Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "Natural gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural gas (also called fossil gas) is a naturally occurring hydrocarbon gas mixture consisting primarily of methane, but commonly including varying amounts of other higher alkanes, and sometimes a small percentage of carbon dioxide, nitrogen, hydrogen sulfide, or helium. It is formed when layers of decomposing plant and animal matter are exposed to intense heat and pressure under the surface of the Earth over millions of years. The energy that the plants originally obtained from the sun is stored in the form of chemical bonds in the gas.

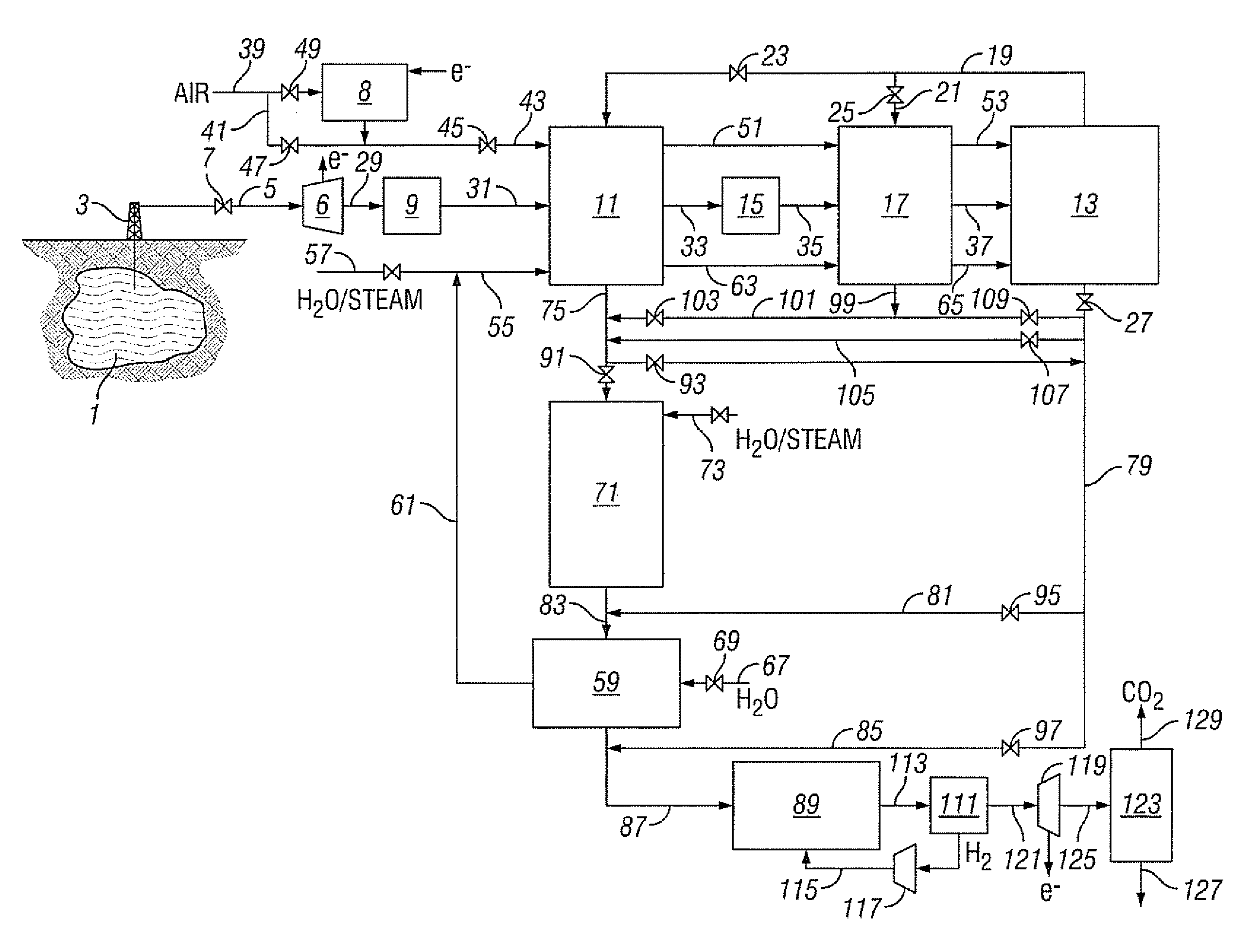

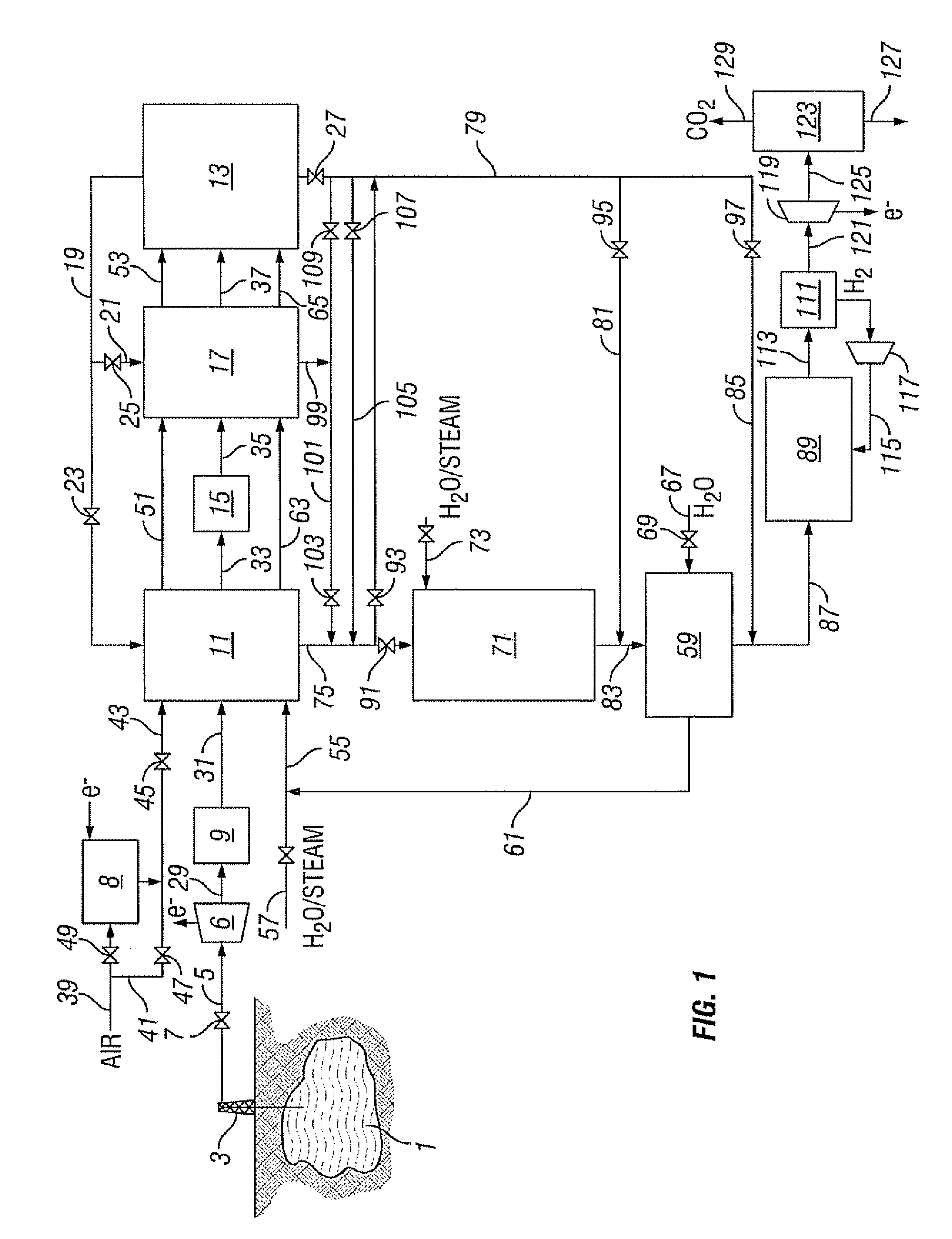

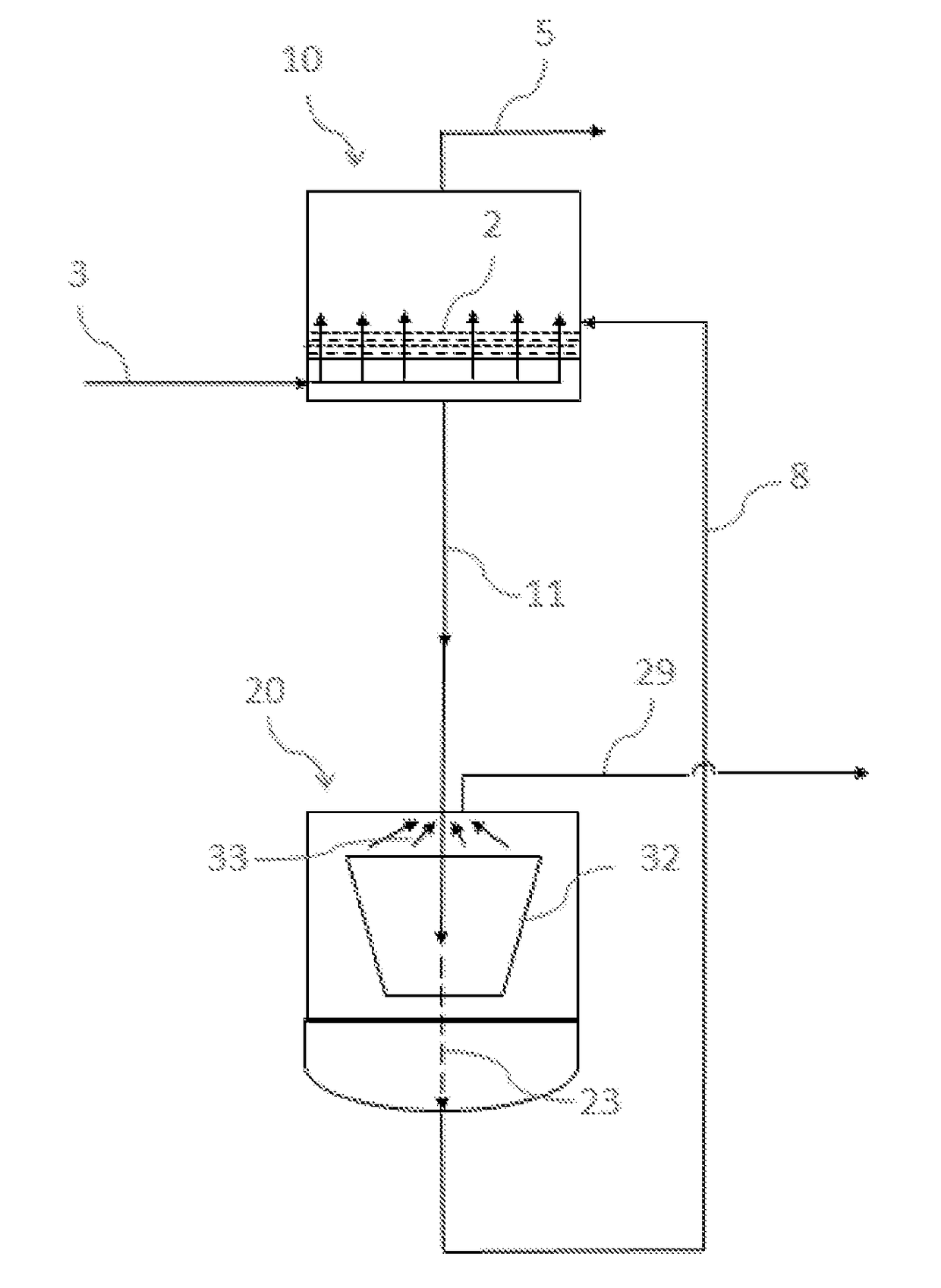

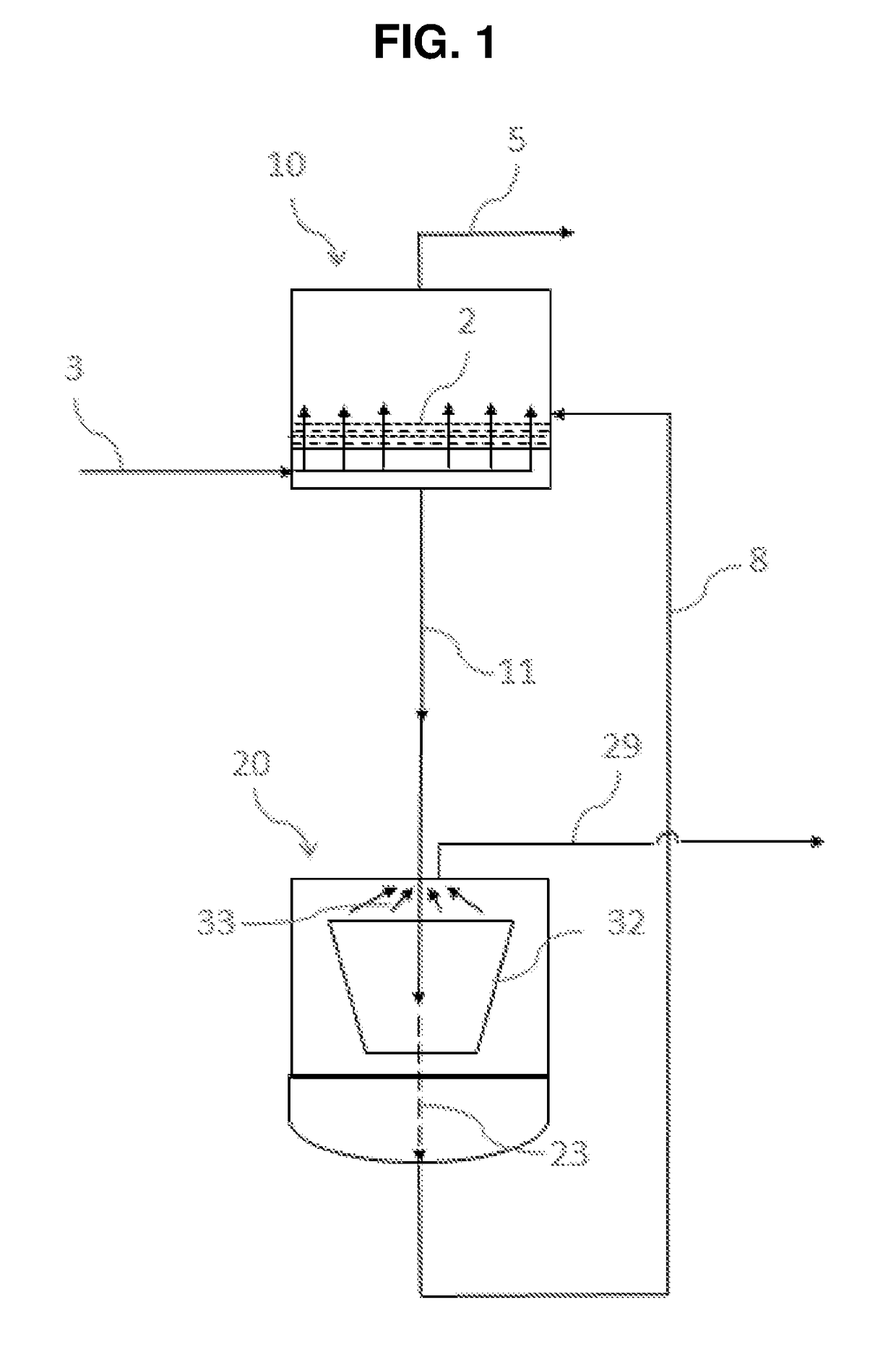

Method for recovering a natural gas contaminated with high levels of co2

Owner:SHELL OIL CO

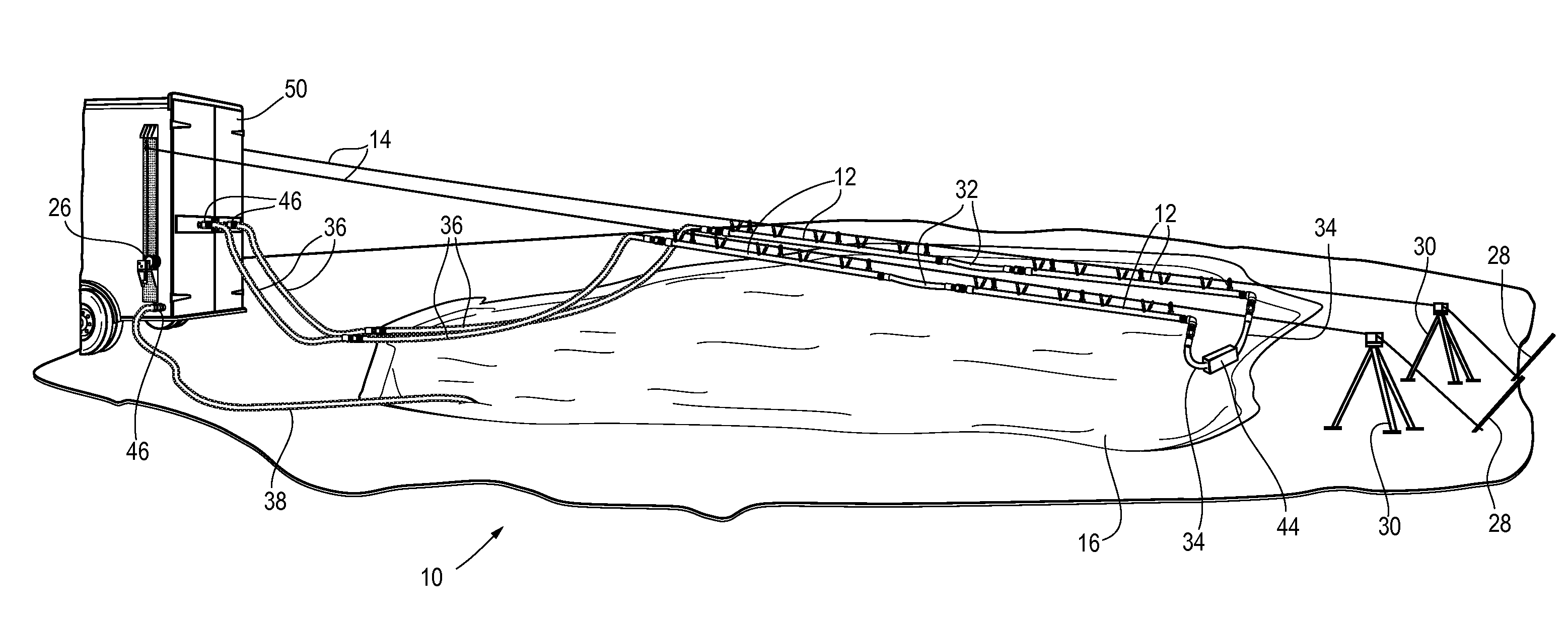

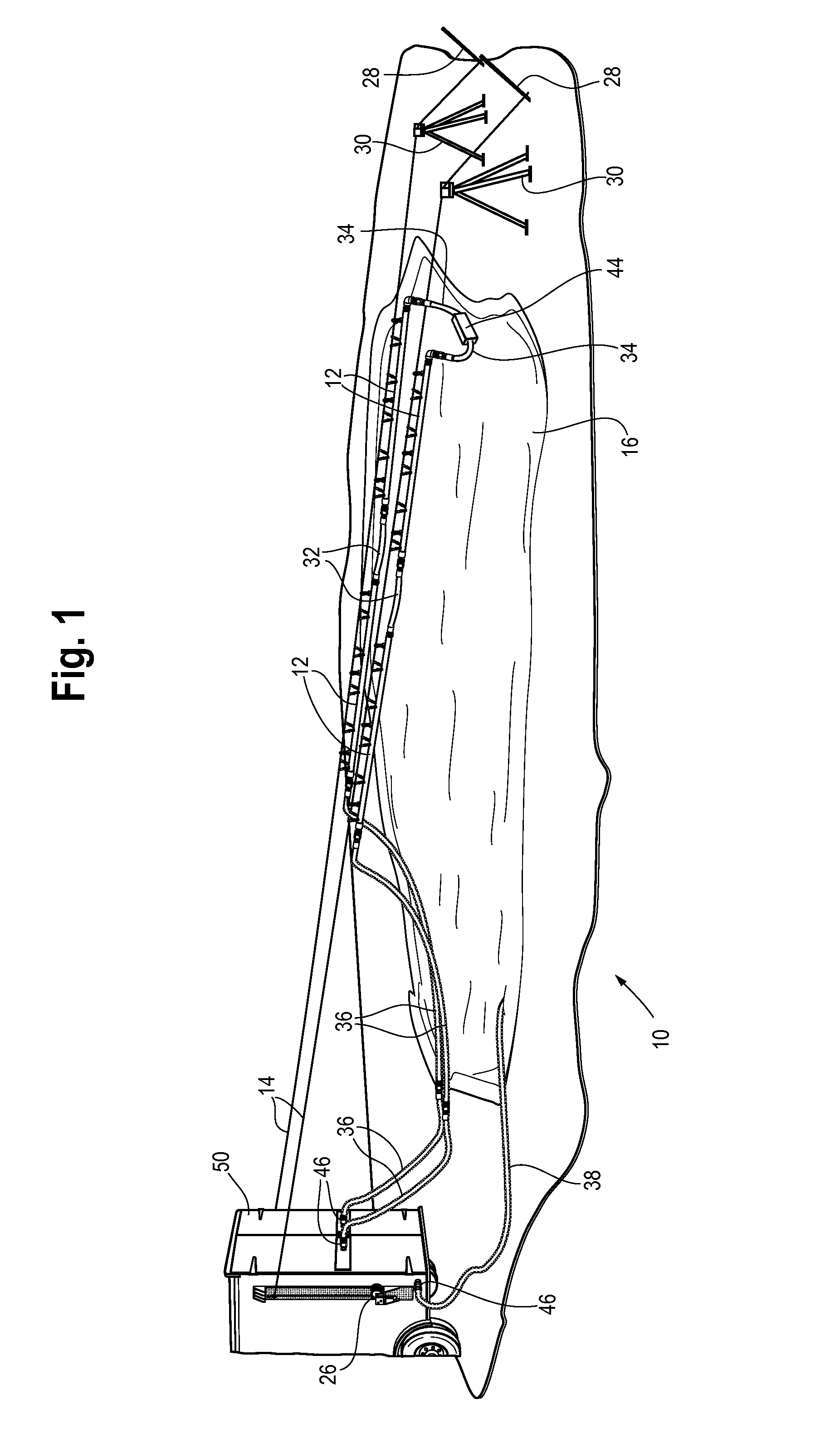

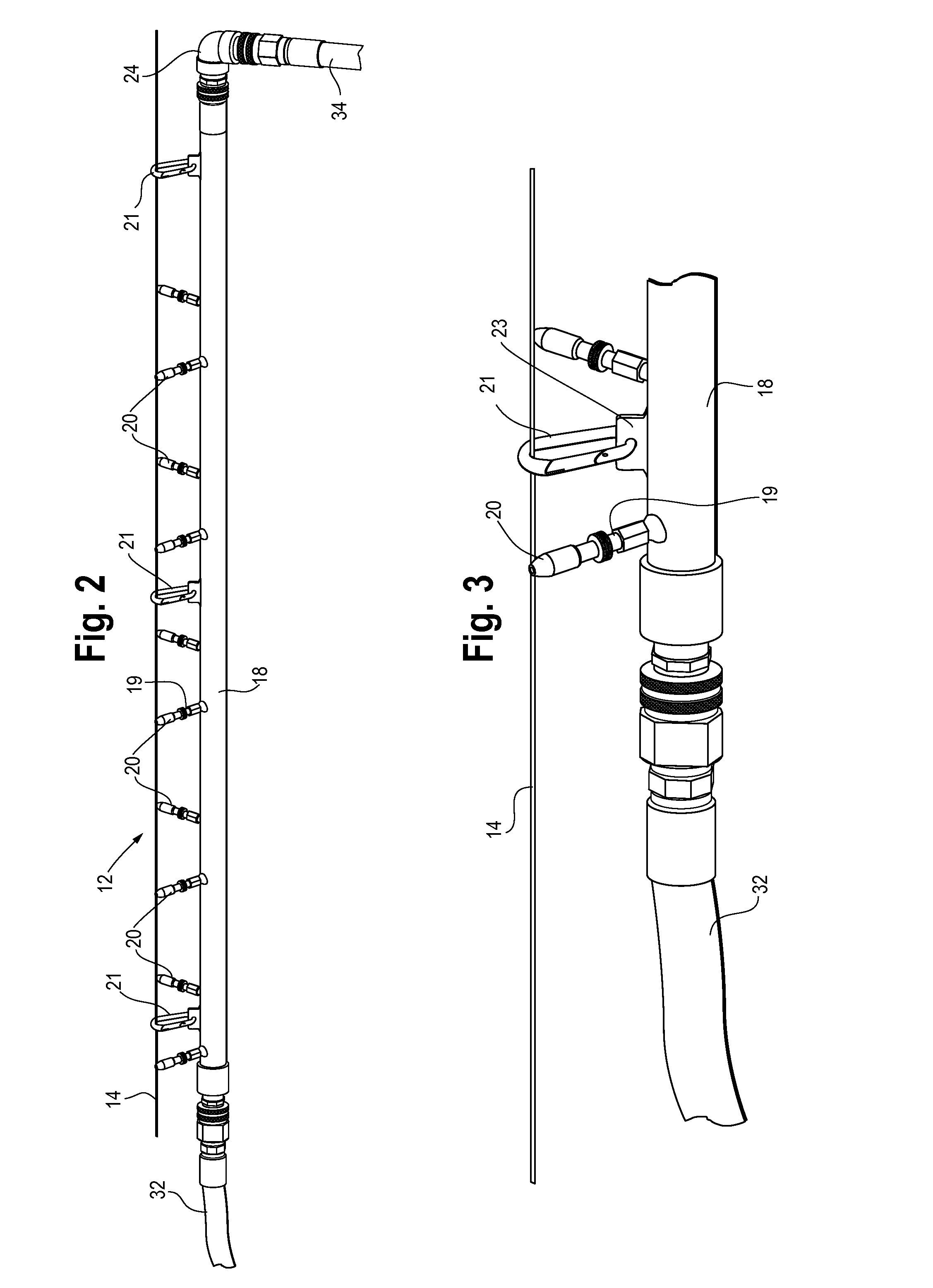

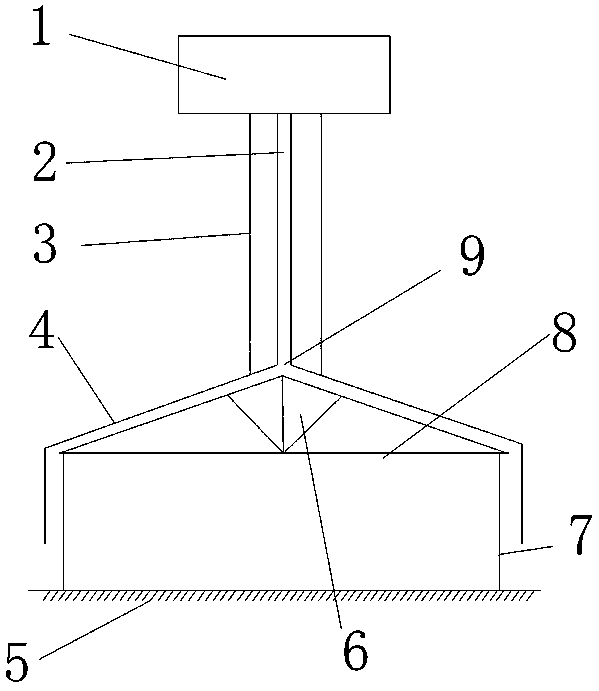

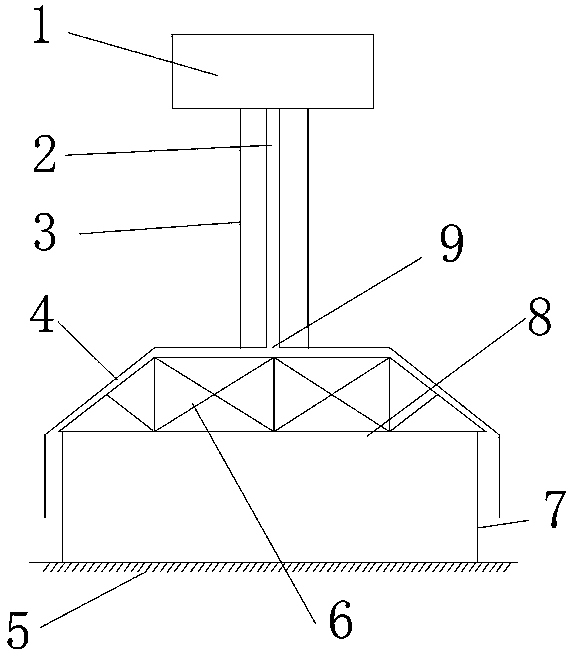

Water evaporation system using nozzles attached to a suspended cable

Owner:EVAPORITE SYST

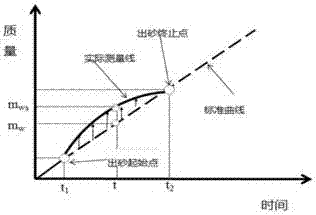

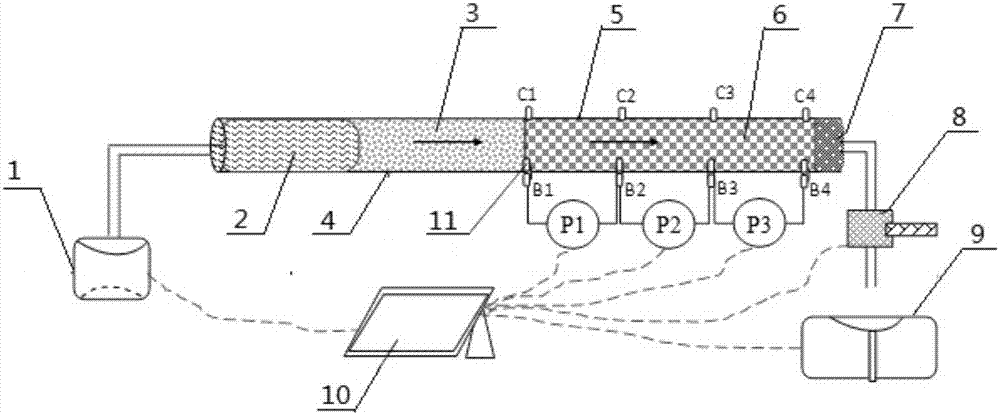

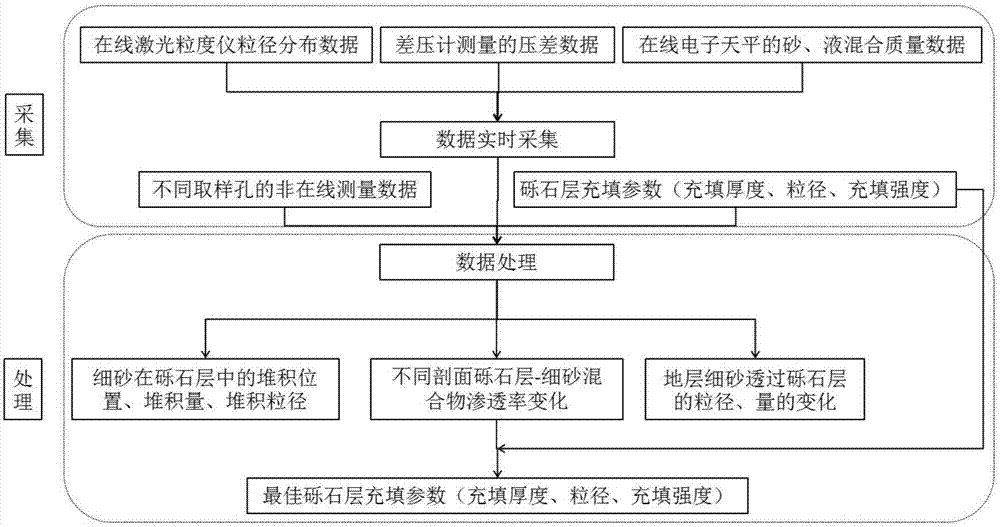

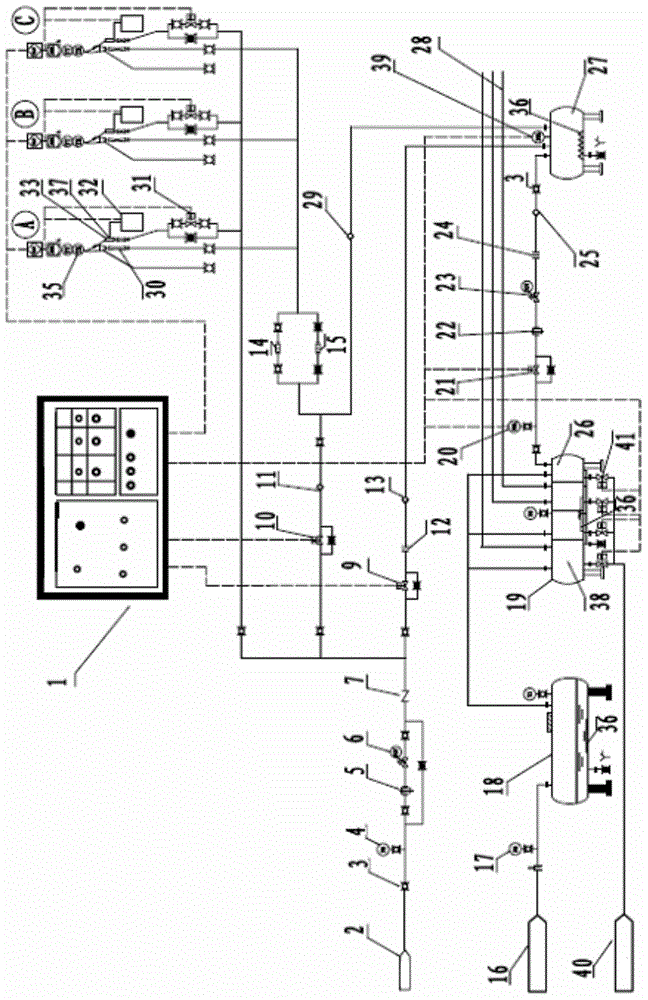

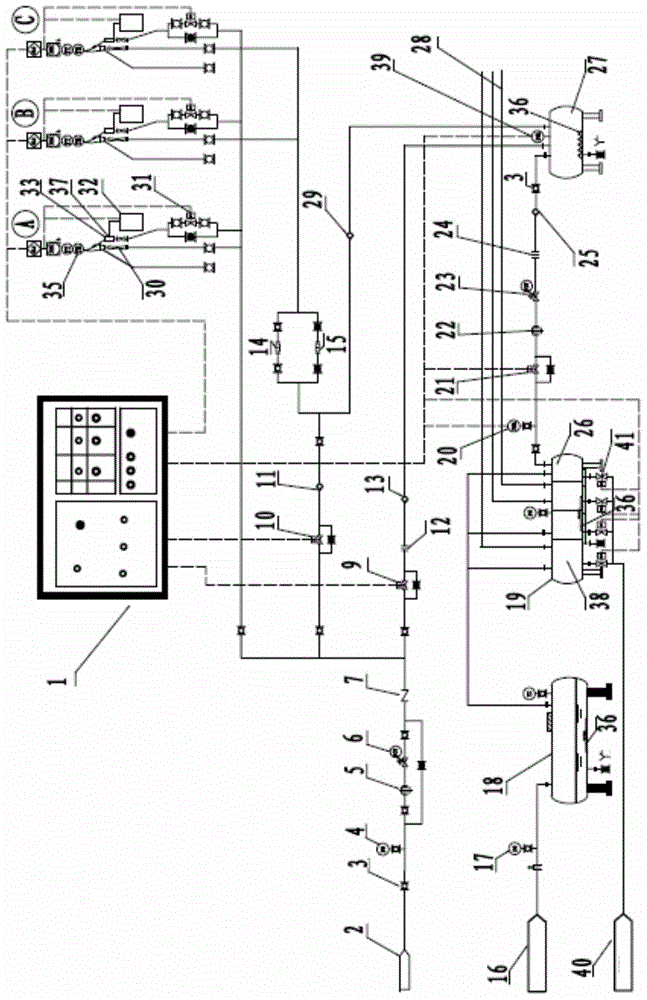

Test method for transport law of hydrate layer output fine sand in gravel layer and test device thereof

ActiveCN106932170AEasy to moveConvenient settling lawHydrodynamic testingResource developmentDifferential pressure

Owner:QINGDAO INST OF MARINE GEOLOGY

Preparation method of sialite binding material for well-cementing in oil-gas field

The invention discloses a preparation method of a sialite binding material for well-cementing in an oil-gas field, which belongs to the field of oil and gas development. The preparation method comprises the steps of mixing (by weight percentage) cement clinker 0-45%, granular blast-furnace cinder 55-95% and pulverized fuel ash 0-5%, and grinding together; mixing (by weight percentage) the ground mixed material 30-59.5%, pulverized fuel ash, coal-fired furnace cinder burnt clay or red mud 40-60% and a diagenetic agent, and grinding together; and mixing (by weight percentage) the ground mixed material 80-95% and ground expanded vermiculite 5-15% to obtain the sialite binding material for well-cementing. The preparation method is not only in favor of solving various problems in well-cementing in the oil-gas field, but also remarkably reduces emission of CO2 and other pollutants compared with that in the conventional oil-well cement production.

Owner:TSINGHUA UNIV +1

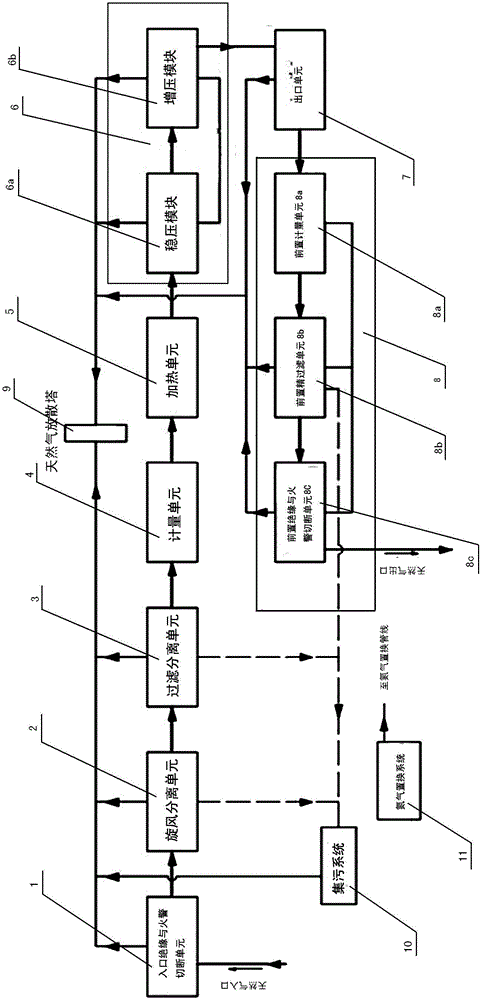

Natural gas pressure regulator station system

Owner:SHANGHAI SAFBON WATER SERVICE CO LTD

Ignition system and ignition method of energy-saving eternal lamp utilizing exhaust gas

ActiveCN104421960AReduce energy consumptionReduce pollutionElectric spark ignitersIncinerator apparatusEngineeringNatural gas

Owner:北京融茂福元科技有限公司

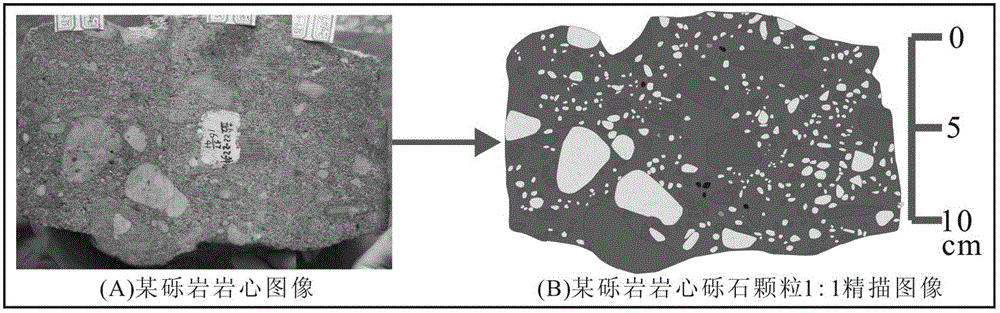

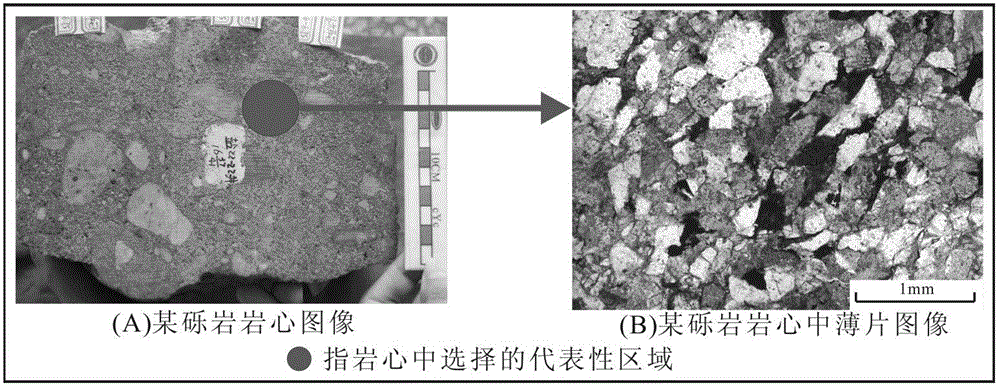

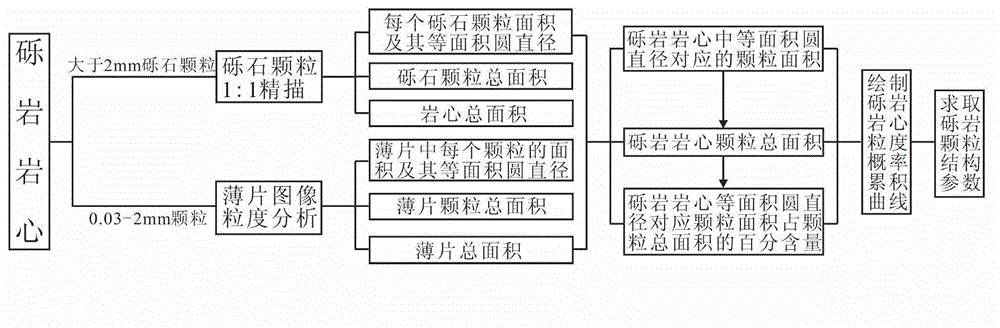

Analytical method for particle size in conglomerate core particle structure

ActiveCN103149130AAccurately obtain granular featuresParticle size analysisMacroscopic scaleChemical physics

Owner:东营市大学科技园发展有限责任公司

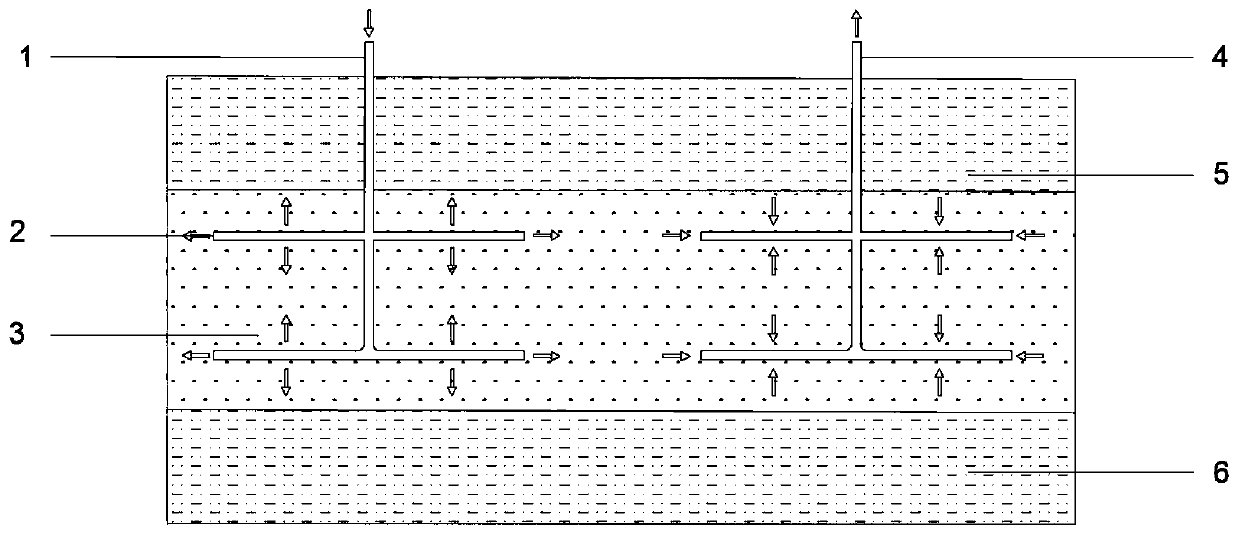

Carbon dioxide inhibitor-combined natural gas hydrate replacement mining method

InactiveCN109915094AExtend build timeIncrease the spread distanceFluid removalPressure differenceInjection well

Owner:DALIAN UNIV OF TECH

Energy scheduling management method and device, readable medium and electronic equipment

ActiveCN109829633AReasonable managementInternal combustion piston enginesResourcesEnergy schedulingTransport network

The invention discloses an energy scheduling management method and device, a readable medium and electronic equipment. The method comprises the steps of obtaining energy operation data of a transportnetwork composed of at least one gas source and at least one gas station; Obtaining vehicle scheduling data of a carrier corresponding to the transport network; Forming an energy efficiency model corresponding to the transport network according to the energy operation data and the vehicle scheduling data; The energy efficiency model is optimized to determine energy scheduling data for the transport network. Through the technical scheme of the invention, the scheduling condition of the natural gas can be managed more reasonably.

Owner:XINAO SHUNENG TECH CO LTD

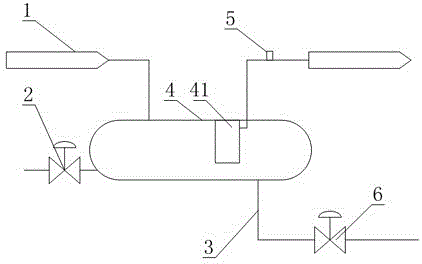

Natural gas differential pressure energy recovery unit device

InactiveCN105757455AQuick meshEasy to separatePipeline systemsSteam engine plantsElectricityDifferential pressure

The invention provides a natural gas differential pressure energy recovery unit device which is arranged between a natural gas inlet pipeline and a natural gas low pressure equipment pipeline.The device comprises a turbo expander, a gas inlet pipeline of the turbo expander is connected with the natural gas inlet pipeline, an exhaust pipeline of the turbo expander is connected with the equipment pipeline in need of natural gas, the turbo expander is further connected with a clutch, an output shaft of a motor is coaxially connected with a compressor, and the other end of the motor is coaxially connected with the turbo expander through the clutch.Compared with the prior art, the turbo expander of the natural gas differential pressure energy recovery unit device and a pressure regulator subcircuit are arranged in parallel, when the turbo expander breaks down and the clutch separates quickly, a gas circuit can be switched to the pressure regulator subcircuit rapidly, and normal operation of a system is not influenced.Through arrangement of the turbo expander, a pressure regulator can be effectively replaced to achieve the function of lowering the pressure, meanwhile, action is conducted outward, the compressor is driven to run, self-consumed electricity is effectively reduced, and full utilization of energy is achieved.

Owner:HUADIAN ZHENGZHOU MECHANICAL DESIGN INST

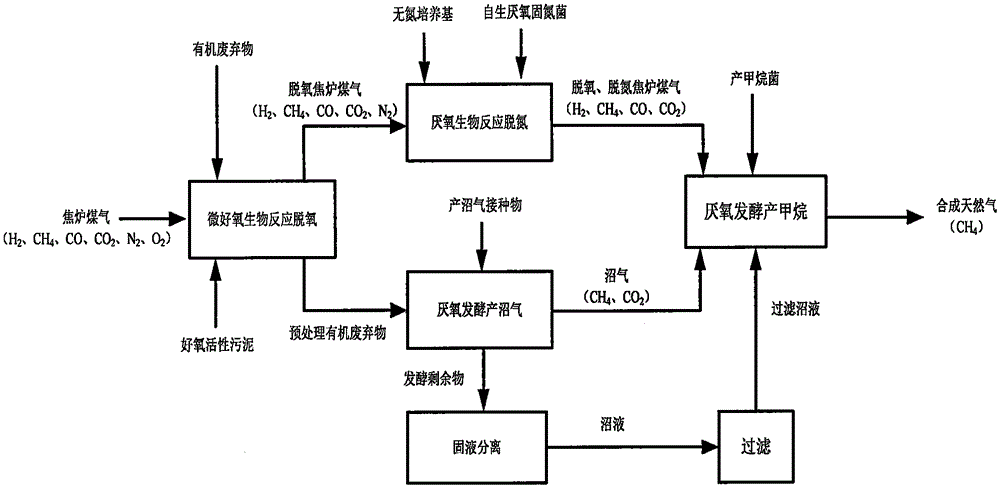

Method for biologically synthesizing natural gas from coke oven gas

ActiveCN105623761AHigh yieldGas production bioreactorsGaseous fuelsActivated sludgeBiogas production

Owner:CHENGDU ZHONGKE ENERGY & ENVIRONMENTAL PROTECTION CO LTD

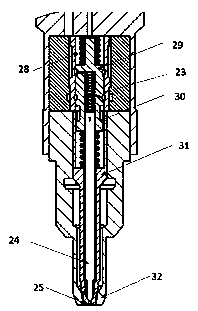

Hydraulic cutting device for deep sea cutting sleeve

Owner:YANGTZE UNIVERSITY

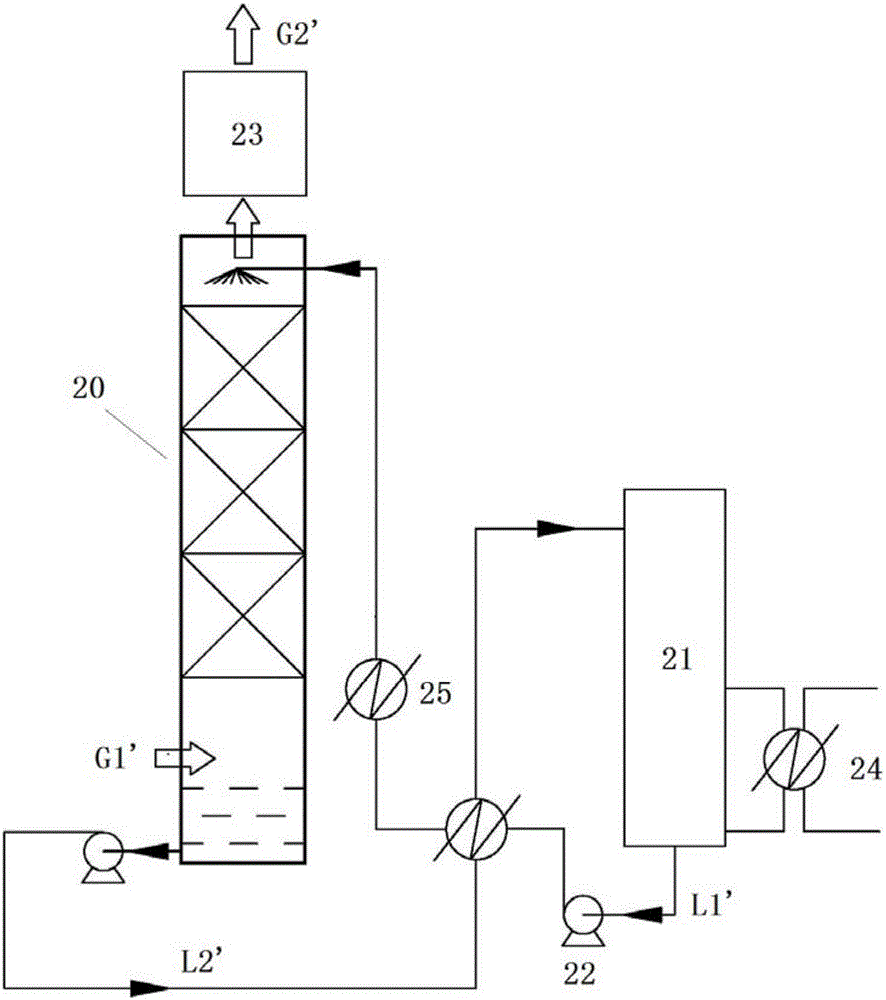

Ionic liquid dehumidifying method and system for regulating gas humidity

InactiveCN106076078AEfficient removalQuick removalGas treatmentDispersed particle separationHigh humidityIonic liquid

Owner:SUZHOU MOEWE ENVIRONMENTAL ENG CO LTD

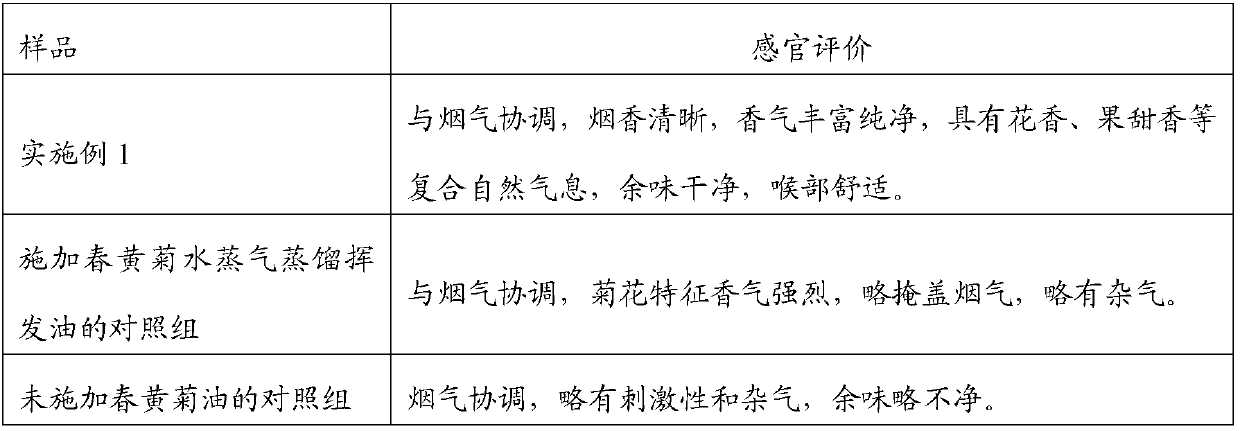

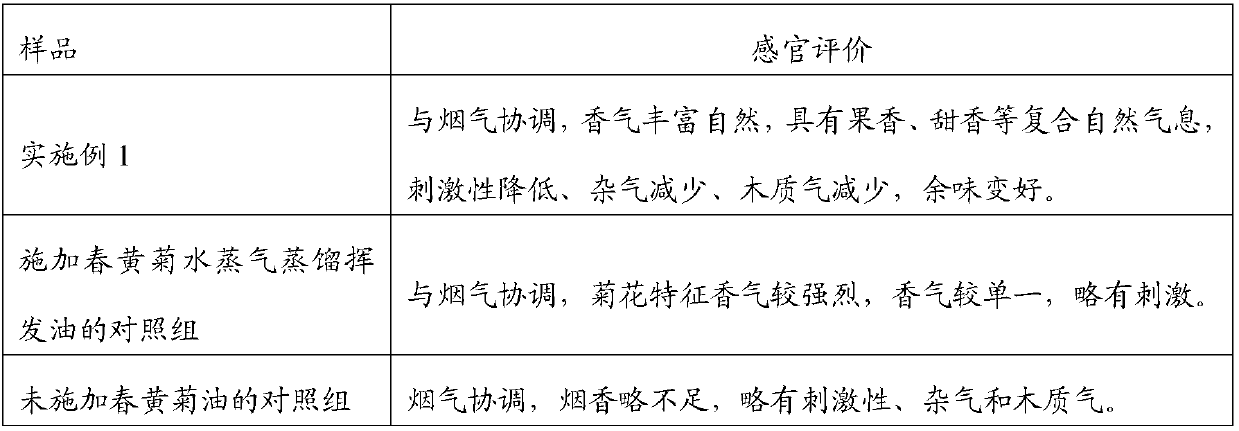

Method for improving euryops pectinatus oil aroma quality and application thereof

InactiveCN107699352ALarge fermentation hydrolysis degreeImprove extraction efficiencyTobacco preparationEssential-oils/perfumesWater vaporIrritation

Owner:HUBEI CHINA TOBACCO IND

Cooling circulating system, natural gas liquefaction device, operation method and improvement method of cooling circulating system

The invention provides a cooling circulating system (61). The cooling circulating system (61) is equipped with a refrigerant compressor (1) for compressing a refrigerant, a condenser (10) for cooling and condensing the refrigerant which is compressed by the refrigerant compressor (1), a reservoir (11) for accommodating the refrigerant which is condensed by the condenser (10), dilation mechanism (18) for dilating the refrigerant from the reservoir (11), an evaporation mechanism (19) for cooling an object to be cooled by heat exchange with the refrigerant which is dilated by the dilation mechanism (18) and vaporizing the refrigerant which is provided by the refrigerant compressor (1), and an auxiliary cooling mechanism (62) which is equipped with a line (47) for an auxiliary refrigerant to flow in and run through the reservoir (11) and cools the refrigerant in the reservoir (11) by the heat exchange with the refrigerant which flow in the line (47) before the refrigerant compressor (1) is started. Therefore, the power for starting the refrigerant compressor can be reduced, and the refrigerant compressor can be stably started by a drive source with a small torque.

Owner:HITACHI LTD

Photon energy vehicle energy-saving device and manufacturing method thereof

ActiveCN103174558AIncrease burn rateIncreased durabilityCombustion-air/fuel-air treatmentMachines/enginesCarbonizationEngineering

The invention discloses a photon energy vehicle energy-saving device and a manufacturing method thereof. The device comprises an air ionizing device and an oil way fine molecularization device. The air ionizing device comprises an outer pipe, side slant wings, a circular air pipe and rhombic air pipes, wherein the number of the side slant wings is plural, the side slant wings are arranged on the outer pipe, the circular air pipe is arranged at the center position of the outer pipe, the rhombic air pipes comprise a plurality of groups, and each group of rhombic air pipes is connected between the circular air pipe and the outer pipe. The oil way fine molecularization device comprises an outer shell, two air guide sleeves, two ceramic bodies and a net structure, wherein the two air guide sleeves are arranged in the outer shell, the two ceramic bodies are respectively connected with the two air guide sleeves, the net structure is arranged between the two ceramic bodies, and connecting bodies are arranged at two ends outside the outer shell. The vehicle energy-saving device has the functions of catalysis fission on petroleum and natural gas, and is capable of achieving ultramicro atomization combustion, improving combustion efficiency, increasing energy, reducing oil consumption or gas consumption, reducing formation of tiny dust, reducing emission of noxious gas such as carbon monoxide and hydrocarbon and achieving energy saving, emission reduction and energy increasing.

Owner:刘贡友

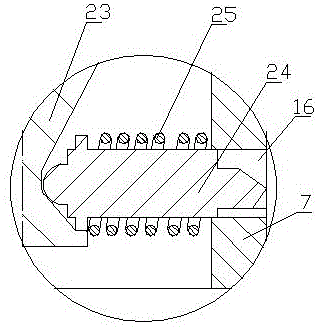

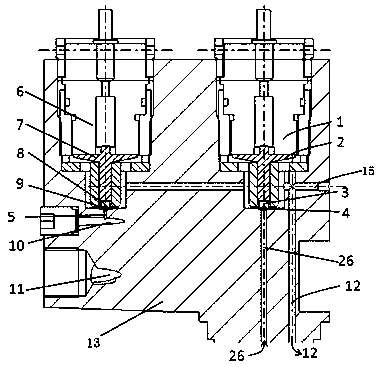

Intake and exhaust valve raceway and intake and exhaust valve assembly of engine

ActiveCN106282783AReduce wearSolve the problem of gap exceptionMachines/enginesLift valveExhaust valveHeat resistance

The invention relates to an intake and exhaust valve raceway and intake and exhaust valve assembly of an engine. The intake and exhaust valve raceway and intake and exhaust valve assembly comprises an intake valve raceway of the engine and an intake valve matched with the intake valve raceway and an exhaust valve raceway and an exhaust valve matched with the exhaust valve raceway; the intake and exhaust valve raceways contain materials of Ni-Co-Mo-Cr and are manufactured by adopting a powder metallurgy technique; the main contents of the intake valve are Cr-Si-Mn-P or Cr-Mn-Ni-N; the main contents of the exhaust valve are Cr-Mn-Ni-Nb-W, or bead welding is performed on the disc part of the exhaust valve with the materials of Cr-W-Ni-Fe-Mo; and the problem of mechanical tappet clearance abnormity of the natural gas engine is solved by lowering abrasion loss between the intake valve raceway and the intake valve as well as abrasion loss between the exhaust valve raceway and the exhaust valve. According to the intake and exhaust valve raceway and intake and exhaust valve assembly, abrasion-resistance, heat-resistance and radial crushing strength of the intake valve raceway and the exhaust valve raceway are improved; and quality problems of valve clearance abnormity and the like caused by abnormal abrasion and deformation between the intake valve raceway and the intake valve as well as between the exhaust valve raceway and the exhaust valve are solved.

Owner:SMAPOW ENGINE

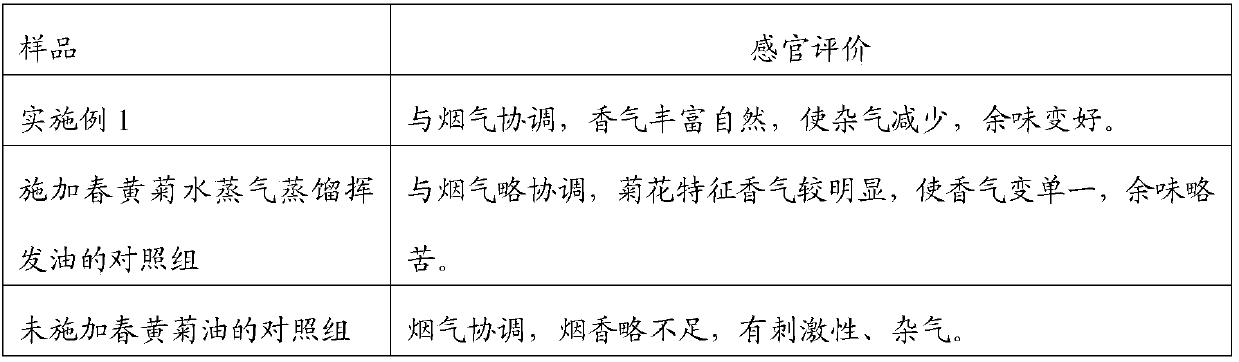

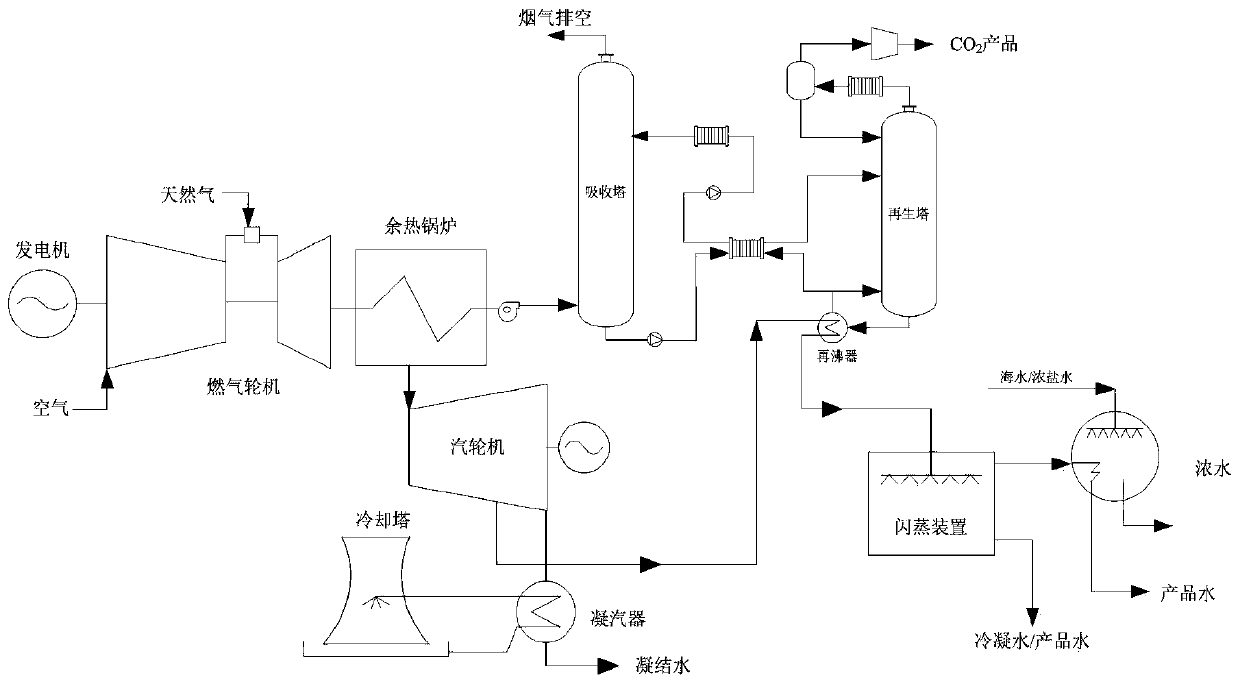

Steam waste heat gradient utilization system for carbon capture absorbent regeneration system

InactiveCN111420516AReduce the temperatureMake full use of waste heatDispersed particle separationSteam useReboilerWater circulation

Owner:北京中冶设备研究设计总院有限公司

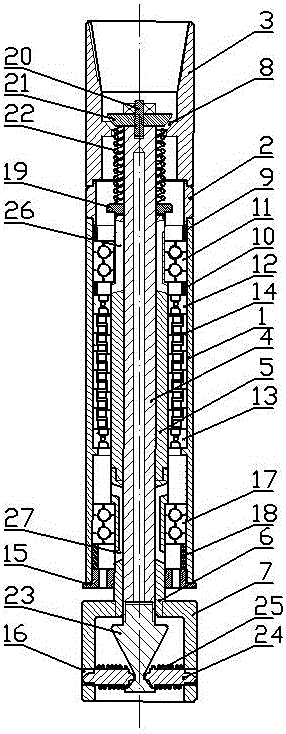

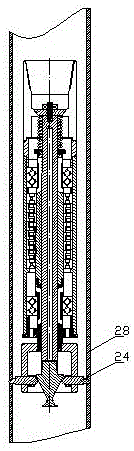

Tubular column lowering power tractor with well grinding and repairing function

InactiveCN103321576AOvercome the problem of not being able to rotate casing stringsIncrease success rateDrilling machines and methodsDrive shaftCasing string

Owner:SOUTHWEST PETROLEUM UNIV

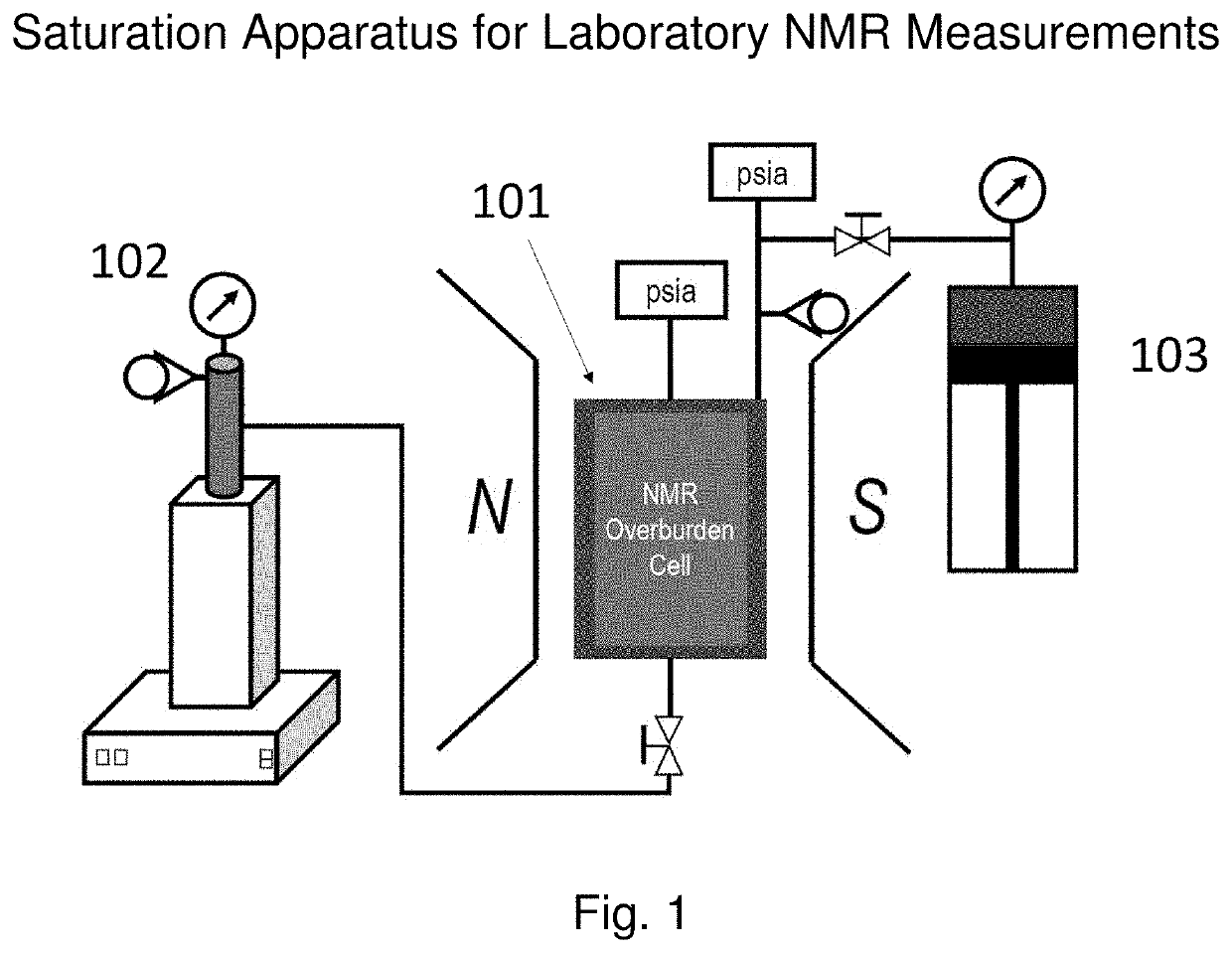

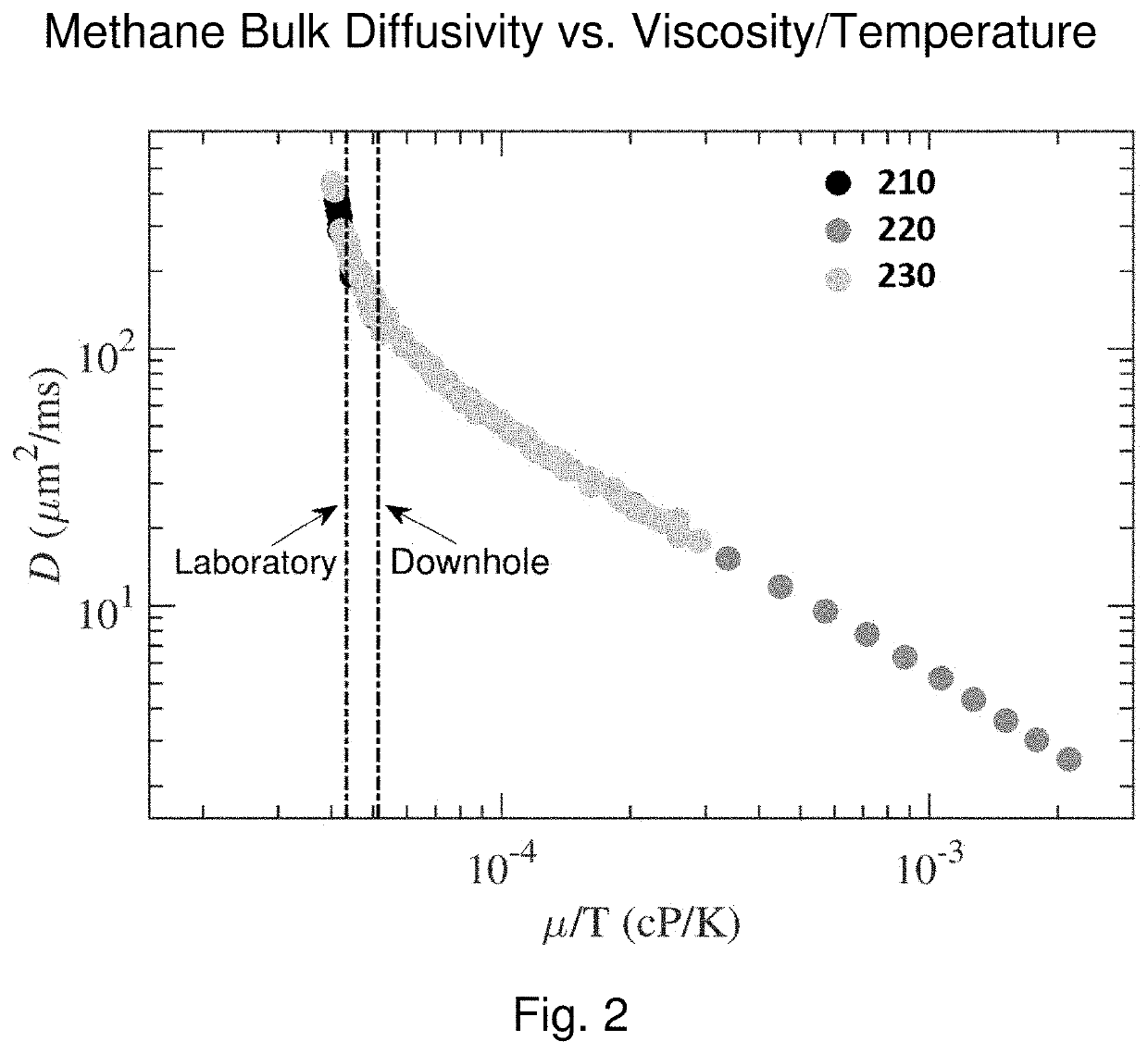

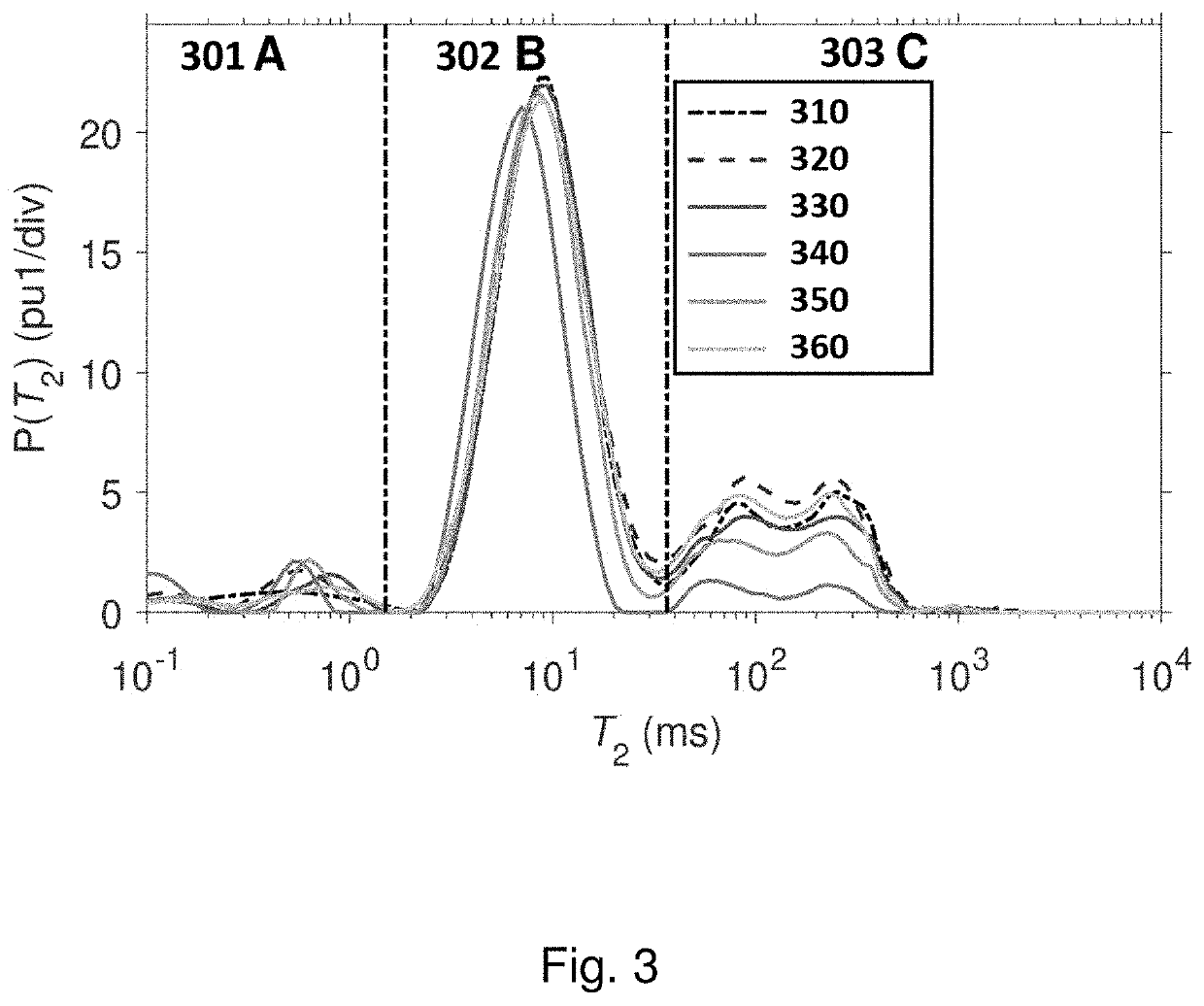

Method for determining the composition of natural gas liquids, mean pore-size and tortuosity in a subsurface formation using NMR

ActiveUS11099292B1Big contrastError minimizationElectric/magnetic detection for well-loggingEarth material testingNMR - Nuclear magnetic resonancePhysical chemistry

Owner:VINEGAR TECH LLC +1

Resin sand for casting shape and sand core of natural gas power cylinder body

InactiveCN103551493AMeet casting requirementsHigh dimensional accuracyFoundry mouldsFoundry coresNatural gasPolyresin

The invention discloses resin for casting a shape and a sand core of a natural gas power cylinder body, and aims at solving the problem that the shape and sand core of the natural gas power cylinder body cast by existing resin sand have casting defects such as low accuracy, poor surface smoothness, sand inclusion and sand expansion. The resin sand comprises crude sand, resin and a curing agent. According to the resin sand, the accuracy of the boundary dimension of a casting can be improved, the surface smoothness is also improved, the casting defects such as sand inclusion and sand expansion are reduced, the quality of the casting is improved, and casting requirements of the natural gas power cylinder body are met.

Owner:CNPC JICHAI POWER EQUIP

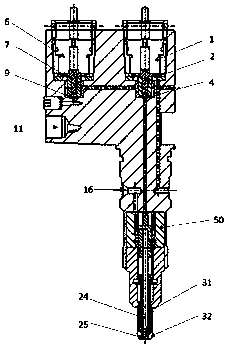

Natural gas and diesel injector of novel control mode

PendingCN109058013AAchieve independent controlRealize independent injectionFuel injection apparatusMachines/enginesDiesel injectorMagnetic valve

Owner:英嘉动力科技无锡有限公司 +1

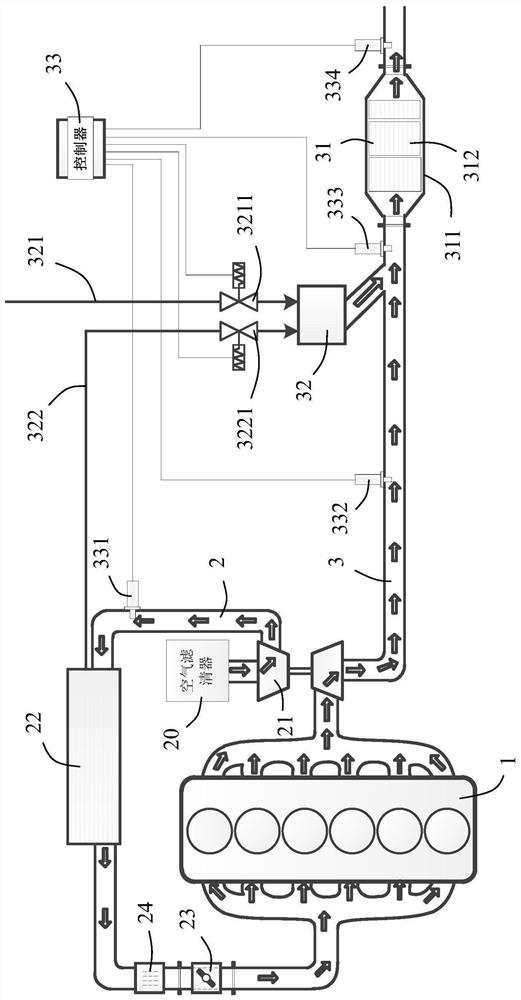

Tail gas after-treatment assembly and system for natural gas engine

PendingCN111852626AIncrease temperatureImprove conversion efficiencyInternal combustion piston enginesExhaust apparatusCombustorPtru catalyst

Owner:TENNECO SUZHOU EMISSION SYST

Method for cracking strata with organic materials to improve recovery ratio of adjacent oil-bearing reservoir stratum

The invention relates to a method for cracking a strata with organic materials to improve the recovery ratio of an adjacent oil-bearing reservoir stratum. The method comprises the following steps that(1), heat is injected to an organic shale, and the shale is heated to above 150 DEG C; (2), CO2, and C2 to C5 light hydrocarbon gases produced by initial cracking of organic materials are conveyed toadjacent oil-bearing reservoir stratum, the pressure of the oil-bearing reservoir stratum increases, contained oil is completely soluble with the CO2 and the light hydrocarbon, and therefore gas flooding and CO2 / light hydrocarbon miscible enhanced oil recovery is formed; (3), crude oil in the oil-bearing reservoir stratum is produced from an oil production well installed in the reservoir stratum;(4), the heat is continuously injected to the shale, the temperature rises to above 320 DEG C, volume gas and light oil are generated and are produced through the oil production well mounted in the shale; and (5), during the termination of shale oil production, the oil production well with the oil-bearing reservoir stratum is started again, gas flooding of oil-bearing reservoir stratum is carriedout by natural gas continuously produced the shale at high temperature, and therefore the recovery ratio of the oil-bearing reservoir stratum is maximized. The high recovery ratio is obtained, and fracture to the oil-bearing reservoir stratum is not required. The economic benefits are obviously improved.

Owner:ANMAN SHALE TECH CO LTD

Drying oven with double air channels for heat setting machine

InactiveCN104420037AReduce resistanceUniform and stable airflowTextiles and paperEnvironmental resistanceProcess engineering

The invention discloses a drying oven with double air channels for a heat setting machine. The drying oven comprises a heat-insulation oven body and two hot-air blowing devices. The hot-air blowing devices are positioned in the heat-insulation oven body, a heat-insulation door is arranged on the heat-insulation oven body, the hot-air blowing devices are connected with a flow guide plate, the flow guide plate is connected with air outlets of a fan, air inlets of the fan are sequentially connected with a natural gas heating system, and the two hot-air blowing devices are respectively positioned above and below needle plates. The drying oven has the advantages that the flow guide plate is arranged at the air outlets of the fan and is connected with the hot-air blowing devices, the double air channels can be formed by the two hot-air blowing devices, the two hot-air blowing devices are respectively positioned above and below the needle plates, accordingly, airflow can uniformly smoothly flow, resistance on the airflow can be reduced, and heat setting effects can be guaranteed; the drying oven is provided with the natural gas heating system and is high in heating-up speed, the heating-up preparation time of the drying oven can be shortened, the drying oven is low in pollution and easy to maintain, the energy utilization rate of the drying oven can be maximized, accordingly, production requirements can be met, the production cost can be greatly reduced, integral production procedures are environmental friendly, and energy can be saved in the integral production procedures.

Owner:WUXI CITY HUAYANG DYEING & FINISHING MACHINERY

Metering device for condensate natural gas pipelines facilitating use of turbine flowmeter

InactiveCN105136214AEasy to measureEasy to control the opening and closing stateGaseous fuelsVolume/mass flow by dynamic fluid flow effectGas phaseBlocked valves

Owner:CHENGDU GUOGUANG ELECTRONICS INSTR

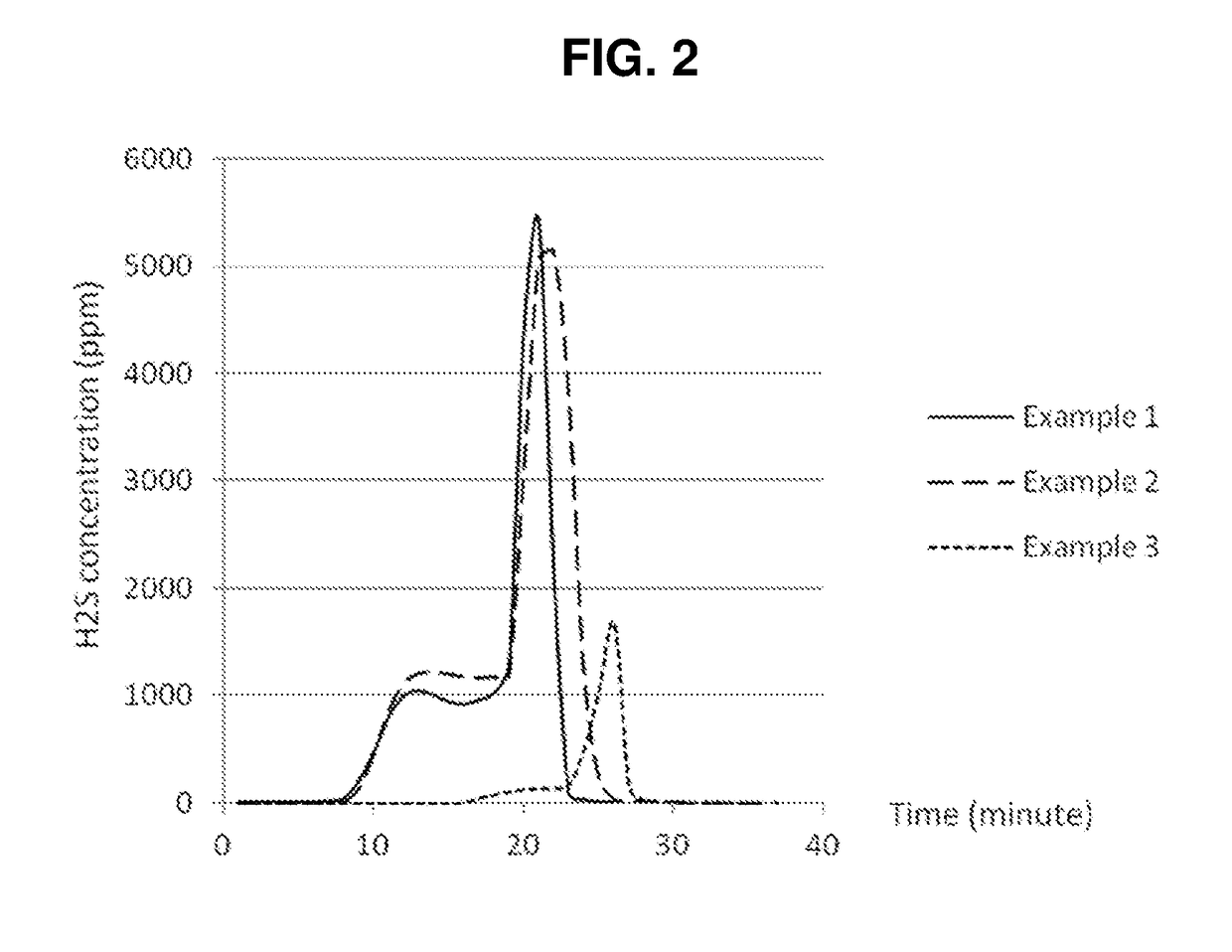

Cross-linked macroporous polymer used for selective removal of hydrogen sulfide from a gas stream

Owner:DOW GLOBAL TECH LLC

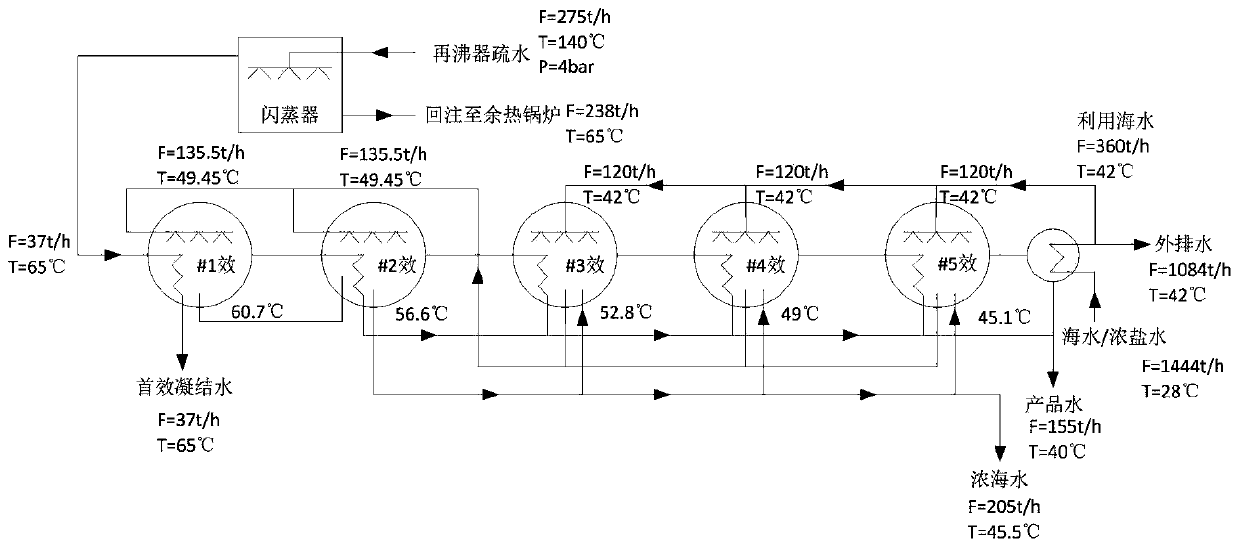

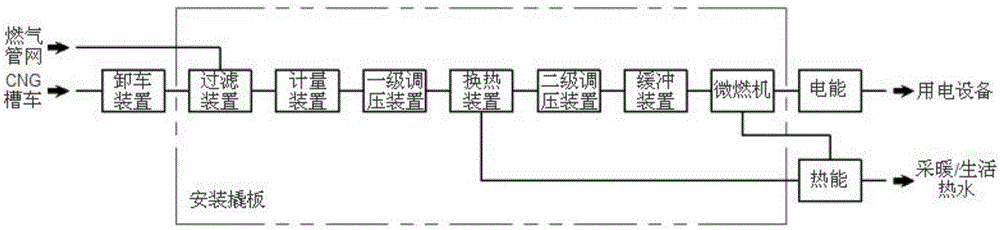

Small movable distributed energy system

Owner:TIANJIN HUAMAI ENVIRONMENTAL PROTECTION EQUIPCO

Diamond drill bit for comprehensive drilling

The invention discloses a diamond drill bit for comprehensive drilling, and belongs to the technical equipment fields of petroleum and natural gas drilling engineering, mine engineering, geological drilling, geothermal drilling, hydrological drilling, tunnel engineering, shielding, non-excavation and the like. The drill bit comprises a drill bit body, a water hole formed in the bit body, and a plurality of cutter wings extending from the drill bit body or fixed to the drill bit body, and fixed cutting elements are arranged on the cutter wings. The drill bit is characterized in that the drill bit further comprises at least one nozzle, and the nozzle comprises a flow mixing body; a flow mixing cavity, an exit port, a central hole communicating with the flow mixing cavity and at least one cut-in groove communicating with the flow mixing cavity are formed in the flow mixing body; and the central hole is used for forming a liquid straight flow in the flow mixing cavity, the cut-in groove isused for forming a liquid swirling flow in the flow mixing cavity, and the exit port is used for forming a channel for liquid ejection in the flow mixing cavity. The invention aims to provide the diamond drill bit suitable for comprehensive drilling, and the problems that in the rock breaking process of an existing drill bit, the working life of the drill bit is shortened and the drilling capacity is reduced due to the unreasonable hydraulic structure are effectively solved.

Owner:SOUTHWEST PETROLEUM UNIV +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap