Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "Sulfuric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfuric acid (alternative spelling sulphuric acid), also known as vitriol, is a mineral acid composed of the elements sulfur, oxygen and hydrogen, with molecular formula H₂SO₄. It is a colorless, odorless, and syrupy liquid that is soluble in water and is synthesized in reactions that are highly exothermic.

Technology for extracting zinc, lead and silver step by step by processing zinc-leached residues by full wet process

ActiveCN102719668AHigh extraction rateAchieve recyclingProcess efficiency improvementHigh concentrationSlurry

Owner:JIANGXI LONGTIANYONG NONFERROUS METAL CO LTD

Positive lead paste of storage battery and preparation method thereof

Owner:HENAN CHAOWEI POWER SUPPLY

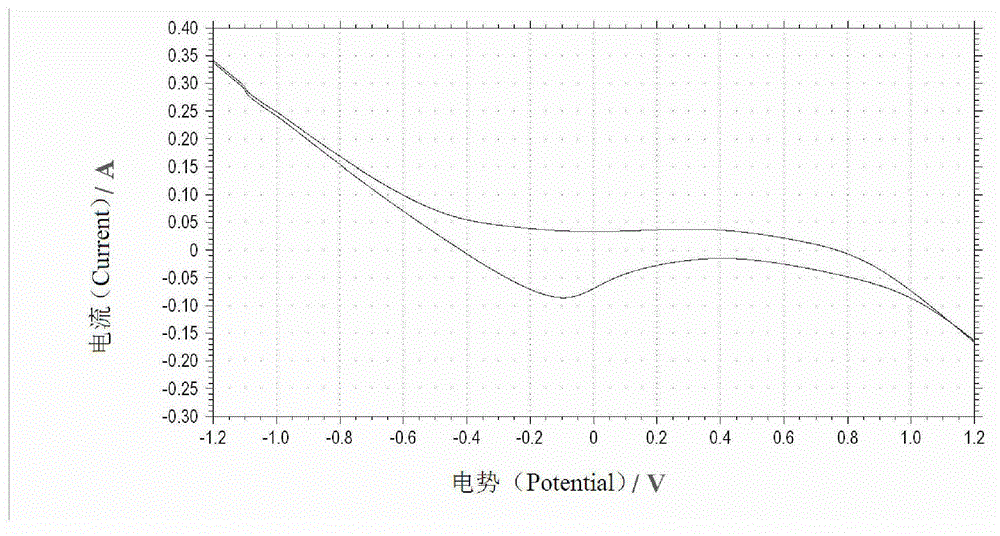

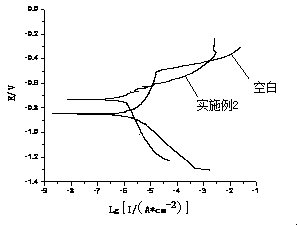

Treatment method of carbon felt for vanadium batteries

ActiveCN103066287AImprove hydrophilicityImprove the activation effectCell electrodesActivated carbonCarbon felt

Owner:承德新新钒钛储能科技有限公司 +1

Preparation method of silicon dioxide used for tooth paste

The invention discloses a preparation method of silicon dioxide used for tooth paste. According to the invention, a two-stage alkali-adding method is adopted, and the method comprises the steps that: a certain amount of sodium silicate water solution and a certain amount of sulfuric acid water solution are prepared firstly; the sulfuric acid water solution is added into a reaction kettle at ordinary temperature, wherein the adding amount is 50% of needed sulfuric acid; the sodium silicate water solution is added until the pH reaches 7-8; the temperature is increased to 70-80 DEG C; mixing is performed for 1-2 h; the rest sodium silicate solution is added into the reaction slurry; the temperature is increased to 70-80 DEG C; the sulfuric acid water solution is added until the pH reaches 4-5; the heat temperature is preserved for 20-30 min; water washing, drying and smashing are conducted to obtain tooth-paste-used silicon dioxide. The silicon dioxide has proper abrasion amount and good thickening property.

Owner:FUJIAN SANMING TONGSHENG CHEM

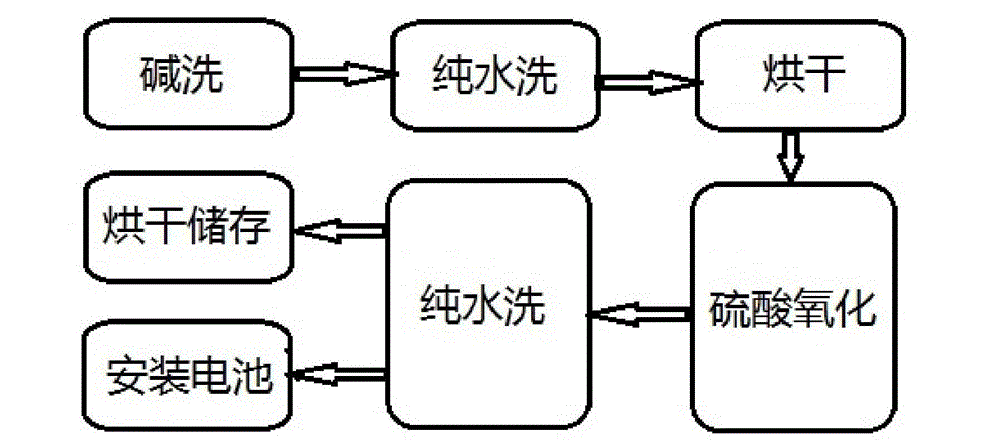

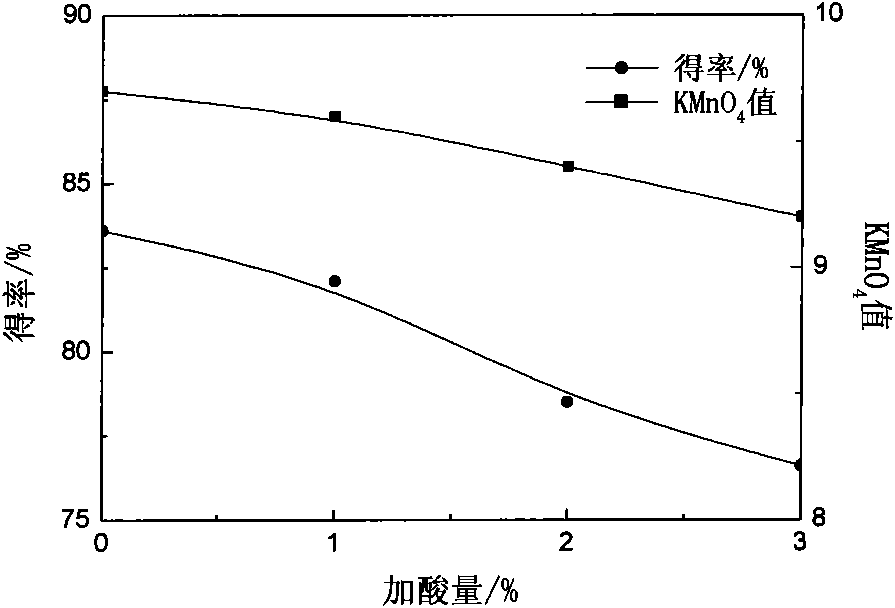

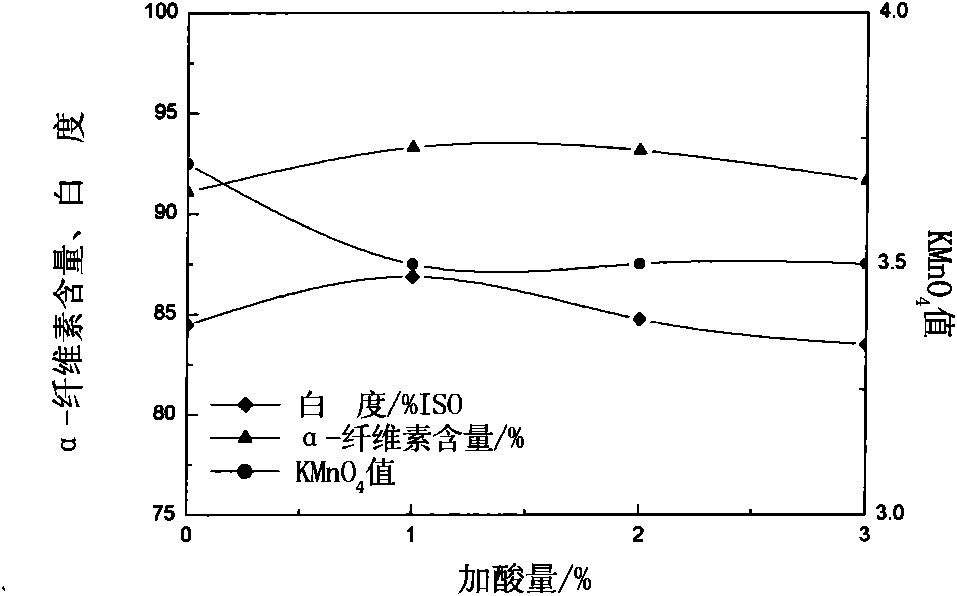

Method for preparing pharmaceutical-grade microcrystalline cellulose from cotton linter

InactiveCN101864684AReduce pollutionEasy to pollutePaper material treatmentGranularityNational standard

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Etimicin sulfate preparation and its preparing method

InactiveCN1569010ASufficient solubilityImprove the bactericidal effectOrganic active ingredientsAntipyreticEtimicin sulfateChemistry

The invention discloses etimicin sulfate preparation and its preparing method which comprises, charging acids or alkali as pH conditioning agent so as to increase the dissolving degree of the etimicin, charging right amount of isoosmotic adjustment agent, thus resulting the action of quick sterilization.

Owner:ZHEJIANG UNIV

Method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas

InactiveCN101691210ALess investmentLow running costSulfur compoundsDispersed particle separationWater vaporTitanium

The invention discloses a method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas. The method comprises the following steps: (1) supplying sulfuric-acid production tail gas to titanium white waste acid sprayed to be in a mist state, concentrating the titanium white waste acid and turning the sulfuric-acid production tail gas from dry gas into wet gas containing steam and titanium white waste acid foam; (2) performing gas-liquid separation on the wet gas, treating and then emptying separated gas, mixing separated liquid with the titanium white waste acid concentrated in a step (1) and then repeatedly concentrating the mixture; and (3) performing sampling test on the titanium white waste acid repeatedly concentrated and recovering the titanium white waste acid when the sulfuric acid content of the titanium white waste acid in percentage by mass is detected to reach over 55 percent. The method has the advantages of simple equipment, convenient operation, low investment, low energy consumption, low operation-maintenance cost, capability of avoiding pipeline blockage because of high-temperature scaling and capability of reducing the pressure to treat sulfuric-acid production tail gas.

Owner:WUHAN QINGJIANG CHEM IND

Method for preparing amorphous ultrafine silicon oxide by hydrothermal method

Owner:BEIJING UNIV OF CHEM TECH

Method for extracting fucoidan polysaccharide sulfate

ActiveCN103980373ASolve difficult problems that are not suitable for separationSimple extraction processOrganic active ingredientsMedicineMicrobiology

Owner:吉林省辉南长龙生化药业股份有限公司

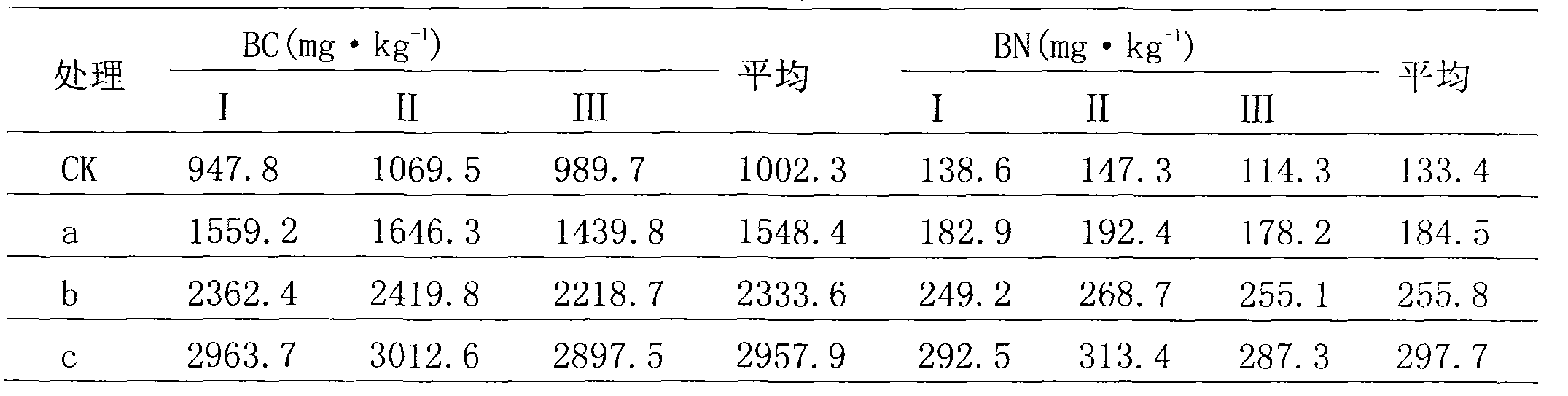

Soil bio-activator for ginseng continuous cropping

InactiveCN103254022AImprove the growing environmentPrevent Soilborne DiseasesFertilizer mixturesContinuous croppingPhosphate

Owner:JILIN AGRICULTURAL UNIV

Sewage treatment manganese dioxide material and preparation method thereof

ActiveCN105523603AEffective recoveryEfficient degradationOther chemical processesWater treatment compoundsAdhesivePollution

The invention discloses a sewage treatment manganese dioxide material and a preparation method thereof. The sewage treatment material comprises, by weight, 5-10 parts of macro-porous resin, 40-50 parts of manganese dioxide, 1-3 parts of sulfuric acid, 1-2 parts of a wetting agent, 1-2 parts of a dispersant and 1-3 parts of an adhesive. The preparation method comprises the following steps: uniformly dispersing manganese dioxide in the surface and the tunnels of the macro-porous resin through using mechanical chemical modification and polymer material hot stretch molding, extruding, and carrying out plastic compression to obtain the sewage treatment manganese dioxide material. The sewage treatment manganese dioxide material can effectively adsorb and degrade organic matters in sewage and reduce and chelate heavy metal ions, and also has the characteristics of high adsorption capacity, low cost and no secondary pollution.

Owner:DONGYING GUOAN CHEM CO LTD

Preparation method of corrosion inhibitor of methanol gasoline

ActiveCN103725335AGood compatibilityAdd lessLiquid carbonaceous fuelsFuel additivesActive agentPolyethylene glycol

Owner:南通市通州区五接农业机电管理站有限公司

Preparation method of rice hull carbon based solid sulfoacid

InactiveCN103157512AHigh densityEasy to dehydrateOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholAcid catalyzed

Owner:TIANJIN POLYTECHNIC UNIV

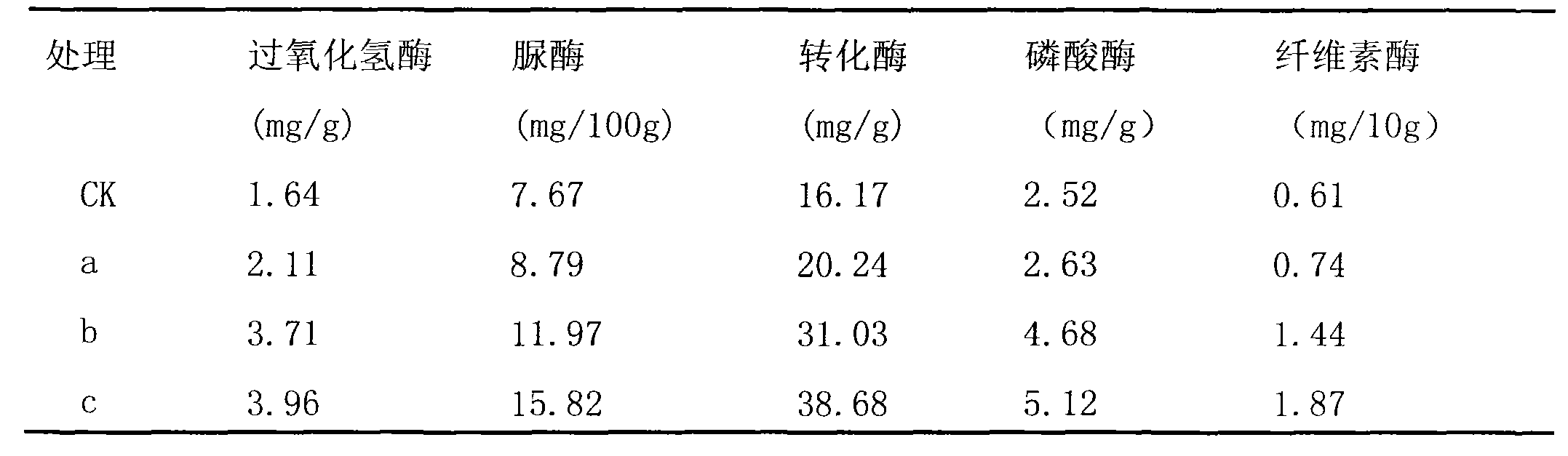

Method for preparing tungsten oxide and tungsten powder from scheelite

ActiveCN108640156AReduce break down costReduce manufacturing costTungsten oxides/hydroxidesProcess efficiency improvementDecompositionCalcination

Owner:CENT SOUTH UNIV

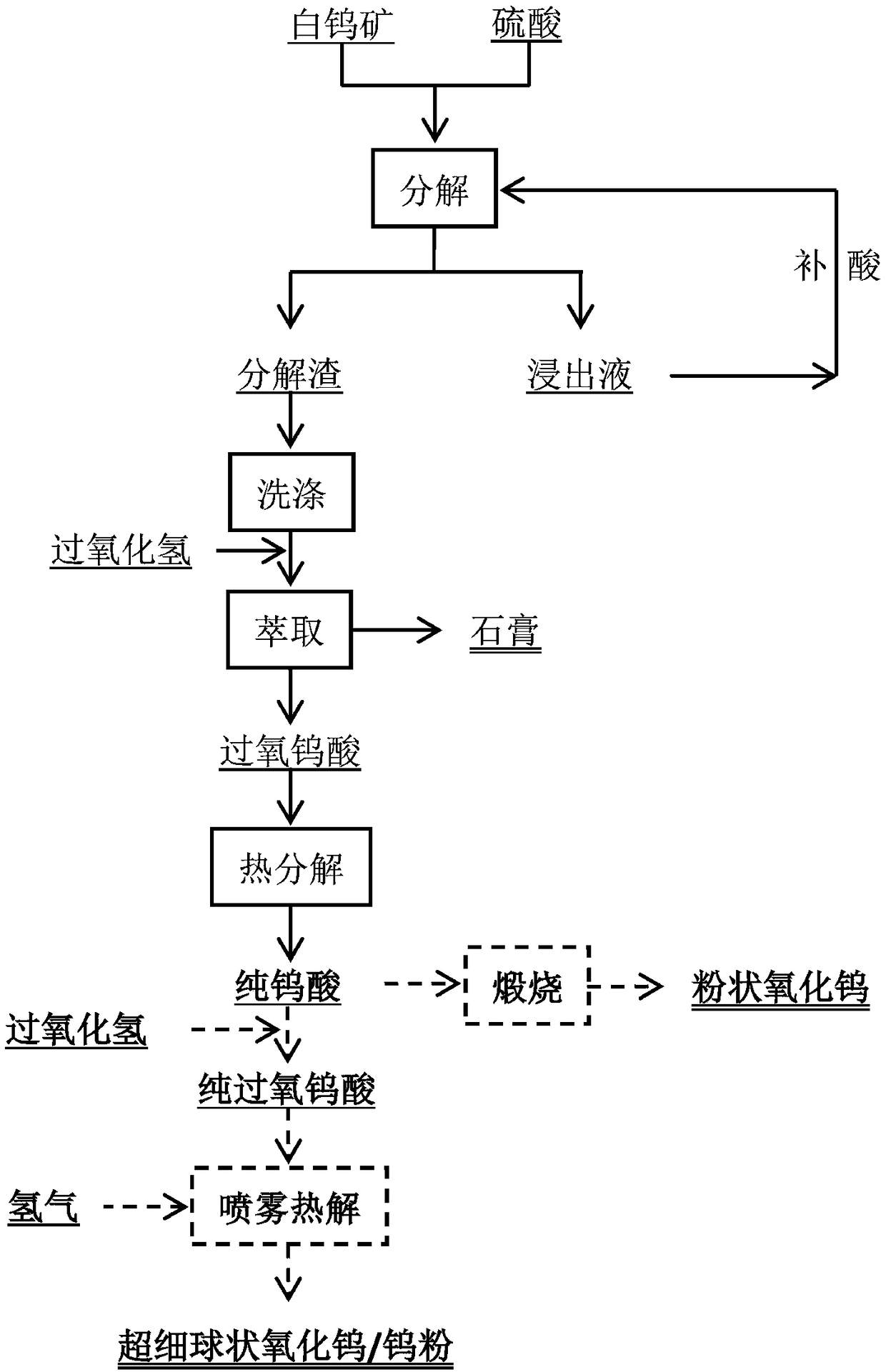

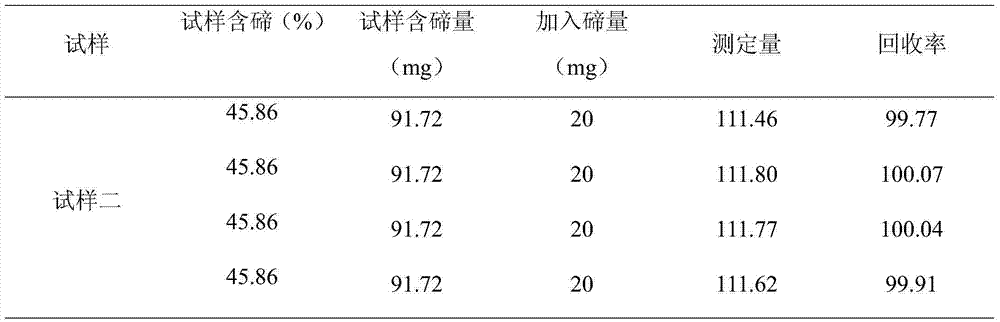

Analyzing method for quickly and precisely measuring tellurium in tellurium smelting process

ActiveCN104237225AFast and accurate determinationImprove accuracyMaterial analysis by observing effect on chemical indicatorValidation methodsTe element

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Method for preparing organic carbon fertilizer from agricultural wastes as raw materials

The invention discloses a method for preparing organic carbon fertilizer from agricultural wastes as raw materials. The method comprises, 1, raw material pretreatment: crushing agricultural wastes, adding water into the agricultural wastes and carrying out blending, 2, acid addition and digestion reaction, and 3, centrifugal separation or settling separation and supernatant collection. The agricultural wastes comprise straws. The straws comprise corn stalks, wheat straws, paddy rice straws, sugar cane stalks, cotton stalks or the rest part of crops treated by seed collection. The acid comprises more or more of sulfuric acid, nitric acid, perchloric acid, hypochlorous acid and hydrogen peroxide. The digestion reaction temperature is in a range of 80-180 DEG C and digestion reaction time is in a range of 1-30min. A mass ratio of the agricultural wastes to the acid is 100: (1-9). The method has simple and fast processes and small energy consumption. The obtained organic carbon fertilizer comprises micromolecule organic carbon and can be absorbed easily by crops.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

Method for preparing particle boric fertilizer

Owner:张纯阳 +2

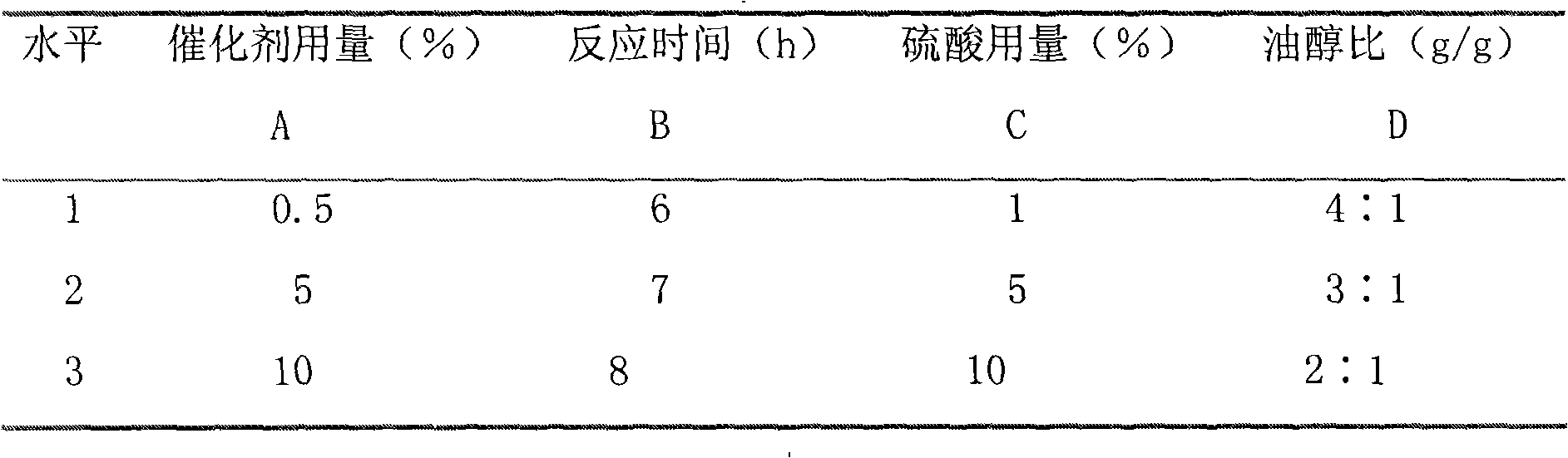

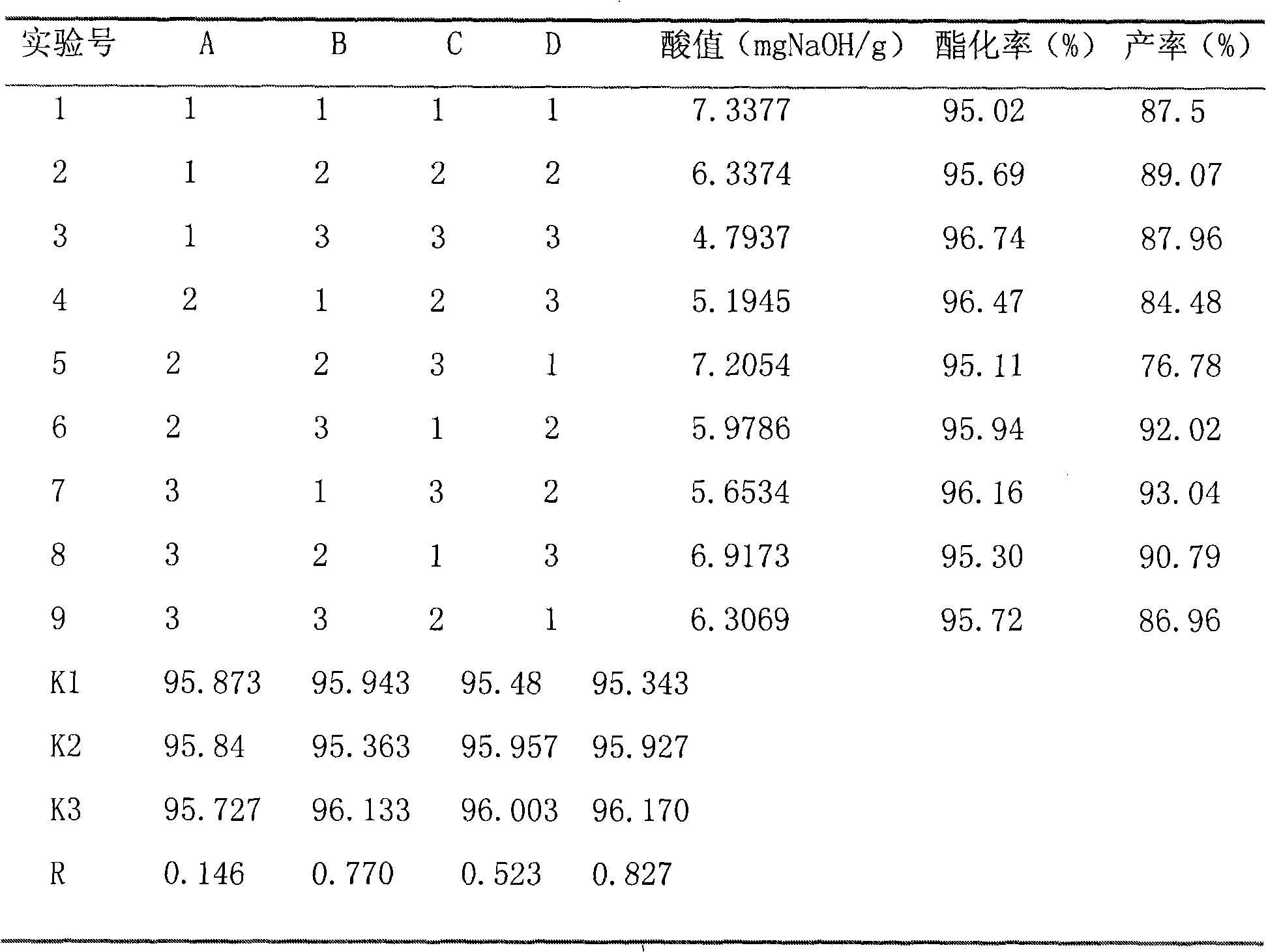

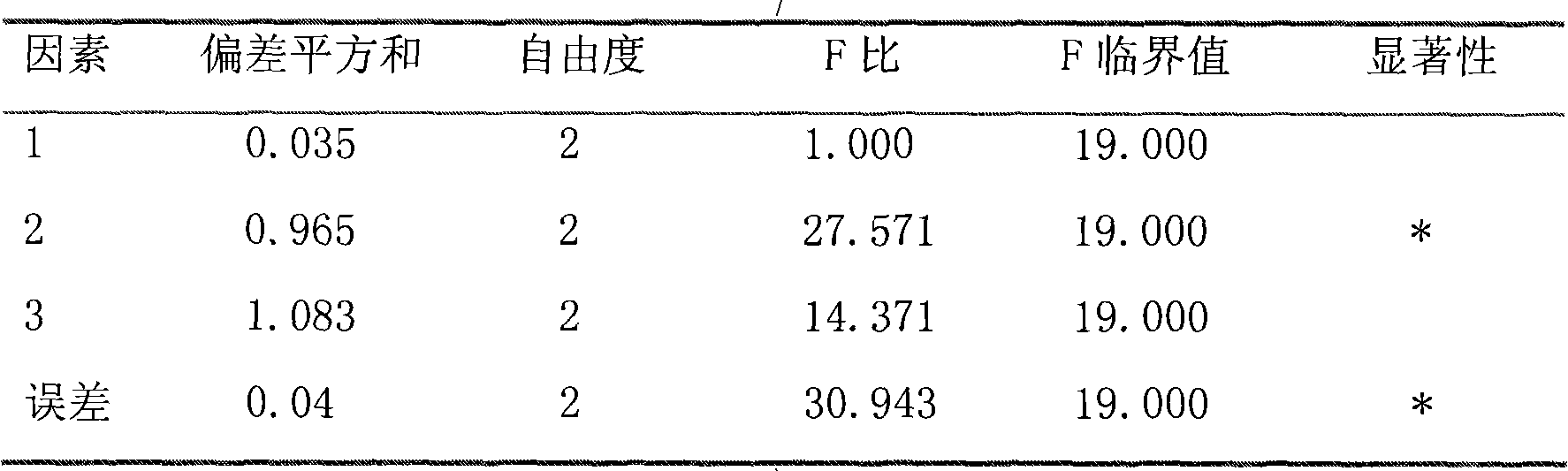

Method for preparing biological diesel oil by using inversed micelle catalyst

InactiveCN101294098AFatty oils/acids recovery from wastePhysical/chemical process catalystsChemistrySulfuric acid

Owner:CHINA THREE GORGES UNIV

Preparation method of 4-nitroimidazole

Owner:JIANGSU CALE NEW MATERIALS

Aluminum alloy surface titanium dioxide conversion coating solution and using method thereof

InactiveCN103924229AUniform colorImprove corrosion resistanceMetallic material coating processesTitanium oxideConversion coating

Owner:无锡铱美特科技有限公司 +1

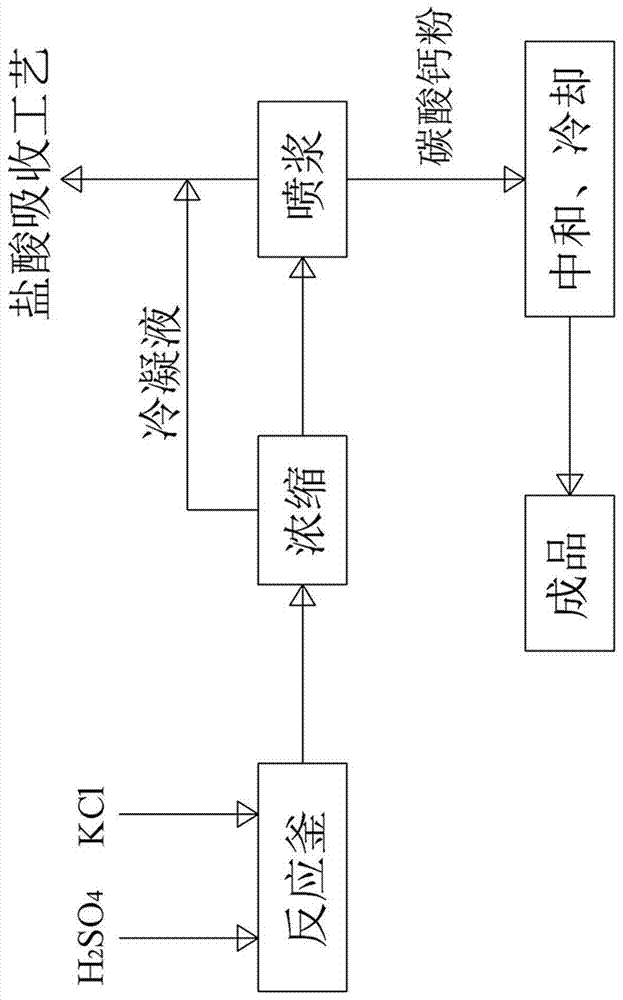

Technology for producing potassium sulphate by liquid-phase grouting method

InactiveCN107032834AImprove product qualitySolve complexityCalcareous fertilisersSulfate/bisulfate preparationHigh energyDecomposition

Owner:KAIFENG UNIV

Methods for producing fulvic acid salt, fulvic acid water-soluble fertilizers and aquatic nutrient solution from alcohol waste liquid from waste molasses

InactiveCN106431528AOvercoming problems such as pollutionSolve emissions that destroy the natural ecological balanceMagnesium fertilisersAlkali orthophosphate fertiliserPhytic acidNutrient solution

Owner:林晓山

Lead paste of lead acid storage battery with long service cycle

InactiveCN105977485AIncrease the speed of chargingIncrease the discharge speedCell electrodesFiberGallic acid ester

Owner:无锡市宝来电池有限公司

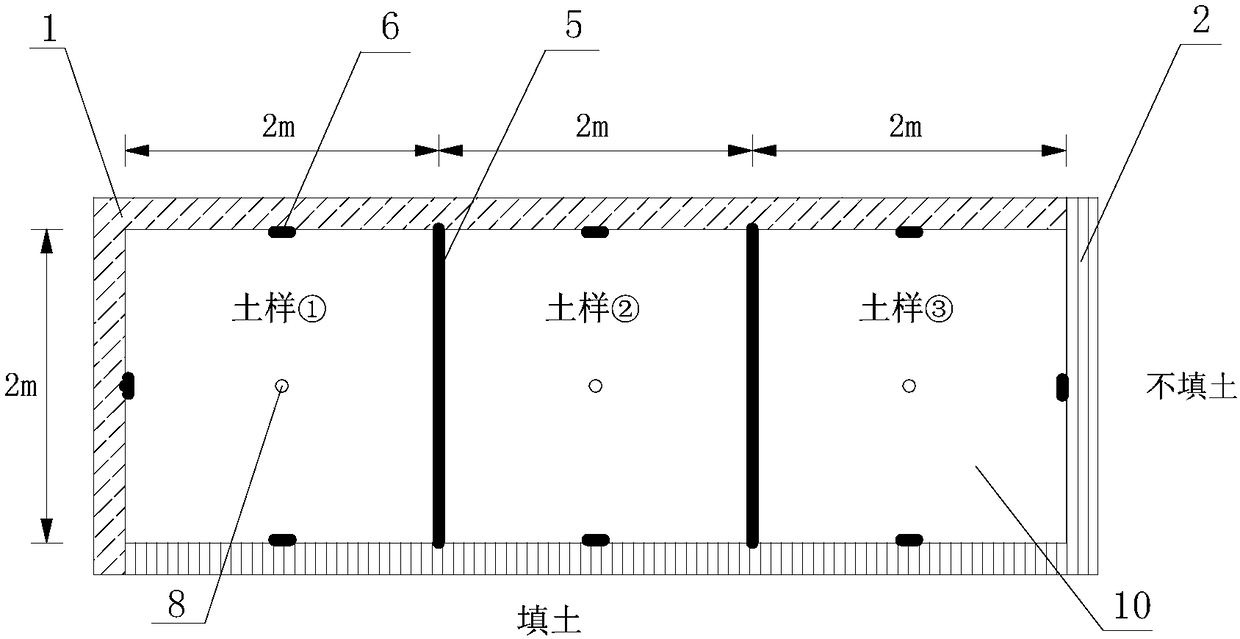

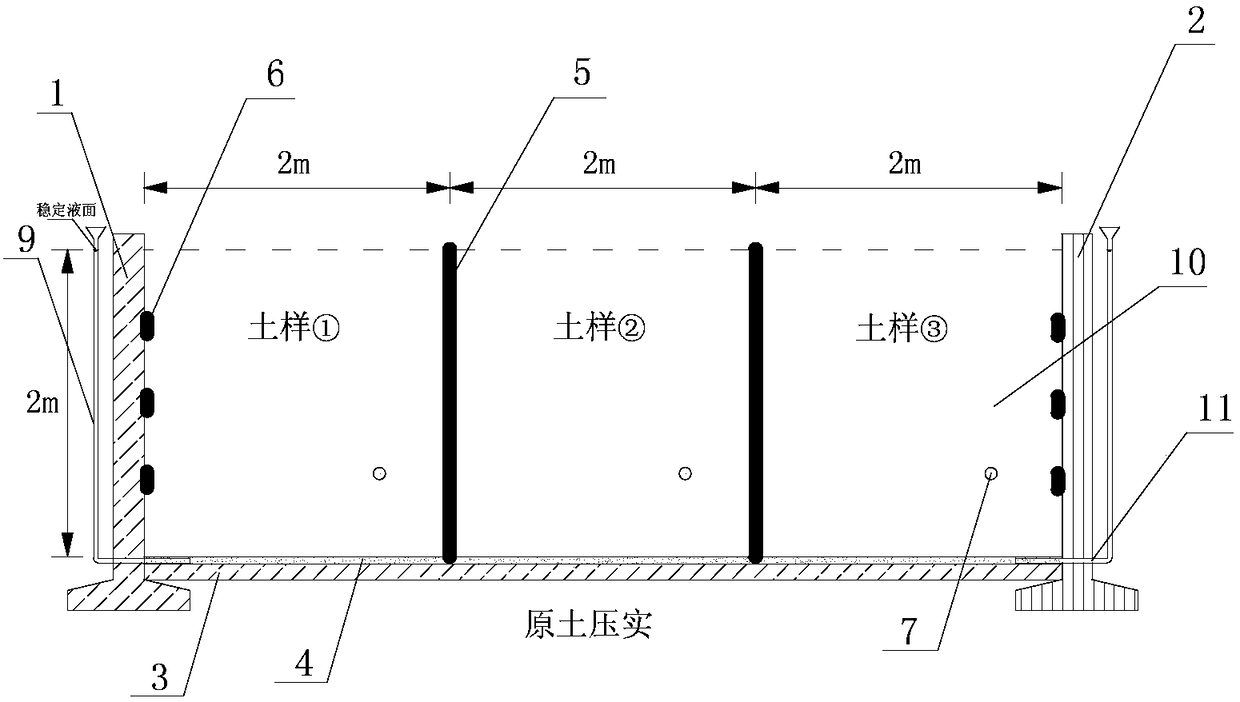

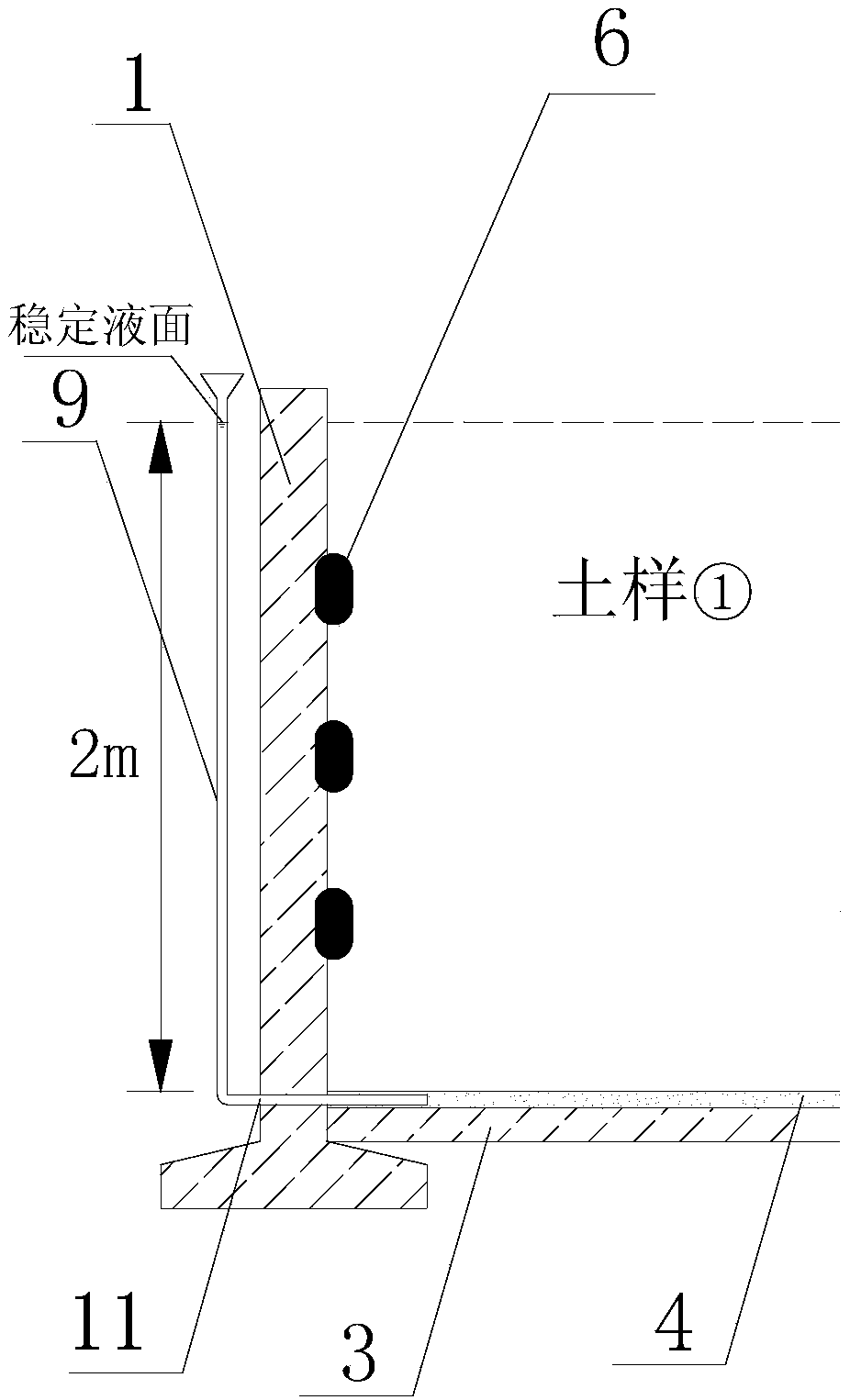

Multifunctional testing apparatus for on-site determination of expansion of sulfuric acid salinized soil saline

ActiveCN108333329AMeasured expansion rateMeasured expansion forceEarth material testingSoil scienceReinforced concrete

Owner:ANHUI GOLDENLAND ARCHITECTURAL DESIGN

Composite electrode material and preparation method thereof, and super capacitor

PendingCN110970226ALarge specific surface areaHigh specific capacitanceHybrid capacitor electrodesElectrolytic agentCapacitance

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing calcium hydrophosphate through double-acidolysis of phosphorite

ActiveCN106044732ALess quantityHigh extraction rateCalcium/strontium/barium sulfatesPhosphorus compoundsSulfatePhosphorite

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

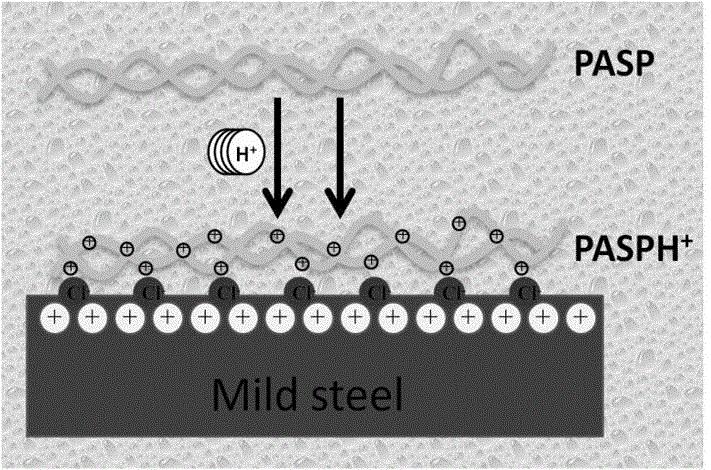

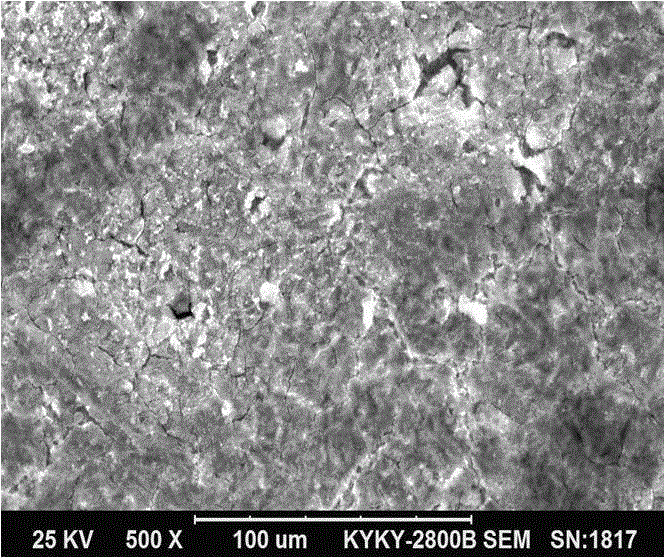

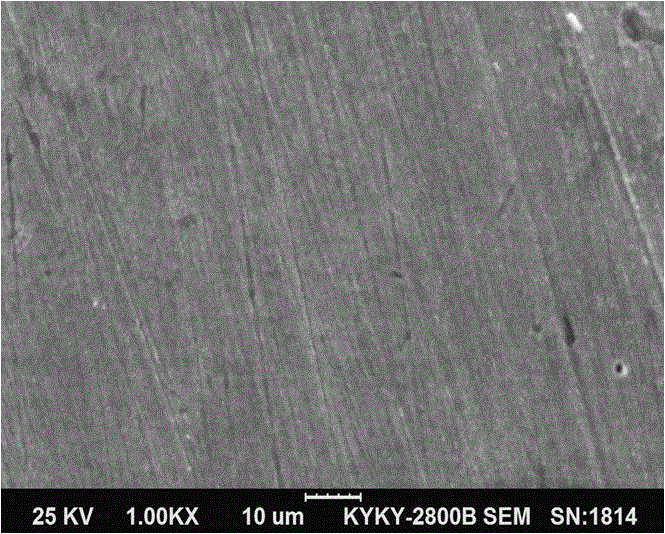

Environment-friendly carbon steel pickling inhibitor and application thereof

Owner:QINGDAO AGRI UNIV

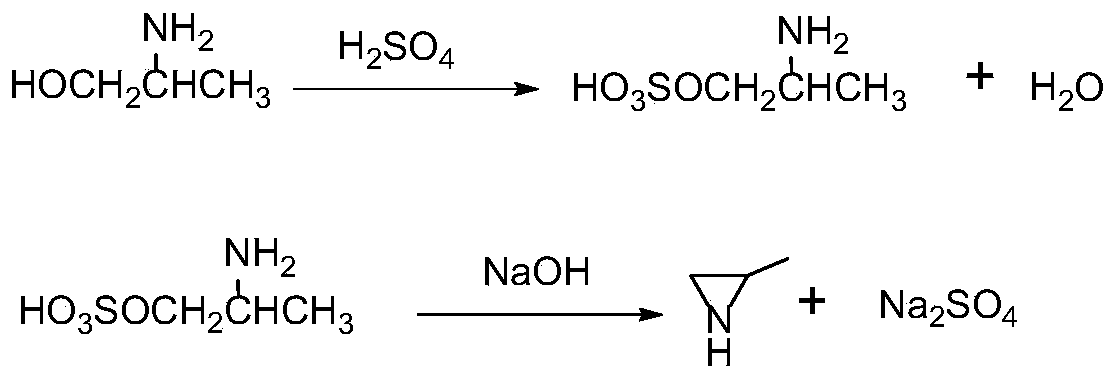

Preparation method of 2-methylaziridine

Owner:NINGXIA JOIE MATERIAL CO LTD

Method for preparing electrolytic manganese by using pyrolusite

PendingCN110331284AAchieve regenerationAchieve recyclingPhotography auxillary processesProcess efficiency improvementElectrolysisPyrolusite

The invention discloses a method for preparing electrolytic manganese by using pyrolusite, and the method comprises the following steps of leaching manganese ore: crushing pyrolusite, mixing a mixed solution containing ammonium sulfate, manganese sulfate and ferrous sulfate with pyrolusite particles to obtain slurry, and leaching; neutralizing and precipitating iron: adding calcium-based neutralizer into the slurry, adjusting pH value, adding oxidant to enable Fe<2+> concentration in the solution to be lower than 1 mg / L, and filtering to obtain manganese sulfate solution and iron hydroxide filter residue; carrying out heavy metal removal: adding a vulcanizing agent into the manganese sulfate solution to enable the concentration of heavy metal ions in the solution to be lower than 1 mg / L, and then filtering to obtain vulcanized slag and electrolyte; and carrying out electrolytic recovery of manganese metal: electrolyzing the obtained electrolyte to prepare electrolytic manganese and electrolytic manganese anolyte containing sulfuric acid. The method can effectively solve the problem that dithionate is generated in the pyrolusite sulfur dioxide leaching method, thereby causing the problems of high electrolysis energy consumption, high sulfur content of electrolytic manganese and large amount of iron-containing waste residue generated in the pyrolusite ferrous sulfate leaching method.

Owner:GUIZHOU UNION MAGANESE CORP CO LTD

Production method for full-resource cyclic utilization of sulfuric-acid-method titanium dioxide production wastewater

InactiveCN112499813ATo achieve the purpose of coupling recyclingEliminate influencing factorsTreatment involving filtrationMultistage water/sewage treatmentSulfateCarbonization

The invention discloses a production method for full-resource cyclic utilization of sulfuric-acid-method titanium dioxide production wastewater, which comprises the following steps of: neutralizing wastewater produced by sulfuric acid method titanium dioxide production by lime, separating gypsum by a filter press to obtain treated wastewater, and adding a recycled sodium carbonate solution to precipitate saturated calcium sulfate in the treated wastewater; clarifying the slurry to separate calcium carbonate precipitate and a sodium sulfate solution, and carrying out membrane separation on theseparated dilute sodium sulfate solution through a membrane filter; adding lime into a concentrated-phase sodium sulfate solution obtained after membrane separation for causticization reaction, takinga filtrate as a sodium hydroxide solution, employing carbon dioxide-containing tail gas generated in the titanium dioxide production process for carbonization, obtaining a sodium carbonate solution,and then returning the treated wastewater to precipitate saturated calcium sulfate. The method economically solves the technical problem that the lime neutralization treatment wastewater cannot be economically recycled in the sulfuric acid method titanium dioxide production process, eliminates the influence factors of outward discharge of the existing neutralization treatment wastewater on the environmental water body, and saves a large amount of raw water resources for production.

Owner:CHENGDU QIANLIJIN TECHCAL INNOVATION CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap