Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

800 results about "Process engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process engineering is the understanding and application of the fundamental principles and laws of nature that allow us to transform raw material and energy into products that are useful to society, at an industrial level. By taking advantage of the driving forces of nature such as pressure, temperature and concentration gradients, as well as the law of conservation of mass, process engineers can develop methods to synthesize and purify large quantities of desired chemical products. Process engineering focuses on the design, operation, control, optimization and intensification of chemical, physical, and biological processes. Process engineering encompasses a vast range of industries, such as agriculture, automotive, biotechnical, chemical, food, material development, mining, nuclear, petrochemical, pharmaceutical, and software development. The application of systematic computer-based methods to process engineering is "process systems engineering".

Apparatuses and Methods for Managing Liquid Volume in a Container

InactiveUS20120097567A1Good for healthTable equipmentsOther accessoriesPotable waterProcess engineering

The present invention proposes an apparatus (100) and method for managing the liquid volume in a container. The apparatus (100) comprises a detector (101) for detecting liquid volume changes in said container during a first preset period, a first determiner (102) for determining whether said changes are lower than said first preset threshold value and a presenter (103) for presenting the first prompt information in the case of said changes being lower than said preset threshold value. The apparatus and method provided in the present invention can prompt people to drink drinkable liquids such as water in time, enable people to control their drinking intake and are beneficial to their health.

Owner:KONINK PHILIPS ELECTRONICS NV

Electricity suppressing type electricity and heat optimizing control device, optimizing method, and optimizing program

ActiveUS20140188295A1Electrical degradationLevel controlBatteries circuit arrangementsTime scheduleProcess engineering

An optimized operating schedule is obtained while avoiding a complexity of formulation and optimization in response to an incentive type demand response. A device includes an energy predictor 10 setting a predicted value of energy of a control-target device 2 within a predetermined future period, a schedule optimizer 11 optimizing the operating schedule of the control-target device 2 within the predetermined period in accordance with a predetermined evaluation barometer, an incentive acceptance determiner 12 determining a time with a possibility that an incentive is receivable, an electricity suppressing schedule optimizer 13 optimizing, for a time with a possibility that the incentive is receivable, the operating schedule of the control-target device 2 based on a unit price of electricity fee having a unit price for calculating the incentive taken into consideration, and an adopted schedule selector 14 selecting either one of the operating schedules.

Owner:KK TOSHIBA

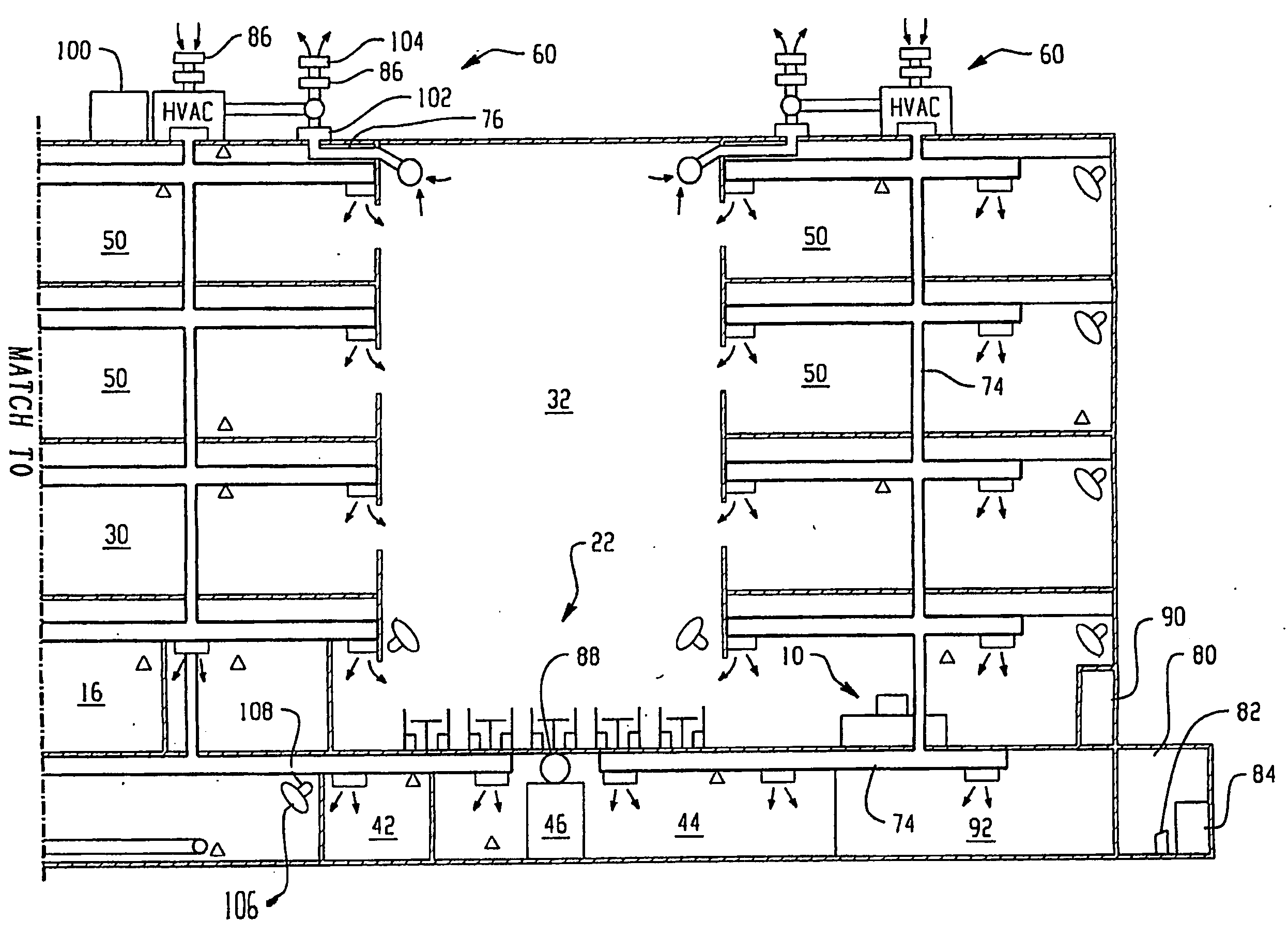

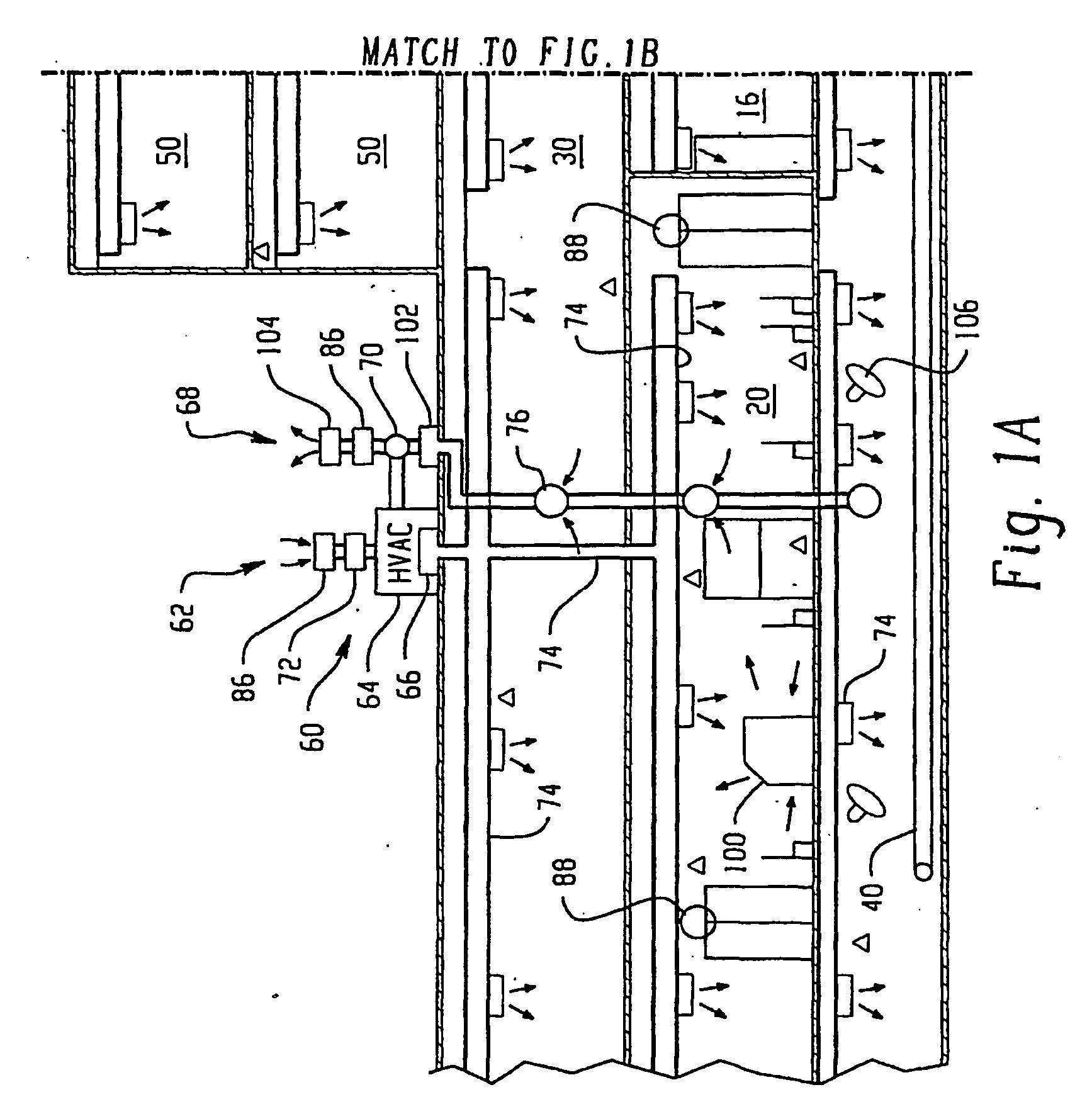

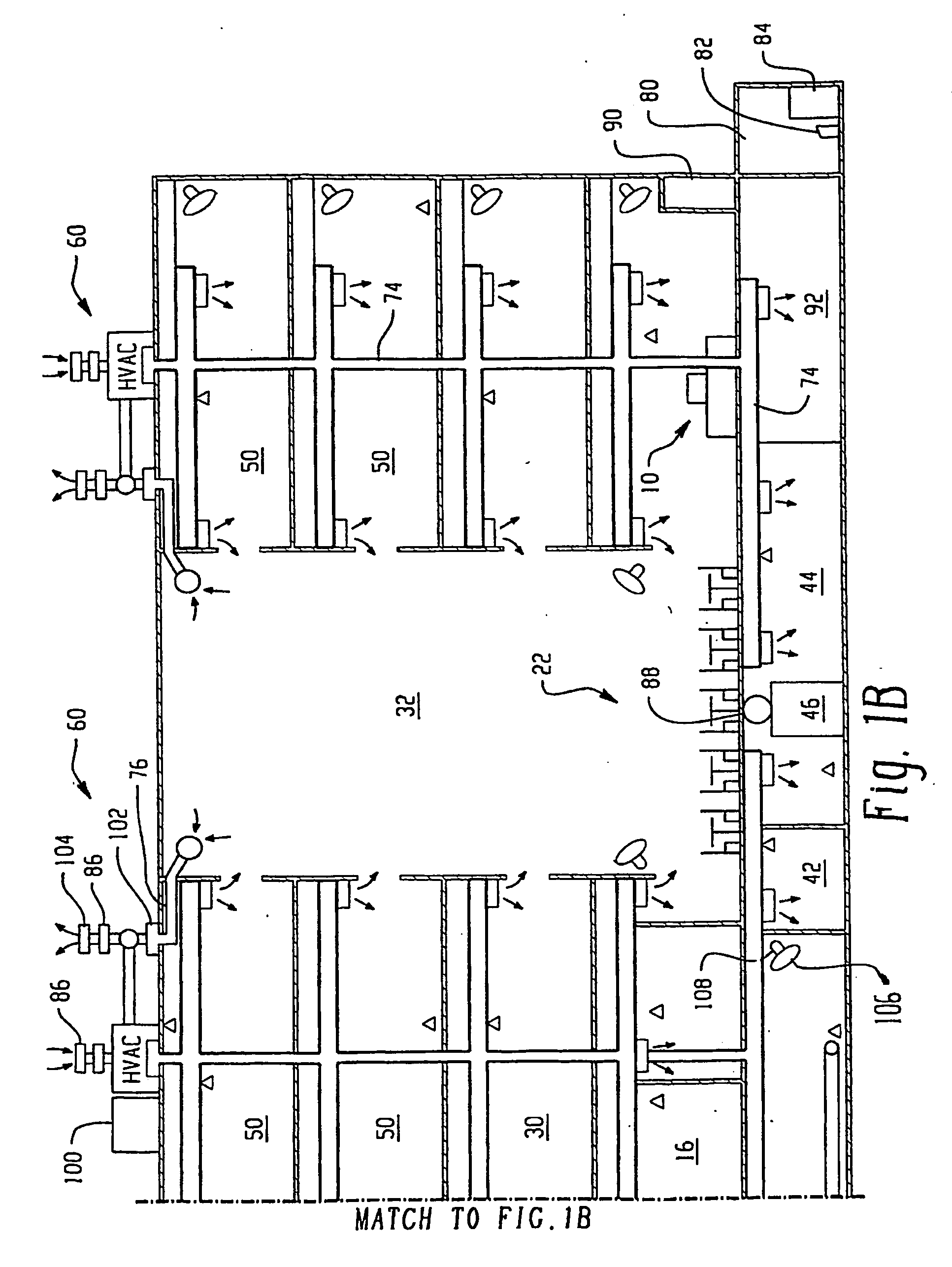

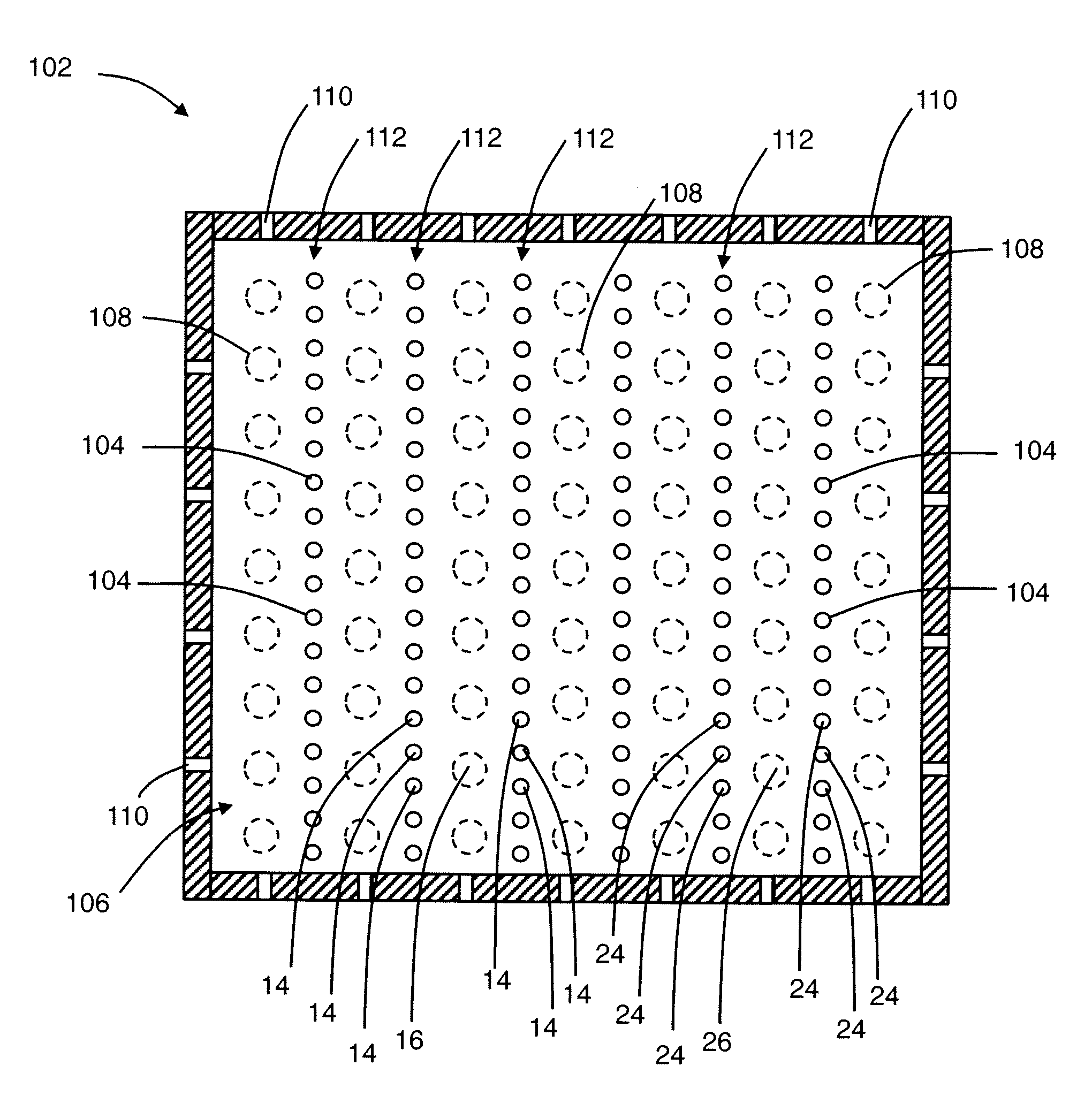

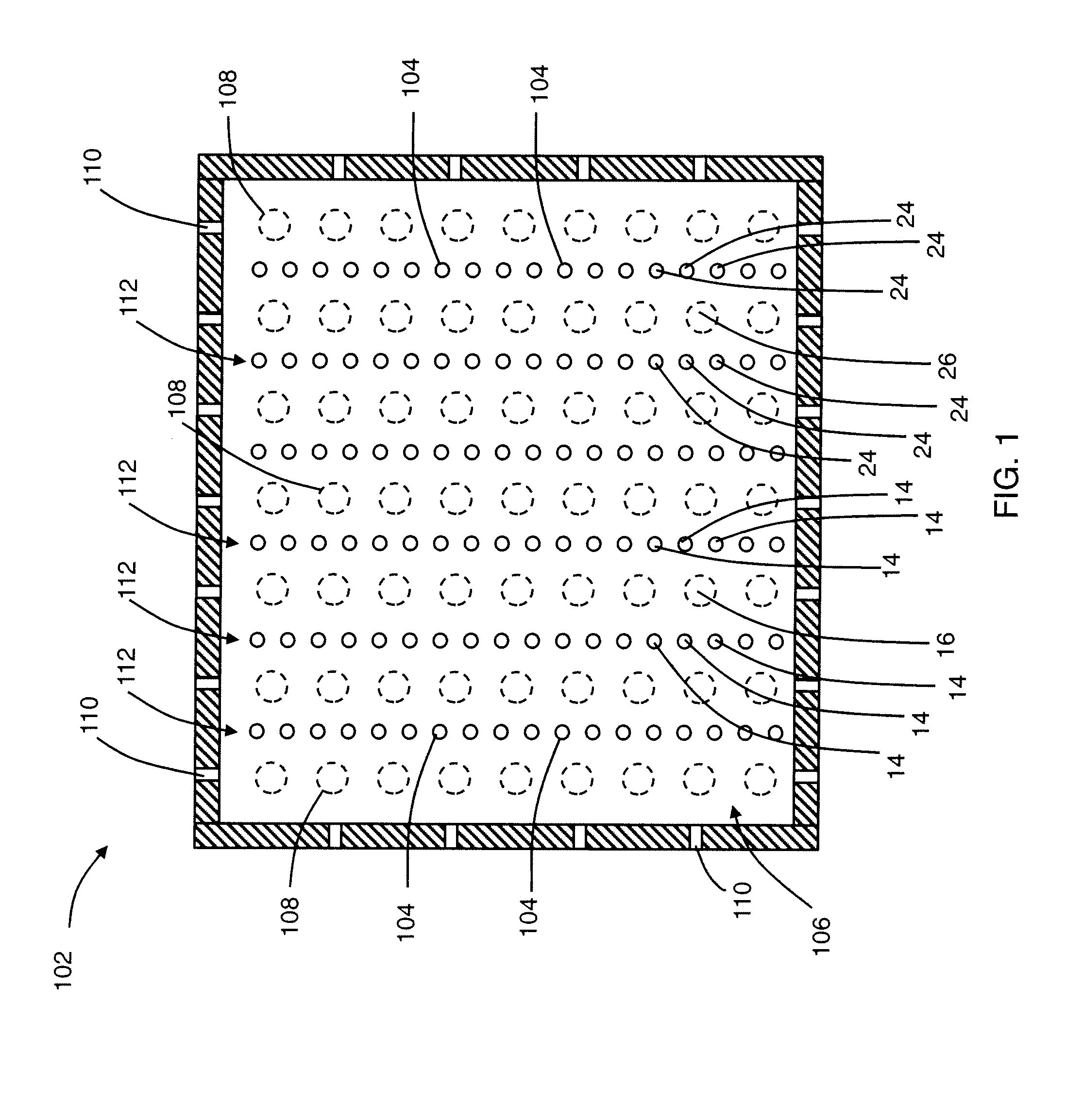

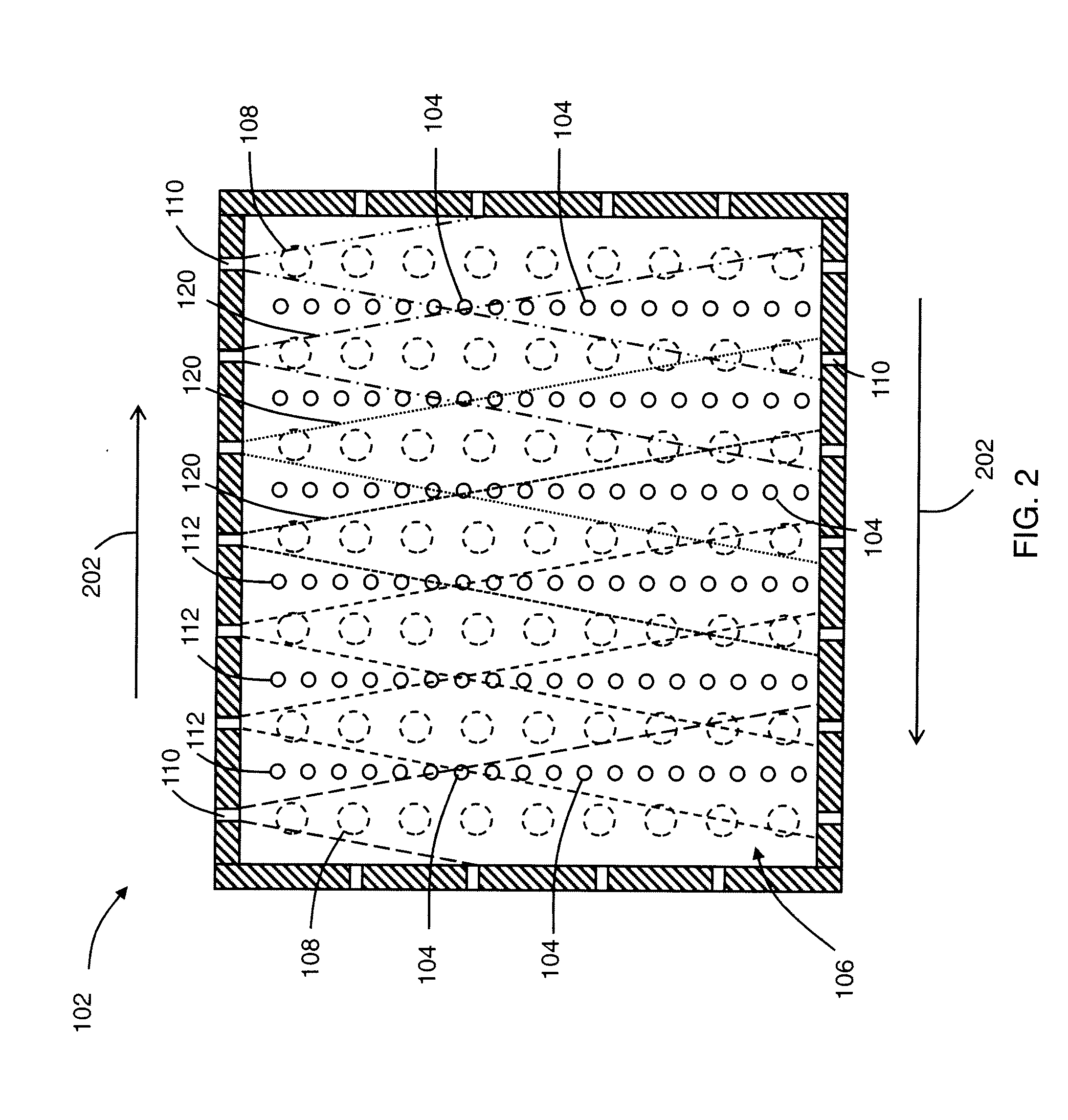

Integrated control and distribution system for the decontamination of large volume convoluted configuration spaces

ActiveUS20070140893A1Big spaceQuick implementationComponent separationSynthetic resin layered productsDistribution systemProcess engineering

Owner:STERIS CORP

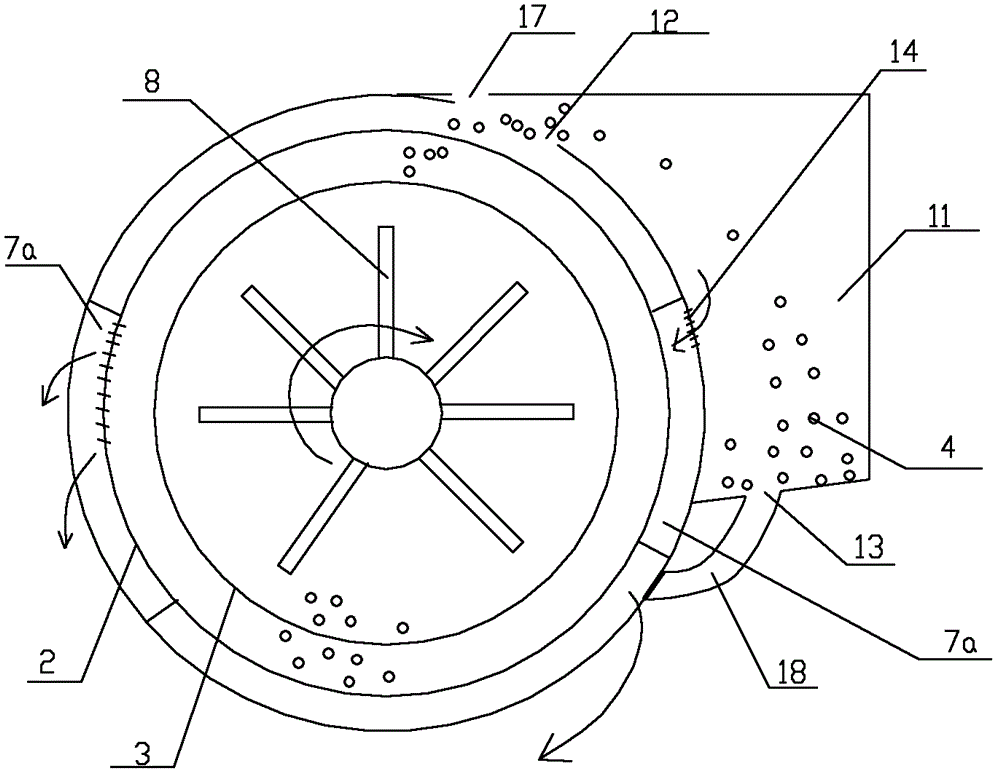

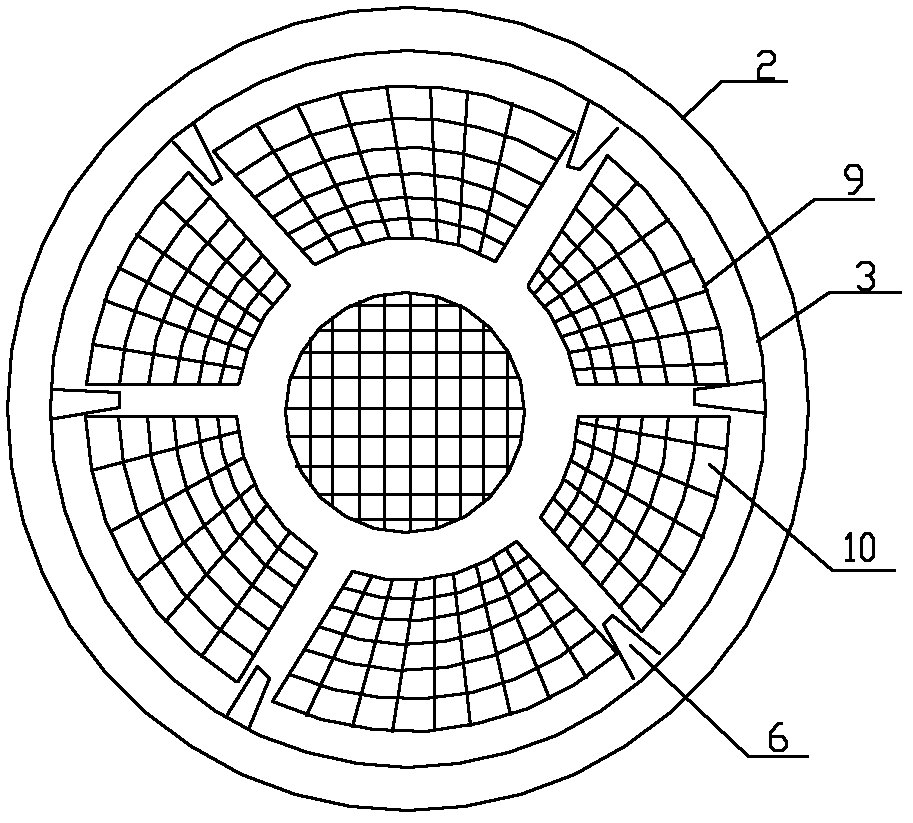

Washing machine and washing method

InactiveCN103061084ARealize deliveryAchieve separationOther washing machinesTextiles and paperSolid particleProcess engineering

Owner:XEROS LTD

Regulation and control testing device for preparation of bio-oil through quick thermal cracking of biomass

Owner:BEIJING FORESTRY UNIVERSITY

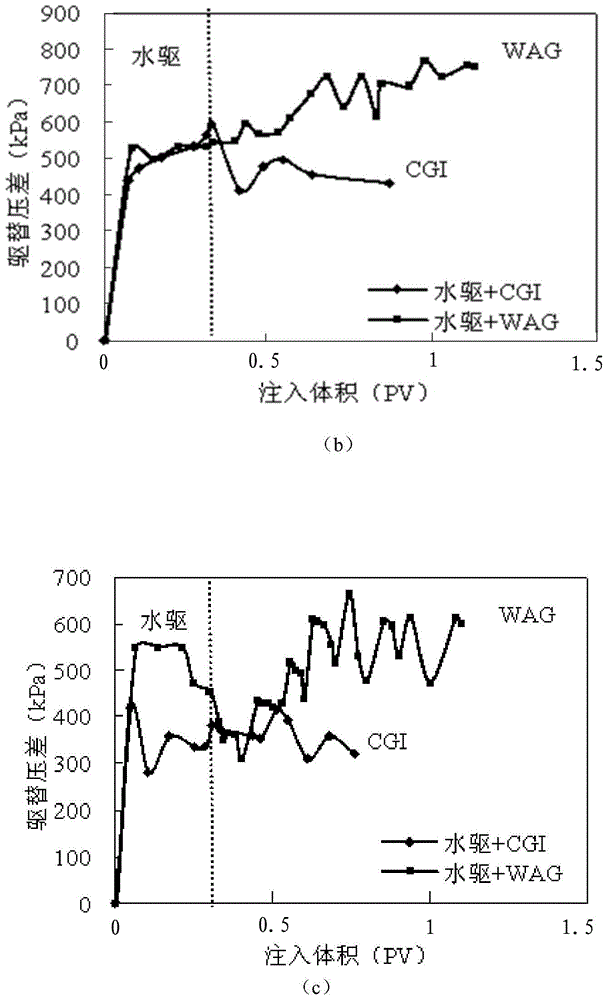

Carbon dioxide drive oil reservoir production method capable of realizing stage control on fluidity

ActiveCN104975829AExpand the affected volumeImprove mobility ratioFluid removalSealing/packingAliphatic amineProcess engineering

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

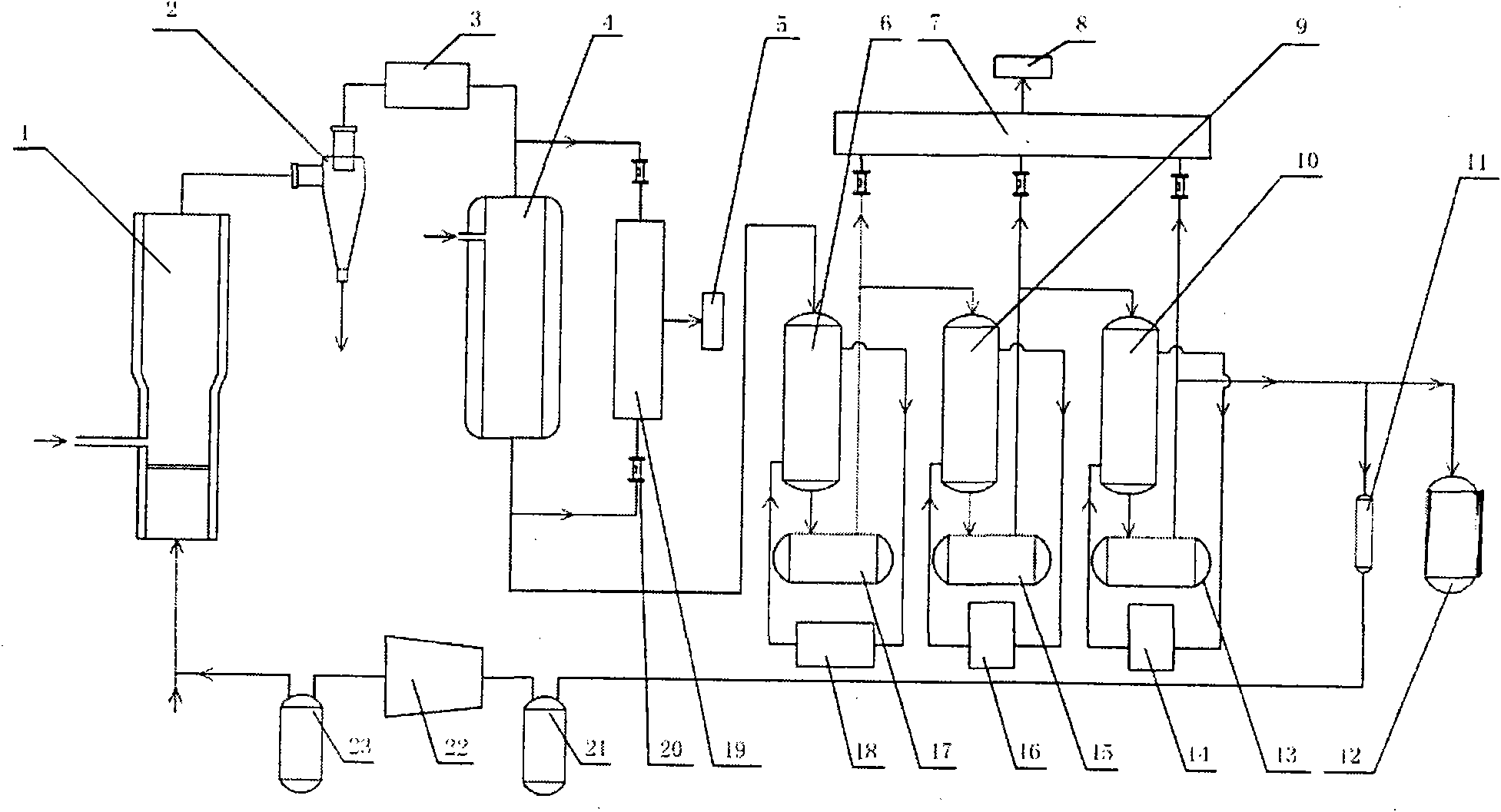

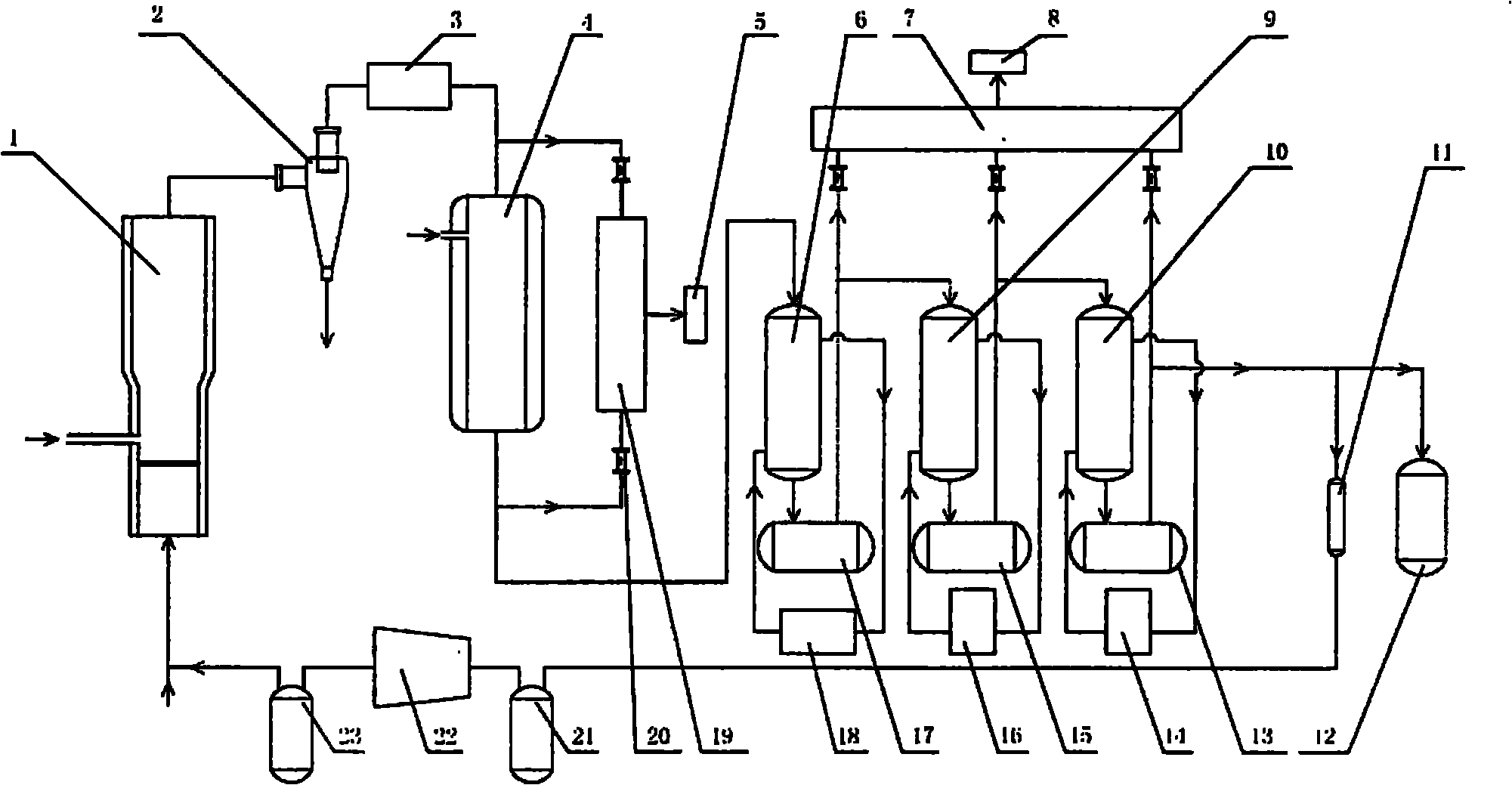

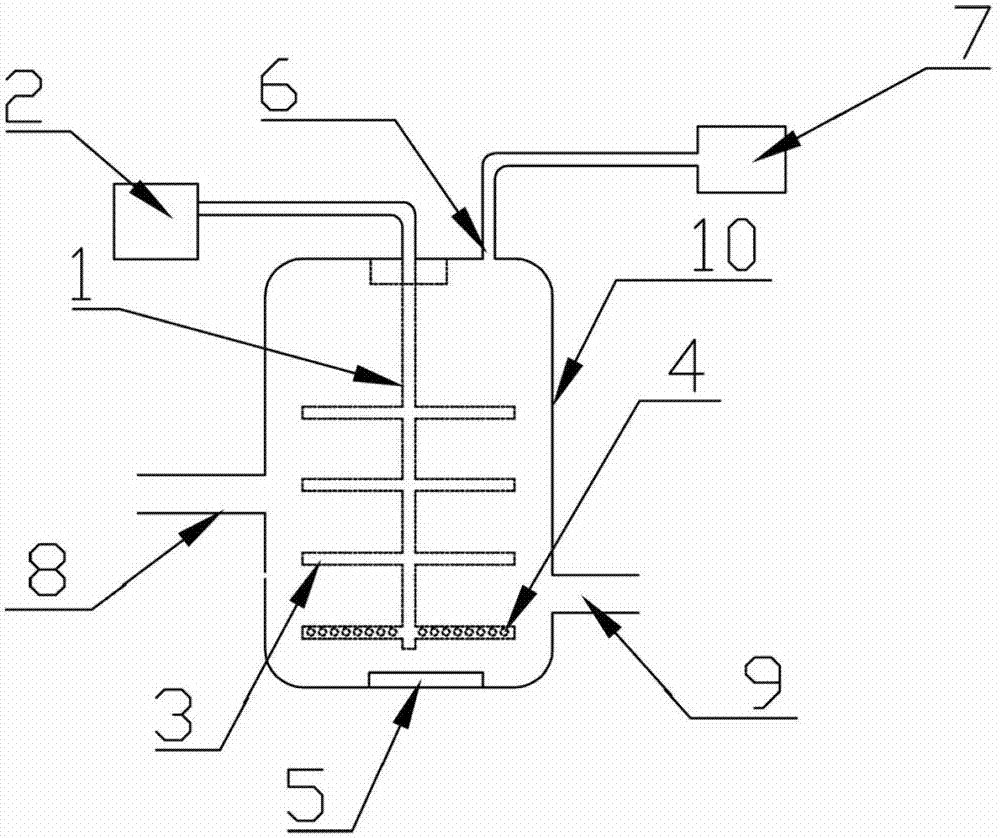

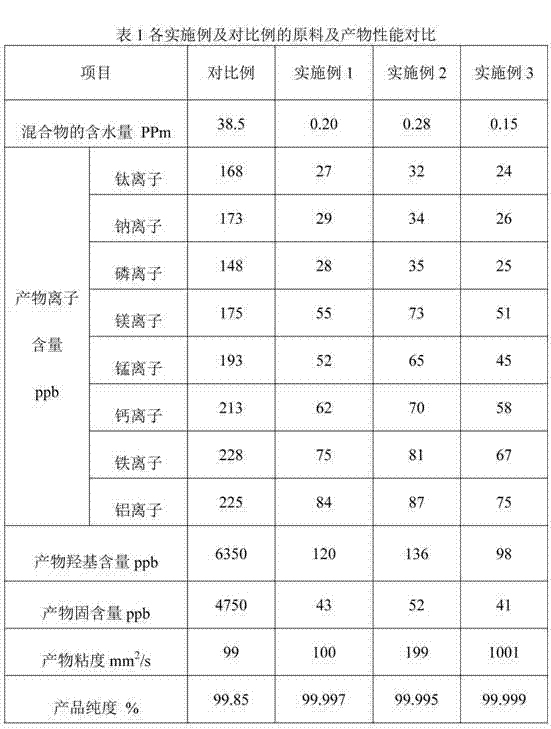

Continuous preparation technology of high-purity low-viscosity dimethicone

ActiveCN103073722AHigh purityMaintain catalytic activityChemical recyclingPtru catalystSilicone fluid

Owner:YICHANG COLLIN SILICON MATERIAL CO LTD

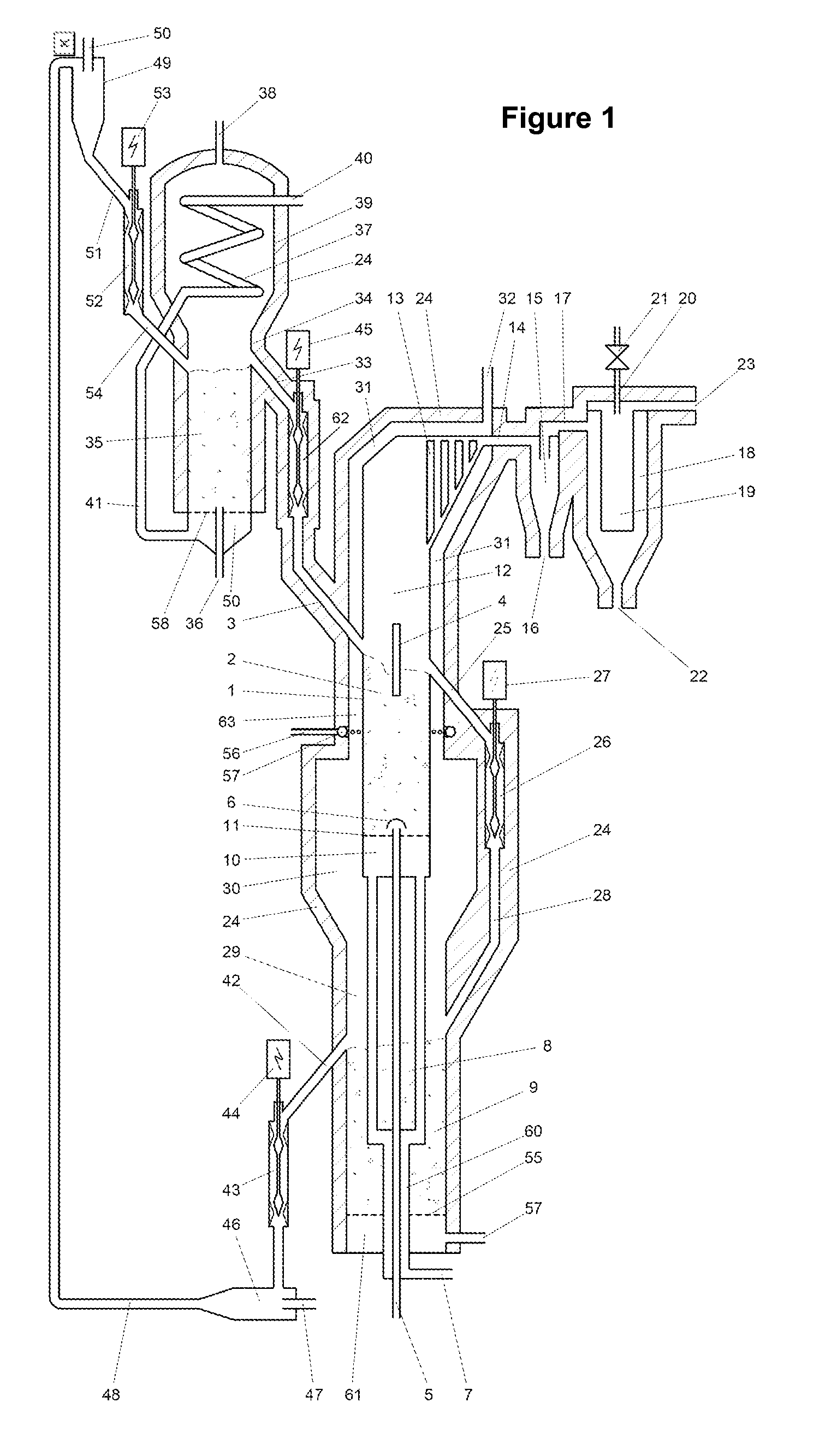

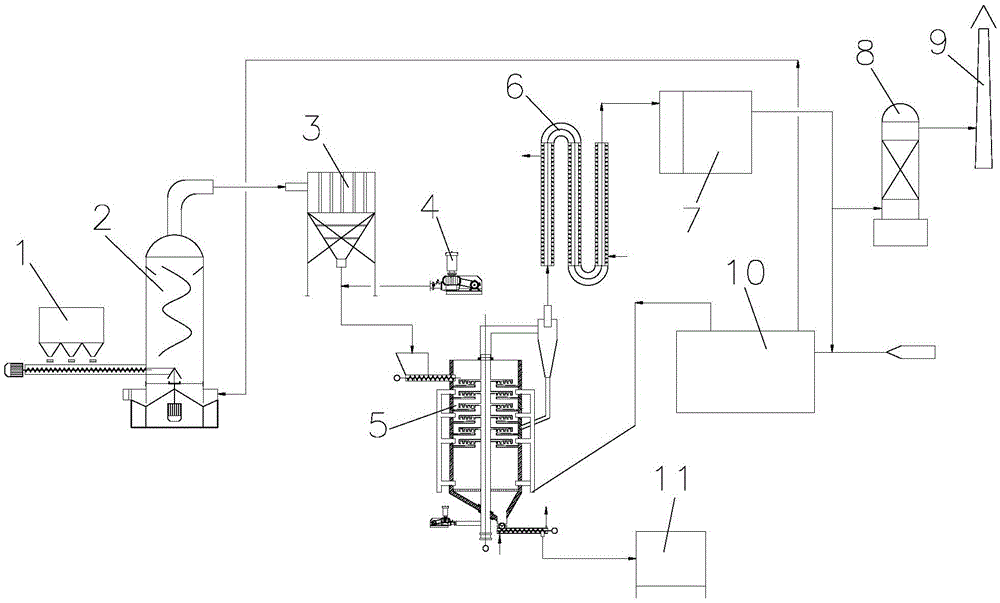

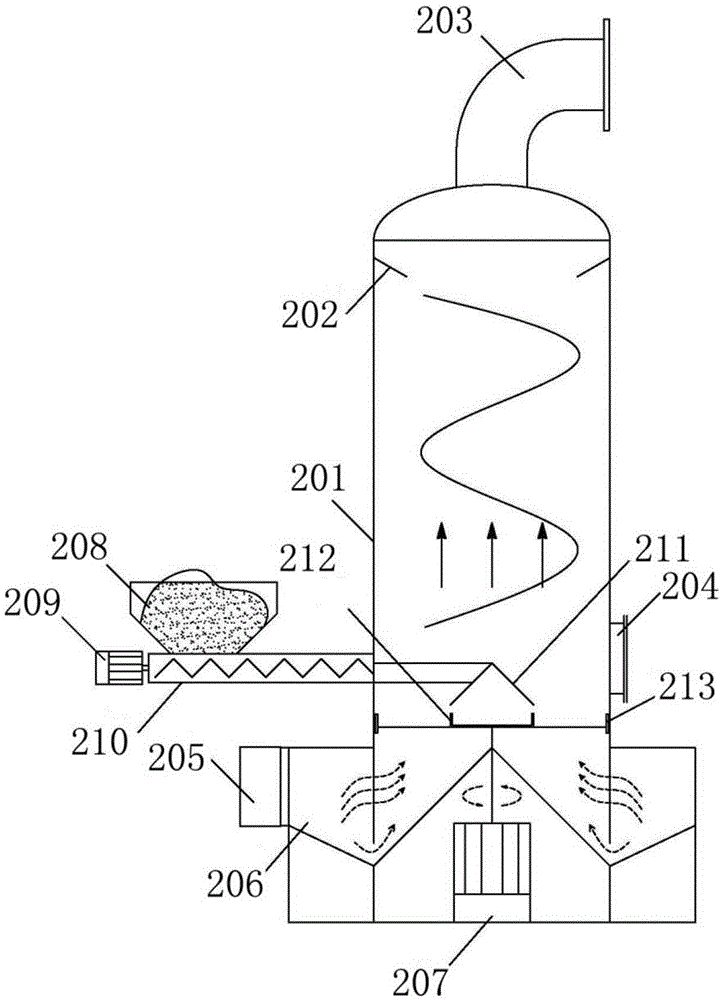

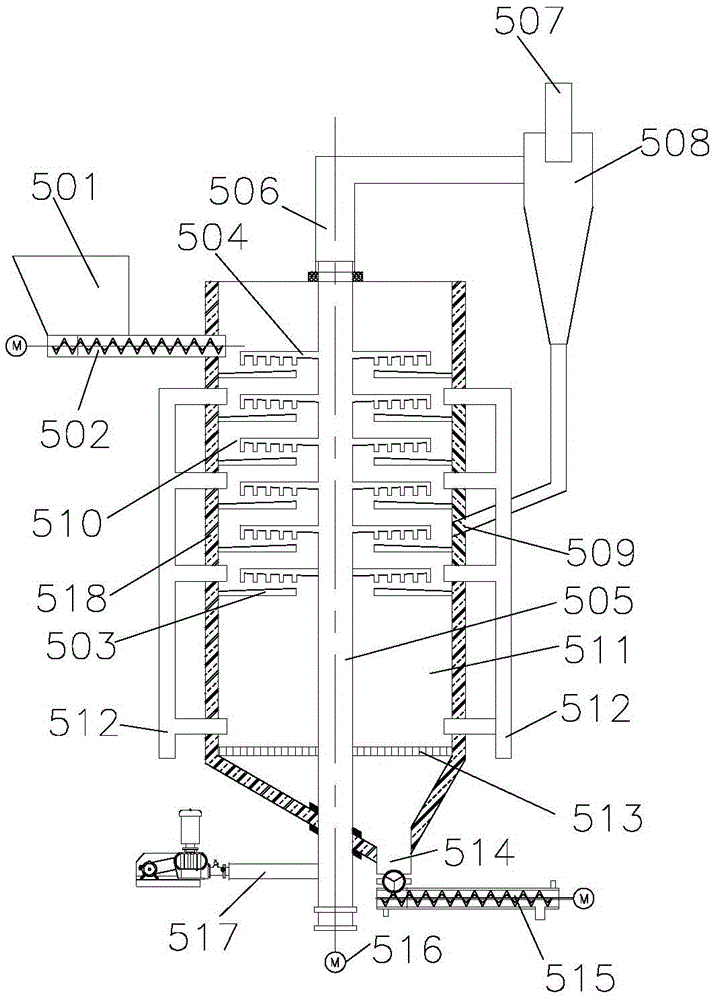

Equipment and a method for generating biofuel based on rapid pyrolysis of biomass

Owner:UNIV DE CONCEPCION

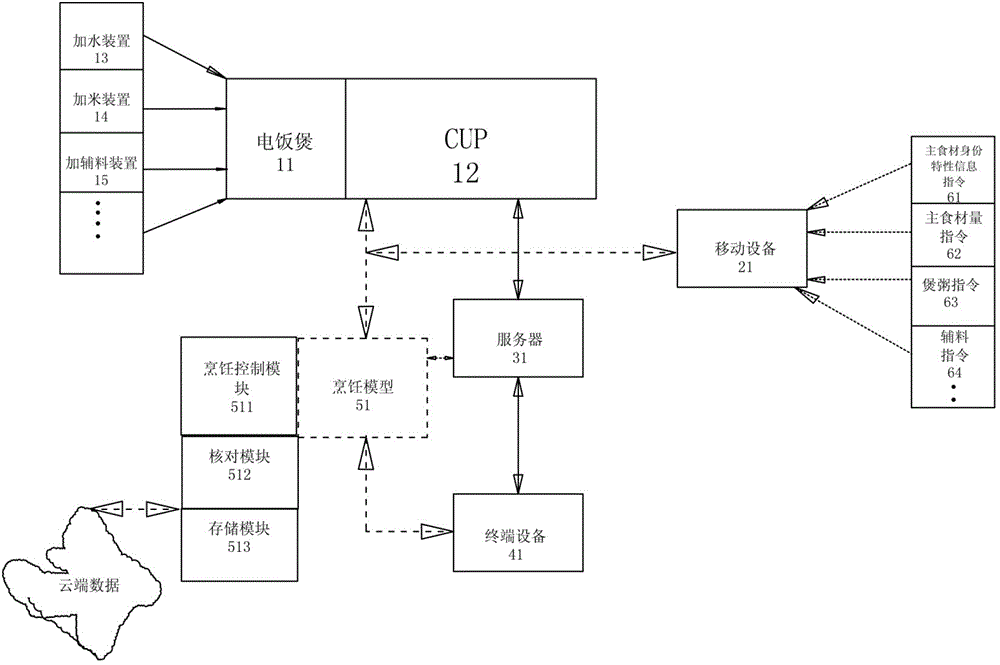

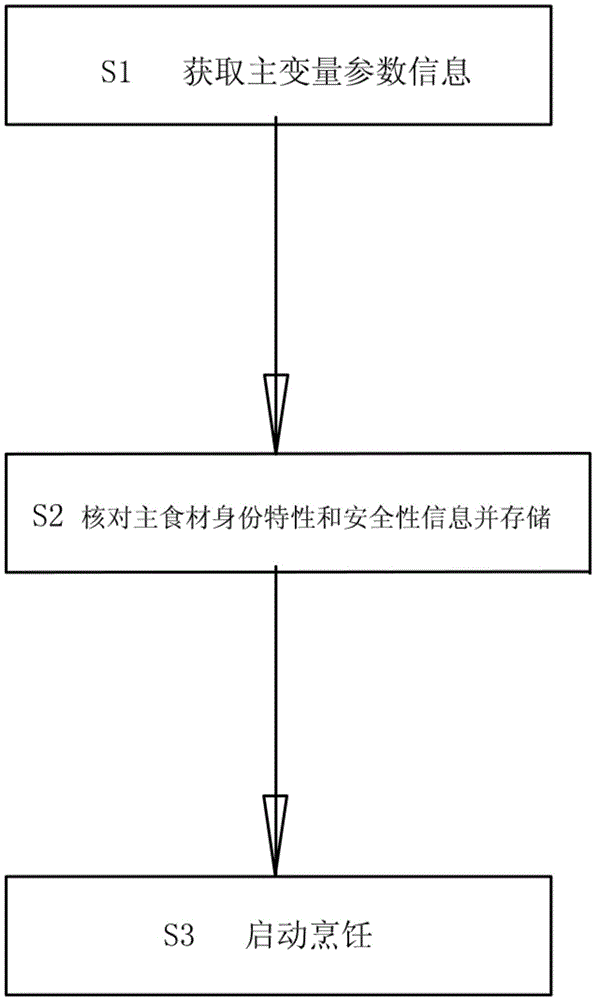

Cooking method and system based on cooking model

InactiveCN105629792ARealize the collectionRealize active intelligenceProgramme control in sequence/logic controllersPersonalizationProcess engineering

Owner:DEA GENERAL AVIATION HLDG CO LTD

Black tea production process

Owner:宜宾市乌蒙韵茶业股份有限公司

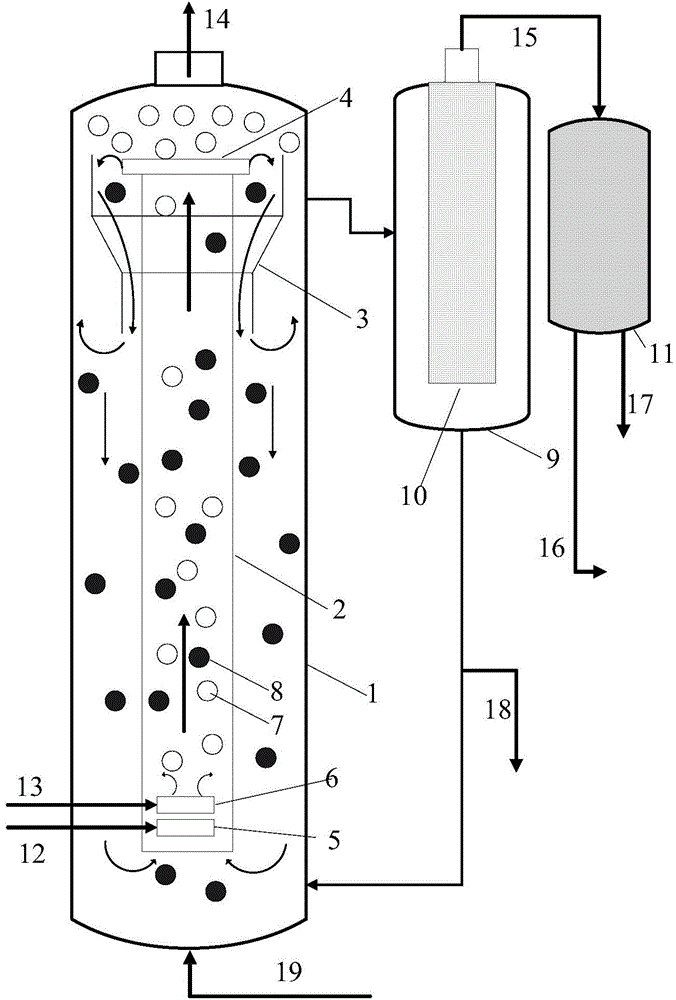

Slurry bed ft synthetic reactor and technique

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

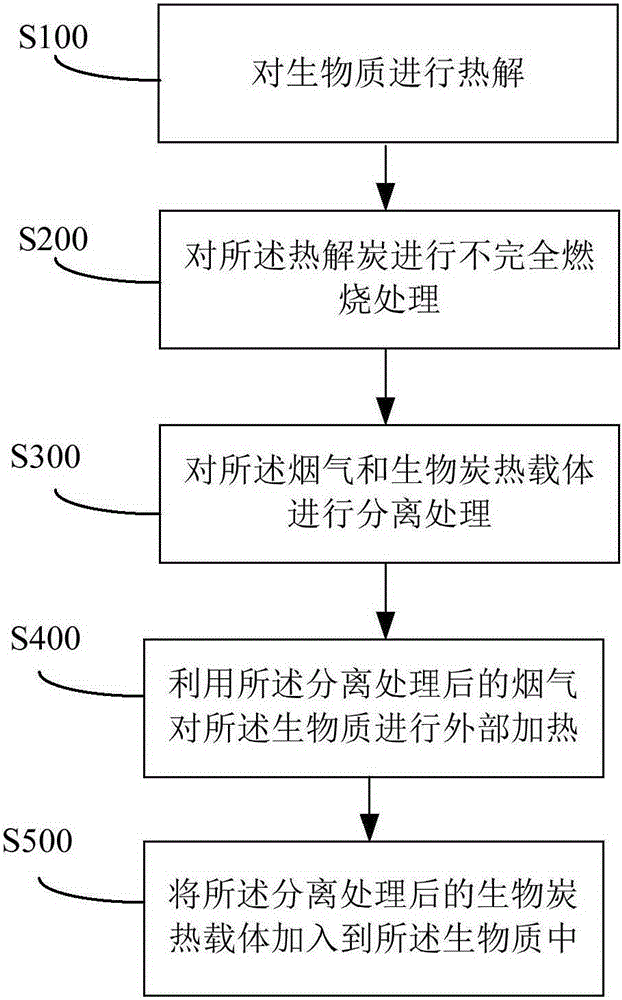

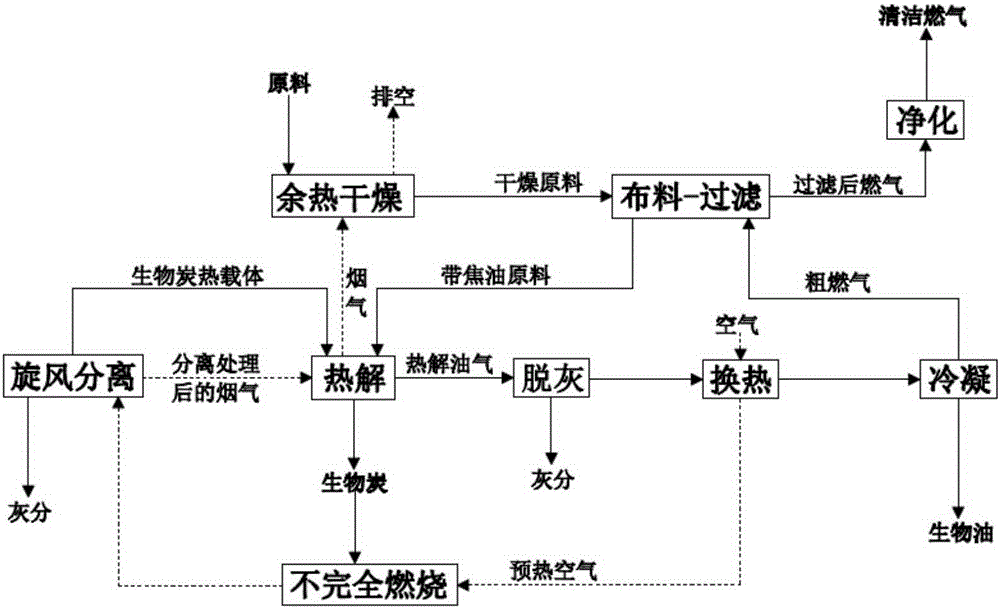

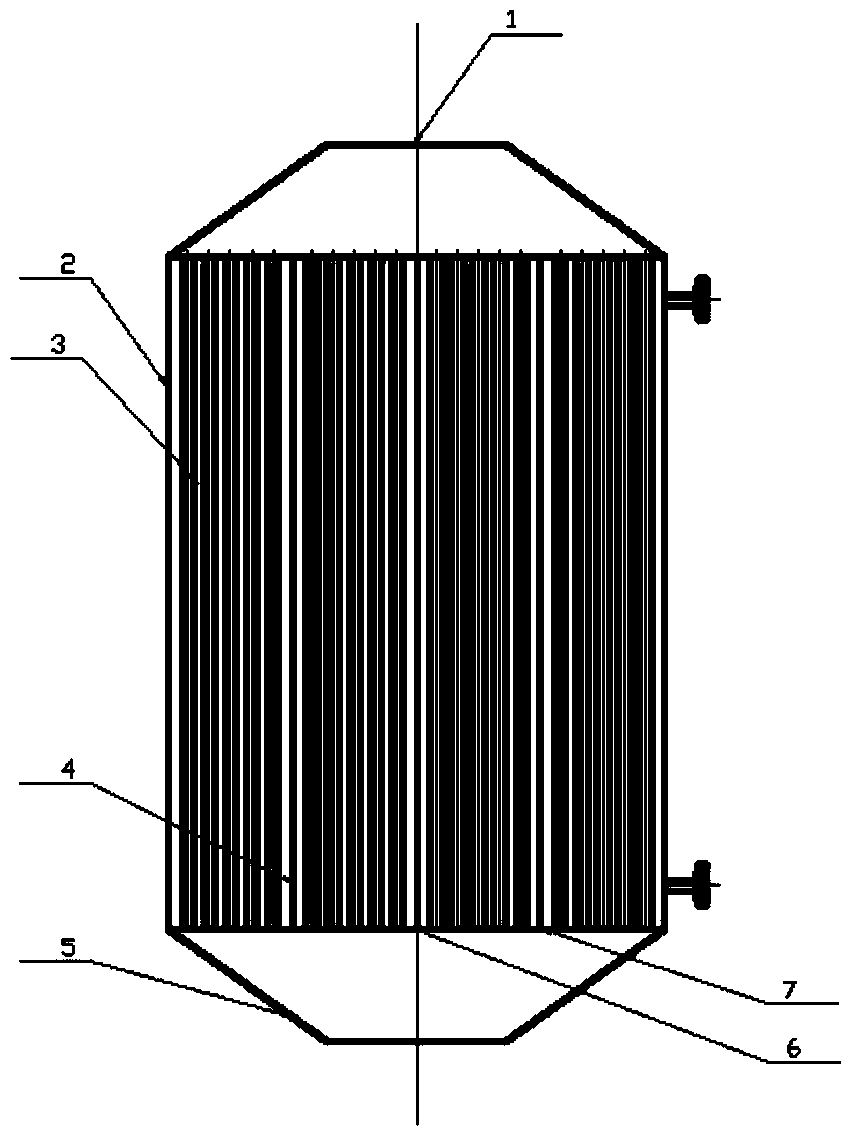

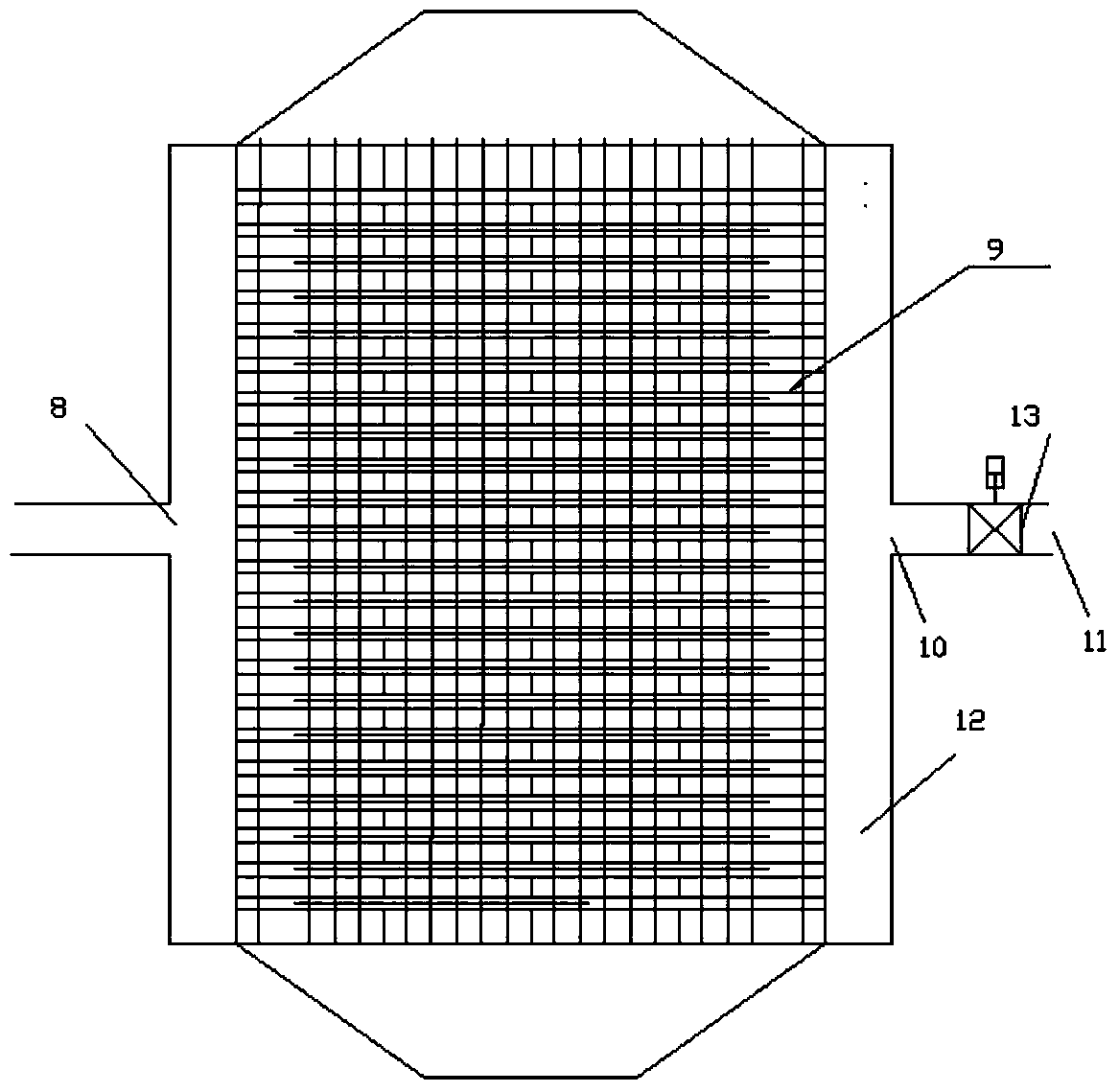

Biomass pyrolysis system and biomass pyrolysis method

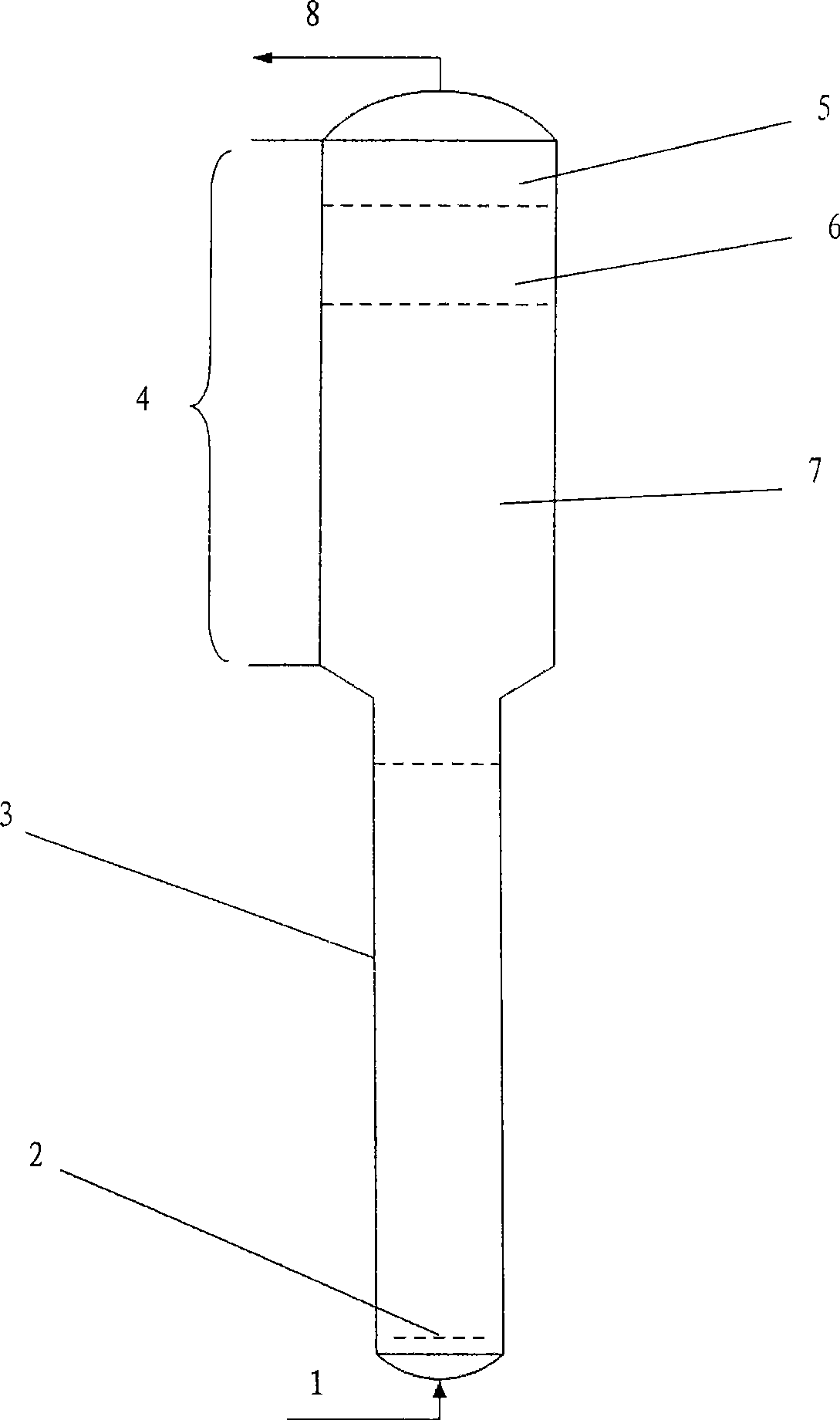

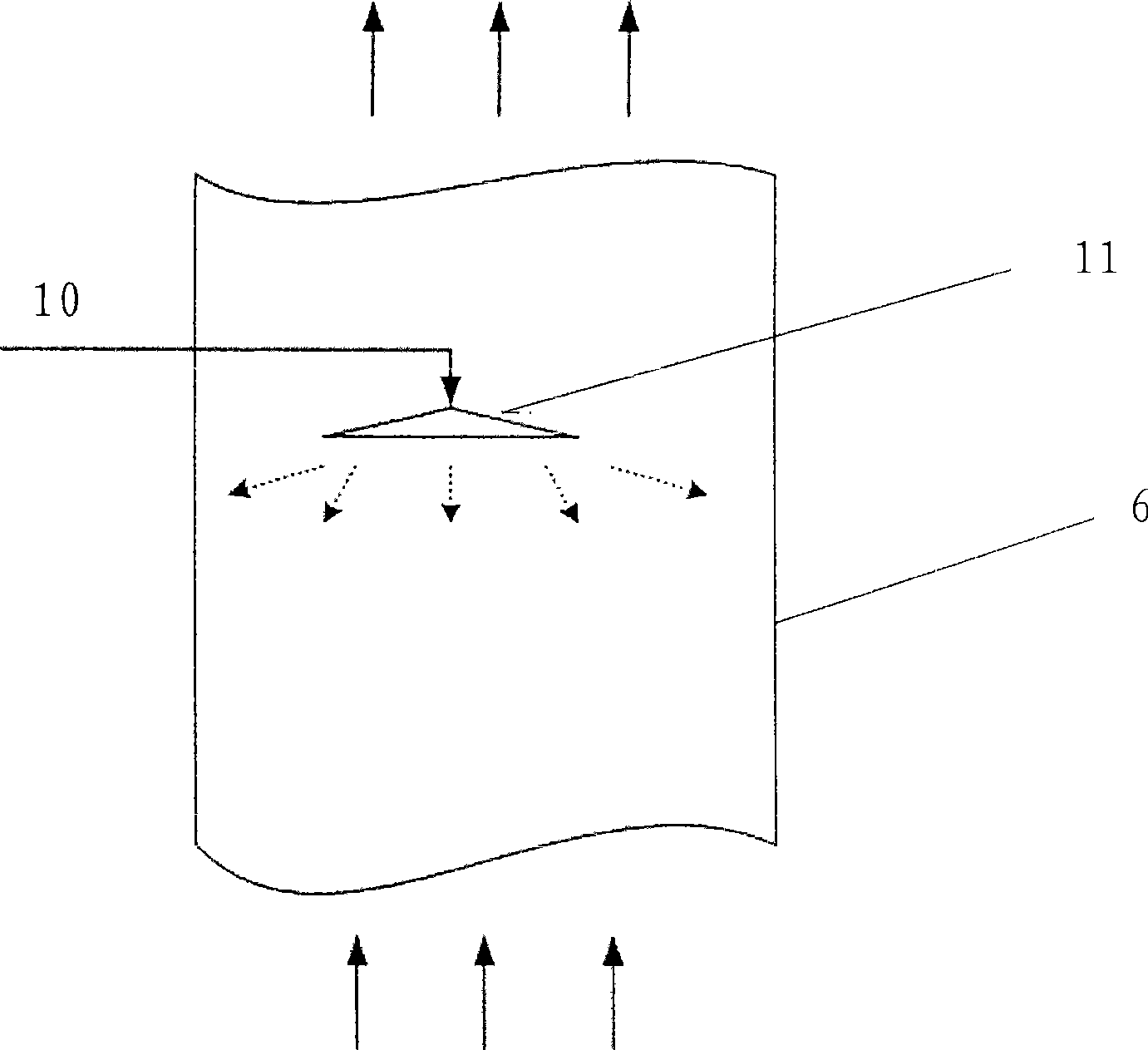

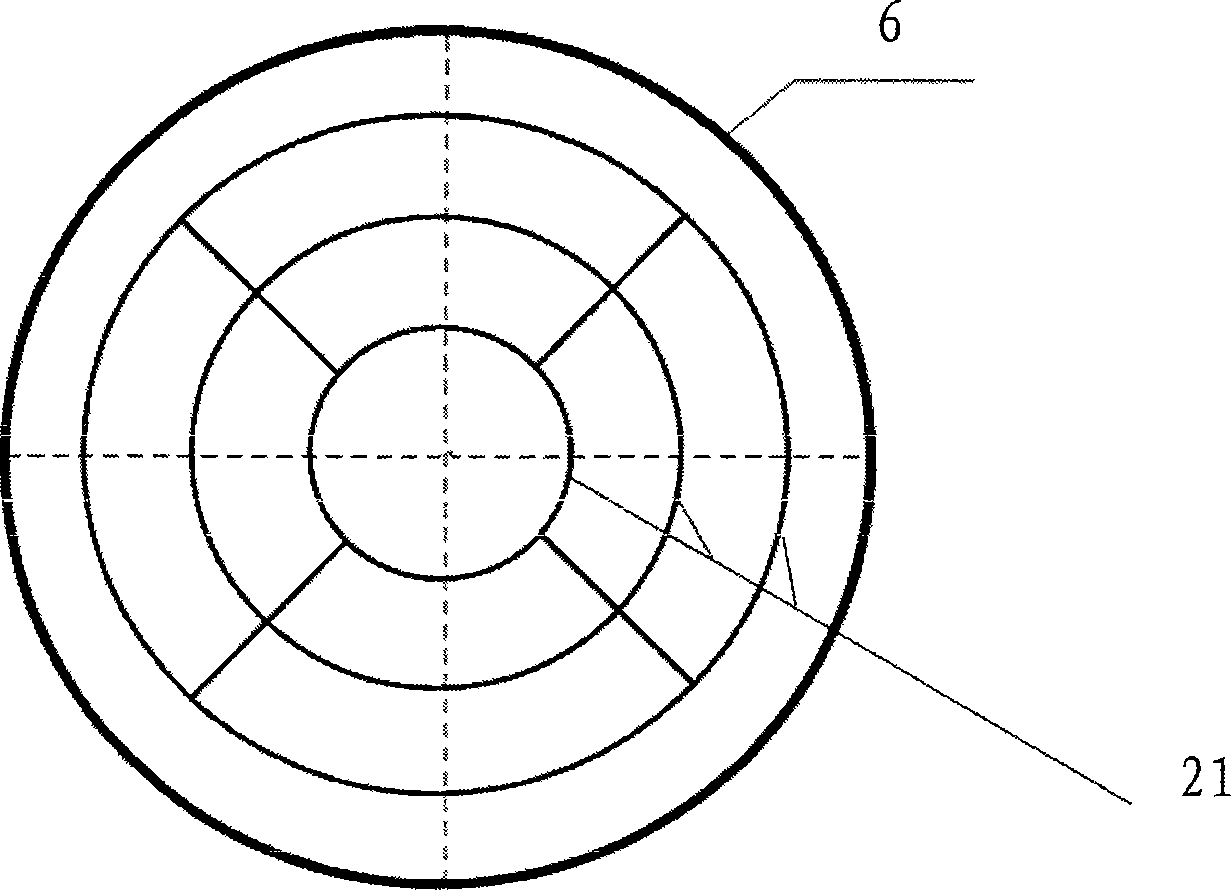

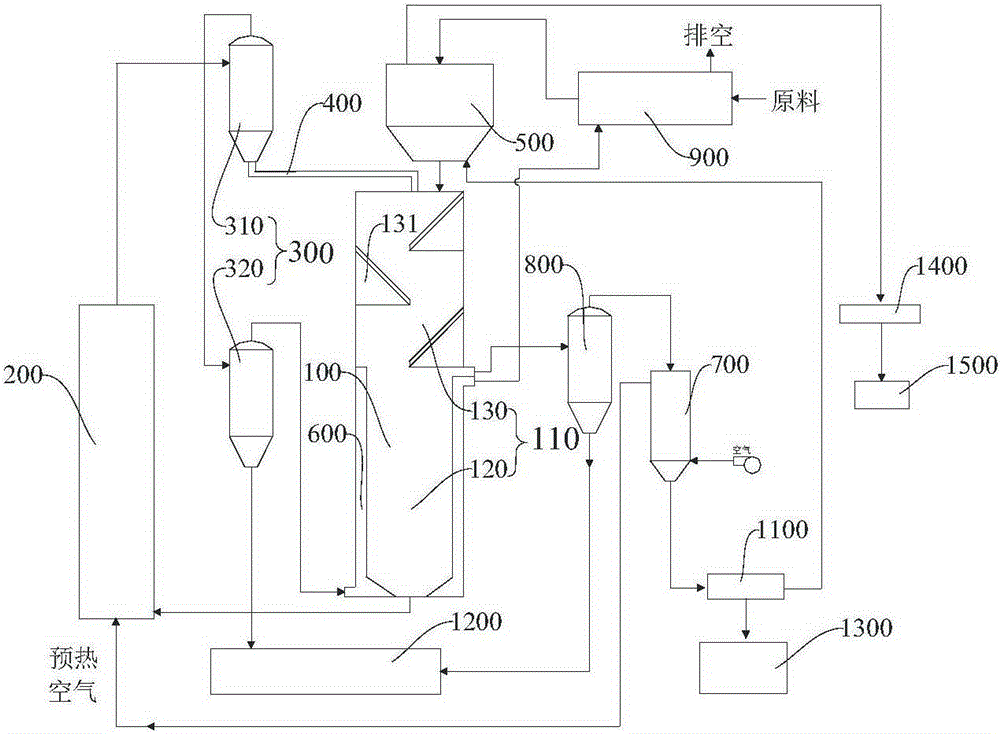

ActiveCN105219417AEfficient pyrolysisLarge processing capacity per unit timeBiofuelsIndirect and direct heating destructive distillationCombustionHeat carrier

Owner:SHENWU TECH GRP CO LTD

System for urban sludge flue gas drying middle-temperature pyrolysis carbonization

InactiveCN105602586AAvoid cokingAvoid blockingSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesEnergy gradientSludge

Owner:HUBEI JIADE TECH

Method of Operating a Furnace

Owner:AIR PROD & CHEM INC

Loop reaction device in slurry bed, application and method for producing hydrogen peroxide

ActiveCN104549066AExtended operating cycleIncrease profitPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

Owner:CHINA PETROLEUM & CHEM CORP +1

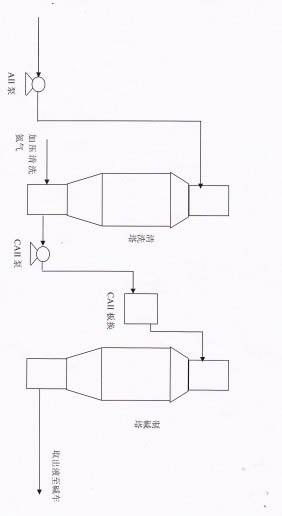

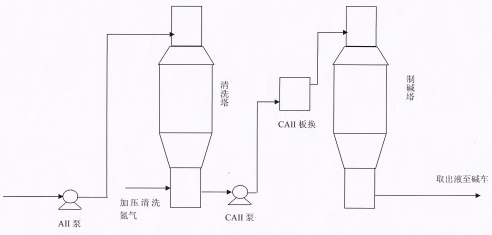

Carbonization cleaning process of carbonizer for producing heavy soda ash

InactiveCN102432041AImprove the degree of carbonization conversionRaise the temperature of IICarbonate preparationCooling towerCarbonization

Owner:SICHUAN HEBANG

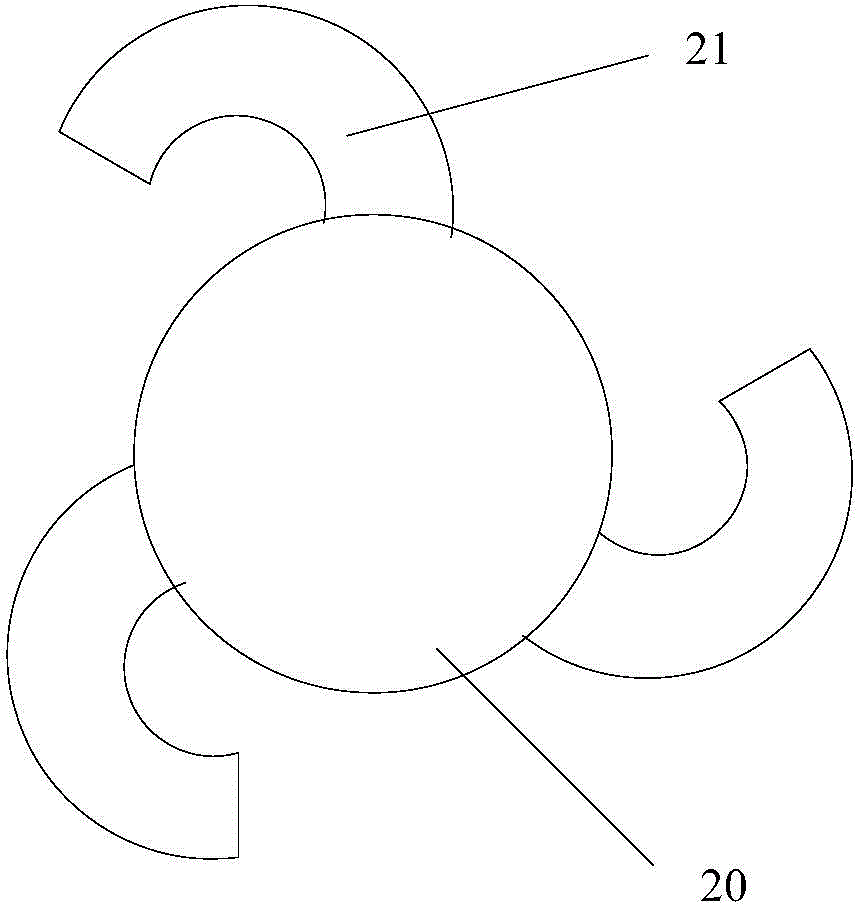

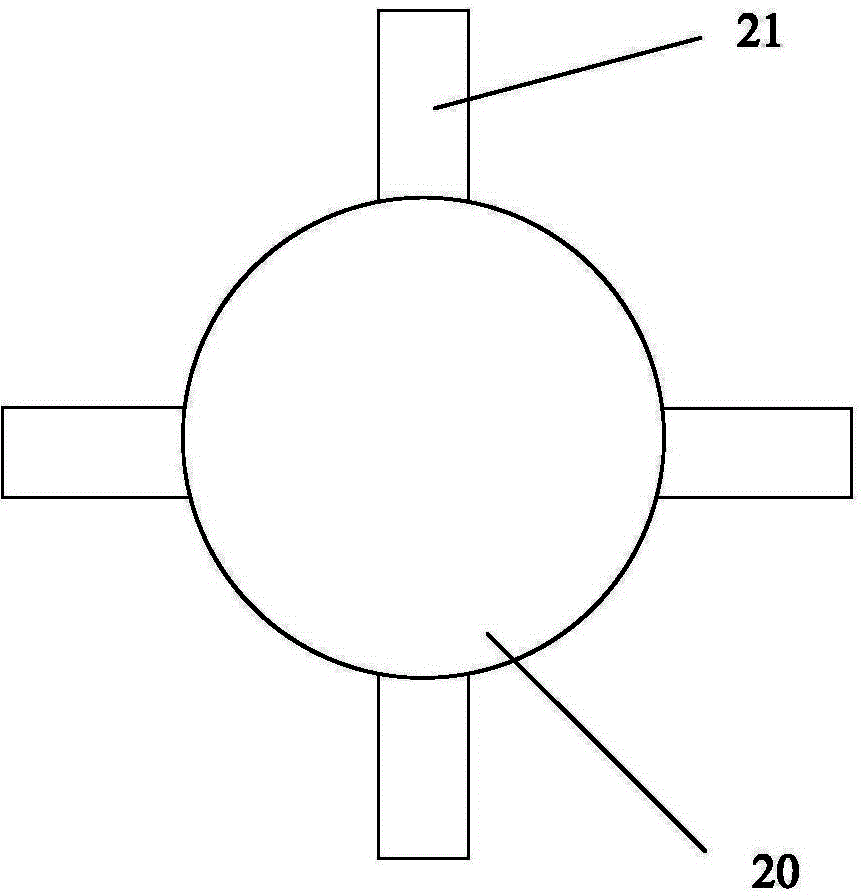

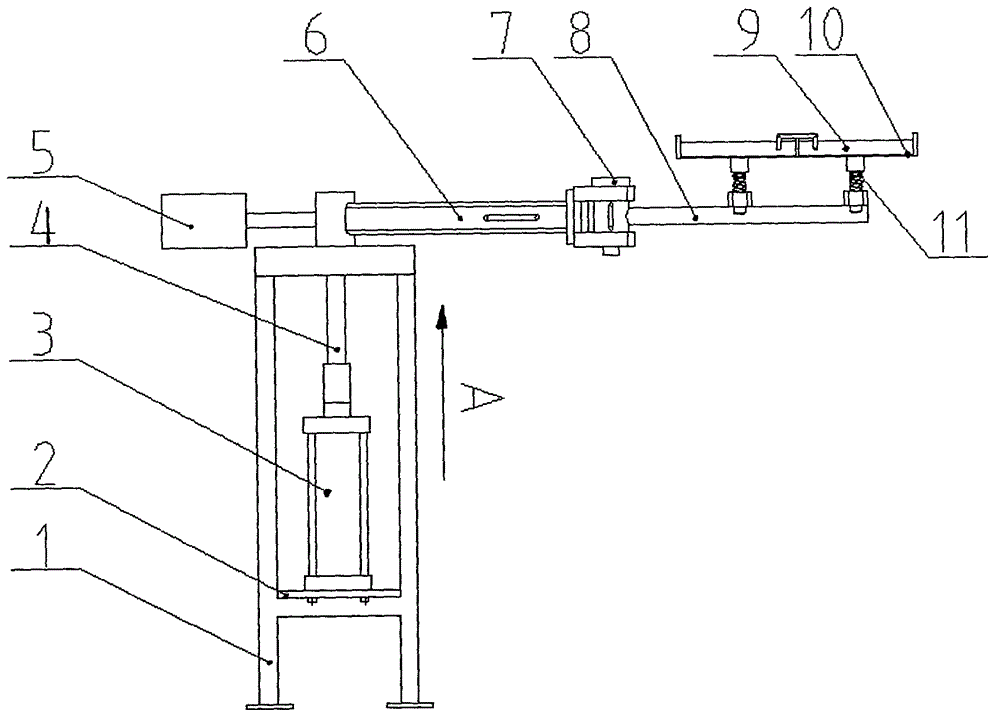

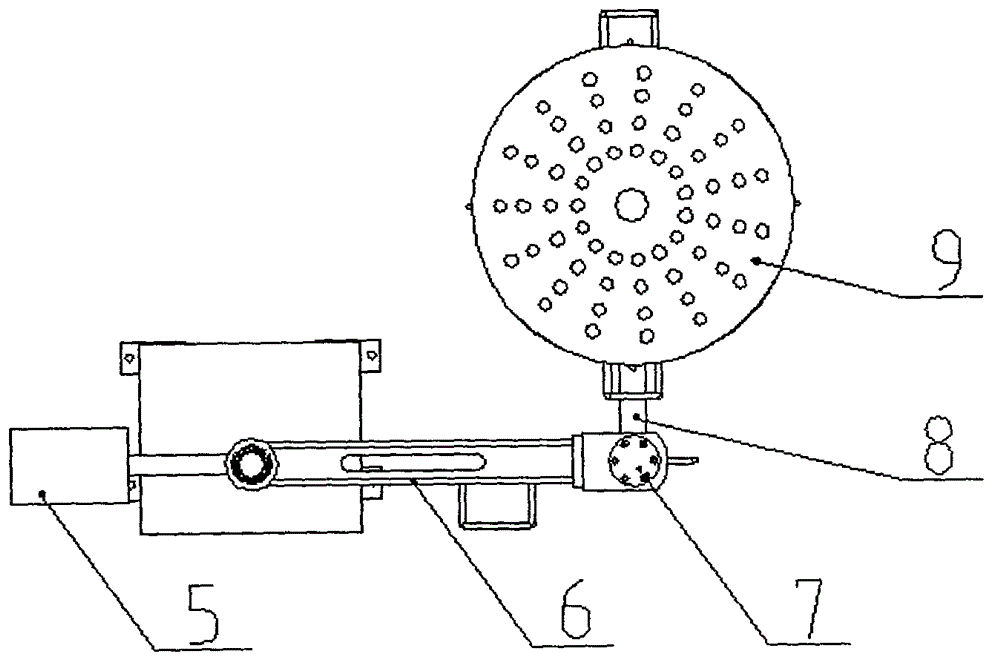

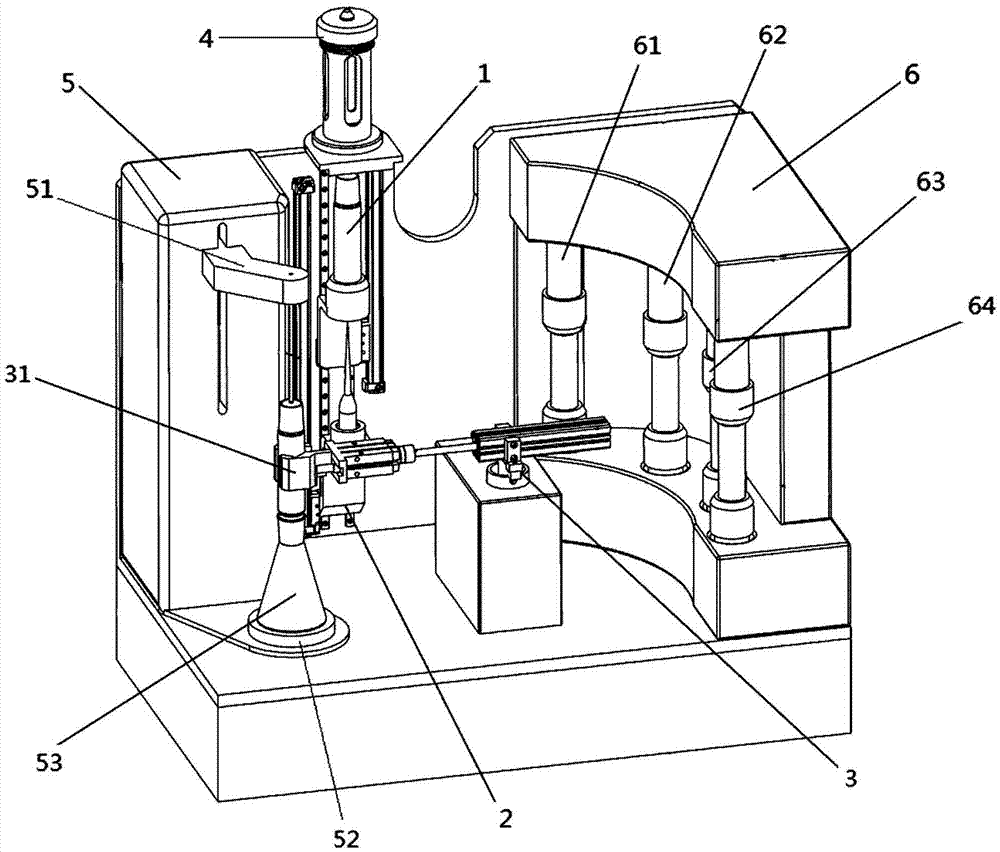

Automatic cast receiving method for rollover casting machine and receiving mechanical arm thereof

InactiveCN102873314AEasy to install and debugReduce manufacturing costProgramme-controlled manipulatorRotational axisManipulator

The invention relates to an automatic cast receiving method for a rollover casting machine. The method comprises the following steps of: after casting and mold opening of the casting machine, firstly rotating a mechanical arm comprising a main arm and an auxiliary arm to extend into the interior of the rollover casting machine, and aligning a disc on the auxiliary arm with a cast in position; then controlling a driving device to drive the mechanical arm to automatically rise and receiving the cast by the disc, and then controlling the driving device to drive the mechanical arm to automatically fall, and rotating the mechanical arm outward to automatically take out the cast. The adopted mechanical arm is characterized in that the driving device is mounted on a base; the driving device is connected with the main arm by a transmission rod; one end of the main arm is connected with a balancing block, and the other end is connected with the auxiliary arm by a rotating shaft; and a tray is mounted to the tail end of the auxiliary arm. The automatic cast receiving method for the rollover casting machine provided by the invention has the beneficial effect that installation and debugging are convenient, the manufacturing cost is low, the production efficiency is obviously improved, the labor intensity is effectively lowered, and potential safety hazard is eliminated.

Owner:WENZHOU RUIMING IND

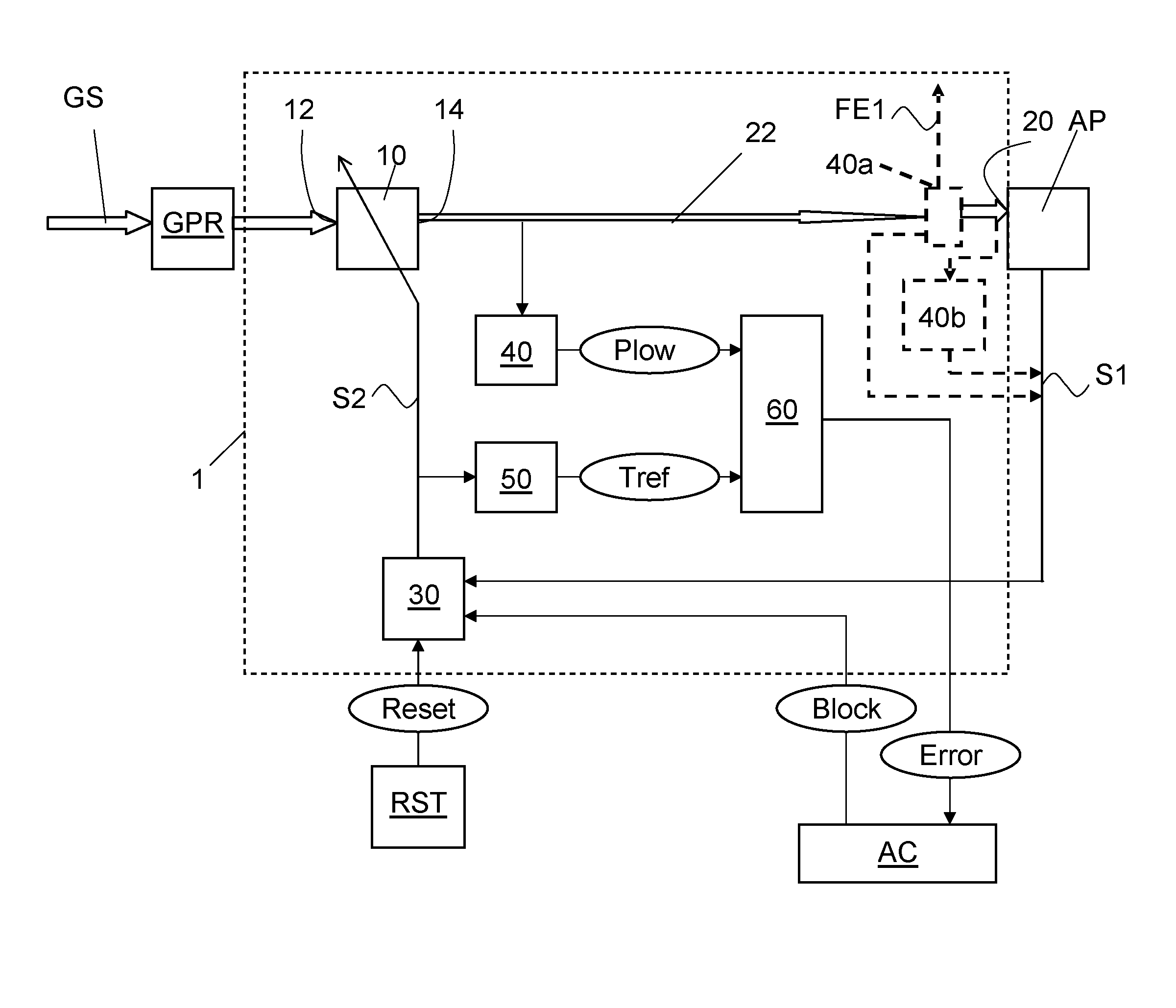

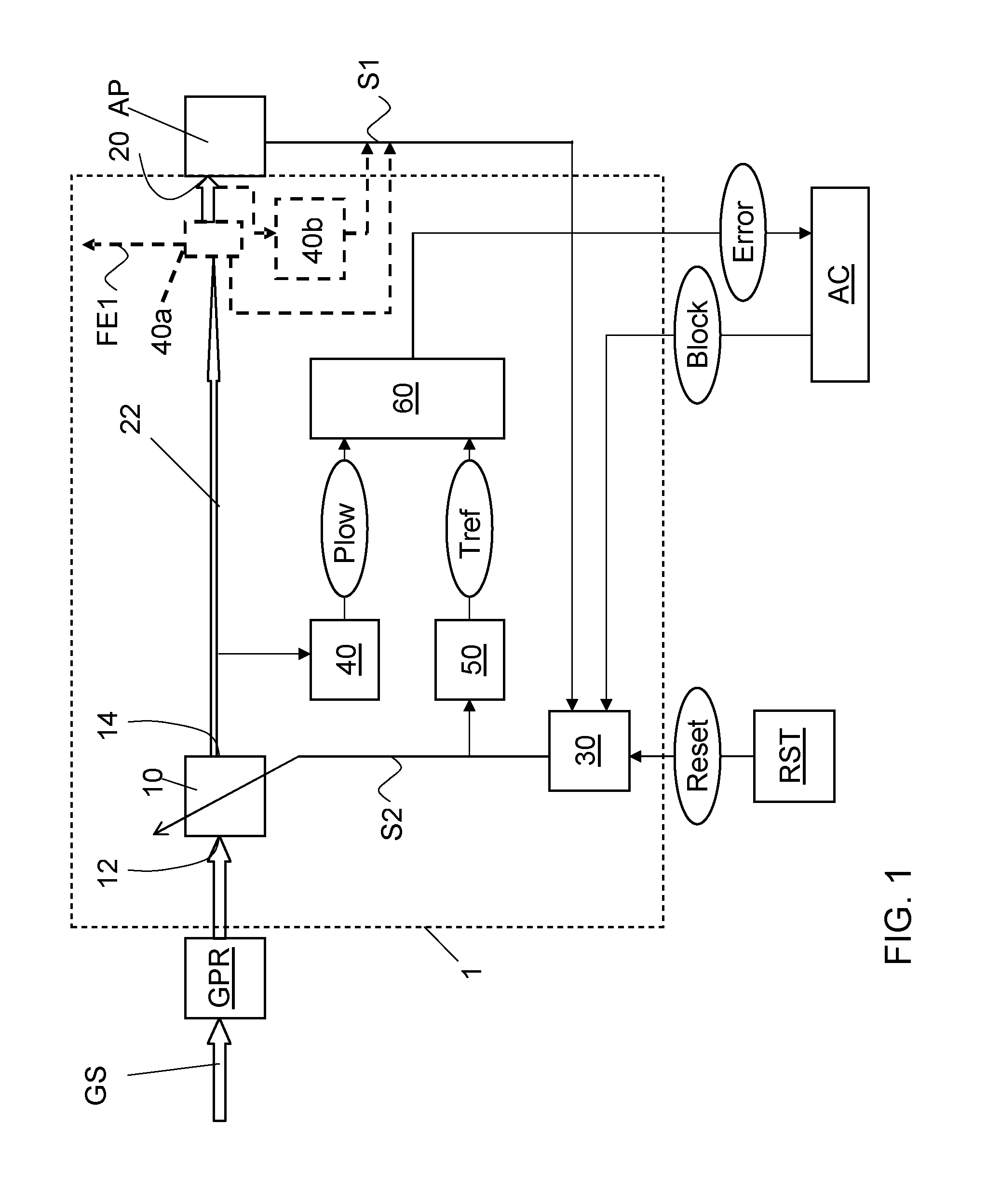

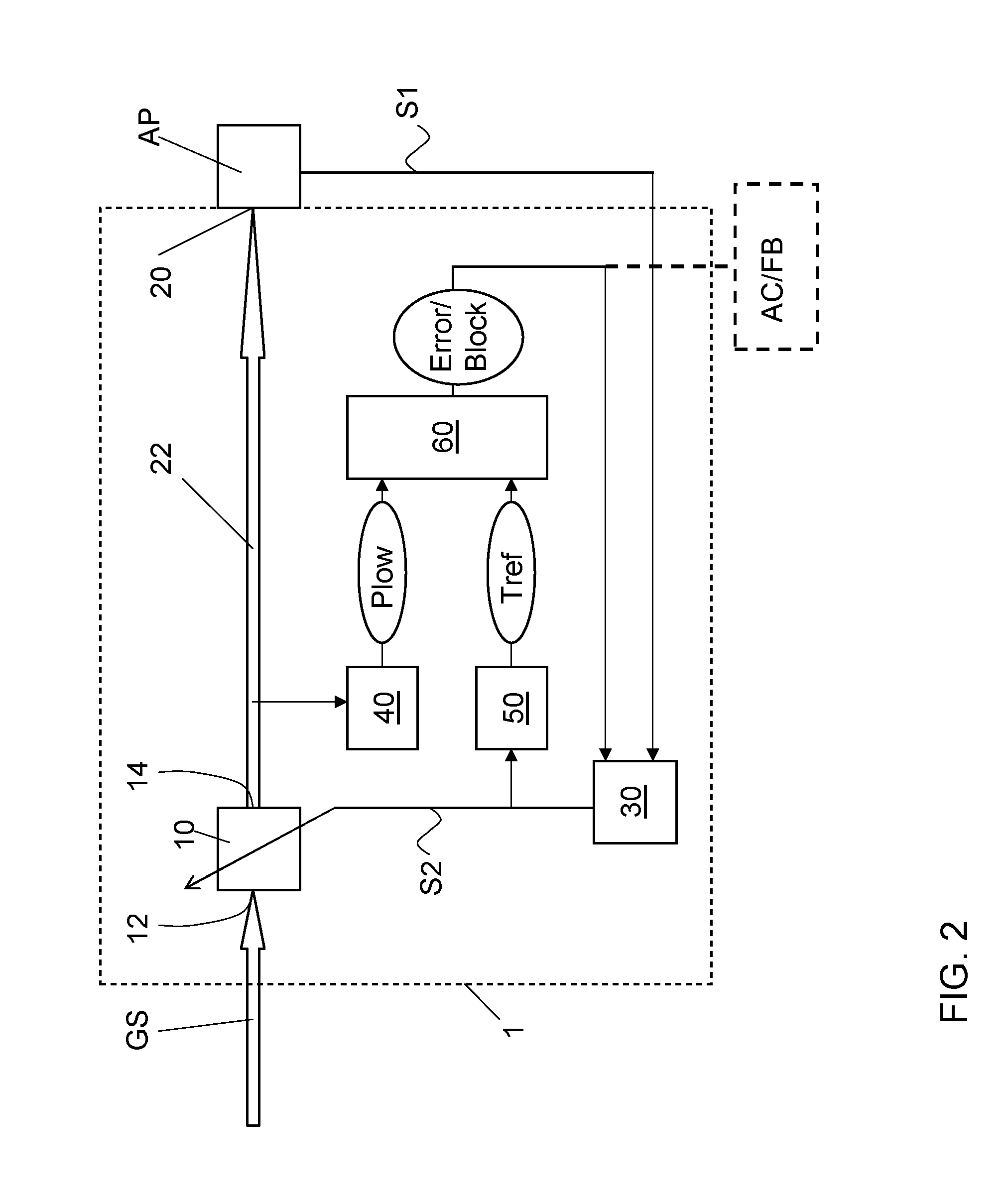

Arrangement comprising a gas delivery control system and a central heating installation and gas delivery control method

InactiveUS20140231531A1Gas handling applicationsSpecial fuel supply arrangementsControl systemComputer module

Owner:RADIX INVENTIVE

Semiconductor processing equipment and process control method thereof

ActiveCN111489949AImprove yieldImprove accuracyElectric discharge tubesFinal product manufactureWaferProcess engineering

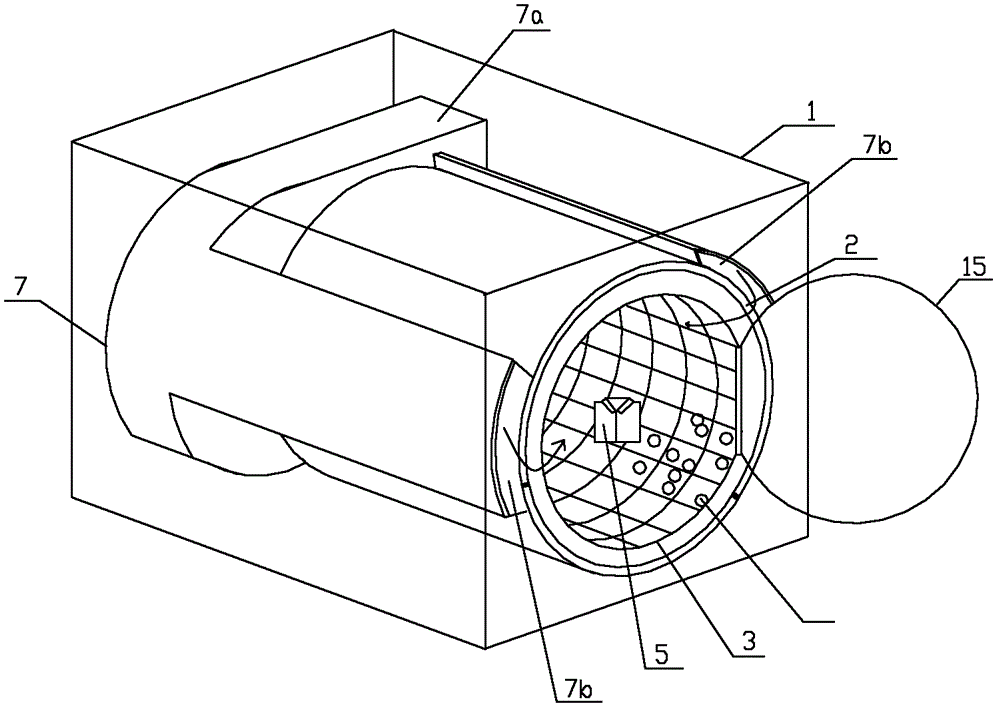

The embodiment of the invention provides semiconductor processing equipment and a process control method thereof. The semiconductor processing equipment comprises a cavity, a lifting assembly, a baseand a temperature measuring assembly, wherein the base and the temperature measuring assembly are arranged in the cavity; the lifting assembly is used for bearing and driving wafers to be selectivelylocated at multiple stations above the base, the multiple stations correspond to the multiple target temperature values in a one-to-one mode, and the distance between each station and an upper surfaceof the base is inversely proportional to the corresponding target temperature value; and the temperature measuring assembly is arranged at positions where the lifting assembly is in contact with thewafers and is used for acquiring actual measurement temperature values of the wafers in real time. According to the embodiment of the invention, the purpose of adjusting the target temperature value according to different types of wafers and different processes is achieved, and the requirement for temperature change in the process can be met such that the yield of the wafers is effectively improved, and the process efficiency is greatly improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Steam device and operation and use method thereof

PendingCN111472156ANormal use workIncrease flexibilityBatteries circuit arrangementsIroning apparatusThermodynamicsLiquid medium

The invention discloses a steam device and an operation and use method thereof. The method comprises the steps that a steam brush and a power supply seat are connected; the power supply seat suppliespower to a steam generator in the steam brush and heats the steam generator; meanwhile, a lithium battery in the steam brush is charged through the power supply seat; an indicating lamp indicates thatthe steam generator reaches prese temperature; the steam brush is taken off from the power supply seat and disconnected with the power supply seat; and a switch element on the steam brush is closed,power is supplied to a water pump in the steam brush through the lithium battery, a liquid medium is conveyed into the steam generator through the water pump, and the liquid medium is heated into steam through the steam generator. Due to the fact that the lithium battery is arranged in the steam brush, after the steam generator is heated to certain temperature, the steam brush can be divorced fromdependence on electric supply to complete normal use work, and the use flexibility is improved.

Owner:CUORI ELECTRICAL APPLIANCES GRP

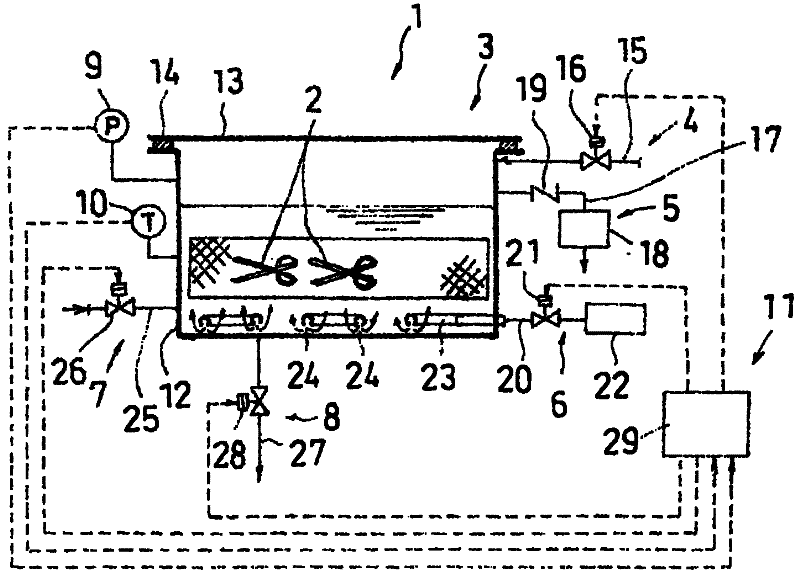

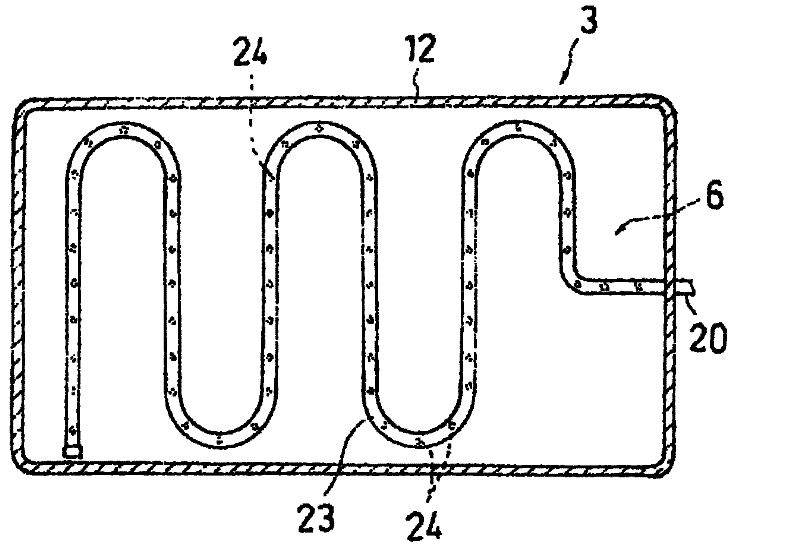

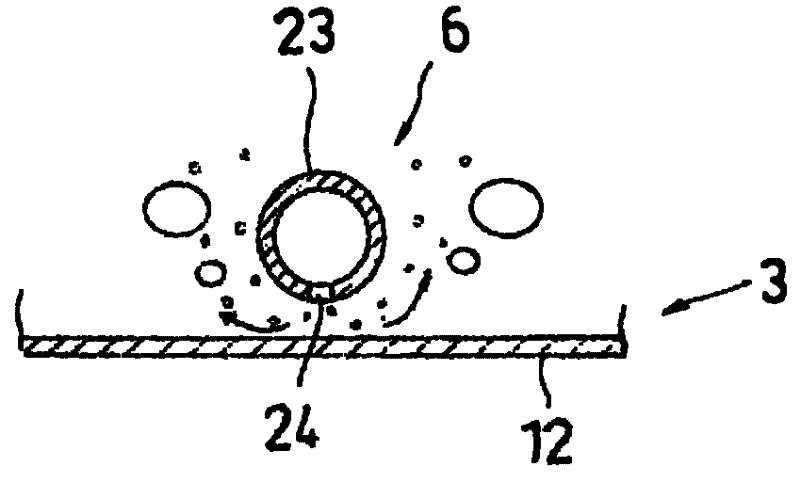

Cleaning device and cleaning method

ActiveCN102413952AAchieve cleaningPrevent bad situationsDiagnosticsSurgeryProcess engineeringCleaning methods

Owner:MIURA COMPANY LIMITED

System and method for producing hydrogen by directly electrolyzing urea-containing wastewater with renewable energy

The invention discloses a system and method for producing hydrogen by directly electrolyzing urea-containing wastewater with renewable energy. The system comprises a renewable energy generation module, a power conditioning module, a urea-containing wastewater pretreatment module, an alkaline urea electrolytic hydrogen production module, a gas / liquid separation, drying and purifying module, an alkaline liquor circulating pump, a hydrogen storage tank and an anode product storage module, wherein an output end of the renewable energy generation module is connected with an input end of the power conditioning module, and an output end of the power conditioning module is connected with the alkaline urea electrolytic hydrogen production module. By means of the system, nearby in-time consumption of renewable energy power is facilitated, the hydrogen production cost is r educed, the tolerance of the hydrogen production system to the volatility and intermittence of a power supply is improved, a hydrogen production technology is combined with a water treatment technology, and while the hydrogen production energy consumption is reduced, environmental pollution is avoided; the applicability of the system is wide, the stability is high, the hydrogen produced by the system is high in purity, the process is simple, and industrial production is facilitated.

Owner:闫巍

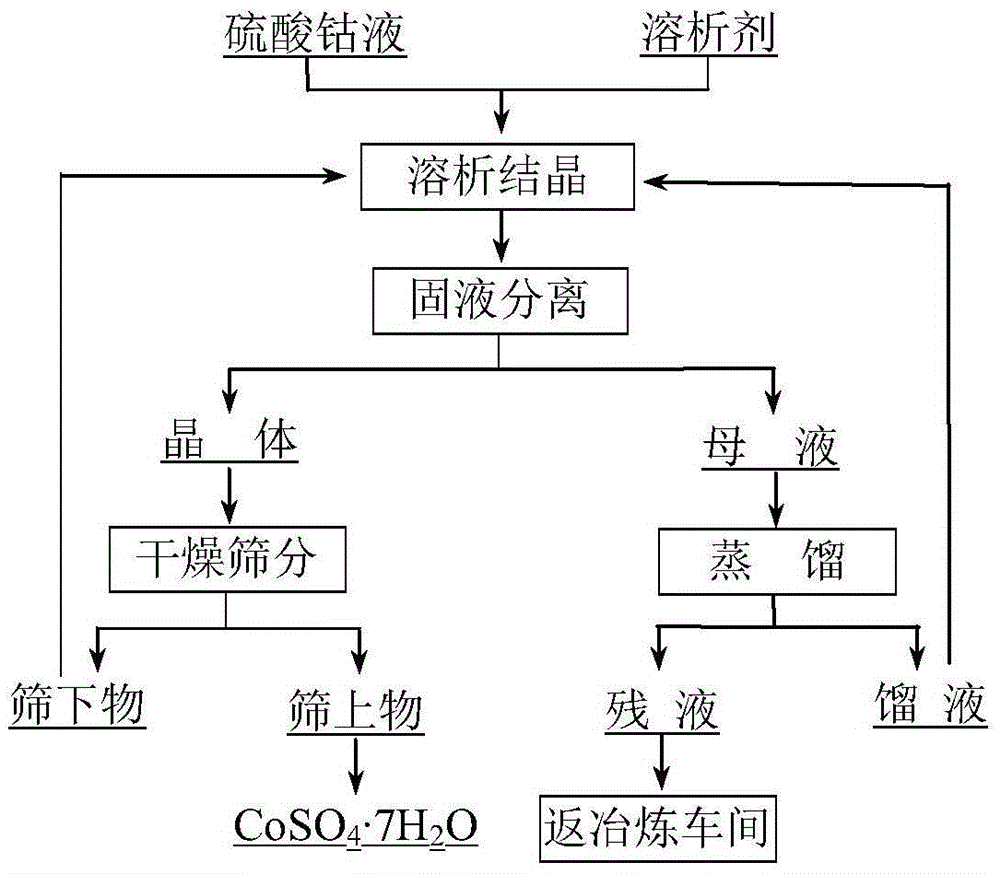

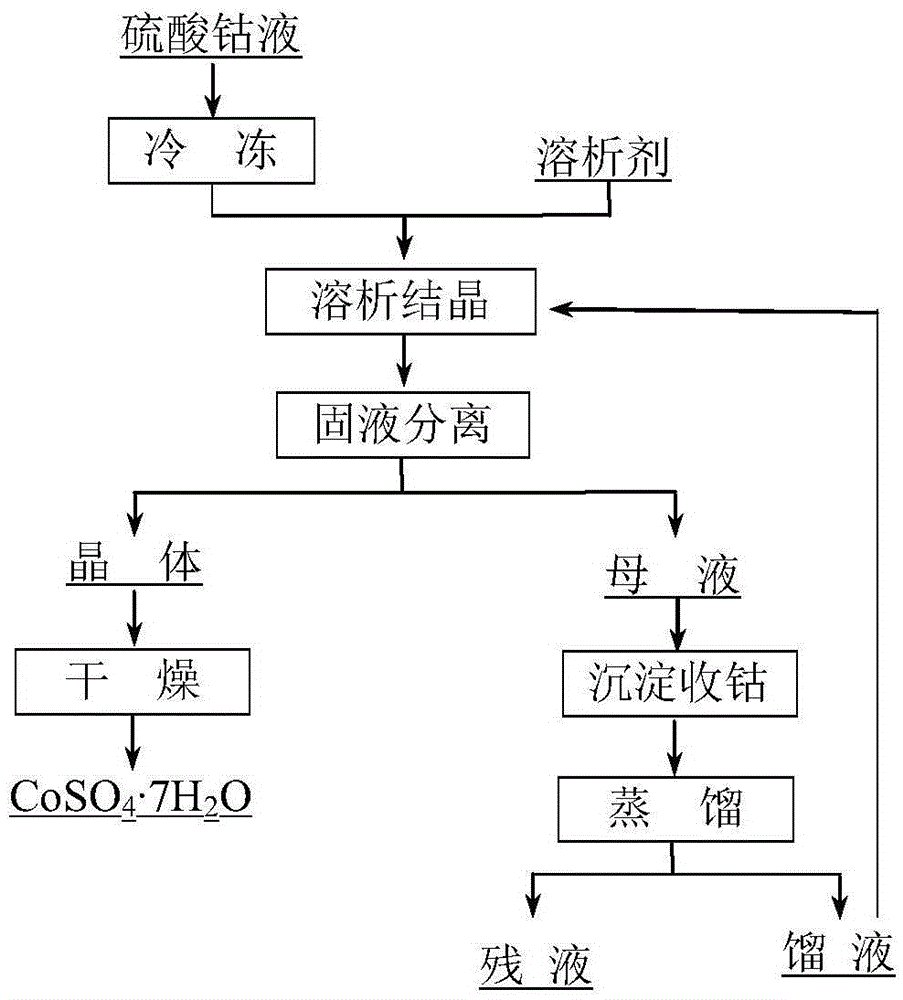

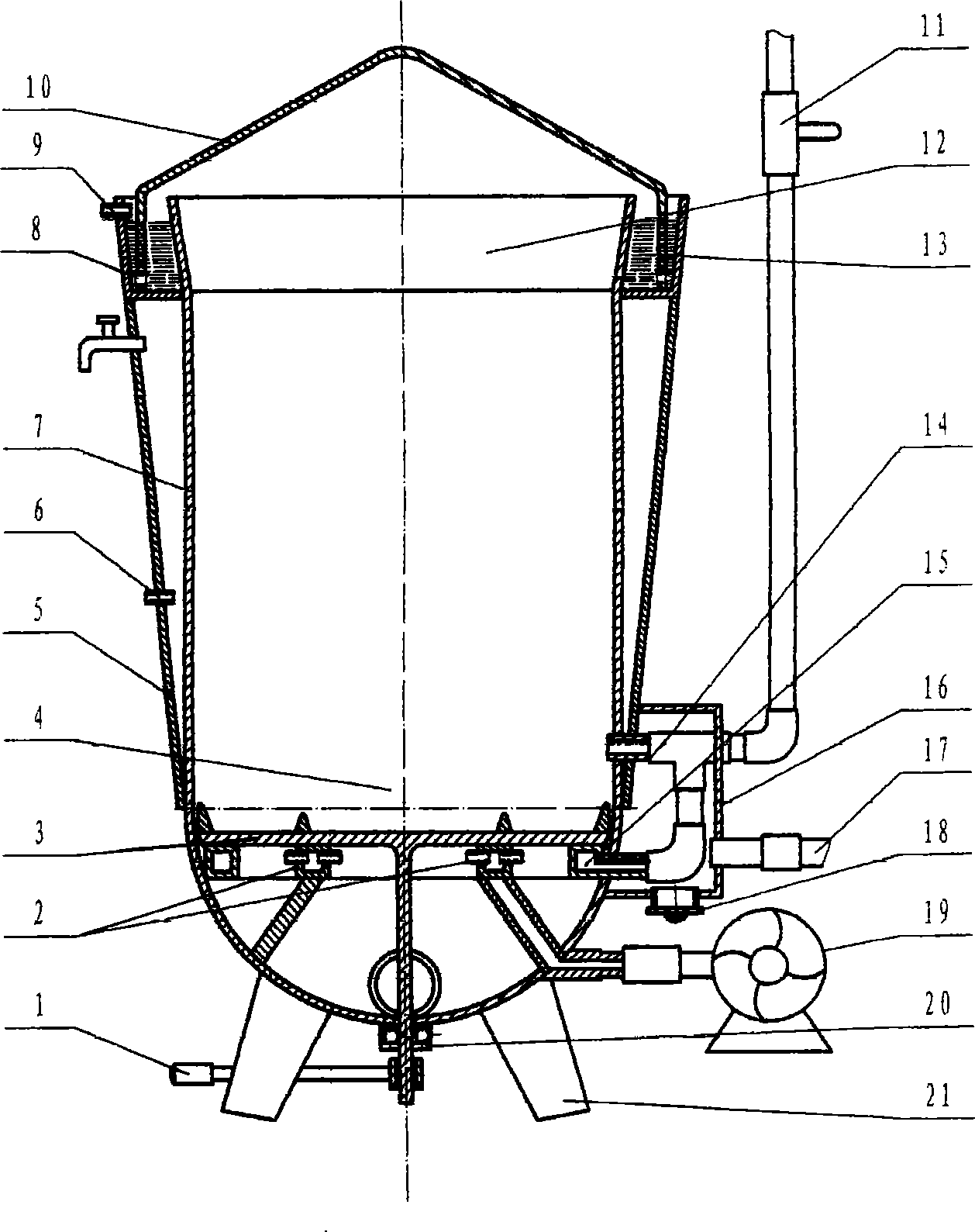

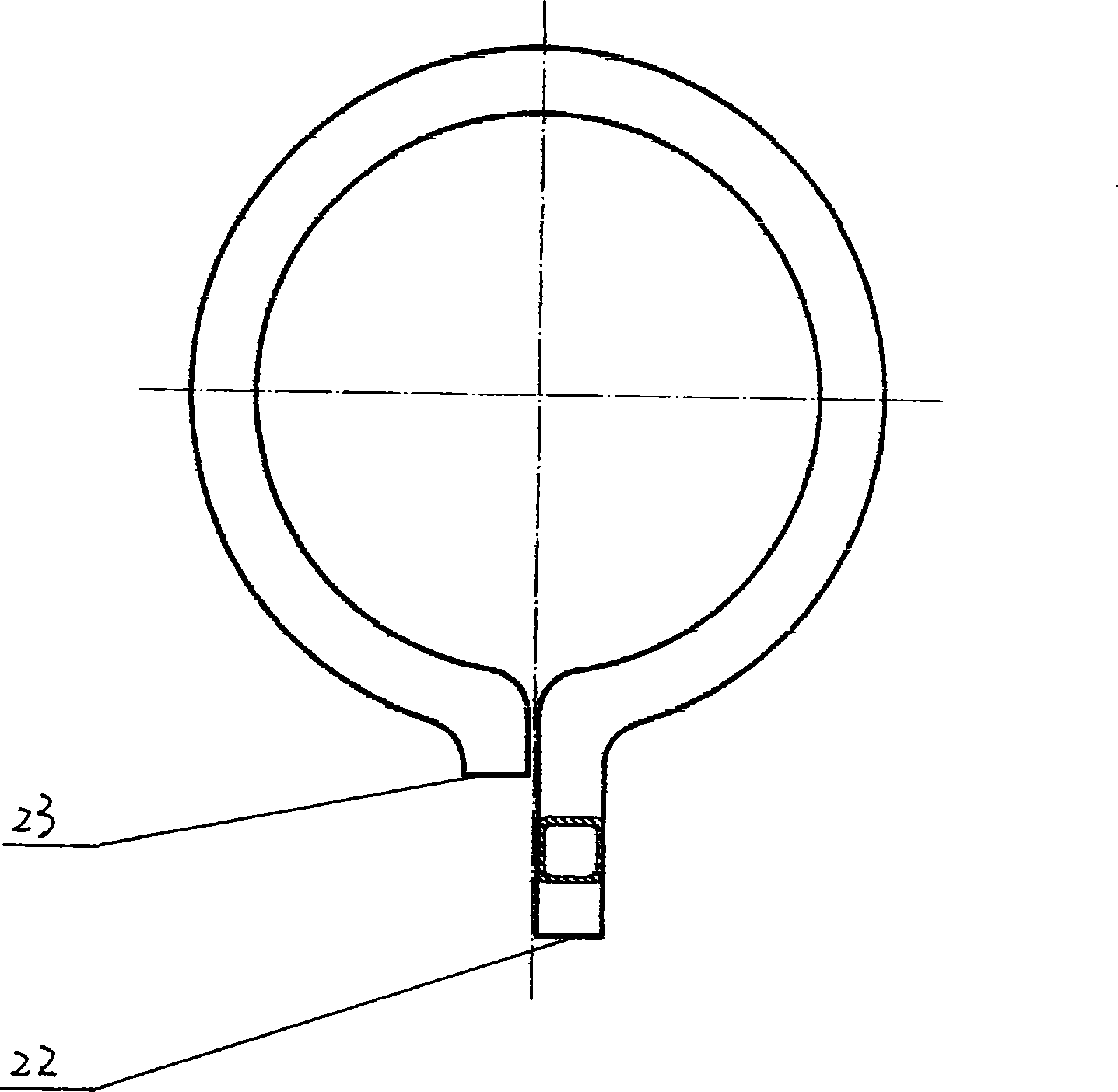

Production method for cobaltous sulfate heptahydrate

Owner:GUANGDONG JIANA ENERGY TECH CO LTD

Pulverization-free, dampness-resistant, coke tar-free biomass gasification oven preventing burning out

InactiveCN101240904AWide variety of sourcesWon't clogProductsDomestic stoves or rangesBiomass gasifierOxygen

Owner:沈桀

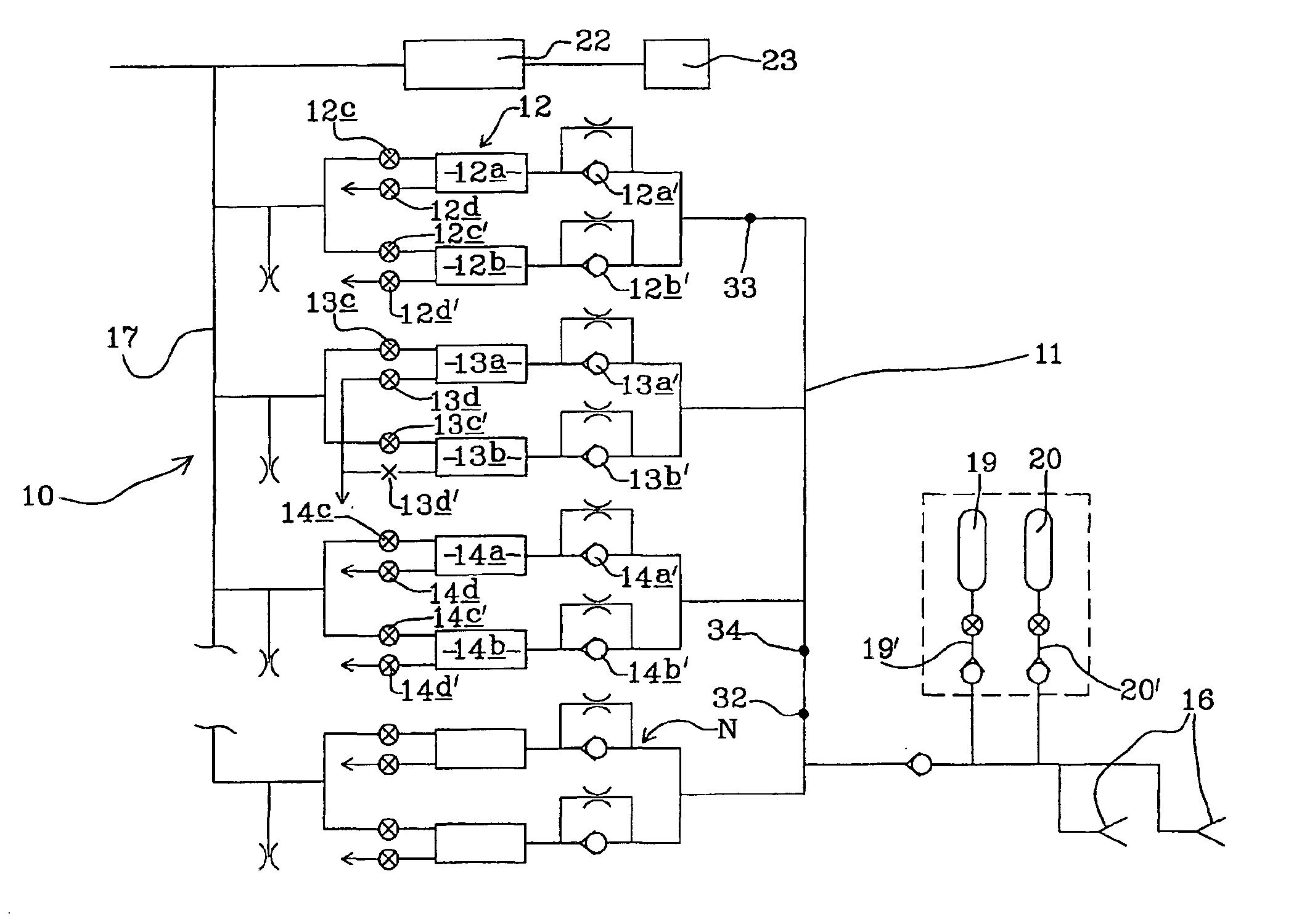

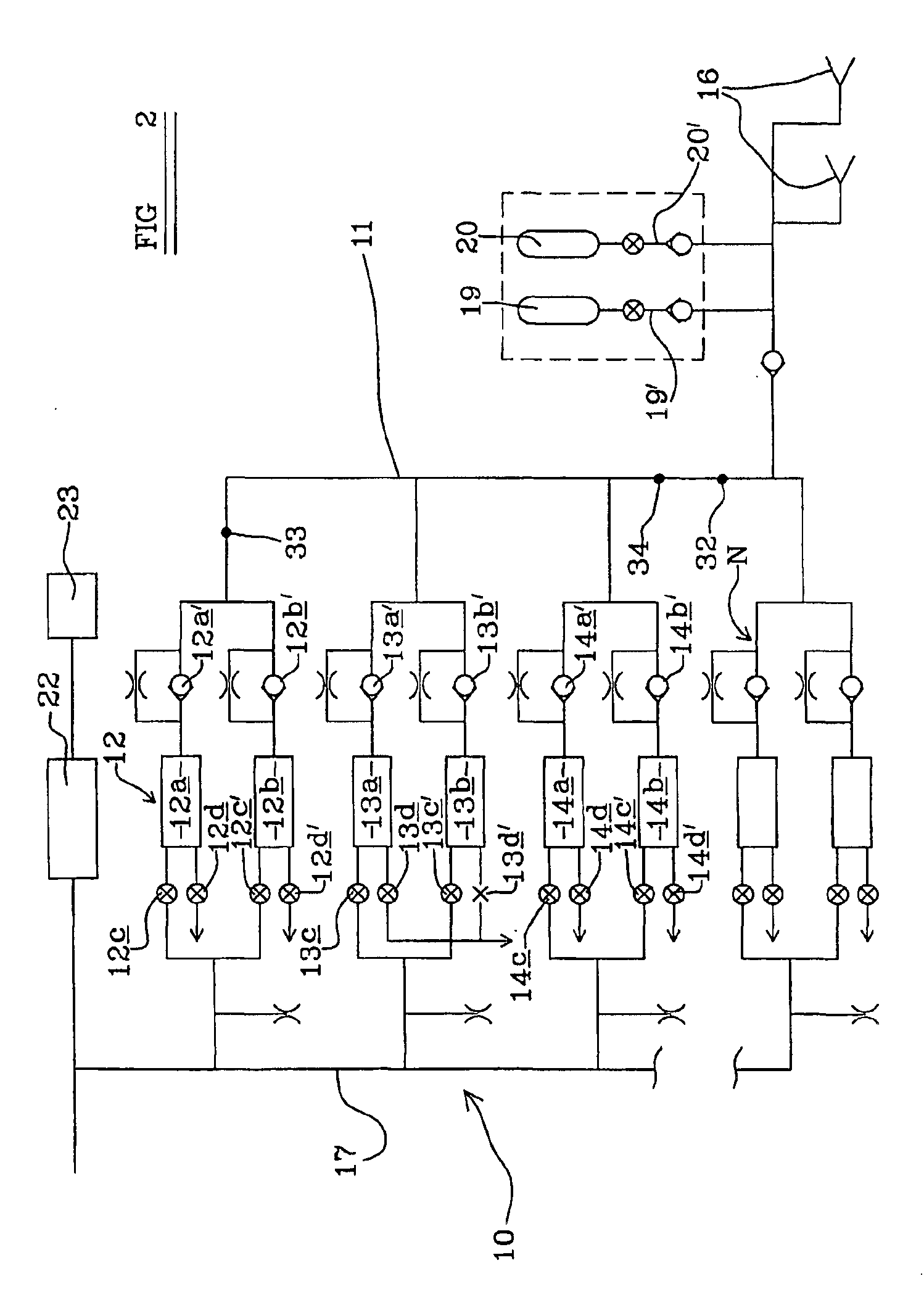

Life support system

InactiveUS6846347B2Reduce weightImprove securityDispersed particle filtrationAir-treatment apparatus arrangementsBreathing gasProduct gas

Owner:HONEYWELL NORMALAIR GARRETT HLDG

Acquisition system for collecting particles of different particle size discharged by fire coal

InactiveCN103323292AEasy to carryGood effectWithdrawing sample devicesPreparing sample for investigationParticulatesCombustion

The invention relates to an acquisition system for collecting particles of different particle size discharged by fire coal. The acquisition system comprises a flue gas collecting box, a flue gas pipeline, a slide plate with wheels, a civil coal-fired furnace, a blower, a frequency converter, a condenser tube, a temperature sensor, a MCI sampler and a MOUDI sampler. The flue gas collecting box, the flue gas pipeline and the slide plate with wheels are made of stainless steel; the civil coal-fired furnace is put inside the flue gas collecting box; the blower can blow air into the flue gas collecting box to dilute flue gas and provide oxygen for combustion; and the particles in the air are filtered by a filter cloth of 120 meshes at the blower air inlet. The apparatus in the invention avoids the defects that original particles in the air cannot be purified to enter the acquisition system, dilution multiple of fire coal flue gas cannot be calculated and flue gas temperature cannot be adjusted, the original apparatus is not convenient for carrying and condensation enters into sampler flue gas etc. The experiment result shows that the effect of collecting particles of different particle size that are discharged by fire coal is obvious and the sampling operation is simple.

Owner:SHANGHAI UNIV

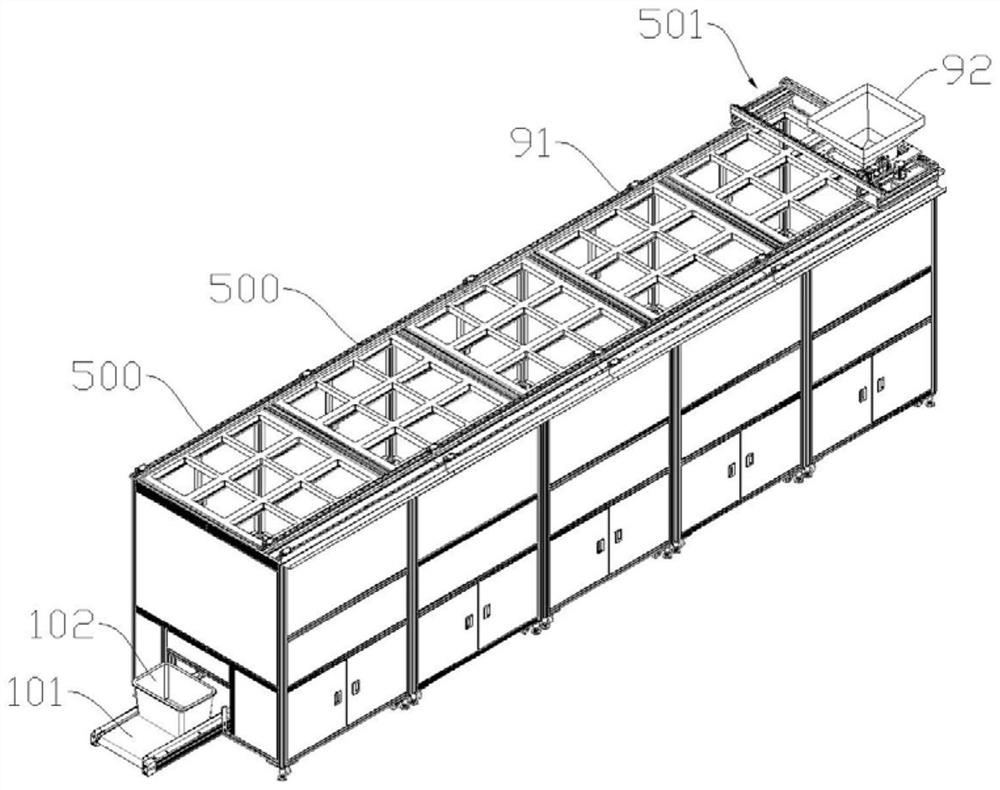

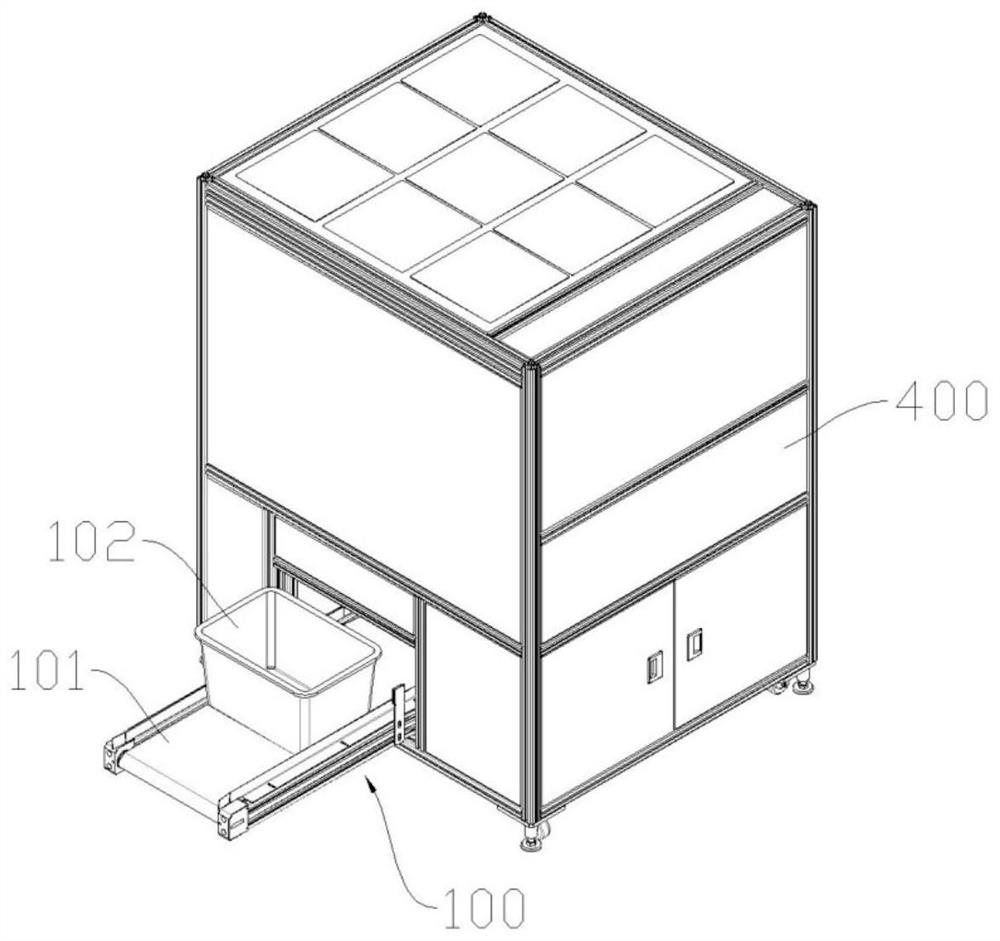

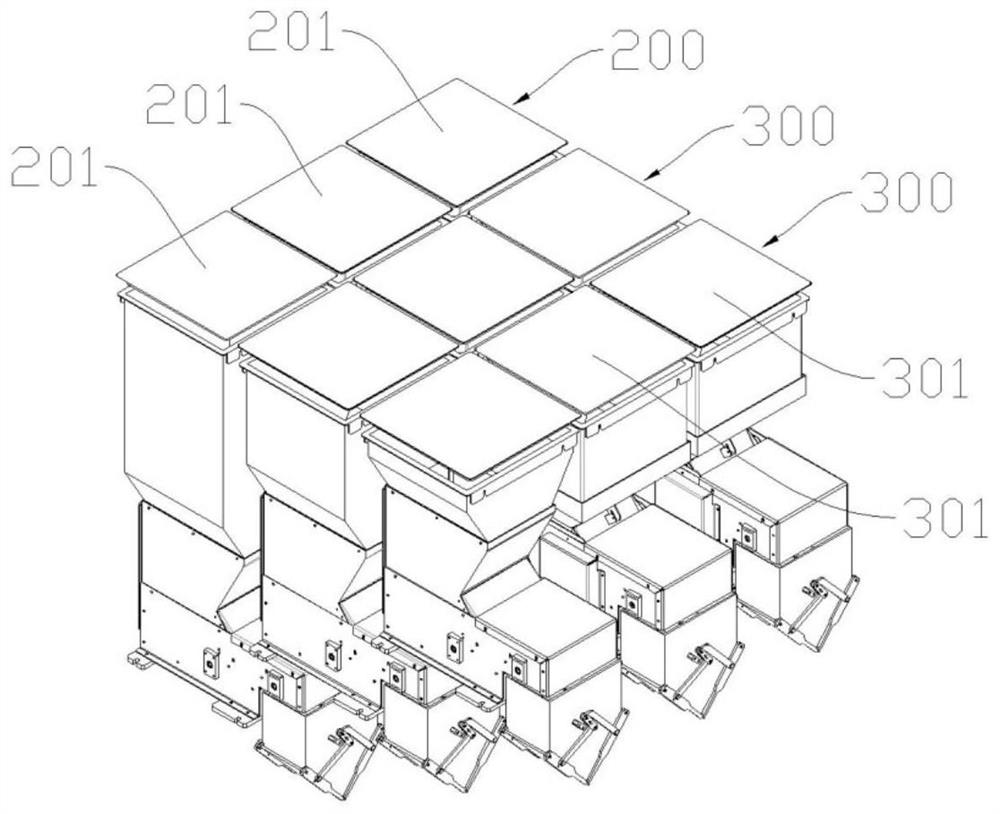

Automatic traditional Chinese medicine dispensing system

ActiveCN112722725AStable outputImprove adjustment efficiencyControl devices for conveyorsPackagingMedicinal herbsProcess engineering

Owner:SUZHOU IRON TECH

Automated flue gas collection device and analysis method

ActiveCN103674629AWithdrawing sample devicesWeighing by absorbing componentManipulatorProcess engineering

Owner:SHANGHAI TOBACCO GRP CO LTD +1

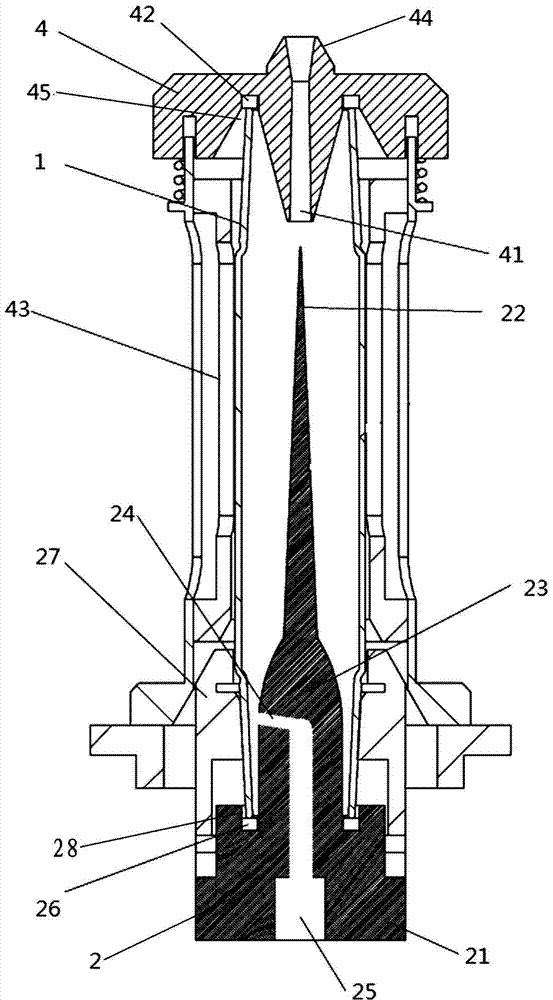

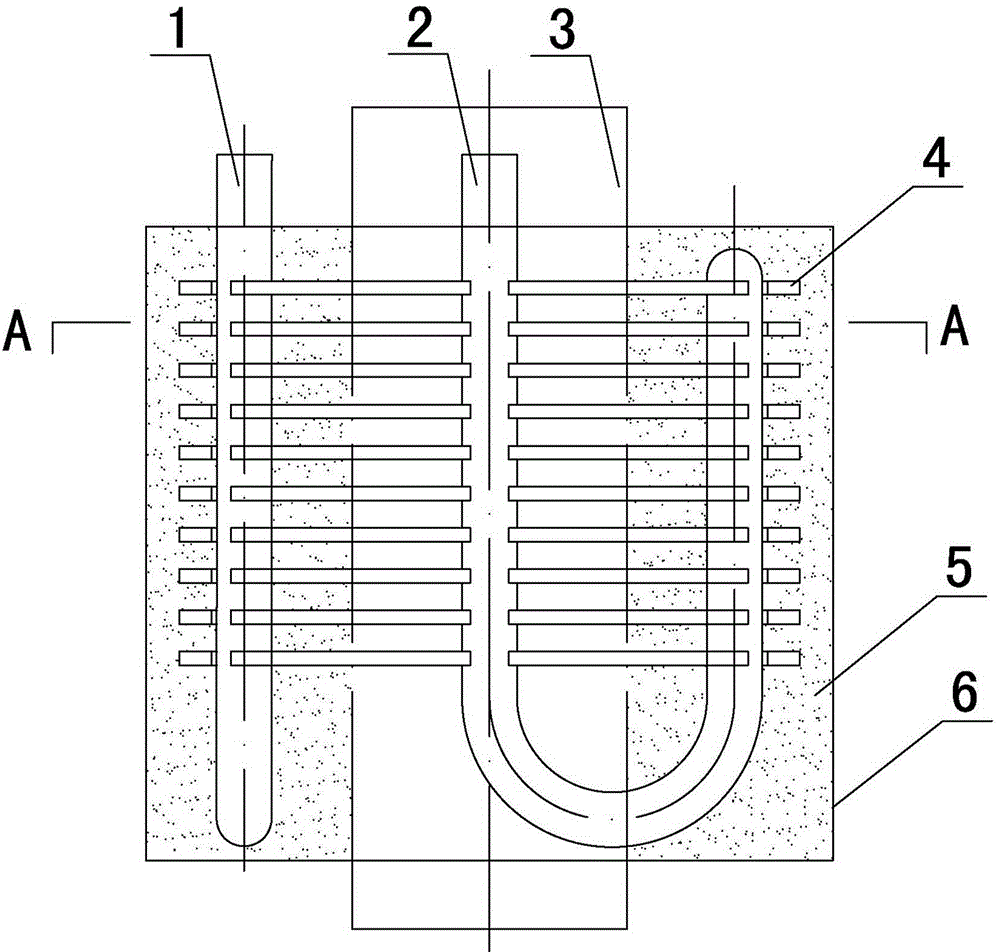

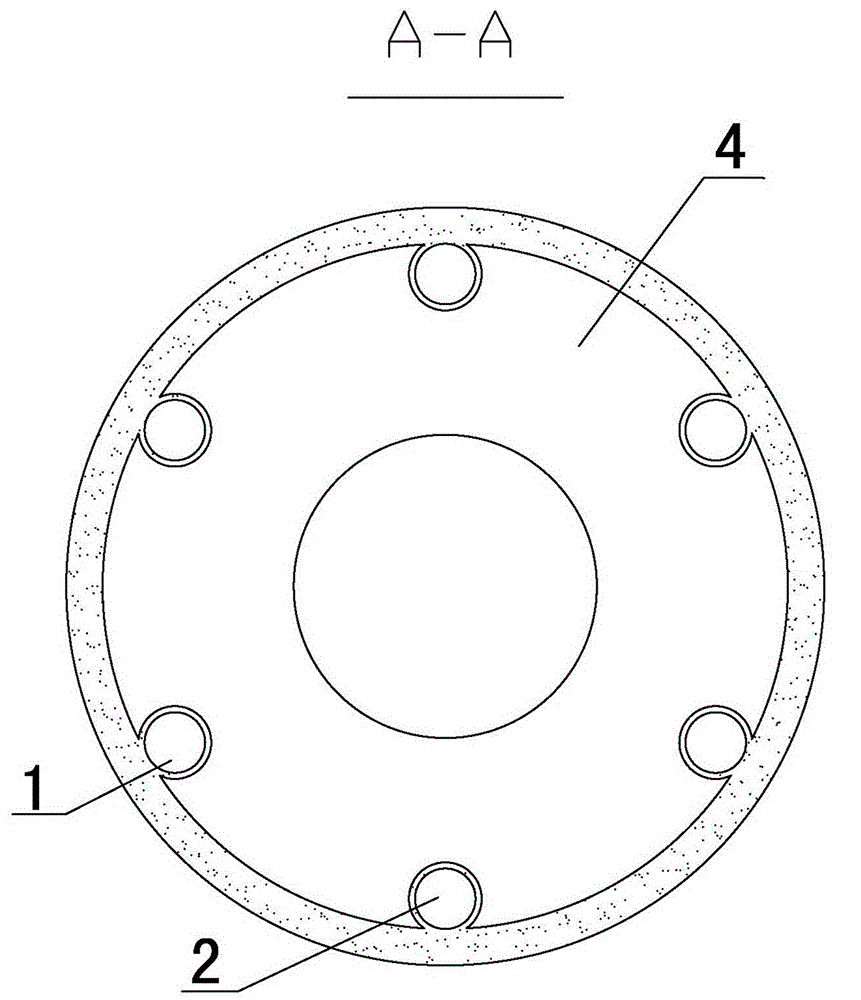

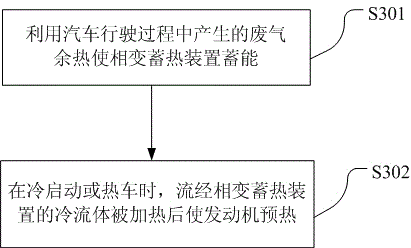

Phase change heat storage device and method utilizing engine waste gas waste heat

InactiveCN104482790AInternal combustion piston enginesHeat storage plantsProcess engineeringHeating cooling

Owner:BRILLIANCE AUTO

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap