Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Relief valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

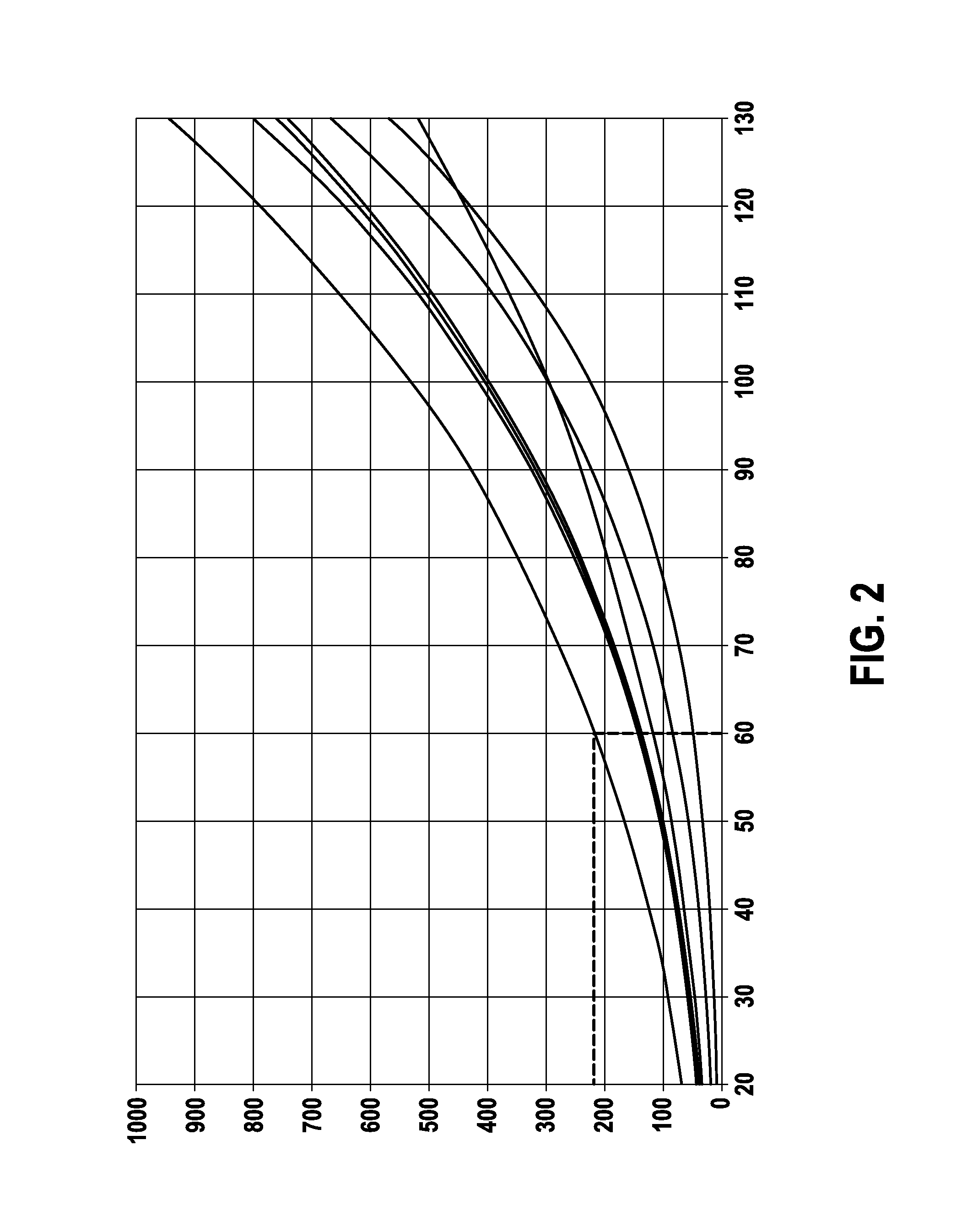

A relief valve or pressure relief valve (PRV) is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or equipment failure, or fire. The pressure is relieved by allowing the pressurised fluid to flow from an auxiliary passage out of the system. The relief valve is designed or set to open at a predetermined set pressure to protect pressure vessels and other equipment from being subjected to pressures that exceed their design limits. When the set pressure is exceeded, the relief valve becomes the "path of least resistance" as the valve is forced open and a portion of the fluid is diverted through the auxiliary route. The diverted fluid (liquid, gas or liquid–gas mixture) is usually routed through a piping system known as a flare header or relief header to a central, elevated gas flare where it is usually burned and the resulting combustion gases are released to the atmosphere. As the fluid is diverted, the pressure inside the vessel will stop rising. Once it reaches the valve's reseating pressure, the valve will close. The blowdown is usually stated as a percentage of set pressure and refers to how much the pressure needs to drop before the valve reseats. The blowdown can vary from roughly 2–20%, and some valves have adjustable blowdowns.

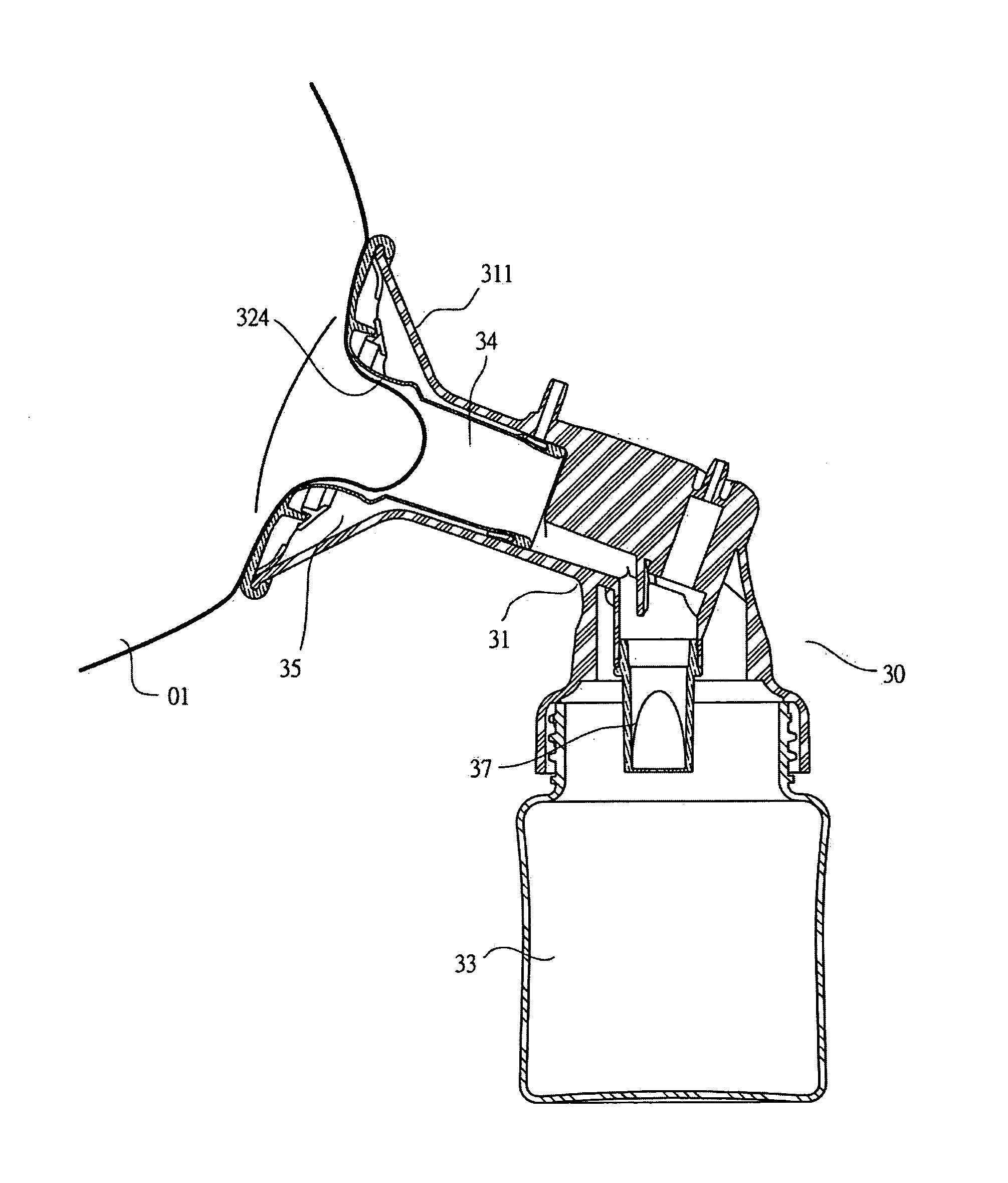

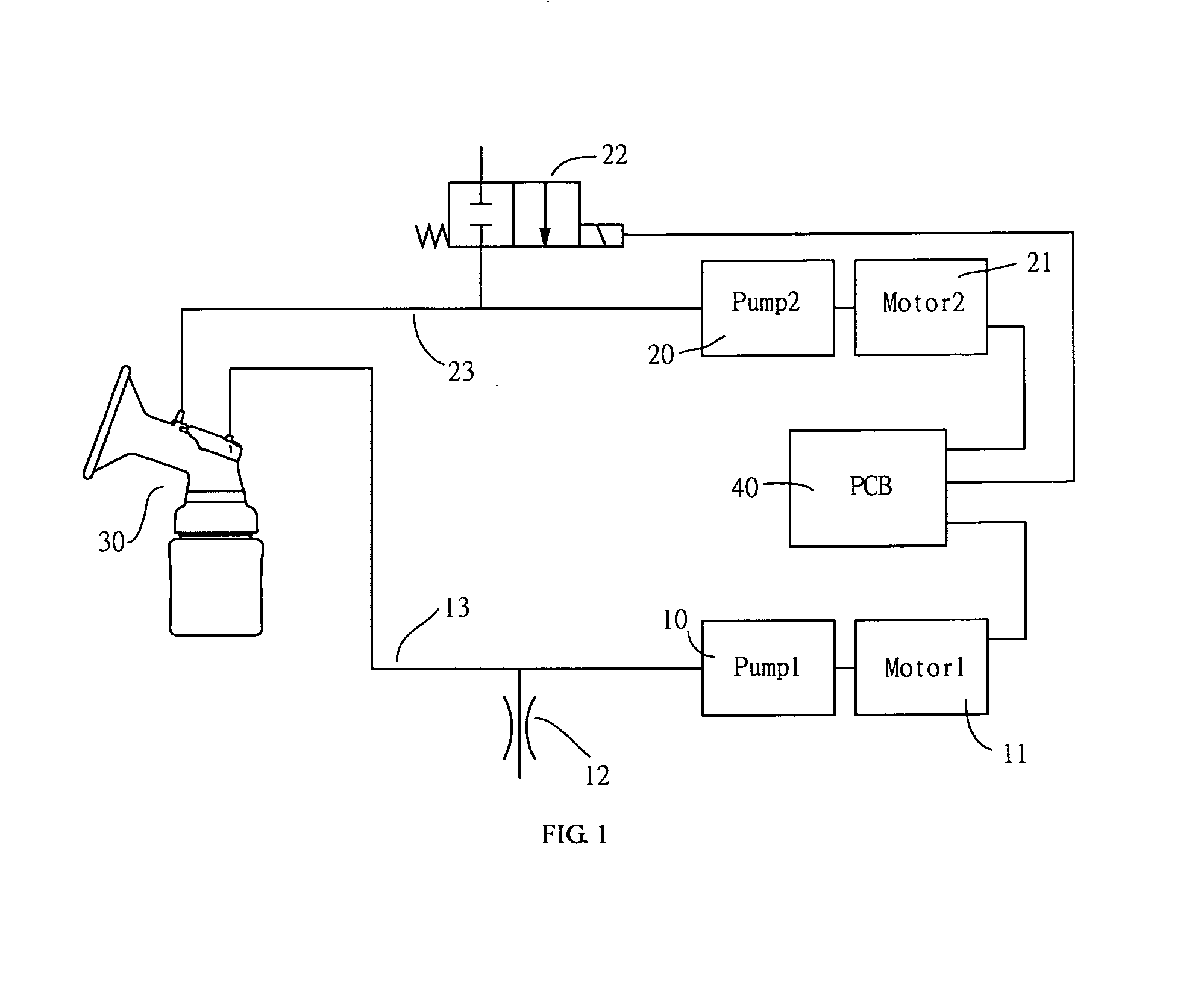

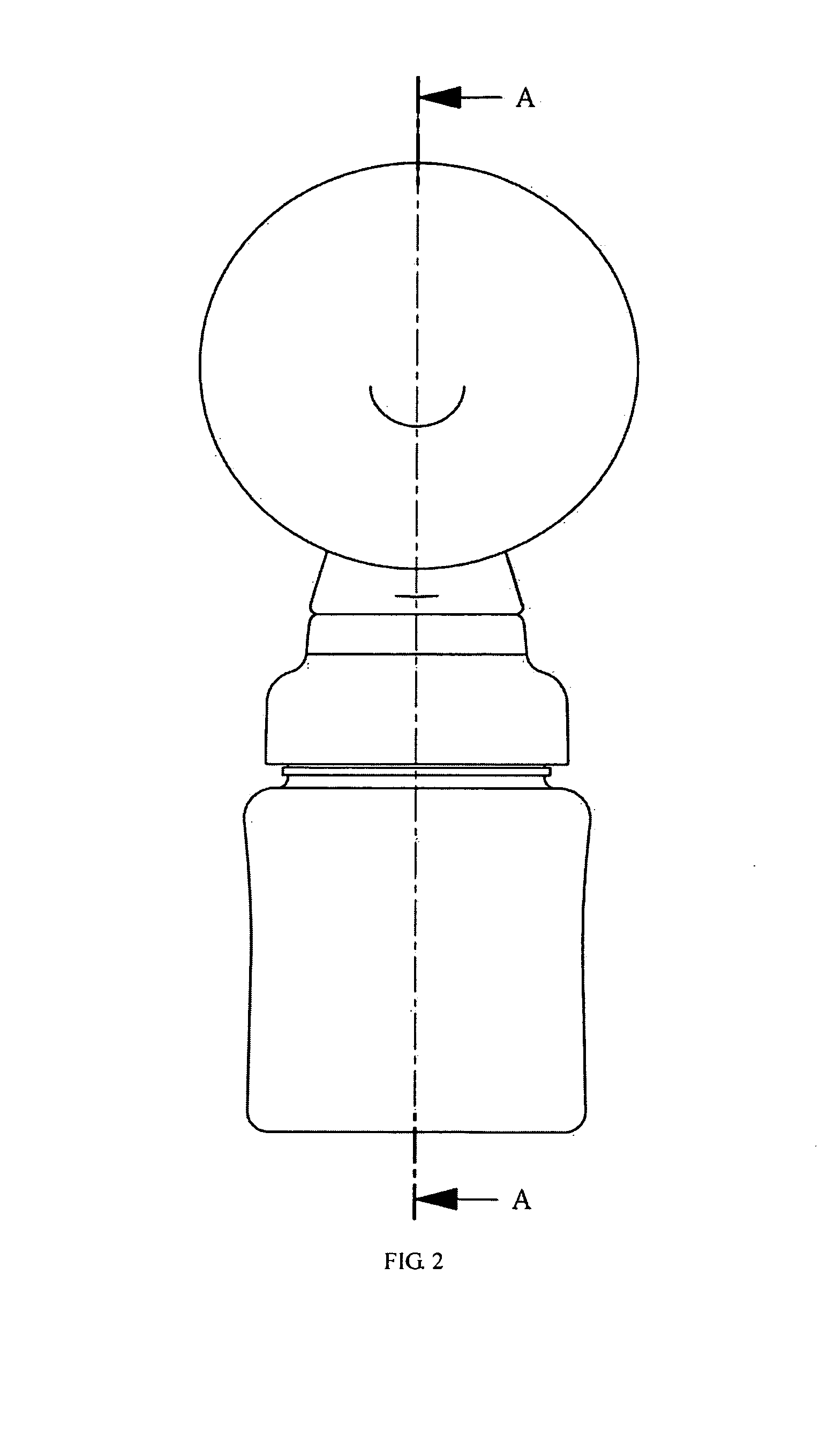

Milk expressing device capable of simulating a baby's suckling

InactiveUS20140031744A1Improve efficiencyImprove comfortMilking pumpMedical devicesEngineeringControl circuit

Owner:CHEN CHEAN SHUI

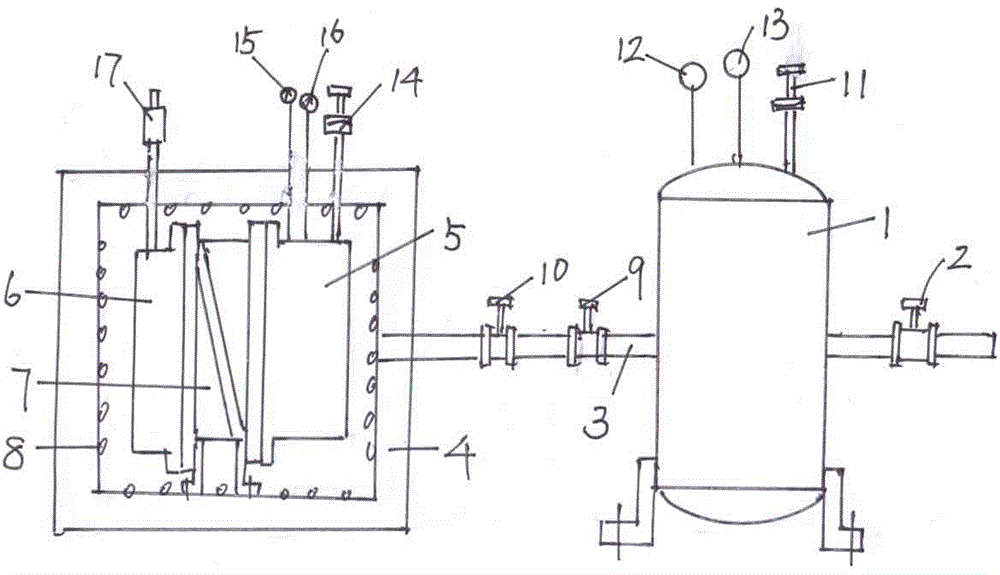

Test device for simulating ecological rock mechanical slope protection under rainfall precipitation condition

InactiveCN101216479ASimple structureAdjustable rainfall intensityFoundation testingEarth material testingFixed bearingSoil science

The invention relates to a device for testing ecological slope protection of ecologic rock and soil mechanics under simulated rainfall condition, which is mainly used for studying scouring (or erosion) characteristics test of rock and soil slope by artificial rainfall and belongs to the field of geotechnical engineering and environmental engineering. The test device comprises an automatic variable slope test rack, a test soil bin and a rainfall simulator with adjustable rain intensity, wherein a rotary support is composed of a guide rail, a crank, a crank brake, an upper shaft and a device for preventing backward sliding; a fixed bearing support is composed of a lower shaft, a bearing seat, a bending guide groove, a capstan and a lower shaft caging device; the rainfall simulator with adjustable rain intensity is disposed on the variable slope test race through a support and includes a rainfall simulator, a pressure sensor, a vibrator, a barometer, a relief valve, etc. The inventive test device has the advantages of simple structure, adjustable rain intensity, uniform rainfall, automatic online collection of air pressure, water pressure and rainfall amount of the rainfall simulator and reduced time and labor force for loading the test soil bin.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

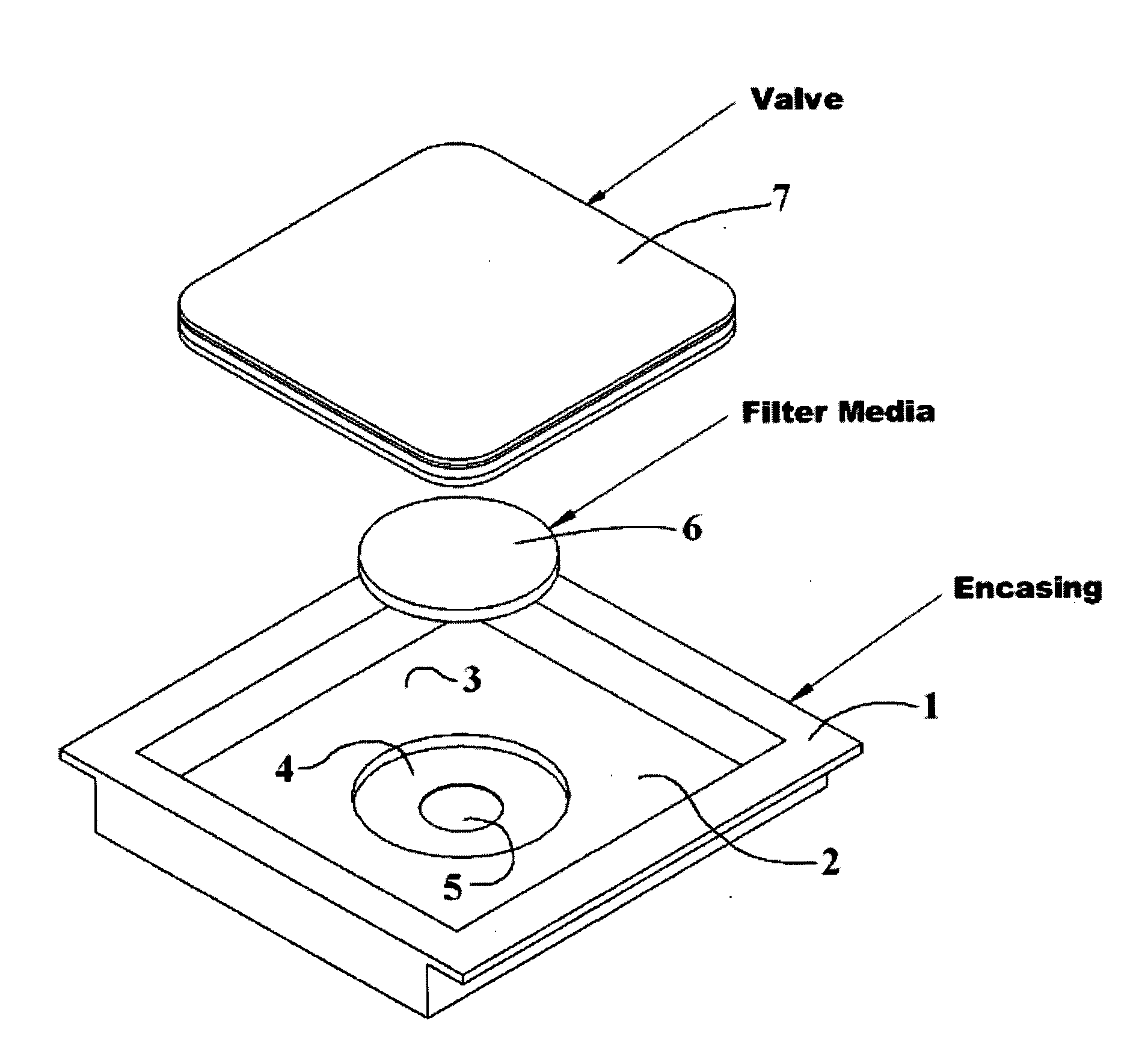

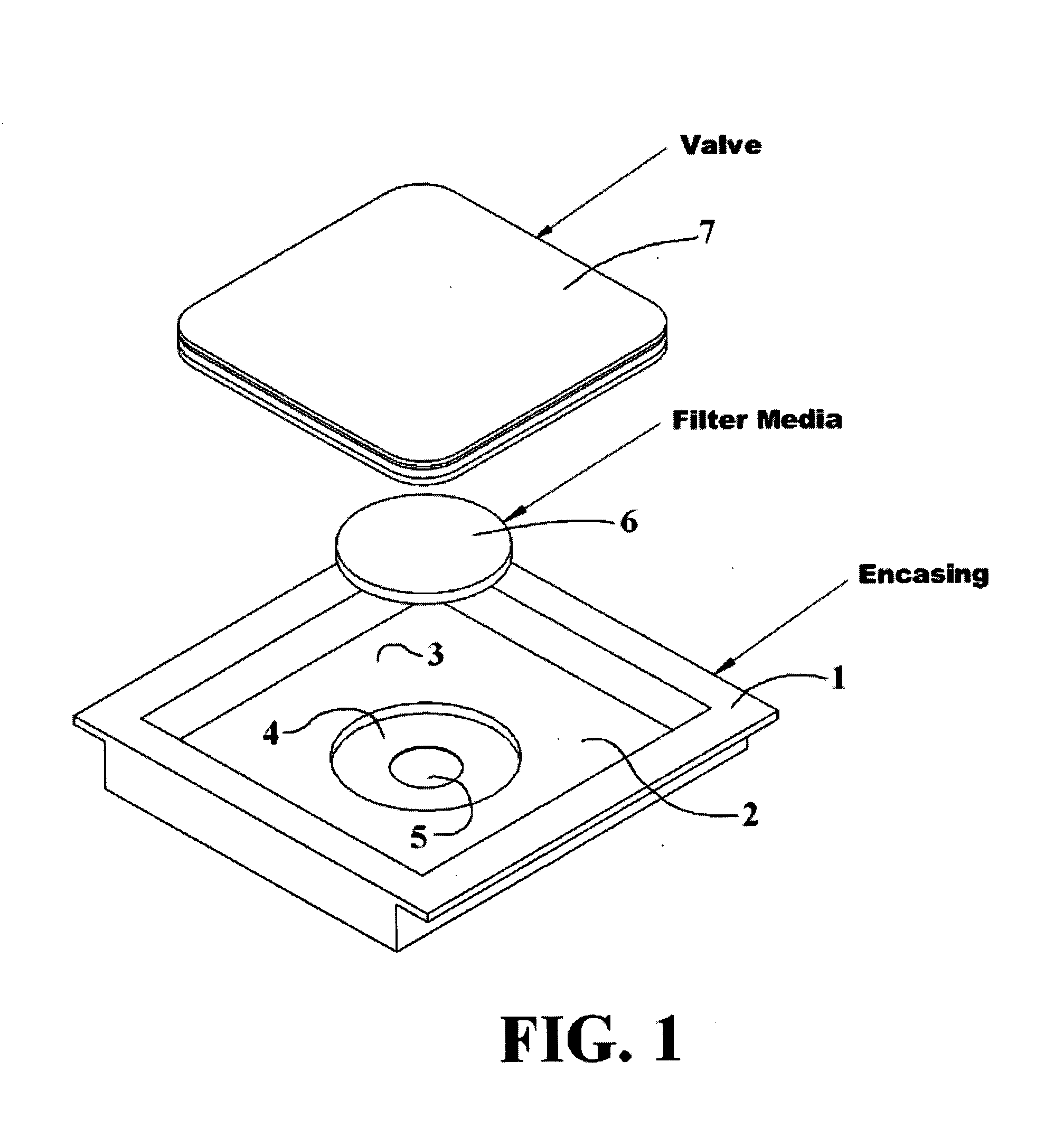

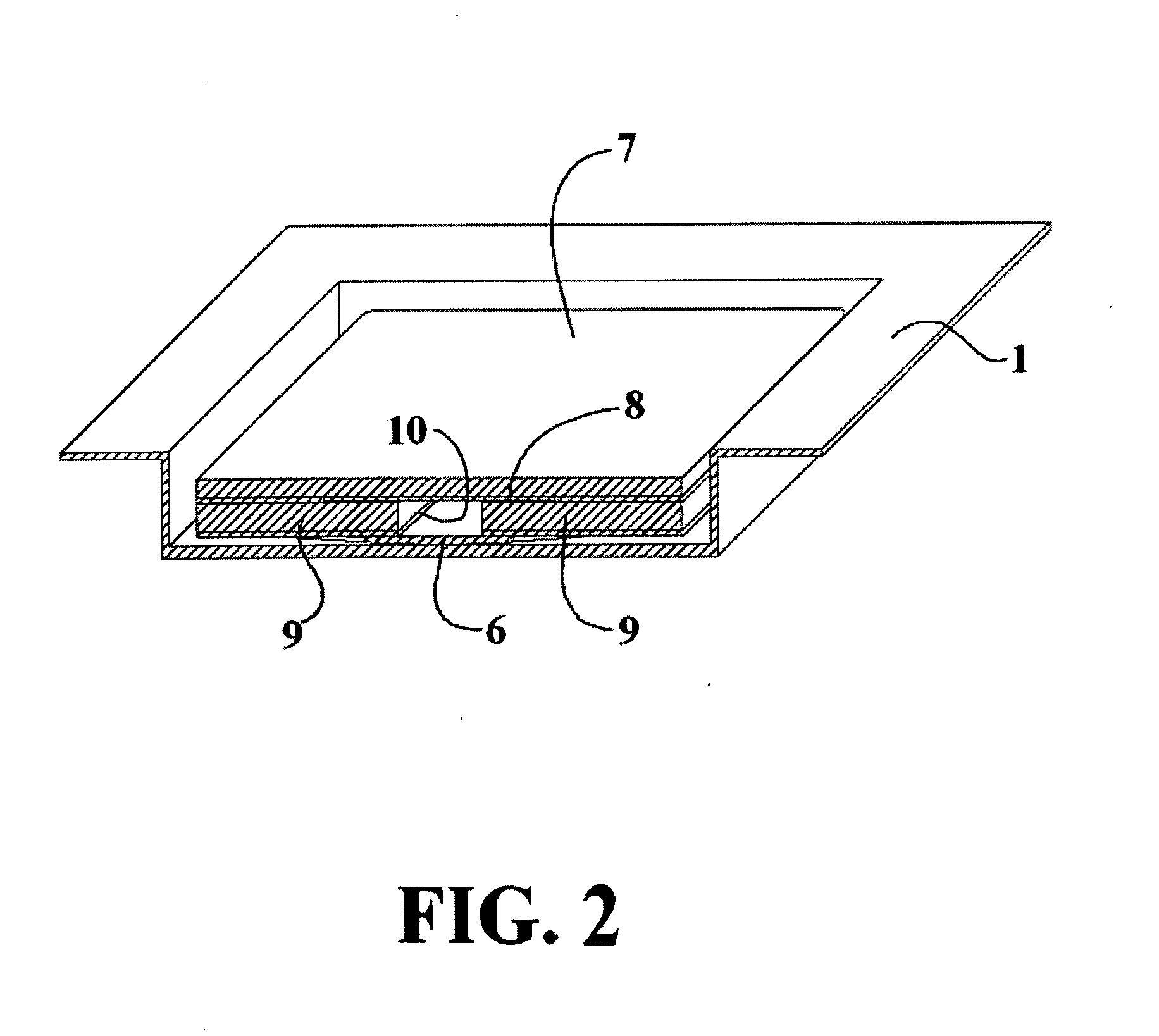

Interior-mountable pressure relief valve

Owner:PLITEK

Large diameter valve high temperature sealing test device

Owner:JIANGSU SHENTONG VALVE

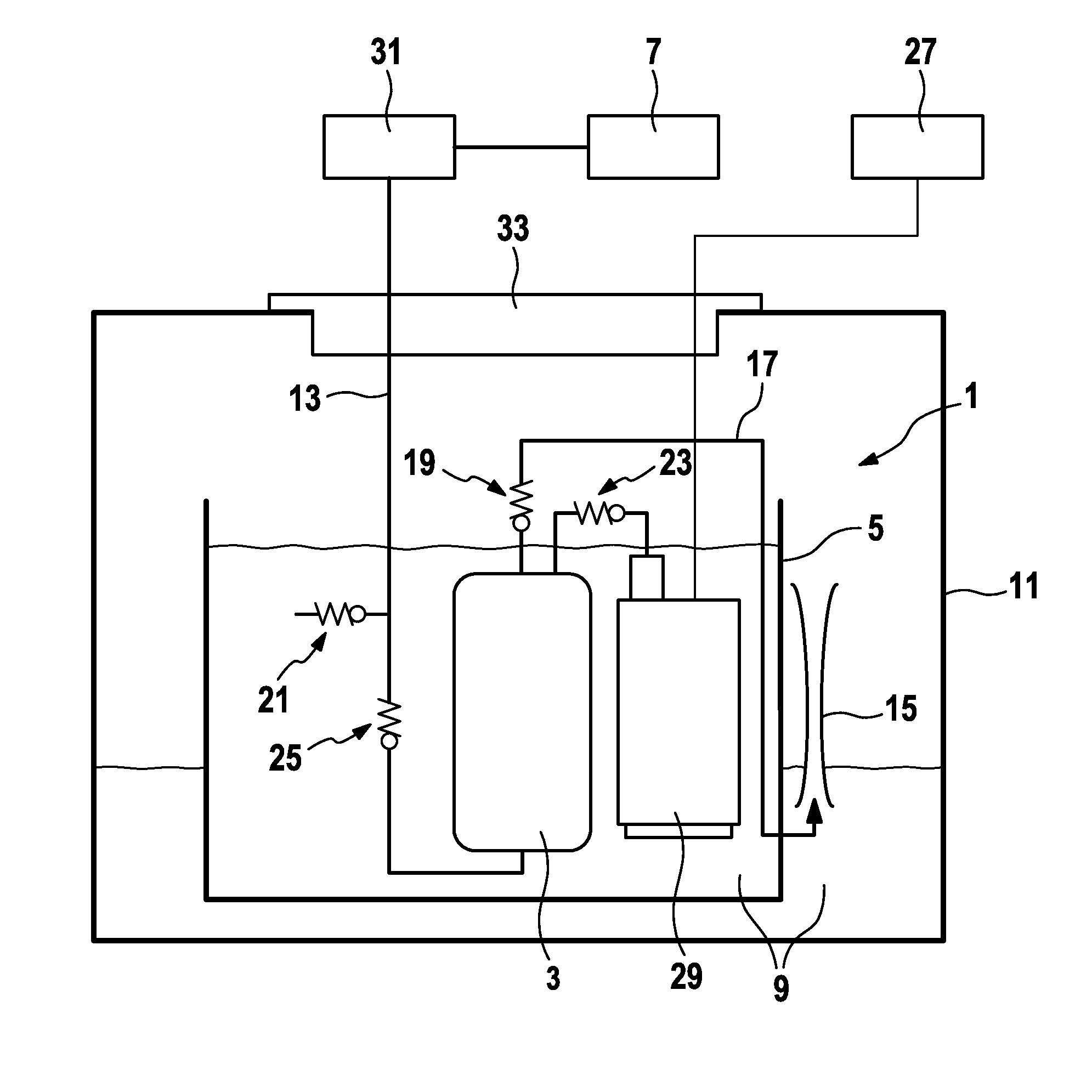

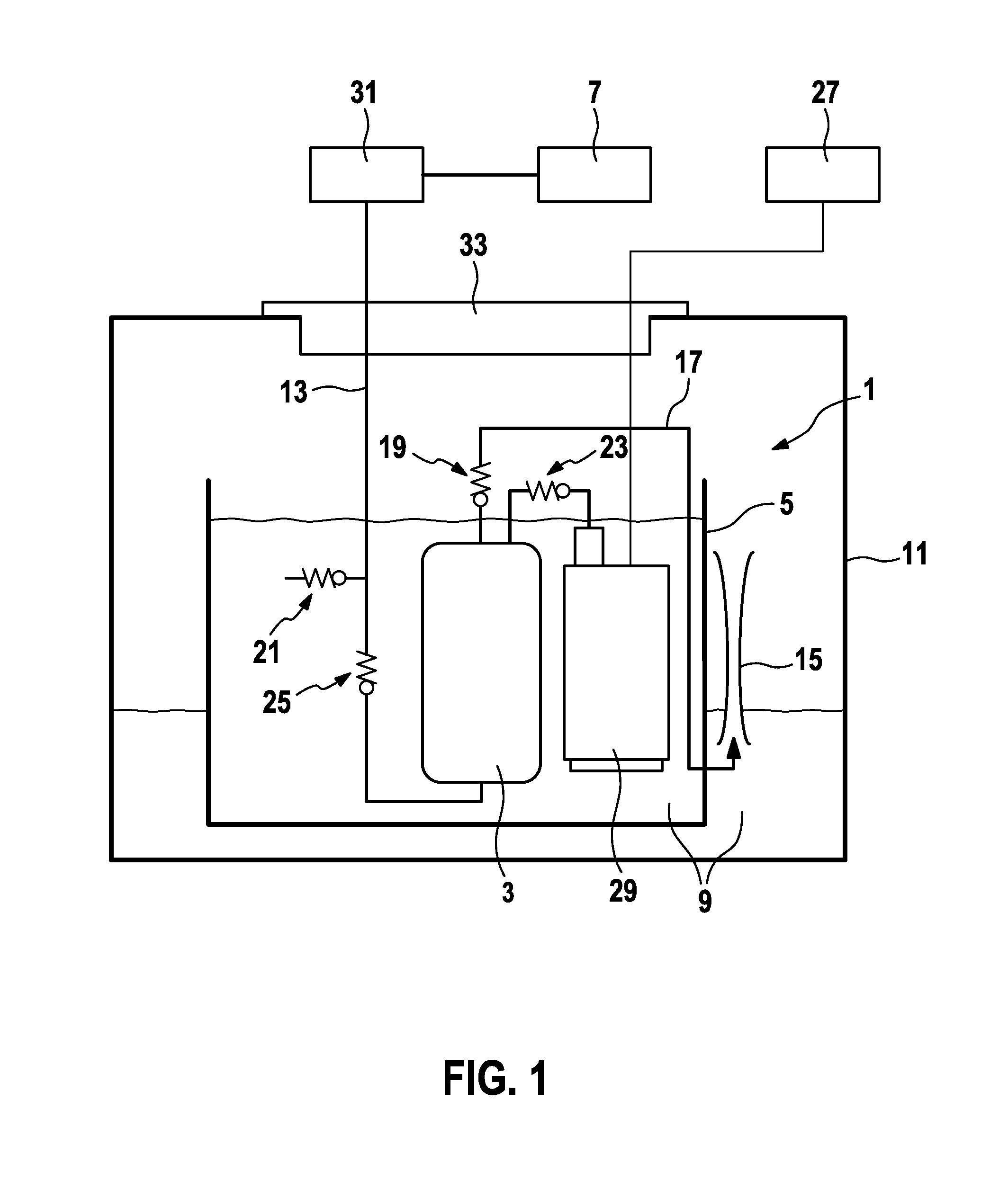

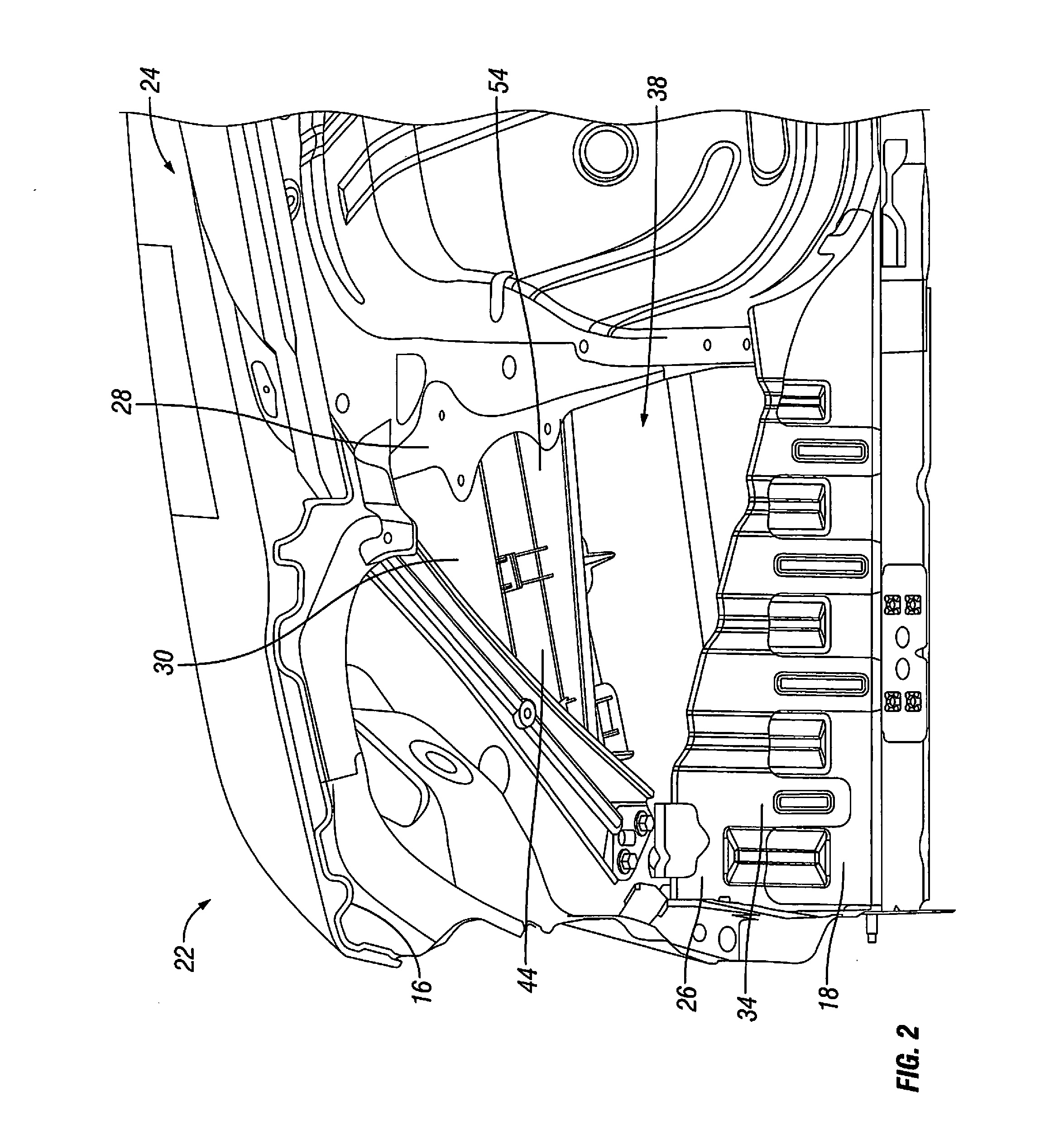

Fuel delivery system with partial pressure relief valve on the drive line of a suction jet pump

InactiveUS20160138537A1Relieve pressureMachines/enginesLiquid fuel feedersRelief valveInjection pump

Owner:ROBERT BOSCH GMBH

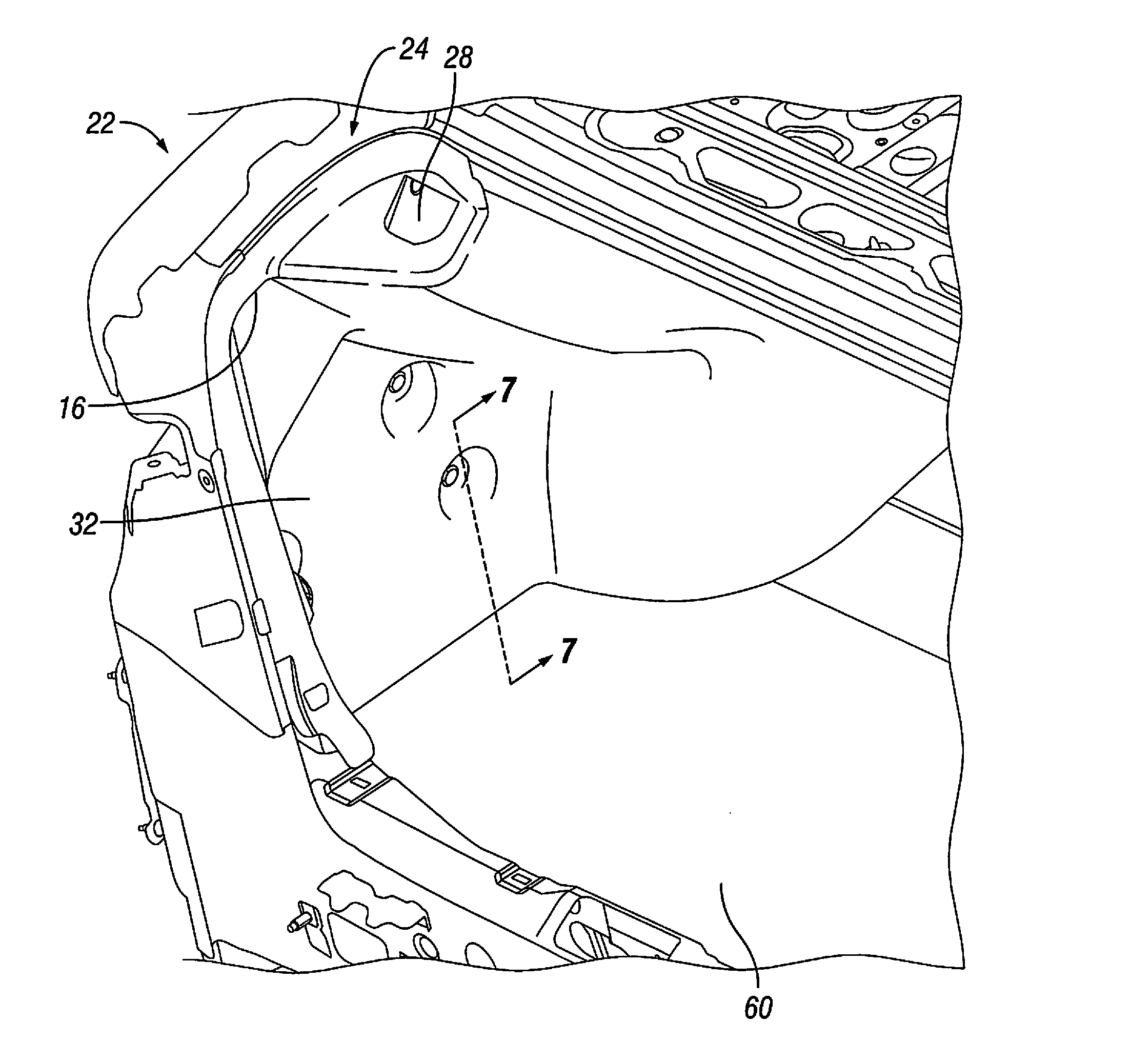

Vehicle noise reducing assembly

Owner:NISSAN MOTOR CO LTD

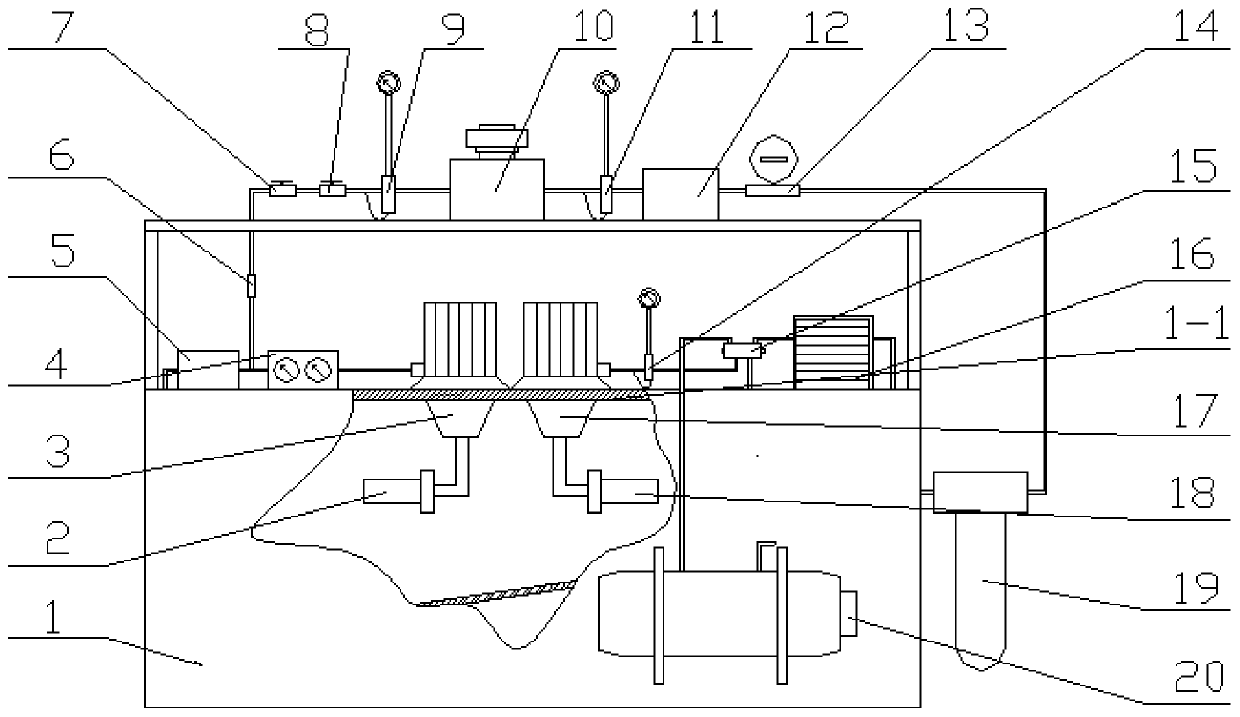

Visualized test bench for testing hydraulic valve performance

Owner:HARBIN INST OF TECH

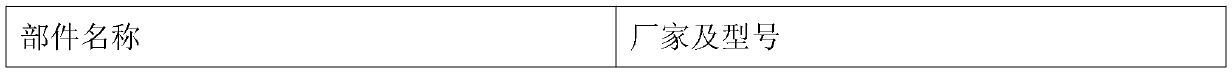

Sealing structure of reciprocating plunger pump

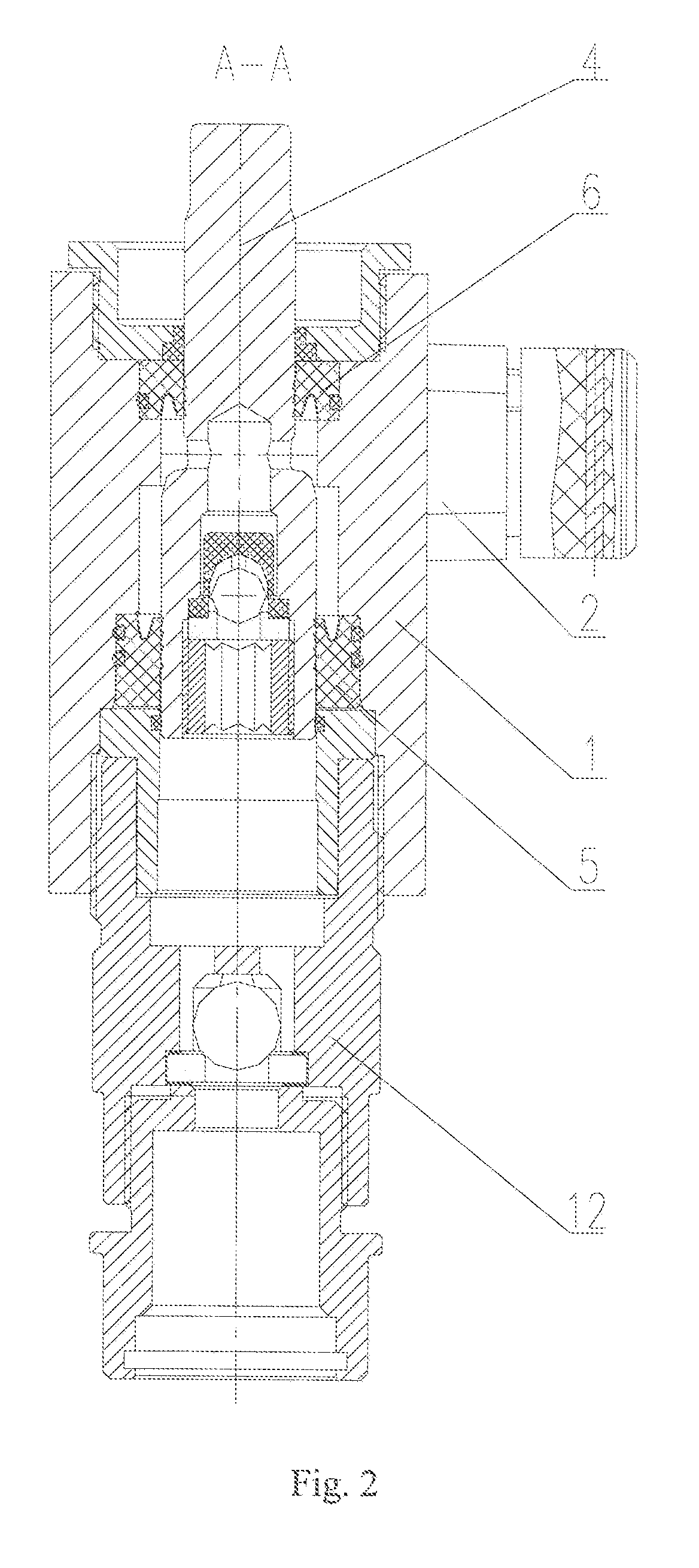

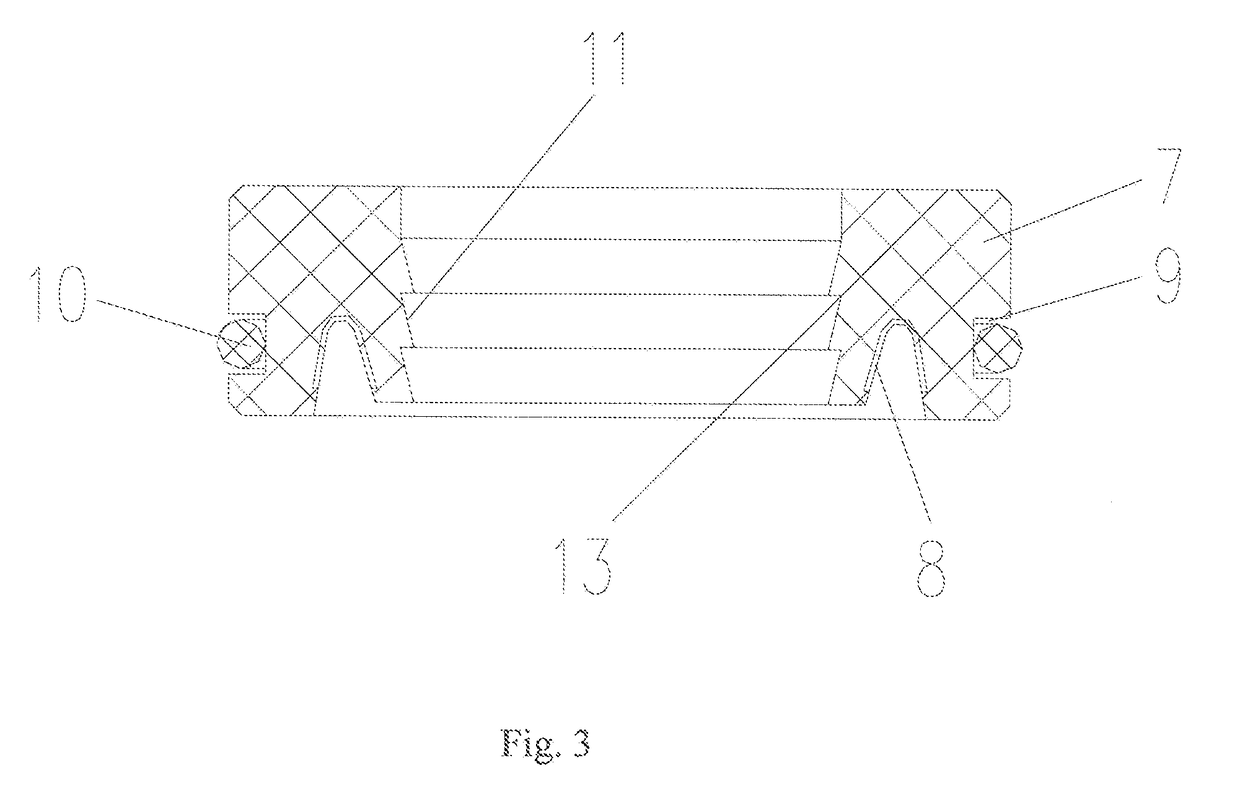

InactiveUS20190017603A1Reduce loadExtended service lifeEngine sealsPositive displacement pump componentsPlunger pumpRelief valve

Owner:ZHEJIANG RONGPENG AIR TOOLS

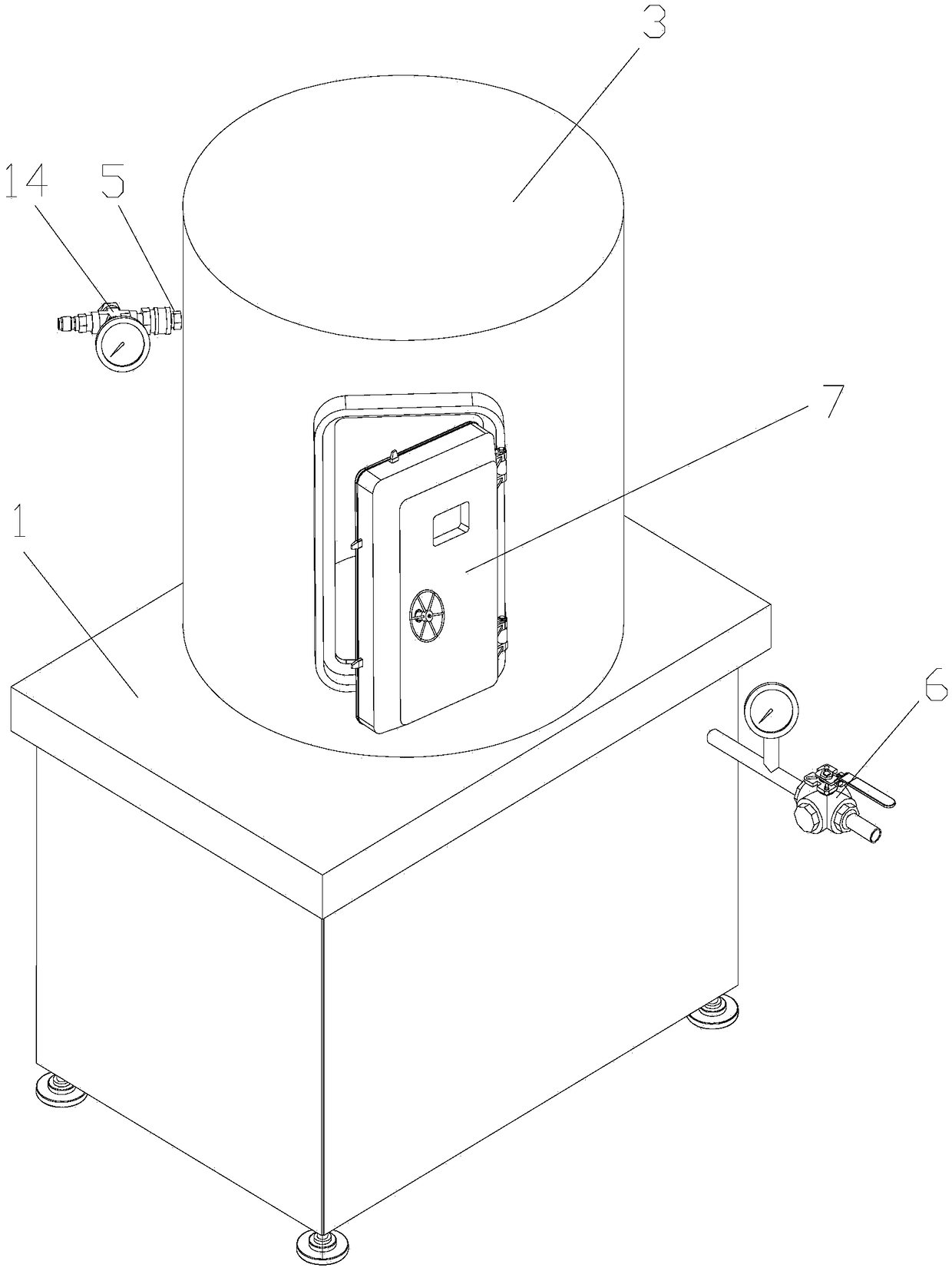

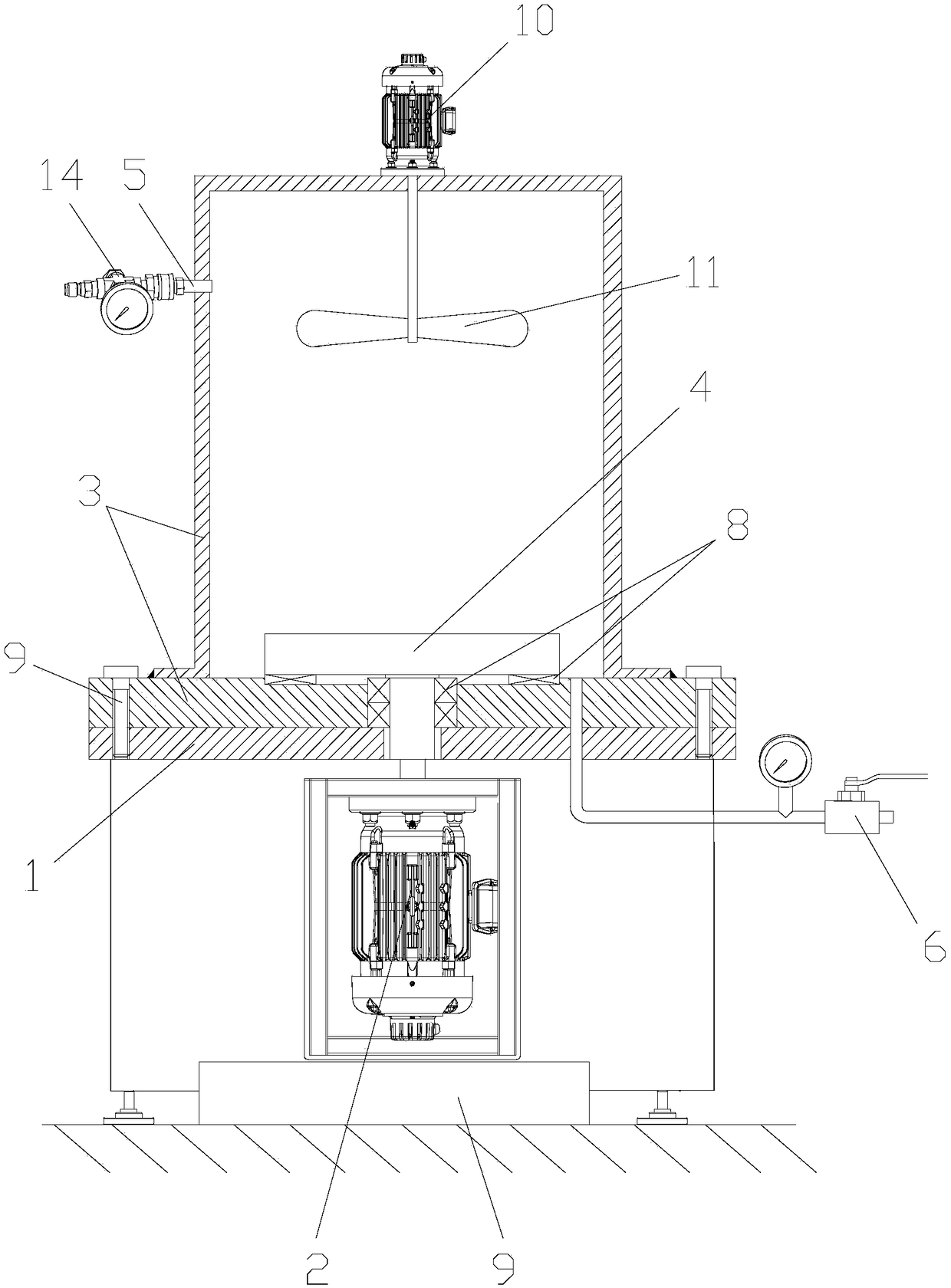

Double-oil-inlet type hydraulic integrated valve group and double-oil-pump type hydraulic station for large filter press

PendingCN114412870APressurize fastPressurization simplifiedFluid-pressure actuator testingServomotor componentsFilter pressOil pump

According to the double-oil-inlet type hydraulic pile-up valve group and the double-oil-pump type hydraulic station for the large filter press, the key points of the innovative scheme are that the hydraulic pile-up valve group comprises a hydraulic pile-up valve, an electro-hydraulic directional control valve, a hydraulic control one-way valve and an electromagnetic relief valve; the double-oil-inlet hydraulic pile-up valve is mainly characterized in that an existing single-oil-inlet hydraulic pile-up valve is improved into a double-oil-inlet hydraulic pile-up valve, so that double large electric oil pump sets and the hydraulic pile-up valve can be directly connected through double hydraulic oil pipes, and a three-way connector is omitted; the functions of hydraulic oil reversing, overflow pressure stabilizing and non-return pressure maintaining are achieved. The double-oil-pump type hydraulic station uses the hydraulic pile-up valve group, and solves the problems that a single-oil-inlet type hydraulic pile-up valve needs to be indirectly connected with a double-large electric oil pump group and the hydraulic pile-up valve by means of a three-way joint, the structure is complex, the number of oil pipe joints is large, the failure rate is high, and certain pressure loss exists after hydraulic oil is converged through the three-way joint; an oil inlet hole of the hydraulic pile-up valve is close to an oil tank cover, the installation space is limited, and the three-way connector is difficult to install and detach.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

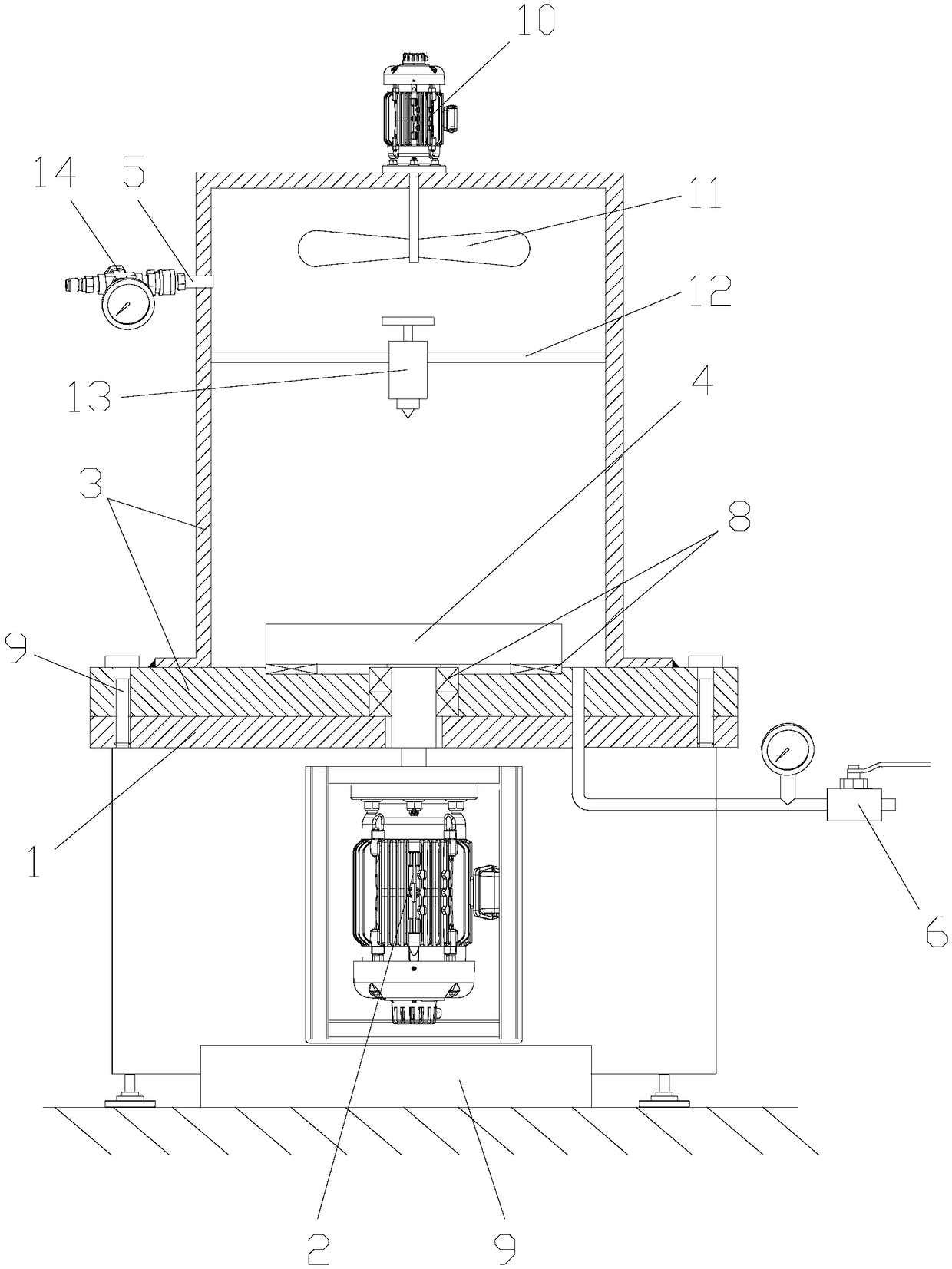

High pressure gas-liquid grinding device

InactiveCN109015392ABreak through the problem that the grinding accuracy is limited by abrasive particlesSmall particle sizeAbrasive machine appurtenancesInlet valveElectric machinery

Owner:CHONGQING CHENSHI CLEANING SERVICE CO LTD

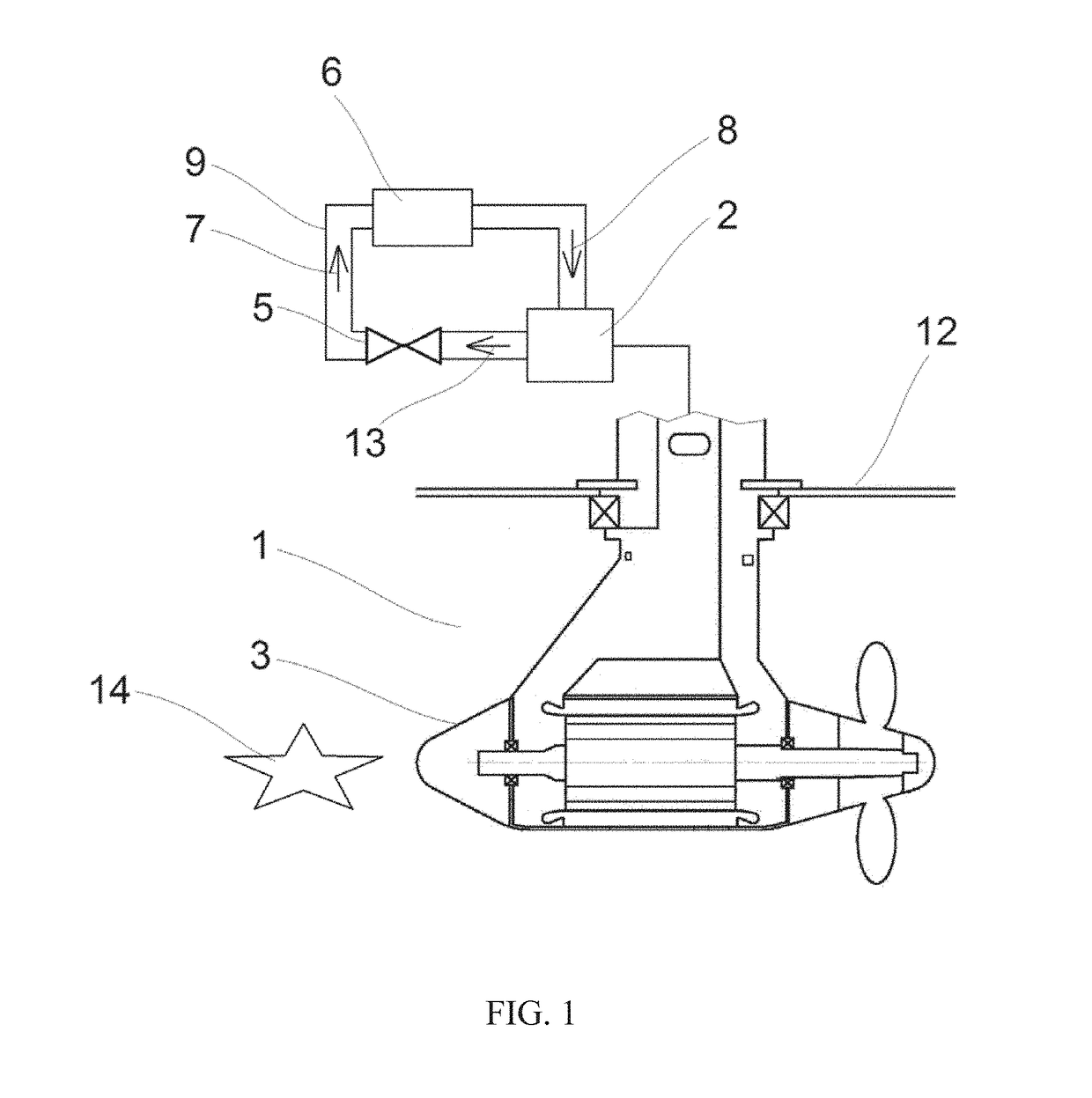

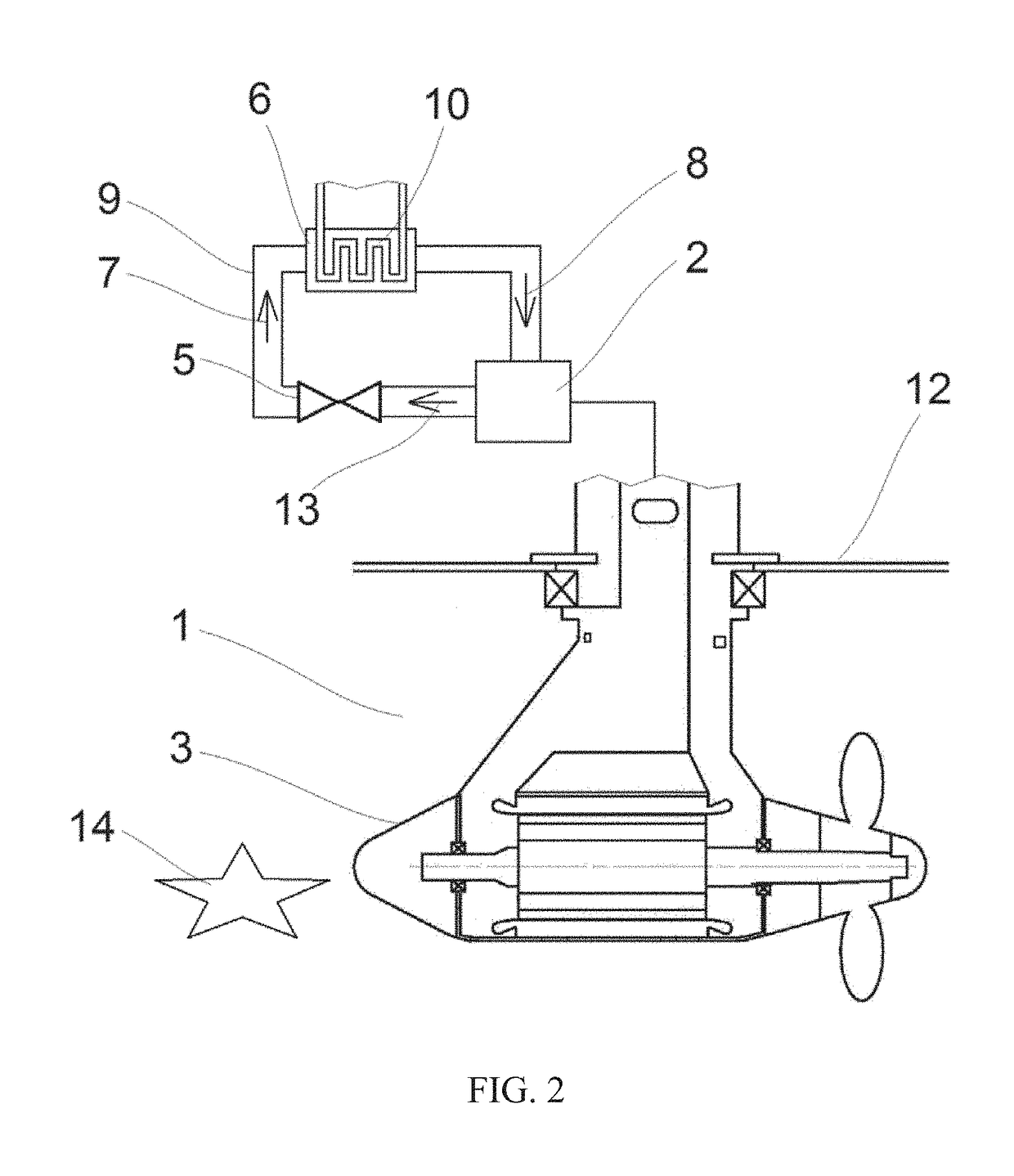

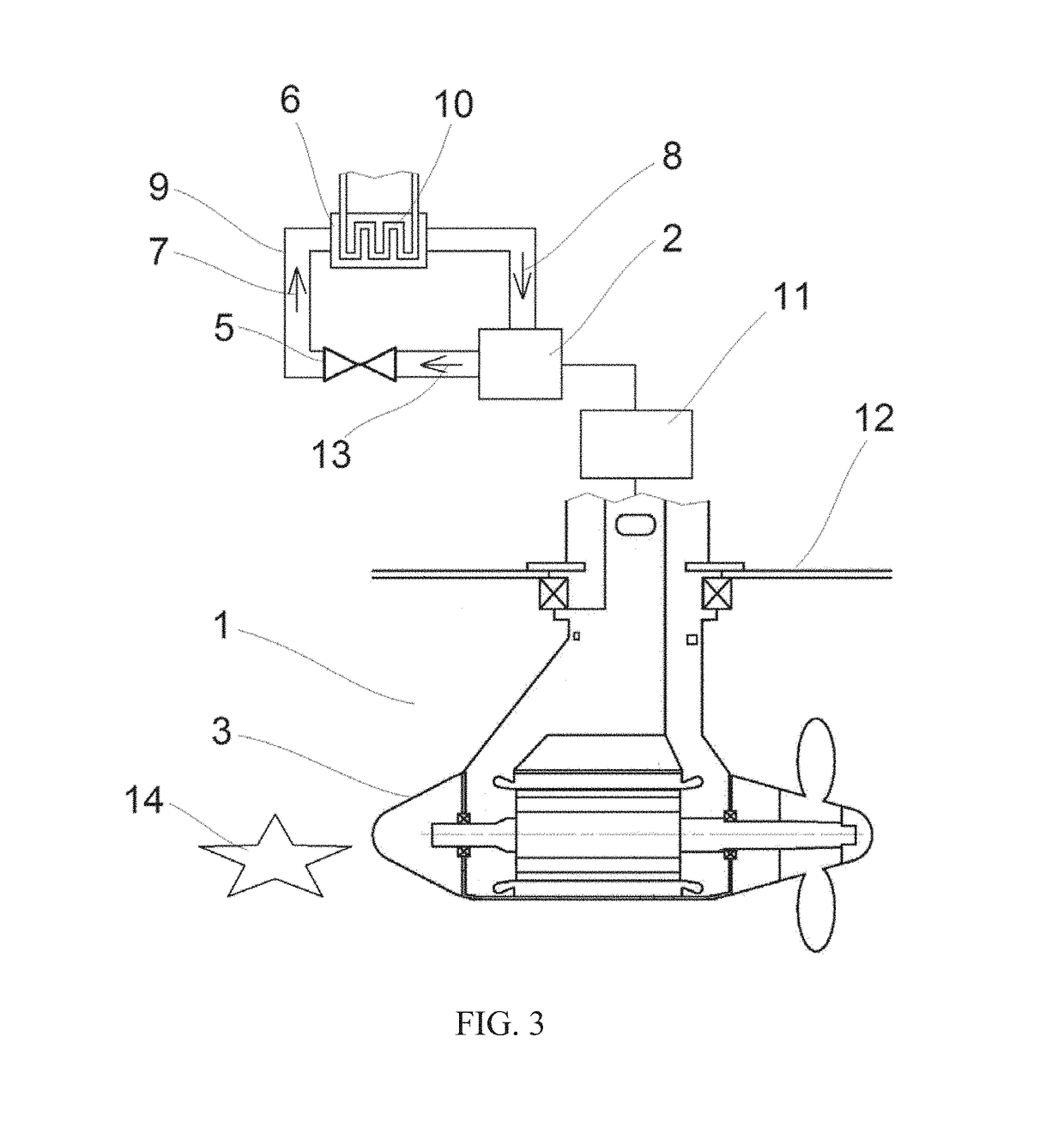

Steering system, azimuthing propulsion system, and method for absorbing heat

InactiveUS20190016431A1Steering ruddersPropulsion power plantsRelief valveSteering system

Owner:ABB OY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap