Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Mineralogy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mineralogy is a subject of geology specializing in the scientific study of the chemistry, crystal structure, and physical (including optical) properties of minerals and mineralized artifacts. Specific studies within mineralogy include the processes of mineral origin and formation, classification of minerals, their geographical distribution, as well as their utilization.

Mineral recovery processes

InactiveUS6077441AQuality improvementEffective sedimentationSeparation devicesDifferential sedimentationPhosphateEvaporation

Owner:CIBA SPECIALTY CHEM WATER TRATMENTS

Mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals

The invention relates to a mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals, and belongs to the fields of mineral process engineering and comprehensive recycling of resources. The mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals comprises the following steps: carrying out low intensity magnetic separation and high intensity magnetic separation pre-concentration by taking bayan obo tailings as raw materials, then carrying out fluid bed roasting on obtained pre-concentrated concentrates, and carrying out low intensity magnetic separation operation on roasted minerals obtained by roasting so as to obtain weak-magnetism concentrates and rare-earth-containing weak-magnetism tailings; and carrying out rare earth flotation operation on the weak-magnetism tailings to obtain rare earth flotation concentrates and rare earth flotation tailings finally, then carrying out acid leaching process on the rare earth flotation tailings to obtain niobium-enriched slag and acid pickling tailings, and meanwhile, carrying out fluorite flotation operation on pre-concentrated strong-magnetism tailings to obtain fluorite flotation concentrates and fluorite flotation tailings. By the method, fluorite concentrates, iron core concentrates, rare earth concentrates and the niobium-enriched slag are obtained finally, and thus, the bayan obo tailings are utilized comprehensively.

Owner:NORTHEASTERN UNIV LIAONING

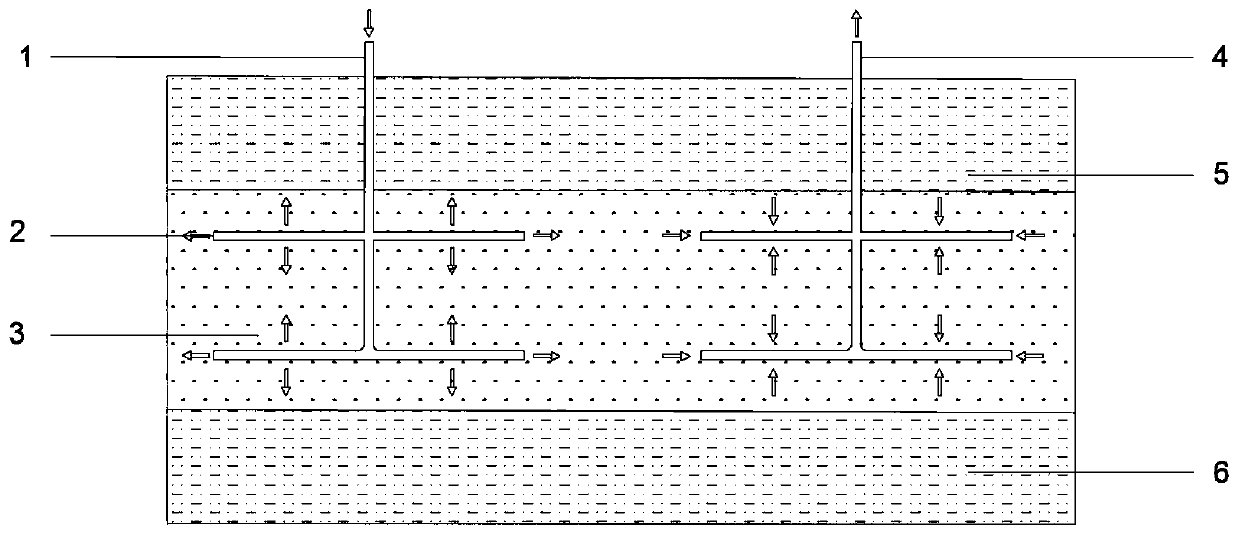

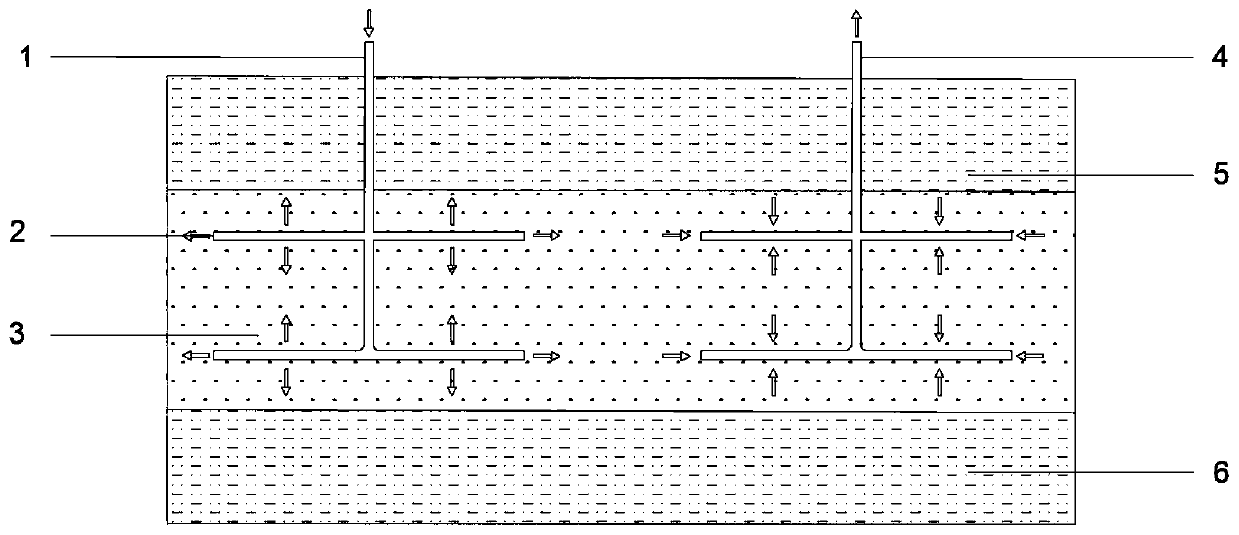

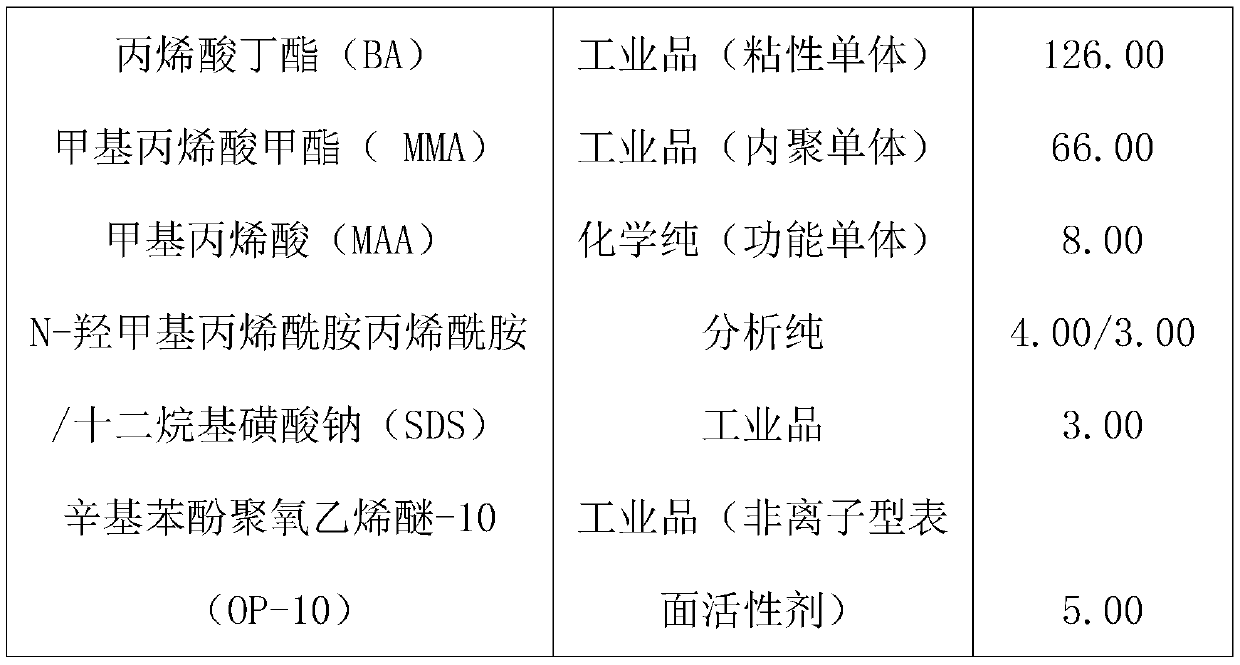

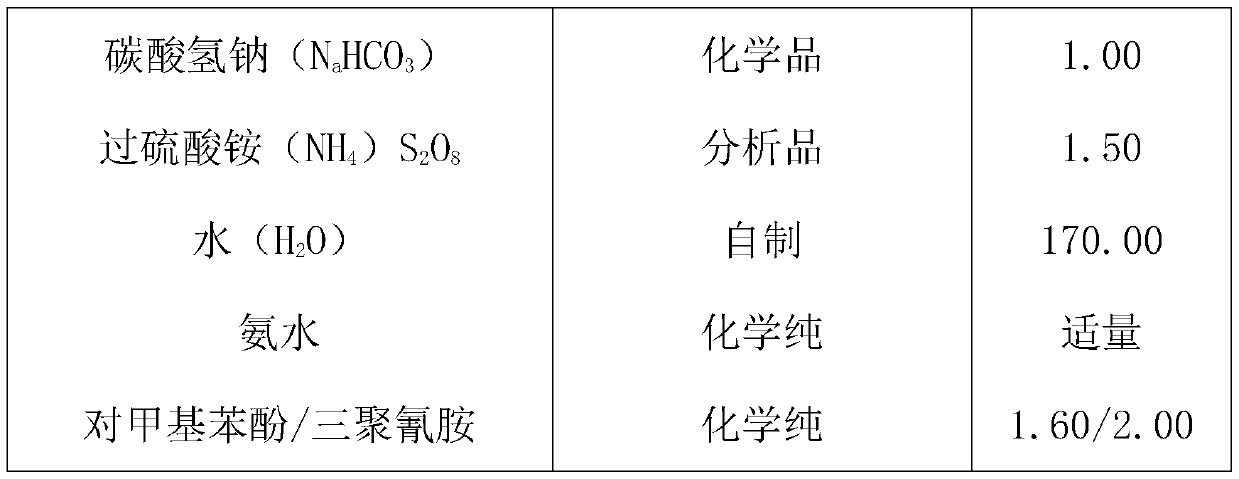

Method for constructing horizontal salt rock dissolving cavity reservoirs

Owner:TAIYUAN UNIV OF TECH

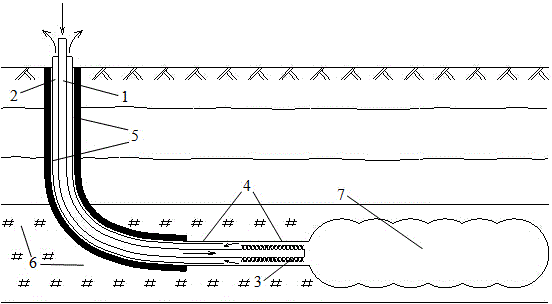

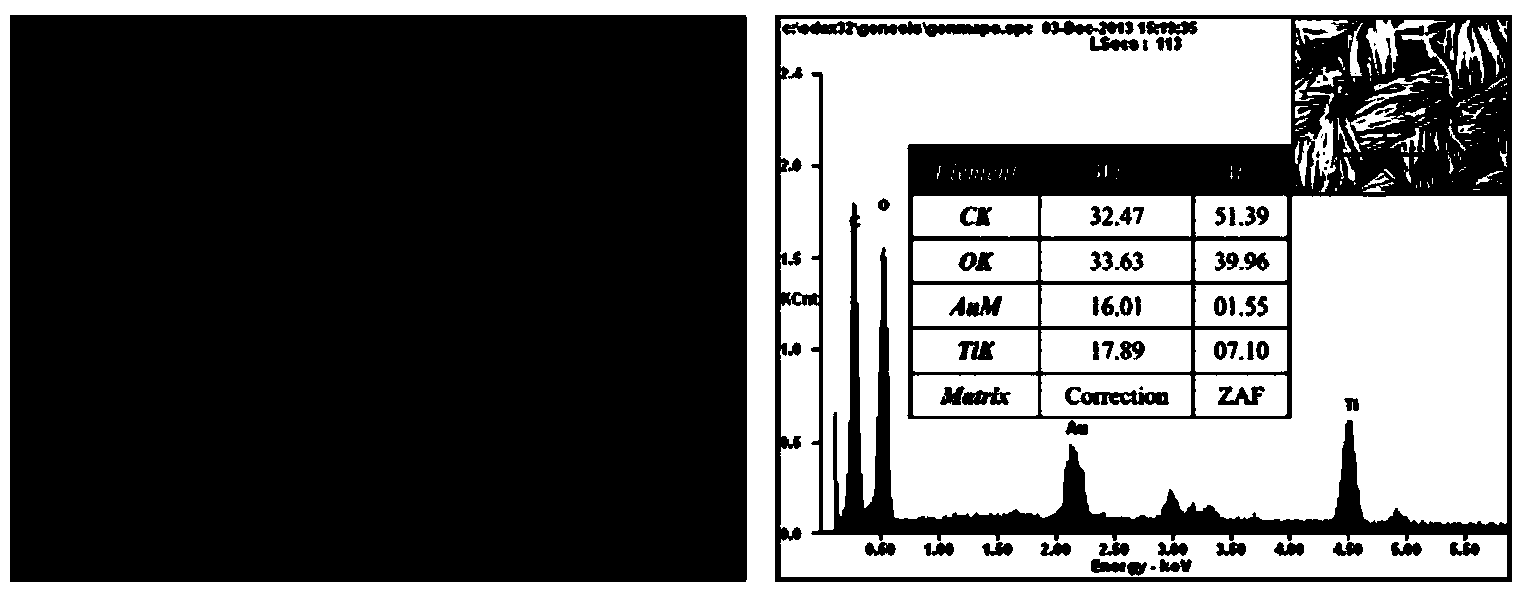

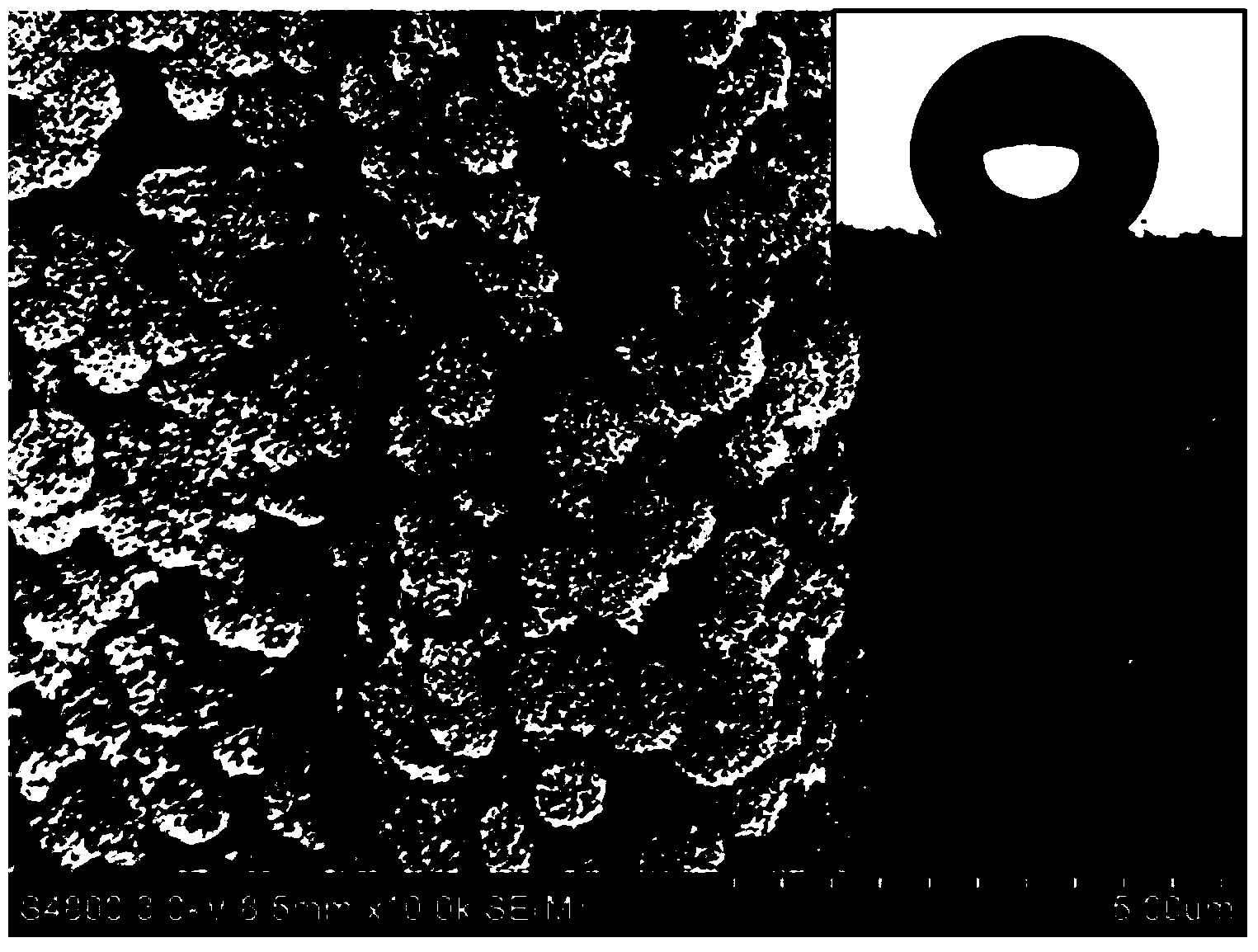

Preparation method of special-infiltration functional fabric surface with self-cleaning and oil-water separation functions

Owner:SUZHOU UNIV

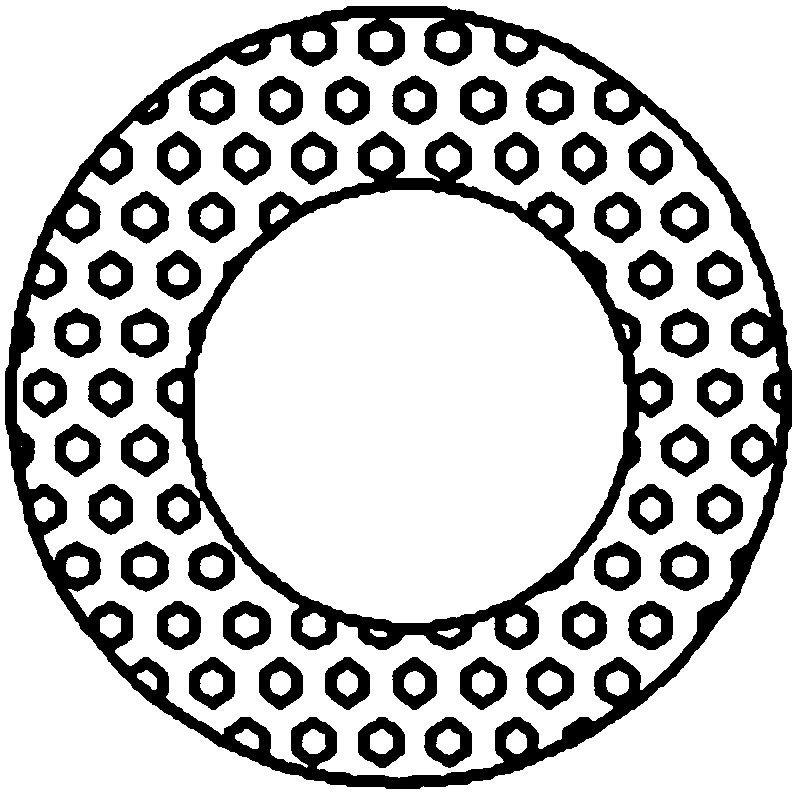

High-temperature iron-based zeolite molecular sieve honeycomb type denitration catalyst and preparation method thereof

ActiveCN107519926AEvenly dispersedSimple preparation processMolecular sieve catalystsDispersed particle separationFerrous saltsStearic acid

Owner:VALIANT CO LTD

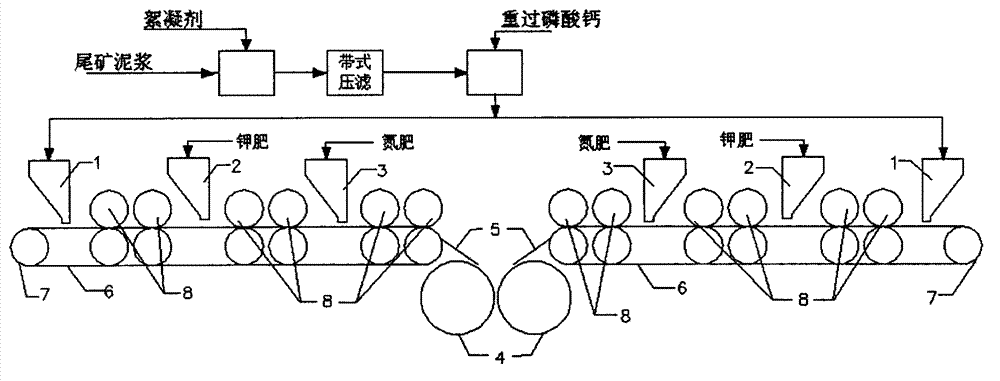

Method and equipment for producing slow-release compound fertilizer from manganese ore tailings

InactiveCN103204743AReduce processing costsSolving Stacking Handling IssuesFertiliser formsFertilizer mixturesElectrolysisManganese

Owner:赵阳臣

Alkali metal ion source with moderate rate of ion release and methods of forming

ActiveUS20140345348A1Inhibition formationSafely raisedCalcareous fertilisersMagnesium fertilisersCalcium hydroxideAlkaline earth metal

An alkali metal ion source with a moderate rate of release of the ion (e.g. potassium) is formed by a method that includes: 1) combining an particulate ore that contains at least one of an alkali metal ion-bearing framework silicate (e.g. syenite ore) with at least one of an oxide and hydroxide of at least one of an alkali metal and alkaline earth metal such as calcium hydroxide; 2) milling the mixture of these two components optionally, with water, optionally, milling the dry components separately and blended thereafter, optionally, with water; 3) forming a mixture by adding water to the solid mixture after milling, if water was not added before milling; 4) exposing the mixture to an elevated temperature and pressure to form a gel that includes silica and the alkali metal of the framework silicate.

Owner:MASSACHUSETTS INST OF TECH

Regional mineral resource prediction system based on geological specimen analysis

ActiveCN110728402AImprove forecast accuracyImprove accuracyForecastingEarth material testingMineral SourcesPrediction system

The invention discloses a regional mineral resource prediction system based on geological specimen analysis. The regional mineral resource prediction system comprises a geological data acquisition unit, a data stratification analysis unit, a geological model establishment unit, a model analysis unit and a result judgment unit. The method comprises the following steps: carrying out region measurement on a region where mineral resources to be predicted are located through a geological data acquisition unit, carrying out division according to geological distribution characteristics, then carryingout fixed-point sampling in the divided region, and acquiring geological information in the region; sorting the obtained data, carrying out hierarchical classification in the same region, then integrating the same-layer data in different regions, and storing the integrated data; analyzing the geological specimen information, and establishing a regional model and a spatial model in combination with the geological information; analyzing and calculating the geologic model according to a standard algorithm to obtain the mineral distribution situation in the distribution region and the total mineral resource amount in the total region; and selecting a comparison specimen collection point again in the region, collecting the comparison specimen, and verifying the result accuracy.

Owner:LIAONING TECHNICAL UNIVERSITY

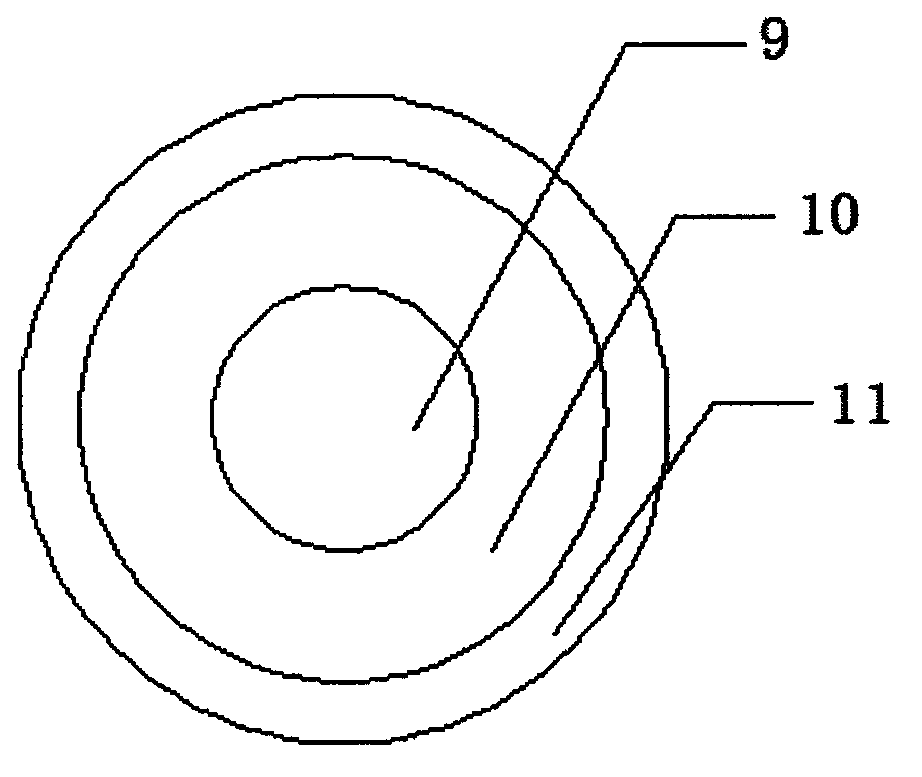

Fly ash ceramsite and preparation method thereof

The present invention relates to fly ash ceramsite and a preparation method thereof, wherein the fly ash ceramsite has a cavity structure, uniform gas pores are distributed in the area outside the cavity, and the inner wall of the cavity is obtained by carrying out high temperature decomposition on low melting point solid waste containing crystal water, structural water or hydroxyl. The preparation method comprises: nucleating by utilizing the raw materials of a nucleating agent to obtain a spherical nucleating agent; mixing fly ash and other auxiliary materials according to a formula ratio; coating the nucleating agent by utilizing the mixture; granulating to obtain pellets; and drying the pellets, roasting, and cooling to obtain the fly ash ceramsite. According to the invention, the prepared fly ash ceramsite has a ceramsite stacking density of 400-600 kg / m<3>, a water absorption rate of 0.5-2.5% and a numerical tube pressure of 3-6 MPa; and with the method, in the case of the ensuring of the strength of ceramsite, the prepared fly ash ceramsite has characteristics of low bulk density, light weight, low water absorption rate and the like, can meet the market requirements on lightweight high-strength fly ash ceramsite, and has good application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

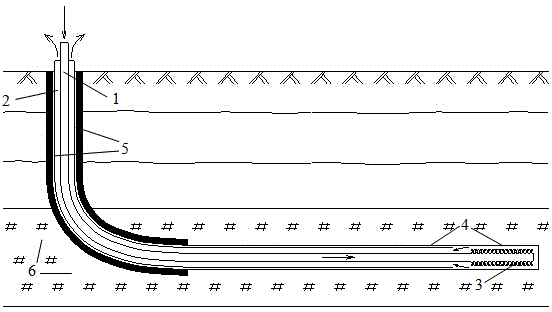

Carbon dioxide inhibitor-combined natural gas hydrate replacement mining method

InactiveCN109915094AExtend build timeIncrease the spread distanceFluid removalPressure differenceInjection well

Owner:DALIAN UNIV OF TECH

Coating material for sealing coal wall of gob-side coal roadway

Owner:SHANDONG UNIV OF SCI & TECH

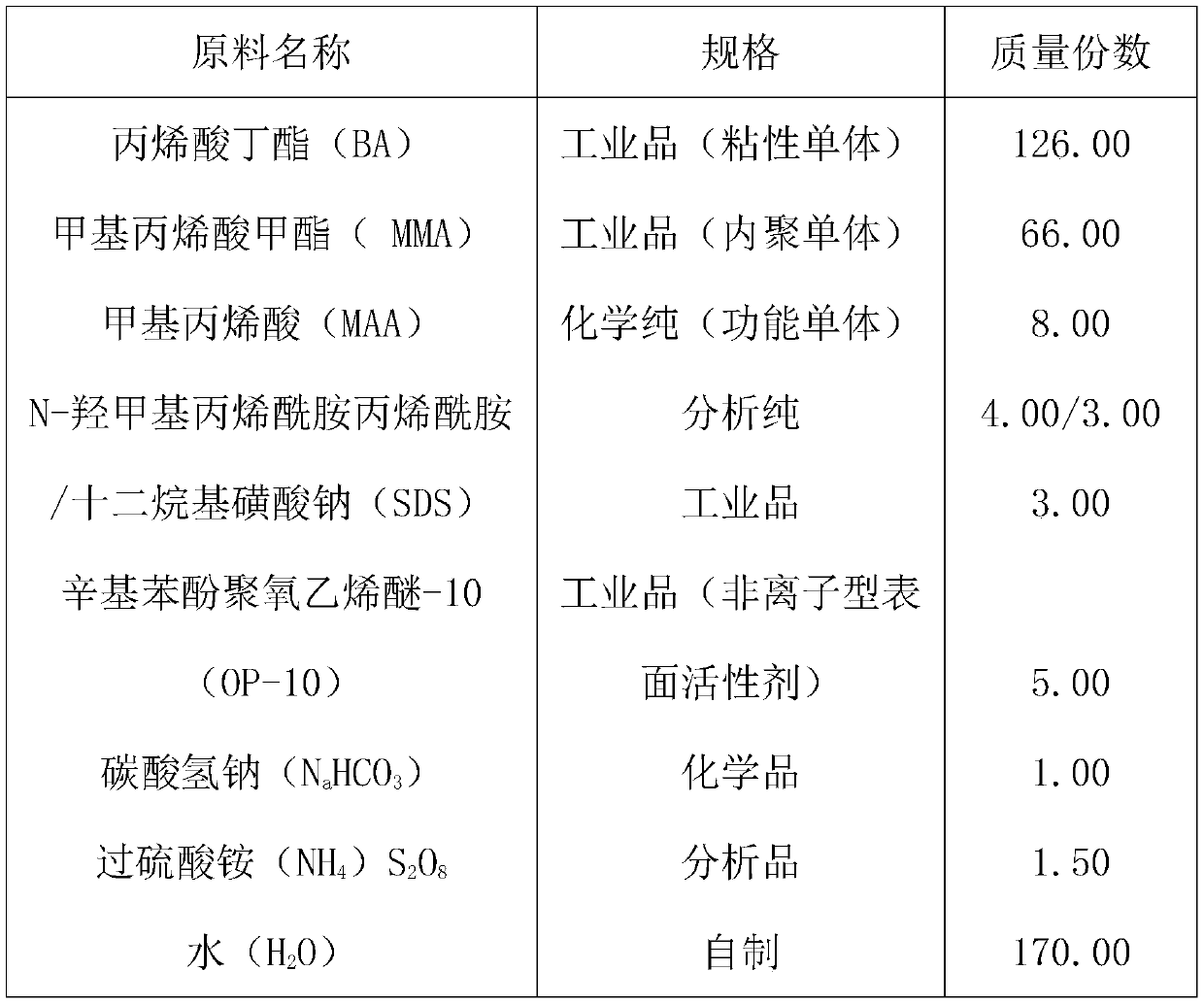

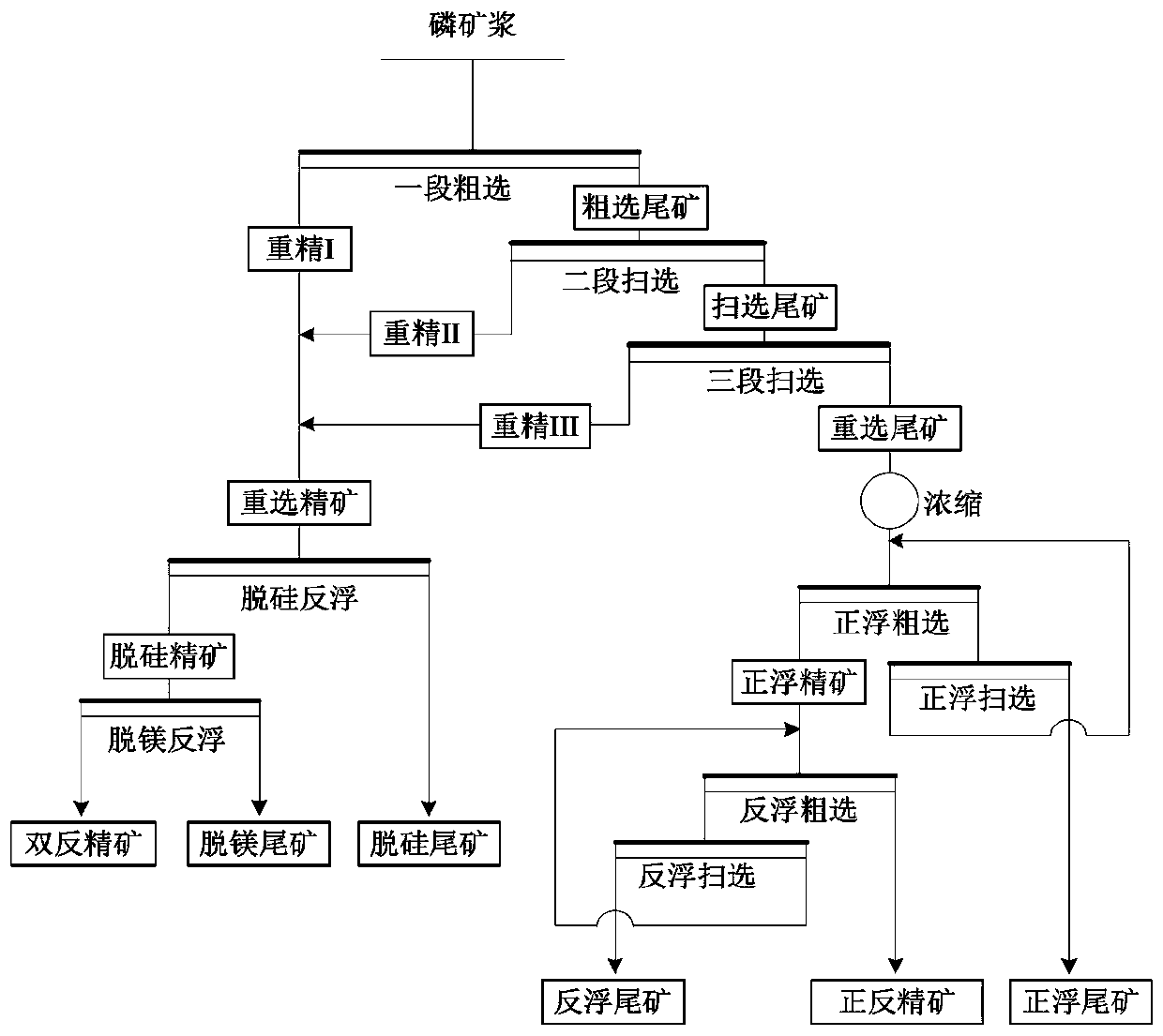

Gravity separation-flotation combined beneficiation process for phosphate ores

PendingCN110369120AReduce grinding costsReduce adverse effectsFlotationWet separationPhosphoriteReverse flotation

Owner:HUBEI XINGFA CHEM GRP CO LTD

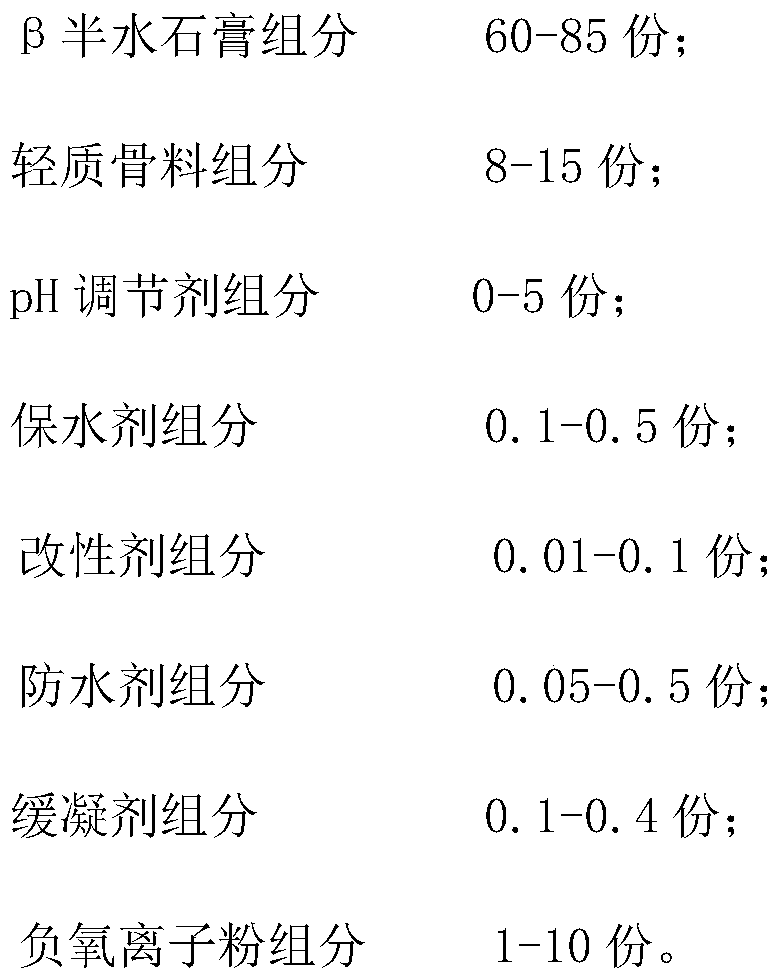

Damp-proof light plastering gypsum capable of releasing negative oxygen ions, and preparation method of plastering gypsum

PendingCN110790558AStrengthen and activate physical activityImprove flame retardant performancePhysical chemistryOxygen ions

Owner:贵州蓝图磷石膏环保科技有限公司

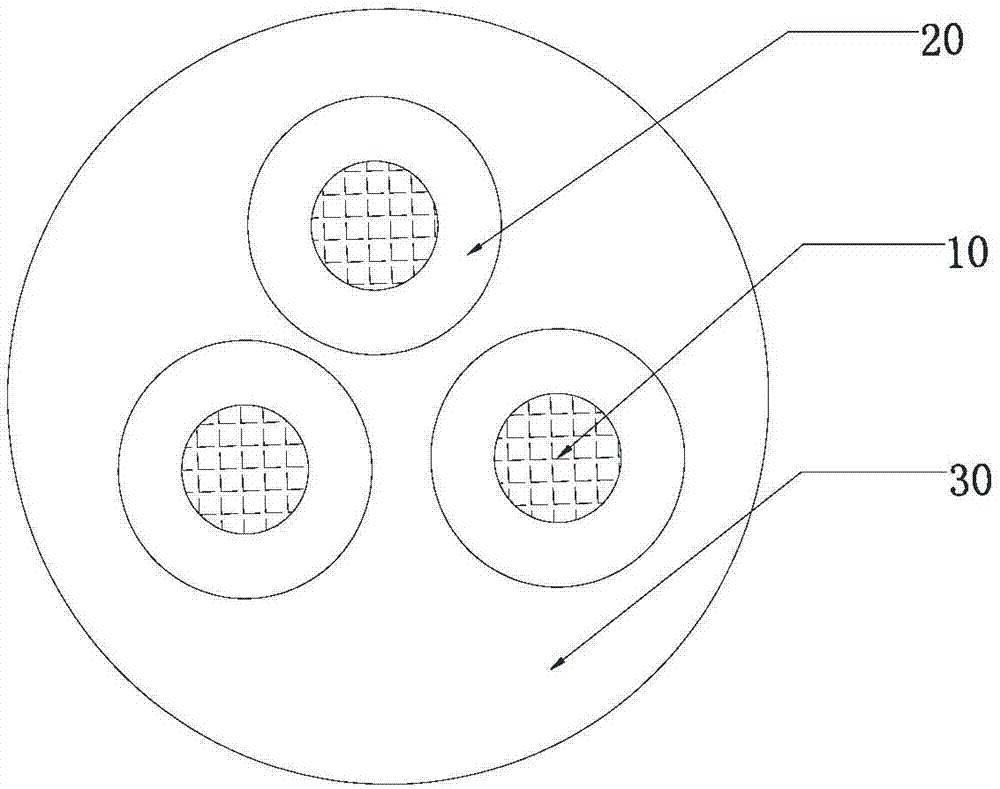

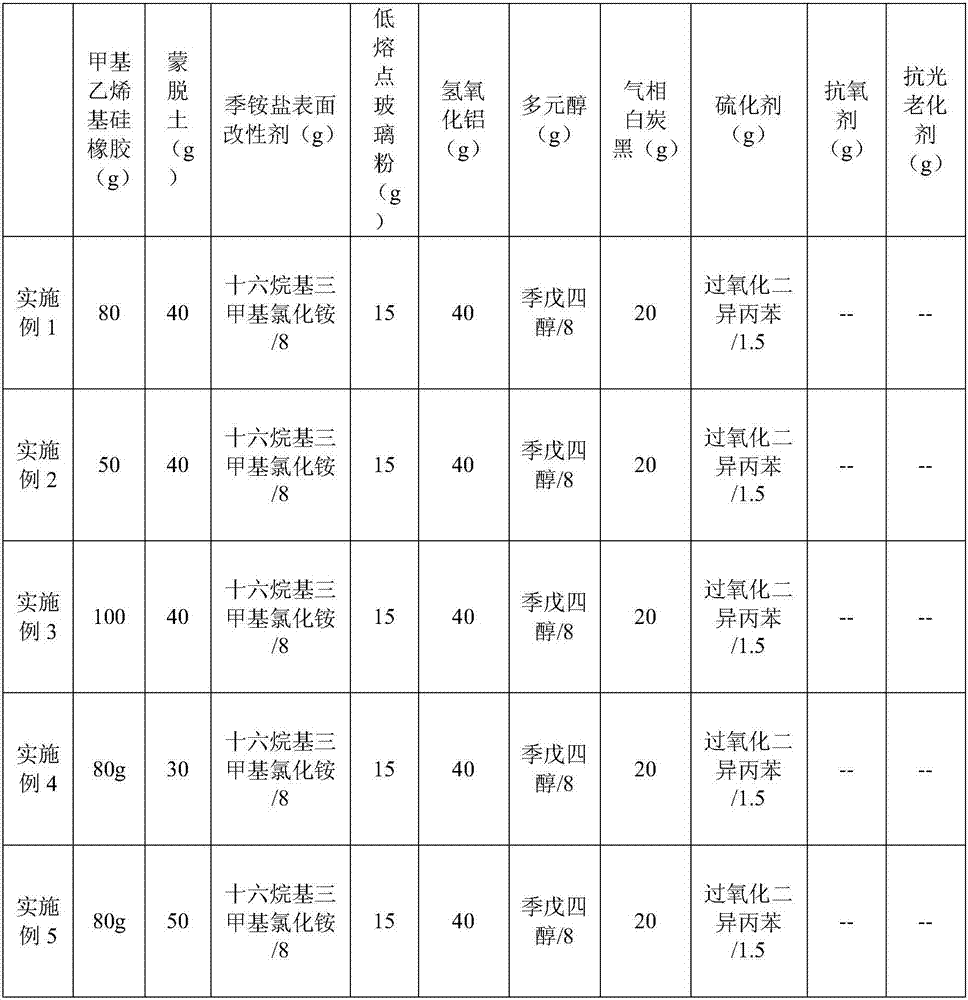

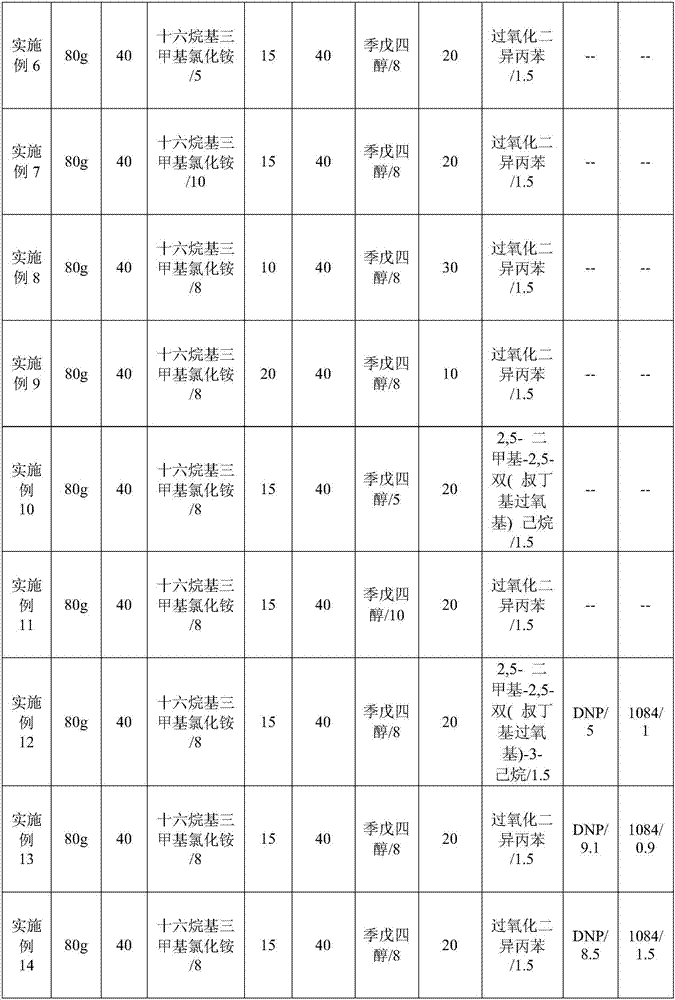

Fireproof mineral silicone rubber composition, fireproof mineral silicone rubber material, preparation method thereof and power line containing fireproof mineral silicone rubber material

Owner:GREE ELECTRIC APPLIANCES INC

Method for up-down replacement collaborative mining of close distance coal seams

Owner:CHINA UNIV OF MINING & TECH

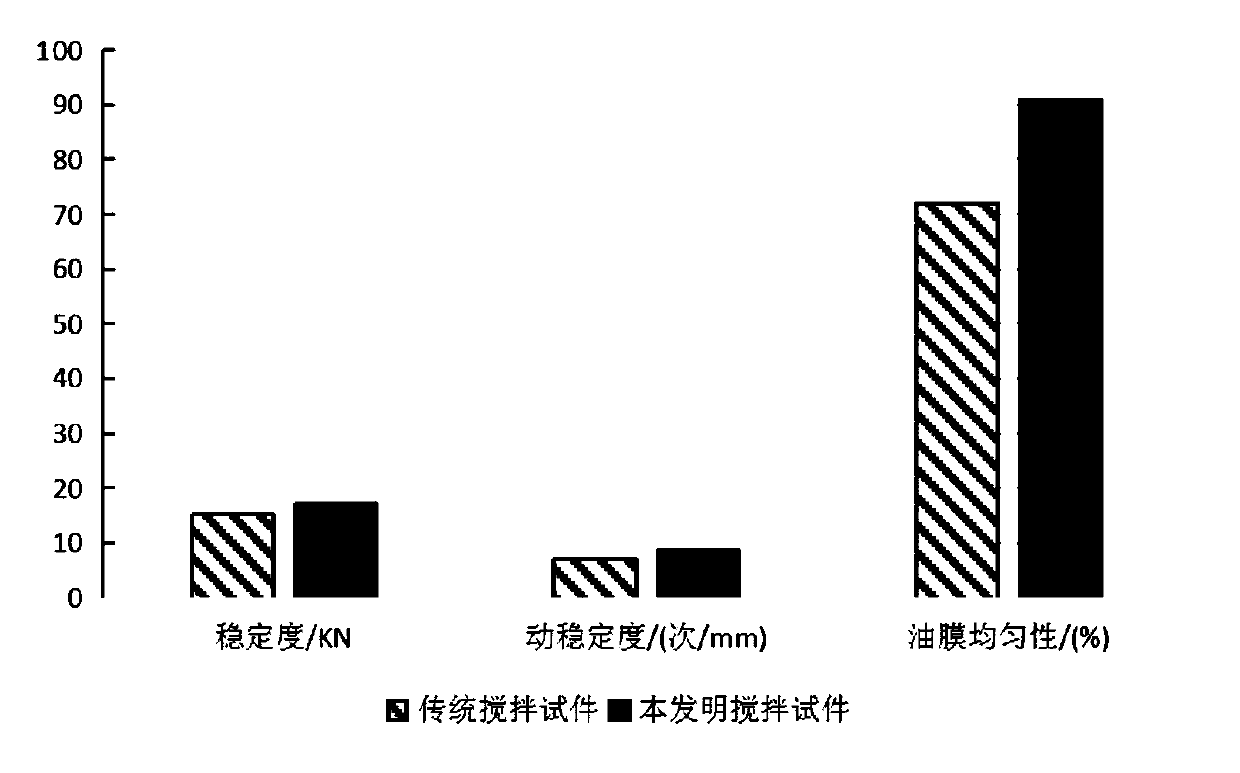

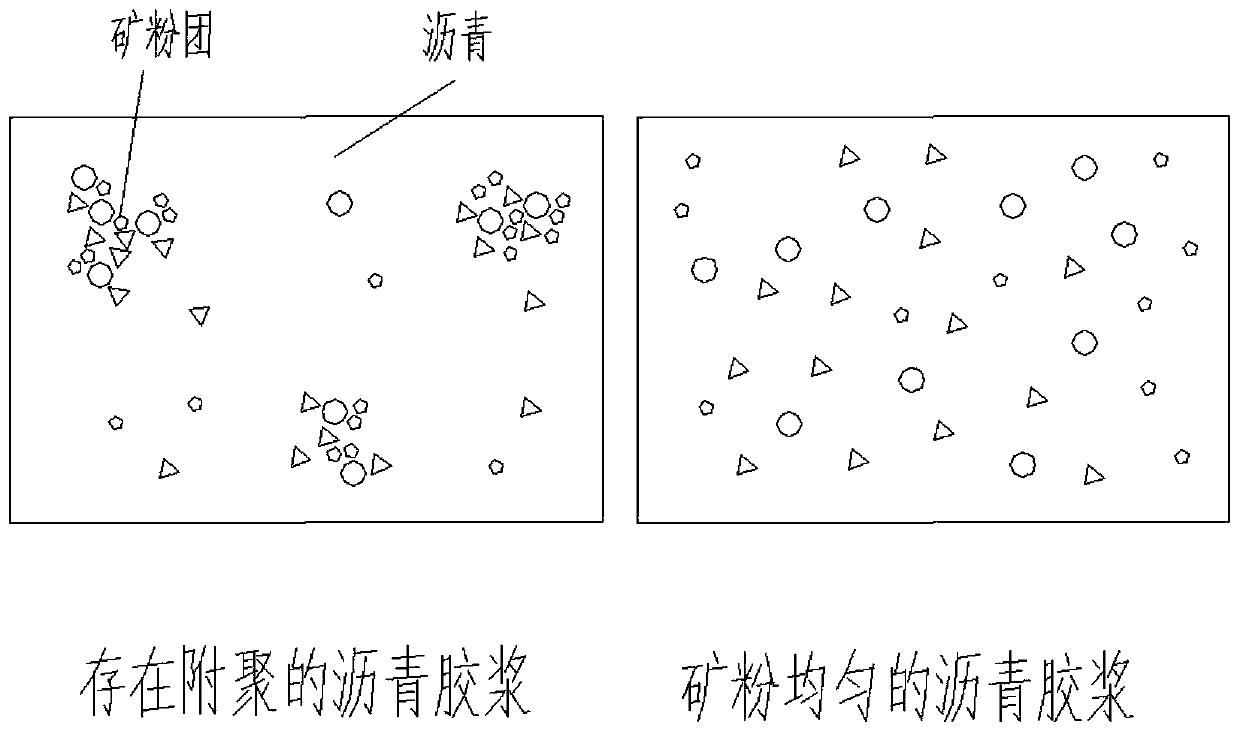

Stirring device for asphalt mixture

Owner:JILIN UNIV

Separation and recovery method for waste mineral oil

InactiveCN107903941AImprove qualityHigh yieldTreatment with plural serial refining stagesLubricant compositionRecovery methodMaceral

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Method for concentrating platinum and palladium from platinum-palladium flotation concentrates

InactiveCN108722675AHigh precious metal contentHigh enrichment ratioFlotationMass ratioPt element

Owner:GUANGDONG INST OF RARE METALS

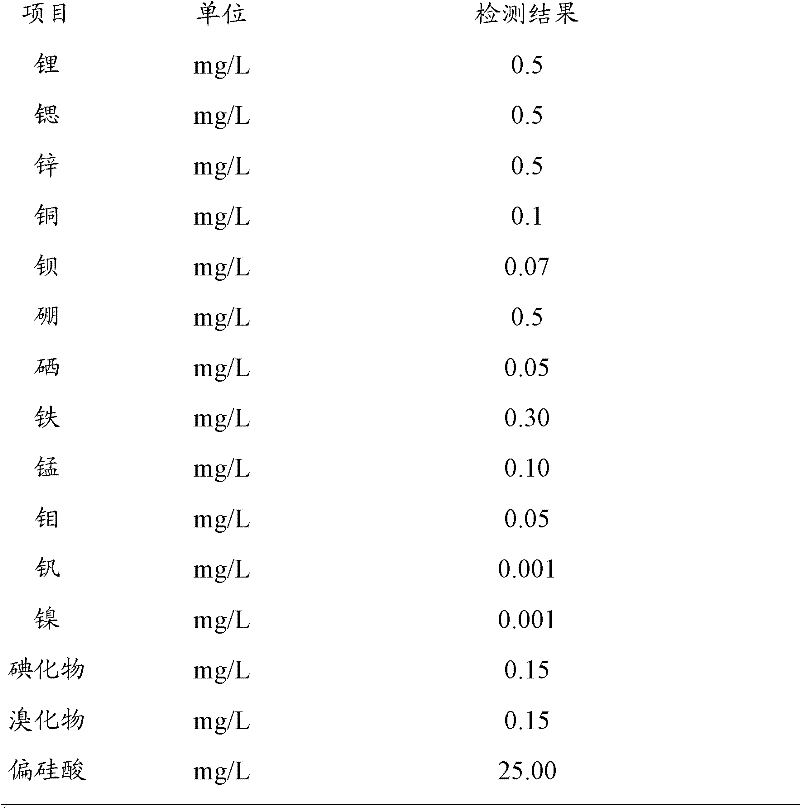

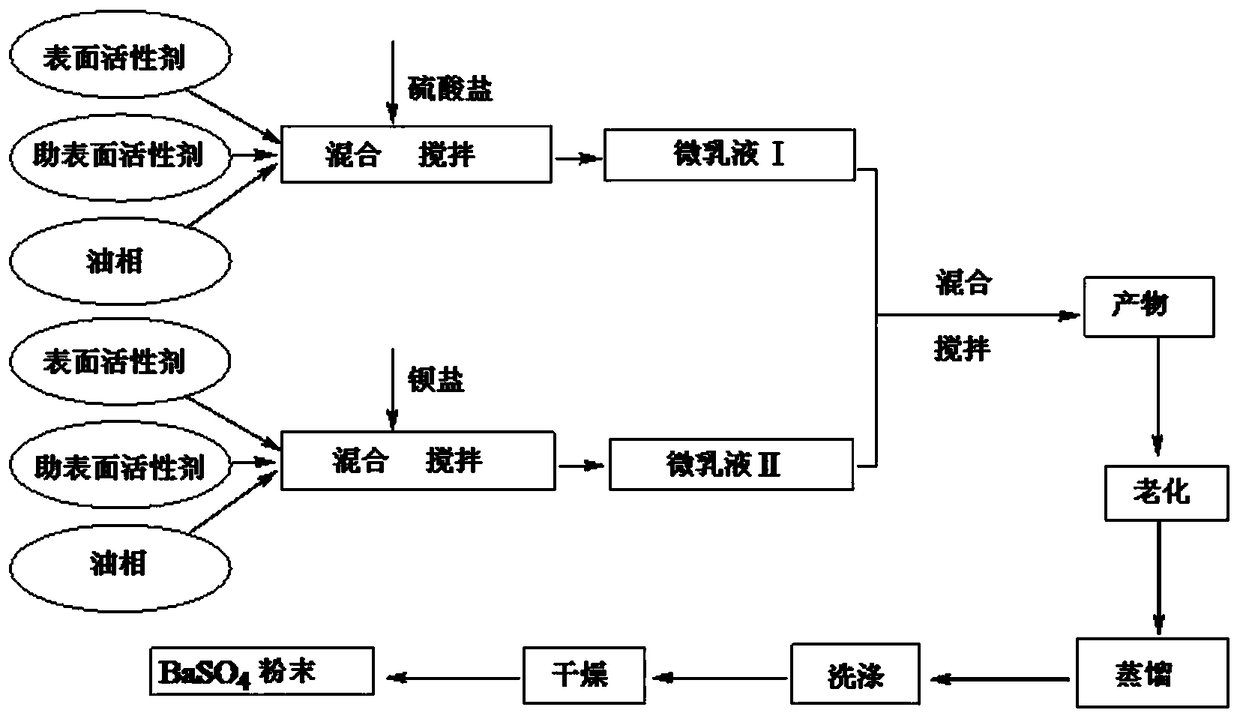

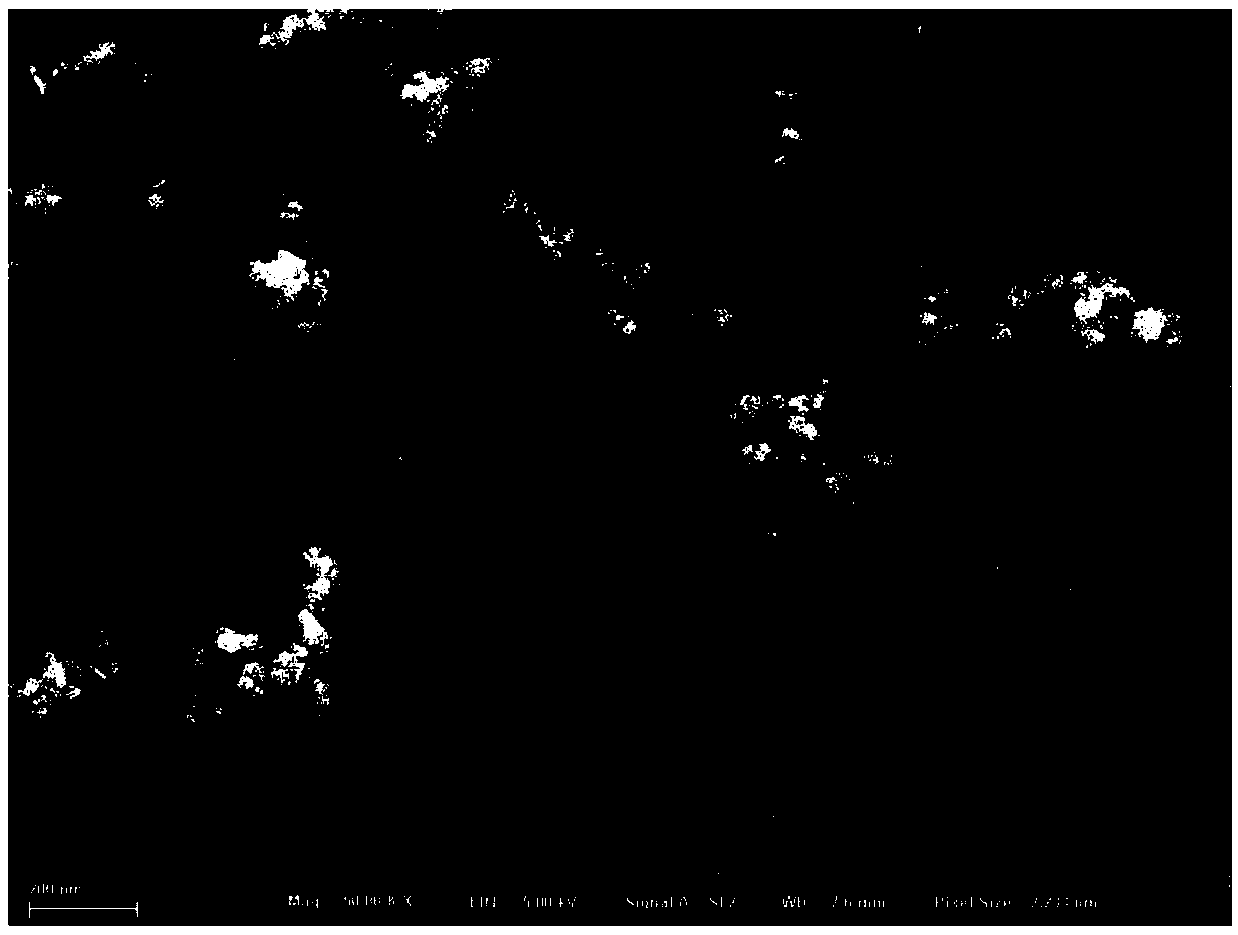

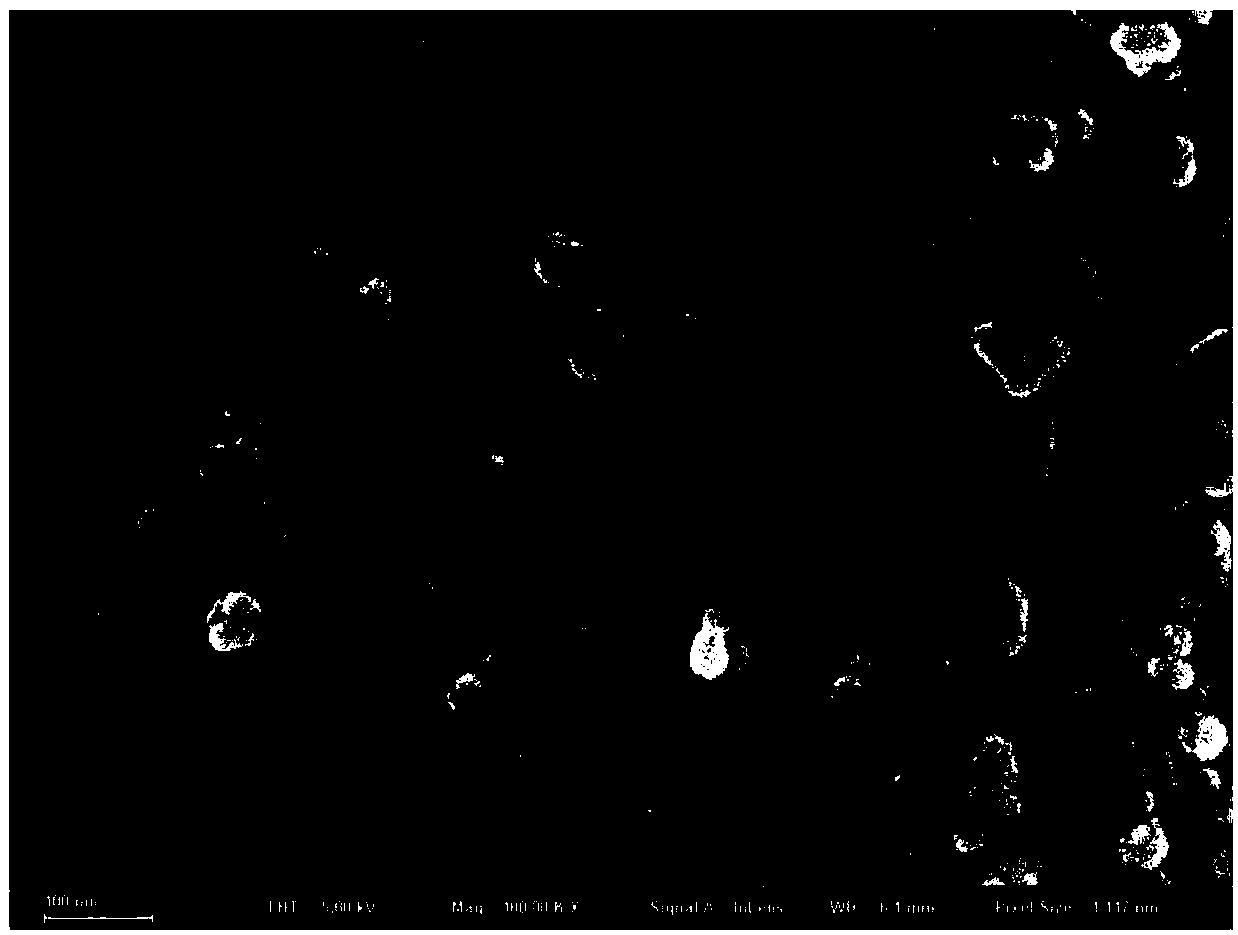

Method for preparing nanometer barium sulfate particles by water in oil type micro-emulsion method

InactiveCN108862356ARegular shapeSmall particle sizeMaterial nanotechnologyCalcium/strontium/barium sulfatesWater in oilMineralogy

The invention belongs to a method for preparing nanometer barium sulfate particles by a water in oil type micro-emulsion method, and belongs to the technical field of nanometer material preparation. Surfactants, cosurfactants, oil phases, sulfate or barium salt water solution are uniformly mixed to respectively obtain micro emulsion I and micro emulsion II; after the mixed reaction of the micro emulsion I and the micro emulsion II, distillation demulsification, centrifugation, washing and drying are performed to obtain the nanometer barium sulfate particles. The high system volume increase water quantity ratio, i.e., the low surfactant and oil phase consumption is used for obtaining the barium sulfate particles with the regular appearance and uniform particle diameter distribution; the particle size and particle diameter distribution are controllable; the reaction cost is effectively reduced.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

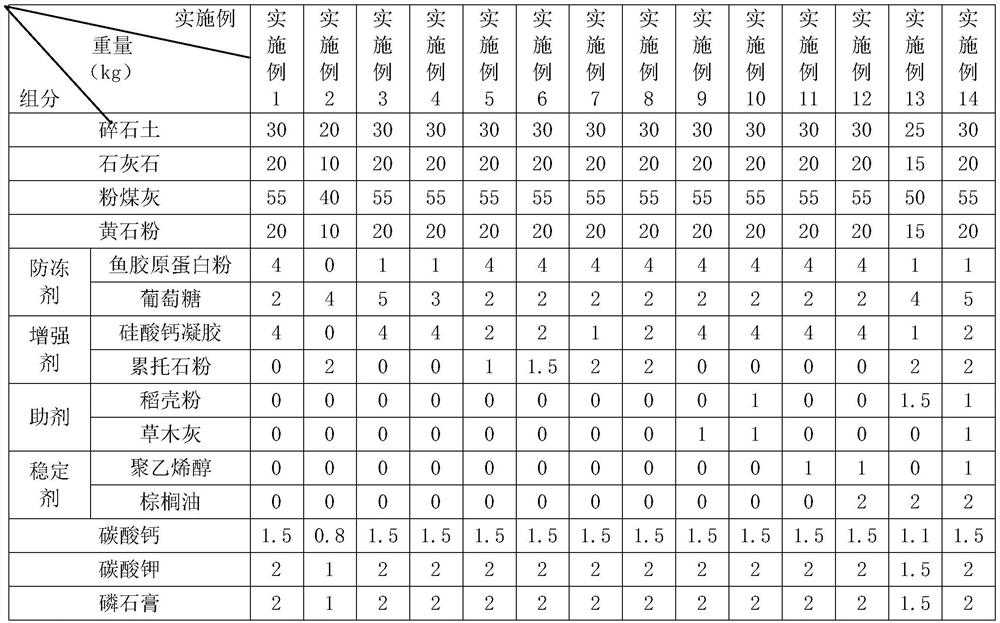

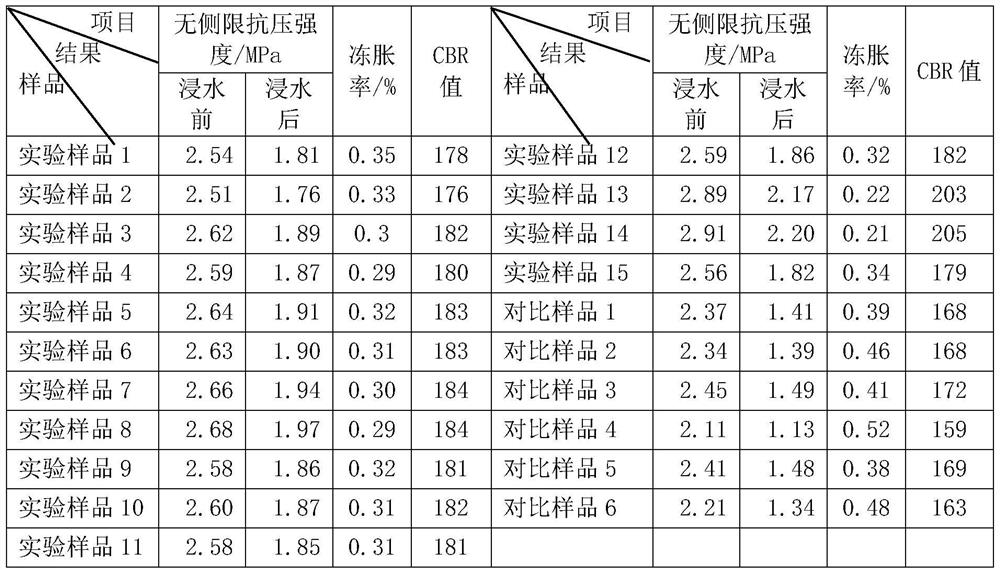

High-stability roadbed filler and preparation method thereof

Owner:杭州航弘建设科技有限公司

Preparation method of bathroom water draining pipeline dredging agent

InactiveCN110125102AImprove dredging effectEasy to transportHollow article cleaningSodium sulfateSodium hydroxide

The invention discloses a preparation method of a bathroom water draining pipeline dredging agent. The bathroom water draining pipeline dredging agent comprises, by weight, 25%-35% of sodium carbonate, 5%-15% of sodium persulfate, 25%-35% of sodium hydroxide, 10%-15% of potassium permanganate, 10%-15% of aluminum particles and 5%-7% of a drying agent. The preparation method comprises the steps that sodium carbonate, sodium persulfate, sodium hydroxide and potassium permanganate are added into a mixer to be mixed at a certain vulcanizing temperature in an environment with a certain humidity; amixture obtained in the step 1 is added into a crushing machine to be crushed, and powder is prepared; the powder obtained in the step 2 is fed into a granulating machine to be granulated and then fedinto a screener to be screened, screened qualified products are fed into a moistureproof treatment device to be subjected to moistureproof treatment, and screened unqualified products return back tothe crushing machine to be crushed; and the qualified products obtained in the step 3 are fed into the mixer to be fully mixed to aluminum particles, drying agents are put into small packaging bags, and the products are obtained. The bathroom water draining pipeline dredging agent has the advantages that the dredging effect is good, transportation is convenient, and the practicability and the safety are achieved.

Owner:NANCHANG HANGKONG UNIVERSITY

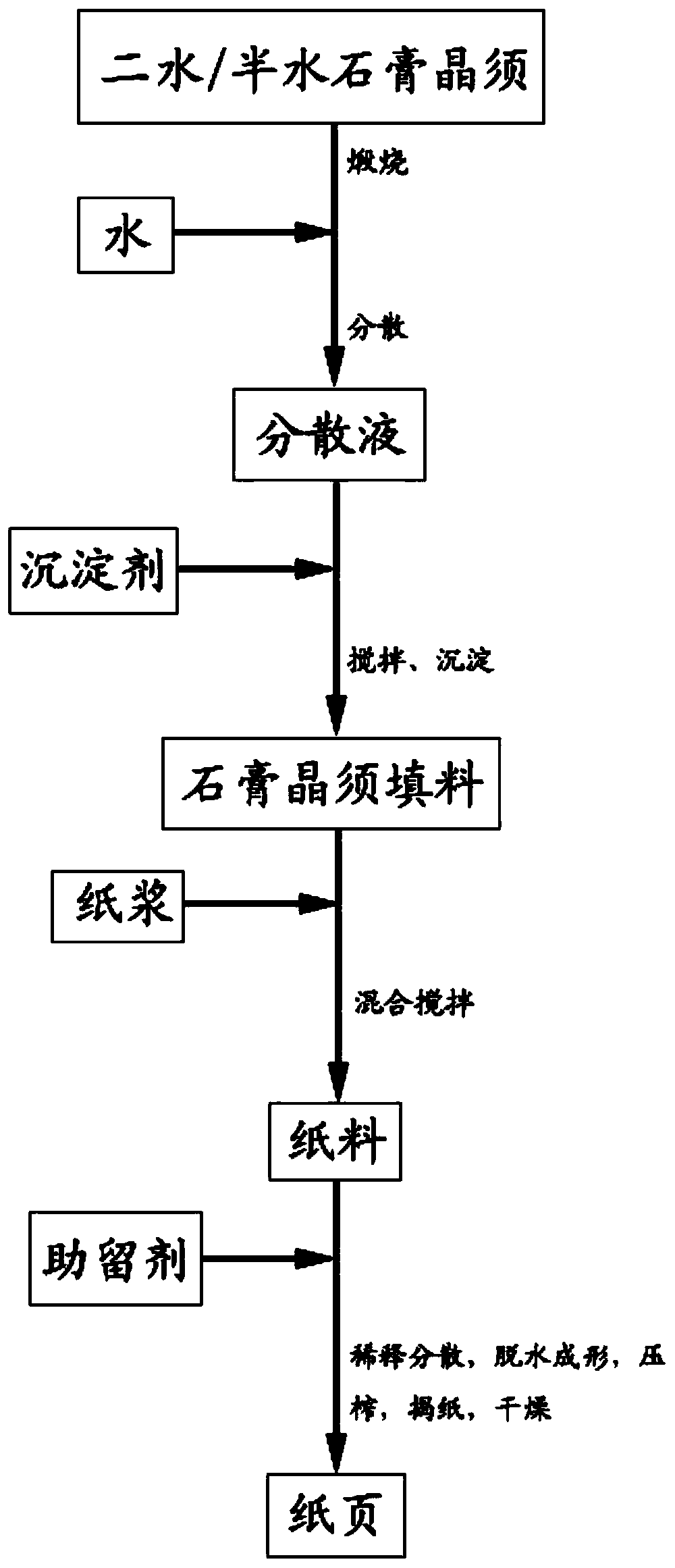

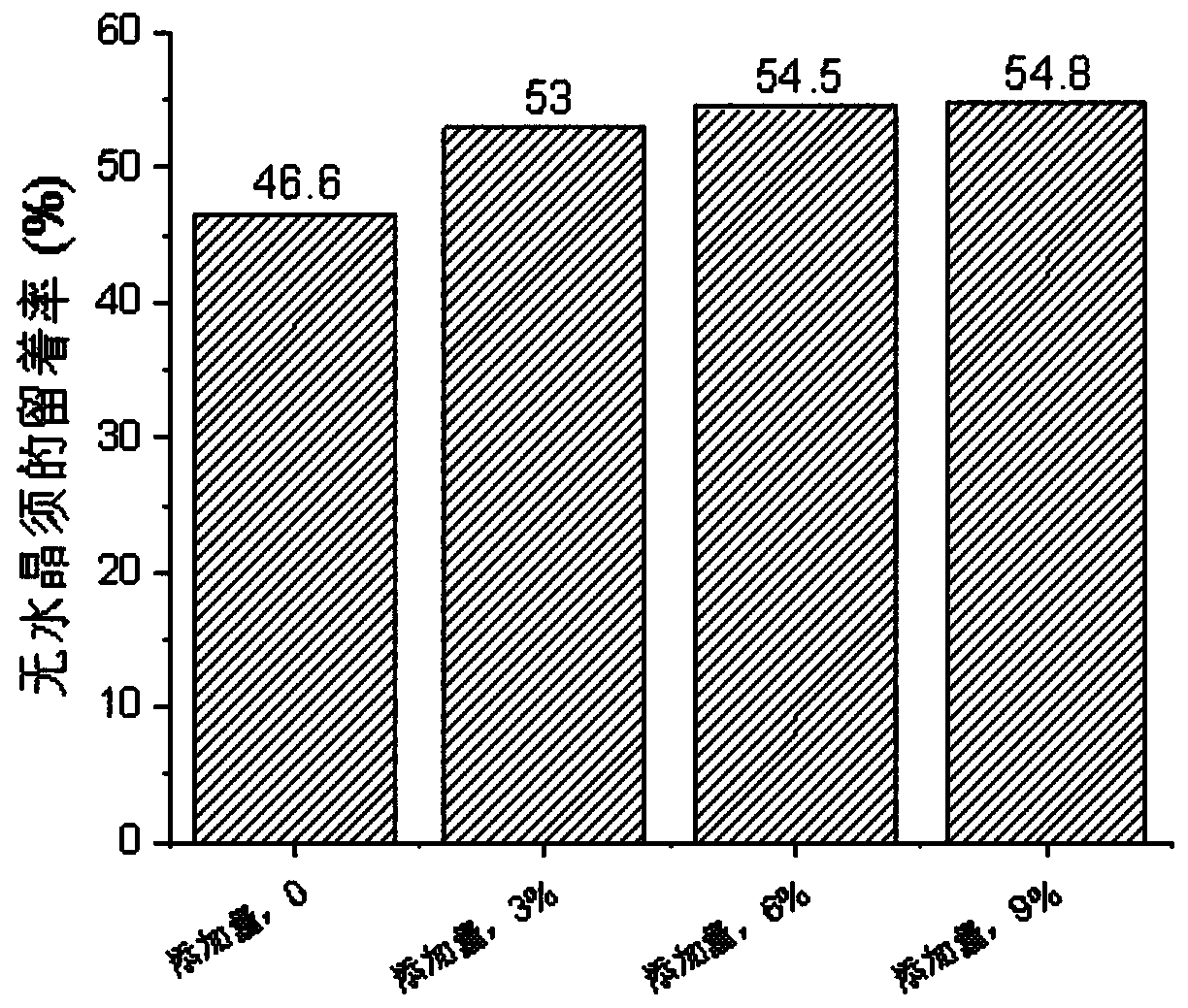

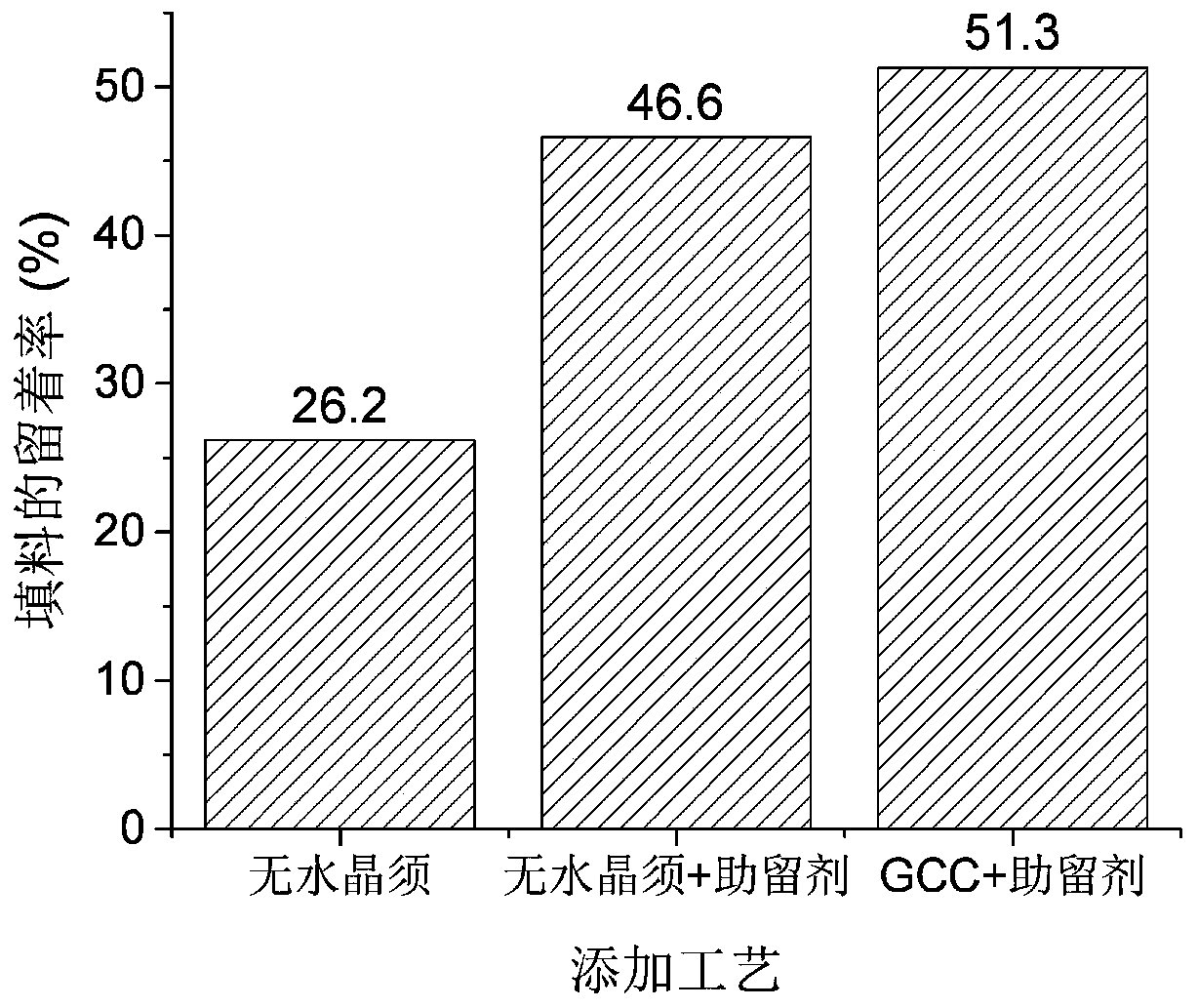

Preparation method of paper sheets with gypsum whiskers

PendingCN110747689AIncreased solubility resistanceCompact structurePaper/cardboardInorganic compound additionPhysical chemistryMaterials science

Owner:NANJING FORESTRY UNIV

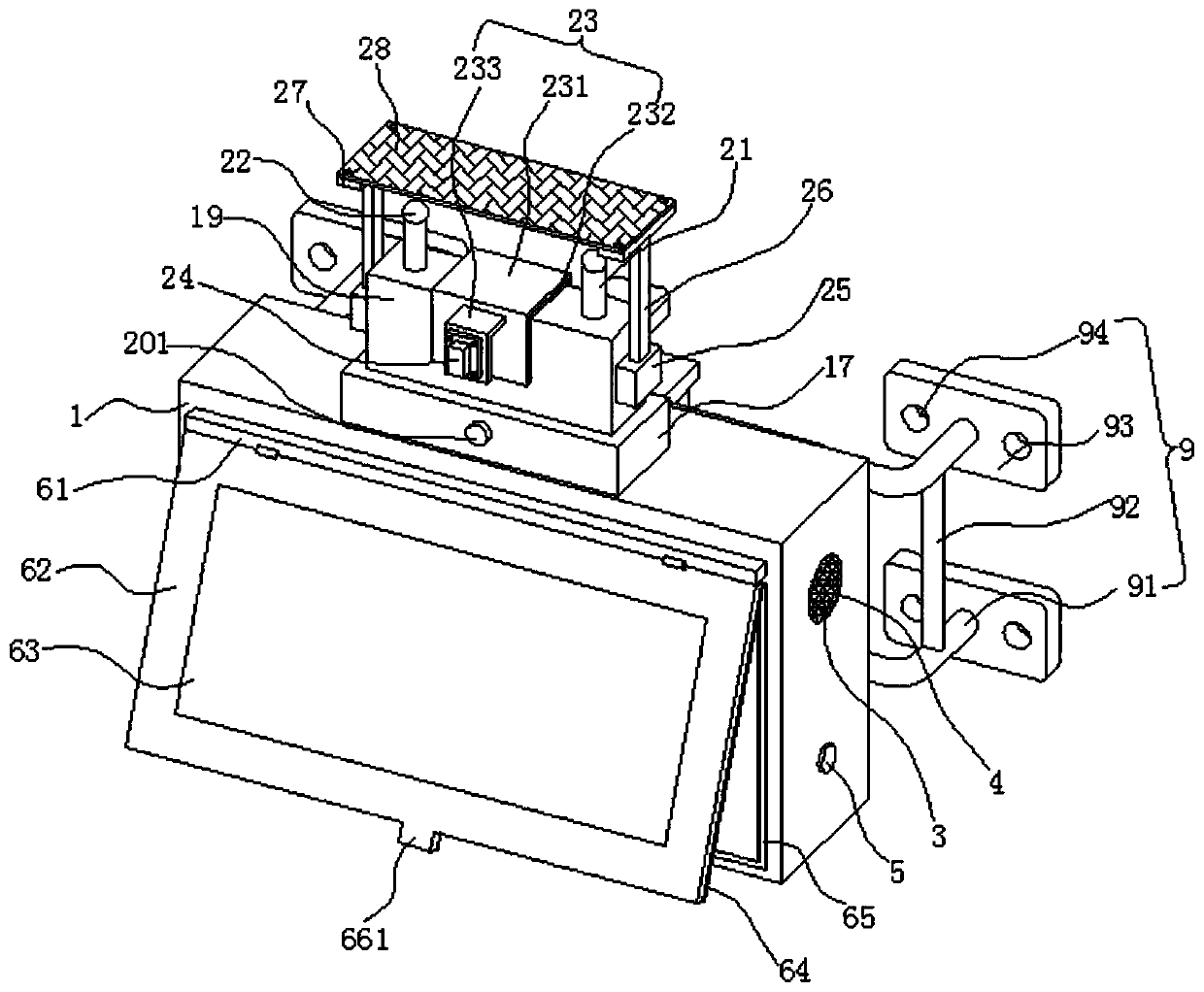

Tungsten ore underground air quality measurement method and device

InactiveCN111089944AImprove detection accuracyMining devicesGas analyser construction detailsMining engineeringGas concentration

Owner:JIANGXI QIANYAN TECH CONSULTING CO LTD

Production method of negative-ion chinlon short fibers

InactiveCN105671674ANegative ion function is goodGood effectMonocomponent polyamides artificial filamentArtifical filament manufactureFiberFlexural strength

The invention discloses a production method of negative ion nylon staple fiber, which comprises the following steps: 1) dropping 5-10 wt% sodium silicate aqueous solution into a suspension liquid of 300-400 mesh tourmaline fine powder with a solid content of 40-60% , keep the constant temperature at 50-70°C for 10-30 minutes, then separate the solid from the liquid and dry the solid to obtain anion particles; 2) mix nylon slices and anion particles at a weight ratio of 10-5:1, and heat up to a molten state , granulating to obtain the masterbatch; 3) spinning the masterbatch, cleaning, drying and winding the spinning to obtain far-infrared nylon staple fibers. Compared with the prior art, the nylon staple fiber obtained by the invention has good anion function, long-lasting effect, a tensile strength of more than 120Mpa, and a bending strength of more than 150Mpa.

Owner:ZHANGJIAGANG ANSHUN TECH DEV

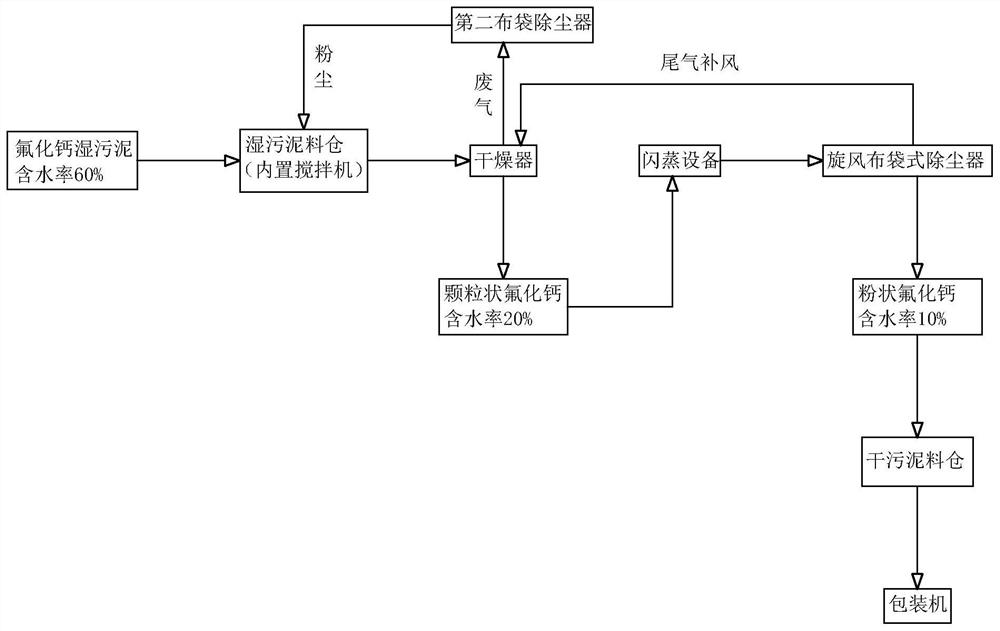

Method for recovering powdery calcium fluoride products from calcium fluoride sludge resources

PendingCN112850768ACompliant with usage standardsAvoid pollutionCalcium/strontium/barium fluoridesSludgeEngineering

Owner:丁学锋 +1

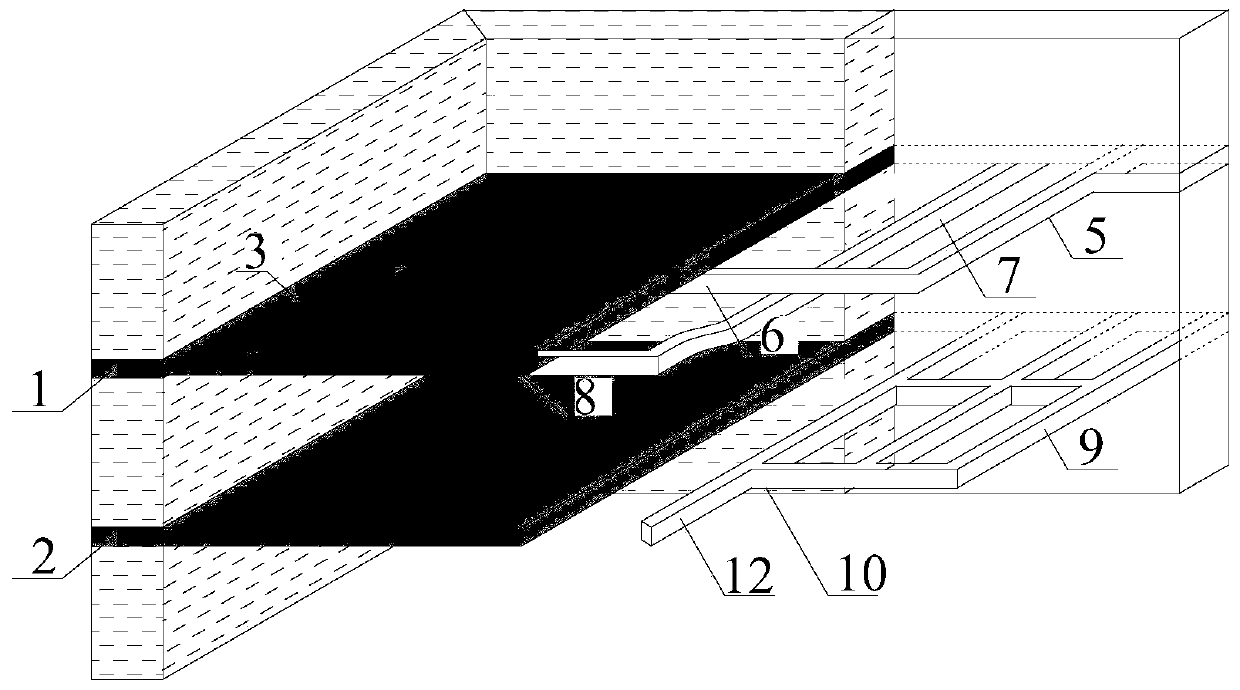

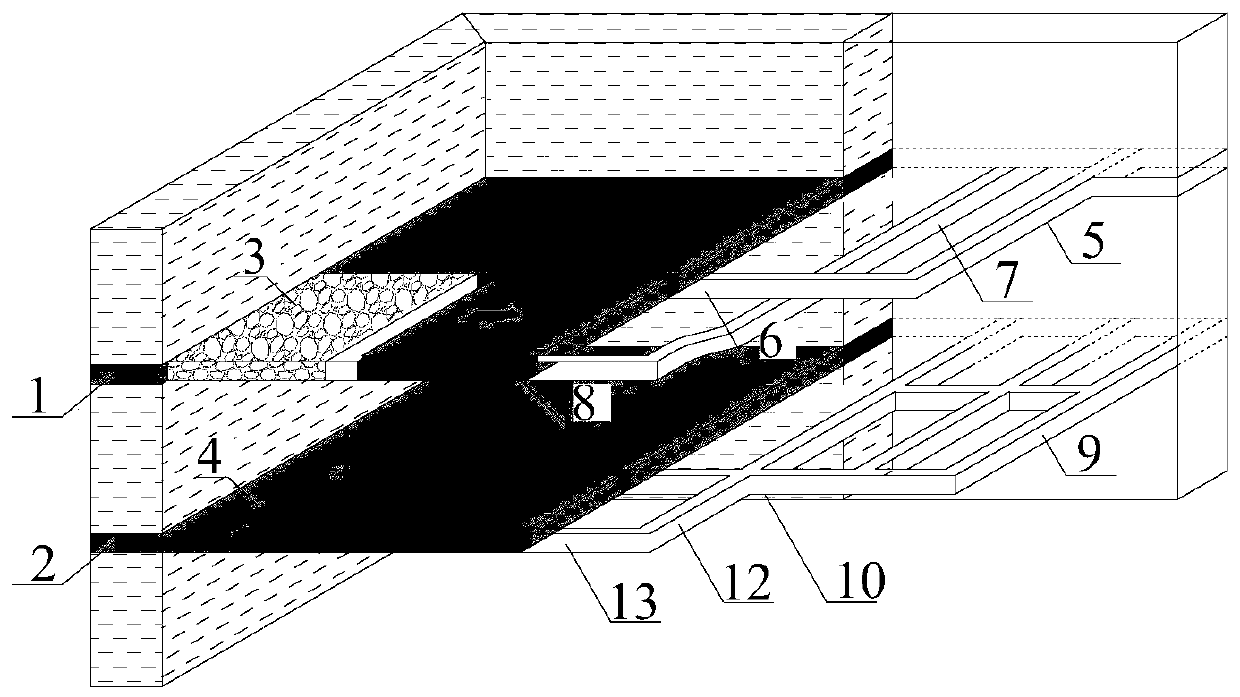

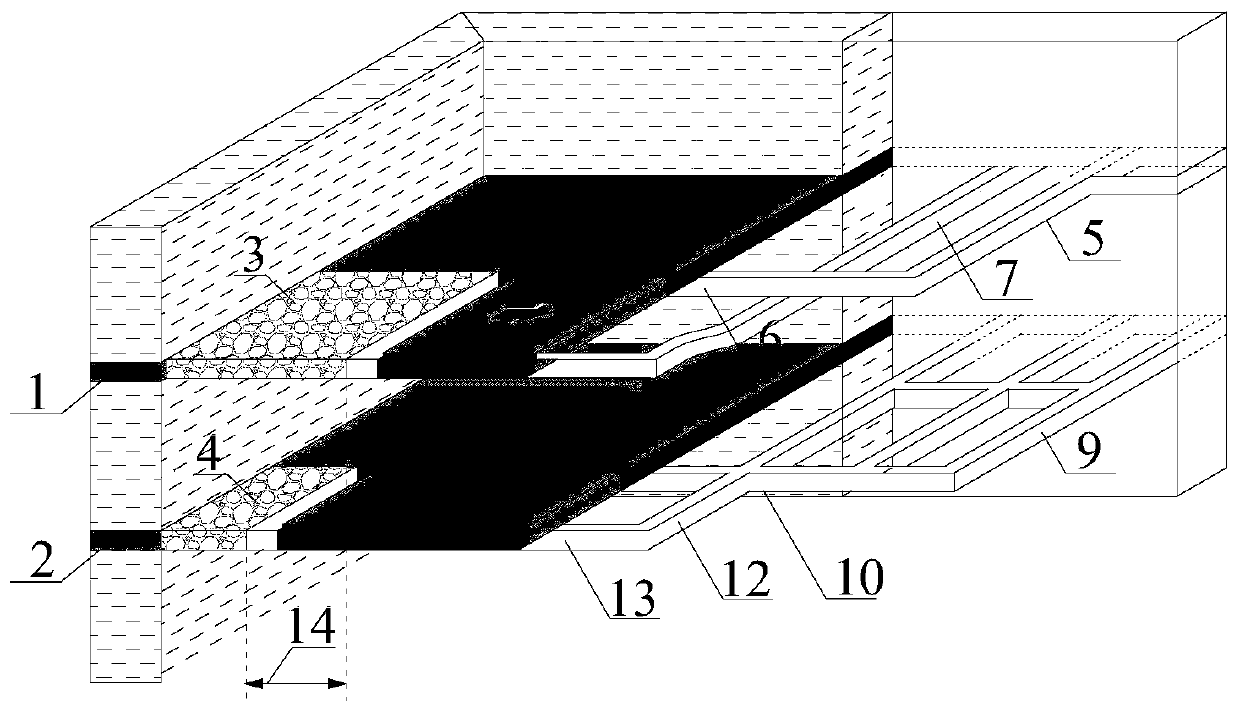

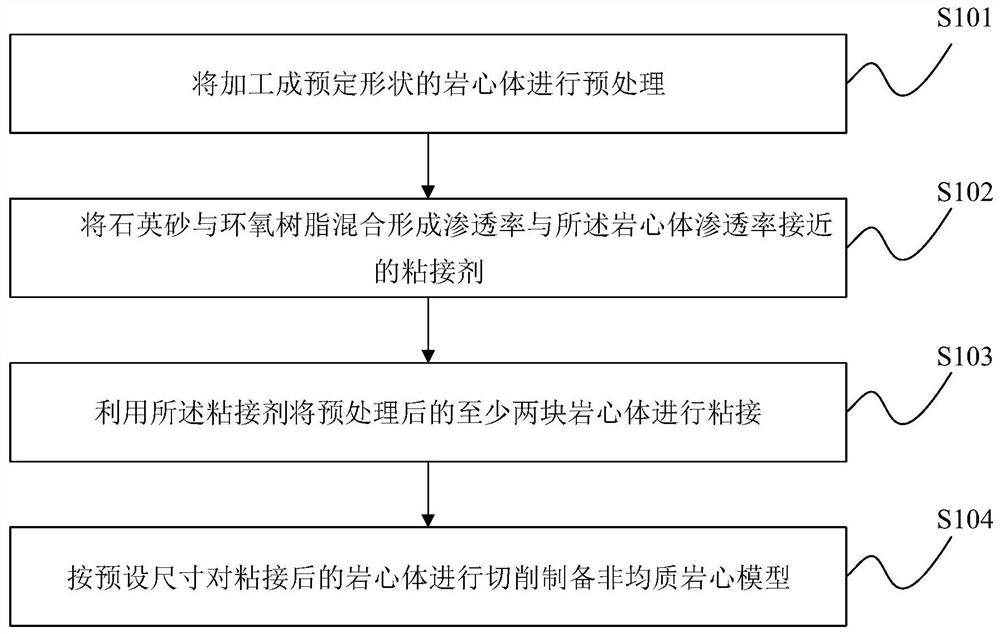

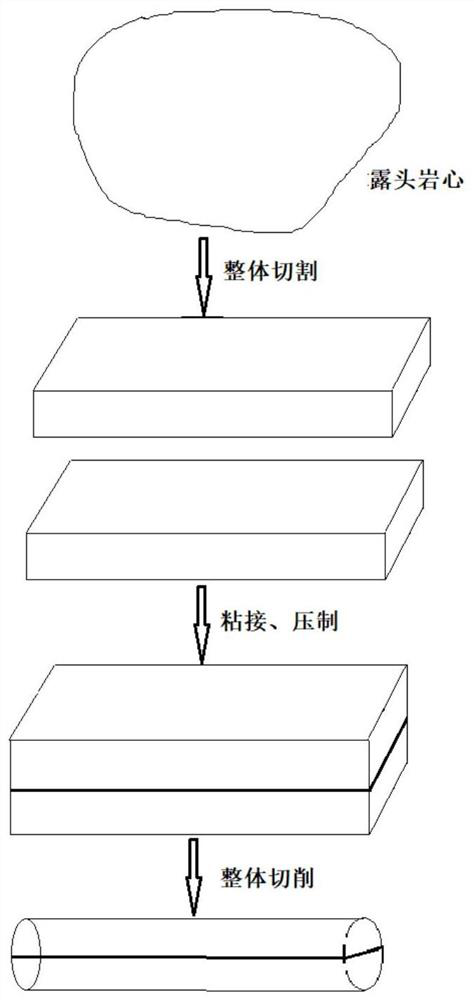

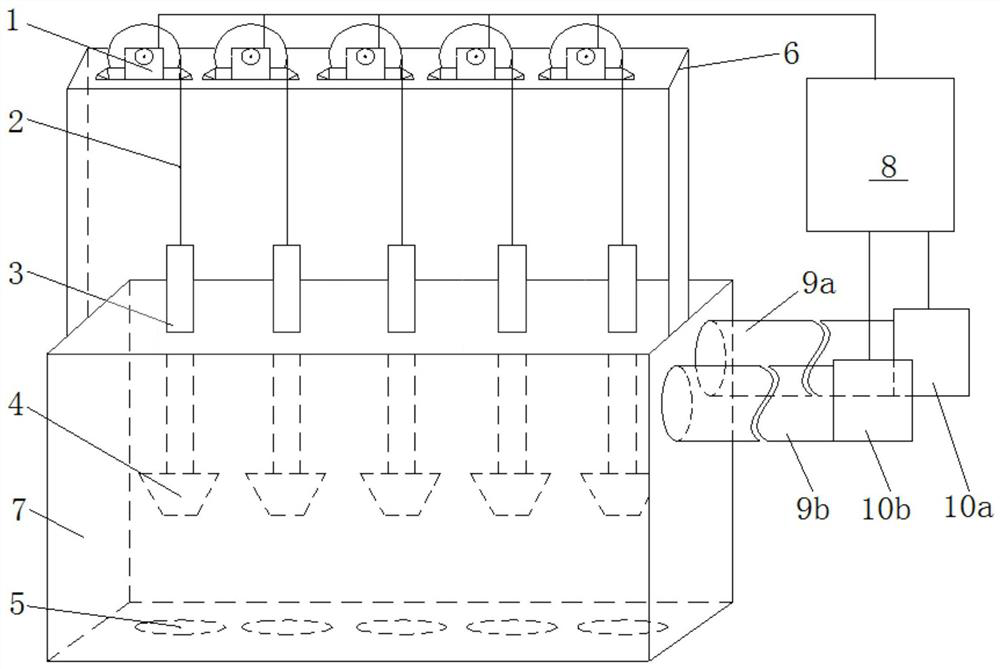

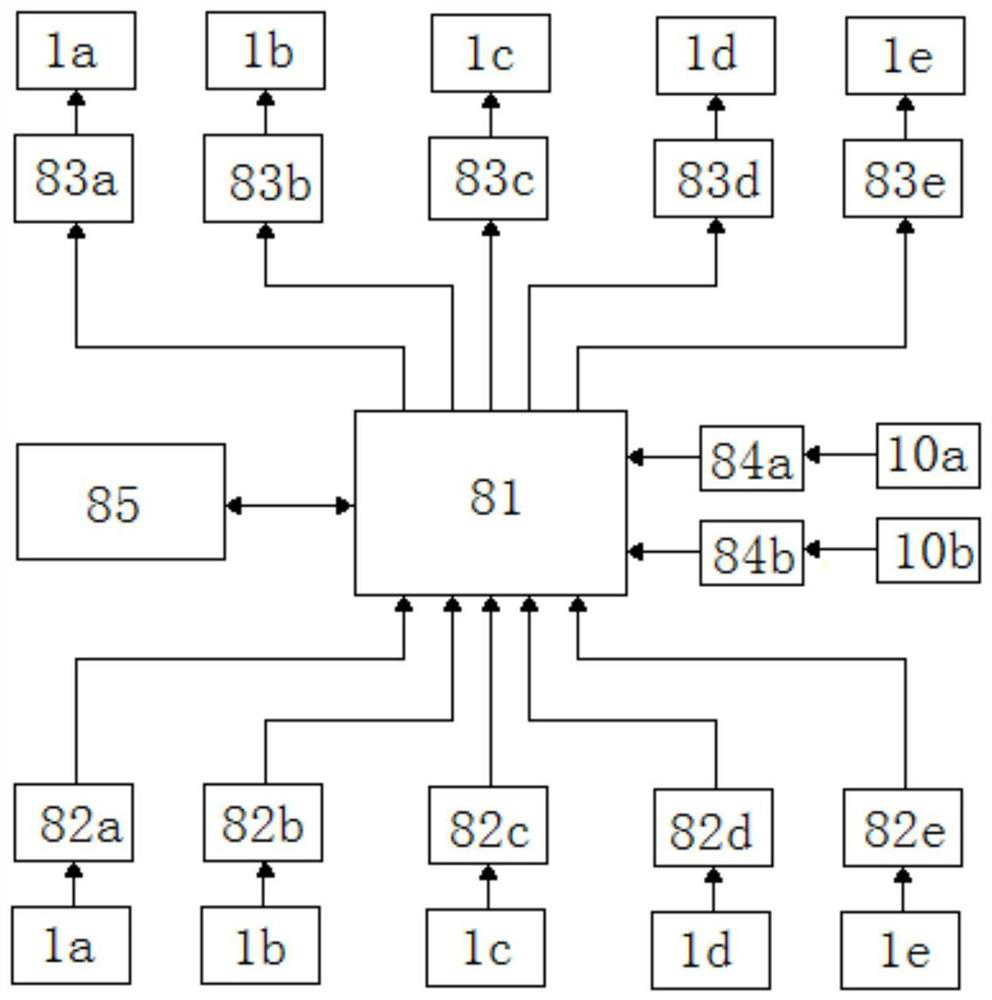

Heterogeneous core model and preparation method thereof

PendingCN114459841APromote technological progressGuaranteed stabilityPreparing sample for investigationEarth material testingStockworkMineralogy

The invention provides a heterogeneous rock core model and a preparation method thereof. The method comprises the following steps: preprocessing a rock core body processed into a predetermined shape; quartz sand and epoxy resin are mixed to form an adhesive with the permeability close to that of the core body; the at least two pretreated rock core bodies are bonded through the bonding agent; and cutting the bonded core body according to a preset size to prepare the heterogeneous core model. According to the method, multiple outcrop cores with the same layer position or similar physical properties as a natural core of a reservoir can be adopted and integrally bonded, pressed and cut to form a multi-layer heterogeneous one-dimensional long core model with the single length of 1 m, the stability of seepage can be guaranteed, the vertical heterogeneity of the reservoir can be simulated, and the method has the advantages of being simple in structure, convenient to operate and high in practicability. And particularly, the method has greater advantages in development of a method for enlarging the swept volume, the technical progress of experimental means is promoted, and a physical simulation oil displacement experimental method is perfected.

Owner:PETROCHINA CO LTD

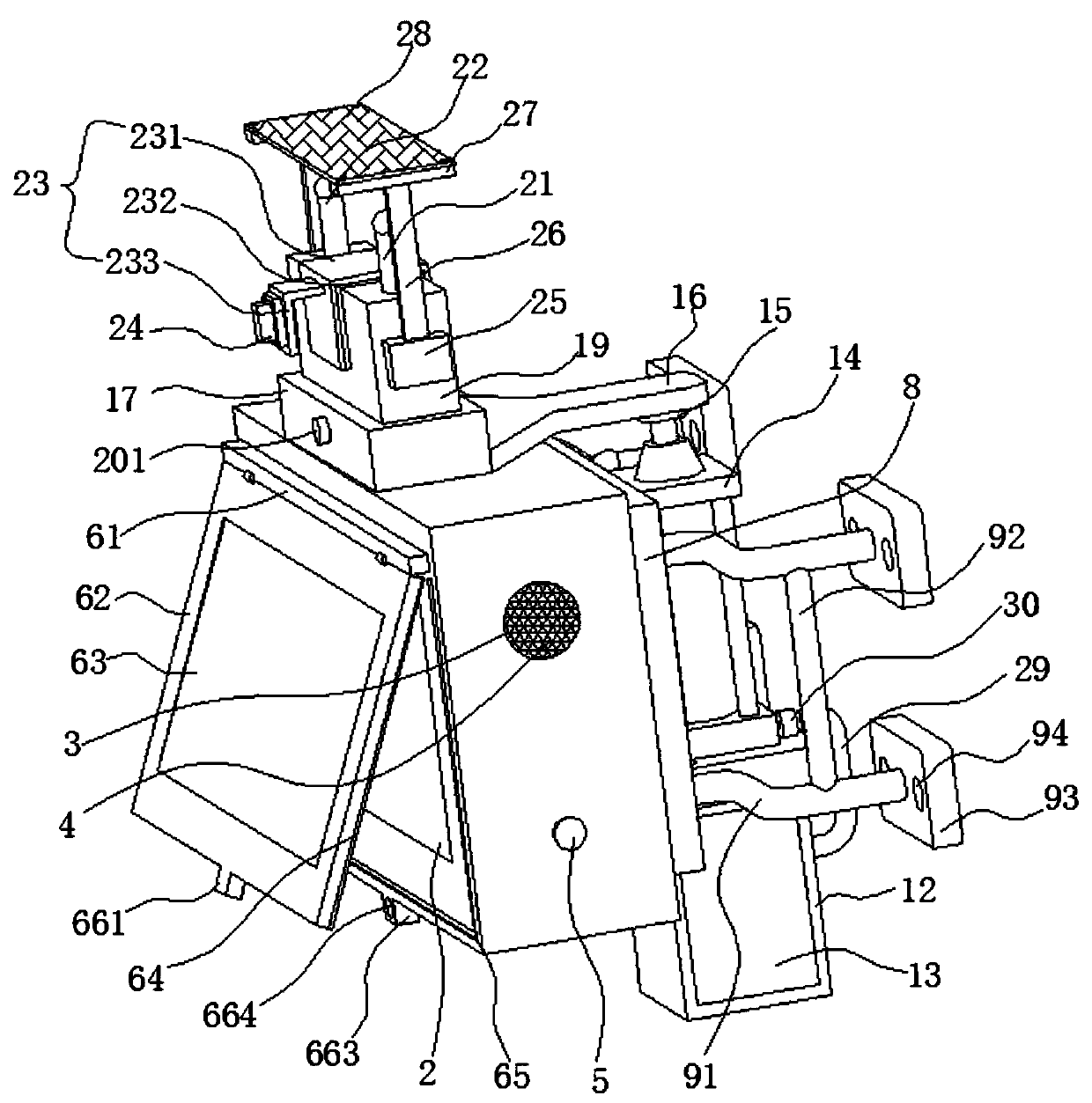

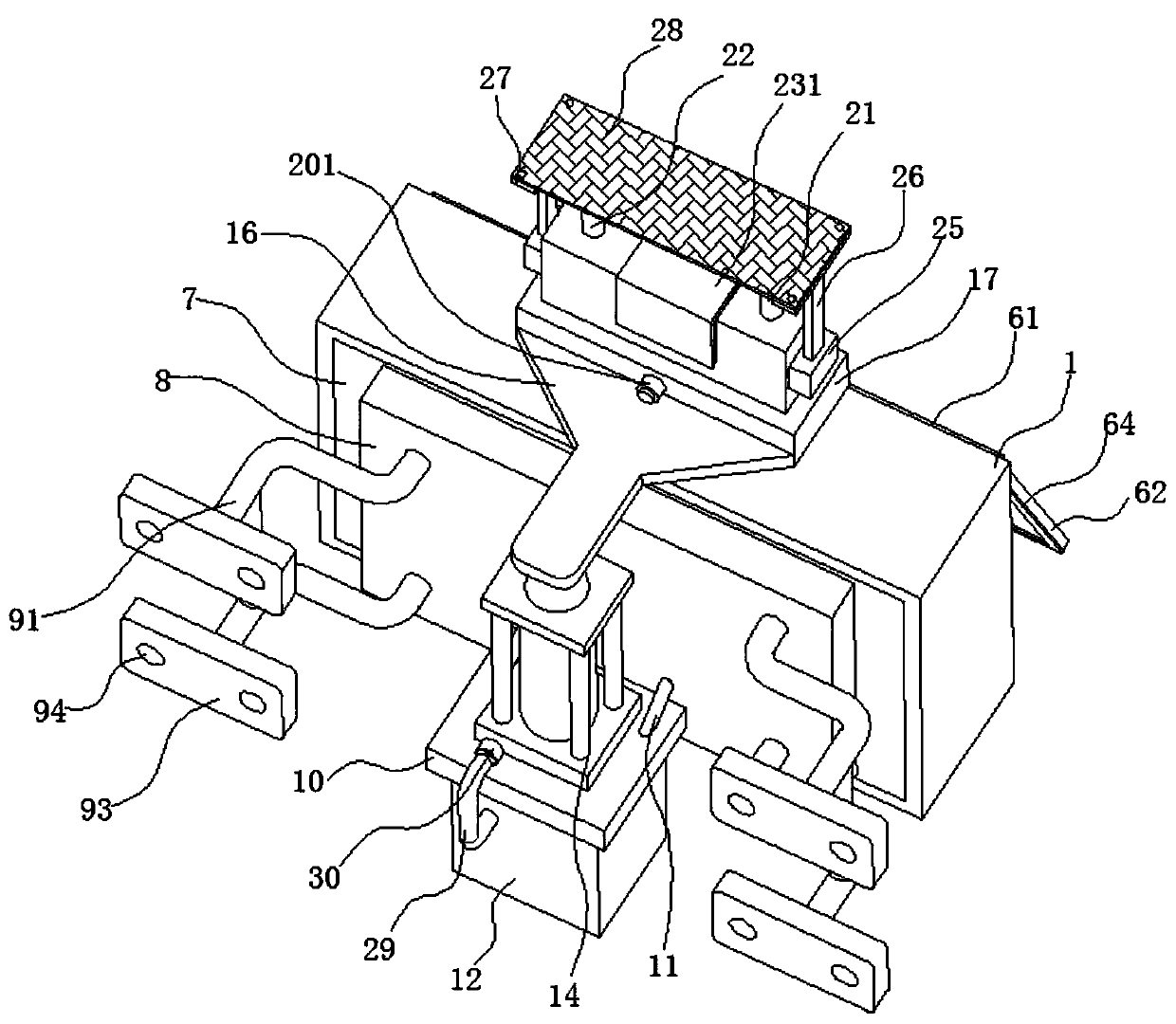

Automatic ore feeding device of magnetic separators and automatic ore feeding control method

ActiveCN112173743AChange open and close stateChange opening sizeConveyorsMagnetic separationMining engineeringMagnetic separator

Owner:SHOUGANG CORPORATION

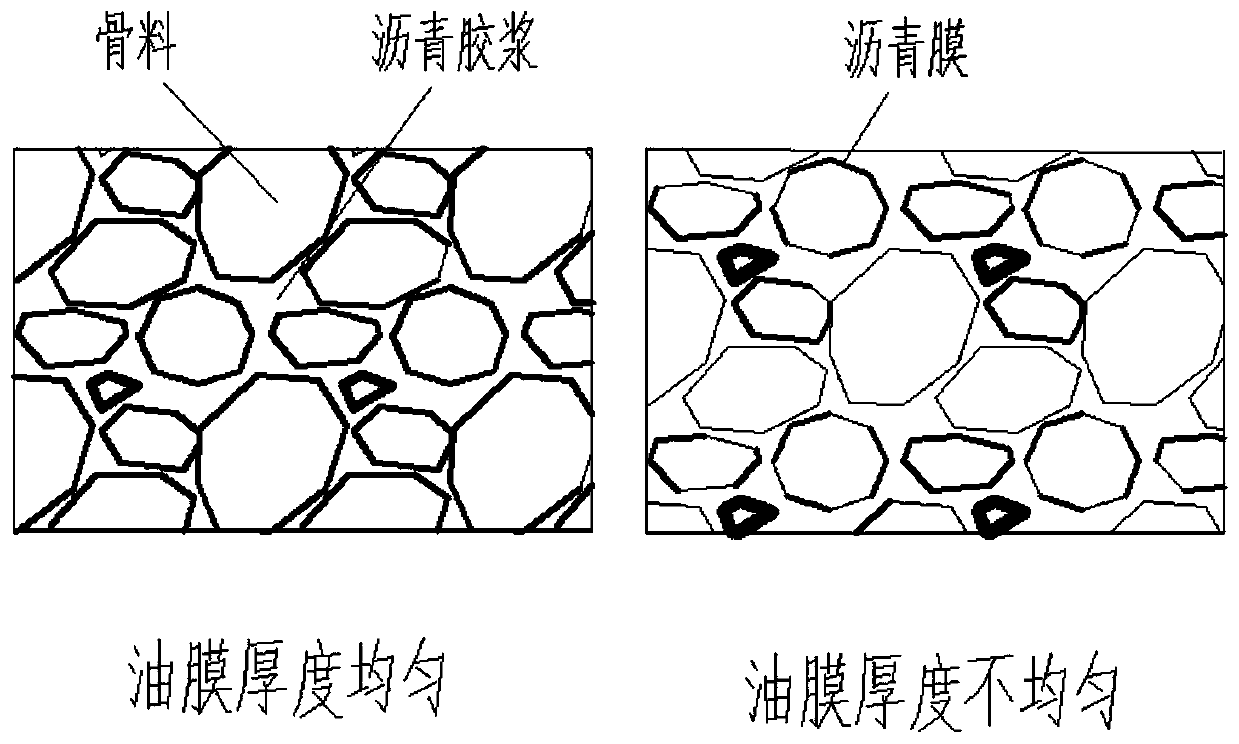

Environment-friendly color pavement cold-patching material and preparation technology thereof

The invention discloses an environment-friendly color pavement cold-patching material and a preparation technology thereof. The preparation technology comprises the following steps of uniformly mixing a pigment and dried stone materials according to a weight ratio of 2: 100, adding an environment-friendly color pavement binder into the mixture according to a weight ratio of the environment-friendly color pavement binder to the dried stone materials of 10: 100, and mixing. The environment-friendly color pavement binder is prepared by mixing 60-70wt% of a material A and 30-40wt% of a material B and carrying out shearing of the mixture by a colloid mill, wherein the material A is obtained by mixing 50 to 55wt% of furfural extract oil and 45 to 50wt% of petroleum resin; and the material B is obtained by mixing 3 to 4 parts by weight of N-alkyl-triethyl-tertiary amine, 6 to 8 parts by weight of cationic SBS latex, 8 parts by weight of Na2SO3, 6 parts by weight of 1-aminoethyl-2-heptadecylimidazoline and 74 to 77 parts by weight of water. The environment-friendly color pavement cold-patching material has a low cost, is convenient for use, does not influence traffic during construction, and has a color and binder properties the same as a color and binder properties of a color pavement needing to be repaired.

Owner:HENAN WANLI ROAD&BRIDGE GRP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap