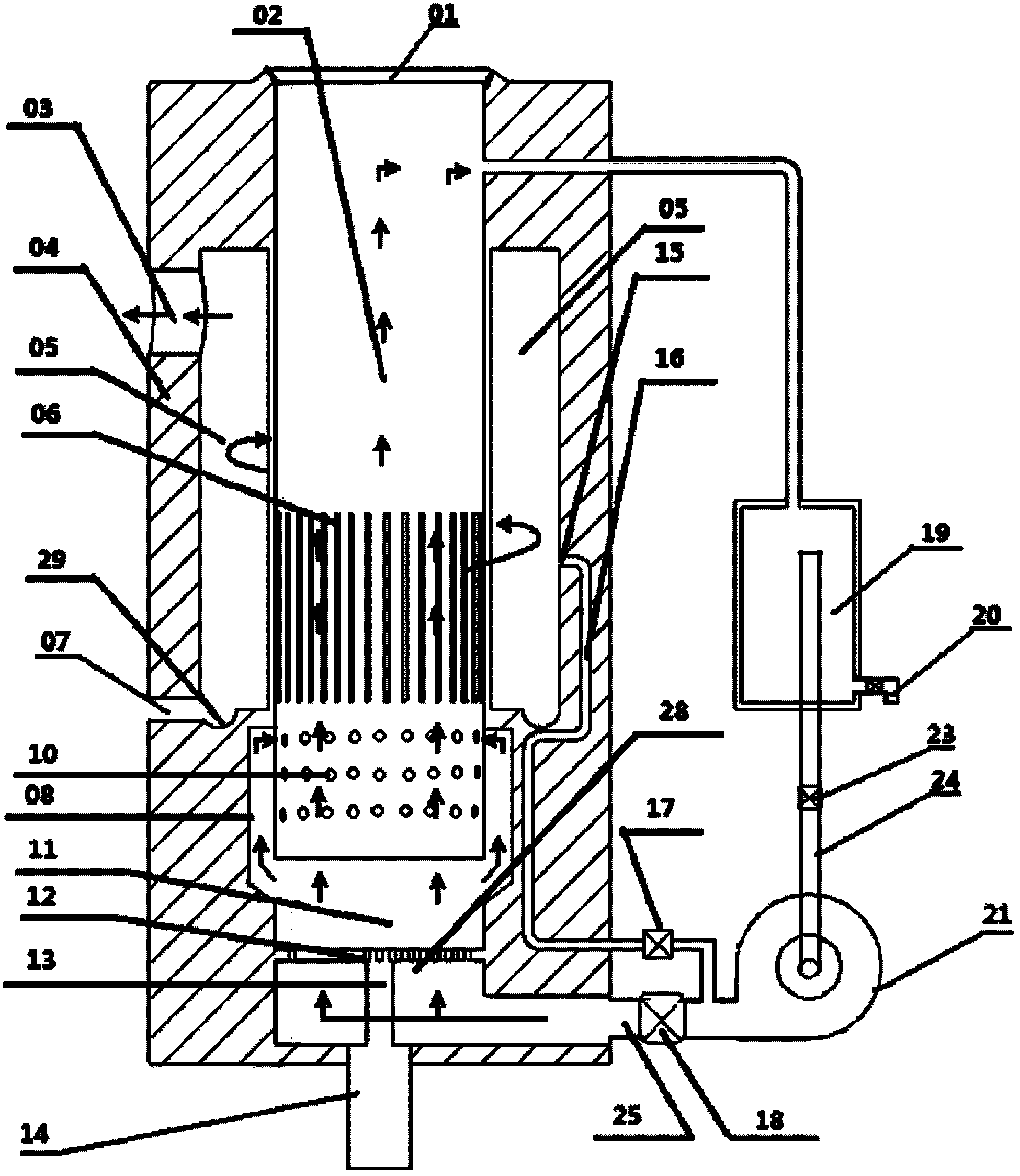

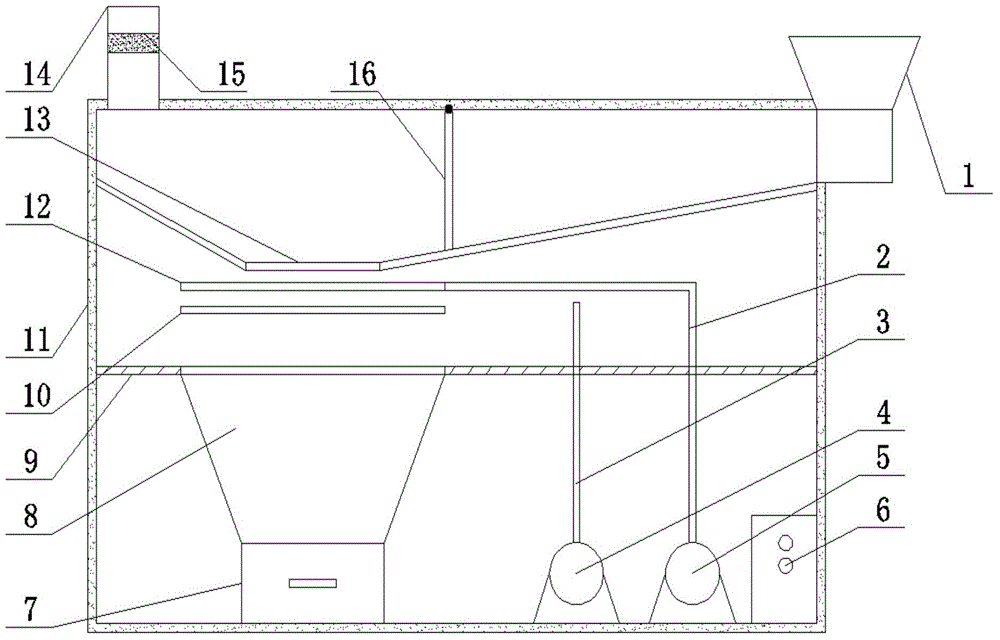

Industrial castoff fusing and solidifying device

InactiveCN101086334AFlammability ControlGood effectIndirect carbon-dioxide mitigationIncinerator apparatusCombustorPesticide residue

There is provided an industrial waste melting / solidifying apparatus comprising: melting furnace; an oxygen generating device for supplying oxygen-enriched air to the melting furnace; and a burner provided so as to face the inside of the melting furnace, wherein industrial wastes, such as asbestos, pesticide residues and incineration ashes, are thrown into the melting furnace, and combustible materials within the industrial wastes and fuel from the burner are combusted at high temperature by using the oxygen- enriched air, whereby a melting process is performed on the industrial wastes. An entrance slot formed on the melting furnace is provided with a water-cooling jacket via a throw-in gate. The water-cooling jacket is provided with a throw-in door for throwing the industrial wastes. The water-cooling jacket is further provided with a pusher for pushing the thrown industrial wastes out toward the entrance slot to control throwing speed and combustion speed.

Owner:高桥 贤三

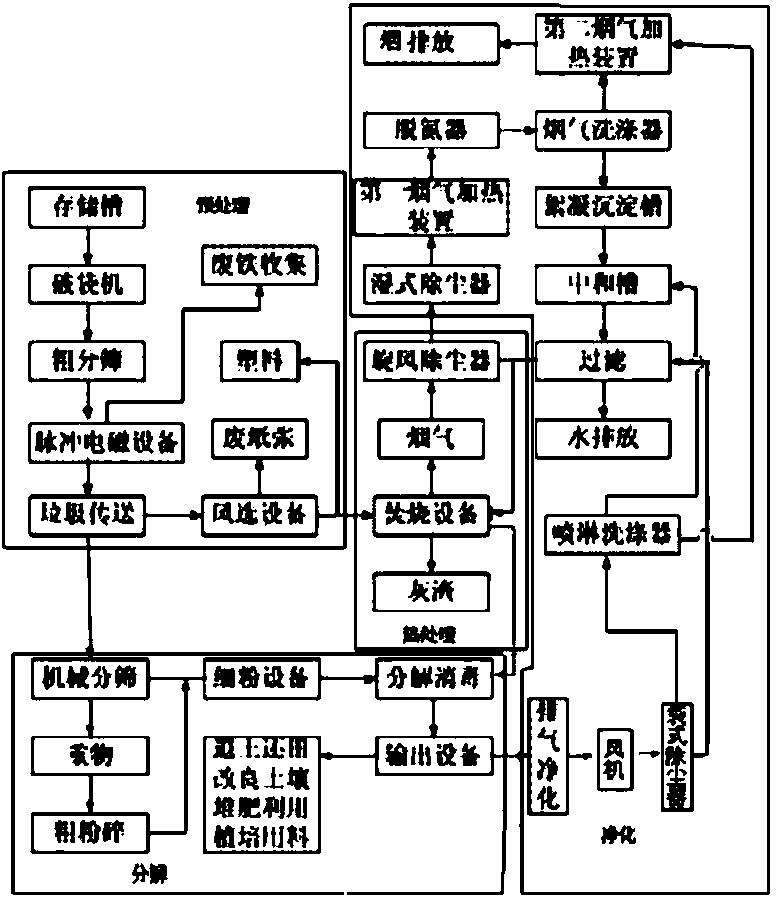

Urban garbage purifying utilizing system and garbage processing method

Owner:广西华都环境投资集团有限公司

Ignition system and ignition method of energy-saving eternal lamp utilizing exhaust gas

ActiveCN104421960AReduce energy consumptionReduce pollutionElectric spark ignitersIncinerator apparatusEngineeringNatural gas

Owner:北京融茂福元科技有限公司

Environment-friendly garbage incineration device

InactiveCN109595560AIncinerator apparatusChamber safety arrangementEnvironmentally friendlyEngineering

Owner:单卫光

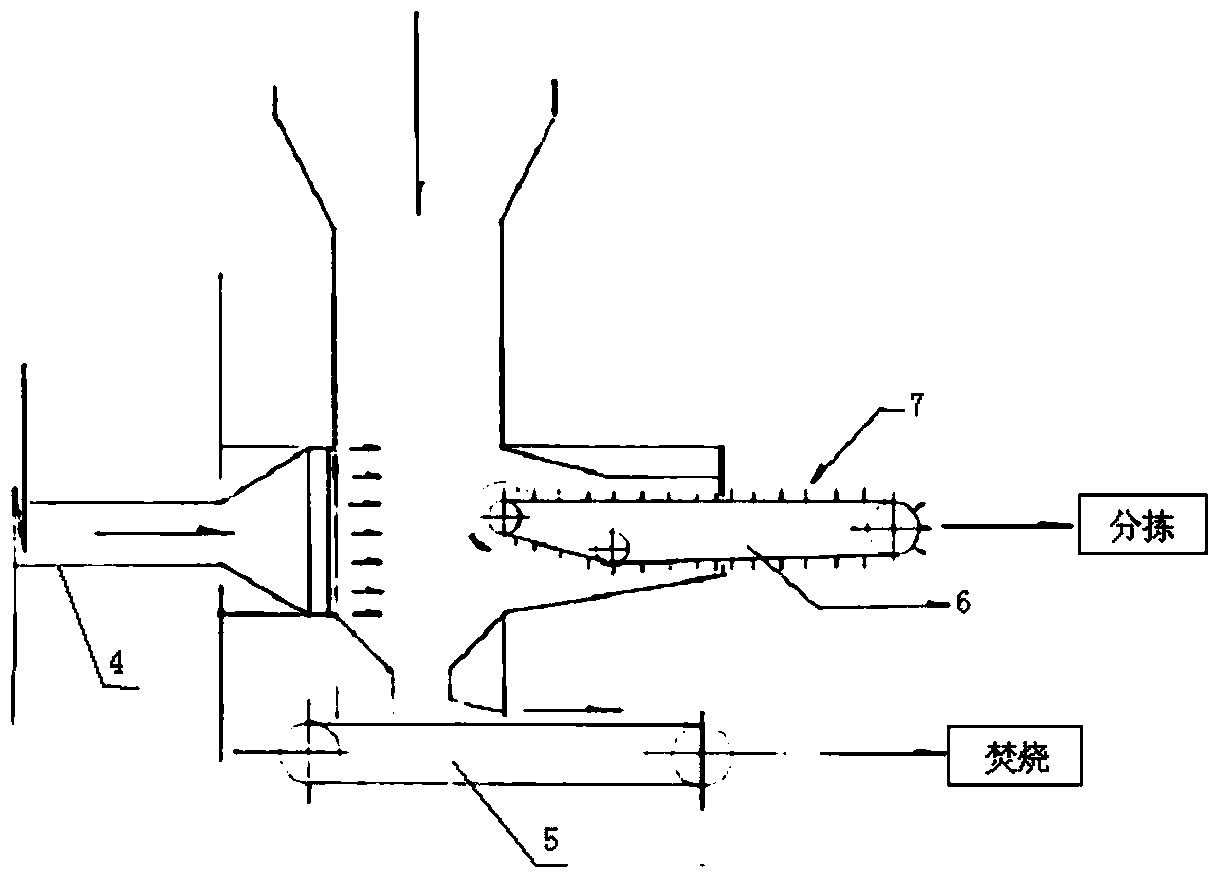

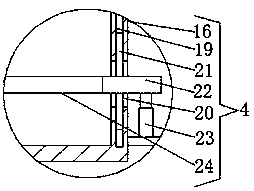

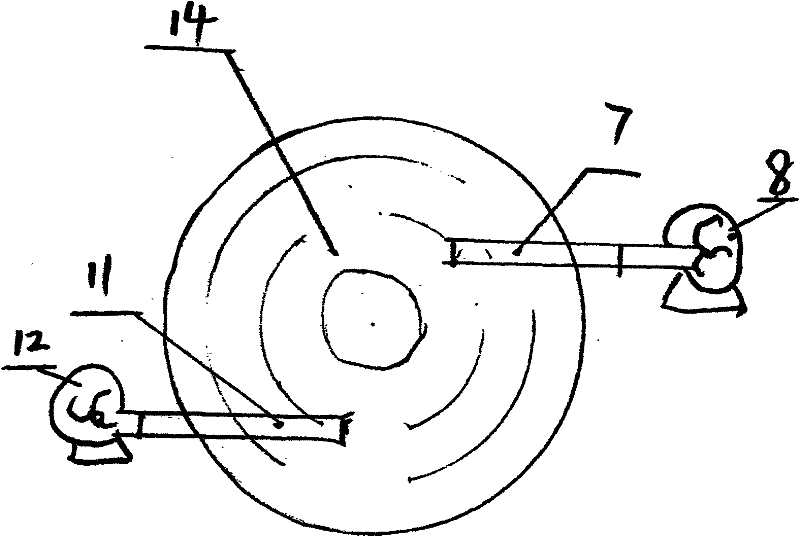

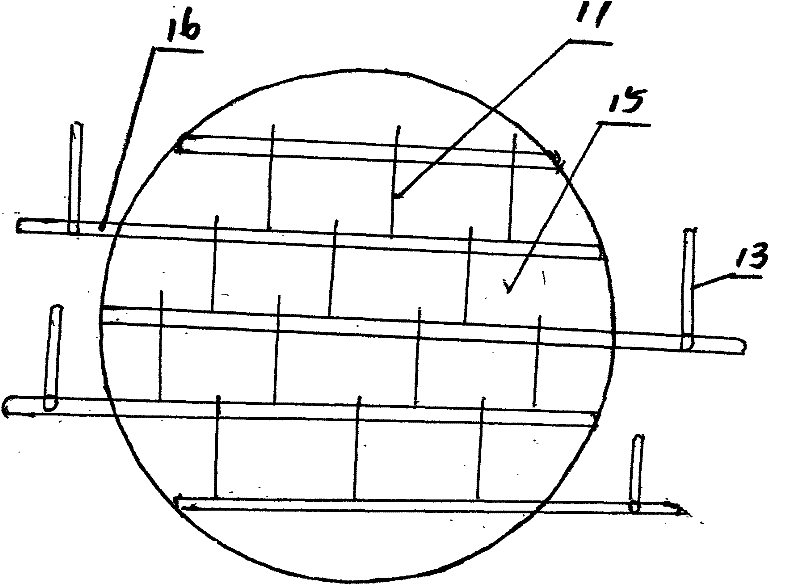

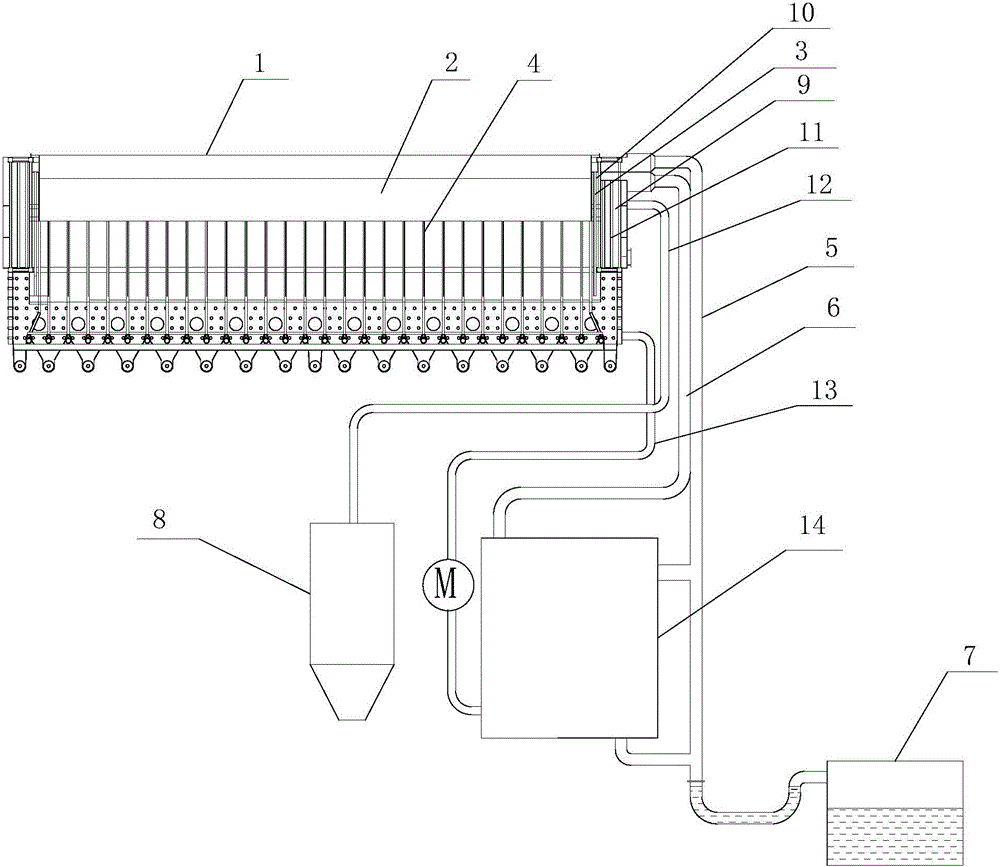

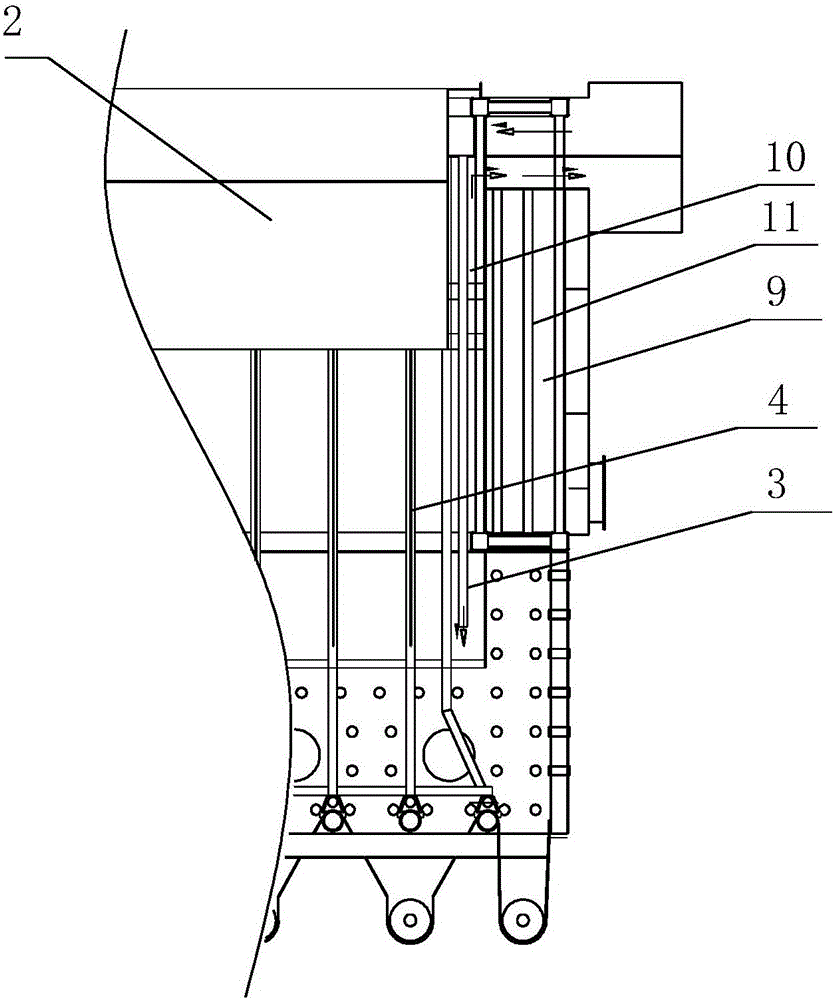

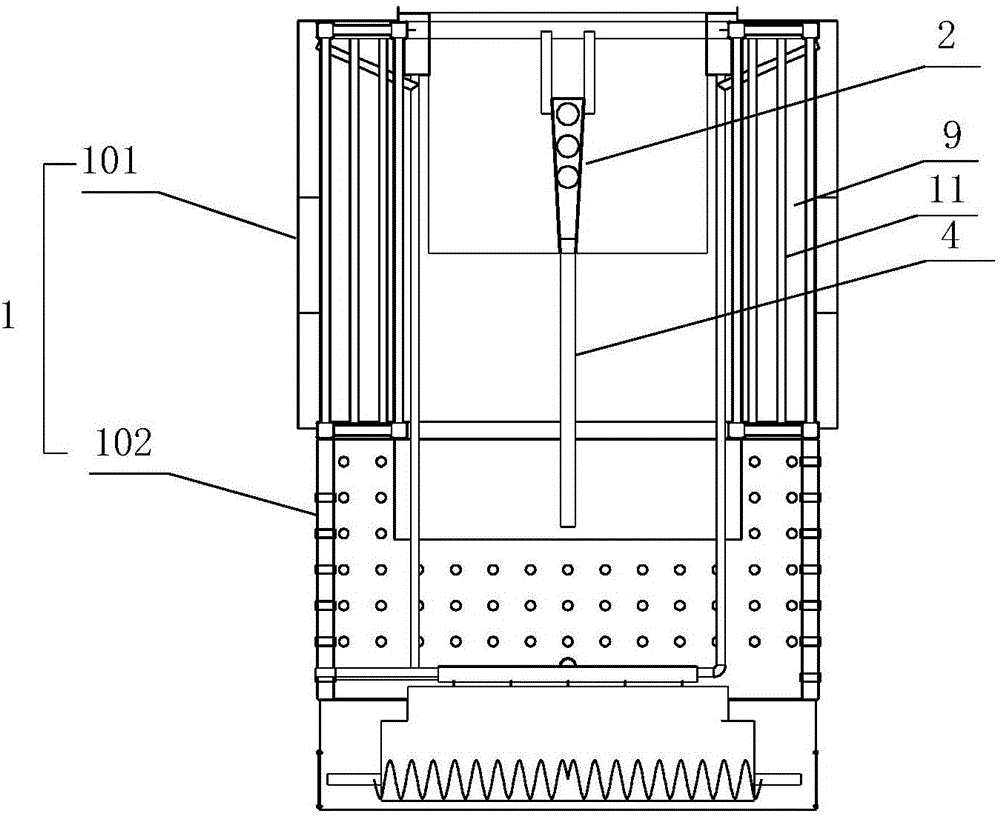

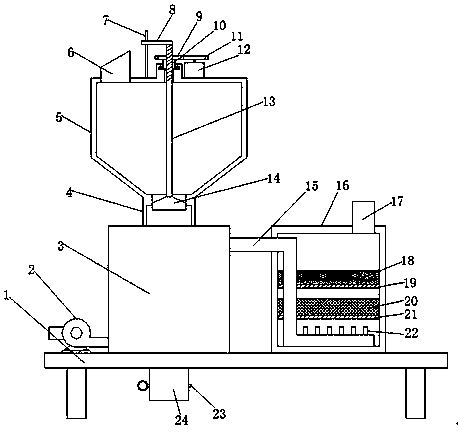

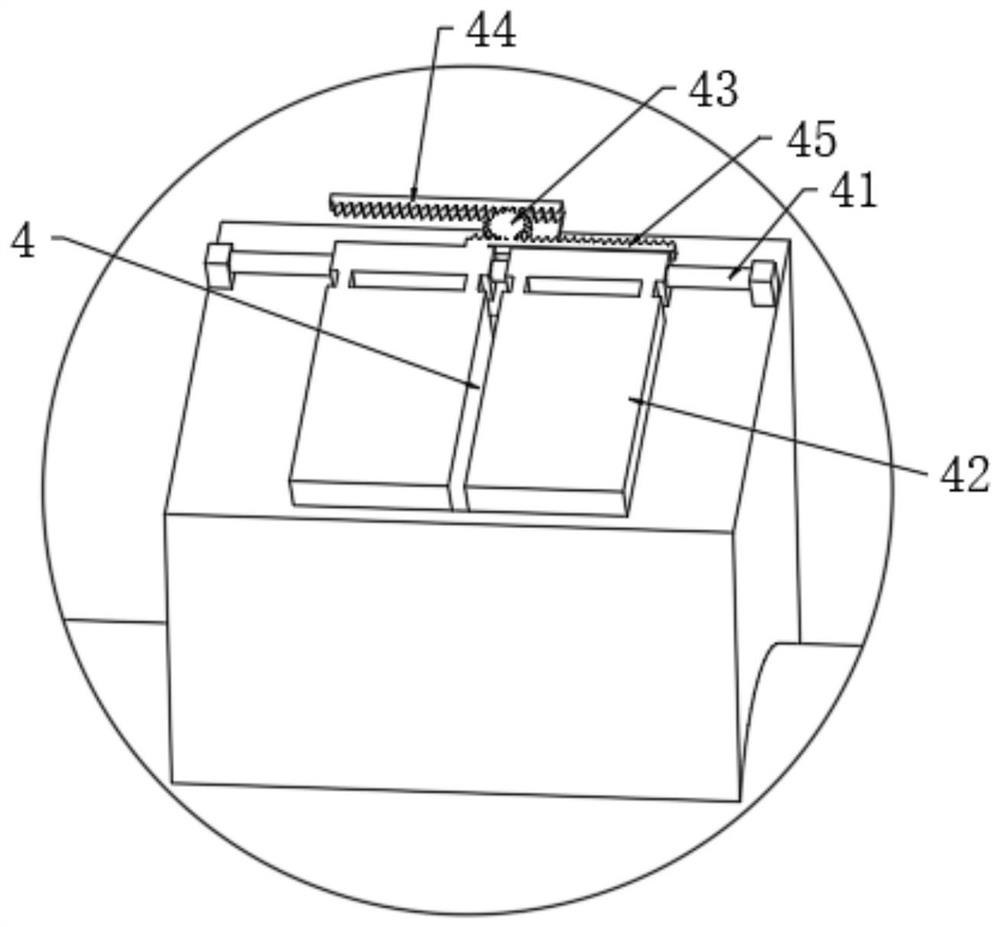

Slag removal machine of waste pyrolysis gasifier

The invention discloses a slag removal machine of a waste pyrolysis gasifier. The slag removal machine structurally comprises a furnace body, a material conveying pipe, a pushing machine, a feeding hopper, a fuel gas outlet, a hot air inlet and a slag removing mechanism, wherein the material conveying pipe is arranged at the top end of the left side of the furnace body, the pushing machine is arranged at the left end of the conveying pipe, the upper surface of the conveying pipe is connected with the feeding hopper, the fuel gas outlet is formed in the right side of the upper portion of the furnace body, and the hot air inlet is formed in the right side of the lower portion of the furnace body. The gasifier has the beneficial effects that a wiper and a scraper are arranged on the two sides of a rotating column, a motor drives the rotating column to rotate, a cutter is installed on the scraper so as to to scrape slag on the inner wall, the slag can fall into a material receiving disc, the inner wall is wiped through a cleaning brush on the wiper after the slag is scrapped, a ball pushing device and a stirring device are arranged inside the rotating column, a stirring rod can control balls in a rolling way, and the scraper and the wiper can be controlled to be stretched by changing the movement of the balls so as to adapt to furnace bodies with different sizes.

Owner:QUANZHOU TONGTONG ELECTRONIC EQUIP CO LTD

Environmentally friendly efficient disposable continuous waste gas treatment device

InactiveCN108114594AEasy to control and useImprove purification efficiencyCombination devicesIncinerator apparatusThermal energyEnvironmental engineering

Owner:苏州艾捷尔斯生物科技有限公司

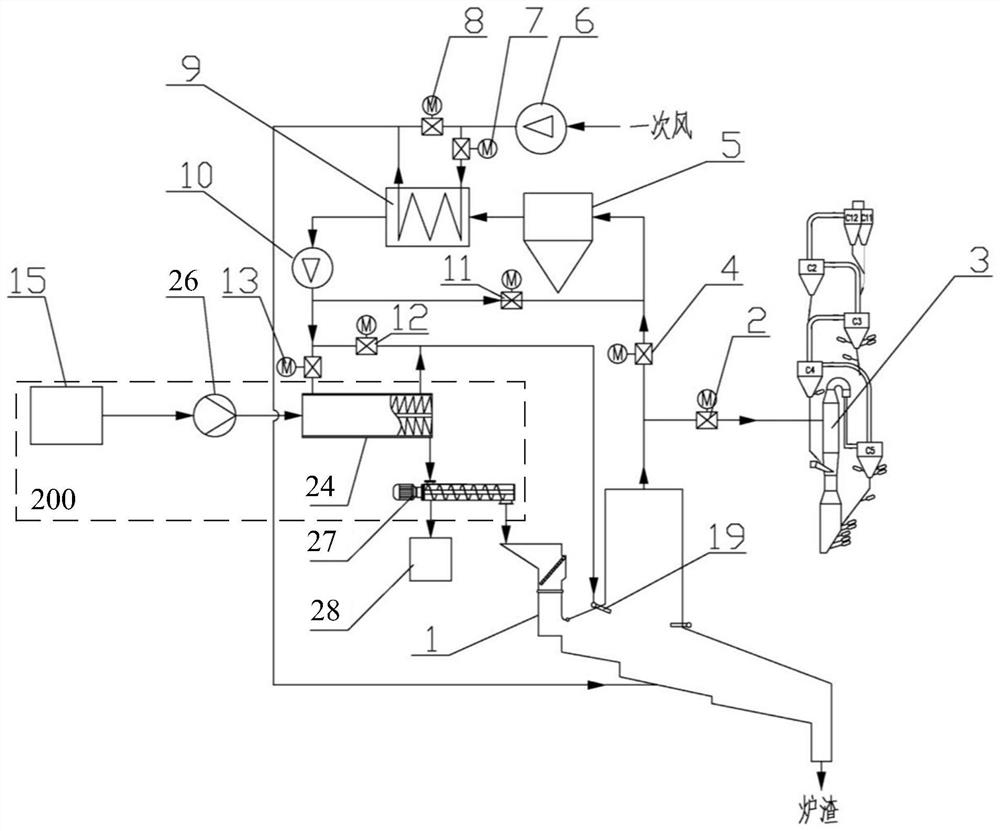

Dual-layer mechanical grate type garbage gasifying incinerator and dual-boiler power generation system thereof

ActiveCN105465793AImprove insulation effectPrevent leakageMachines/enginesIncinerator apparatusCycloneCombustion chamber

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Waste gas treatment device for garbage storing workshop of cement kiln co-processing domestic garbage system and treatment method thereof

PendingCN107716505AGuaranteed not to leakRealize harmless treatmentDirt cleaningIncinerator apparatusCombustion systemThermodynamics

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD

Method for treating dinitro-diazophenol (DDNP) primary explosive production wastewater

ActiveCN102003715AHandling safety and environmental protectionZero emissionGeneral water supply conservationEnergy based wastewater treatmentHigh concentrationSolid fuel

Owner:山东圣世达化工有限责任公司

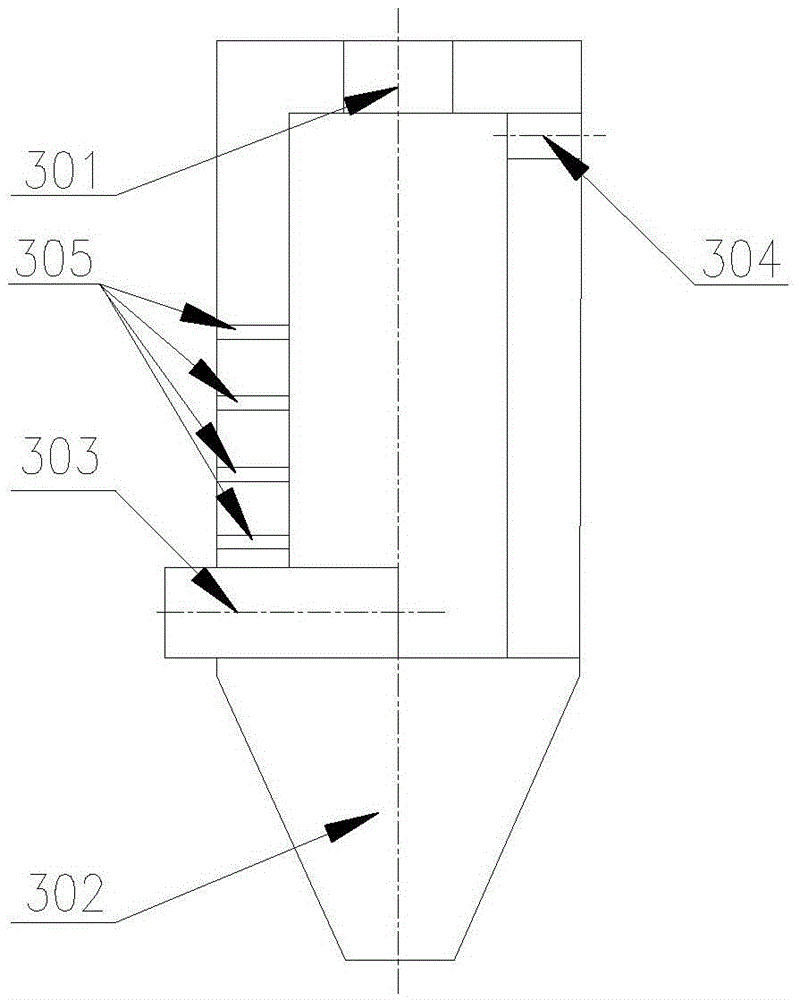

Oxygen-deficiency pyrolyzing circular sludge incinerator

Owner:TIANJIN BIAO DASI TECH

Cracking equipment

PendingCN110578923AIncrease heat transfer areaAvoid direct dischargeIncinerator apparatusCombustionHeat transfer efficiency

Owner:ZHAOYUAN HUICHAO NEW ENERGY TECH CO LTD

Device and process for purifying and treating tar tail gas and asphalt fume

ActiveCN110425550ASolve the problem that it is difficult to purify asphalt fumeImprove thermal efficiencyIncinerator apparatusChimneysCombustion chamberEnvironmental geology

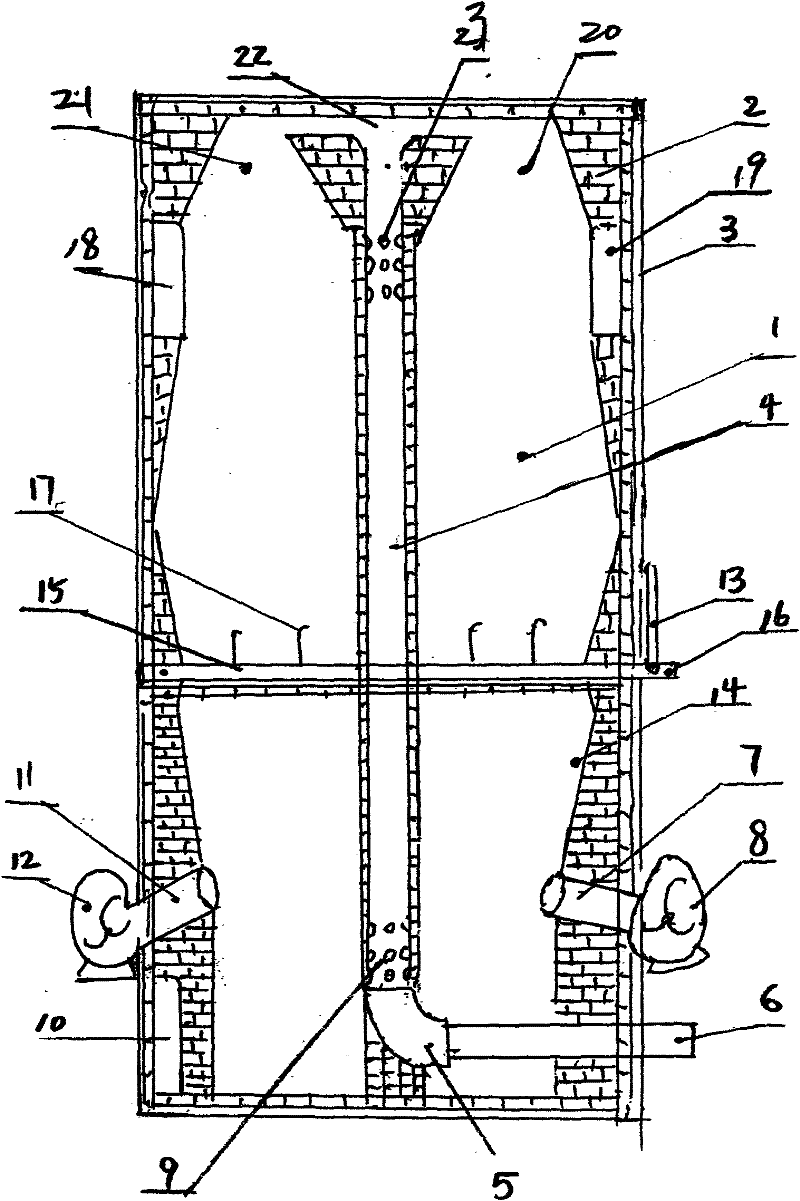

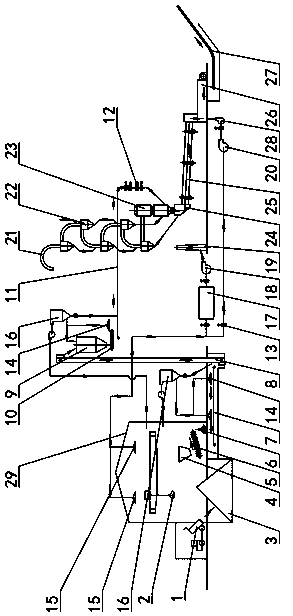

The invention relates to a device and process for purifying and treating tar tail gas and asphalt fume. The device comprises an incinerator and a chimney, wherein the incinerator is composed of a first combustion chamber, a second combustion chamber, a first heat storage chamber and a second heat storage chamber, the first combustion chamber is arranged below the second combustion chamber, and thefirst combustion chamber and the second combustion chamber communicates with each other; the two ends of the first combustion chamber communicates with the top of the first heat storage chamber and the top of the second heat storage chamber respectively, a first combustor is arranged inside the first combustion chamber, a second combustor is arranged inside the second combustion chamber, and a heat accumulator is arranged inside the first heat storage chamber and the second heat storage chamber. By adopting a process combining a heat storage type incinerator and a direct combustion type incinerator, the tar tail gas and the asphalt fume can be purified at the same time, the problem that the heat storage type incinerator is difficult to purify the asphalt fume and the direct combustion type incinerator is low in heat efficiency is solved, meanwhile, waste gas waste heat is recycled, the operation cost of the incinerator is reduced, and the purposes of energy conservation and environmental protection are achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Improved cobalt-based catalyst and preparing method and application thereof

ActiveCN108554416AIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsAmmonium hydroxideMixed solution

Owner:SHANGHAI RES INST OF CHEM IND

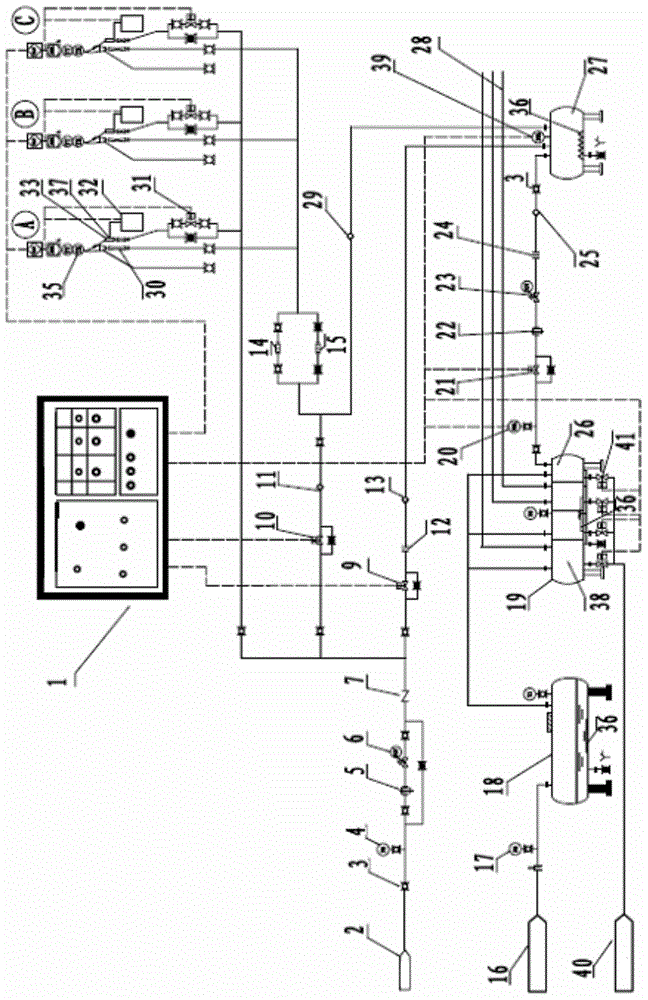

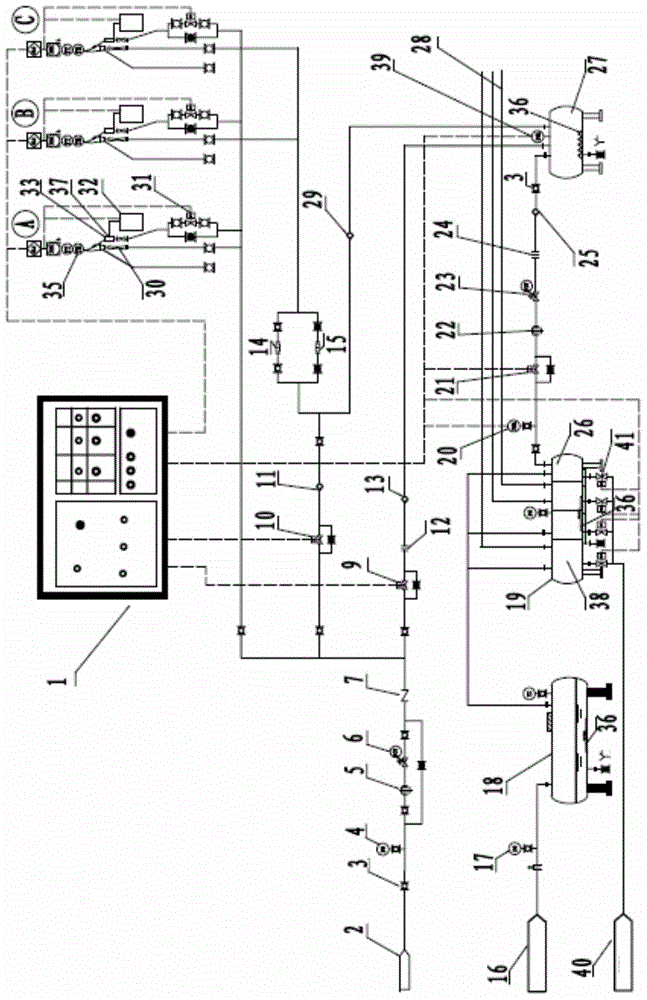

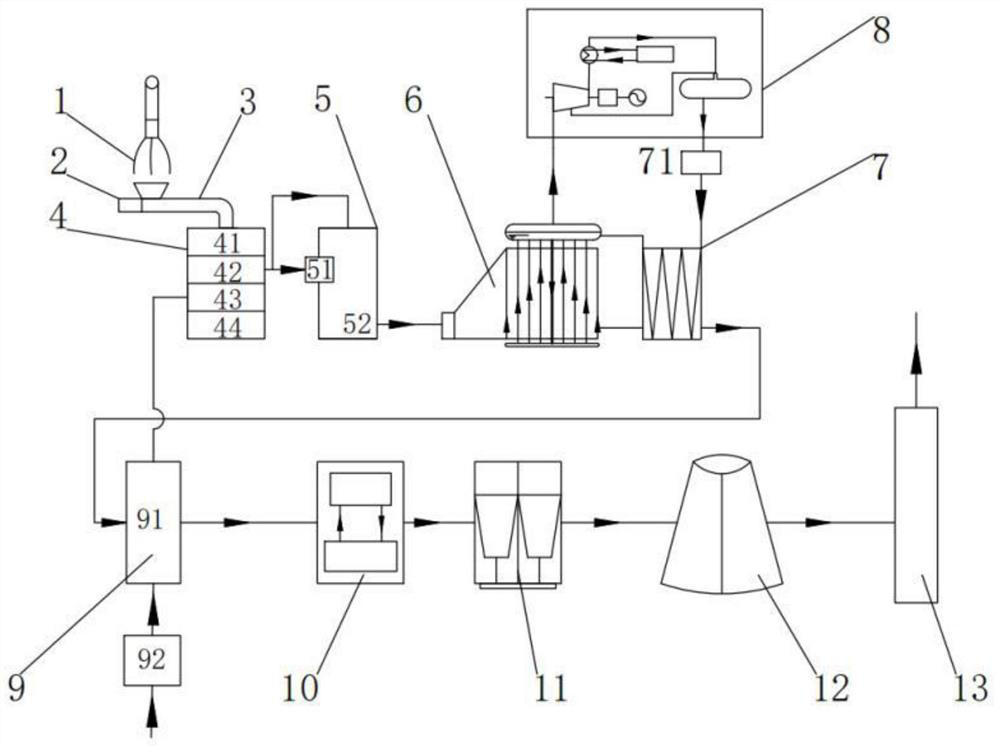

VOC runner performance testing device

InactiveCN107727795AWill not cause secondary pollutionMeet the needs of wheel testingGas treatmentDispersed particle separationCombined testDesorption

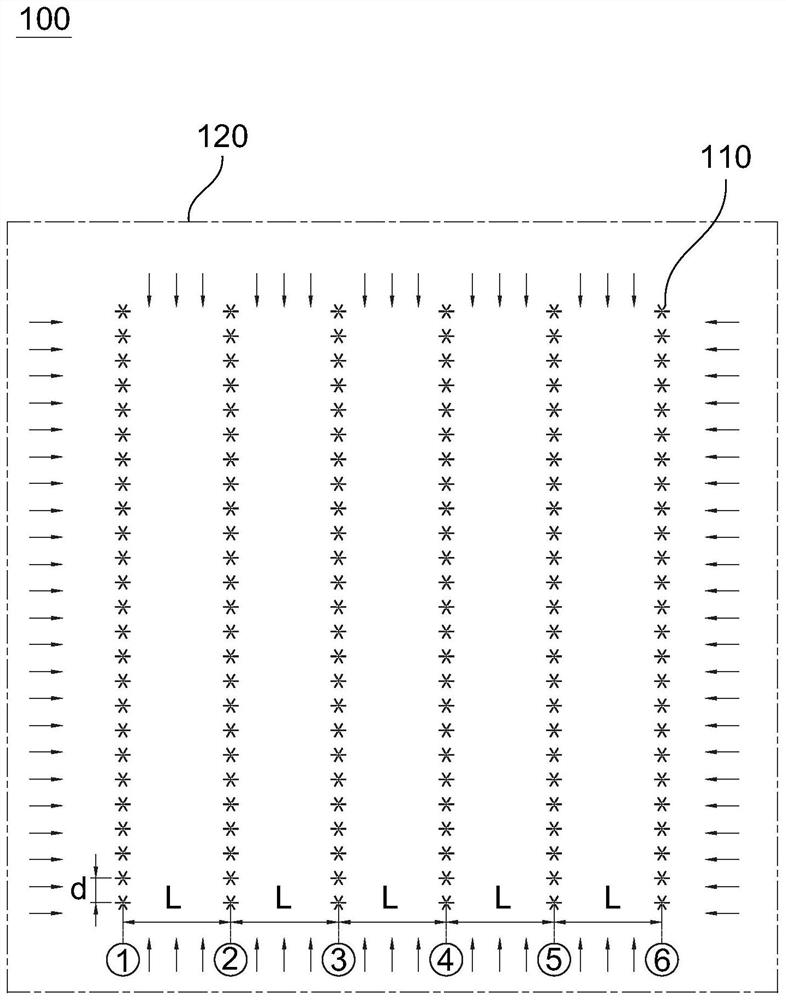

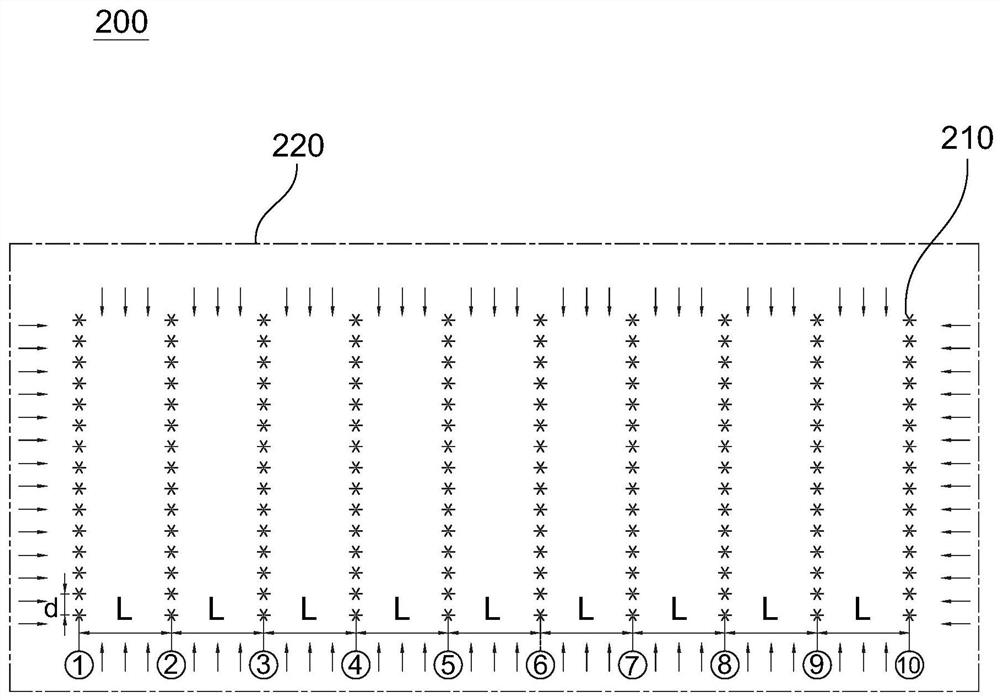

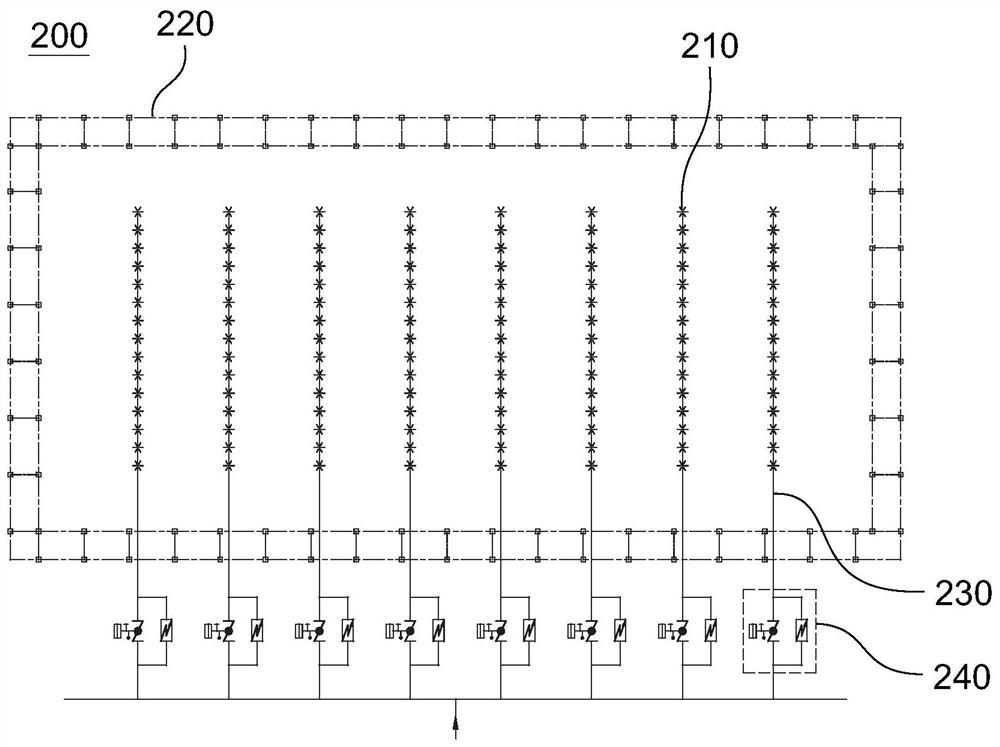

The invention discloses a VOC runner performance testing device. According to the device, a large circulating pipe, a VOC solvent box and an air compressor are sequentially connected by virtue of airpipes; the large circulating pipe is sequentially connected with a fresh air mixing box, a VOC adsorption runner, a fan and an air exhausting device; a middle circulating pipe is sequentially connected with the VOC adsorption runner, a purifier, a heat exchanger, a heat exchange unit and a fan; a small circulating pipe is sequentially connected with the heat exchange unit and a catalytic combustion device; the heat exchanger is connected with the large circulating pipe by virtue of an air pipe penetrating through the VOC adsorption runner, and is connected with the air exhausting device by virtue of an air pipe. Compared with the prior art, the VOC runner performance testing device disclosed by the invention has the advantages that the VOC runner can be subjected to comprehensive evaluation, secondary pollution is avoided, and requirements on various runner tests are met. Moreover, the device disclosed by the invention is creative, is provided with the novel large circulating pipe, middle circulating pipe and small circulating pipe, is capable of comprehensively testing the treatment capacity and desorption ability of the VOC runner and is high in efficiency and excellent in effect.

Owner:PURESCI ENVIRONMENTAL TECH CO LTD

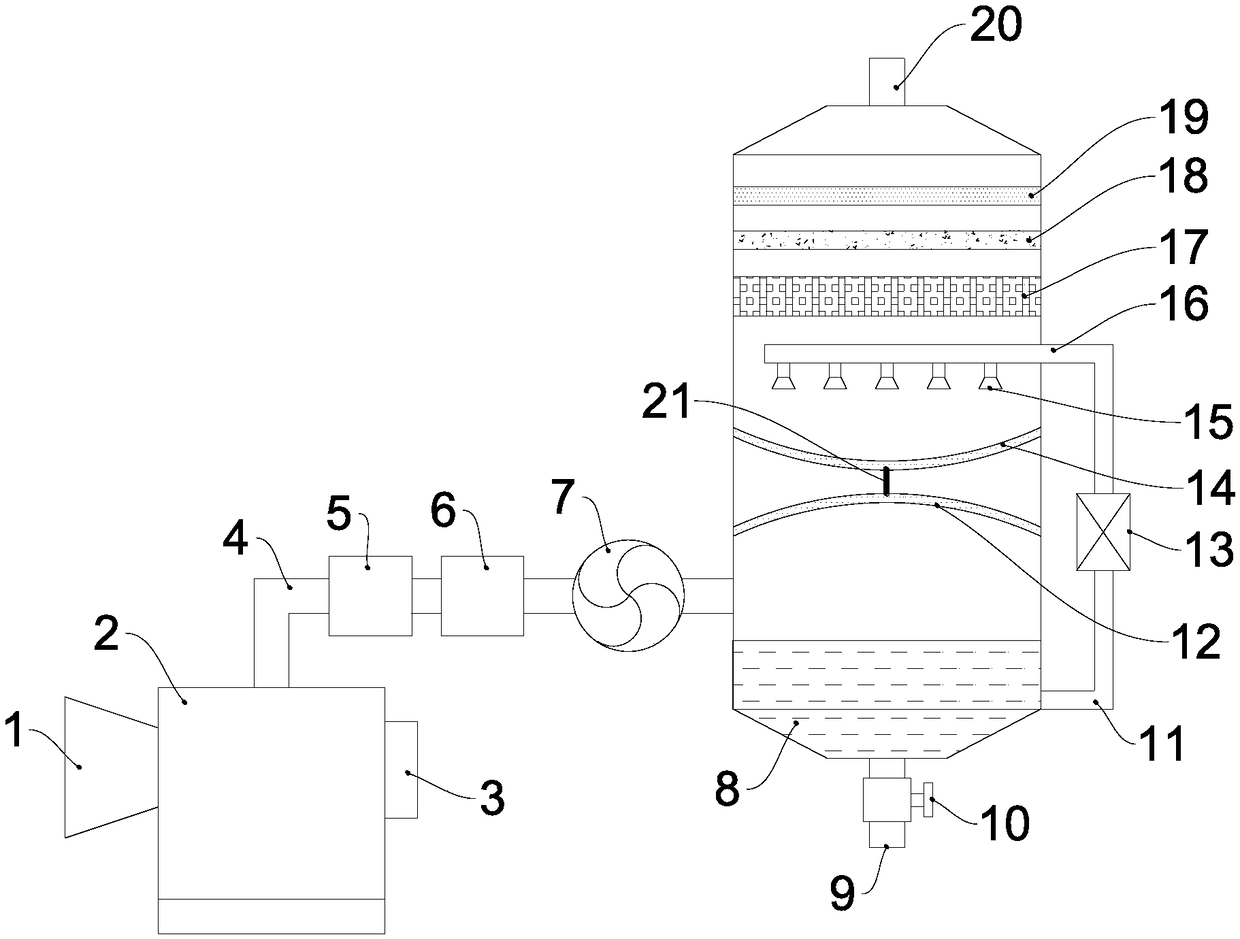

Air purification device and method

PendingCN110180324AEfficient removalTo achieve the purification effectGas treatmentDispersed particle separationMolecular sieveDesorption

Owner:GUANGDONG CHENGYU IND CO LTD

Self-circulating type garbage disposal equipment

Owner:SINOBIOWAY BIOENVIRONMENT CO LTD

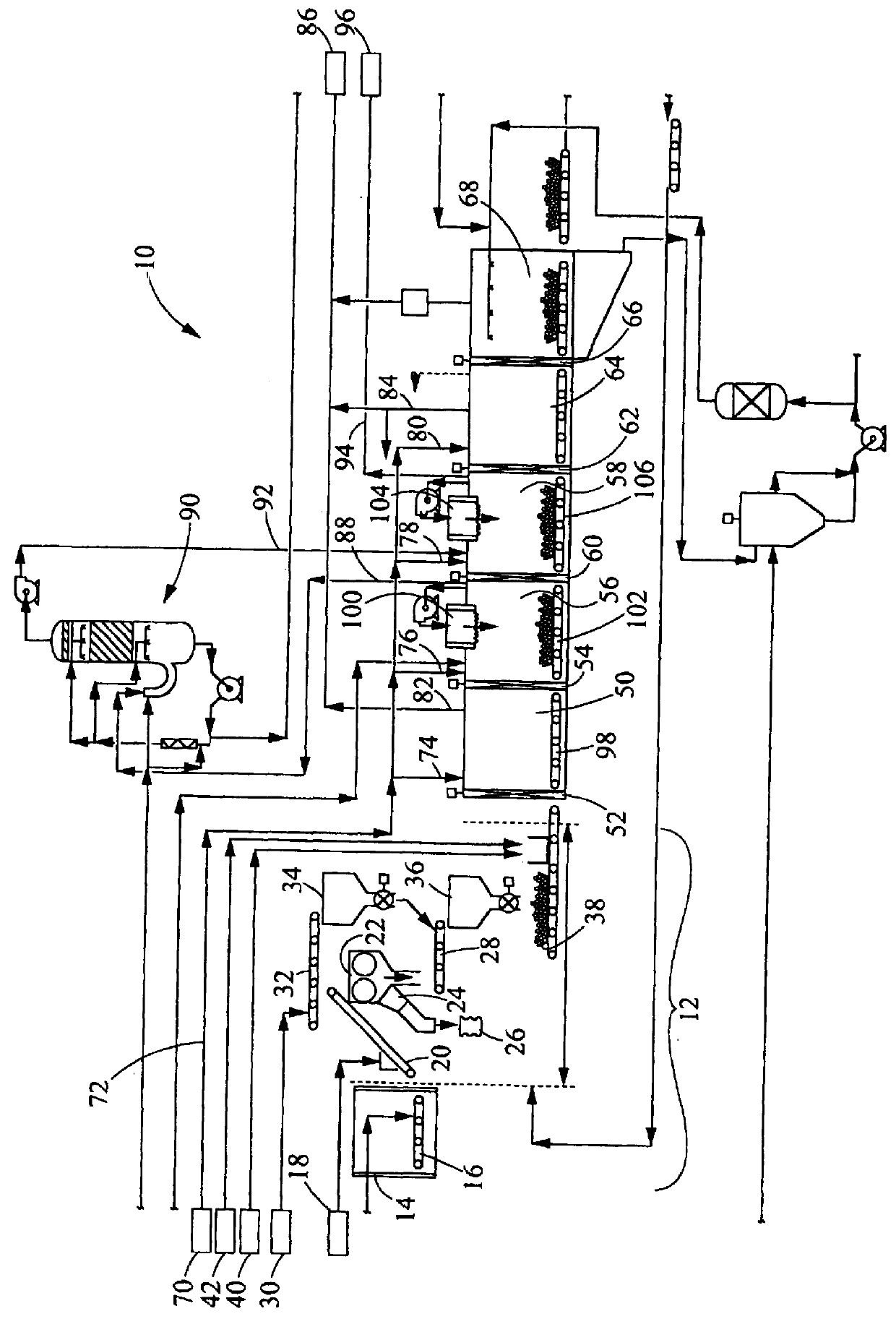

Multi-stage pyrolysis systems for treating chlorine contaminated wastes

InactiveUSH2198H1Minimize the possibilityMinimizes dioxinUsing liquid separation agentIncinerator apparatusFuranOxygen

Owner:CH2M HILL

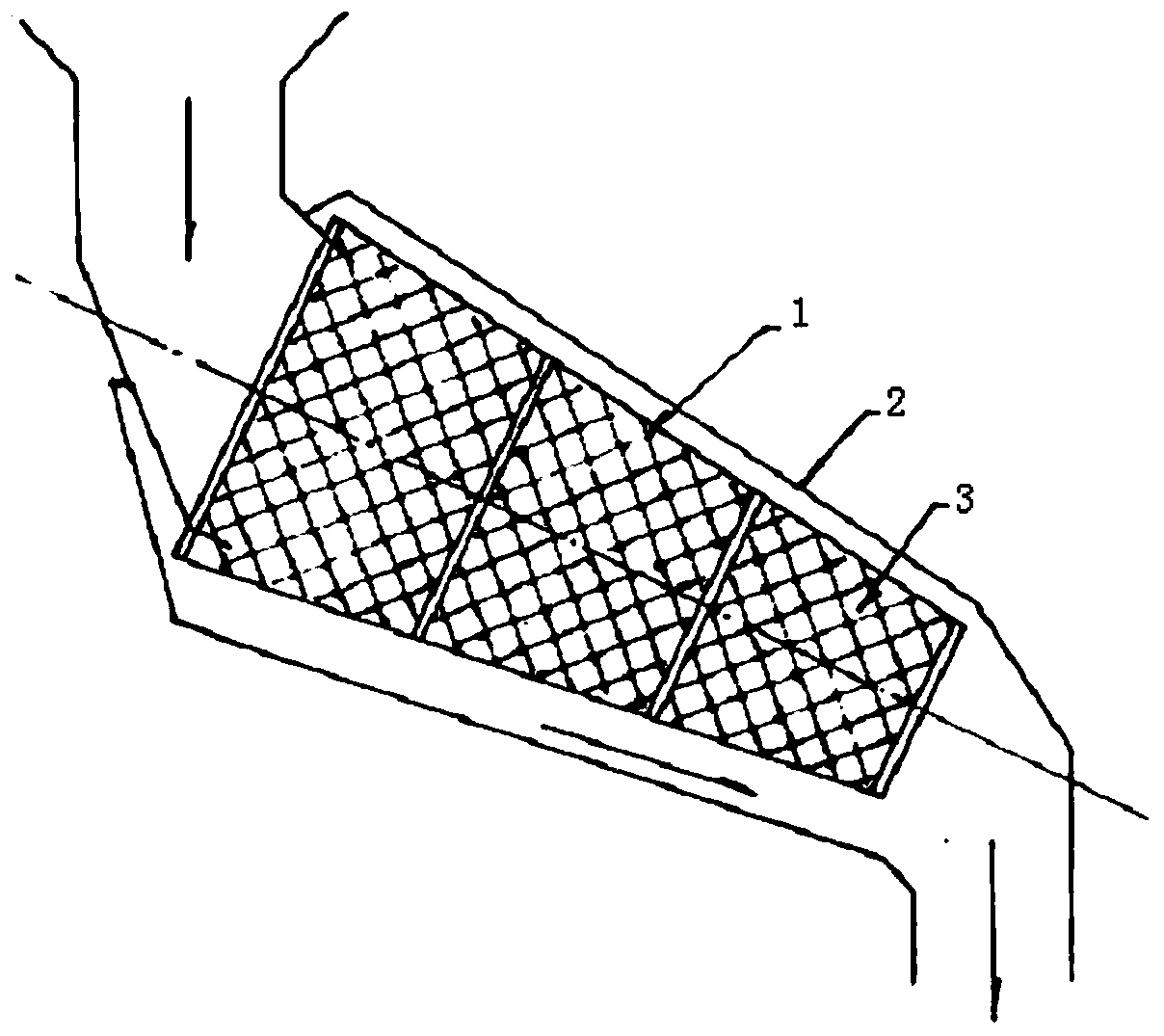

Trash burning chamber structure

Owner:XIAN ALL SAFE SCI & TECH

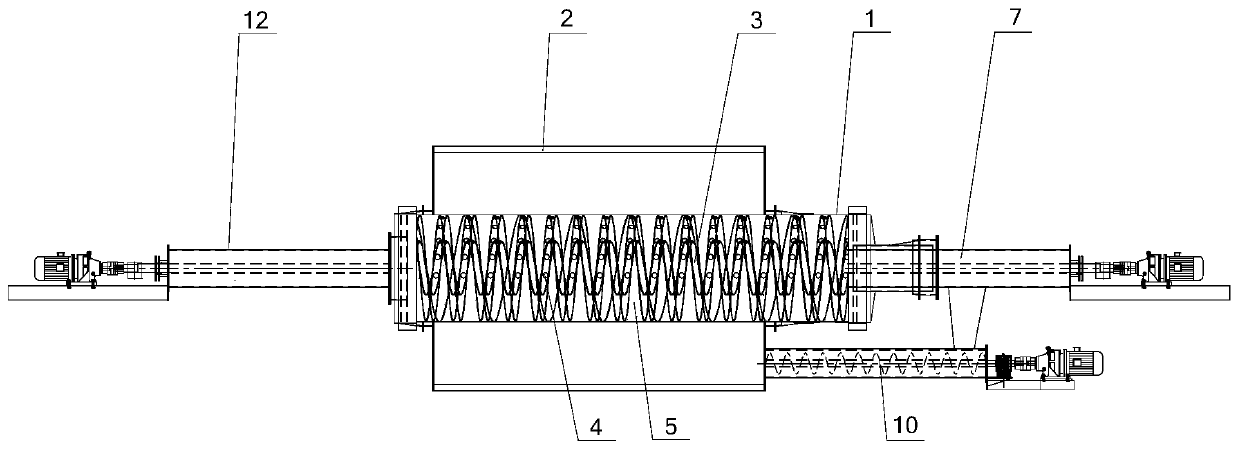

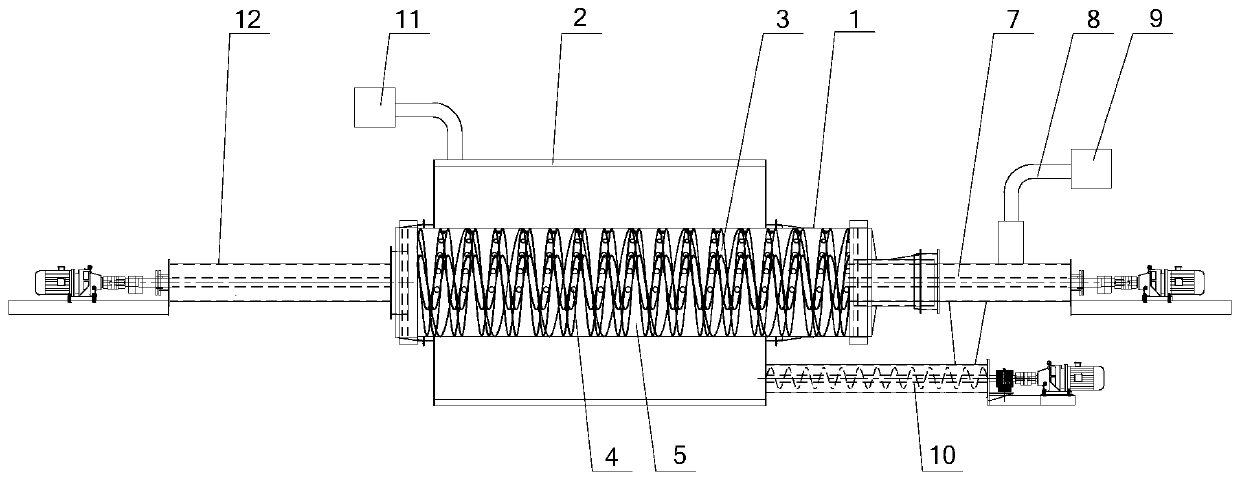

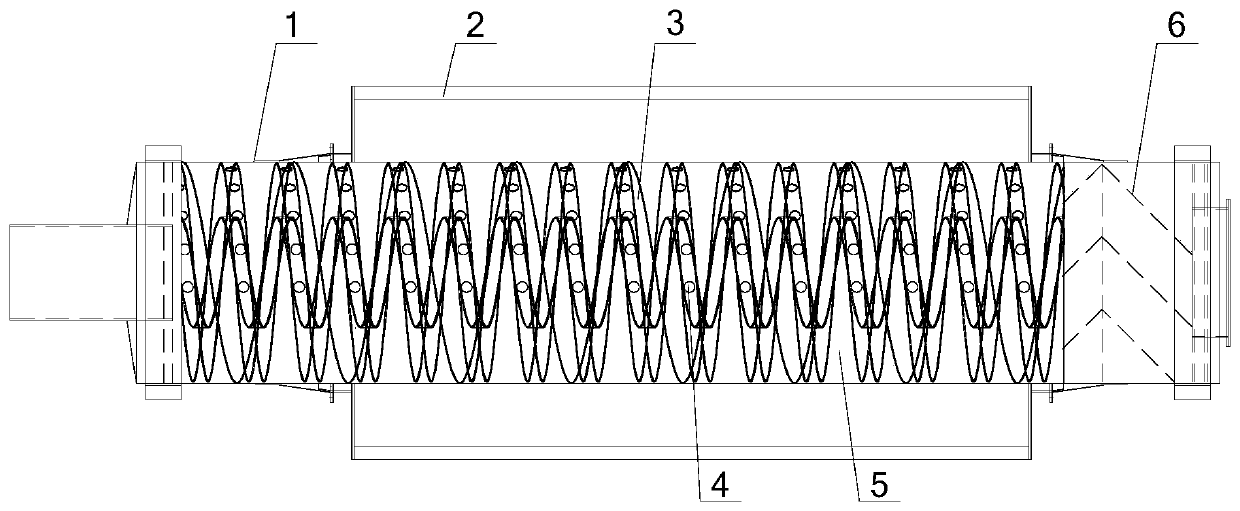

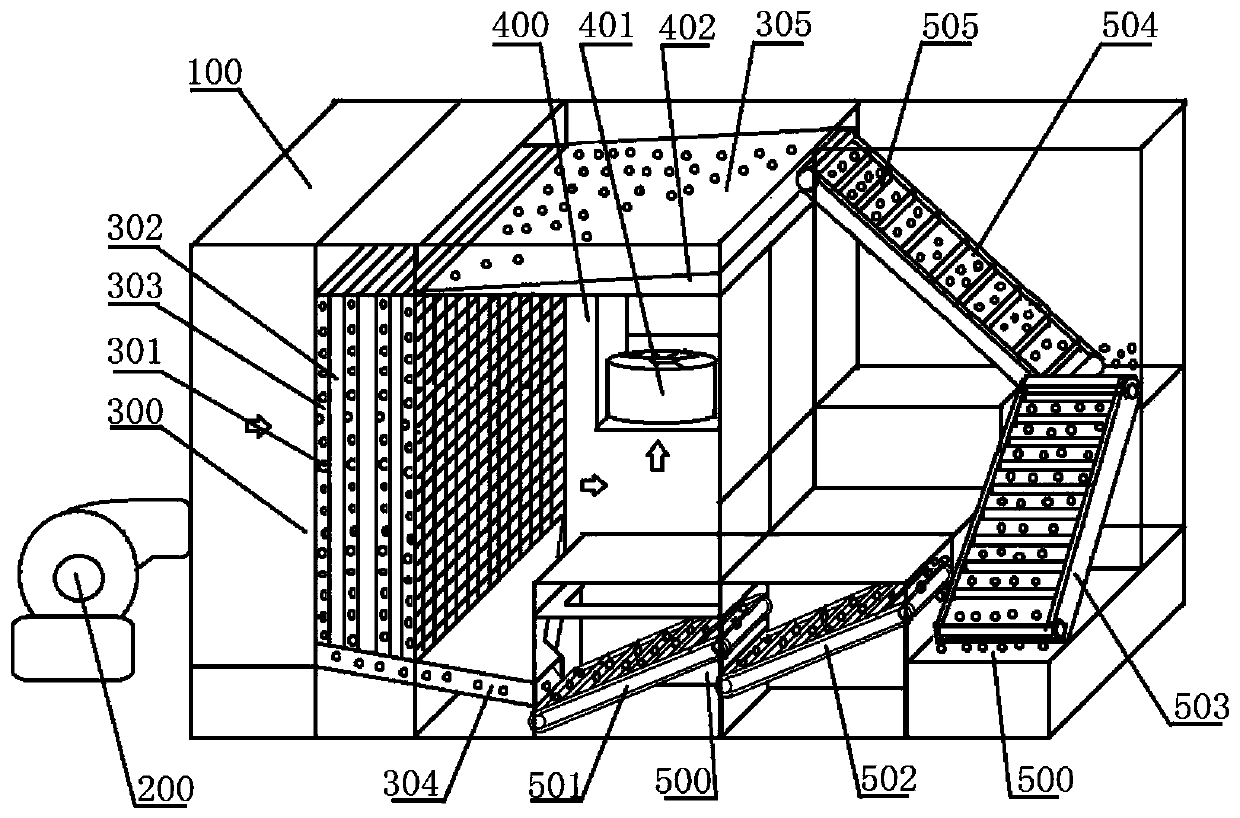

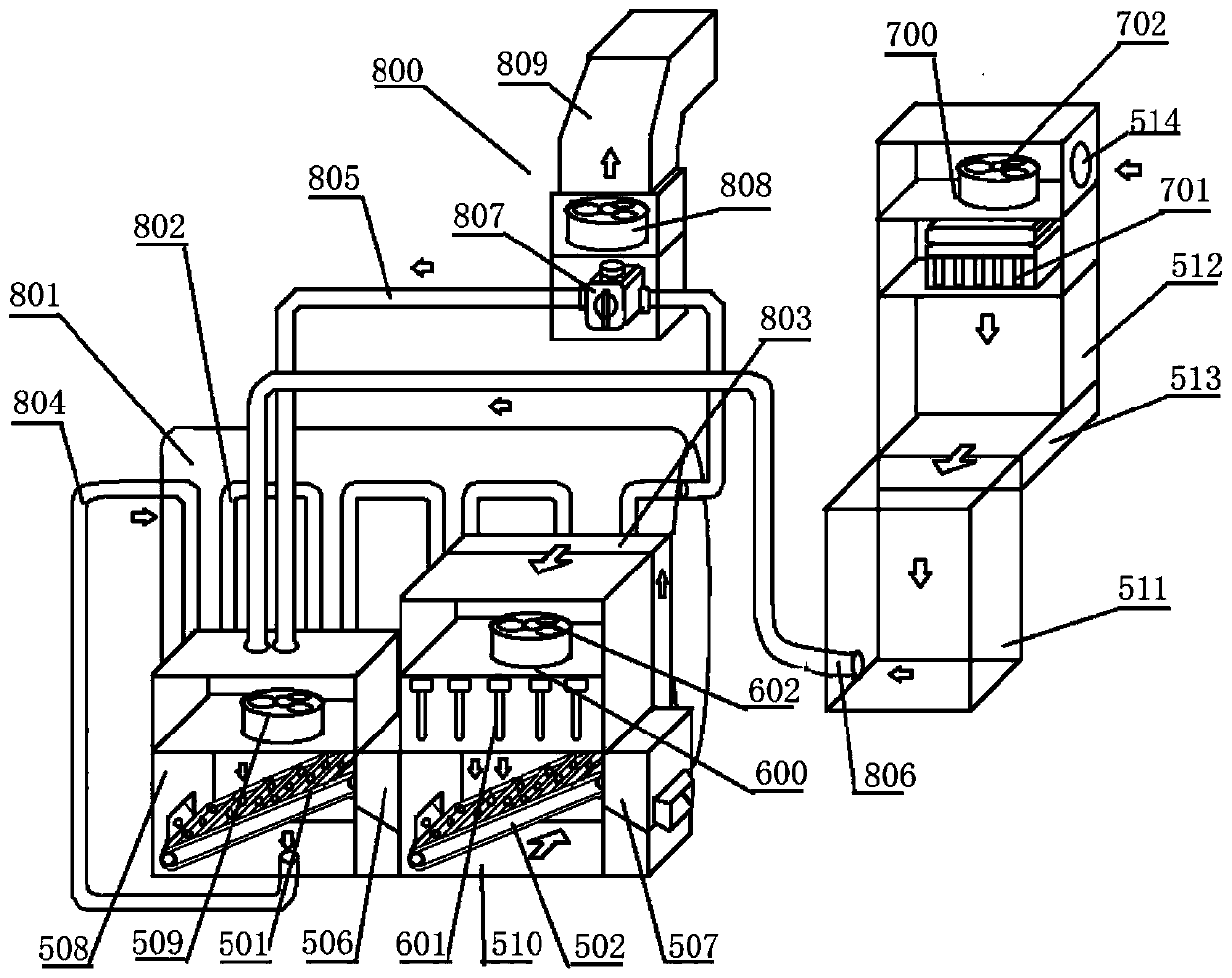

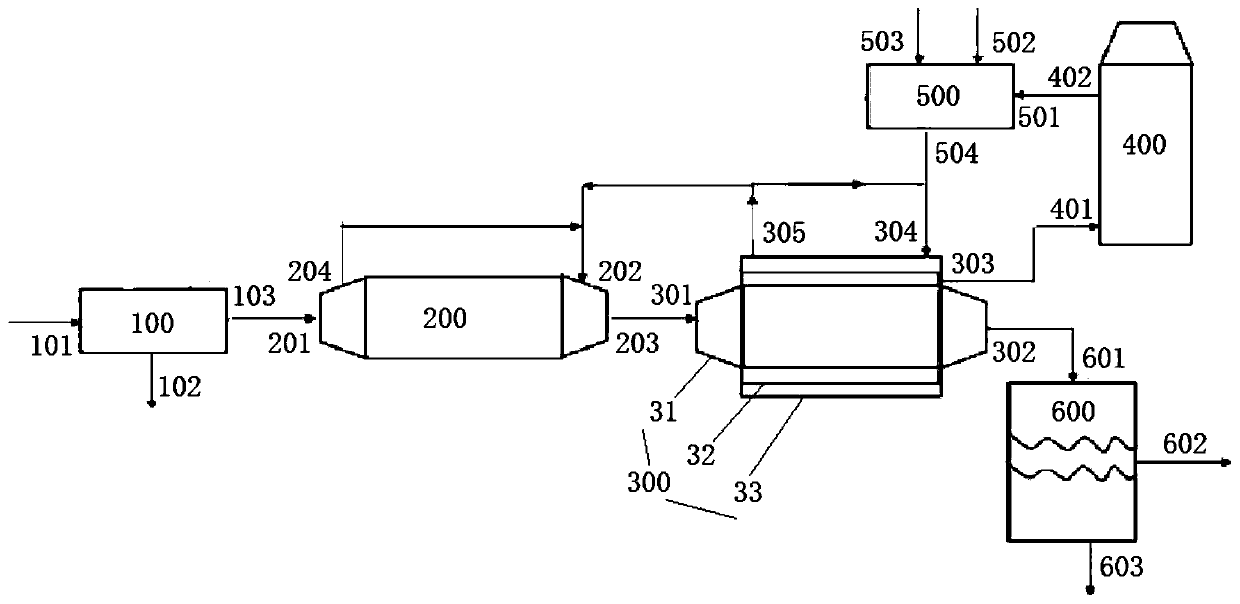

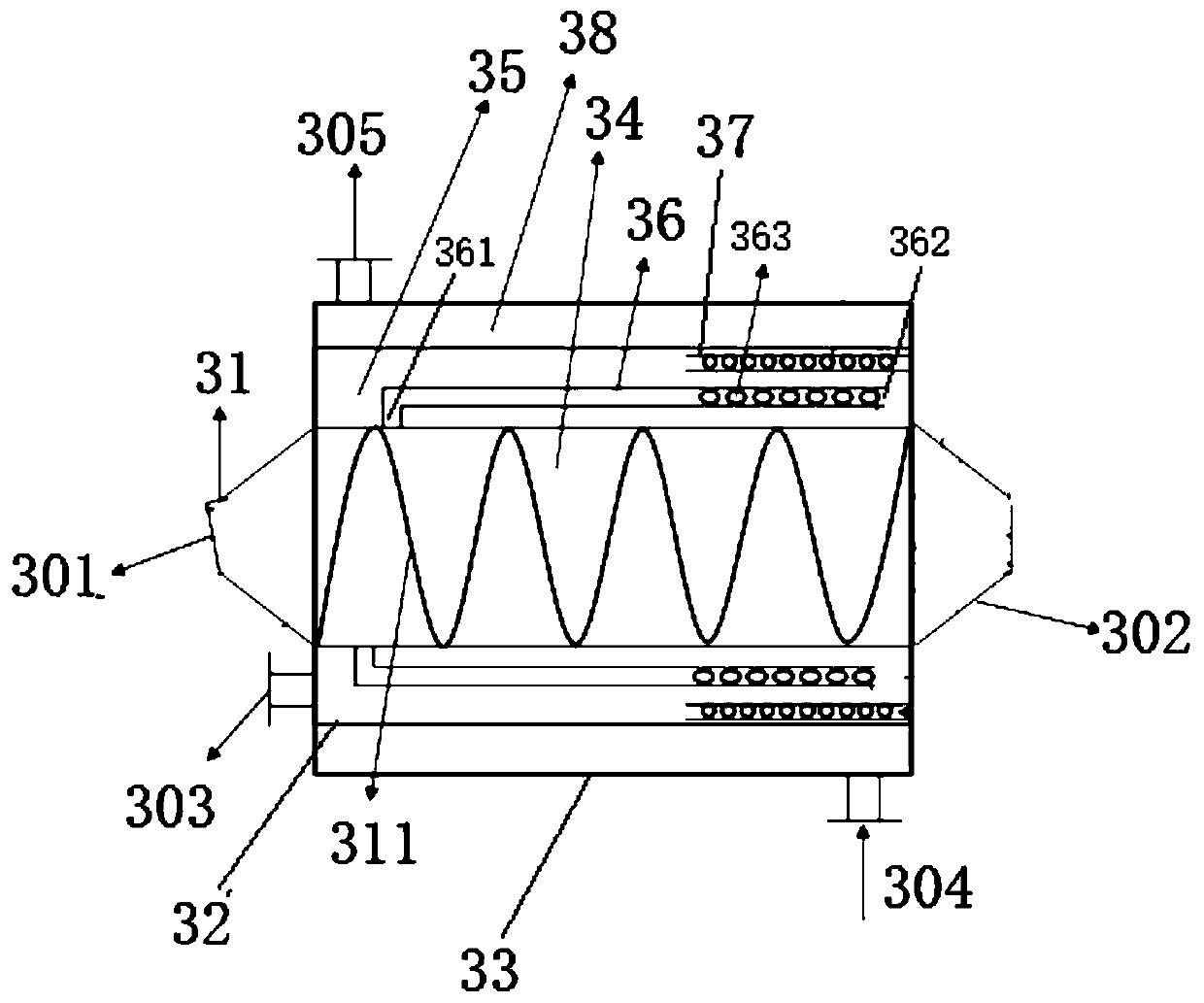

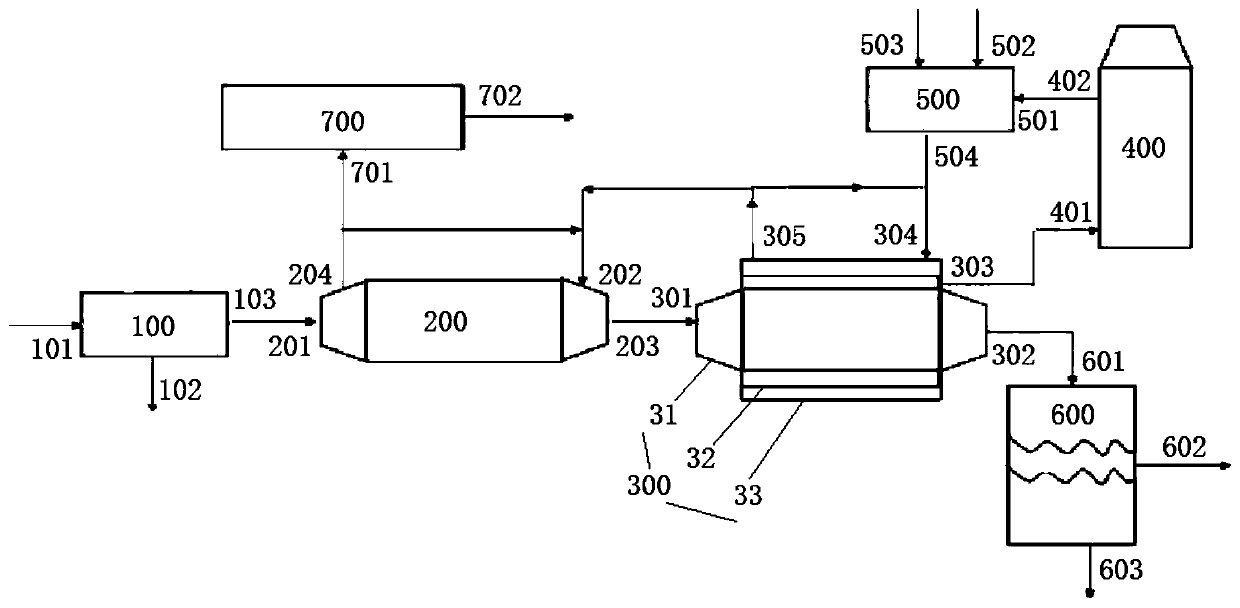

System and method for treating solid wastes

The invention discloses a system and method for treating solid wastes. The system comprises a pre-treatment unit, a drying unit, a pyrolyzation unit, a purifier, a burner and a screening unit, whereinthe pyrolyzation unit comprises an internal cylinder, a secondary external cylinder and an external cylinder. The internal cylinder is rotationally arranged, a pyrolyzation space is formed in the internal cylinder, a helical blade is arranged on the inner wall of the internal cylinder, a drying material inlet is formed in the front end of the internal cylinder, and a solid material outlet is formed in the rear end of the internal cylinder. The internal cylinder is sleeved with the secondary external cylinder to form a gasification space, a pyrolytic oil gas pipeline and an atomized water pipeline are arranged in the gasification space, one end of the pyrolytic oil gas pipeline is communicated with the pyrolyzation space, the other end of the pyrolytic oil gas pipeline extends into the gasification space, and a gasified gas outlet is formed in the portion, at the other end away from the pyrolytic oil gas pipeline, of the secondary external cylinder; the secondary external cylinder is sleeved with the external cylinder to form a heat exchange space, a high-temperature flue gas inlet and a heat-exchange flue gas outlet are formed in the heat exchange space, and the heat-exchange fluegas outlet and a drying cold air outlet are connected with a drying hot air inlet.

Owner:北京云水浩瑞环境科技有限公司

Ground torch system

PendingCN111928279AReasonable locationAvoid insufficient combustionIncinerator apparatusCombustorCombustible gas

Owner:SHANGHAI QIYAO THERMAL ENERGY ENG CO LTD +1

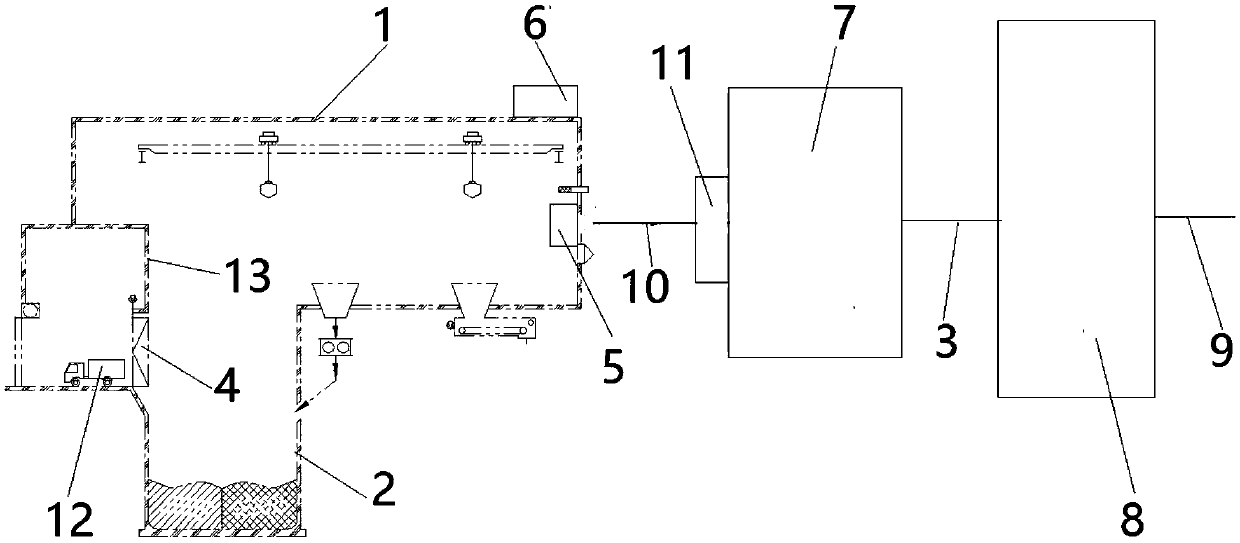

Device for disposing leather sludge and waste by using cement kiln and process method of device

PendingCN110195868AAvoid pollutionReduce processing costsRotary drum furnacesCement productionCombustionSludge

Owner:山东东华科技有限公司

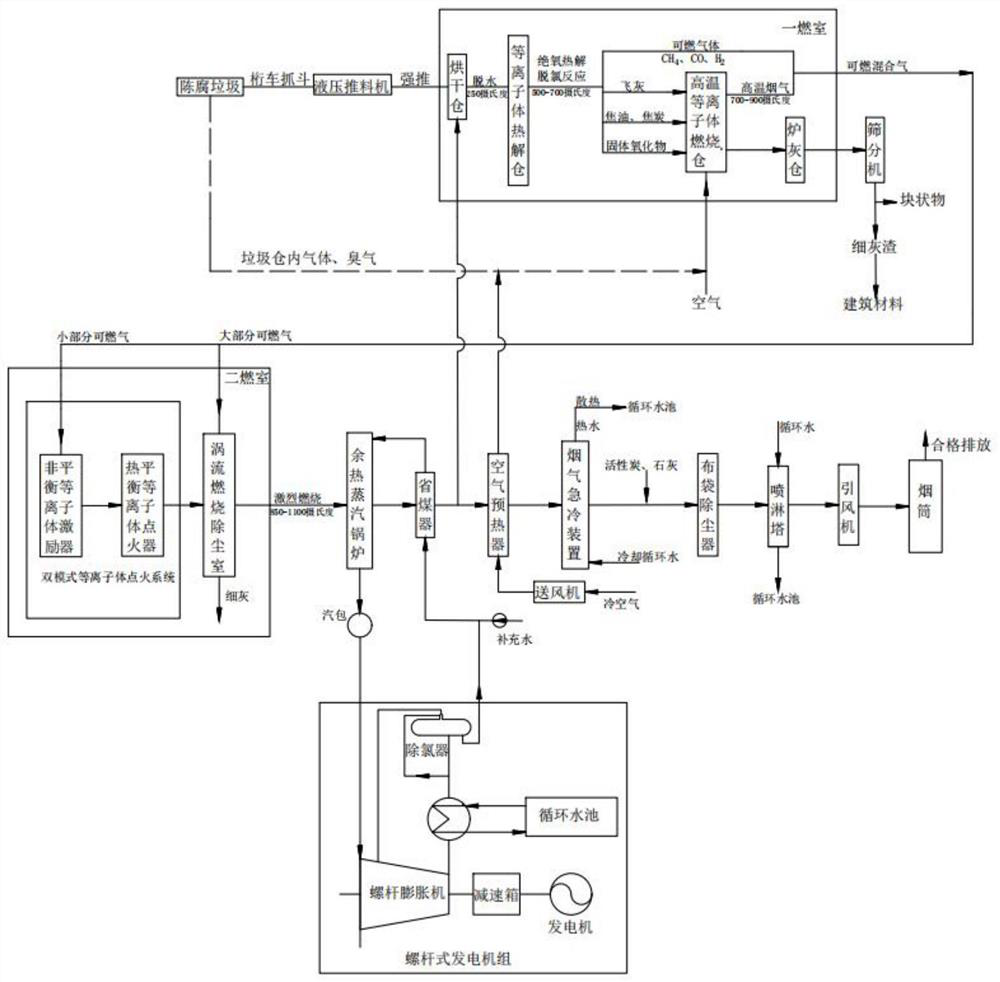

Treatment system and method for purifying stale garbage by adopting plasma technology

Owner:SHENYANG AEROSPACE UNIVERSITY

Modification method for energy utilization of sludge or organic waste

ActiveCN105927986ASimple processLess investmentIncinerator apparatusCombustionHydrocotyle bowlesioides

Owner:湖南省小尹无忌环境能源科技开发有限公司 +1

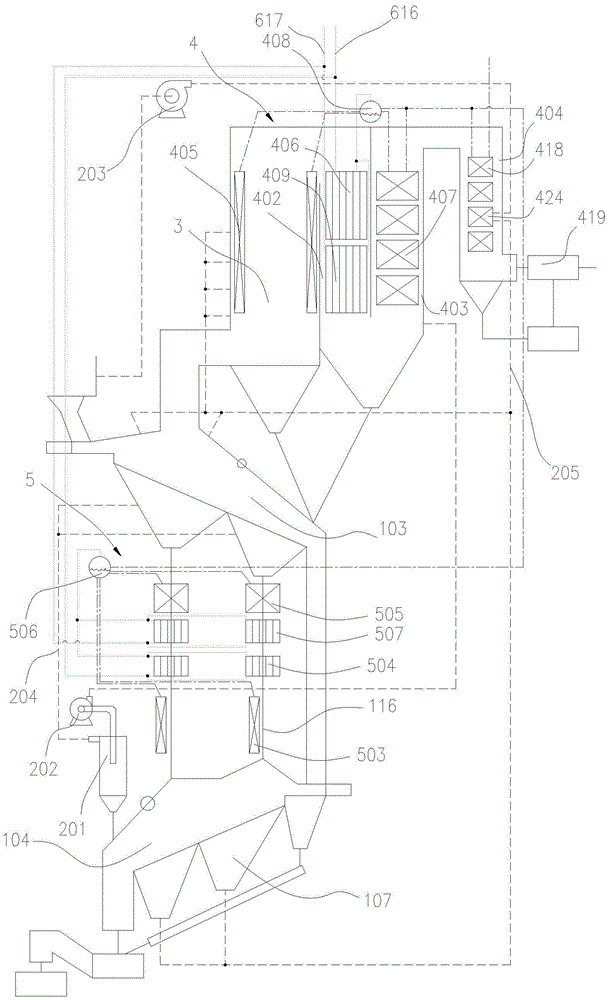

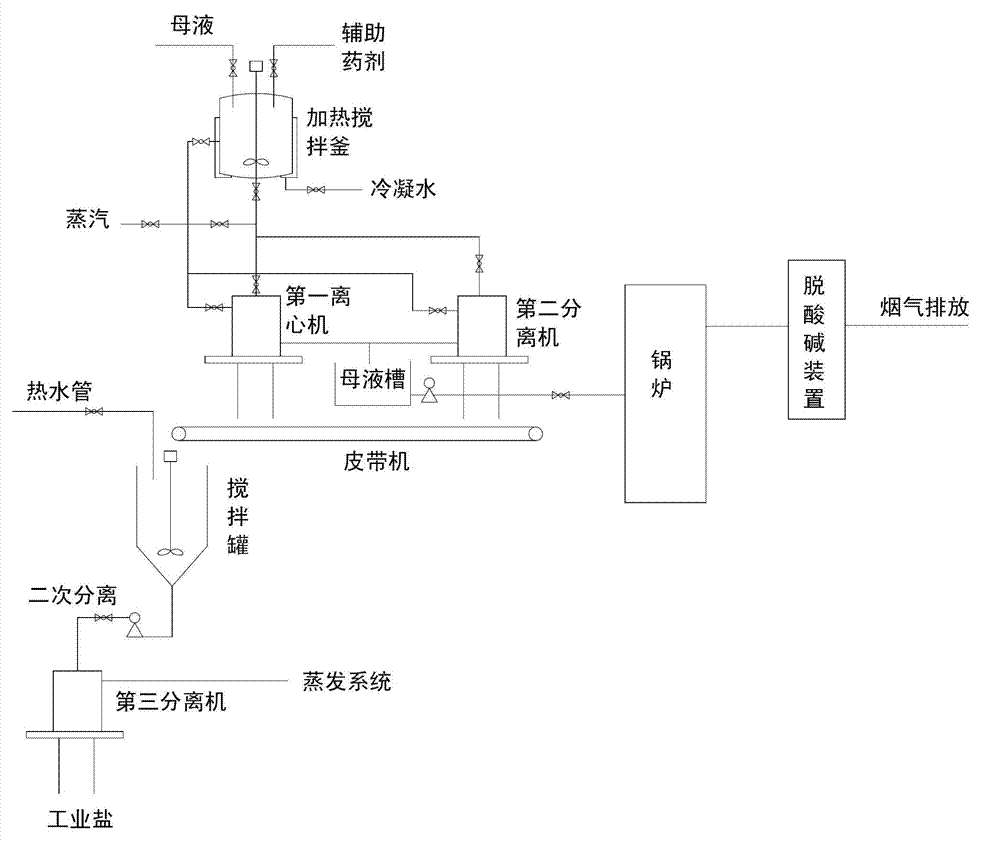

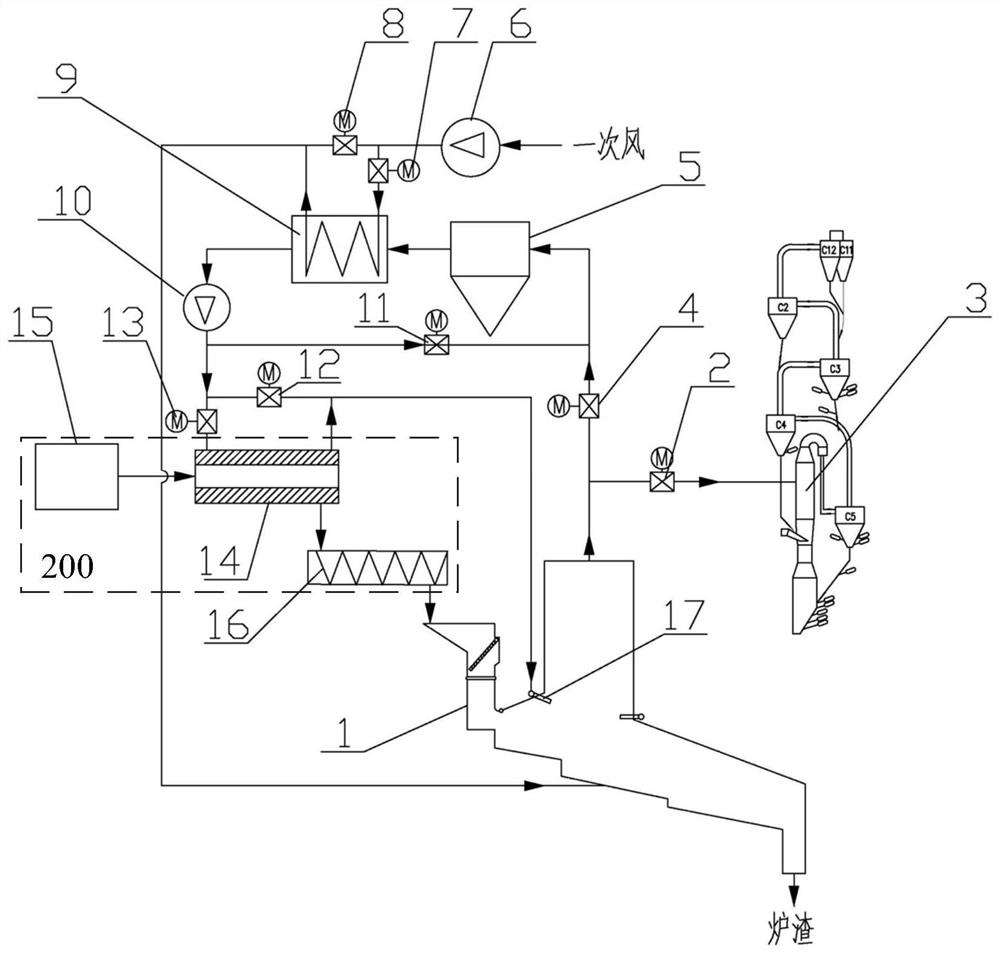

System for co-processing household garbage and sludge in cement kiln

PendingCN113483335ASludge treatment by de-watering/drying/thickeningIncinerator apparatusFlueProcess engineering

Owner:SHANGHAI SUS ENVIRONMENT

Industrial solid waste incineration treatment device

Owner:响水新宇环保科技有限公司

Solid waste incineration method

Owner:重庆知翔科技有限公司

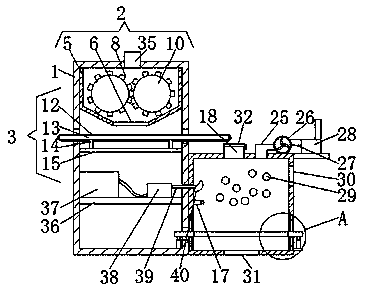

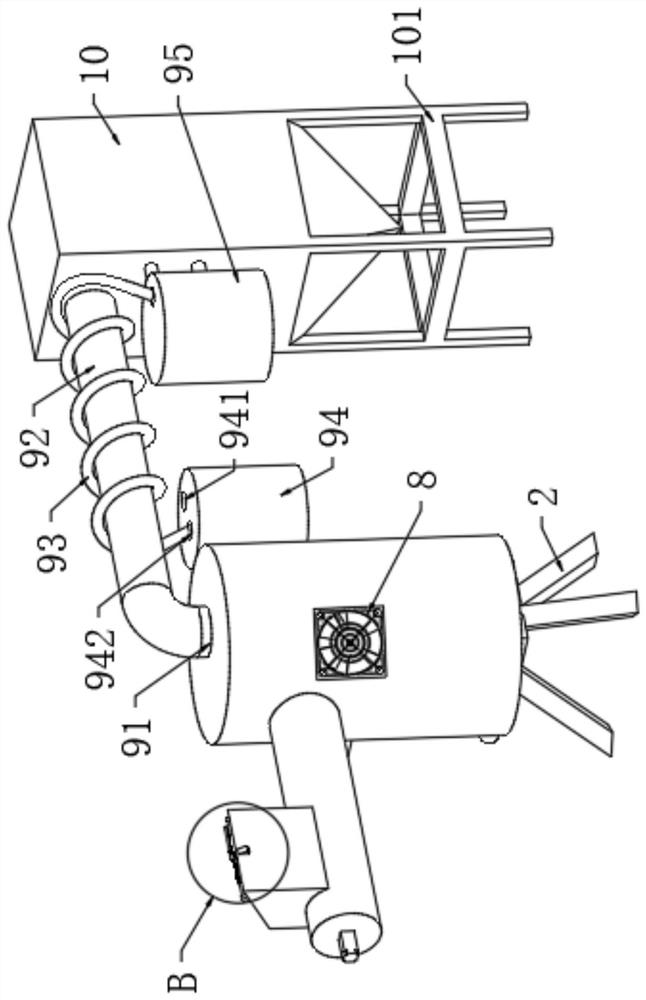

Chemical waste incinerator

InactiveCN111928250ABurn fullyReduce the likelihood of an explosionIncinerator apparatusCombined combustion mitigationCombustorExhaust fumes

The invention discloses a chemical waste incinerator. The chemical waste incinerator comprises a furnace body, wherein a feed hopper is arranged on one side of the furnace body, a feed inlet is formedin the upper end of the feed hopper, a baffle plate is arranged in the position, corresponding to the feed hopper, of the interior of the furnace body, a rotating roller is arranged in the feed hopper, a guide blade is arranged on the rotating roller, a burner is arranged in the furnace body, an ash discharge hopper is arranged below the furnace body, an air supplement opening is arranged on oneside of the furnace body, a waste heat recovery device is arranged at the upper end of the furnace body, an air outlet is arranged at the top end of the furnace body, a water tank is arranged on one side of the furnace body, an air outlet pipe is arranged at the air outlet, an air exhaust opening is arranged on the water tank, and a spraying device is arranged in the furnace body. A user directlydumps chemical engineering garbage into the feed hopper, materials are conveyed through the inner guide blade, the baffle plate is pushed away under the action of gravity, the materials enter the furnace body for combustion, oxygenation work is regularly carried out through an air supplement opening, the interior of the furnace body is fully combusted, and then generated hot waste gas is subjectedto heat exchange work through the waste heat recovery device at the top.

Owner:HUNAN DELI SAFETY & ENVIRONMENTAL PROTECTION TECH CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap