Multi-stage pyrolysis systems for treating chlorine contaminated wastes

a pyrolysis system and waste technology, applied in the direction of combustion types, separation processes, lighting and heating apparatuses, etc., can solve the problems of contaminated dunnage wastes, production of harmful dioxins and furans, and contaminated dunnage wastes with chlorinated organic compounds, so as to minimize the possibility of the formation minimize the possibility of dioxins and furans, and minimize the effect of dioxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

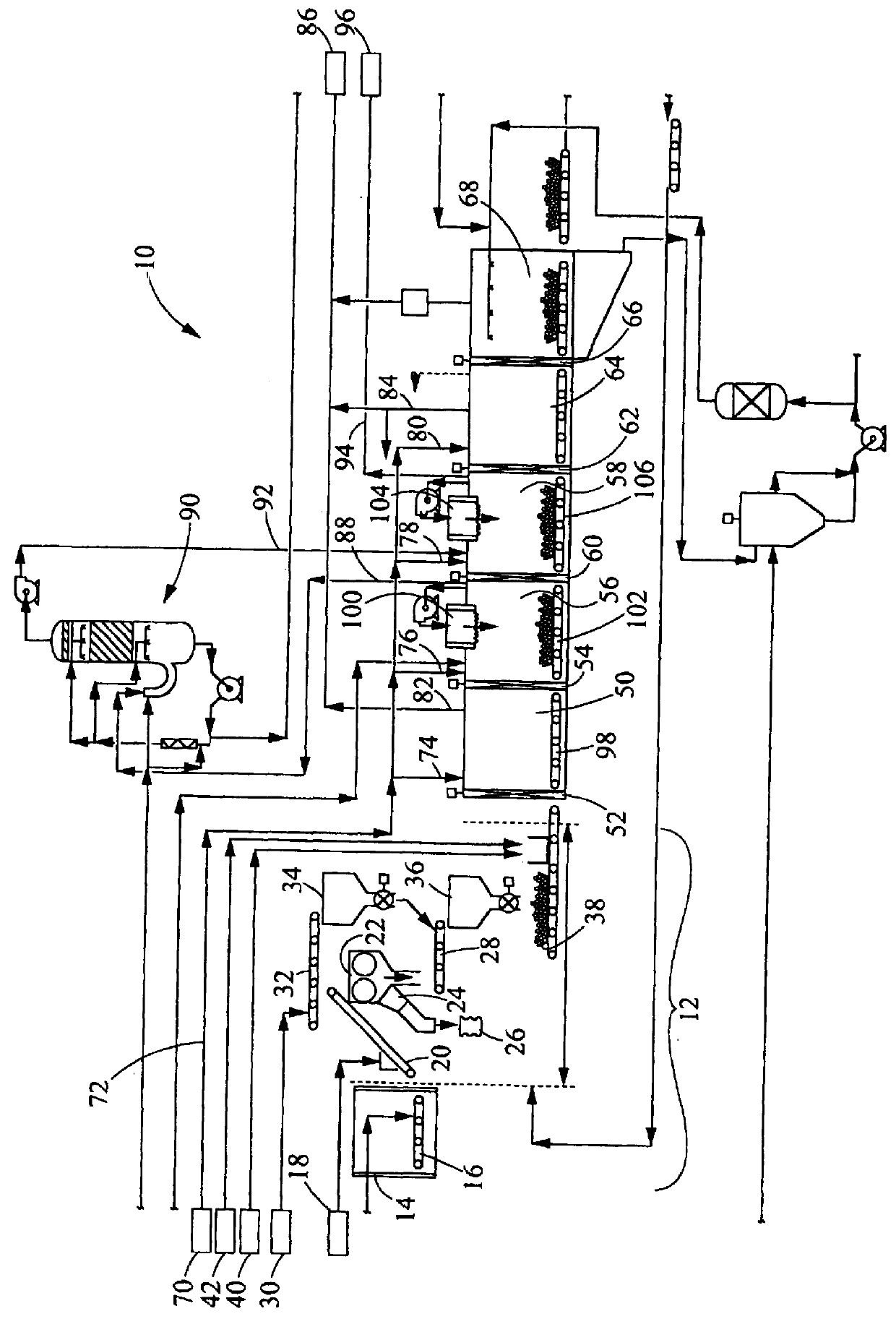

[0012]A multi-stage pyrolysis apparatus 10 is illustrated schematically in the FIGURE. Located upstream from the multi-stage pyrolysis apparatus 10 is an optional dunnage processor 12 for processing and delivering dunnage to the multi-stage pyrolysis apparatus 10. The dunnage processor 12 includes an airlock chamber 14 containing a conveyor 16 for receiving wood products contaminated with chlorinated hydrocarbons, such as the pesticide pentachlorophenol. The airlock chamber 14 isolates the dunnage and possible harmful contaminates from the area of a building or grounds where it is located. It further limits transport of gas phase contaminants from one area to another. These contaminated wood products are combined with other contaminated or potentially contaminated wood from a wood supply 18 and conveyed by conveyor 20 to a shredder 22. The shredder 22 shreds the input wood material into small pieces suitable for further processing. The shredder 22 includes a magnetic separator 24 for s

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap