Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about "Multiple way valves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Valve

ActiveUS8397758B2Reduce partEasy to adaptServomotor componentsMultiple way valvesFuel tankEngineering

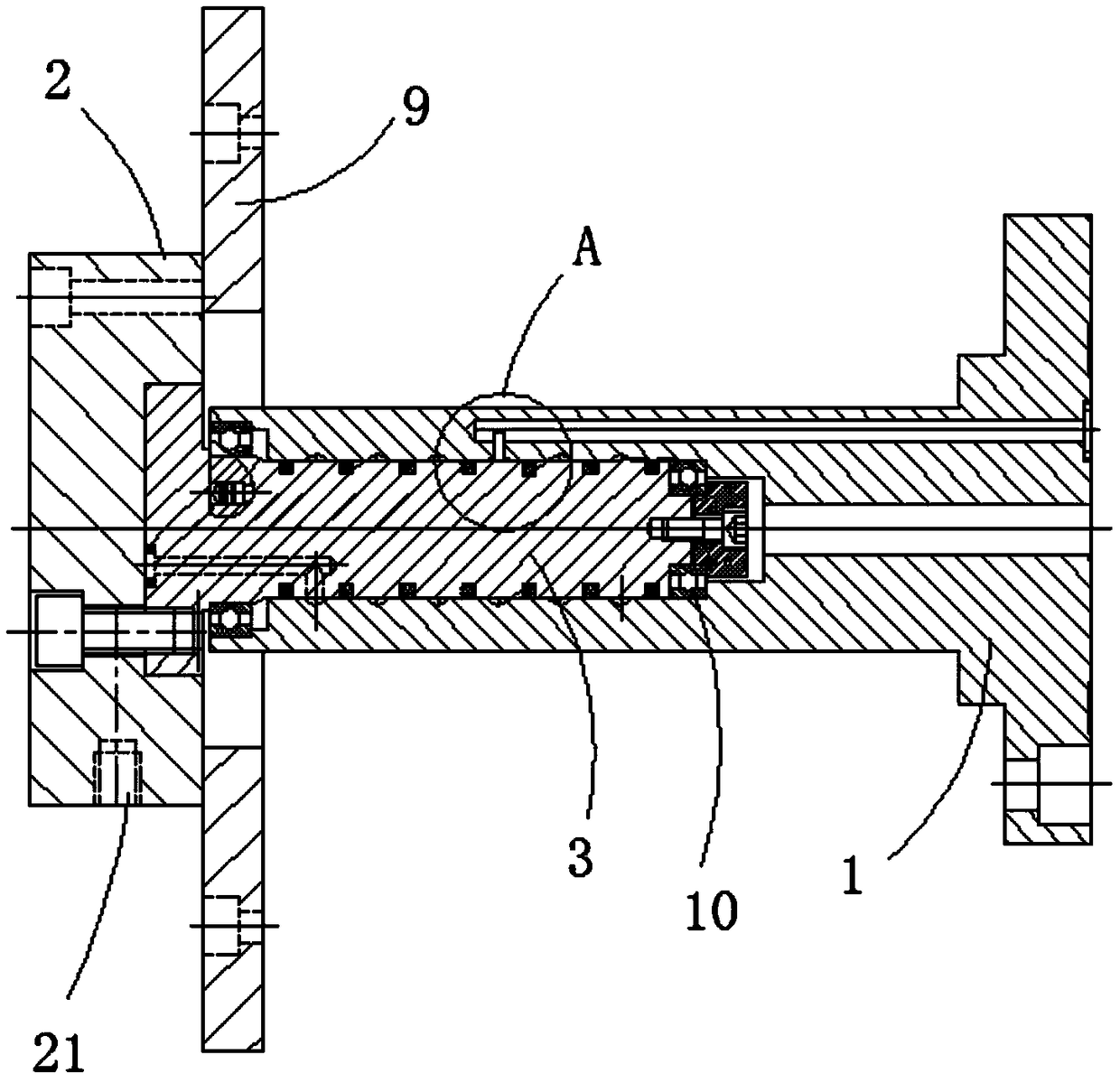

A valve, particularly a proportional pressure control valve for controlling fluid flows, includes a valve housing (10) having at least three fluid-conducting connections in the form of a pump connection (P), a use connection (A) and of a tank (T) connection. To connect the pump connection (T) to the use connection (A) and the use connection (A) to the tank connection (T), a control piston (18) can be guided in a longitudinally displaceable manner inside the valve housing (10). This control piston is provided for establishing a fluid-conducting connection between at least one of the connections (P) and a pilot chamber (20) of a pilot valve (22) having a connecting channel (24). A valve part (40) of the pilot valve (22) is guided in the pilot chamber (20) in a longitudinally displaceable manner. The connecting channel (24) has a throttle in the direction of the pilot chamber (20) of the pilot valve (22) with its valve part. A guiding device (38) oriented toward the pilot chamber (20) and provided for guiding the fluid flow is provided next to the throttle to divert the fluid flow, conveyed inside the connecting channel (24) and flowing toward the valve part (40), at least partially away from this valve part.

Owner:HYDAC FLUITECHNIK GMBH

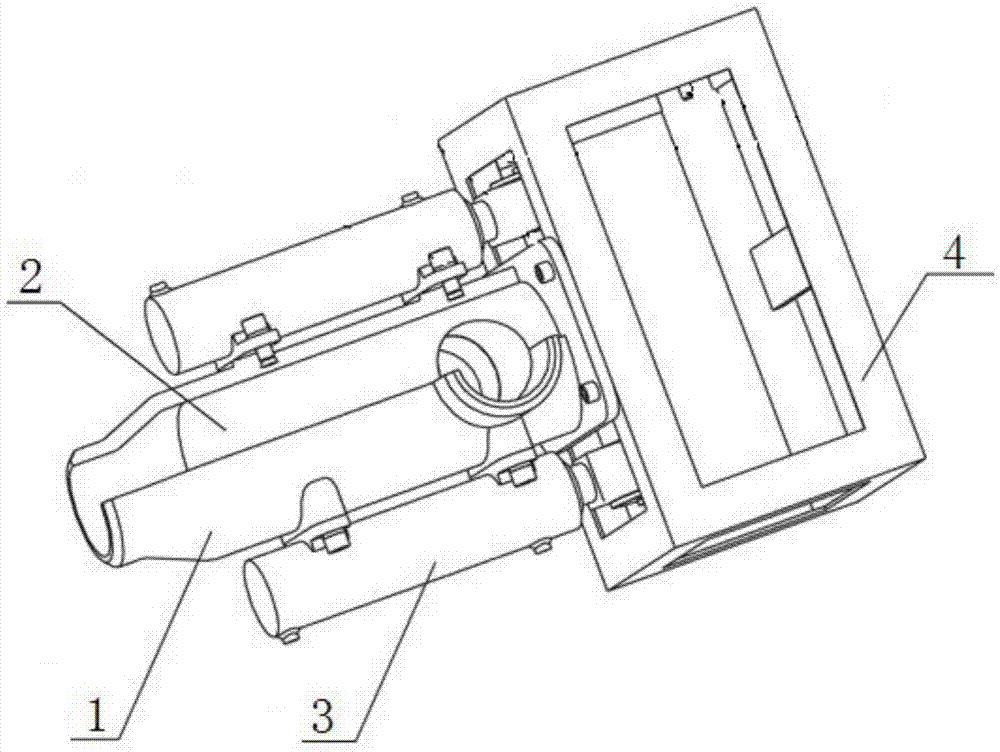

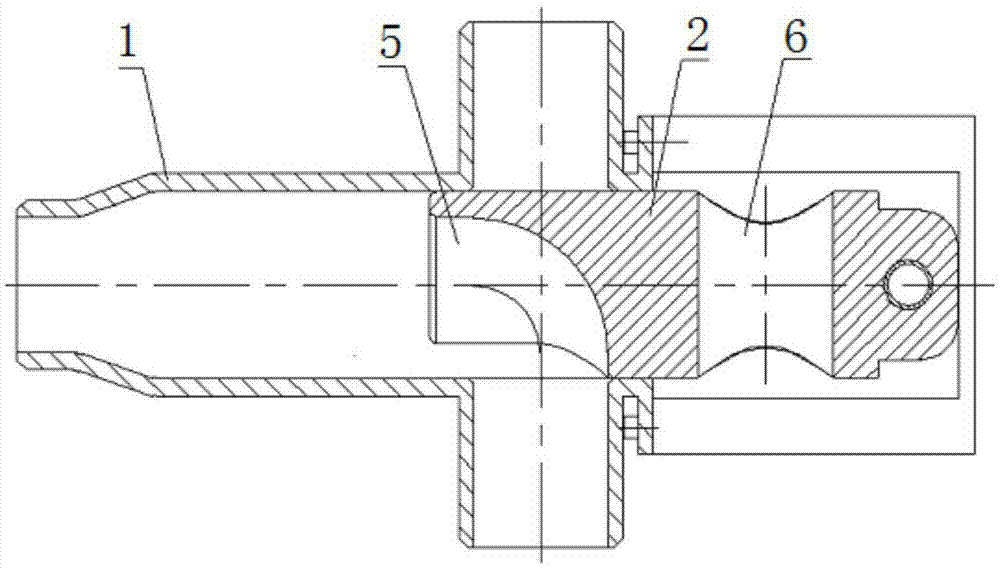

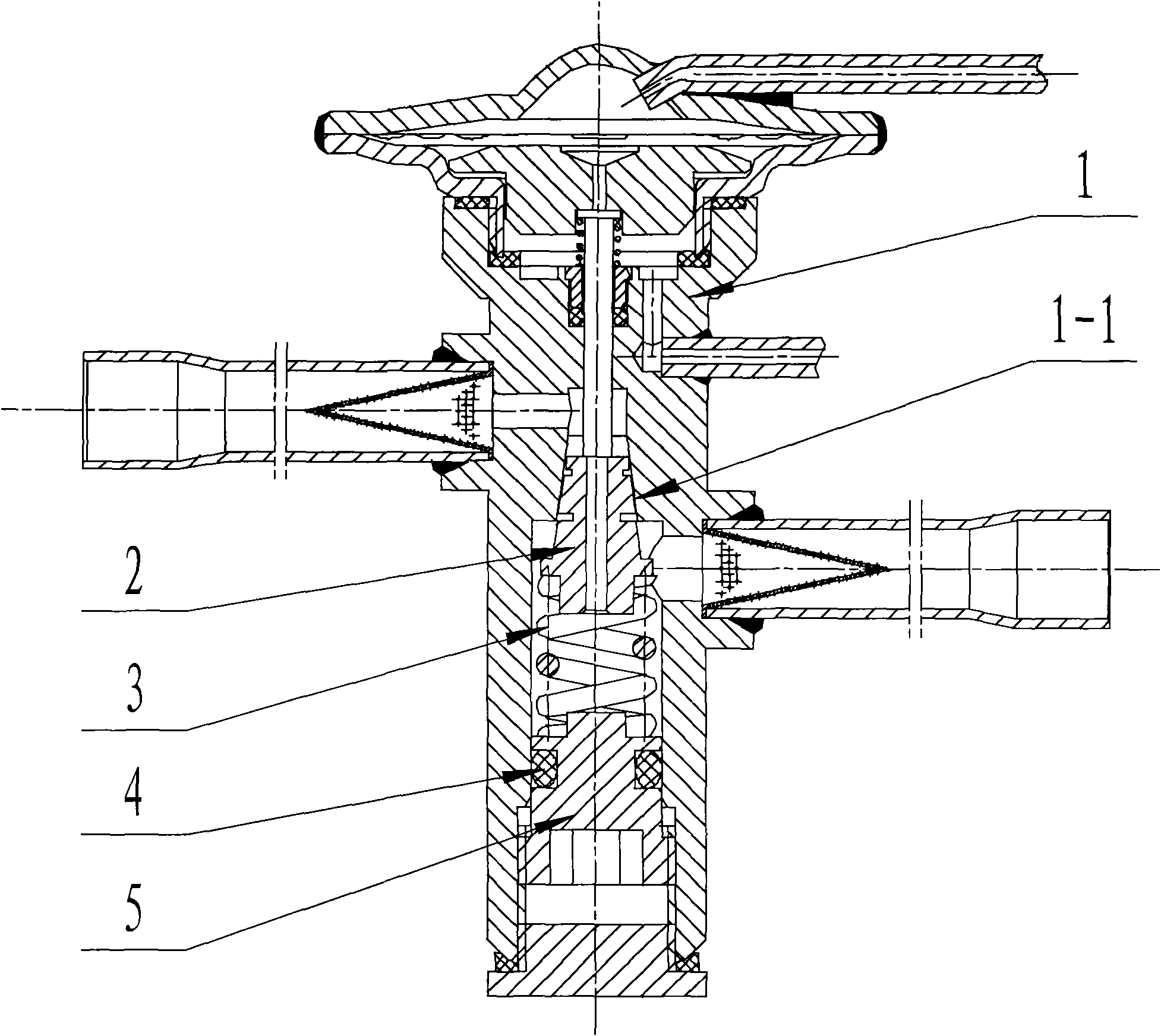

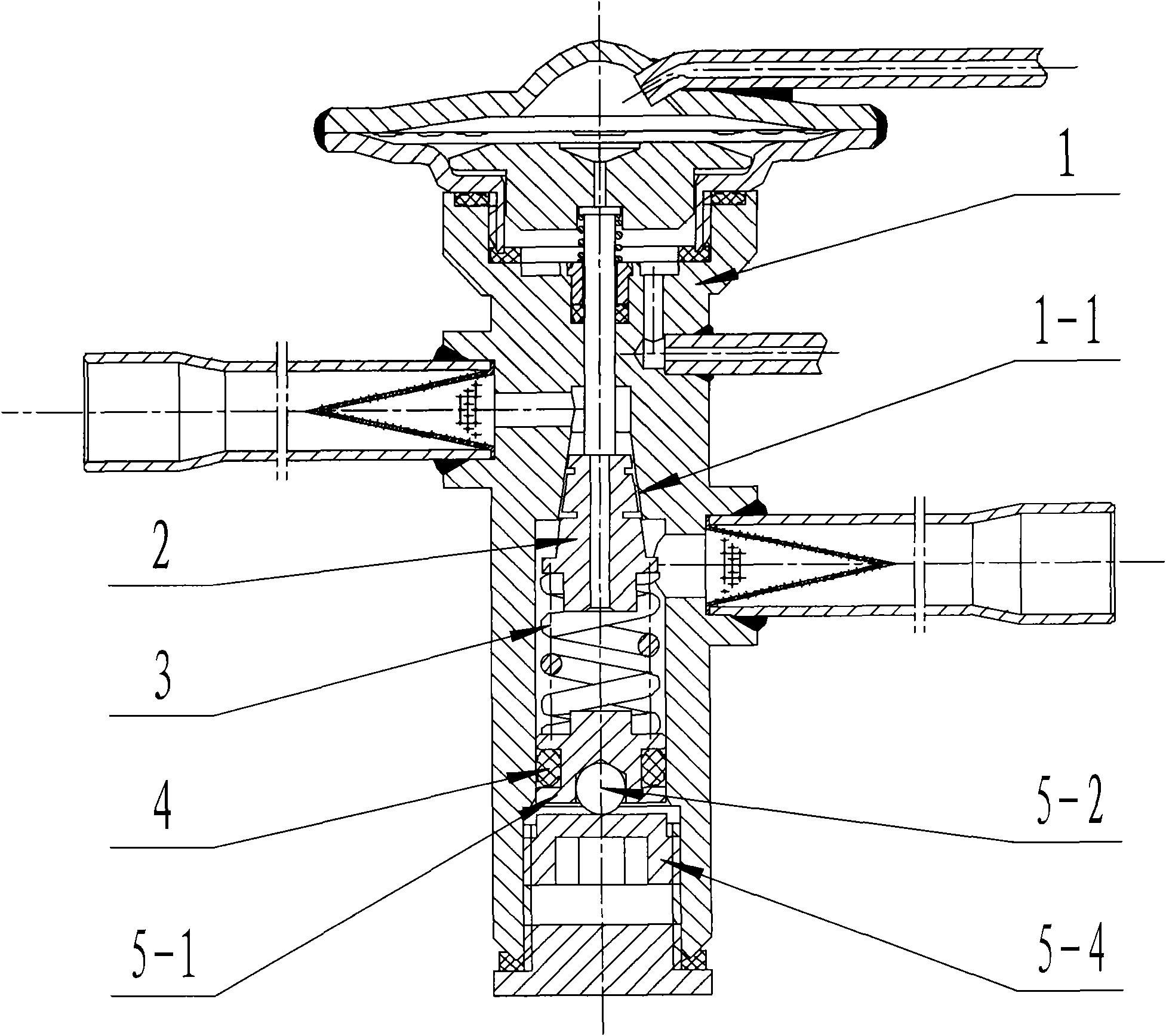

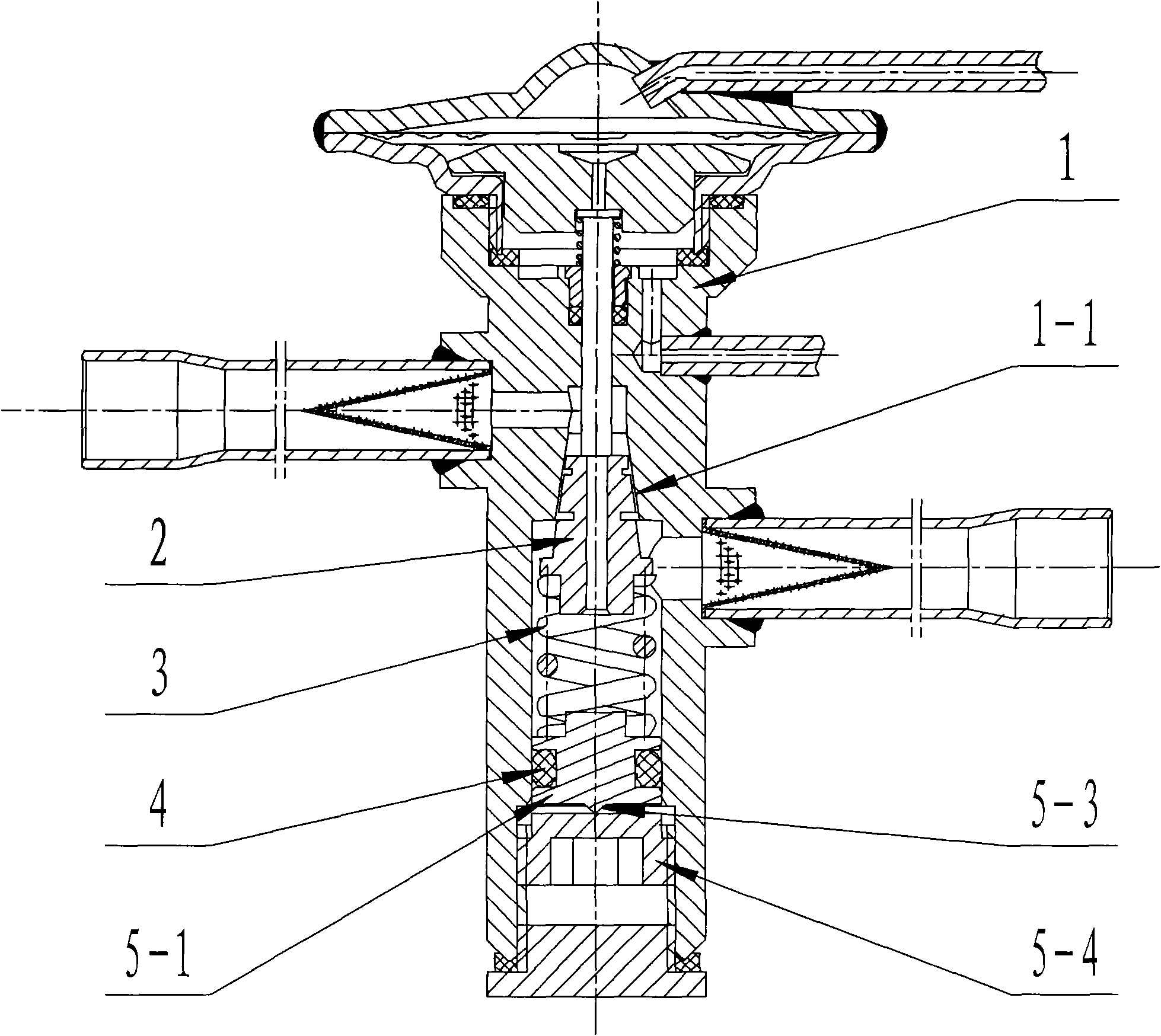

Shuttle valve, shuttle valve driving type device, winding drum brake cylinder control loop and crane

ActiveCN102889398AImprove buffer positioning functionWith buffer positioning functionMultiple way valvesHoisting equipmentsEngineeringShuttle valve

The invention relates to a shuttle valve which comprises a valve rod type valve core (11), when the output end of the shuttle valve is communicated with one of a first input end and a second input end; and one end face of the valve core and an inner wall surface, which is corresponding to one end of a valve cavity form an end face seal, and the periphery surface of the valve core (11) and an inner periphery surface of the valve cavity corresponding to one section form a cylindrical surface sealing, and an output end and the other one of the first input end and the second input end are mutually closed through the end face seal and the cylindrical surface seal. In addition, the invention also provides a shuttle valve driving type device comprising the shuttle valve, a winding drum brake cylinder control loop and a crane. The shuttle valve provided by the invention adopts a unique valve rod type valve core, the double seal is formed in a shuttle valve working process through an end face seal and the cylindrical surface seal, and the shuttle valve is capable of effectively working in a hydraulic system with relatively higher oil pressure; and the shuttle valve can effectively receive impaction and is not easy to transform, the service performance is reliable, the sealing property is relatively better, and the service life of the products is observably prolonged.

Owner:CHANGDE ZHONGLIAN ZHONGKE HYDRAULIC

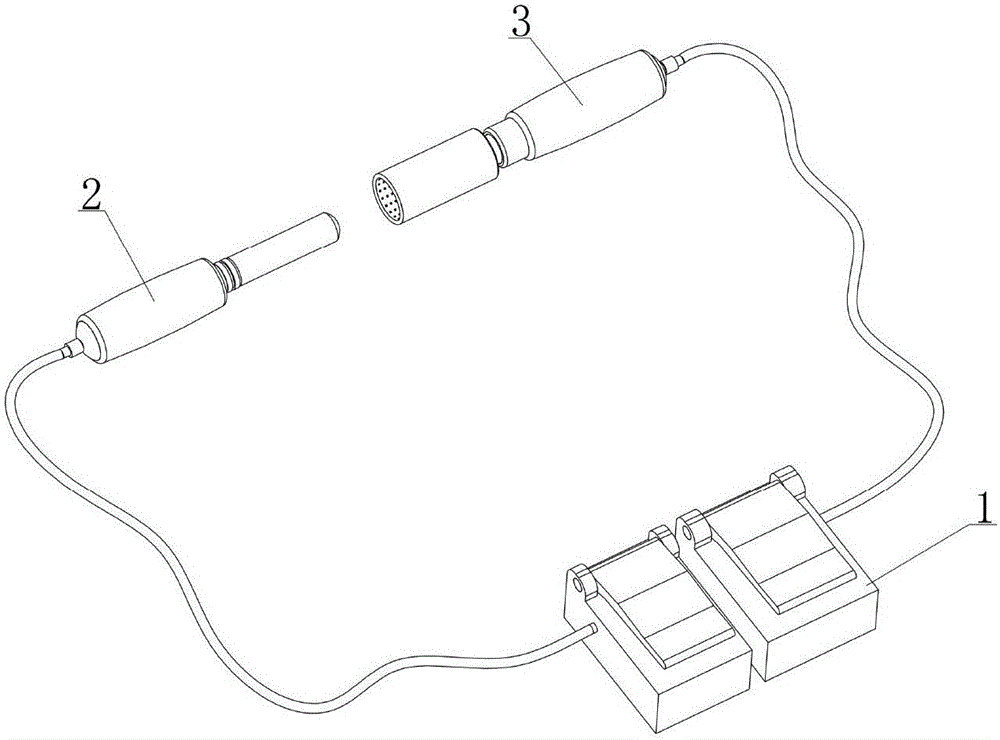

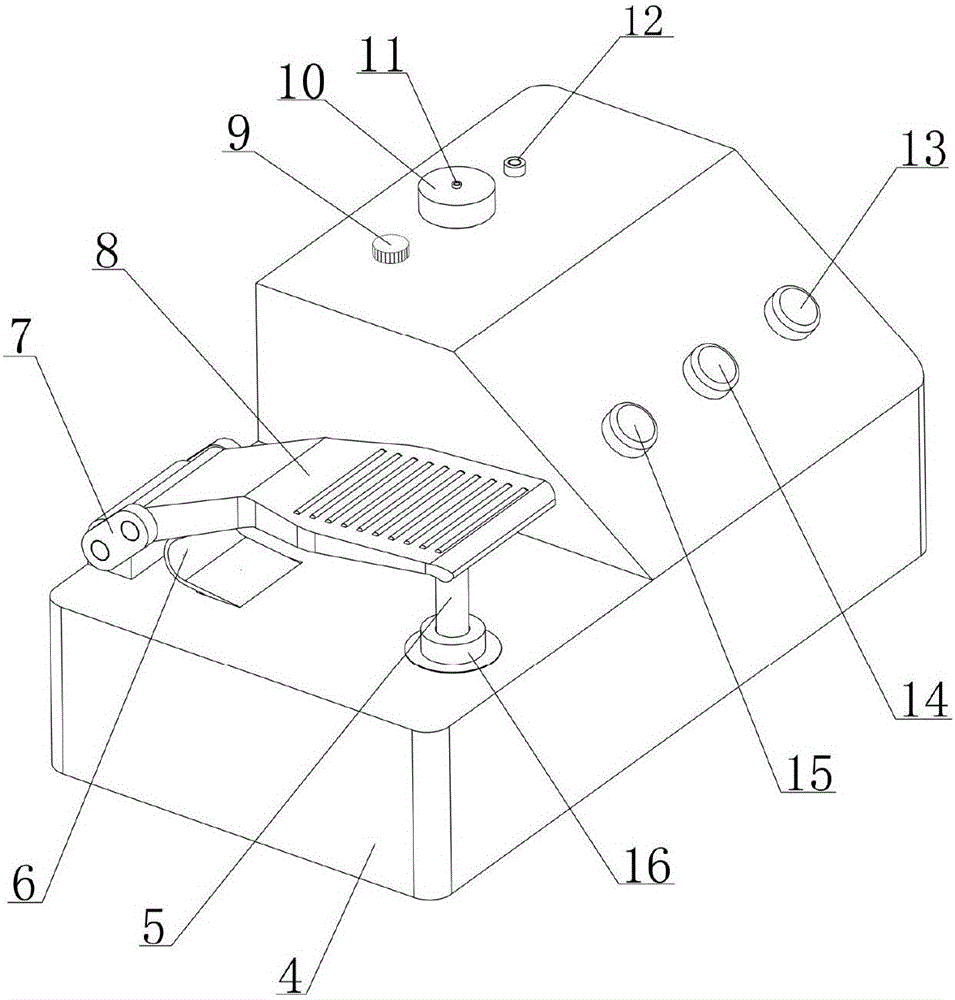

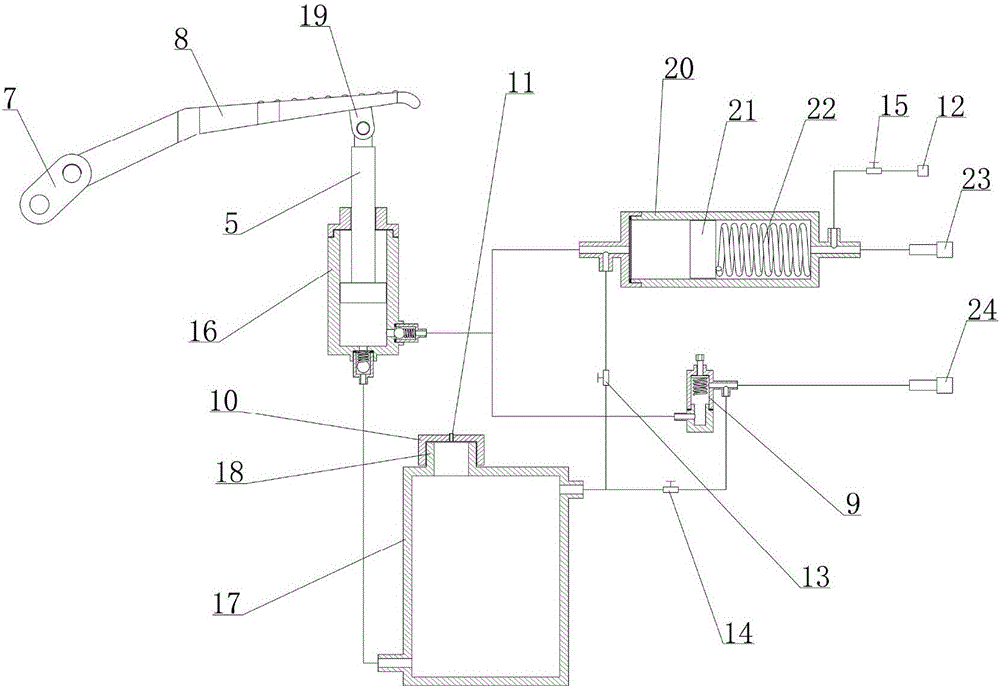

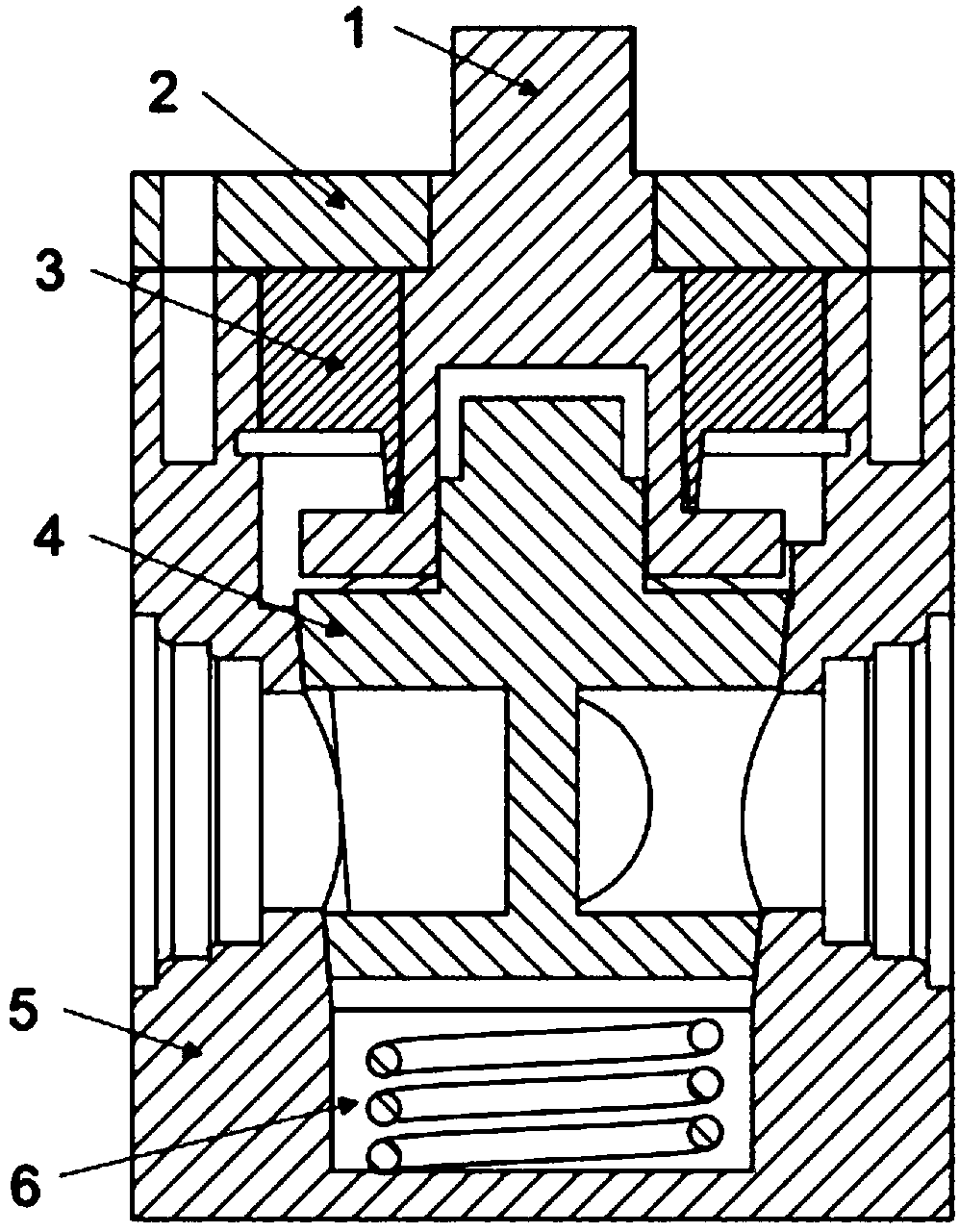

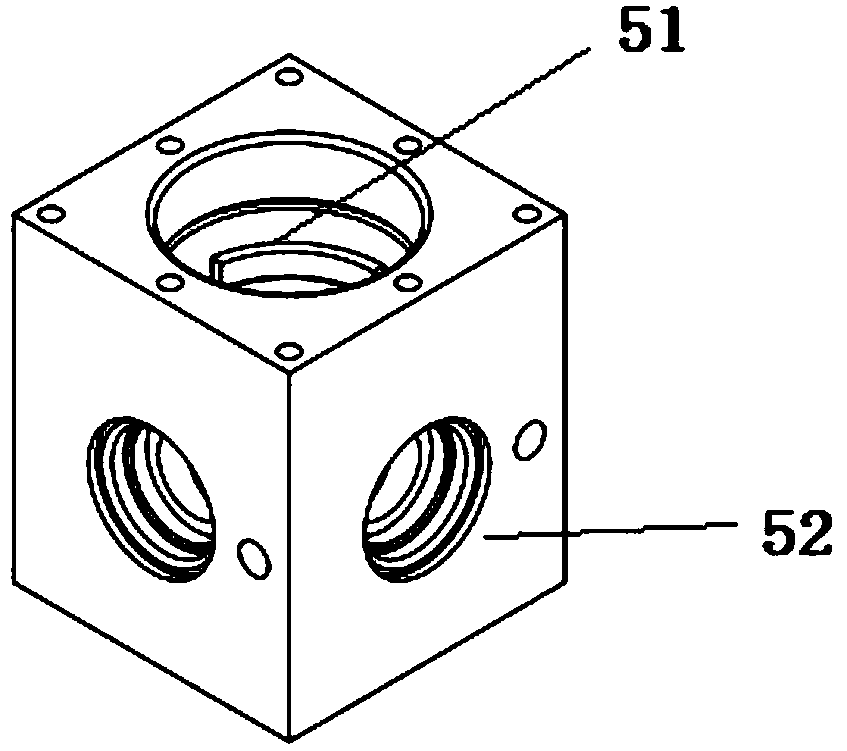

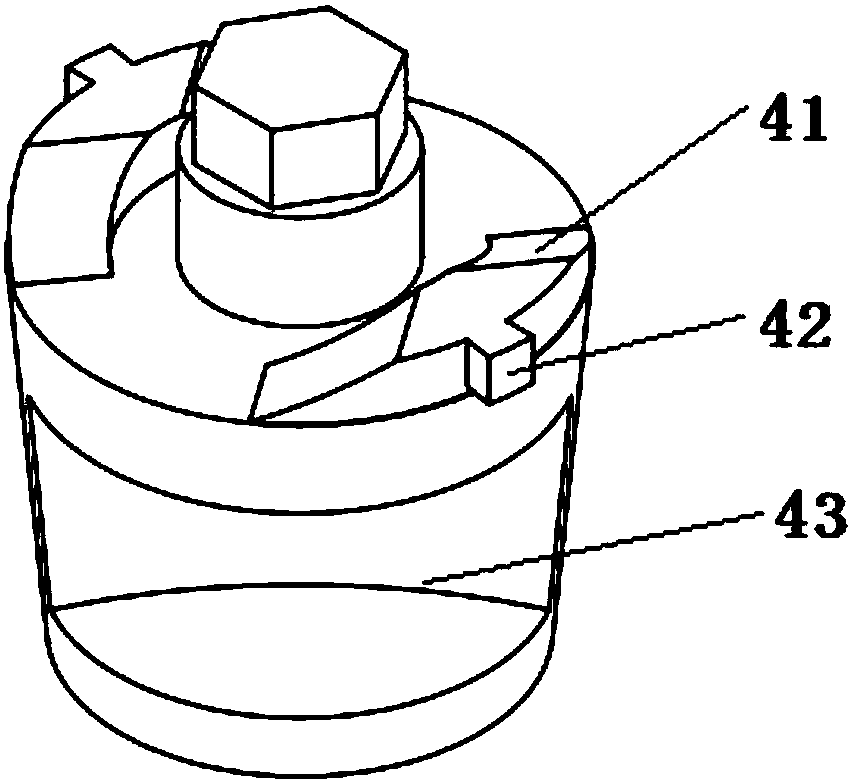

Positive-and-negative pressure driving device for mounting tool of cold shrinking cable sealing cap

ActiveCN106015148AEasy to prepareCompact structureServomotor componentsServomotorsFailure rateAdjustable pressure limiting valve

Owner:江苏智光创业投资有限公司

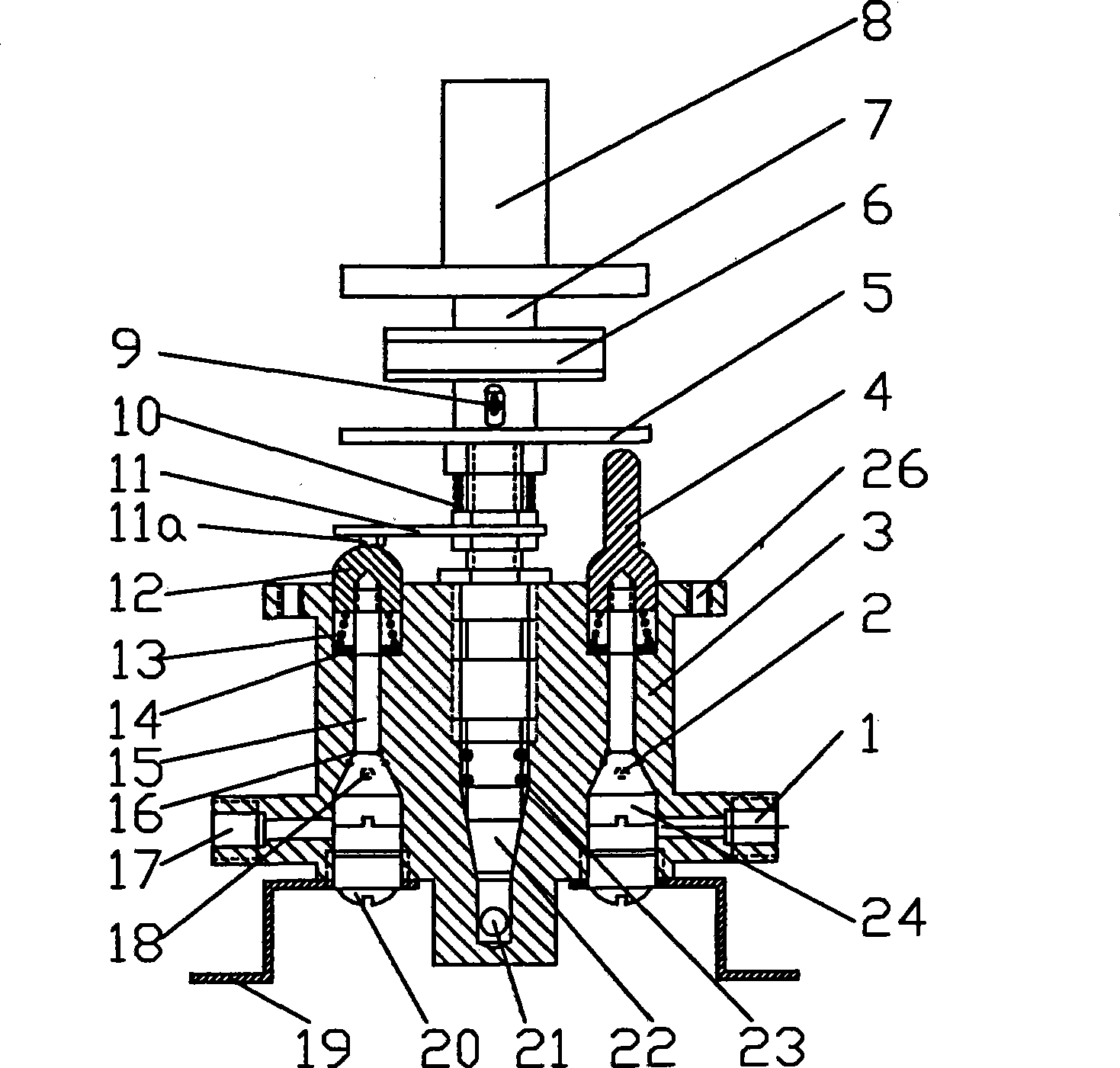

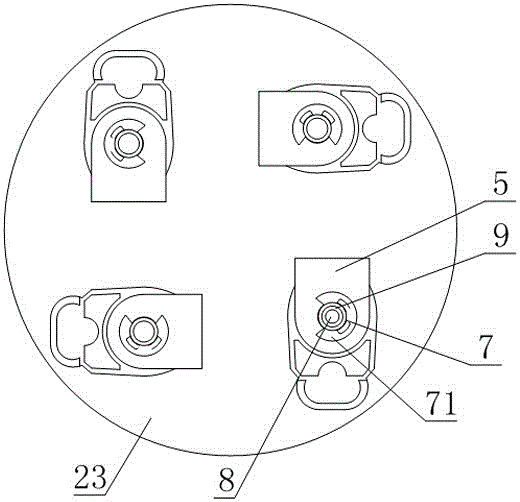

Four-way switching valve

InactiveUS6860294B2Operating means/releasing devices for valvesAir-treating devicesSolenoid valveReciprocating motion

To provide a four-way solenoid valve having a three-way solenoid valve of which non-concentricity between a valve element and a valve hole is small, if any. A core of a three-way solenoid is integrally formed with a refrigerant passage extending axially therethrough, an annular projection forming a valve seat, and a guide for guiding reciprocating motion of a needle forming a valve element. A plug closing a cylinder of a body to define the pressure control chamber is also integrally formed with a valve seat and a guide for guiding reciprocating motion of a needle forming a valve element associated with the valve seat. This causes the needles to be seated on the valve seats associated therewith in respective states guided by the guides substantially concentric with the valve holes, which makes it possible to impart sufficient sealing properties to the valve portions when each valve is closed.

Owner:TGK

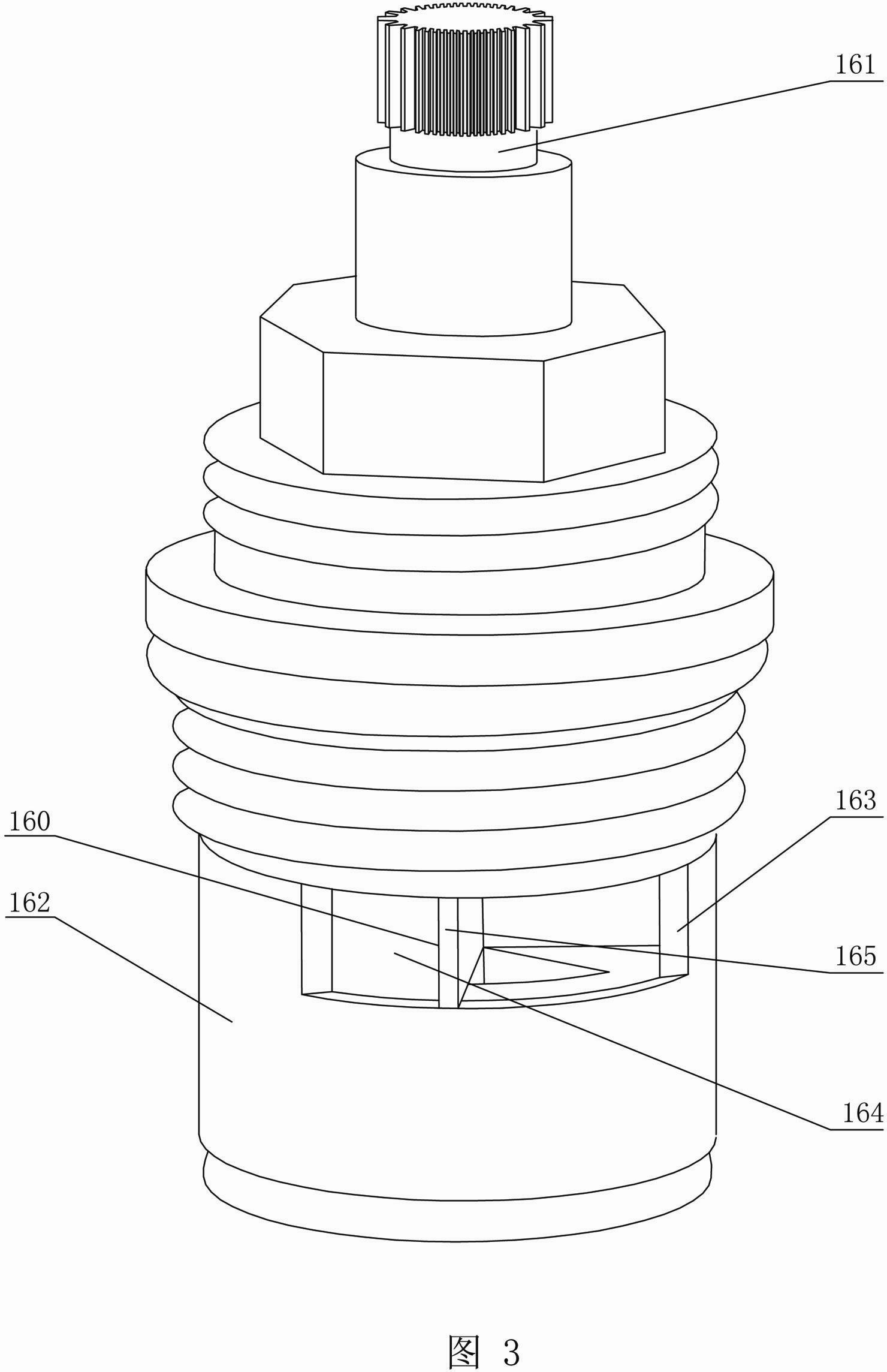

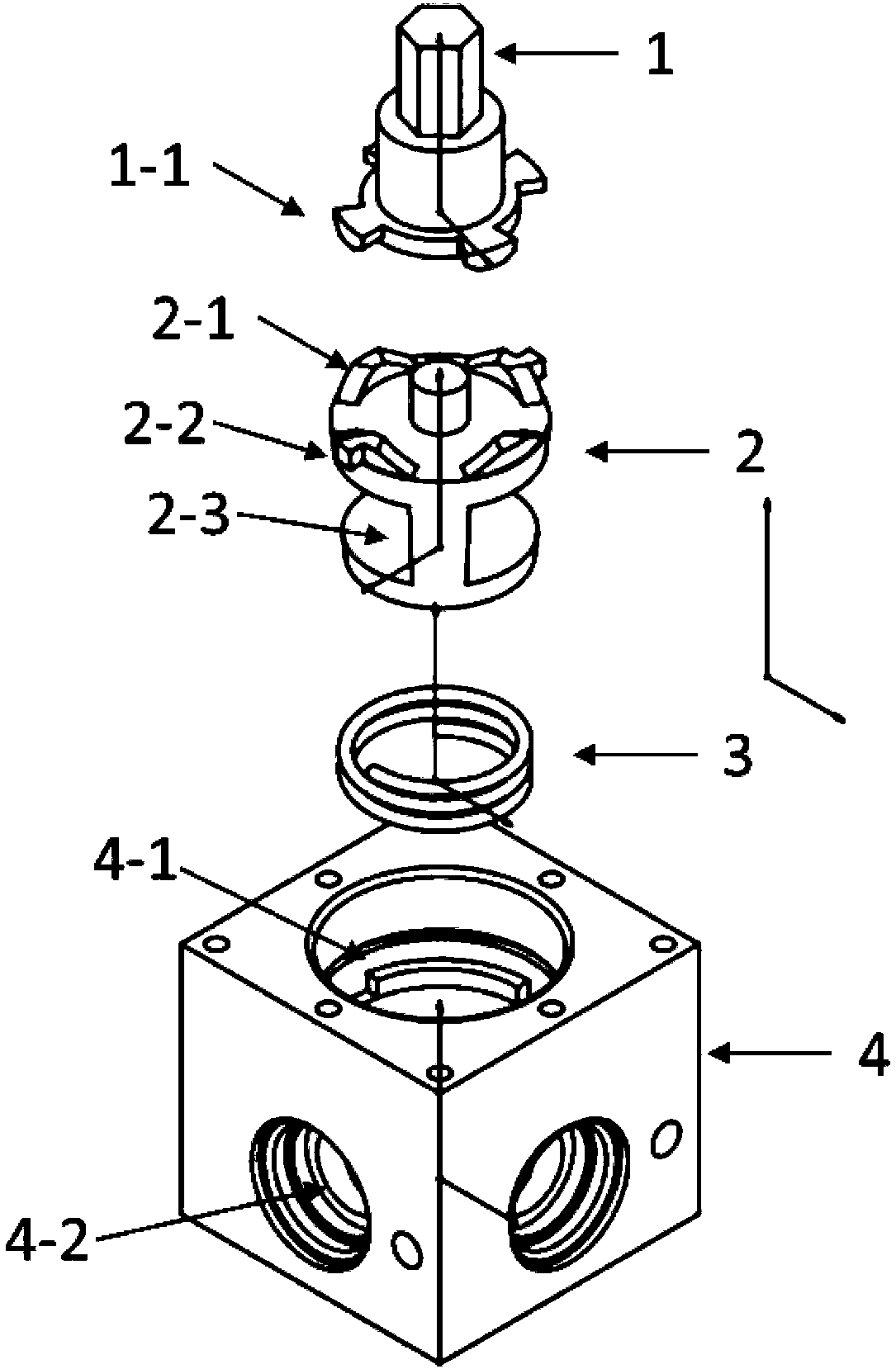

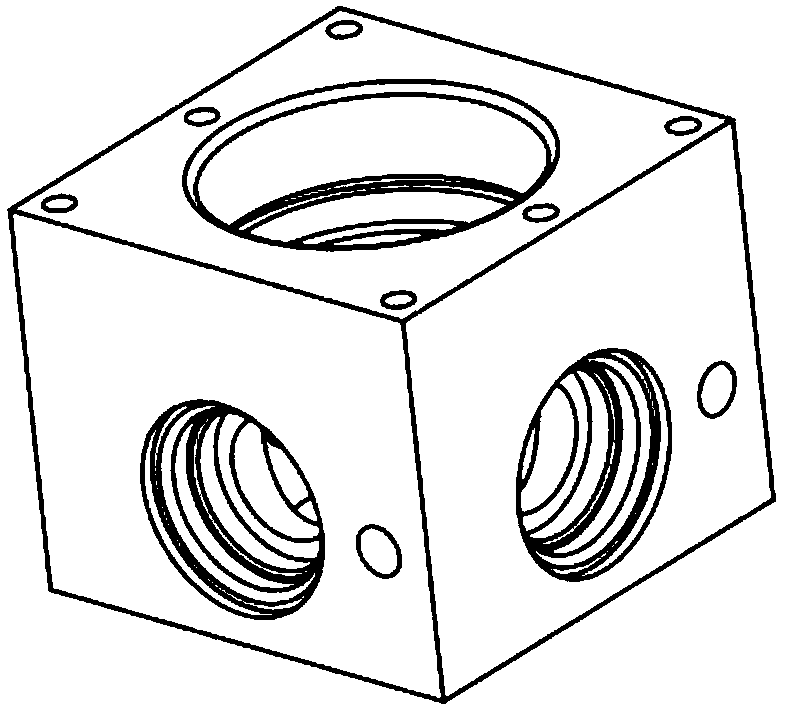

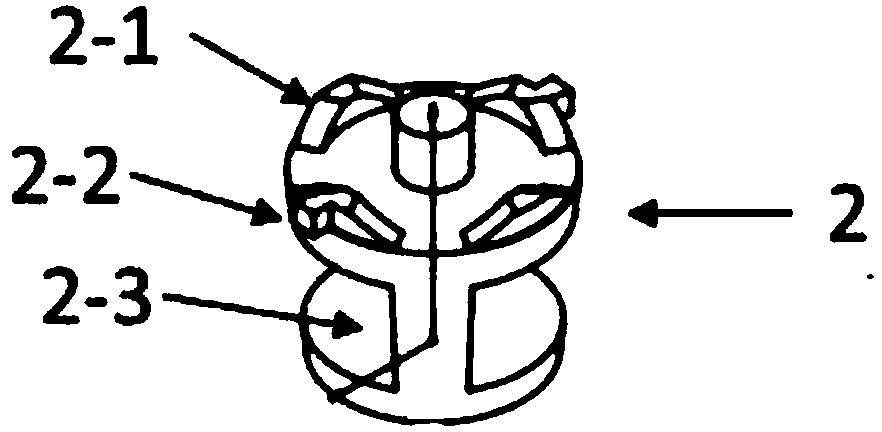

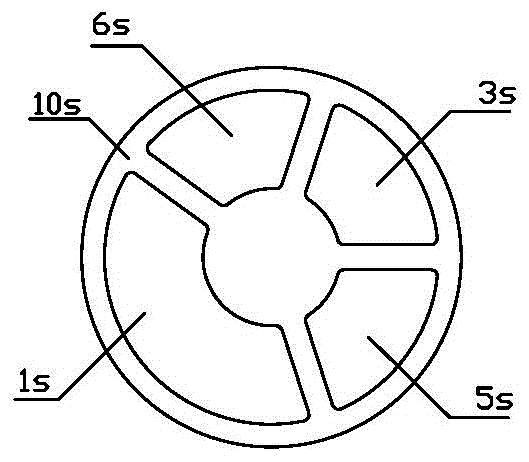

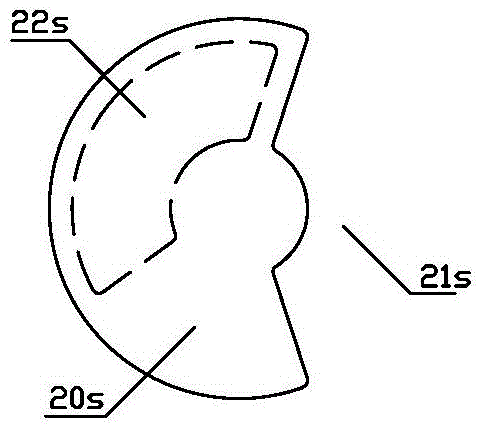

Ceramic valve element with drinking water control function

The invention discloses a ceramic valve element with a drinking water control function. The ceramic valve element is formed in the manner that a rotating base is arranged in a valve shell in an assembled manner, a linking block, a movable valve block and a fixed valve block which are sequentially overlapped are arranged below the rotating base, a valve rod upwards extending out of the valve shell is arranged in the rotating base in pivoted manner, a stirring part at the bottom end of the valve rod and the linking block are embedded, the movable valve block is embedded through the linking block, and the movable valve block is driven by the linking block to move horizontally or rotate through the operation of the valve rod; by means of the change of the position corresponding relation between the movable valve block and the fixed valve block, a tap is controlled to allow water to flow or stop water flowing, or the mixing proportion of cold water and hot water and the output water flow are changed, and internal members such as the fixed valve block, the movable valve block, the linking block and the rotating base are stopped from dropping out through combination of a valve seat below the valve shell. The ceramic valve element can control use of tap water and drinking water, and the complexity of the whole structure is effectively simplified.

Owner:SHANGHAI GEAR PLASTIC

Electromagnetic valve

ActiveUS20180128385A1Improve sealingImproved ease of maintenanceOperating means/releasing devices for valvesMultiple way valvesSpool valveEngineering

An electromagnetic valve includes a valve casing, which has a valve hole, a spool valve in the valve hole, first and second output ports each communicating with the valve hole, first and second pressure introduction holes, which respectively communicate with the first and second output ports, first and second pressure sensors, which is respectively fitted in the first and second pressure introduction holes, sealing members, which are arranged between the respective pressure sensors and the pressure introduction holes, first and second substrates, on which the corresponding first and second pressure sensors are mounted, and a housing, which accommodates the first and second substrates, has the first and second pressure introduction holes, and is attached to the valve casing. The first and second substrates are arranged to be opposed to each other in a state of being upright in a direction perpendicular to the movement direction of the spool valve.

Owner:CKD

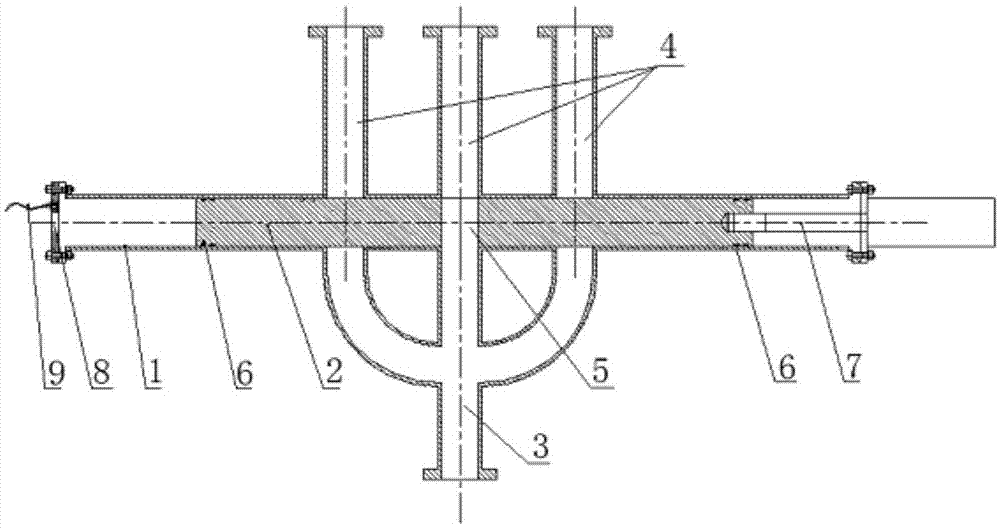

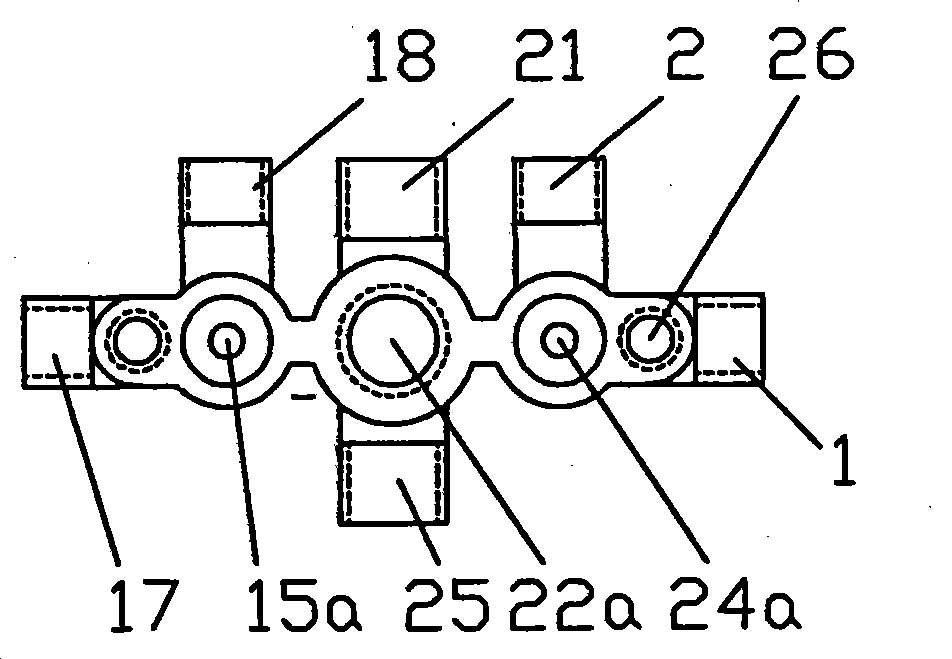

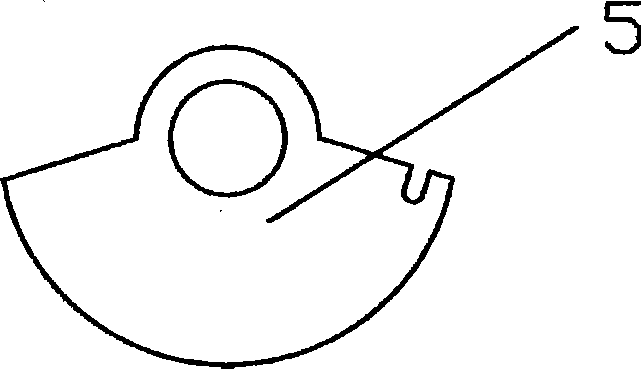

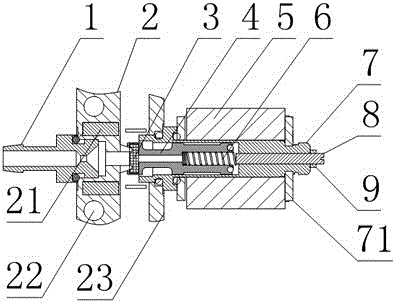

Valve core for four-way switching valve and four-way switching valve thereof

InactiveCN101644347AEasy to moveHigh mechanical strengthMultiple way valvesSlide valveValve seatPhysics

The present invention provides a valve core for a four-way switching valve, which can ensure smooth fluid movement in the valve core and can improve mechanical strength. The four-way switching valve (2) comprises the following components: a valve body (3) with a closed space; a first pipe (5) connected with one side of the valve body (3); a second pipe (7) connected with the other side of the valve body (3); a third pipe (11) and a fourth pipe (12) which are separated by the second pipe (7) and configured adjacently with two sides; a valve seat (16) which is provided in the valve body (3) andis provided with an opening communicated with each pipe; and a valve core (1) which is slidably configured to the valve seat (16). Through the sliding of the valve core (1), the communication state between the first pipe (5) and the third pipe (11) or between the first pipe (5) and the fourth pipe (12) is selectively switched. The valve core (1) comprises the following components: a supporting rod (1d) which is configured to penetrate an opening end face part (1j) adjacently with the opening end face part (1j) of a bowl-shaped body (1c); and a flange part (projected part) (1k) which is formedintegrally with the a main body (1c) at the position of the of the opening end face part (1j) that is next to the main body (1c). The flange part (1k) projects to a position that is next to the innerwall surface (3c) of the valve body (3) from the outer surface of the main body (1c) along the axial direction of the supporting rod (1d).

Owner:FUJIKOKI MFG CO LTD

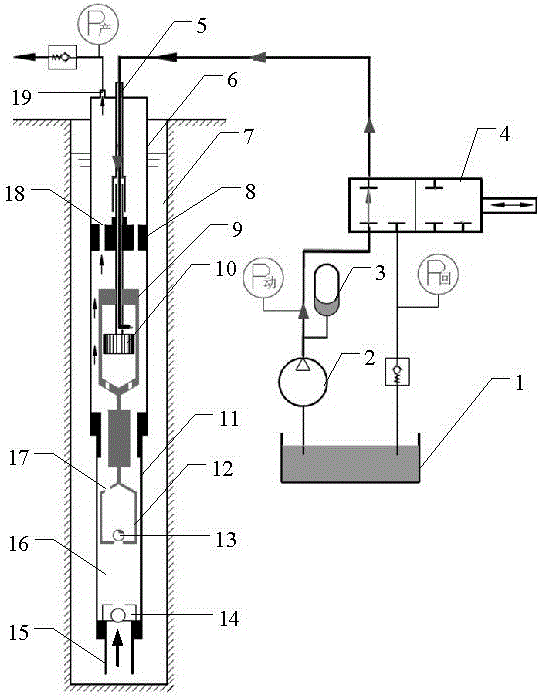

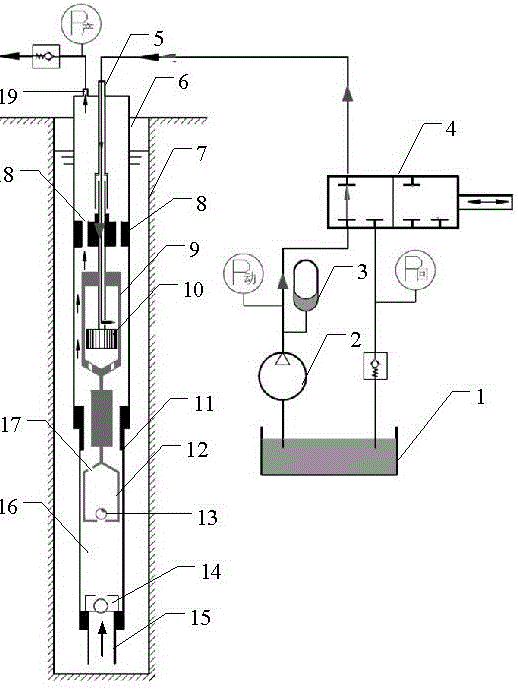

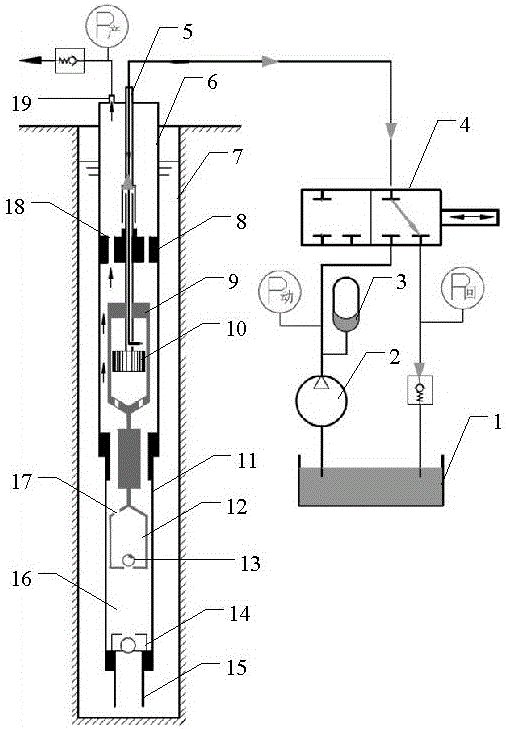

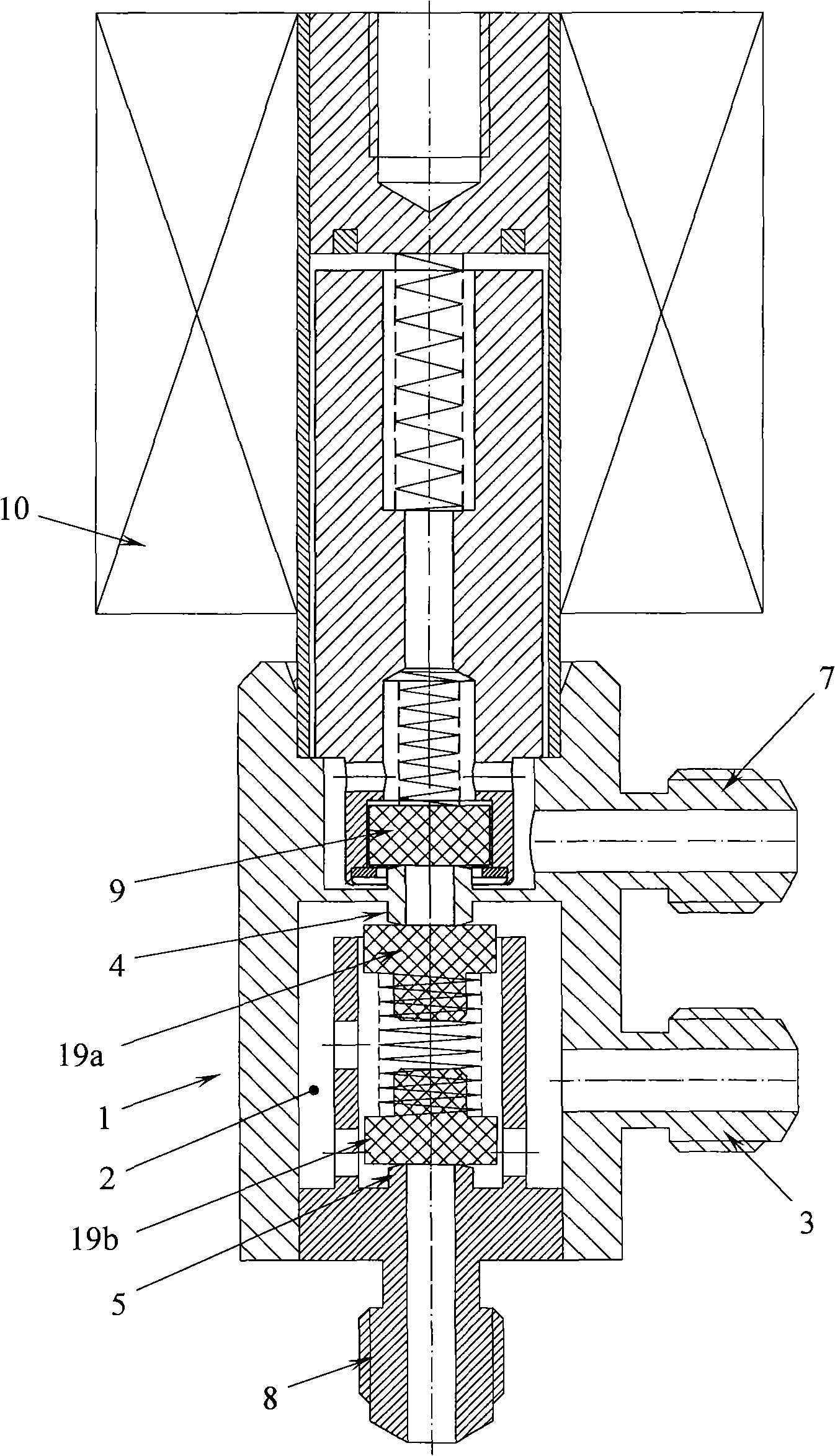

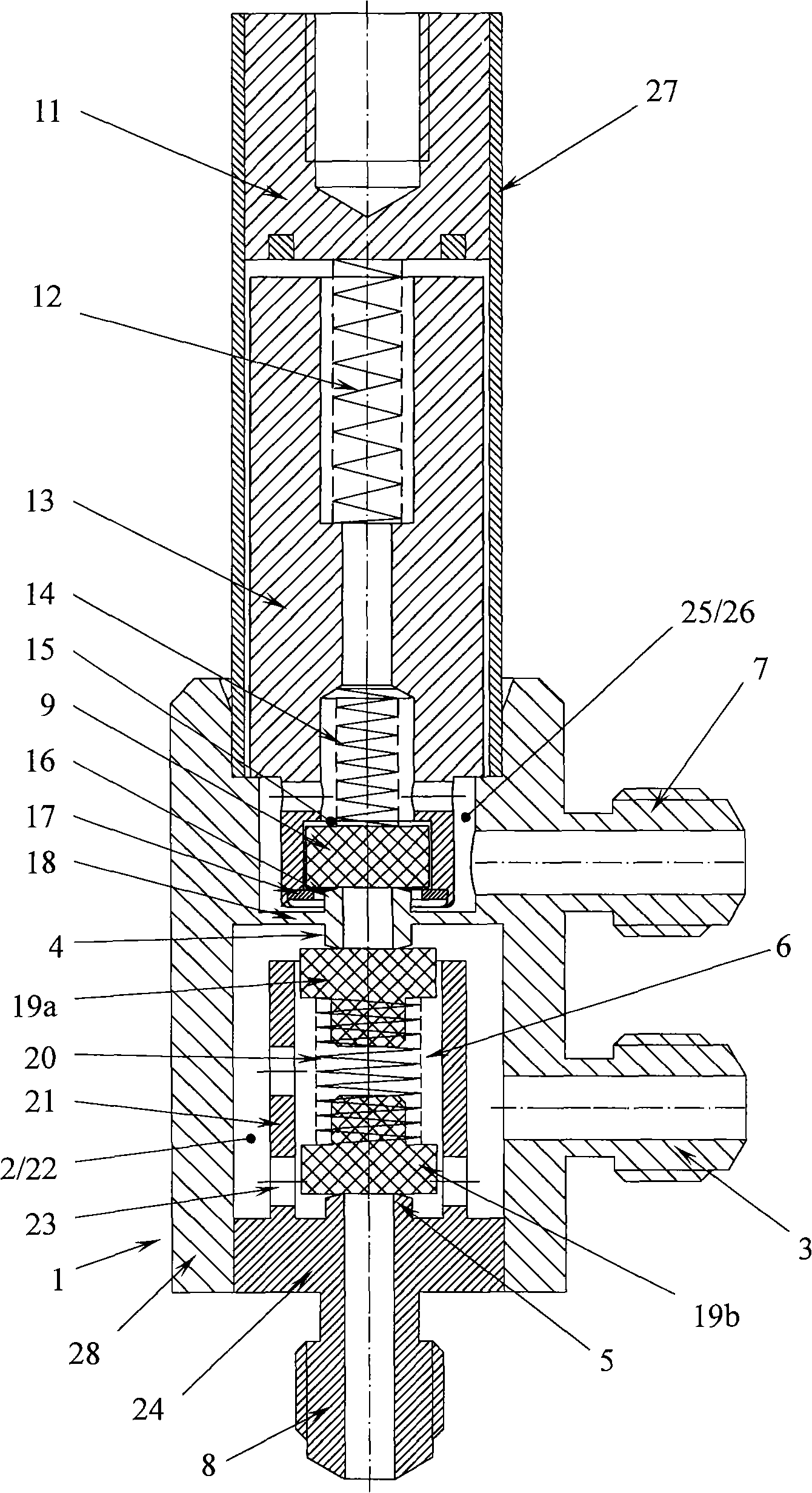

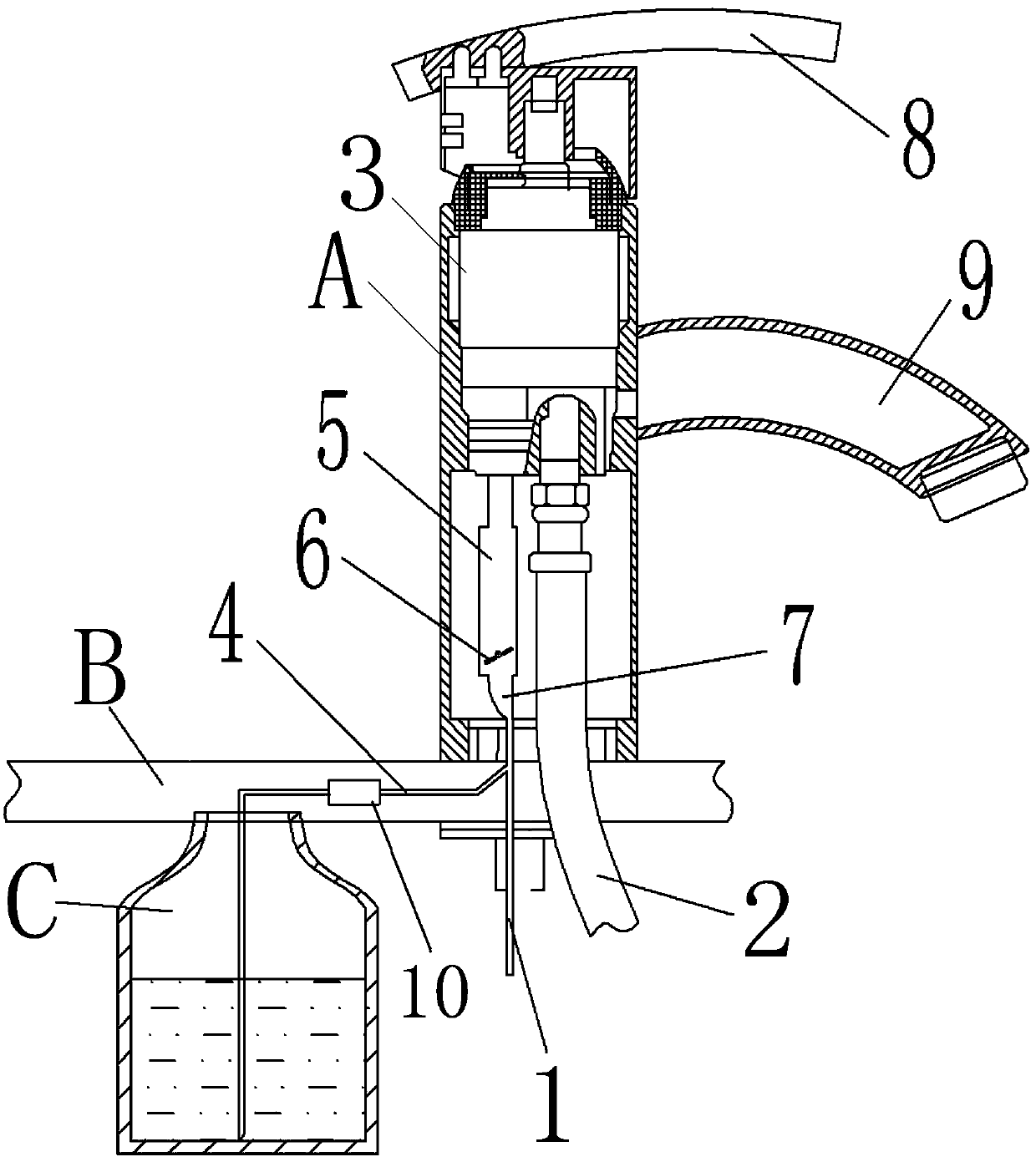

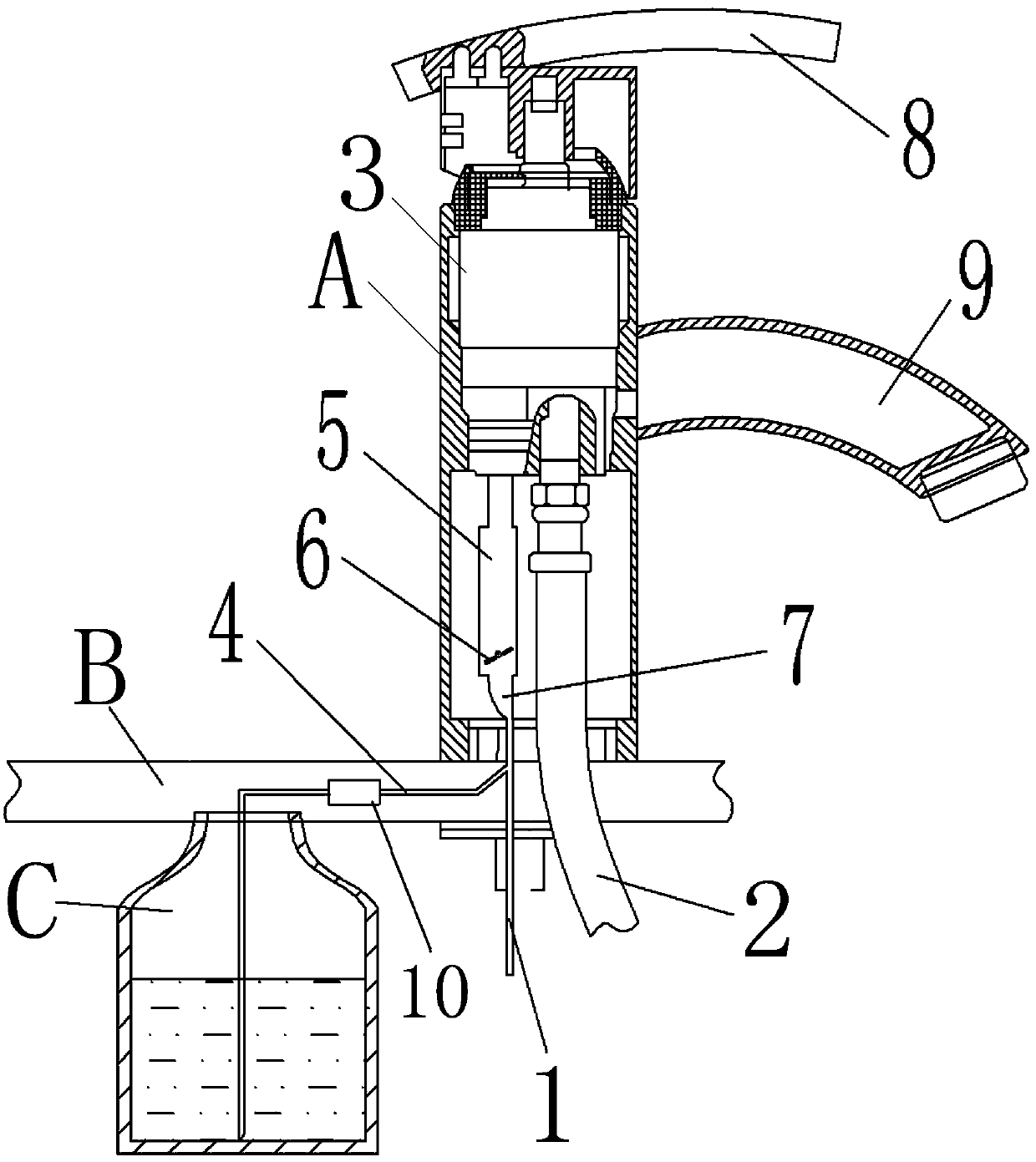

Novel anti-eccentric wear hydraulic oil extraction device

InactiveCN105041629ANo loadShort schedule of activitiesOperating means/releasing devices for valvesFlexible member pumpsLiquid storage tankPower equipment

Owner:盐城市佳鑫石化机械制造有限公司

Solenoid valve for controlling flow path

ActiveCN101311590AEasy to switchImprove qualityOperating means/releasing devices for valvesMultiple way valvesFluid controlSolenoid valve

Owner:浙江三花商用制冷有限公司

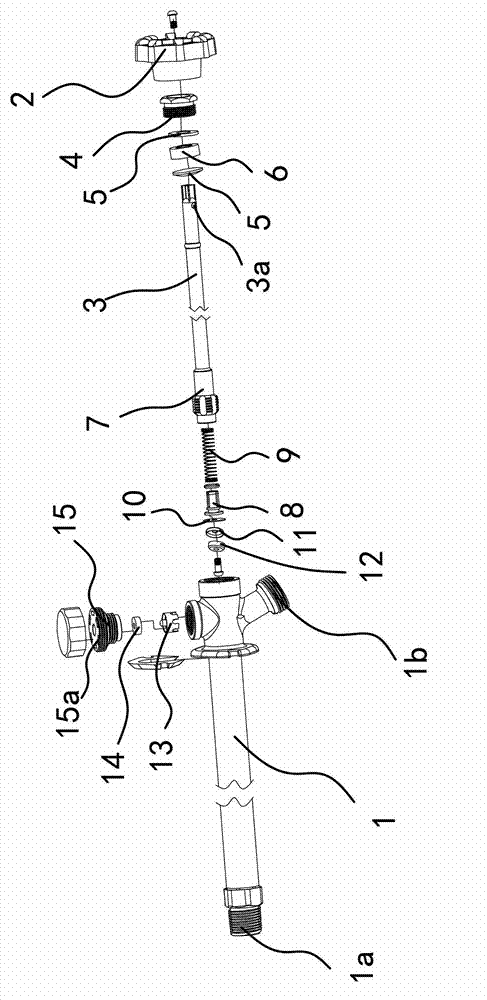

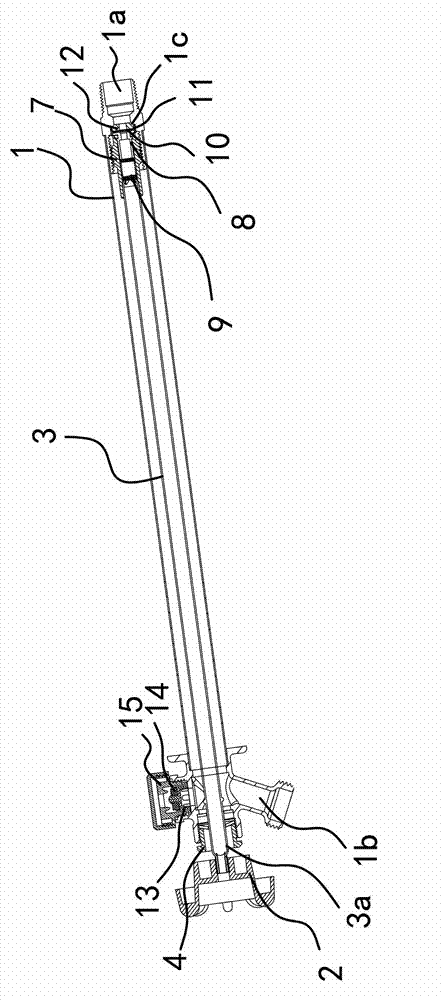

Through-wall antifreezing valve

Owner:宁波宏特工贸有限公司

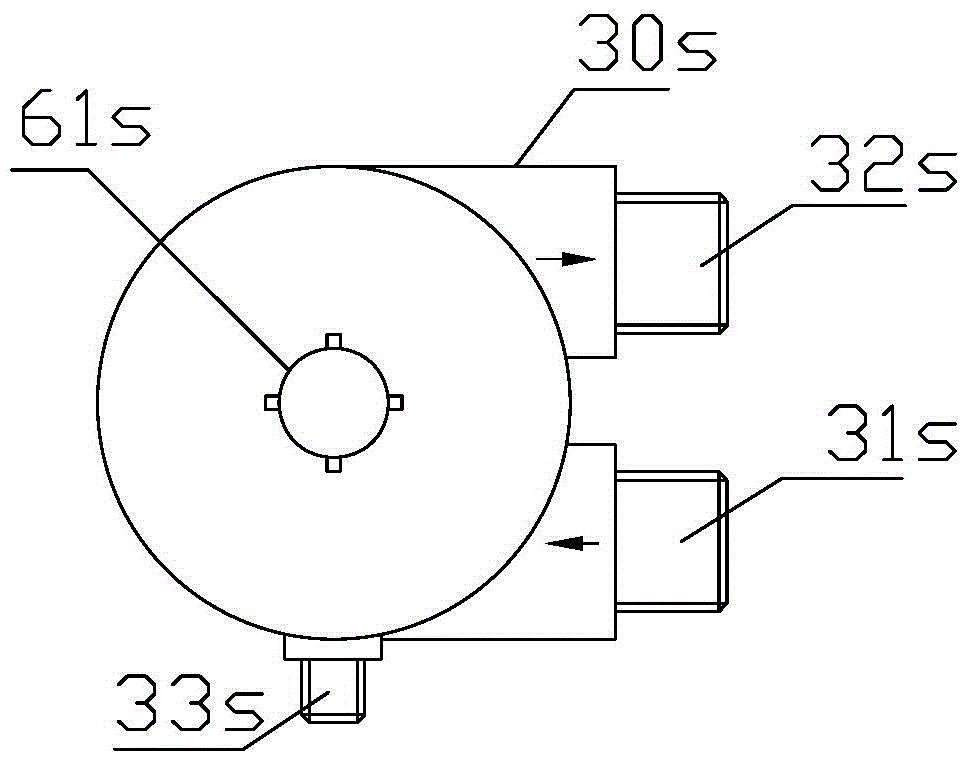

Rotary oil way distributor

PendingCN108953679AOil supply realizedOverall small sizeMultiple way valvesSlide valveDistributorPetroleum engineering

Owner:NINGBO FENGZHOU MACHINERY

Water channel switching structure of water discharging device and water faucet

ActiveCN109764162ASimple structureEasy to assembleOperating means/releasing devices for valvesMultiple way valvesInlet channelWater discharge

The invention discloses a water channel switching structure of a water discharging device and a water faucet. A first driving part is used for controlling a water inlet channel to be turned on and off; a second driving part is in driving fit with an automatic resetting unit; the automatic resetting unit is used for turning off a second water outlet channel and turning on a first water outlet channel under an initial state; the water inlet channel is communicated with the first water outlet channel at the moment; when the second driving part is driven, the second driving part is used for driving the automatic resetting unit to turn off the first water outlet channel and turn on the second water outlet channel; water pressure of the water inlet channel is used for overcoming resetting forceof the automatic resetting unit and limiting the automatic resetting unit in a position of the second water outlet channel, so that the water inlet channel is communicated with the second water outletchannel; if the water inlet channel is turned off at the moment, the automatic resetting unit loses water pressure action force and resets under action of resetting force. According to the scheme, the water pressure of the water inlet channel is ingeniously used for matching with the automatic resetting unit to switch water discharging states; product parts can be simplified; the structure is simple and is convenient to assemble.

Owner:KAIPING HANSHUN SANITARY WARE IND

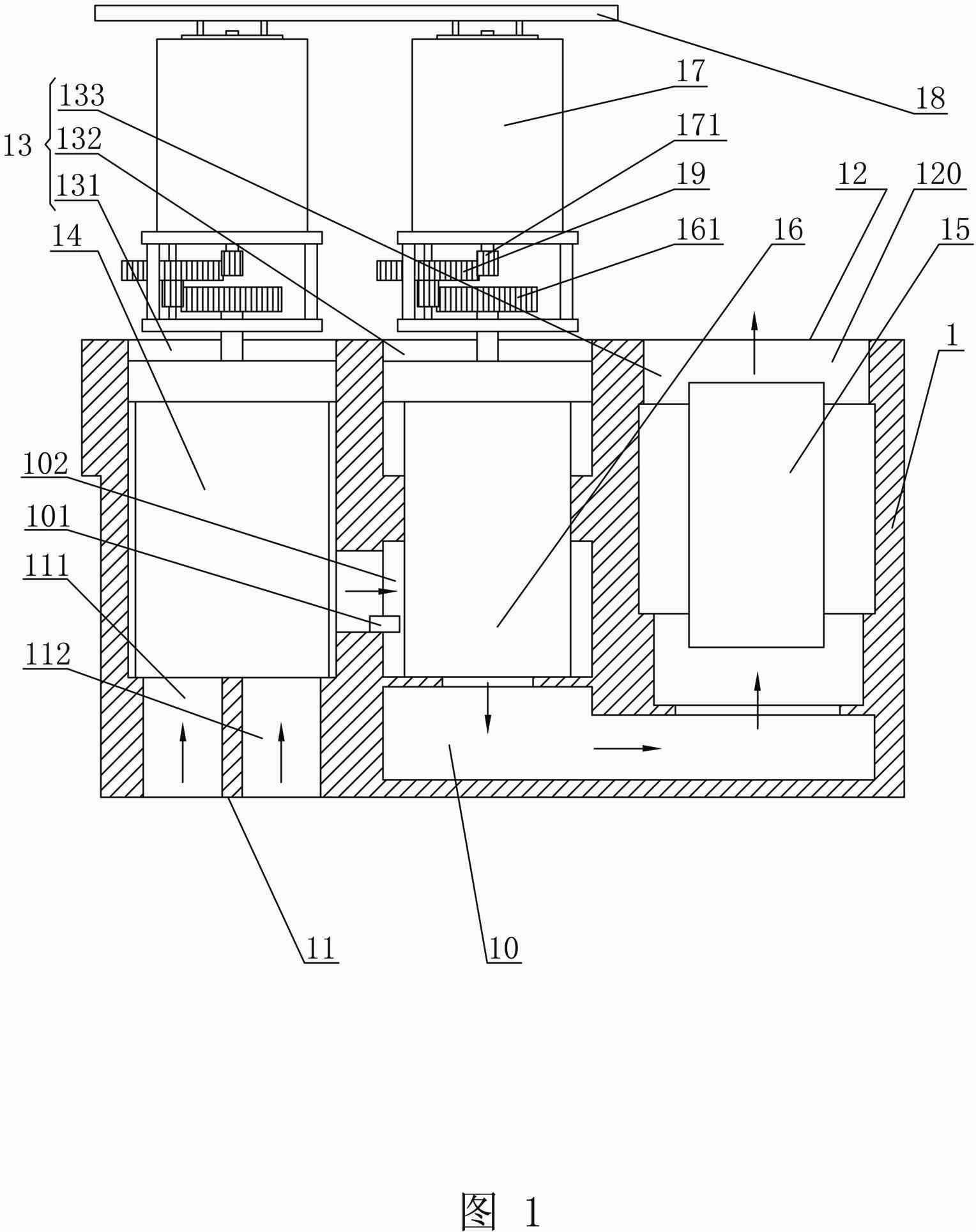

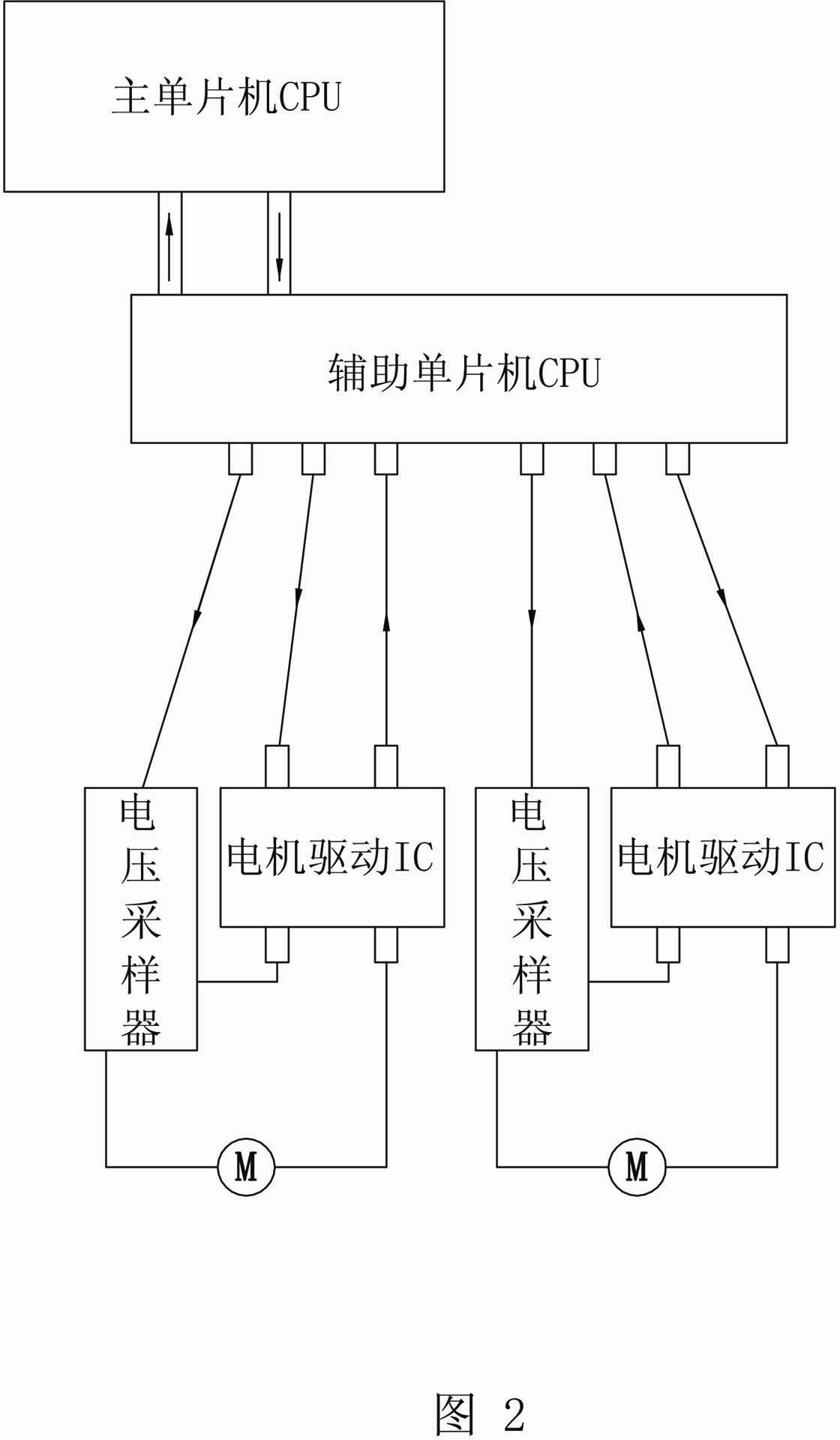

Small volume smart faucet

ActiveCN102287552AOperating means/releasing devices for valvesMultiple way valvesIntegrated circuitVoltage

Owner:陈丽君

Switch assembly of synthetic liquid fuel range

InactiveCN101435597ACompact structureFlexible structureDomestic stoves or rangesLighting and heating apparatusEngineeringLiquid fuel

Owner:张世贵

Heating power expansion valve

InactiveCN101865310ARotation will notGuaranteed not to deviate fromMultiple way valvesSlide valveEngineeringSteel ball

Owner:ZHEJIANG CHUNHUI INTELLIGENT CONTROL

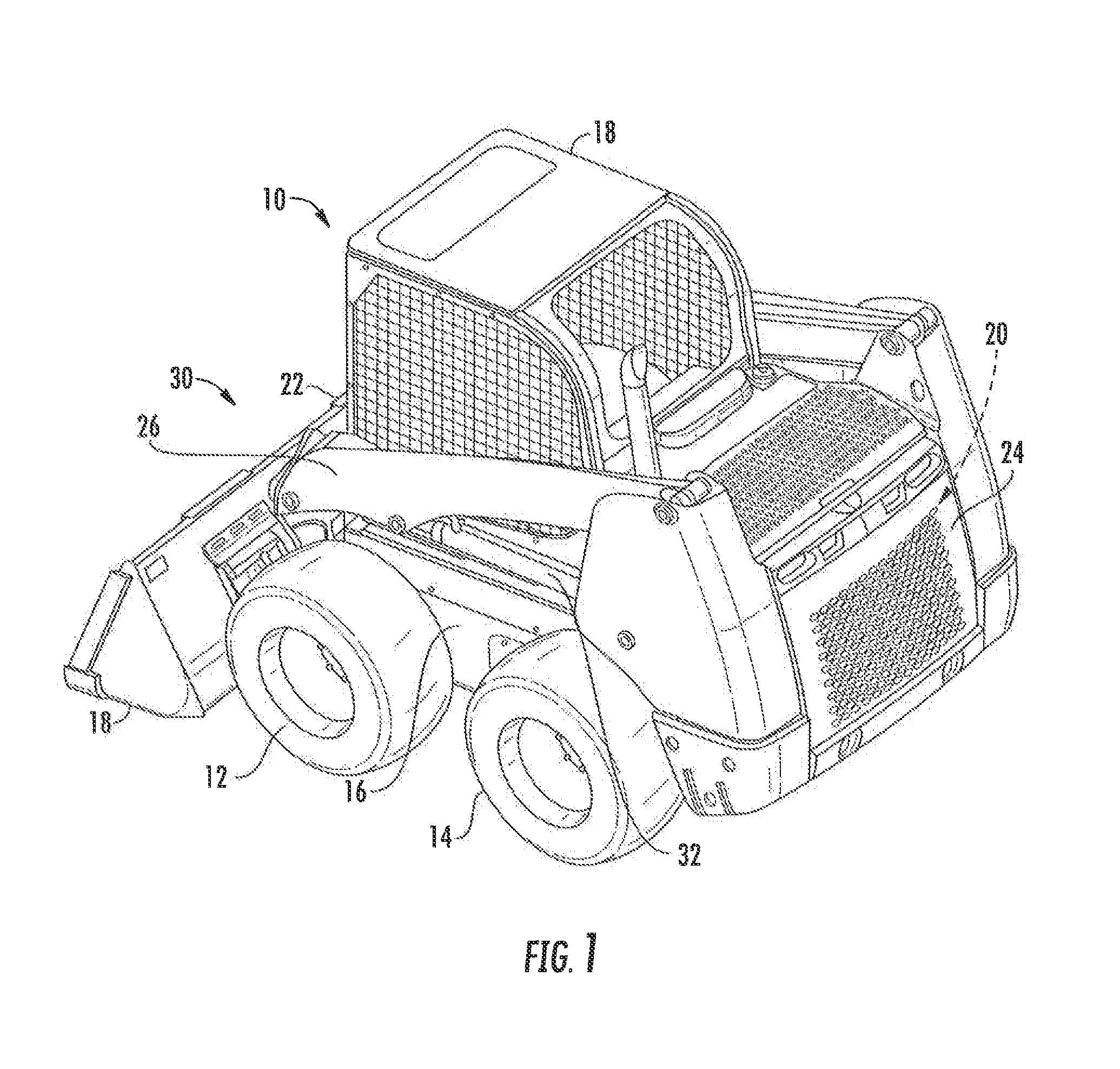

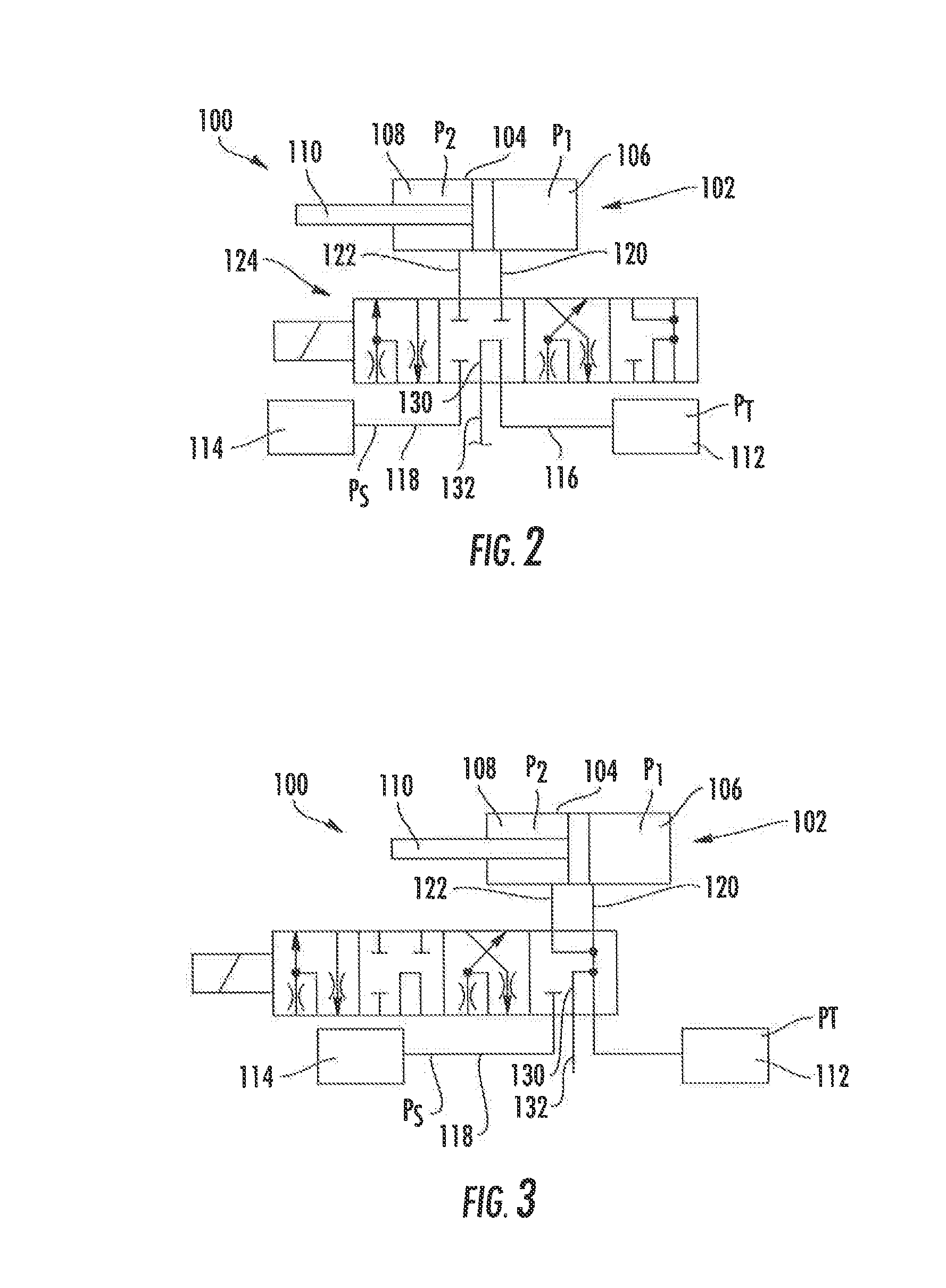

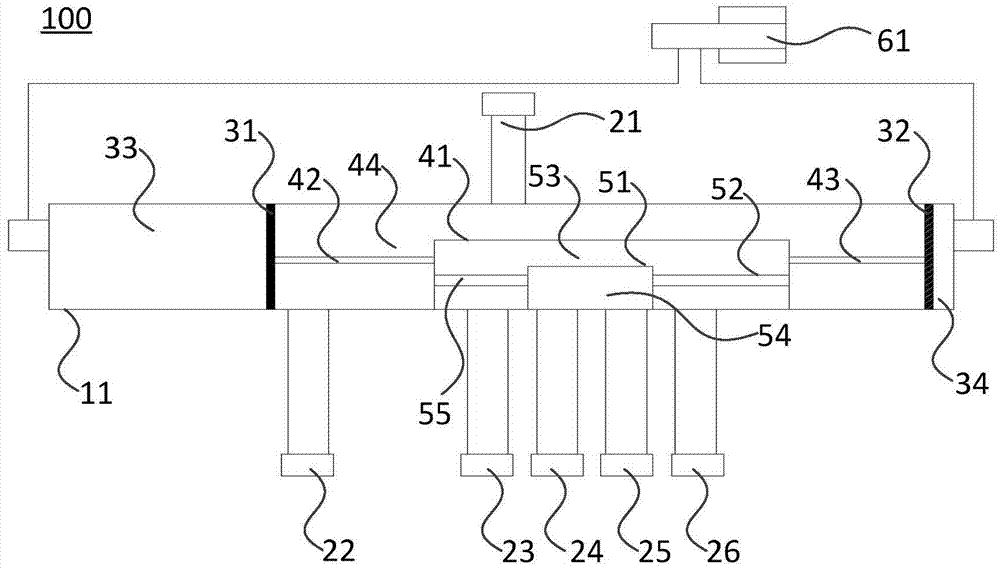

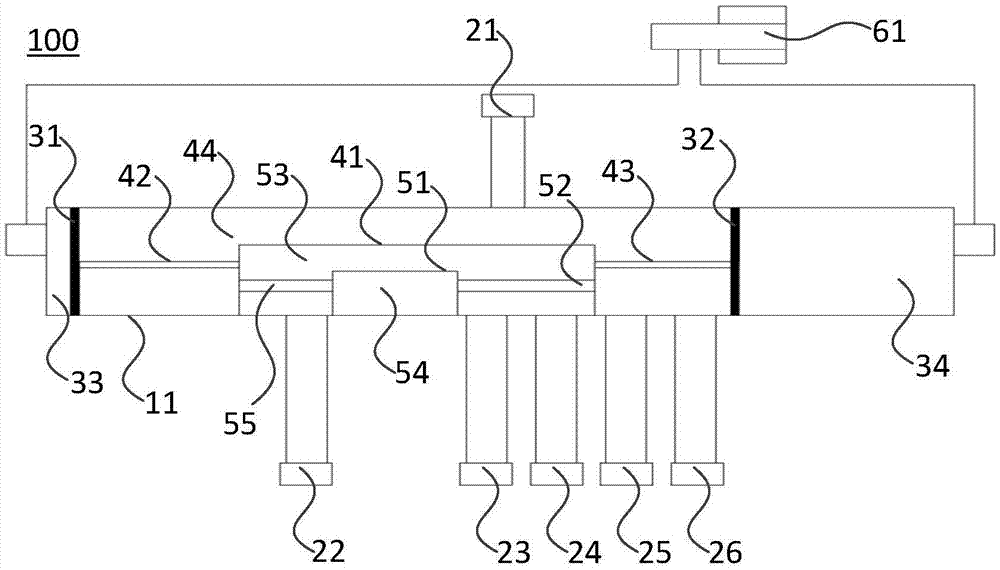

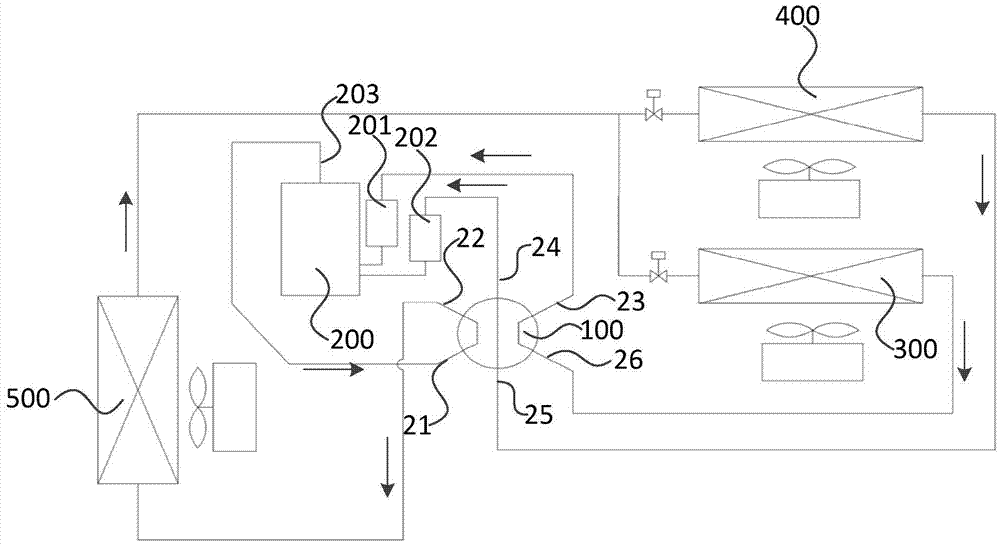

Hydraulic system

Owner:BLUE LEAF I P

Lifting and reversing four-way valve of optimized structure and fluid switching method

Owner:江苏中关村科技产业园节能环保研究有限公司

Liquid mixing faucet

ActiveCN109973680ANormal cleaningReduce concentrationDomestic plumbingMultiple way valvesWater flowEngineering

Owner:TAIZHOU SANYANG TAI SANITARY WARE CO LTD

Four-way valve adopting lifting reversing

PendingCN108302219AExtended service lifeReduce switching torqueOperating means/releasing devices for valvesMultiple way valvesFour-way valveEngineering

Owner:江苏中关村科技产业园节能环保研究有限公司

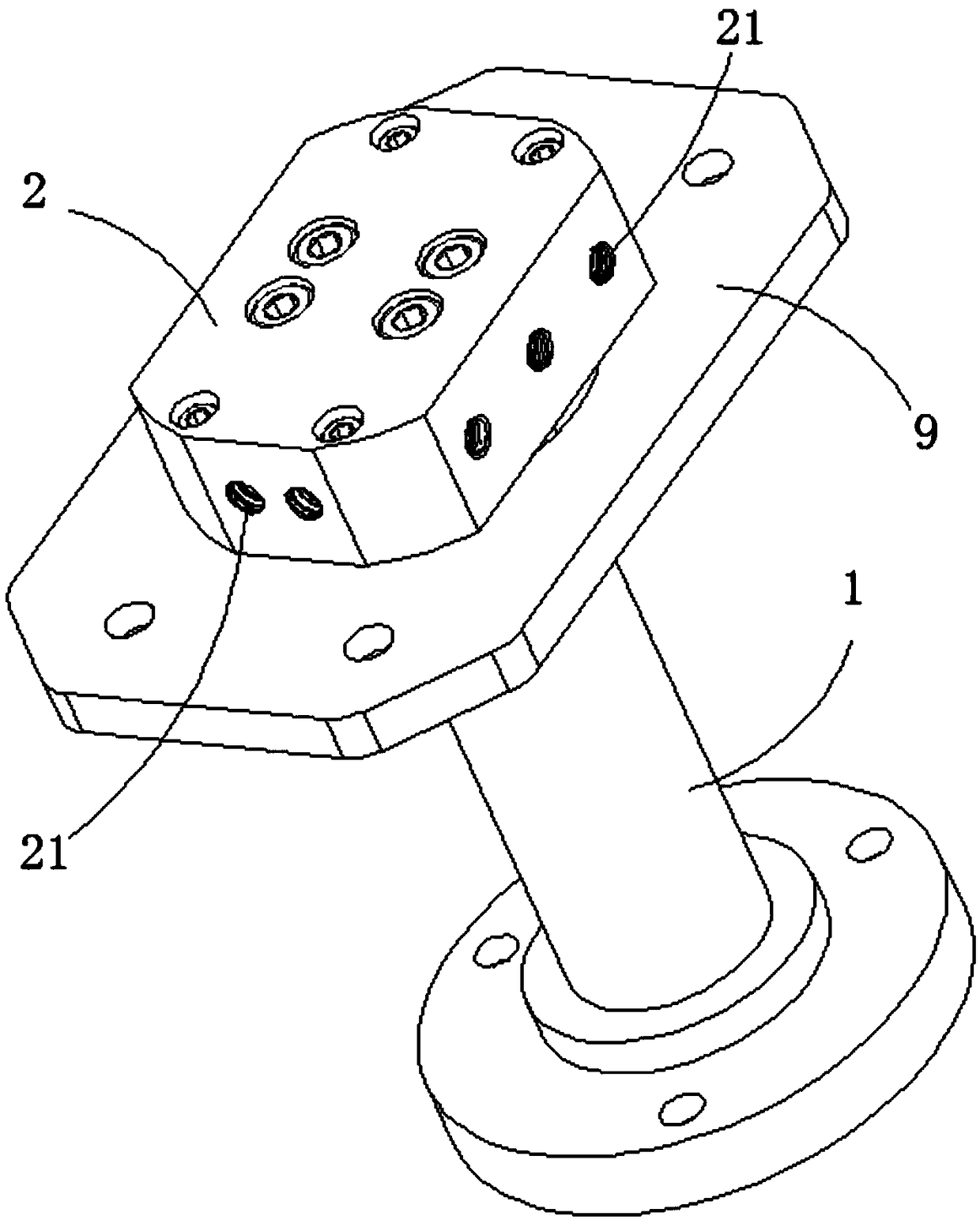

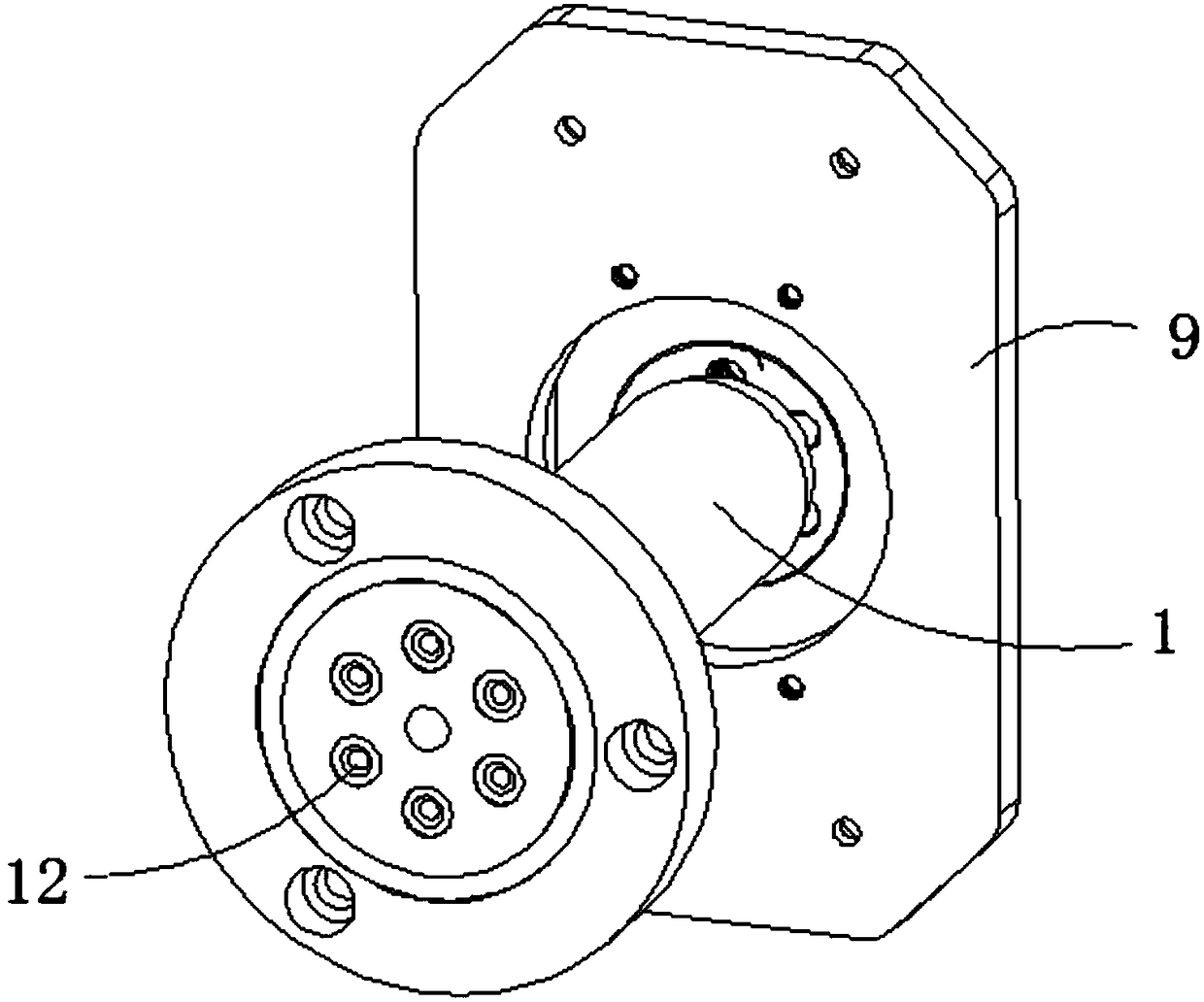

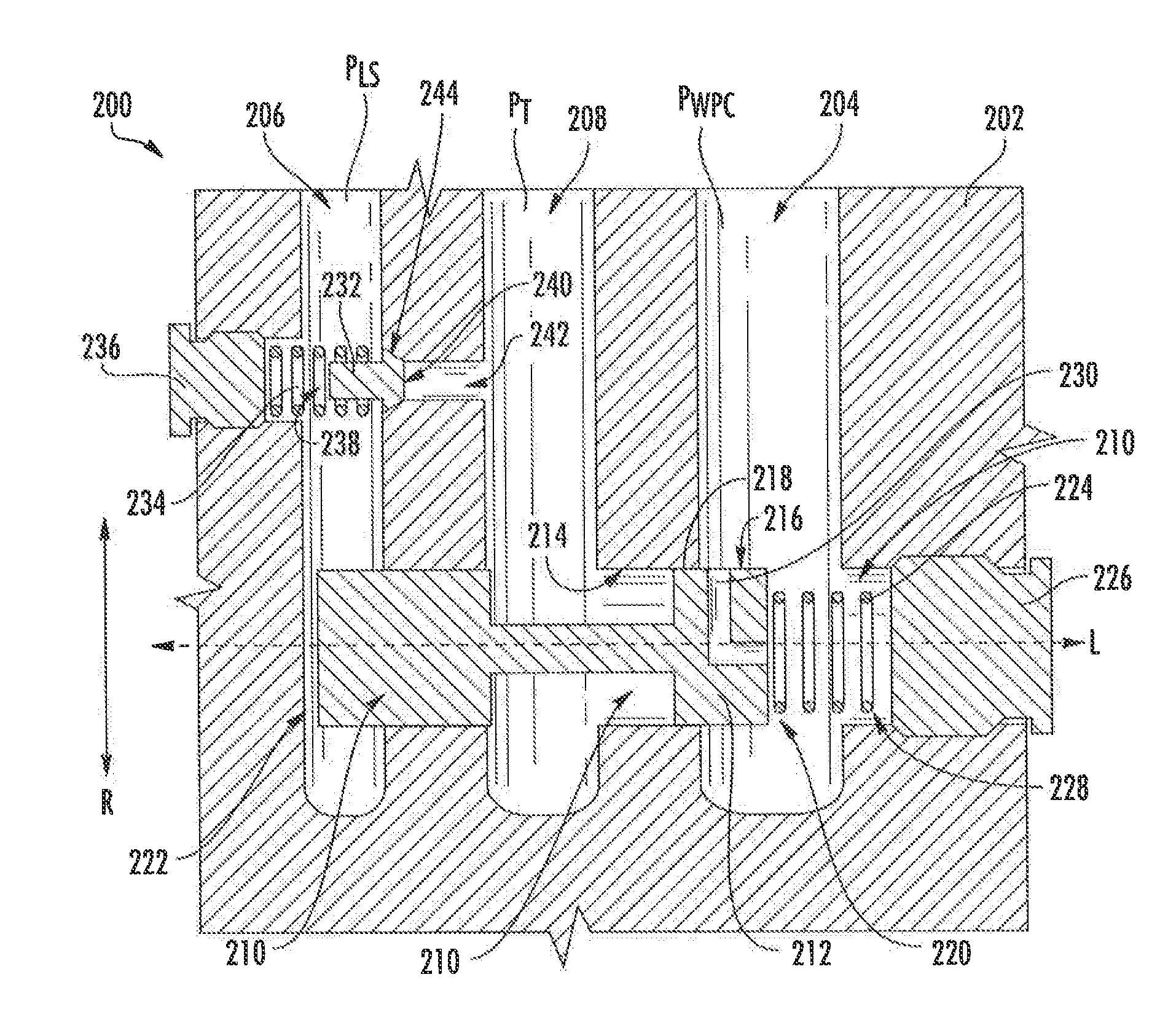

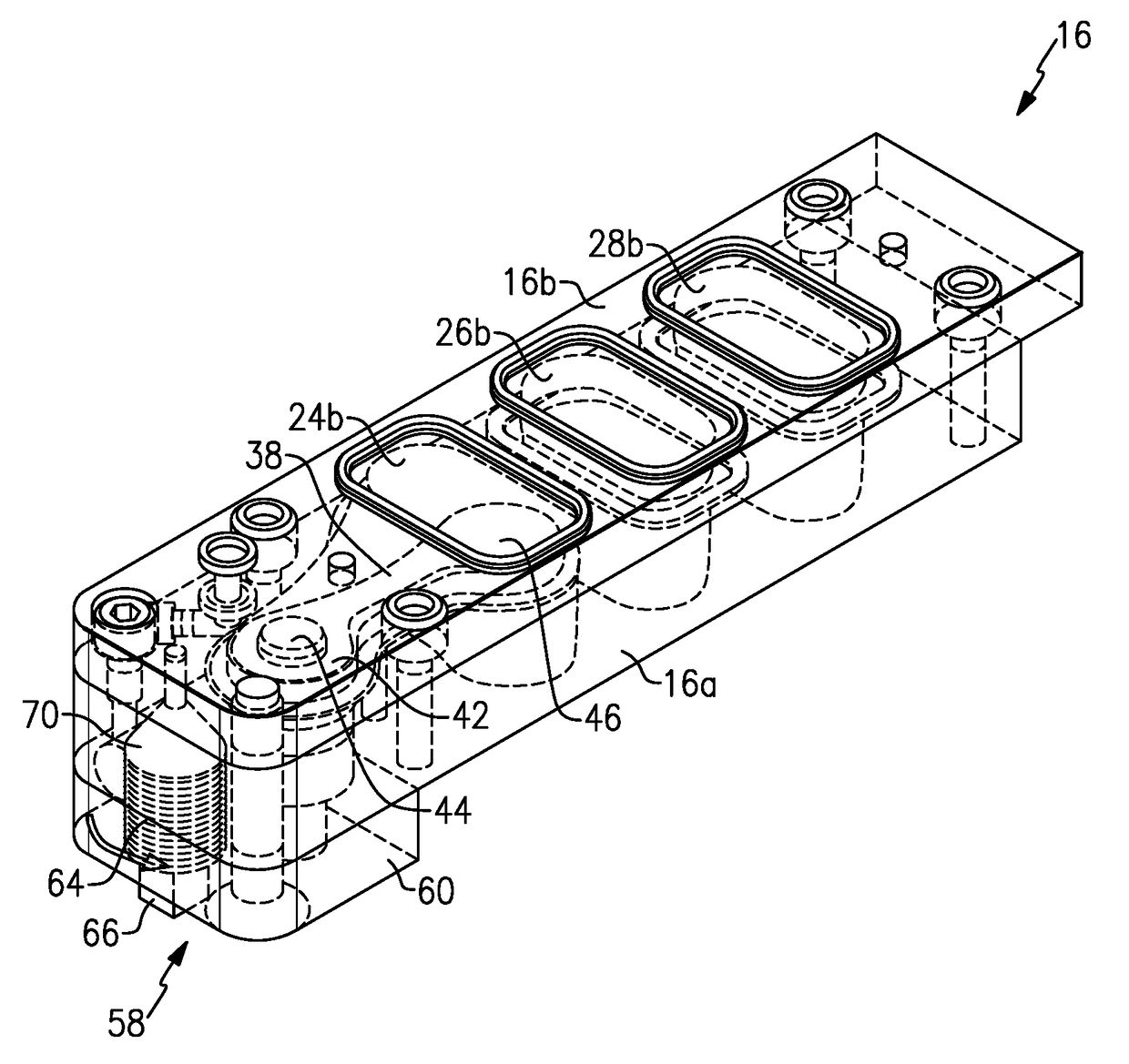

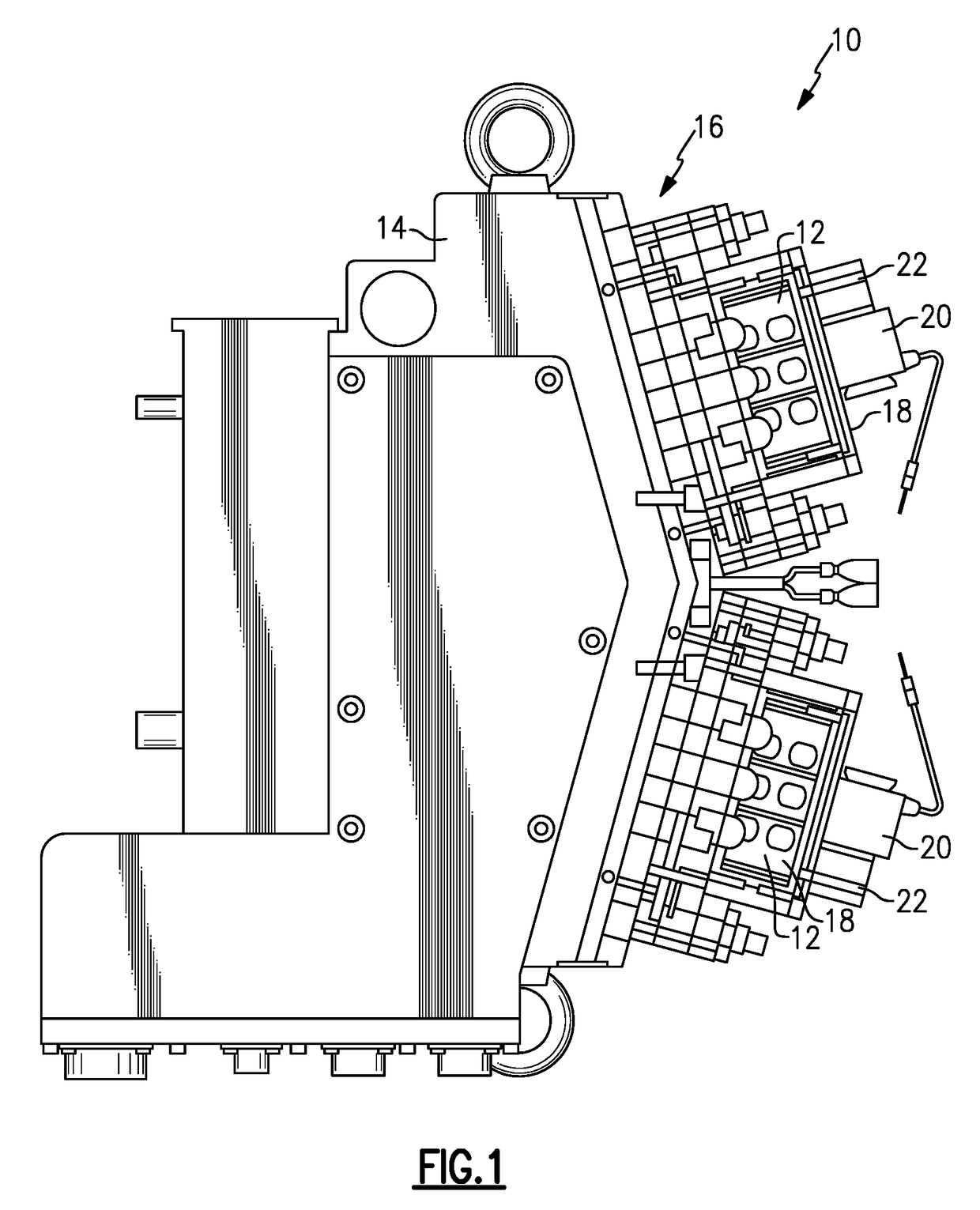

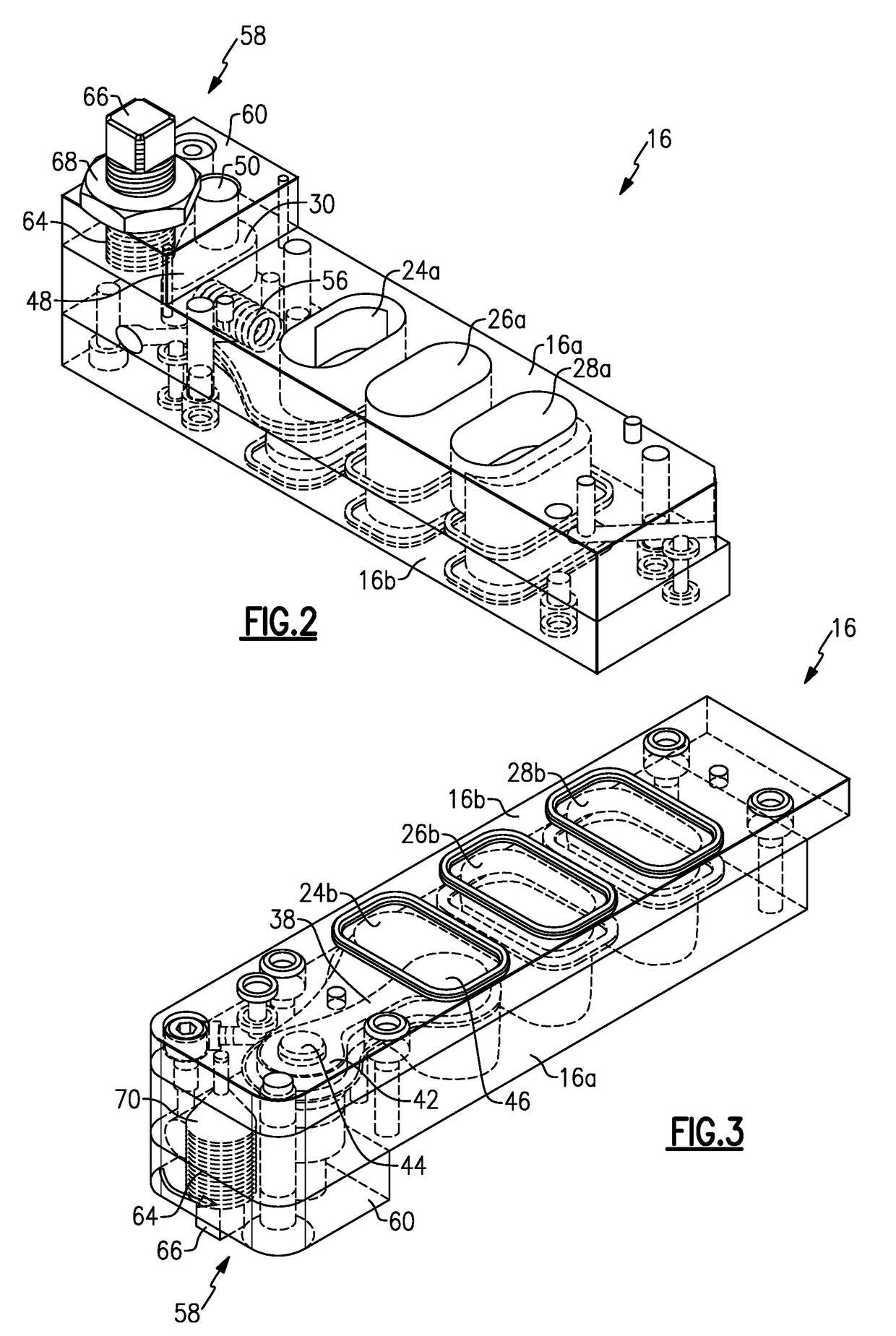

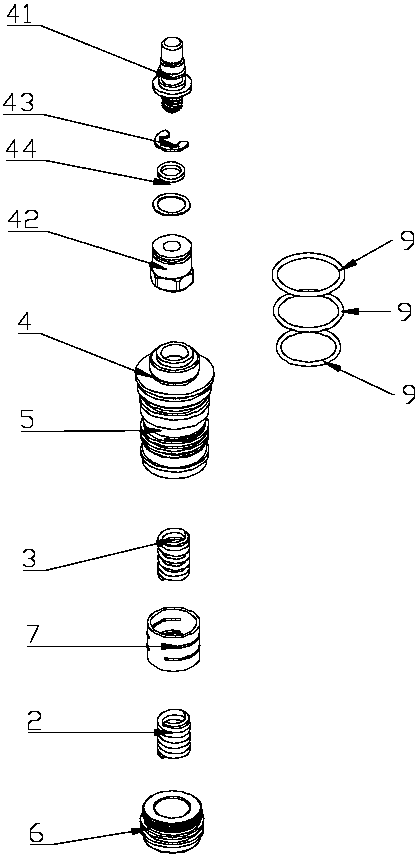

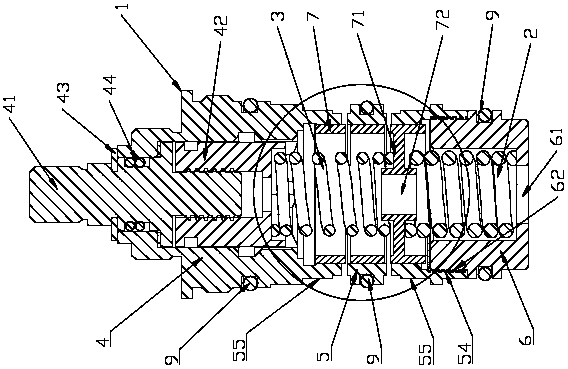

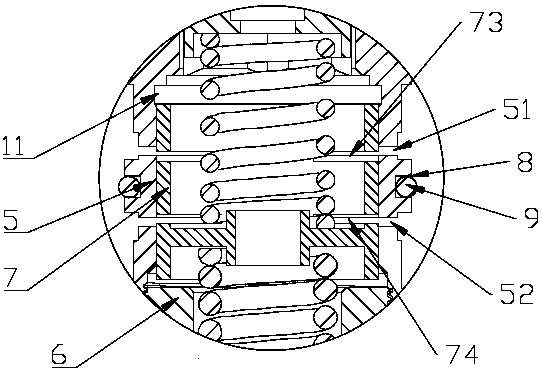

Flow control mounting assembly for a valve

ActiveUS20170175902A1Control flowServomotor componentsMultiple way valvesEngineeringMechanical engineering

Owner:ROSS EUROPA

Automatic non-gooseneck water draining type faucet with handle

ActiveCN103807461AReduce circulationSmall and delicate structureMultiple way valvesValve housingsStructural engineeringThermal water

Owner:郝莉

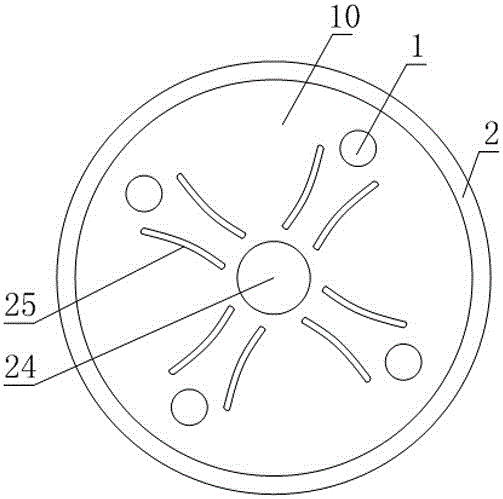

Special gas distributing valve for oxygen generator and distributing method

ActiveCN106481844AContinuous Oxygen GuaranteeImprove oxygen production efficiencyOperating means/releasing devices for valvesMultiple way valvesEngineeringOxygen

Owner:重庆鬼谷子医疗器械科技有限公司

Pressure blocking device

ActiveCN110873202ADoes not affect operating pressureGuaranteed uptimeOperating means/releasing devices for valvesMultiple way valvesControl cellControl theory

The invention relates to the field of chemical equipment, in particular to a pressure blocking device which comprises a six-way valve, a first operation assembly, a second operation assembly and a control unit. The six-way valve comprises a first port, a second port, a third port, a fourth port, a fifth port and a sixth port; the first operation assembly comprises a first chamber, a first piston and a first drive mechanism; the second operation assembly comprises a second chamber, a second piston and a second drive mechanism; and the control unit controls the six-way valve to switch between afirst state and a second state according to detection results of a first limiting sensor and a second limiting sensor, and controls the first drive mechanism and the second drive mechanism to drive. According to the pressure blocking device, media can be transferred from low pressure to high pressure, and the operation continuity of a connecting device is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

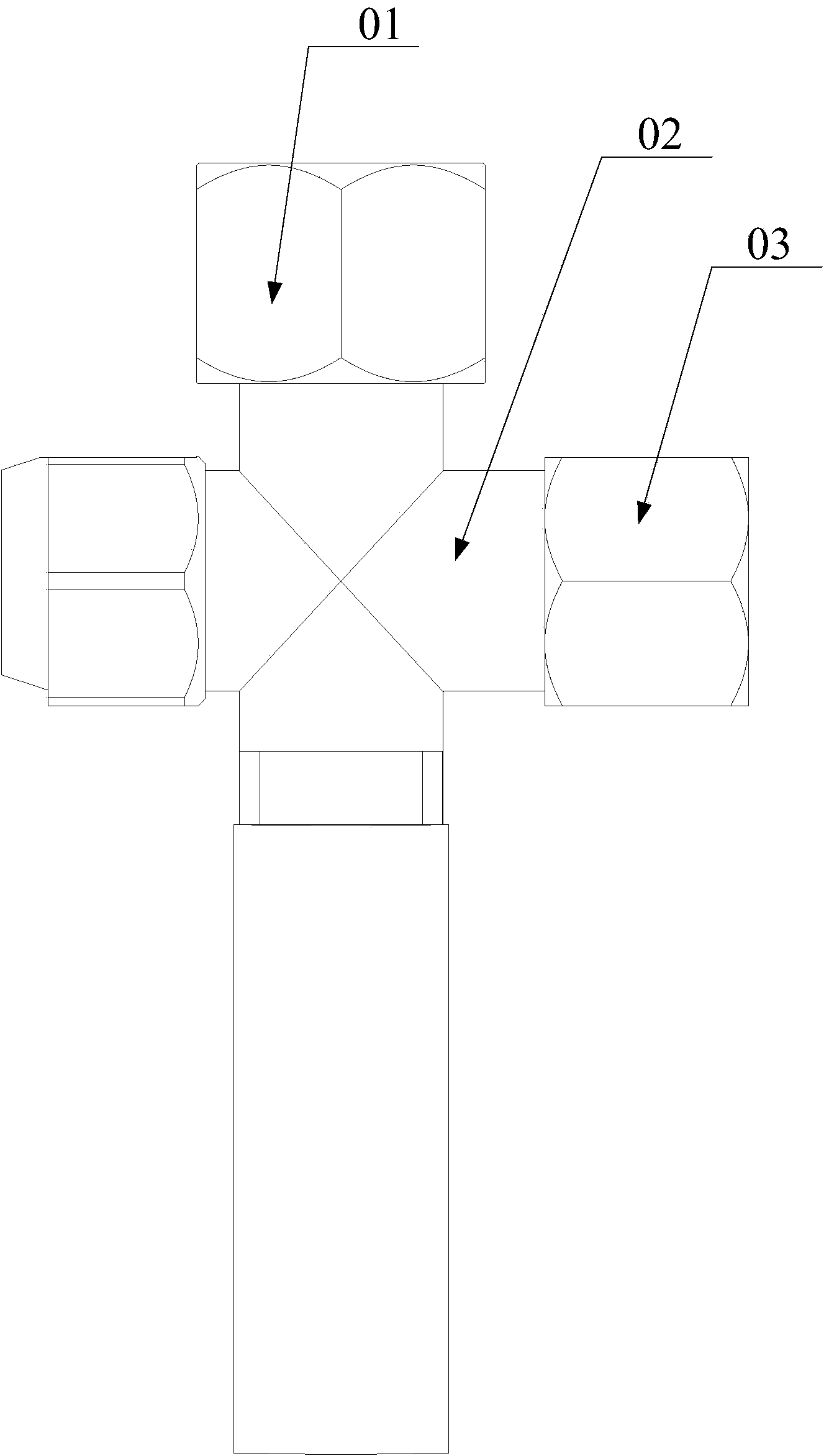

Tee joint connector

Owner:SHENZHEN MCQUAY AIR CONDITIONING

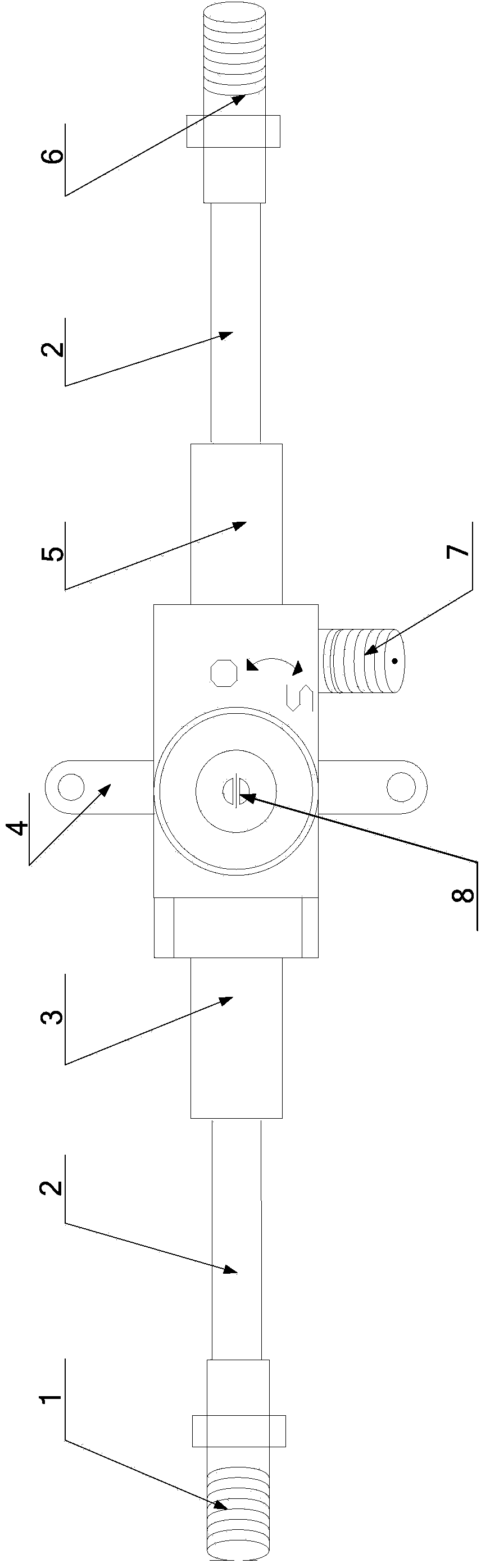

Reversing valve

ActiveCN107166059ASimple designGuaranteed installation effectMultiple way valvesFluid circulation arrangementFour-way valveEngineering

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

a gas supply device

InactiveCN104595548BRealize equal flow and size exhaustUniform power outputOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringShape of the distribution

Owner:SICHUAN SENJIE GAS EQUIP CO LTD

Constant-temperature valve core with stainless steel sliding sleeves

InactiveCN107654695AOperating means/releasing devices for valvesMultiple way valvesEngineeringThermal water

Owner:TAIZHOU GUOREN TEMPERATURE CONTROL SANITARY WARE TECH CO LTD

Flow controller and water treatment system

Owner:胡霄宗 +2

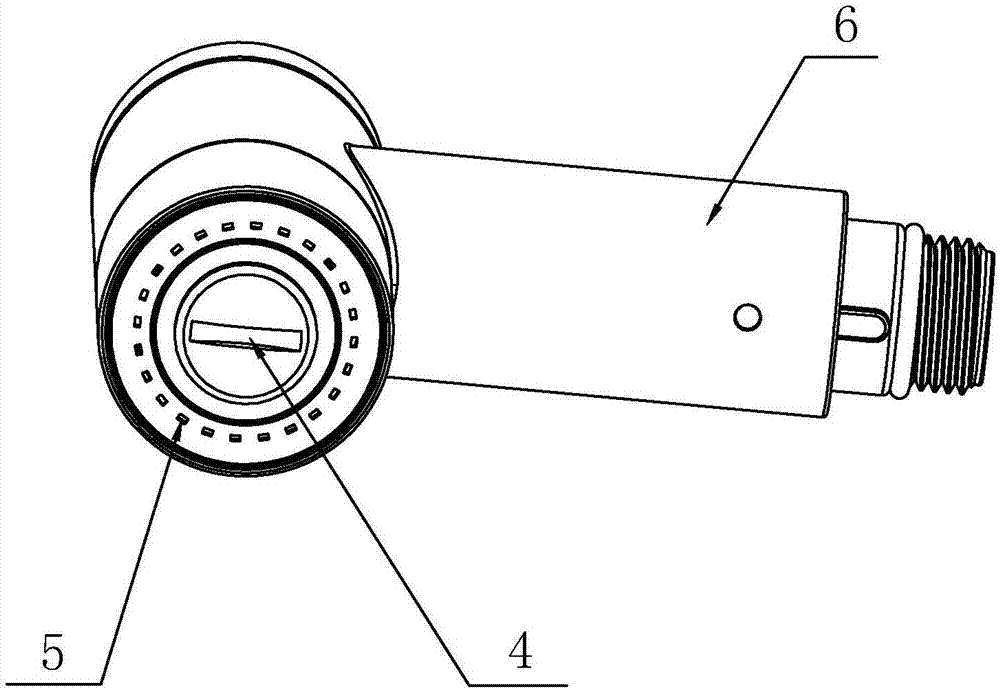

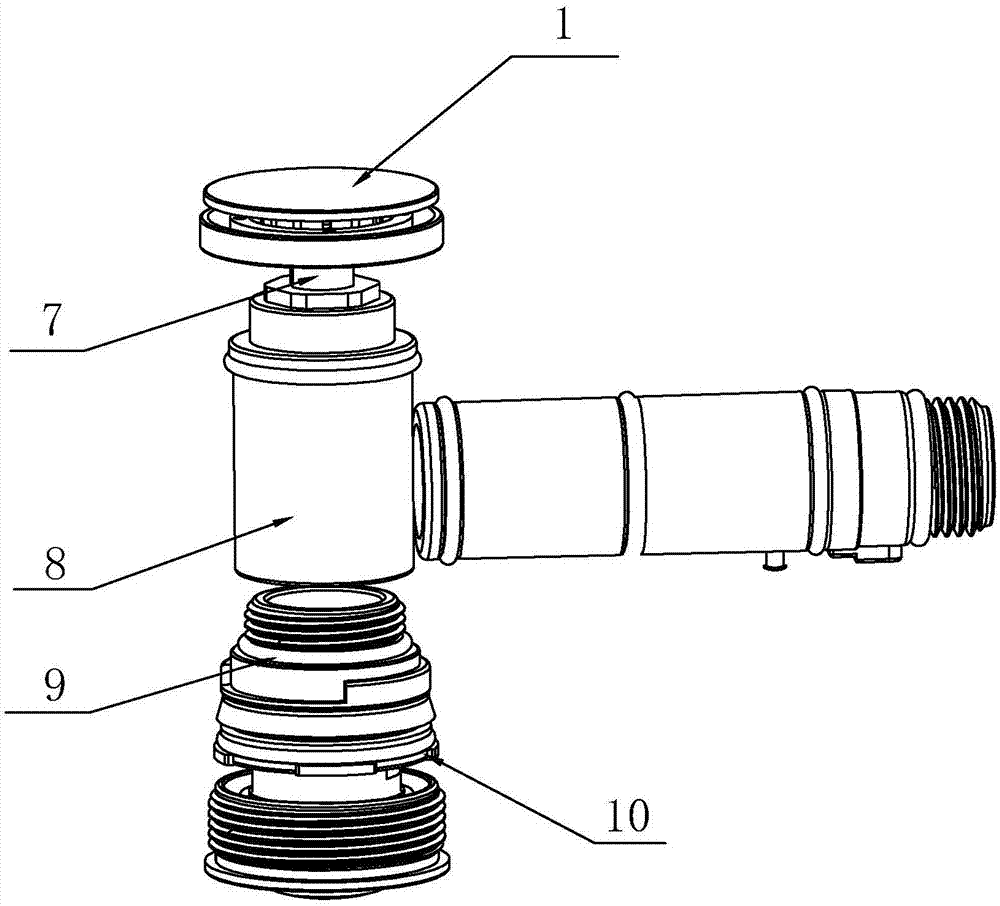

Kitchen sprinkler with switch

PendingCN107269889AImprove efficiencyConserve the use of water resourcesOperating means/releasing devices for valvesMultiple way valvesWater resourcesControl valves

The invention discloses a kitchen sprinkler with a switch. The kitchen sprinkler comprises the bounce type switch, a valve body and a water outlet body. The bounce type switch controls water opening and water closing of the valve body. The lower portion of the valve body is connected with the water outlet body. The water outlet body is provided with a mesh mouth water outlet and a sprinkler water outlet. Switchover of water outflow of the mesh mouth water outlet and water outflow of the sprinkler water outlet is finished through rotation of the water outlet body. The bounce type switch is used for controlling the valve body, water opening can be achieved through one-time pressing, water closing can be achieved through one-time pressing, convenience and rapidness are achieved, and the hand does not need to be released to stir a faucet for opening or closing. In addition, a user can switch the water outflow manners of the valve body through rotation of the water outlet body according to the demand, the water outflow manners include moderate sprinkler spraying water outflow and pressured centralized water outflow, targeted cleaning can be conducted, accordingly, the efficiency is improved, and meanwhile water resource utilization is saved.

Owner:开平韩信卫浴有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap