Interior-mountable pressure relief valve

a pressure relief valve and interior mount technology, applied in the field of interior mountable pressure relief valves, can solve the problems of valve protruding slightly beyond the package boundary, pressure buildup inside the package, undesirable in many applications, etc., and achieve the effect of preventing disassembly or contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

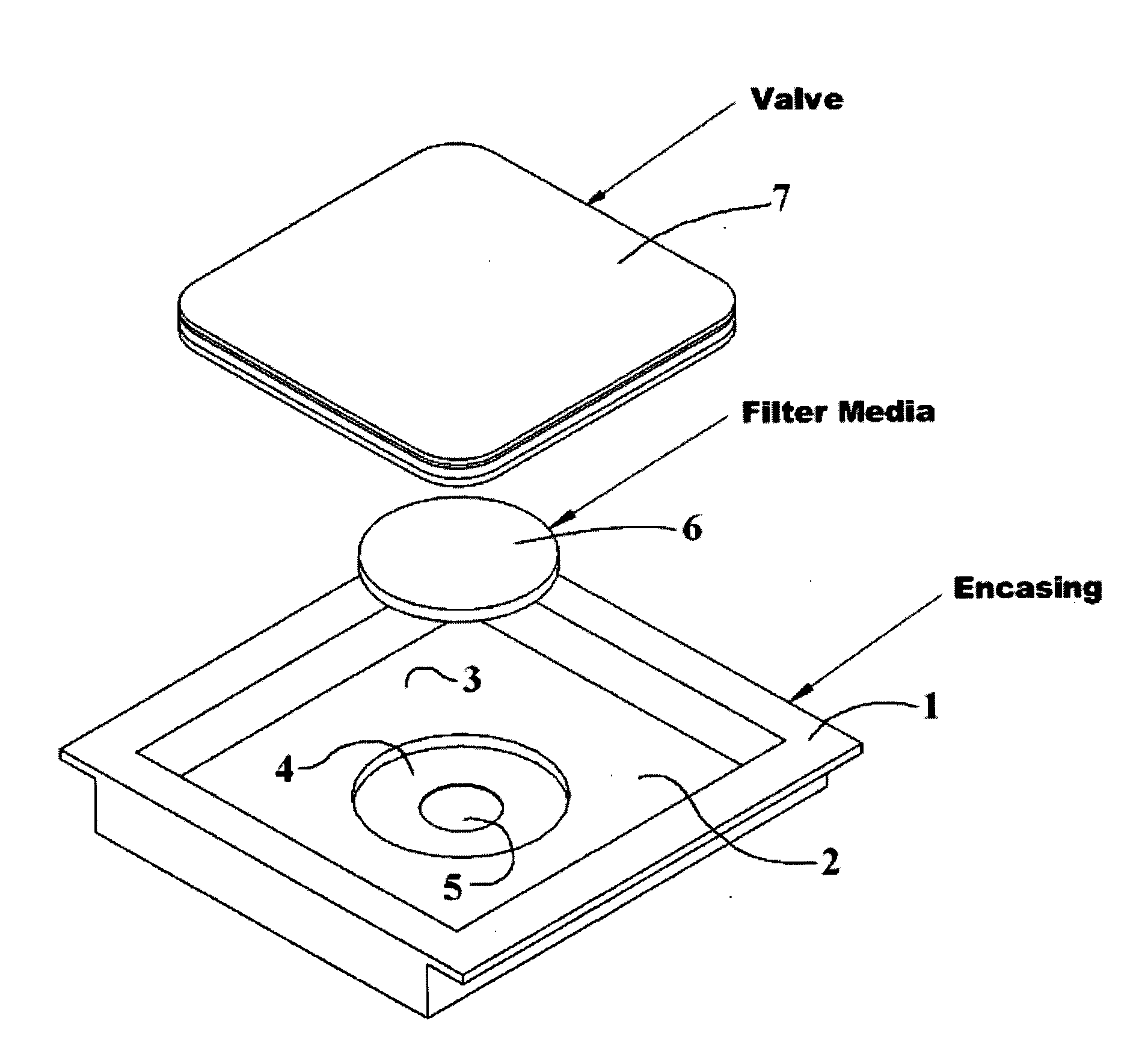

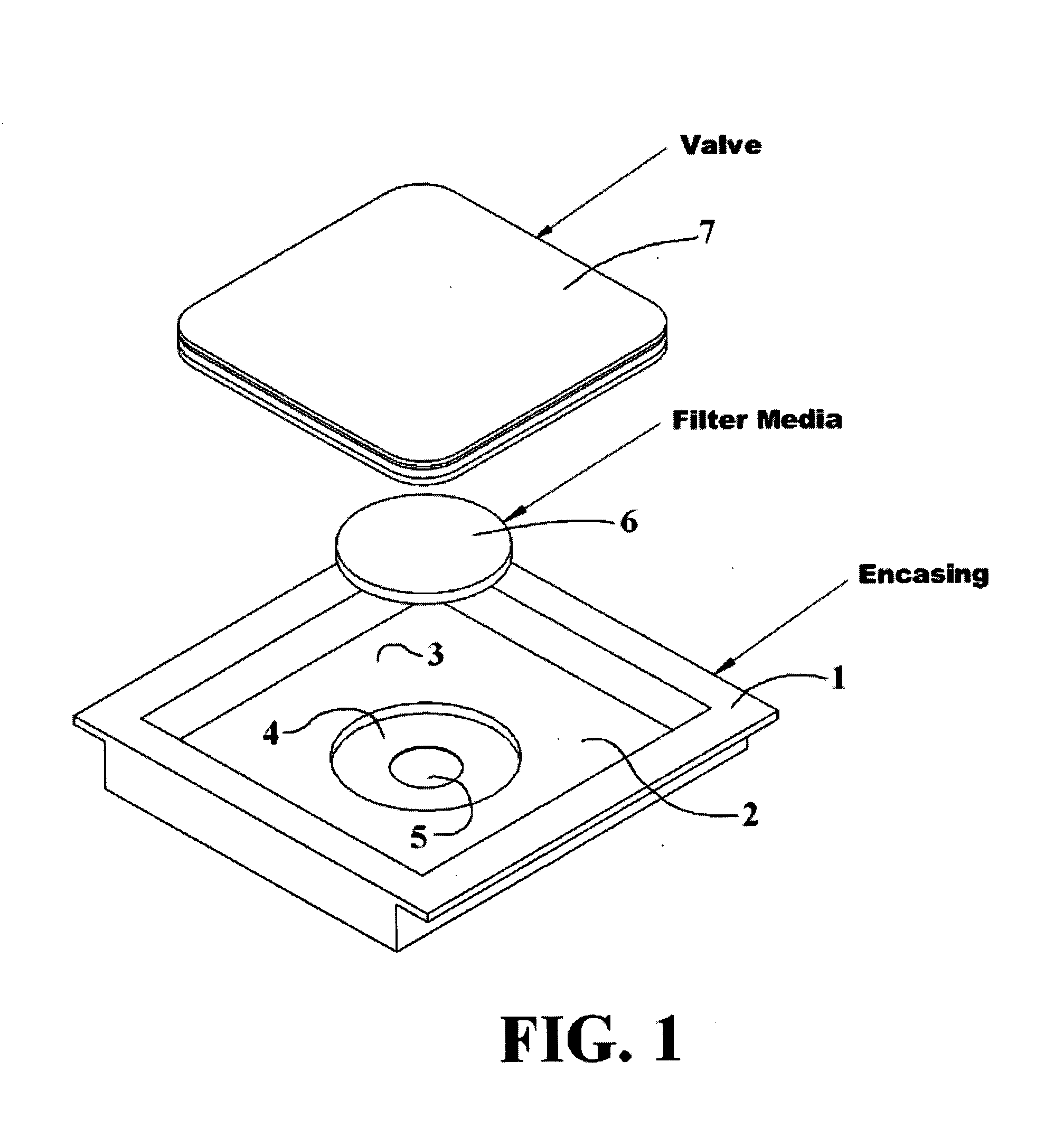

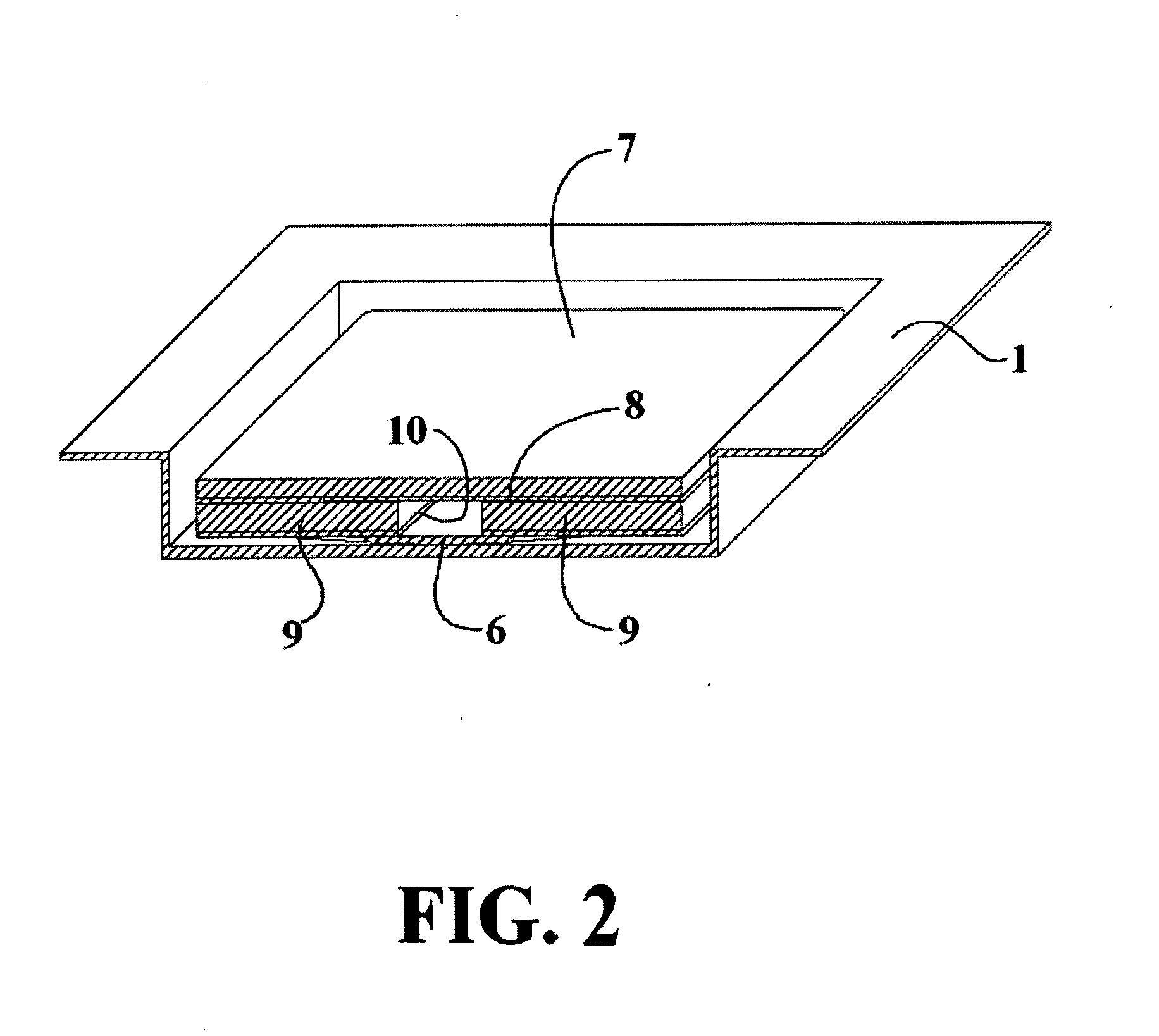

[0016]The present invention relates to an interior-mountable pressure relief valve for packaged products such as coffee. In many applications, an exterior-mounted valve is undesirable for various reasons including the protrusion it produces on the outside of the package. The present invention places the valve on the inside of a package carrier that can include a filter medium. This carrier can be processed and the delivered to a packaging company that takes it from a carrier tape and dispenses it as a single piece dose. The carrier can then be heat sealed to the inside wall of the packaging material. The interior-mounted valve of the present invention can be a pre-oiled assembly with a valve in a pocket containing the filter medium and can be delivered and dispensed in a single button style using a simple cut off, pick and place and heat staking methods.

[0017]Turning to FIG. 1, an exploded perspective view of an embodiment of the valve device 1 of the present invention can be seen. A p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap