Carbon dioxide inhibitor-combined natural gas hydrate replacement mining method

A carbon dioxide and hydrate inhibitor technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of slow replacement rate and low efficiency of natural gas hydrate replacement, and achieve increased contact area, increased Large storage capacity and storage efficiency, the effect of increasing the diffusion depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a natural gas hydrate replacement production method combined with inhibitor method, the steps are as follows:

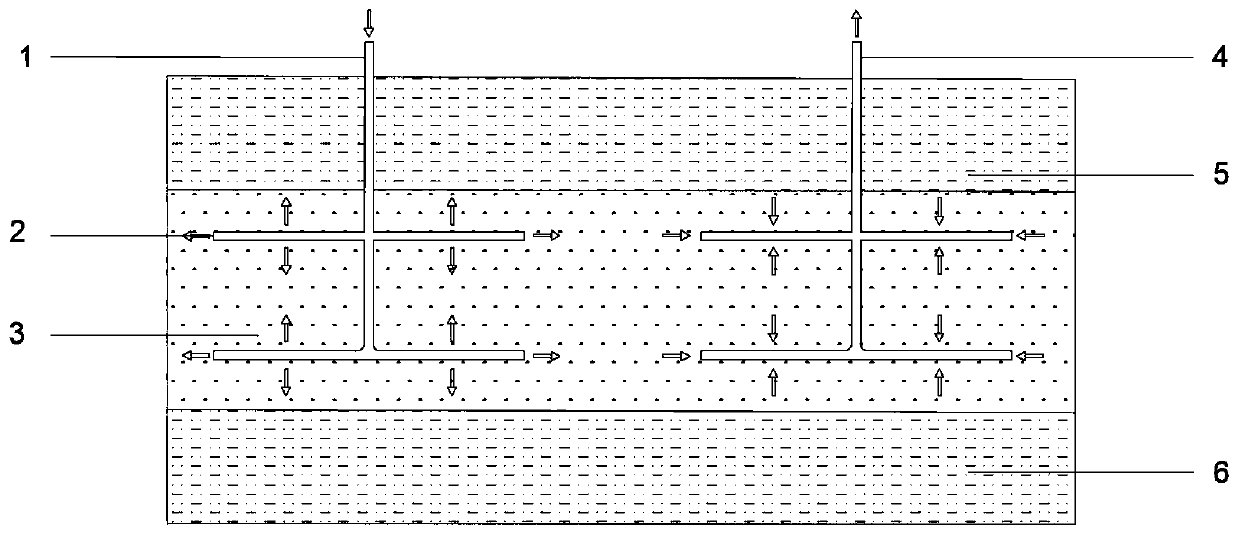

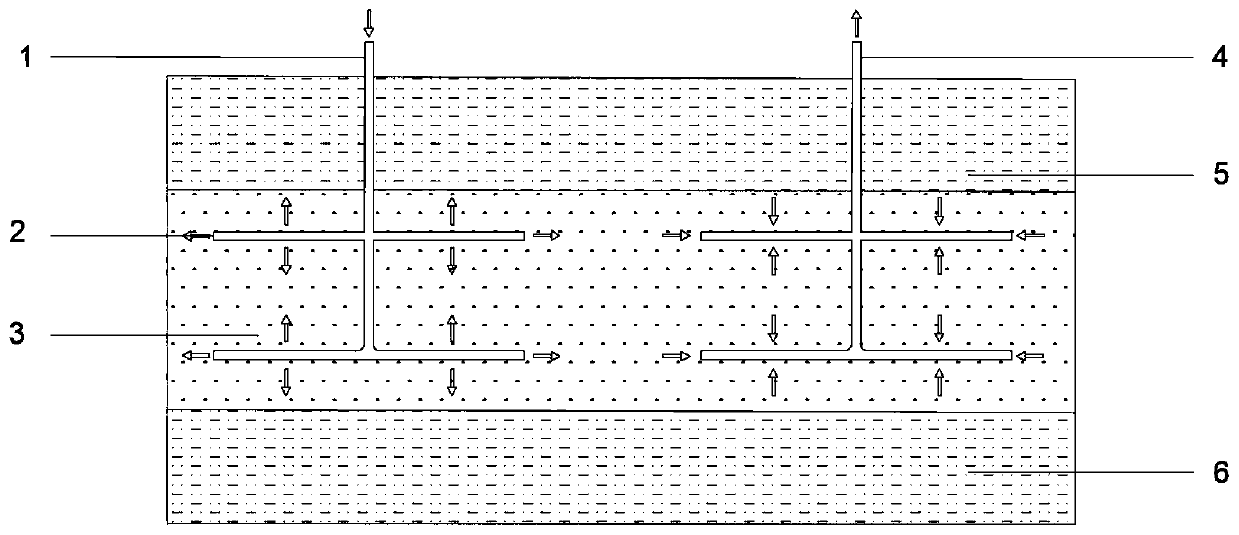

[0023] (1) According to the accumulation location of the hydrate deposit, select the appropriate drilling location, and use the low-density mud drilling method to drill multiple production wells to the inside of the gas hydrate reservoir. One is used as an injection well, and the other is used as a natural gas collection well Wells, and staggered distribution;

[0024] (2) Initial mining; reduce the pressure of the collection well to below the equilibrium pressure of the natural gas hydrate phase, decompose the natural gas hydrate, and carry out initial mining; after the initial mining is completed, start the injection pump, and inject glycine with a concentration of 3.5mol% (or 4.0mol% Alanine, 3.8mol% valine) are injected into the gas hydrate reservoir through the injection well, and the injection is stopped when the horizontal well sec

Embodiment 2

[0028] (1) According to the accumulation location of the hydrate deposit, select the appropriate drilling location, and use the low-density mud drilling method to drill multiple production wells to the inside of the gas hydrate reservoir. One is used as an injection well, and the other is used as a natural gas collection well Wells, and staggered distribution;

[0029] (2) Initial mining: Inject natural gas hydrate inhibitors into hydrate reservoirs through collection wells to promote the decomposition of natural gas hydrates for initial mining; after initial mining, start the injection pump to inject polyvinylcaprolactam with a concentration of 23ppmw (or 28ppmw of N-vinylpyrrolidone), injected into the natural gas hydrate reservoir through the injection well, when the horizontal well section of each injection well is filled with polyvinyl caprolactam, the injection is stopped, and the polyvinyl caprolactam begins to flow into the natural gas through the horizontal well section.

Embodiment 3

[0033] (1) According to the accumulation location of the hydrate deposit, select the appropriate drilling location, and use the low-density mud drilling method to drill multiple production wells to the inside of the gas hydrate reservoir, one for injection and the other for natural gas collection Wells, and staggered distribution;

[0034](2) Initial mining: reduce the pressure of the collection well to below the equilibrium pressure of the natural gas hydrate phase, decompose the natural gas hydrate, and carry out initial mining; after the initial mining, start the injection pump, and inject the methanol solution with a concentration of 35% through the injection well In the natural gas hydrate reservoir, when the horizontal well section of each injection well is full of methanol, the injection is stopped, and methanol begins to diffuse to the surrounding gas hydrate reservoir through the horizontal well section; methanol will destroy the equilibrium condition of natural gas hydra

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap