Method for up-down replacement collaborative mining of close distance coal seams

A mining method and short-range technology, applied in underground mining, surface mining, earth-moving drilling and other directions, can solve the problems of affecting the safety of coal mine production, the working face being affected by the mining movement, and the low efficiency of mining replacement, so as to alleviate the tension of mining replacement. Difficulties, wide adaptability and field applicability, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

[0029] The method for synergistic mining up and down of the short-distance coal seam of the present invention, its steps are:

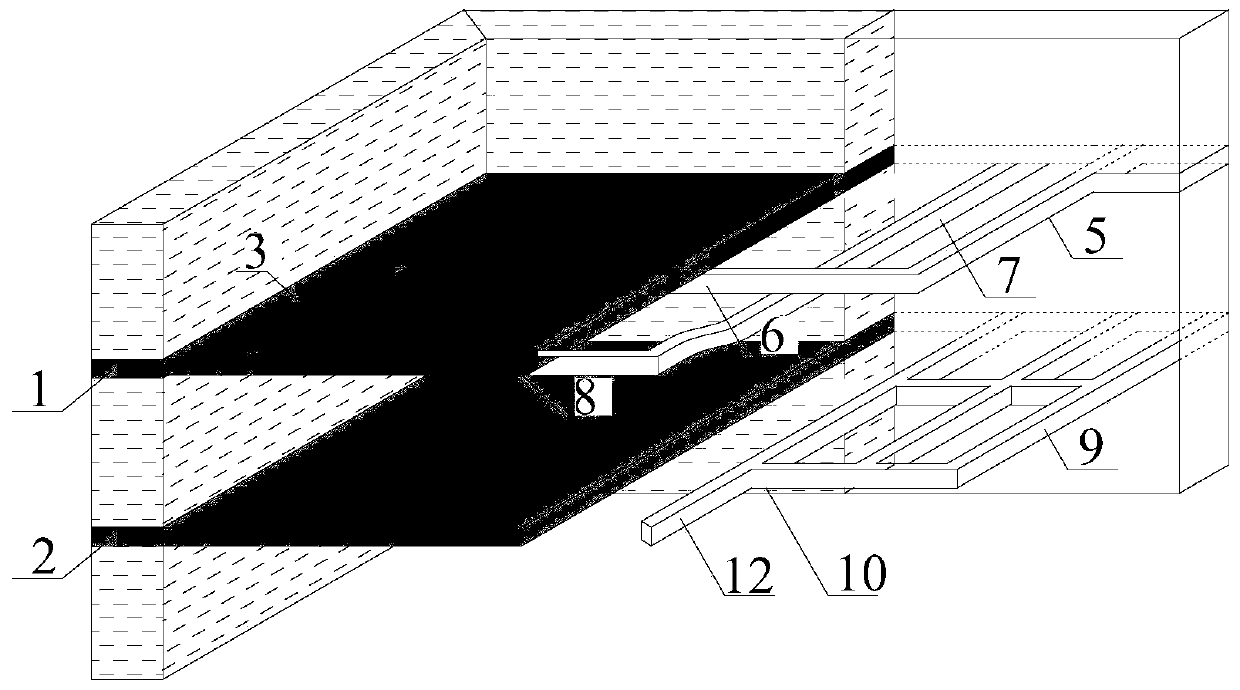

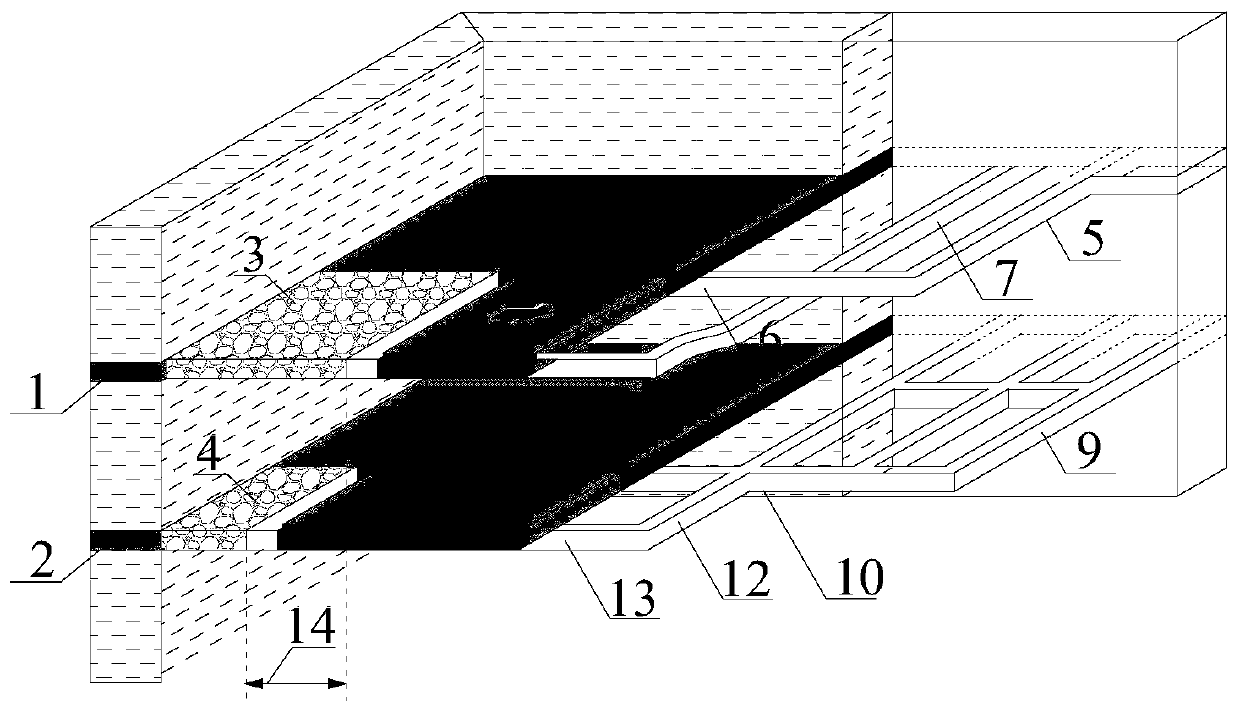

[0030] like figure 1 As shown, a) Select the upper coal seam as the main mining seam, and the lower coal seam as the auxiliary mining coal seam, and set the working faces in the main coal mining seam and the auxiliary mining coal seam at a certain stacking distance of 14 or staggering distance of 17, in order Gradually take over the mining, the first mining face is arranged in the main coal seam, and the first replacement face is arranged in the auxiliary coal seam;

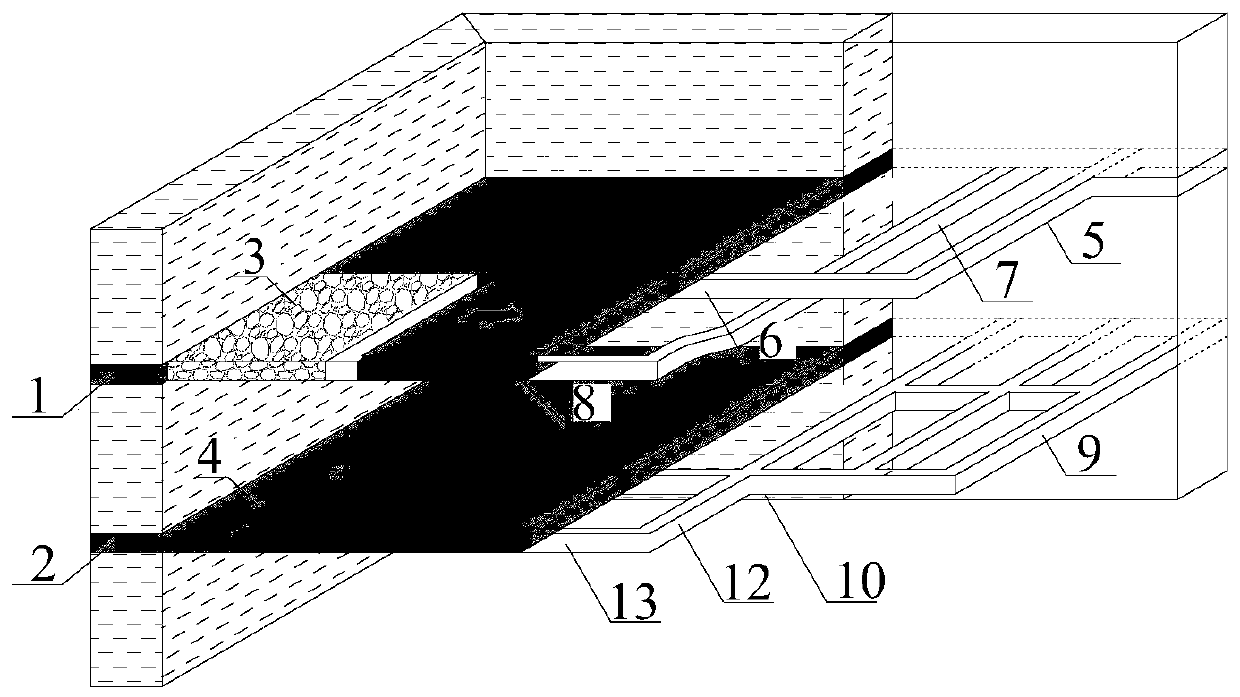

[0031] like figure 2 As shown, b) In the main coal mining seam, excavate from the coal transportation

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap