Production method for cobaltous sulfate heptahydrate

A production method, technology of cobalt sulfate, applied in the direction of cobalt sulfate, etc., can solve the problems of high equipment investment, low production efficiency, many process control parameters, etc., and achieve the effect of low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

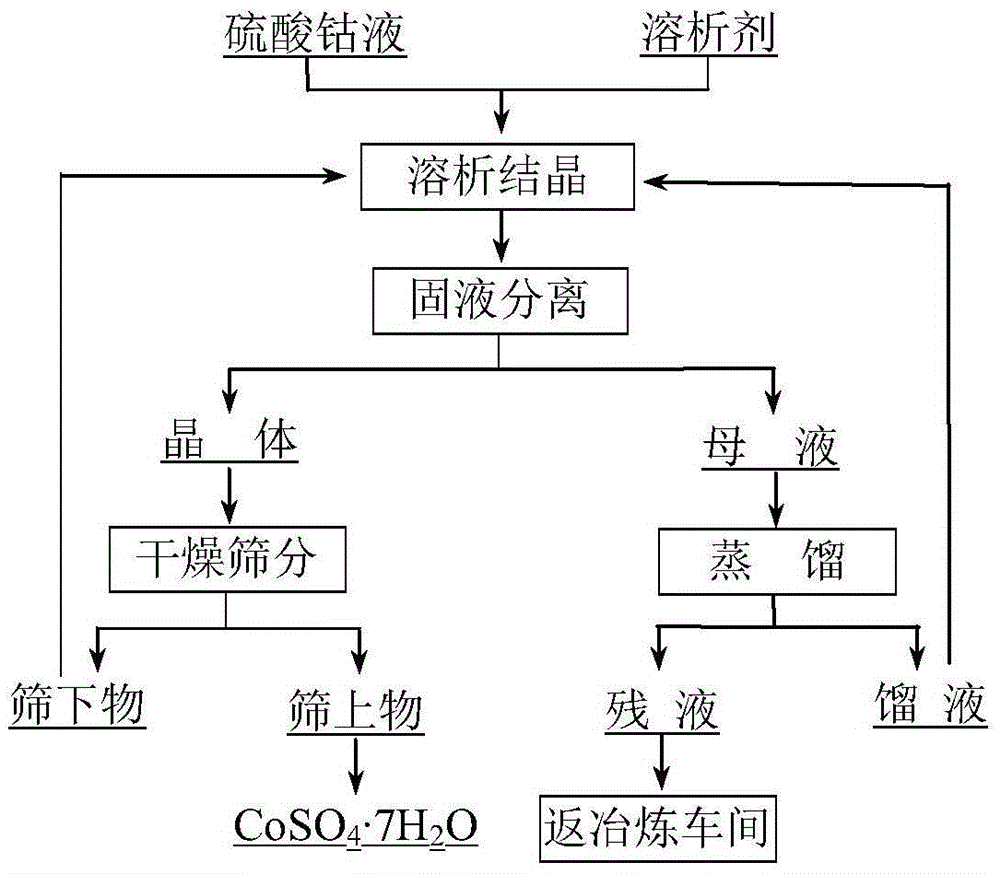

[0028] Use Co130g / L cobalt sulfate evaporation and crystallization mother liquor as cobalt liquid (air temperature is 20oC), pump cobalt sulfate solution into crystallization tank, start stirring, without heating or cooling, then pump ethanol as eluent; monitor mother liquor at any time Middle Co 2+ When the concentration of Co in the mother liquor reaches 0.5g / L, stop adding ethanol, and use a centrifuge to separate the solid and liquid after stirring and aging for 0.5h; The sieved material is packaged and sold, and the obtained mother liquor is distilled; the distilled liquid is returned to the crystallization process as a dissolving agent, and the raffinate is returned to the leaching workshop of the cobalt hydrometallurgy for pulping the ore pulp. See the specific process figure 1 ..

[0029] The crystallization rate of this elution crystallization is 99.9%, the obtained cobalt sulfate product +24 mesh accounts for 95%, the product water-insoluble matter is <0.0005%, an

Embodiment 2

[0031] The water cobalt ore leaching solution is extracted by P204 to remove impurities, P507 is separated from nickel and cobalt, and back-extracted to obtain a Co120g / L cobalt sulfate solution (air temperature is 40oC), start stirring, pump in isopropanol as a solvent, and when it is saturated, The undersize is returned to the crystallization tank as crystal seeds, and isopropanol is continued to be pumped; the Co in the mother liquor is monitored at any time. 2+ concentration, when the Co concentration in the mother liquor is 5g / L, stop adding benzene, and use a centrifuge to separate the solid and liquid after stirring and aging for 2 hours; The sieve is packaged and sold, and the resulting mother liquor is distilled; the distilled liquid is returned to the crystallization process as a dissolving agent, and the raffinate is returned to the cobalt hydrometallurgy extraction workshop for P507 extraction and recovery of Co. The specific process is only in the figure 1 The o

Embodiment 3

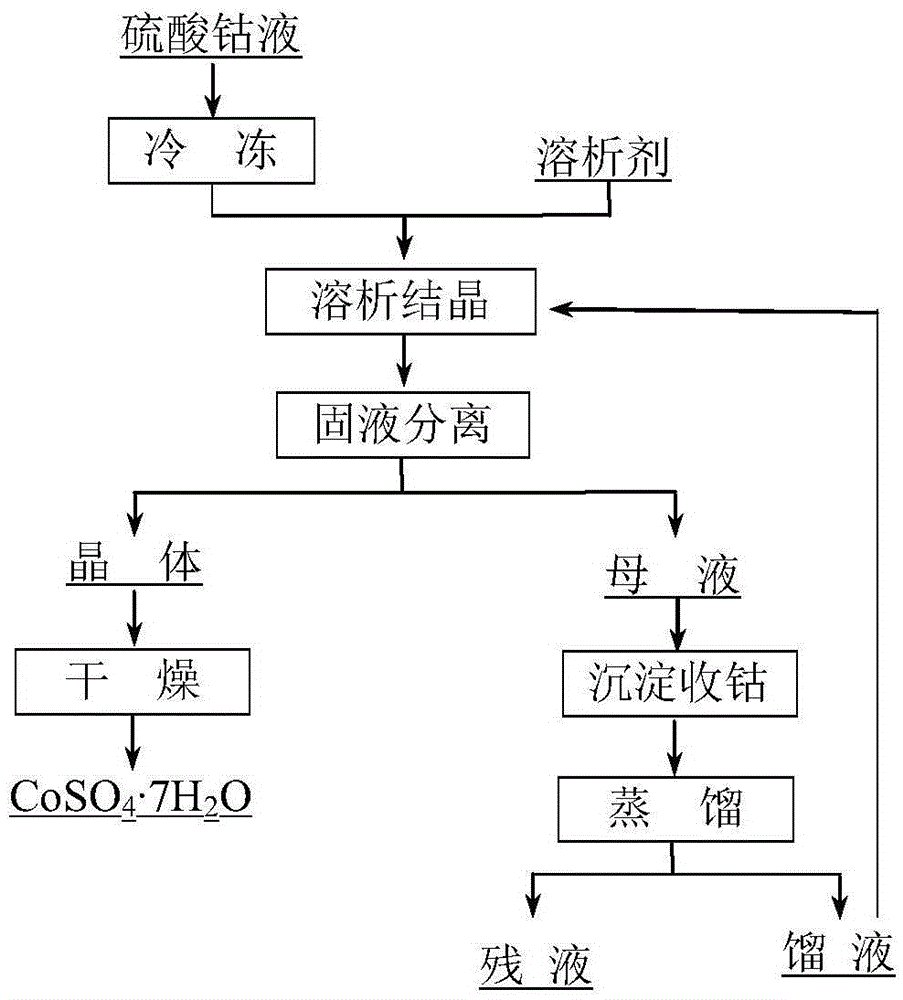

[0034] The water cobalt ore leaching solution is extracted by P204 to remove impurities, P507 is separated from nickel and cobalt, and then back-extracted to obtain a Co60g / L cobalt sulfate solution, which is frozen to 0oC and pumped into the crystallization tank, started stirring, and then pumped into tetrahydrofuran as a solvent; monitor the mother liquor at any time co 2+ Concentration, when the Co concentration in the mother liquor reaches 10g / L, stop adding isopropanol, use a centrifuge to separate the solid and liquid after stirring and aging for 1 hour; the obtained solid is directly packaged and sold after drying, and the obtained mother liquor is distilled after sulfide precipitation; The liquid returns to the crystallization process as a dissolving agent, and the residual liquid is discharged. See the specific process figure 2 ..

[0035] The crystallization rate of this eluted crystal is 80.0%, the water insoluble matter of the product is <0.0005%, and the pH (C

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap