Clean production process and device for sulfur recycling and alkylated waste acid combined treatment

A technology of combined treatment of alkylation waste acid, applied in the direction of sulfur compounds, inorganic chemistry, sulfur preparation/purification, etc., can solve the problems of low conversion rate, emission can not meet the national requirements, etc., to reduce emissions and improve atomization effect, the effect of high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

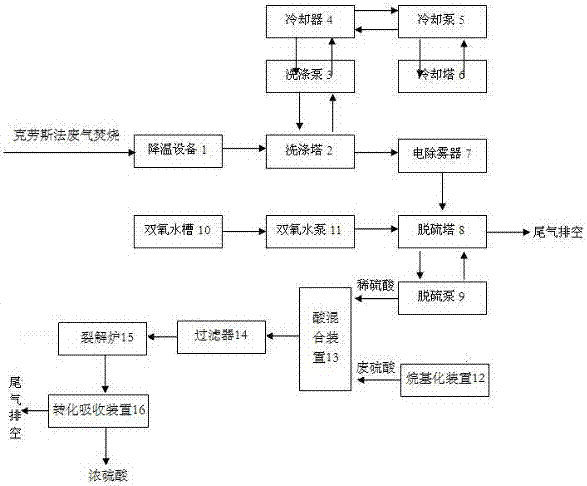

[0039] An oil refinery affiliated to a petrochemical group, Claus sulfur flue gas 7700Nm 3 / h,SO 2 Content 670mg / Nm 3 , H 2 The O content is 9.4%, and the temperature is 750°C. Firstly, 0.5MPa saturated steam is produced as a by-product of heat recovery by waste heat boiler, and the flue gas temperature is as low as 180°C; then, after washing and dust removal in the scrubber, the temperature is reduced to below 35°C, and the plate heat exchanger and cooling tower are used to indirect heat exchange and reduce circulation The temperature of the washing liquid; then the sulfur-containing flue gas passes through the electric demister to remove impurities such as water droplets and mist, and then enters the desulfurization tower, where it is sprayed and absorbed by hydrogen peroxide solution, and the SO in the tail gas 2 Reduced to 20mg / Nm 3 Next, empty the drain. As the desulfurization cycle absorbs, the concentration of dilute acid in the circulating fluid increases gradu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap