Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Filter press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An industrial filter press is a tool used in separation processes, specifically to separate solids and liquids. The process uses the principle of pressure drive, as provided by a slurry pump. Among other uses, filter presses are utilized in marble factories in order to separate water from mud in order to reuse the water during the marble cutting process.

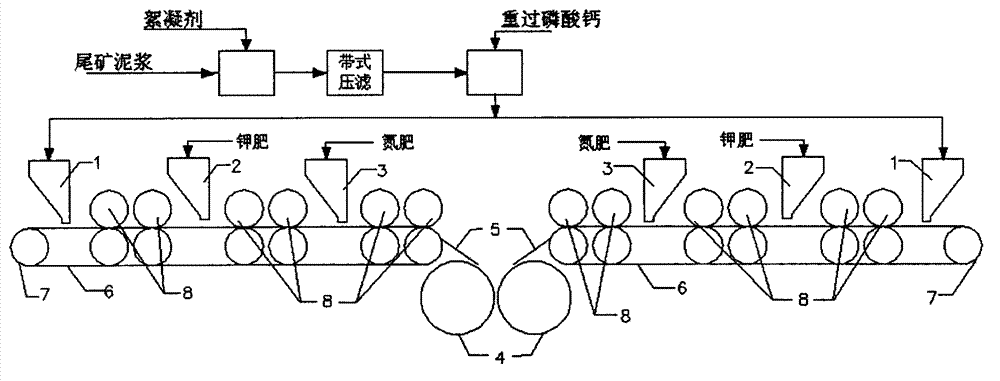

Method and equipment for producing slow-release compound fertilizer from manganese ore tailings

InactiveCN103204743AReduce processing costsSolving Stacking Handling IssuesFertiliser formsFertilizer mixturesElectrolysisManganese

Owner:赵阳臣

Beauxite applied pipeline transportation method

InactiveCN1730363AImprove working environmentSave engineering investmentBulk conveyorsWorking environmentEngineering

Owner:GUIYANG AL-MG DESIGN & RES INST

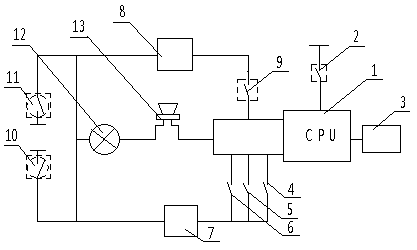

Squeezing safety and automatic alarm device of diaphragm filter press

PendingCN111298490AImprove the safety requirements of automatic control operationEasy to useAlarmsElectric transmission signalling systemsText displayAutomatic control

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

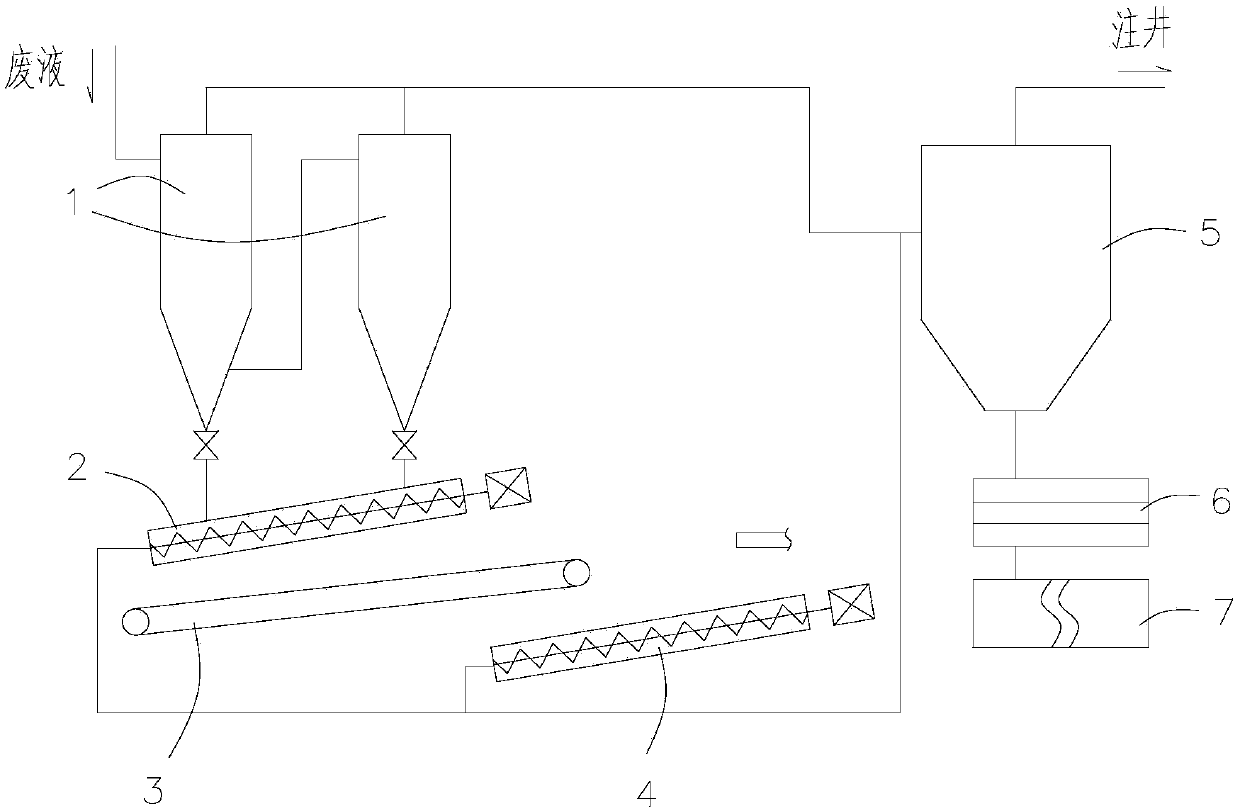

Reutilization method for alkali-making waste residue liquid and system using reutilization method

InactiveCN109570186AReduce pressure on environmental protectionReduce effluxSolid waste disposalTransportation and packagingBrickFilter press

Owner:湖北云应矿业技术开发有限公司

Disease-dried livestock and poultry drying wastewater treatment technology

InactiveCN110092510AReduce the content of suspended solidsFacilitate flocculation removalWater treatment parameter controlFatty/oily/floating substances removal devicesWater qualityFilter press

Owner:东营市利民无害化处理有限公司 +1

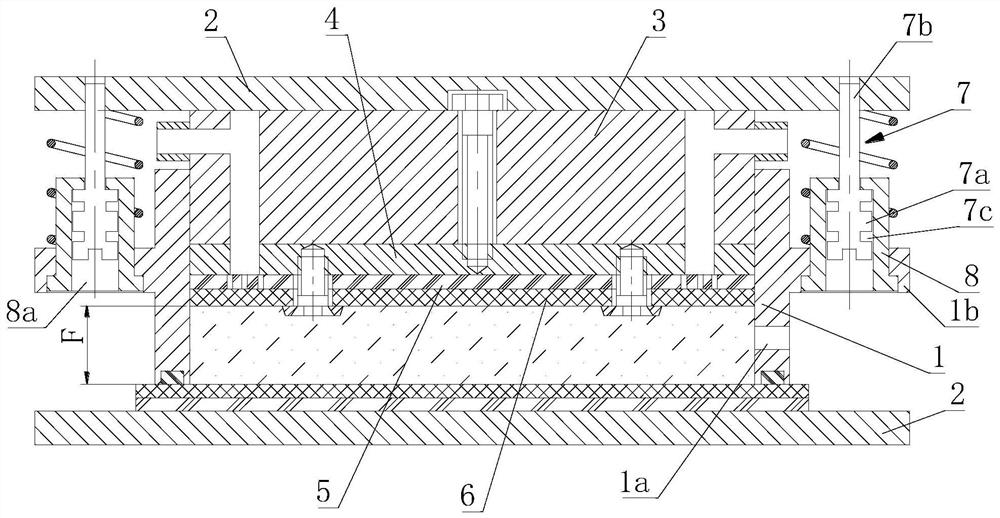

Double-oil-inlet type hydraulic integrated valve group and double-oil-pump type hydraulic station for large filter press

PendingCN114412870APressurize fastPressurization simplifiedFluid-pressure actuator testingServomotor componentsFilter pressOil pump

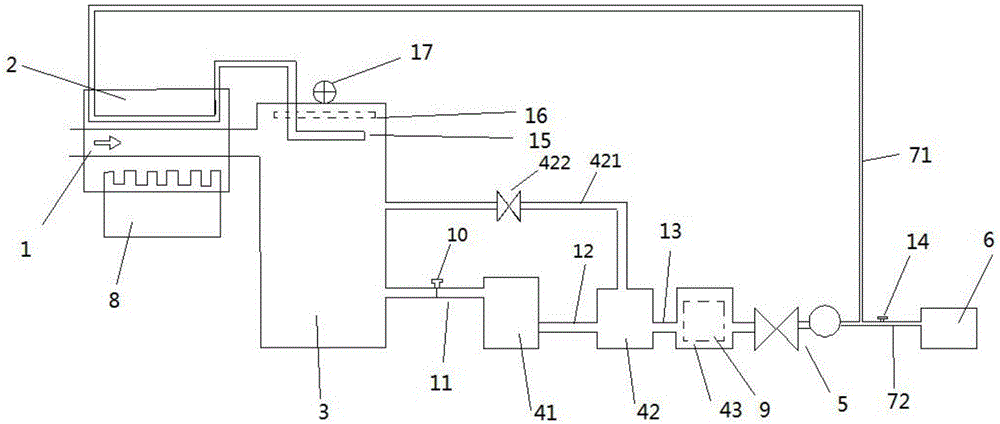

According to the double-oil-inlet type hydraulic pile-up valve group and the double-oil-pump type hydraulic station for the large filter press, the key points of the innovative scheme are that the hydraulic pile-up valve group comprises a hydraulic pile-up valve, an electro-hydraulic directional control valve, a hydraulic control one-way valve and an electromagnetic relief valve; the double-oil-inlet hydraulic pile-up valve is mainly characterized in that an existing single-oil-inlet hydraulic pile-up valve is improved into a double-oil-inlet hydraulic pile-up valve, so that double large electric oil pump sets and the hydraulic pile-up valve can be directly connected through double hydraulic oil pipes, and a three-way connector is omitted; the functions of hydraulic oil reversing, overflow pressure stabilizing and non-return pressure maintaining are achieved. The double-oil-pump type hydraulic station uses the hydraulic pile-up valve group, and solves the problems that a single-oil-inlet type hydraulic pile-up valve needs to be indirectly connected with a double-large electric oil pump group and the hydraulic pile-up valve by means of a three-way joint, the structure is complex, the number of oil pipe joints is large, the failure rate is high, and certain pressure loss exists after hydraulic oil is converged through the three-way joint; an oil inlet hole of the hydraulic pile-up valve is close to an oil tank cover, the installation space is limited, and the three-way connector is difficult to install and detach.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

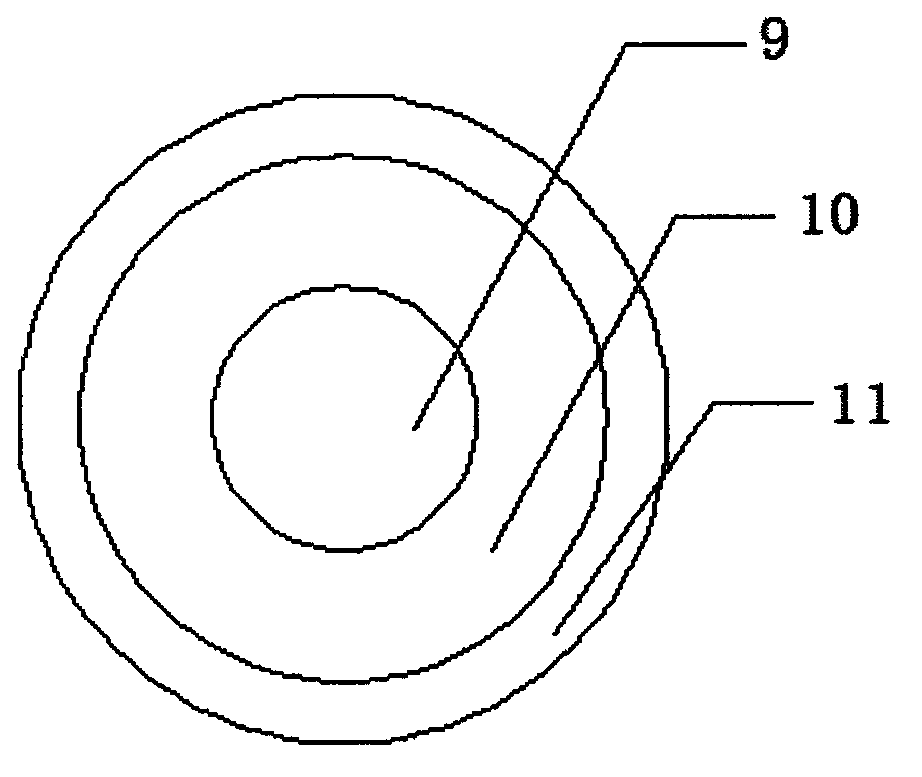

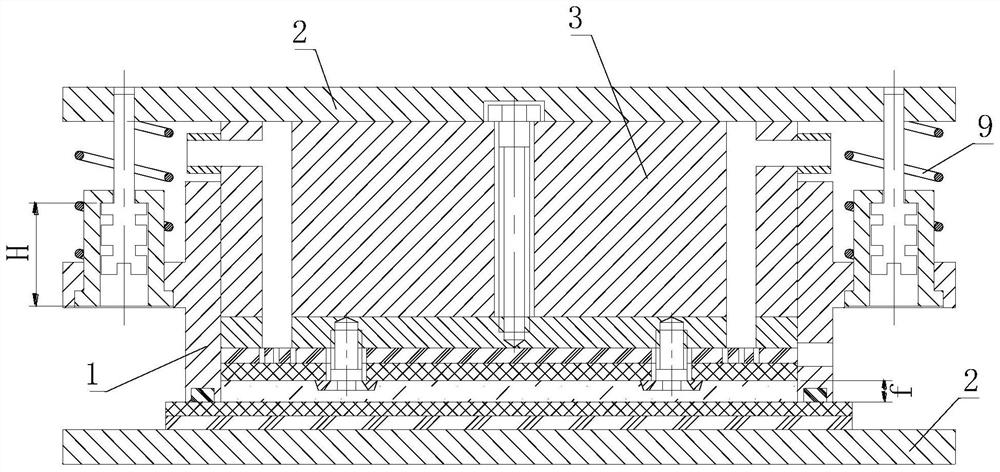

Filter pressing unit and filter press

Owner:华汇生态环境产业有限公司

Filter press for preparing nano cerium oxide

InactiveCN113082801AGuarantee the effect of crushing and dispersingMeet needsFiltration separationGrain treatmentsElectric machinePhysical chemistry

The invention discloses a filter press for preparing nano cerium oxide. The filter press comprises a rack and a filter press body installed on the rack. A crushing frame is fixed between the inner walls of the rack, the bottom of the crushing frame is connected with a hopper, and a crushing assembly driven by a motor is arranged in the crushing frame. A centrifugal disc is in transmission connection with the crushing assembly, crushing rods which are uniformly arranged are connected to the outer side of the centrifugal disc, and centrifugal rods which are arranged at equal intervals are fixed to the outer side of the bottom surface of the centrifugal disc. A material receiving hopper is restrained below the rack. According to the device, on the basis of a traditional filter press, materials subjected to filter pressing are further crushed, the crushing and dispersing effects can be guaranteed through crushing, and then the recycled raw materials can better meet the actual requirements.

Owner:SHENZHEN GEMINI MICROELECTRONICS CO LTD

Full-tooth continuous quenching method for slewing bearing

PendingCN114317906AHigh hardnessImprove mechanical propertiesFurnace typesIncreasing energy efficiencyRare-earth elementKerosene

Owner:安徽省宁国顺昌机械有限公司

Industrial wastewater discharge treatment device

InactiveCN106587486ASolve the fouling problem of the medium channelReduce maintenance timesFatty/oily/floating substances removal devicesTreatment with anaerobic digestion processesWater storageIndustrial effluent

Owner:济宁市水质研究所有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap