Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about "Using liquid separation agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

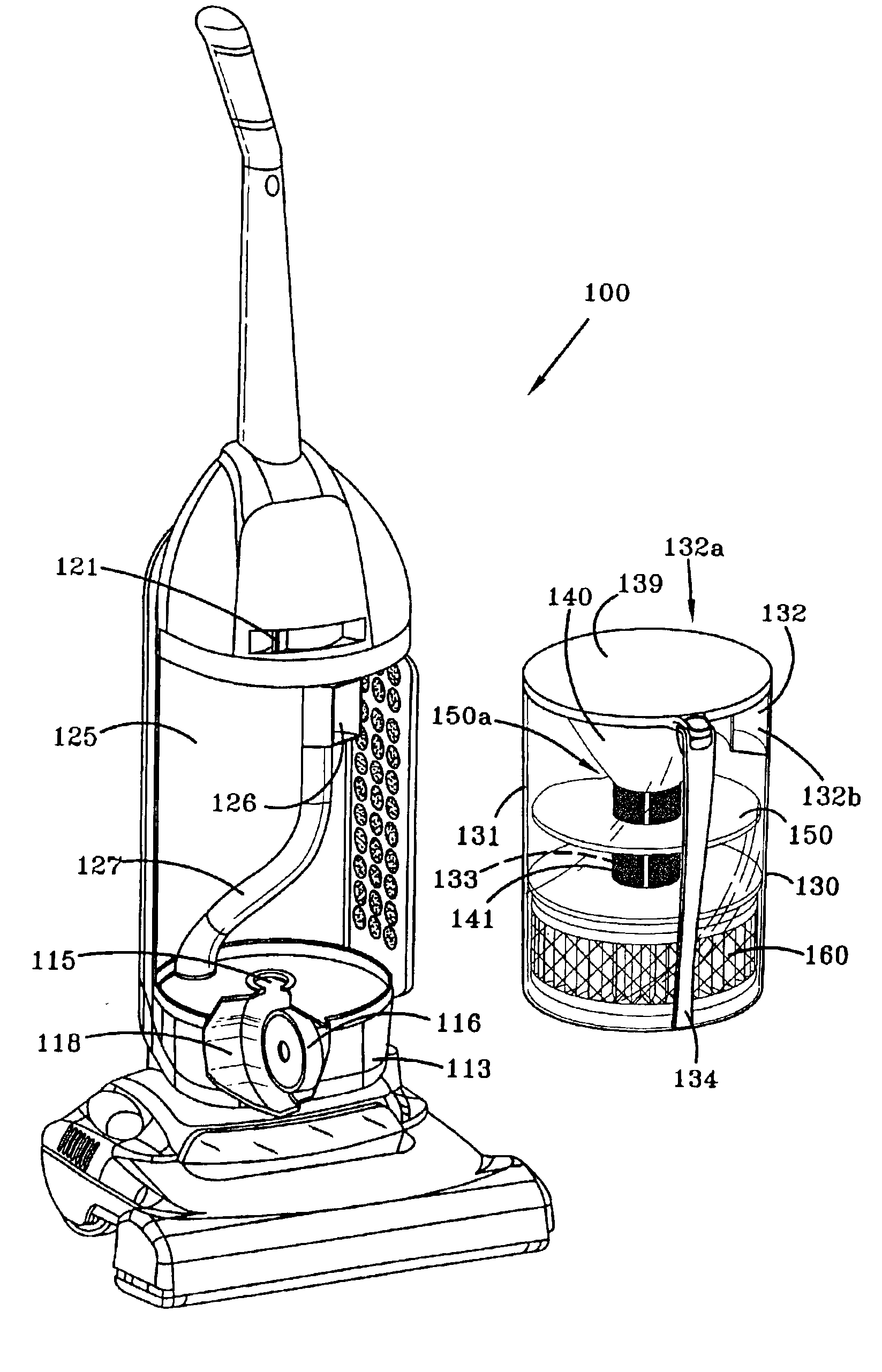

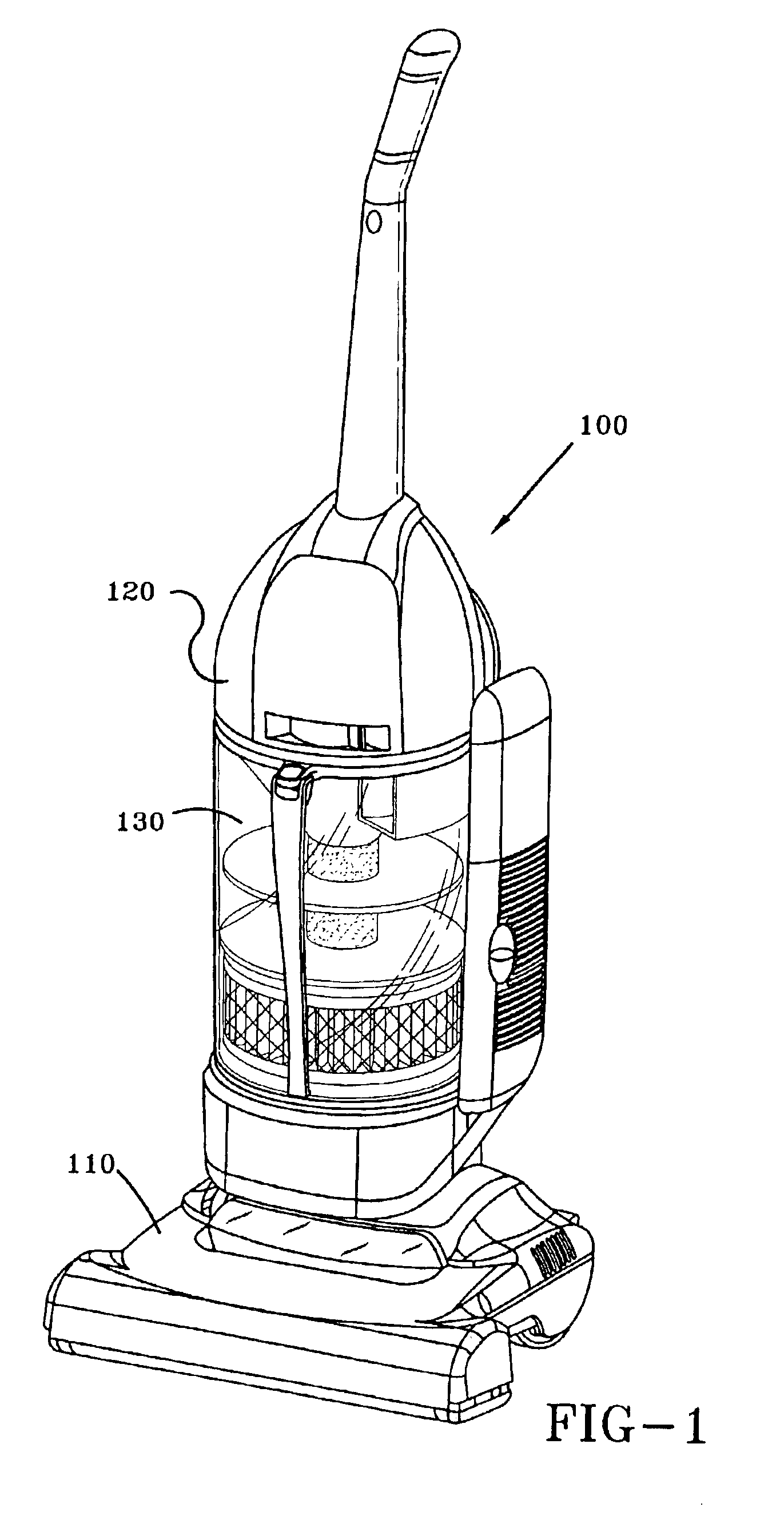

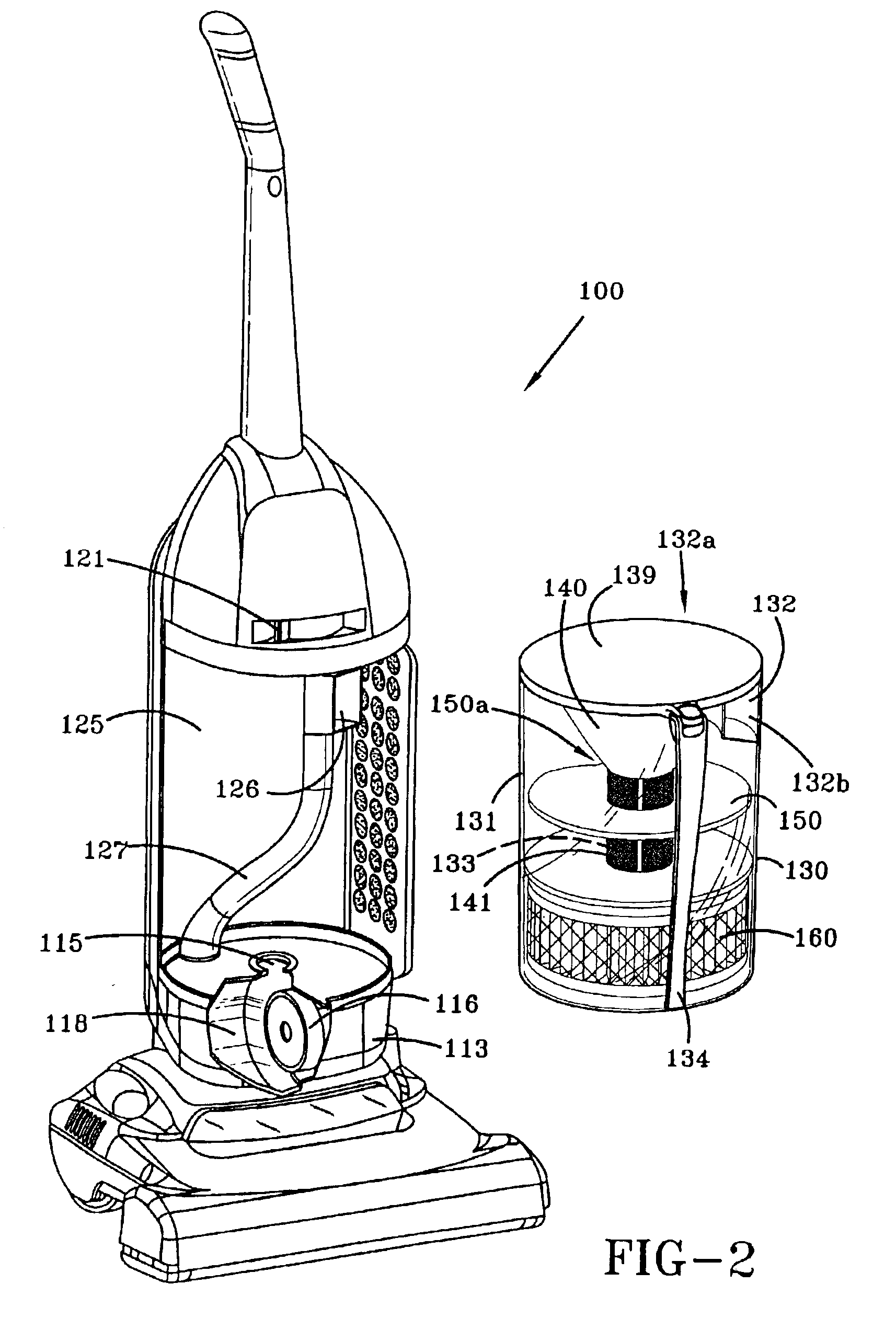

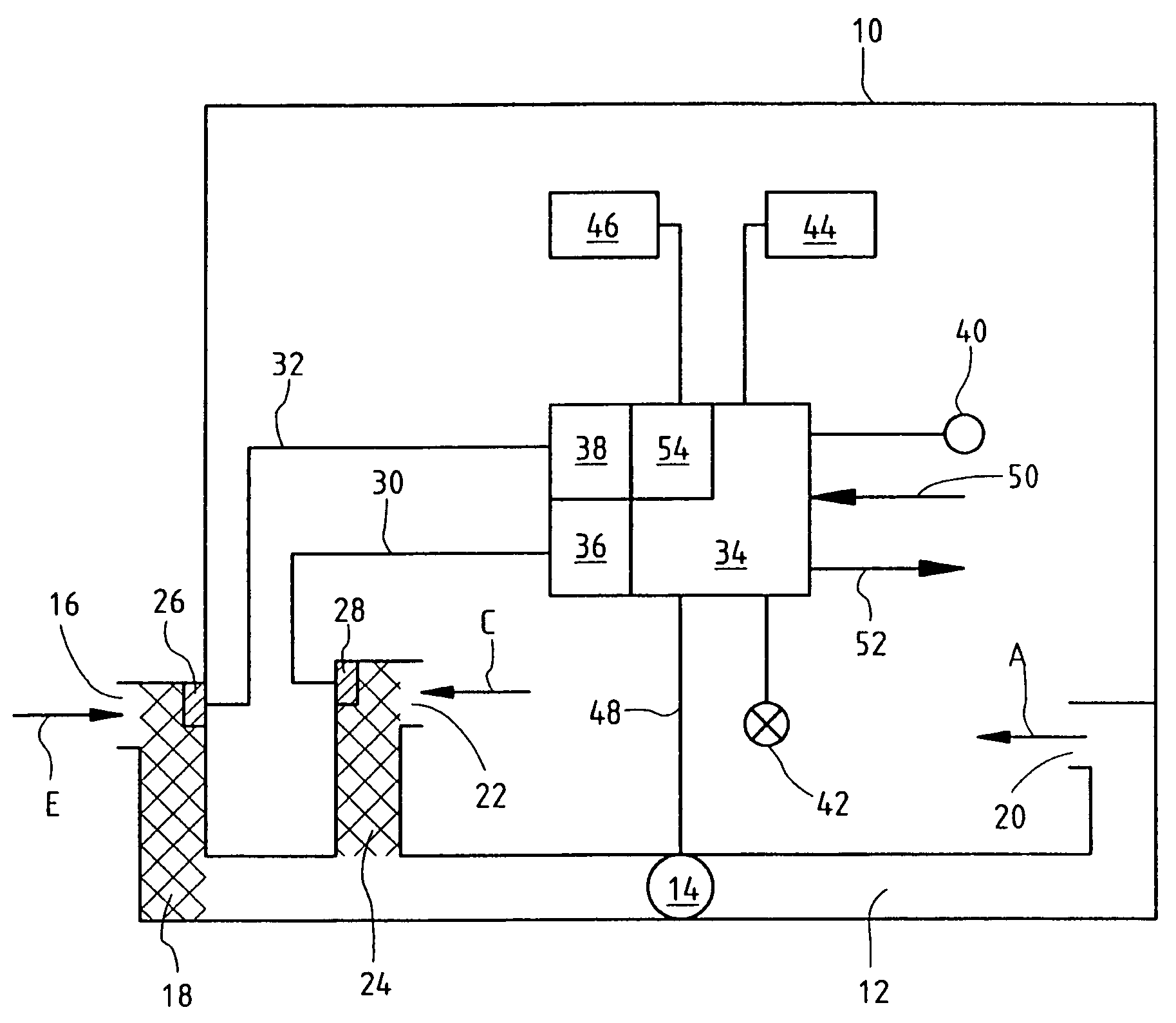

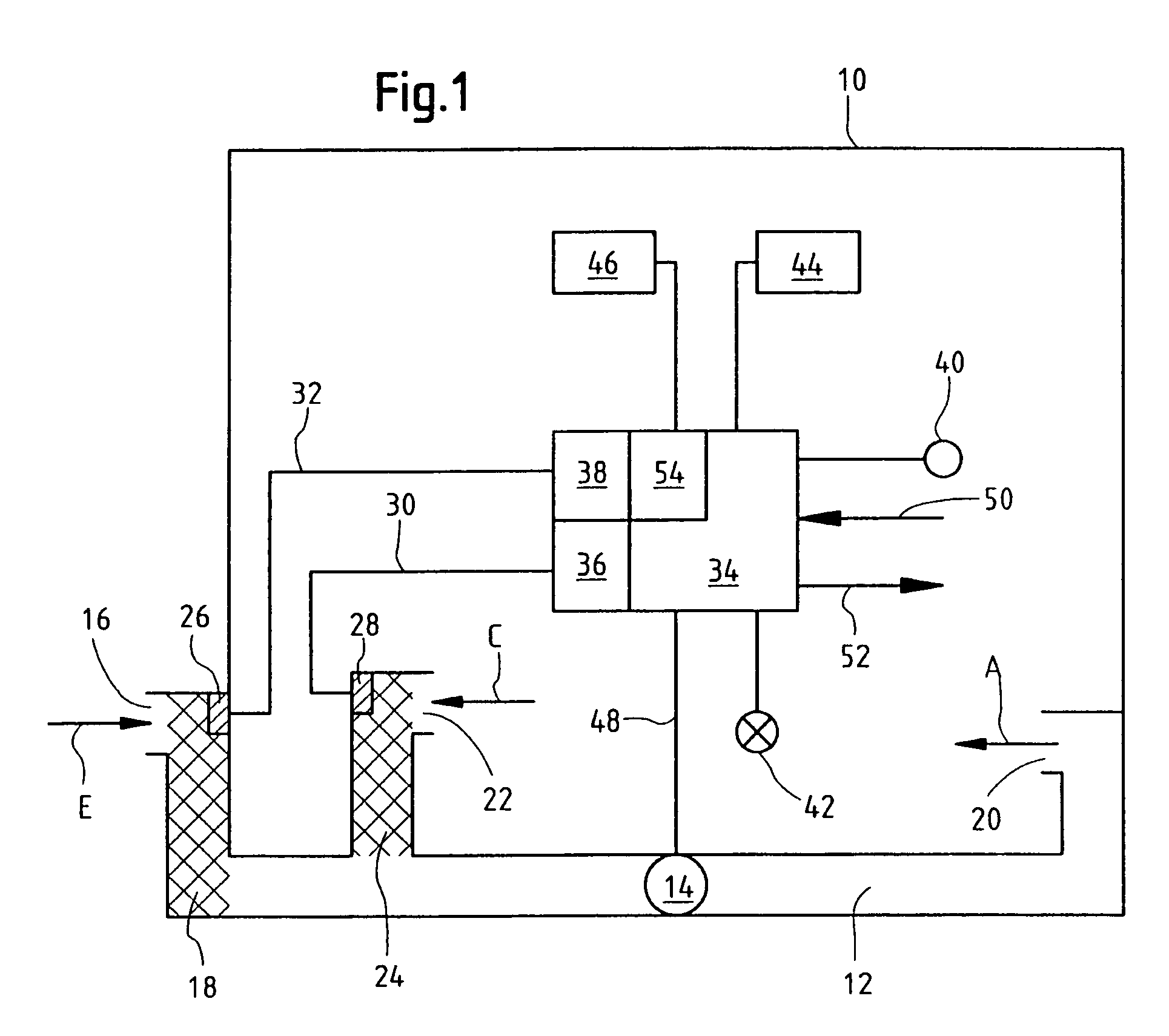

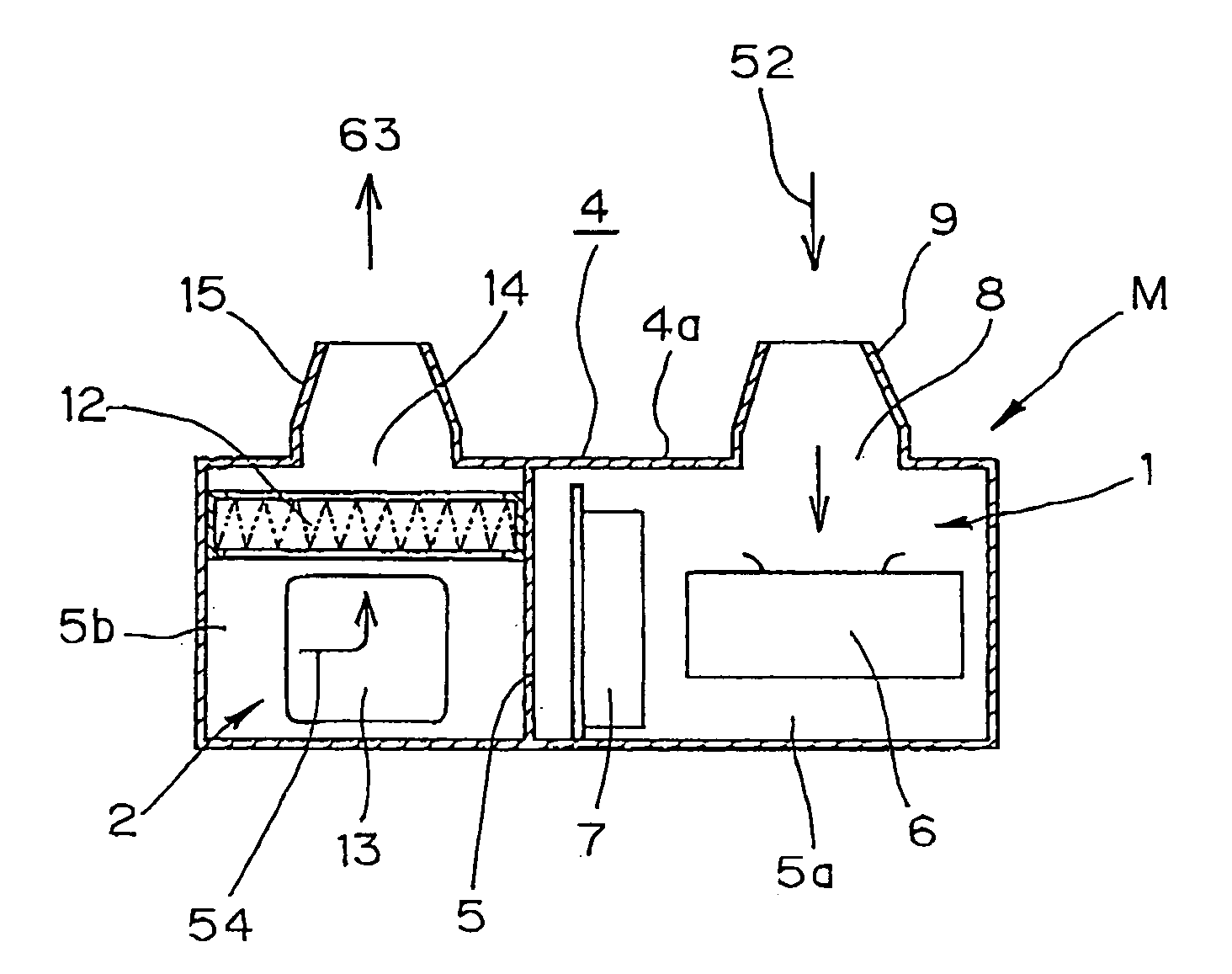

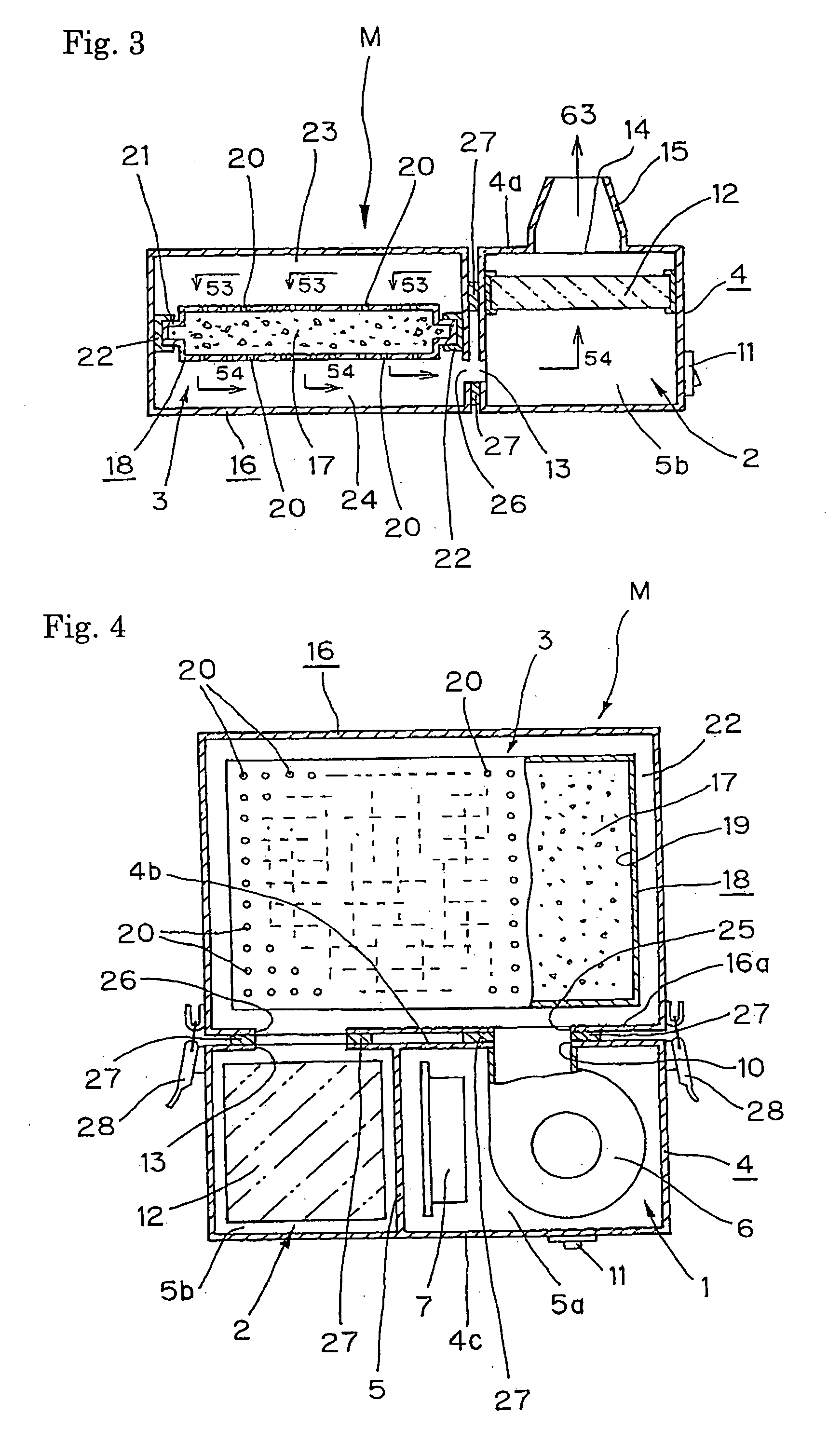

Dirt collecting system for a floor care appliance

InactiveUS6896719B2Improve filtering effectEasy to emptyCleaning filter meansCombination devicesEngineeringGuide tube

Owner:HEALTHY GAIN INVESTMENTS

Dust Prevention And Removal Device

ActiveUS20100064895A1Reduce the amount requiredLess dustCombination devicesAuxillary pretreatmentInterior spaceParticulates

A device is provided that is capable of circulating air throughout a personal space as well as collecting and preventing the build up of dust and other particulate matter by drawing in air from the surrounding environment and removing some dust, allergens and other such particulate matter therefrom. The filtered air is then expelled out of the device and back into the surrounding environment. The device includes a housing defining an interior space having a motor and fan assembly disposed therein. The housing includes an inlet with a filter provided therein such that air drawn in through the inlet is filtered. The air is then expelled through a circumferentially disposed outlet. The filter element preferably includes a lock and key system configured to prevent operation of the device in the absence of a properly keyed filter.

Owner:SC JOHNSON & SON INC

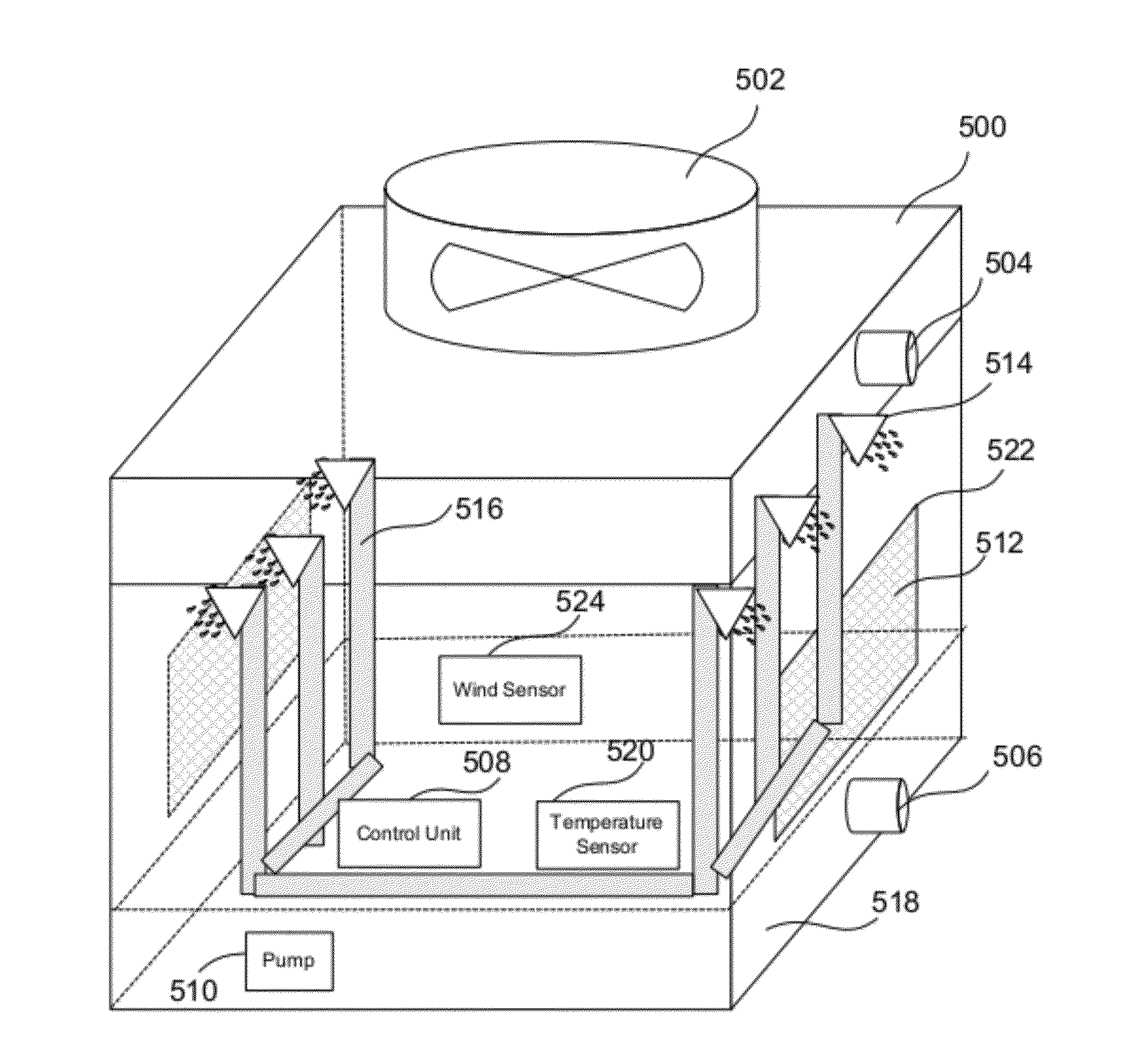

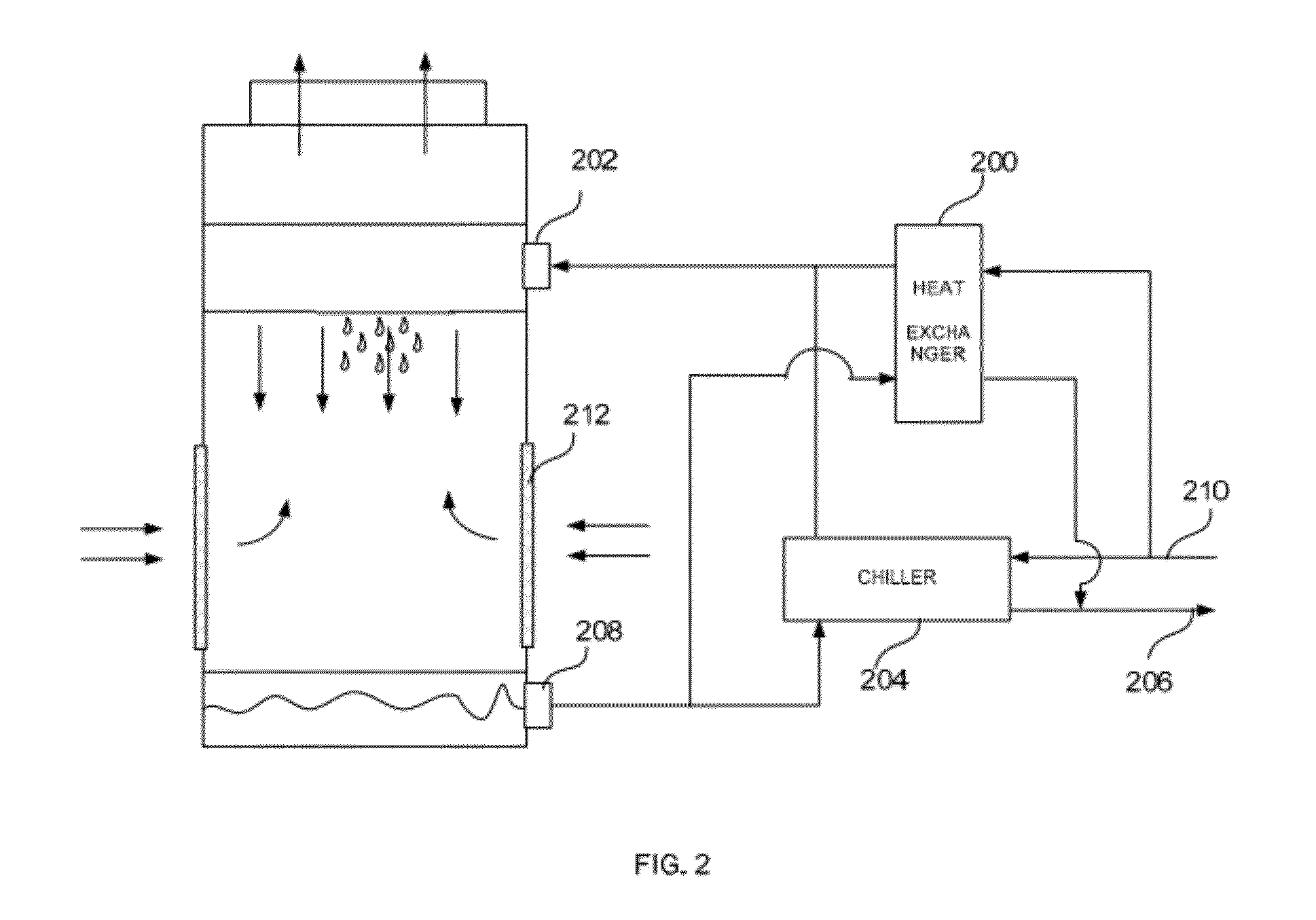

System and method for reducing mineral buildup on drift eliminators of a cooling tower

InactiveUS20120161340A1Reduce mineral buildupMixing methodsUsing liquid separation agentCooling towerEngineering

Owner:R2 SOLUTIONS

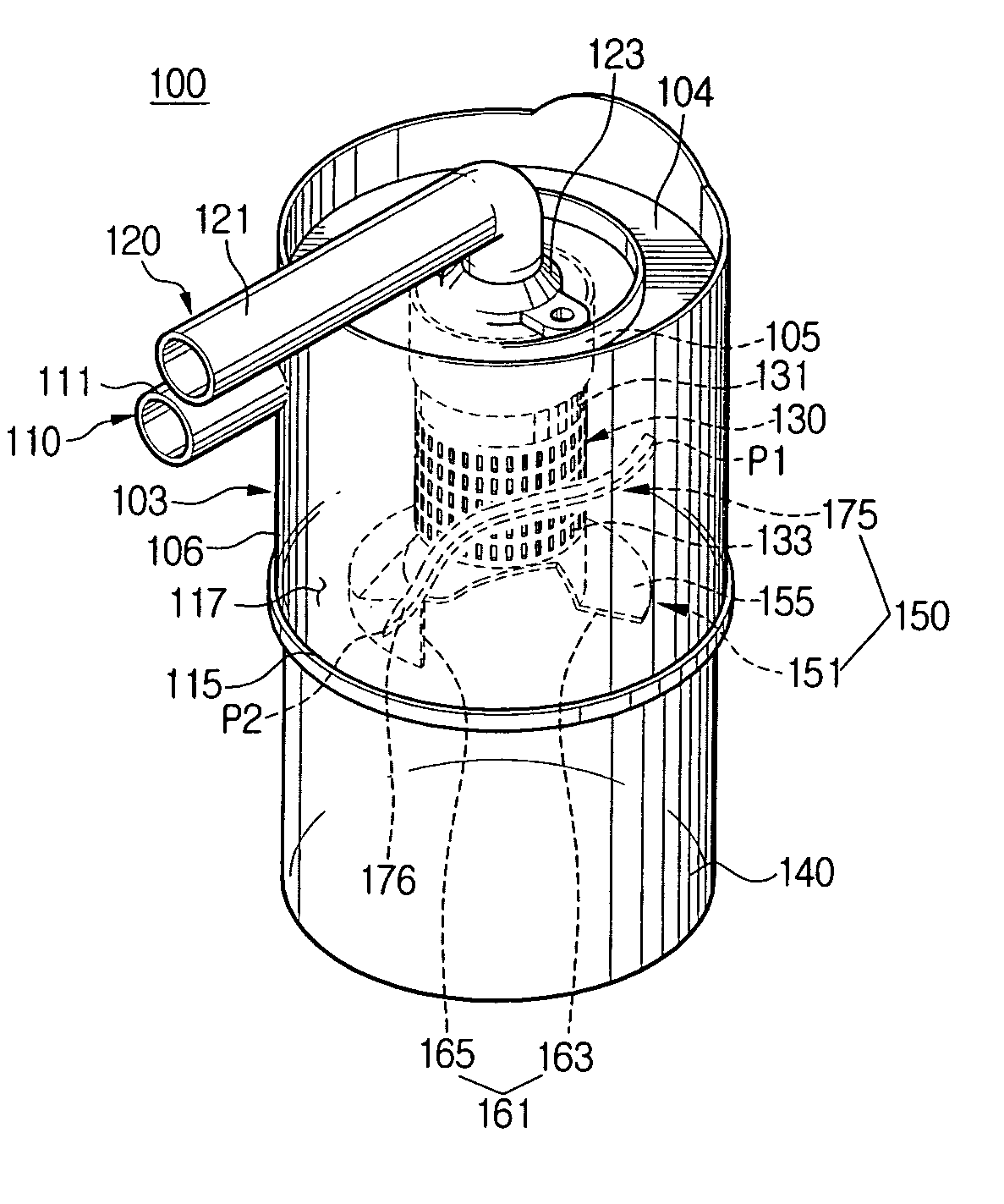

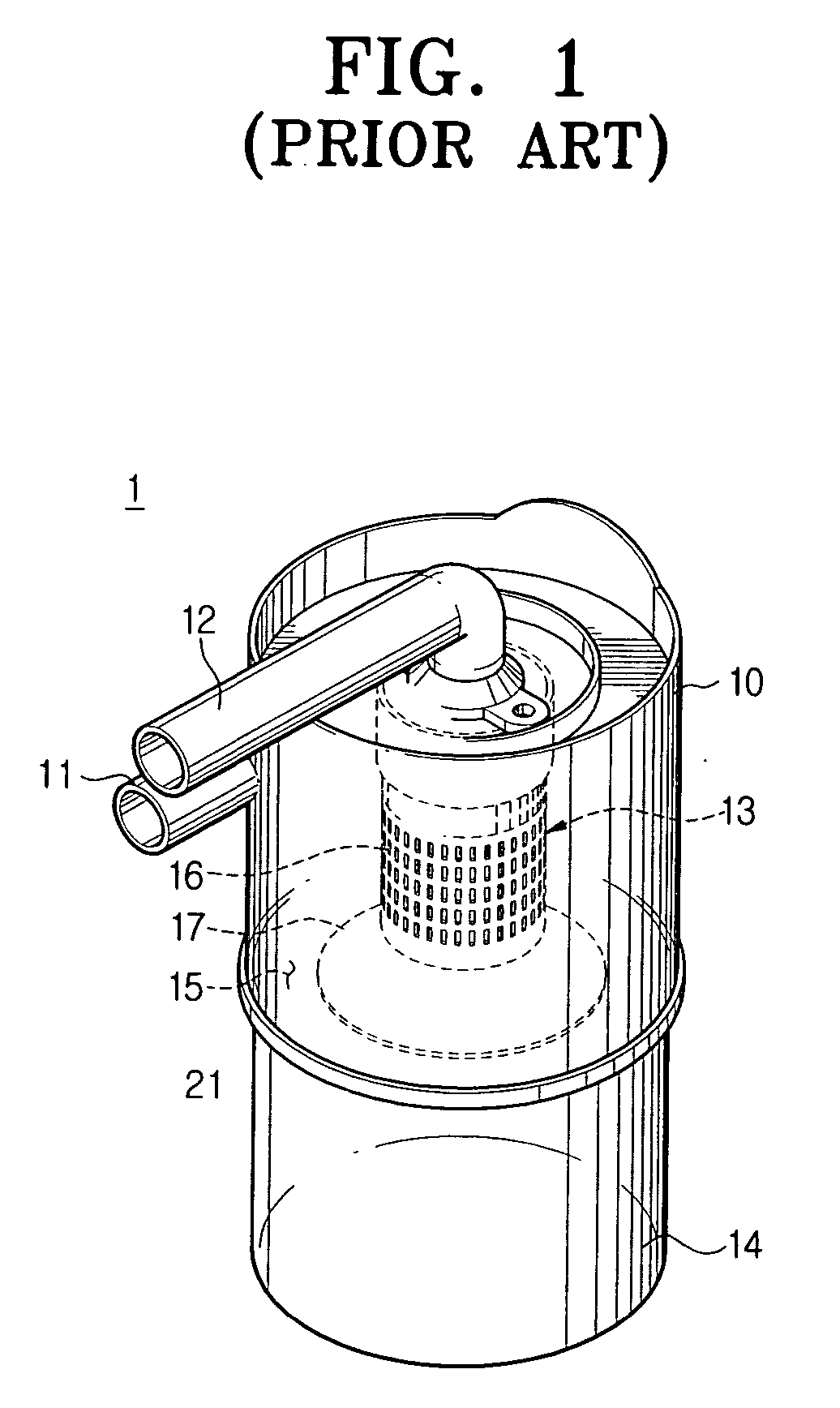

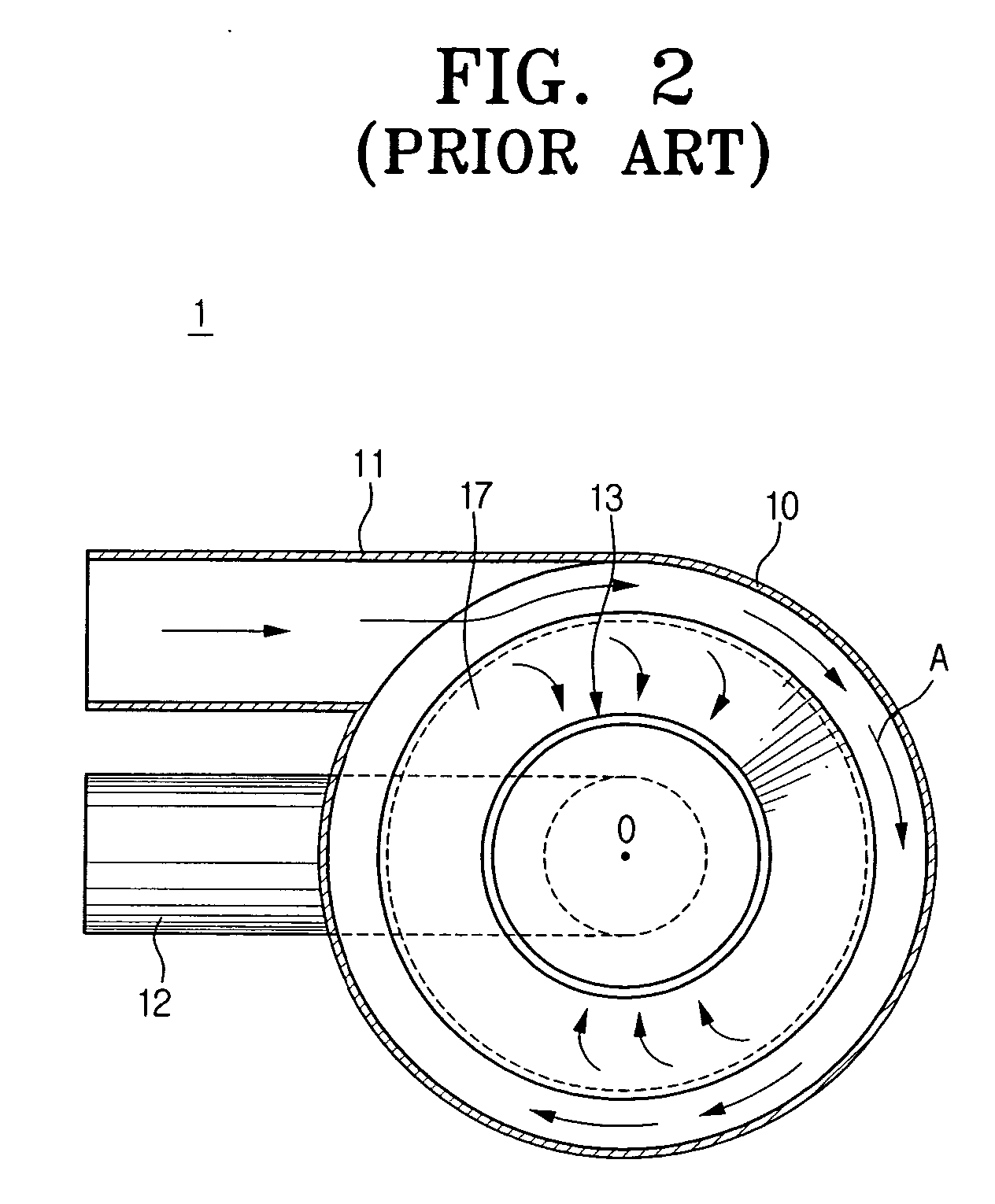

Grille for a cyclone vacuum

InactiveUS20060130441A1Simple structureAvoid problemsCleaning filter meansCombination devicesEngineeringVacuum cleaner

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

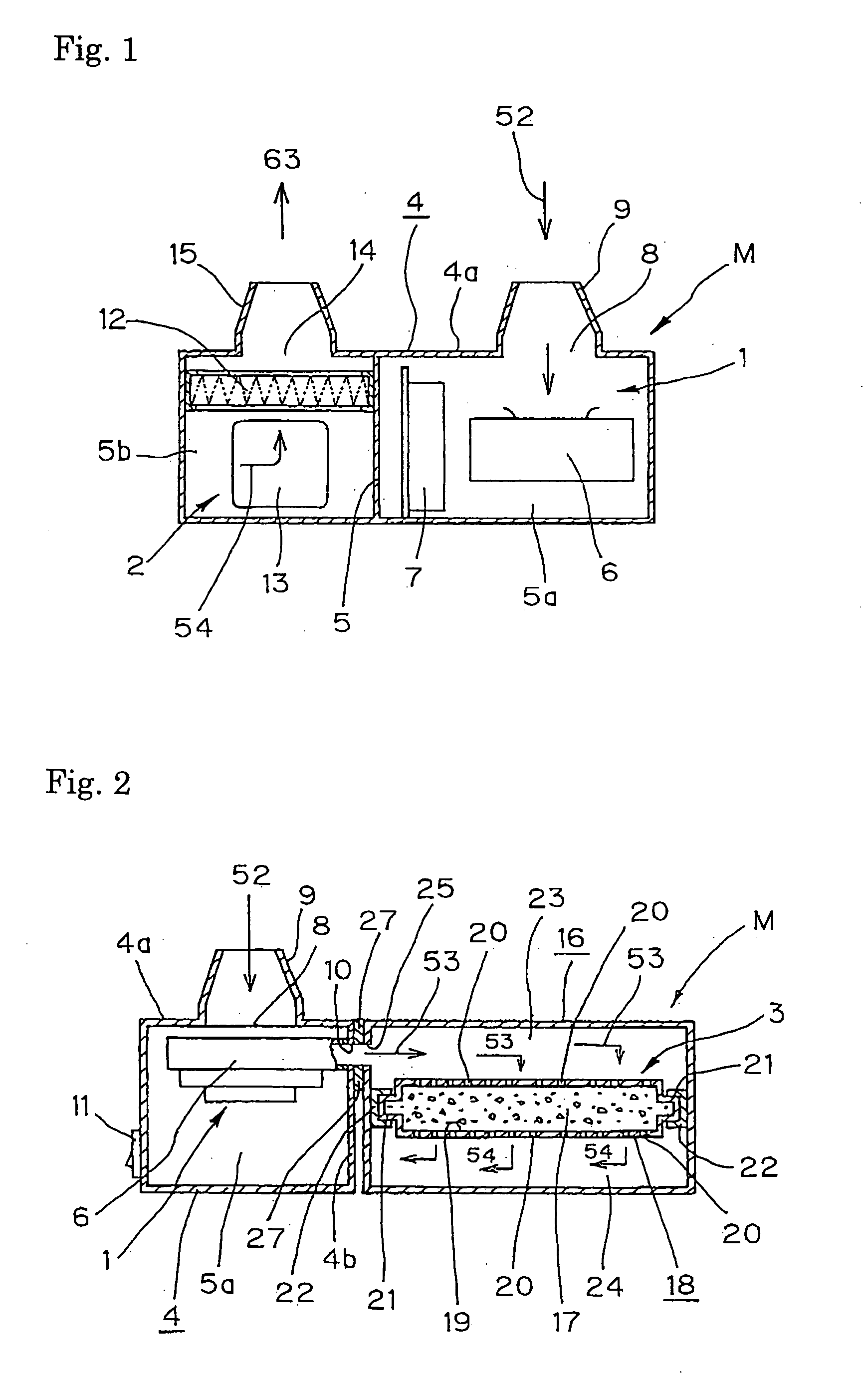

Air cleaning system

InactiveUS20050284114A1Avoid performanceCombination devicesDucting arrangementsAir cleaningEngineering

The present invention provides a structure of an air cleaning system that prevents a suction performance from being decreased, the air cleaning system including a cabinet provided to a ceiling or a wall, discharging purified air to a room, and having a first inlet formed on a side thereof for drawing room air, a fan is provided to a cabinet and drawing air into the cabinet, a filter for purifying the room air flowed into the cabinet via the fan, and at least one panel for selectively opening / closing the first inlet of the cabinet.

Owner:LG ELECTRONICS INC

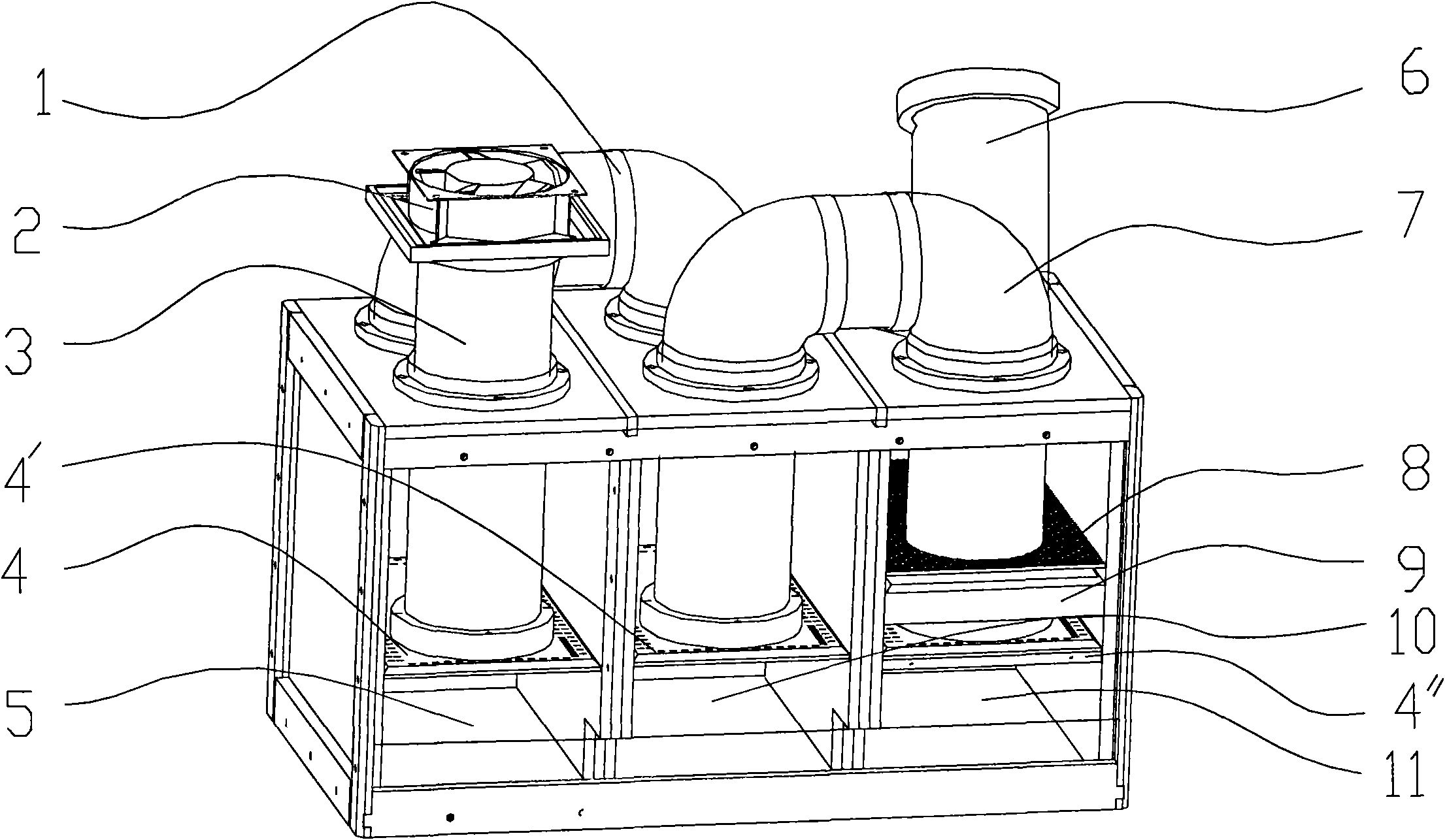

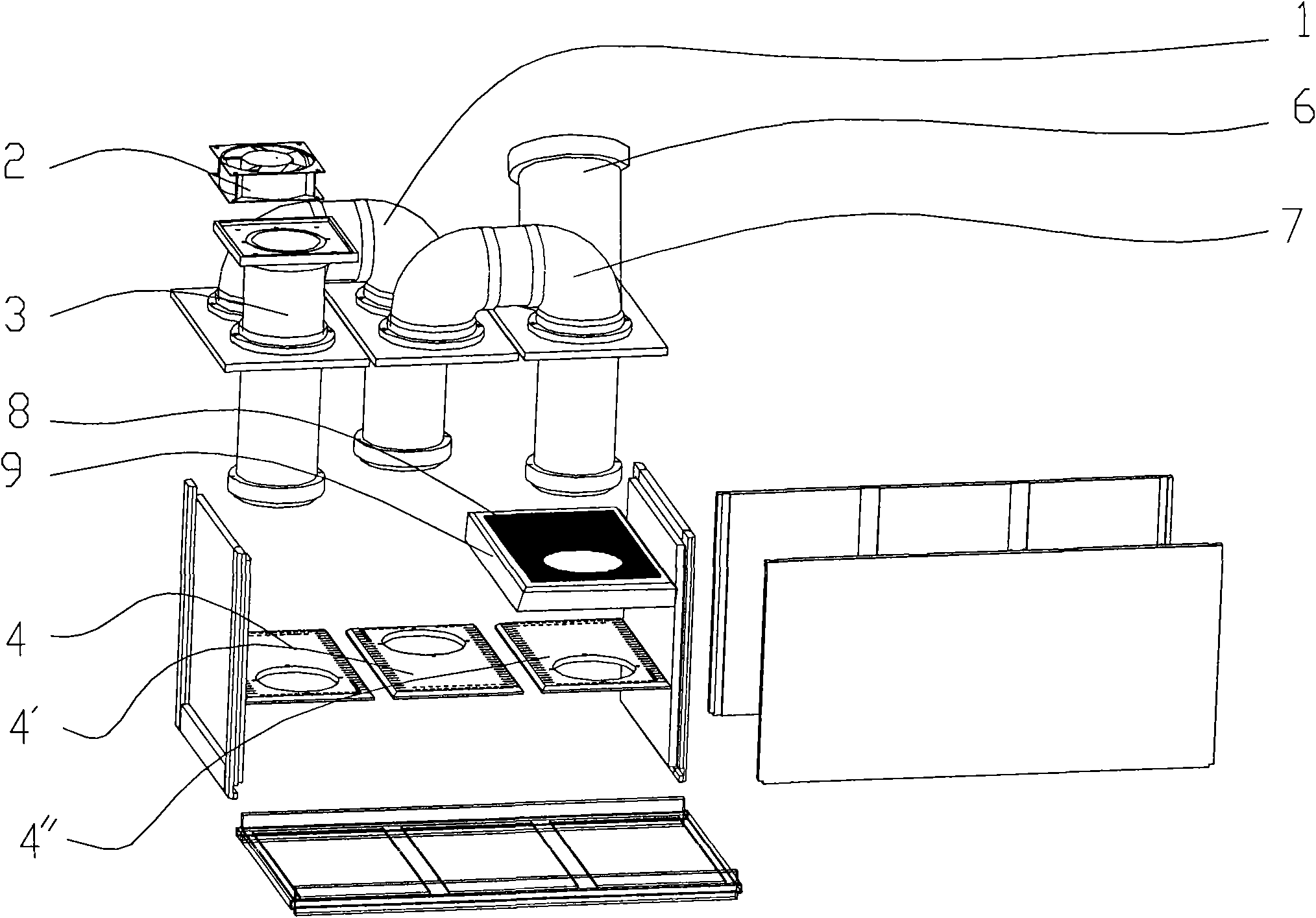

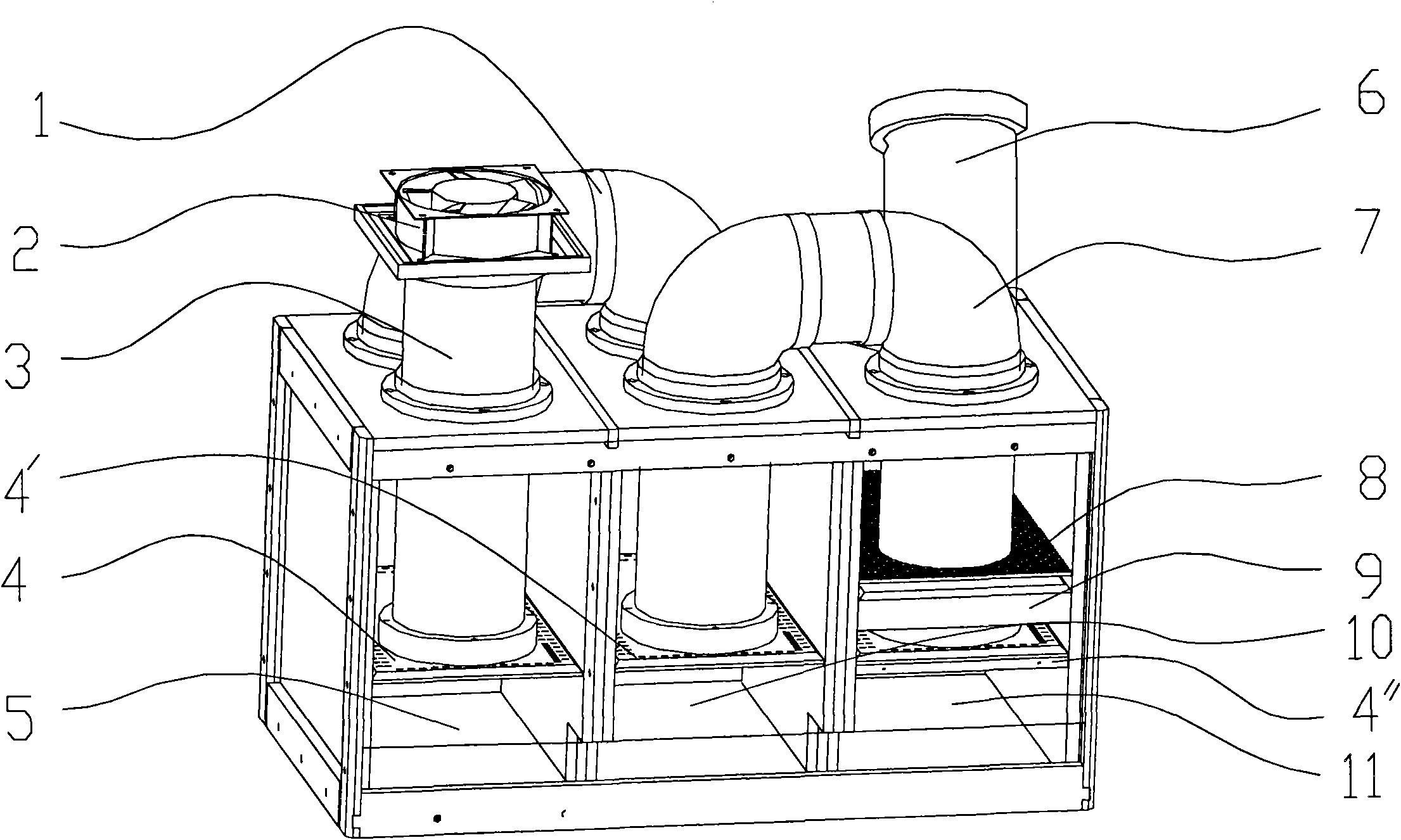

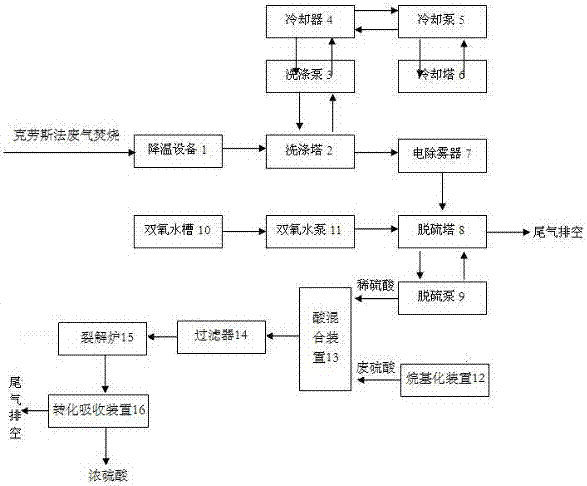

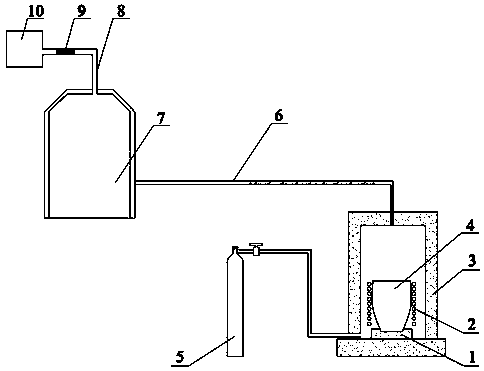

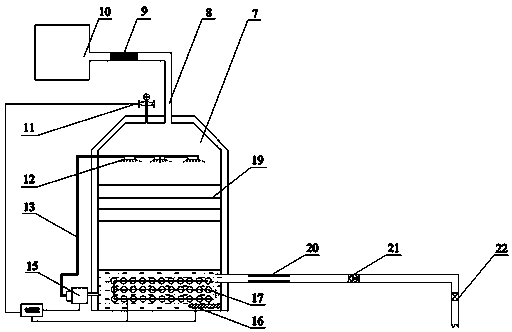

Clean production process and device for sulfur recycling and alkylated waste acid combined treatment

Owner:HULUDAO DESIGN INST PETROCHINA NORTHEAST REFINING & CHEM ENG +1

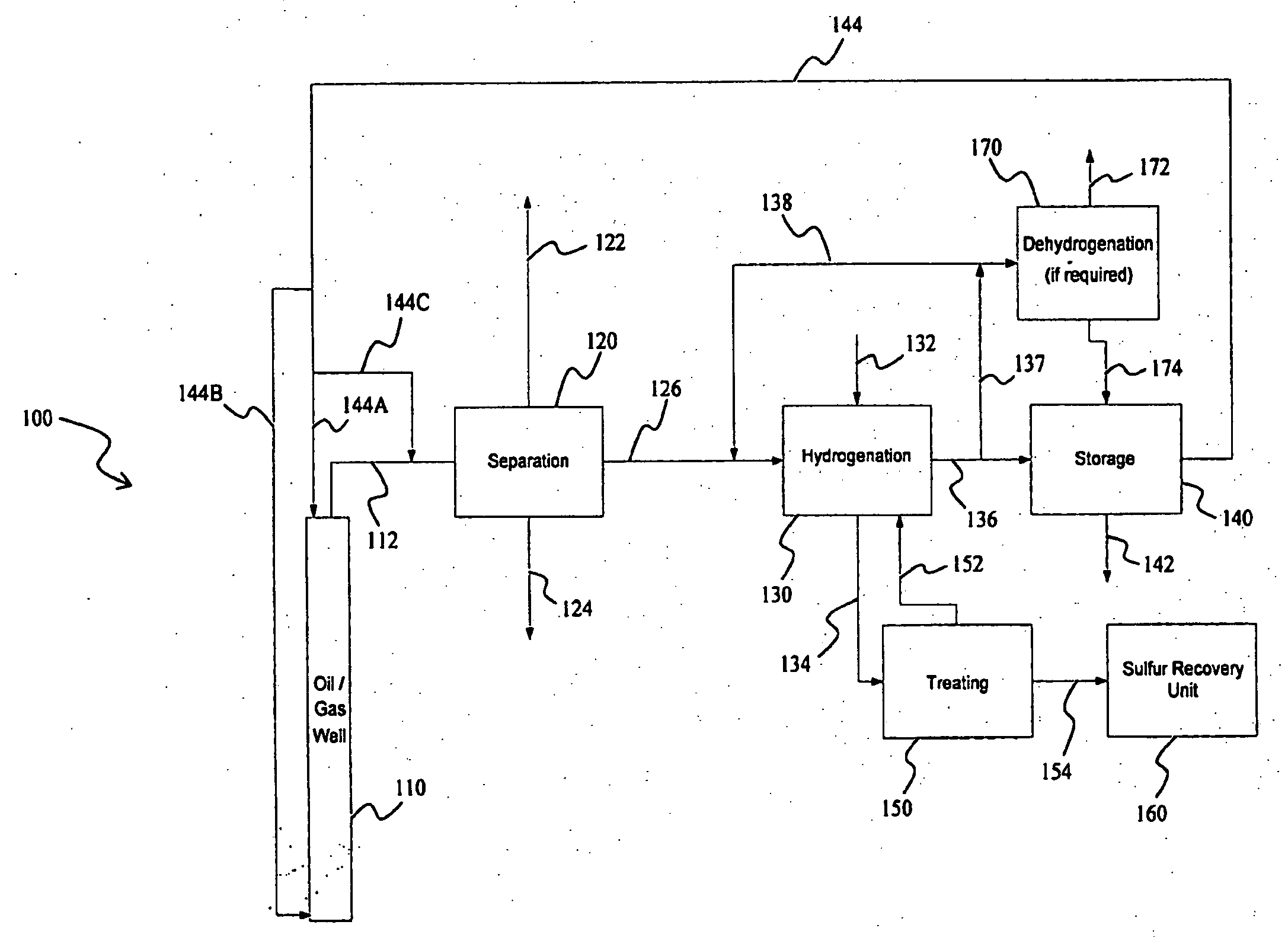

Hydrocarbon Based Sulfur Solvent Systems and Methods

Owner:FLUOR TECH CORP

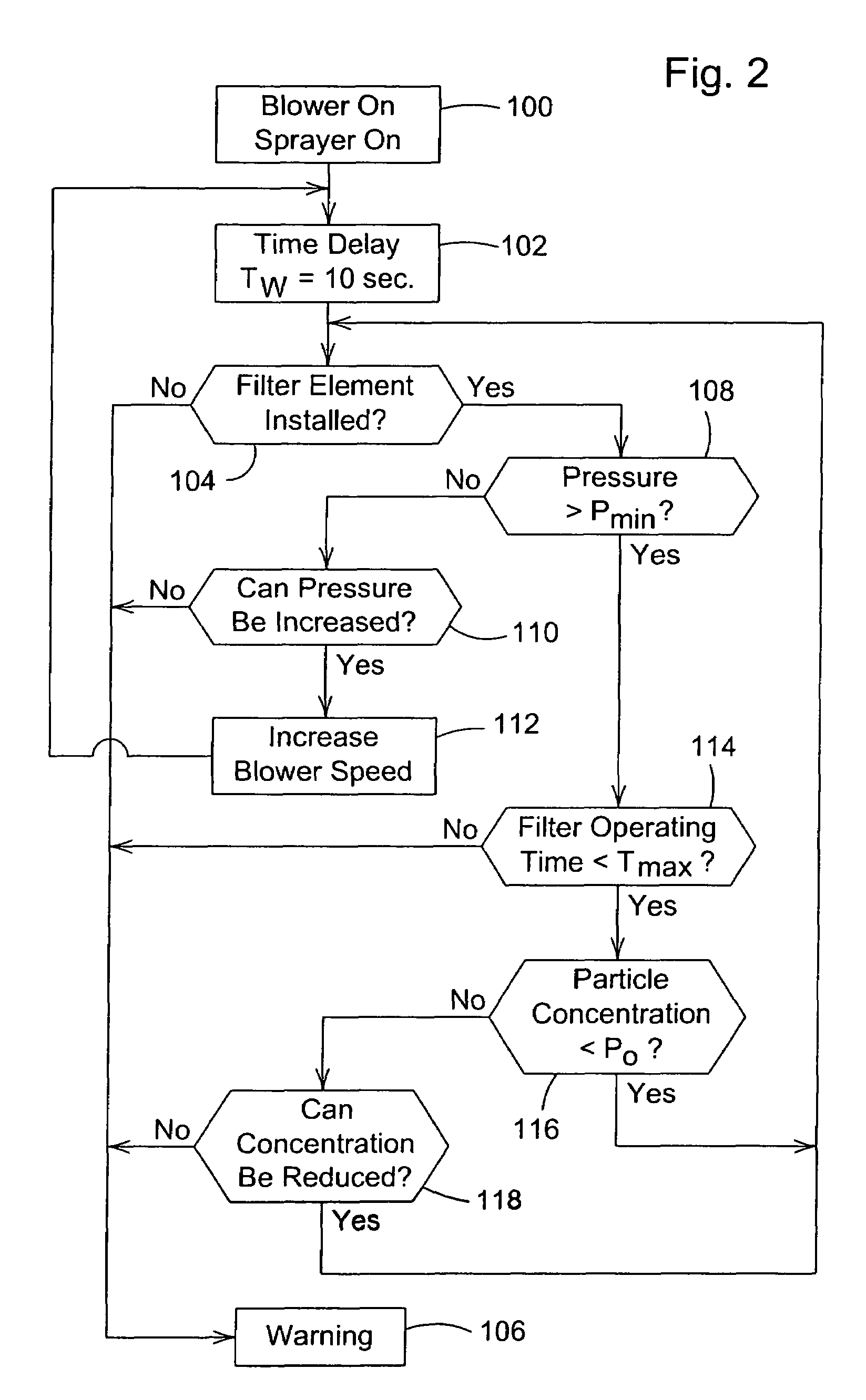

Monitoring arrangement for compartment air contamination

Owner:DEERE & CO

Ultra-low emission absorption tower

Owner:CHINA HUADIAN ENG +1

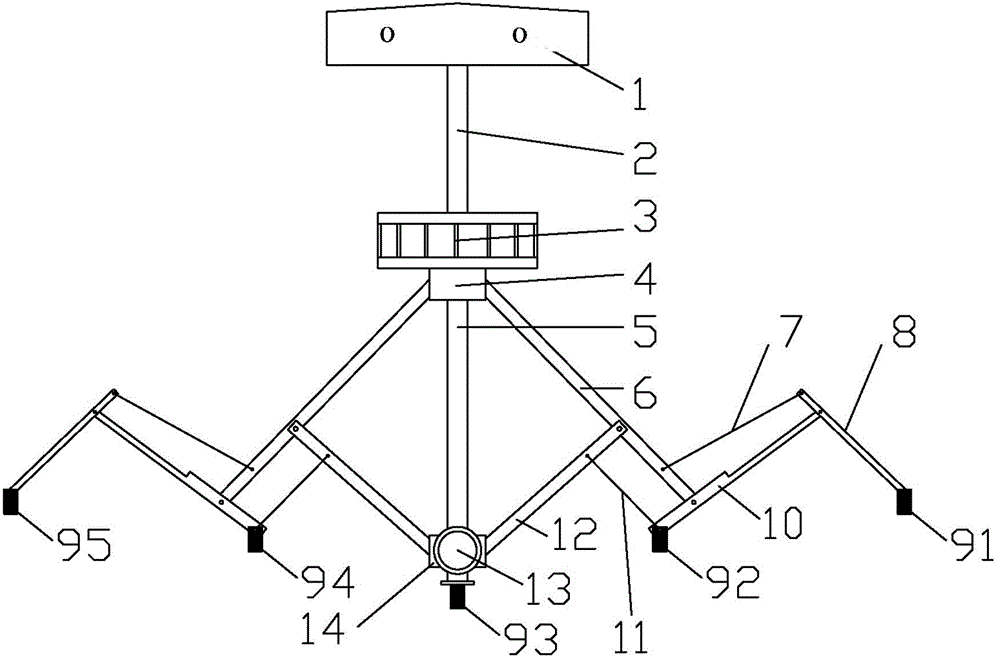

Concrete crushing and recycling device

ActiveCN112495476APrevent looseningReal-time adjustmentSievingSolid waste managementEnvironmental engineeringCrusher

The invention discloses a concrete crushing and recycling device. The concrete crushing and recycling device comprises a crushing mechanism, a dust channel and a mud generating mechanism, wherein thedust channel is formed in one side of the crushing mechanism; and the mud generating mechanism is arranged on one side of the dust channel. According to the concrete crushing and recycling device, a crushing roller adjusting mechanism is additionally arranged, and the distance between crushing rollers can be adjusted in real time according to concrete of different sizes, so that the crushing effect is better, jamming is prevented, and the crushing efficiency is improved; and dust generated in the crushing process is collected and made to form mud under the action of an atomization spraying mechanism, and the mud is discharged under the combined action of a mud settling mechanism and a discharge box, so that the dust is effectively controlled, and the environmental pollution is prevented; and meanwhile, the dust can be reprocessed and reutilized, so that raw materials are saved, and waste is prevented.

Owner:GUI ZHOU CHANG TONG DIAN LI XIAN LU QI CAI YOU XIAN GONG SI

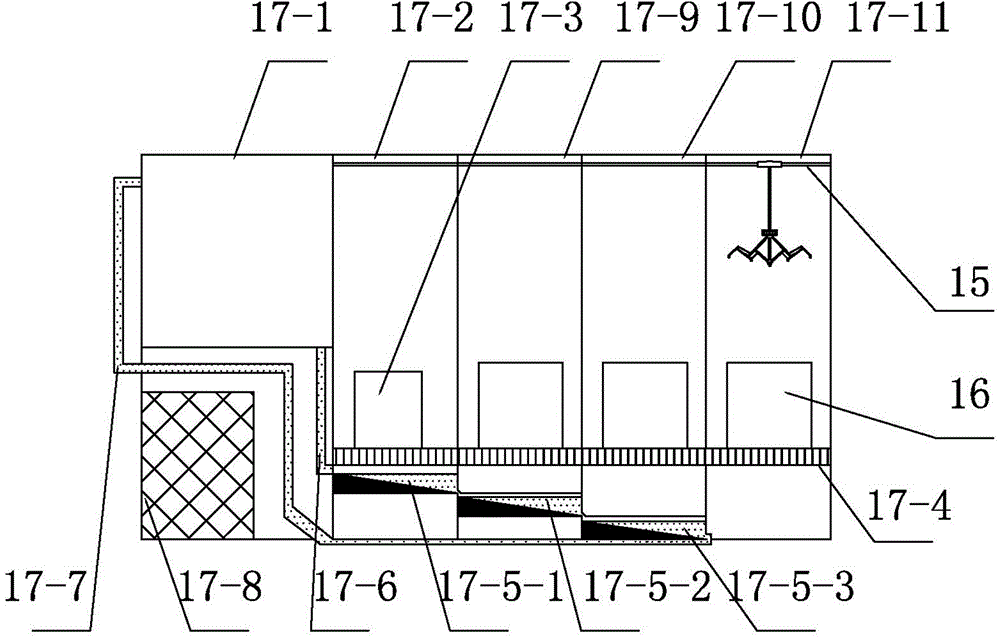

Dust-free workshop

InactiveCN104906892AReasonable designLow running costMeasurement devicesUsing liquid separation agentWater treatment systemDust control

Owner:浙江触捷光电科技有限公司

Air-purifying device for a front-opening unified pod

InactiveUS20050268580A1Maintain purityCombination devicesAuxillary pretreatmentCompound (substance)Engineering

Owner:CAMBRIDGE FILTER JAPAN +2

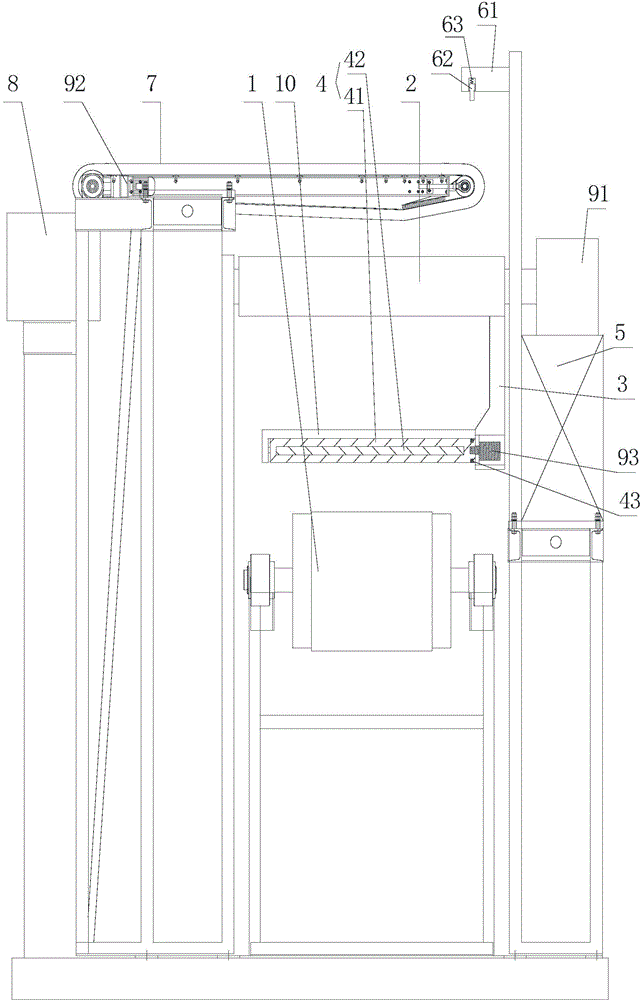

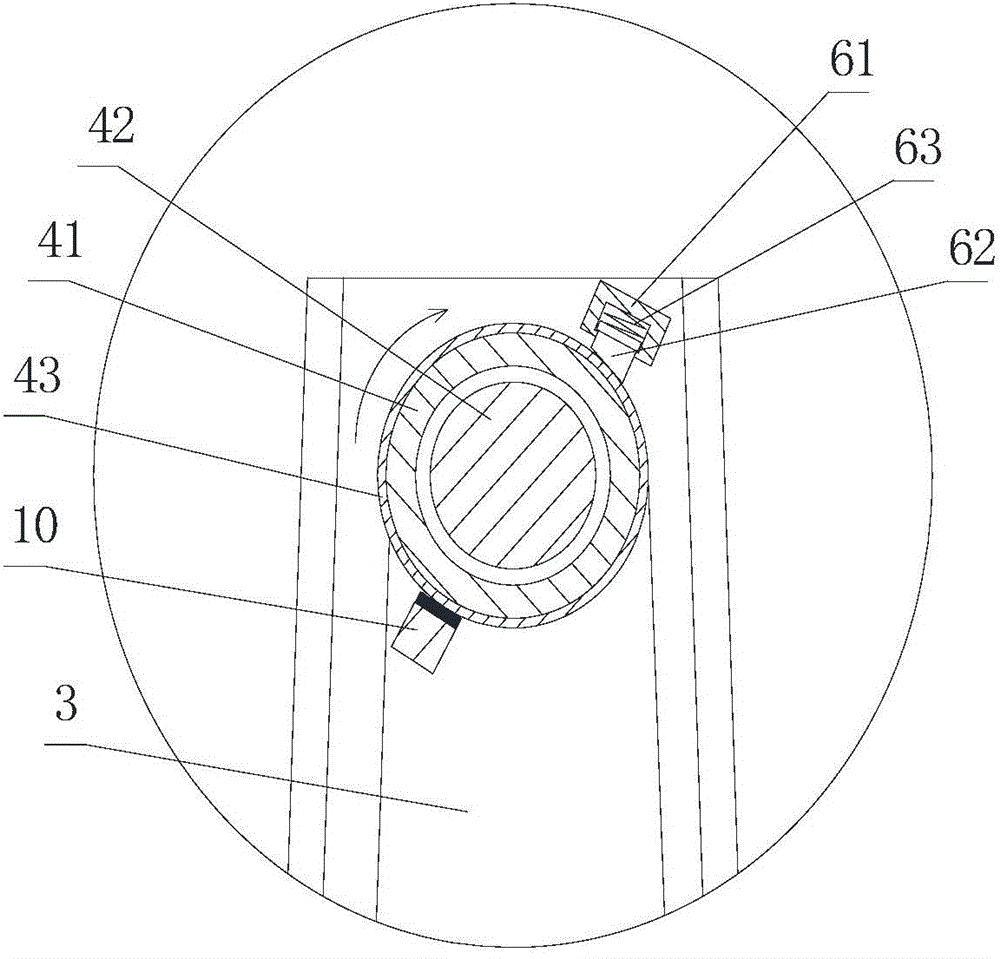

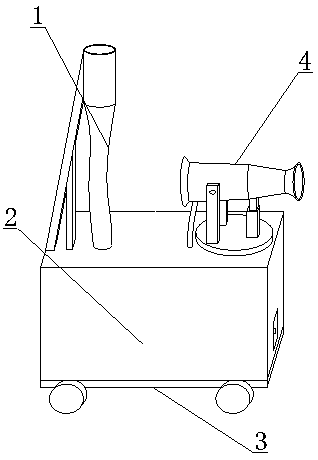

Castable powder treatment device

The invention provides a castable powder treatment device, comprising a conveyor belt I, a rotary shaft, a magnetic separation shaft and a control system, wherein the magnetic separation shaft comprises a shaft barrel and an electromagnet assembly, the outer wall of the shaft barrel is provided with a pressure sensor, a fixed seat, a sleeve and a spring are arranged above the rotary shaft, one end, away from the fixed seat, of the sleeve is blocked on the motion track of the pressure sensor on the magnetic separation shaft, the electromagnet assembly and the pressure sensor are both electrically connected with the control system, a conveyor belt II is arranged above the rotary shaft, is connected with a driving mechanism II and is located right below the position of the sleeve when the pressure sensor is in contact with the sleeve, and the output end of the conveyor belt II is provided with a powder collection box. The castable powder treatment device can be used for effectively removing impurity iron in castable materials, greatly enhancing the purity of the castable materials, greatly improving the performance of refractory brick products, reducing dust generated in processes of powder collection and retreatment, reducing bodily injury to workers, realizing automatic operation and reducing human cost.

Owner:唐山东盛旺业科技有限公司

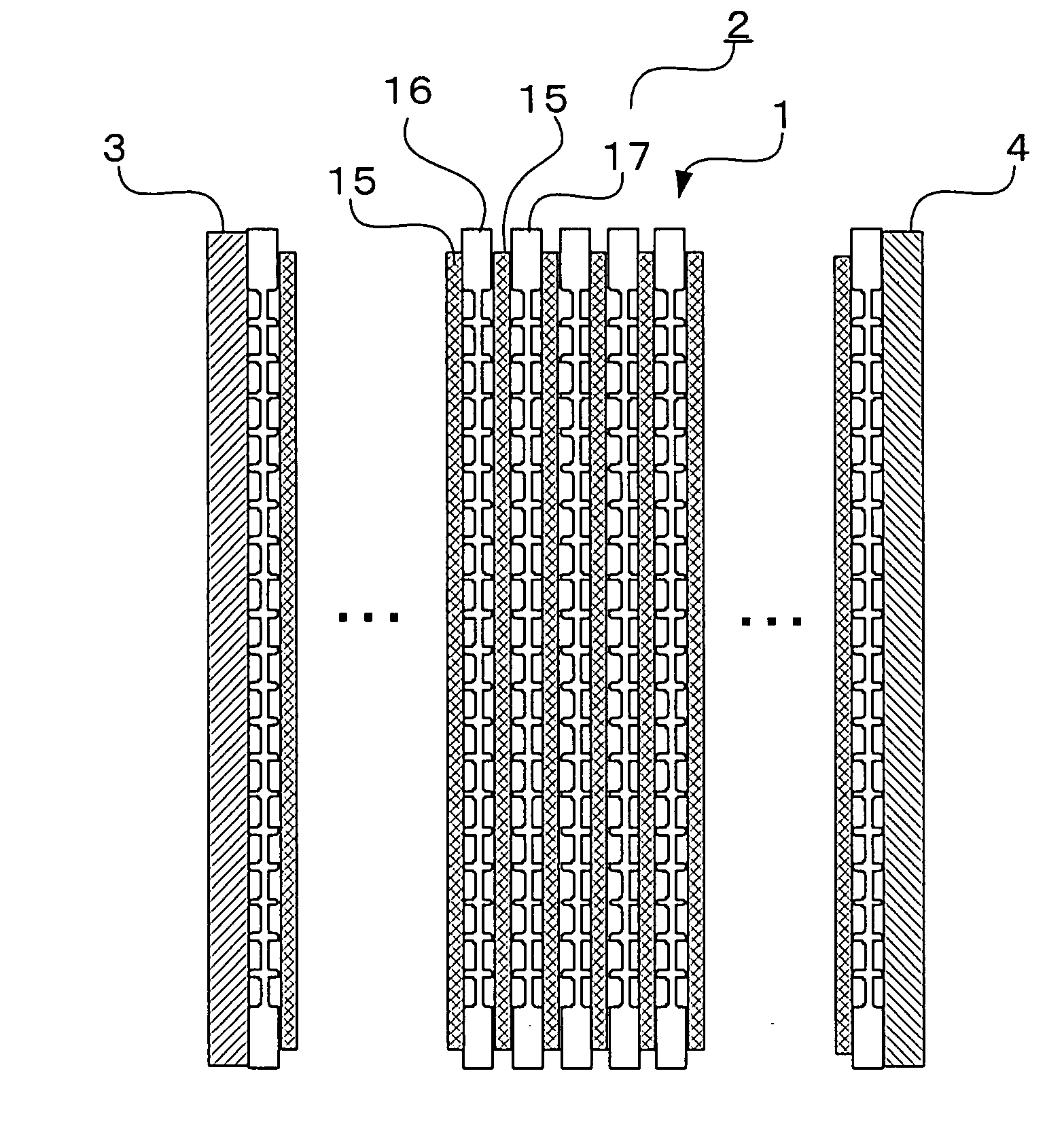

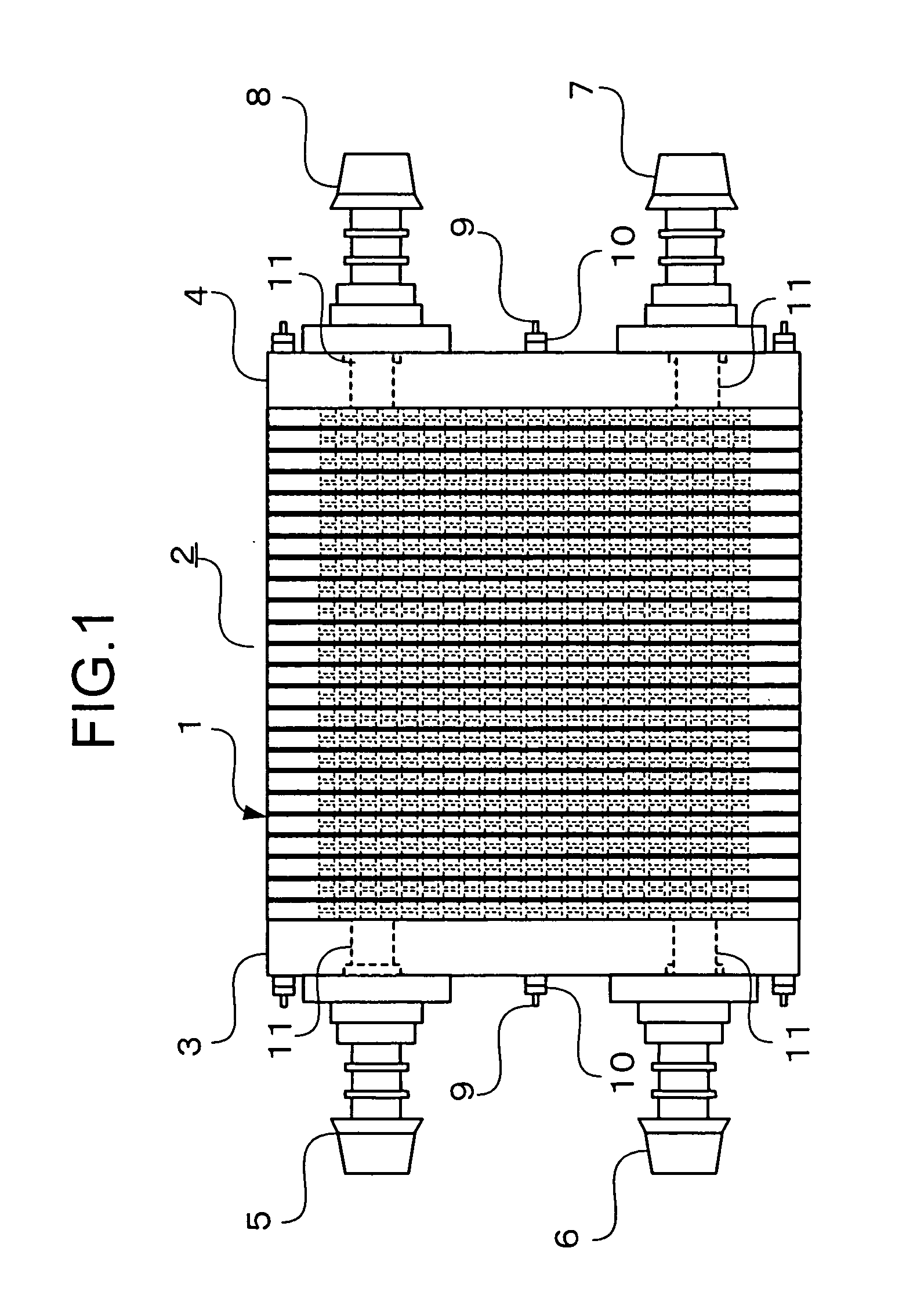

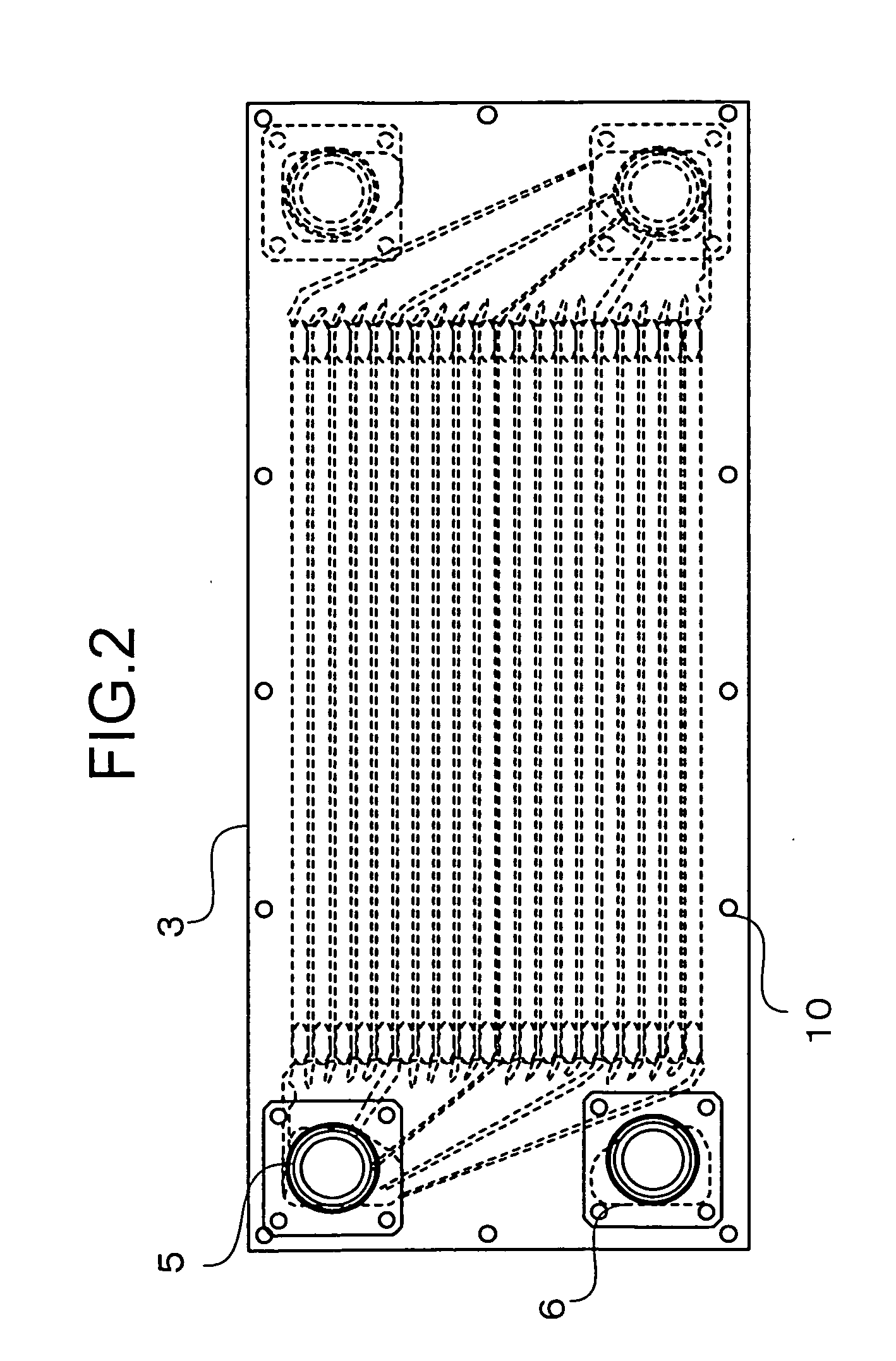

Temperature/humidity exchanger

InactiveUS20070107454A1Raise the dew pointRestrict pressure lossUsing liquid separation agentSolid sorbent liquid separationProduct gasEngineering

Owner:MITSUBISHI ELECTRIC CORP

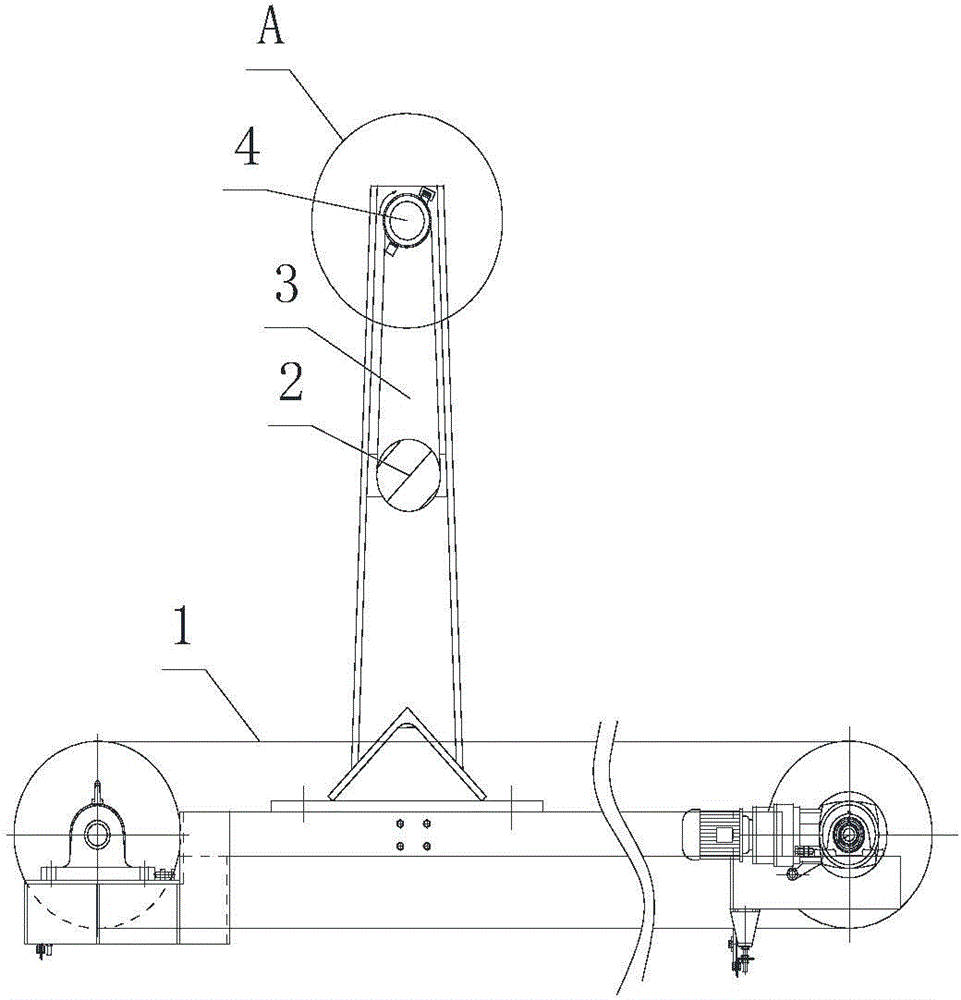

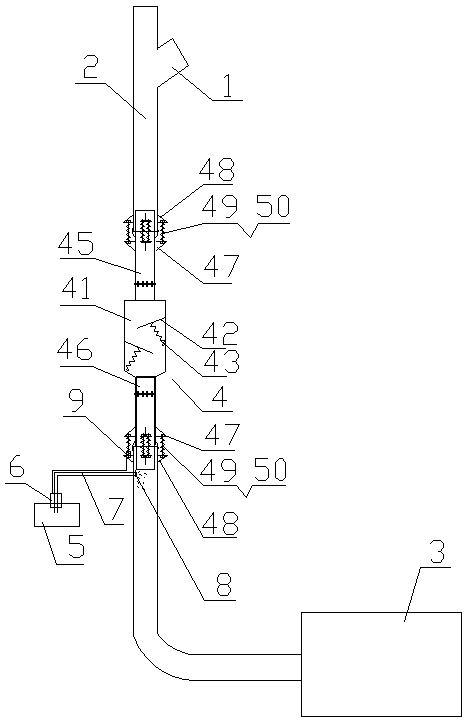

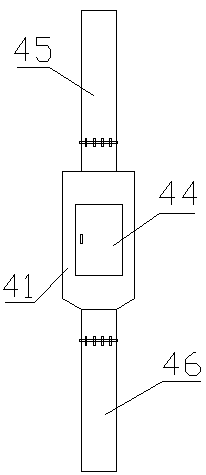

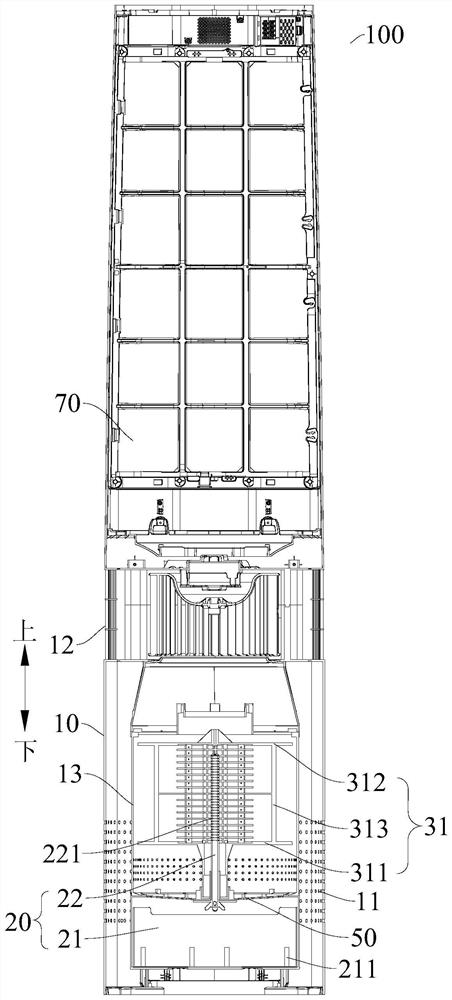

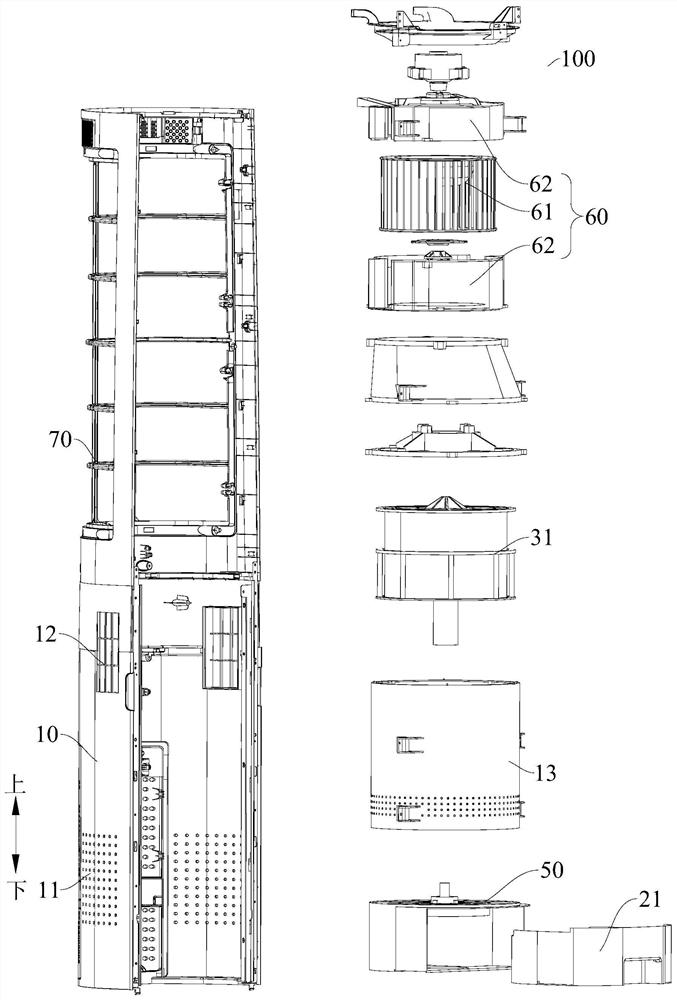

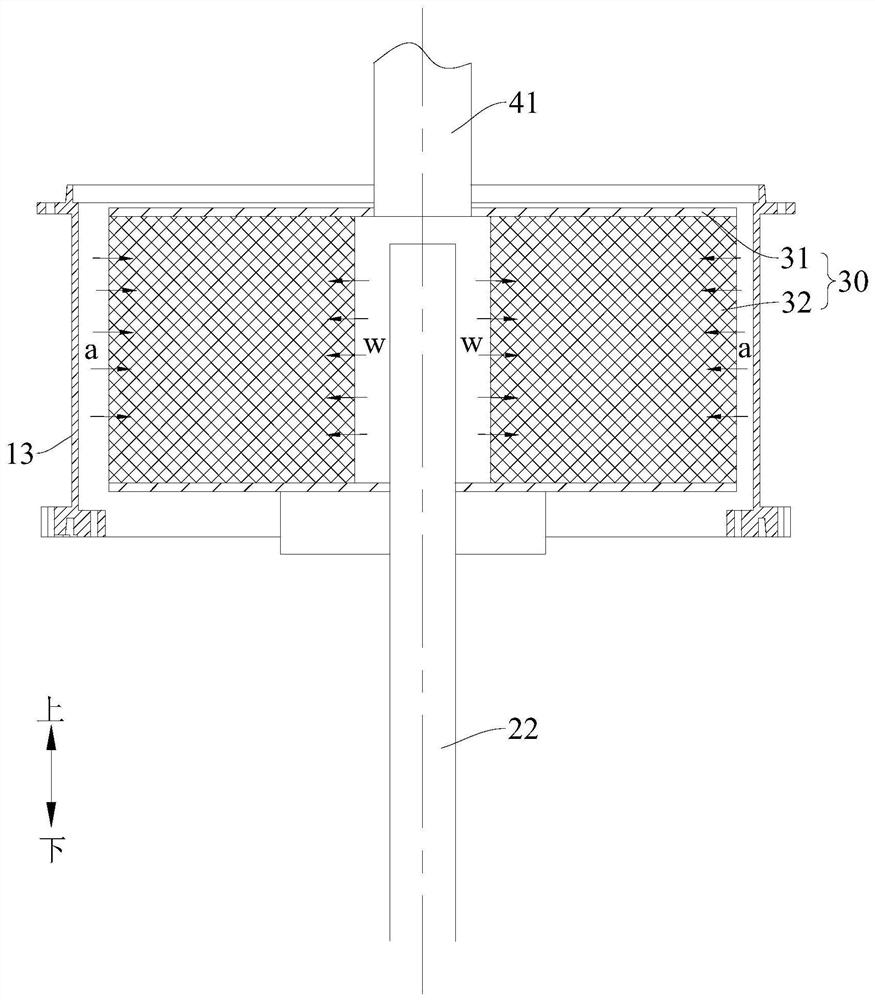

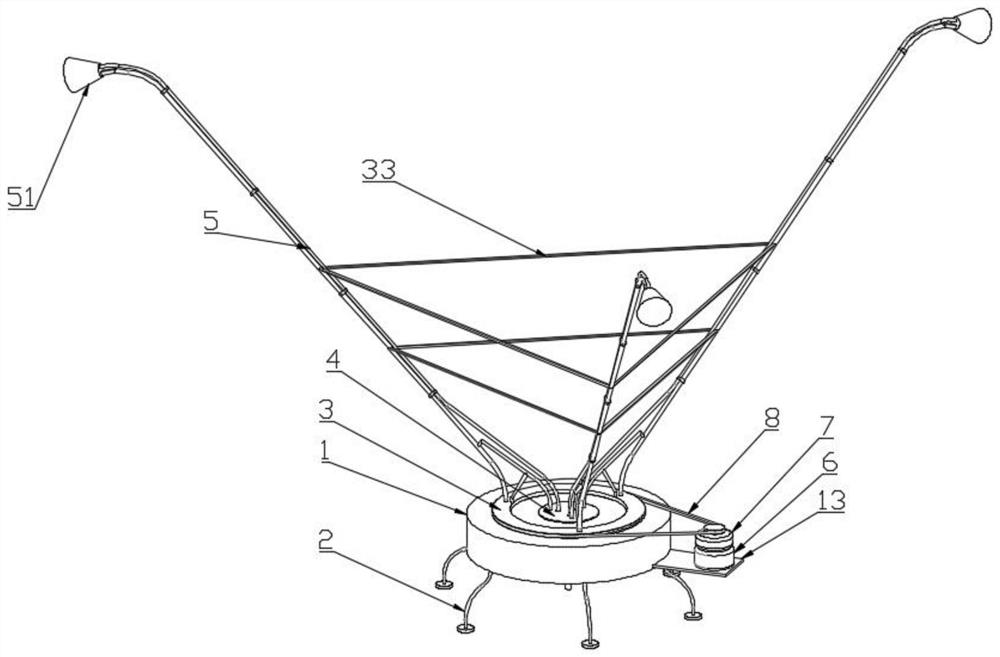

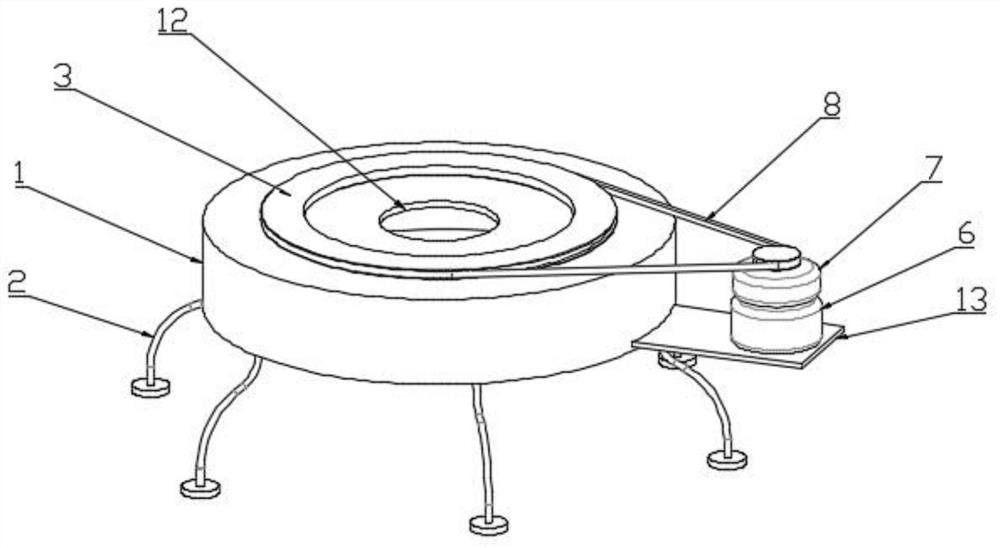

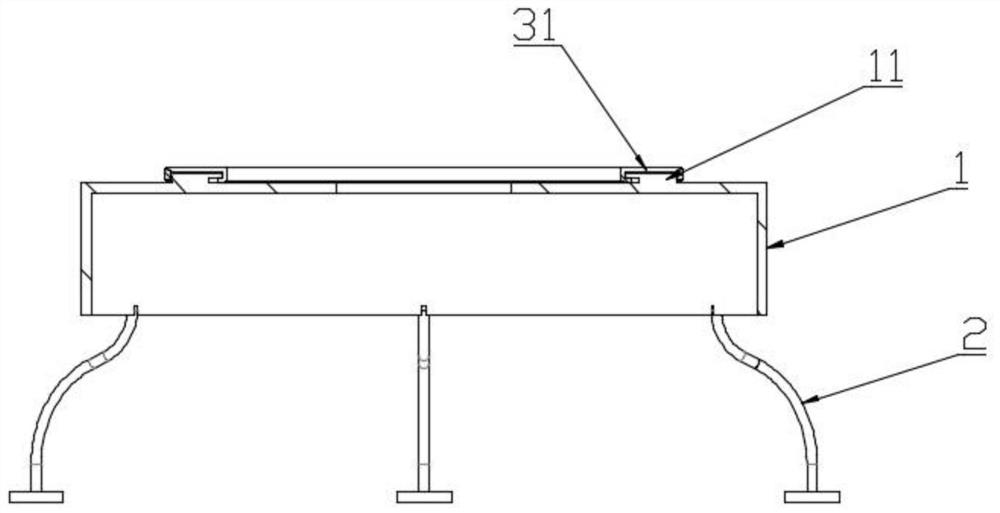

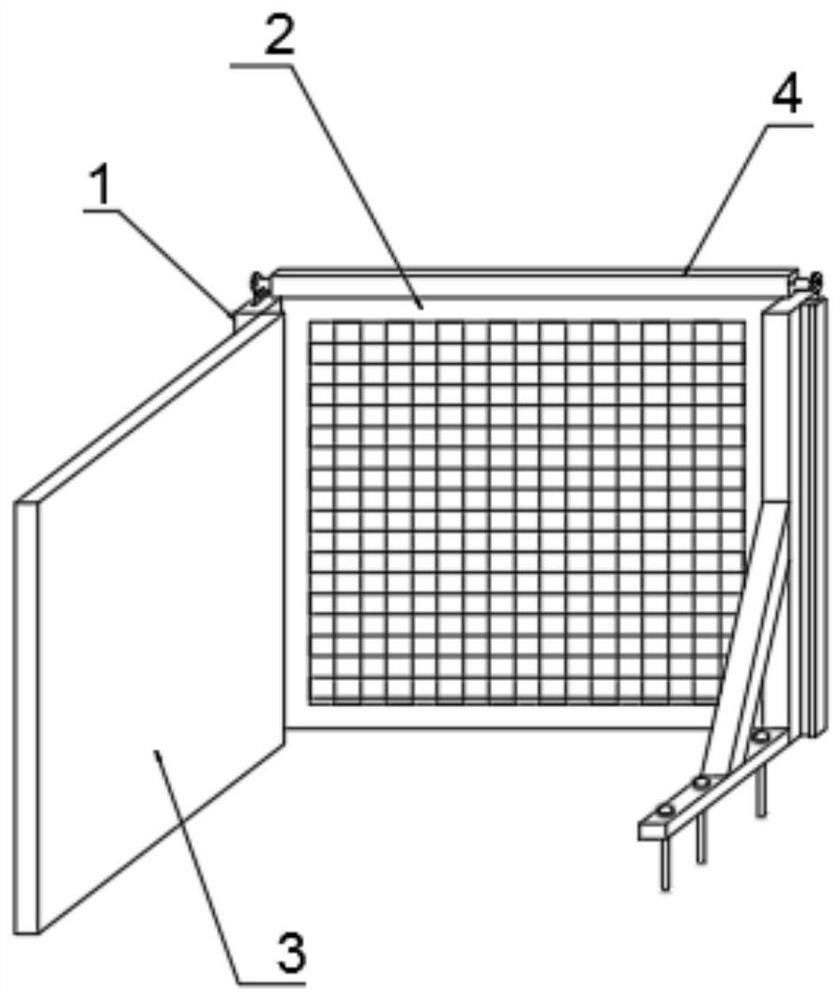

Construction waste vertical transportation system for super high-rise buildings

Owner:SHANGHAI BAOYE GRP CORP

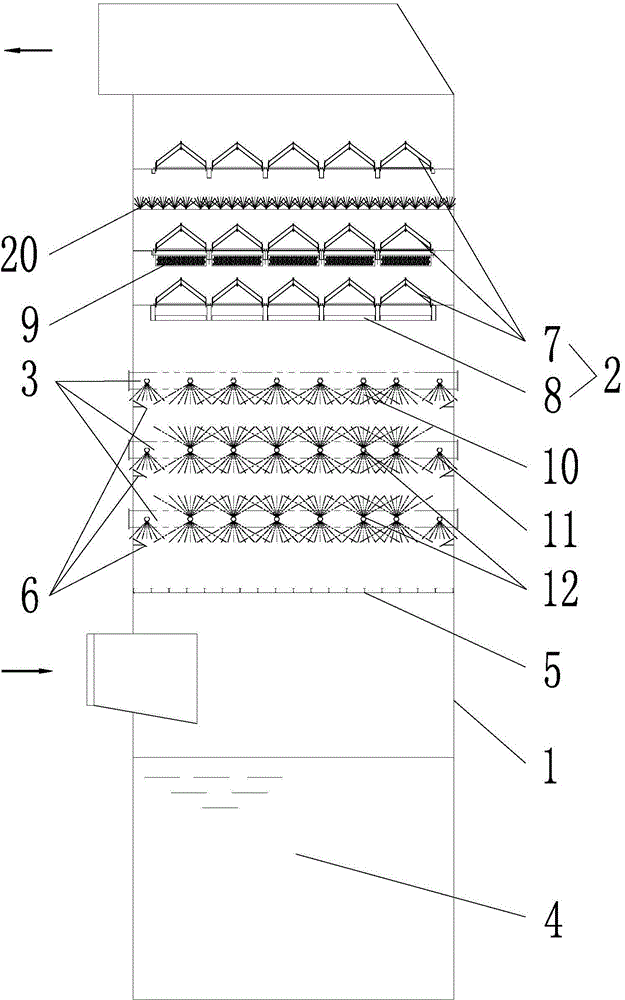

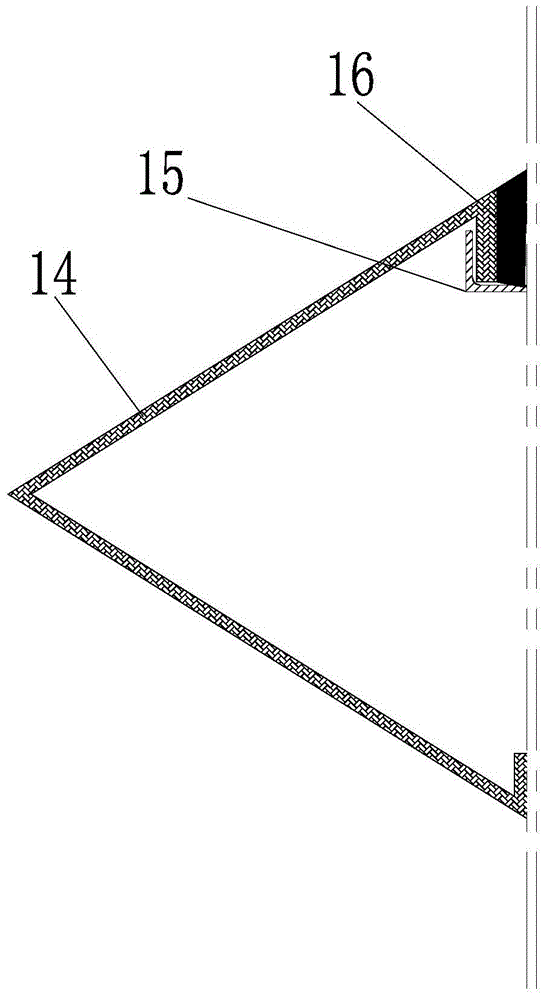

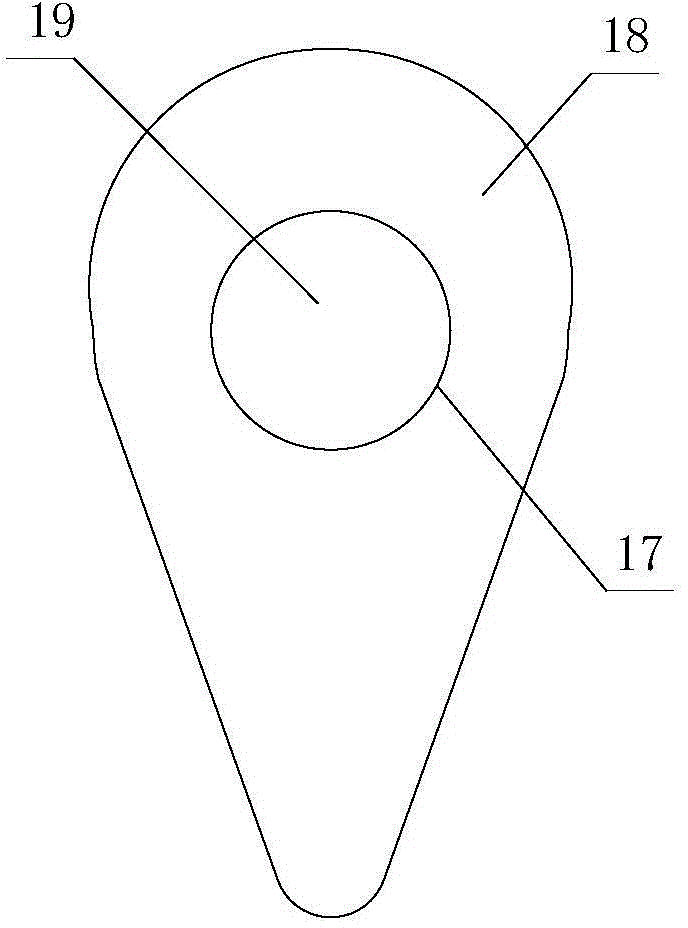

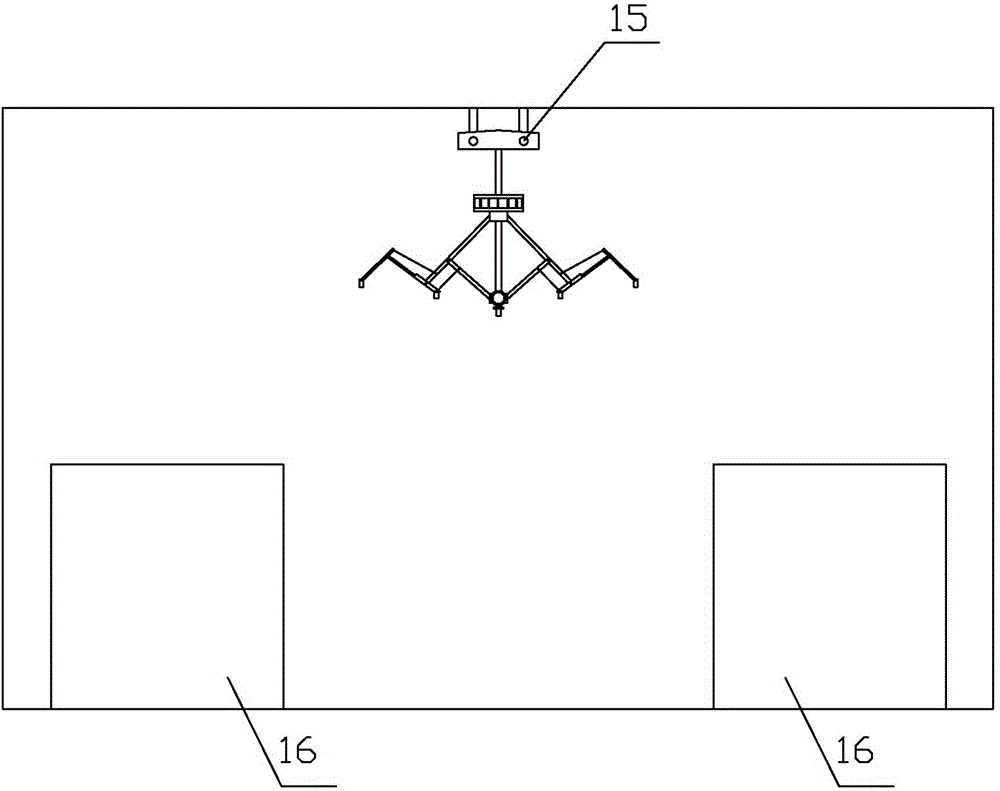

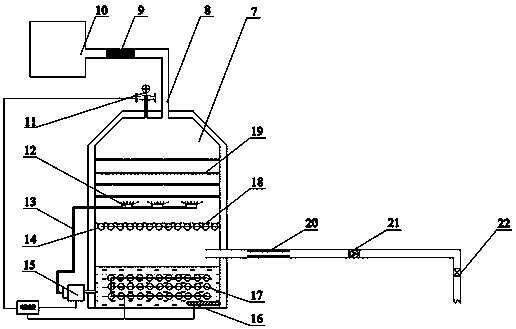

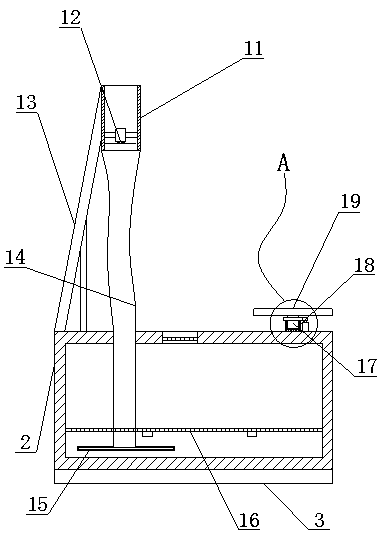

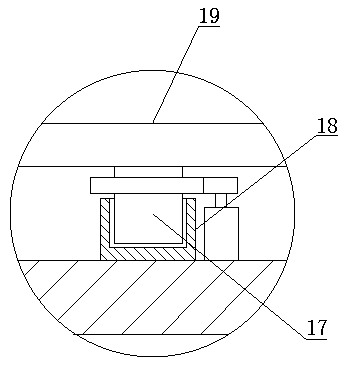

Intelligent wet-type dust removal equipment

PendingCN113648759AUnique principleReduce volumeUsing liquid separation agentDust detectionDust control

The invention provides intelligent wet-type dust removal equipment which comprises an air outlet, a rear shell, a sewage port, a front shell and an air inlet, the rear shell is connected with the front shell, a gutter channel is installed at the lower end of the rear shell and the lower end of the front shell, the sewage port is installed at the lower end of the gutter channel, a cyclone flow guide body is installed in the rear shell, and the air outlet is formed in one end of the rear shell. A driving device, a swirler and a fan impeller are respectively mounted in the front shell, the swirler is mounted on the driving device, the driving device is connected with the fan impeller, a temperature sensor is mounted on the driving device, an air inlet is formed in one end of the front shell, a dust detection module and a spraying system are respectively arranged on the air inlet, and an electric control water valve is mounted on the air inlet; the electric control water valve is connected with the spraying system through a pipeline, and the pipeline is provided with a flow sensor; the equipment is reasonable in structure, free of consumables, free of a cleaning period, high in trapping and self-cleaning capacity, capable of continuously working for a long time, free of blockage, free of disassembly, cleaning and maintenance, simple in structure and convenient to use.

Owner:SHENWEIDE (TIANJIN) MASCH EQUIP CO LTD

Chip removal filter device for graphite production

InactiveCN107952314AEasy to installEasy to replaceUsing liquid separation agentFiltration circuitsFiltrationSludge

Owner:SICHUAN CHAOYING TECH CO LTD

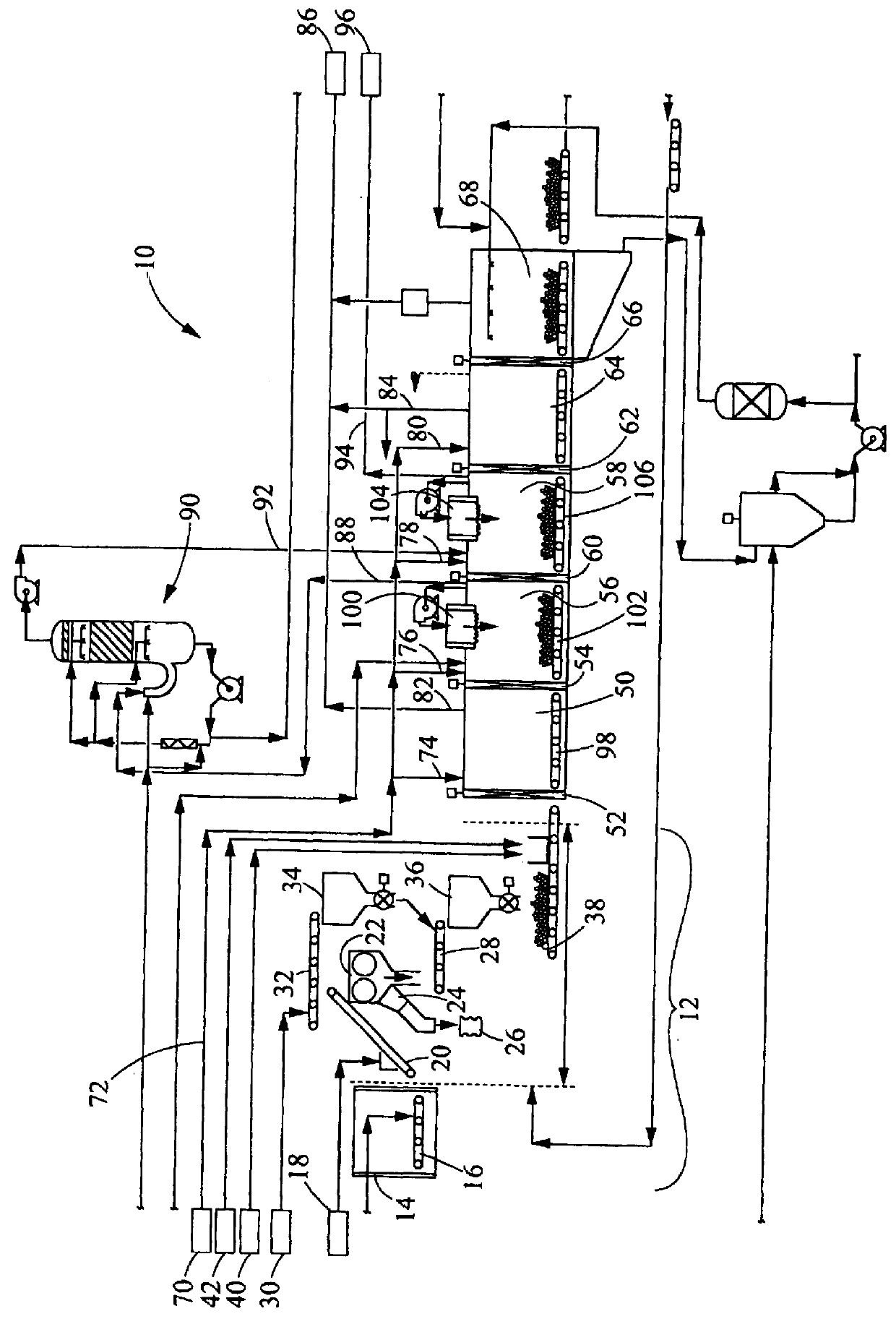

Multi-stage pyrolysis systems for treating chlorine contaminated wastes

InactiveUSH2198H1Minimize the possibilityMinimizes dioxinUsing liquid separation agentIncinerator apparatusFuranOxygen

Owner:CH2M HILL

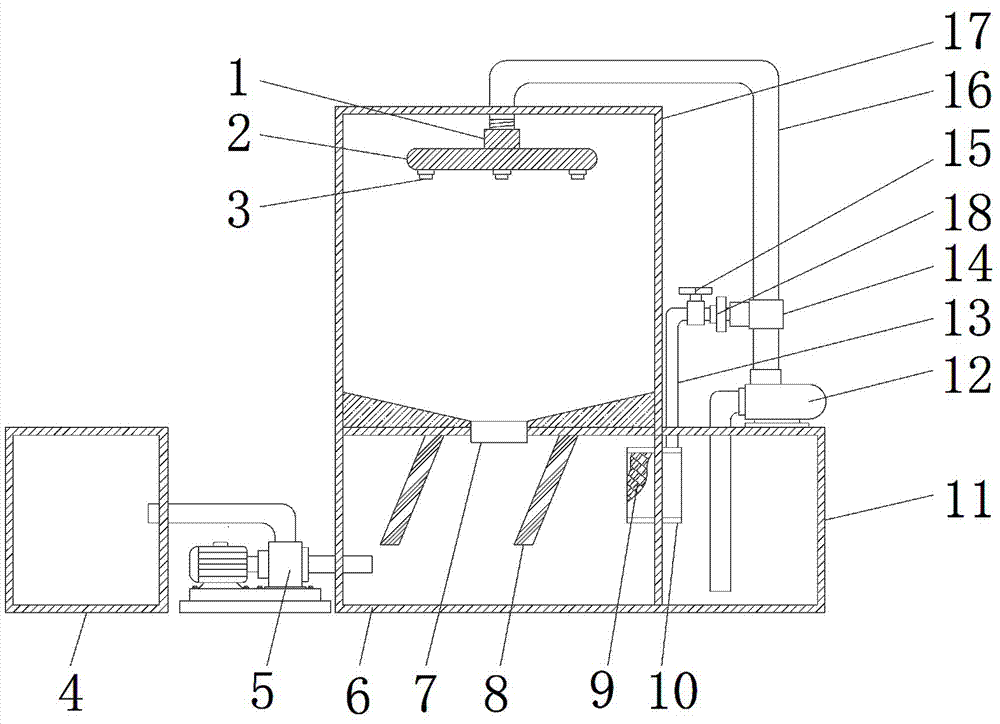

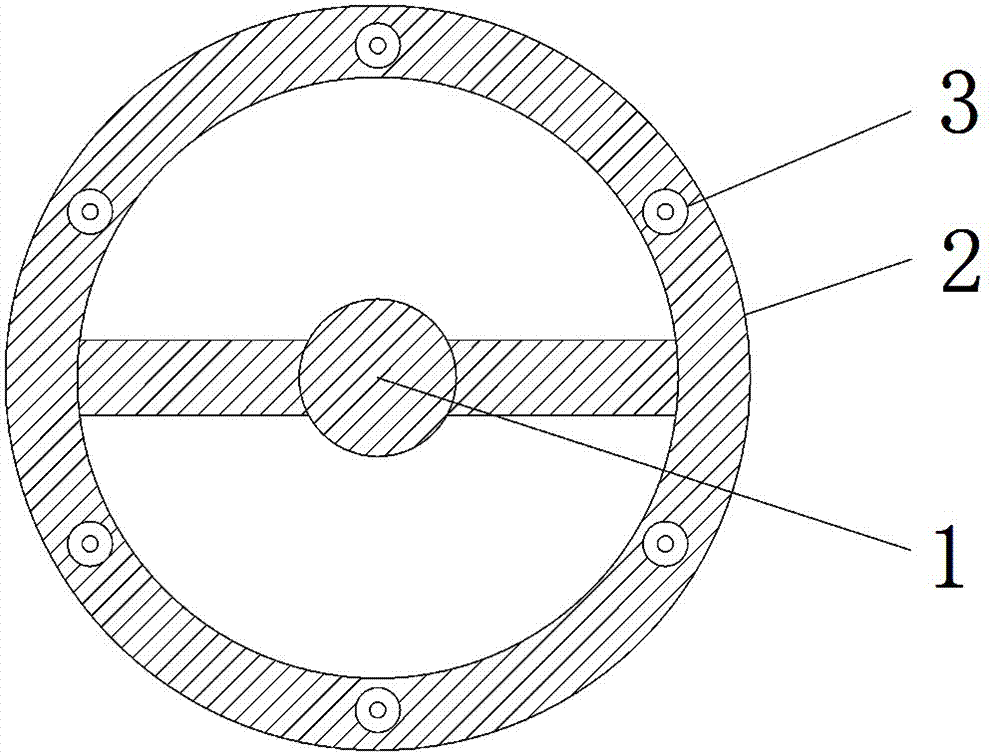

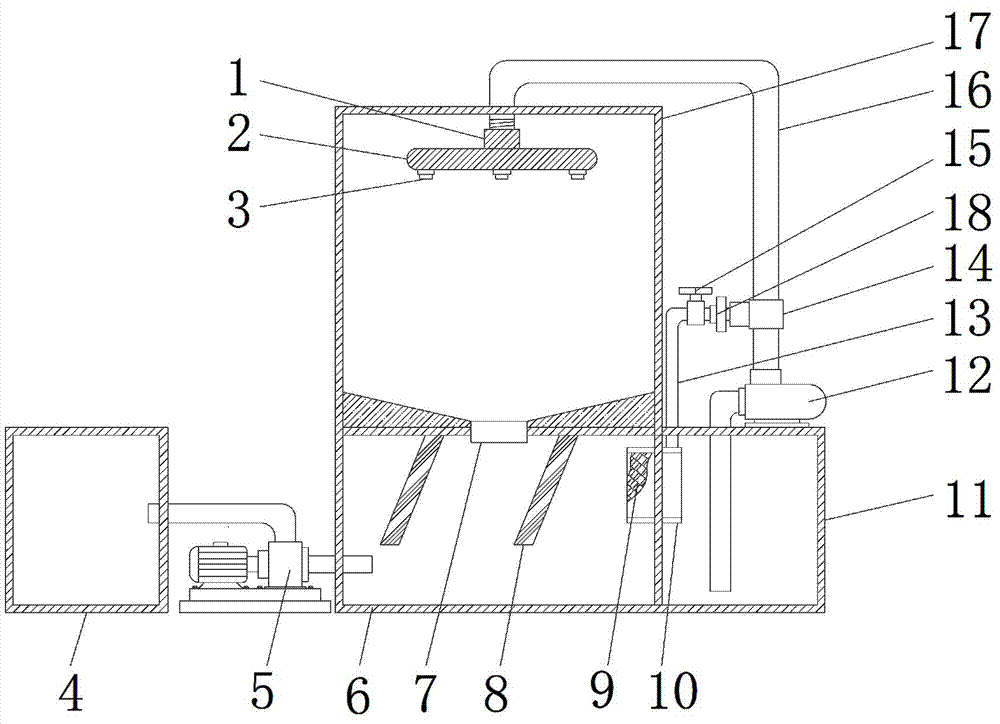

Mixing device for color concentrate production

InactiveCN107553766AEfficient removalAvoid pollutionUsing liquid separation agentElectric machineEngineering

The invention relates to a mixing device for color concentrate production. The mixing device can fully mix resin with a dye, and can effectively remove dust produced in the mixing process. A motor isconnected to the top of a mixing box; the motor is connected with a stirring rod in a driving mode; the stirring rod is vertically arranged and the bottom end of the stirring rod is close to the bottom wall of the mixing box; a first spraying arm is further arranged in the mixing box; a plurality of first nozzles are arranged along the axial direction of the first spraying arm; a partition plate is arranged in a liquid storage box; the partition plate divides the inner cavity of the liquid storage box into a left liquid chamber and a right liquid chamber; the dye is contained in the left liquid chamber and a purification liquid is contained in the right liquid chamber; a second spraying arm is further arranged in the right liquid chamber; a plurality of second nozzles are arranged along the axial direction of the second spraying arm; a first lifting pump communicates with the first spraying arm through a first liquid outlet pipe; a second lifting pump communicates with the second spraying arm through a second liquid outlet pipe; an air inlet communicates with the mixing box through an air inlet pipe; the air inlet pipe is provided with a fan; and a gas outlet communicates with themixing box through an air outlet pipe.

Owner:TIANJIN CHUNXIA TECH CO LTD

An air purification apparatus and air purification equipment using air purification apparatus

InactiveCN106422603AAchieve replacementLow costCombination devicesUsing liquid separation agentDistributorAir purification

Owner:宋嘉

Air purifier

PendingCN112007458AImprove purification efficiencyUsing liquid separation agentAir purifiersMechanical engineering

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Air purification spraying device for printing and dyeing room and spraying control method of air purification spraying device

ActiveCN113350935AAvoid drips etc.Spray evenlySpecific water treatment objectivesUsing liquid separation agentSprayerWater source

The invention discloses an air purification spraying device for a printing and dyeing room, and belongs to the technical field of air purification. The device comprises a main body box and suction pumps arranged in the left side and the right side of the main body box and used for pumping a water source into the main body box for circulation and then discharging. The device overcomes the defects in the prior art, multiple sprayers can be installed at the upper end of a water pipe by screwing connectors into the water pipe one by one through sprayers, an adjusting ring, nozzles and the connectors, the spraying direction of the device is effectively increased, and after the adjusting ring moves up and down, the impact force generated when water flow collides with the adjusting ring can be adjusted; water flow can be extruded out of the nozzles at different injection speeds according to the magnitude of impact force to be sprayed, then the spraying range of the device is changed, and the device can conduct wide-range spraying or fixed-point spraying on part of areas with serious air quality according to the actual air conditions of different areas in the printing and dyeing room, resources are saved, and the working efficiency is improved.

Owner:TONGXIANG KYOTO PRINTING & DYEING CO LTD

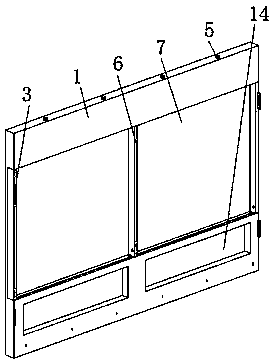

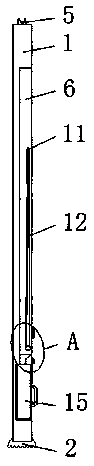

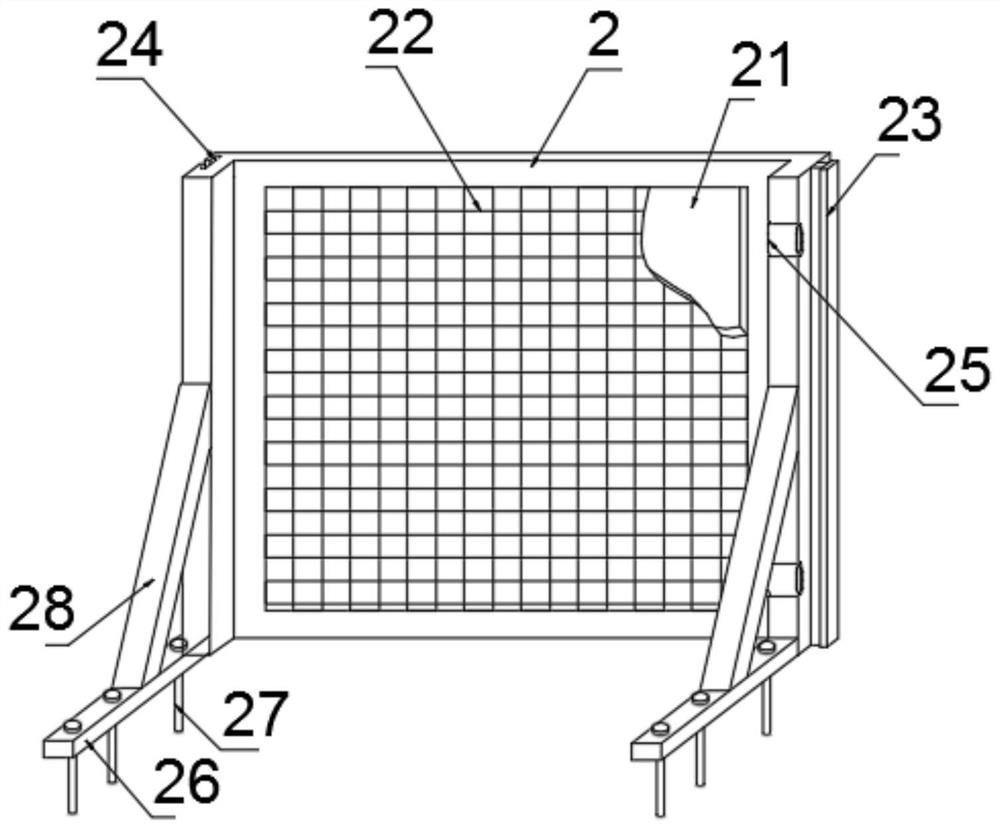

Highway bridge widening reconstruction project line-crossing protection structure

ActiveCN111441651AEasy to use for dust suppressionEasy to store and adjustUsing liquid separation agentFencingArchitectural engineeringStructural engineering

Owner:黑龙江省龙建路桥第一工程有限公司

Method and device for recovering soot generated in preparation process of copper-phosphorus brazing filler metal

PendingCN110180292ADirect synthesisAvoid consumptionHuman health protectionGas treatmentWater vaporPhosphoric acid

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD +1

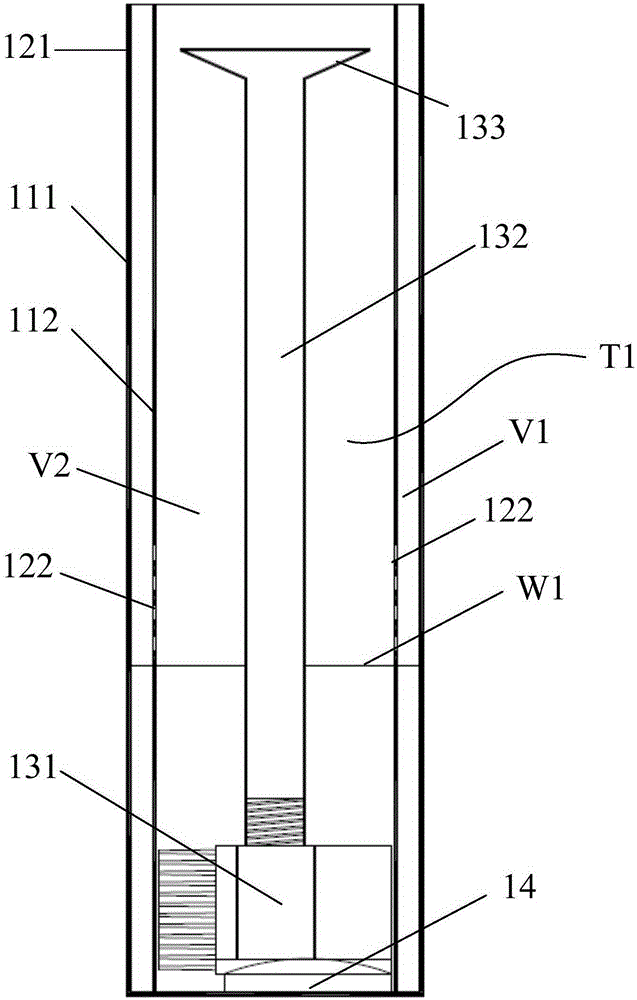

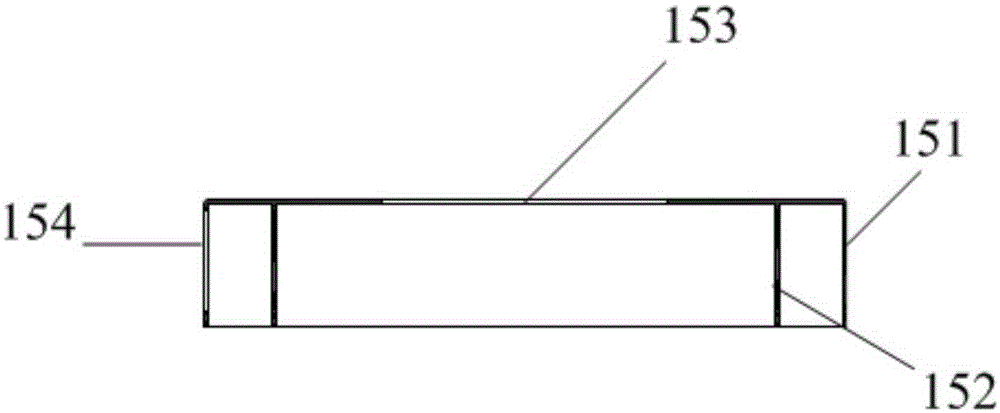

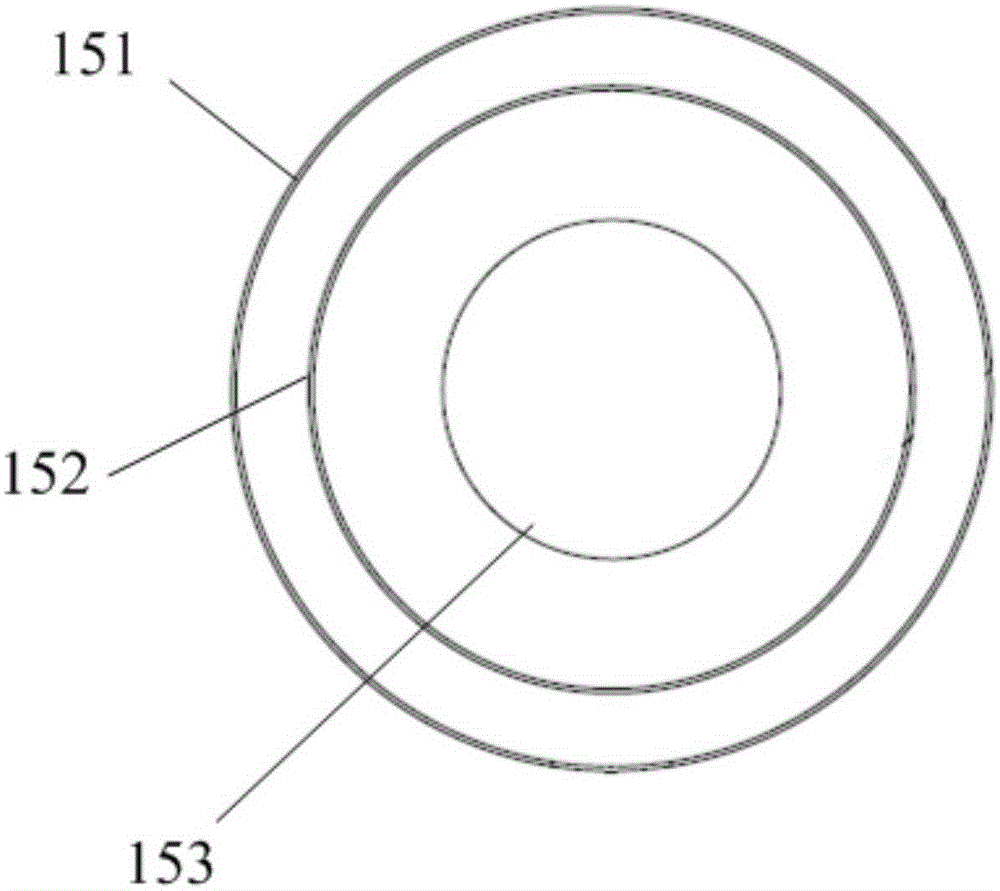

3D blaze humidifier

InactiveUS20140097550A1Easy to replaceIncrease volumeCarburetting airLighting and heating apparatusClosed chamberEngineering

A 3D blaze humidifier includes a box body. The box body is divided into an upper portion and a lower portion. The upper and lower portions are one-piece. The lower portion includes a fog generator, a closed chamber to collect fog and a separate water bottle. The upper portion includes an imitational charcoal bed, an elongated fog outlet, and an illumination unit under the elongated fog outlet. The separate water bottle can be taken out for replacement and cleaning and is a normal water bottle. The illumination unit generates fluttering blaze so that the blaze effect is almost real. The humidifier combines with the imitational blaze. The humidifier improves the function and single structure of the normal humidifier, and is novel, convenient for use and environment-friendly.A

Owner:QUANZHOU SHUNTONG CRAFTS

Dust collection device used at explosion site

InactiveCN108355456AFast and effective adsorption treatmentSmall working areaCombination devicesUsing liquid separation agentJackhammerArchitectural engineering

Owner:ANQING XIANGKE EXPLOSION ENG TECH

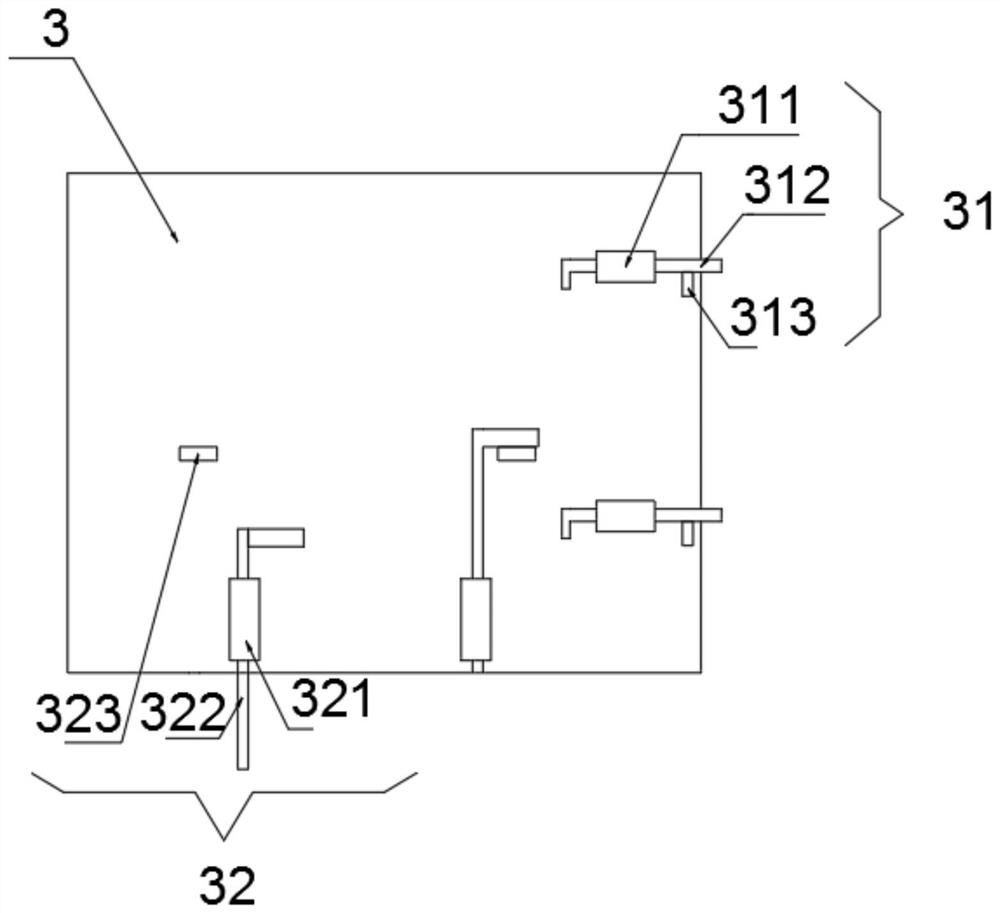

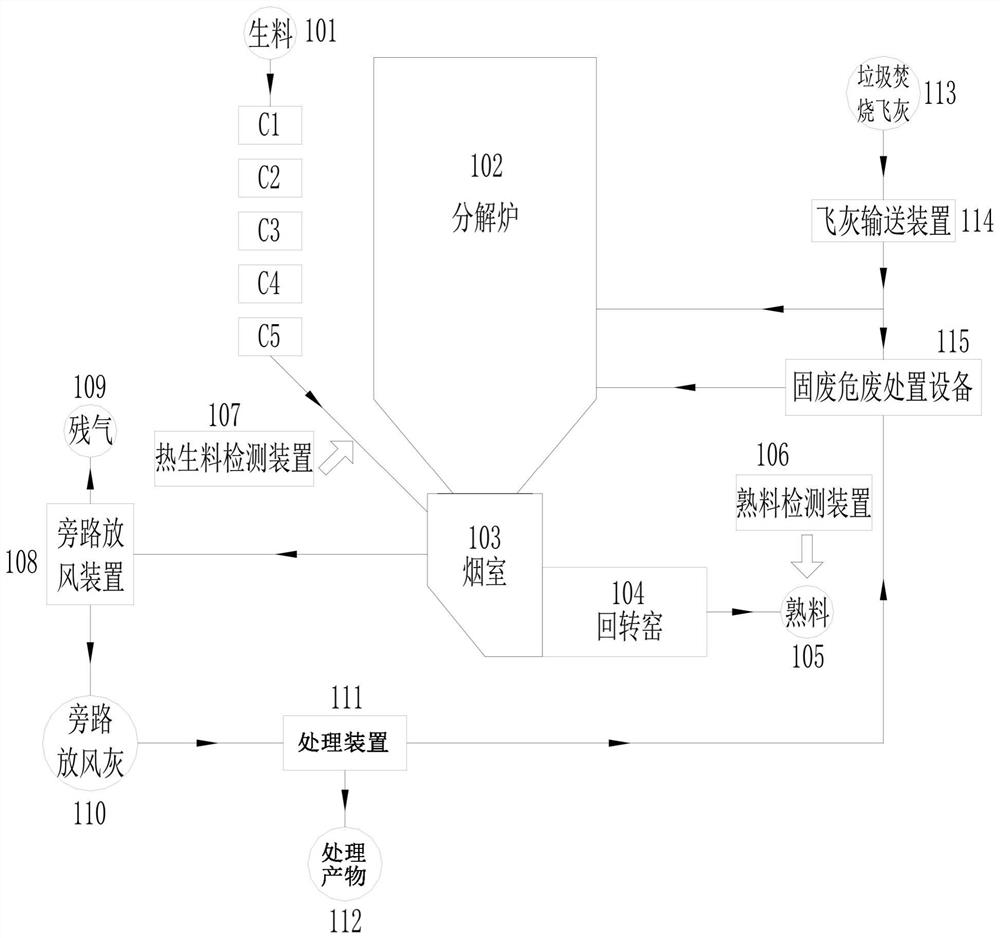

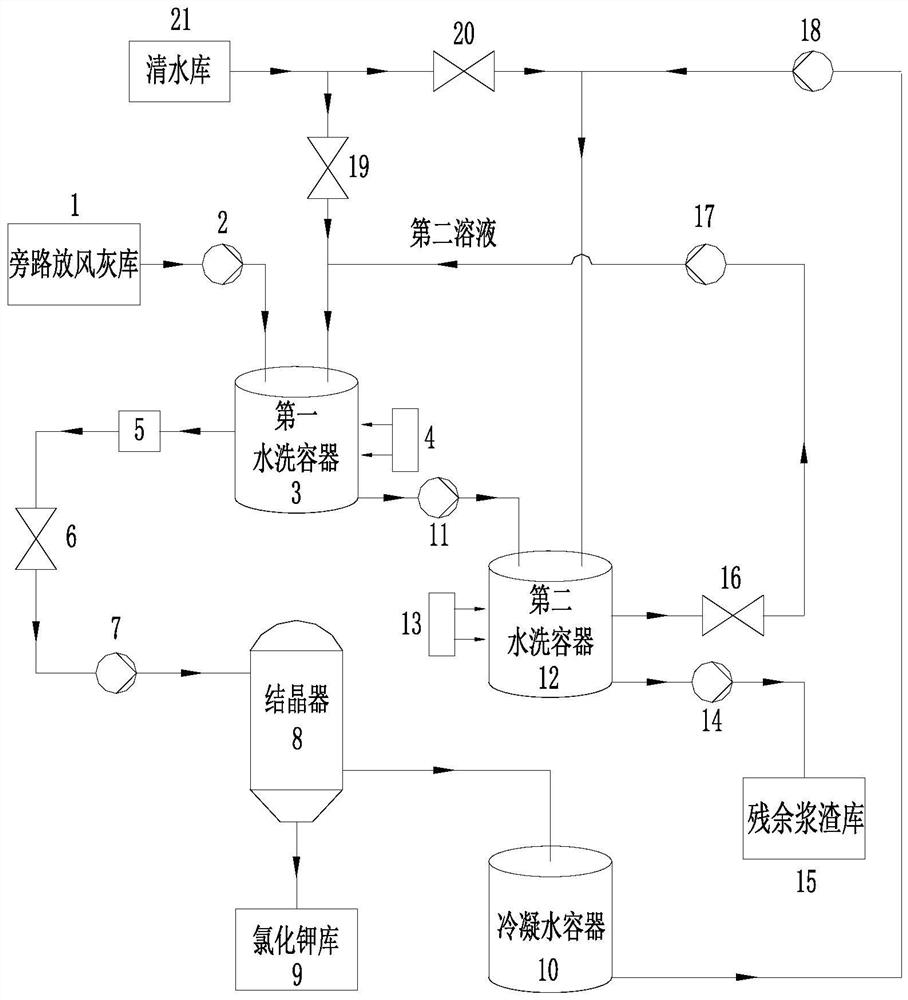

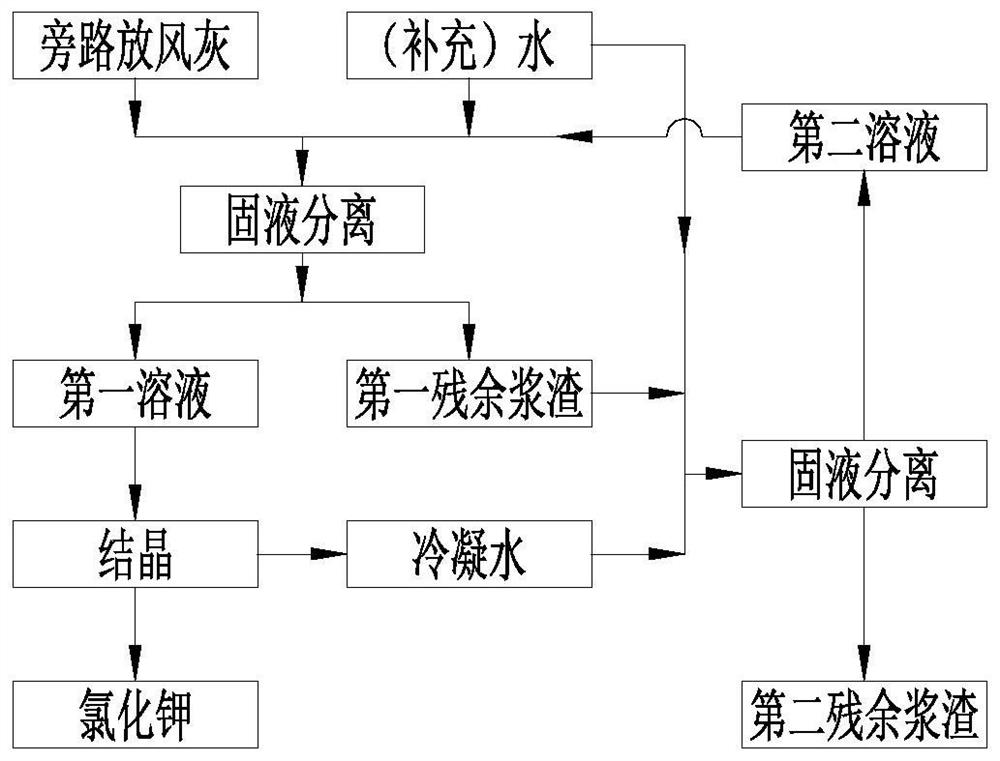

Method for monitoring and treating chlorine in cement clinker production system for co-treating waste incineration fly ash and cement clinker production system thereof

PendingCN114368922AReduce disposal costsReduce shipping costsMaterial analysis using wave/particle radiationUsing liquid separation agentClinker (waste)Process engineering

Owner:北京优巨源环保工程技术有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap